Page 1

MODEL

LBH-761-762

763

HIGH

STRAIGHT

industrial

SPEED,

BUTTON

sewing

Instruction

SI*

-v;

HOLING

machines

Book

•

TOKYO

-

JUKI

INDUSTRIAL

CO.,lTD

Page 2

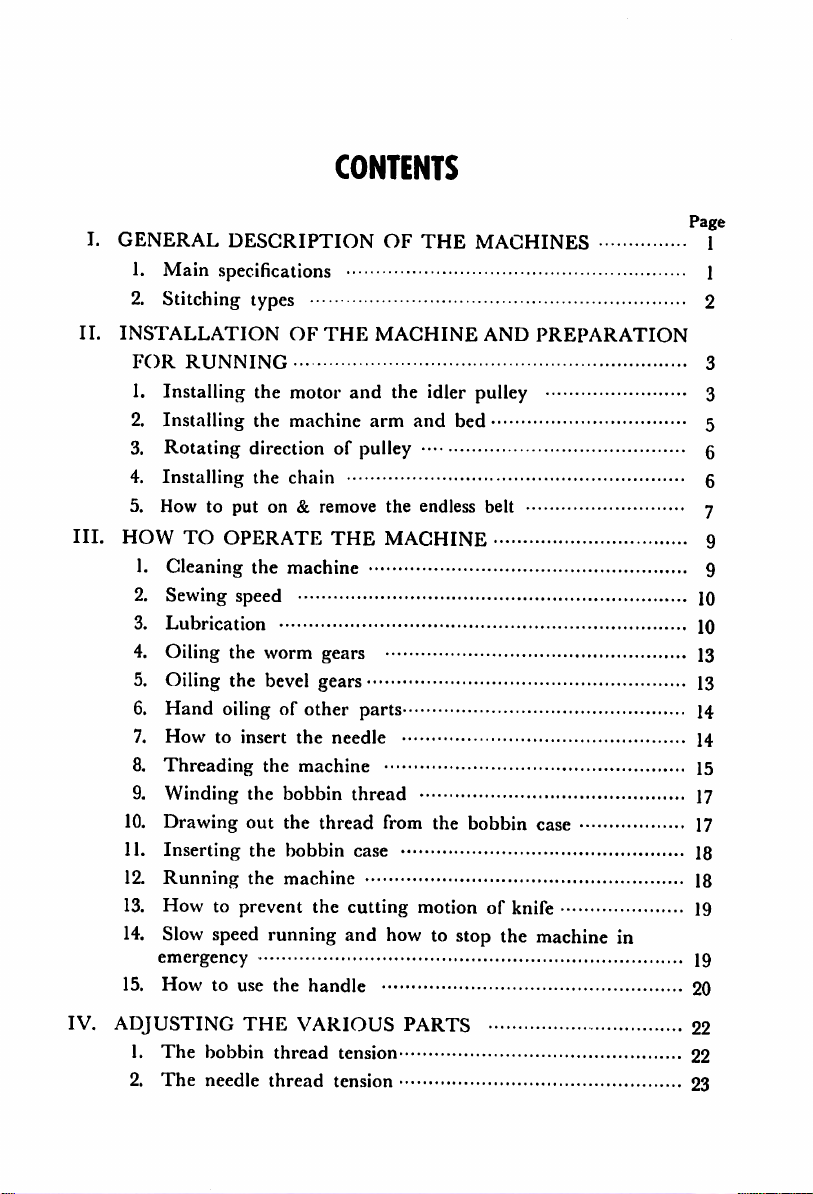

CONTENTS

I.

GENERAL

1.

Main

DESCRIPTION

OF

THE

MACHINES

specifications 1

2. Stitching types 2

II.

INSTALLATION

FOR

RUNNING

OF

THE

MACHINE

AND

PREPARATION

1. Installing the motor and the idler pulley 3

2. Installing the machine

3.

Rotating

4.

Installing

5.

How

to put on &

III.

HOW

TO

1.

Cleaning the

OPERATE

direction of pulley 6

the

chain

machine

remove

THE

arm

and

the

endless

MACHINE

bed 5

belt 7

2. Sewing speed 10

3.

Lubrication

4. Oiling the worm gears 13

5. Oiling the bevel gears 13

6.

Hand

oiling of other parts 14

7.

How

to insert

8.

Threading

9. Winding the bobbin

10.

Drawing

11.

Inserting

Running

12.

13.

Howtoprevent

14.

Slow speed running and how to stop the machine in

emergency

15.

How

to use the

the

needle

the machine 15

thread

out

the

the

the

thread

bobbin

machine

the

from the

case 18

cutting

bobbin

case 17

motionofknife 19

handle

Page

1

3

6

9

9

10

14

17

18

19

20

IV.

ADJUSTING

THE

VARIOUS

1.

The

bobbin

2.

The

needle thread tension 23

thread

tension 22

PARTS

22

Page 3

3. Adjusting the take-up spring 25

4. Timing of the needle and the hook 26

5. Adjusting the positions of seam and barring in relation to

the

button

hole

6. Adjusting the clamp carrying motion 29

7. Changing the number of stitches 30

8. Adjusting the

9. Adjusting the

10.

Adjusting the bobbin thread trimmer blade 35

11.

Adjusting the pressure of the work clamp check 36

12.

Adjusting the installing angle of the button hole length

regulating shaft bell crank 36

13.

Adjusting the device to prevent the knife from cutting when

the

needle

14.

How to change the number of stitches at barred ends 38

15.

Adjustment of the tension releasing movement 38

16.

Adjusting the cutting timing of the knife 42

17.

Adjusting the amount of the presser bar lift 42

18.

Adjusting the stop-motion components 44

19.

Adjusting the belt tension 45

20.

Adjusting the bobbin winder 45

thread

positions

needle

breaks

of the

knife

thread trimmer blades 32

27

32

37

V.

MALFUNCTIONS

1. Defective stitching conditions

2.

3. Reasons for malfunctions other

VI.

MAINTENANCE

VII.

THE

adjustment of

Malfunctions

measures

and

corrective

DIMENSION

AND

thread

other

measures

OF

GRAPH

CORRECTIVE

and

MEASURES

reasons due to mal

tensions 46

than

THE

tension:

MACHINE

OF

reasons

than

THE

and

corrective

stitching conditions

INSTALLING

TABLE

46

48

49

51

52

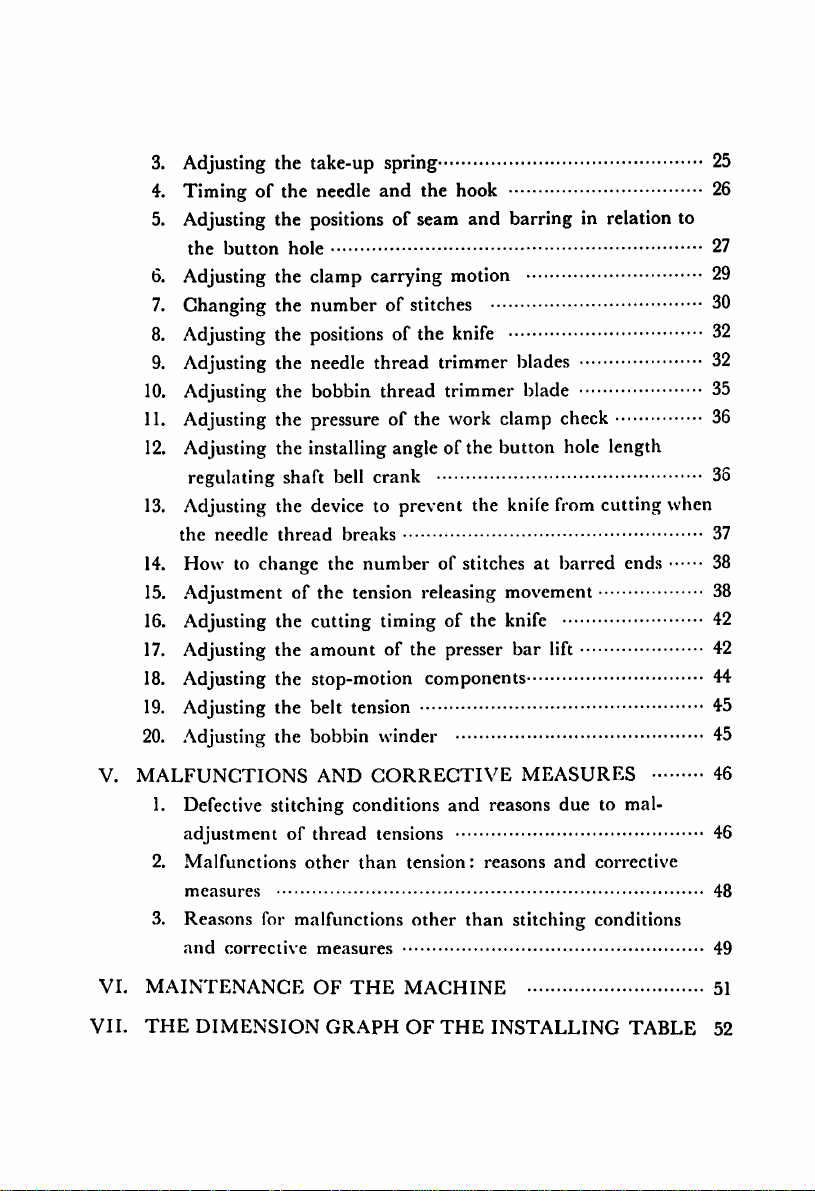

Page 4

I.

GENERAL

1.

Main

speciHcations

DESCRIPTION

OF

THE

MACHINE

JUKI

holing industrial sewing machines with a maximum sewing speed of

s.p.m. (standard speed

Models LBH-761, 762

2,500

s.p.m.)

and

763 are high speed, straight button

3,000

Page 5

LBH-761

garments

2.5-4

mm (3/32"-5/32") while the length of the button hole (width of

knife)is6.5

of up to

Model

LBH-762.

is designed to button hole men's shirts,

and all

mm-19

1"isrequired

other

garments

and the

mm (l/4"-3/4"). When,

for

This

gowns,

model's

pajamasorladies'

barred

ends

width

however,

widthis2.5-5

blouses,

of the

barred

button holelength

suits,

use

mm

under

ends

JUKI

(3/32"-

3/16") [one side is 1.2-2.5 mm (l/16"-3/32")] and the length of the button

hole

is 6

mm—25.4

When a large button hole is required such as

Model

LBH-762

1 >/4".

can be changed within the range of

for these machines, at an extra cost, by which by

LBH-763.

but the length of the button hole (width of

Besides

The

Furthermore, an automatic attachment known as AO-1 is available

the above models, many sub-class models are available.

feeding

mm

(1/4"

—1").

This

model

has

the

same

and the driving are of gear

54—340

sweaters

barred

endsasthe

knife)

feed

type and the stitches

stitches.

just

stepping lightly

etc. use the

Model

is 1/4"—

on the treadle type switch, the work clamp check comes down automa

tically and the sewing can be started and as soon as the sewing is

completed, the

automatic

slightly altering the table.

work

attachment

clamp check automatically

can

be installed, on order, to the

goes

up. This special

LBH

table by

It is highly recommended that the high speed feature ot these models

be advantageously utilized together with the automatic attachment AO-1

to increase the button holing production of your plant.

is

2.

Stitching

1)

types

Namesofstitching

types

As in the case of zigzag lockstitch sewing by a zigzag machine,

these machines can do

appears only on the front surface of the sewing cloth

thread appears in a zigzag form on the back of the sewing garment.

"whip

stitching"

— 2 —

by which the needle

and

the bobbin

thread

Page 6

Another

which

passes

the

bobbin

of

men's

2) Typesofstitching

Purl

With

these

stitchedtomake

ends can be purl stitched also.

