Page 1

Bedienungsanweisung

Manual de instrucciones

Libretto d’Istruzioni

Lesen Sie diese Hinweise zur Handhabung des

Geräts aufmerksam durch. Verwenden Sie es erst,

wenn Sie sicher sind, daß Sie alle Anweisungen

verstanden haben.

Lea atentamente las instrucciones y asegúrese de

entenderlas antes de utilizar este unidad.

Leggere attentamente queste istruzioni e accertarsi

di averle comprese prima di usare l’unità.

530086909

2/26/02

Deutsch

Italiano

Español

Instruction Manual

Manuel d’instructions

English

Français

Please read these instructions carefully and make

sure you understand them before using this unit.

Avant d’utiliser cet appareil, veuillez lire attentivement les instructions et assurez--vous de les avoir

comprises.

ENGLISH

FRANÇAIS DEUTSCH

ITALIANO

ESPANOL

Lees deze instructies zorgvuldig en wees er zeker

van dat u ze begrijpt alvorens dit apparaat te gebruiken.

Handleiding

Nederlands

NEDERLANDS

JONSERED SERVICE

Page 2

-- 2 --

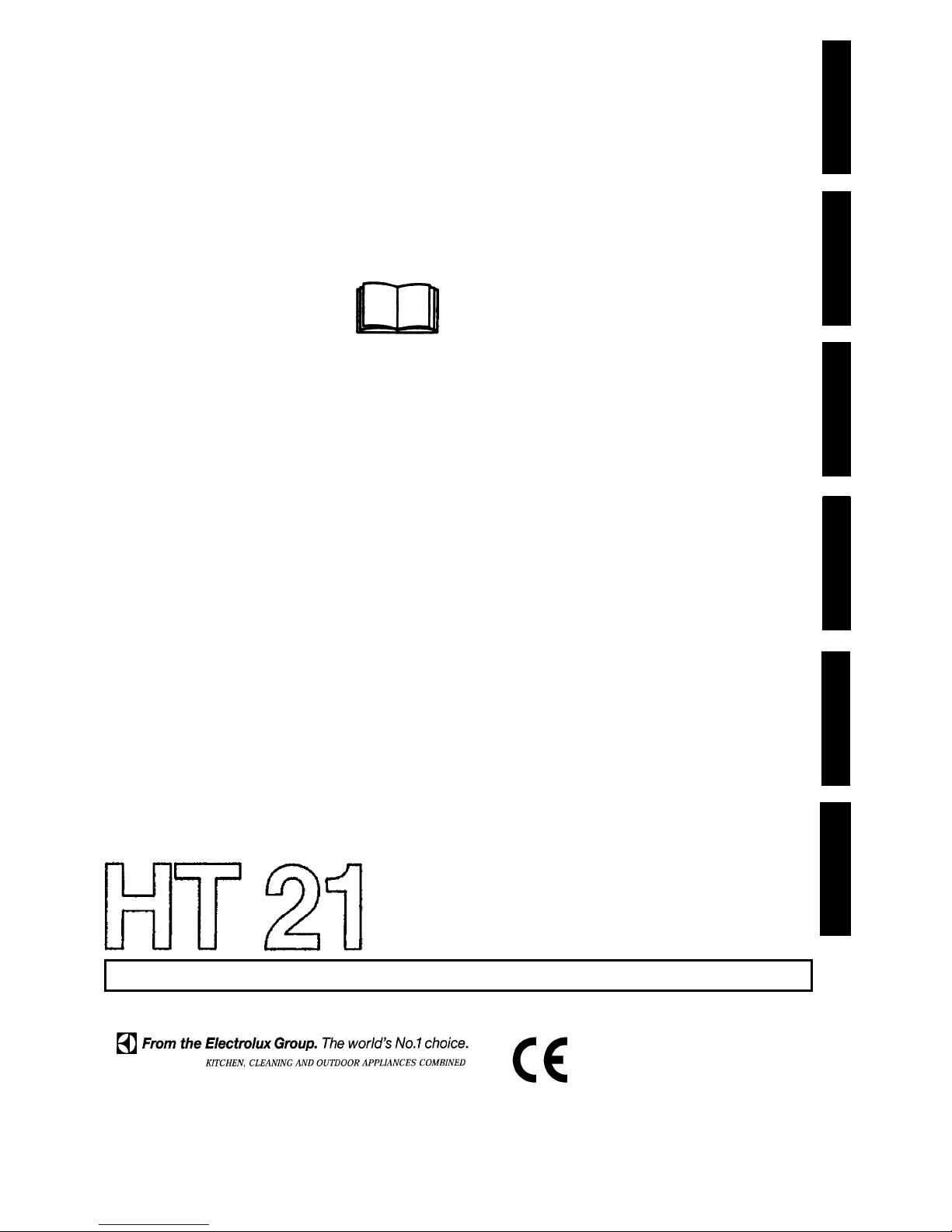

IDENTIFICATION (WHAT IS WHAT?)

