JRpropo XP8103 User Manual

AIRCRAFT SYSTEM - AIRPLANE MODE

USER MANUAL

AIRCRAFT SYSTEM - GLIDER MODE

HELICOPTER SYSTEM - HELICOPTER MODE

8 CHANNELS 10 MODEL MEMORY 3 MODEL TYPE S • Z PCM/PPM SELECTABLE

THE

ULTIMATE

RADIO CONTROL

SYSTEM

XP8103 2

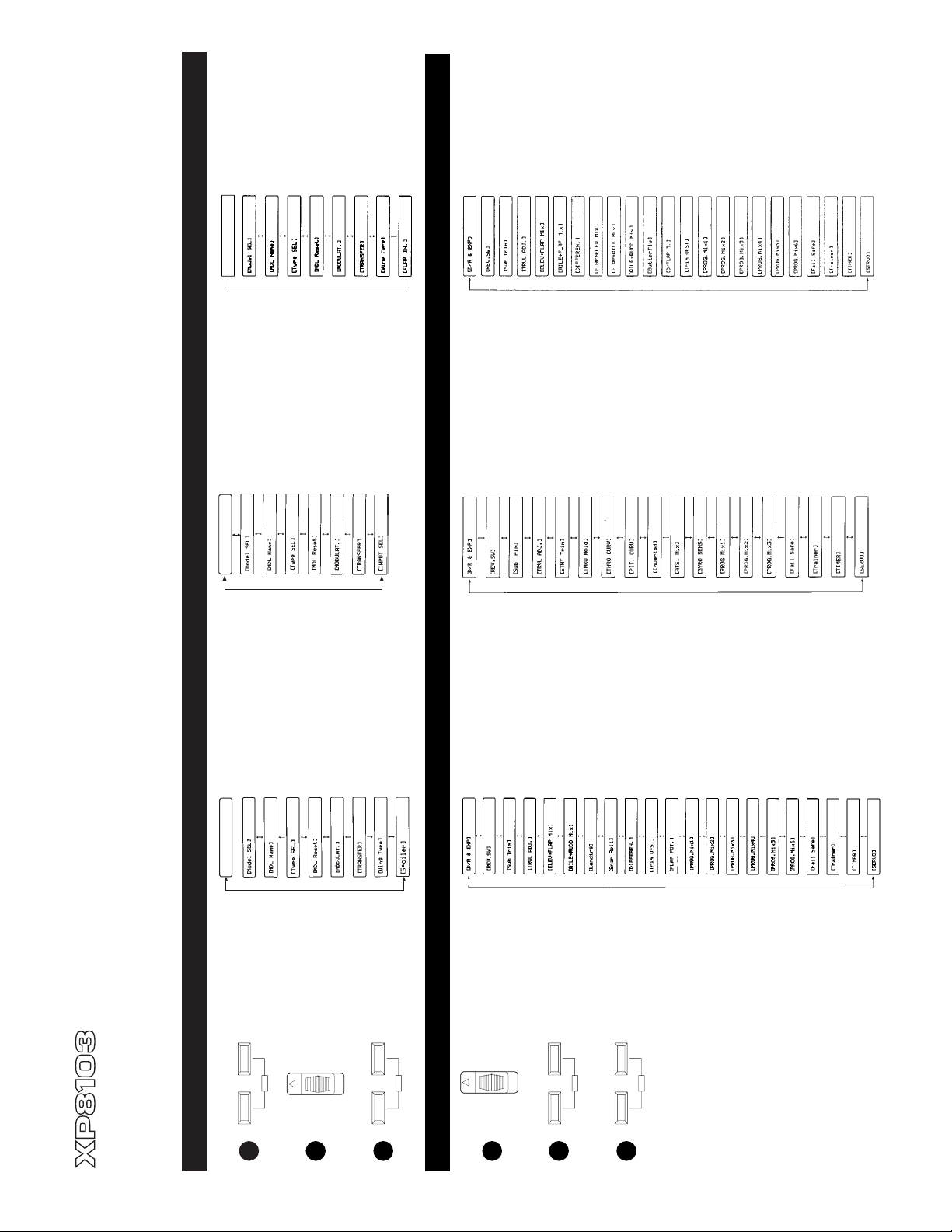

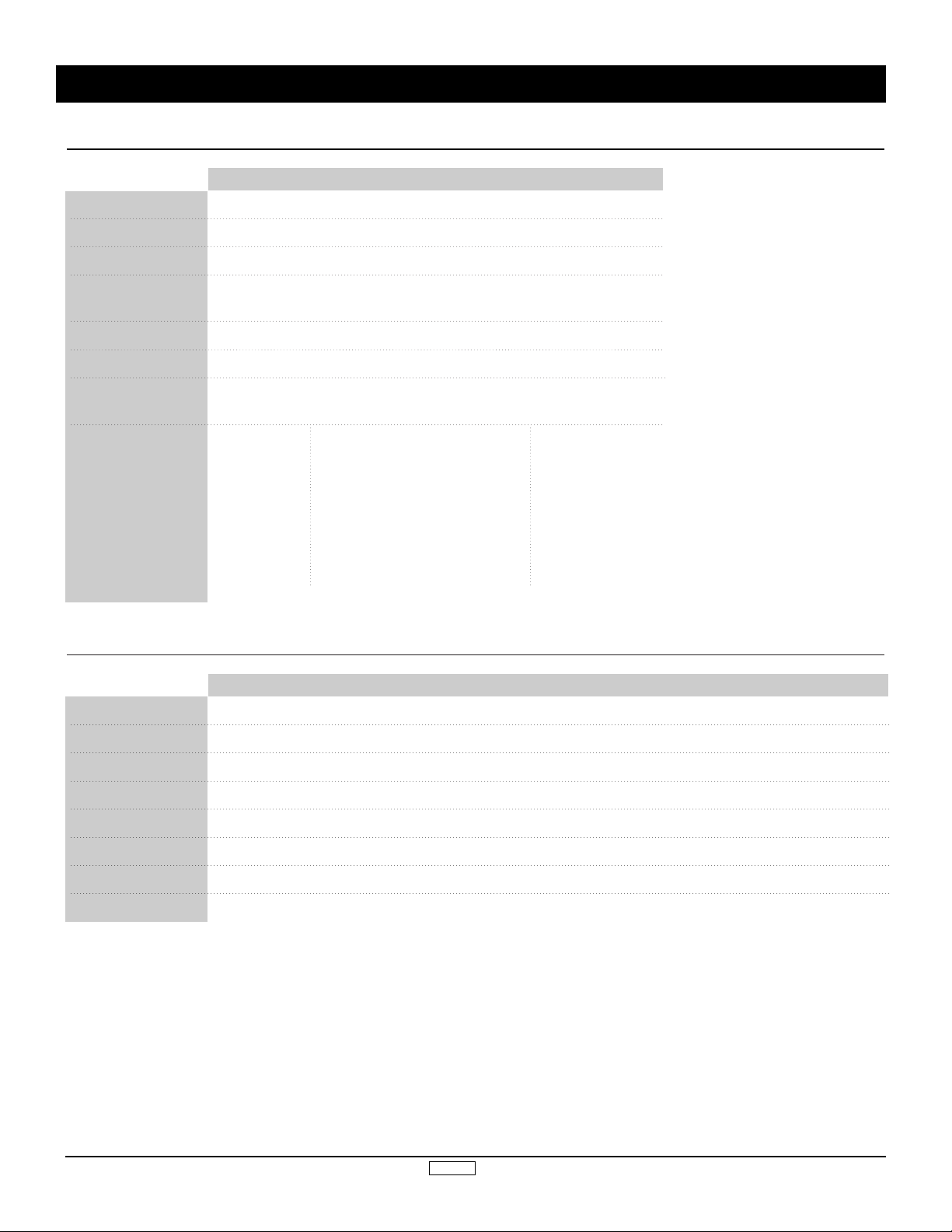

Airplane Mode Helicopter Mode Glider Mode

1-2-3 Programming

System Set-Up Mode

Function Mode

ENT

UP – MODE – DN

Push these two buttons

simultaneously and

hold.

Turn the power switch

ON (up).

ENT

UP – MODE – DN

Push these two buttons

simultaneously.

Turn the power switch

ON (up).

1

ENT

UP – MODE – DN

Scroll through options

using one of these

buttons.

3

2

ENT

UP – MODE – DN

Scroll through the

functions using one of

these buttons.

1

3

2

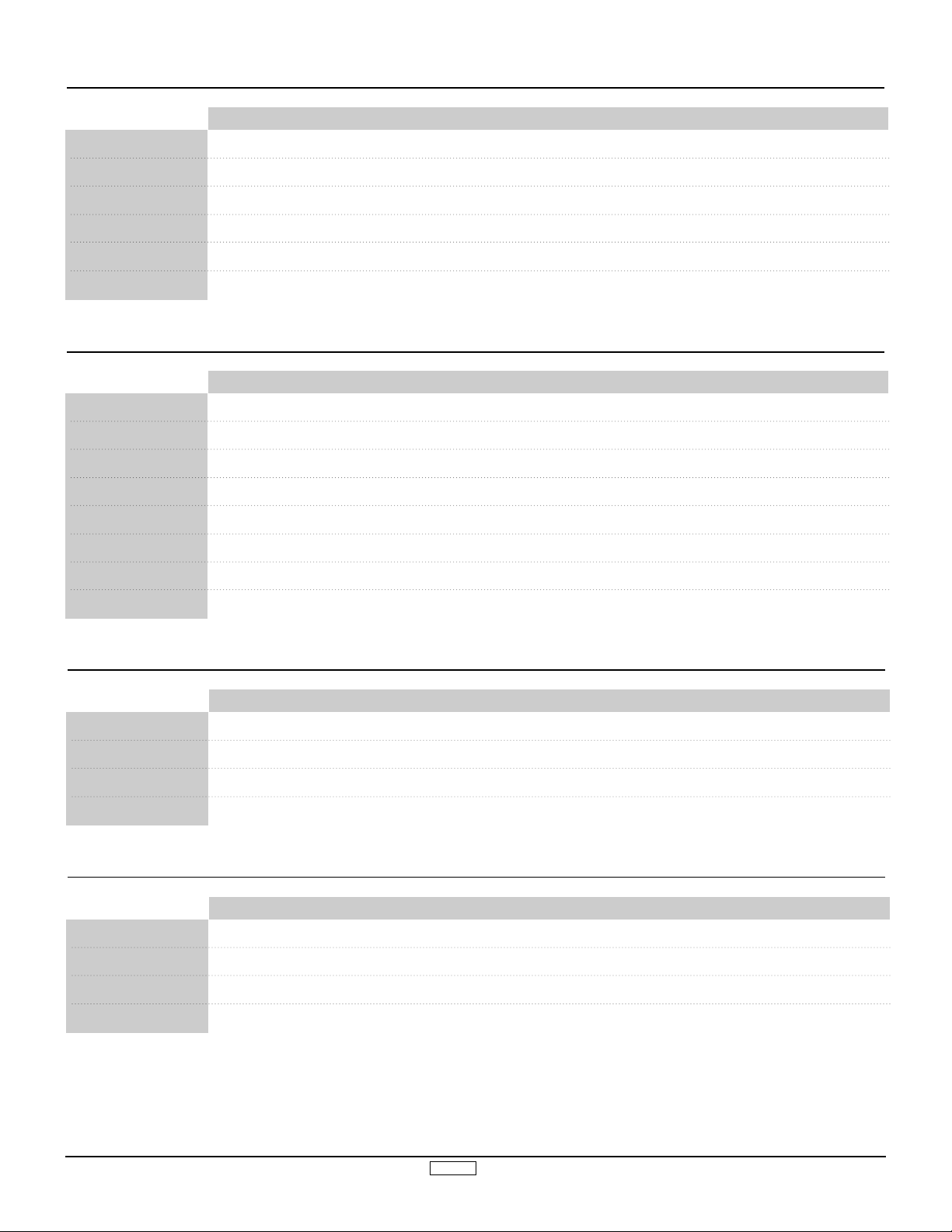

[INFO-DISP]