"Whip

the

thread

II

typeofstitchingiscommonly

the

needle

straight

thread

through

tensionisstrengthened

the upper

threadisinterlocked,asin

shirts.

stitching"

machines,

is

eveninpurl

the

ends

appliedtogeneral

sturdier.

stitching"isgenerally

tension,

the

purl

stitching

INSTALLATIONOFTHE

called

"purl

and

the

center

However,ifyousodesire,

used

part of the

the

caseofbutton

stitching,

for

knit

fabric

the

goods

stitch

except

barred

but

canbeconvertedtowhip

MACHINE

stitching"

needle

hole

ends

by

thread

and to this

stitching

knit

goods.

are

the

barred

changing

stitching.

AND

by

whip

PREPARATION

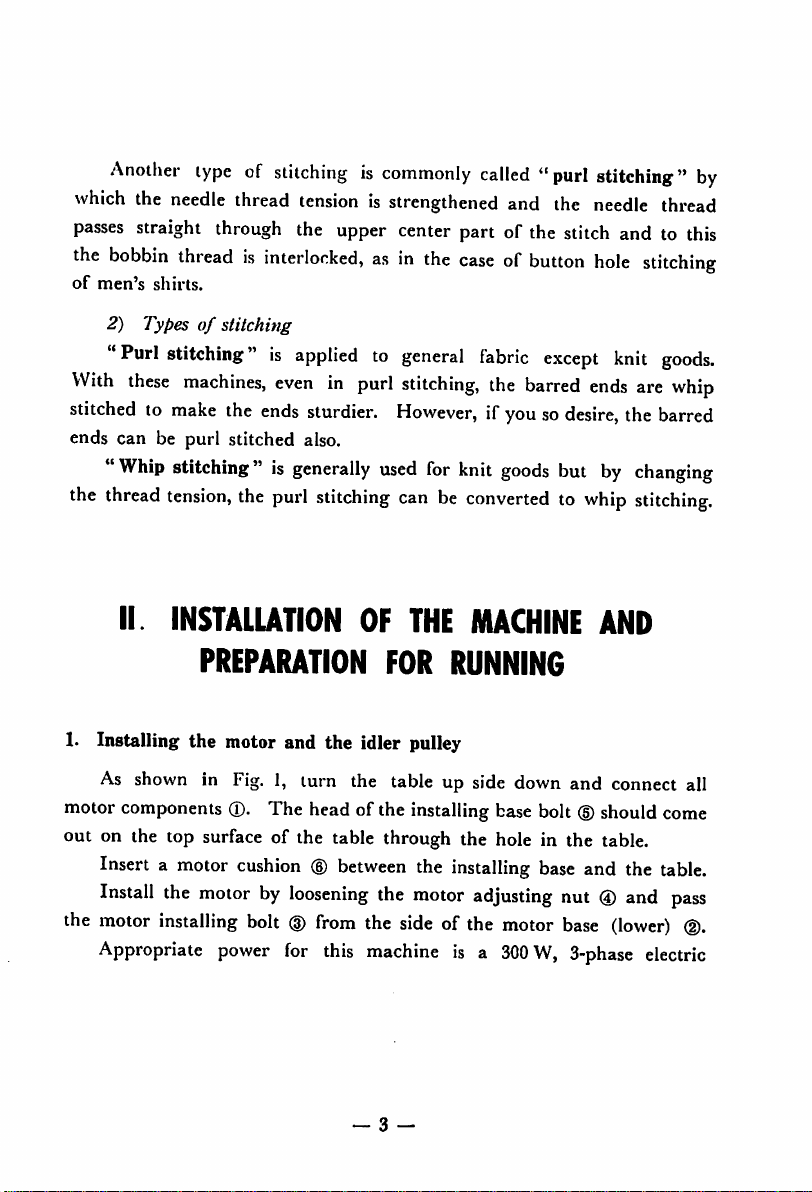

1. Installing the motor and the idler pulley

As

shown

motor components ®. The head of the installing base bolt(Dshould come

out on the top surface of the table through the hole in the table.

Insertamotor

Install

the

motor

Appropriate

in

Fig.1,turn the table up side down and connect all

cushion(Dbetween

the

motorbyloosening

installing

bolt

power

(§)

for

from

this

FOR

the

the

motor

the

side

of the

machineisa

- 3 -

RUNNING

installing

adjusting

base

motor

300W,3-phase

and the

nut

base

(g)

and

(lower)

table.

pass

(5).

electric

Page 7

Fig.

1

induction motor

phase

currentisavailable,

motor

(1,500

The

motor

long

hole

50"^,

the motor should be installed so that the installing bolt

nearly

the motor

by

Also,

50°o,

install so that the installing bolt

to the

pushingitfully

when

install the

When

The

reasons

tionsasexplained

(1,500

r.p.m./50oo,

r.p.m./50'^,

installing

but if the

1,800

hole

motor

centerofthe

pulleyof2,500

motor

motorbypushingitfully

2,800

r.p.m.

for installing the motor to the different,

toward

pulley

or

above

r.p.m.

the

of

3,000

are

1,800

r.p.m./60°o),

usea300

r.p.m./OO*^).

at the

W or

bottom

pulleyof2,500

long

hole

under

is to be

opposite

2,800

r.p.m.

comes

because

_ 4 —

usedat60°°,

direction

r.p.m.or3,000

pulley

to the center of the long

when

250Wsingle

of the

r.p.m.

the

from

toward

is to be

the

size

but

motor

speed

motor

r.p.m.isto be

the

of the

when

is to be

base

install

the

arrow

only

phase

base

(lower).

the motor

arrow

direction.

direction.

used

respective

motor

single

electric

(D

is a

used

comes

used

at

GO'H',

hole.

posi

pulley

at

If

at

Page 8

is

changed,

motion

standard

accordingly.

Please note also

3-phase or single phase motor, use a motor base

when a steel frame motor is to be used, use a motor base

When a National Brand

used, the motor installing position is different, so be careful.

The idler pulley components @ should be installed to the bottom

surface

installing

baseofthe

motor

each

other.

2.

Installing

ihe

bell

device.

in

For this

installing

of the table by

hole

is rather

head

part and the

pulley

@

the

should

machine

should

not

contact

reason,

the

motor

that

when cast frame

single

hexagonal

large,besure

positionsofthe

be so adjusted that

arm

and

either

the

head

partorthe

follow

and

phase electric motor of

bolts

the

foregone

adjust

the

motor

B-7101-761-AAO

(§)of15/64",

method

respective

is used with

B-7101-761-BAG.

250

W is to be

Fig.

1.

that the belt is not contacting the

idler

bed

they

pulley

will

® and the

not be

stop-

as the

positions

either

and

As

the

touching

Turn the table

(A),

place the felt pads ® in line with the

install the

machine

Hook up the

is

attached

chain and let it hang down.

As

base, insert the hinge arm

interlock

guard

Caution

After

screw in the following manner: (Fig. 2 B)

Verify

lever

to the back of the machine bed

showninFig.2(A),

this

with the hinge at the rear

the

that the

(J)

toward

over

in an upright

arm ® on top of it.

S-shaped

with

the

hinge

machine

arm is installed, adjust the starting

machineisin

the

rear.

position

latch on the starting lever

place

the

machine

(3)

to the hole on the left side of the bed and

shaft

bushing

endofthe machine bed.

stop

Then,

loosen

- 5 -

and, as

4~70

showninFig.

holes

of the table and

(Fig.5(A)(D)

and

to this connect the shorter

head on top of the head

®.

position,

nut ® and

Lastly,

then

install

push

adjust

which

the belt

lever

set

the starting

so

that

2

Page 9

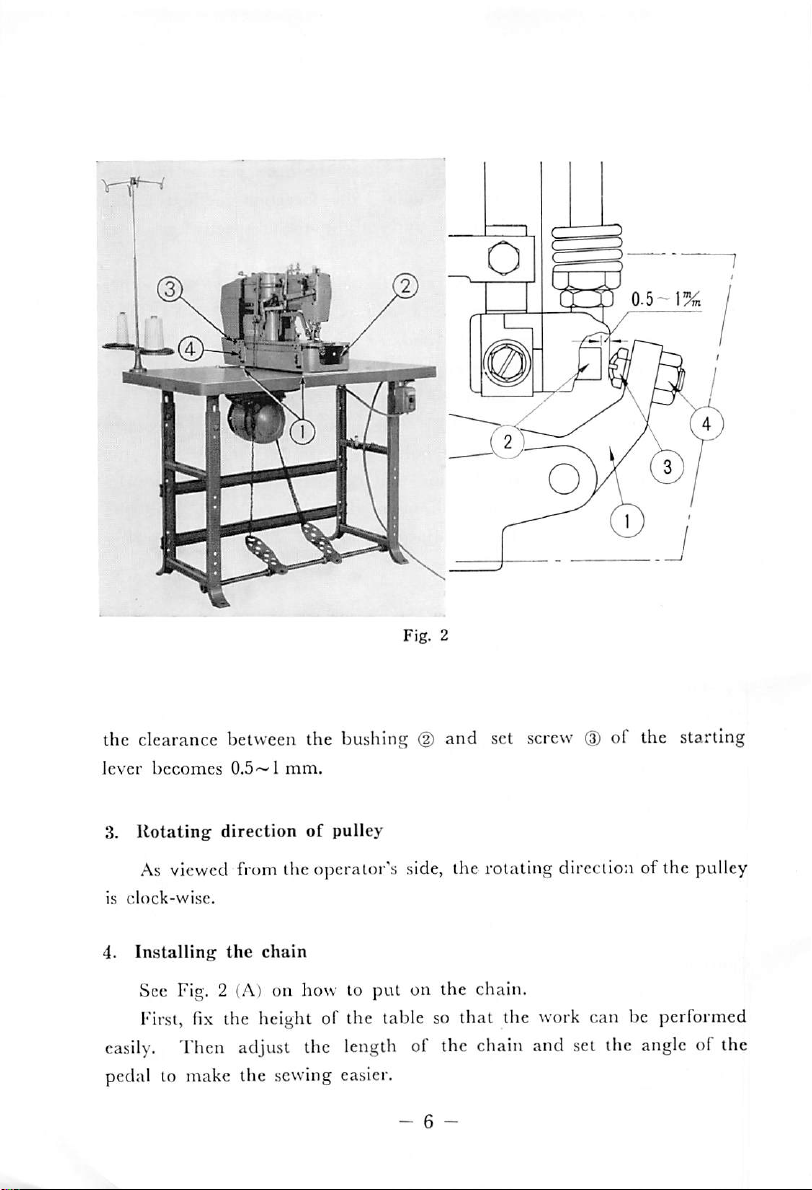

the clearance between the bushing

lever

3.

becomes

Rotating

0.5~lmm.

direction

of

pulley

(2)

and set screw(Dof the starling

As viewed from the operator's side, the rotating direction of the pulley

is

clock-wise.

4.

Installing

the

chain

See Fig. 2 (A) on how to put on the chain.

First, fix the height of the table so that the

easily.

Then adjust the length of the chain and set the angle of the

vvork

can be performed

pedal to make the sewing easier.

