Page 1

BE4150S0B0B

MODEL

HIGH

SPEED, SINGLE NEEDLE,

LOCKSTITCH

INDUSTRIAL

DLN-415

NEEDLE

SEWING

FEED

MACHINE

Instruction

Book

TOKYO

JOKI

CiiE=>

INDUSTRIAL

OLN'A1S

C0..1TD

Page 2

DLN-415

SPECIFICATIONS

Sewing

Stitch length

Stitch adjuster Dial system

Reverse sewing Lever system

Needles DBx

Lubricating oil New Defrix Oil No. 1

speed Upto 5,000 s.p.m.

04mm

(DLN

{5/32")

1(16

415L

(DLN415L

x 231)

DB x 1

#11,

(DLN-415L

0~6mm

#14,

#16,

#22)

3,000 s.p.m.)

(15/64"))

#18

Page 3

DLN-415

Installing

Motor

Cautionsonoperating

Lubrication

1.

2.

3.

Threading

Preparationofthe

1. Inserting &

2.

3.

The

Adjusting

Thread

Adjusting

Presser

Adjusting

The

Heightofthe

The

Adjusting

Reverse

Pushing

Inserting

Installing

Relation

Adjusting

Adjusting

DLN-415-L

the

oil

reservoir

pulley

and

the

belt

the

machine

Adjusting

The

Adjusting

Winding

Howtoinsert

thread

presser

stitch

the

oil

supplytothe

face

oil adjusting pin 4

the

oil

the

tension

the

take-up

the

foot

the

the

and

foot

supplytothe

machine

bobbin

removing

bobbin

needle

the

the

thread

bobbin

thread

spring

bobbin

thread

feed

dog

pressureofthe

hand

lifter

feed

dog

hook

thread

bobbin

case

tension

.tension

presser

.'. ; 8

length

the

stitch

length

sewing

pressureofthe

the

needle

and

removing

between

the

heightofthe

the

amountofthe

INSTRUCTION

the

feed

hook

the

lever

sewing

and

presser

thread

BOOK

the

hook

needle

bar

take-up

(Note) Duetoimprovementsonthe

this

INSTRUCTION

BOOK

mightbechanged

part

components

foot

machine,

CONTENTS

some

parts of

without

the

operational

notice.

•.

