Page 1

Attention

Please read this instruction manual before using

the machine as it contains important operational

and safety information.

Keep this manual accessible so that you may

refer to it at anytime while operating the machine.

INSTRUCTION MANUAL

COMPUTER SEWING MACHINE

HZL-DX series

Page 2

Page 3

1

“IMPORTANT SAFETY INSTRUCTIONS”

When using an electrical appliance, basic safety precautions should always be followed, including the following: Read all instructions before using this sewing machine.

“DANGER

____ To reduce the risk of electric shock:”

1. The appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the electric outlet immediately after using and before

cleaning.

“WARNING

____

To reduce the risk of burns, re, electric shock, or injury to persons:”

1.

Do not allow this appliance to be used as a toy. Close attention is necessary when this appliance is used by or near children. This appliance can be used by children aged from 8 years and

above

and persons with reduced physical, sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or instruction concerning use of the appli

-

ance in a safe way and understand the hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children without supervision.

2. Use this appliance only for its intended use as described in this manual. Use only attachments recommended by the manufacturer as contained in this manual.

3.

Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged, or dropped into water. Return the appliance to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation openings of the

sewing machine and foot control free from the accumulation of lint, dust, and loose cloth.

5.

Keep ngers away from all moving parts. Special care is required around the sewing machine needle.

6. Always use the proper stitch plate. The wrong plate can cause the needle to break.

7. Do not use bent needles.

8. Do not pull or push fabric while stitching. It may deect the needle causing it to break.

9. Switch the sewing machine off “O” when making any adjustments in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot.

10. Always unplug the machine from the electrical outlet when removing covers, when lubricating

or when making any other user servicing adjustments mentioned in the instruction manual.

11. Never drop or insert any object into any opening.

12. Do not use outdoors.

13.

Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

14. To disconnect, turn all controls to the off “O” position, then remove plug from outlet.

15. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

16. Basically, the machine should be disconnected from the electricity supply when not in use.

17. If the power cord of this appliance is damaged, it must be replaced with a special cord by

your nearest authorized dealer or service center.

18. (Except USA/Canada) This machine is provided with double insulation.

Use only identical replacement parts. See instructions for servicing Double-Insulated machine.

“SERVICING DOUBLE-INSULATED PRODUCTS”

In a double-insulated product, two systems of insulation are provided instead of grounding. No

grounding means is provided on a double-insulated product nor should a means for grounding be

added to the product. Servicing a double-insulated product requires extreme care and knowledge

of the system and should only be done by qualied service personnel. Replacement parts for a

double-insulated product must be identical to those parts in the product. A double-insulated product is marked with the words DOUBLE INSULATION or DOUBLE INSULATED.

The symbol

may also be marked on the product.

“SAVE THESE INSTRUCTIONS”

“This sewing machine is intended for household use only.”

Page 4

2

Danger

warning

which is not

specied

There is a

risk of electrical shock

There is a

risk of re

There is

a risk of

injury to

hands, etc.

Prohibited matter

which is not

specied

Disassembly/

alteration is

prohibited

Do not

place ngers under

the needle

Do not

pour oil,

etc.

Generally

required

behavior

Disconnect

the power

plug

Congratulations on your purchase of a JUKI sewing machine.

Please be sure to read safety precautions in “To use the sewing machine safely” in the Instruction

Manual before use to fully understand the functions and operating procedures of the sewing machine so as to use the sewing machine for a long time.

After you have read the Instruction Manual, please be sure to keep it together with the warranty

so that you can read it whenever necessary.

To use the sewing machine safely

Marks and pictographs included in the Instruction Manual and shown on the sewing machine are

used so as to ensure safe operation of the sewing machine and to prevent possible risk of injury

to the user and other people.

Warning marks are used for different purposes as described below.

WARNING

Indicates that there is a possible risk of death or serious injury if this

mark is ignored and the sewing machine is used in a wrong manner.

ATTENTION

Indicates the operation, etc. which can cause a possible risk of person-

al injury and/or physical damage if this mark is ignored and the sewing

machine is used in a wrong manner

.

Pictographs mean the following:

Page 5

3

● Do not wipe the sewing machine with solvent such

as thinner.

When the sewing machine

is soiled, put a small quantity of neutral detergent on

a piece of soft cloth and

carefully wipe off the sewing machine with it.

● Be sure to use the sewing machine

in the temperature range from 5ºC

to 40ºC.

If the temperature is excessively

low, the machine can fail to operate

normally.

WARNING

For the combination of the material and the thread and needle, in particular, refer to the explanation table in “Replacement of the needle”.

If the needle or thread does not match the material used such as in the case that an extra heavyweight material (e.g., denim) is sewn with a thin needle (#11 or higher), the needle can break resulting in an unexpected personal injury.

Other precautions

● Do not put the sewing machine

under the direct sunlight or in a

humid place.

Be aware that the following state can take place since the sewing machine incorporates

semi-conductor electronic parts and precise electronic circuits.

* The operating temperature of the sewing machine is between 5ºC and 40ºC. Do not use the

sewing machine under the direct sunlight, near the burning things such as a stove and candle,

or in a humid place. By so doing, the temperature in the interior portion of the sewing machine

can rise or the coating of the power cord can melt, causing re or electrical shock.

● The safety device of the sewing machine will work

to stop the sewing machine in order to prevent the

generation of abnormal heat in the case the sewing machine is continuously engaged in sewing at

a low sewing speed for a long time or it is continuously engaged in sewing for a long time under the

high temperature environment. In this event, Start

and Stop button will not light.

The sewing machine will

return to working condition

after about 10 minutes.

Stop!

Page 6

4

“IMPORTANT SAFETY INSTRUCTIONS” .....1

Contents .........................................................4

Principal parts .................................................6

Accessories ....................................................7

Connecting to the power supply ....................8

Function of operational buttons ......................9

Name and function of other operational buttons...

10

Speed control ...............................................12

Adjustable starting stitch speed ........ 13

Low-speed inching sewing ............................. 13

Adjustable reverse stitch speed

........ 13

Lifting/lowering of the presser foot................14

Automatic presser foot lifting .......................... 14

Presser foot auto lift button ............................ 14

Presser foot lifting lever .................................. 14

Installation of knee lifting lever ....................... 15

Foot switch function

.......................... 15

Changing the presser foot ............................16

Bobbin thread preparation ............................18

Needle thread preparation ............................22

Threading the needle thread .......................... 22

Automatic needle threader ............................. 24

Pulling up the bobbin thread ........................... 25

Attaching the needle .....................................26

Fabric, thread and needle table ....................27

How to adjust thread tension ........................28

How to adjust the presser foot pressure .......29

How to lower the feed dog ............................29

Changeover of needle holes (straight stitch

slide plate) ....................................................30

DX7

How to select a stitch pattern ............31

DX5

How to select a stitch pattern ............34

Contents

Basic operations

Practical sewing

Patchwork quilt

Straight stitch ................................................37

Seam guide line on the throat plate ................ 38

Automatic lock stitch and thread trimming ...... 40

How to change needle positions .................... 41

How to change the stitch length ..................... 41

Other straight stitch patterns .......................... 42

Zigzag stitch .................................................43

Overcasting stitch .........................................44

Blind stitch ....................................................46

Buttonhole stitches .......................................49

Buttonhole with gimp ...................................... 53

When changing the width of the buttonhole ... 54

When changing the density of the seam ........ 54

Manual 2-step buttonhole .............................55

Sewing buttons .............................................57

Bartacking.....................................................58

Inserting zippers ...........................................60

Lapped insertion ............................................. 61

How to use the quilt guide ............................62

Scallop stitches.............................................63

Decorative stitches .......................................64

Patchwork piecing ........................................66

Appliqué (1) ..................................................67

Appliqué (2) ..................................................68

Crazy quilt.....................................................69

Stitch in ditch quilting ....................................70

Quilting (straight stitch) .................................71

Quilting (free motion) ....................................72

Page 7

5

Basic operations

Practical sewing

Patchwork quilt

Decorative stitches

Decorative stitches

One-point stitch/sewing letters .....................74

Preparation before sewing ............................. 74

Test sewing ..................................................... 74

Operational buttons and screen ..................... 75

How to select pattern (letters) ........................ 76

How to edit patterns (letters) .......................... 78

How to stitch a pattern (letters) ...................... 79

Disposing thread ends of jump stitches .......... 79

Save/call of patterns (letters) .......................... 80

To sew patterns continuously ......................... 81

Character selecting methods ........................82

Type and usage of options ...............83

1

Change of seam width of buttonhole ......... 84

2

Change of needle position ......................... 85

3

Selecting the stop position of needle ......... 86

4

Twin needle sewing ................................... 87

5

Foot switch function ................................... 89

6

Presser foot pivot function ......................... 90

7

Setting the pivot height .............................. 91

8

Setting the oat-function height ................. 92

9

Setting of the presser foot lifting after thread

trimming..................................................... 93

!0

Adjusting the darning ................................. 94

!1

Adjustable starting stitch speed ................. 95

!2

Adjustable reverse stitch speed ................. 96

!3

Guide ......................................................... 97

!4

Adjusting the touch panel sensitivity .......... 98

!5

Contrast of Liquid Crystal Display (LCD) ... 99

!6

Button reception buzzer volume settings . 100

!7

Language setting ..................................... 101

!8

Elongation ................................................ 102

!9

Deleting the settings ................................ 104

Message catalog ........................................105

Introduction of optional accessory parts .....107

● Rolled hemming presser foot .................... 107

● Button attaching presser foot .................... 107

●

Quilt presser foot (Transparent zigzag type)

. 107

● Cording and Embroidery presser foot ....... 107

● Pearl attaching presser foot ...................... 107

● Presser foot with guide .............................. 107

● Binder presser foot .................................... 107

● Hemming presser foot for zigzag .............. 107

● Quilt presser foot (open type) .................... 107

● Appliqué presser foot ................................ 107

● Cording presser foot ................................. 107

● Invisible zipper foot .................................... 107

● Smooth presser foot .................................. 108

● Eyelet punch ..............................................108

● Wide Table ................................................. 108

● Open toe presser foot ................................ 108

● Edge sewing presser foot .......................... 108

● Magnier ....................................................109

● Spool holder .............................................. 109

How to install Wide Table ........................... 110

Machine Maintenance ................................ 111

Performance check list ............................... 112

DX7

List of stitch patterns .......................114

DX5

List of stitch patterns .......................116

Specication list .............................. back cover

Page 8

6

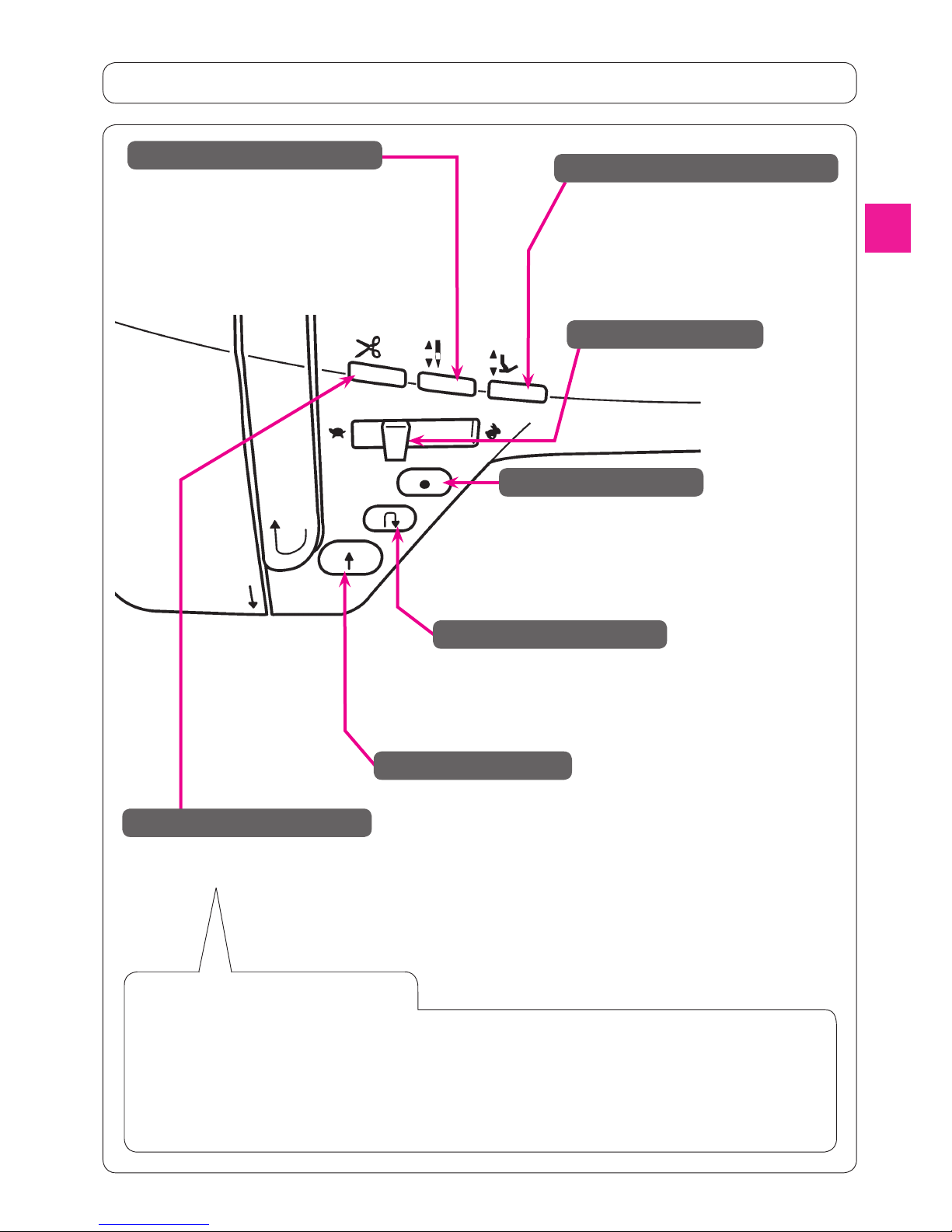

Lock stitch button

Principal parts

Hand wheel (pulley)

Power switch

Machine-socket-inlet

Foot-controller-jack

Spool cap (large)

Spool pin

LCD Screen

Operational

buttons

Face plate cover

Threading lever

Start/stop button

Auxiliary bed

(accessory case)

Presser foot lifting lever

Drop feed knob

Needle setscrew

Needle

Presser foot

Sensor pinhole for buttonholing

Presser foot releasing button

Feed dog

Throat plate

Hook cover

Bobbin winding

shaft

Hook cover release

button

Presser foot holder setscrew

Presser foot holder

Thread trimming button

Hard case

Wide table

* Do not put heavy ob-

jects onto hard case

and wide table.

