Page 1

the fastest way to purchase parts

www.speedepart.com

™

OWNERS MANUAL

MANUAL DEL USUARIO

MANUEL DU PROPRIÉTAIRE

BEDIENUNGSANLEITUNG

MANUALE DEL PR OPRIETARIO

Model No.

Modelo nº

Modèle nº

Modell-Nr.

Modello nº

LST42C-669

CAUTION:

Read Rules for Safe Operation

and Instructions Carefully

PRECAUCIÓN:

Lea cuidadosamente las

instrucciones y las reglas para

una operación segura

AVERTISSEMENT :

Lire et suivre attentivement les

instructions et consignes de

sécurité

AACHTUNG:

Lesen Sie bitte sowohl die

Hinweise zum sicheren Betrieb

sowie auch die Anweisungen

sorgfältig durch

ATTENZIONE:

Leggere attentamente le norme

di sicurezza e le istruzioni

42" SNOW THROWER

SOPLADOR DE NIEVE DE 42" (106 cm)

SOUFFLEUSE À NEIGE 42 PO. (106 cm)

SCHNEEFRÄSE 42" (106 cm)

SPARTINEVE A TURBINA 42" (106 cm)

• Safety

• Assembly

• Operation

• Maintenance

• Seguridad

• Montaje

• Funcionamiento

• Mantenimiento

• Sécurité

• Assemblage

• Utilisation

• Entretien

• Sicherheit

• Zusammenbau

• Betrieb

• Wartung

• Sicurezza

• Montaggio

• Funzionamento

• Manutenzione

PRINTED IN U.S.A. FORM NO. 40429 (REV. 1/7/08)

Page 2

E

B

D

G

H

I

K

O

F

X

U

Y

C

W

L

Q

S,T

R

Z

KK

EE

N

CC

BB

AA

DD

M

J

JJ

FF

GG

II

V

P

HH

A

LL

NN

MM

REF. QTY DESCRIPTION

A 1 Hex Bolt, 3/8" x 3-1/4"

B 2 Hex Bolt, 5/16" x 1-3/4"

C 4 Hex Bolt, 5/16" x 3/4"

D 6 Hex Bolt, 1/4" x 1"

E 6 Hex Bolt, 3/8" x 1" (Thread

Forming)

F 2 Hex Bolt, 5/16" x 3/4"

(Thread Forming)

G 6 Carriage Bolt, 3/8" x 1"

H 2 Carriage Bolt, 5/16" x

I 2 Carriage Bolt , 5/16" x

J 4 Carriage Bolt, 5/16" x 1"

K 2 Carriage Bolt, 5/16" x 3/4"

1-3/4"

1-1/4"

REF. QTY DESCRIPTION

L 4 Shoulder Bolt

M 2 Shoulder Bolt

N 2 Shear Bolt (spare parts)

O 7 Lock Washer, 3/8"

P 7 Washer, 1/4"

Q 6 Washer, 5/16"

R 8 Washer, 1/2"

S 1 Washer, 3/8" (Thin)

T 3 Washer, 3/8"

U 2 Bowed Washer

V 6 Flanged Nut, 1/4"

W 1 Flanged Nut, 5/16"

X 10 Flanged Nut, 3/8"

Y 17 Nylock Nut, 5/16" (2 spare

parts)

REF. QTY DESCRIPTION

Z 2 Hex Lock Nut, 3/8"

AA 1 Spring

BB 3 Chute Keeper

CC 1 Trunnion

DD 2 Hairpin Cotter, 5/64"

EE 4 Hairpin Cotter, 1/8"

FF 1 Hairpin Cotter, 3/32"

GG 2 Lock Pin

HH 1 Plastic Cap

II 2 Nylon Tie

JJ 2 Chain, Tensioning

KK 2 Tail Reector

LL 1 Small Spacer

MM 1 Large Spacer

NN 1 Pulley

2

Page 3

REF. CANT. DESCRIPCIÓN

A 1 Tuerca hexagonal de 3/8”

x 3-1/4"

B 2 Tuerca hexagonal de

5/16” x 1-3/4"

C 4 Tuerca hexagonal de

5/16" x 3/4"

D 6 Perno de cabeza

hexagonal de 1/4” x 1"

E 6 Perno de cabeza

hexagonal de 3/8” x 1"

(auto-roscante)

F 2 Perno de cabeza

hexagonal de 5/16” x 3/4"

(auto-roscante)

G 6 Perno de cabeza de

hongo y cuello cuadrado

de 3/8" x 1"

H 2 Perno de cabeza de

hongo y cuello cuadrado

de 5/16 x 1-3/4"

I 2 Perno de cabeza de

hongo y cuello cuadrado

de 5/16 x 1-1/4"

REF. CANT. DESCRIPCIÓN

J 4 Perno de cabeza de

hongo y cuello cuadrado

de 5/16” x 1"

K 2 Perno de cabeza de

hongo y cuello cuadrado

de 5/16 x 3/4"

L 4 Perno de tope

M 2 Perno de tope

N 2 Perno de seguridad

(piezas de repuesto)

O 7 Arandela de presión de

3/8"

P 7 Arandela de 1/4"

Q 6 Arandela de 5/16"

R 8 Arandela de 1/2"

S 1 Arandela de 3/8"

(delgada)

T 3 Arandela de 3/8"

U 2 Arandela curvada

V 6 Tuerca con brida de 1/4"

W 1 Tuerca con brida de 5/16"

X 10 Tuerca con brida de 3/8"

REF. CANT. DESCRIPCIÓN

Y 17 Tuerca Nylock de 5/16" (2

piezas de repuesto)

Z 2 Tuerca hexagonal de

cierre de 3/8

AA 1 1 resorte

BB 3 Sujetador del conducto

CC 1 Muñón de sujeción

DD 2 Pasador de horquilla de

5/64"

EE 4 Pasador de horquilla de

1/8"

FF 1 Pasador de horquilla de

3/32"

GG 2 Pasador de traba

HH 1 Tapa plástica

II 2 Tirante de Nylon

JJ 2 Cadena, tensora

KK 2 Reector de cola

LL 1 Espaciador pequeño

MM 1 Espaciador grande

NN 1 Polea

RÉF. QTÉ DESCRIPTION

A 1 Boulon hex., 3/8 x 3-1/4 po.

B 2 Boulon hex., 5/16 x 1-3/4 po.

C 4 Boulon hex., 5/16 x 3/4 po.

D 6 Boulon hex., 1/4 x 1 po.

E 6 Boulon hex., 3/8 x 1 po.

(auto-taraudeur)

F 2 Boulon hex., 5/16 x 3/4 po.

(auto-taraudeur)

G 6 Boulon de carrosserie, 3/8

x 1 po.

H 2 Boulon de carrosserie, 5/16

x 1-3/4 po.

I 2 Boulon de carrosserie , 5/16

x 1-1/4 po.

J 4 Boulon de carrosserie, 5/16

x 1 po.

K 2 Boulon de carrosserie, 5/16

x 3/4 po.

L 4 Boulon à épaulement

RÉF. QTÉ DESCRIPTION

M 2 Boulon à épaulement

N 2 Boulon de cisaillement

(pièces de rechange)

O 7 Rondelle de blocage, 3/8 po.

P 7 Rondelle, 1/4 po.

Q 6 Rondelle, 5/16 po.

R 8 Rondelle, 1/2 po.

S 1 Rondelle, 3/8 po. (ne)

T 3 Rondelle, 3/8 po.

U 2 Rondelle frein

V 6 Écrou à embase, 1/4 po.

W 1 Écrou à embase, 5/16 po.

X 10 Écrou à embase, 3/8 po.

Y 17 Écrou mécanique de

sécurité, 5/16 po. (2 pièces

de rechange)

Z 2 Écrou de blocage hex. 3/8

po.

RÉF. QTÉ DESCRIPTION

AA 1 1 Ressort

BB 3 Gâches de la goulotte

d’éjection

CC 1 Tourillon

DD 2 Goupille fendue, 5/64 po.

EE 4 Goupille fendue, 1/8 po.

FF 1 Goupille fendue, 3/32 po.

GG 2 Axe de blocage

HH 1 Capuchon en plastique

II 2 Attache en nylon

JJ 2 Chaîne de tension

KK 2 Catadioptre arrière

LL 1 Petite rondelle d’espacement

MM 1 Grande rondelle

d’espacement

NN 1 Poulie

3

Page 4

BEZ. ANZ. BESCHREIBUNG

A 1 Sechskantschraube, 3/8"

x 3-1/4"

B 2 Sechskantschraube, 5/16"

x 1-3/4"

C 4 Sechskantschraube, 5/16"

x 3/4"

D 6 Sechskantschraube, 1/4"

x 1"

E 6 Sechskantschraube, 3/8" x

1" (gewindeschneidend)

F 2 Sechskantschraube,

5/16" x 3/4"

(gewindeschneidend)

G 6 Schlossschraube, 3/8" x 1"

H 2 Schlossschraube, 5/16" x

1-3/4"

I 2 Schlossschraube, 5/16" x

1-1/4"

J 4 Schlossschraube, 5/16"

x 1"

BEZ. ANZ. BESCHREIBUNG

K 2 Schlossschraube, 5/16"

x 3/4"

L 4 Gelenkschraube

M 2 Gelenkschraube

N 2 Scherschraube

(Ersatzteile)

O 7 Sicherungsscheibe, 3/8"

P 7 Unterlegscheibe, 1/4"

Q 6 Unterlegscheibe, 5/16"

R 8 Unterlegscheibe, 1/2"

S 1 Unterlegscheibe, 3/8"

(dünn)

T 3 Unterlegscheibe, 3/8"

U 2 Gewölbte Unterlegscheibe

V 6 Flanschmutter, 1/4"

W 1 Flanschmutter, 5/16"

X 10 Flanschmutter, 3/8"

Y 17 Sechskantmutter mit

Klemmteil, 5/16" (2

Ersatzteile)

BEZ. ANZ. BESCHREIBUNG

Z 2 Sechskantsicherungsmut

ter, 3/8"

AA 1 1 Feder

BB 3 Leitblechhalterung

CC 1 Zapfen

DD 2 Haarnadelsplint, 5/64"

EE 4 Haarnadelsplint, 1/8"

FF 1 Haarnadelsplint, 3/32"

GG 2 Steckbolzen

HH 1 Plastikkappe

II 2 Kabelbinder

JJ 2 Spannkette

KK 2 Rückwärtiger Reektor

LL 1 Kleines Distanzstück

MM 1 Großes Distanzstück

NN 1 Riemenscheibe

RIF. QTÀ. DESCRIZIONE

A 1 Bullone esagonale da 3/8"

x 3-1/4"