- 6 -

Page 10

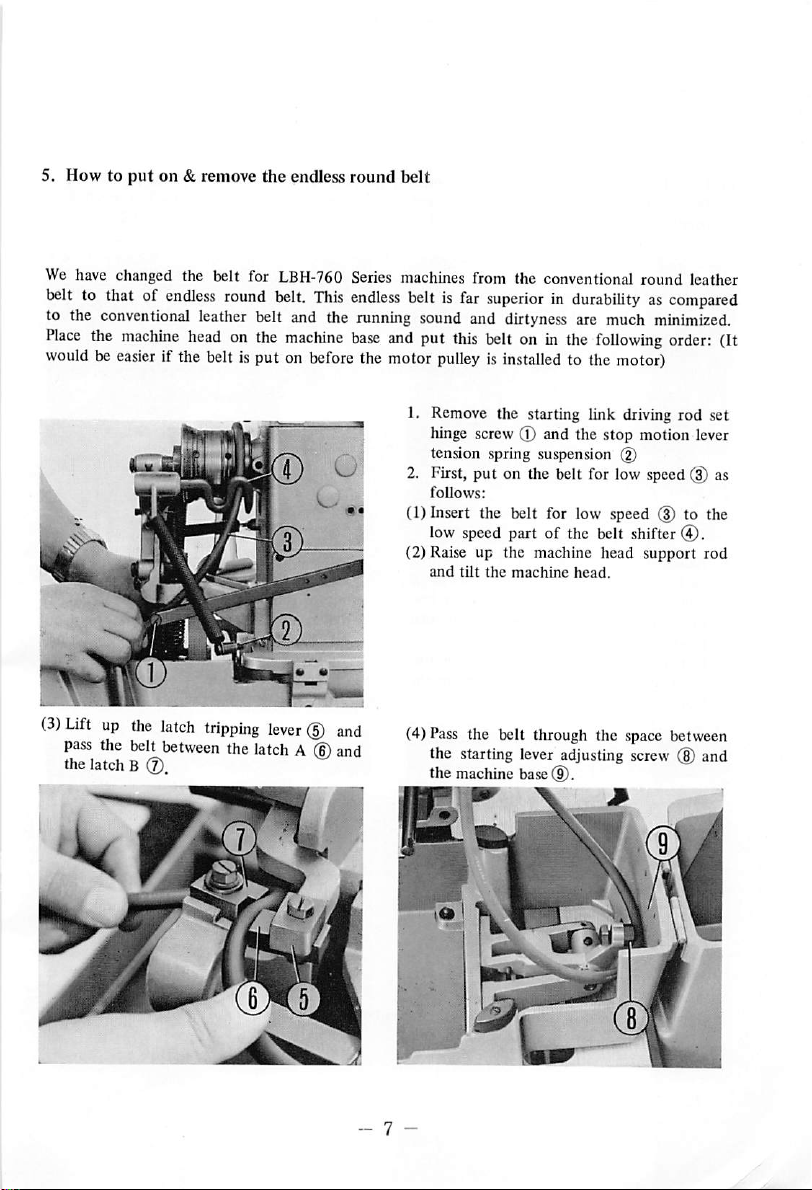

5. How to

We have changed the belt for LBH-760 Series machines from the conventional round leather

belt

to the conventional leather belt and the running sound and dirtyness are much

Place

wouldbeeasier

(3)

Liftupthe

pass

the latch B (J).

put

to that of

the

machine

the

belt

on & remove the endless

endless

round

belt.

This

head

on the

machine

if the belt is put on

latch

tripping

between

the

before

lever

(5)

latchA(D

round

endless

base

the motor

and

and

belt

belt is

far

superiorindurabilityascompared

minimized.

and

put

this

belt

on in the

pulleyisinstalled

1.

Remove

hinge screw ® and the stop motion lever

tension spring suspension (D

2. First,

follows:

(1) Insert the belt for low speed (3) to the

low speed part of the belt shifter

(2) Raise up the machine

and

(4) Pass the belt through the space between

the starting lever adjusting screw (8) and

the

the starting link

put

on the belt for low speed (3) as

tilt

the

machine

machine

base

(9).

following

to the

head.

motor)

head

driving

support

order:

rod set

®.

rod

(It

i

Page 11

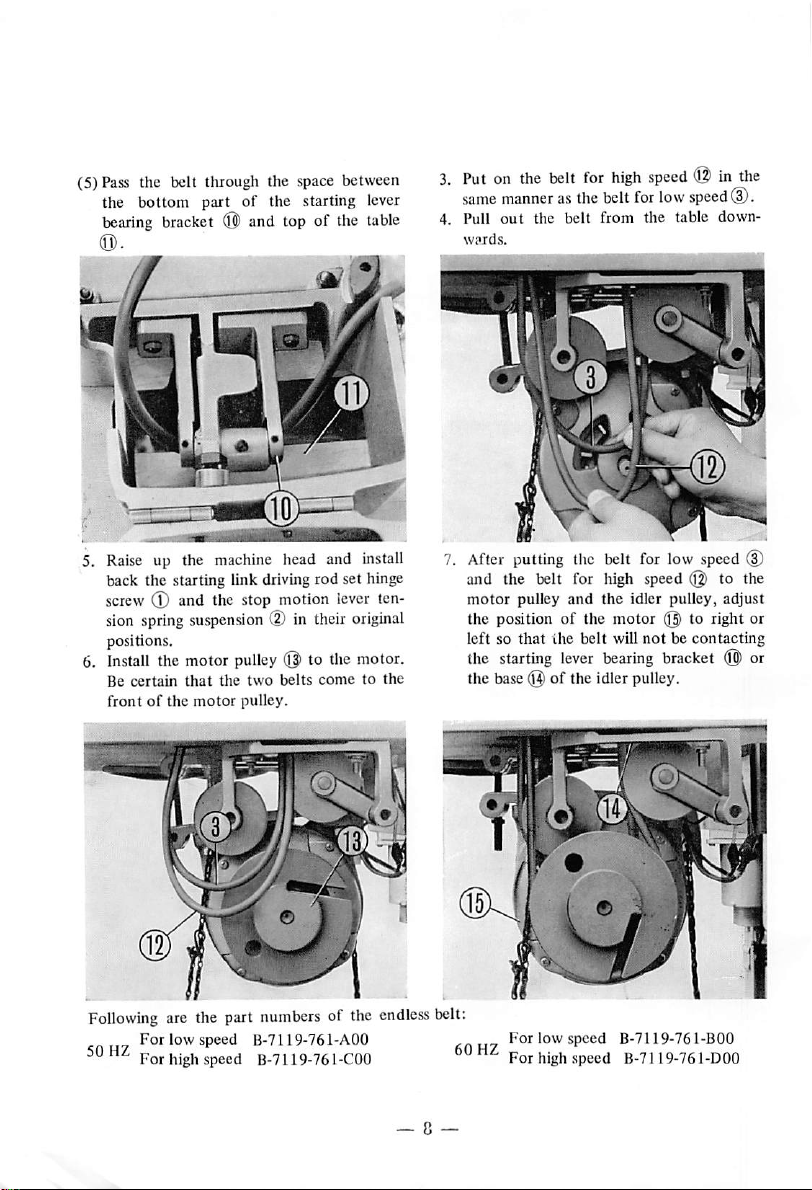

(5) Pass the belt through the space between

the

bottom

bearing

part of the starting lever

bracket

(0 and top of the

table

3.

Put

same

4. Pull

on the

manner

out

belt

for

high

speed

asthe beltfor lowspeed®.

the

belt

from

the table down-

© in

the

K

5. Raise up the machine head and install

back the starting link driving rod set hinge

screw ® and the stop motion lever ten

sion

spring

positions.

6.

Install

Be

frontofthe

the motor

certain

suspension

that

motor

the

(D in their

pulley

two

pulley.

m

(I|)

to the motor.

belts

cometothe

original

After putting the belt for low speed @

and the belt for high speed @ to the

motor

pulley and the idler pulley, adjust

the position of the motor @ to right or

leftsothat

the starting lever

the base

the

belt

will

bearing

(Q'

of Ihe idler pulley.

notbecontacting

bracket ® or

Following

For

For

are the part

low speed

high

speed

numbers

B-7119-761-A00

B-7U9-761-C00

of the

endless

belt:

For

For

low

high

speed

speed

B-7119-761-BOO

B-7119-761-DOO

Page 12

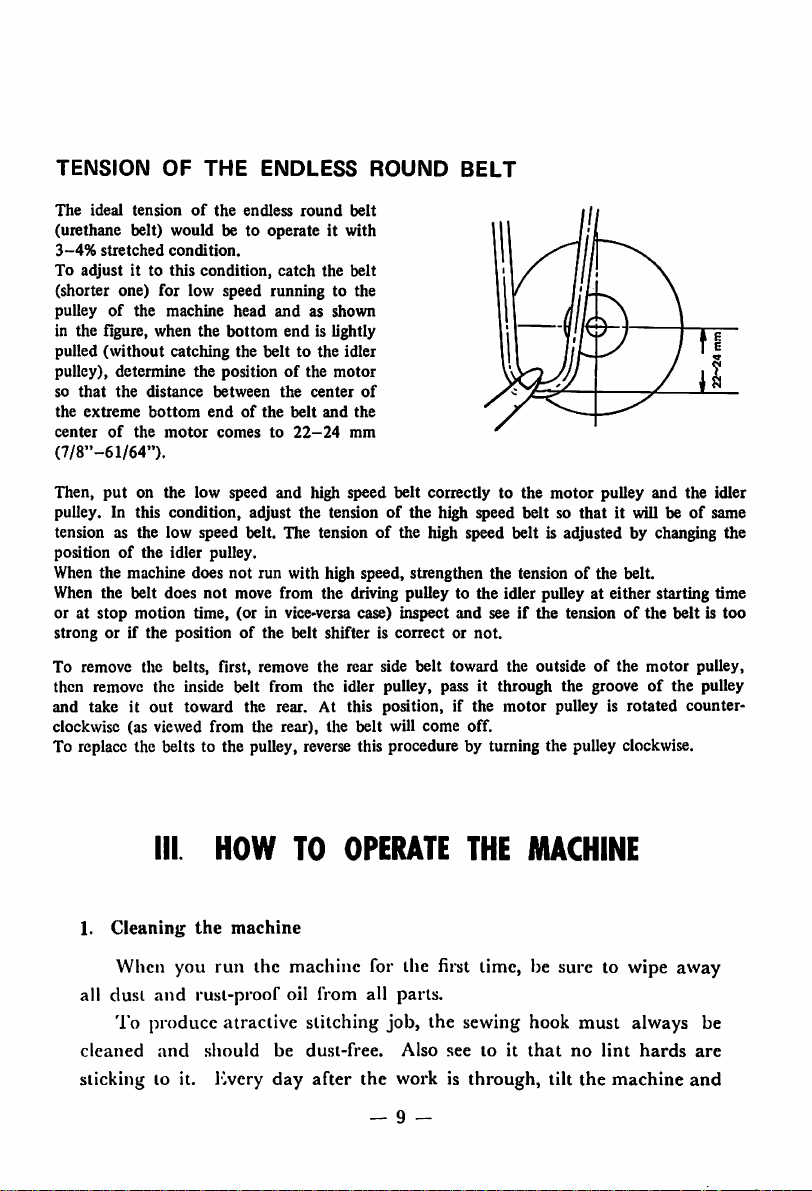

TENSION

The

ideal

(urethane belt)

3-4%

stretched

To

adjust

OF

THE

tensionofthe

would

condition.

it to

this

condition,

ENDLESS

endless

be to

operateitwith

catch

round

the

ROUND

belt

belt

BELT

(shorter one) for low speed running to the

pulleyofthe

in the figure, when the

(without

pulled

pulley), determine the position

so

that

the

extreme

center

(7/8"-61/64").

Then,

put

pulley. In this condition, adjust the tension

machine

head

bottom

andasshown

end

catching the belt to the idler

of

the

distance

bottom

of

the

motor

between

endofthe

comesto22-24

the

the

center

belt

on the low speed and high speed

is lightly

motor

and

the

mm

of

belt

of

correctly to the

the high speed

motor

beltsothat

pulley

and

the idler

it will beofsame

tension as the low speed belt. The tensionofthe high speed belt is adjusted by changing the

positionofthe idler pulley.

When the machine does not run with high speed, strengthen the tension of the belt.

When the belt does

or at

stop

strong or if

motion

not

time,

the

positionofthe

move from the driving pulley to the idler pulley at either starting time

(or

in vice>versa case)

belt shifter is

inspect

conectornot.

and

seeifthe

tensionofthe

beltistoo

To remove the belts, first, remove the rear side

belt

toward

the

outsideofthe

motor

pulley,

then remove the inside belt from the idler pulley, pass it through the grooveofthe pulley

out

and take it

clockwise (as viewed

toward the rear. At this position, if the

from

tlie rear), the

belt

will

come

off.

motor

pulley is rotated

counter

To replace the belts to the pulley, reverse this procedure by turning the pulley clockwise.

