Page 1

GC 2225

GC 2225C

Please read the operator’s manual carefully and make sure you understand the instructions before using the

machine.

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Prima di usare la macchina, leggere per intero le istruzioni per l’uso e accertarsi di averne compreso il contenuto.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Leia as instruções para o uso com toda a atenção e compreenda o seu conteúdo antes de fazer uso da máquina.

¢И·Я¿ЫЩВ ЪФЫВОЩИО¿ ЩИ˜ √‰ЛБ›В˜ ¯Ъ‹ЫВˆ˜ О·И О·Щ·УФ‹ЫЩВ ЩФ ВЪИВ¯fiМВУФ ЪИУ ¯ЪЛЫИМФФИ‹ЫВЩВ ЩФ МЛ¯¿УЛМ·.

Operator′s manual

Manuel d’utilisation

Bedienungsanweisung

Istruzioni per l’uso

Manual de instrucciones

Instruções para o uso

√‰ËÁ›Â˜ ¯Ú‹Ûˆ˜

GB (2-26)

FR (27-51)

DE (52-76)

IT (77-101)

ES (102-126)

PT (127-151)

GR (152-177)

Page 2

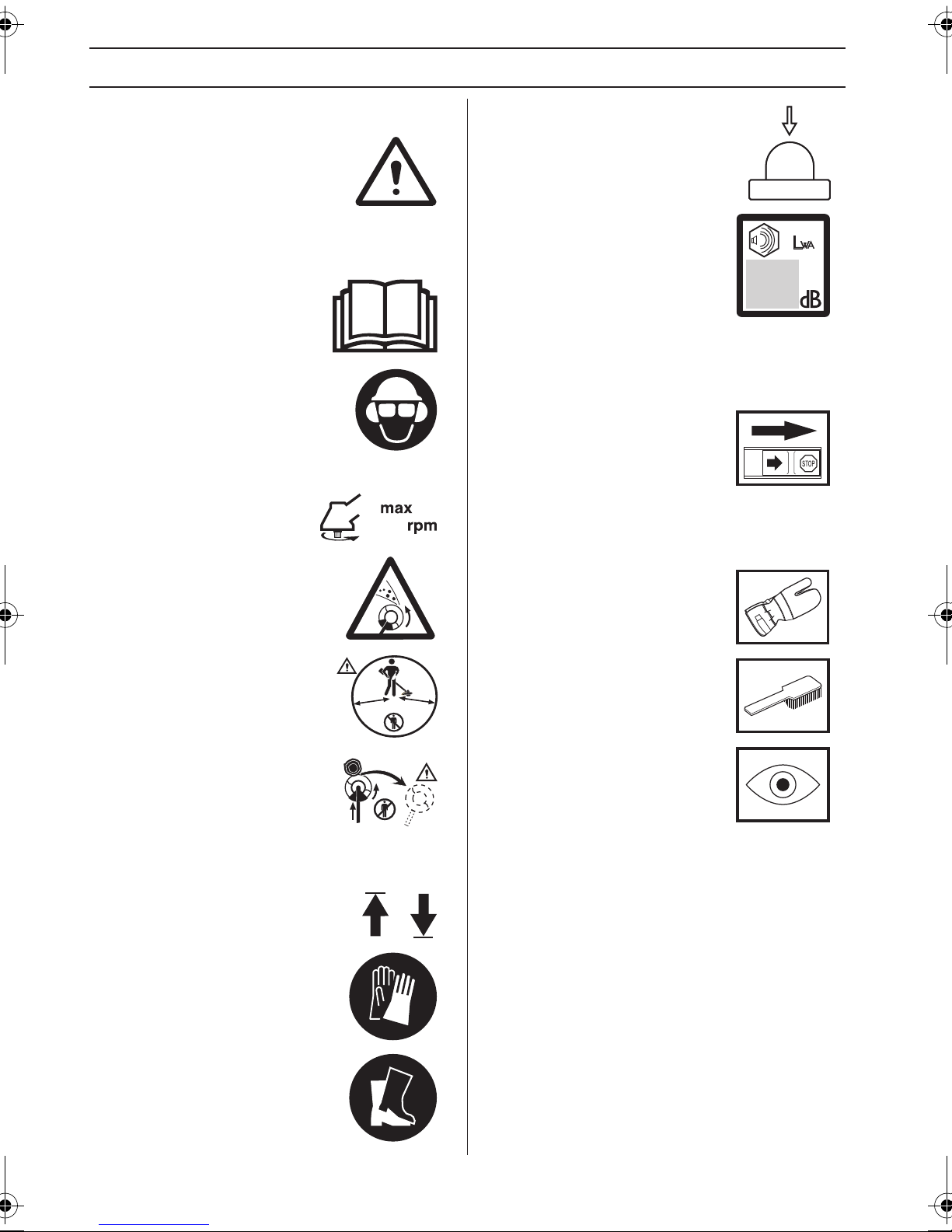

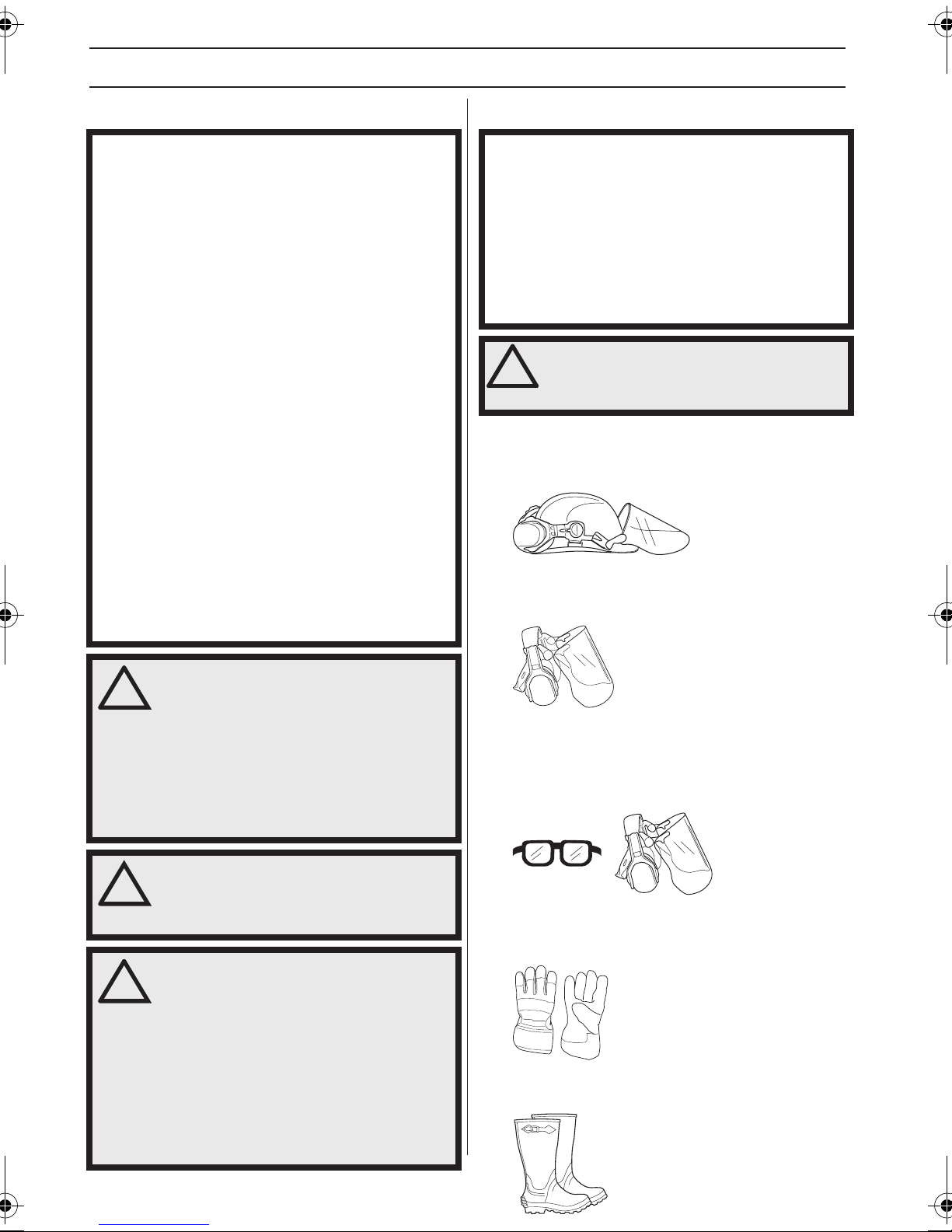

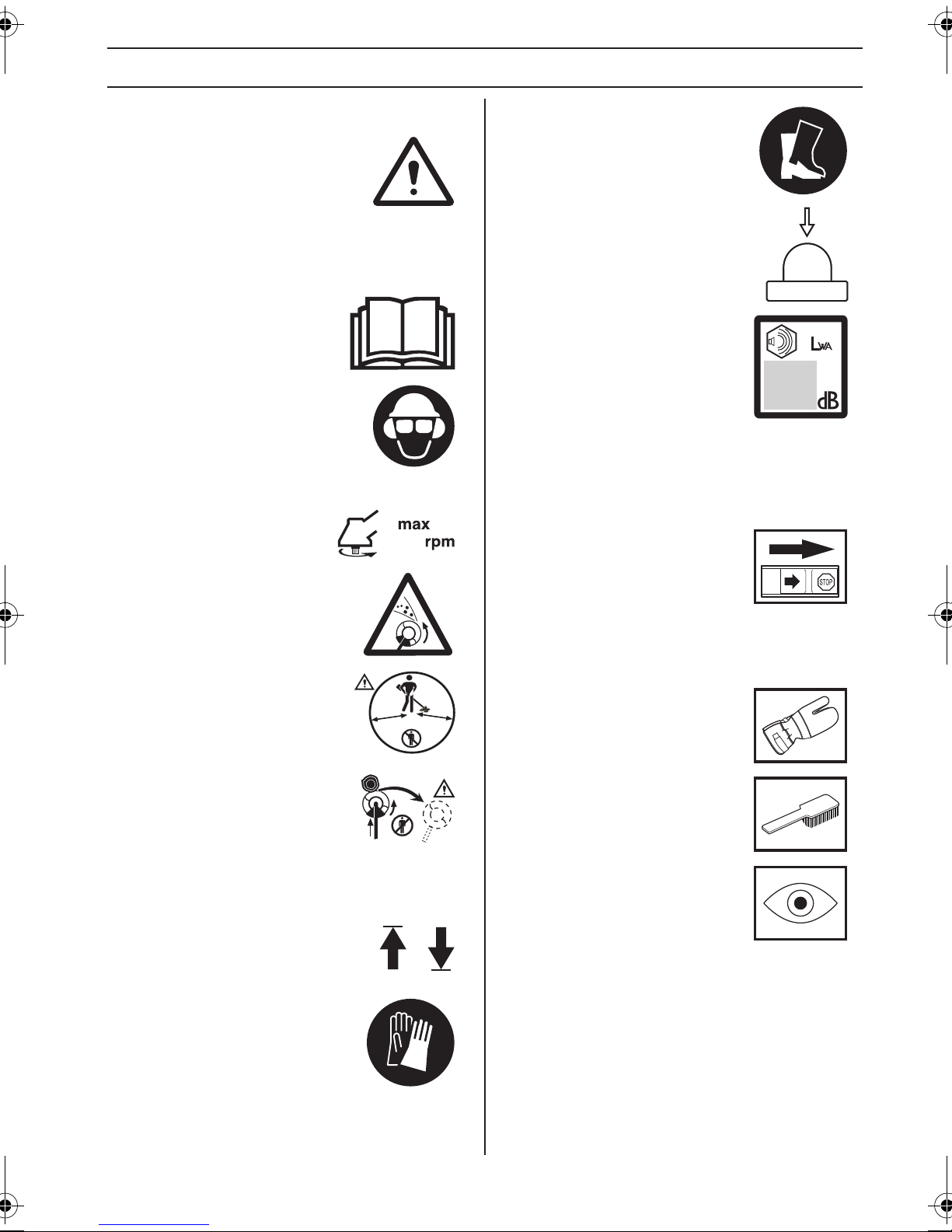

KEY TO SYMBOLS

Symbols

WARNING! Clearing saws,

brushcutters and trimmers can be

dangerous! Careless or incorrect use

can result in serious or fatal injury to

the operator or others. It is extremely

important that you read and understand the contents of

the operator's manual.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Always wear:

• Wear a protective helmet where

there is a risk of falling objects

• Approved hearing protection

• Approved eye protection

Max. speed of output shaft, rpm

10000

Watch out for thrown objects and

ricochets.

Primer bulb

Noise emission to the environment

according to the European

Community’s Directive. The

machine’s emission is specified in

the Technical data chapter and on the

label.

Other symbols/decals on the machine refer to

special certification requirements for certain

markets.

The engine is switched off by moving

the stop switch to the stop position.

CAUTION! The stop switch

automatically returns to the start

position. In order to prevent

unintentional starting, the spark plug cap must be

removed from the spark plug when assembling, checking

and/or performing maintenance.

Always wear approved protective

gloves.

The operator of the machine must

ensure, while working, that no

persons or animals come closer

15 m

50FT

15

m

5

0

FT

than 15 meters.

Machines fitted with saw blades or

grass blades can be thrown violently

to the side when the blade comes

into contact with a fixed object. This is

called blade thrust. The blade is

capable of amputating an arm or leg. Always keep people

and animals at least 15 meters from the machine.

Arrows which show limits for handle

positioning.

Always wear approved protective

gloves.

Wear sturdy, non-slip boots.

Regular cleaning is required.

Visual check.

2 – English

Page 3

CONTENTS

Contents Note the following before

KEY TO SYMBOLS

Symbols ................................................................ 2

CONTENTS

Contents ............................................................... 3

Note the following before starting: ........................ 3

INTRODUCTION

Dear Customer, .................................................... 4

WHAT IS WHAT?

What is what? ....................................................... 5

GENERAL SAFETY PRECAUTIONS

Important .............................................................. 6

Personal protective equipment ............................. 6

Machine′s safety equipment ................................. 7

Cutting equipment ................................................ 9

ASSEMBLY

Fitting the loop handle .......................................... 11

Fitting the J-handle .............................................. 11

Fitting the suspension ring ................................... 11

Assembling the cutting equipment ....................... 11

Fitting the trimmer guard and trimmer head ......... 12

Assembling and dismantling the two-piece shaft . 12

Fitting a blade guard, grass blade and grass cutter 13

FUEL HANDLING

Fuel safety ............................................................ 14

Fuel ...................................................................... 14

Fueling .................................................................. 15

STARTING AND STOPPING

Check before starting ........................................... 16

Starting and stopping ........................................... 16

WORKING TECHNIQUES

General working instructions ................................ 18

MAINTENANCE

Carburettor ........................................................... 21

Cooling system ..................................................... 21

Spark plug ............................................................ 21

Two-piece shaft ................................................... 22

Air filter ................................................................. 22

Maintenance schedule ......................................... 23

TECHNICAL DATA

Technical data ...................................................... 24

EC Declaration of Conformity ............................... 26

starting:

Please read the operator's manual carefully.

WARNING! Long-term exposure to noise

!

!

!

can result in permanent hearing

impairment. So always use approved

hearing protection.

WARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use original

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING! A clearing saw, brushcutter

or trimmer can be dangerous if used

incorrectly or carelessly, and can cause

serious or fatal injury to the operator or

others. It is extremely important that you

read and understand the contents of this

operator’s manual.

English – 3

Page 4

INTRODUCTION

Dear Customer,

Congratulations on your choice to buy a Jonsered product!

We are convinced that you will appreciate with great satisfaction the quality and performance of our product for a very

long time to come. The purchase of one of our products gives you access to professional help with repairs and service

whenever this may be necessary. If the retailer who sells your machine is not one of our authorised dealers, ask for the

address of your nearest service workshop.

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this

operator′s manual as a valuable document. By following its content (usage, service, maintenance, etc), the life span and

the second-hand value of the machine can be extended. If you sell this machine, make sure that the operator′s manual

is passed on to the buyer.

Good luck on using your Jonsered machine!

Jonsered has a policy of continuous product development and therefore reserves the right to modify the design and

appearance of products without prior notice.

4 – English

Page 5

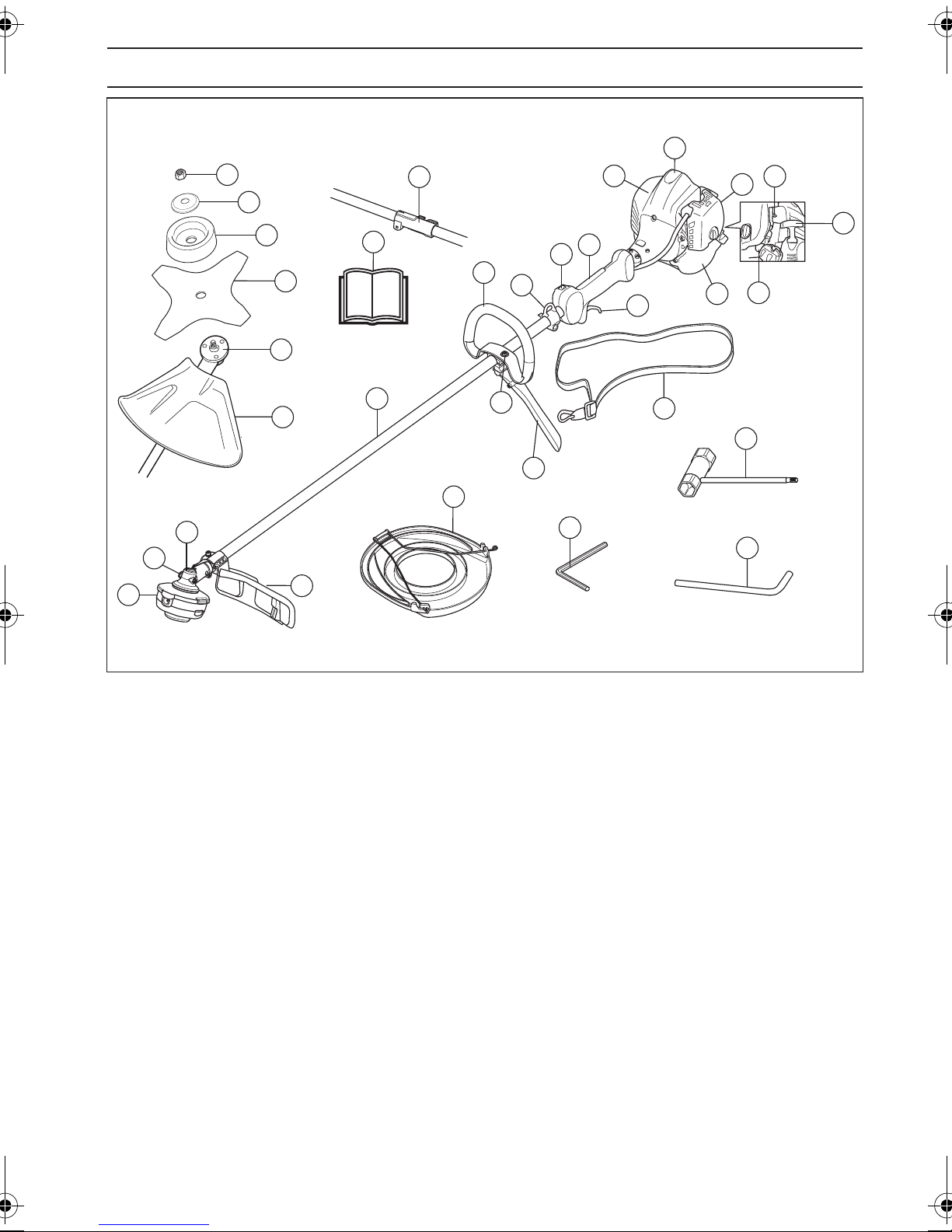

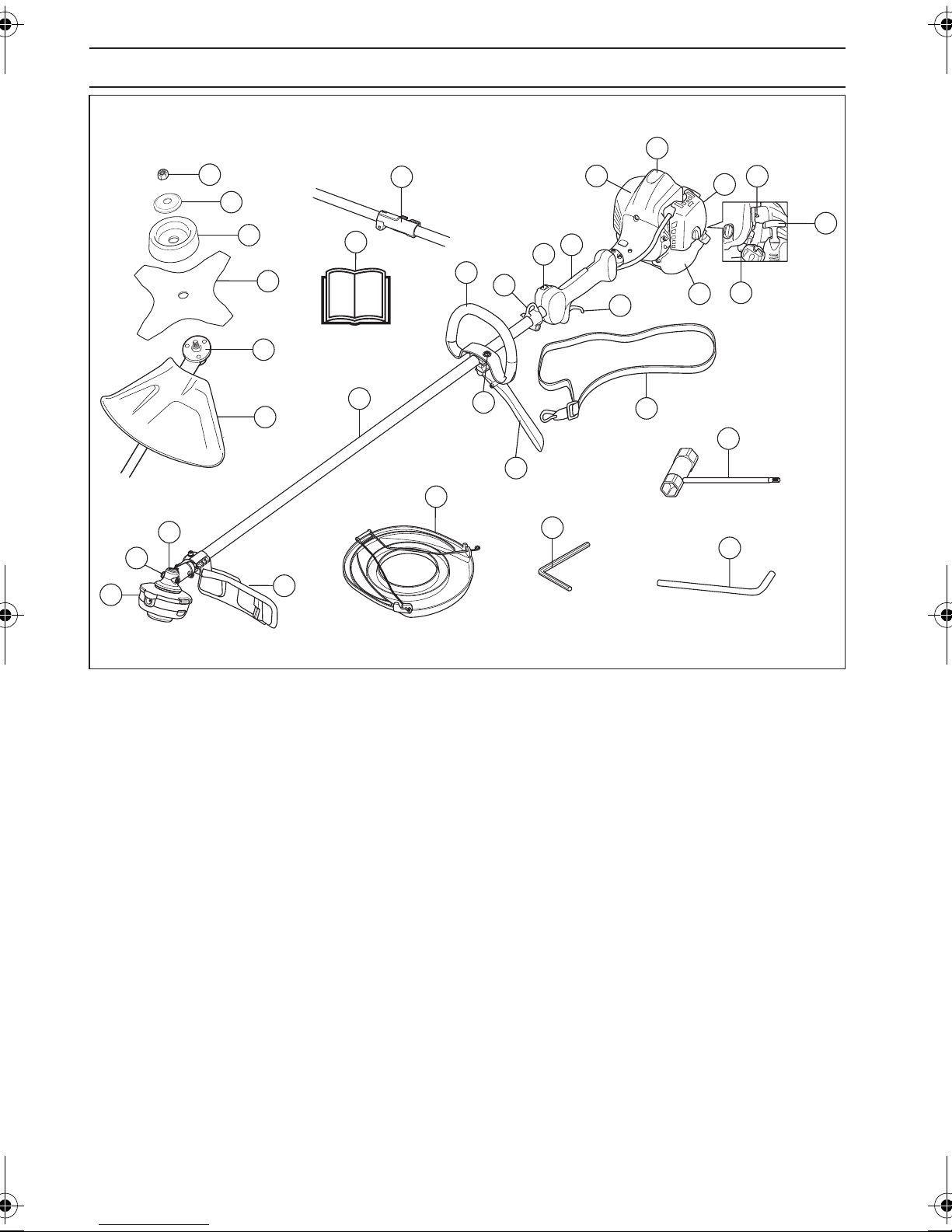

WHAT IS WHAT?