1. Cutter blades

2. Hand guard

3. Spark plug

4. Starter grip

5. Air filter

6. Primer bulb

7. Choke lever

8. ON/OFF Switch

9. Throttle trigger

10. Throttle trigger lock--out

11. Fuel cap

12. Transport guard

13. Blunt extension

14. Front handle

15. Rear handle

16. Instruction Manual

1

2

3

4

16

58

9

10

11

7

12

6

14

15

13

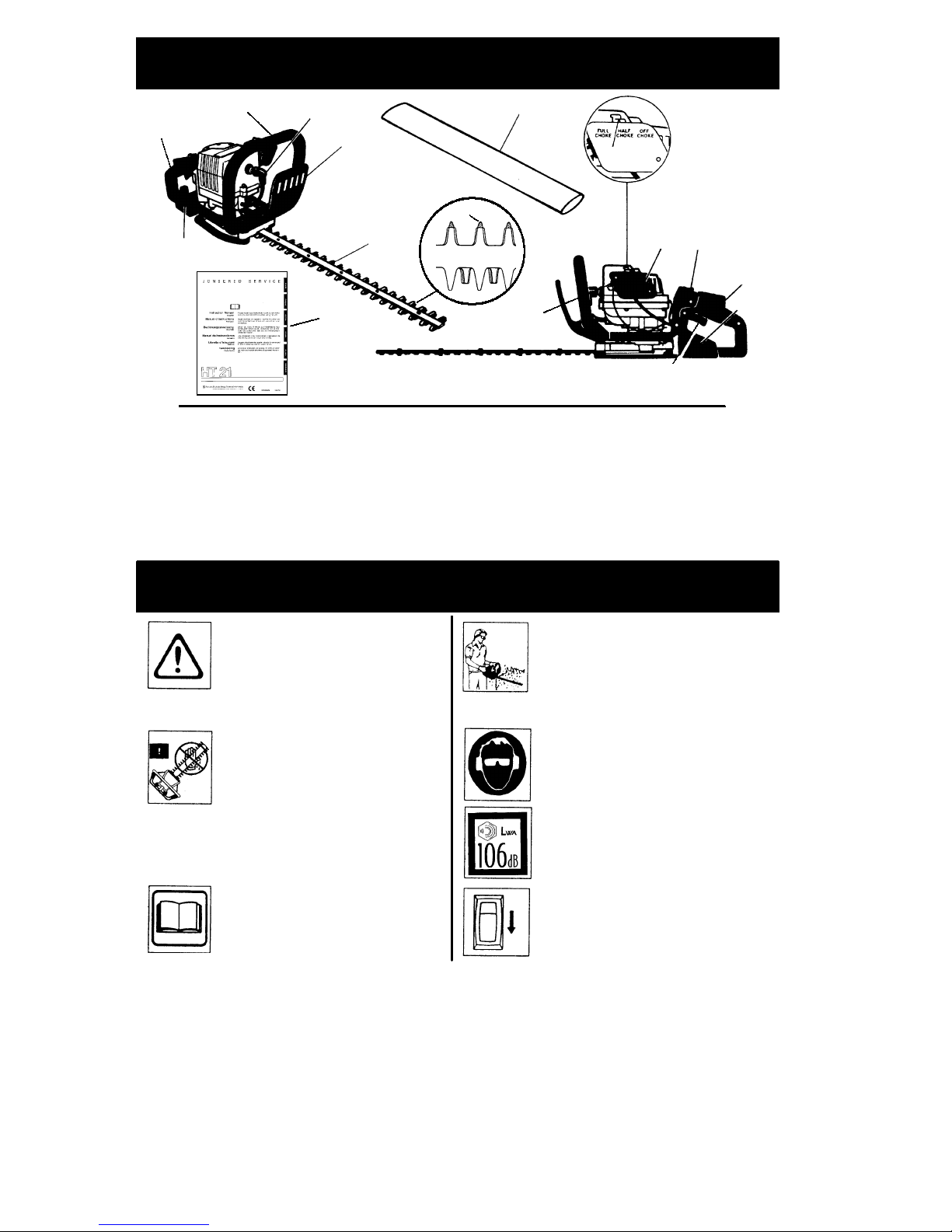

IDENTIFICATION OF SYMBOLS

WARNING:

This

hedge trimmer can be dangerous! Careless or improper use can cause serious or

even fatal injury.