procedures

Page

2

2

3

3

4

4

5

6

6

6

6

7

7

7

7

8

8

8

9

9

9

9

10

10

11

12

12

13

of

Page 4

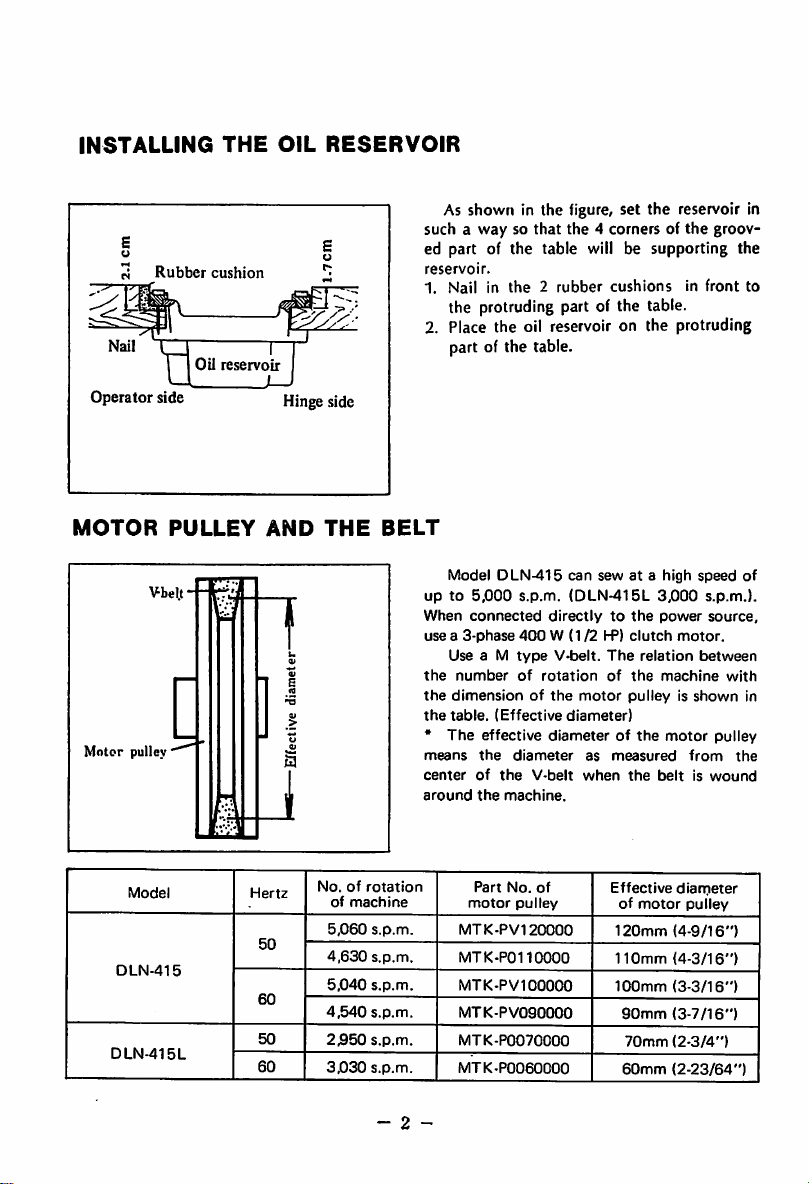

INSTALLING

Rubber

I 1

Operator

side

Oil

THE

cushion

reservoir

OIL

1_

Hinge side

RESERVOIR

such a way so that the 4 corners of

ed part of the table will be supporting the

reservoir.

1. Nail in

2. Place the oil reservoir on the protruding

As shown in the figure, set the reservoir in

the

groov

the2rubber

cushionsinfront

the protruding part of the table.

part of the table.

to

MOTOR

Motor

DLN-415

DLN-415L

pullev

Model

PULLEY

Hertz

50

60

50

60

AND

THE

BELT

No.ofrotation

of

machine

5,060

s.p.m.

4,630

s.p.m.

5,040

s.p.m.

4,540

s.p.m.

2,950

s.p.m.

3,030

s.p.m.

Model

DLN-415

upto5,000

When

connected

usea3-phase

Use a M

the

number

the

dimensionofthe

the

table.

•

mrans

centerofthe

around

(Effective

The

effective

the

the

Part

motor

MTK-PV120000

MTK-P0110000

MTK-PV100000

MTK-PV090000

MTK-P0070000

MTK-P0060000

s.p.m.

directlytothe

400

W (1/2HP)

type

V-belt.

of

rotation

diameterofthe

diameter

V-belt

machine.

No.

of

pulley

can

sewata

(DLN-415L

The

of

motor

diameter)

as

measured

when

Effective

of

120mm

110mm

100mm

90mm

70mm

60mm

high

speed

3,000

s.p.m.).

power

source,

clutch

motor.

relation

the

between

machine

pulleyisshown

motor

pulley

the

from

beltiswound

dian^ieter

motor

pulley

(4-9/16")

(4-3/16")

(3-3/16")

(3-7/16")

(2-3/4")

(2-23/64")

of

with

in

the

- 2 -

Page 5

CAUTIONS

ON

OPERATING

THE

MACHINE

® Do not run the

with

fresh

oil.

machine,

under any

circumstances,

before the oil

reservoirisfilled

up

® Always rotate the machine toward the operator. Do not run the machine in the re

verse

direction.

® This machine can run with a speed of up to 5,000 s.p.m. but for the first month drop

the speed to

about

4,500 s.p.m. (DLN-415L 2,500 s.p.m.)