* Do not remove the

styrene foam tted

inside the hard case.

If it is removed, the

sewing machine can

be damaged when it

is placed in the hard

case or other problems can occur.

Thread cutter

Reverse stitch

button

Speed controller

Needle up/down button

Presser foot pressure adjustment dial

Thread tension

adjustment dial

Knee lifting lever

hole

Light under arm

DX7 Only

DX7 Only

Presser foot auto lift button

Straight stitch slide plate

Straight stitch slide plate

lever

Page 9

7

Draw the auxiliary bed out to the left.

Accessories

● Inside the auxiliary bed.

Quilt guide

T-shape

screwdriver

Blind stitch presser

foot (D)

Ripper

Zipper presser

foot (B)

Overcasting

presser foot (C)

Cleaning brush

Eyelet punch

Standard presser foot (A)

Buttonhole presser

foot (E)

Bobbin (3)

Needle set

HA X 1 # 11 (1)

# 14 (1)

# 16 (1)

for knit # 11 (1)

Smooth

presser foot (T)

● Inside the accessories bag.

● Supplied with the machine

● Inside hard case

Walking

foot (N)

Foot Controller

model name; JC-001

Bobbin (1) Spool cap (large)

Spool cap (Small)

Spool cap (Middle)

Manual buttonhole

presser foot (I)

Patchwork

presser foot (P)

Open toe presser

foot (O)

Twin needle

Quilt presser

foot (Q)

Edge Sewing

presser foot (R)

Auxiliary

spool pin

Instruction manual

(This manual)

Knee-lifting lever

Power cord

DX7 Only

DX7 Only

DX7 Only

DX7 Only

DVD

(One set)

Page 10

8

Connecting to the power supply

Not-using foot-controller that using start/stop-

button:

1. Turn OFF the power switch (turn to “O”)

2. Insert cord-connector into machine-socket-inlet.

3. Insert plug into socket-outlet.

4. Turn ON the power switch. (Turn to “I”)

Using the foot-controller:

1. Turn OFF the power switch (turn to “O”)

2. Insert the foot-controller-plug into the foot-controller-jack.

3. Insert cord-connector into machine-socket-inlet.

4. Insert plug into socket-outlet.

5. Turn ON the power switch. (Turn to “I”)

* When the foot controller is plugged in, the start/stop but-

ton cannot be used to start sewing.

Start button: Can not operate to start sewing.

Stop button: Can operate to stop sewing.

• Disconnect the plug and turn off the power switch (turn

to “O”) that always sewing machine is not to use.

WARNING

Power switch

Power switch

Plug

Plug

Foot controller

Foot-controller-plug

Foot-controllerjack

Machine receptacle

Operating power switch:

Turn OFF the machine, set the power switch to "0"

Turn ON the machine, set the power switch to "I"

ON

OFF

WARNING (For U.S.A.,Canada only)

This appliance has a polarized plug (one blade wider than

the other). To reduce the risk of electric shock, this plug is

intended to t in a polarized outlet only one way. If the plug

does not t fully in the outlet, reverse the plug. If it still does

not t, contact a qualied electrician to install the proper

outlet. Do not modify the plug in any way.

* Be aware that the presser foot comes down automatical-

ly if you turn the power ON with the presser foot lifted.

Page 11

9

While sewing, speed can be adjusted.

For straight stitch/zigzag stitch: The sewing machine performs

reverse stitch as long as this button is

held pressed.

For other stitch types: The sewing machine performs lock

stitch.

When machine stops, press this button to change

the needle position. (When the needle is up, the

needle moves down and vise versa.)

The sewing machine performs sewing at a low

speed by keeping this button held pressed for a

long time.

* The needle will not move when the presser foot

is in its upper position or no pattern is selected.

After sewing, press this button to trim

both threads automatically.

Function of operational buttons

Notes for thread trimming:

1. Do not use thread thicker than No.30.

2. After trimming, the stitch can be done without pulling up bobbin thread.

3. When sewing again after thread trimming, if you pull up the bobbin thread again and place it under-

neath the presser foot together with needle thread, you can avoid birds nest on the wrong side of the

fabric.

4. Regularly clean the machine (refer to page 111), as dust in the area of the thread trimming unit may

cause malfunction.

When this button is pressed, the sewing machine

performs lock stitch.

When this button is pressed while the sewing machine is engaged in pattern sewing, the sewing machine stops after it has completed the sewing of the

one-cycle/one-point of the pattern.

When pressing this button, machine starts to sew slowly and then

up to the speed set by speed controller. Another press of this button

stops the sewing machine.

Color of button indicates machine status.

Green: Ready to start and/or while sewing

Red: Not ready to start

Orange: When the lock stitch button is pressed while the sewing

machine is engaged in pattern sewing (The sewing machine performs lock stitch after it has completed the sewing of the pattern by one cycle. Then, the sewing machine

stops.)

When this button is pressed while the

sewing machine is at rest, the presser

foot position is changed.

When the presser foot is in its upper position, it comes down to its lower position

and vice versa.

Presser foot auto lift button

Speed controller

Reverse stitch button

Start/stop button

Thread trimming button

Needle up/down button

Lock stitch button

Page 12

10

Presser foot to

be used (marking)

Stitch pattern

Zigzag width

Stitch length

2

Stitch length ad-

justing dial

3

Conrmation

button

6

Automatic lock

stitch and thread

trimming button

7

Float function

button

8

Continuous

stitch button

9

Mirror image but

-

ton

!0

Option button

4

Selection button

1

Zigzag width adjust-

ing dial

5

Clear button

!3

Pattern selection mode

switching button

!2

Pattern selection button

Needle stop position

Pattern number

Name and function of other operational buttons

* Patterns on the

screen will be sewn.

Operational buttons and screen

!1

Save/Call button

Description of screen

Name of operational button

Needle stops

at its highest

position

No

indication

Needle stops

at its lowest

position

Needle position

(Center needle position in

this pattern.)

Direct patterns

Practical patterns

Buttonhole patterns

Quilt patterns

Decorative patterns

1

Decorative patterns

2

Letters

10 most often used

patterns can be selected.

A pattern can be selected

by inputting the pattern

number. (Refer to pages

114 and 117 for the

pattern numbers.)

Patterns such as letters

which can be combined,

can be selected.

Setting of automatic lock

stitch and thread trimming

Reverse stitch and

thread trimming

Lock stitch and

thread trimming

No

indication

No setting

Float function setting

Float function

No

indication

No setting

* Adjusting

buttons on DX5.

Direct pattern

Letters

Number

selection (Input

by number)

* Adjusting

buttons on DX5.

Page 13

11

1

Zigzag width

adjustment dial

This is used to change the zigzag width and the needle position.

2

Stitch length

adjustment dial

This is used to change the stitch length.

In the case of the free motion, this dial is used for adjusting the presser foot height.

3

Conrmation

button

This is used to conrm the selected stitch pattern and/or settings.

4

Selection button

This is used to move the cursor.

5

Clear button

This is used to delete the selected stitch pattern and to cancel each setting.

When pressing the button continuously, all the saved stitch patterns will be deleted.

6

Automatic lock

stitch and thread

trimming button

When this button is pressed, or is displayed on the screen.

The machine will automatically lock stitches at sewing-start and sewing-end and

then trim both threads.

7

Float function

button

When this button is pressed, is displayed on the screen.

When using the oat function, the sewing machine performs sewing with its presser

foot slightly lifted.

This function is used in the case of sewing materials such as velvet or sewing quilting that is likely to cause cloth slippage between two layers.

Another press on this button cancels this function.

(Refer to page 92 for more details.)

8

Continuous

stitch button

This button is valid only when “ “ mode.

When this button is pressed,

(Continuous stitch with large intervals) is displayed

on the screen.

When this button is pressed again,

(Continuous stitch with small intervals) is dis-

played on the screen.

(The interval between letters and gures cannot be changed.)

The machine will sew the selected stitch patterns continuously.

When it is pressed again, the machine will cancel this function.

* When it is pressed while sewing, the machine will stop after the selected patterns

are sewn completely.

9

Mirror Image

button

After selecting a stitch pattern, press this button to make a mirror image of the selected pattern.

* There are some patterns that can not make a mirror image.

*

For the symmetric pattern, the sewing start position is changed and ▼ is displayed.

!0

Option button

Optional functions (19 functions) can be set.

* Optional functions vary from stitch pattern to stitch pattern.

(Refer page 83 for more details.)

!1

Save/call button

This is used to save and/or call a pattern. The machine can save maximum 10 patterns. (Refer to page 80 for more details.)

!2

Pattern selection

button

A stitch pattern can be selected.

* Usage of the buttons varies by pattern selecting mode.

(Refer to page 31 and 34 for more details.)

!3

Pattern selection

mode switching

button

When the pattern selection mode needs to be changed, press the desired button.

The selected button will be illuminated.

Name and function of operational buttons

* Adjusting buttons on DX5.

* Adjusting buttons on DX5.

Page 14

12

Foot controller

To run the machine, press the foot controller.

The harder you press, the faster the machine sews.

Speed controller will set the maximum sewing speed.

Pressing harder → faster speed

Pressing weaker → slower speed

* Always clean the foot controller.

It is important that you do not place any objects on the foot

controller as it may cause injury to the user and may cause

malfunctions.

Speed control

How to adjust the speed:

Speed controller

Maximum sewing speed can be freely set by the speed

controller.

Faster speed

Faster speed

Slower speed

Foot switch function

The sewing machine can be set to carry out one of the

following operations when the front section of the foot controller is depressed:

1

Reverse stitch

5

Presser foot lift

2

Lock stitch

6

Thread trimming

3

Half stitch sewing

7

No function

4

One stitch sewing

This function has been

factory-set to "1 Reverse

stitch" at the time of ship-

ment.

Slower speed

(Refer to page 89)

Page 15

13

The sewing speed at the start of sewing can be increased by

using the option button.

When the needle up/down switch is held pressed, the sewing machine performs sewing at a low speed.

★

Adjustable starting stitch speed

★

Low-speed inching sewing

(Refer to page 95)

The reverse stitch speed can be increased by using the option button.

Adjustable reverse stitch speed

★

(Refer to page 96)

Page 16

14

Presser foot lifting lever

Lifting/lowering of the presser foot

The presser foot is lifted/lowered with the presser foot lifting

lever.

The presser foot can be lifted higher than the ordinary lift

position. This feature is useful when placing a heavy-weight

material on the sewing machine.

Even after the presser foot has been lifted with the presser

foot lifting lever, the presser foot can be lowered with the

presser foot auto lift button.

1

Lowered position …… Presser foot should be lowered

when sewing.

2

Ordinary lift position …… This position is used for fabric

removal and/or changing the

presser foot.

3

Extra lift position …… This position is used to put heavy

materials underneath the presser

foot.

* Be careful that the presser foot and the needle should

not interfere when the needle is in down position and the

presser foot is raised to the extra lift position.

1

2

3

1

2

3

The presser foot of the sewing machine automatically goes up slightly when the sewing

machine stops. (Presser foot pivot function)

When the sewing machine is re-started, the presser foot comes down automatically to

allow the user to start sewing with no additional operation.

When the thread trimming button is pressed, the presser foot automatically goes up after the completion of thread trimming.

This function can be set to OFF using the option button.

In addition, when the needle stop position is set to "Stop with its needle up", the presser

foot pivot function is automatically set to OFF.

Automatic

presser foot

lifting

Presser foot

auto lift button

The presser foot can be lifted/lowered by pressing the presser foot auto lift

button.

(Refer to page 9)

Presser foot lifting lever

Presser foot

The presser foot auto lift button and the presser foot lifting lever are interoperable.