↕

Pg. 28 Information Display

Pg. 29 Model Select and Copy

Pg. 29 Model Name Input

Pg. 30 Model Type Selection Function

Pg. 30 Data Reset

Pg. 31 Modulation Selection

Pg. 32 Data Transfer between traqnsmitters

Pg. 34 Wing Type Selection

Pg. 35 Spoiler Channel Input Selection

Pg. 36 Dual Rate Exponential

Pg. 38 Reverse Switch

Pg. 38 Sub-Trim

Pg. 39 Travel Adjust (end point adjustment)

Pg. 39 Elevator to Flap Mixing

Pg. 40 Aileron to Rudder Mixing

Pg. 41 Landing System

Pg. 42 Snap Roll

Pg. 44 Differential Aileron Mixing (only if flaperon or

elevons mixing is active)

Pg. 45 Trim Offset Memory

Pg. 46 Flap Knob Operating Value Adjustment

Pg. 47 Programmable Mixing 1

Pg. 47 Programmable Mixing 2

Pg. 47 Programmable Mixing 3

Pg. 47 Programmable Mixing 4

Pg. 47 Programmable Mixing 5

Pg. 47 Programmable Mixing 6

Pg. 50 Fail-Safe/Hold (PCM Only)

Pg. 52 Trainer

Pg. 54 Timer

Pg. 55 Servo Output Values

Pg. 106 Information Display

Pg. 106 Model Select And Copy Function

Pg. 107 Model Name Input

Pg. 108 Model Type Selection Function

Pg. 108 Data Reset

Pg. 109 Modulation Selection

Pg. 110 Model Data Transfer

Pg. 112 Wing Type Selection

Pg.112 Flap Channel Input Selection

[INFO-DISP]

↕

Pg. 113 Dual Rate/Exponential

Pg. 114 Reverse Switch

Pg. 114 Sub-Trim

Pg. 115 Travel Adjustment

Pg. 115 Elevator To Flap Mixing

Pg. 116 Aileron To Flap Mixing

Pg. 117 Differential

Pg. 118 Flap To Elevator Mixing

Pg. 119 Flap To Aileron Mixing

Pg. 120 Aileron To Rudder Mixing

Pg. 121 Butterfly Mixing (Crow)

Pg. 122 Dual Flap Trim

Pg. 123 Trim Offset

Pg. 125 Programmable Mixing

Pg. 125 Programmable Mixing

Pg. 125 Programmable Mixing

Pg. 125 Programmable Mixing

Pg. 125 Programmable Mixing

Pg. 125 Programmable Mixing

Pg. 127 Fail-Safe (PCM Only)

Pg. 130 Trainer

Pg. 131 Timer Setting

Pg. 133 Servo Output Monitoring

(Only available when Dual Flap

setting is active)

[INFO-DISP]

Pg. 66 Information Display

Pg. 66 Model Selection and Copy Function

Pg. 67 Model Name Input

Pg. 68 Model Type Selection

Pg. 68 Data Reset

Pg. 69 Modulation Selection

Pg. 70 Data Transfer

Pg. 72 Aux 2, channels can be used for gyro

sensitivity adjustment

Pg. 73 Dual Rate Exponential

Pg. 75 Reverse Switch

Pg. 75 Sub-Trim Adjustment

Pg. 76 Servo Travel Adjust (End Point Adjustment)

Pg. 76 Stunt Trim

Pg. 77 Throttle Hold

Pg. 78 Throttle Curve

Pg. 81 Pitch Curve

Pg. 83 Inverted Flight

Pg. 84 Revolution/Acceleration Mixing

Pg. 85 Gyro Sensitivity Adjustment

Pg. 87 Programmable Mixing 1

Pg. 87 Programmable Mixing 2

Pg. 87 Programmable Mixing 3

Pg. 91 Fail-Safe/Hold (PCM Only)

Pg. 94 Trainer

Pg. 95 Timer Setting

Pg. 97 Servo Output Indicator

ON

ON

XP8103 4

1-2-3 Programming Charts .........................3

Table of Contents ...............................4

I. Introduction

How to Use This Manual...........................8

2. Features

2.1 Transmitter NET-G128FS/HS Computer.........8

2.2 Receiver .............................9

2.3 Servo Features.........................9

3. Component Specifications

3.1 System Specifications (Air/Heli).............10

3.2 Transmitter Specifications (Air/Heli) ..........10

3.3 Servo Specifications ....................11

3.4 Receiver Specifications...................11

3.5 Charger Specifications...................11

3.6 Airborne Battery Pack ...................11

4. Battery Charging

4.1 Transmitter/Receiver ....................14

4.2 Charger ............................14

5. General Information

5.1 Control Stick Length Adjustment .............15

5.2 Control Stick Tension Adjustment ............15

5.3 Transmitter Rear........................16

5.4 DSC Cord...........................17

5.5 Neck Strap Adjustment ..................17

5.6 Base Loaded Antenna ...................17

5.7 Frequency Notes/Aircraft Only Frequencies.....18

5.8 Lithium Battery Indicator/Backup Error Display . . . 18

5.9 Screen Contrast Adjustment................19

5.10 Installation Requirements..................19

1. Transmitter Controls

1.1 Control Identification and Location...........22

A. Airplane Version Tx .................22

B. Heli Mode.......................23

C.Glider Mode .....................23

1.2 Connections .........................24

2. General Information

2.1 Input Key Functions .....................25

2.2 Normal Display .......................25

3. System Set-Up Mode Functions

3.1 System Set-Up Mode....................26

3.2 Function Mode........................27

3.3 List Mode ...........................28

3.4 Model Select.........................28

3.5 Copy Select Function ...................29

3.6 Model Names........................29

3.7 Model Type Selection ...................30

3.8 Data Reset...........................30

3.9 Modulation Select......................31

3.10 Data Transfer .........................32

3.11 Wing Type Selection....................34

3.12 Spoiler Channel Input Selection.............35

4. Function Mode Functions

4.1 Dual Rate, Exponential...................36

4.2 Automatic Dual Rate, Exponential ...........37

4.3 Reverse Switch........................38

4.4 Sub-Trim Adjustment.....................38

4.5 Travel Adjust .........................39

4.6 Elevator to Flap Mixing ..................39

4.7 Aileron to Rudder Mixing .................40

4.8 Landing System .......................41

4.9 Snap Roll ...........................42

4.10 Differential Aileron Mixing ................44

4.11 Trim Offset Memory ....................45

4.12 Flap Knob Adjustment ...................46

4.13 Programmable Mixing...................47

4.14 Fail-Safe/Hold........................50

4.15 Trainer .............................52

4.16 Timer ..............................54

4.17 Servo Output Indicator...................55

5. XP8103 Data Sheet ........................56

1. Transmitter Controls

1.1 Control Identification and Location...........58

A.Helicopter Version Tx..................58

B. Airplane Mode .....................59

C.Glider Mode .......................59

1.2 Switch Warning Safety Feature (Heli Mode) ....60

1.3 Connections .........................60

1.4 Gyro Connections .....................61

2. General Information

2.1 Input Key Functions .....................62

2.2 Normal Display .......................62

2.3 Aux 3 Function (Channel #8) ..............63

3 System Set-Up Mode Functions

3.1 System Set-Up Mode....................64

3.2 Function Mode........................65

3.3 List Mode ...........................66

3.4 Model Select ........................66

3.5 Copy Select Function .................. 67

3.6 Model Names ....................... 67

3.7 Model Type Selection .................. 68

3.8 Data Reset ......................... 68

3.9 Modulation Select .................... 69

3.10 Data Transfer ........................ 70

3.11 Input Selection Function ................. 72

Table of Contents

II. Common Features

I. Introduction

III. Airplane Section

IV. Helicopter Section

XP8103 5

4. Function Mode Functions

4.1 Dual Rate, Exponential...................73

4.2 Automatic Dual Rate, Exponential............74

4.3 Reverse Switch ........................75

4.4 Sub-Trim Adjustment ....................75

4.5 Travel Adjust .........................76

4.6 Stunt Trim............................76

4.7 Throttle Hold .........................77

4.8 Throttle Curve ........................78

4.9 Pitch Curve ..........................81

4.10 Inverted Switch........................83

4.11 Revolution/Acceleration Mixing ............84

4.12 Gyro Sensitivity Adjustment................85

4.13 Programmable Mixing ...................87

4.14 Fail-Safe/Hold ........................91

4.15 Trainer .............................94

4.16 Timer ..............................95

4.17 Servo Output Indicator...................97

5. XP8103 Data Sheet.........................98

1. Transmitter Controls

1.1 Control Identification and Location ..........100

A. Glider Mode ....................100

B. Airplane Mode ...................101

C.Heli Mode ......................101

1.2 Connections.........................102

2. General Information

2.1 Input Key Functions ....................103

2.2 Normal Display ......................103

3. System Set-Up Mode Functions

3.1 System Set-Up Mode...................104

3.2 Function Mode.......................105

3.3 List Mode ..........................106

3.4 Model Select ........................106

3.5 Copy Select Function ..................107

3.6 Model Names .......................107

3.7 Model Type Selection ..................108

3.8 Data Reset .........................108

3.9 Modulation Select ....................109

3.10 Data Transfer ........................110

3.11 Wing Type Selection ...................112

3.12 Input Selection .......................112

4. Function Mode Functions

4.1 Dual Rate Exponential ..................113

4.2 Reverse Switch .......................114

4.3 Sub-Trim Adjustment ....................114

4.4 Travel Adjust ........................115

4.5 Elevator To Flap Mixing .................115

4.6 Aileron To Flap Mixing ..................116

4.7 Differential Aileron Mixing ...............117

4.8 Flap to Elevator Mixing .................118

4.9 Flap to Aileron Mixing ..................119

4.10 Aileron to Rudder Mixing ................120

4.11 Butterfly Mixing (Crow) .................121

4.12 Dual Flap Trim .......................122

4.13 Trim Offset Memory ...................123

4.14 Programmable Mixing (1-6) ..............125

4.15 Fail-Safe/Hold .......................127

4.16 Trainer ............................130

4.17 Timer .............................131

4.1 8 Servo Output Indicator ..................133

5. Practical Applications.......................134

5.1 Setting Up Your Sailplane ................134

5.2 Basic Set-Up and Mixing ................134

5.3 Launch and Reflex Presets ................135

5.4 Landing Mode Program .................135

5.5 Full Span/Variable Crow/Camber..........136

5.6 Special Mixing .......................136

6. XP8103 Data Sheet ........................138

1. Servo Precautions .........................140

2. General Notes ...........................140

3. Federal Aviation Administration ................141

4. Daily Flight Checks ........................141

5. Frequency Chart ..........................142

6. Warranty Information

6.1 Warranty Coverage ...................143

6.2 Repair Service Directions ................143

6.3 Warranty Repairs .....................143

6.4 Normal Non-Warranty Repairs ............144

V. Glider Section

V. Important Information for All Versions

XP8103 6

XP8103 7

I. Introduction

XP8103 8

In the beginning of this manual you will find the specifications

for the radio and its various accessories. In addition, guidelines

for the initial installation of the accessories have been included.

For your convenience, this manual is arranged with a separate

sections for airplane, helicopter and glider software functions:

Airplane Software: Page 21

Helicopter Software: Page 57

Glider Software: Page 99

You will find instructions for setting all of the functions and

programs of the XP8103 to suit your personal preferences. These

features are discussed in the same order that they appear on

your radio, as you will see on the accompanying system

function mode programming charts. An explanation of the use

and purpose of each feature is provided, followed by a labeled

illustration of its respective LCD display.

A blank data sheet has been included at the end of each

section. Once all data has been input for a particular model, it

is highly recommended that you also record it on a copy of the

data sheet provided. If you should experience memory loss or

battery failure, or want to make changes to the current settings,

this step will save you a great deal of time. In the back of this

manual you will find information on precautionary measures and

general guidelines for safe use of your new equipment.

Use of the Instructions With This Radio

As stated previously, while the XP8103 has a dedicated, or

single use, switch and potentiometer layout, it may be used for

multiple model types. We have provided control identification

diagrams with the manual that explain the different switch

configurations.