B 2 Bullone esagonale da 5/16"

x 1-3/4"

C 4 Bullone esagonale da 5/16"

x 3/4"

D 6 Bullone esagonale da 1/4"

x 1"

E 6 Bullone esagonale da 3/8" x

1" (autolettante)

F 2 Bullone esagonale da 5/16"

x 3/4" (autolettante)

G 6 Chiavarda a testa rotonda

da 3/8" x 1"

H 2 Chiavarda a testa rotonda

da 5/16" x 1-3/4"

I 2 Chiavarda a testa rotonda

da 5/16" x 1-1/4"

J 4 Chiavarda a testa rotonda

da 5/16" x 1"

RIF. QTÀ. DESCRIZIONE

K 2 Chiavarda a testa rotonda

da 5/16" x 3/4"

L 4 Vite con gambo

parzialmente lettato

M 2 Vite con gambo

parzialmente lettato

N 2 Perno di sicurezza (pezzi di

ricambio)

O 7 Rondella elastica da 3/8"

P 7 Rondella da 1/4"

Q 6 Rondella da 5/16"

R 8 Rondella da 1/2"

S 1 Rondella da 3/8" (Thin)

T 3 Rondella da 3/8"

U 2 Rondella arcuata

V 6 Dado a colletto da 1/4"

W 1 Dado a colletto da 5/16"

X 10 Dado a colletto da 3/8"

RIF. QTÀ. DESCRIZIONE

Y 17 Dado Nylock da 5/16" (2

parti di ricambio)

Z 2 Controdado esagonale da

3/8"

AA 1 1 molla

BB 3 Fissatore dello scivolo

CC 1 Perno di articolazione

DD 2 Chiavetta a forcella da 5/64"

EE 3 Chiavetta a forcella da 1/8"

FF 1 Chiavetta a forcella da 3/32"

GG 2 Spinotto di bloccaggio

HH 1 Tappo di plastica

II 2 Tirante di plastica

JJ 2 Catena, Messa in tensione

KK 2 Riettore di coda

LL 1 Piccolo distanziale

MM 1 Grande distanziale

NN 1 Puleggia

4

Page 5

14

1

2

4

5

6

12

9

8

10

20

19

11

17

16

15

18

13

7

3

CARTON CONTENTS

1. Suspension Arms (2)

2. Left Hand Side Plate

3. Right Hand Side Plate

4. Anti-rotation Bracket

5. Engagement Rod (Not used on some models)

6. Engine Pulley Keeper (Not used on some models)

7. Chute Crank Rod Assembly

8. Support Tube, Crank Rod

9. Lift Handle and Cable

10. Cable Bracket

11. L.H. Hanger Bracket (Outside Mounting)

12. R.H. Hanger Bracket (Outside Mounting)

13. Clutch Idler Assembly

14. V-Belt, Drive (Short) #46989

15 V-Belt, Drive (Long) #48138

16. V-Belt, Auger (Attached to Housing Assembly)

17. Chute and Control Cable Assembly

18. Housing Assembly

19. L.H. Hanger Bracket (Inside Mounting)

20. R.H. Hanger Bracket (Inside Mounting)

Hardware Package (Stored inside Plastic Keg)

5

Page 6

CONTENIDO DE LA CAJA

1. Brazos de suspensión (2)

2. Placa lateral izquierda

3. Placa lateral derecha

4. Soporte antirrotación

5. Varilla de enganche (No se utiliza en algunos modelos)

6. Sujetador de la polea motor (No se utiliza en algunos

modelos)

7. Conjunto varilla manivela del conducto

8. Tubo soporte, varilla de la manivela

9. Manivela de elevación y cable

10. Soporte para el cable

11. Soporte de suspensión lado izquierdo (Se monta en el

exterior)

12. Soporte de suspensión lado derecho (Se monta en el

exterior)

13. Conjunto de embrague/polea libre

14. Correa trapezoidal, transmisión (corta) #46989

15. Correa trapezoidal, transmisión (larga) #48138

16. Correa trapezoidal, barrena (enganchada al conjunto de la

carcasa)

17. Conjunto de cable de control y de conducto.

18. Carcasa

19. Soporte de suspensión lado izquierdo (Se monta en el

interior)

20. Soporte de suspensión lado derecho (Se monta en el

interior)

Paquete de accesorios (se guarda en el interior de una bolsa

de plástico)

CONTENU DU CARTON

1. Bras de suspension (2)

2. Plaque latérale gauche

3. Plaque latérale droite

4. Patte anti-rotation

5. Biellette de mise en prise (n'est pas utilisée sur certains

modèles)

6. Gâche de la poulie du moteur (n'est pas utilisée sur certains

modèles)

7. Bielle de la goulotte d’éjection

8. Tube de support de la bielle de la goulotte

9. Poignée d’élévation et câble

10. Support de xation du câble

INHALT DES KARTONS

1. Aufhängungsarme (2)

2. Linke Seitenplatte

3. Rechte Seitenplatte

4. Verdrehschutzhalterung

5. Einrückstange (kommt nicht bei allen Modellen zum

Einsatz)

6. Keilriemenhalter (kommt nicht bei allen Modellen zum

Einsatz)

7. Leitblechverstellstangenbaugruppe

8. Stützrohr, Verstellstange

9. Hebergriff und Kabel

11. Support suspendu gauche (montage extérieur)

12. Support suspendu droit (montage extérieur)

13. Ensemble embrayage et galet tendeur

14. Petite courroie en V du mécanisme d’entraînement no.

46989

15. Longue courroie en V du mécanisme d’entraînement no.

48138

16. Courroie en V de la tarière (xée au carter de protection)

17. Ensemble de la goulotte d’éjection et du câble de

commande

18. Carter de protection

19. Support suspendu gauche (montage intérieur)

20. Support suspendu droit (montage intérieur)

Sac de pièces de quincaillerie (située à l’intérieur d’un baril en

plastique)

10. Kabelkonsole

11. linke Hängerhalterung (Außenmontage)

12. rechte Hängerhalterung (Außenmontage)

13. Kupplungs-/Umlenkrollenbaugruppe

14. Keilriemen, Antrieb (kurz) Nr. 46989

15 Keilriemen, Antrieb (lang) Nr. 48138

16. Keilriemen, Schnecke (Mit der Gehäusebaugruppe

verbunden)

17. Leitblech- und Steuerkabelbaugruppe

18. Gehäusebaugruppe

19. linke Hängerhalterung (Innenmontage)

20. rechte Hängerhalterung (Innenmontage)

Kleinteilepackung (im Plastikfass untergebracht)

CONTENUTO DEI CARTONI

1. Bracci di sospensione (2)

2. Piastra laterale sinistra

3. Piastra laterale destra

4. Staffa antirotazione

5. Asta di inserimento (Non usato in alcuni modelli)

6. Fissatore della puleggia motrice (Non usato in alcuni

modelli)

7. Gruppo asta manovella dello scivolo

8. Tubo di supporto, Asta manovella

9. Maniglia e cavo di sollevamento

10. Staffa del cavo

11. Staffa del gancio sinistro (montaggio esterno)

12. Staffa del gancio destro (montaggio esterno)

13. Gruppo innesto ingranaggio folle

14. Cinghia a V, motrice (corta) no.46989

15 Cinghia a V, motrice (lunga) no. 48138

16. Cinghia a V, Coclea (Attaccata al gruppo

alloggiamento)

17. Gruppo scivolo e cavo di comando

18. Gruppo alloggiamento

19. Staffa del gancio sinistro (montaggio interno)

20. Staffa del gancio destro (montaggio interno)

Pacchetto bulloneria (conservato all’interno del barilotto

di plastica)

6

Page 7

SAFETY

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate the equipment.

Exercise caution at all times, when using power equipment.

• Read this owner's manual carefully and know how to

operate your snow thrower and how to stop the unit and

disengage the controls quickly.

• Never allow children to operate the equipment.

• Never allow adults to operate the equipment without

proper instruction.

• Keep the area of operation clear of all persons, especially

small children, and pets.

• Thoroughly inspect the area where the equipment is to

be used and remove all door mats, sleds, boards, wires

and other foreign objects.

• Disengage all clutches and shift into neutral before

starting engine.

• Do not operate equipment without wearing adequate

winter outer garments.

• Wear substantial footwear which will protect feet and

improve footing on slippery surfaces.

• Check fuel before starting the engine. Do not remove the

fuel cap or ll the fuel tank while the engine is running

or hot. Do not ll the fuel tank indoors. Gasoline is an

extremely ammable fuel.

• Make sure the snow thrower height is adjusted to clear

the type surface it will be used on.

• Do not use the snow thrower without the rear weight

attached to the tractor.

• Never make any adjustments while the engine is

running.

• Always wear safety glasses or eye shield during operation

or while performing adjustment or repair.

• Do not place hands or feet near rotating parts. Keep

clear of the discharge opening at all times.

• Use extreme caution when operating on or crossing

gravel surfaces.

• Do not carry passengers.

• After striking a foreign object, stop the engine, remove

the wire from the spark plug and then thoroughly inspect

the snow thrower for damage. Repair any damage before

restarting and operating the snow thrower.

• If the snow thrower starts to vibrate abnormally, stop the

engine immediately and check for the cause. Vibration

is generally a warning of trouble.

• Stop the engine whenever you leave the operating

position, before unclogging the snow thrower or making

any adjustments or inspections.

• Take all possible precautions when leaving the unit

unattended. Disengage the attachment clutch lever or

switch, lower the snow thrower, shift into neutral, set the

parking brake, stop the engine and remove the key.

• When cleaning, repairing or inspecting, make certain all

moving parts have stopped. Disconnect the spark plug

wire and keep it away from the plug to prevent accidental

starting.

• Do not run engine indoors except when transporting the

snow thrower in or out of the building. Open the outside

doors. Exhaust fumes are dangerous.

• Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes. Refer to the slope

guide on page 79 of this manual.

• Never operate the snow thrower without guards, plates

or other safety protection devices in place.

• Never operate the snow thrower near glass enclosures,

automobiles, window wells, drop offs etc. without proper

adjustment of the snow thrower discharge angle.

• Never direct discharge at bystanders or allow anyone in

front of the snow thrower.

• Never run the snow thrower into material at high

speeds.

• Do not overload the machine capacity by attempting to

clear snow at too fast a rate.