When the presser foot lifting lever is once lifted to position 3 after the presser foot

has been lifted with the presser foot auto lift button, the presser foot lifting lever can

be used for lifting/lowering the presser foot.

Page 17

15

The knee lifting lever is useful when a guilt is being sewn

and for other projects that require the use of both hands.

With the knee lifting lever, you are able to control the position

of the presser foot without using your hands.

Insert the knee lifting lever so that concave and

convex meet.

Push the lever to right-hand side to lift the presser foot.

The presser foot is lowered when the lever goes back to the

original position.

* Do not touch the knee lifting lever while sewing.

It may cause a deformation of a stitch pattern.

Knee lifting lever

convex portion

concave portion

Lifting

Optional function can be set so that the presser foot can be lifted/lowered by depressing the front part of the foot

controller.

Foot switch function

Installation of knee lifting lever

(Refer to page 89)

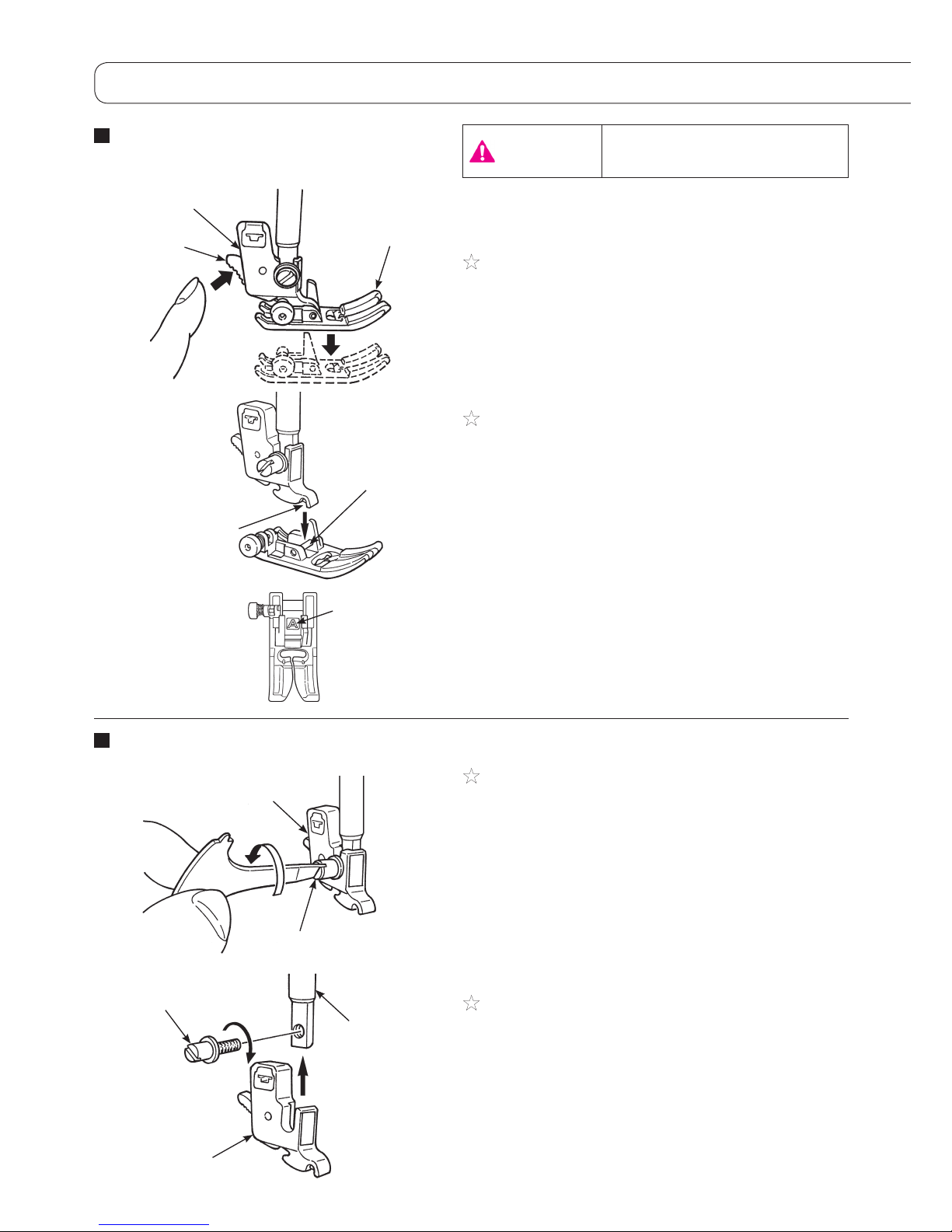

Page 18

16

Removing and installing the

presser foot

Removing and installing presser foot holder

★

Removing presser foot

1. Raise the needle and presser foot.

2. Press the presser foot releasing button to remove the

presser foot.

★

Installing presser foot

Align the pin of the presser foot and the groove in the

presser foot holder. Then lower the presser foot holder

with the presser foot lifting lever.

* Each presser foot has a marking. Use the appropriate

presser foot for the stitch pattern to be sewn.

★

Removing presser foot holder

1. Lift the needle and presser foot lifting lever.

2. Loosen the setscrew of the presser foot holder to the

left and remove the presser foot holder.

★

Installing presser foot holder

Align the screw hole at the presser bar with the hole of

presser foot holder (long groove). Tighten the setscrew

rmly by turning it to the right side.

Changing the presser foot

Turn OFF the power before

replacing presser foot.

Attention

Presser foot

releasing button

Presser foot holder

Presser foot

Groove in presser

foot holder

Pin

Presser foot

marking

Setscrew of presser

foot holder

Presser foot holder

Setscrew of presser

foot holder

Presser foot holder

Presser bar

* Do not lift the presser foot with the presser foot auto

lift button before turning the power OFF.

Page 19

17

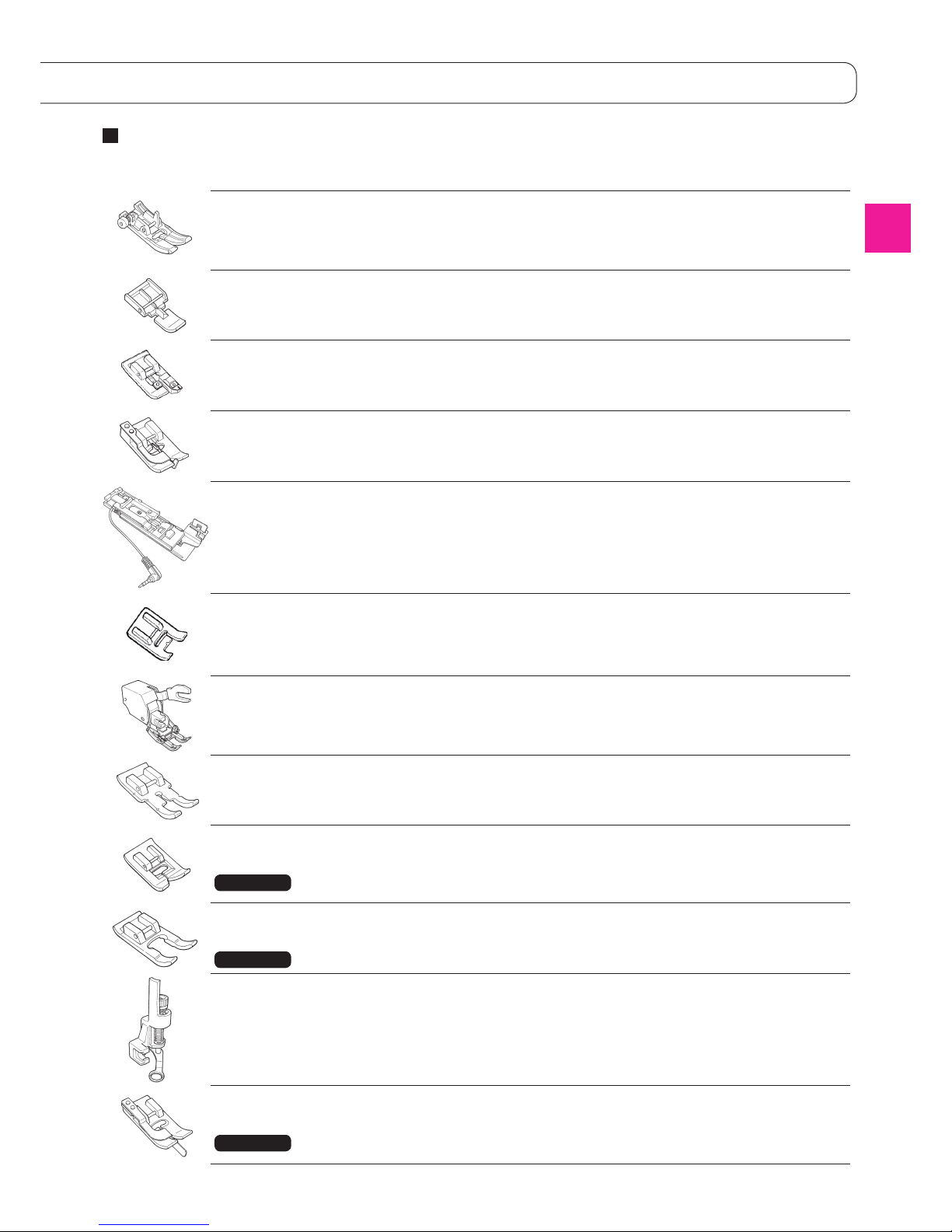

The type and application of the presser foot

Standard presser

foot

A

This is used mainly for straight stitch and zigzag stitches.

Use this presser foot especially when sewing heavy-weight

materials.

Zipper presser foot B

This is used to attach zippers.

Overcasting presser

foot

C

This presser foot is used exclusively for overcasting to prevent

the cut edge of fabrics from fraying.

Blind stitch presser

foot

D

This presser foot is used for blind stitch on hems of trousers

and skirts, or sleeves.

Buttonhole presser

foot

E

This presser foot is used for automatic buttonholing.

Manual buttonhole

presser foot

I

This is used for sewing decorative stitches, letters and bartacks.

Also for manual buttonhole (pattern No. 03).

Walking foot N

In general, this presser foot is used for difcult-to-feed” materials such as knits, jersies, vinyl, articial leather and leather or

quilting.

Patchwork presser

foot

P

This presser foot is used for patchwork stitches. There are two

seam lines, 1/4-inch and 1/8-inch from center needle position.

Smooth presser

foot

T

This presser foot is used for non-slippery materials like vinyl

and satin stitches.

Open toe presser

foot

O

This is used for the applique and decorative stitches.

(Front part of the presser foot is open for better visibility.)

Quilt presser foot Q

This is used for the quilt stitch.

(Machine setting: Straight Stitch and Center needle position)

Refer to page 72 for more details.

Edge Sewing

presser foot

R

This is used for patchwork, sewing center line of joined

materials by using the center guide of the presser foot.

* Fine tune the needle position by zigzag width adjustment dial.