Read and understand the

Instruction Manual and

all warning labels before

using the hedge trimmer.

WARNING:

Cutting blade

can throw objects violently.

--- You can be blinded or

injured.

--- Always wear eye

protection.

Always use:

--- Ea r p r o t e c t i o n

--- Protective glasses or visor

WARNING:

Blade moves

momentarily after trigger is

released.

---The cutting blade can seriously

cut you or others and can

amputate fingers.

---Allow cutting blade to stop

before removing it from the cut.

Checks and/or maintenance

should be carried out with the

engine switched off, with the

ON/OFF switch in the OFF

position.

ON

OFF

Sound power level

Page 3

-- 3 --

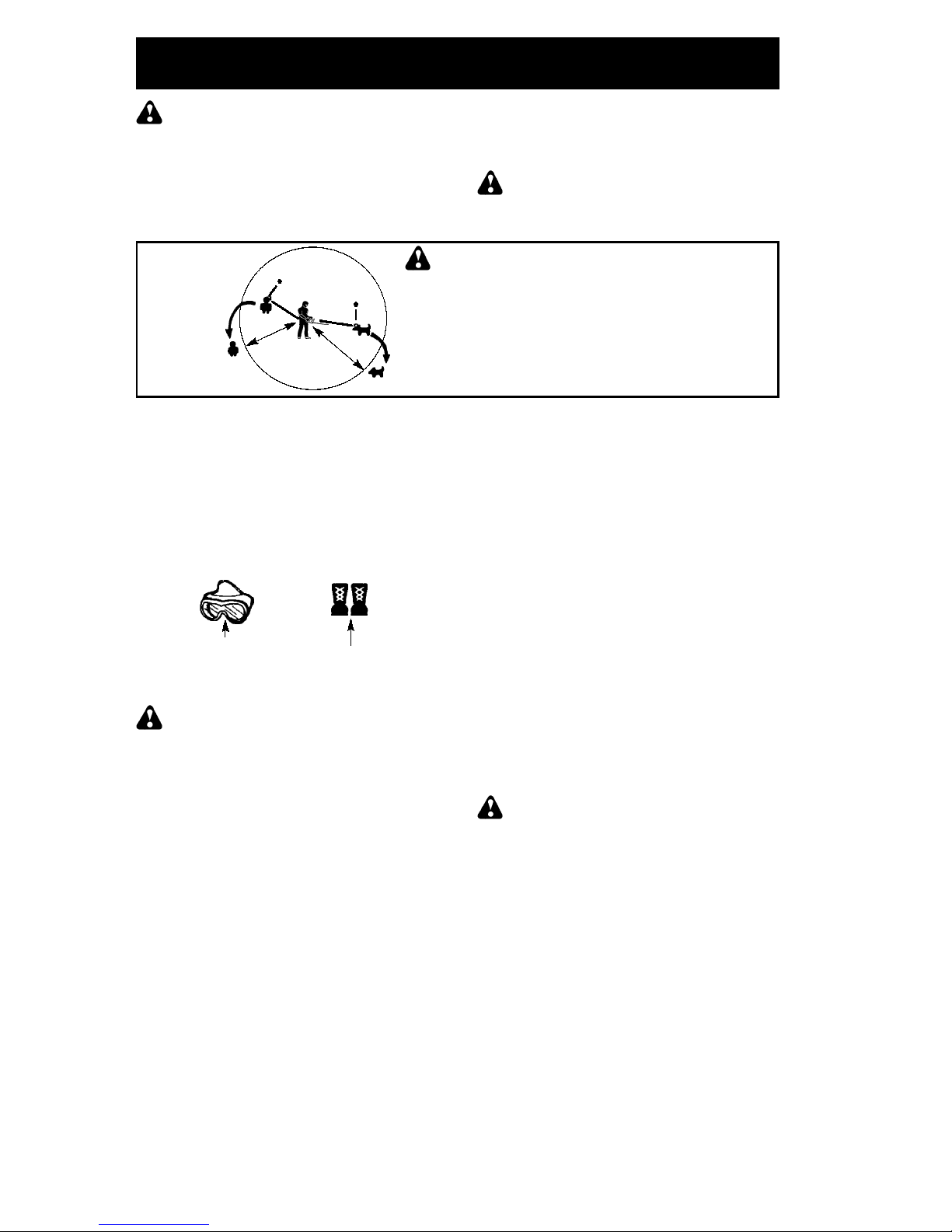

SAFETY RULES

DANGER

-- THIS POWER TOOL

CAN BE DANGEROUS! This unit can cause

serious injury including amputation or blindness to the operator and others. The warnings and safety instructions in this manual

must be followed to provide reasonable

safety and efficiency in using this unit.

