Page 1

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 1 of 16

Rev A : Date 02/1/2002

Table of Contents

1 Installation Instructions 2

2 Placards and Markings 2

3 Installing the Fuel Flow Transducer: 3

4 Mounting Procedure 700921 4

5 Mounting Procedure: 700922 5

6 Mounting Procedure 700923 6

7 Mounting Procedure:700924 7

8 Specifications and Limitations 8

9 TSO Conditions 8

10 Specifications and Limitations 9

11 TSO Label 10

12 Operating Instructions 11

13 Initial Check Out 12

14 List of Major components: 14

15 Instructions for Continued Airworthiness (ICA) 14

16 Wiring Drawing 15

17 Template Drawing 16

J.P.INSTRUMENTS

PO BOX 7033

HUNTINGTON BEACH CA 92646

Last printed in USA

02/19/13

Page 2

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 2 of 16

Rev A : Date 02/1/2002

1 Installation Instructions

General: A complete thorough familiarization and understanding of the system and this manual is necessary before

commencing the installation. All work must conform with A.C. 43.13.1Ach. 11 sec. 2, 3, 7. The accuracy of this

instrument depends entirelyupon the accuracy of the data entered. A periodical checking of the actual fuel onboard

will eliminate the accumulation of errors due to evaporation leaks, etc.

Route the (Optional) External Warning Control Line: The wire from pin 4 on the J-1 (D-SUB 9) can be

connected to an external warning light or buzzer. This pin goes to ground when the display flashes a warning. The

current in this line must be limited to 0.25amps (maximum). Exceeding this limit willdamage the unit. Tie off this wire

if not in use as not too obstruct the freedom of the controls. The FS-450 can be connected in parallel to any existing

digital fuel flow system. When connected to an existing flow sensor pin 3 red is not connected. See drawing 450508.

Install the Instrument in the Panel: Locate a 2.25 diameter hole or 3.125 diameter in the instrument panel,

where you would like to mount the indicator per drawing 450124. The instrument configures itself automatically for

14/28 volt aircraft. The instrument is 1.5” deep less connectors and is 2.6 or 3.5 square behind the panel.

Route the Fuel Flow Transducer Wires: Route thefuel flow wires from the probes through the firewall

using fireproof rubber grommets and flame retarding silicone. Use an existing hole if possible. Following the existing

wiring harness. All wires must be routed away from high temperature areas (exhaust stacks, turbochargers, etc.).

Secure Probe leads to a convenient locationon the engine, being sure there is sufficient slack to absorb engine

torque. It is essential in routing thefuel flow transducer wires not be allowed to touch metal parts of the air-frame or

engine since abrasionwill destroy this wire. Connect wires in accordance with DWG 450508.

2 Placards and Markings

Do not use the PN 700900-1 Flow Transducer on aircraft with a gravity feed system.

Transducer Identification Markings

PN 700900-1 stamped on TSO label and Marked "20l " on the top of the unit,

PN 700900-2 stamped on TSO label and Marked "231" on the top of the unit.

PN FT4-8AEXS-LEA-2029 stamped on transducer side

The placard PN 700905

"Do Not Rely on Fuel Flow Instrument to Determine Fuel Levels in Tanks.”

Must be mounted on the aircraft instrument panel near the P/N 450000( ).

If the aircraft is equipped with a primary fuel flow gage, the following placard must be mounted on the

aircraft instrument panel near the P/N 450000().

"Refer to Original Fuel Flow Instrumentation for Primary Information.”

Page 3

J.P.Instruments Fuel Flow Installation Manual Report # 400

fuel pump.

