Page 1

Operator’s manual

Manual d’utilisation

Manual de instrucciones

Please read these instructions and make sure you understand them before using the machine.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

EN (2-21)

FR (22-43)

ES (44-65)

Page 2

E n g l i s h --- 2

545186855 Rev. 8 5/15/12

CONTENTS

Contents

CONTENTS

Contents 2........................

Note the following before starting 2....

KEY TO SYMBOLS

Symbols 3.........................

SAFETY INSTRUCTIONS

Personal protective equipment 4......

Machine’s safety equipment 4........

Cutting equipment 5.................

Checking, maintaining and servicing

the machine’s safety equipment 5.....

General safety precautions 7.........

Starting 8.........................

Fuel safety 8.......................

Transporting and storage 8...........

General working instructions 8........

Basic safety rules 8.................

Basic working techniques 9..........

WHAT IS WHAT?

What is what? 11....................

ASSEMBLY

Fitting the loop handle 12.............

Fitting the trimmer guard and

trimmer head 12.....................

FUEL HANDLING

Fuel 13............................

Fueling 13..........................

STARTING AND STOPPING

Check before starting 14..............

Starting and stopping 14..............

MAINTENANCE

Carburetor 15.......................

Muffler 16..........................

Spark plug 16.......................

Air filter 17..........................

Maintenance schedule 17.............