• Never operate the machine at high transport speed

on slippery surfaces. Look behind and use care when

backing up.

• Watch for trafc and stay alert when crossing or operating

near roadways.

• Disengage power to the snow thrower when transporting

or when not in use.

• Use only attachments and accessories approved by

the manufacturer of the snow thrower (such as wheel

weights, counter weights, cabs etc.)

• Never operate the snow thrower without good visibility

or light.

IMPORTANT:

Rear wheel weights and tire chains are required to

provide extra traction and stability when using this

snow thrower attachment. These items are available

where you purchased your tractor.

WHEEL WEIGHTS TIRE CHAINS

7

Page 8

REMOVE

FRONT SCREWS

REMOVE

BROWNING SHIELD

MOWER DECK

SUSPENSION

BRACKET

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

(2) 7/16" Wrenches

(2) 1/2" Wrenches

(2) 9/16" Wrenches

(2) 3/4" Wrenches

(1) Screw Driver

(1) Knife

ADDITIONAL ITEMS REQUIRED

General Purpose Grease

REMOVAL OF PARTS FROM CARTON

• Remove all parts and hardware packages from the

carton. Lay out parts and hardware and identify using

the illustrations on pages 2 and 5.

NOTE: Not all of the supplied parts and hardware will be

needed for your particular tractor. Unneeded items may

be discarded after you have completed assembly and

checked operation of unit. DO NOT DISCARD the two

spare shear bolts (N) and 5/16" nylock nuts (Y). Refer to

the Service and Adjustments section on page 28.

IDENTIFY YOU TRACT OR

STEP 1: (SEE FIGURE 1)

• Look under the front of your tractor. If there is a single

mower deck suspension bracket located underneath

the middle of the front axle, continue on to step 2.

If your tractor does not have a mower deck

suspension bracket underneath the middle of the

front axle, skip to step 21 on page 14 for tractors

with dual suspension brackets.

CAUTION: Before starting to assemble the

snow thrower, remove the spark plug wire(s),

set the parking brake and remove the key

from the tractor ignition.

TRACTOR PREPARATION

Before performing these instructions, refer to the Service

and Adjustments section of your tractor owner's manual

for specic safety instructions.

• Allow engine, mufer and exhaust deector to cool

before beginning.

• Remove any front or rear attachment which is

mounted to your tractor.

• Remove the mower deck. Refer to your tractor owner's

manual for removal instructions. Mark all loose parts

and save for reassembly.

• Remove the tractor hood. Refer to your tractor owner's

manual for removal instructions.

FIGURE 1

INSTRUCTIONS FOR TRACTORS WITH

SINGLE FRONT DECK SUSPENSION

BRACKET

STEP 2: (SEE FIGURE 2)

• Remove the browning shield from the front of the

tractor as shown. Hold onto the shield as you remove

the second screw to prevent it from falling.

• Be sure to reinstall the browning shield when so

instructed in step 3.

IMPORTANT: Right hand (R.H.) and left hand (L.H.) side

of the tractor are determined from the operators position

while seated on the tractor.

FIGURE 2 RIGHT SIDE VIEW

8

Page 9

5/16"

NYLOCK

NUT (Y)

5/16" x 1"

CARRIAGE BOLT (J)

ENGINE MOUNTING

PLATE

(4) 1/2" WASHERS (R)

(3) 3/8" FLANGE NUTS (X)

(3) 3/8" x 1"

CARRIAGE

BOLTS (G)

SEE NOTE

3/8" WASHER (T)

SHOULDER

BOLT (L)

3/8" FLANGED

NUT (X)

INSTALL SIDE PLATES

5/16" x 3/4" SELF

THREADING BOLT (F)

L.H. HANGER

BRACKET

BRAKE ROD

3/8" FLANGED

NUT (X)

SHOULDER

BOLT (M)

5/16" x 3/4" SELF

THREADING BOLT (F)

R.H. HANGER

BRACKET

RIGHT END OF

BRAKE ROD

3/8" FLANGED

NUT (X)

SHOULDER

BOLT (M)

STEP 3: (SEE FIGURE 3)

• Fasten the R.H. Side Plate (bend facing out) to the

front three holes in the tractor frame using three 3/8"

x 1" carriage bolts (G), three 1/2" washers (R) (see

note) and three 3/8" ange nuts (X). For the rear hole,

use a 5/16" x 1" carriage bolt (J), a 1/2" washer (R)

and a 5/16" nylock nut (Y). Place the 1/2" washers (R)

between the tractor frame and the side plate. Repeat

for L.H. side plate.

• Reinstall the browning shield onto the tractor frame

using the original screws.

NOTE: If there is an engine mounting plate (shown with

dotted lines) leave the 1/2 washer off the bolt that goes

through the plate.

INSTALL HANGER BRACKETS AND SHOULDER

BOLTS TO OUTSIDE OF FRAME

STEP 5: (SEE FIGURE 5)

Remove the bolt, if present, in the hole directly behind

•

the brake rod on the left side of the tractor frame.

• Attach the L.H. Hanger Bracket (tube facing out) to the

hole using a 5/16" x 3/4" self threading bolt (F).

• Install a round head shoulder bolt (M) into the hole

that is 9-1/2" to the rear of the bolt you just installed.

Secure it with a 3/8" ange nut (X) on the inside of the

frame.

FIGURE 3 RIGHT SIDE VIEW

STEP 4: (SEE FIGURE 4)

• Assemble a shoulder bolt (L) and a 3/8" washer (T) to

the outside of R.H. side plate, securing it with a 3/8"

anged nut (X). Repeat for L.H. side plate.

FIGURE 5 LEFT SIDE VIEW

STEP 6: (SEE FIGURE 6)

• Remove the bracket, if present, from the hole directly

behind the end of the brake rod on the right side of

the tractor frame. Store the bracket and bolt.

• Attach the R.H. Hanger Bracket to the hole using a

5/16" x 3/4" self threading bolt (F).

• Install a round head shoulder bolt (M) into the hole

that is 9-1/2" to the rear of the bolt you just installed.

Secure it with a 3/8" ange nut (X) on the inside of the

frame.

FIGURE 4 RIGHT SIDE VIEW

FIGURE 6 RIGHT SIDE VIEW

9

Page 10

3/8" X 3-1/4"

HEX BOLT

(A)

LARGE SPACER (MM)

PULLEY (NN)

3/8" LOCKWASHER (O)

3/8" HEX LOCK NUT (Z)

3/8"

WASHER (T)

LONG END

OF HUB

CABLE

BRACKET

5/16" x 3/4"

CARRIAGE BOLT (K)

5/16" NYLOCK

NUT (Y)

THIS SECTION IS FOR TRACTORS WITH A

HEX BOLTS

(#48138)

DRIVE BELT

FLAT IDLER

PULLEYS

5/16" NYLOCK

NUT (Y)

5/16" x 3/4"

HEX BOLT (C)

TENSIONING CHAIN (JJ)

MANUAL ATTACHMENT CLUTCH

If your tractor has an electric attachment clutch go to

step 14 on page 12.

STEP 7: (SEE FIGURE 7)

• Attach the pulley (long end of hub facing down) and

the large spacer (MM) to the hole shown in the clutch/

idler assembly. Use a 3/8" x 3-1/4" hex bolt (A), a 3/8"

washer (T), a 3/8" lock washer (O) and a 3/8" hex lock

nut (Z).

STEP 9: (SEE FIGURE 9)

• Attach the cable bracket to the slot shown in the

clutch/idler assembly using a 5/16" x 3/4" carriage

bolt (K) and a 5/16" nylock nut (Y). Place the bolt in

the front hole of the bracket and in the end of the slot

closest to the pulley. Do not tighten yet.

FIGURE 9

FIGURE 7

STEP 8: (SEE FIGURE 8)

• Attach the two suspension arms to the rear of the

clutch/idler assembly using two 5/16" x 3/4" hex bolts

(C) and 5/16" nylock nuts (Y) for each arm. Place the

arms on the outside of the frame with the notches to

the rear.

• Insert a tensioning chain through the hole shown and

attach the end link to the spring on the lower idler arm.

STEP 10: (SEE FIGURE 10)

• Two different length drive belts are included with

your snow thrower. Tractors with manual attachment

clutches and single front deck suspension brackets use

the 56" drive belt with #48138 printed on the outside of

the belt. DO NOT USE the other belt.

• Slightly loosen the hex bolt next to the at idler pulley.

Install the drive belt down between the hex bolt and the

at idler pulley with the at side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

Place the belt to the inside of the other at idler pulley.

FIGURE 10

FIGURE 8

10

STOP

Did you select the correct drive belt for your

tractor? Using the wrong length belt may

cause premature bearing or belt failure.

Page 11

PIVOT LOCK PIN (GG)

(use this hole)

SHOULDER

BOLT (M)

L.H. HANGER

BRACKET

1/8" HAIRPIN

COTTER (EE)

NYLON TIE (II)

MOWER

CLUTCH

CABLE

ENGINE

PULLEY

ENGINE

PULLEY

Left Side

of Tractor

ENGINE

PULLEY

KEEPER

ENGINE

PULLEY

KEEPER

KEEPER BOLT

IDLER

PULLEY

5/64" HAIR

COTTER PIN (DD)

1/4" WASHER (P)

SPACER (LL)

TRACTOR'S

CLUTCH CABLE

CABLE

BRACKET

5/64" HAIR

COTTER PIN (DD)

STEP 11: (SEE FIGURE 11)

• Find the cable clip that is attached to the left side

of the tractor frame underneath the footrest. Open

the clip and remove the mower clutch cable. Do not

remove the clip from the tractor frame. The cable

reattaches to the clip when using the mower deck.

• Move the attachment clutch lever on the dash panel to

the disengaged position.

• Place the clutch/idler assembly on the oor on the left

side of the tractor.

• Attach the tractor's mower clutch cable to the cable

bracket on the clutch/idler assembly. Secure the cable

housing guide (groove down) to the cable bracket

using the original collar and a 5/64" hair cotter pin (DD).

• Place a spacer (LL) on the welded pin on the idler

arm. Hook the end of the clutch cable spring over the

pin and secure it with a 1/4" washer (P) and a 5/64"

hair cotter pin (DD).

• Align cable bracket with welded pin and tighten the

nut assembled in step 9.

FIGURE 12 VIEWED FROM LEFT SIDE

STEP 13: (SEE FIGURE 13)

• Assemble the drive belt onto the engine pulley rst

and then onto the large pulley on top of the clutch/

idler assembly. The belt must be placed inside the

engine pulley belt keeper(s) and between the large

pulley and the keeper bolt next to it.