1. How To Use This Manual

2. Features

2.1 Transmitter NET-G128FS/HS Computer

• The micro computer system used in the XP8103 is the easiest to

understand, easiest to operate multi-function 8-channel computer

radio developed to date.

• The computer designed, ergonomically styled transmitter case

features a newly designed, large LCD display for outstanding,

easy-to-read graphics.

• The control sticks offer adjustable spring tension and length.

The throttle stick offers a ratchet for smooth travel (airplane only).

• Ten model memory storage allows programming of all

characteristics of ten separate helicopters, airplanes or gliders,

or you can program more than one set-up for a single aircraft,

allowing you to change the flight characteristics for that aircraft.

• Increased number of mixing functions that include multi-point

programmable mixing.

• Programmable gyro sensitivity with automatic adjustment

(helicopter only).

• All channel servo operation allows you to visually monitor

servo travel.

• A five-year lithium back-up battery prevents loss of memory in

the event that the battery discharges completely or is removed.

• Features automatic fail-safe and information update in PCM

mode when fail-safe is used.

• A programmable trainer function allows the student to practice

with individual channels separately.

• Direct Servo Control (DSC) permits operation of all the

controls and servos while also making transferable all data

between transmitters without generating a radio signal.

• Functions are also directly selectable from the newly employed

Function List Display.

• Screen contrast is easily adjustable for improved clarity in all

conditions.

XP8103 9

NER-649S (PCM Systems)

• This is a high performance PCM-FM single conversion receiver

with 10 KHz super narrow band ABC&W circuitry.

• The latest “S” type Central Processing Unit (CPU) is used in the

PCM receiver. The new NER-649S offers the highest resolution

available in any receiver.

• A narrow band ceramic filter for high signal selectivity also

assists in rejecting cross modulation from other common radio

frequencies (e.g., R/C transmitters, local paging systems). It has

the highest degree of resistance to electro-mechanical “noise” to

improve signal reception.

• This receiver features Direct Servo Control (DSC) permits

control of surfaces without radio frequency output.

• The receiver has low current consumption.

• 3-point gold plated connectors allow increased conductivity.

NER-549 (FM Systems)

• The NER-549 is a high performance FM single conversion

receiver with 10 KHz super-narrow band ABC&W circuitry.

• A narrow band ceramic filter for high signal selectivity assists

in rejecting cross modulations from other common radio

frequencies (e.g., R/C transmitters, local paging systems).

• This receiver features Direct Servo Control (DSC) for control of

surfaces without radio frequency output.

• The receiver has low current consumption.

• 3-point gold plated connectors allow increased conductivity.

2.3 Servo Features

2.2 Receiver

507 Servo

• A zero deadband amplifier insures accurate neutral centering.

• The 507 has low current drain.

• An indirect drive feedback potentiometer gives additional

protection from vibration.

• Redesigned features include SMT (Surface Mount Technology)

circuitry.

• The 507 features a 3-pole ferrite cored motor.

517 Servo

• The 517 features a ball bearing output shaft for precise

movement of your aircraft’s control outputs.

• A zero deadband amplifier insures accurate neutral centering.

• The 517 has low current drain.

• An indirect drive feedback potentiometer gives additional

protection from vibration.

• Includes SMT (Surface Mount Technology) circuitry.

• The 517 features a 3-pole ferrite cored motor.

531 Servo

• The 531 features a ball bearing output shaft for precise

movement of your aircraft’s control outputs.

• A zero deadband high performance amplifier insures accurate

neutral centering and high torque (51oz./in.) with a speed of

.23 sec/60°.

• The 531 has low current drain.

• An indirect drive feedback potentiometer gives additional

protection from vibration.

• Includes SMT (Surface Mount Technology) Circuitry.

• The 531 features a 3-pole ferrite cored motor.

XP8103 10

3. Component Specifications

3.1 System Specifications (Air/Heli)

Aircraft Helicopter

System Name

XP-8103A XP-8103H

Transmitter Body NET-G128FS NET-G128HS

Transmitter RF Module

NET-J72P / NET-J50P / NET-J53P NET-J72P / NET-J50P / NET-J53P

Receiver NER-649S (PCM) NER-649S (PCM)

NER-549 (FM) NER-549 (FM)

Charger NEC-221 NEC-222

Airborne Battery 4N-600 (flat) 4N-1000 (Flat)

Servos

NES-507x4 NES-517x4 NES-517x5 NES-531x5

(FM Only) (PCM Only) (FM only) (PCM Only)

Accessories Deluxe Switch Deluxe Switch Deluxe Switch Deluxe Switch

12"ALIE Ext. 12"AILE Ext. 12"AILE Ext 12"AILE Ext.

Charge Jack Charge Jack Charge Jack Charge Jack

Servo Accys Servo Accys Servo Accys Servo Accys

Hex Wrench Hex Wrench Hex Wrench Charge Jack

Instruction Instruction Instruction Instruction

Manual Manual Manual Manual

3.2 Transmitter Specifications (Air/Heli)

Aircraft Helicopter

Model Number

NET-G128FS NET-G128HS

Encoder 8-Channel Computer System 8-Channel Computer System

RF Module 50/53/72MHz 50/53/72MHz

Modulation PCM (S or Z) or PPM PCM (S or Z) or PPM

Output Power Approximately 750mw Approximately 750mw

Current Drain 200mA (70mA with DSC) 200mA (70mA with DSC)

Power Source

1.2Vx8 NiCad (9.6v) 550mAh 1.2Vx8 NiCad (9.6v) 550 mAh

Output Pulse 1000-2000 (1500 Neutral) 1000-2000 (1500 Neutral)

XP8103 11

3.3 Servo Specifications

3.4 Receiver Specifications

3.5 Charger Specifications

Aircraft Helicopter

Model Number

NEC-221 NEC-222

Input Voltage AC 100-120V AC 100-120V

Output Current 50mA Tx / 50mA Rx 50mA Tx / 120mA Rx

Charging Time 15 Hours 15 Hours

3.6 Airborne Battery Pack

Aircraft Helicopter

Model Number

4N-600 (Flat) 4N-1000 (Flat)

Voltage 4.8V 4.8V

Size (in.) (W x L x H) 2.24 x 0.59 x 2.05 2.60 x 0.63 x 1.70

Weight (oz.) 3.3 4.9

PCM FM

Model Number

NER-649S NER-549

Type 9-Channel / FM-ABC&W / S-PCM 9-Channel / FM-ABC&W / Micro

Frequency 50/53/72MHz 50/53/72MHz

Sensitivity

(Microseconds)

5µS Minimum 5µS Minimum

Selectivity 8KHz / 50dB 8KHz / 50dB

Weight (oz.) 1. 5 1.5

Size (in.) (W x L x H) 1. 42

x 2.00 x 0.63 1.42 x 2.00 x 0.82

Receiver Antenna 39” for all Aircraft Frequencies 39” for all Aircraft Frequencies

507 517 53 1

Torque (oz./in.)

40.3 40.3 51 .0

Speed (sec./60°) .2 5 .25 .2 3

Weight (oz.) 1. 4 7 1. 5 8 1.50

Size (in.) (W x L x H) 1.52 x 0.73 x 1.32 1.52 x 0.73 x 1.32 1.52 x 0.73 x 1.32

BB N/A Single Single

Motor 3-Pole Ferrite 3-Pole Ferrite 3-Pole Ferrite

XP8103 12

XP8103 13

II. Common Features

14

Note: It is imperative that you fully charge both the transmitter

and the receiver battery packs prior to each flight.

To do so, leave the charger and batteries hooked up overnight

(16 hours). The first charge should be approximately 20–24

hours in order to fully charge both battery packs to peak capacity.

The charger supplied with this system is designed to recharge

your batteries at a rate of 50 mA for the transmitter and

50 mA (120 mA for helicopter) for the receiver battery pack.

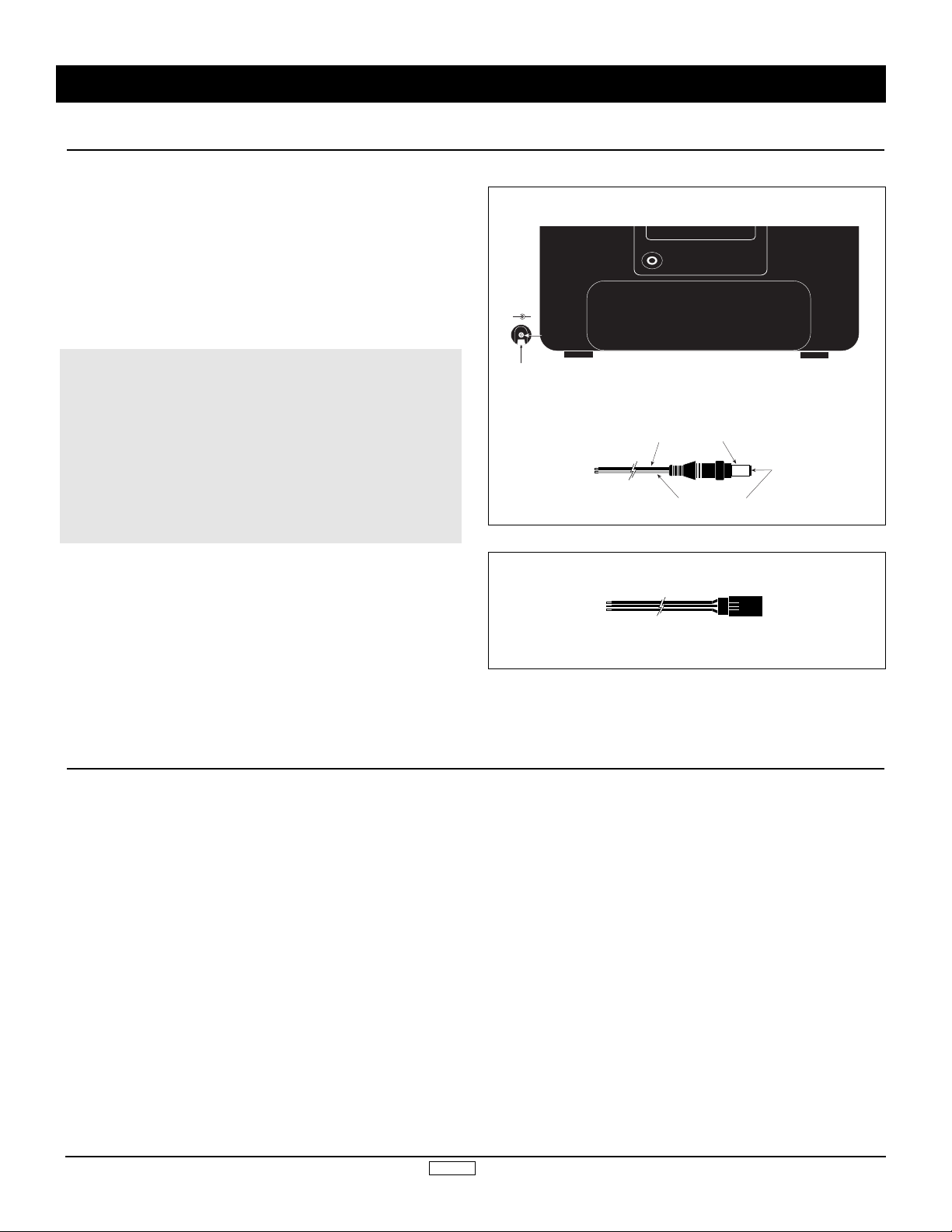

Transmitter Polarity

The center pin on all JR Remote Control Systems is negative.

Therefore, the center pin on all JR chargers is negative, not

positive. This is different from many other manufacturers’

chargers and radio systems. Beware of improper connections

based on “color coded” wire leads as they do not apply in this

instance. You must make sure that the center pin of your JR

transmitter is always connected to the negative voltage for

correct polarity hookup.

XP8103

4. Battery Charging

4.1 Transmitter/Receiver

4.2 Charger

The pilot lamps should always be ON during the charging

operation. If they’re not, check to make sure that both the

transmitter and receiver are switched OFF.

Do not use this charger for equipment other than JR. The

charging plug polarity may not be the same and equipment

damage can result.