Marking of presser foot

↓

DX7 Only

DX7 Only

DX7 Only

Page 20

18

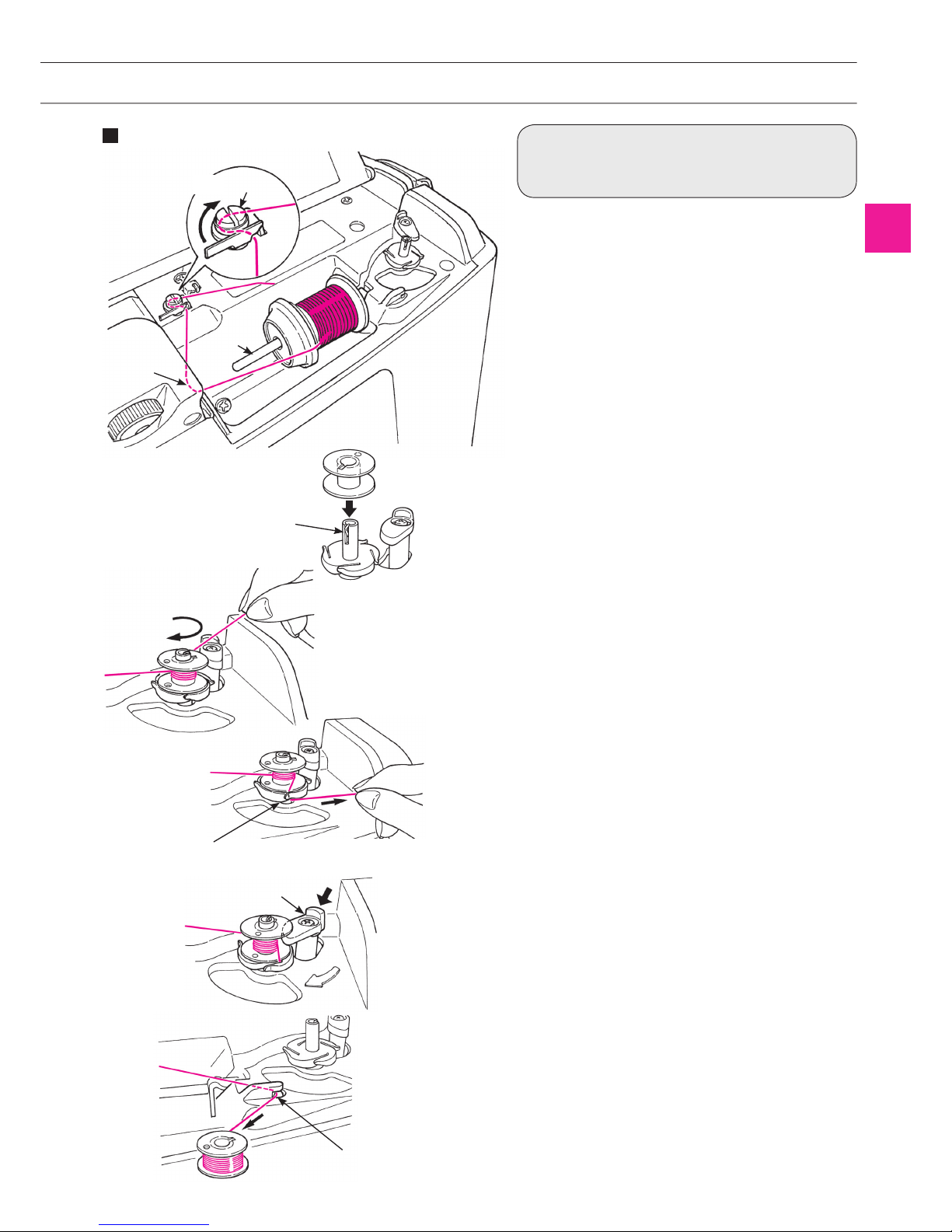

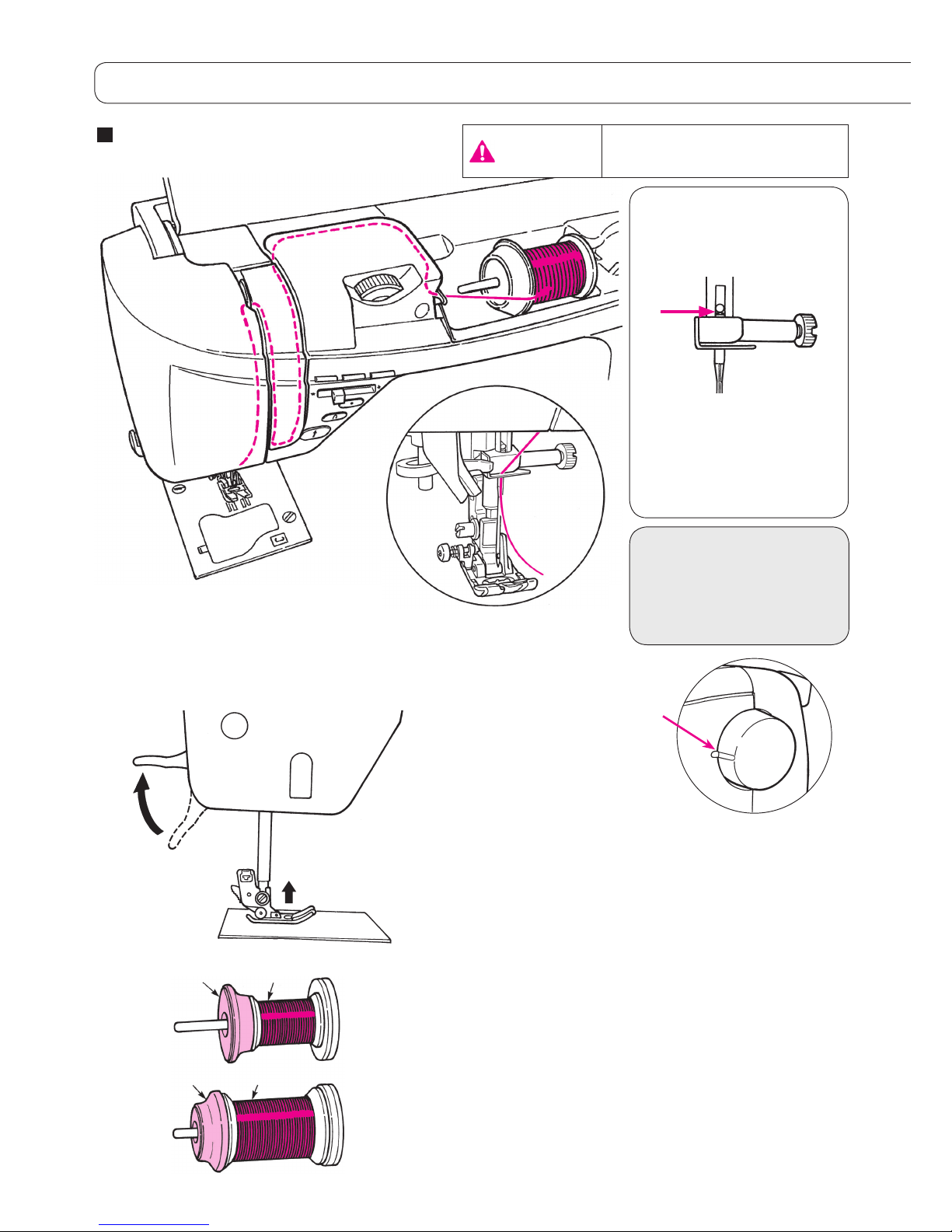

Bobbin thread preparation

Open the hook cover.

Take out the bobbin.

* If the bobbin has too little thread, do not use it as the

thread will get tangled.

* Use only the designated bobbin. Other bobbins may

cause malfunction.

1

2

Taking out the bobbin

1

Small spool

Large spool

Spool Cap

Place a thread spool to spool pin and a

spool cap onto the spool pin.

* Be aware that a spool with a small remaining

amount of thread can cause tangling or slip-off of

thread.

There are three types of the spool caps, large, medium and small. Choose the size of spool cap according

to the thread spool to be used.

Setting thread spool

Hook cover

Spool Cap

<Exclusive bobbin>

Made of transparent plastic

11.5 mm

20.5 mm

When the bobbin is taken

out and/or put into the bobbin case, turn off the power

(turn to “O”).

Attention

Page 21

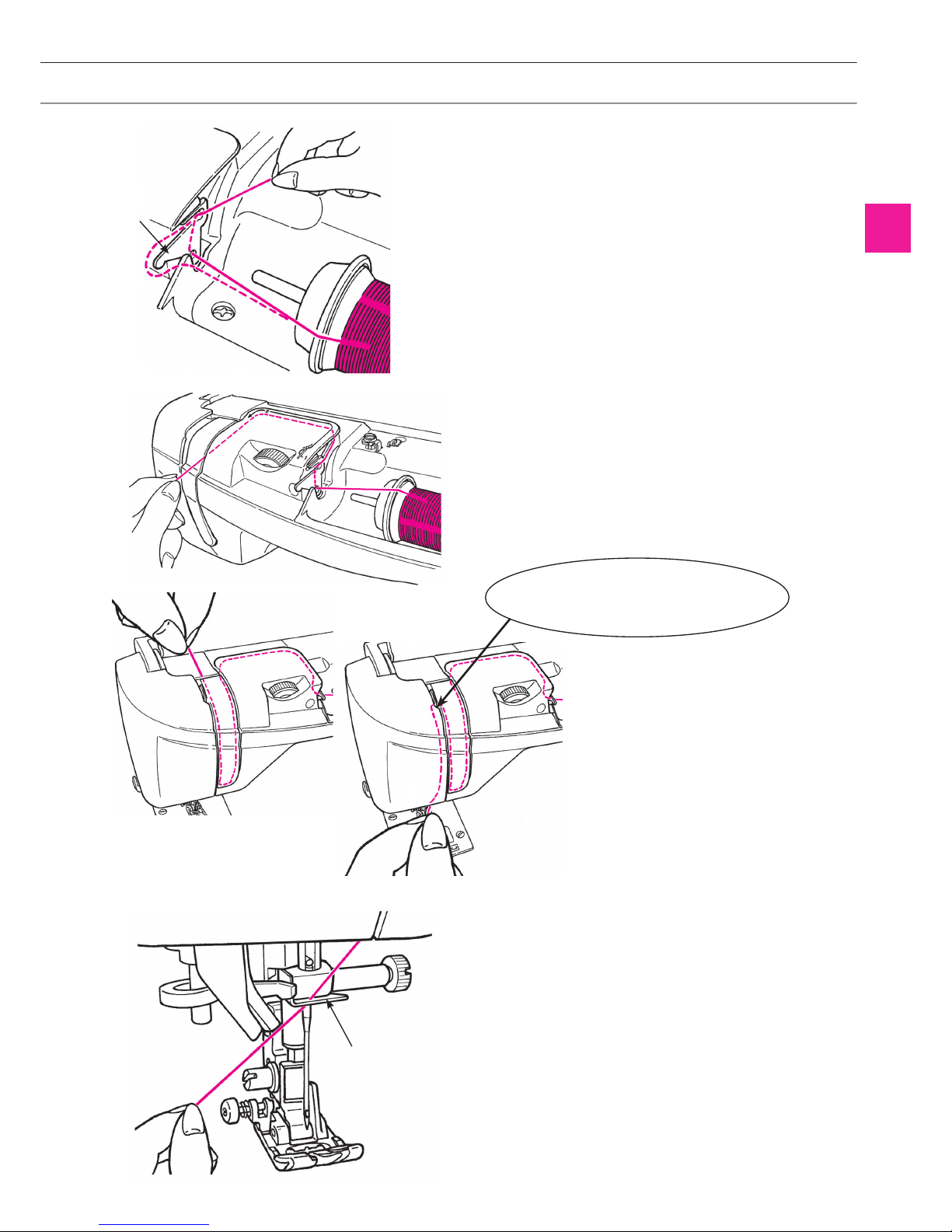

19

Thread the guide A and then

thread the thread guide (guide in

the circle) for bobbin winding

1

Place the thread spool to the spool

pin.

2

Winding the bobbin thread

* An exclusive motor is built-in for winding

bobbin so that you can wind bobbin at any

time.

Set the bobbin on the bobbin winding

shaft.

3

4

Wind the thread to the bobbin 4-5 times in

clockwise direction.

Put the thread end into the guide at the

bobbin winding shaft and pull it to the

right side to cut it.

5

7

Push the bobbin winding regulator

towards the bobbin to start winding the

bobbin.

* Be careful that the bobbin winding regulator

works as a switch.

6

When winding is nished, the shaft

stops automatically, the bobbin winding

regulator moves to right and return to the

original position.

Remove the bobbin from the bobbin

winding shaft and cut the thread by cutter.

* Bobbin winding will automatically stop even

while winding, when the winding speed is reduced due to a load to the bobbin winding motor

caused by thread tangling.

Bobbin winding regulator

Guide (with cutter)