FIGURE 11

ATTACH CLUTCH IDLER ASSEMBLY TO TRACTOR

STEP 12: (SEE FIGURE 12)

• Attach the clutch/idler assembly to the tractor frame.

Hook the notched suspension arms onto the two

shoulder bolts (M) assembled to the outside of the

tractor frame. Lift the front of the assembly and attach

it to the R.H. and L.H. hanger brackets using two pivot

lock pins (GG) and 1/8" hairpin cotters (EE).

• Loosely attach the mower clutch cable to the left side

of the tractor frame with a nylon tie (II). Do not pull

the nylon tie completely tight. The cable may need to

be removed from the nylon tie when using the mower

deck.

IMPORTANT: Do Not assemble the "V" belt outside of

the engine pulley keepers or outside of the keeper bolt

next to the large pulley.

• Go to step 48 on page 21.

CLUTCH/IDLER ASSEMBLY

FIGURE 13 VIEWED FROM UNDERNEATH

11

Page 12

THIS SECTION IS FOR TRACTORS WITH AN

CHAIN

(L.H. SIDE)

3/32" HAIR

COTTER PIN (FF)

5TH LINK

LEFT

SIDE

3/8" HEX

LOCK NUT (Z)

SPRING

RIGHT

SIDE

ATTACH

SPRING

HERE

TENSIONING CHAIN (JJ)

LEFT FRONT HOLE

5/16" NYLOCK

NUT (Y)

5/16" x 3/4"

HEX BOLT (C)

TENSIONING CHAIN (JJ)

ELECTRIC ATTACHMENT CLUTCH

STEP 14: (SEE FIGURE 14)

• Attach the two suspension arms to the rear of the

clutch/idler assembly using two 5/16" x 3/4" hex bolts

(C) and 5/16" nylock nuts (Y) for each arm. Place the

arms on the outside of the frame with the notches to

the rear.

• Insert a tensioning chain through the hole shown and

attach the end link to the spring on the lower idler arm.

STEP 16: (SEE FIGURE 16)

• Hook one end of the spring supplied in the parts bag

through the end link of the tensioning chain.

• With the clutch/idler assembly turned upside down,

hook the other end of the spring onto the end of the

bolt and nut which secure the idler pulley to the upper

idler arm. Assemble a 3/8" hex lock nut (Z) onto the

bolt and nut, leaving enough gap between the nuts for

the spring to pivot freely.

• Attach a 3/32" hairpin cotter (FF) to the chain, placing

it in the fth link from the spring.

FIGURE 14

STEP 15: (SEE FIGURE 15)

• Turn the clutch/idler assembly upside down and insert

the second tensioning chain (JJ) through the left front

hole.

FIGURE 15

FIGURE 16 VIEW OF BOTTOM

SELECT THE CORRECT DRIVE BELT

(Electric clutch tractors with a single front deck

suspension bracket)

STEP 17: (SEE TABLE 1)

• Two different length drive belts are included with

your snow thrower. Use the table below to select

the correct drive belt for your type tractor. The part

number is printed on the outside of the belt .

• Set aside the belt that is not for your tractor to avoid

accidentally using it.

55" BELT (PART #46989)

TRACTOR TYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 38", 42" Electric

56" BELT (PART #48138)

TRACTOR TYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 48" Electric

(GT) Garden Tractor 48", 54" Electric

TABLE 1

12

Page 13

PIVOT LOCK PIN (GG)

(use second hole)

SHOULDER

BOLT (M)

1/8" HAIRPIN

COTTER (EE)

L.H. HANGER

BRACKET

1/8" HAIRPIN

COTTER (EE)

ENGINE

PULLEY

ENGINE

PULLEY

KEEPER

BOLT

IDLER

PULLEY

CHAIN (JJ)

(L.H. SIDE)

STEP 18: (SEE FIGURE 17)

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

• Turn the clutch/idler assembly right side up.

• Slightly loosen the hex bolt next to the at idler pulley.

Install the drive belt down between the hex bolt and the

at idler pulley with the at side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

FIGURE 17

STEP 20: (SEE FIGURE 19)

• Assemble the drive belt onto the engine pulley rst

and then onto the large pulley on top of the clutch/

idler assembly. Place the belt to the inside of the idler

pulley and the belt keeper bolt located beside the

large pulley.

• Place tension on the belt by pulling the left side

tensioning chain (JJ) out as far as the 3/32" hairpin

cotter in the chain will allow. Secure the chain in this

position by inserting a 1/8" hairpin cotter (EE) through

the chain.

IMPORTANT: Do Not assemble the drive belt around the

outside of the keeper bolt beside the large pulley.

• Go to step 48 on page 22.

CLUTCH/IDLER ASSEMBLY

STOP

STEP 19: (SEE FIGURE 18)

• Attach the clutch/idler assembly to the tractor frame.

Hook the notched suspension arms onto the two

shoulder bolts (M) assembled to the outside of the

tractor frame. Lift the front of the assembly and attach

it to the R.H. and L.H. hanger brackets using two pivot

lock pins (GG) and 1/8" hairpin cotters (EE).

Did you choose the correct drive belt for

your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

FIGURE 19 VIEWED FROM UNDERNEATH

FIGURE 18 VIEWED FROM LEFT SIDE

13

Page 14

(3) 3/8" x 1"

THREAD FORMING

BOLTS (E)

5/16" FLANGED

NUT (W)

(SEE NOTE)

(3) 3/8" LOCK

WASHERS (O)

1/2" WASHER (R)

5/16" x 1"

CARRIAGE BOLT (J)

(SEE NOTE)

SUSPENSION

BRACKET

REMOVE BOLTS

IF PRESENT

FRONT

SUSPENSION

BRACKET

REPLACE BOLT

(IF PRESENT)

REMOVE BOLTS

(IF PRESENT)

INSTRUCTIONS FOR TRACTORS WITH DUAL

3/8" WASHER (T)

SHOULDER

BOLT (L)

3/8" FLANGED

NUT (X)

(3) 3/8" x 1"

THREAD FORMING

BOLTS (E)

(3) 3/8" LOCK

WASHERS (O)

3/8" FLANGED NUT (X)

(SEE NOTE)

(3) 1/2" WASHERS (R)

FRONT DECK SUSPENSION BRA CKETS

FASTEN SIDE PLATES TO TRACTOR

If your tractor resembles gure 20, go to step 21.

If your tractor resembles gure 22, go to step 23.

STEP 21: (SEE FIGURE 20)

Remove bolts from front three holes shown.

•

• If a bolt is present in the fourth hole, replace it with a

5/16" x 1" carriage bolt (J) without a nut. The bracket

fastened to inside of frame must remain in place.

STEP 23: (SEE FIGURE 22)

•

Remove any bolts found in the holes shown.

FIGURE 22 RIGHT SIDE VIEW

STEP 24: (SEE FIGURE 23)

• Fasten the R.H. Side Plate (bend facing out) to the

three holes shown in the tractor frame. Use three 3/8"

x 1" thread forming bolts (E), 3/8" lock washers (O)

and 1/2" washers (R). Use the 1/2" washers as shims

between the Side Plate and the tractor frame. Tighten

all bolts and repeat for the L.H. side.

NOTE: If the bolt inserts freely into the front hole, assemble

a 3/8" anged nut (X) onto the bolt.

FIGURE 20 RIGHT SIDE VIEW

STEP 22: (SEE FIGURE 21)

• Fasten the R.H. Side Plate (bend facing out) to the

front three holes shown in the tractor frame using

three 3/8" x 1" thread forming bolts (E), three 3/8"

lock washers (O) and one 1/2" washer (R) placed on

the third bolt as a shim between the side plate and

the frame. Tighten all bolts. Repeat for the L.H. side.

NOTE: If you installed a bolt in the fourth hole in step 21,

assemble a 5/16" ange nut (W) onto the bolt after the

side plate is installed.

• Go to step 25 on this page.

FIGURE 23 RIGHT SIDE VIEW

STEP 25: (SEE FIGURE 24)

Assemble a shoulder bolt (L) and a 3/8" washer (T) to

•

the outside of each side plate, securing them with a

3/8" anged nut (X).

FIGURE 21 RIGHT SIDE VIEW

FIGURE 24 RIGHT SIDE VIEW

14

Page 15

INSTALLING HANGER BRACKETS

BOLT REMOVED

FROM THIS HOLE

SWAY BAR

BRACKET

SHOULDER BOLT (L)

3/8"

FLANGED

NUT (X)

3/8" x 1"

CARRIAGE

BOLT (G)

3/8" FLANGED

NUT (X)

L.H. HANGER

BRACKET

SUSPENSION ARM

SHOULDER BOLT (L)

3/8"

FLANGED

NUT (X)

R.H. HANGER BRACKET

BOLT REMOVED

FROM THIS HOLE

3/8" x 1"

CARRIAGE

BOLT (K)

3/8" FLANGED

NUT (X)

L.H. HANGER

BRACKET

SUSPENSION ARM

For better clearance, lower the tractor's suspension arms

using the attachment lift lever.

STEP 26: (SEE FIGURE 25 or 26)

On Tractors With Foot Rest Brackets

• Remove the bolt and nut that fasten the L.H. and R.H.

foot rest brackets to the frame.

• Attach the L.H. Hanger Bracket (marked "L") to the

inside of the tractor frame using two 3/8" x 1" carriage

bolts (G) and 3/8" anged nuts (X). Bolt heads go on

inside of tractor frame. Repeat for the R.H. side.

INSTALLING SHOULDER BOLTS

STEP 27: (SEE FIGURE 27)

• Remove the bolt, washer and nut which fasten the

sway bar bracket to the L.H. side of the tractor frame.

Replace with a shoulder bolt (L) and a 3/8" anged

nut (X). Bolt goes on inside of frame.

FIGURE 25 LEFT SIDE VIEW

On Tractors Without Foot Rest Brackets

• Find the empty hole beneath the foot rest. Attach the

L.H. Hanger Bracket (marked "L") to the inside of the

frame using a 3/8" x 1" carriage bolt (G) and a 3/8"

anged nut (X). Bolt head goes on inside of tractor

frame. Repeat for the R.H. side.

FIGURE 27 LEFT SIDE VIEW

STEP 28: (SEE FIGURE 28)

• Assemble a shoulder bolt (L) and 3/8" anged nut (X)

to the R.H. side of the tractor frame, using the rst

empty hole to the rear of the R.H. hanger bracket. Bolt

goes on inside of frame.