END VIEW UP

transducer and the

FS-450 Page 3 of 16

Rev A : Date 02/1/2002

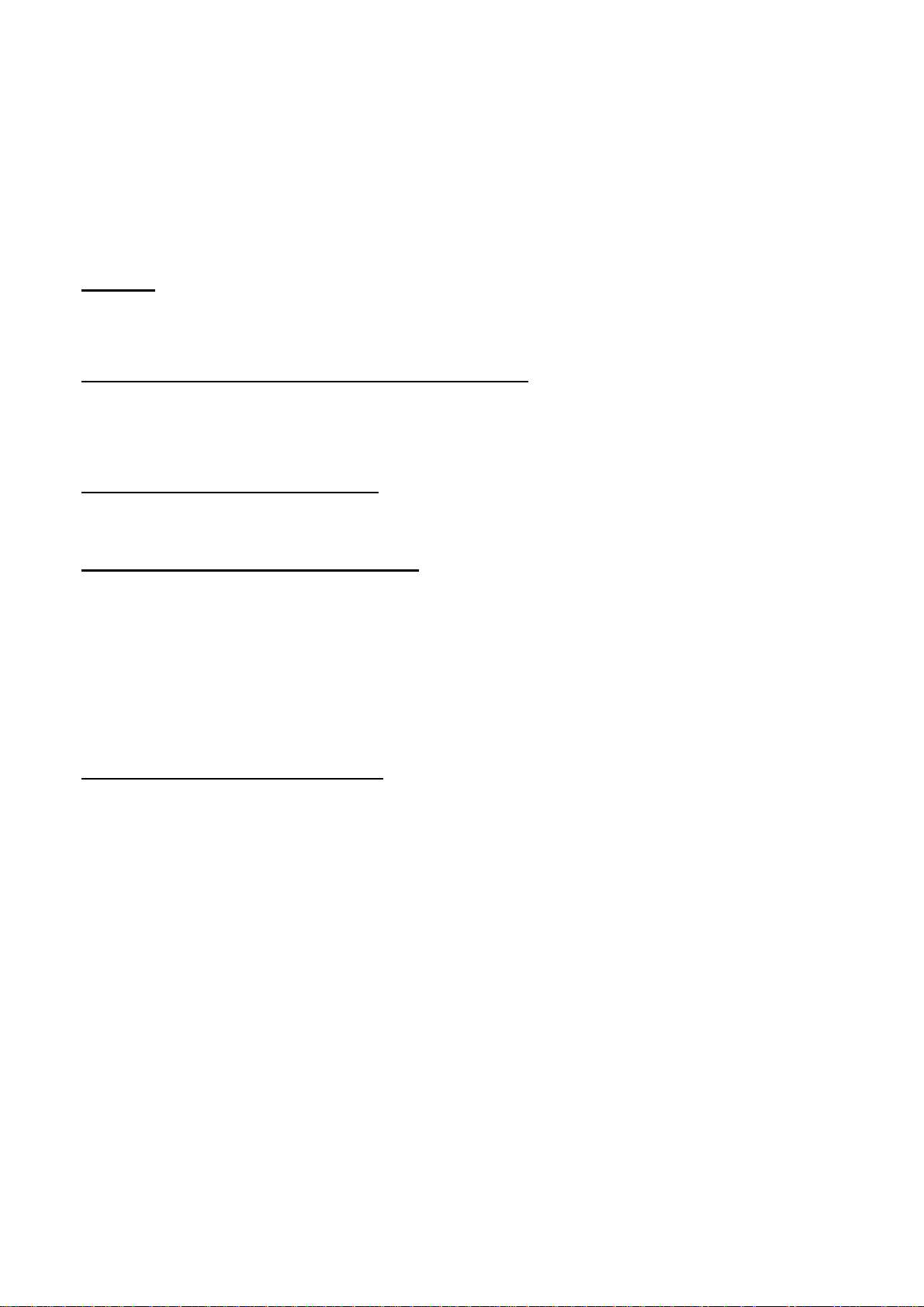

Aircraft Configuration

1. PN 450000-G All gravity Flow installations without

Must use transducer PN 700900-2

2. PN 450000-P All Fuel injected engines with vapor return lines

to fuel tank , all Continental and certain Lycoming engines.

3. PN 450000-P,-H All pump fed carbureted and Fuel injected

engines without vapor return lines. PN 450000-P range up to

Drawing Location

700923

700922

700921

Between Fuel tank and

Carburetor.

Between throttle body and

fuel flow divider.

Between engine driven pump

and servo/throttle body or

carburetor

60 GPH and PN 450000-H range up to 120 GPH

4. PN 450000-D Pressure Carbureted engines with vapor return

lines. Requires Dual transducers

5. PN 450000-M- If “M” is after the PN it signifies that the displayis

3” Fuel flow for twin engine aircraft single indicator.

700924

450508

700922

One transducer in Carb inlet

line and one transducer in

outlet line

Between throttle body and

fuel flow divider.

3 Installing the Fuel Flow Transducer:

Mount the Fuel Flow Transducer using the appropriate drawing in this manual.

The instructions listed below must be followed when installing a Fuel Flow Transducer.

Note: If your engine is equipped witha fuel return line from the carburetor back to the fuel tank two transducers are

required.

The transducer output port should be mounted lower or even with the carburetor inlet port(or fuel servo on a fuel

injected engine). If this is not possible, a loop should be put in the fuel line between the Fuel Flow Transducer and

the carburetor or fuel servo(see diagram below). It is recommended not to hard mount the transducer to the

carburetor or fuel servo.

Do not remove the caps on the flow transducer until the fuel hoses are ready to be installed.

The flow of fuel through the transducer must follow the direction marked on the transducer.

If the transducer is

higher than the

Mount the

transducer

with the

wires up.

carburetor or fuel

servo, put a loop in the

fuel line between the

¼ NPT

SIDE VIEW

Carburetor or Servo

The direction of the fuel

flow through the transducer

is marked on top

The flow transducer must be mounted so the wires exiting the transducer are pointing up.

Before connecting any hoses, thoroughly clean them and insure they are free of any loose material. High air

pressure my be used, However, do not allow high air pressure to pass through the flow transducer.