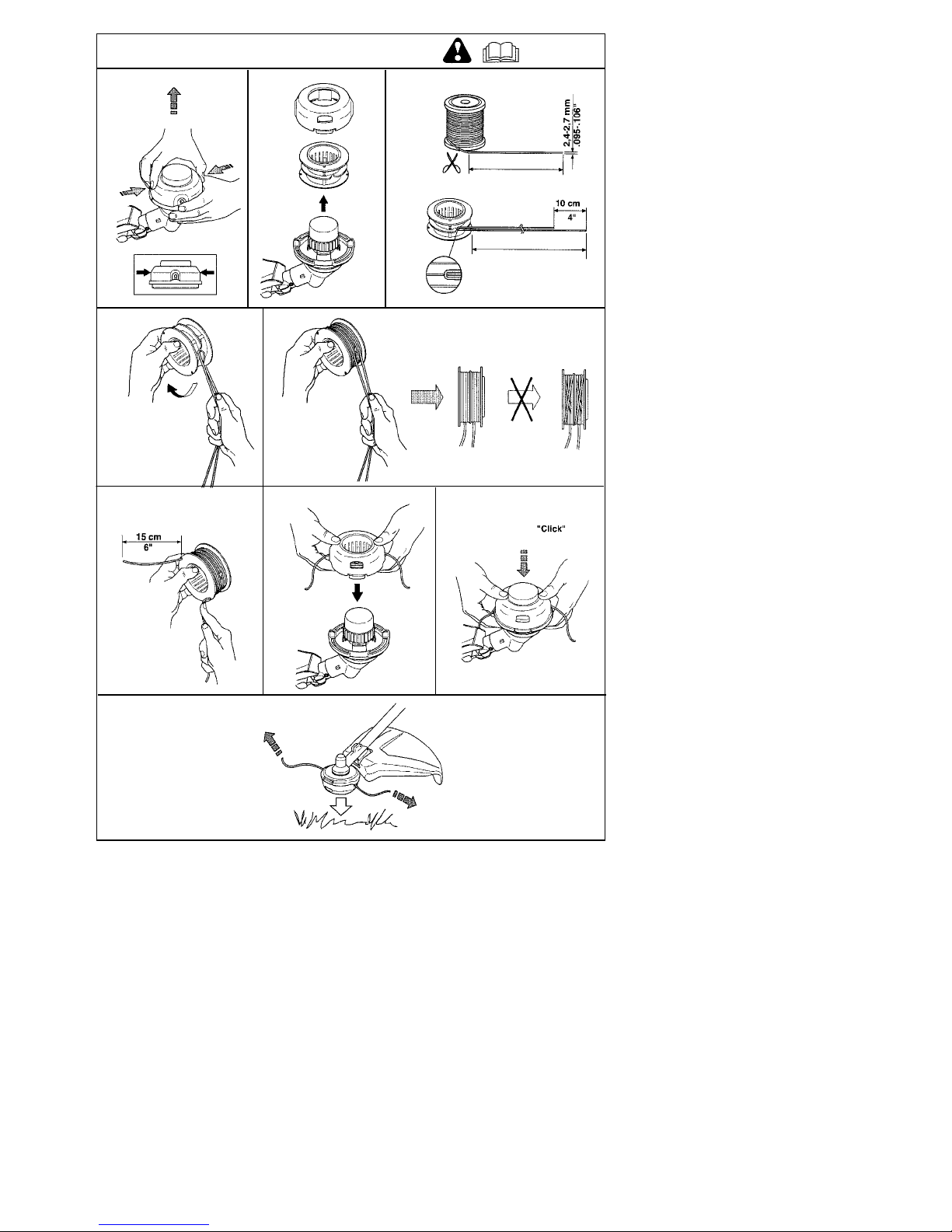

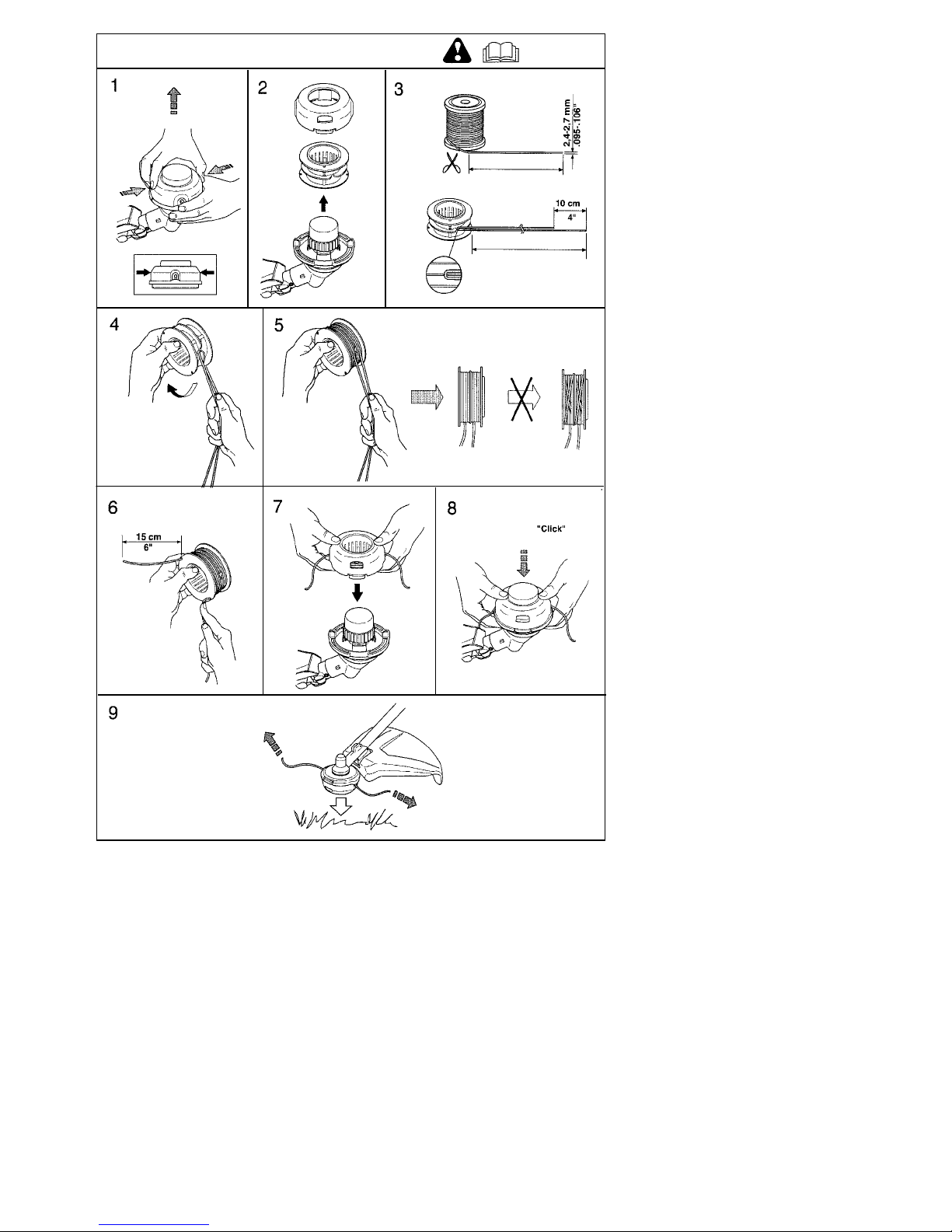

Trimmer head line loading instructions 18..

TECHNICAL DATA

Technical data 19....................

EMISSION CONTROL

WARRANTY STATEMENT 20.........