1.

Ill HOW TO

Cleaninj;

the

machine

OPERATE

THE

MACHINE

When you run the machine for the first lime, be sure to wipe away

all dust

and

rust-proof oil from all parts.

To produce alractive stitching job, the sewing hook must always be

cleaned

sticking to it. Iwery day after the work is through, tilt the machine

and

should

be

dust-free.

Also

— 9 -

seetoit

that

no

lint

hards

are

and

Page 13

take

out

the bobbin case

from

the

surface

Also, remove all dust

check

and

the

needle

of

the

hook.

thread

and

and

dirt

trimmer

with a

from in

pairoftweezers remove all

and

blades.

When tilting the machine, at first, remove the belt

head

ing the

tilt it to your left. Be sure to see

support block at the left side of the machine (Fig. 12 ®),

that

the machine

standing up straight.

2.

Sewing

speed

around

arm

dirt

the work clamp

and

by upright-

support rod is

For the first 4 months, sew with a speed of

2,500

s.p.m. When the

machine is properly adjusted and oiled and the sewing cloth is not too

thick, the machine can be run at

sory box is for

2,500

s.p.m.

3,000

s.p.m. The pulley in the acces

butifyou desire a pulley of

2,800or3,000

s.p.m., please order separately as they are all available.

3.

Lubrication

J)

Oiling

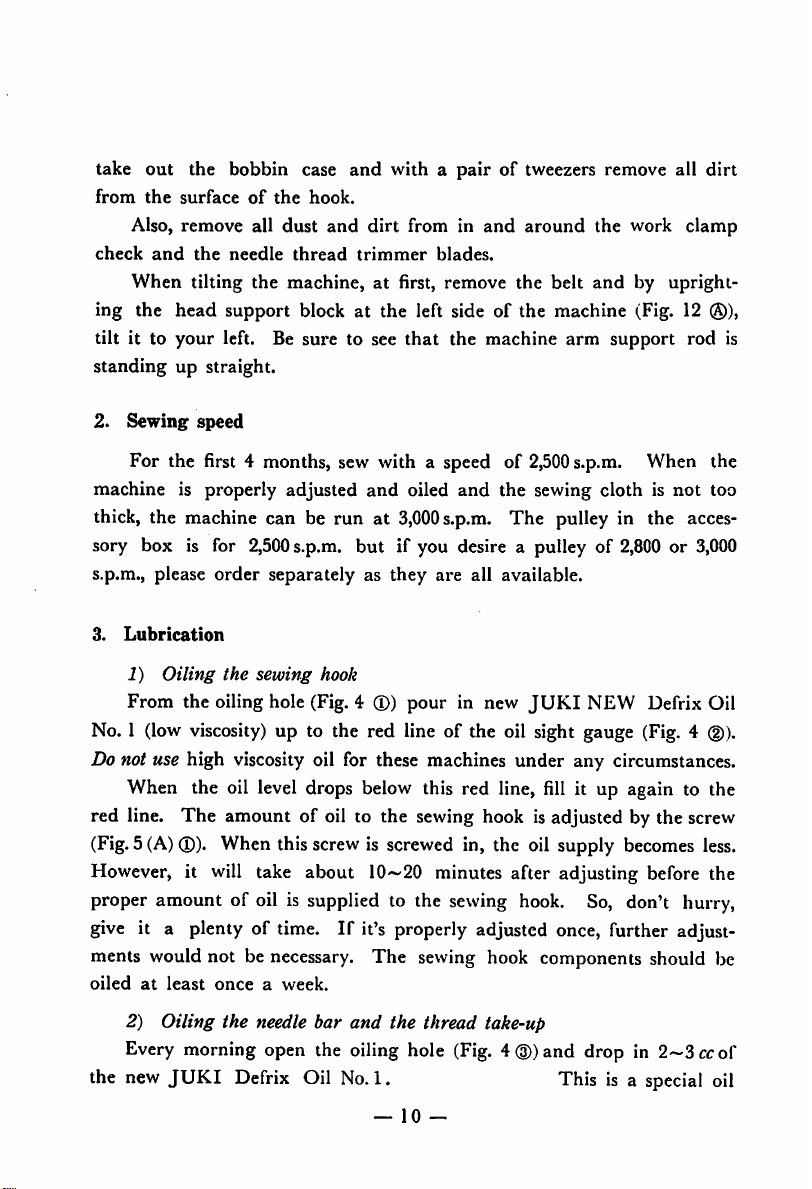

From the oiling hole (Fig. 4 ®) pour in new

No. 1 (low viscosity) up to the red line of the oil sight gauge (Fig. 4

the

sewing

hook

JUKI

NEW Defrix Oil

(D).

Do not use high viscosity oil for these machines under any circumstances.

When the oil level drops below this red line, fill it up again to the

red line. The amount of oil to the sewing hook is adjusted by the screw

(Fig.5 (A)

However, it will take about

proper amount of oil is supplied to the

(D).

When this screw is screwed in, the oil supply becomes less.

10-^20

minutes after adjusting before the

sewing

hook.

So, don't hurry,

give it a plenty of time. If it's properly adjusted once, further adjust

ments would not be necessary. The sewing hook components should be

oiled

at

least

onceaweek.

2) Oiling the needle bar

Every morning open the oiling hole (Fig.

the new

JUKI

Defrix

Oil

and

the thread take-up

4®)

and drop in

No.

1. This is a

2~3ccof

special

oil

—

10

—

Page 14

for

needle

oil leakage. Be careful.

3) Oiling the needle throw components

Every

5~8ccolJUKI

leak, so donl'l worry.

bar

components

morning,

NEW Defrix Oil No. I, The oil in this hole does not

open

only,soif

the

oil

you

hole

oil

too

(Fig.4@)

much,itmight

and

pour in

%/

cause

about

Page 15

Fig. 5 (B)