Page 4

J.P.Instruments Fuel Flow Installation Manual Report # 400

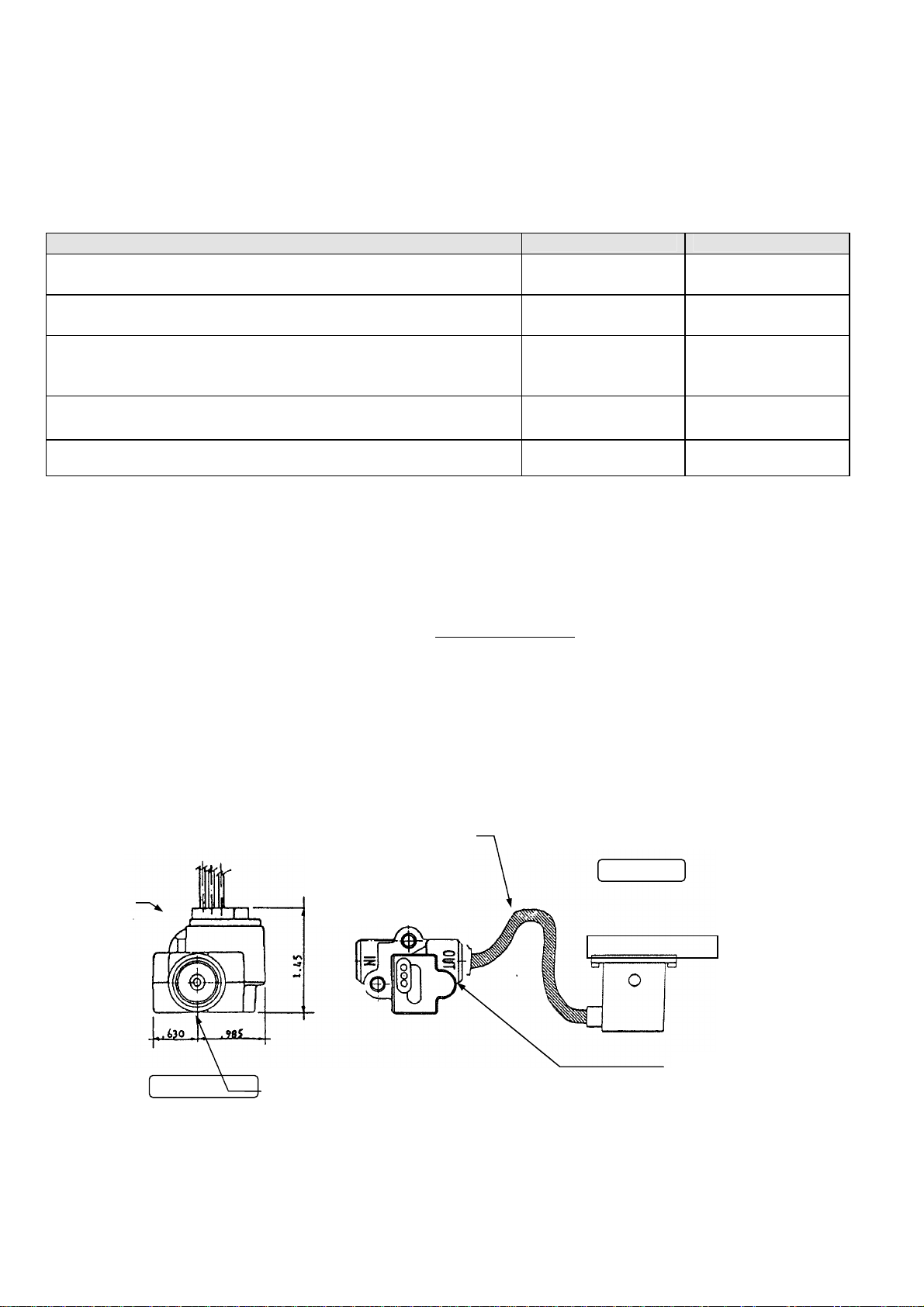

Existing Fitting

support

MS21919 Clamp

as required

FS-450 Page 4 of 16

Rev A : Date 02/1/2002

Fuel injector

Aeroquip

900591B Clamp

AE102/624-24

TRANSDUCER

2-AN816- Pipe to

Flare fitting. Do not

use aluminum fittings

To Engine Driven Fuel

Pump Existing

8" max from

New 303Aeroquip hoseAeroquip Fire Sleeve

4 Mounting Procedure 700921

1. Find a convenient location within 8" of a hose support or fitting and away from anyhot exhaust pipes to suspend

the Fuel Flow Transducer. The hose support or fitting may be on the input or output line of the Flow Transducer.

2. Remove the fuel hose which goes from the Fuel Pump to theCarburetor (or Fuel Servo).

3. Purchase two new hoses, one from the fuel pump (or the Fuel Filter) to the Fuel Flow Transducer and the other

from the Fuel FlowTransducer to thecarburetor (or fuel servo). There must be flexible hose in and out of the

Transducer. The hoses must meet TSO-C53a Type C or D FAA specification. The new hoses must be the

same size as the current hose in the aircraft.

4. Before connecting fuel hose to the carburetor, verifythat the boost pump delivers at least 125% of takeoff fuel

consumption at minimum fuel pressure as marked on fuel pressure gage.

5. Mount the FuelFlow Transducer in the fuelline. The Flow Transducer must be wrapped with Fire Sleeving

available at JPI. Place a small hole in the fire sleeve and pass the transducer wires through it. Seal with High

temperature Silicone RTV sealant

6. For best results it is advisable to have two inches of straight tube just before the inlet to the transducer

J.P.INSTRUMENTS

PO Box 7033

Huntington Beach CA 92646

Title : Installation of a Fuel Flow Transducer in the fuel line fromthe

fuel pump to the carburetor or fuel servo.

Drawing No. 700921

Date

02/14/97

Drawn Approved

Rev NC

Page 5

J.P.Instruments Fuel Flow Installation Manual Report # 400

IN

303 hose

FS-450 Page 5 of 16

Rev A : Date 02/1/2002

To the Flow Divider

OUT

5 Mounting Procedure: 700922

1. Find a convenient location between the Throttle Body and the Flow

Divider and away from any hot exhaust pipes to suspend the Fuel Flow

Transducer.