The operator is responsible for following the

warnings and instructions in this manual and

on the unit. Never allow children to use this

tool.

WARNING:

Failure to follow all Safety Rules and Precautions can result in serious

injury.

10 m

HAZARD ZONE

WARNING:

Hazard Zone

D

Blades can throw objects violently.

D

Others can be blinded or injured.

D

Keep children, bystanders, and animals

away from work area a minimum of 10

meters when starting or operating unit.

KNOW YOUR UNIT

S

Read your Instruction Manual carefully until

you completely understand and can follow all

warnings and safety rules before operating

the unit.

D

Restrict unit to users who understand and will

follow all warnings an d sa fe ty rules in this

manual and on the unit.

PLAN AHEAD

Boots

Safety

Glasses

WARNING:

Inspect the area before

starting the unit. Remove all debris and hard objects such as rocks, glass, wire, etc. that can

ricochet, be thrown, or otherwise cause injury or

damage during operation.

D

Always wear eye protection when operating,

servicing, or performing maintenance on unit.

Wearing eye protection will help to prevent

rocks, brush or debris from being thrown or

ricocheting into eyes and face which can result in blindness and/or serious injury . Eye

protection should be marked Z87.

D

Always wear foot protection. Do not go barefoot or wear sandals.

D

Wear hearing protection when using this unit.

D

Secure hair above shoulder length. Secure or

remove jewelry, loose clothing, or clothing

with loosely hanging straps, ties, tassels, etc.

They can be caught in moving parts.

D

Do not operate unit when you are tired, ill, upset, or if you are under the influence of alcohol, drugs, or medication.

D

Keep children, bystanders, and animals away

from work area a minimum of 30 feet (10 m)

when starting or operating unit.

HANDLE FUEL WITH CAUTION, IT

IS HIGHLY FLAMMABLE

D

Eliminate all sources of sparks or flame (including smoking, open flames, or work that

can cause sparks) in the areas where fuel is

mixed, poured, or stored.

D

Mix and pour fuel in an outdoor area; store

fuel in a cool, dry, well ventilated place; use an

approved, marked container for all fuel purposes.

D

Do not smoke while handling fuel or while operating the unit.

D

Do not fill fuel tank while engine is running.

D

Turn the engine off and let hedge trimmer cool

in a non--combustible area, not on dry leaves,

straw , paper, etc. Slowly remove fuel cap and

refuel unit.

D

Wipe up fuel spills before starting the engine.

D

Move at least 10 feet (3 meters) away from

fuel and fueling site before starting engine.

D

Always store gasoline in a container approved for flammable liquids.

OPERATE YOUR UNIT SAFELY

DANGER:

RISK OF CUT; KEEP

HANDS AWAY FROM BLADE! Blade moves

momentarily after the trigger is released. Do

not attempt to clear away cut material when

the blade is in motion. Make sure the switch is

in the OFF position, the spark plug wire is disconnected, and the blade has stopped moving before removing jammed material from

the cutting blade. Do not grab or hold the unit

by the cutting blade.

D

Inspect unit before each use for worn, loose,

missing, or damaged parts. Do not use until

unit is in proper working order .

D

Keep outside surfaces free from oil and fuel.

D

Never start or run engine inside a closed

room or building. Breathing exhaust fumes

can kill.

D

Avoid dangerous environments. Do not use in

unventilated areas or where explosive vapors

or carbon monoxide build up could be present.

Page 4

-- 4 --

D

Do not overreach or use from unstable surfaces such as ladders, trees, steep slopes,

rooftops, etc. Keep firm footing and balance at

all times.

D

Do not raise unit above your shoulders; the

cutting blade can come dangerously close to

your body.

D

Always keep unit in front of your body. Keep

all parts of your body away from the cutting

blade.

D

Keep the cutting blade and air vents free from

debris.

D

Use only for jobs explained in this manual.

SAFETY EQUIPMENT

NOTE:

This section describes the hedgetrimmer’s safety equipment, its function and

how checks and maintenance are carried out

to ensure that it operates correctly (see

WHAT IS WHAT? to locate where this equipment is positioned on your machine).

WARNING:

Never use a machine

with damaged or inoperative safety equipment. Follow the control, maintenance and

service instructions described in this section.

D

ON/O FF swit c h

-- The ON/OFF switch

should be used to stop the engine.

D

Throttle lock

-- The throttle lock is used to

hold the throttle in the run position to free the

hands during starting or prolonged periods of

operation.