10

17

18

24

25

19

4

3

2

1

4

23

26

8

6

29

5

28

27

31

21

11

9

7

30

13

14

16

12

15

20

22

What is what?

1 Trimmer head

2 Grease filler cap, bevel gear

3 Bevel gear

4 Cutting attachment guard

5 Shaft

6 Loop handle

7 Throttle trigger

8 Stop switch

9 Throttle lockout

10 Spark plug cap and spark plug

11 Cylinder cover

12 Starter handle

13 Fuel tank

14 Air filter cover

15 Primer bulb

16 Choke control

17 Locking nut

18 Support flange

19 Drive disc

20 Combination spanner

21 Allen key

22 Locking pin

23 Operator′s manual

24 Support cup

25 Blade

26 Shaft coupling (GC2225C)

27 J-handle

28 Handle adjustment

29 Suspension ring

30 Harness

31 Transport guard

English – 5

Page 6

GENERAL SAFETY PRECAUTIONS

Important Personal protective equipment

IMPORTANT!

The machine is only designed for trimming grass.

National or local regulations may regulate the use.

Comply to given regulations.

The only accessories you can operate with this engine

unit are the cutting attachments we recommend in the

chapter on Technical data.

Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the ”Personal protective equipment” heading.

Never use a machine that has been modified in any way

from its original specification.

Never use a machine that is faulty. Carry out the safety

checks, maintenance and service instructions described

in this manual. Some maintenance and service measures

must be carried out by trained and qualified specialists.

See instructions under the Maintenance heading.

All covers, guards and handles must be fitted before

starting. Ensure that the spark plug cap and ignition lead

are undamaged to avoid the risk of electric shock.

The machine operator must ensure that no people or

animals come closer than 15 metres while working. When

several operators are working in the same area the safety

distance should be at least 15 metres.

IMPORTANT!

A clearing saw, brushcutter or trimmer can be dangerous

if used incorrectly or carelessly, and can cause serious or

fatal injury to the operator or others. It is extremely

important that you read and understand the contents of

this operator’s manual.

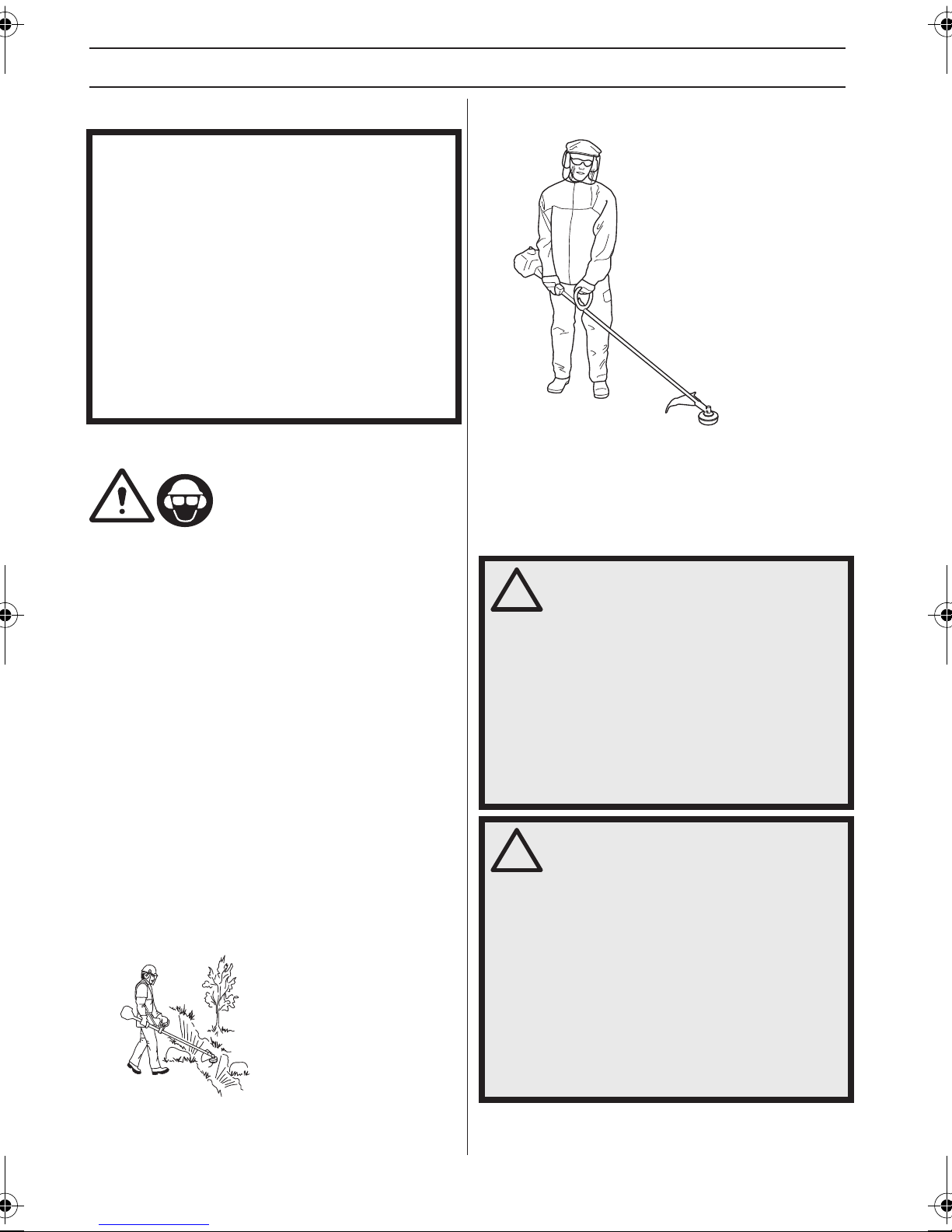

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

WARNING! Listen out for warning signals

!

HELMET

Wear a protective helmet where there is a risk of falling

objects

HEARING PROTECTION

Wear hearing protection that provides adequate noise

reduction.

or shouts when you are wearing hearing

protection. Always remove your hearing

protection as soon as the engine stops.

WARNING! This machine produces an

!

!

!

electromagnetic field during operation.

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

WARNING! Running an engine in a

confined or badly ventilated area can

result in death due to asphyxiation or

carbon monoxide poisoning.

WARNING! Never allow children to use or

be in the vicinity of the machine. As the

machine is equipped with a springloaded stop switch and can be started by

low speed and force on the starter

handle, even small children under some

circumstances can produce the force

necessary to start the machine. This can

mean a risk of serious personal injury.

Therefore remove the spark plug cap

when the machine is not under close

supervision.

EYE PROTECTION

Always wear approved eye protection. If you use a visor

then you must also wear approved protective goggles.

Approved protective goggles must comply with the ANSI

Z87.1 standard in the USA or EN 166 in EU countries.

GLOVES

Gloves should be worn when necessary, e.g. when fitting

cutting attachments.

BOOTS

Wear boots with steel toe-caps and non-slip sole.

6 – English

Page 7

GENERAL SAFETY PRECAUTIONS

CLOTHING

Wear clothes made of a strong fabric and avoid loose

clothing that can catch on twigs and branches. Always

wear heavy, long pants. Do not wear jewellery, shorts

sandals or go barefoot. Secure hair so it is above shoulder

level.

FIRST AID KIT

Always have a first aid kit nearby.

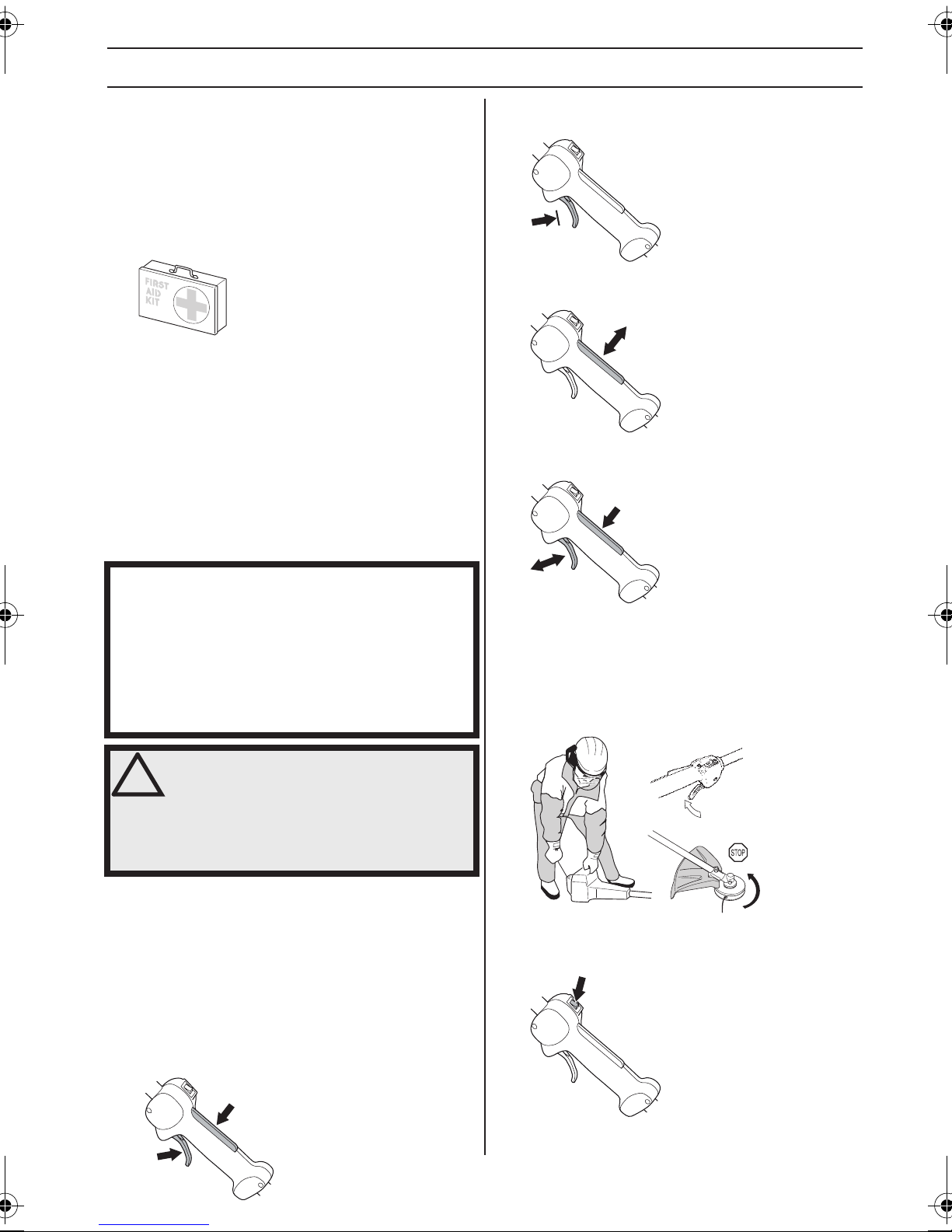

Machine′s safety equipment

This section describes the machine′s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

carried out professionally. If you need further information

please contact your nearest service workshop.

Make sure the throttle control is locked at the idle setting

when the throttle lockout is released.

Press the throttle lockout and make sure it returns to its

original position when you release it.

Check that the throttle trigger and throttle lockout move

freely and that the return springs work properly.

IMPORTANT!

All servicing and repair work on the machine requires

special training. This is especially true of the machine′s

safety equipment. If your machine fails any of the checks

described below you must contact your service agent.

When you buy any of our products we guarantee the

availability of professional repairs and service. If the

retailer who sells your machine is not a servicing dealer,

ask him for the address of your nearest service agent.

WARNING! Never use a machine with

!

faulty safety equipment. The machine's

safety equipment must be checked and

maintained as described in this section. If

your machine fails any of these checks

contact your service agent to get it

repaired.

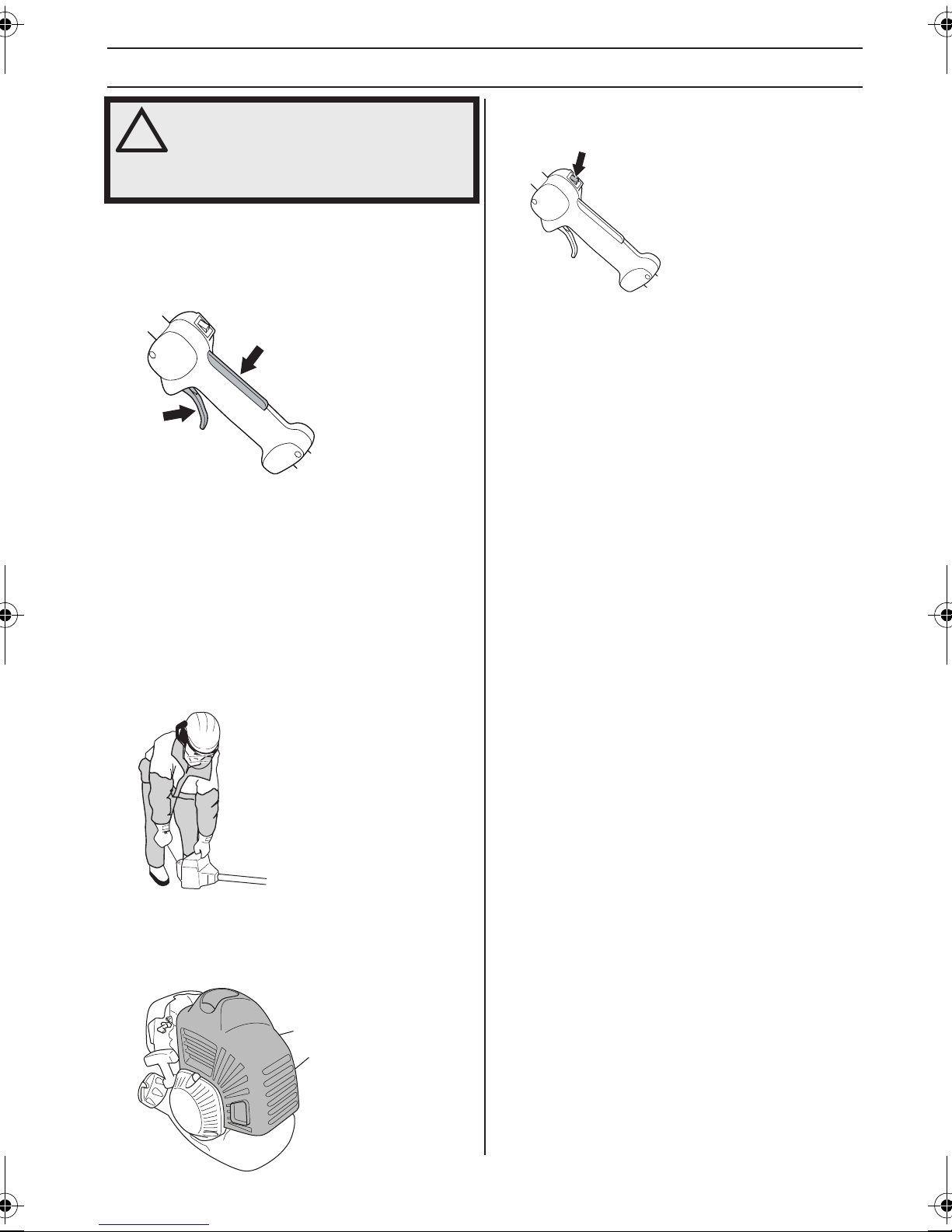

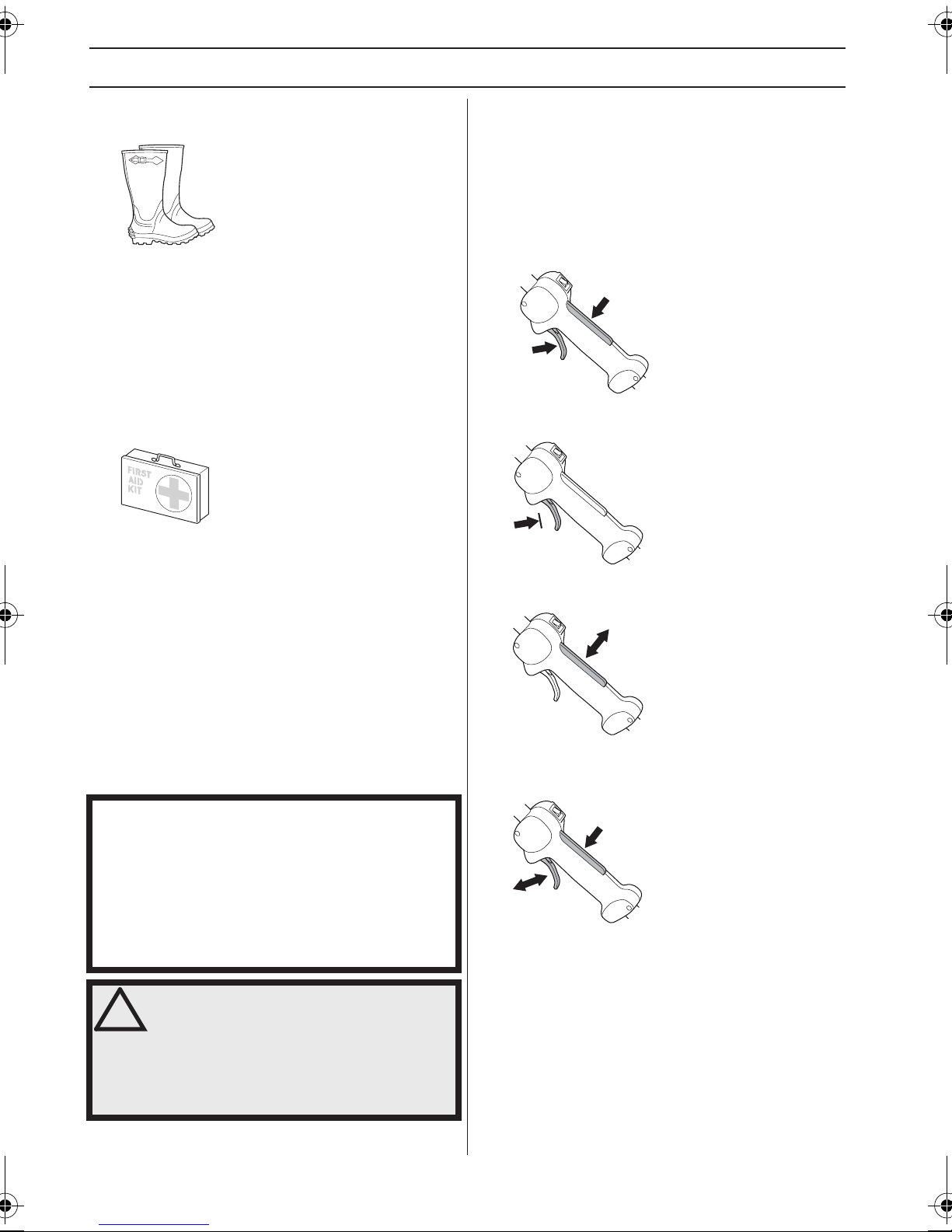

Throttle lockout

The throttle lockout is designed to prevent accidental

operation of the throttle control. When you press the lock

(A) (i.e. when you grasp the handle) it releases the throttle

control (B). When you release the handle the throttle

control and the throttle lockout both move back to their

original positions. This movement is controlled by two

independent return springs. This arrangement means that

the throttle control is automatically locked at the idle

setting.

See instructions under the heading Start. Start the

machine and apply full throttle. Release the throttle and

check that the cutting attachment stops and remains at a

standstill. If the cutting attachment rotates with the throttle

in the idle position then the carburettor idle setting must

be checked. See instructions under the heading

Maintenance.

Stop switch

Use the stop switch to switch off the engine.

A

B

Start the engine and make sure the engine stops when

you move the stop switch to the stop setting.