2. Remove the fuel hose which goes from the Throttle Body to the Flow

Divider.

3. Purchase two new hoses, one from the Fuel Servo to the Fuel Flow

Transducer and the other from the Fuel Flow Transducer to the Flow

Divider. There must be flexible hose in and out of the Fuel

Transducer. The hoses must meet TSO-C53a Type C or D FAA

specification. The new hoses must be the same size as the current

hose in the aircraft.

4. Mount the Fuel Flow Transducer in the fuel line. The Flow Transducer

must be wrapped with Fire Sleeve available at JPI. Place a small

hole in the fire sleeve and pass the transducer wires through it. Seal

with High temperature Silicone RTV sealant.

Aeroquip

900591B Clamp

Fittings ¼ NPT to

Fuel Hose (do not

use aluminum

fittings

Aeroquip Fire

Sleeve

AE102/62-24

Aeroquip

See note 5

From theFuel Servo

5. Secure at either end of the transducer to any convenient point on the engine with MS21919 clamps or

equivalent.

6. For Continental fuel injected engines adjust the fuel pressure to account for the pressure drop across the

transducer per Continental Service Bulletin M89-10, available at JPI.

J.P.INSTRUMENTS

PO Box 7033

Huntington Beach CA 92646

Title Installation of the Fuel Flow Transducer in the fuel line

between the Throttle Body and the Flow Divider. Only applicable

for Continental Fuel Injected Engines

Drawing No. 700922

Date

02/14/97

Drawn/ Approved

Rev NC

Page 6

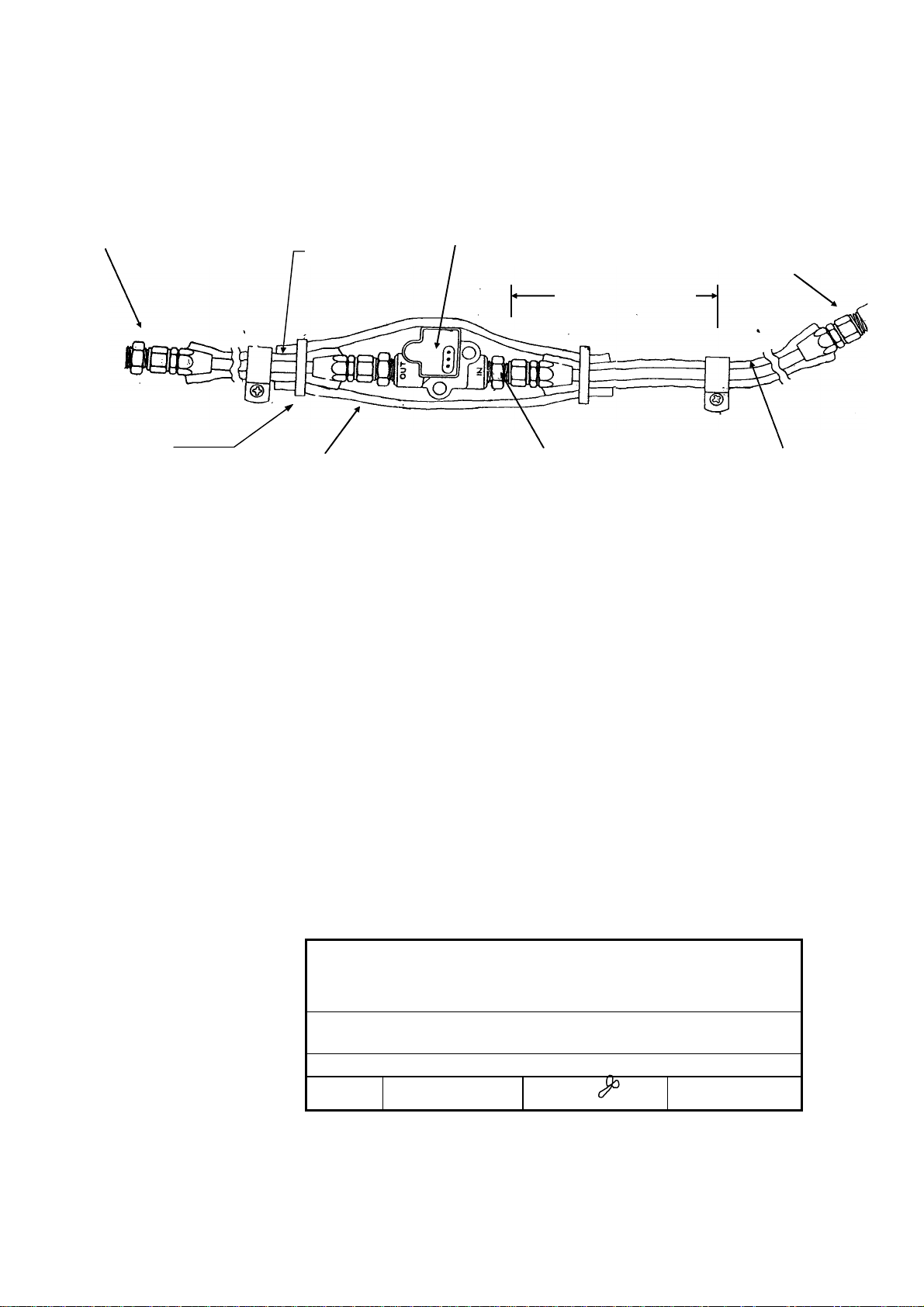

J.P.Instruments Fuel Flow Installation Manual Report # 400

Aeroquip Fire

aluminum fittings

Engine

FS-450 Page 6 of 16

Rev A : Date 02/1/2002

Fuel line to the

Carburetor

MS 21919 Clamp

as required

Aeroquip Fire sleeve

AE102/62-24

8 inches

Maximum from

support

OUT

TRANSDUCER

Sleeve

AE102/62-24

Fuel IN

Fittings ¼ NPT to Fuel

Hose (do not use

From theFuel Tank

Aeroquip

900591B Clamp

Mount to

Firewall or

6 Mounting Procedure 700923

1. Find a convenient location within 8" of a hose support or fitting and away from any hot exhaust pipes to suspend the

Fuel Flow Transducer. The hose support or fitting may be onthe input or output line of the Flow Transducer.

2. Remove the fuel hose which goes from the Carburetor to the Fuel Tank.

3. Mount the Fuel Flow Transducer in the fuel line. You must use the 700900-2 Fuel Flow Transducer on a gravity

feed system. The PN 700900-2 Transducer is marked "Model 231" on the top of the transducer. The Flow

Transducer must be wrapped with Fire Sleeving available at JPI. Place a small hole in the fire sleeve andpass

the transducer wires through it. Seal with High temperature Silicone RTV sealant.

4. Purchase two new hoses, one from the Fueltank to the Fuel FlowTransducer and the other from the Fuel Flow Trans-

ducer to the Carburetor. There must be flexible hose in and out of the Fuel Transducer. The hoses must meet

TSO-C53a Type C or D FAA specification. The newhoses must be the same size as the current hose in the

aircraft.

5. For best results it is advisable to have two inches of straight tube just before the inlet to the transducer.

J.P.INSTRUMENTS

PO Box 7033

Huntington Beach CA 92646

Title : Gravity Installation of a Fuel Flow Transducer in

the fuel supply line from the fuel tank to the carburetor

without a fuel pump.