D

Blunt entension

-- The blunt extensions of

the cutting blade are designed to prevent contact with the blade.

D

Hand guard

-- The guard is intended to prevent objects from being throw n towards the

operator .

D

Vibration damping syst em

-- Your hedgetrimmer is equipped with a vibration damping

system which is designed to provide comfortable use.

D

Tr anspor tguard

-- The transport guard is designed to cover the cutting blades during

transport and storage.

D

Silencer --

The silencer is designed to give

the lowest possible noise level and to direct

the engine’s exhaust fumes away from the

operator . The engine’s exhaust fumes are hot

and can contain sparks which can lead to the

outbreak of fire.

WARNING:

During use and for some

time after, the silencer is very hot. Do not

touch the silencer if it is hot. A hot silencer can

cause serious burns.

D

Cutting equipment

-- The trimmer is in-

tended for trimming hedges.

CONTROL, MAINTENANCE AND

SERVICE OF THE SAFETY EQUIPMENT

WARNING:

All service and repairs to

the hedgetrimmer require special training.

This applies especially to the safety equipment. If the hedgetrimmer does not meet any

of the controls listed below, you should contact your authorised service dealer.

D

ON/O FF switch

-- Start the engine and make

sure that the engine stops when the ON/OFF

switch is moved to the OFF position.

D

Throttle lock

-- The throttle lock is used to

hold the throttle in the run position to free the

hands during starting or prolonged periods of

operation.

D

Blunt extension

-- Ensure that all blunt extensions are in place the full length of the cutting blade and are not damaged.

D

Hand guard

-- Ensure that the guard is undamaged and is not cracked. Replace the

guard if it has been exposed to impact or is

cracked.

D

Vibration damping system

-- Check the

vibration damping element regularly for material cracks and distortion. Check that the

vibration damping element is securely attached between the engine unit and the

hands.

D

Silencer --

Never use a machine that has a

damaged or inoperative silencer. Check regularly that the silencer is secure.

D

Cutting equipment --

Only use the cutting

equipment we recommend (see TECHNICAL DATA). Check the cutting equipment

with regard to damage and crack formation.

Damaged cutting equipment should always

be replaced.

WARNING:

Never use a machine

with damaged or inoperative safety equipment. The safety equipment should be maintained as described in this section. If your

machine does not meet any of these controls,

you should contact your authorised service

dealer.

MAINTAIN YOUR UNIT PROPERLY

D

Have all maintenance other than the recommended procedures described in the Instruction Manual performed by an authorised service dealer.

D

Disconnect spark plug before performing

maintenance except for carburetor adjustments.

D

Do not use a cutting blade that is bent,

warped, cracked, broken, or damaged in any

other way. Have worn or damaged parts replaced by your authorised service dealer.

D

Use only recommended Jonsered! c u tting

blades and replacement parts; use of any other parts may void your warranty and cause

damage to your unit.

D

Empty fuel tank before storing the unit. Use

up fuel left in carburetor by starting engine and

letting it run until it stops.

Page 5

-- 5 --

D

Hand carry the unit with the engine stopped

and the muffler and cutting blade away from

your body.

D

Allow engine to cool, empty the fuel tank, and

secure the unit before storing or transporting it

in a vehicle.

D

Do not store the unit or fuel in a closed area

where fuel vapors can reach sparks or an

open flame from hot water heaters, electric

motors or switches, furnaces, etc.

D

Store the unit so the cutting blade cannot accidentally cause injury.

D

Store in a dry area out of reach of children.

GENERAL WORKING INSTRUCTIONS

This section describes the basic safety precautions for working with the hedgetrimmer. If

you encounter a situation where you are uncertain how to proceed, you should ask an expert. Contact your authorised service dealer.

Avoid all usage which you consider to be beyond your capability.

WARNING:

Never use a machine

without the possibility of calling for help in the

event of an accident.

BASIC SAFETY PRECAUTIONS

D

Observe your surroundings to ensure that

people, animals or other things cannot affect

your control of the machine and to ensure that

the above mentioned do not come into contact with the cutting equipment or objects that

can be thrown by the cutting equipment.

D

Avoid usage in unfavorable weather conditions. For example, thick fog, heavy rain,

strong winds or extreme cold, etc. To work in

bad weather conditions is tiring and can

create dangerous circumstances, e.g. slippery surfaces.

D

Make sure you can walk and stand safely.

Look out for any obstacles with unexpected

movement (roots, stones, branches, pits,

ditches, etc.) Take great care when working

on sloping ground.