) ®

(HJ

(10

Page 16

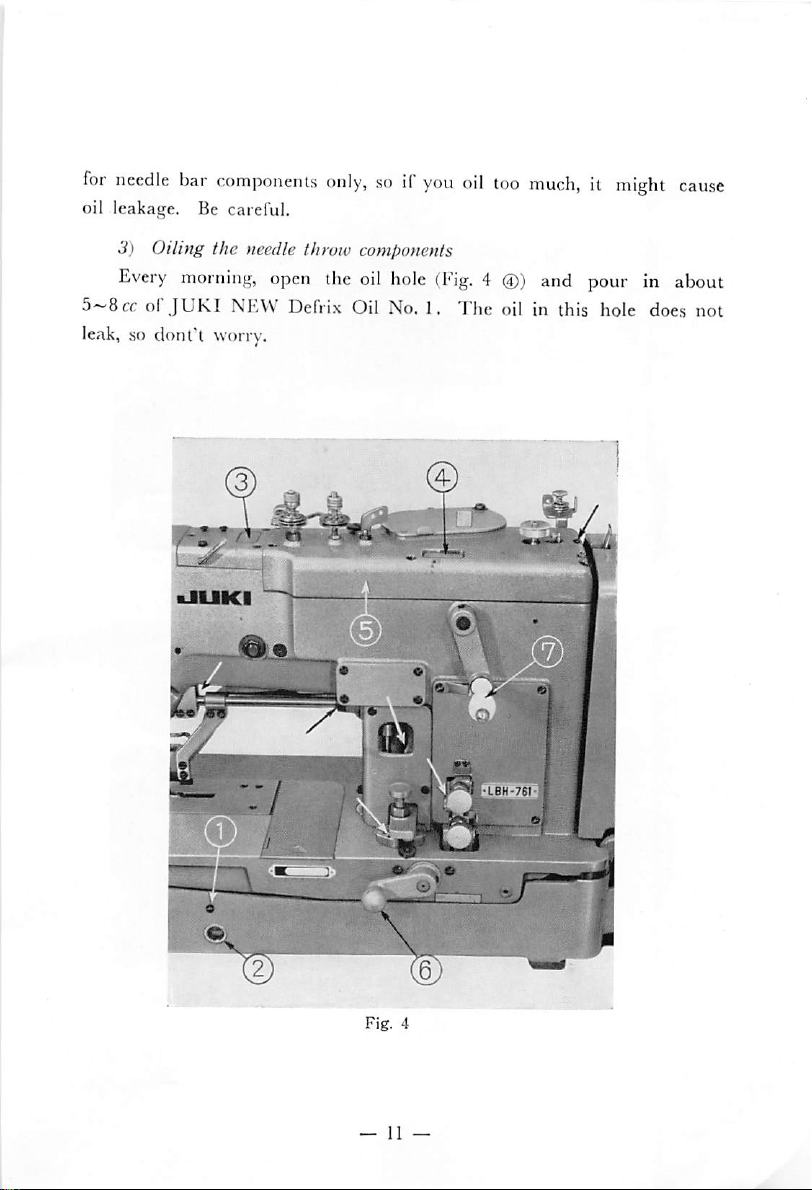

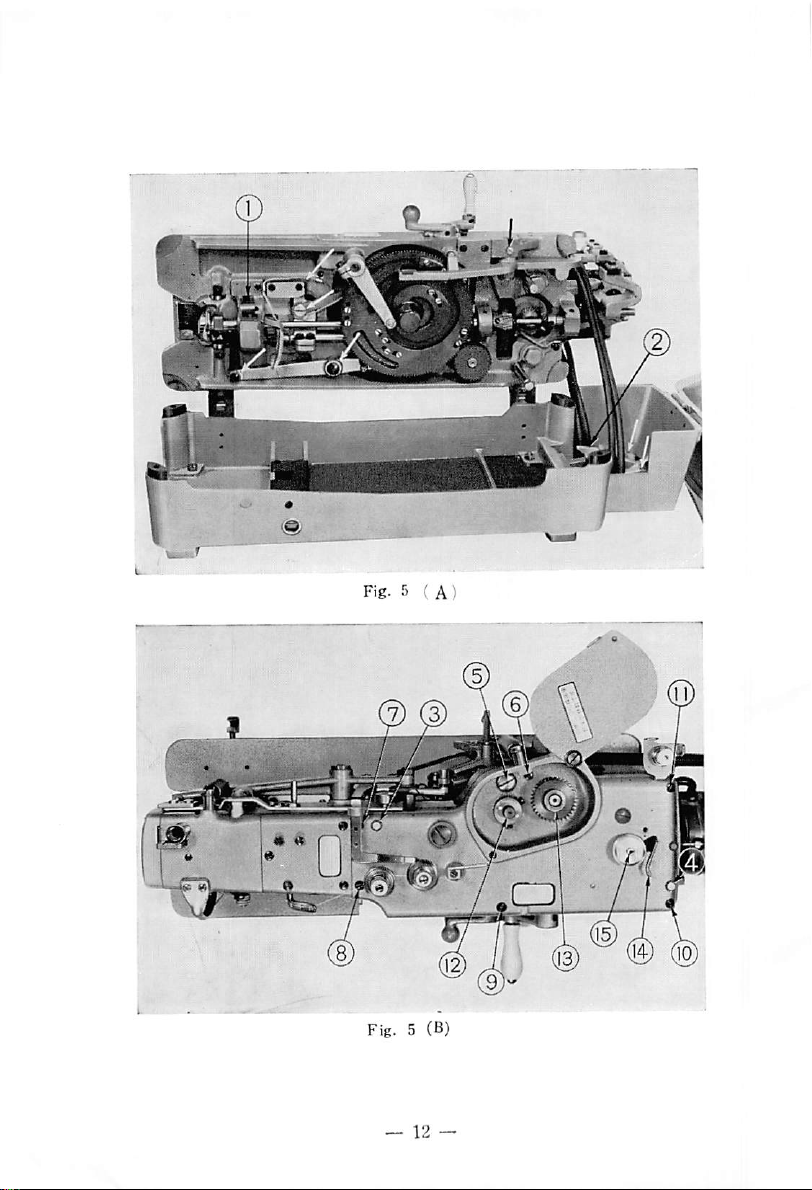

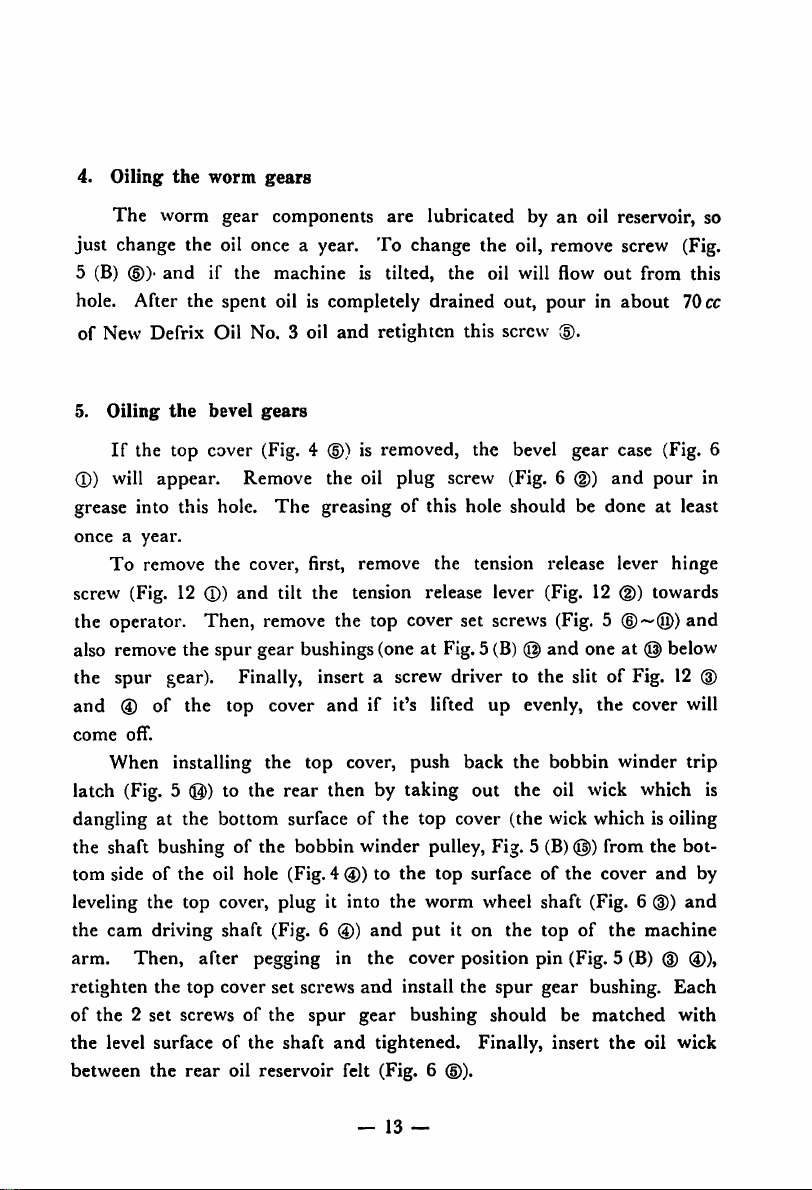

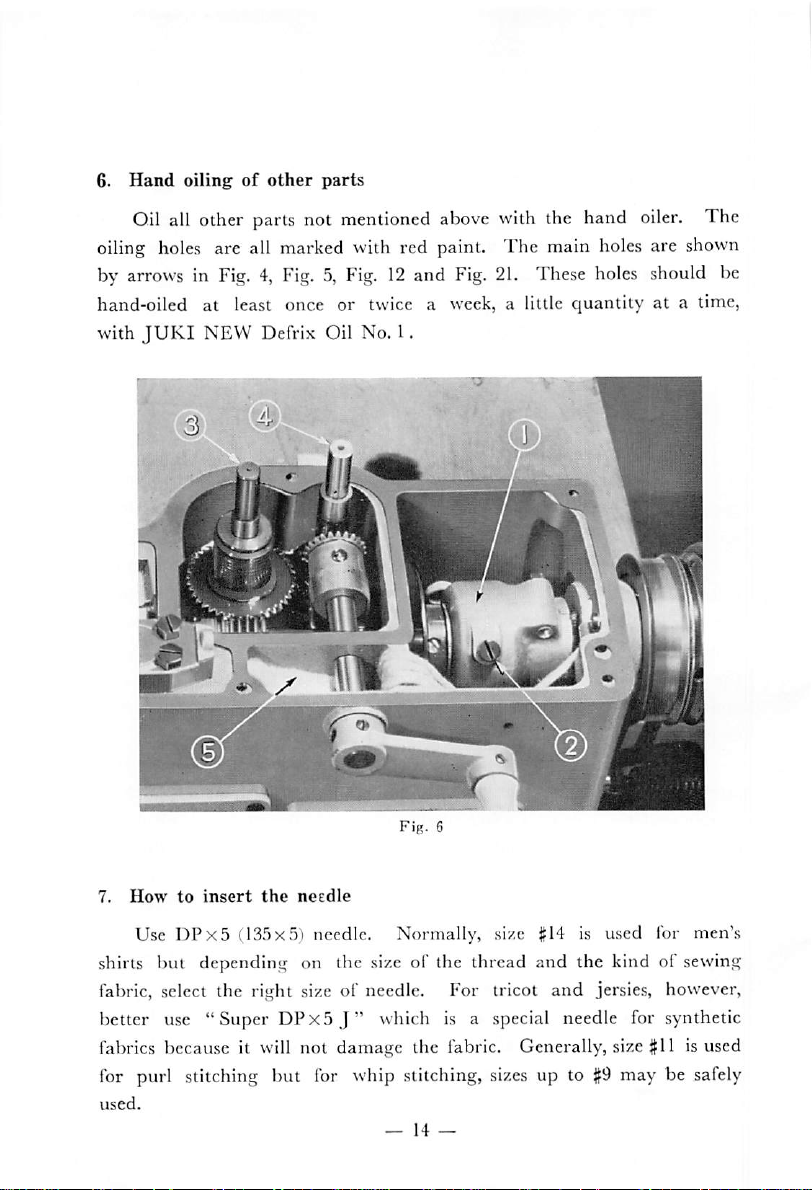

4.

Oiling

the

worm

gears

The

worm gear components are lubricated by an oil reservoir, so

just change the oil once a year. To change the oil, remove screw (Fig.

5 (B)

(§))•

and

if

the

machine

is

tilted,

the

oil will flow

out

from

this

hole. After the spent oil is completely drained out, pour in about 70cc

of

New Defrix Oil No. 3 oil

5.

Oiling

the

bevel

If

the top cover (Fig. 4

gears

and

retightcn

(D)

is removed, the bevel gear case (Fig. 6

this screw

(§).

®) will appear. Remove the oil plug screw (Fig. 6 d)) and pour in

The

grease into this hole.

onceayear.

To

remove the cover, first, remove the tension release lever hinge

screw (Fig. 12

(T))

and

the operator. Then, remove the top cover set screws (Fig. 5

also remove the spur gear bushings (one at Fig.5 (B)@

greasing of this hole should be done at least

tilt the tension release lever (Fig. 12

and

one at @ below

(§))

towards

and

the spur gear). Finally, insert a screw driver to the slit of Fig. 12

and @ of the top cover and if it's lifted up evenly, the cover will

come

off.

When installing the top cover, push back the bobbin winder trip

latch (Fig. 5

(g>)

to the rear then by taking out the oil wick which is

dangling at the bottom surface of the top cover (the wick which is oiling

the shaft bushing of the bobbin winder pulley, Fig. 5 (B)@) from the bot

tom sideofthe oil hole (Fig. 4

leveling the top cover, plug it into the worm wheel shaft (Fig. 6 d))

the

cam

driving shaft (Fig. 6

arm.

Then,

after pegging in

retighten the top cover set screws

of

the

2 set screwsofthe

the

level surfaceofthe

between

the

rear

shaft

oil reservoir felt (Fig. 6 (D).

(D)

spur

and

<D)tothe

and

the

and

gear

top surfaceofthe

put

it on the top of the machine

cover position

install the

bushing

spur

should

tightened. Finally, insert

cover

and

and

pin

(Fig. 5 (B) d) ®)»

gear bushing. Each

be

matched

the

with

oil wick

by

(§)

—

13

—

Page 17

6.

Hand

oilingofother

parts

Oil all other parts not mentioned above with the hand

oiler.

The

oiling holes are all marked with red paint. The main holes are shown

by arrows in Fig. 4, Fig. 5, Fig.12and Fig.

hand-oiled at least once or twice a week, a little

with

JUKI

NEW

Defrix Oil No. 1.

21.

These holes should be

quantity

N

at a time,

7.

How

to

insert

the

needle

Use

DPx5

(135x5) needle. Normally, size #14 is used lor men's

shins but depending on the size of the thread and the kind of sewing

fabric, select the right size of needle. For tricot

better use

"Super

DPx5

J"

which is a special needle for synthetic

fabrics because it will not damage the fabric. Generally, size

for purl stitching but for whip stitching,

used.

—14—

sizes

and

jersies, however,

#11

is used

up to#9may be safely

Page 18

To insert the needle, put the grooved side of the needle toward the

operator, insert the

bar hole until it stops and then tighten it with the set

face

the

grooveofthe

8.

Threading

the

needle

deep up the

needlealittletothe

machine

needle

bar through the

lefttoprevent

screw.

skip-stitching.

needle

Better

-15

Page 19

For button holing, use best grade cotton thread of even size and

even

left

twist

for

the

needle

and

the

strands

from

3~6

nylon or super polyester threads can be used as

nylon

synthetic fiber

threadisto be

thread.

thread.

fiber twists.

used,

be sure to

The

sizes

For

useaspecial

the

should

needle

well.

be

from

thread,

However,

sewing

#40~60

polyester,

when

hook

for

Right twist or inferior grade thread will, not only mar the beauty

of stitched job, but will invite thread breakage, thus lowering the

effici

ency of the button holing operation. Nothing is gained by inferior grade

thread, so be sure to select the best grade of thread for this operation.