Drawing No. 700923

Date

02/14/97

Drawn/

02/14/97

Approved

Rev NC

Page 7

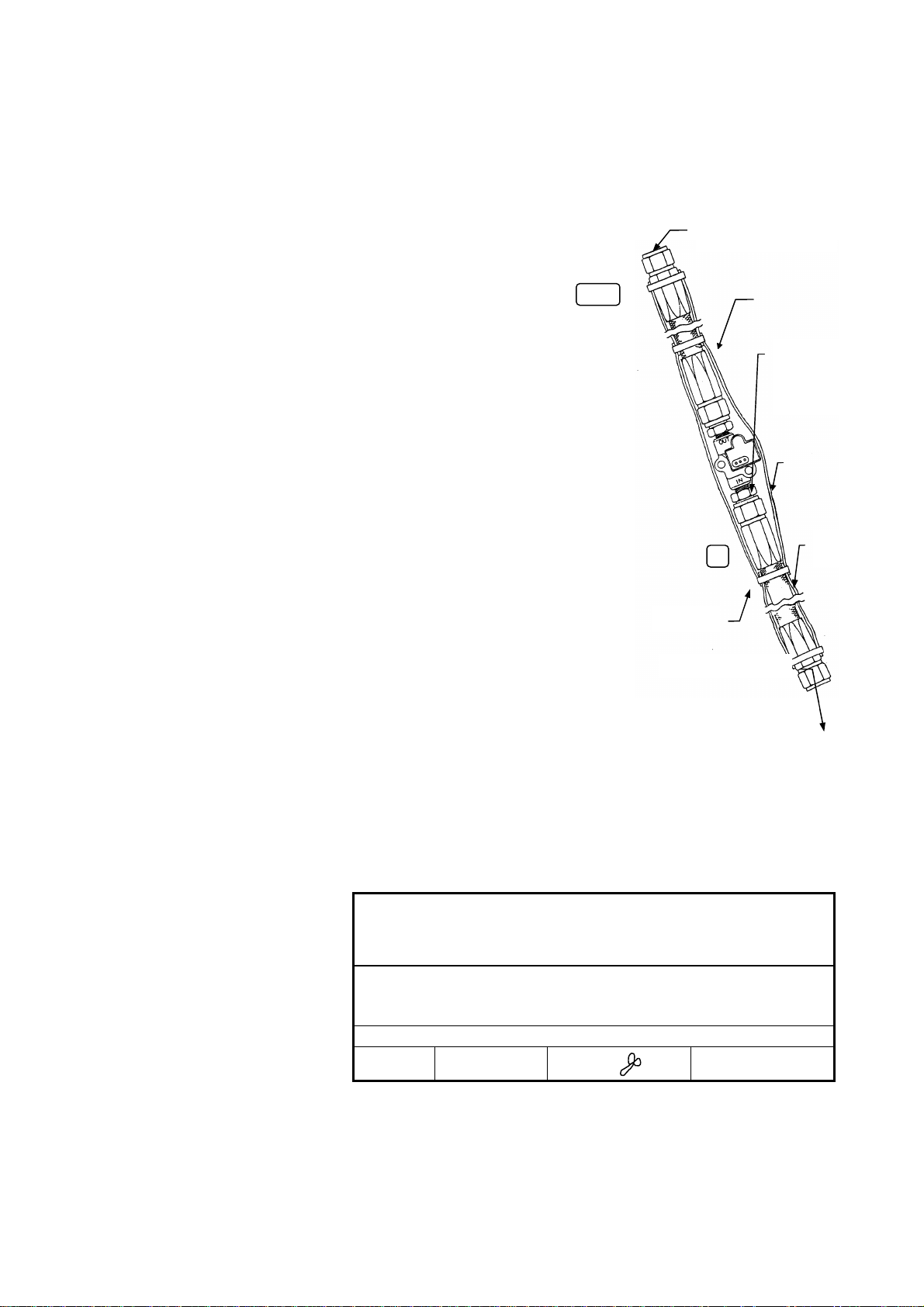

J.P.Instruments Fuel Flow Installation Manual Report # 400

Aeroquip Fire

aluminum fittings

Engine

Carburetor

Main Fuel Transducer

FS-450 Page 7 of 16

Rev A : Date 02/1/2002

Fuel line to the

8 inches

Maximum from

support

Sleeve

AE102/62-24

Aeroquip

900591B Clamp

From themechanical

pump

Fuel IN

Fittings ¼ NPT to Fuel

Hose (do not use

Mount to

Firewall or

MS 21919 Clamp

as required

OUT

Aeroquip Fire sleeve

AE102/62-24

7 Mounting Procedure:700924

1. Find a convenient location within 8" of a hose support or fitting and away from any hot exhaust pipes to suspend the

Fuel Flow Transducer. The hose support or fitting may be on the input or output line of the Flow Transducer.

2. Remove the fuel hose which goes from the mechanical pump to the Carburetor.

3. Remove the fuel hose which goes from the Carburetor return line to the Fuel Tank.

4. Mount the Fuel Flow Transducer in the fuel line from the mechanical pump to the Carburetor per the above drawing;

note the flowdirection on the transducer. Mount the return Fuel flow transducer in the return line from the Carburetor

to the fuel tank, note the transducer willbe reversed. This kit is supplied with two PN 700900-1 transducers. Check

the K factors to be within 0.1. Either transducer may be used as thesupply transducer. Both Flow Transducers

must be wrapped with Fire Sleeving available at JPI. Place asmall hole in the fire sleeve and pass the transducer

wires through it. Seal with Hightemperature Silicone RTV sealant.

5. There must be flexible hose in and out of the Fuel Transducer. The hoses must meet TSO-C53a Type C or D FAA

specification. The new hoses must be the same size as the current hose in the aircraft.

6. Before connecting fuel hose to the carburetor, verifythat the boost pump delivers at least 125% of takeoff fuel