English – 7

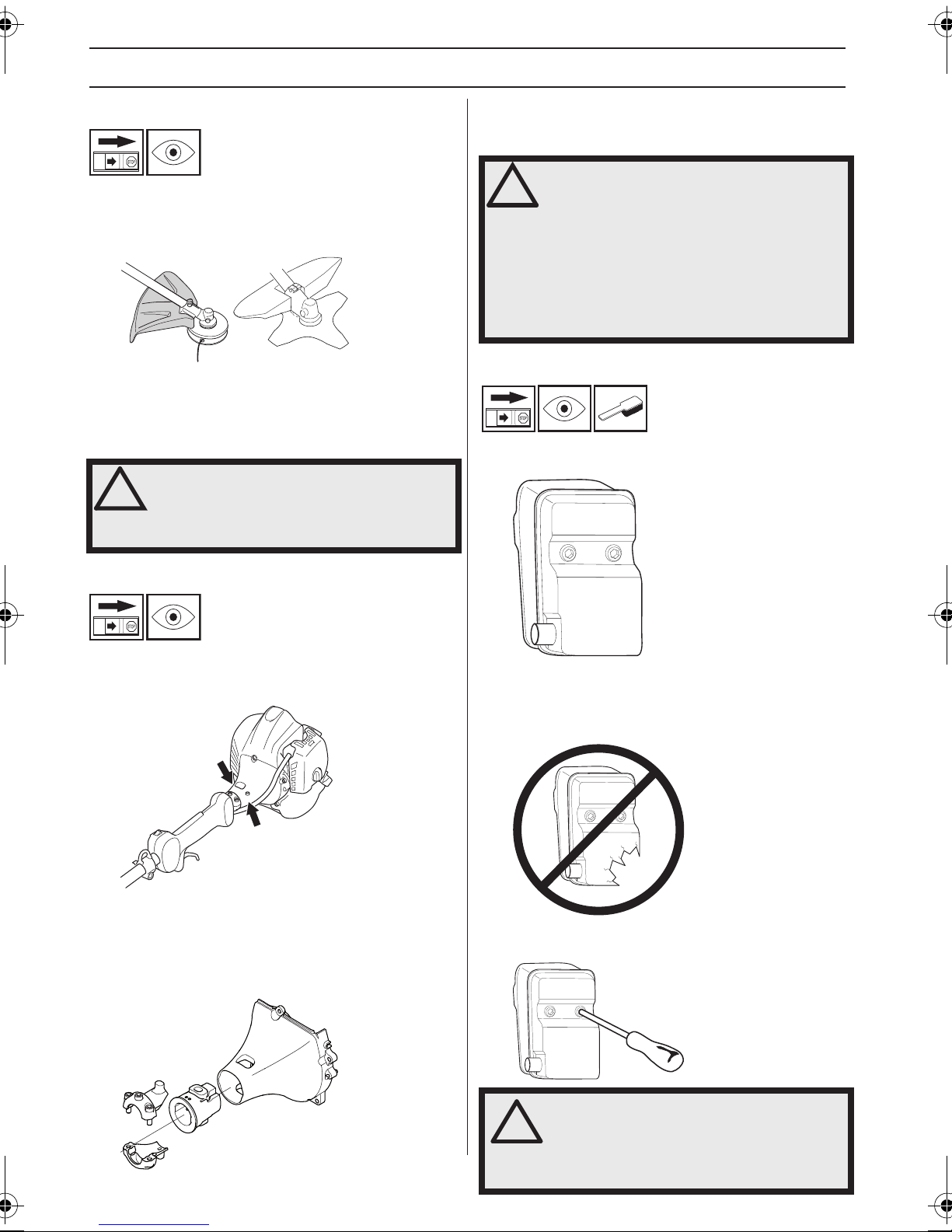

Page 8

GENERAL SAFETY PRECAUTIONS

Cutting attachment guard

This guard is intended to prevent loose objects from being

thrown towards the operator. The guard also protects the

operator from accidental contact with the cutting

attachment.

Check that the guard is undamaged and not cracked.

Replace the guard if it has been exposed to impact or is

cracked.

Always use the recommended guard for the cutting

attachment you are using. See chapter on Technical data.

WARNING! Never use a cutting

!

attachment without an approved guard.

See the chapter on Technical data. If an

incorrect or faulty guard is fitted this can

cause serious personal injury.

Regularly check the vibration damping units for cracks or

deformation. Check that the vibration damping element is

undamaged and securely attached.

WARNING! Overexposure to vibration can

!

lead to circulatory damage or nerve

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure to

vibration. These symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the fingers,

hands or wrists.

Muffler

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

Vibration damping system

Your machine is equipped with a vibration damping

system that is designed to minimize vibration and make

operation easier.

Use of incorrectly wound cord or an incorrect cutting

attachment increases the level of vibration. See

instructions under the heading Cutting equipment.

The machine´s vibration damping system reduces the

transfer of vibration between the engine unit and the

machine´s shaft unit.

For mufflers it is very important that you follow the

instructions on checking, maintaining and servicing your

machine.

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to

the machine.

8 – English

WARNING! The inside of the muffler

!

contain chemicals that may be

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

Page 9

GENERAL SAFETY PRECAUTIONS

WARNING! Bear in mind that:

!

The exhaust fumes from the engine are

hot and may contain sparks which can

start a fire. Never start the machine

indoors or near combustible material!

Locking nut

A locking nut is used to secure some types of cutting

attachment.

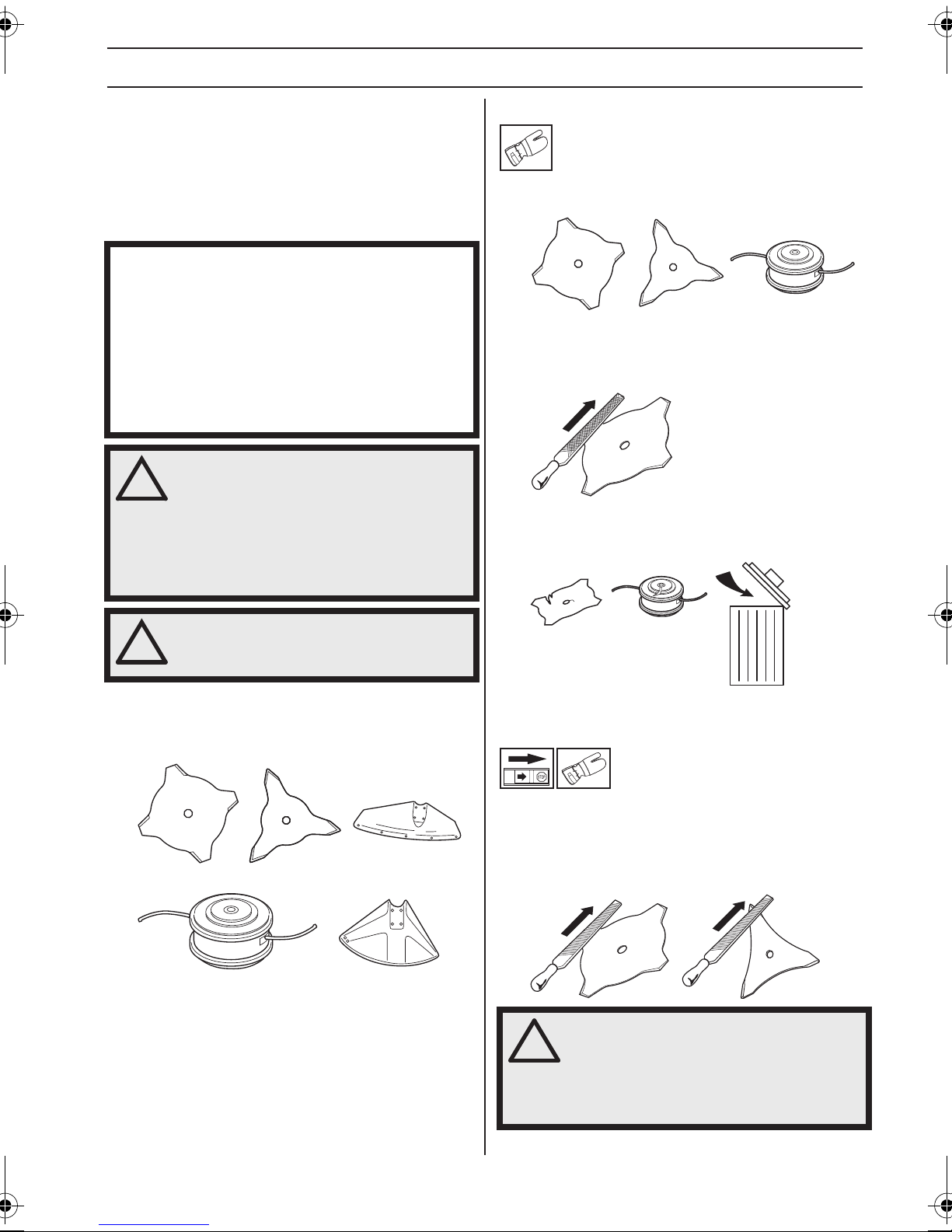

Cutting equipment

This section describes how to choose and maintain your

cutting equipment in order to:

• Reduce the risk of blade thrust.

• Obtain maximum cutting performance.

• Extend the life of cutting equipment.

IMPORTANT!

Only use cutting attachments with the guards we

recommend! See the chapter on Technical data.

Refer to the instructions for the cutting attachment to

check the correct way to load the cord and the correct

cord diameter.

Keep the teeth of the blade correctly sharpened! Follow

our recommendations. Also refer to the instructions on

the blade packaging.

WARNING! Always stop the engine

!

before doing any work on the cutting

attachment. This continues to rotate even

after the throttle has been released.

Ensure that the cutting attachment has

stopped completely and disconnect the

spark plug cap before you start to work

on it.

When fitting, tighten the nut in the opposite direction to the

direction of rotation of the cutting attachment. To remove

it, undo the nut in the same direction as the cutting

attachment rotates. (CAUTION! The nut has a left-hand

thread.)

When loosening and tightening the saw blade nut, there

is a risk of injury from the teeth of the saw blade. You

should therefore always ensure that your hand is shielded

by the blade guard when doing this. Always use a socket

spanner with a shaft that is long enough to allow this. The

arrow in the diagram shows the area where you should

operate the socket spanner when loosening or tightening

the nut.

The nylon lining inside the locking nut must not be so worn

that you can turn it by hand. The lining should offer a

resistance of at least 1.5 Nm. The nut should be replaced

after it has been put on approx. 10 times.

WARNING! Using an incorrect cutting

!

attachment or an incorrectly sharpened

blade increases the risk of blade thrust.

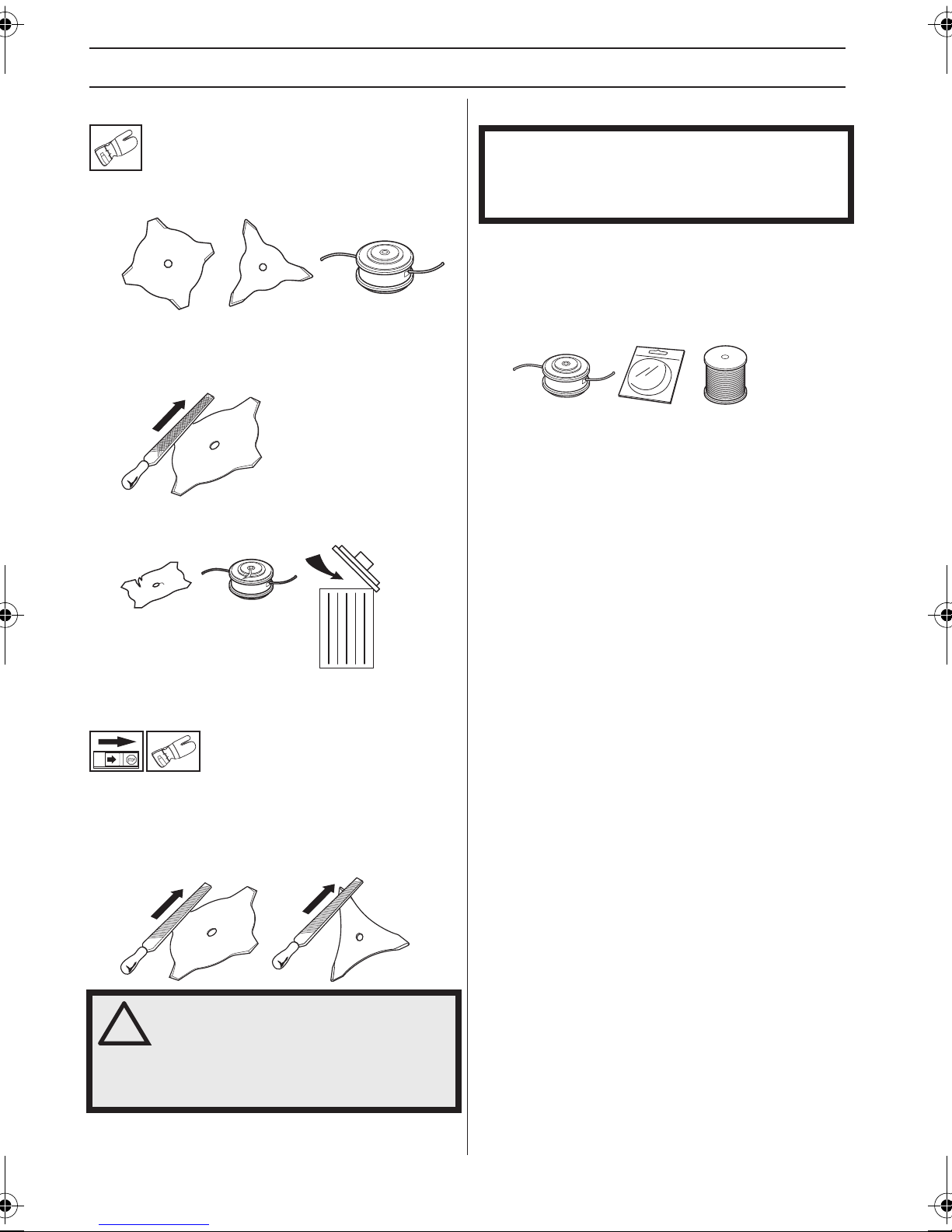

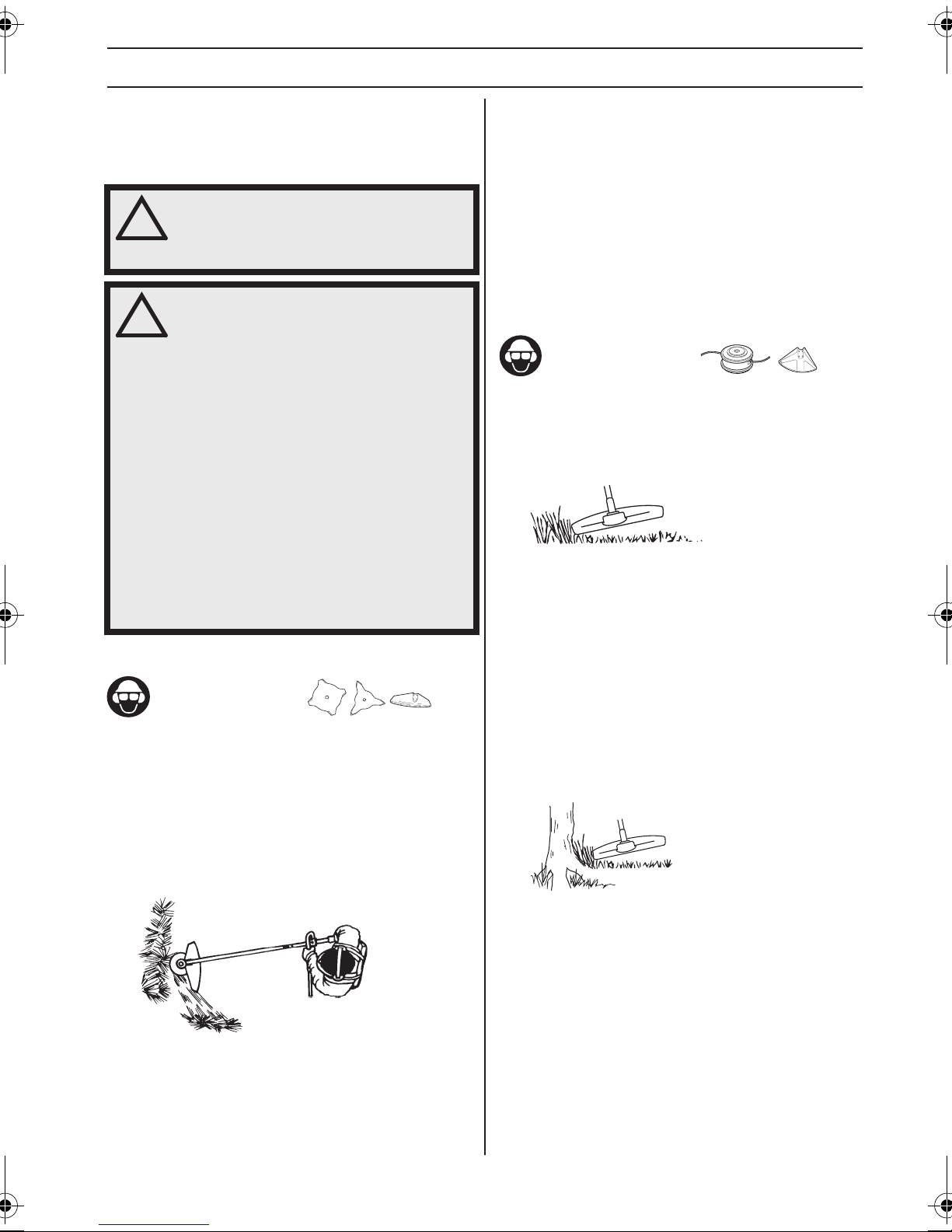

Cutting equipment

Grass blades and grass knifes are intended for cutting

coarse grass.

A trimmer head is intended for trimming grass.

English – 9

Page 10

GENERAL SAFETY PRECAUTIONS

General rules

Only use cutting attachments with the guards we

recommend! See the chapter on Technical data.

Keep the teeth of the blade correctly sharpened! Follow

our instructions and use the recommended file gauge. An

incorrectly sharpened or damaged blade increases the

risk of accidents.

Check the cutting attachment for damage or cracks. A

damaged cutting attachment should always be replaced.

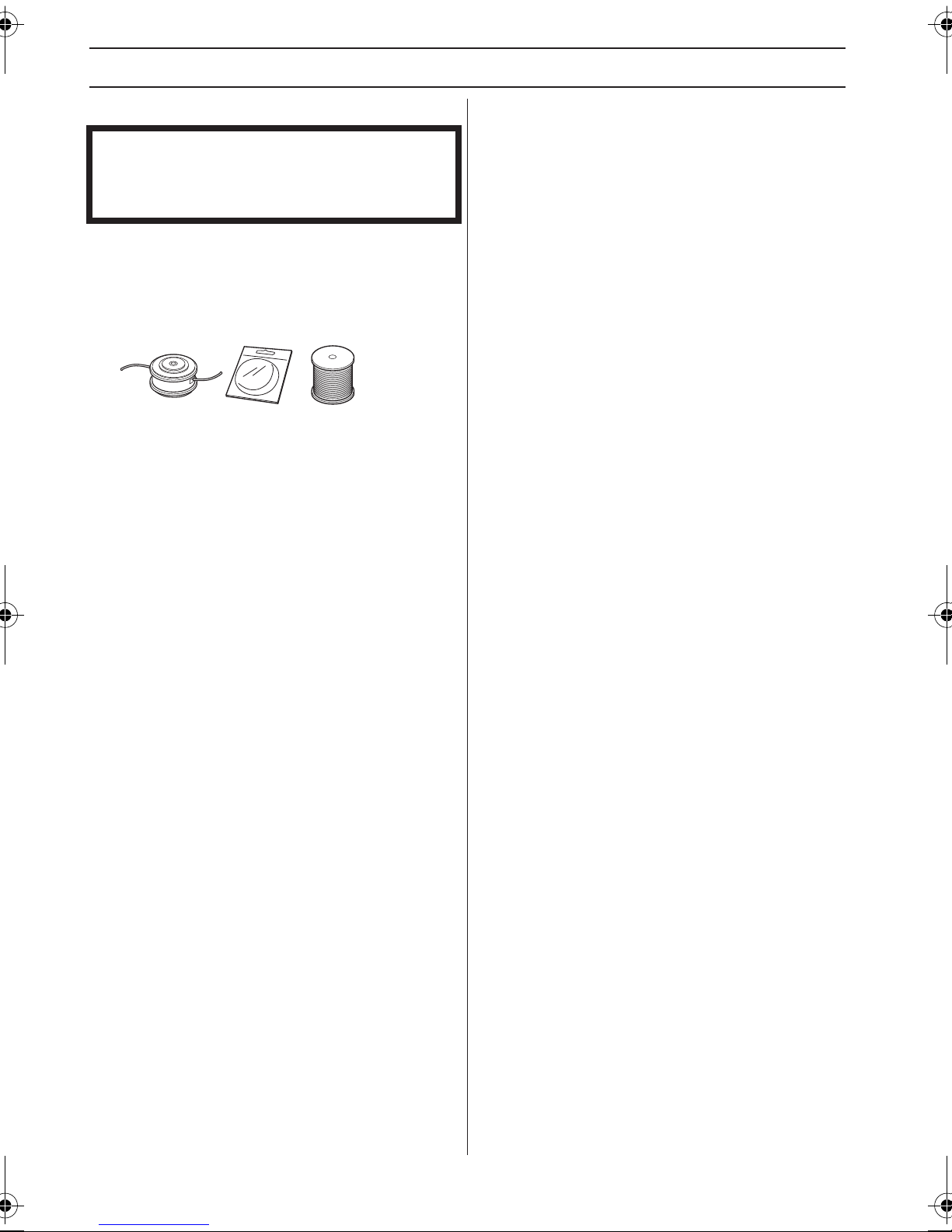

Trimmer head

IMPORTANT!

Always ensure the trimmer cord is wound tightly and

evenly around the drum, otherwise the machine will

generate harmful vibration.

• Only use the recommended trimmer heads and

trimmer cords. These have been tested by the

manufacturer to suit a particular engine size. This is

especially important when a fully automatic trimmer

head is used. Only use the recommended cutting

attachment. See the chapter on Technical data.

• Smaller machines generally require small trimmer

heads and vice versa. This is because when clearing

using a cord the engine must throw out the cord

radially from the trimmer head and overcome the

resistance of the grass being cleared.

• The length of the cord is also important. A longer cord

requires greater engine power than a shorter cord of

the same diameter.

• Make sure that the cutter on the trimmer guard is

intact. This is used to cut the cord to the correct length.

• To increase the life of the cord it can be soaked in

water for a couple of days before use. This will make

the cord tougher so that it lasts longer.

Sharpening grass knifes and grass

blades

• See the cutting attachment packaging for correct

sharpening instructions. Sharpen blades and knifes

using a single-cut flat file.

• Sharpen all edges equally to maintain the balance of

the blade.

WARNING! Always discard a blade that is

!

bent, twisted, cracked, broken or

damaged in any other way. Never attempt

to straighten a twisted blade so that it

can be reused. Only use original blades

of the specified type.