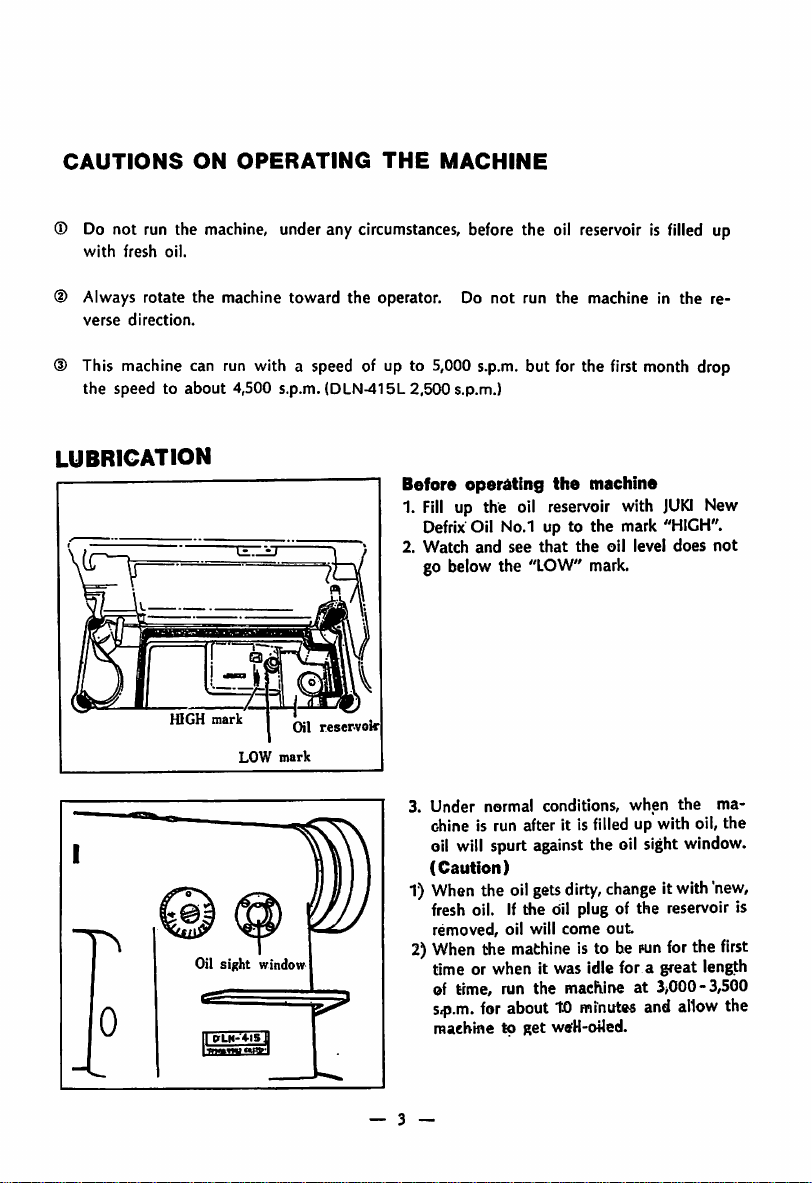

LUBRICATION

Before

1.

2.

HIGH

mark

Oil sight window

0

OLM-4-15]

LOW

mark

Oil

reservoir

operating

Fill

up the oil reservoir with

Defrix

Oil No.1 up to the mark

Watch

and

go below the

3.

Under

normal

chine is run after it Is filled up with oil, the

oil

will

spurt

(Caution)

1) When the oilgets

see

"LOW"

against

the

machine

that

the

mark.

conditions,

the oil sight

dirty,

oil level

when

change

JUKI

"HIGH".

does

the

window.

itwith

fresh oil. Ifthe oil plug of the reservoir is

removed,

2)

When

the

oil will

machine

come

isto be

out

pun

for

time or when it was idle for a great length

of time, run the

S4).m.

for

machine to get wtfH-oUed.

macFiirieat3>000-3,500

abouttO

minutes

and

allow

New

not

"new,

the

ma

first

the

— 3 —

Page 6

Oil

adjusting pin

Oil

amount

gets

less

Oil amount

' I I

Needle

bar

Oil

adjusting

Arm

Oil adjusting pin

Counterweight

Crank

gets

more

fl

crank

Grooveofeccentric

shaft

screw

1.

Adjusting

part

the

oil

supplytothe

face

When adjusting the oil supply to the thread

take-up and needle bai crank components,

remove the face plate and the oil prevent

ing plate and adjust by turning the oil ad

justing pin at the tip of the main

1. When

the

red mark of the adjusting pin

comes near the crank, the oil

less.