consumption at minimum fuel pressure as marked on fuel pressure gage.

J.P.INSTRUMENTS

PO Box 7033

Huntington Beach CA 92646

Title : Differential Installation, of a Fuel Flow Transducer

in the fuel supply or return line from the carburetor to the

fuel tank

Drawing No. 700924

Date

02/14/97

Drawn/

02/14/97

Approved

Rev NC

Page 8

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 8 of 16

Rev A : Date 02/1/2002

8 Specifications and Limitations

Model:

FS-450, PN 450000()

Case Dimensions:

2.6" x 2.6" x 1.5" depth, 2 1/4" round Bezel.

3.26” x 3.26” x 1.56” depth, 3.12 round Bezel

Weight:

Unit Only 0.08 lbs

Indicator & Harness: 0.25 Lbs.

Flow Transducer: PN 700900-1,-2 0.19 Lbs.

Hi flow PN FT4-8AEXS-LEA-2029 0.5 Lbs.

Power Requirements:

10 to 35 Volts, 0.2 Amp. 1 amp CB

Low Fuel Warning Display

The display message will blink anytime the programmed, Low Fuel Warning or the Time to Empty Limit are violated.

External Warning Control Line:

Takes wire on pin 4 to ground when blinking. Current should be limited to 0.25 amp.

Accuracy:

Flow: 2% or better in accordance with TSO C44b.

Resolution

Fuel Flow: 0.1 Gal. or 1 Lb. or 1 Lt.

Fuel Remaining: 0.1 Gal. or 1 Lb. or 1 Lt.

Fuel Used: 0.1 Gal. or 1 Lb. or 1 Lt.

Time to Empty: 10 minute default

Max Displayed Range (Unit Only):

Fuel Flow: 199.9 Gals. or 162.0 or Gal/Hr or 1199 Lbs./Hr or 749 Ltr./Hr.

Fuel Remaining: 999 Gals. or 811 or Gals. or 1999 Lbs. or 1999 Ltrs.

Fuel Used: 999 Gals. or 811 or Gals. or 1999 Lbs. or 1999 Ltrs.

Time to Empty: 19 hours 59 minutes

9 TSO Conditions

“The conditions and test required for TSO approval of this article are minimum performance standards. It is the

responsibility of those desiring to install this article either on or within a specific type or class of aircraft to determine that

the aircraft installation conditions are within the TSO standards. The article may be installed only if installation of the article

is approved bythe Administrator.”