Spool

pin

Cutter

Thread guide

Bobbin

winding shaft

A

Page 22

20

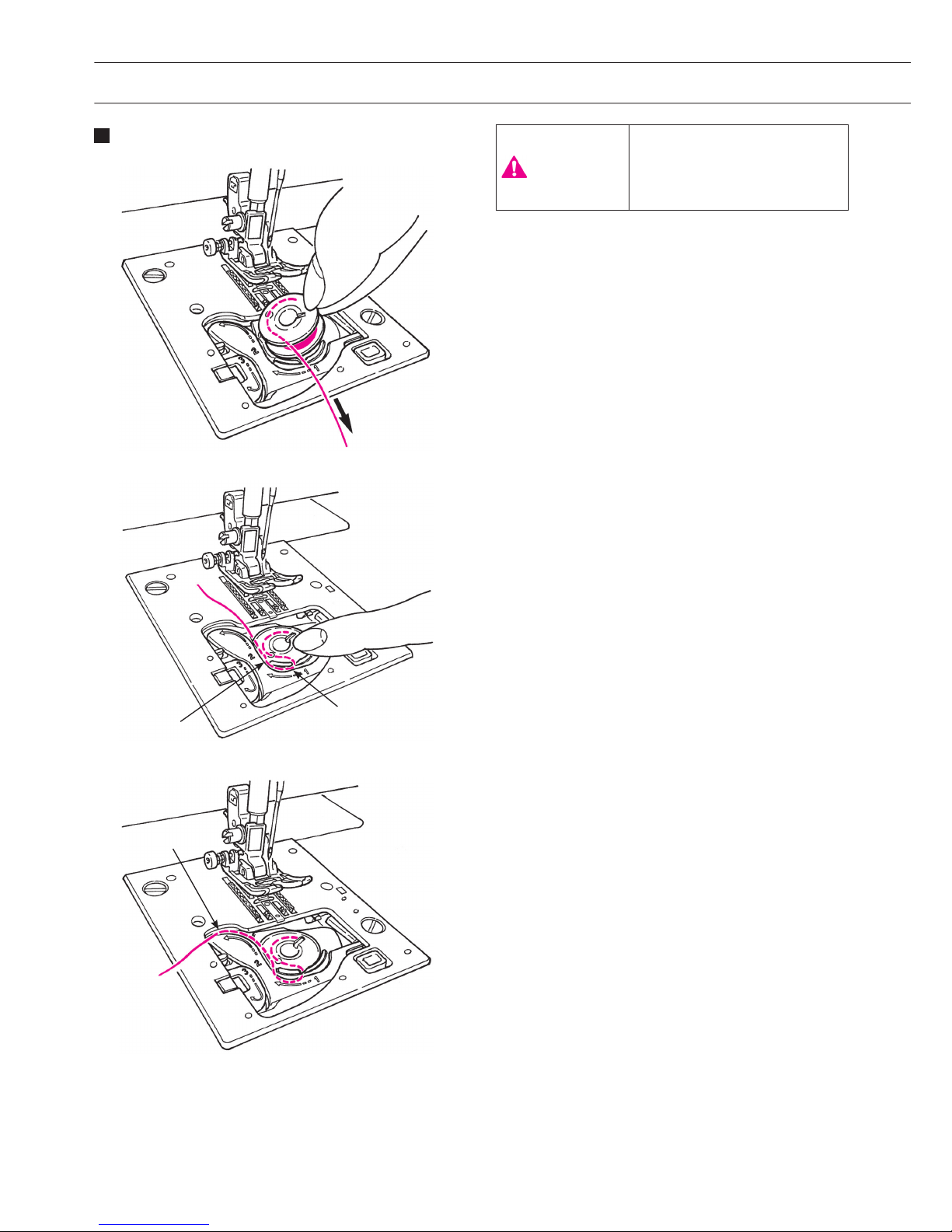

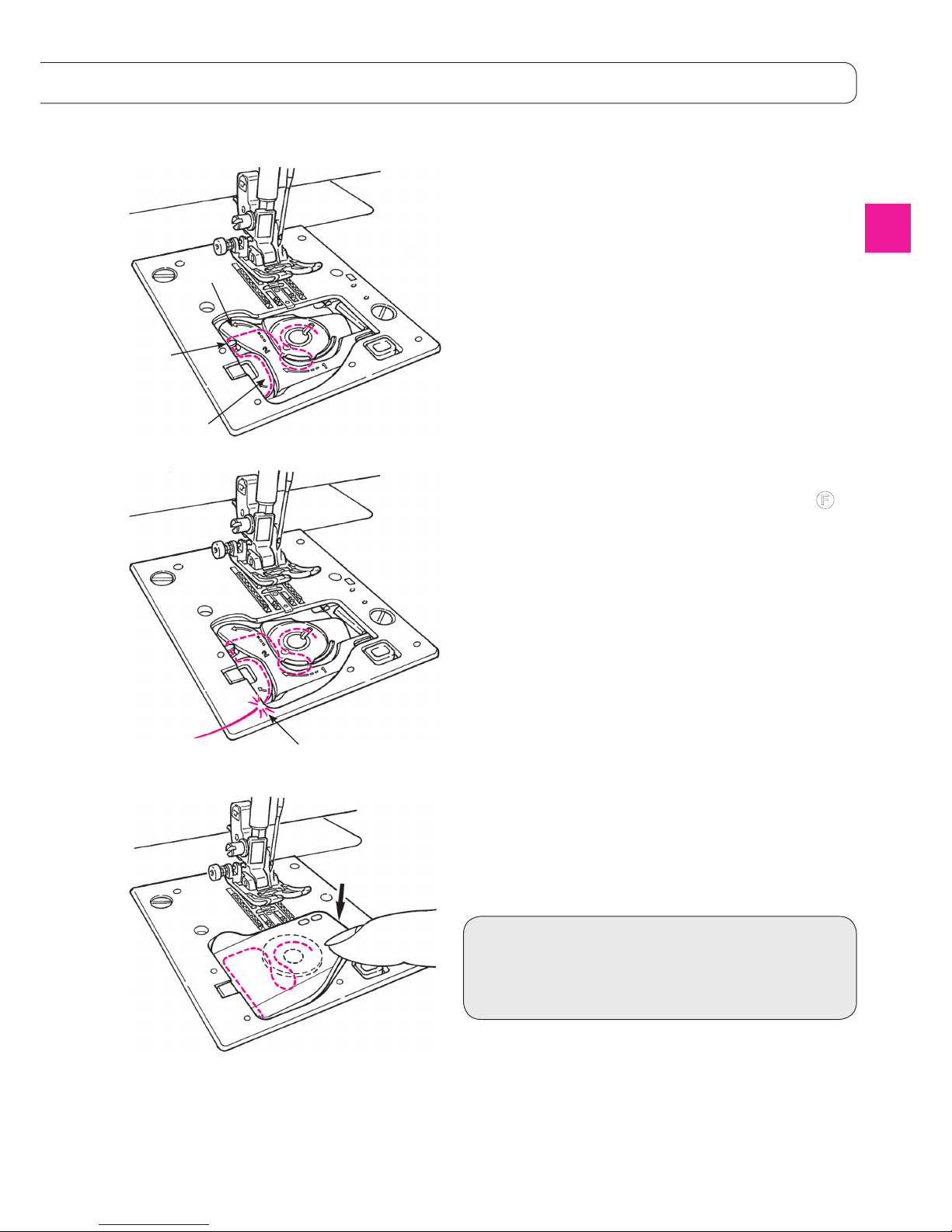

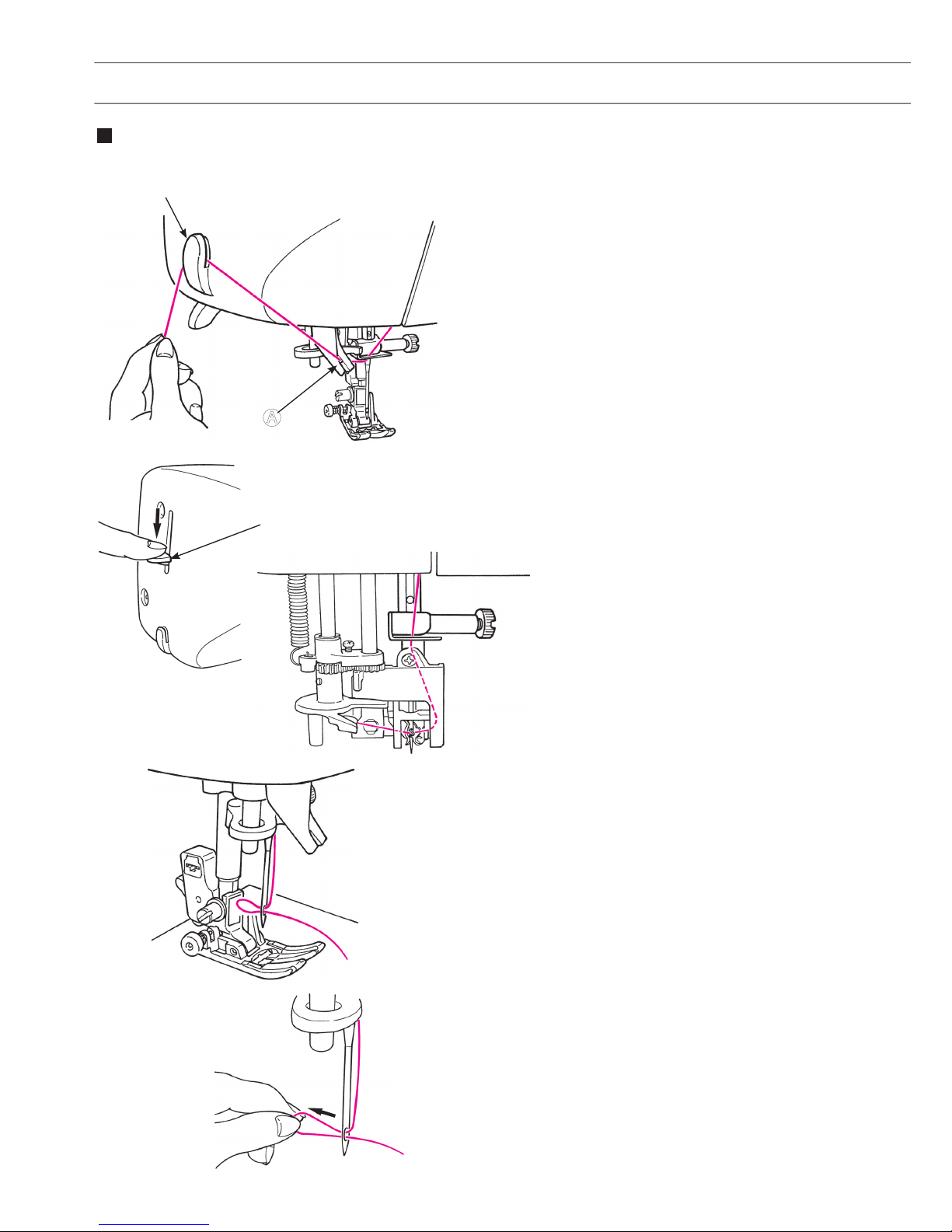

Put the bobbin in the bobbin case.

* Place the bobbin so that thread winds counter-

clockwise.

Thread groove A and B by pulling the

thread end.

* It will be easier to thread grooves when you

press the bobbin lightly with your nger.

Thread guide C by pulling the thread to

left side.

1

3

2

B

A

Setting the bobbin

C

When the bobbin is taken

out and/or put into the bobbin case, turn off the power

(turn to “O”).

Attention

Page 23

21

Thread to guide D and E leave the thread

underneath. (Thread guide E first and it

will thread to guide D as well.)

* When pulling bobbin thread, bobbin rotates

counterclockwise. If bobbin rotates clockwise,

put the bobbin upside down.

4

D

E

Cut the thread with the built-in cutter

F

.

5

Close the hook cover.

6

F

You can start to sew in this condition (without

pulling up the bobbin thread), however, if you want

to sew with the bobbin thread pulled out, refer to

“Pulling up the bobbin thread” in the page 25.

C

Page 24

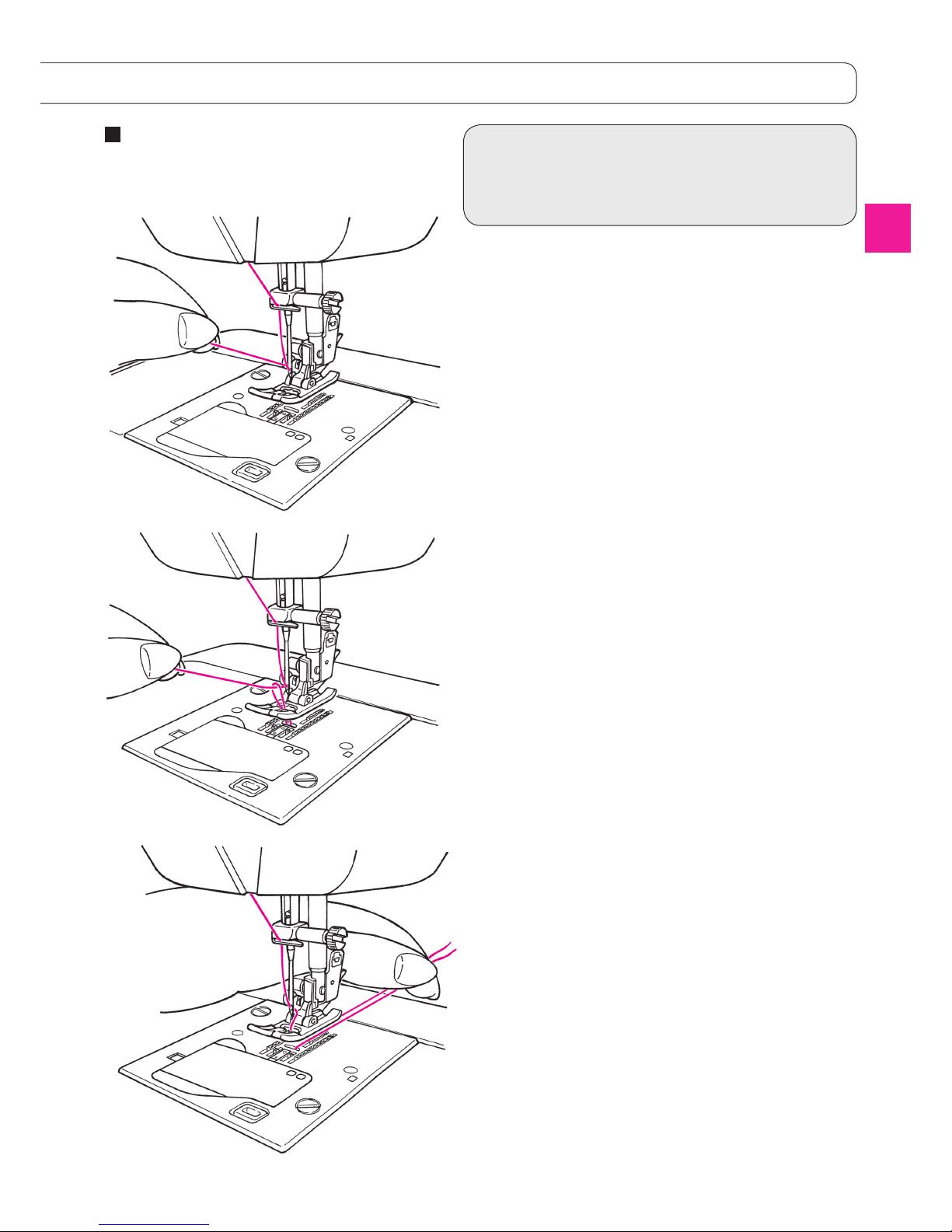

22

1

Lift the presser foot lifting lever.