10 – English

Page 11

ASSEMBLY

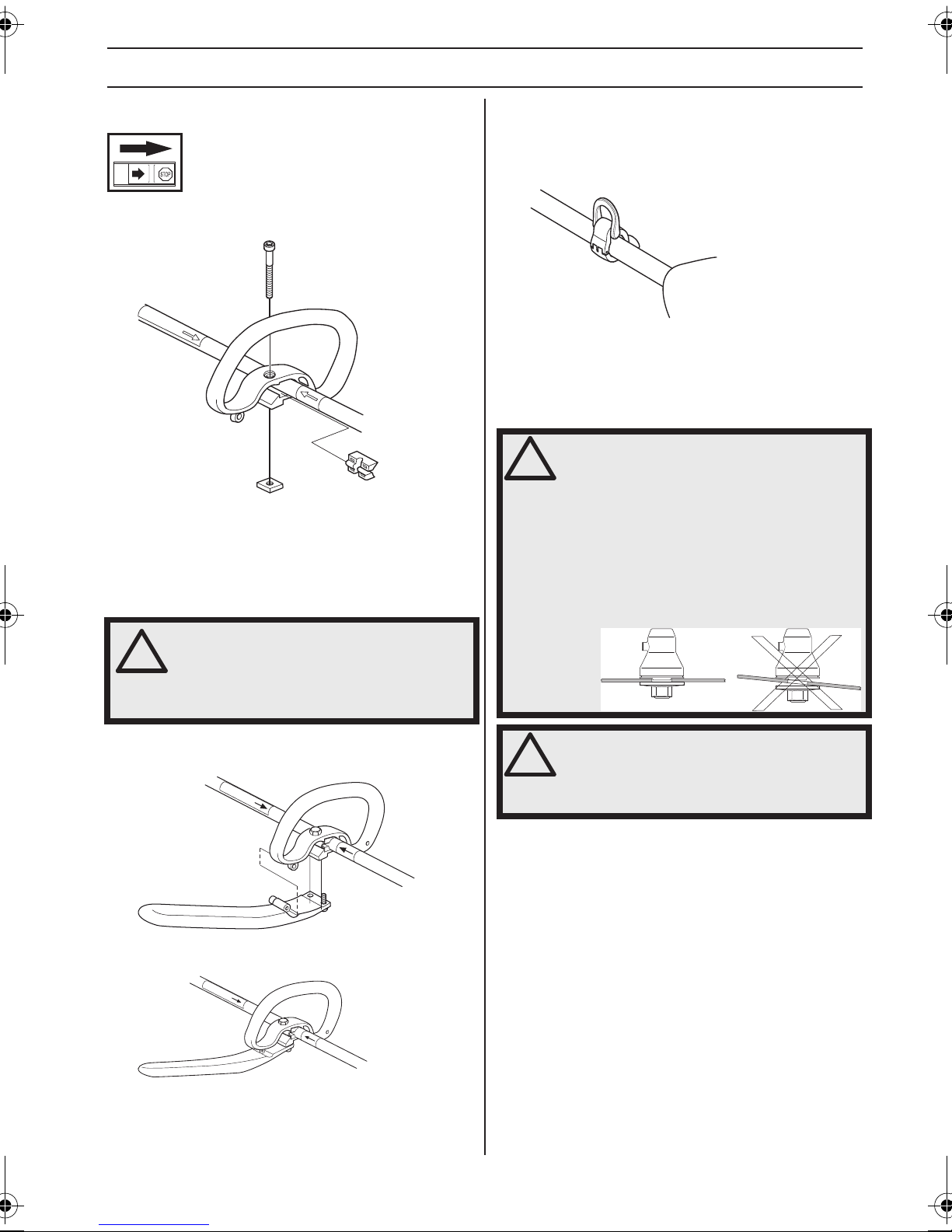

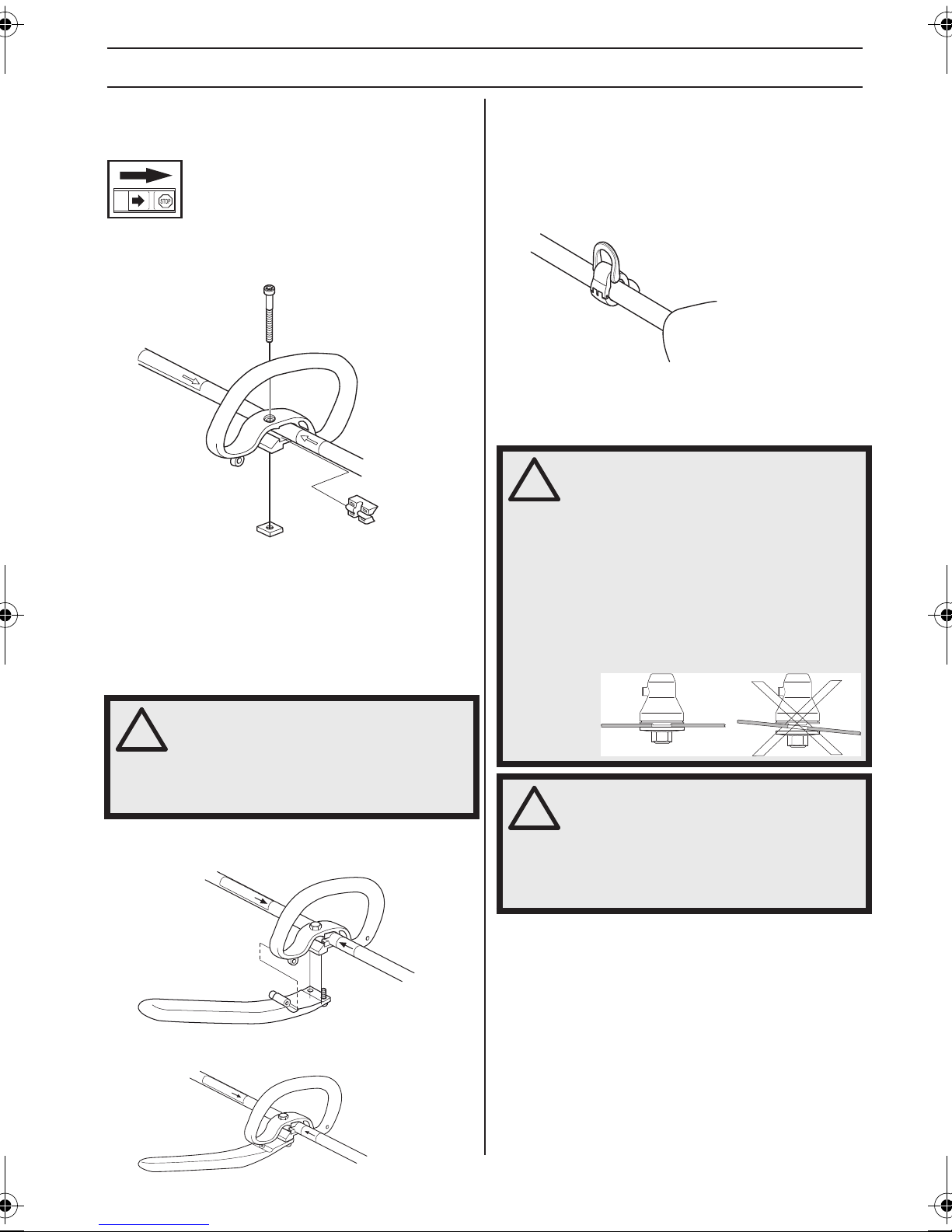

Fitting the loop handle

• Clip the loop handle onto the shaft. Note that the loop

handle must be fitted between the arrows on the shaft.

• Slide the spacer into the slot in the loop handle. Fit the

nut, knob and screw. Do not overtighten.

• Now adjust the trimmer to give a comfortable working

position. Tighten the bolt.

Fitting the J-handle

Fitting the suspension ring

Fit the suspension ring between the rear handle and the

loop handle. Position the hanging ring so that the machine

is balanced and comfortable to work with.

Use the harness and attach it to the suspension ring when

using grass blades.

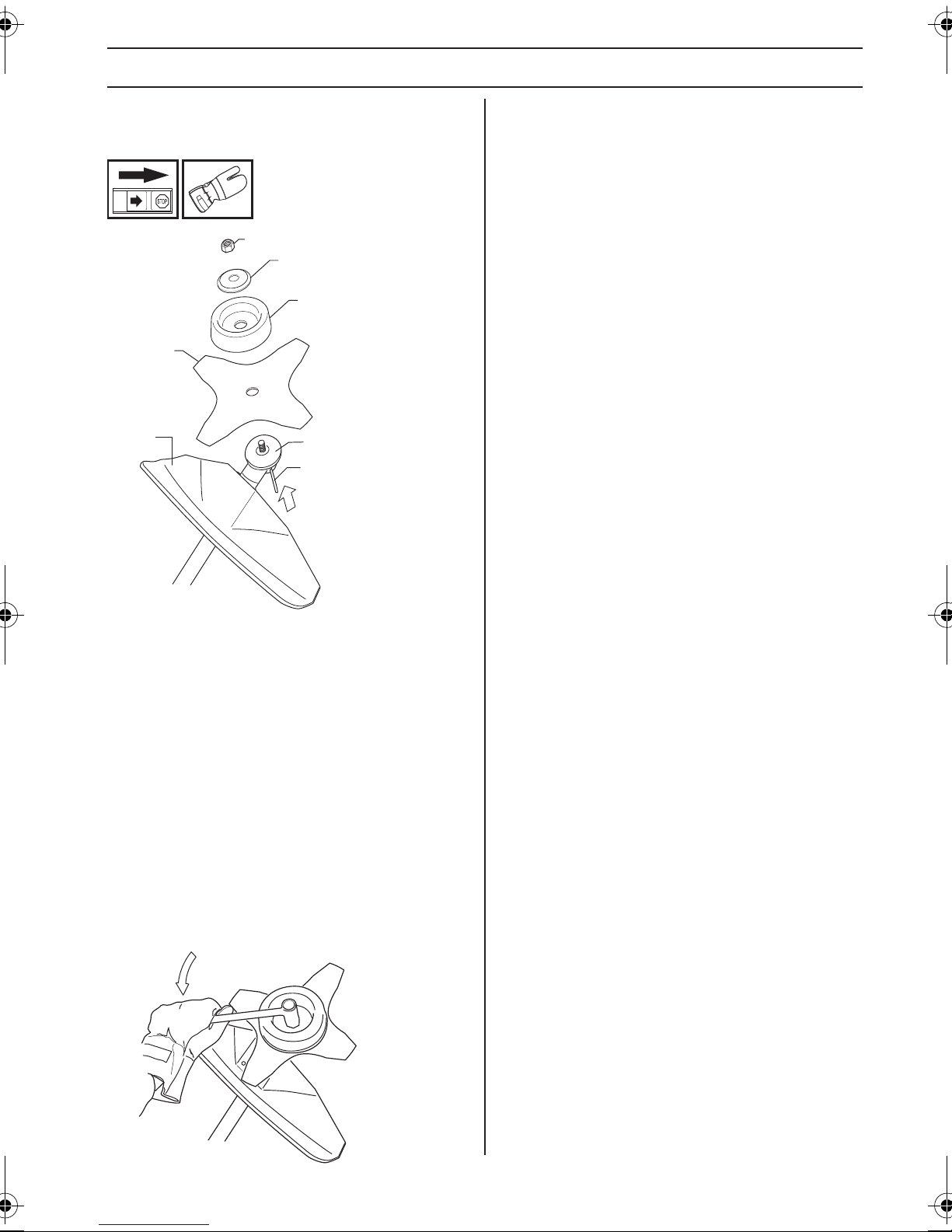

Assembling the cutting

equipment

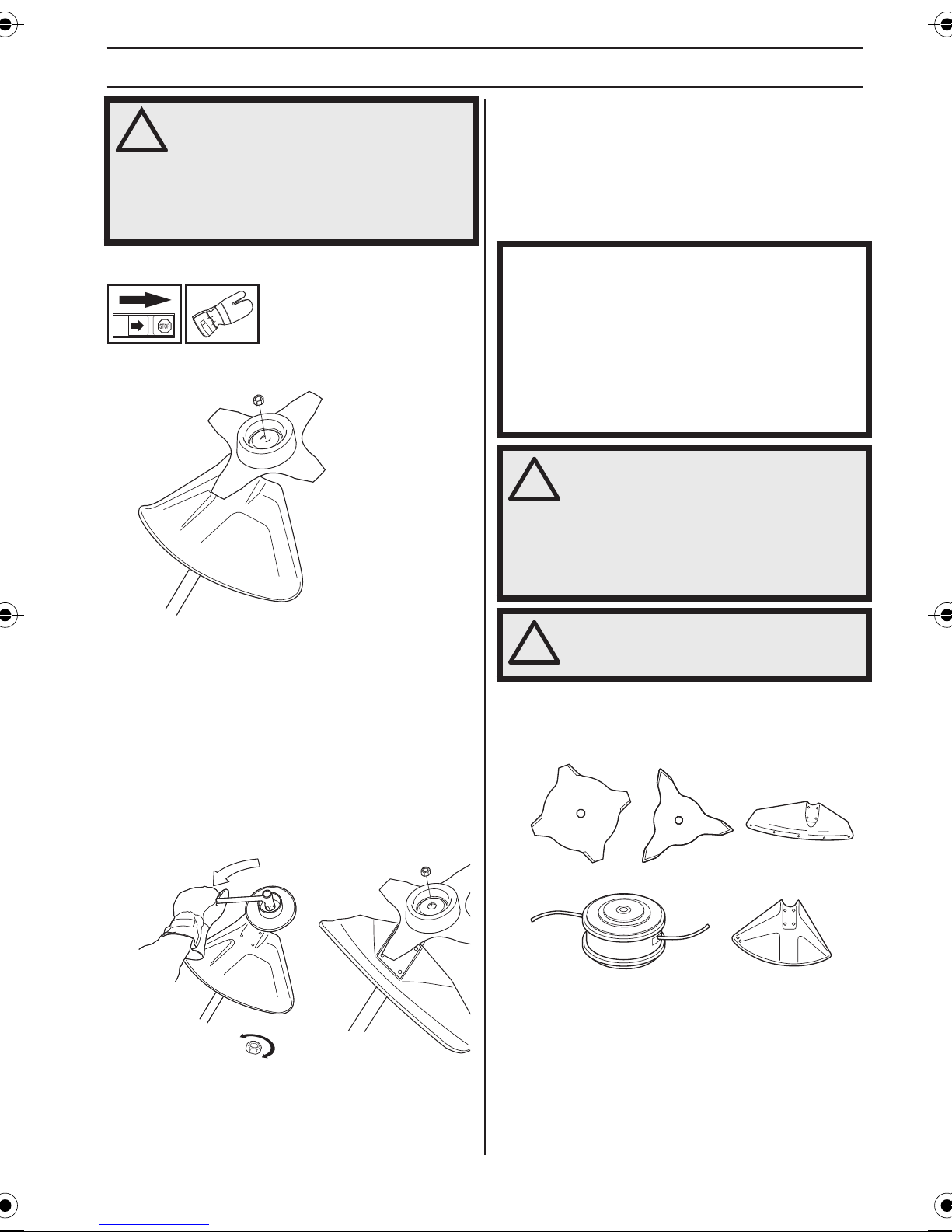

WARNING!

!

When fitting the cutting attachment it is

extremely important that the raised

section on the drive disc/support flange

engages correctly in the centre hole of the

cutting attachment. If the cutting

attachment is fitted incorrectly it can

result in serious and/or fatal personal

injury.

WARNING! Only grass blades/grass

!

Attach the J-handle to the loop handle using the three

screws, as shown.

Now carry out fine adjustment to give yourself a

comfortable working position. Tighten the screws.

cutters or trimmer heads/plastic blades

may be used when the J-handle is fitted.

Saw blades must never be used with the

J-handle.

WARNING! Never use a cutting

!

attachment without an approved guard.

See the chapter on Technical data. If an

incorrect or faulty guard is fitted this can

cause serious personal injury.