Page 9

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 9 of 16

Rev A : Date 02/1/2002

10 Specifications and Limitations

Instrument P/N 450000-P, -D

Transducer P/N, 700900-1

Range: 0.6 to 60 GPH Range: 3 to 90 GPH

Linearity: %1 (8 to 60 GPH) Linearity: %1 (8 to 60 GPH)

K Factor Approx. 29,000 K Factor: Approx. 19500

Pressure Drop: 1.2 PSI at 30 GPH

4.8 PSI at 60 GPH

Working Press: 200 PSI Working Press: 200 PSI

Min. Burst Press: 2000 PSI Min. Burst Press: 2000 PSI

Operating Temp. Range -55oC to 70oC Operating Temp. Range -55oC to 70oC

Non Operating Temp. Range: -65oC to 100oC Non Operating Temp. Range: -65oC to 100oC

Fuel Ports: 1/4" Female NPT Fuel Ports: 1/4" Female NPT

Instrument P/N 450000-G

Transducer P/N 700900-2

Pressure Drop: .31 PSI at 30 GPH

2.8 PSI at 90 GPH

Instrument P/N 450000-H .

Transducer P/N (FT 4-8AEXS-LEA-2029)

Range: 3 to 120 GPH

Linearity: %1 (9 to 120 GPH)

K Factor Approx. 48,000

Pressure Drop: 0.23 PSI at 30 GPH

0.8 PSI at 60 GPH

Working Press: 1500 PSI

Min. Burst Press: 2000 PSI

Operating Temp. Range -55oC to 70oC

Non Operating Temp. Range: -65oC to 100oC

Fuel Ports: AN816-8-8

RS232/422 Input Ports FS-450 .

Single Line Receive Method: RS-232C, RS-423, or 5 Volt Serial.

Protocol: 1 Start bit, 8 Data bits, 1 Stop bit.

Baud Rate: Automatic: 9600,4800,1200

Format: Automatic: Aviation Date, Northstar Binary, NMEA-183

RS232 Output Port

Transmit Method: RS-232 Single Line.

Protocol: 1 Start bit, 8 Data bits, 1 Stop bit.

Baud Rate: 9600

Transmit Format: Garmin, Allied Signal, Arnav, UPS

Page 10

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 10 of 16

Rev A : Date 02/1/2002

11 TSO Label

Page 11

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 11 of 16

Rev A : Date 02/1/2002

12 Operating Instructions

The FS-450 Fuel Scan uses a small turbine transducer that measures the fuel flowing into the engine. Higher fuel flow

causes the transducer turbineto rotate faster which generates a faster pulse rate. Prior to engine start youinform the

FS-450 Fuel Scan of the known quantityof fuel aboard, and itwill keep track of all fuel used. There are two standard

operating modes of the FS-450: Automatic Scanning, and Manual Scanning. The FS-450 has programmable alarms.

When the remaining amount of fuel falls below the alarm limit the bottom displaywill show the amount of fuel REMaining

and the specific cue light will flash. When the remaining time falls below the alarm limit the bottom display will showthe

MINutes of fuel remaining and the specific cue light will flash. When an alarm is displayed, tapping the STEP button will

temporarily disable the alarm indication for the next ten minutes. When an alarm is displayed, holding the STEP button

until the word appears will disable that alarm indication for the remainder of the flight. After initial self-test, youwill

be asked to inform the FS-450 of start up fuel. The FS-450 willdisplay (or liters or

pounds) for one second, and then flash until anybutton is pressed. The displaywill pause at each

parameter for a few seconds in the Automatic scanning mode. In the Manual scanning mode, tap the STEP button to

advance to next parameter. Holding the STEP button willdisplay the previous parameters in the sequence (rapidly

backwards).

Procedure—Changing the Set Up by entering the program mode.

Hold both

buttons for 5

seconds until

the words

Tap STEP

button until

the words

Hold both

buttons for 5

seconds until

the words

Tap STEP

to next item

AUTO sequencesthrough

these values

Hold or tapAUTO to

select main capacity

Hold or tapAUTO to

select AUX capacity

Hold or tapAUTO to

select low time limit

Hold or tapAUTO to

select low quantity limit

Description

Selects fuel units

Main tank capacity, in units selected

Y—Yes—aircraft has auxiliary tanks (next step)

Auxiliary tank capacity (skipped if AUX? is no)

Alarm limit in minutes for low time in tanks

Alarm limit for low fuel quantity in tanks, in units selected

Y—Yes—carbureted engine

Y—Yes toexit; N—No to review list again

Page 12

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 12 of 16

Rev A : Date 02/1/2002

Digital displayfor numeric readouts and messages: top displayis fuel flow and the lower displayfor all other

parameters.

Indicator lights to show what information is beingdisplayed on thedigital display

FlowScan® 450M

Flow Scan® -450M

Flow per Hr.

Left Engine Right Engine

LEFT ENGINE RIGHTENGINE

15.3 15.6

Function

Function

TUSD LUSD RUSD REM H.M. REQ RES

TUSD LUSD RUSD REM H.M. REQ RES

Parameter Description

USD—Total Fuel Used

REM—Fuel Remaining

H.M.—Time to Empty

REQ—Fuel required to nextGPS WPT or

Destination

RES—Fuel Reserve at next GPS WPT or

Destination

50.7

50.7

STEP AUTO

STEP AUTO

J

P

I

TSO

J

TSO

P

I

Always shows fuel

Always shows fuel flow

flow of each engine

of each engine

shows all other

shows all other fuel

Flow

fuel parameters

parameters

Per Hr

AUTO enters the

AUTO enters the automatic

automatic scan mode

scan mode

38.2

37.2

02.45

25.8

I I.3

Function

USD REM H.M. REQ--RES

Example Comments

Since last refueling or trip total.