1

2

3

4

5

Make sure to push the

needle to the top.

It is impossible to perform

stitching if the needle is not

correctly installed or a bent

needle is used. Pay close attention as this will cause machine malfunction.

Note:

2

Small spool

Large spool

Place a thread spool to the spool pin and

a spool cap onto the spool pin.

There are three types of the spool caps, large, medium and small. Choose the size of spool cap according

to thread spool to be used.

Threading the needle thread

* Use the needle: No.11-16

and the thread: No.30-90.

*

When twin needle is used,

the automatic needle

threader can not be used.

* Align the marking at the

hand wheel with the one

on the machine body.

Spool cap

Spool cap

Needle thread preparation

Turn OFF the power switch before threading the machine head.

Attention

Page 25

23

Thread to guide A.

Hold the thread end and thread according

to the arrow marking.

* Make sure that the presser foot is raised.

Otherwise the machine is not correctly thread-

ed.

3

4

Thread the guide B from the right-hand

side.

Draw the needle thread out from the guide by approximately 10 cm.

5

B

A

* Check that the thread take-up

is correctly threaded.

Page 26

24

Release the threading lever and the

needle thread is threaded to the needle

eye.

1

Lower the presser foot.

* The automatic needle threader sometimes fails

to thread the needle when the presser foot is

raised.

2

Thread to A and cut the thread with the

thread cutter.

4

3

Lower the threading lever until it comes to

a complete stop.

*

Lower the threading lever slowly.

Threading lever

A

Thread cutter

Lift the presser foot. Then, draw the

needle thread backward.

Pull out the thread from the needle eye by approx.

10 cm or 4 inches long.

5

* Be careful that the cutter is inside.

Automatic needle threader

Page 27

25

Basic operation:

You can start to sew without pulling up the bobbin

thread, however, if you want to sew with the bobbin thread pulled out, follow the directions below.

Pull out both needle and bobbin threads

by approx. 10 cm (4 inches) long and pass

them under the presser foot towards the

back of the machine.

1

Lift the presser foot and lightly hold the

end of the needle thread.

2

Turn the hand wheel towards you to move

the needle up and down. Loop of bobbin

thread will be pulled out when you will

pull the needle thread lightly.

3

Pulling up the bobbin thread

Page 28

26

Attaching the needle

Needles to be purchased

When purchasing spare needles,

specify HA X 1 (130/705H) or HA X 1

SP (needle for knits) .

Checking the needle

Check the needle for its straightness occasionally.

Any bent needle would cause skipped stitches, thread

breakage or damage to materials.

Flat object

The at part of the needle

Shank

Needle size:

The larger the number, the thicker the needle.

Needle setscrew

Stopper pin

Hold the needle

with its at part

facing away

from you

If the needle is not properly installed or a bent

needle is used, needle breakage can be caused.

It will cause damage to the machine.

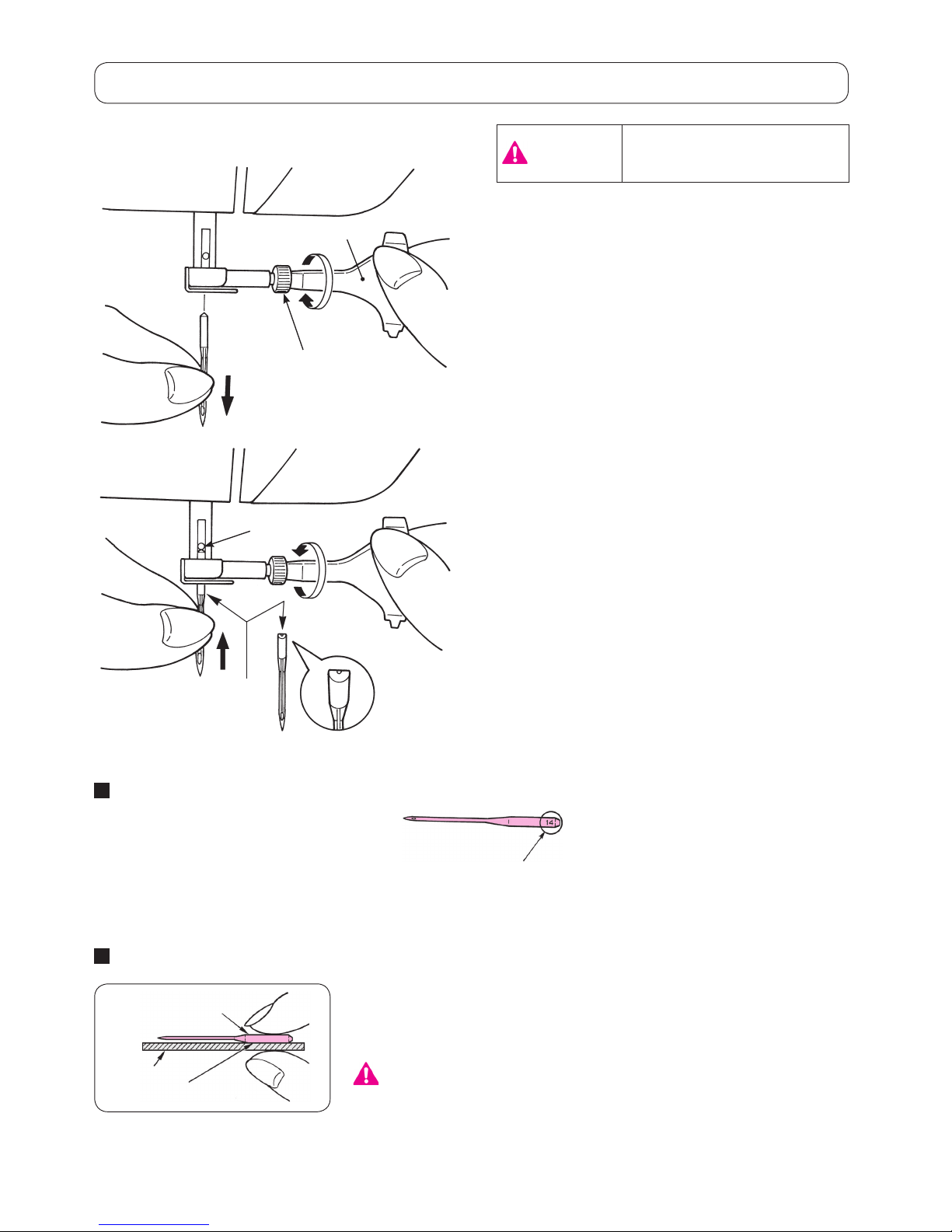

1

Removing needle

1. Turn the hand wheel towards you until the needle

comes to the highest position and lower the presser

foot.

2. Turn the needle setscrew towards you 1-2 times

and remove the needle.

2

Attaching the needle

(The needle cannot be inserted unless it

is correctly positioned.)

Hold the needle with its at part facing away from you,

and insert it fully until it touches the stopper pin.

Securely tighten the needle setscrew.

Attention:

Screwdriver

When changing the needle,

turn off the power.

Warning

Page 29

27

Fabric, thread and needle table

Fabric Thread Needle

HA×1

Light-weight

materials

Lawn

Silk thread

…………………………………………

No.80,90

Spun thread

………………………………………

No.80,90

No.11

Georgette

Tricot Spun thread

………………………………………

No.60-90

Knit needle

No.11

Wool and synthetic

fabrics

Silk thread

………………………………………………

No.80

Spun thread

……………………………………

No.60-90

No.11-14

Medium-weight

materials

Cotton and synthetic

fabrics

Spun thread

……………………………………

No.50, 60 No.11-14

Light jersey

Silk thread

………………………………………………

No.50

Spun thread

……………………………………

No.50, 60

Knit needle

No.11

Ordinary wool and

synthetic fabrics

Silk thread

………………………………………………

No.50

Spun thread

……………………………………

No.50, 60

No.11-14

Heavy-weight

materials

Denim Spun thread

………………………………………

No.30-50 No.14-16

Jersey

Silk thread

………………………………………………

No.50

Spun thread

……………………………………

No.50, 60

Knit needle

No.11-14

Coat Silk thread

………………………………………………

No.50 No.11-14

* In general, the same thread is used for both needle and bobbin threads.

* Thin thread and needle will be used for light-weight fabrics and thick thread and needle will be used for heavy-

weight materials.

* Check that the combination of needle and thread is OK by trial sewing on the material which will be sewn.

* Knit needle is good for stretchy fabrics (such as knits) and synthetic fabrics.

* Use thread No. 30 - 90.

* When it is difcult to go over an overlapped section, guide the fabric by hand.

* When sewing “quilt patterns”, “decorative patterns” or “letters” (refer to pages 31 to 36), better nish will be

ensured by using a knit needle.

Page 30

28

How to adjust thread tension

When the needle thread is too

strong:

The bobbin thread will be pulled to the front side of the

fabric. Turn the thread tension adjustment dial towards

"-1" to "-3".

When the needle thread is too

low:

The needle thread will be pulled to the wrong side of

fabric. Turn the thread tension adjustment dial towards

"+1" to "+3".

In case a correct tension setting is not obtained, check

thread paths for both needle and bobbin threads.

Needle thread

Bobbin thread

A

Fabric (right side)

Fabric (right side)

Needle thread

Bobbin thread

Bobbin thread

Needle thread

Fabric (right side)

Well-balanced thread tension

Straight stitch: Needle and bobbin threads interlace

with each other at the middle of the

fabric thickness. (

A

)

Zigzag stitch: Needle thread is pulled a little bit to the

wrong side of the fabric.

If the machine is set to “Auto”, it is suitable for most

fabrics. However, adjustment may be necessary according to fabrics and sewing applications.

If the tension is not correctly set, it will cause imbalanced stitch formation, puckering, and/or thread

breakage.

Weaker tension

Stronger tension

Thread tension

adjustment dial

Fabric (wrong side)

Fabric (wrong side)

Fabric (wrong side)

Page 31

29

How to adjust presser foot pressure

Turn the presser foot pressure adjustment dial to set the

proper pressure.

When sewing in general, set the presser foot pressure

adjustment dial to “5”.

When sewing on light synthetic fabrics, stretchy fabrics,

appliqué which seam allowance is overlapped, etc., lower the number on the presser foot pressure adjustment

dial. (reducing the presser foot pressure)

How to lower the feed dog

Move the drop feed knob to the right-hand side, in case

the feed dog is in the down position for free motion quilting, button sewing, etc.

* Move the drop feed knob to the left-hand side after

sewing. The feed dog will be engaged automatically

when the machine starts to sew.

When lowering the feed dog

When lifting the feed dog

Drop feed knob

Presser foot

pressure adjustment

dial

How to adjust the presser foot pressure

How to lower the feed dog

Stronger

Weaker

Page 32

30

Changeover of needle holes (straight stitch slide plate)

Patterns which can be used

with the straight stitch

selection

After you have changed the needle hole to the needle hole for

straight stitches, press to display the patterns that can

be used.

Select a pattern with or and press to

conrm the pattern.

How to use the straight

stitch slide plate

Do not turn the handwheel by hand when using the

needle hole for straight stitches. Be aware that the

needle can come in contact with the straight stitch

slide plate if you turn the handwheel by hand.

Attention

2

Normal needle hole

1

Needle hole for straight stitches

2

1

Lever

Straight stitch

slide plate

It is possible to change the needle hole between the needle

hole for straight stitches and the normal needle hole without

changing the throat plate.

In the case of starting sewing from the edge of material, the

material can be smoothly sewn without being pulled into the

needle hole by using the needle hole for straight stitches.

It is possible to change the needle hole to be used only by

changing over the lever position.

Lift the needle and the presser foot.

1

By moving the lever to the left: The

needle hole for straight stitches is

selected.

2

By moving the lever to the right while

slightly pushing it away from you: The

normal needle hole is selected.

1

2

* Change the needle hole from the needle for straight

stitches to the normal needle hole before turning the

power OFF.

DX7

DX5

* When a pattern other than those which can be sewn with

the straight stitch selection is selected, the needle hole

for straight stitches cannot be used.

If a pattern other than the straight stitch selection is se-

lected when the needle hole for straight stitches is select-

ed,

will be displayed on the screen.

1. The screen will be restored to the normal one by re-

turning the lever to the right.

2. The screen will be changed over to the Direct 1 when

is pressed.