Do not use other manufacturers’ after-market accessories that

plug into the transmitter’s charging jack. If you do, any damage

that results will not be covered by the warranty. If you are unsure

of compatibilities with your radio, seek expert advice before

doing anything to avoid possible damage.

During the charging operation, the charger’s temperature is

slightly elevated. This is normal. Also, note that the voltage

shown on the charger is higher than the battery in use. This

voltage cannot be measured with a voltmeter. Only current can

be measured with any accuracy using this type of charger.

Be sure to use the proper charge rate (120 mA) when using

battery packs of 1000 mAh or larger for your receivers.

D.S.C

TRAINER

CHARGE

(–) (+)

Center pin

is negative

Outside is

positive

Red to negative

Black to positive

Red = Positive

Brown = Negative

Orange = Signal

Back of Transmitter

Charger Pigtail for Transmitter

Charger Pigtail to Receiver

Transmitter

Receiver

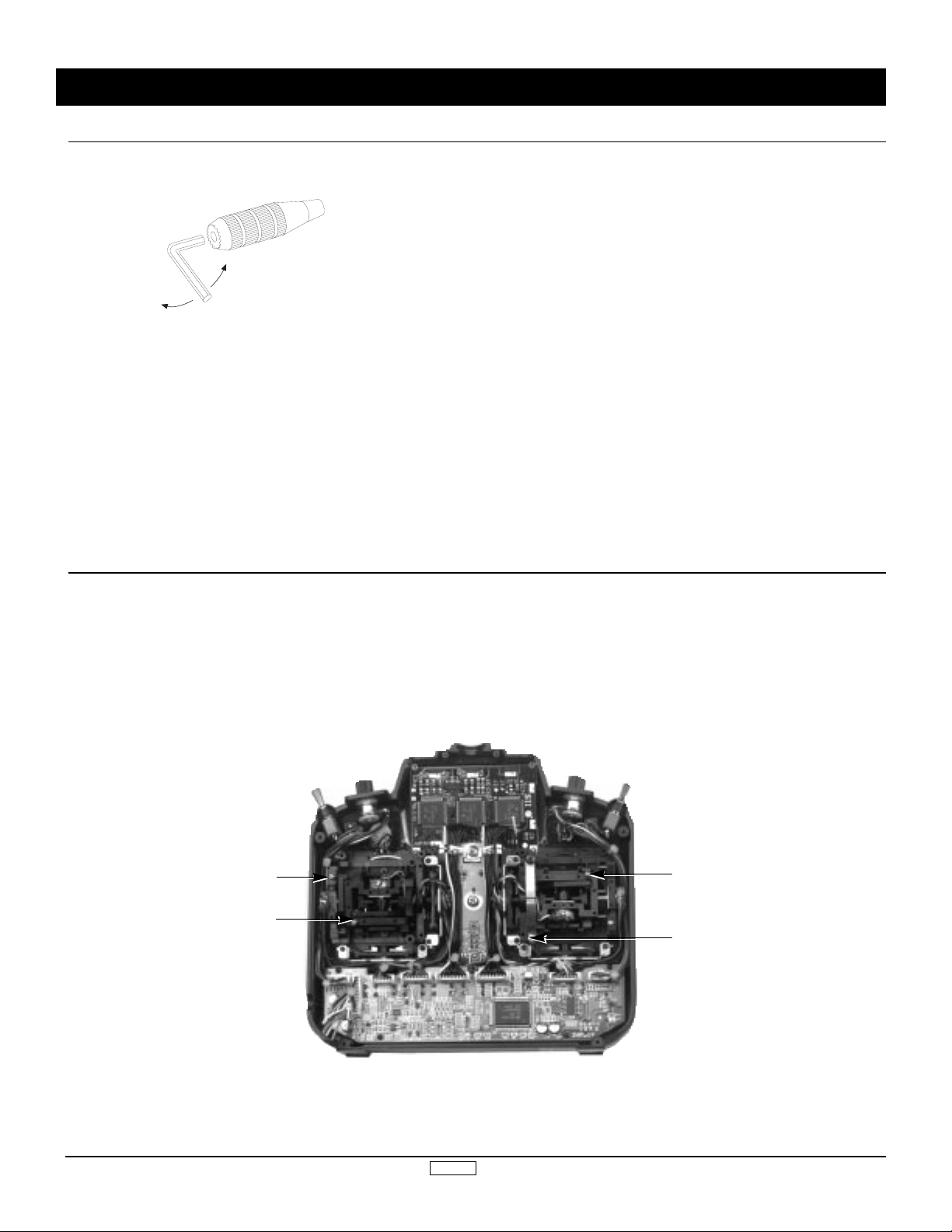

Elevator Tension Screw

Aileron Tension Screw

Throttle Tension Screw

Rudder Tension Screw

15

The XP8103 allows you to adjust the control sticks’ length.

To adjust the stick length, use the 2 mm Allen wrench (supplied

with your XP8103 transmitter) to unlock the set screw.

Note: Turn the wrench counterclockwise to loosen the screw.

Then, turn the stick clockwise to shorten or counterclockwise to

lengthen.

After the control stick length has been adjusted to suit your flying

style, tighten the 2 mm set screw.

If you desire longer sticks, JR offers a thicker stick (JRPA047) that

is approximately one inch longer than the standard stick. This

stick, crafted from bar stock aluminum, is available at your local

JR dealer.

Remove the transmitter RF module, Nicad battery, and six (6)

transmitter back cover screws. Remove the transmitter back,

being careful not to bend or damage the RF module pins. Adjust

each screw for the desired tension (counterclockwise to loosen

stick feel, clockwise to tighten stick feel). When adjusting the

throttle ratchet tension, make sure the adjusting screw does not

touch the PC board after the adjustment is complete.

XP8103

5.1 Control Stick Length Adjustment

5.2 Control Stick Tension Adjustment

5. General Information

Loosen

Tighten

16XP8103

5.3 Transmitter Rear

Cord Hook

When a trainer cord is used, place the

cord between this hook and the

transmitter body to avoid possible cord

detachment during use.

Transmitter Module

When the transmitter module is removed,

you will find that the fuse is located at the

bottom of the module cavity for easy

replacement.

DSC/Trainer Jack

Charging Jack for

Nicad Battery Only

(8N600S)

Battery Cover (Removed)

Caution: The battery connector is keyed so that it

can only be plugged in in one direction. Do not

force.

XP8103 17

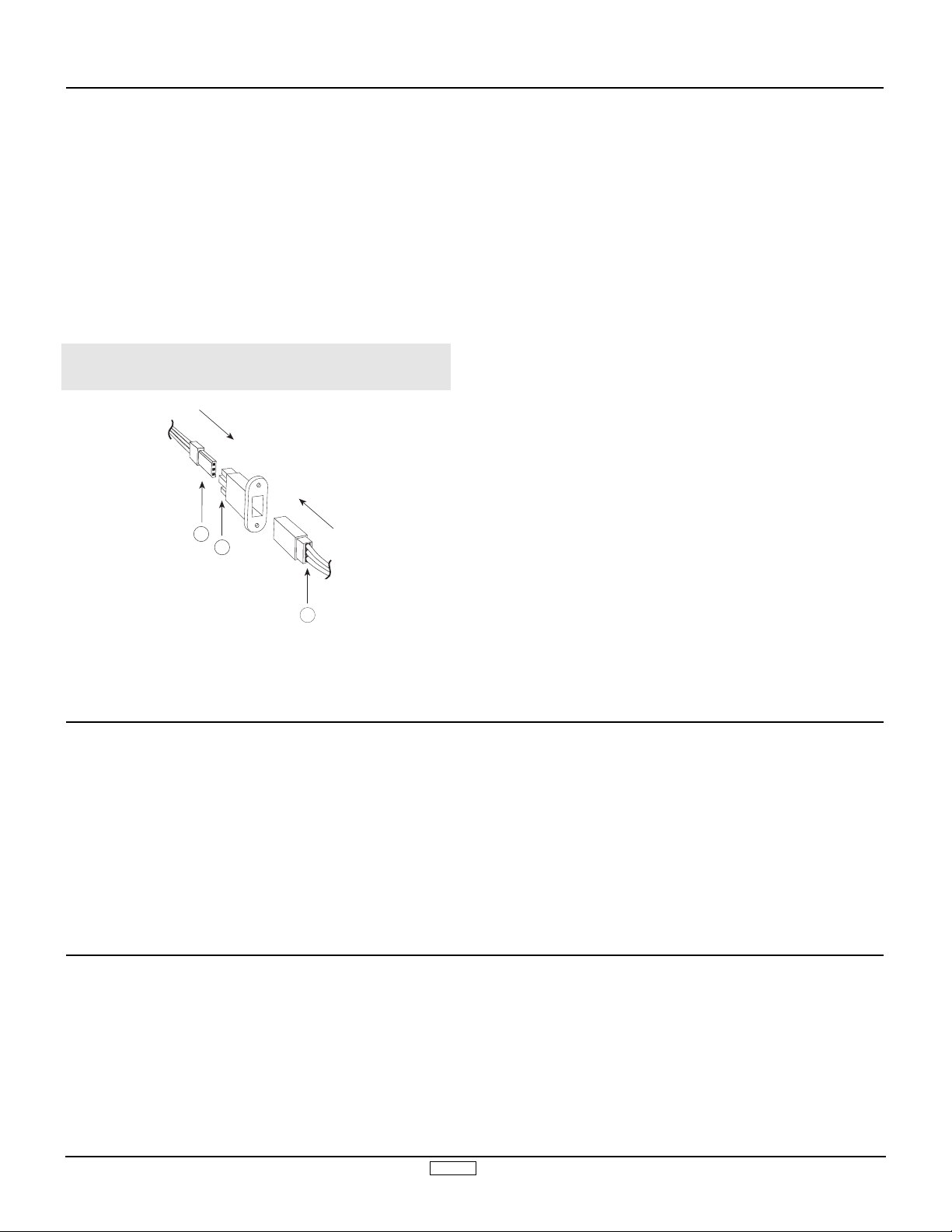

For proper DSC hook up and operation:

1. Leave the transmitter power switch in the OFF position. The

transmitter will not transmit any radio frequency (RF) in this

position.

2. Plug the DSC cord (optional) into the DSC port in the rear of

the transmitter.

3. The encoder section of the transmitter will now be

operational and the LCD display will be lit.

4. Plug the other end of the DSC cord into the receiver charge

receptacle. Turn the switch harness to the ON position.

Note: The DSC function will only operate with the JRPA001

Deluxe Switch Harness, or the JRPA004 Charge Switch.

When you install the charging jack, be sure to hook the

charging jack receptacle securely into the switch harness charge

cord.

Why you should use the DSC function:

1. The DSC enables you to check the control surfaces of your

airplanes without drawing the fully operational 200 mAh from

your transmitter battery pack. Instead, you will only draw 70

mAh when using the DSC function.

2. The DSC function allows you to make final adjustments to

your airplane without transmitting any radio signals. Therefore, if

another pilot is flying on your frequency, you can still adjust your

airplane and not interfere with the other pilot’s aircraft.

Note: Under no circumstances should you attempt to fly your

airplane with the DSC cord plugged in! This function is for

bench checking your airplane only.

5.4DSC Cord

An eyelet is provided on the face of the XP8103 transmitter

which allows you to connect a neck strap (JRPA023). This hook

has been positioned so that your transmitter has the best possible

balance when you use the neck strap.

Note: Double check to ensure that the neck strap is securely

fastened to the transmitter.

5.5Neck Strap Adjustment

An optional base loaded antenna is available for use with the

XP8103 transmitter. It is considerably shorter than the standard

antenna. However, the base loaded antenna cannot be

collapsed for storage in the side of the transmitter. You must also

use an adaptor (JRPA156) to attach the antenna to your XP8103.

The base loaded antenna (JRPA155) is made of a flexible coil

and is covered with a soft plastic material. Your range will not

be affected when using the base loaded antenna.