In gallons, liters or pounds

Hours. Minutes Remaining at current fuel burn

Present with GPS interface Valid signal and way point

Present with GPS interface Valid signal and way point

J

FS 450

P

I

Fuel Flow GPH

STEP AUTO

Gallons

Per Hr.

-MPG

Always shows fuel flow

shows fuel parameter

corresponding to indicator light

indicator lights index through

each parameter

AUTO enters the automatic

scan mode

STEP enters manual scan mode,

steps through each paramerter

13 Initial Check Out

Electronics Warranty: The aircraft owner must read the Warranty before starting the installation. There is

information in the Warranty that may alter your decision to install this instrument. If you do not accept

the terms of the Warranty, JPI offers a 30 day money back guarantee.

Transducer Warranty: All transducers suspected of malfunctioning must be sent back to JPI to be bench

flow tested. JPI sends the transducer back to the original manufacturer for testing, who in tern charges

JPI, $70 for the testing. If the transducer is found defective a new transducer will be issued.

If you are not an FAA Certified Aircraft Mechanic familiar with the issues of installing aircraft fuel

flow, Do Not attempt to install this instrument. The installer should use current aircraft standards and

practices to install this instrument (refer to AC 43.13).

Read the entire Installation Instructions and resolve any issues you may have before starting the installa-

tion.

THIS INSTALLATION WILL REQUIRE SOME PARTS UNIQUE TO YOUR AIRCRAFT THAT ARE NOT

SUPPLIED IN THE KIT (including, but not limited to hoses and fittings). Acquire all the parts

necessary to install this instrument before starting the installation. Do not use aluminum fittings with the

PN 700900-1 or PN 700900-2 transducer.

Page 13

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 13 of 16

Rev A : Date 02/1/2002

Check that the instrument make and model are correct before starting the installation (check the markings

on the side of the instrument). A gravity feed system requires an PN 700900-2 flow transducer (marked

"231" on top). A carbureted engine with a fuel return line requires two transducers at additional cost

If this instrument is to replace an existing unit in the aircraft, it is the installer's responsibility to move or

replace any existing instruments or components in accordance with FAA approved methods and procedures. The following Installation Instructions do not cover moving or the removal of any existing

instruments or components.

Before connecting any hoses to the transducer, thoroughly clean them and insure they are free of any

loose material. Never pass high pressure air through or blow through the transducer, damage will

occur.

Remove the transducer cap plugs when ready to install hoses. Do not use aluminum fittings with the fuel

flow transducer or Gauling may occur.

The inlet and outlet ports of the transducer have ¼ NPT threads. When assembling fittings into the inlet

and outlet Do Not Exceed a torque of 15 ft. lbs. Or screw the fittings in more than 2 full turns past hand

tight.

A screen or filter should be installed upstream of the transducer. As turbulence upstream of the

transducer affects it’s performance, there should be a reasonable length of straight line between the

transducer inlet.

Install the transducer with the wires leads UP to vent bubbles and insure that the rotor is totally immersed

in fluid.

Note the direction of fuel flow marked on the transducer. Fuel must flow in this direction.

Note and record the K-factor engraved in the side of the transducer and also on the white tag attached to

the transducer. Most transducers have a K- factor of 29.90.

10. System Checkout: Check instrument operation as follows:

Turn the aircraft master switch on (engine off). Tap the step switch until 0 GPH is displayed. Turn the

boost pump on for a few seconds. The display should indicate 3 to 8 GPH.. A problem at this step could

be caused by poor connections on the red or black power and ground leads.

A reading of “ --- “ dashes indicate no fuel flow transducer signals. A problem at this step could be caused

by a poor connection or crossed flow transducer wires.

With the engine running, check the "FLOW" Display to read properly.

After running the engine, check the fuel hoses, transducers and fittings for leaks.

Page 14

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 14 of 16

Rev A : Date 02/1/2002

14 List of Major components:

PN 450000-( ) -P -G -D -H -M

Indicator PN 450000 1 1 1 1

Indicator PN 450000-M 1

Harness PN 450507 1 1 1

Harness PN 450510 1

Harness PN 450506 1

Transducer PN 700900-1 1 2 2

Transducer PN 700900-2 1

Transducer High Flow PN FT4-8AEXS-LEA-2029 1

Part Number Description

PN 450000-P All pump fed Carburetor and injected engines with

maximum take-off flow range to 60 GPH

PN 450000-G All Gravity feed systems without mechanical pump

PN 450000-D All pressure carburetor systems with return line to tank

PN 450000-H All mechanical pump fed systems with a high flow

range, on take-off, to 120 GPH.

PN 450000-M Fuel flow for twin engine aircraft single indicator

15 Instructions for Continued Airworthiness (ICA)

There are no field adjustments and or calibration requirements for the P/N 450000 series instrument after initial

installation. ICA is not required. Maintenance of nonfunctioning or malfunctioning components is limited to

removal and replacement of JPI factorysupplied new or repaired components as described in the

troubleshooting section of the installation instructions

Page 15

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 15 of 16

Rev A : Date 02/1/2002

16 Wiring Drawing

Page 16

J.P.Instruments Fuel Flow Installation Manual Report # 400

FS-450 Page 16 of 16

Rev A : Date 02/1/2002

17 Template Drawing

Loading...

Loading...