FIGURE 26 LEFT SIDE VIEW

FIGURE 28 RIGHT SIDE VIEW

15

Page 16

INSTALLING CLUTCH/IDLER ASSEMBLY

ENGAGEMENT ROD

5/64" HAIRPIN

COTTER (DD)

TRACTOR'S CLUTCH ARM

SUSPENSION ARM

TRUNNION (CC)

REMOVE EXTENSION,

BOLT AND NUT

(IF PRESENT)

5/16" x 3/4"

HEX BOLT (C)

5/16" NYLOCK

NUT (Y)

TENSIONING CHAIN (JJ)

5/16" WASHER (Q)

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

This section covers the installation of the Clutch/Idler

assembly to tractors with attachment clutches that are

either rod operated (p. 16), cable operated (p. 19) or

electric (p. 20). Use the appropriate instructions for your

tractor.

ROD OPERATED MANUAL ATTACHMENT CLUTCH

STEP 29: (SEE FIGURE 29)

• Move the attachment clutch lever on the dash panel to

the disengaged (down) position.

• Screw the trunnion (CC) onto the end of the snow

thrower engagement rod.

• Locate the clutch arm (where the mower clutch rod

was connected) underneath the right hand side the

tractor, just to the inside of the suspension arm. If

there is an extension attached to the clutch lever, the

extension, bolt and nut must be removed and stored

with the mower deck.

IMPORTANT: Re-attach the extension to the clutch

lever before reinstalling the mower deck.

• Position the engagement rod to the inside of the

clutch arm and insert the drilled end of the rod

through the arm. Secure with a 5/64" hairpin cotter

(DD).

FIGURE 30

STEP 31: (SEE FIGURE 31)

• Two different length drive belts are included with

your snow thrower. Tractors with manual attachment

clutches and dual front deck suspension brackets use

the 55" drive belt with #46989 printed on the outside

of the belt. DO NOT USE the other belt.

• Slightly loosen the hex bolt next to the at idler pulley.

Install the drive belt down between the hex bolt and the

at idler pulley with the at side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

FIGURE 29 RIGHT SIDE VIEW

STEP 30: (SEE FIGURE 30)

• Attach the two suspension arms to the inside of the

clutch/idler assembly using two 5/16" x 3/4" hex bolts

(C), 5/16" washers (Q) and 5/16" nylock nuts (Y) for

each arm. Place the washers between the arms and

the assembly frame.

• Insert a tensioning chain through the hole shown and

attach the end link to the spring on the lower idler arm.

(#46989)

FIGURE 31

16

STOP

Did you choose the correct drive belt for

your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

Page 17

PIVOT LOCK PIN (GG)

(use second hole)

1/8" HAIRPIN COTTER (EE)

ENGAGEMENT

ROD

IDLER ARM

5/64" HAIRPIN

COTTER (DD)

TRUNNION (CC)

STOP BOLT

3/8" THIN

WASHER (S)

NEW ENGINE PULLEY KEEPER WITH

ORIGINAL BOLT, NUT AND WASHER

ENGINE

PULLEY

KEEPER BOLT

IDLER

PULLEY

ENGINE

PULLEY

KEEPER

Left Side

of Tractor

STEP 32: (SEE FIGURE 32)

• Be sure to lift up the front end of the engagement rod

as shown when performing the next operation. You

can temporarily support the rod using a rubber band

tied to the engine pulley keeper.

• Attach the clutch/idler assembly to the tractor frame

as follows. Hook the assembly's notched arms onto

the two shoulder bolts you assembled to the inside

of the tractor frame. Lift the front of the assembly and

attach it to the R.H. and L.H. hanger brackets using

two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

FIGURE 33 RIGHT SIDE VIEW

STEP 34: (SEE FIGURE 34)

• Assemble the short "V" belt onto the engine pulley

and then onto the large pulley on top of the clutch/

idler assembly. The belt must be placed to the inside

of the engine pulley keeper, the idler pulley and the

keeper bolt located beside the large pulley.

FIGURE 32 RIGHT SIDE VIEW

STEP 33: (SEE FIGURE 33)

• Make sure the attachment clutch lever on the dash

panel is in the disengaged (down) position.

• Pivot the upper idler arm so that it rests against the

stop bolt and is pointing toward the front as shown.

Screw the trunnion (CC) along the threads of the

engagement rod until it is aligned at the front end of

the idler arm slot. Attach the trunnion (CC) to the slot

using the 3/8" thin washer (S) and a 5/64" hairpin

cotter (DD).

• Remove the engine pulley keeper from the side of

the tractor frame by removing the washer and nut

that secure the keeper. Attach the new pulley keeper

supplied with the snow thrower, reusing the original

bolt, washer and nut.

NOTE: Some tractors may already be equipped with a

pulley keeper that is identical to the new one supplied.

IMPORTANT: Do Not assemble the "V" belt around the

outside of the engine pulley keeper or the keeper bolt.

• Go to step 48 on page 22.

CLUTCH/IDLER ASSEMBLY

FIGURE 34 VIEWED FROM UNDERNEATH

17

Page 18

CABLE

BRACKET

5/16" x 3/4"

CARRIAGE BOLT (K)

5/16" NYLOCK

NUT (Y)

42"

DECKS

46"

DECKS

TRACTOR'S

CLUTCH CABLE

5/64" HAIR

COTTER PIN (DD)

1/4" WASHER (P)

SPACER (LL)

5/64" HAIR

COTTER PIN (DD)

5/16" x 3/4"

HEX BOLT (C)

5/16" NYLOCK

NUT (Y)

TENSIONING CHAIN (JJ)

5/16" WASHER (Q)

CABLE OPERATED MANUAL ATTACHMENT CLUTCH

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

STEP 35: (SEE FIGURE 35)

• Attach the two suspension arms to the rear of the

clutch/idler assembly using two 5/16" x 3/4" hex bolts

(C), 5/16" washer (Q) and 5/16" nylock nuts (Y) for

each arm. Place the arms on the outside of the frame

with the notches to the rear.

• Insert a tensioning chain through the hole shown and

attach the end link to the spring on the lower idler arm.

• Slightly loosen the hex bolt next to the at idler pulley.

Install the drive belt down between the hex bolt and the

at idler pulley with the at side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

(#46989)

FIGURE 37

Did you choose the correct drive belt for

STOP

your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

FIGURE 35

STEP 36: (SEE FIGURE 36)

• Assemble the cable bracket to the clutch/idler

assembly using two 5/16" x 3/4" carriage bolts (K) and

5/16" nylock nuts (Y). Use the two front holes in the

cable bracket if your tractor has a 42" mower deck.

Use the two rear holes if your tractor has a 46" mower

deck.

STEP 38: (SEE FIGURE 38)

• Move the attachment clutch lever on the dash panel to

the disengaged (down) position.

• Place the clutch/idler assembly on the oor on the right

side of the tractor.

• Attach the tractor's clutch cable to the cable bracket.

Secure the cable housing guide (groove down) to the

cable bracket using the original collar and a 5/64" hair

cotter pin (DD).

• Place a spacer (LL) on the welded pin on the idler arm.

Hook the end of the clutch spring over the pin and

secure it with a 1/4" washer (P) and a 5/64" hair cotter

pin (DD).

FIGURE 36

STEP 37: (SEE FIGURE 37)

• Two different length drive belts are included with

your snow thrower. Tractors with manual attachment

clutches and dual front deck suspension brackets use

the 55" drive belt with #46989 printed on the outside

of the belt. DO NOT USE the other belt.

FIGURE 38

18

Page 19

STEP 39: (SEE FIGURE 39)

NEW ENGINE PULLEY KEEPER WITH

ORIGINAL BOLT, NUT AND WASHER

PIVOT LOCK PIN (GG)

(use second hole)

1/8" HAIRPIN COTTER (EE)

ENGINE

PULLEY

KEEPER BOLT

IDLER

PULLEY

ENGINE

PULLEY

KEEPER

Left Side

of Tractor

• Remove the engine pulley keeper from the side of

the tractor frame by removing the washer and nut

that secure the keeper. Attach the new pulley keeper

supplied with the snow thrower, reusing the original

bolt, washer and nut.

NOTE: Some tractors may already be equipped with a

pulley keeper that is identical to the new one supplied.

STEP 40: (SEE FIGURE 40)

• Assemble the short "V" belt onto the engine pulley

and then onto the large pulley on top of the clutch/idler

assembly. The belt must be placed to the inside of the

engine pulley keeper, the idler pulley and the keeper

bolt located beside the large pulley.

IMPORTANT: Do Not assemble the "V" belt around the

outside of the engine pulley keeper or the keeper bolt.

• Attach the clutch/idler assembly to the tractor frame

as follows. Hook the assembly's notched arms onto

the two shoulder bolts you assembled to the inside

of the tractor frame. Lift the front of the assembly and

attach it to the R.H. and L.H. hanger brackets using

two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

• Go to step 48 on page 22.

CLUTCH/IDLER ASSEMBLY

FIGURE 39

FIGURE 40 VIEWED FROM UNDERNEATH

19

Page 20

ELECTRIC ATTACHMENT CLUTCHES

TENSIONING CHAIN (JJ)

LEFT FRONT HOLE

CHAIN

(L.H. SIDE)

3/32" HAIR

COTTER PIN (FF)

5TH LINK

LEFT

SIDE

3/8" HEX

LOCK NUT (Z)

SPRING

RIGHT

SIDE

ATTACH

SPRING

HERE

5/16" x 3/4"

HEX BOLT (C)

5/16" NYLOCK

NUT (Y)

TENSIONING CHAIN (JJ)

5/16" WASHER (Q)

STEP 41: (SEE FIGURE 41)

• Attach the two suspension arms to the rear of the

clutch/idler assembly using two 5/16" x 3/4" hex bolts

(C), 5/16" washer (Q) and 5/16" nylock nuts (Y) for

each arm. Place the arms on the outside of the frame

with the notches to the rear.

• Insert a tensioning chain through the hole shown and

attach the end link to the spring on the lower idler arm.

STEP 43: (SEE FIGURE 43)

• Hook the spring from the parts bag through the end of

the tensioning chain.

• Hook the other end of the spring onto the bottom of

the bolt and nut which secure the idler pulley to the

upper idler arm. Hold the bolt head and assemble a

3/8" hex lock nut (Z) onto the bolt, leaving enough

space for the spring to pivot freely between the two

nuts.