English – 11

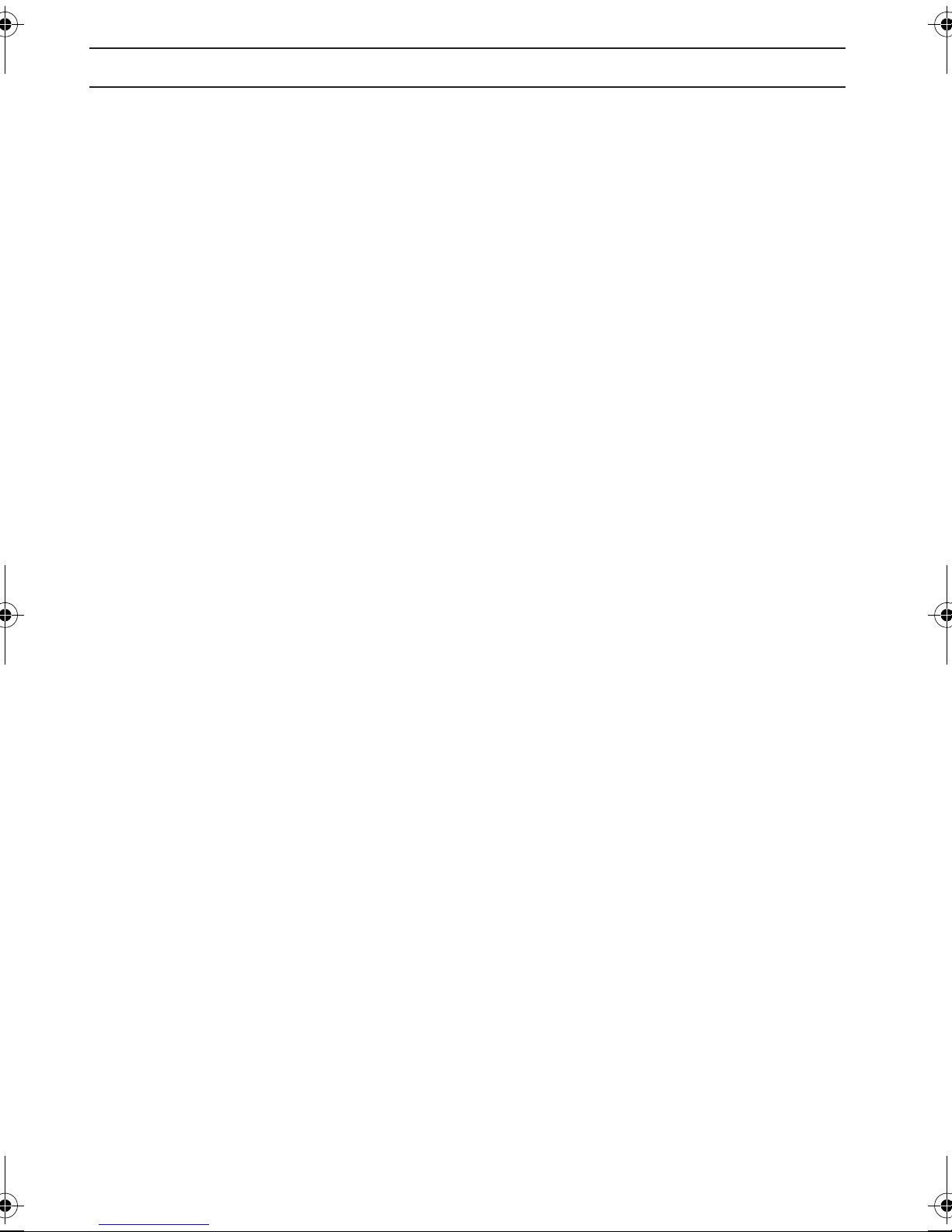

Page 12

ASSEMBLY

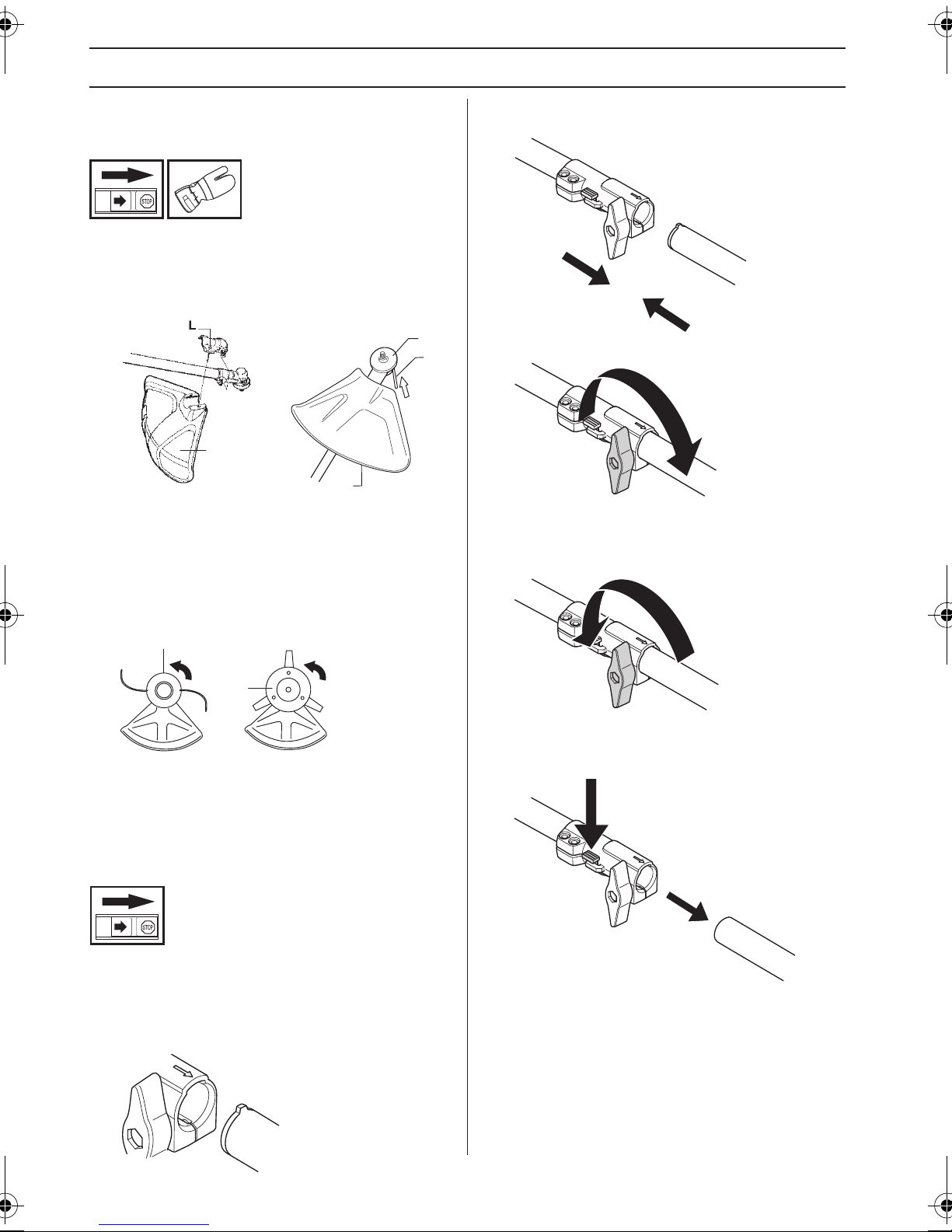

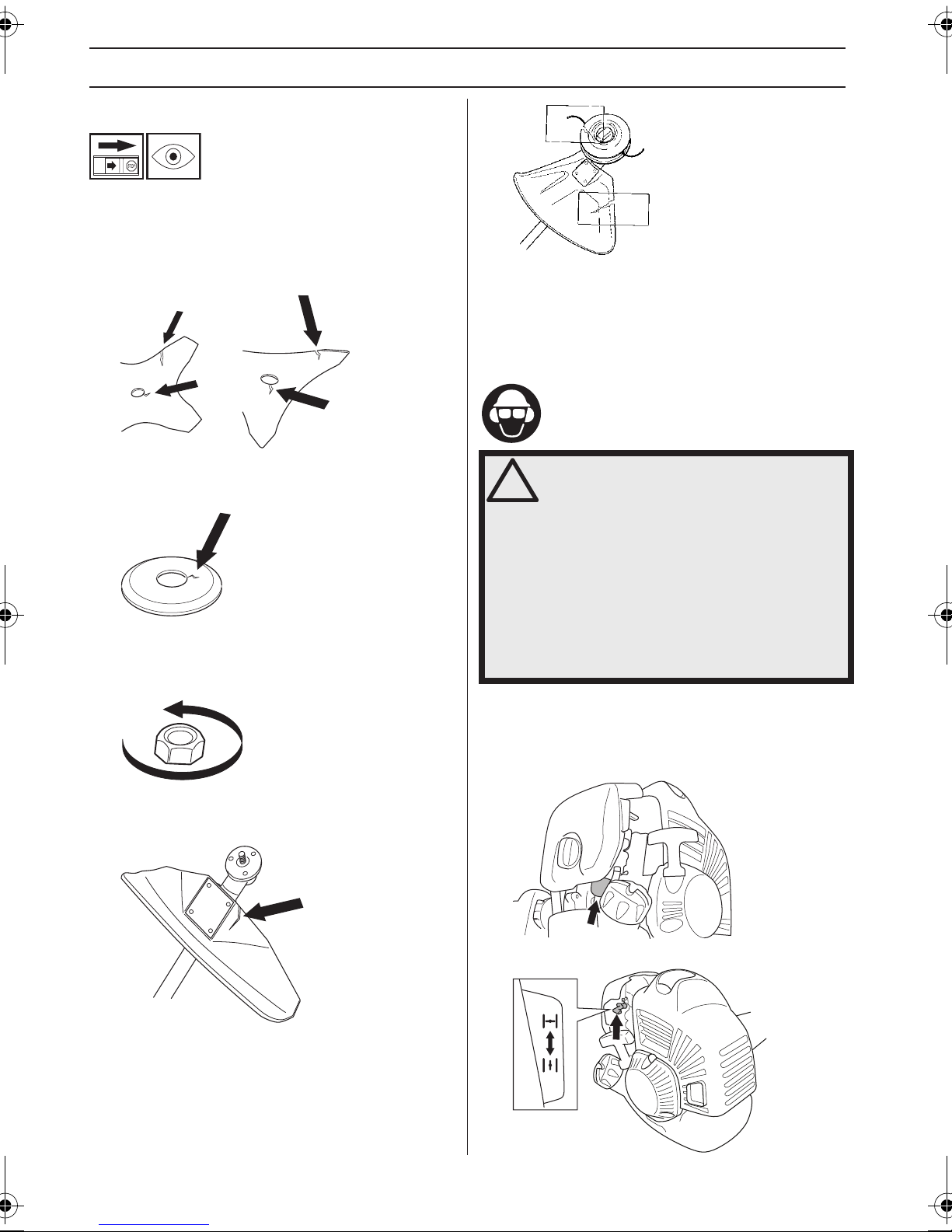

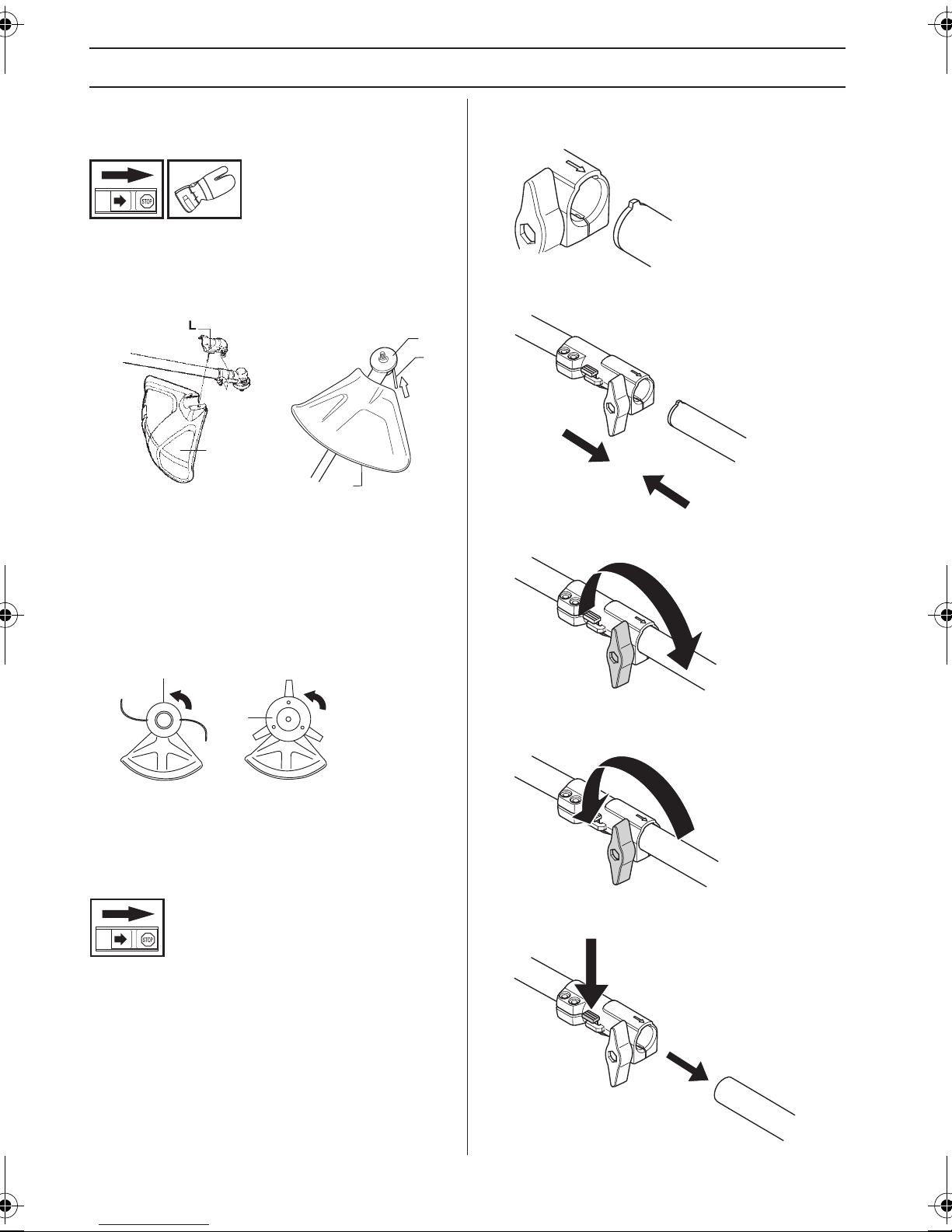

Fitting the trimmer guard and

trimmer head

• Fit the correct trimmer guard (A) for use with the

trimmer head. Hook the trimmer guard/combination

guard onto the fitting on the shaft and secure with the

bolt (L).

B

C

A

A

• Fit the drive disc (B) on the output shaft.

• Turn the output shaft until one of the holes in the drive

disc aligns with the corresponding hole in the gear

housing.

• Insert the locking pin (C) in the hole to lock the shaft.

• Screw on the trimmer head/plastic blades (H) in the

opposite direction to the direction of rotation.

H

• Push the attachment into the coupling until the

attachment snaps into place.

• Before using the unit, tighten the knob securely.

Dismantling

• Loosen the coupling by turning the knob (at least 3

times).

H

• To dismantle, follow the instructions in the reverse

order.

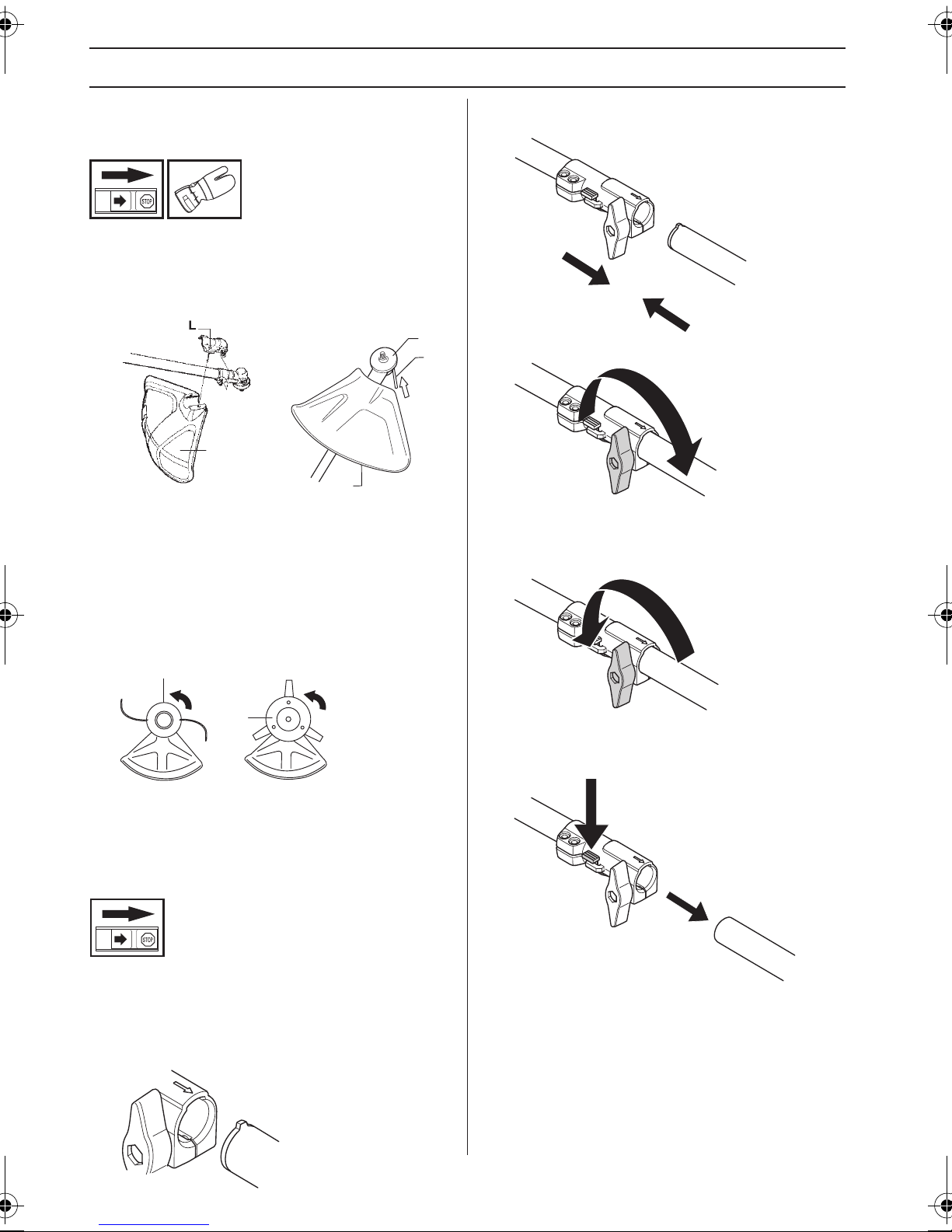

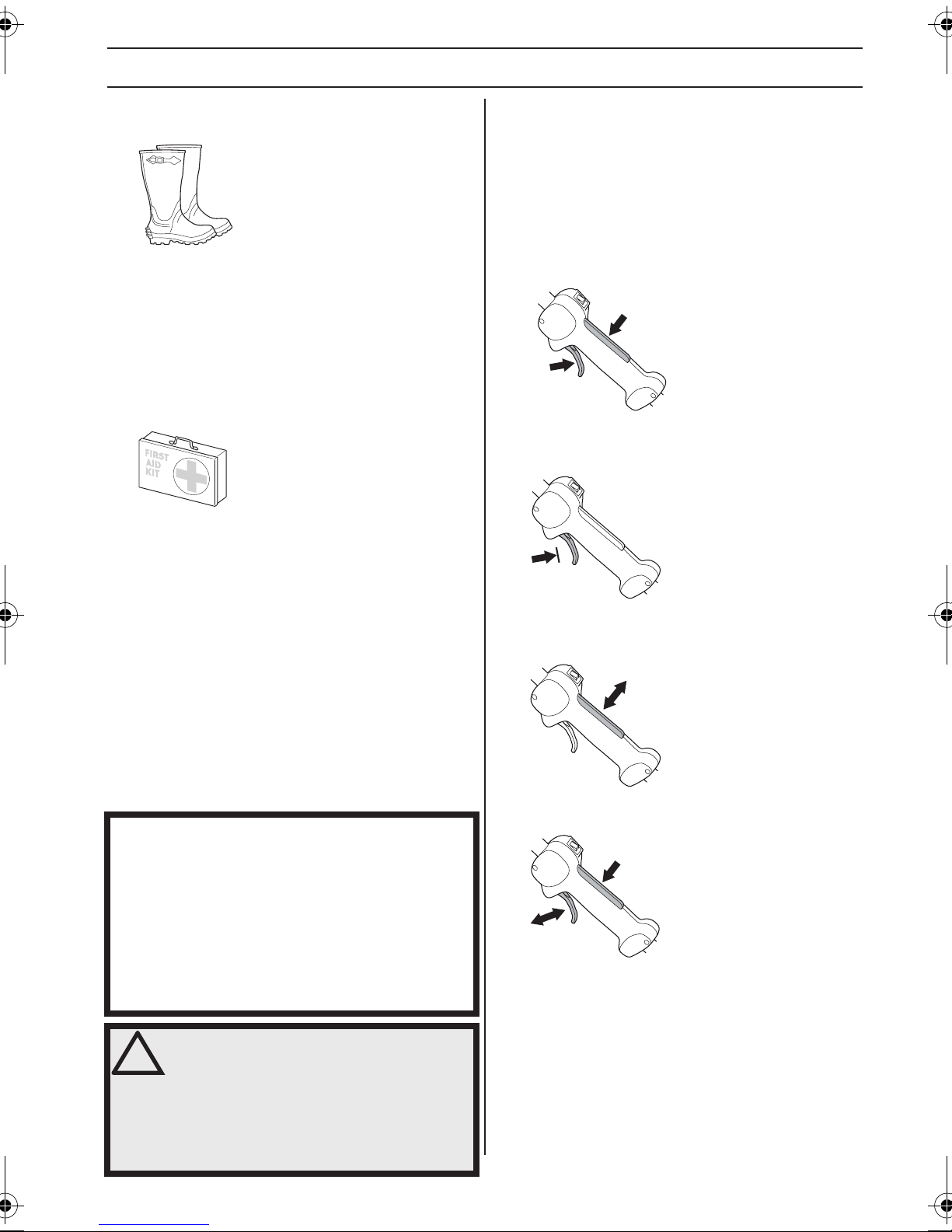

Assembling and dismantling the

two-piece shaft

(GC2225C)

Assembly

• Loosen the coupling by turning the knob.

• Align the tab of the attachment (A) with the arrow on

the coupling (B).

B

A

Push and hold the button (C). While securely holding the

engine end, pull the attachment straight out of the

coupling.

C

12 – English

Page 13

ASSEMBLY

Fitting a blade guard, grass blade

and grass cutter

G

F

E

D

A

• Hook the blade guard/combination guard (A) onto the

fitting on the shaft and secure with the bolt.

CAUTION! Use the recommended blade guard. See the

Technical data section.

• Fit the drive disc (B) on the output shaft.

• Turn the output shaft until one of the holes in the drive

disc aligns with the corresponding hole in the gear

housing.

• Insert the locking pin (C) in the hole to lock the shaft.

• Place the blade (D), support cup (E) and support

flange (F) on the output shaft.

• Fit the nut (G). The nut must be tightened to a torque

of 35-50 Nm (3.5-5 kpm). Use the socket spanner in

the tool kit. Hold the shaft of the spanner as close to

the blade guard as possible. To tighten the nut, turn

the spanner in the opposite direction to the direction

of rotation (Caution! left-hand thread).

B

C

English – 13

Page 14

FUEL HANDLING

Fuel safety

Never start the machine:

1 If you have spilled fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

2 If you have spilled fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for

leaks from the fuel cap and fuel lines.

Transport and storage

• Store and transport the machine and fuel so that there

is no risk of any leakage or fumes coming into contact

with sparks or open flames, for example, from

electrical machinery, electric motors, electrical relays/

switches or boilers.

• When storing and transporting fuel always use

approved containers intended for this purpose.

• When storing the machine for long periods the fuel

tank must be emptied. Contact your local petrol

station to find out where to dispose of excess fuel.

• Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

• The transport guard must always be fitted to the

cutting attachment when the machine is being

transported or in storage.

• Secure the machine during transport.

• In order to prevent unintentional starting of the engine,

the spark plug cap must always be removed during

long-term storage, if the machine is not under close

supervision and when performing all service

measures.

WARNING! Take care when handling fuel.

!

Bear in mind the risk of fire, explosion

and inhaling fumes.

Fuel

CAUTION! The machine is equipped with a two-stroke

engine and must always be run using a mixture of petrol

and two-stroke oil. It is important to accurately measure

the amount of oil to be mixed to ensure that the correct

mixture is obtained. When mixing small amounts of fuel,

even small inaccuracies can drastically affect the ratio of

the mixture.

WARNING! Fuel and fuel fumes are

!

highly inflammable and can cause

serious injury when inhaled or allowed to

come in contact with the skin. For this

reason observe caution when handling

fuel and make sure there is adequate

ventilation.

Petrol

CAUTION! Always use a quality petrol/oil mixture at least

90 octane (RON). If your machine is equipped with a

catalytic converter (see chapter on Technical data) always

use a good quality unleaded petrol/oil mixture. Leaded

petrol will destroy the catalytic converter.

Use low-emission petrol, also known as alkylate petrol, if

it is available.

Ethanol blended fuel, E10 may be used (max 10%

ethanol blend). Using ethanol blends higher than E10 will

create lean running condition which can cause engine

damage.

• The lowest octane recommended is 90 (RON). If you

run the engine on a lower octane grade than 90 socalled knocking can occur. This gives rise to a high

engine temperature, which can result in serious

engine damage.

• When working at continuous high revs a higher octane

rating is recommended.

Two-stroke oil

• For best results and performance use JONSERED

two-stroke engine oil, which is specially formulated for

our air-cooled two-stroke engines.

• Never use two-stroke oil intended for water-cooled

engines, sometimes referred to as outboard oil (rated

TCW).

• Never use oil intended for four-stroke engines.

• A poor oil quality and/or too high oil/fuel ratio may

jeopardise function and decrease the life time of

catalytic converters.

• Mixing ratio

1:50 (2%) with JONSERED two-stroke oil.

1:33 (3%) with oils class JASO FB or ISO EGB

formulated for air-cooled, two-stroke engines.

Petrol, litre

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Two-stroke oil, litre

2% (1:50) 3% (1:33)

14 – English

Page 15

FUEL HANDLING

Mixing

• Always mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to

be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

petrol.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

• Clean the area around the fuel cap. Contamination in

the tank can cause operating problems.

• Ensure that the fuel is well mixed by shaking the

container before filling the tank.

Fueling

!

WARNING! Taking the following

precautions, will lessen the risk of fire:

Mix and pour fuel outdoors, where there

are no sparks or flames.

Do not smoke or place hot objects near

fuel.

Always shut off the engine before

refuelling.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

Always move the machine away from the

refuelling area and source before

starting.

• If you have spilled fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

• Always use a fuel container with an anti-spill valve.

English – 15

Page 16

STARTING AND STOPPING

Check before starting

Check the blade to ensure that no cracks have formed at

the bottom of the teeth or by the centre hole. The most

common reason why cracks are formed is that sharp

corners have been formed at the bottom of the teeth while

sharpening or that the blade has been used with dull

teeth. Discard a blade if cracks are found.

• Never use the machine without a guard nor with a

defective guard.

• All covers must be correctly fitted and undamaged

before you start the machine.

Starting and stopping

• Check that the support flange is not cracked due to

fatigue or due to being tightened too much. Discard

the support flange if it is cracked.

Ensure the locking nut has not lost its captive force. The

nut lock should have a locking force of at least 1.5 Nm.

The tightening torque of the locking nut should be 35-50

Nm.

Check that the blade guard is not damaged or cracked.

Replace the blade guard if it is exposed to impact or is

cracked.

WARNING! The complete clutch cover and

!

shaft must be fitted before the machine is

started, otherwise the clutch can come

loose and cause personal injury.

Always move the machine away from the

refuelling area and source before starting.

Place the machine on a flat surface.

Ensure the cutting attachment cannot

come into contact with any object.

Make sure no unauthorised persons are in

the working area. Otherwise there is a risk

of serious personal injury. The safety

distance is 15 meters.