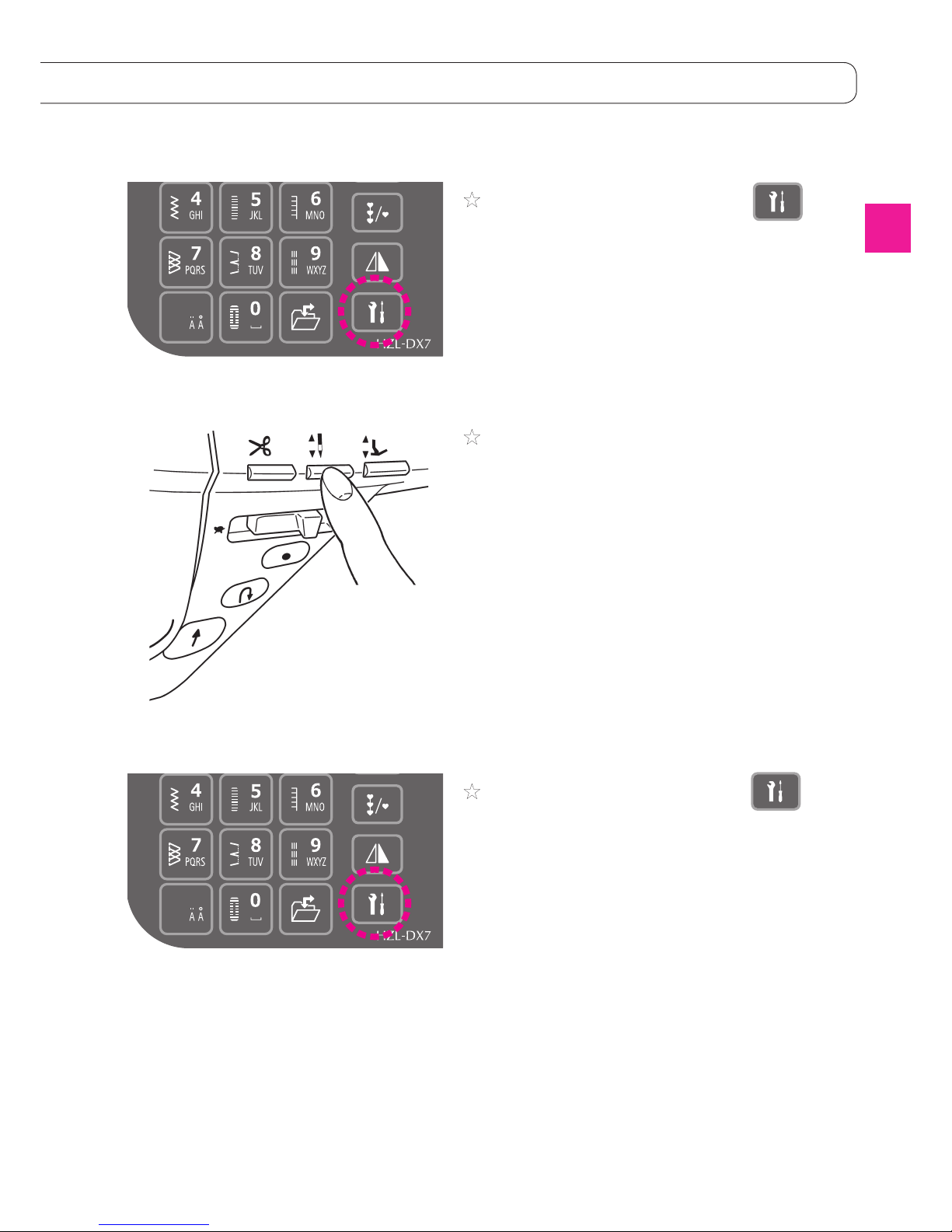

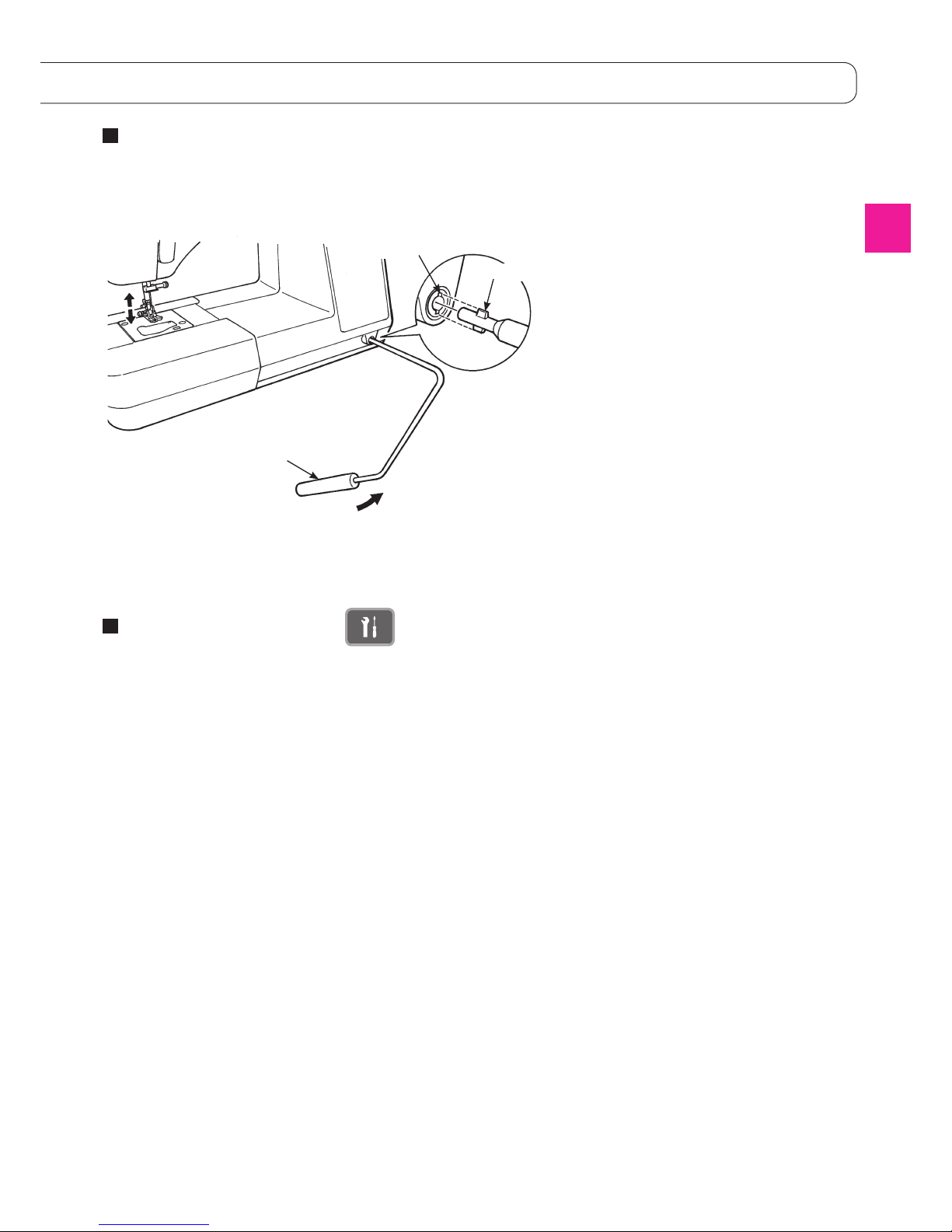

Page 33

31

Push and check the stitch pattern in this

portion and select.

Push and select a pattern type from with select button

(

or ). Then, select a pattern with its pattern number.

Select stitch pattern by number.

Pattern can also be selected using .

DX7

How to select a stitch pattern

☆

There are 287 types of stitch patterns.

☆

When turning on the machine, the straight stitch of the center needle position is chosen automatically.

☆

There are 4 methods to select stitch pattern.

Pattern

No.

1 2 3 4 5 6 7 8 9 0

Pattern Application

Center

needle

position

Piecing

7mm

Piecing

1/4”

Zigzag stitch

Applique

Over casting

stitch

Blind stitch

Straight

reinforced stitch

Buttonhole

Straight

stitch

Refer

to

page

37 66 66 43 67 68 44 46 42 49

Pattern

No.

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22

Pattern Application

Left

needle

position

Center

needle

position

Left

needle

position

Right

needle

position

Three point zig zag

Two point zig zag

Overcasting stitch

Overcasting stitch

Used for lightweight material

Overcasting stitch

Used for exible material

Ornamental pattern

Blind stitch

Used for lightweight material

Blind stitch

Used for exible material

Shell tuck

Back straightline stitch

Back zigzag stitch

Bar tack

Eyelet

Button sewing

Fly stitch

Straight stitch

Straight stitch for

elastic

Zigzag stitch

Refer

to

page

37 42 43 43 45 - 44 45 - - - 64 46 46 - 42 - 58 - - 57 -

On the LCD screen you will see

the selected stitch pattern and

the marking of the presser foot

to be used.

・

Practical patterns

❶

Direct patterns

❷

Other patterns

Page 34

32

Pattern

Refer

to

page

68 ~ 70, 72

Pattern

No.

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

Pattern

Application

Standard

buttonholes

2-step

buttonhole

Rounded

end

Keyhole

buttonholes

For knit

Decorative

Refer

to

page

49 ~ 56

Pattern

Refer

to

page

64

Pattern

Refer

to

page

64

・

Buttonhole patterns

・

Quilt patterns

・

Decorative patterns 1

Patterns for crazy quilt

・

Decorative patterns 2

Combination patterns

Patterns for elongation

Page 35

33

Push and select a pattern type from with select button

(

or ). Then, select a pattern with its pattern number.

The pattern types are same with those of "Quilt patterns", "Decorative patterns 1" and "Decorative patterns 2".

“Quilt patterns” numbers 01 and 02 are not available for one-point sewing.

Some patterns can overlap when combined. In such cases, combine them while inserting a space (decorative

patterns 2: No. 52) between the patterns.

Pattern

Refer

to

page

74 ~ 82

Pattern

Refer

to

page

74 ~ 82

❸

One point pattern

❹

Letters

Select stitch pattern

by number.

Quilt patterns Decorative patterns 1 Decorative patterns 2

Push

and select a letter type from with the select

button (

or ). Check this portion.

(Refer to page 75 for how to select letters.)

Page 36

34

Push and check the stitch pattern in this

portion and select.

DX5

How to select a stitch pattern

☆

There are 185 types of stitch patterns.

☆

When turning on the machine, the straight stitch of the center needle position is chosen automatically.

☆

There are 4 methods to select stitch pattern.

Pattern

No.

1 2 3 4 5 6 7 8 9 0

Pattern Application

Center

needle

position

Piecing

7mm

Piecing

1/4”

Zigzag stitch

Applique

Over casting

stitch

Blind stitch

Straight

reinforced stitch

Buttonhole

Straight

stitch

Refer

to

page

37 66 66 43 67 68 44 46 42 49

Pattern

No.

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20

Pattern Application

Left

needle

position

Center

needle

position

Left

needle

position

Right

needle

position

Three point zig zag

Two point zig zag

Overcasting stitch

Overcasting stitch

Used for lightweight material

Overcasting stitch

Used for exible material

Ornamental pattern

Blind stitch

Used for lightweight material

Blind stitch

Used for exible material

Shell tuck

Fly stitch

Bar tack

Eyelet

Button sewing

Straight stitch

Straight stitch for

elastic

Zigzag stitch

Refer

to

page

37 42 43 43 45 - 44 45 - - - 64 46 46 - - 58 - - 57

On the LCD screen you will see

the selected stitch pattern and

the marking of the presser foot

to be used.

・

Practical patterns

❶

Direct patterns

❷

Other patterns

Push and select a pattern type from with select button

(

or ). Then, select a pattern with its pattern number.

Select stitch pattern by number.

Pattern can also be selected using .

Page 37

35

Pattern

No.

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

Pattern

Application

Standard

buttonholes

2-step

buttonhole

Rounded

end

Keyhole

buttonholes

For knit

Decorative

Refer

to

page

49 ~ 56

・

Buttonhole patterns

Pattern

Refer

to

page

64

Pattern

Refer

to

page

68 ~ 70, 72

・

Quilt patterns

・

Decorative patterns

Combination patterns

Patterns for elongation

Page 38

36

Push and select a pattern type from with select button

(

or ). Then, select a pattern with its pattern number.

The pattern types are same with those of "Quilt patterns" and "Decorative patterns".

“Quilt patterns” numbers 01 and 02 are not available for one-point sewing.

Some patterns can overlap when combined. In such cases, combine them while inserting a space (decorative

patterns: No. 71) between the patterns.

Pattern

Refer

to

page

74 ~ 82

❸

One point pattern

❹

Letters

Pattern

Refer

to

page

74 ~ 82

Select stitch pattern

by number.

Quilt patterns Decorative patterns

Push

and select a letter type from with the select button

(

or ). Check this portion.

(Refer to page 75 for how to select letters.)

Page 39

37

Straight stitch

Sewing start

Pull the needle and bobbin threads under the presser

foot to the rear of the machine and lower the presser

foot to start sewing.

Sewing end

Stop sewing and push the thread trimming button to trim

the threads.

<by thread trimming button>

When you push the thread trimming button, the thread is

trimmed and the presser foot automatically goes up.

You can also set the function to lift the presser foot after

thread trimming to OFF.

(Refer to page 93 )

<by foot controller>

* You can also cut the threads by the thread cutter at

the face plate cover.

Pattern No. Direct 1

Presser foot

Standard presser

foot (A)

Thread tension Auto

Attention

Turn OFF the power switch

before replacing the presser

foot.

This means presser foot is up.

Lower the presser foot to start

sewing.

Foot switch function

It is possible to set so that the thread is trimmed by

depressing the front section of the foot controller.

(Refer to page 89 )

Page 40

38

When sewing the edge of thick

fabrics

Turn the hand wheel and let the needle enter at the position of sewing start. Push the black button A by nger and

lower the presser foot. Release the finger from the black

button and start sewing. When the presser foot will be on

the fabric completely, the black button will be disengaged

automatically.