D

The engine should be switched off before

moving. When moving over longer distances

and transporting, the transporting guard

should be used.

D

Never put the machine down with the engine

running unless you have good sight of it.

BASIC WORKING TECHNIQUES

As y ou become familiar with your unit, y ou will

be able to determine your own operating

pace. Conditions such as the type and size of

material being cut will regulate the speed and

time required for your job.

D

Allow the cutting blades to reach full speed

before entering the material to be cut.

D

Always work going away from people and

solid objects such as walls, large stones,

trees, automobiles, etc.

D

If the blade stalls, immediately stop the engine. Make sure the ignition switch is off, the

spark plug is disconnected, and the blade has

stopped moving before clearing jammed debris from the cutting blade. Inspect the blade

for damage and have it repaired or replaced

as needed.

D

Always keep the air vents clean. Stop the

unit, make sure the cutting blade has completely stopped moving, and disconnect the

spark plug before cleaning.

SPECIAL NOTICE:

Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of people prone to circulation disor ders or abnorm al

swelling. Prolonged use in cold weather has

been linked to blood vessel damage in otherwise healthy people. If symptoms occur such as

numbness, pain, loss of strength, change in skin

color or texture, or loss of feeling in the fingers,

hands, or joints, discontinue the use of this tool

and seek medical attention. An antivibration

system does not guarantee the avoidance of

these problems. Users who operate power tools

on a continual and regular basis must monitor

closely their physical condition and the condition

of this tool.

ASSEMBLY

NOTE:

It is normal for the fuel filter to rattle in

the empty fuel tank.

ASSEMBLY

No assembly is required.

OPERATION

BEFORE STARTING ENGINE

WARNING:

Be sure to read the fuel

information in the safety rules before you begin. If you do not understand the safety rules,

do not attempt to fuel your unit.

FUELING ENGINE

WARNING:

Remove fuel cap slowly

when refueling.

This engine is certified to operate on unleaded petrol. Before operation, petrol must

be mixed with a good quality 2-stroke aircooled engine oil. Mix petrol and oil at a ratio

of 40:1 (2.5%). A 40:1 ratio is obtained by

mixing 5 liters of unleaded petrol with 0,125 liter of oil. DO NOT USE automotive oil or boat

oil. These oils will cause engine damage.

When mixing fuel, follow instructions printed

on oil container. Once oil is added to petrol,

shake container momentarily to assure that

the fuel is thoroughly mixed. Always read and

follow the safety rules relating to fuel before

fueling your unit.

Page 6

-- 6 --

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads to

separation and formation of acids during storage. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine

problems, empty the fuel system before storage for 30 days or longer. Drain the gas tank,

start the engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel next

season. Never use engine or carburetor

cleaner products in the fuel tank or permanent

damage may occur.

OPERATING INSTRUCTIONS

IMPORTANT POINTS

S

Use the minimum throttle speed necessary

to effectively cut hedges for optimal hedge

trimmer performance.

S

Never attempt to use this hedge trimmer to

cut hedges that have any branches with a

diameter larger than 1 cm.

OPERATING POSITION

Eye

Protection

Hearing

Protection

STOPPING YOUR ENGINE

D

To stop engine, move the ON/OFF switch to

OFF position.

STARTING YOUR ENGINE

D

Fuel engine. Move at least 10 feet (3 meters)

away from the fueling site.

D

Hold the unit on the ground in the starting position as shown. Support unit so the blade is

off of the ground and away from trees,

bushes, onlookers, etc.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

WARNING:

The cutting blade will be

moving once the throttle lock has been set

and the engine is started. Wear your protective equipment and observe all safety instructions.

Throttle Lock

Throttle

Lock-out

Throttle

Trigger

1. Move the ON/OFF switch to the ON position.

2. Engage the throttle lock as follows:

D

press the throttle lock-out;

D

squeeze and hold throttle trigger;

D

press and hold throttle lock, then

D

release the throttle trigger

NOTE:

Keep the throttle lock engaged until

the engine starts.

Switch

ON OFF

3. Slowly press the primer bulb 6 times.

4. Move the choke lever to the FULL

CHOKE position.

Choke

Primer Bulb

5. Pull starter rope handle sharply until engine sounds as if it is trying to run, but do

not pull rope more than 6 times.

6. Move the choke lever to the HALF

CHOKE position.

7. Pull starter rope sharply until the engine

runs, but no more than 6 pulls. If the engine doesn’t start after 6 pulls (at the

HALF CHOKE position), check to make

sure the ON/OFF switch is in the ON position. Move the choke lever to the FULL

CHOKE position and press the primer

bulb 6 times; pull the starter rope 2 more

times. Move the choke lever to the HALF

CHOKE position and pull the starter rope

until the engine runs, but no more than 6

more pulls.