Starting

Primer bulb: Press the air purge repeatedly until fuel

begins to fill the bulb. The bulb need not be completely

filled.

• Check that the trimmer head and trimmer guard are

not damaged or cracked. Replace the trimmer head or

trimmer guard if they have been exposed to impact or

are cracked.

16 – English

Choke: Move choke control up to choke position.

Page 17

STARTING AND STOPPING

WARNING! When the engine is started

!

Hold the body of the machine on the ground using your

left hand (CAUTION! Not with your foot!).

Firmly grasp throttle lockout (A) and throttle control (B)

with left hand, pull the starter knob quickly until engine

attempts to start, or maximum 5 pulls.

with the choke in either the choke or

start throttle positions the cutting

attachment will start to rotate

immediately.

A

B

Never twist the starter cord around your hand.

After engine attempts to start, or maximum 5 pulls, move

the choke lever down to run position.

Grasp the throttle lockout (A) and the throttle trigger (B)

and repeat pulling the cord until the engine starts. Make

sure that the machine reaches full throttle and then

release the throttle trigger. Once the engine starts, allow

the engine to warm up for 30 seconds before applying full

throttle.

CAUTION! Do not pull the starter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

Stopping

Stop the engine by switching off the ignition.

CAUTION! The stop switch automatically returns to the

start position. In order to prevent unintentional starting,

the spark plug cap must be removed from the spark plug

when assembling, checking and/or performing

maintenance.

CAUTION! Do not put any part of your body in marked

area. Contact can result in burns to the skin, or electrical

shock if the spark plug cap has been damaged. Always

use gloves. Do not use a machine with damaged spark

plug cap.

English – 17

Page 18

WORKING TECHNIQUES

General working instructions

IMPORTANT!

This section describes the basic safety precautions for

working with brush cutters and trimmers.

If you encounter a situation where you are uncertain

how to proceed you should ask an expert. Contact your

dealer or your service workshop.

Avoid all usage which you consider to be beyond your

capability.

You must understand the difference between forestry

clearing, grass clearing and grass trimming before use.

Grass blades or grass knives may only be used when

the J-handle is fitted. Clearing blades must never be

used with the J-handle. Use the harness and attach it to

the suspension ring when using grass blades.

Basic safety rules

1 Look around you:

• To ensure that people, animals or other things cannot

affect your control of the machine.

• To ensure that people, animals, etc., do not come into

contact with the cutting attachment or loose objects

that are thrown out by the cutting attachment.

• CAUTION! Do not use the machine unless you are

able to call for help in the event of an accident.

2 Inspect the working area. Remove all loose objects,

such as stones, broken glass, nails, steel wire, string,

etc. that could be thrown out or become wrapped

around the cutting attachment.

3 Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

Working in bad weather is tiring and often brings

added risks, such as icy ground, unpredictable felling

direction, etc.

4 Make sure you can move and stand safely. Check the

area around you for possible obstacles (roots, rocks,

branches, ditches, etc.) in case you have to move

suddenly. Take great care when working on sloping

ground.

6 Always hold the machine with both hands. Hold the

machine on the right side of your body.

7 Keep the cutting attachment below waist level.

8 Switch off the engine before moving to another area.

Fit the transport guard before carrying or transporting

the equipment any distance.

9 Never put the machine down with the engine running

unless you have it in clear sight.

WARNING! Neither the operator of the

!

!

machine nor anyone else may attempt to

remove the cut material while the engine

is running or the cutting equipment is

rotating, as this can result in serious

injury.

Stop the engine and cutting equipment

before you remove material that has

wound around the blade shaft as

otherwise there is a risk of injury. The

bevel gear can get hot during use and

may remain so for a while afterwards. You

could get burnt if you touch it.

WARNING! Watch out for thrown objects.

Always wear approved eye protection.

Never lean over the cutting attachment

guard. Stones, rubbish, etc. can be

thrown up into the eyes causing

blindness or serious injury.

Keep unauthorised persons at a

distance. Children, animals, onlookers

and helpers should be kept outside the

safety zone of 15 metres. Stop the

machine immediately if anyone

approaches. Never swing the machine

around without first checking behind you

to make sure no-one is within the safety

zone.

5 Keep a good balance and a firm foothold.

18 – English

Page 19

WORKING TECHNIQUES

Basic working techniques

Always slow the engine to idle speed after each working

operation. Long periods at full throttle without any load on

the engine can lead to serious engine damage.

WARNING! Sometimes branches or

!

!

grass get caught between the guard and

cutting attachment. Always stop the

engine before cleaning.

WARNING! Machines fitted with saw

blades or grass blades can be thrown

violently to the side when the blade

comes into contact with a fixed object.

This is called blade thrust. A blade thrust

can be violent enough to cause the

machine and/or operator to be propelled

in any direction, and possibly lose

control of the machine. Blade thrust can

occur without warning if the machine

snags, stalls or binds. Blade thrust is

more likely to occur in areas where it is

difficult to see the material being cut.

Avoid cutting with the area of the blade

between the 12 o'clock and 3 o'clock

positions. Because of the speed of

rotation of the blade, blade thrust can

occur if you attempt to cut thick stems

with this area of the blade.

Grass clearing using a grass blade

• Grass blades and grass knifes must not be used on

woody stems.

• A grass blade is used for all types of tall or coarse

grass.

• The grass is cut down with a sideways, swinging

movement, where the movement from right-to-left is

the clearing stroke and the movement from left-toright is the return stroke. Let the left-hand side of the

blade (between 8 and 12 o’clock) do the cutting.

• Let the support cup rest lightly against the ground. It

is used to protect the blade from hitting the ground.

• Reduce the risk of material wrapping around the blade

by following these instructions:

1Always work at full throttle.

2Avoid the previously cut material during the return

stroke.

• Stop the engine, unclip the harness and place the

machine on the ground before you start to collect the

cut material.

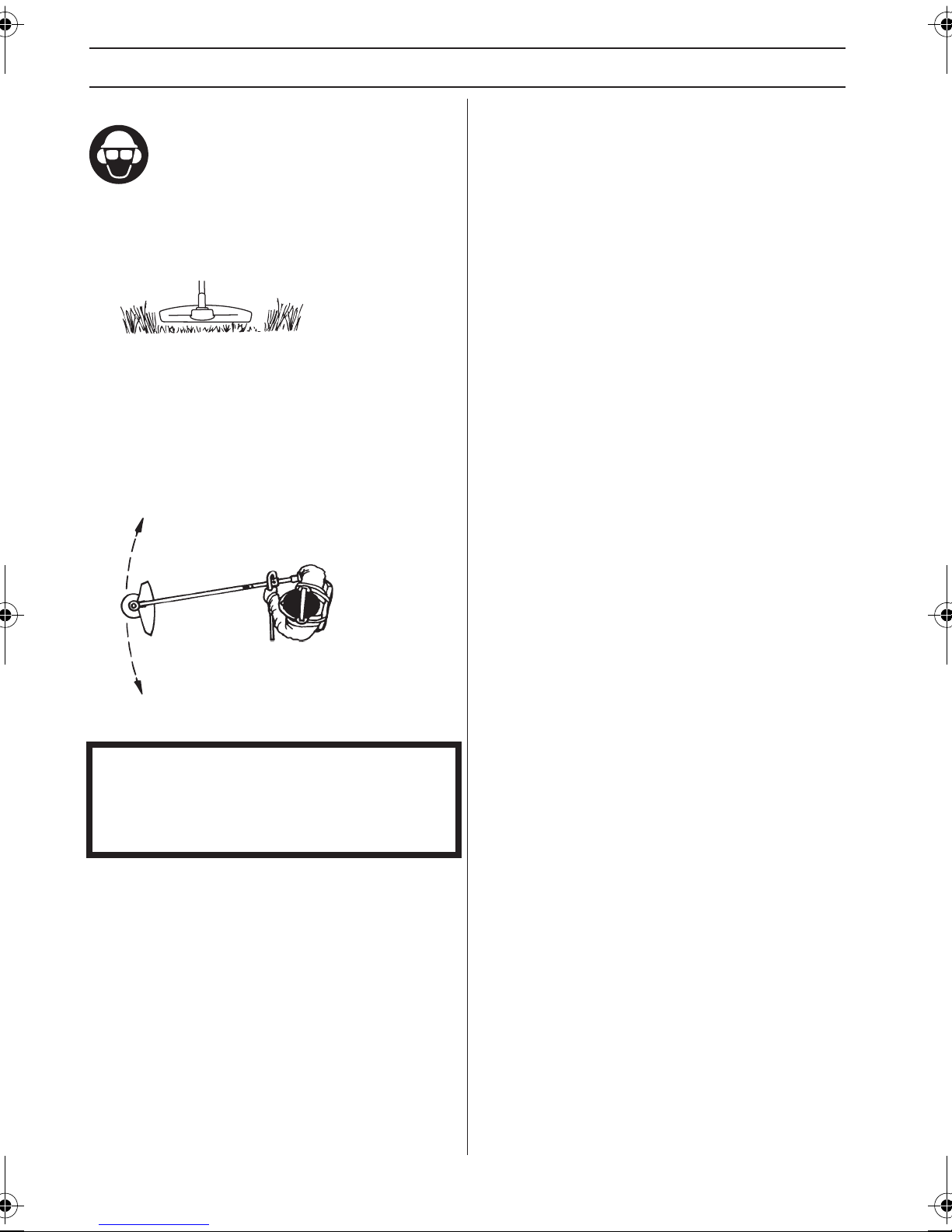

Grass trimming with a trimmer head

Trimming

• Hold the trimmer head just above the ground at an

angle. It is the end of the cord that does the work. Let

the cord work at its own pace. Never press the cord

into the area to be cut.

• The cord can easily remove grass and weeds up

against walls, fences, trees and borders. However it

can also damage sensitive bark on trees and bushes,

and damage fence posts.

• Reduce the risk of damaging plants by shortening the

cord to 10-12 cm and reducing the engine speed.

Clearing

• The clearing technique removes all unwanted

vegetation. Keep the trimmer head just above the

ground and tilt it. Let the end of the cord strike the

ground around trees, posts, statues and the like.

CAUTION! This technique increases the wear on the

cord.

• The cord wears quicker and must be fed forward more

often when working against stones, brick, concrete,

metal fences, etc., than when coming into contact with

trees and wooden fences.

• When trimming and clearing, you should use less than

full throttle (80%) so that the cord lasts longer and to

reduce the wear on the trimmer head.

• If the blade is angled to the left when clearing grass,

the grass will collect in a line, which makes it easier to

collect, e.g. by raking.

• Try to work rhythmically. Stand firmly with your feet

apart. Move forward after the return stroke and stand

firmly again.

English – 19

Page 20

WORKING TECHNIQUES

Cutting

• The trimmer is ideal for cutting grass that is difficult to

reach using a normal lawn mower. Keep the cord

parallel to the ground when cutting. Avoid pressing the

trimmer head against the ground as this can ruin the

lawn and damage the tool.

• Do not allow the trimmer head to constantly come into

contact with the ground during normal cutting.

Constant contact of this type can cause damage and

wear to the trimmer head.

Sweeping

• The fan effect of the rotating cord can be used for

quick and easy clearing up. Hold the cord parallel to

and above the area to be swept and move the tool side

to side.

• When cutting and sweeping you should use full

throttle to obtain the best results.

IMPORTANT!

To avoid unbalance and vibrations in handles trimmer

head cover need to be cleaned every time cord is

refilled. In addition, check other part of the head if

needed to be cleaned.

20 – English

Page 21

MAINTENANCE

Carburettor

Your Jonsered product has been designed and

manufactured to specifications that reduce harmful

exhaust fumes. The engine will be run in after it has used

8-10 tanks of fuel. To ensure that the engine runs at peak

performance and produces as little harmful exhaust

fumes as possible after the running-in period, ask your

dealer/service workshop (which has a rev counter for this

purpose) to adjust your carburettor.

Basic setting

• The basic carburettor settings are adjusted during

testing at the factory. The basic setting is richer than

the optimal setting and should be maintained for the

first few hours the machine is in use. The carburettor

should then be finely adjusted. Fine adjustment

should be carried out by a skilled technician.

CAUTION! If the cutting attachment rotates when the

engine is idling the idle adjustment screw T should be

turned anti-clockwise until the cutting attachment stops.

Adjustment of the idle speed

Before any adjustments are made, make sure that the air

filter is clean and the air filter cover is fitted.

Adjust the idle speed using the idle adjustment screw T, if

it is necessary to readjust. First turn the idle adjustment

screw T clockwise until the cutting attachment starts to

rotate. Then turn the screw anticlockwise until the cutting

attachment stops. The idle speed is correctly adjusted

when the engine will run smoothly in every position. The

idle speed should also be well below the speed at which

the cutting attachment starts to rotate.

T

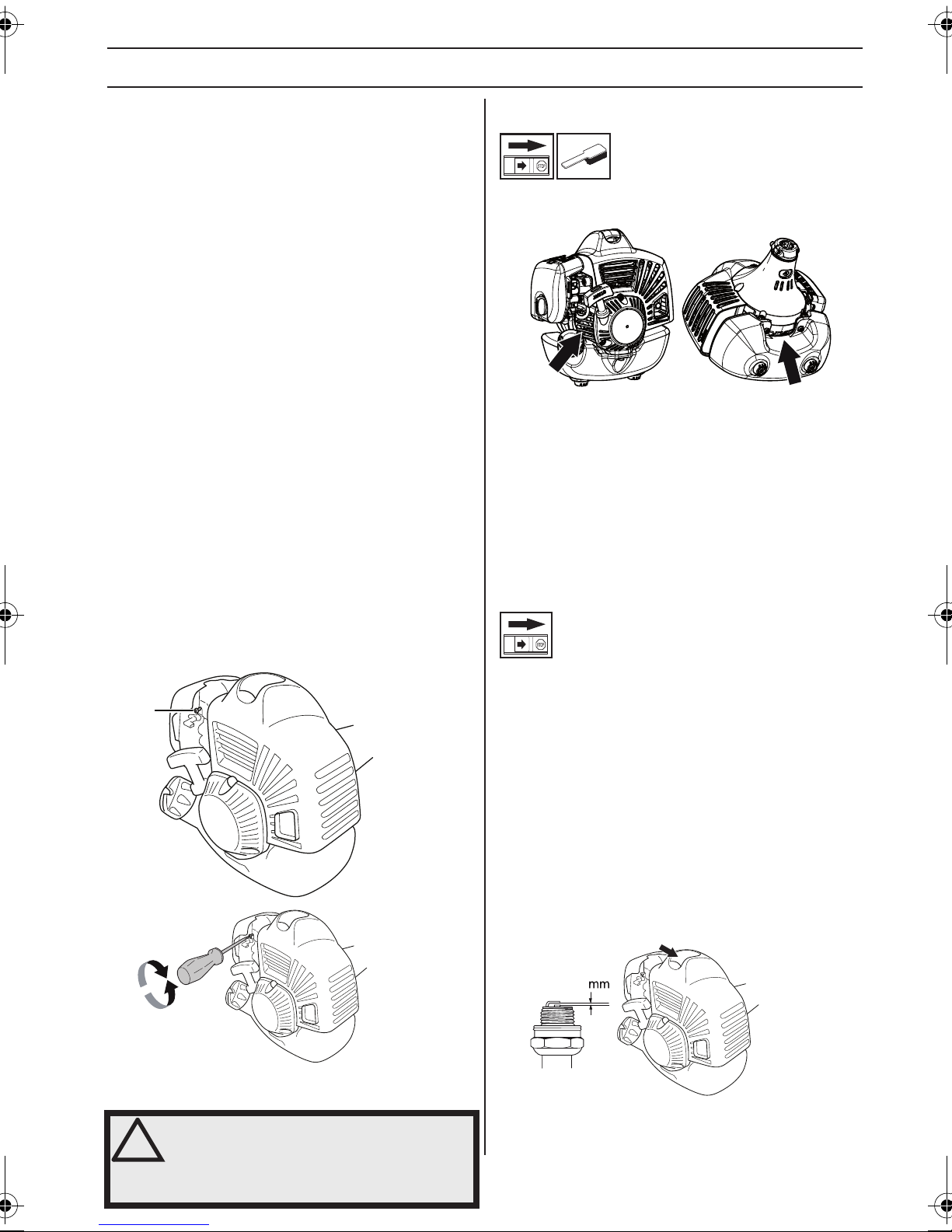

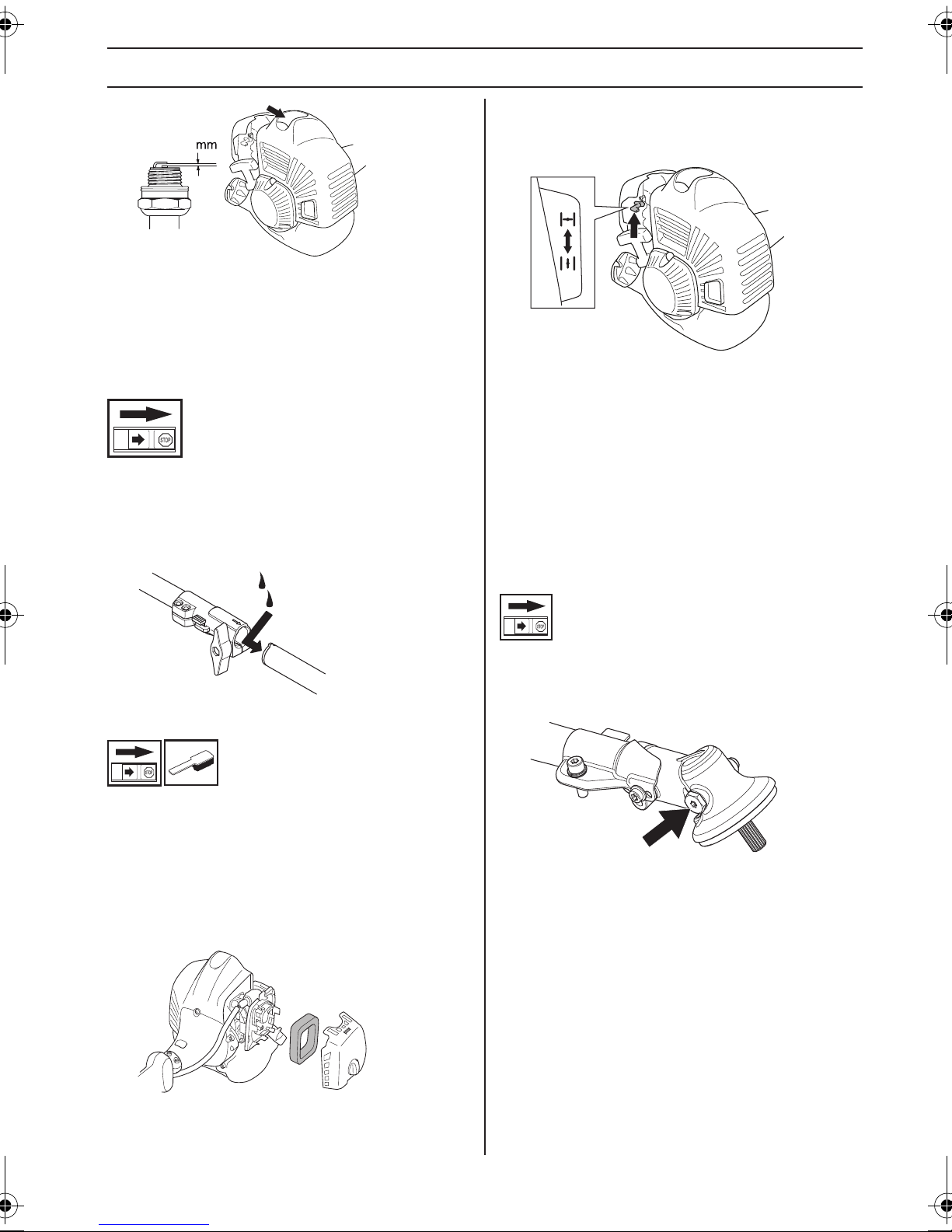

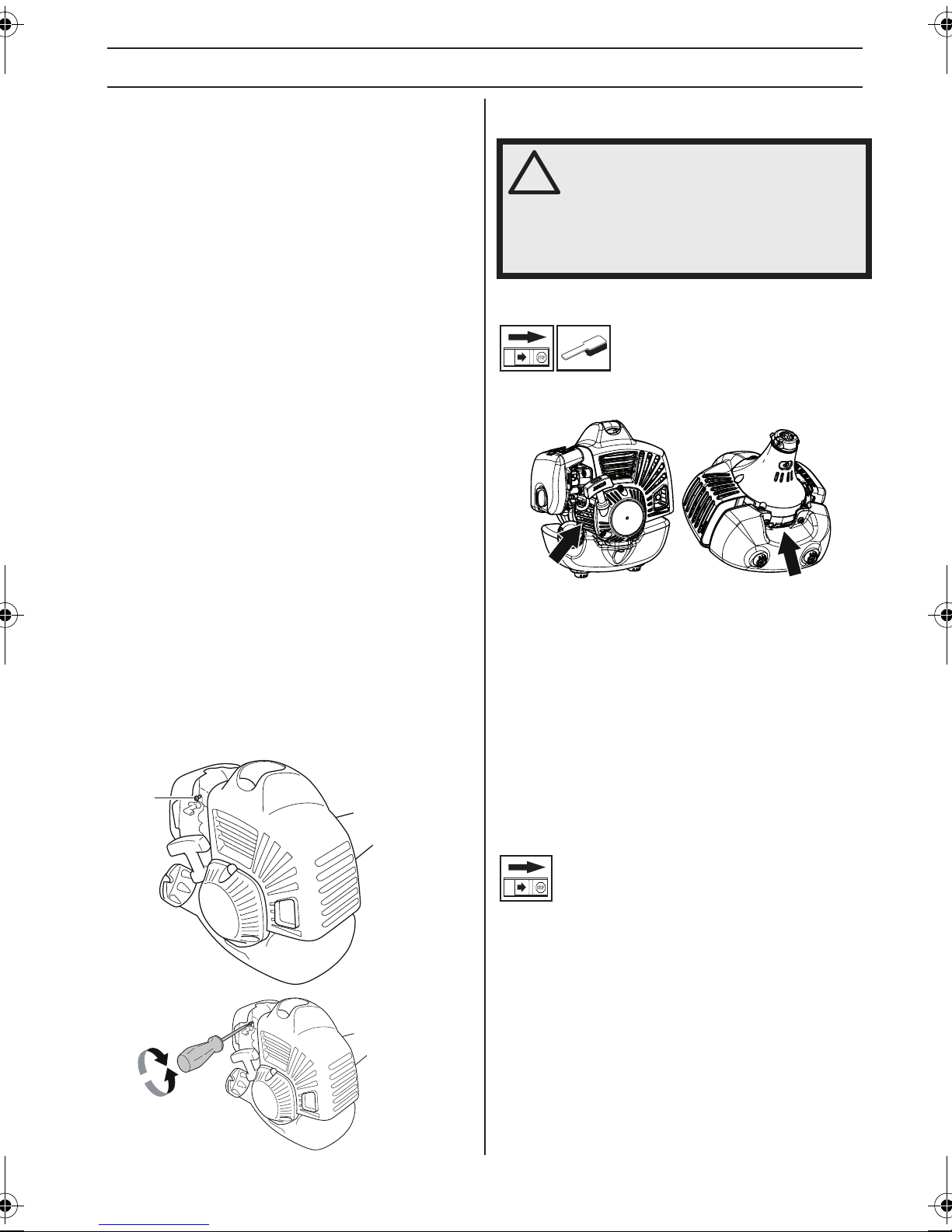

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

1

2

The cooling system consists of:

1 Check and clean the cooling air openings.

2 Air intake through the crankcase (inside the tank).

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

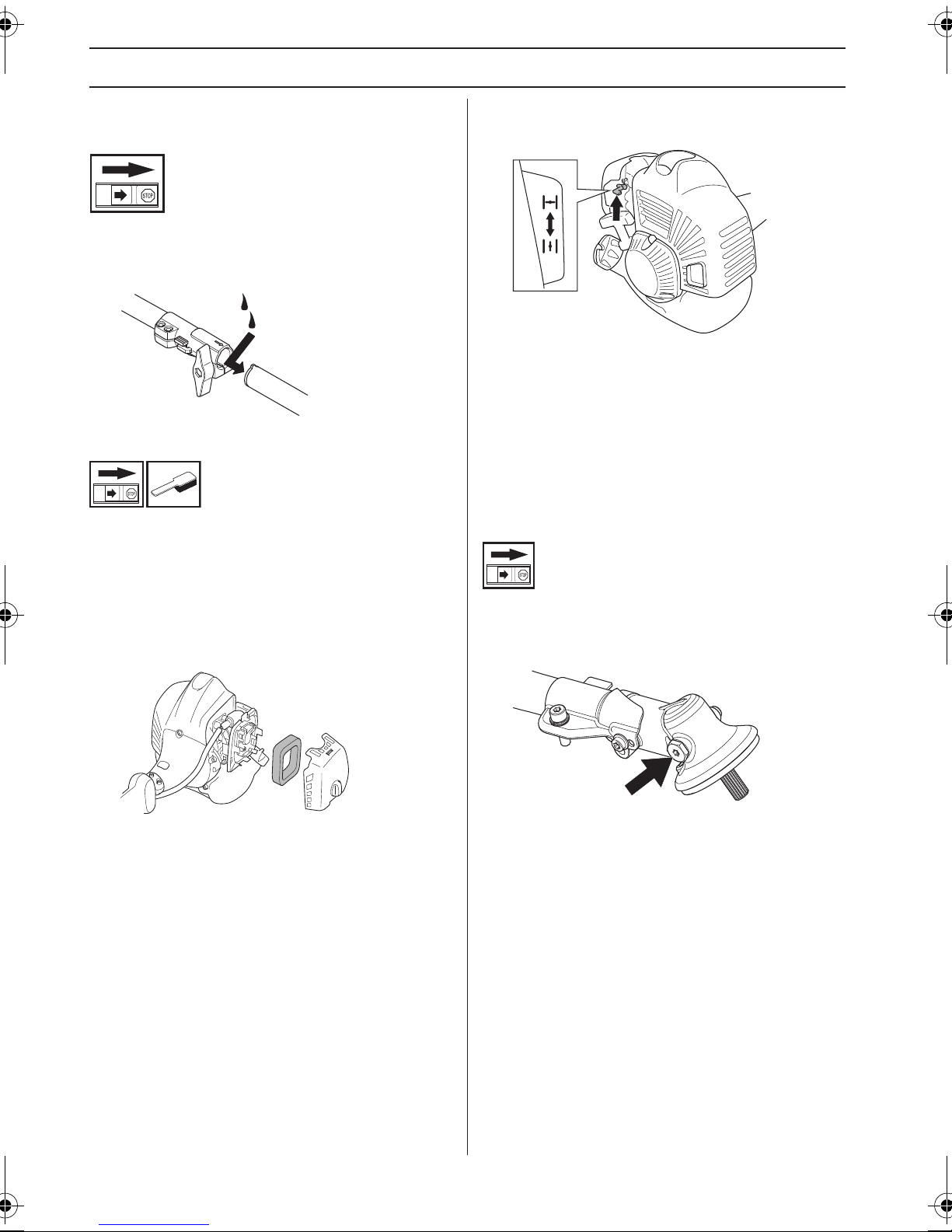

Spark plug

The spark plug condition is influenced by:

• Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0,65 mm. The

spark plug should be replaced after about a month in

operation or earlier if necessary.

Recommended idle speed: See the Technical data

section.

WARNING! If the idle speed cannot be

!

adjusted so that the cutting attachment

stops, contact your dealer/service

workshop. Do not use the machine until it

has been correctly adjusted or repaired.

0,65

CAUTION! Always use the recommended spark plug

type! Use of the wrong spark plug can damage the piston/

cylinder. Check that the spark plug is fitted with a

suppressor.

English – 21

Page 22

MAINTENANCE

Two-piece shaft

(GC2225C)

The drive shaft end in the lower shaft should be lubricated

with grease every 30 hours. There is a risk that the drive

shaft ends (splined coupling) on models with two-piece

shafts will seize if they are not lubricated regularly.

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts.

• Excessive fuel consumption.

Cleaning the air filter

Close the choke valve by moving the choke control up.

Remove the air filter cover and take out the filter. Wash it

clean in warm, soapy water. Clean also the inside of the

filter cover by using air or a brush. Ensure that the filter is

dry before refitting it.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals. A damaged air filter

must always be replaced. Damaged, very dirty, or fuelsoaked air filter must always be replaced.

Bevel gear

The bevel gear is filled with the right quantity of grease at

the factory. However, before using the machine you

should check that the bevel gear is filled three-quarters

full with grease. Use JONSERED special grease.

Clean the filter every 25 hours, or more regularly if

conditions are exceptionally dusty.

22 – English

The grease in the bevel gear does not normally need to

be changed except if repairs are carried out.

Page 23

MAINTENANCE

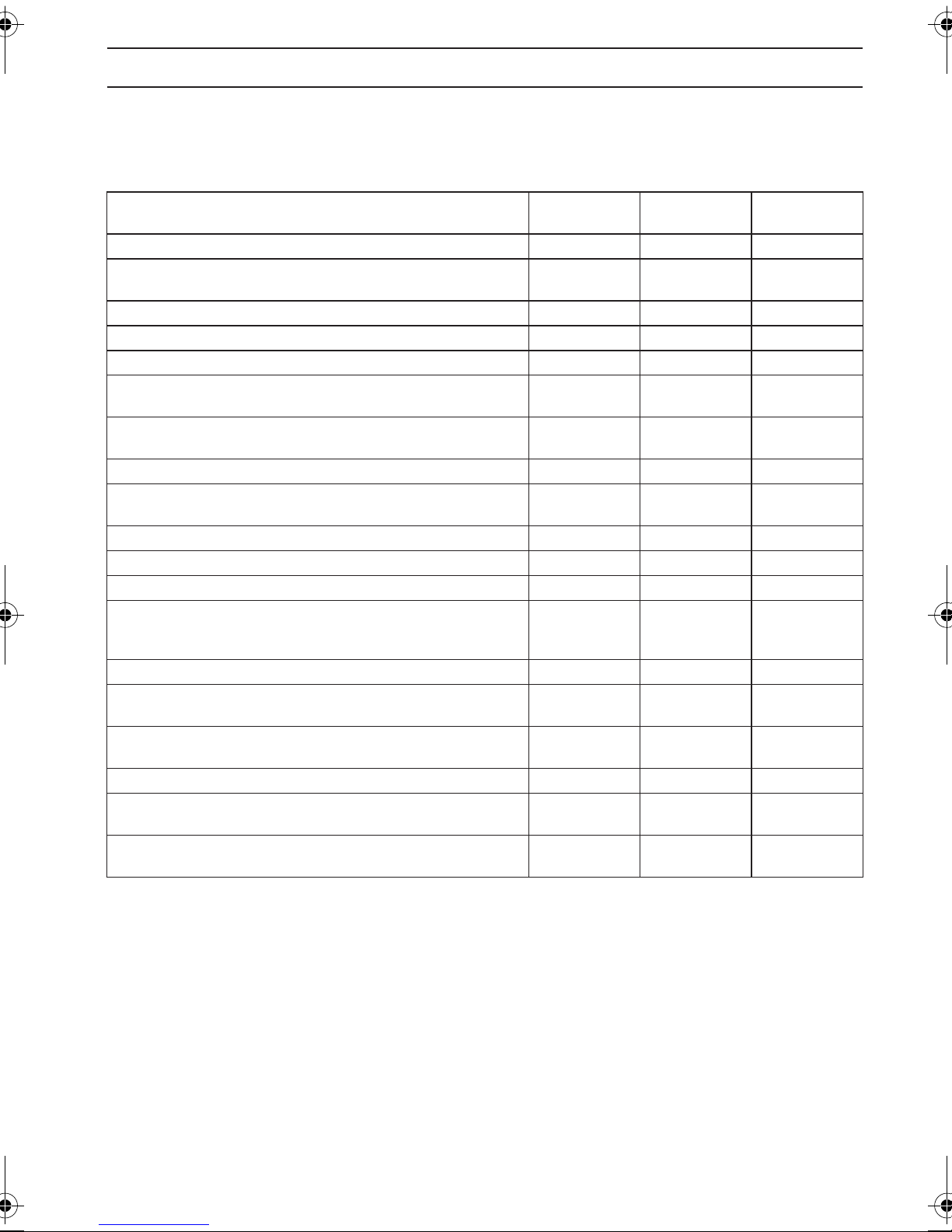

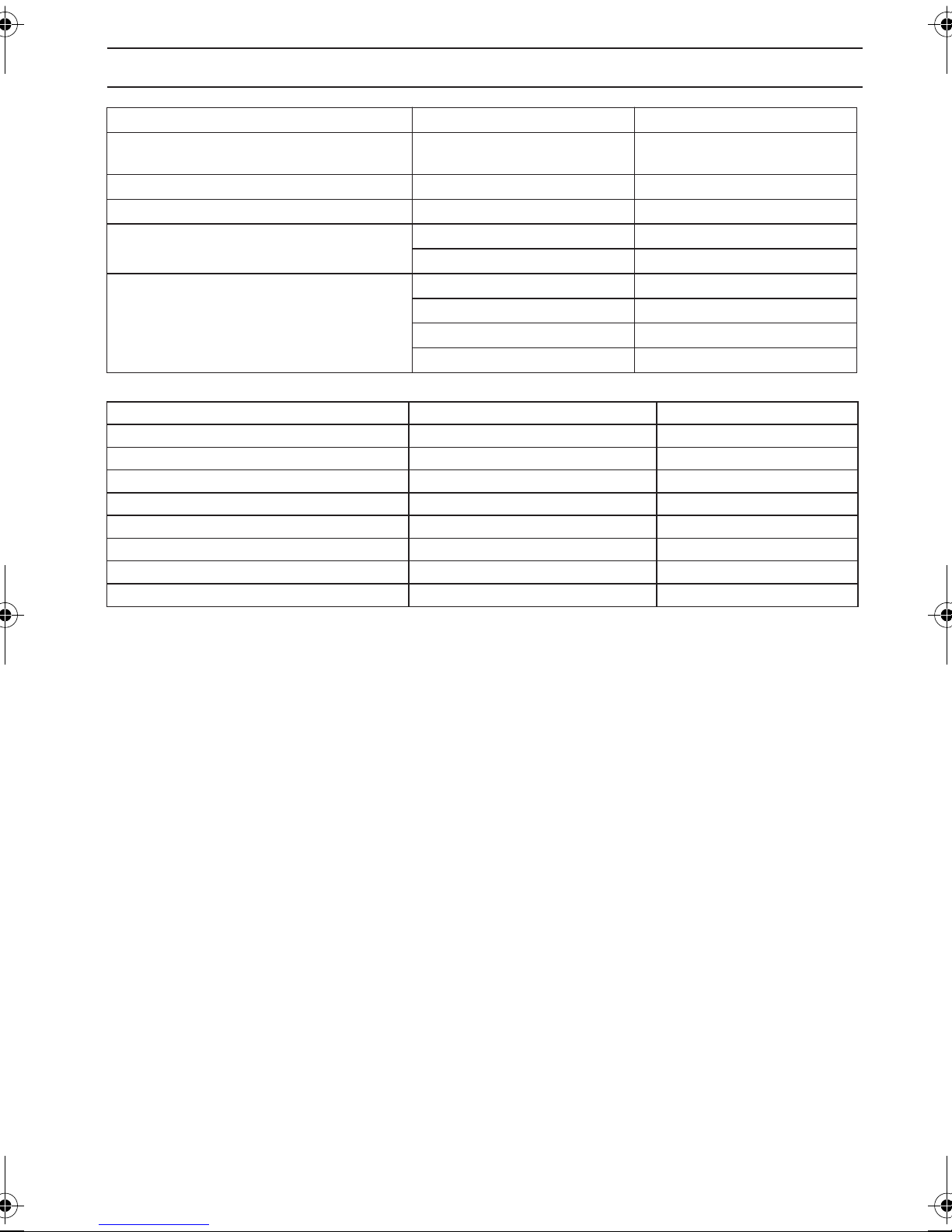

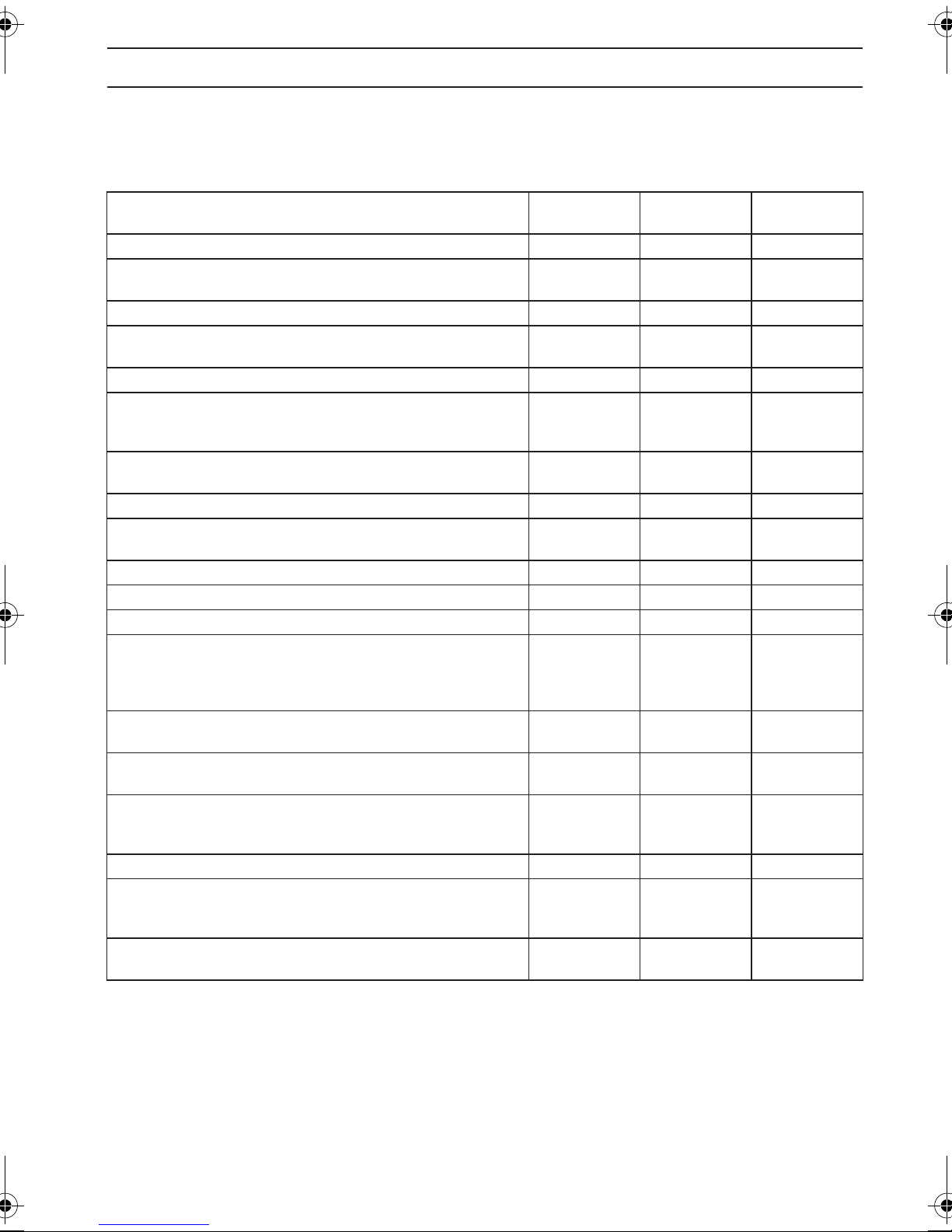

Maintenance schedule

The following is a list of the maintenance steps that must be performed on the machine. Most of the items are described

in the Maintenance section. The user must only carry out the maintenance and service work described in this Operator's

Manual. More extensive work must be carried out by an authorized service workshop.

Maintenance

Clean the outside of the machine. X

Make sure the throttle trigger lock and the throttle function

correctly from a safety point of view.

Check that the stop switch works correctly. X

Check that the cutting attachment does not rotate at idle. X

Clean the air filter. Replace if necessary. X

Check that the guard is undamaged and not cracked. Replace

the guard if it has been exposed to impact or is cracked.

Check that the trimmer head is undamaged and not cracked.

Replace the trimmer head if necessary.

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the engine, tank or fuel

lines.

Clean the machine’s cooling system. X

Check the starter and starter cord. X

Check that the vibration damping elements are not damaged. X

Clean the outside of the spark plug. Remove it and check the

electrode gap. Adjust the gap to 0,65 mm or replace the spark

plug. Check that the spark plug is fitted with a suppressor.

Clean the outside of the carburettor and the space around it. X

Check that the bevel gear is filled three-quarters full with

lubricant. Fill if necessary using special grease.

Check the fuel filter for contamination and the fuel hose for cracks

or other defects. Replace if necessary.

Check all cables and connections. X

Check the clutch, clutch springs and the clutch drum for wear.

Replace if necessary by an autorized service workshop.

Replace the spark plug. Check that the spark plug is fitted with a

suppressor.

Daily

maintenance

X

X

X

X

Weekly

maintenance

X

X

Monthly

maintenance

X

X

X

English – 23

Page 24

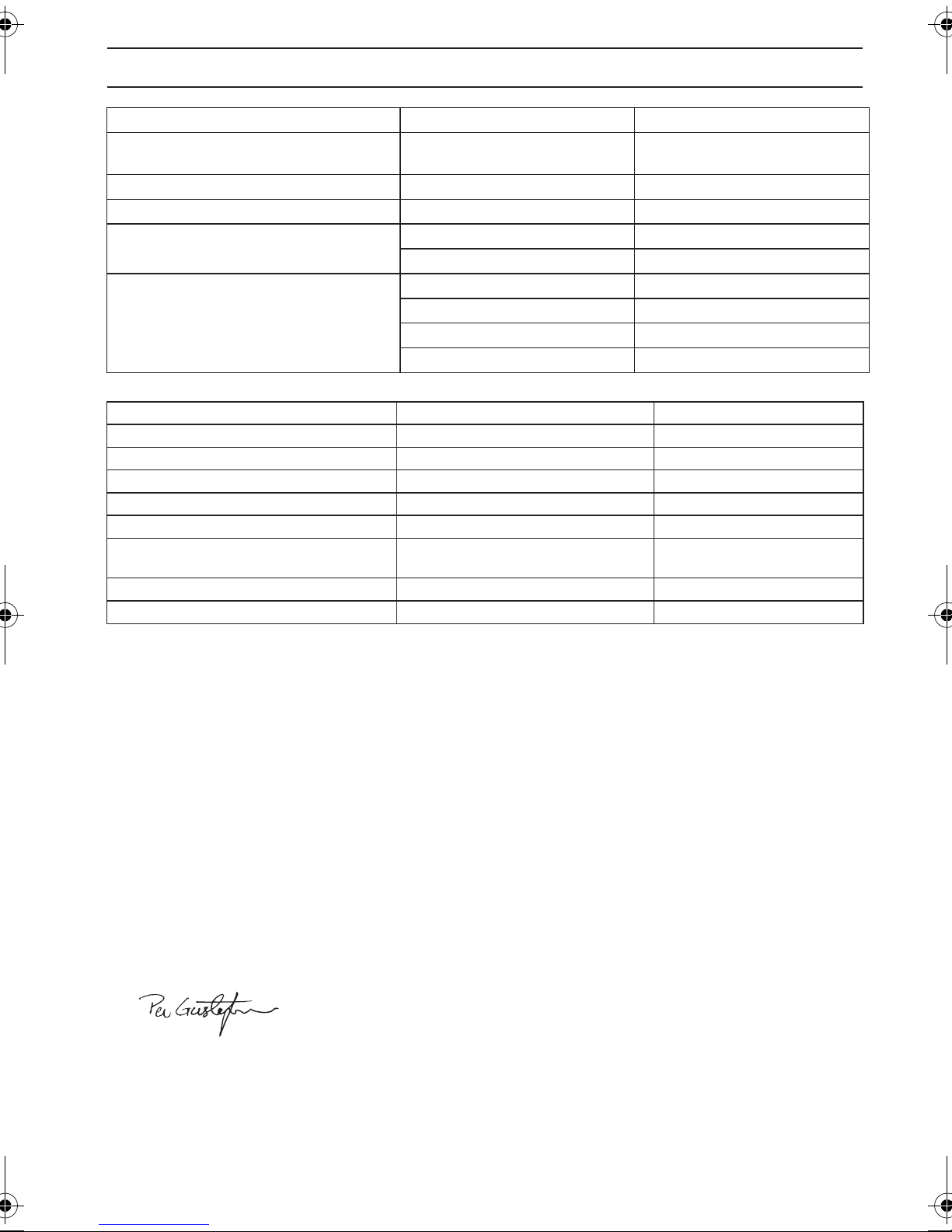

TECHNICAL DATA

Technical data

GC2225 GC2225C

Engine

Cylinder displacement, cm

Cylinder bore, mm 34,0 34,0

Stroke, mm 28 28

Idle speed, rpm 3000 3000

Recommended max. speed, rpm 9500±500 9500±500

Speed of output shaft, rpm 6500 6500

Max. engine output, acc. to ISO 8893, kW/ rpm 1,0/8500 1,0/8500

Catalytic converter muffler No No

Speed-regulated ignition system Yes Yes

Ignition system

Manufacturer/type of ignition system IKEDA/UK IKEDA/UK

Spark plug NGK BPMR8Y NGK BPMR8Y

Electrode gap, mm 0,65 0,65

Fuel and lubrication system

Manufacturer/type of carburettor Walbro WYA-218 Walbro WYA-218

Fuel tank capacity, litre 0,65 0,65

Weight

Weight without fuel, cutting attachment and guard, kg 4,4 4,7

Noise emissions

(see note 1)

Sound power level, measured dB (A) 109 109

Sound power level, guaranteed L

Noise levels

(see note 2)

Equivalent sound pressure level at the operator’s ear, measured

according to EN/ISO 11806 and ISO 7917, dB(A), min./max.:

Vibration levels

(see note 3)

Equivalent vibration levels (a

according to EN ISO 11806 and ISO 22867, m/s

Equipped with trimmer head (original), left/right 4,4/2,5 4,3/2,6

3

dB (A) 111 111

WA

) at handles, measured

hv,eq

25,4 25,4

101 101

2

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/

EC. Reported sound power level for the machine has been measured with the original cutting attachment that gives the

highest level. The difference between guaranteed and measured sound power is that the guaranteed sound power also

includes dispersion in the measurement result and the variations between different machines of the same model

according to Directive 2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard

deviation) of 1 dB (A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s

24 – English

2

.