5.6 Base Loaded Antenna

A

B

C

A. Charge cord/DSC receptacle

B. Switch harness lead

C. Charge cord/DSC lead

XP8103 18

The XP8103 employs a plug-in module system for transmitter

frequency changes. If you want to change a frequency, you can

simply change the radio frequency (RF) module, commonly

referred to as either an RF module or transmitter module. The JR

modules are universal for all modular frequency controlled

systems. In other words, if you currently own a modular JR

system, you can use the RF module from your current system with

the XP8103.

The XP8103 can transmit in either Pulse Code Modulation (PCM)

or in Pulse Position Modulation (PPM, commonly referred to as

FM). Be certain to observe the following guidelines:

1. Do not operate your transmitter when another transmitter is

using the same frequency, regardless of whether the second

transmitter is PCM, PPM (FM) or AM. You can never operate

two transmitters on the same frequency simultaneously without

causing interference to both receivers and crashing both aircraft.

2. For operation of your XP8103 with additional receivers, you

should refer to the receiver compatibility chart. The chart is

located in the Modulation Select Section of this manual.

(pg. 31)

Aircraft Only Frequencies

JR RF modules and receivers are available on 50, 53, and 72

MHz frequencies in the United States for use with model aircraft.

Employing 72 MHz frequencies does not require a special

operators license from the Federal Communications Commission

(FCC). However, the 50 and 53 MHz frequencies require that

you carry a Technician II license.

• A chart for all available frequencies is located on page 142

of this manual.

5.7Frequency Notes/Aircraft Only Frequencies

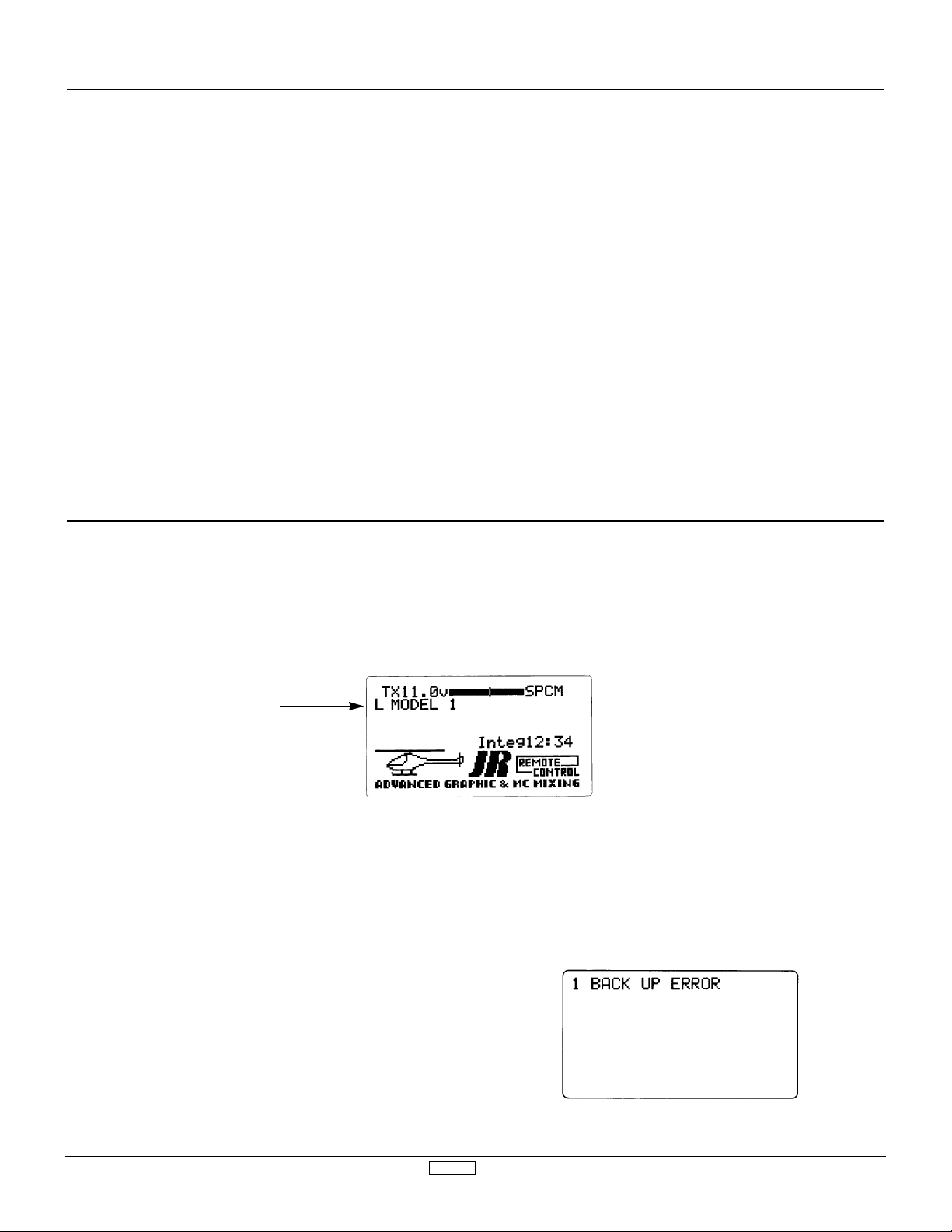

5.8 Lithium Battery Indicator/Backup Error Display

Lithium Battery Indicator

If the voltage level of the lithium battery drops below an

acceptable level (2.2v), an “L” will appear and flash to the left

of the model number. This indicates that the lithium battery will

no longer maintain program memory if the main battery is

disconnected. When the flashing “L” appears on the screen, the

system should be sent to the JR/Horizon Service Center for a

lithium battery replacement.

Alarm and Backup Error Display

All pre-programmed data is protected by a five-year lithium

battery that guards against main transmitter battery failure.

Should the lithium battery fail, the display will indicate 1 back

up error regardless of the position of the ON/OFF switch. If

this occurs, it will be necessary to replace the battery and

reprogram all data. All transmitter programs will return to the

factory default setting, and the data you have input will be lost.

When it becomes necessary to replace the lithium back-up

battery, contact the JR/Horizon Service Center. Due to the

possibility of extensive damage caused by improper removal or

replacement, only the JR/Horizon Service Center is authorized

to make the change.

JR/Horizon Service Center

4105 Fieldstone Road

Champaign, IL 6182 1

"L" indicates

lithium battery

needs to be

replaced

XP8103 19

5.9 Screen Contrast Adjustment

The screen contrast adjustment feature of the XP8103 allows the

user to select the proper tint of the screen for improved clarity

and visibility in all weather conditions and temperatures.

To increase the contrast (darken the screen), simply turn the

power switch ON and press the SEL and DATA + keys

simultaneously. To decrease the contrast (lighten the screen),

press the SEL and DATA - keys simultaneously.

5.10Installation Requirements

It is extremely important that your radio system be correctly

installed in your model. Here are a few suggestions on the

installation of your JR equipment.

1. Wrap the receiver in protective foam rubber that is no less

than 3/8 inch thick. Secure the foam to the receiver with #64

rubber bands. This protects the receiver in the event of a crash

or a very hard landing.

2. The servos should be mounted using rubber grommets and

brass bushings to isolate them from vibration. Do not over-tighten

the mounting screws — this will negate the vibration absorption

effect of the rubber grommets. The diagram at left will assist you

in properly mounting your servo.

The brass bushings are pushed from the bottom up in the rubber

grommets. When the servo screw is tightened securely, it

provides the proper security, as well as the proper vibration

isolation, for your servo.

3. The servos must be able to move freely over their entire

range of travel. Make sure that the control linkages do not bind

or impede the movement of any of the servos.

4. Mount all switches away from the engine exhaust and away

from any high vibration areas. Make sure each switch operates

freely and is able to operate over its full travel.

5. Mount the receiver antenna firmly to the airplane to ensure

that it will not become entangled in the propeller or control

surfaces.

Screw

Servo Mounting Tab

Brass Bushing

Rubber Grommet

XP8103 20

ACRO 21

III. Airplane Section

ACRO 22

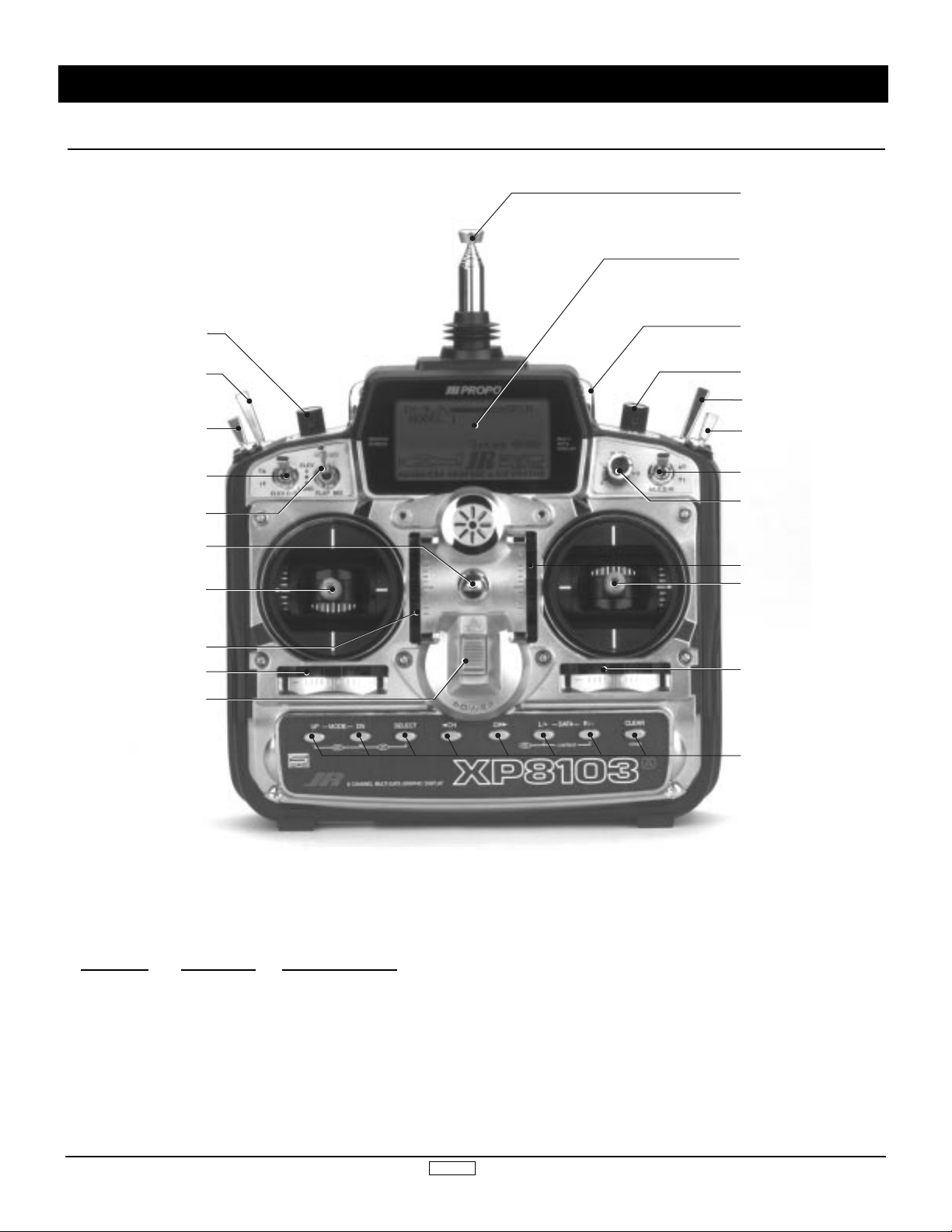

1. Transmitter Controls

1.1 Control Identification and Location

Channel Assignment/Throttle ALT

Channel # TX Function Airplane Function

1 Thro Throttle Channel

2 Aile Aileron Channel

3 Elev Elevator Channel

4 Rudd Rudder Channel

5 Gear Gear Channel

6 Flap Auxillary 1 Channel (Flap)

7 SPOI Auxillary 2 Channel (Spoiler)

8 Aux 3 Auxillary 3 Channel

Throttle ALT

The Throttle ALT function makes the throttle stick trim active only

when the throttle stick is at less than half throttle. This gives easy,

accurate idle adjustments without affecting the high throttle

position.