When changing the sewing direction

When you stop the sewing machine, the sewing machine

stops with its needle down and the presser foot automatically goes up.

Then, change the sewing direction and re-start the sewing

machine.

★

Seam guide line on the throat plate

Align the fabric edge with a seam guide line and sew.

* Numbers on the guide line show the distance in mm and

inches between the center needle position and the guide

line.

Numbers, 7, 10 and 20 are millimeter.

Numbers, 1/ 4, 5/ 8 and 1 are inches.

5 mm

On center needle position basis

(Refer to page 90 )

Presser foot pivot function

The presser foot pivot function can also be turned

OFF.

A

Page 41

39

Lock stitch after sewing-end

<When start/stop button is used>

After the sewing is nished, push the reverse stitch button.

While it is pressed, the machine will sew reverse and when

it is released, the machine will stop sewing reverse.

<When foot controller is used>

While the reverse stitch button is pressed, the machine will

sew reverse. When the reverse stitch button is released,

the machine sews straight.

In the case of sewing one-point stitches or letters, the sewing machine stops after the completion of lock stitches.

Lock stitch

It is used for sewing lock stitches which are inconspicuous.

<When start/stop button is used>

Push the lock stitch button at the end of sewing.

The sewing machine sews lock stitches and stops.

<When foot controller is used>

Push the lock stitch button at the end of sewing.

The sewing machine sews lock stitches and stops.

* When you push the button while sewing one-point stitch-

es or letters, the sewing machine sews until one cycle of

the selected pattern is completed, sews lock stitches and

stops. The start/stop button lights up in orange during

the one cycle.

★

★

Foot switch function

It is possible to set so that the sewing machine performs sewing of reverse stitches or lock stitches by

depressing the front section of the foot controller.

(Refer to page 89)

Adjustable reverse stitch speed

Reverse stitch speed and lock stitch speed can be

set.

(Refer to page 96)

Page 42

40

Example: straight stitch

B

Fabric

A

The sewing machine operates differently

according to the button you press.

B

: Press the reverse stitch button.

The machine sews reverse stitches, stop sewing and trim both needle and bobbin threads

automatically.

: Press the lock stitch button.

The sewing machine sews lock stitches, auto-

matically stops and trims both the needle and

bobbin threads.

1

After selecting a pattern, you can press

.

is displayed on the screen.

When you press the button again,

is displayed to

show that the lock stitch is set.

2

Place the fabric in the sewing start

position and begin sewing.

A

:

The machine sews a few back stitches and continue.

: The sewing machine sews a few lock stitches

and continues sewing.

3

Automatic lock stitch and t

hread trimming

★

B

Fabric

A

The sewing machine automatically sews reverse stitches and lock

stitches at the start of sewing. Then, it starts normal sewing.

When you push the reverse stitch button at the end of sewing, the sewing machine sews reverse stitches, trims threads and stops.

Press

to change the settings.

Straight stitch/zigzag stitch Pattern

Press once

Screen display:

(Reverse stitch)

Screen display:

(Lock stitch)

Press twice

Screen display:

(Lock stitch)

Screen display: None

(No setting)

Press three times

Screen display: None

(No setting)

Example) In the case of straight stitches

Page 43

41

When changing the needle position

of straight stitch

It is possible to change the needle position with the zigzag

width adjusting dial/button.

Turning to the left (- side), the needle moves to the left.

Turning to the right (+ side), the needle moves to the right.

Pushing “-”, the needle moves to the left.

Pushing “+”, the needle moves to the right.

When changing the stitch length

It is possible to change the stitch length with the stitch

length adjusting dial/button.

Turning to the left (- side), the displayed value becomes

smaller and the stitch length becomes smaller accordingly.

Turning to the right (+ side), the displayed value becomes

larger and the stitch length becomes larger.

Pushing “-”, the displayed value becomes smaller and the

stitch length becomes smaller accordingly.

Pushing “+”, the displayed value becomes larger and the

stitch length becomes larger.

★

How to change needle positions How to change the stitch length

DX7

DX5

DX7

DX5

DX7

DX5

DX7

DX5

Page 44

42

Reinforced stretch stitch

The reinforcing stretch stitch helps reinforce seams

when used for sewing of elastic fabric or the force-exerted part of fabric that is likely to fray.

Straight stitch for elastic fabric

Finished seams are elastic. This stitch system can be

used for producing straight stitches on elastic fabrics

such as knits and jersey.

Other straight stitch patterns

★

Reverse straight stitch

Machine starts to sew reverse and when reverse stitch

button is pushed, it sews forward.

DX7 Only

Page 45

43

Zigzag stitch

When changing the zigzag width

The zigzag width can be adjusted while sewing.

Turning to the left (- side), displayed value becomes smaller

and the zigzag width becomes smaller accordingly.

Turning to the right (+ side), displayed value becomes larger and the zigzag width becomes larger accordingly.

Pushing “-”, displayed value becomes smaller and the zigzag width becomes smaller accordingly.

Pushing “+”, displayed value becomes larger and the zigzag width becomes larger accordingly.

When changing the stitch length

The stitch length can be adjusted while sewing.

Turning to the left (- side), the displayed value becomes

smaller and the stitch length becomes smaller accordingly.

Turning to the right (+ side), the displayed value becomes

larger and the stitch length becomes larger accordingly.

Pushing “-”, the displayed value becomes smaller and the

stitch length becomes smaller accordingly.

Pushing “+”, the displayed value becomes larger and the

stitch length becomes larger accordingly.

Width

Length

Pattern No. Direct 4

Presser foot

Standard presser

foot (A)

Attention

Turn OFF the power switch

before replacing the presser

foot.

DX7

DX5

DX7

DX5

DX7

DX5

DX7

DX5

Page 46

44

Pattern No. Practical 07

Presser foot

Overcasting presser

foot (C)

Push the fabric towards the guide and sew.

If the fabric and guide are apart, it will not make a

nice stitch formation. Make sure to guide the fabric

along the guide and sew slowly.

* Before sewing, make sure to check that the needle

will not hit the presser foot.

Overcasting stitch

Overcasting stitch 1

Pattern No. Direct 7

Presser foot

Overcasting presser

foot (C)

This stitch is used for overcasting medium- to heavyweight materials.

Guide the fabric along the guide and sew.

* Before sewing, make sure to check that the needle

will not hit the presser foot.

Overcasting stitch 2

・

This stitch is used to prevent the edge of fabric from fraying.

Attention

Turn OFF the power switch

before replacing the presser

foot.

Attention

Turn OFF the power switch

before replacing the presser

foot.

Page 47

45

This stitch is used to prevent the cut edge of fabric

from fraying.

Keep some seam allowance and cut the sewn fabric

carefully so that stitches are not cut by the scissors.

Overcasting by 3-point zigzag

Pattern No. Practical 05

Presser foot

Standard presser

foot (A)

This overcasting stitch is used for overcasting lightweight materials.

Guide the fabric along the guide and sew.

* Before sewing, make sure to check that the needle

will not hit the presser foot.

Overcasting stitch 3

Pattern No. Practical 08

Presser foot

Overcasting presser

foot (C)

* Do not use overcasting presser foot (C).

Attention

Turn OFF the power switch

before replacing the presser

foot.

Attention

Turn OFF the power switch

before replacing the presser

foot.

Page 48

46

Blind stitch

Fabric

(wrong side)

Fabric

(wrong side)

Basting line

Fabric

(wrong

side)

0.5 to 0.6 cm

Fabric

(wrong side)

Finish line

Finish line

0.5 to 0.6 cm

Finish line

1

Sewing overcasting stitches on the edge

of fabric.

● Refer to page 44 for overcasting stitches.

2

Carry out basting by hand.

3

Fold from basting line.

Leave 0.5 to 0.6 cm.

Folding fabrics

Pattern No.

Direct 8

Practical 13 (Lightweight material)

Practical 14

(Stretchy fabrics)

Presser foot

Blind stitch presser

foot (D)

Pattern

number

Attention

Turn OFF the power switch

before replacing the presser

foot.

Page 49

47

Finish line

Fabric

(right side)

Fabric

(wrong

side)

Fabric

(wrong side)

Guide

Fabric

(wrong

side)

Folded edge

Guide

Needle

Folded

edge

Guide

4

Align the guide of the presser foot with

the folded edge.

Turn the hand wheel and adjust with

the zigzag width adjusting dial so that

stitches reach the folded edge.

* Pay attention so that needle will not hit the

presser foot.

5

Position the folded edge against the guide

and sew.

6

Turn over the fabric after sewing.

Page 50

48

Turn the zigzag width

adjusting dial to the

right side.

2. If the stitches fail to reach the folded edge

1. If the stitches reach too far beyond the folded edge

When changing the needle entry point

Turn the handwheel

to check the needle

entry point. When

adjusting, make sure

the needle is in the

up position.

Turn the handwheel

to check the needle

entry point. When

adjusting, make sure

the needle is in the

up position.

DX7

DX5

Push the zigzag width

adjusting button "+".

Turn the zigzag width

adjusting dial to the

left side.

Push the zigzag width

adjusting button "-".

DX7

DX5

Page 51

49

Buttonhole stitches

Buttonhole type

* The buttonhole length is automatically determined only by placing a button on the buttonhole press-

er foot.

*

The machine can sew buttonholes for buttons with diameters of 0.7 - 3.2 cm.

*

In case of stretchy fabrics, use non-elastic interlining on the wrong side of the fabric.

*

Make sure to perform test sewing to see that the machine sews buttonholes correctly.

*

Buttonhole Nos. 09 - 12 are for knit fabrics and should be used with a knit needle.

Pattern No.

Direct 0

Buttonhole 01, 02,

04~15

Presser foot

Buttonhole presser

foot (E)

0

Standard buttonhole

Buttonhole for medium to heavy

weight materials

Standard buttonhole

01

Stitch length is larger.

Buttonhole for heavy weight materials

02

Sews buttonhole double

03

Manual 2-step buttonhole

Use this buttonhole, when there

is an overlapped section in the

fabric or when you want to sew

larger buttonhole than 3.2 cm

diameter. (Refer to page 55)

04

Rounded end

Buttonholes for women’s blouses

and children’s clothes.

Also for light weight materials

05

06

Keyhole

Keyhole buttonhole for heavy

weight materials such as suits,

jackets, coats, etc.

07

Round keyhole

08

Large and thick keyholes for

heavy weight materials

09

For knit

Buttonhole for light weight knit

(also used as decorative buttonhole)

10

Buttonhole for medium weight

knit (also used as decorative

buttonhole)

11

Buttonhole for light weight knit

Sews buttonhole double

12

Buttonhole for medium weight

knit

Sews double buttonhole

13

Decorative

Decorative buttonholes

Decorative buttonhole which look

like hand-sewn

14

15

* Refer to page 55 for button-

hole 03.

Pattern

number

Attention

Turn OFF the power switch

before replacing the presser

foot.

Page 52

50

Groove

Button holder

1

Set the presser foot.

Lift the needle and lift the presser foot.

Align the groove of the presser foot holder with the pin

of the presser foot and lower the presser foot holder to

set.

2

Set the button.

Pull the button holder toward A, place the button on

the button holder, and then push the holder toward B

to set the buttonhole length.

* It is impossible to set a button thicker than

4mm.

Pin

A

B

3

Set the buttonhole sensor pin.

Insert the sensor pin into the sensor pin hole at the

face plate cover.

* Insert the pin into the hole completely.

* If the machine starts to sew without inserting

the pin into the hole, the following message will

be shown on the display.

Set the sensor pin

and restart.

Sensor pin

* Check the following

points after setting the

presser foot and then

start to sew buttonholes.

Check that there

is a clearance.

If there is not a

clearance, the

machine will

not sew neat

stitches.

Page 53

51

4

Place the fabric under the presser foot.

Raise the presser foot, pass the needle thread through

the hole on the presser foot and pull it out sideways.

Place the fabric under the presser foot, align the marking with the sewing-start point. Penetrate the needle

into the fabric by turning the hand wheel and lower the

presser foot.

5

Start sewing.

The machine will stop automatically after sewing the

buttonhole.

* If a buttonhole of the same size will be sewn

again, push the thread trimming button to trim

the threads and raise the presser foot.

Under this condition move to another point,

lower the presser foot and then start sewing.

*

Do not change stitch length and/or zigzag width

during buttonholing. Otherwise this will cause

imbalanced stitches.

*

If thread trimming button is pushed while sew

ing buttonhole, the machine will stop and will

not complete the buttonhole.

* Depending on material to be sewn and weaving di-

rection of the material, there might be a slight difference in zigzag widths between right and left lines of

buttonholes. Test sewing is recommended.

Hole on the

presser foot

Sewingstart point

Needle

thread

Marking

Start from here

Page 54

52

Eyelet

punch

It will be easier to sew buttonholes on the thin fabrics

and/or near the overlapped sections, if the clamping

plate is used.

Clamping plate

1. Attach the buttonhole presser foot

to the presser foot holder, with the

clamping plate together.

2. Place the fabric between the presser

foot and the clamping plate.

* You can remove the clamping plate by holding A.

● Buttonhole clamping plate

Stopper

pin

6

Unplug the sensor pin after sewing.

7

Opening the buttonhole using a ripper.

[double bartack]