Page 25

TECHNICAL DATA

GC2225, GC2225C

Approved accessories Type

Blade shaft thread M10

Plastic blades Polytrim 503 93 42-02

Grass blade/grass cutter

Trimmer head

GC 2225C

Approved accessories Art No. Use with

Cultivator attachment with shaft CA 150 537 42 54-02 GC 2225C

Hedge trimmer attachment with shaft HA 110 537 19 66-03 GC 2225C

Hedge trimmer attachment with shaft HA 850 537 19 66-04 GC 2225C

Clean sweep attachment with shaft SR600 537 19 67-02 GC 2225C

Trimmer attachment with shaft TA 850 537 35 35-02 GC 2225C

Saw attachment with shaft PA 1100 537 18 33-24 GC 2225C

Blower attachment BAC 952 71 19-21 GC 2225C

Grass 255-4 1" (Ø 255 4-teeth) 503 93 42-02

Grass 255-8 (Ø 255 8 teeth) 503 93 42-04

Fix 35 503 93 42-04

Tap-N-Go 25 (L) 503 93 42-02

Tap-N-Go 35 / Tap-N-Go 35 Spin 503 93 42-04

Support cup Fixed

Cutting attachment guard, Art.

no.

English – 25

Page 26

TECHNICAL DATA

EC Declaration of Conformity

(Applies to Europe only)

We, Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500, declare that the grass trimmers Jonsered

GC2225, GC2225C with serial numbers dating from 2013 onwards (the year is clearly stated on the rating plate, followed

by the serial number), comply with the requirements of the COUNCIL’S DIRECTIVE:

- of May 17, 2006 ”relating to machinery” 2006/42/EC

- of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

- of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC. Conformity assessment according

to Annex V.

For information relating to noise emissions, see the Technical data chapter.

The following harmonised standards have been applied: EN ISO 12100:2010, EN ISO 11806-1:2011, ISO 14982:2009,

CISPR 12:2009

SMP Svensk Maskinprovning AB, Box 7035, SE-750 07 Uppsala, Sweden, has carried out voluntary type approval for

Husqvarna AB. The certificates have the numbers: SEC/13/2387 - GC 2225, GC 2225C

Huskvarna, 21 December 2013

Per Gustafsson, Development manager (Authorized representative for Husqvarna AB and responsible for technical

documentation.)

26 – English

Page 27

EXPLICATION DES SYMBOLES

Symboles

AVERTISSEMENT! Les

débroussailleuses et les coupe-herbes

peuvent être dangereux! Une utilisation

erronée ou négligente peut

occasionner des blessures graves,

voire mortelles pour l’utilisateur ou d’autres personnes. Il

est extrêmement important de lire et de comprendre le

contenu de ce manuel de l’opérateur.

Lire attentivement et bien assimiler

le manuel d’utilisation avant

d’utiliser la machine.

Toujours utiliser:

• Portez un casque de protection là

où il y a risque de chute d’objets

• Protecteurs d’oreilles homologués

• Des protège-yeux homologués

Régime maxi. recommandé de

l’axe sortant, tr/min

10000

Attention: projections et ricochets.

L’utilisateur de la machine doit

s’assurer qu’aucune personne ou

animal ne s’approche à moins de 15

15 m

50FT

15

m

5

0

FT

mètres pendant le travail.

Utiliser des bottes antidérapantes et

stables.

Pompe à carburant

Émissions sonores dans

l’environnement selon la directive de

la Communauté européenne. Les

émissions de la machine sont

indiquées au chapitre

Caractéristiques techniques et sur

les autocollants.

Les autres symboles/autocollants présents sur

la machine concernent des exigences de certification

spécifiques à certains marchés.

Arrêter le moteur en déplaçant

l’interrupteur d’arrêt en position

d’arrêt. REMARQUE! L'interrupteur

d'arrêt se remet automatiquement en

position de démarrage. Toujours

retirer le chapeau de bougie de la bougie lors du

montage, contrôle et/ou entretien, afin d'éviter tout

démarrage accidentel.

Toujours porter des gants de

protection homologués.

Les machines équipées de lames

d’éclaircissage ou de disques à

herbe peuvent être projetées

violemment d’un côté quand la lame

heurte un objet fixe. Ce phénomène

est appelé rebond. La lame peut amputer un bras ou une

jambe. Veiller à ce que les personnes et les animaux

soient toujours à au moins 15 mètres de la machine.

Flèches indiquant les limites quant à

l’emplacement de la fixation de la

poignée.

Toujours porter des gants de

protection homologués.

Un nettoyage régulier est

indispensable.

Examen visuel.

French – 27

Page 28

SOMMAIRE

Sommaire Contrôler les points suivants

EXPLICATION DES SYMBOLES

Symboles .............................................................. 27

SOMMAIRE

Sommaire ............................................................. 28

Contrôler les points suivants avant la mise en

marche: ................................................................. 28

INTRODUCTION

Cher client, ............................................................ 29

QUELS SONT LES COMPOSANTS?

Quels sont les composants? ................................. 30

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Important! ............................................................. 31

Équipement de protection personnelle ................. 31

Équipement de sécurité de la machine ................. 32

Équipement de coupe ........................................... 35

MONTAGE

Montage de la poignée en boucle ......................... 37

Montage de la poignée en J ................................ 37

Montage de l’œillet de suspension ....................... 37

Montage de l’équipement de coupe ...................... 37

Montage de la protection de la tête et de la tête de

désherbage .......................................................... 38

Montage et démontage d’un tube de transmission

démontable ........................................................... 38

Montage du protège-lame, de la lame à herbe et

du couteau à herbe ............................................... 39

MANIPULATION DU CARBURANT

Sécurité carburant ................................................ 40

Carburant .............................................................. 40

Remplissage de carburant .................................... 41

DÉMARRAGE ET ARRÊT

Contrôles avant la mise en marche ...................... 42

Démarrage et arrêt ............................................... 42

TECHNIQUES DE TRAVAIL

Méthodes de travail ............................................... 44

ENTRETIEN

Carburateur ........................................................... 47

Système de refroidissement ................................. 47

Bougie ................................................................... 47

Tube de transmission démontable ........................ 48

Filtre à air .............................................................. 48

Schéma d’entretien ............................................... 49

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques techniques ................................. 50

Déclaration CE de conformité ............................... 51

avant la mise en marche:

Lire attentivement le manuel d’utilisation.

AVERTISSEMENT! Une exposition

!

!

!

prolongée au bruit risque de causer des

lésions auditives permanentes. Toujours

utiliser des protecteurs d'oreille agréés.

AVERTISSEMENT! Ne jamais modifier

sous aucun prétexte la machine sans

l’autorisation du fabricant. N’utiliser que

des accessoires et des pièces d’origine.

Des modifications non-autorisées et

l’emploi d’accessoires non-homologués

peuvent provoquer des accidents graves

et même mortels, à l’utilisateur ou

d’autres personnes.

AVERTISSEMENT! Utilisés de manière

négligente ou erronée, les

débroussailleuses et les coupe-herbes

peuvent devenir des outils dangereux

pouvant occasionner des blessures

graves, voire mortelles pour l’utilisateur

ou d’autres. Il est très important de lire

attentivement et de bien comprendre les

instructions contenues dans ce mode

d’emploi.

28 – French

Page 29

INTRODUCTION

Cher client,

Félicitations pour ce choix d’un produit Jonsered.

Nous sommes persuadés que vous apprécierez la qualité et les performances de nos produits pendant de longues

années. L’achat d’un de nos produits vous garantit une assistance professionnelle au niveau du service et des

réparations en cas de besoin. Si la machine n’a pas été achetée chez un de nos revendeurs autorisés, demandez à un

revendeur l’adresse de l’atelier d’entretien le plus proche.

Nous espérons que cette machine vous donnera toute satisfaction et qu’elle vous accompagnera pendant de longues

années. N’oubliez pas que ce manuel d’utilisation est important. En suivant les instructions qu’il contient (utilisation,

révision, entretien, etc.), il est possible d’allonger considérablement la durée de vie de la machine et d’augmenter sa

valeur sur le marché de l’occasion. En cas de vente de la machine, ne pas oublier de remettre le manuel d’utilisation au

nouveau propriétaire.

Bonne chance avec votre nouveau produit Jonsered!

Jonsered travaille continuellement au développement de ses produits et se réserve le droit d’en modifier, entre autres,

la conception et l’aspect sans préavis.

French – 29

Page 30

QUELS SONT LES COMPOSANTS?

10

17

18

24

25

19

4

3

2

1

4

23

26

8

6

29

5

28

27

31

21

11

9

7

30

13

14

16

12

15

20

22

Quels sont les composants?

1 Tête de désherbage

2 Ravitaillement en lubrifiant, renvoi d’angle

3 Renvoi d’angle

4 Protection pour l’équipement de coupe

5 Tube de transmission

6 Poignée anneau

7 Commande de l’accélération

8 Bouton d’arrêt

9 Blocage de l’accélération

10 Chapeau de bougie et bougie

11 Capot de cylindre

12 Poignée de lanceur

13 Réservoir d’essence

14 Carter de filtre à air

15 Pompe à carburant

16 Commande de starter

17 Contre-écrou

18 Bride de support

19 Toc d’entraînement

20 Clé universelle

21 Clé à six pans

22 Goupille d’arrêt

23 Manuel d’utilisation

24 Bol de garde au sol

25 Lame

26 Raccord du tube de transmission (GC2225C)

27 Poignée en J

28 Réglage de poignée

29 Œillet de suspension

30 Harnais

31 Dispositif de protection pour le transport

30 – French

Page 31

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Important! Équipement de protection

IMPORTANT!

La machine est conçue uniquement pour le désherbage.

La législation nationale ou locale peut réglementer

l’utilisation. Respectez la législation en vigueur.

Les seuls accessoires pouvant utiliser le moteur comme

source motrice sont les équipements de coupe que nous

recommandons au chapitre Caractéristiques techniques.

Éviter d’utiliser la machine en cas de fatigue,

d’absorption d’alcool ou de prise de médicaments

susceptibles d’affecter l’acuité visuelle, le jugement ou la

maîtrise du corps.

Utiliser les équipements de protection personnelle. Voir

au chapitre ”Équipement de protection personnelle”.

Ne jamais utiliser une machine qui a été modifiée au point

de ne plus être conforme au modèle original.

Ne jamais utiliser une machine qui n’est pas en parfait

état de marche. Appliquer les instructions de

maintenance et d’entretien ainsi que les contrôles de

sécurité indiqués dans ce manuel d’utilisation. Certaines

mesures de maintenance et d’entretien doivent être

confiées à un spécialiste dûment formé et qualifié. Voir

les instructions à la section Maintenance.

Tous les capots, toutes les protections et toutes les

poignées doivent avoir été montées avant d’utiliser la

machine. Vérifier que le capuchon de la bougie et le câble

d’allumage sont en bon état afin d’éliminer tout risque de

choc électrique.

L’utilisateur de la machine doit s’assurer qu’aucune

personne ou animal ne s’approche à moins de 15 mètres

pendant le travail. Lorsque plusieurs utilisateurs

travaillent dans une même zone, il convient d’observer

une distance de sécurité d'au moins 15 mètres.

AVERTISSEMENT! Cette machine génère

!

!

un champ électromagnétique en

fonctionnement. Ce champ peut dans

certaines circonstances perturber le

fonctionnement d’implants médicaux

actifs ou passifs. Pour réduire le risque de

blessures graves ou mortelles, les

personnes portant des implants médicaux

doivent consulter leur médecin et le

fabricant de leur implant avant d’utiliser

cette machine.

AVERTISSEMENT! Faire tourner un

moteur dans un local fermé ou mal aéré

peut causer la mort par asphyxie ou

empoisonnement au monoxyde de

carbone.

personnelle

IMPORTANT!

Utilisés de manière négligente ou erronée, les

débroussailleuses et les coupe-herbes peuvent devenir

des outils dangereux pouvant occasionner des blessures

graves, voire mortelles pour l’utilisateur ou d’autres. Il est

très important de lire attentivement et de bien

comprendre les instructions contenues dans ce mode

d’emploi.

Un équipement de protection personnelle homologué

doit impérativement être utilisé lors de tout travail avec la

machine. L’équipement de protection personnelle

n’élimine pas les risques mais réduit la gravité des

blessures en cas d’accident. Demander conseil au

concessionnaire afin de choisir un équipement adéquat.

AVERTISSEMENT! Soyez toujours

!

CASQUE

Portez un casque de protection là où il y a risque de chute

d’objets

PROTÈGE-OREILLES

Porter des protège-oreilles ayant un effet atténuateur

suffisant.

PROTÈGE-YEUX

Toujours porter des protège-yeux homologués. L’usage

d’une visière doit toujours s’accompagner du port de

lunettes de protection homologuées. Par lunettes de

protection homologuées, on entend celles qui sont en

conformité avec les normes ANSI Z87.1 (États-Unis) ou

EN 166 (pays de l’UE).

attentifs aux signaux d’alerte ou aux

appels en portant des protège-oreilles.

Enlevez-les sitôt le moteur arrêté.

AVERTISSEMENT! Ne jamais laisser des

!

enfants utiliser la machine ou se tenir à

proximité. La machine est équipée d'un

interrupteur d'arrêt à détente et peut être

démarrée par une activation à faible

vitesse et de faible puissance de la

poignée de démarrage ; dans certaines

circonstances, de jeunes enfants peuvent

produire la force nécessaire au démarrage

de la machine. Ceci peut entraîner un

risque de blessures personnelles. Retirer

donc le chapeau de bougie lorsque la

machine n'est pas sous surveillance.

GANTS

Au besoin, utiliser des gants, notamment lors du montage

de l’équipement de coupe.

French – 31

Page 32

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

BOTTES

Utiliser des bottes avec coquille en acier et semelle

antidérapante

HABITS

Porter des vêtements fabriqués dans un matériau

résistant à la déchirure, éviter les vêtements

excessivement amples qui risqueraient de se prendre

dans les broussailles et les branches. Toujours utiliser des

pantalons longs et robustes. Ne pas porter de bijoux, de

shorts ou de sandales, et ne pas marcher pieds-nus.

Veiller à ce que les cheveux ne tombent pas sur les

épaules.

PREMIERS SECOURS

Une trousse de premiers secours doit toujours être

disponible.

Blocage de l’accélération

Le blocage de l’accélération a pour but d’empêcher toute

accélération involontaire. Une fois le cliquet (A) enfoncé

dans la poignée (= en tenant celle-ci), la commande de

l’accélération (B) se trouve libérée. Quand la poignée est

relâchée, la commande de l’accélération et le cliquet

reviennent en position initiale, Ce retour en position

initiale s’effectue grâce à deux ressorts de rappel

indépendants. Cette position signifie que la commande

d’accélération est alors automatiquement bloquée sur le

ralenti.

A

B

Vérifier d’abord que la commande de l’accélération est

bloquée en position de ralenti quand le blocage de

l’accélération est en position initiale.

Équipement de sécurité de la

machine

Ce chapitre présente les équipements de sécurité de la

machine, leur fonction, comment les utiliser et les

maintenir en bon état. Voir au chapitre Quels sont les

composants? pour trouver leur emplacement sur la

machine.

La durée de vie de la machine risque d'être écourtée et le

risque d'accidents accru si la maintenance de la machine

n'est pas effectuée correctement et si les mesures

d'entretien et/ou de réparation ne sont pas effectuées de

manière professionnelle. Pour obtenir de plus amples

informations, contacter l'atelier de réparation le plus

proche.

IMPORTANT!

L’entretien et la réparation de la machine exigent une

formation spéciale. Ceci concerne particulièrement

l’équipement de sécurité de la machine. Si les contrôles

suivants ne donnent pas un résultat positif, s’adresser à

un atelier spécialisé. L’achat de l’un de nos produits offre

à l’acheteur la garantie d’un service et de réparations

qualifiés. Si le point de vente n’assure pas ce service,

s’adresser à l’atelier spécialisé le plus proche.

AVERTISSEMENT! Ne jamais utiliser une

!

machine dont les équipements de sécurité

sont défectueux. Contrôler et entretenir

les équipements de sécurité de la

machine conformément aux instructions

données dans ce chapitre. Si les contrôles

ne donnent pas de résultat positif, confier

la machine à un atelier spécialisé.

Appuyer sur le blocage de l’accélération et vérifier qu’il

revient de lui-même en position initiale quand il est

relâché.

Vérifier que le blocage de l’accélération, la commande

d’accélération et leurs ressorts de rappel fonctionnent

correctement.

32 – French

Page 33

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Voir le chapitre Démarrage. Démarrer la machine et

donner les pleins gaz. Relâcher l’accélérateur et

s’assurer que l’équipement de coupe s’arrête et qu’il reste

immobile. Si l’équipement de coupe tourne lorsque

l’accélérateur est au régime de ralenti, contrôler le

réglage du ralenti du carburateur. Voir le chapitre

Entretien.

Bouton d’arrêt

Le bouton d’arrêt est utilisé pour arrêter le moteur.

Système anti-vibrations

La machine est équipée d’un système anti-vibrations

conçu pour assurer une utilisation aussi confortable que

possible.

L’utilisation d’un fil mal enroulé ou d’un équipement de

coupe inadéquat augmente le niveau de vibration. Voir les

instructions au chapitre Équipement de coupe.

Le système anti-vibrations réduit la transmission des

vibrations entre l’unité moteur et l’unité de l’arbre de la

machine.

Mettre le moteur en marche et s’assurer qu’il s’arrête

lorsque le bouton d’arrêt est amené en position d’arrêt.

Protection pour l’équipement de coupe

Cette protection a pour but d’empêcher que des objets ne

soient projetés en direction de l’utilisateur. La protection

prévient aussi le contact entre l’utilisateur et l’équipement

de coupe.

S’assurer que la protection est intacte et qu’elle ne

présente pas de fissures. Remplacer la protection si elle

a subi des coups ou si elle présente des fissures.

Toujours utiliser la protection recommandée prévue pour

l’équipement de coupe en question. Voir Caractéristiques

techniques.

AVERTISSEMENT! Un équipement de

!

coupe ne peut en aucun cas être utilisé si

une protection homologuée n’a pas été

préalablement montée. Voir le chapitre

Caractéristiques techniques. La mise en

place d’une protection erronée ou

défectueuse peut provoquer des

blessures graves.

Vérifier régulièrement l’état des éléments afin de détecter

fissures et déformations. Vérifier que les éléments antivibrations sont entiers et solidement fixés.

AVERTISSEMENT! Une exposition

!

excessive aux vibrations peut entraîner

des troubles circulatoires ou nerveux

chez les personnes sujettes à des

troubles cardio-vasculaires. Consulter

un médecin en cas de symptômes liés

aux vibrations, tels qu’insensibilisation

ou irritation locale, douleur,

chatouillements, faiblesse musculaire,

décoloration ou modification

épidermique. Ces symptômes affectent

généralement les doigts, les mains ou

les poignets.

French – 33

Page 34

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Silencieux

Le silencieux est conçu pour réduire au maximum le

niveau sonore et détourner les gaz d’échappement loin

de l’utilisateur.

En ce qui concerne le silencieux, il importe de bien suivre

les instructions de contrôle, de maintenance et

d’entretien.

Ne jamais utiliser une machine dont le silencieux est

défectueux.

Contre-écrou

Un contre-écrou est utilisé pour la fixation de certains

types d’équipements de coupe.

Pose: serrer l’écrou dans le sens contraire de la rotation

de l’équipement de coupe. Dépose: desserrer l’écrou

dans le sens de la rotation de l’équipement de coupe.

(NOTA! L’écrou est fileté à gauche.)

Les dents de la lame d’éclaircissage risquent de causer

des blessures aussi bien lors du serrage que du

desserrage de l’écrou de la lame. Veiller à ce que la main