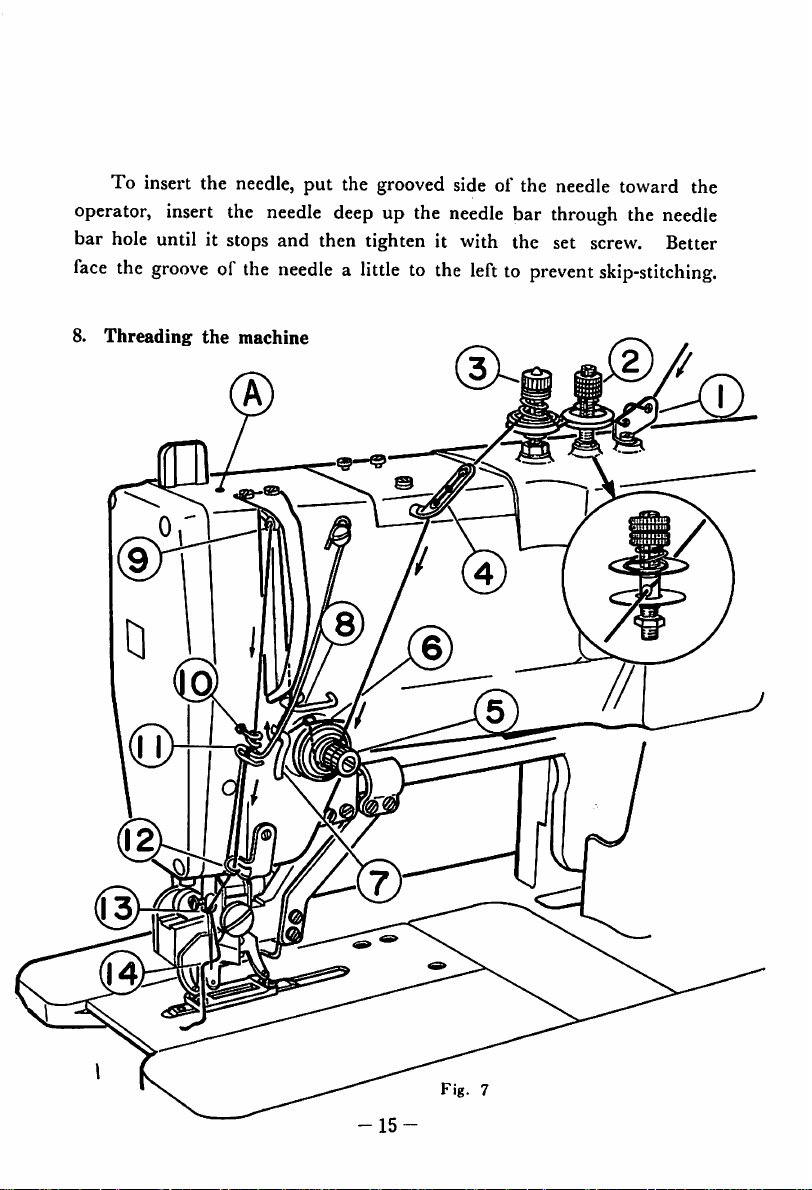

Refer to Fig. 7 for the

orderofneedle threading.

The needle thread, which came out of the thread spool, should be

passed in the following

The thread guide pin ©^tension disc No. 1

(D^three-hole thread eyelet • tension disc No. 3 »take-up spring

order:

(§)—•tension

disc No. 2

(D

tension thread guide @ • take up thread guide A ® • thread take up

® • take up thread guide B ® • thread check wire ®

thread guide ©

•needle

thread guide ®

•needle

eye

®.

•needle

bar

In passing the thread through the needle eye, be sure to pass it from

the opposite side of the operator.

Please note also that, as shown in Fig. 7, the tension disc No. 1

(D

has a hole with a slit, so pass the thread through the center hole of

this slit by lifting the upper tension disc.

--

lb

Page 20

m

m

.f_r<

9.

Winding

The

caseofneedle thread, synthetic threads can also be used.

The bobbin thread should be passed in the order as shown in Fig.

9. First, insert the bobbin into the pulley shaft ® and pass the thread

which came out of the shaft in the order of thread guide eyelet

bobbin winder tension disc

the

bobbin

the

bobbin winder trip latch d) is pressed against the bobbin, the

thread

fixed

amount

cannot

the

bobbin

optimal

sizes

in

the

will be wound

thread

of

the

d)—»

counter-clockwise

during

the

bobbin

thread

are

150—100

thread guide eyelet @ and wind it to

direction

as

viewed

runningofthe machine

is wound, the winding will stop automatically.

be wound when the machine is not running.

from

and

and

as in

above.

bobbin

when the

The

bobbin

the

(g)—»

If

10.

Drawing

out

the

thread

from

Fig.

—

(B)

the

17

10

—

bobbin

case

Page 21

The

order of

drawing

out

the

thread

from the bobbin case is shown

in Fig. 10 (a) (b) (c).

Hold the bobbin inside the bobbin case so you can see clearly from

the

front

and

when

the

threadisdrawn

out

from

the

bobbin

case, see

to it that the bobbin turns in the counter-clockwise direction. (Fig. 10c)

11.

Inserting

the

bobbin

case

Fig.

11

See Fig.11for inserting the

the

bobbin

sound

might

inserted

12.

Running

Step

insert

work

clamp

the

right pedal is stepped on fully. After the

case is correctly inserted to its position in the hook, a click

can

be

jump

out

in.

on

the

the

sewing cloth.

the

heard.

when

machine

left

If

the

pedal

check is lowered,

the

machine

and

the

When

the

bobbin

bobbin

the

machine

—

case

into

the sewing hook.

case is

not

properly

starts. So, be sure

work

clamp

check will go up.

left lifter pedal is raised

will

starttorun

button

18

—

holing is through

that

just

When

inserted,

it's snugly

Now

and

the

as soon as

and

it

Page 22

the

knife

has

cutaholeinthe

Then,

raise

up the

This

machineisequipped

machine

work

starting

way, the starting pedal will not start.

at a

running, it will

Caution

from

clamp

pedalissteppedonwhile

When

slow

the starting

speed

If the starting

stopping

speed

13. How to prevent the cutting motion of knife

gone,

produce better sewn garment. This machine is so constructed

the

cutting.

thread is all

wrong with the

of the knife stop lever (Fig. 12

until the machine stops. This will prevent the machine from cutting.

time,

or the

When the needle thread is broken or when the bobbin thread is all

needle

When

stop-motion

it is better to

thread is

However,

gone,

the

work

starting

checktogo

pedalissteppedonlightly,

but if

run

faster.

pedal

the

knife

resew

broken,

when

the

knife

bobbin

thread is all gone or

sewing

cloth,

the

machine

clamp

while

is left in the

might

device

check

and

pull

withasafety

the

work

clamp

up

before

the

pedalissteppedonfully

cut at

without the

the

the

stepped-in

high

may not

machine

lifter

speed

function

motion

clutch

pedalisstepped

it automatically

the

needle

will

condition, push down the

(D)

thread

cut at the

with your

is

finish

when

hand

will

stop

automatically.

out the

sewn

which

prevents

checkisraised

stops

and

evenifthe

the

machine

during

condition

without

properly.

of the cutting

prevents

intact

of the

you detect

at the

shiftingtolow

the

but

sewing

finger

(Fig.

and

hold it there

Be

knife

the

cloth.

or the

down

half

will

run

this

slow

machine

careful.

knife

that

when

from

bobbin

cycle.

something

12

the

to

®)

14. Slow speed

1) Low speed

When the machine is to be adjusted or when the stitching condition

running

running

and

how to stop

—19—

the

machine in emergency

Page 23

is

extremely

bad,itcanberun

(D)islowered

even

though

and

the

kept

starting

at a

low

speed.Ifthe

there,

the

machine

pedalissteppedonfully.

will

run

at a

handle

slow

(Fig.

speed

4

2) Stopping the machine in

If the

needle

the

sewingiscontinuedinthis

ped.

In

suchacase,

this,

turn

the

stop

bolt.

clamp

to

or starting the

15.

also

checktothe

the

original

How

to

This

handleisused

when

breakage.Ifthis

work

clamp

the same manner as in normal

if

this

handleisreversed,soif

move

carrier

the handle

will

should

hand

stop

The

machine

original

position

machine,

use

the

handle

it is

desiredtoresew

handleisrotated

carrier

move.

(Fig.12@)

forward

break

the

machine

crank

will

sewing

and

complete

for

emergent

emergency

during

by

sewing.

you

and backward, a little at a time, and the

the

running

condition,

the

sewing

canbestopped

180°

counter-clockwise

stop

instantly.

position,

either

the

stoppingasmentioned

from

and

the

want

return

turning

sewing

in

cycle.

the point just

the

clock-wise

work

clamp

The carrier will not move even

to

move

of the

cloth

machine

mayberip

emergently.Todo

untilithits

To

the

return

the

handle

before

check

the

hand

the

stop

(Fig.4(2))

above

the thread

direction,

will

carrieralittle,

work

crank

move

and

the

and

the

in

Caution

1)

During

(Fig.12(§))ispulled

12

(D)

is rotated and if the machine is started by turning the handle

before

with the stop link

the

the

machine

the

groove

starts.

maintenanceofthis

to the rear by hand and the

of the stop cam

(Fig.12©), the

—

knife

20

machine,

(Fig.

12

often cuts at the instant when

ifthe

stop-motion

driving

@)istightly

lever

pulley

(Fig.

interlocked

Page 24

Fig.

12

This action results only when, as shown in Fig.

of the knife bar driving lever bell crank (i) is not

(B)

(D,

ratchet pawl

(D

and

ratchet pawl (A) ®

In such a case, pull the finger

crank

(T)

towards you.

part @ will be released and the pawl

of the claw part

thus creating a space between the ratchet pawl

and

the claw part(Dis trapped between them.

(J)

of the knife

The

interlocking of the pawl

(g)

will return to the under side

(?)

and the above trouble will not occur again.

13,

the ratchet pawl

"riding"

bar

driving lever bell

(3)

and the claw

When the machine stops correctly and the stop motion cam and

the interlocking link are interlocked each other, the claw part

w-ill

starting lever

(D

screw

bell

and is pushing up the(Dpart of the knife bar driving lever

crank.

So

contact the knife bar driving lever bell crank hinge

the

above

mentioned

trouble

will

not

occur.

2) Use the handle only when the needle is not piercing the cloth.

It

will be safe if the

at

the

correct

handleisrotated

angle.

when

the

driving

—

21

—

pulley is

atop the

(5)

of the

stopping

(B)

Page 25

Fig.

13

iV.

ADJUSTING

1.

The

bobbin

thread

tension

THE

VARIOUS

PARTS

The optimal bobbin thread tension is for the bobbin case to gradually

slide downwards when the tip of the thread is held by your hand and

lightly shaken up

If

the bobbin thread tension is too strong, wobbling stitching will

result

and

and

down. (Fig.

further, it will invite

14)

thread

breakage of the needle

thread

due to the strong needle thread tension caused by the strong tension of

the

ing

bobbin

job.

thread, a detrimental factor to produce an attractive stitch

—22—

Page 26

FiM. M

On

the

other

hand,

bobbin thread will not stay taut

cloth, making it impossible to do finish sewing -of the

cycle, causing slipping

2.

The

needle

1)

The

mannertoproduce

When

ing"

up.

On

all

three

No. 2 floats up

thread

needle

the

machineisat

the

start

and

tension discs

and

thread

beantijul

if

the

bobbin

and

will

thread

''float"

tensionistoo

weak,

on top of the sewing

starting

outofthe needle thread.

tension

tensionofthis

whip

rest, all

return

are

sewing

working. At all

stitchingofbarred

machine changes in

the

thread

around

tension

the

edgeofthe

barred

ends.

ends,

the

discs

button

the

tension disc

following

are

forms a whip stitching. Also when the machine is

running at a low speed, the tension disc No. 3, too, is floating up.

At the

a low speed, so

will

No. 1

second

barred

at

have

been

working

and

No. 3 will be working.

the

end,

second

and

the

speedofthe

barred

at

the

end,

first

machineisswitched

only

the

tension disc No. 1

barred

end, the tension discs

Accordingly, the three tension discs will adjust the following:

0

Thread

second

tension disc No. 1

barred

end.

adjusts

the

needle

thread

tension,

the

sewing

"float

hole,

at

the

to

—

23

—

Page 27

(D

the

(3)

first

Thread

needle

Thread

barred

tension disc No. 2 adjusts the seaming thread tension of

throwing.

tension disc No. 3 adjusts

end.

the

needle

thread

tensionofthe

2) To produce good stitching tension

Once

the

thread

tension is

for

properly

purl

stitching

adjusted, it is

not

necessary to

adjust the tension of tension discs No. 1 and 3. Just adjust the tension

disc No. 2 only.

To produce optimal stitching condition, do as

(D

Adjust the bobbin thread tension according to Par. 1, above.

(D

Adjust the tension disc No. 1 so that a beautiful whip stitching is

follows:

produced at the second barred end.