2. When

the

red mark comes to the opposite

shaft

amount

gets

side of the crank, the oil amount gets more.

(Caution)

The oil amount

does

not

change

immedi

ately after the adjustment, so when ad

justing,

2.

1. The oil adjusting pin has a carved groove

2. When the groove is at the opposite side of

3. The red mark on the oil adjuster shows the

have

this in mind.

The

oil

adjusting

pin

as shown in the figure. When this groove

and

the

oil

holeofthe

main

shaft

come

together, the oil amount gets more.

the oil hole,

the

oil

amount

gets less.

side without the carved groove.

Oil regulating valve

3. Adjusting

components

the

oil

supplytothe

The supply of oil to the hook components

can be adjusted by the oil regulating valve on

the

hook

shaft.

1.Ifthis valve is turned toward © side(right),

the oil amount gets more,

2. Ifthis valve is turned to © side (left), the

amount

- 4 -

gets less.

hook

Page 7

THREADING

Rotate

the

hand

1. Pass the needle thread in the order shown by the

2.

Pass

the

3.

Pull

jDut

THE

MACHINE

wheeltoright

thread

to the

and

needle

about10cm(4")of the

eye

place

from

thread

the

leftto

from

thread

the

take-up

figure.

right.

needle

eye.

to the

highest

position.

- 5 -

Page 8

PREPARATION

OF

THE

BOBBIN THREAD

Bobbin

Pulleys

Trip

case

latch

Adjusting

screw

Tension

base

disc

Inserting&removing

the

bobbin

case

1. Rotate the hand wheel with your hand and

bring the needle to its highest position.

2. Tilt the machine and support it by the head

support on the table.

3. Lift up

the

takeitout.

knob of

the

bobbin

case

and

* If you hold the knob in open condition,

bobbin

will

not

fall

off.

4. To insert the bobbin case, insert it deep

into

the

shaftofthe

hooksothat

the

nose

of the bobbin case fully enters the groove

of

the

hook

and

then

close

the

knob.

Winding

1.

2.

the

bobbin

Set

the

screws.

Pass

bobbin

the

threadinthe

figure and wind it

al

times.

winder

around

thread

to

order

the

showninthe

the

bobbin sever

table

with

3. Knock down the trip latch and contact the

pulley to the belt.

4. Adjust the winding amount by the winding

adjusting screw so

that

about

80% is wound.

5. When the thread is wound unevenly, move

the

thread

tension

disc

base

to

left

and

correct to even winding condition.

6. When the winding is completed, the trip

latch will be released and the pulley will

stop automatically.

Thread

hole

Thread

passing

hole

- 6 -

Howtoinsert

1.

Hold

the

casesothat

condition.

2. Pass

3.

of

Then

the

out

*When

the

the

the

bobbin

pull

thread

through

pulling

bobbininthe

the

bobbin

bobbin

and

the

thread

threadtothe

case.

the

thread

tension

spring

the

thread

the

bobbin

arrow

insertitto

willbein

thread

and

it will

and

hole.

thread,

direction.

the

bobbin

right-twist

passing

hole

pass

under

canbepulled

rotate

Page 9

THE

THREAD

TENSION

Moving

®ow»

range

Thread

M I

Weaker

n

'-'Thread tension nut

Thread

take-up

tension

bar

Set

_

spring

screw

Stronger

Adjusting

Ideal

the

stitches

needle

are

formed

thread

when

tension

the

needle

thread and the bobbin thread are perfectly

interlockedatthe

centerofthe

cloth.

The tension of the needle thread is adjusted

by the thread tension nut.

1. Turn it to right to make the tension stronger

andtothe

Thread

*Tochange

tension

1. Loosen

bracket

2.

Rotate

*Tochange

up spring

lefttomakeitweaker.

take-up

the

the

spring:

the

thread

the

spring

moving

screwofthe

tension

strength

range

bar.

of the

ofthe

thread

tliread

thread

tension

take-

1. Loosen the set screw, remove the thread

tension

2. Loosen

3. When

turned

bar

the

and adjust.

the

right,

the

to left, it will

thread

tension

bar

set

screw

thread tension bar is turned to

spring

will

get

get

stronger

weaker.