Page 7

-- 7 --

NOTE:

If the engine still doesn’t start, it

is probably flooded. Proceed to STARTING A FLOODED ENGINE.

8. Once the engine starts, allow the engine to

run 10 seconds, then move the choke lever

to the OFF CHOKE position. Allow the unit

to run for 30 more seconds at the OFF

CHOKE position before squeezing and releasing the throttle trigger to release the

throttle lock.

NOTE:

If engine dies with the choke lever in the OFF CHOKE position, move the

choke lever to the HALF CHOKE position

and pull the rope until the engine runs, but

no more than 6 pulls.

STARTING A WARM ENGINE

1. Move the ON/OFF switch to the ON position.

2. Slowly press the primer bulb 6 times.

3. Move the choke lever to the HALF

CHOKE position.

4. Engage the throttle lock as directed in

STARTING A COLD ENGINE.

NOTE:

Keep the throttle lock engaged until

the engine starts.

5. Pull starter rope sharply until engine runs,

but no more than 5 pulls.

6. Allow the engine to run 10 seconds, then

move the choke lever to the OFF CHOKE

position.

7. Release the throttle lock by squeezing

and releasing the trigger.

NOTE:

If engine has not started, pull starter

rope 5 more pulls. If engine still does not run, it

is probably flooded. Proceed to STARTING A

FLOODED ENGINE.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing

the ON/OFF switch in the ON position and the

choke lever in the OFF CHOKE position and

engaging the throttle lock as directed in the

STARTING A COLD ENGINE section; then,

pull the rope to clear the engine of excess

fuel. Starting could require pulling the starter

rope many times depending on how badly the

unit is flooded.

If the unit still doesn’t start, refer to the TROUBLESHOOTING TABLE.

SERVICE AND ADJUSTMENTS

WARNING:

Ensure ON/OFF switch

is in the OFF position and disconnect the

spark plug before performing service except

for carburetor adjustments.

We recommend all service and adjustments

not listed in this manual be performed by an

authorised service dealer.

CLEAN AIR FILTER

Air Filter Cover

Air

Filter

Screws

Cleaning the air filter:

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep debris from falling into the carburetor chamber when the cover is removed.

2. Remove parts as illustrated.

NOTE:

Do not clean filter in gasoline or other

flammable solvent. Doing so can create a fire

hazard or produce harmful evaporative emissions.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Add a few drops of oil to the filter; squeeze

filter to distribute oil.

6. Replace parts.

REPLACE SPARK PLUG

Replace spark plug each year to ensure the

engine starts easier and runs better. Set

spark plug gap at 0,6 mm. Ignition timing is

fixed, nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and discard.

3. Replace with Champion RCJ-8Y spark

plug and tighten with a 19 mm socket

wrench.

4. Reinstall the spark plug boot.

REPLACE FUEL FILTER

To replace fuel filter, drain unit by running it dry

of fuel, then remove fuel cap and its connected retainer from tank. Pull filter from tank

and remove it from the fuel line. Install new

fuel filter on fuel line; reinstall parts.

CARBURETOR ADJUSTMENTS

Y our carburetor is equipped with limiter caps.

Damage will occur if you turn the needles beyond the limiter caps. Carburetor adjustment

is a complicated task. We recommend that

you take your unit to an authorised service

dealer.

Page 8

-- 8 --

STORAGE

WARNING:

Perform the following

steps after each use:

S

Allow engine to cool, and secure the unit

before storing or transporting.

S

Store unit and fuel in a well ventilated area

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

S

Store unit with all guards in place. Position

unit so that any sharp object cannot accidentally cause injury.

S

Store unit and fuel well out of the reach of

children.

SEASONAL STORAGE

Prepare unit for storage at end of season or if

it will not be used for 30 days or more.

If your unit is to be stored for a period of time:

S

Clean the entire unit.

S

Store in a clean dry area.

S

Clean all parts and check for damage.

Have damaged parts repaired or replaced

by an authorized service dealer.

S

Keep all nuts, bolts, and screws tight.

S

Lightly oil external metal surfaces, including the blade.

To oil the blade, do the following:

S

Stop the engine and allow blade to come to

a complete stop.

S

Ensure ON/OFF switch is in the OFF position.

S

Disconnect the spark plug wire.

S

Apply a light machine oil along the edge of

the top strap as shown.

Top Str ap

OIL

ENGINE

S

Remove spark plug and pour 1 teaspoon of

40:1, 2-cycle engine oil (air cooled) through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

S

Replace spark plug with new one of recommended type and heat range (see REPLACE SPARK PLUG section).