• Attach a 3/32" hairpin cotter (FF) to the chain, placing

it in the fth link from the spring.

FIGURE 41

STEP 42: (SEE FIGURE 42)

• Pace the extra tensioning chain (JJ) through the left

front hole in the clutch/idler assembly and then turn

the assembly upside down.

FIGURE 42

FIGURE 43 VIEW OF BOTTOM

STEP 44: (SEE TABLE 2)

• Two different length drive belts are included with

your snow thrower. Use the table below to select

the correct drive belt for your type tractor. The part

number is printed on the outside of the belt .

• Set aside the belt that is not for your tractor to avoid

accidentally using it.

55" BELT (PART #46989)

TRACTOR TYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 38", 42", 46" Electric

56" BELT (PART #48138)

TRACTOR TYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 48" Electric

TABLE 2

20

Page 21

1/8" HAIRPIN

COTTER (EE)

ENGINE

PULLEY

ENGINE

PULLEY

Left Side

of Tractor

KEEPER

BOLT

IDLER

PULLEY

PIVOT LOCK PIN (GG)

(use second hole)

1/8" HAIRPIN COTTER (EE)

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

STEP 45: (SEE FIGURE 44)

• Turn the clutch/idler assembly right side up.

• Slightly loosen the hex bolt next to the at idler pulley.

Install the drive belt down between the hex bolt and the

at idler pulley with the at side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

Place the belt to the inside of the other at idler pulley.

FIGURE 44

STEP 47: (SEE FIGURE 46)

• Assemble the drive belt onto the engine pulley and

then onto the large pulley on top of the clutch/idler

assembly. The belt must be placed to the inside of

the idler pulley and the keeper bolt located beside the

large pulley.

• Place tension on the belt by pulling the left side

tensioning chain out as far as the 3/32" hairpin cotter

(FF) will allow. Secure the chain in this position by

inserting a 1/8" hairpin cotter (EE) through the chain.

IMPORTANT: Do Not assemble the "V" belt around the

outside of the engine pulley keeper or the keeper bolt.

CLUTCH/IDLER ASSEMBLY

Did you choose the correct drive belt for

STOP

your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

STEP 46: (SEE FIGURE 45)

• Attach the clutch/idler assembly to the tractor frame

as follows. Hook the assembly's notched arms onto

the two shoulder bolts you assembled to the inside

of the tractor frame. Lift the front of the assembly and

attach it to the R.H. and L.H. hanger brackets using

two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

FIGURE 46 VIEWED FROM UNDERNEATH

FIGURE 45 RIGHT SIDE VIEW

21

Page 22

LIFT RELEASE

CABLE

HEX NUT

LOCK

WASHER

HEX NUT

CABLE

WIRE

LIFT

ROD

TRIGGER

ASSEMBLY

5/16" NYLOCK NUT (Y)

5/16" x 1-3/4"

HEX BOLT (B)

ASSEMBLY OF THE SNOW THROWER

CHUTE CRANK ROD

CRANK SUPPORT TUBE

TILT CONTROL HANDLE

5/16" x 1-3/4"

CARRIAGE BOLT (H)

BOWED WASHER (U)

5/16" NYLOCK NUT (Y)

TILT

CONTROL

ASSEMBLY

5/16" NYLOCK NUT (Y)

5/16" x 1-1/4"

CARRIAGE BOLT (I)

CRANK ROD

SUPPORT TUBE

DISCHARGE

HOUSING

STEP 48: (SEE FIGURE 47)

• Place the lift handle into the lift bracket on the right side

of the snow thrower. Fasten the handle to the bracket

using two 5/16" x 1-3/4" hex bolts (B) and 5/16" Nylock

nuts (Y).

FIGURE 47 RIGHT SIDE VIEW

STEP 50: (SEE FIGURE 49)

• Tilt the snow thrower back down to the ground.

• Remove the nylon tie which fastens the auger

drive belt to the discharge housing, leaving the belt

assembled around the pulleys.

• Remove the nylon tie which fastens the chute crank

rod to the crank rod support tube.

• Assemble the crank rod support tube to the bracket

on the left side of the discharge housing using two

5/16" x 1-1/4" carriage bolts (I), and 5/16" Nylock nuts

(Y).

NOTE: Be sure the lift release cable's plastic covering

stays inserted into the trigger assembly for the next step.

STEP 49: (SEE FIGURE 48)

• Push the lift handle down into the locked position.

HINT: For easier assembly of the lift release cable, tilt the

snow thrower forward onto the spiral auger.

Insert the end of the cable wire into the hole in the

lift rod. Place the threaded tting into the slot in the

lift bracket, with one hex nut above and one hex nut

and the lock washer below the slot. Tighten the nuts,

adjusting them to eliminate slack in the cable wire.

Refer also to the Service and Adjustments section on

page 28 in this manual.

FIGURE 49 LEFT SIDE VIEW

STEP 51: (SEE FIGURE 50)

• Attach the chute tilt control assembly to the top side

of the crank support tube using two 5/16" x 1-3/4"

carriage bolts (H), bowed washers (U) and 5/16"

Nylock nuts (Y).

FIGURE 48 RIGHT SIDE VIEW

FIGURE 50 LEFT SIDE VIEW

22

Page 23

5/16" NYLOCK NUT (Y)

CHUTE CRANK

BRACKET

5/16" WASHER (Q)

CHUTE

CRANK

ROD

ROD

SUPPORT

BRACKET

5/16" x 1"

CARRIAGE BOLT (J)

SPIRAL

CHUTE KEEPER (BB)

ANTI-ROTATION

BRACKET

1/4" FLANGED

LOCK NUT (V)

1/4" FLAT

WASHER (P)

1/4" x 1"

HEX BOLT (D)

PLASTIC CAP (HH)

GREASED

SURFACE

FLANGE

STEP 52: (SEE FIGURE 51)

STOP BOLT

• Attach the chute crank rod assembly brackets to

the plastic bracket on the left side of the discharge

housing. Align the chute crank bracket beneath the

rod support bracket and assemble both to the plastic

bracket using two 5/16" x 1" carriage bolts (J), 5/16"

washers (Q) and 5/16" Nylock nuts (Y). Do not

tighten yet.

STEP 53: (SEE FIGURE 52)

• Coat the top of the ring around the discharge opening

with general purpose grease.

• Place the discharge chute (facing forward) onto the

ring. Place the anti-rotation bracket on top of the chute

ange, aligning it with the holes on the right hand side

of the ange. Attach the three chute keepers (BB)

(right side up as shown) to the bottom of the ange

using six 1/4" x 1" hex bolts (D), 1/4" at washers (P)

and 1/4" anged lock nuts (V). Tighten carefully so

that the nuts are snug but do not dig into the plastic

chute keepers.

• Place the plastic cap (HH) onto the short end of the

anti-rotation bracket.

• Position the crank rod spiral (see gure 51) so that it

does not rub against the bottoms of the notches in the

chute ange. Tighten the nuts.

• Check if the crank rod rotates the chute freely. If not,

loosen by 1/4 turn each of the six hex bolts holding

the chute keepers to the chute ange.

• Secure the control cables to the crank rod support

tube using a nylon tie (II).

FIGURE 51 LEFT SIDE VIEW

FIGURE 52 RIGHT SIDE VIEW

STEP 54: (SEE FIGURE 53)

Skip this step if you have a lawn tractor.

This step is for garden tractors only.

• If you have a (GT) Garden Tractor, remove the stop

bolts from each side of the snow thrower frame.

FIGURE 53 RIGHT SIDE VIEW

23

Page 24

ATTACHING SNOW THROWER TO TRACTOR

IDLER

PULLEY

AUGER PULLEY

TWIST

1/4 TURN

TWIST

1/4 TURN

IDLER

PULLEY

ATTACHMENT PIN

(After installing auger belt)

1/8" HAIRPIN

COTTER (EE)

SHOULDER

BOLT

MOUNTING

PLATE

SIDE PLATE

IDLER

ARM

REAR

PULLEY

LEFT SIDE

OF

TRACTOR

NOTE: An additional person's help may be required to

mount the snow thrower to the front of the tractor.

STEP 55: (SEE FIGURE 54)

• Place the tractor and snow thrower on a at, level

surface so that the tractor can be rolled forward to

attach the snow thrower.

• Remove the Attachment Pin from the snow thrower.

• Extend the auger belt out behind the snow thrower,

making sure the belt is still looped over the top of

the large drive pulley and underneath the two idler

pulleys. The "V" side of the belt must be seated in the

grooves of all three pulleys.

• Roll the tractor up behind the snow thrower, centering

it between the snow thrower's mounting plates.

• Raise the rear of the snow thrower by lifting up on

the lift handle until the notches in the mounting plates

align with the shoulder bolts in the tractor's side

plates. Guide the bolts into the notches.

• To ease the assembly of the auger drive belt, delay

the installation of the attachment pin until you have

assembled the belt as instructed in steps 56 and 57.