Thread

bar

and if

tension

set

screw

Adjust

inff

0

Li

Adjusting

Rotate

Thread take-up spring

the

bobbin

the

thread

thread

tension

tension

screw of

the

bobbin case to adjust the bobbin thread

tension.

1. Rotateit to rightto makethe bobbin thread

tension stronger and to left to make it

sc

- 7 -

weaker.

Page 10

PRESSER

FOOT

AND

FEED

DOG

Pressure

Hand

lifter

adjusting

screw

_///

\I

W

ffi

Adjusting

foot

the

pressureofthe

presser

1. Turn the pressure adjusting screw to right

to make the pressure stronger and to left

to

makeitweaker.

Normal pressure for general fabric is about

5 kg (11 lbs).

Ifa pressure of more than 6 kg

required, use the

accessory box.

Presser

lifter

Turn

the

rear of

the

machine

and

the

presser

(13/64")

will

lifter,

10 mm

Push

come

the

125/64")

from

down

downtopress

presser

hand

foot

the

hand

from

exchanging

lifting lever

head

either

will goupfor

throat

plate

lifter,

the

foot

will go up for

the

throat

and

(13.2

spring in the

locatedinthe

to left or right,

about5mm

surface.

the

presser

work.Bythe

plate

surface.

lbs) is

foot

knee

about

Feed

driving fork

Clamp

TA

screw

Heightofthe

feed

dog

The height of the feed dog from the surface

of the throat plate is set from 0.7-0.8mm. In

sewing light weight materials, if this height is

too high,shrink-stitching may

To adjust the height of the

1. Loosen the clamping screw of the feed driv

ing fork of the compound feed.

result.

feed

dog:

2. Move the feed dog base up and down and

adjust.

3.

After

8 -

adjusting,

screw.

f\NN\N\NNv5

I

Feed

doR

tightly

0.7--0.8Em

tighten

the

Throat plate

clamping

Page 11

THE

STITCH

LENGTH

Feed

adjusting

DLN-4-15

dial

Lever

Adjusting

The

stitch

the

length

stitch

length

can be adjusted by

turning

the feed adjusting dial above the feed lever.

The figures on the graduator are shown in

mm.

1. Rotate the feed adjusting dial either to right

or

left.

2. And match the desired

which is coming

* The

maximum

Reverse

stitch length is 4mm(5/32")

sewing

figure

out

from the arm.

with the pin

1. For reverse sewing, push the feed lever

down.

2. As long as this lever is kept down, reverse

sewing can be performed.

3.

Release

this

lever

and

the

feed

lever

will

return to original position and normal

A

straight stitching can be resumed.

AdjustinK nut

Pushing

pressure

of

the

food

Irrespective of the length of stitches, the

pull-up spring is somewhat strengthened so

that during high speed sewing if the hand is

released from the feed lever, it will positively

return to the original position.

When

shorter

the

rotationofthe

stitches

are

machineistobeslowed

desiredorwhen

down, it is possible to decrease the pushing

pressure of

the

feed lever.

1. When the adjusting nut is loosened, the

pressure will

become

weaker

is tightened, the pressure will become

stronger.

- 9 -

and

lever

if the

nut

Page 12

INSERTING

THE

NEEDLE

Set

screw

Needle

INSTALLING

Feed

base

screw

AND

Bobbin

Groove

REMOVING

case

positioning

screw

Use DB X 1 needles. There

numbers

and

sizes of

the

needle,

are

so

many

select

the correct size and number depending on the

thickness of

material.

1. Rotate the hand wheel and bring

the

thread or kinds of sewing

the

needle

bar to the highest position.

2. Loosen

3. Hold the needle so

the

needle clamp screw.

that

the long groove of

the needle comes to your left side.

the

4. Insert the needle deep into

needle

5. Then securely tighten the needle clamping

screw.

THE

SEWING

HOOK

During the runningof the machine, if thread

hards get into the hook or the position of the

hook changes for some reason or to exchange

the

hook

bar to

Remove

withanew

the

hand wheel and bring

the

highest position.

the

the

order:

1. Rotate

2.

3. Remove

finger set screw and take

bobbin

one,doas

case

and

the

follows

the

needle

needle

bobbin case base positioning

out

the bobbin

case positioning finger.