Throttle/Rudder Stick

Input Keys

Aileron Trim

Elevator Trim

Elevator/Aileron Stick

Antenna

Aux 3 Knob

Carrying Handle

LCD Display (Do Not Press)

Flap Knob

Aileron Dual Rate Switch

Rudder Dual Rate Switch

P. Mix Switch/Aux 2

Power Switch

Rudder Trim

Throttle Trim

Neck Strap Eyelet

Snap Roll/

Timer/T rainer Switch

Aux 2 Knob

Elevator Dual Rate Switch

Gear Switch

Flap/Mixing Switch

Flaperon/Flap Trim Knob (Pot. 7)

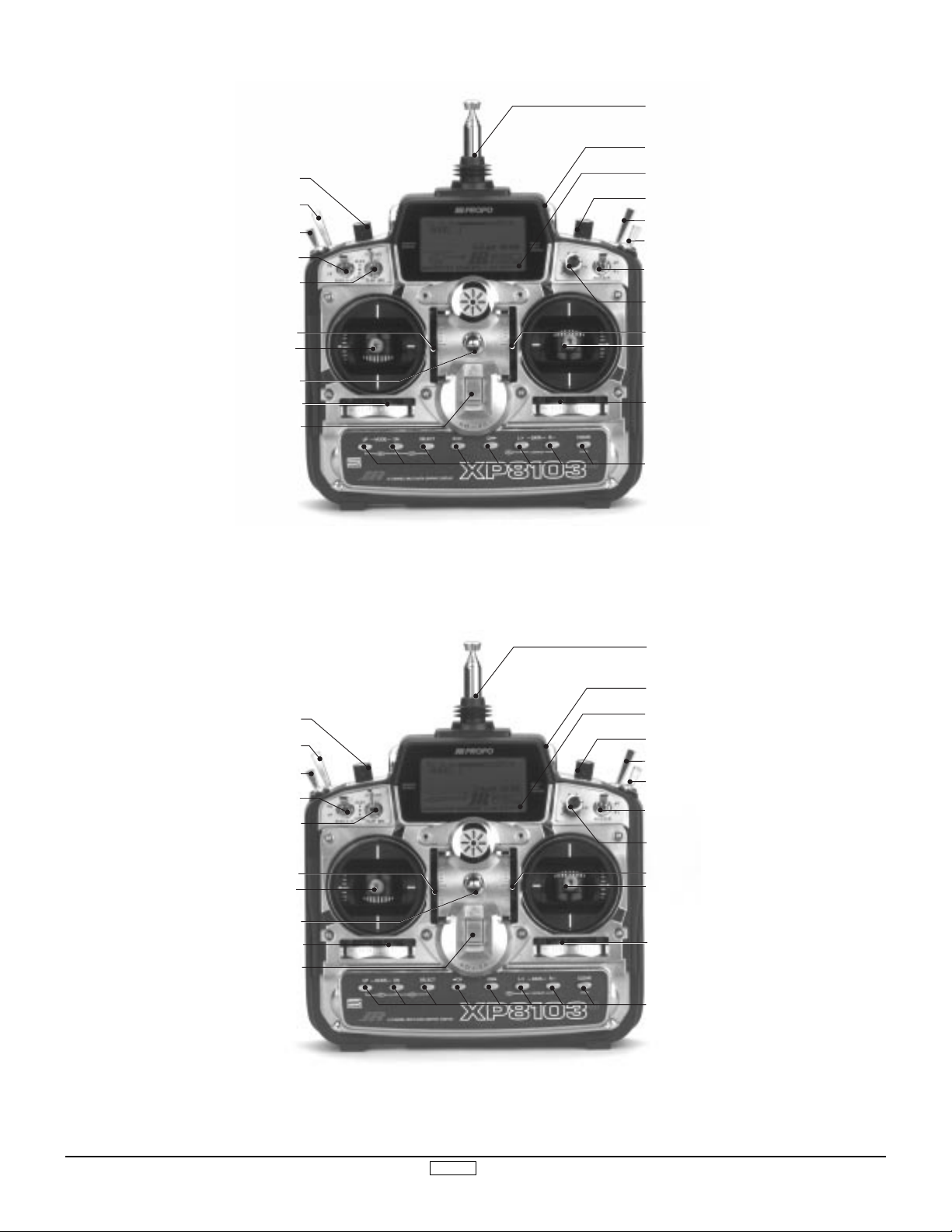

Snap Roll/

Timer/Trainer Switch

Crow Switch

Elevator Dual Rate Switch

Flap/Mixing Switch

Spoiler Trim

Spoiler/Rudder Stick

Neck Strap Eyelet

Rudder Trim

Power Switch

Input Keys

Aileron Trim

Aileron/Elevator Stick

Elevator Trim

Flap Trim Knob (Pot. 6)

Aileron Dual Rate Switch

Rudder Dual Rate Switch

Mixing Switch

Carrying Handle

LCD Display –

DO NOT PRESS

Antenna

Dual Flap Aileron Trim Knob (Pot. 5)

Reflex

■-Off

Launch

Pitch Trim Knob

Trainer/Timer Switch

Invert Switch

Elevator Dual Rate Switch

Flight Mode Switch

Throttle Trim

Throttle/Rudder Stick

Neck Strap Eyelet

Rudder Trim

Power Switch

Input Keys

Aileron Trim

Aileron/Elevator Stick

Elevator Trim

Hovering Throttle Knob

Aileron Dual Rate Switch

Rudder Dual Rate Switch

Throttle Hold Switch

Carrying Handle

LCD Display –

DO NOT PRESS

Antenna

Hovering Pitch Knob

N-Normal Position

1-Flight Mode 1

2-Flight Mode 2

ACRO 23

Channel Assignment

Channel Assignment

Airplane Version Transmitter–Glider Mode

Airplane Version Transmitter–Heli Mode

1. SPOI Spoiler Channel

2. AIL1 Left Aileron Channel

3. ELEV Elevator Channel

4. RUDD Rudder Channel

5. AIL2 Gear Channel

(Right Aileron Channel–AILE 2)

6. FLAP Auxiliary 1 Channel

(Left Flap Channel for Dual Flaps)

7. AUX 2 Auxiliary 2 Channel

(Right Flap Channel for Dual Flaps)

8. AUX 3 Auxiliary 3 Channel

1. THRO Throttle Channel

2. AILE Aileron Channel

3. ELEV Elevator Channel

4. RUDD Rudder Channel

5. GEAR Gear Channel

6. AUX 1 Auxiliary 1 Channel (Pitch)

7. AUX 2 Auxiliary 2 Channel

(Gyro Sensitivity)

8. AUX 3 Auxiliary 3 Channel

ACRO 24

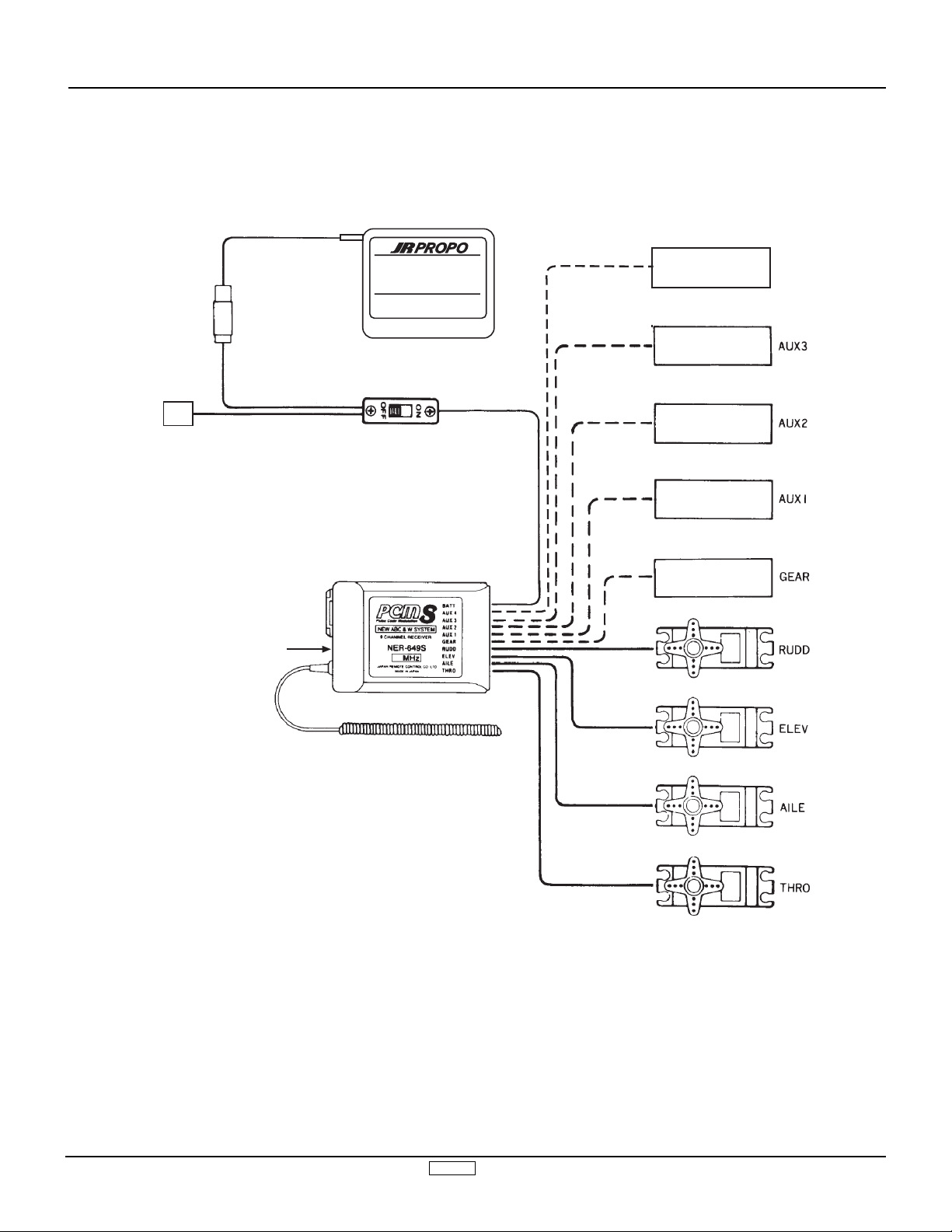

1.2 Connections

Aux Channel

Aux Channel

Spoiler Channel

Flap Channel

Retract

Gear Channel

Deluxe Switch Harness

(JRPA001)

Charge Cord or DSC

Receptacle

(JRPA024)

72

NER-649S

S-PCM Receiver

(JRPR649)

PCM Version

NER-549S

FM Receiver

(JRPR549)

FM Version

4N600

4.8V 600mAh

JAPAN REMOTE CONTROL CO., LTD.

®

not

used

ACRO 25

• You will hear a clicking (beeping) sound to confirm input has

been achieved.

• Except for the CLEAR key, the AUTO advance system (two

speed scrolling) is active when you continue pressing down on

a key.

• The SEL keys or CH keys are used to scroll through, or

manipulate functions within a specific program or display.