If

the

tension disc No. 1 is

tighter

(3)

end

and

the bobbin

thread

Adjust the strength of the tension disc No. 3 so that the first barred

forms a

beautiful

whip

stitching.

strengthened,

is pulled

out

more.

the

needle

thread

gets

Finally, adjust the strength of the tension disc No. 2 so that the

mounts

erect.

of

the

starting

If

the

tension disc No. 2 is strengthened, the wobblingofstitches

apd

returningofthe needle

throwing

stand

up

will be prevented. However, if it's strengthened too much, the needle

thread

CAUTION

needle thread tension is too weak at the whip stitching places, a so-called

" double locking" (hooking up of the stitch by the hook point of the

second

the sewing surface) will result

tensionofthe needle

the

might

break. Be careful.

The

first and the second barred ends are whip stitching

stitching

bobbin

thread

thread

before

thread

the

first

stitching

and

may

should be so

cut

the needle thread.

adjusted

will not come up on the surfaceofthe cloth.

but

threadispulled

to the

extent

if the

up to

The

that

3) To

produce

good

stitching

tension

for

whip

stitching

Loosen the tension disc No. 2 fully for whip stitching. Also adjust

the

bobbin

thread

tension

justsostrong

—

24

—

as to allow

the

bobbin

case to

Page 28

droop down

bobbin case is held by the hand

nance

with

slowly

the

tensionofthe

when the bobbin thread which came out from the

and

waved strongly.

bobbin

thread,

adjust

Then,

the

second

in conso

barred

end tension by changing the tension of the tension disc No. 1 and adjust

the tension of the

by

the

tension disc No. 3.

starting

and

returning

as well as the first

barred

end

It is a common practice to use the same size of thread for the

needle

3.

and

Adjusting

The

tension

bobbin

Fig.

the

and

threads

take-up

15 (A)

the

for all

spring

moving

the beauty of stitches as well as

locking".

The

tensionofthe take-up spring at the

whip

stitching.

rangeofthe

thread

Fig.

15 (B)

take-up

spring

greatly

affect

breaking due to the " double

start

of sewing should be

25—30g when it is pulled along the circumference of the tension discs.

(Fig. 15 (A)).

and

loosening

post No. 3 assembly (Fig. 15

The

moving

-7/16").

Please note

must

be 2- times

stitch

machine.

This

can

be

the

screw ® Fig. 15 (B)

rangeofthe

that

the

tensionofthe

stronger

than

adjusted

(B)\

take-up

the

by loosening

after

spring

take-up

removing

should

take-up

springofa

the

screw (D Fig. 24

the

thread

be

9—11mm.

springofthis

conventional

tension

(3/8"

machine

lock

Page 29

4.

Timingofthe

i)

Height0/the

When the

needle

needle

needle

bar is

and

bar

lowered

the

hook

to the

lowest

point,

the

space

hciwcen

the needle plate surface and the bottom part of the needle bar should

be

10.3

mm (3/8").

the timing gauge in the accessory box (Fig.

screw

driver into the hole

tionofthe needle

12.6

bf

2)

Timing

The

best timing of the needle with the sewing hook is when the

Fig.

the

If

the height of the needle bar is not correct, use

16(1))

and by inserting a

(Fig.21(g))

bar

connection (Fig. 27

16

hook

adjust the correct installing

).(»—

Fig.

17

posi

l.Kntii)

needle stitches right in the center of the needle hole of the needle plate.

When the needle has begun to rise from its lowest point and the

point of the hook point is timed with the center of the needle, the space

between the upper

(1/16"). (Fig.

better.

For correct timing adjustment, use timing gauge of Fig.

the driving pulley in the

17).

part

of the needle eye and die hook point is 1.6~l.8 mm

For jer.sies

and

knit goods, 1.6mm (l/16"i space is

16.

regular

direction,

and

when the needle has

Rotate

begun to rise up from the lowest point, insert the 2 part of timing gauge

(Fig. 16) between the needle

needle

center

bar

contacting the gauge, time the point of the hook with the

of

the

needle.

The

bar

clearance

and

the needle plate and with the

between

the

needle

and

the

hook

point is about 0.05mm but when the needle is swung from right to

left, or vice-versa, be sure that they don't touch each other.

—26—

Page 30

I-ig. 18

To

To

i-emove

them

out.

(§)olthe

adjust the timing ol' tiie hook, loosen tlie set screw

the

hook

To

sewing

replace

sleeve

hook, loosen

the

sewing hook,

with

that

ofthe

the

set screws (Fig. 18 d))

time

the tipofthe oiling

hole

oi"

the

oil

reservoir

(l'"ig.18(T;k

and

take

tube

and

install

the hook back. In doing so, the bobbin case stop must also be

removed

positions

but

to replace it, be sure to adjust the right

of

the bobbin case stop so that the

thread

and

left installing

will easily pass

through the space of tlie corner between the bobbin case stop.

5.

Adjusting

button

1)

hole

The

Ihroivof/he

the

positions of seam

needle

and

barringinrelationtothe

Fig.

19

—27—

Straight

Page 31

For

the guide

of

A

needle

barred

position;

width.

2)

seaming or barring, this machine always keeps the left side as

and

throws

Fig. 19 is

Adjusting

Wi

the

the

called

is

Wi

called

and

needle to the

the

right

needle

the

seam

W2

right

position;

width

and

keeps on stitching.

B is

called

and

W2 is called

the

left

the

Please

adjusting

is

returned

when

the

this

screw

in mm

3)

When

to left

refer

to Fig. 20.

screw

adjusting

and

Adjusting

and

(T)

is screwed in

toward

the

screw

is

returned.

the

graduation

the

the screw

(2)ispushed

if it's lowered, it will move to

operator.

(2)

The

right-left

The

is screwed in

graduation

(D

needle

Fig.

20

seam

width

and

will get smaller

The

barred

indicates

positions

and

(D

the

W1 gets

width

will get

indicates

barred

bigger

when

W2 will

narrower

the

width

when

this screw

get

seam

also in

up, the needle position A will move

right.

—

28

—

When

the

adjusting

the

bigger

when

width

mm.

Page 32

screw

(§)

is screwed in, the needle position B

returned,

knife

so that the thread of the right side of the seam width will not be cut

by the knife. Finally, adjust the barred width.

CAUTION

® After all of the above adjustments are made, be sure that all the

locking nuts

(D

Due to a certain amount of rattling by the throw of the needle

it will move to

4)

Orderofadjustment

Adjust

the right

needle

from cutting into the

are

firmly tightened.

right.

position

seams.

and the

Next, adjust the left needle position

moves

seam

tc left and it it's

width to prevent the

and tighteningofthe cloth by the needle, there may be a slight tolerance

between the graduation figure and the actual button holing length. So,

make correct adjustments by actual sewing.

@ The needle is so constructed to throw more than the hole length of

the

work

clamp

widened to over 3.8mm (5/32")

the

driving

and return

check.

pulley

sewing,

So,

after

adjusting

and

moving the needle position,

with your hand and

the

needle

will not contact the work clamp

the

ascertain

barred

widthsothat it

that during both start

rotate

check.

After the driving pulley is rotated by hand, be sure to return the

pulley

camofthe

to the

stop.

angle

where

the

stop

linkisinterlocking

with

the

groove

is

6. Adjusting

Pull out the bed slide

and by

show same graduation as the width of the knife, tighten the nut.

sliding

the

work clamp

the regulating

carrying

(A)

Fig. 20 to your right, loosen nut(DFig.

hinge

motion

stud

(2)sothat the

scale

(3)

will

The graduation is set to the amount of carrier corresponding to the

width of the knife, but if desired, this carrying amount may be increased.

—

29

21

Page 33

7.

Changing

the

number

of

Fig.

stitches

21

<K

Page 34

By changing the spur gears, this machine can change the number

of

stitches in a

When

gear

(D

A, B, C

alphabets show the pairing

the

same

which is on

wide

rangeasshowninTable

the

numberofstitches

are

desired to be changed,

below.

change

the

Fig. 22. All the spur gears have alphabet marks such as

etc.

or

alphabet

the

numbers

gears.

rear

side,

such

number

The

figures

indicate

as 123, 152

etc.

branded

on

them.

of each gear, so be sure to interlock

branded

the

numberofstitches

on the

gear

required.

d) Fig. 22,

The

When installing the gear, insert the pin holes firmly into the 2 pins

of

the

spur

gear

bushing0,Fig. 22.

As the shaft

(3)

and

the shaft

(3)

(Fig. 22) rotate freely to opposite

directions, respectively, insert the gear into the shaft and after interlock

ing, rotate the gear by pressing it downwards and it will go in easily.

This machine is provided with the following 15 gear sets, as acces

sory parts, besides the sets in the machine, but if other gear sets are

desired besides these sets, please order them separately.

'FABLF

Set

A

B

C

D

!•:

F

G

H

The

Small

Teeth

No.

ones

21

23

24

25

26

27

28

29

gear

Stitch

No.

circled

Large

Teeth

No.

54

62

66

70

74

79

83

88

withOare

gear

Stitch

No.

345

53

300

51

285

50

238

49

252

48

238

47

225

46

212

45

standard

—

accessory

31

Set

Small

Teeth

I

K

©

M

®

No.

Stitch

No.

30

100

31

32

150

110

33

34

35

36

sets

—

gear

115

123

130

Large

gear

No.

Stitch

No.

44

200

190

43

42

180

41

170

40

160

39

38

152

145

Teeth

93

Page 35

The

beauty and durability of all button holes depend largely upon

the

pitchofthe stitches, so select

8.

Adjusting

the

positions of

the

the

knife

correct

numberofstitches.

As the positions

ol"

the knife bar cannot be adjusted, when the right

or left positions of the needle plate knife groove is out of alignment due

to loosening

of

screws etc., loosen screws @C®Fig. 21

and

make slight

adjustment on the installing positions of the needle plate or work clamp

carrier

ling positions of the knife holder @ Fig.21back

knifeisinstalled,

beatleast

knifeislowered,

plate.

.•\djust the front

the

0.2

mm

The

installing

the highest point of the

and

rear positions of the knife by moving the instal

clearance

(1/160").

heightofthe

between

knife

the

should

knife

and

forth. When the

knife

and

needle

be

such

that

(g)

Fig.21should be 3mm

bar

when

should

(1/8") below the suiface of the needle plate.

9.

Adjusting

the

needle

thread

trimmer

blades

the

Fig.

23

i)

Adjusting

the

gripping

powerofthe needle

thread

trimmer

blade

When the gripping power of the needle thread trimmer blades

Page 36

becomes

sewing.

becomes

blades

23,

the blade

matter

strong

with

and

trimmer blades

starts to rise and at the same time it will rotate to right with the needle

thread

will

and

thread

change

(D,

blades

blade should come out 3.8'~4.3mm

centerofthe

the above measured distance, the chances are either the blades are too

far in the rear or they

the blades close too soon,

guide

unsteady,

When

the

weak, remove the set

and by

the entire length of the blade trimming part

(2)

without any

where the blades trim the needle thread, the blades will have a

gripping

2) Honing the needle thread trimmer blades

When

the

spare

bladesorsharpen

®

with

an

3) Adjusting the installing positions of the upper blade

When

the

trimmer

contact

the

blades

To

adjust

trimming

the

positions

Fig.21and be

completed

When the blades will not trim even though blades have moved to

and

move

the

needle

gripping

bending

power.

trimming

oiled

power

the tip of the thread

spaceinbetween.

power

whetstone.

sewingisfinished

vvill

advance forward before the work clamp check

shaft

©,

Fig.21as its

the

edgeofthe

will

close.

the

front-rearorright-left

time,

first

and

angles

suretosee

the

movement

needle plate.

closeupbefore

loosen

the

blades

thread

of the

screws

beginstofall

needle

(D

Fig.

21,

out at the start of

thread

take out the trimmer

tension

should

Finally, adjust so that no

of the

the

needle

blades

thread

and the

center

thread

become

trimming

lifter

pedalisstepped

and

trimmer

tips

the

dull,

of the

pin ®,

guide

positionsofthe

loosen

the

of the

blade

needle

clamp

thread

screw©Fig.

that the threadisgrasped.

to right, the right end of the

(l/8"~5/32")

the set screw

toward

the

the

blades

operator.

to the right of the

gripthe thread. When

(i|)

Fig.12of the trimmer

The

trimmer

spring ®

closely

change

blade

Fig.