BEFORE INSTALLING THE AUGER BELT

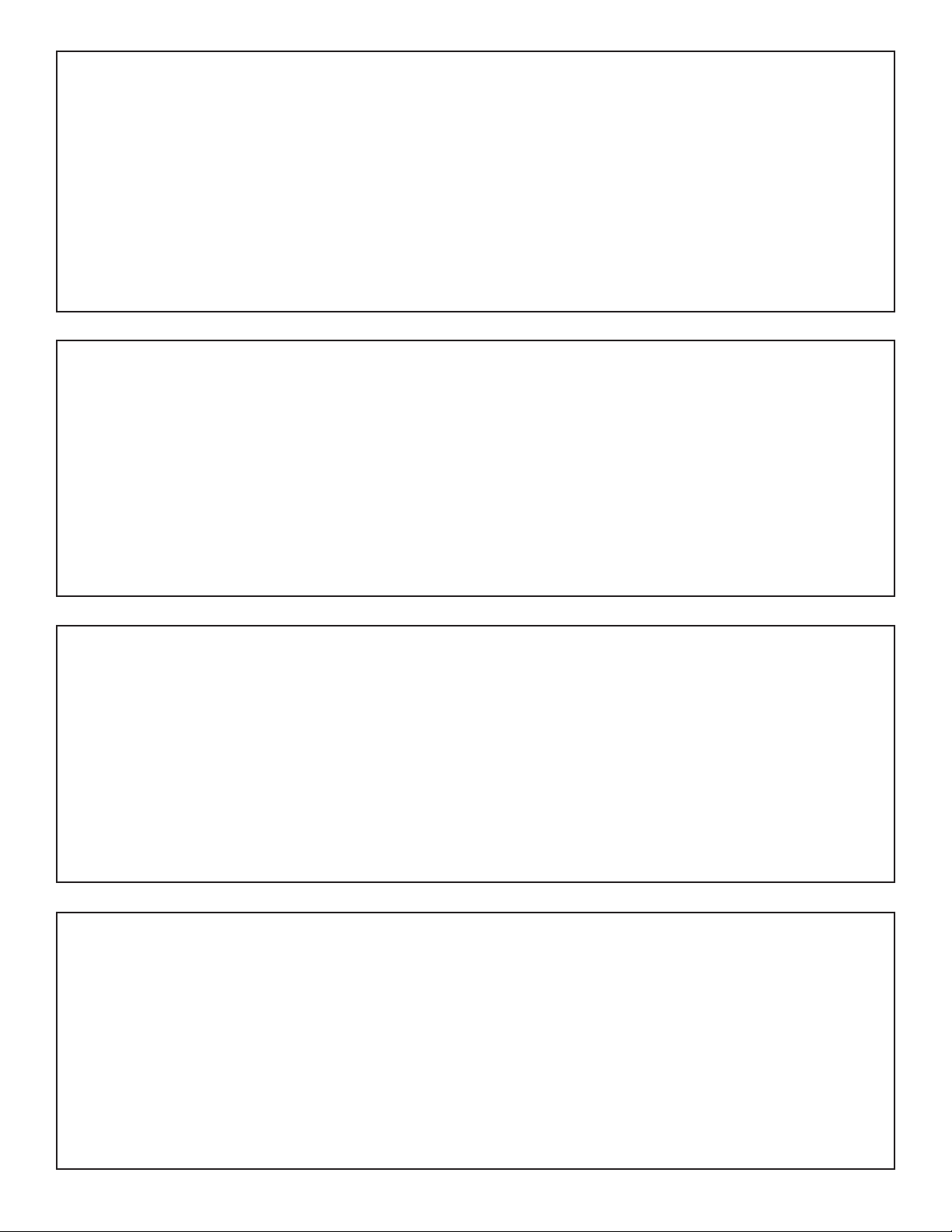

STEP 56: (SEE FIGURE 55)

• The auger belt comes preassembled to the pulleys on

the snow thrower housing. Make sure the belt passes

over the top of the auger pulley and then twists 1/4

turn to pass underneath each side idler pulley. The

"V" side of the belt must mate with the grooves of the

pulleys.

FIGURE 55

FIGURE 54 RIGHT SIDE VIEW

INSTALLING THE AUGER BELT

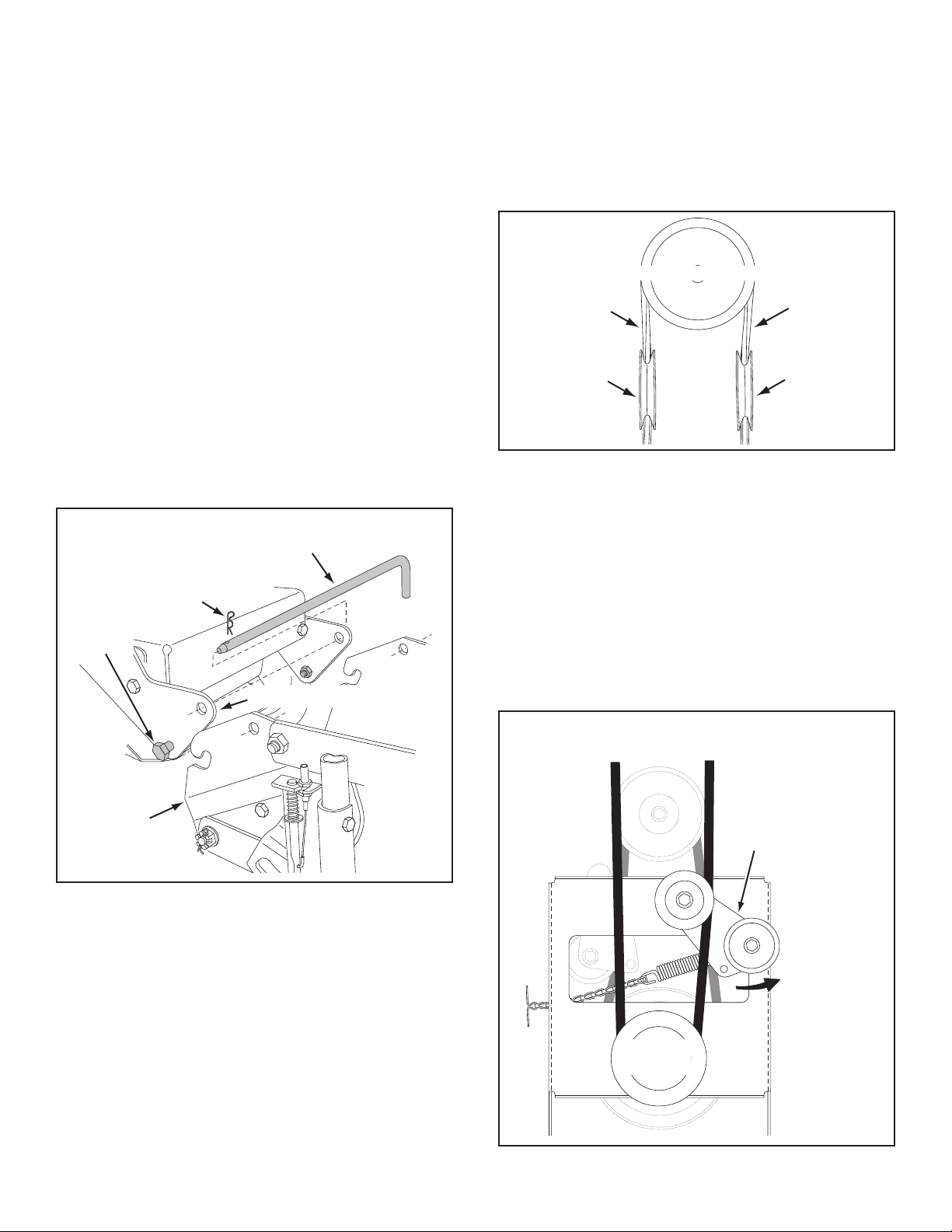

STEP 57: (SEE FIGURE 56)

• Push the lift handle down to increase slack in the belt

(attachment pin must rst be removed).

• Swing the idler arm over to the left side.

• Place the auger belt around the rear pulley and

between the two pulleys on the idler arm. The "V" side

of the belt must be seated in the grooves of the v-

pulleys.

CLUTCH/IDLER ASSEMBLY

FIGURE 56 VIEWED FROM UNDERNEATH

24

Page 25

INSTALLING THE ATTACHMENT PIN

END OF

SPRING

1/8"

HAIRPIN

COTTER (EE)

LEFT SIDE

OF

TRACTOR

FLAT

PULLEY

REAR REFLECTORS (KK)

STEP 58: (REFER BACK TO FIGURE 54 ON PAGE 24)

• Lift the front of the snow blower to align the holes in

the mounting plates and the side plates. From the left

side of the tractor insert the attachment pin through

the holes. Secure it with by reinstalling the 1/8" hairpin

cotter (EE).

SETTING THE AUGER BELT TENSION

STEP 59: (SEE FIGURE 57)

• Pull the tensioning chain until the end of the spring is

pulled through the hole in the side of the Clutch/Idler

assembly. Install a 1/8" hairpin cotter (EE) through

the end of the spring, securing it on the outside of the

Clutch/Idler assembly.

IMPORTANT: For correct belt tension, the 1/8" hairpin

cotter must attach to the end of the spring, not to the

chain.

NOTE; To prevent the chain from dragging on the

ground, loop the end of the chain though the pivot lock

pin. Refer to gure 45 on page 21.

ATTACH REFLECTORS TO REAR FENDER

STEP 59: (SEE FIGURE 58)

• If your tractor is not equipped with rear reectors,

assemble the supplied rear reectors (KK) to the rear

fender. Place the reectors as close to the bottom of

the fender and as far apart as the shape of the fender

will allow.

FIGURE 57 VIEWED FROM UNDERNEATH

CLUTCH/IDLER ASSEMBLY

FIGURE 58

CHECKLIST

Before you operate your snow thrower, please review the

following checklist to help ensure that you will obtain

the best performance from your snow thrower.

1. All assembly instructions have been completed with all

bolts and nuts properly tightened.

2. Check the engine belt and the auger belt. Make sure

they are routed properly around pulleys and inside all

belt keepers.

3. Check discharge chute for proper rotation.

4. Check operation of tilt control for upper chute.

5. Verify that the lift handle will lock into and release from

the raised transport position. (Refer to the Service and

Adjustments section.)

6. Check skid shoe adjustment. (Refer to the Service and

Adjustments section.)

Operating instructions begin on page 26.

25

Page 26

OPERATION

LIFT HANDLE

LIFT RELEASE TRIGGER

CRANK ROD

CHUTE TILT HANDLE

UPPER CHUTE

LOWER CHUTE

SPIRAL AUGERS, R.H. & L.H.

SKID SHOE

SCRAPER PLATE

KNOW YOUR SNOW THROWER

Read this owner's manual and safety rules before operating your snow thrower.

Compare the illustration below with your snow thrower to familiarize yourself with the various controls and their locations.

CHUTE TILT HANDLE Pivots the Upper Chute up or

down to control the angle and distance of discharge.

CRANK ROD Rotates the Lower and Upper Chutes to

control the direction of discharge.

LIFT HANDLE Used to lift or lower the snow thrower

to transport or operating position.

LIFT RELEASE TRIGGER Releases the lock which

holds the snow thrower in the transport position

BEFORE STARTING

• Use the end of assembly checklist to verify that all

instructions have been properly completed.

• Make sure the skid shoes are adjusted to maintain

adequate ground clearance between the snow

thrower and the type of surface to be cleared. (Refer

to the Service and Adjustments section.)

• Make sure the tractor engine has the correct oil

for winter operation (SAE 5W-30). Refer to tractor

owner's manual.

HOW TO START YOUR SNOW THROWER

• The tractor should be sitting with the engine running

at full throttle. Move the attachment clutch to the

engaged position, starting the snow thrower before

the tractor clutch is engaged.

HOW TO STOP YOUR SNOW THROWER

• To stop the snow thrower, disengage the tractor's

attachment clutch lever for manual clutches or the

clutch switch for electric clutches. Refer to your tractor

owner's manual.