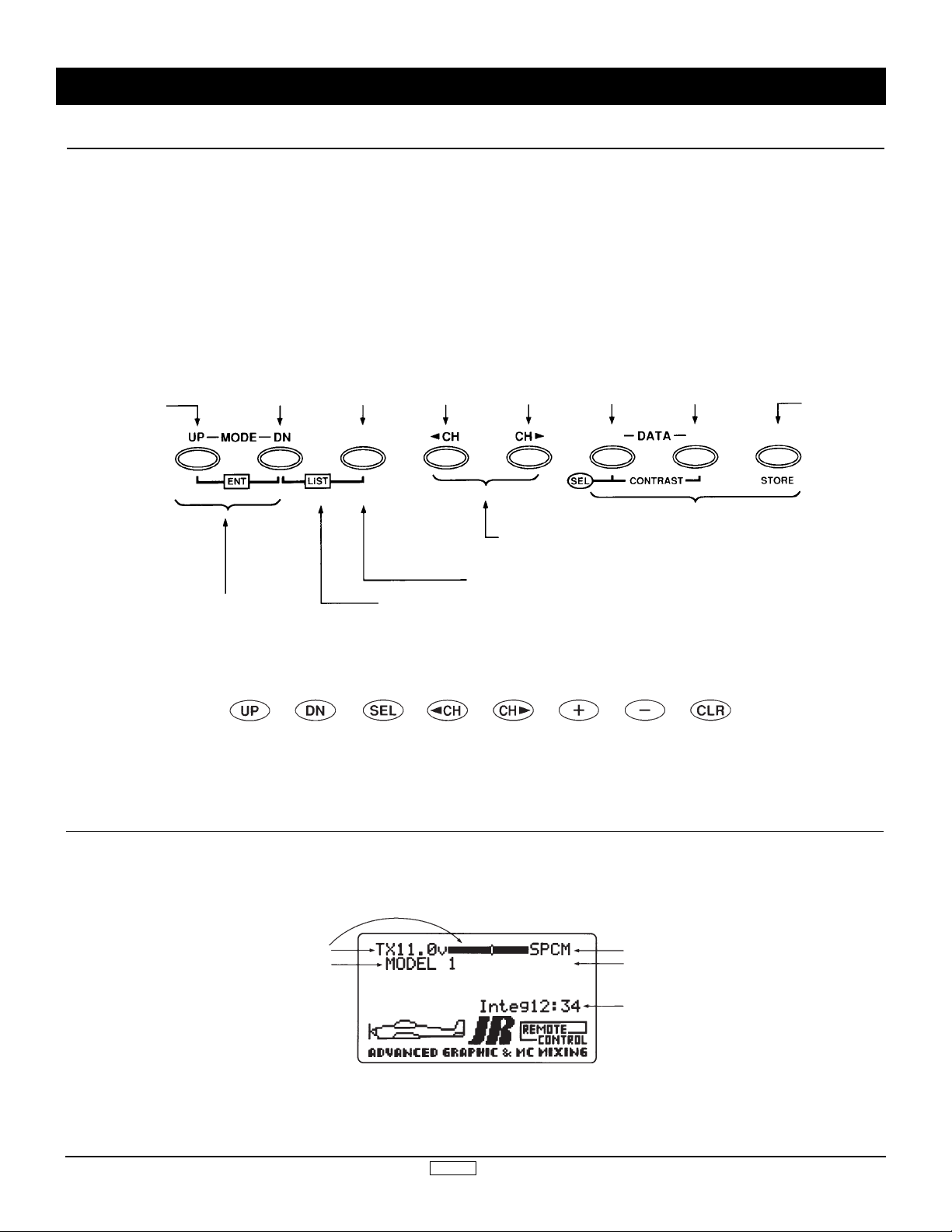

2.1 Input Key Functions

Function Selection keys

(press both keys

simultaneously to enter or

exit the function mode)

Normal Display Screen

Press both keys simultaneously

to access the system mode or

function mode lists.

used for changing pages or

indicated displays

used for channel changes in the

model set-up and function modes

Data Entry Keys

Up Key

Down Key Select Key Channel Key Increase Key Decrease Key

Clear Key

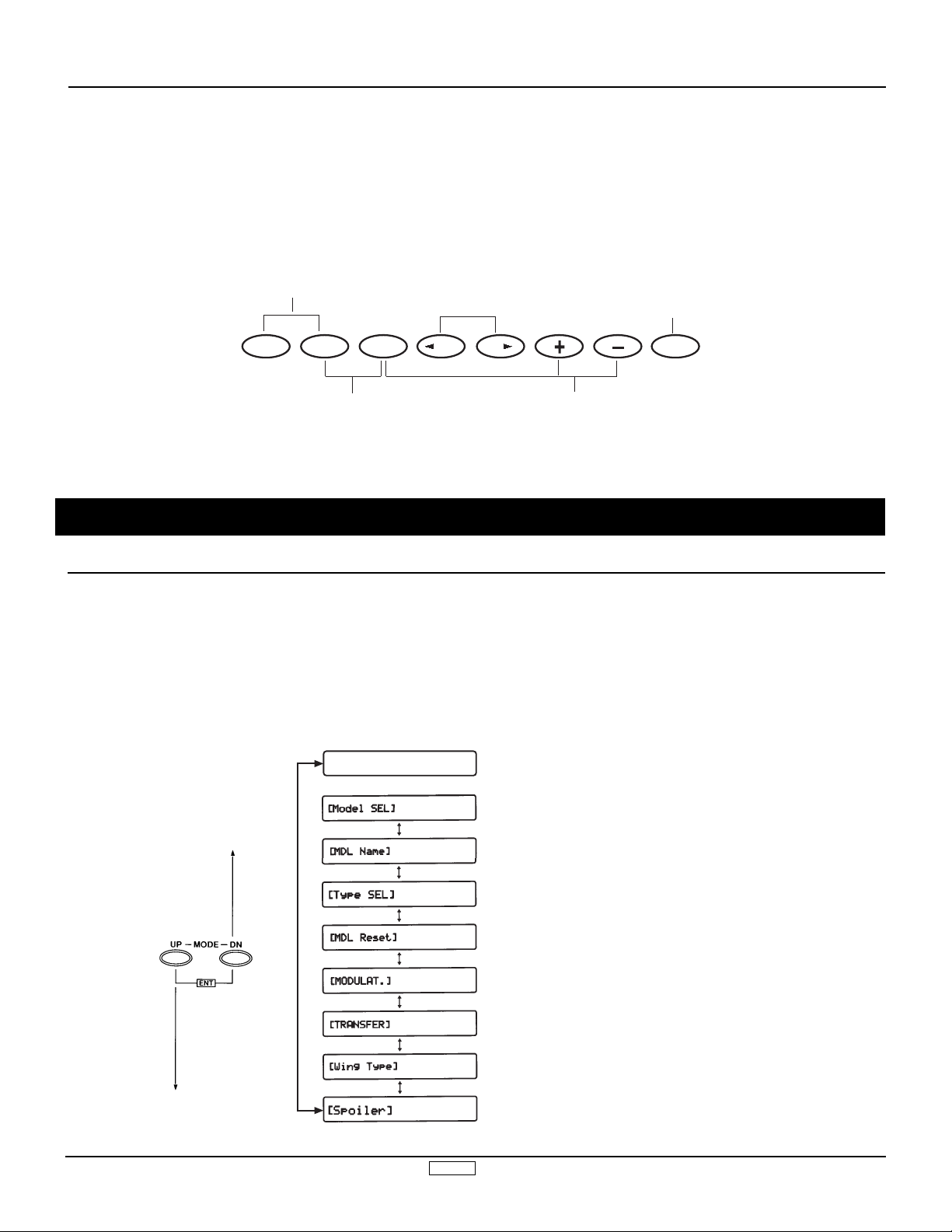

2.2 Normal Display

2. General Information

transmitter voltage

model number

modulation type

model name (when

names are entered)

integrated timer

SELECT

L/+

R/-

CLEAR

ACRO 26

2.2 Normal Display, cont.

DN

SELECT

CH CH CLEARUP

Press simultaneously

to access the List

Mode/System Set-Up Mode

Press Select and

either the + or - keys

simultaneously to

adjust the contrast of

the LCD display

Press the Clear key

to reset to factory

settings

Press the UP and DN keys

simultaneously to change

to Function Mode (with

power switch ON)

When timer function is

active, use CH key to

start/stop timer

Press the UP and DN keys

simultaneously and switch the

power from OFF to ON to

change the system to the

System Set-Up Mode

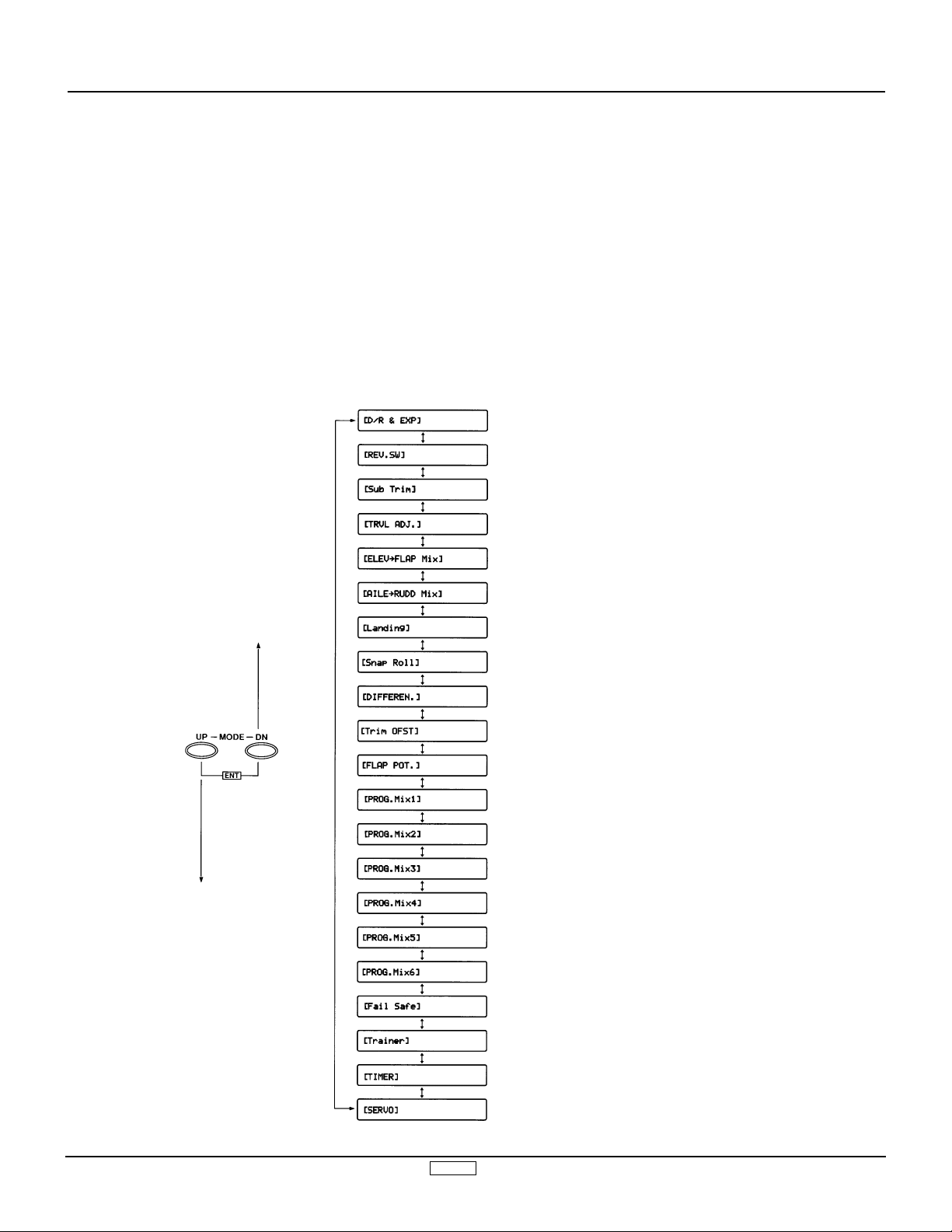

To set the System Set-Up Mode, press the UP and DN keys

simultaneously and turn the power switch from OFF to ON.

Functions are selectable by pressing either the DN or UP keys.

Individual settings are explained later at each function. In this

mode, servos are not activated, but operating signals are

transmitting (only when the Tx module is in place). However, use

extra caution not to interfere with other frequencies. By pressing

the DN and UP keys simultaneously, you can return to the normal

display, which allows the servos to again operate.

3.1 System Set-Up Mode

[INFO-DISP]

↕

From the Normal Display, the following inputs can be made:

When setting various functions with the buttons shown below,

start either in the Function Mode or the System Set-Up Mode.