4. Loosen the 3 screws of the sewing hook.

hole.

in

5. Rotate

the

hand

wheel

and

feed base to its highest position.

6. Rotate the sewing hook with your hand

and place it in the position as shown in

the figure.

7. Pull the hook to your left and take it out.

-

10

* To install

cedure.

the

hook back, reverse this pro

raise up

the

Page 13

RELATION

BETWEEN

Clamp

screw

THE

HOOK

AND

Match

follows:

THE

the

needle with

NEEDLE

the

1. Rotate the hand wheel and bring

bar to Its lowest position.

2. Loosen

the

needle bar clamping

(Note)

When matching the timing of the needle and

the sewing hook, be sure to set

adjusting dial to "0".

sewing hook as

the

needle

set

screw.

the

feed

(D

DETERMINE

OF

THE

THE

NEEDLE

HEIGHT

BAR

Needle

lower bushing

Upper

indicating

"Lower

\Needle

(2) DETERMINE THE POSITION

OF

THE

Blade

the

hook

Needle

point

sewing

SEWING

of

HOOK

VA

Lower

indicating

(At

this position,

the blade

^ sewinghook with

pointofthe

the

Sewing

bar

line

indicating

bar

line

match

center

the

needle)

hook

line

(Determine

the

heightofthe

3. Match the upper carved line of the needle

bar with the lower edge of the needle bar

lower bushing.

4. Tighten the needle bar clamping set screw.

(Determine

hook)

the

positionofthe

5. Loosen the 3 clamping screws of the hook

so

that

the hook can be rotated freely with

the

hand.

6. Place the hook with your hand to the thread

of

passing position

7.

Rotate

the

hand

wheel

and

carved

lineofthe

needle

bar

edge of the needle bar lower bushing.

8. In this condition, match

the

hook

with

9.

Make

and

the

the

the

clearance

hook blade point to 0.05 mm and

center

the

line of

between

10. Securely tighten the hook clamping set

match

with

blade

needie

sewing

the

the

point

the.needle

the

bar)

lower

lower

of

needle

- 11 -

Page 14

ADJUSTING

THE

HEIGHT

OF

THE

PRESSER

BAR

ADJUSTING

Thread

iC

Presser

THE

bar

guide

clamp

screw

AMOUNT

When the height or

presser bar is to be changed due to the

exchange of presser foot:

1. Remove the rubber plug of the face plate

2.

From

this hole, adjust by loosening the

presser bar clamping screw.

3. After the adjustment, securely tighten the

set

screw.

OF

THREAD TAKE-UP

The amount of the thread take-up should

be changed according to the length of stitches

or thickness of the sewing cloth to produce

ideal

thread

1. When sewing heavy weight materials, move

the thread guide to your left

The thread take-up amount of the take-up

gets

2. When sewing light weight materials, move

the thread guide to your right.

The thread take-up amount gets less.

tension.

more.

the

direction of the

-12-

Page 15

SPECIFICATIONS

Sewing

speed

Stitchlength 0 ~

Needle

USAGE

For

top

stitchingofheavy weight

(Example)

Seats

of cars,

INSTRUCTION

DLN-415-L

Upto3,000

DB X 1

materials

brief

cases, slippers etc.

6mni(

BOOK

15/64")

#22

s.p.m.

(upto12

sheetsofCanton

material)

TIMING

IT

eo

OF

THE

NEEDLE

Blade

the

sewing

Needle

Yl

Jf

Needle

•—O.lmni

k

\ Blade point of

<j

the

sewing

point

hook

of

hook

WITH

THE

SEWING

When

the needle has risen 1.8mm(5/64"), from

its

lowest

upper

endofthe

dead

HOOK

point,

needle

the

distance

eye

and

the

of the sewinghook should be 2.8mm(7/64").

At

that

point,

the

clearance

and the blade point of the sewing hook should

be0.lmm(l/256").

(when

the

between

feed

amount

between

blade

the

is"0".)

the

point

needle

With

the

exception of above, all

other

specifications are identical with DLN-415.

-

13

-

Page 16

TOKYO

JOKI

Loading...

Loading...