UPPER AND LOWER DISCHARGE CHUTE Controls

direction and height of snow discharge.

SCRAPER PLATE Replaceable plate that absorbs

wear and impact from contact with ground.

SKID SHOE Controls amount of clearance between

the scraper plate and the ground.

SPIRAL AUGER, R.H. & L.H. Feed snow to the

impeller fan at the center of the housing.

HOW TO USE YOUR SNOW THROWER

CONTROLLING SNOW DISCHARGE

• To control the direction snow is thrown, the discharge

• To control the distance snow is thrown, the upper

26

CAUTION: Never direct discharge

towards bystanders or windows. Do not

allow anyone in front of unit.

chute has 180 degrees of rotation. Turn the crank rod

clockwise to rotate the chute to the right. Turn the

crank rod counterclockwise to rotate the chute to the

left.

section of the discharge chute pivots up and down.

Push forward on the chute tilt handle to pivot the

chute down, decreasing the distance snow is thrown.

Pull back on the handle to pivot the chute up,

increasing the distance snow is thrown.

Page 27

RAISING AND LOWERING

• To raise, push down on the lift handle until the snow

thrower locks in the raised transport position.

• To lower, push down slightly on the lift handle and pull

the trigger. With the trigger pulled, slowly lower the

snow thrower until it reaches the ground.

CAUTION: Do not operate the snow

thrower without the rear weight attached

to the tractor to provide extra traction and

stability.

REMOVING SNOW

Snow removal conditions vary greatly from light uffy

snowfall to wet heavy snow. Operating instructions must

be exible to t the conditions encountered. The operator

must adapt the lawn tractor and snow thrower to depth of

snow, wind direction, temperature and surface conditions.

• Before beginning operation, thoroughly inspect the

area of operation and remove all door mats, sleds,

boards, wires and other foreign objects.

• The spiral auger speed is directly related to engine

speed. For maximum snow removal and discharge,

maintain high engine r.p.m. (full throttle). It is advisable

to operate the lawn tractor at a slow ground speed

(1st gear) for safe and efcient snow removal.

• In deep, drifted or banked snow it will be necessary to

use full throttle and a slow ground speed (1st gear).

Drive forward into the snow, depress the tractor's

clutch-brake pedal and allow the spiral auger to clear

the snow. Repeat this method until a path is cleared.

On the second pass, overlap the rst enough to allow

the snow thrower to handle the snow without repeated

stopping and starting of forward motion.

• In extremely deep snow, raise the snow thrower from

the ground to remove the top layer and drive forward

only until the tractors front tires reach the uncleared

bottom layer of snow. Depress the tractor's clutchbrake pedal and allow the spiral auger to clear the

snow. Reverse the tractor and lower the snow thrower

to the ground. Drive the tractor forward until the snow

again becomes too deep. Repeating this process into

and out of drifts will eventually clear even the deepest

of snow piles.

• If the snow thrower becomes clogged with snow or

jammed with a foreign object, disengage the snow

thrower immediately and shut off the tractor engine.

Unclog the snow thrower before resuming operation.

DANGER: Shut off engine and

disengage snow thrower before

unclogging discharge chute. Unclog using

a wooden stick, not your hands.

OPERATING TIPS

• Discharge snow down wind whenever possible.

• To help prevent snow from sticking to the snow thrower,

allow the snow thrower to reach outdoor temperature

before using it. A light coat of wax may also be applied

to the inside surface of the snow thrower housing and

discharge chute.

• Use tire chains to improve traction.

• Use rear wheel weights to improve traction.

• Before the rst snowfall, remove all stones, sticks and

other objects which could become hidden by the snow.

Permanent obstacles should be marked for visibility.

• Overlap each pass slightly to assure complete snow

removal.

MAINTENANCE

CUSTOMER RESPONSIBILITIES

• Read and follow the maintenance schedule and the maintenance procedures listed in this section.

MAINTENANCE SCHEDULE

Fill in dates as you

complete regular service.

Check for loose fasteners X

Check scraper and shoes for wear X X

Cleaning X

Lubrication Section X

Before each use

Every season

After each use

Before storage

LUBRICATION

• Oil all pivot points on the snow thrower.

• Oil the pivot points of the two idler arms on the clutch/

idler assembly.

• Apply penetrating oil to the control cables of the

discharge chute.

• Apply a good grade of spray lubricant to the trigger

assembly and the chute tilt control assembly.

CHECK SCRAPER AND SHOES FOR WEAR

(Refer to gures 59 and 60 on page 28)

• The scraper plate and skid shoes on the bottom of the

snow thrower are subject to wear. To prevent damage

to the spiral auger housing, replace plate and shoes

before wear is excessive.

27

Service Dates

Page 28

SERVICE AND ADJUSTMENTS

CAUTION: Before servicing or adjusting

the snow thrower, shut off the engine, remove

the spark plug wire(s), set the parking brake

and remove the key from the tractor ignition.

REPLACING AUGER BELT

• Disengage the tractor's attachment clutch.

• Lower the snow thrower to the ground.

• Remove the attachment pin.

• Lock the snow thrower's lift handle in the down

position to decrease belt tension.

• Release the spring tension from the auger belt idler

arm on the bottom of the clutch/idler assembly.

• Remove the auger drive belt from the clutch/idler

assembly and from the spiral auger housing.

• Install new belt over top of large auger drive pulley

and under the two side idler pulleys. Twist the belt 1/4

turn to seat the "V" of the belt in the groove of each

idler pulley. Refer to gure 55 on page 24.

• Assemble the belt onto the clutch/idler assembly.

SKID SHOE ADJUSTMENT

• The skid shoes are mounted on each side of the spiral

auger housing. They regulate the distance the scraper

plate is raised above the plowing surface. When

removing snow from a gravel driveway or and uneven

surface, it is advisable to keep the scraper plate as

high above the surface as possible to prevent possible

damage to the spiral auger. On blacktop or concrete

surface, keep the scraper plate as close to the surface

as possible.

• Raise the snow thrower off the ground and place a

block under each end of the scraper plate. Loosen the

six hex nuts securing the skid shoes to the housing.

Adjust the skid shoes up or down and retighten the

nuts securely. Adjust both skid shoes to the same

height to keep the housing and the scraper plate level.

See gure 59.

LIFT RELEASE CABLE ADJUSTMENT

• If the lift rod does not lock the snow thrower securely

in the transport position, loosen the upper hex nut on

the lift bracket a few turns and tighten the lower hex

nut. Refer to gure 48 on page 22.

• If the lift rod fails to unlock completely to lower the

snow thrower, loosen the lower hex nut on the lift

bracket a few turns and tighten the upper hex nut.

Refer to gure 48 on page 22.

CLUTCH DISENGAGEMENT ADJUSTMENT

(For tractors with engagement rod clutches only.

Not for electric clutches or cable clutches)

If the spiral auger on the snow thrower does not stop

when the attachment clutch lever on the tractor is

disengaged, then adjustment is necessary. Proceed as

follows. Refer back to gure 33 on page 17.

• Place the attachment clutch lever in the disengaged

position.

• Remove the hairpin cotter from the engagement rod

trunnion and lift the trunnion out of the hole in the idler

arm.

• Screw the trunnion a few turns towards the front end

of the rod.

• Replace the trunnion into the hole in the idler arm and

secure it with the hairpin cotter.

Check the operation of the snow thrower. If the spiral

augers still do not stop, repeat the above steps until

the augers stop when the attachment clutch lever is

placed in the disengaged position.

SPIRAL AUGERS

• The spiral augers are secured to the auger shaft with

two shear bolts and nylock nuts. If you hit a foreign

object or if ice jams the augers, the snow thrower is

designed so that the bolts will shear.

• If the augers will not turn, check to see if the shear

bolts have sheared. See gure 60. Two replacement

shear bolts and nylock nuts have been provided with

the snow thrower. For future use order part number

710-0890A shear bolt and number 47810 nylock nut.

FIGURE 59

FIGURE 60

28

Page 29

STORAGE

STORAGE RECOMMENDATIONS

• Lower the snow thrower to the ground.

• Remove the snow thrower from the tractor.

• Clean the snow thrower thoroughly. Wash off any salt

deposit which may have dried on the thrower and

housing.

• Any bare metal that has become exposed should be

painted or coated with a light oil to prevent rust.

• Store in a dry place.

REMOVING THE SPIRAL AUGER HOUSING

• Lower the snow thrower to the ground.

• Remove the attachment pin. See gure 54 on page

24.

• Lock the snow thrower's lift handle in the down

position to decrease belt tension.

• Release the spring tension from the auger belt idler

arm on the bottom of the clutch/idler assembly.

• Remove the auger drive belt from the clutch/idler

assembly. See gure 56 on page 24.

• Pull the spiral auger housing assembly off of the

tractor.

PARTS TO REMOVE AT END OF SEASON

• Remove the clutch/idler assembly. (The two hanger

brackets and the two shoulder bolts may be left

attached to the tractor frame.)

• Remove the drive belt from the engine pulley.

• If you replaced the engine pulley keeper on a manual

attachment clutch tractor, reinstall the tractor's original

engine pulley keeper. See gure 33 on page 17 or

gure 39 on page 19.

• If you have a rod operated attachment clutch, remove

the engagement rod from the tractor's clutch arm. See

gure 29 on page 16.

• If a rear mounted attachment is to be used, remove

the rear weight tray, leaving the bolts that you installed

in the sides of the tractor draw bar. Retighten the

bolts.

• If a front mounted attachment is to be used, remove

the side plates from the tractor. Be sure to assemble

bolts back into the empty holes in the tractor frame.

Spiral augers don't turn

Clogged discharge chute

Snow thrower stalls tractor engine

Front wheels slide instead of steering

TROUBLESHOOTING

CAUSEPROBLEM CORRECTION

1. Upper or lower V belt too loose 1. Increase tension on V belt

2. Upper or lower V belt broken 2. Replace V belt

3. Shear bolts are sheared. 3. Replace shear bolts

1. Tractor ground speed too fast 1. Use lower tractor gear

2. Tractor throttle set too low 2. Increase to full throttle

3. Snow too deep 3. Raise the snow thrower

4. Snow melts during contact with 4. Allow snow thrower to cool to

the snow thrower outdoor temperature before using

1. Object jammed in spiral auger 1. Stop engine, disengage the snow

thrower clutch and clear the auger

2. Hard or heavy snow 2. Increase to full throttle and

decrease ground speed

Not enough traction at front wheels 1. Increase scraper plate clearance