3. System Set-Up Mode Functions

Pg. 28 Information Display

Pg. 29 Model Select and Copy

Pg. 29 Model Name Input

Pg. 30 Model Type Selection Function

Pg. 30 Data Reset

Pg. 31 Modulation Selection

Pg. 32 Data Transfer between traqnsmitters

Pg. 34 Wing Type Selection

Pg. 35 Spoiler Channel Input Selection

SYSTEM SET-UP MODE

Use either the UP

or DN key to scroll

through the menu

and access the

applicable function

ACRO 27

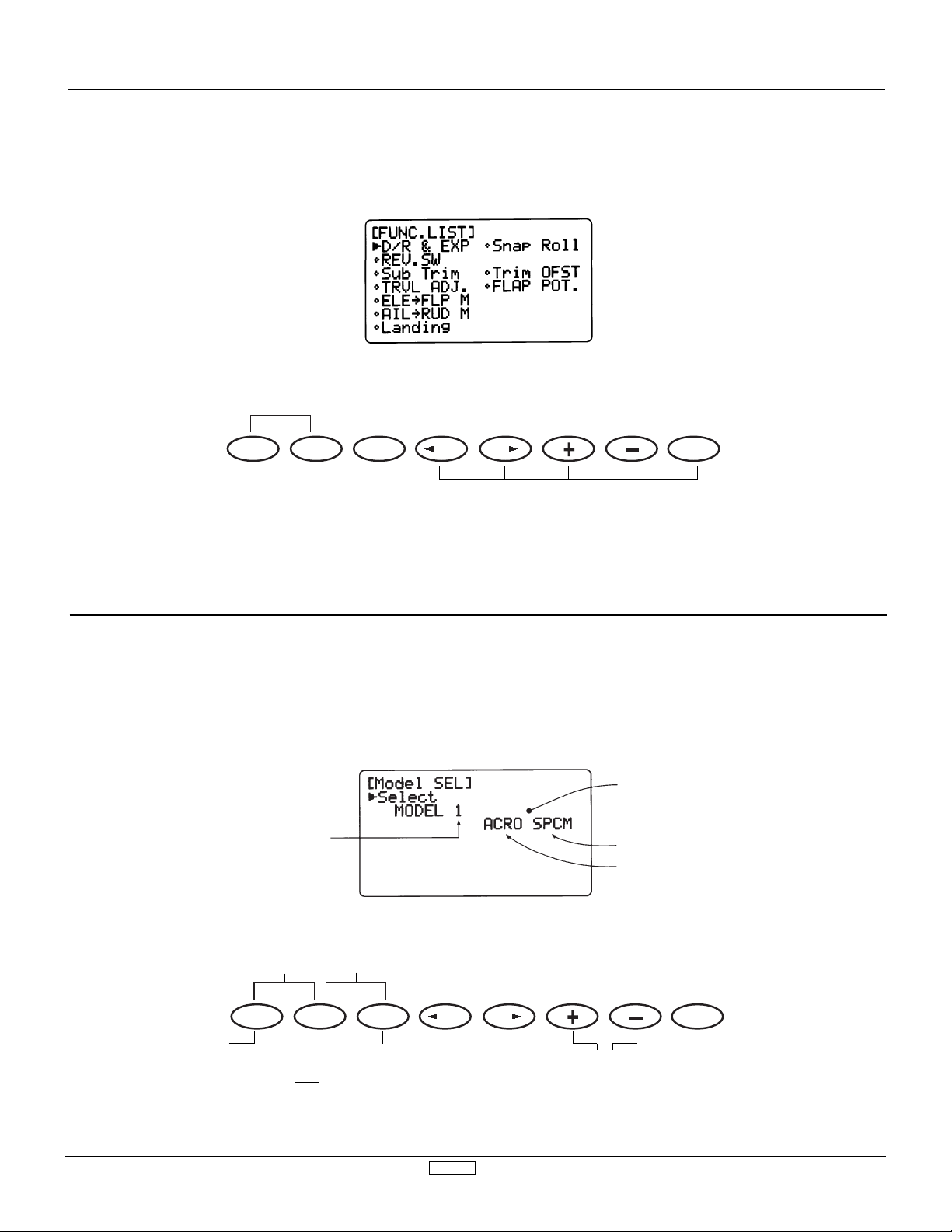

From Normal Display, press the UP and DN keys simultaneously

to enter the Function Mode. In this mode, by using the UP or DN

keys, the desired functions can be selected. When channel

selection or an additional function change is desired, use the

CH keys or SEL key. For example, Dual Rate Function is selected

and the elevator channel is displayed by pressing the UP key

once; the function is changed to the next mode, Reverse Switch,

but the channel is still displayed as elevator.

Function Mode Flowchart

Information pertaining to each function is explained on the page

number listed next to the function name. Functions will appear

on the screen in the same order they are shown on the flow

chart below:

Therefore, by scrolling through the program, you can adjust

each function related to the elevator channel quickly and easily.

To Access The Function Mode

1. Switch the power switch to the ON (upper) position.

2. Press the UP and DN keys simultaneously.

3. Use either the UP or DN keys to scroll through the menu and

access the appropriate function.

3.2 Function Mode

Pg. 36 Dual Rate, Exponential

Pg. 38 Reverse Switch

Pg. 38 Sub-Trim

Pg. 39 Travel Adjust (end point adjustment)

Pg. 39 Elevator to Flap Mixing

Pg. 40 Aileron to Rudder Mixing

Pg. 41 Landing System

Pg. 42 Snap Roll

Pg. 44 Differential Aileron Mixing (only if flaperon or

elevons mixing is active)

Pg. 45 Trim Offset Memory

Pg. 46 Flap Knob Operating Value Adjustment

Pg. 47 Programmable Mixing 1

Pg. 47 Programmable Mixing 2

Pg. 47 Programmable Mixing 3

Pg. 47 Programmable Mixing 4

Pg. 47 Programmable Mixing 5

Pg. 47 Programmable Mixing 6

Pg. 50 Fail-Safe/Hold (PCM Only)

Pg. 52 Trainer

Pg. 54 Timer

Pg. 55 Servo Output Values

Use either the UP

or DN key to scroll

through the menu

and access the

applicable function

ACRO 28

3.4 Model Select (System Set-Up Mode)

The XP8103 transmitter employs a memory function which

memorizes data for up to 10 individual aircraft. All settings

along with type selection, function, and different aircraft are

used by one transmitter. For example, Model 1 is helicopter and

Model 2 is airplane. To avoid confusing models, inputing model

names for each aircraft is recommended (see page 29). Press

the UP and DN keys simultaneously and turn the power switch

ON to access the System Set-Up Mode.

The display below shows the model selection function.

model name

(if dot is shown, model

name is blank)

modulation

type

model number (1-10)

To enter the List Mode, press the DN and SEL keys

simultaneously. From this display, pressing the UP and DN keys

simultaneously will move the system from the list mode to the

function shown at the cursor. Note that the cursor is moved by

the UP and DN keys.

3.3 List Mode (Function Mode)

DN

SELECT

CH CH CLEARUP

DN

SELECT

CH CH CLEARUP

Press simultaneously

to access function at

cursor

Press UP and DN keys

simultaneously to exit the

System Set-Up Mode

To Model Name function

To Info Display function

Function select

(select model/copy)

Model selection

(1-10)

Press UP and Select keys

simultaneously to access the

System Mode info display

Press to select either of

two Function List screens

Inactive while in List Mode screen

ACRO 29

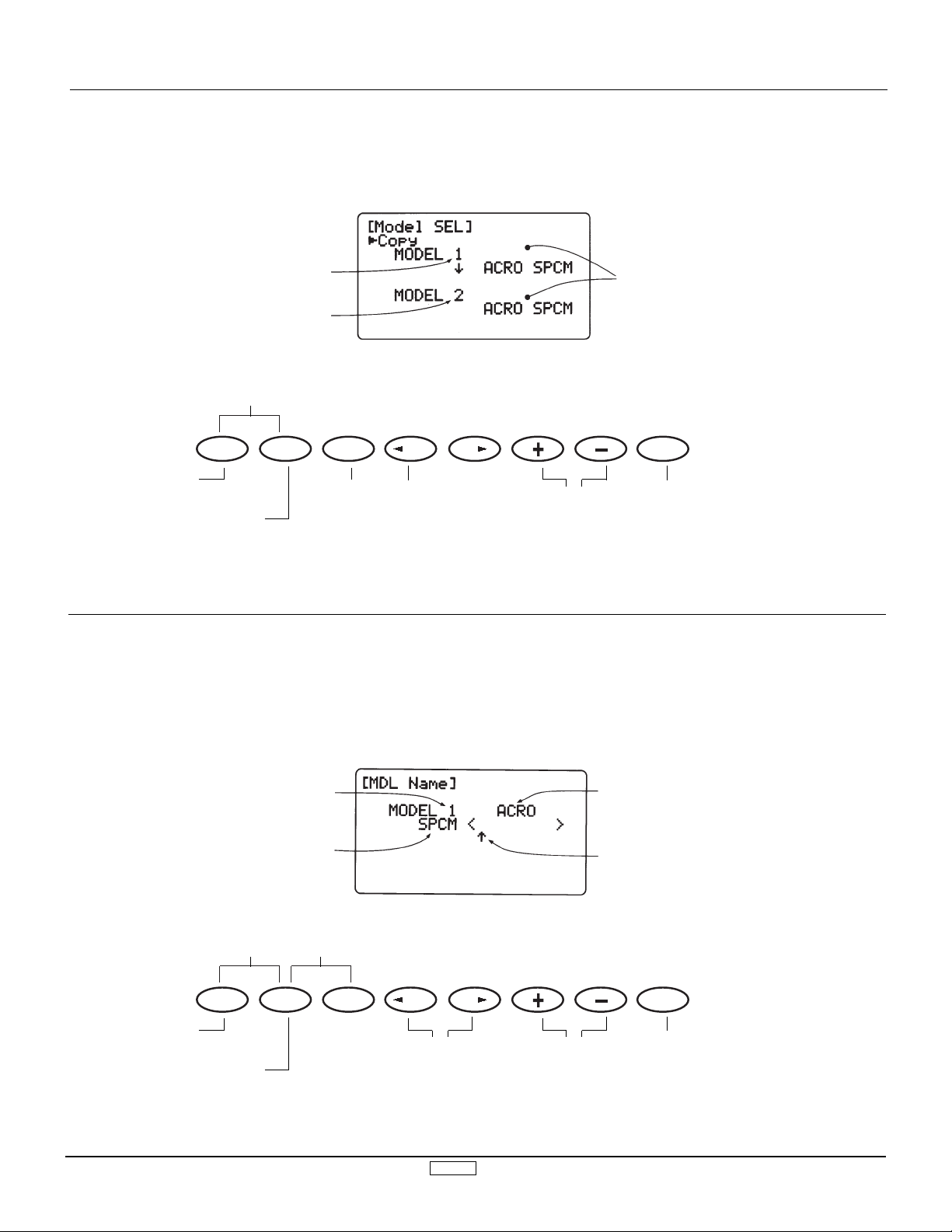

3.5 Copy Select Function (System Set-Up Mode)

The Copy Select Function enables you to copy all of the settings

of your current model to another memory (model number) within

the same transmitter. This is very useful when setting up one

aircraft several different ways.

model names

(if dot is shown, model

name is blank)

existing model

number

model number to be

transferred to.

3.6 Model Names (System Set-Up Mode)

This function is used to input model names individually. Each

model’s name is displayed in the normal screen automatically.

when that model is selected. To avoid confusing models,

inputing model names is recommended. You can input a

maximum of 8 characters for each model name.

In the System Set-Up Mode, select the Model Name Function

using the UP or DN key. Once selected, simultaneously press the

UP and DN keys to access.

model number

modulation

model type

letter position being

inputed

DN

SELECT

CH CH CLEARUP

Press UP and DN keys

simultaneously to exit the

System Set-Up Mode

Press the Select key to

access the copy function

in Model Select mode

To Model Name function

To Spoiler Channel input

selection function

Function select

(select model/copy)

Model selection —

use to select model

to be copied to

Activate copy

function

DN

SELECT

CH CH CLEARUP

Press UP and DN keys

simultaneously to exit the

System Set-Up Mode

Press the DN and Select keys

simultaneously to access the

System Mode info display

(8 characters)

To Model Type Selection

function

To Model Select/Copy

function

Press to change

input letter at arrow

Press to change

input letter arrow

position

Changes input letter

to blank space only

where arrow is

located

Loading...

Loading...