S

Clean air filter.

S

Check entire unit for loose screws, nuts,

and bolts. Replace any damaged, broken,

or worn parts.

S

At the beginning of the next season, use

only fresh fuel having the proper gasoline to

oil ratio.

OTHER

S

Do not store petrol from one season to

another.

S

Replace your petrol can if it starts to rust.

Page 9

-- 9 --

TROUBLE CAUSE REMEDY

Engine will not

start.

Engine will

not idle

properly.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. See “Carburetor Adjustment” in

Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

Engine will not

accelerate,

lacks power,

or dies under

a load.

1. Clean or replace air filter.

2. Clean or replace plug

and regap.

3. See “Carburetor Adjustment” in

Service and Adjustments Section.

4. Contact an authorized service dealer.

5. Contact an authorized service dealer.

Engine

smokes

excessively.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. See “Carburetor Adjustment” in

Service and Adjustments Section.

Engine runs

hot.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

1. See “Fueling Engine” in Operation

section.

2. Replace with correct spark plug.

3. See “Carburetor Adjustment” in

Service and Adjustments Section.

WARNING:

Always stop unit and disconnect spark plug before performing all of the

recommended remedies below except remedies that require operation of the unit.

TROUBLESHOOTING TABLE

1. ON/OFF switch in the

OFF position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

6. Carburetor requires

adjustment.

1. Move ON/OFF switch to the ON

position.

2. See “Starting a Flooded Engine”

in Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. See “Carburetor Adjustment” in

Service and Adjustments Section.

DECLARATION OF CONFORMITY

relating to 2000/14/EC

Michael S. Bounds, Director

Product Safety and Standards

EU Declaration of Conformity relating to 2000/14/EC

We,

Poulan/Weed Eater, Division Electrolux North America, Inc.,

Texarkana, TX,

75501, USA, Tél. : +1 903 223 4100, declare under sole responsibility that the

Jonsered

model HT21 hedge trimmer

was assessed in accordance with Annex V of the

DIRECTIVE and from serial numbers 2001--305(N or D)00001 and onwards, conforms to

the provisions of the DIRECTIVE. The net power is 0,306 kW. The measured sound power

is 102,7 dB and the guaranteed sound power is 106 dB.

Texarkana 01--12--17

Page 10

-- 1 0 --

DECLARATION OF CONFORMITY

relating to 98/37/EC

Michael S. Bounds, Director

Safety and Standards

EU Declaration of Conformity

(Directive 89/392/EEC, Annex II, A) (Only applies to

Europe)

We,

Poulan/Weed Eater, Division Electrolux North America, Inc.,

Texarkana, TX,

75501, USA, Tel: +1 903 223 4100, declare under sole responsibility that the

Jonsered

model HT21 hedge trimmer

from serial numbers 2001--305N00001 and onwards, follows

the provisions of the DIRECTIVES:

98/37/EC

(machinery) and

89/336/EEC

(electromagnetic compatibility), including amendments and is in conformity with the

following standards:

EN 292--2, prEN 774 and CISPR 12.

SMP, The Swedish Machinery Testing Institute,

Fyrisborgsgatan 3 S--754 50 Uppsala,

Sweden, has carried out voluntary type approval. The certificate(s) are numbered:

SEC/94/086

.

Texarkana 01--12--17

TECHNICAL DATA SHEET

MODEL: HT21

ENGINE AND FUEL SYSTEM

Displacement 21 cm

3

Idling speed 3000

Maximum engine power, according to ISO 8893 0,3 kW/6000 rpm

Fuel tank capacity 0,21 liters

WEIGHT

Mass with empty fuel tank 4,3 kg

CUTTING DEVICE

Type Double sided

Blade length 19"/48 cm

Blade speed at 8000 rpm 1430 cut/min

SOUND LEVELS

Equivalent sound pressure levels at the user’s ear

According to ISO 11806 and ISO 7917

Idle: 52 dB(A)

Racing: 67 dB(A)

Equivalent sound power levels measured according to

ISO 11806 and ISO 10884

Idle: 72 dB(A)

Racing: 102,7 dB(A)

VIBRATIONS

According to ISO 11806 and ISO 7916

Idling: Front handle 2,4 m/s

2

Rear handle 1,9 m/s

2

Racing: Front handle 4,5 m/s

2

Rear handle 3,6 m/s

2

YEAR OF CONSTRUCTION:

2002

MANUFACTURER’S ADDRESS:

Jonsered

SE--561 82 Huskvarna

Huskvarna, Sweden

Loading...

Loading...