(D,

blades

trimmer

When

closing

blades

Fig.

contact

them

on,

the

Fig.

at the

holder

the

lower

time

(D

23,

21

21,

—33—

Page 37

of the

Conversely, if the trimmer guide is moved to the rear, the blades will

close up

tions of the blades as well as the trimmer guide to be sure that the

blades

after cutting the thread, they

adjustedbyloosening

the

so

each

one

the

21.

so

there should be a space of

the

blades

Accordingly,

1 he installing heightofthe needle

blades

that

other.

After the trimmer

stitching

blades

Also

The

adjusted

lower

will

much

faster.

will

close

and

the

when

the

cycle

will

not hit the

see

to it that

height

of the

that

when

surfaceofthe

be

delayed

make

proper adjustment of the

when they have completed the

the

work

clothisinserted

blades

and,

before

the

needle

the

blades.

and they

firmly

set

screws

clamp

carrier

are adjusted, be sure to

the

lower

surface

closed

blades

thread

needle

thread

0.2'—0.4mm(1/500")

will

grip the thread

forward

movement

grip the tip of the thread.

thread

(§)

Fig.

should

between

actual

of the

will

trimmer

cutting

trimmer

21,

and

be

as

them,

sewing

operation,

work

openupduring

finger

blades

between

and rear

blades can be

the

space

narrowaspossible

they

will

move

clamp

(g)

Fig.12should

begin

the hook and

firmly.

posi

to right and

between

not

contact

the handle

verify

that

arm @

the

Fig.

carrying.

to

move,

be

4) Adjusting the

shaft

After

the

blade

pull-up

shaft

crank

affects

startofsewing.

thread

by

thread

after

the

When

trimmer

the

trimmer

trimmer

trimming

enfolding

the

locking

crank

needle

locking

threadiscut,

are

determinedbythe

bracket

actionofthe

work

clamp

shaft

crank

shaft

crank

blades,

too,

and at that

bracket

latch of the

the

right

installing

latch

(Fig.21(ip).

needle

thread

carrierislowered,

(rear)

Fig.21@)

locking

will

bracket

returntoleft

latch.

position,itwill

—34—

needle

thread trimmer

and

left

positions

This

into

the

the

tip of

will

gradually

Accordingly,

(l.Smm'-Smm)

grasp

the

needle

positions

of the

position

of the

trimmer

greatly

stitchingatthe

the

needle

returntoleft

the

needle

(l/16'-l/8")

thread

and

Page 38

start

to

sew.

When the locking bracket latch is leaned too much to the right, the

and

needle thread will stick out to the right side

too

muchtothe

sticking

out

left,

the

thread

to the left, when it's

will

stick

outtothe

cut

by the knifeatthe last stage, there

conversely, when it is

left.

(Evenifit's

is no problem).

The

adjustment of the left

and

right positions should be done by

either increasing or decreasing the number of spacers to be inserted to

the installing

The

part

of the locking bracket latch.

reason why the installing hole of the locking bracket latch is so

long is for the purpose of adjusting the interval from the start of sewing

to the

grippingofthe needle thread.

If

the locking bracket latch is pulled out toward the operator, the

gripping interval of the needle thread becomes short and if it's withdrawn

to the opposite side, this interval becomes longer. In other words, if the

thread is released quickly, the needle thread might fall out at the start of

sewing or the enfoldingofthe needle

careful.

10.

Adjusting

the

bobbin

thread

thread

trimmer

might

blade

not be

adequate.

Be

1)

Exchanging

the

bobbin

thread

trimmer

blade

When the cutting power of the bobbin thread trimmer blade has

become dull, remove the work

with a spare blade. Pull in the counter knife (Fig.21(@))

clamp

carrier

(Fig. 24 ®)

and

exchange it

tip 0.3~0.5 mm

(abot 1/50") away from the needle plate needle hole so that it will not

contact

2)

the

needle

Honing

the

or

blade

bobbin

thread.

When sharpening the blade, be careful and don't change the original

angle of the

blade

tip.

—35—

Page 39

Fig.

24

II.

Adjusting

the

pressureofthe

work clamp cheek

The pressure of the work clamp check is adjusted by the presser

spring i-eguiator (Fig. 24

pressure becomes stronger

on

the

clotli.

12.

ward

each

the

Adjusting

shaft

If

the

motion

other

installing

the

installing

bell

crank

handleIsrotated

or if the blades

during

the

angleofthe

(X>).

and

angle

(Fig. 26

while

and

adjustment

bell

H this is screwed in light, the clamping

makes it

(7))

of the

crank

of

the

the

harder

the

buttonhole

knife

work

needle

becomes

for the wrinkles to form

has

clamp

not

thread

out

length

completed

check are

of

regulating

trimmer

alignment,

the

up

contacting

blades,

some-

Page 40

In such cases, loosen the clamping screw (Fig. 26

handle and after timing the center of the sliding roller (Fig. 26

that

of the indicating line (Fig. 26

(g))

of the feed cam

the work clamp arm at about the same place as the start ol

move the work clamp arm back and forth and find the position where

21

the scale (Fig.

stud (Fig.

21

@).

13.

21

At this

Adjusting the

needle

@) will not move even if the scale adjusting hinge

(D)

is fully moved from left to right inside the

position,

thread

tighten the clamping

device

breaks

to prevent the knife from cutting when the

screw

(D),

turn the

(D)

with

and

by matching

sewing,

groove

(Fig.

of the bell crank.

When the

wire

(Fig.

the

thread

is

not

broken.

To correct these defects,

(Fig.24(D)

it doesn't touch the take-up thread guide A

in-between

Next,

and

fix the tension so that there will be no sagging of the thread bet

ween

the

Then

of

knife

stop

ring)

(Fig.25(i^)

angle of the knife stop lever.

Even after the above adjustment is made, the knife does not cut

when

the

the needle thread is cut, move the bracket of the knife stop lever

to the left.

it's

knife

knife

stop

lever

(Fig.

24

®) are installed

is broken or the knife will not

of the thread

should

pass

take-up

loosen

be

the

guide

the

lever

supposed

(Fig.25(£))

will

check

around1mm

needle

(A)

and the

sci-ew

(g)

be 1.5-2

to cut, then

stop lever to the right.

When

this balance is not

wrong,

first,

wireashighaspermissable

thread

tension

Fig. 25 so that the space Ijetween the edge

and the

mm

Conversely,

25

®) and the thread

the

knife

might cut even if

cut

even when the needle

set the height ol the thread eyelet

as

check

thread

long

(Fig.24®). The space

(1/25").

through

move

the

thread

knife

stop

(about

1/16")

the bracket

if the

maintained,

regular

guide

lever

passing

channel

No.3(Fig.24(§)).

stop

roller

and

then

adjust

(Fig.25(D)

knife

cuts evenwhen

the knife stop lever

(rubber

the

as

of

—

37

"

Page 41

might waver up and

knile does

® and

contact each

washer

driving bell crank finger Fig. 25

Next,

not

cut,

steponthe

when

the

other,

so

that the

down

sometimes.

starting

knife

stop

adjust the

space

during the running of the machine and the

pedal,

push

down

the

knife

stop

lever

lever

height

between

(2)

and the

will become

knife

stop

lever

of the

knife

stop

the tip © of the stop

l~l.5mm.

lever

lever

screw

stop

When the set screw is tightened, the knife stop lever screw washer

will

move,

so be careful and tighten the screw

firmly.

Fig.

25

washer

screw

and the

14. How to

The

ratio

between

In most cases it will not be necessary to change this ratio but when

it is desired to increase the number of stitches at the barred ends, change

change

number

ol

stitchesatthe

the

number

the

numberofstitchesatbarred

of

barred

stitches

and

endsofthis

the

total

ends

machine

number

of

stitches.

is a fixed

the bar tripping segment No. 1 (Fig. 26 ®) and the bar tripping segment

No. 2 IFig. 26 d)).The

which

are

20% less stitches

supply of

and

bar

tripping segment No. I and No. 2

also 45% less stitches

are

available. So,

if desired, please order them separately.

If

other

bar

tripping segments are wanted, besides the ones cited,

please consult our representatives and ask them in case of so many total

stitches,

how

many

stitches should be increasedordecreasedatbarred

ends.

In exchanging the segments, do not remove the feed cam (Fig. 26®)

but

just

tilt the

machine

arm.

First, remove

the

cover

of

the

carrier

adjusting part, place the exchanging segment atop the feed cam and screw

in Irom the bottom ol the feed cam. There are many indicating lines

by

the

segment

these

lines.

15.

Adjustmentofthe

installing

tension

holes, so

releasing

match

movement

the

center

of

screws

with

1) Tension

releasingofthe

thread

—38—

tension disc No. 1

Page 42

When

the

edge

(D

the

two

(Fig. 25 ®)

25

(2)).

In

No. 1

matches

2)

Tension

The

machine

of

the tension release lever

thread

and

puttinginand

doing

with

releasingofthe

thread tension disc No. 2 floats up at every barred end but the

is idle,

tension discs, as

so, be sure

the

that

directionofthe

adjustment

shown

taking

thread

out the tension post No. 1 (Fig.

the

tension disc No. 2

should

(.Fig-

25 @) goes in between

in Fig. 25 by

thread

thread

eyeletofthe

path.

be

made

loosening

so

that

the

the

nut

tension post

amount of this floating should be 1mm (1/25"). To adjust this floating

amount, the height of the tension post No. 2 should be raised or lowered

just as in the case of the thread tension disc No. 1.

To adjust the floating timing of the thread

the first barred end, loosen the set screw (Fig. 26

tension

disc

(5))

and il it's moved

No.2for

around the circumference, it will change the position of the tension release

,

5^2

%i

11^

/

Page 43

Fig.

26

tripping segment No. I Fig. 2

feed

cam. Thus, the position of the tension

(D)

whith is on the upper surface of the

release

tripping segment

Page 44

No.1will

end

center of the set screw with the indicating line of the feed cam but

adjustitso

the

first

The standard adjustment of the

2

(Fig.26©)isto

indicating

endsatabout

3) Tension releasingofthread tension disc No. 3

When

disc No. 3 does not float up, adjust as follows:

First,

pedal. (Stop the motor also)

Remove the head cover and after releasing the lever set screws (Fig.

25

(D)

necting rod so that the tip of the tension release pin (Fig.27@)

contact the step part

(Grab it by a pointed pincer and it

With this position, tighten the tension release lever set

carefully watching that the

lever

Next, loosen the set screw of the tension post socket (Fig. 24

move

that the thread tension disc No. 3 will float up about 1mm (1/25"). (Be

careful

change).

When all above adjustments are completed and the pedal is stepped

on, the thread

when

hand stop crank to the high

change

will

change.

that

barred

lineofthe

the

set the hand stop crank at

(2 each), adjust the front and rear po.utions of the lever crank con

shaftisnot

the

tension

and

the pedal is

and

The

the

endorlittle

3~4

stitches from

sewing

crooked.

post

see

that

tension

the

tension

normal

tension

time

feed

speed

released.

release

earlier.

the center of the

cam

has

(D

of the lever crank connecting rod (Fig. 27 ®).

socket

(Fig.27®) to right and lelt and adjust so

the moving range of the take-up spring does

disc

No.3will

speed

release

tension

starts

tension

but

adjustitso

the

startofsewing.

slowed

tension

When

position.

timingatthe

release

immediately

release

screw

down

low

speed

will

move

release

lever's

go into

all of this is

first

timingisto

after

the

tripping

segment

(Fig.26@)

that

the

tension

and the thread

and step on the starting

forward

action

and

direction toward the

and

will

verified,

barred

match

end

with

releasing

tension

backward).

float

return the

the

No.

the

will

screw,

(g)),

not

of

up

— 41 —

Page 45