Note the following before

starting:

Jonsered has a policy of continuous product development and therefore

reserves the right to modify the design and

appearance of products without prior

notice. Long--term exposure to noise can

result in permanent hearing impairment.

Always use approved hearing protection.

Maintenance, replacement, or repair of the

emission control devices and system may

be performed by any nonroad engine repair establishment or individual.

The Emissions Compliance Period referred

to on the Emissions Compliance label indicates the number of operating hours for

which the engine has been shown to meet

Federal emissions requirements.

Category C = 50 hours, B= 125 hours, and

A = 300 hours.

For reference, please fill out the following

information that will be needed for future

servicing of your trimmer:

Model Number:

Serial Number:

Purchase Date:

Purchased From:

WARNING: A clearing saw,

brushcutter or trimmer can be

dangerous if used incorrectly or

carelessly, and can cause serious

or fatal injury to the operator or

others. It is extremely important

that you read and understand the

contents of this operator’s manual.

WARNING: Under no circum-

stances may the design of the

machine be modified without the

permission of the manufacturer.

Always use genuine accessories.

Non--authorized modifications

and/or accessories can result

in serious personal injury or the

death of the operator or others.

Your warranty may not cover

damage or liability caused by the

use of non --authorized accessories or replacement parts.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Page 3

E n g l i s h --- 3

545186855 Rev. 8 5/15/12

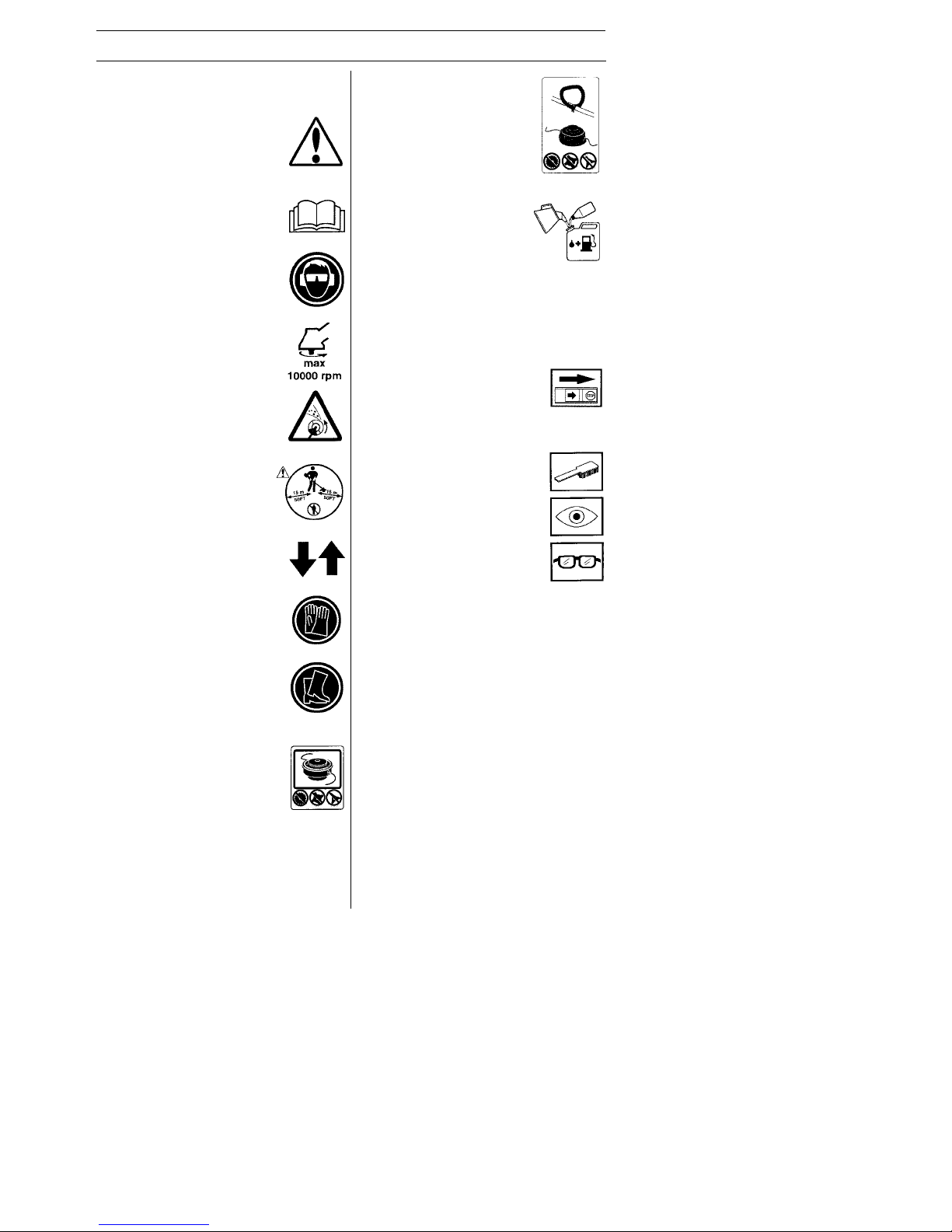

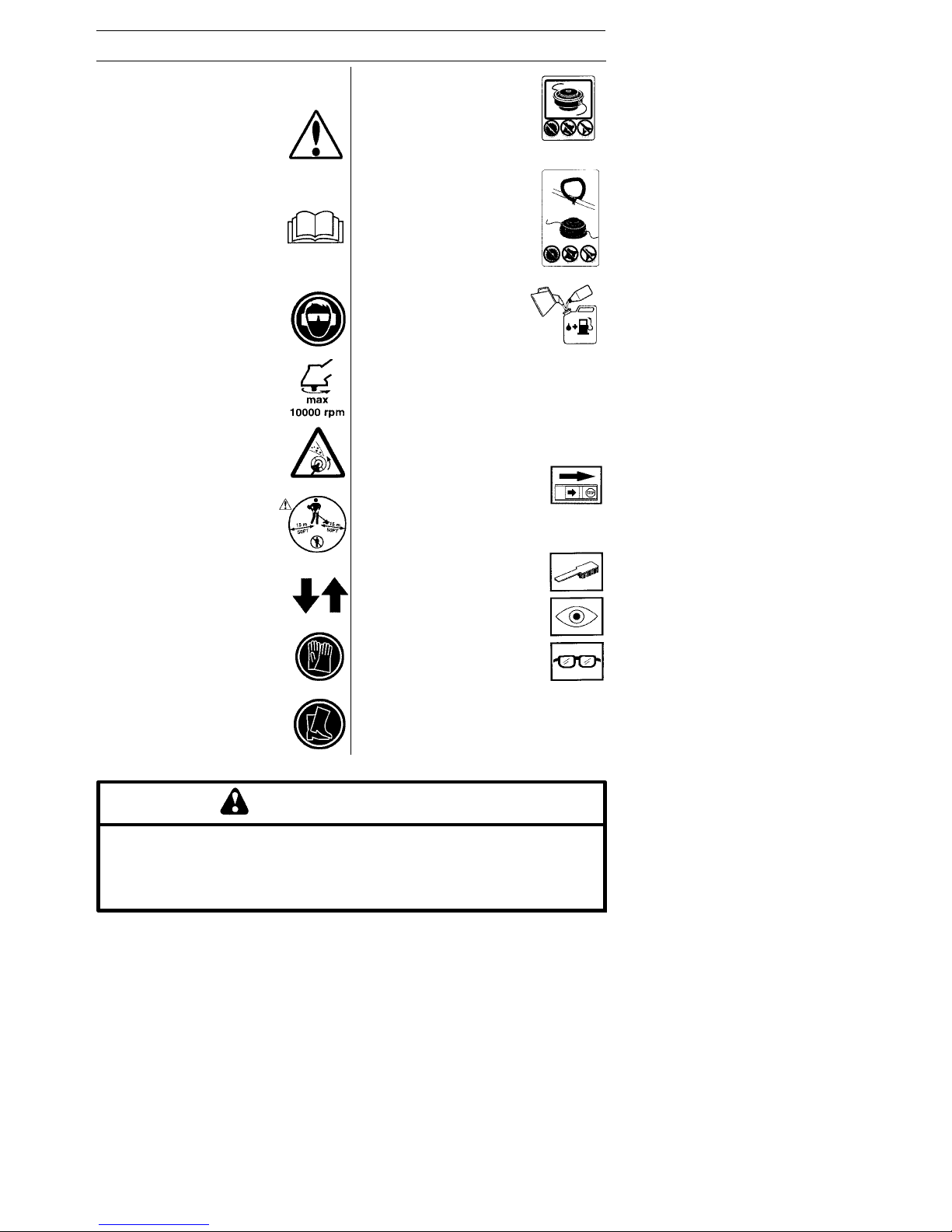

KEY TO SYMBOLS

Only intended for trimmer heads.

Use unleaded or quality leaded

gasoline and two--stroke oil

mixed at a ratio of 2% (1:50).

Other symbols/decals on the machine

refer to special certification requirements

for certain markets.

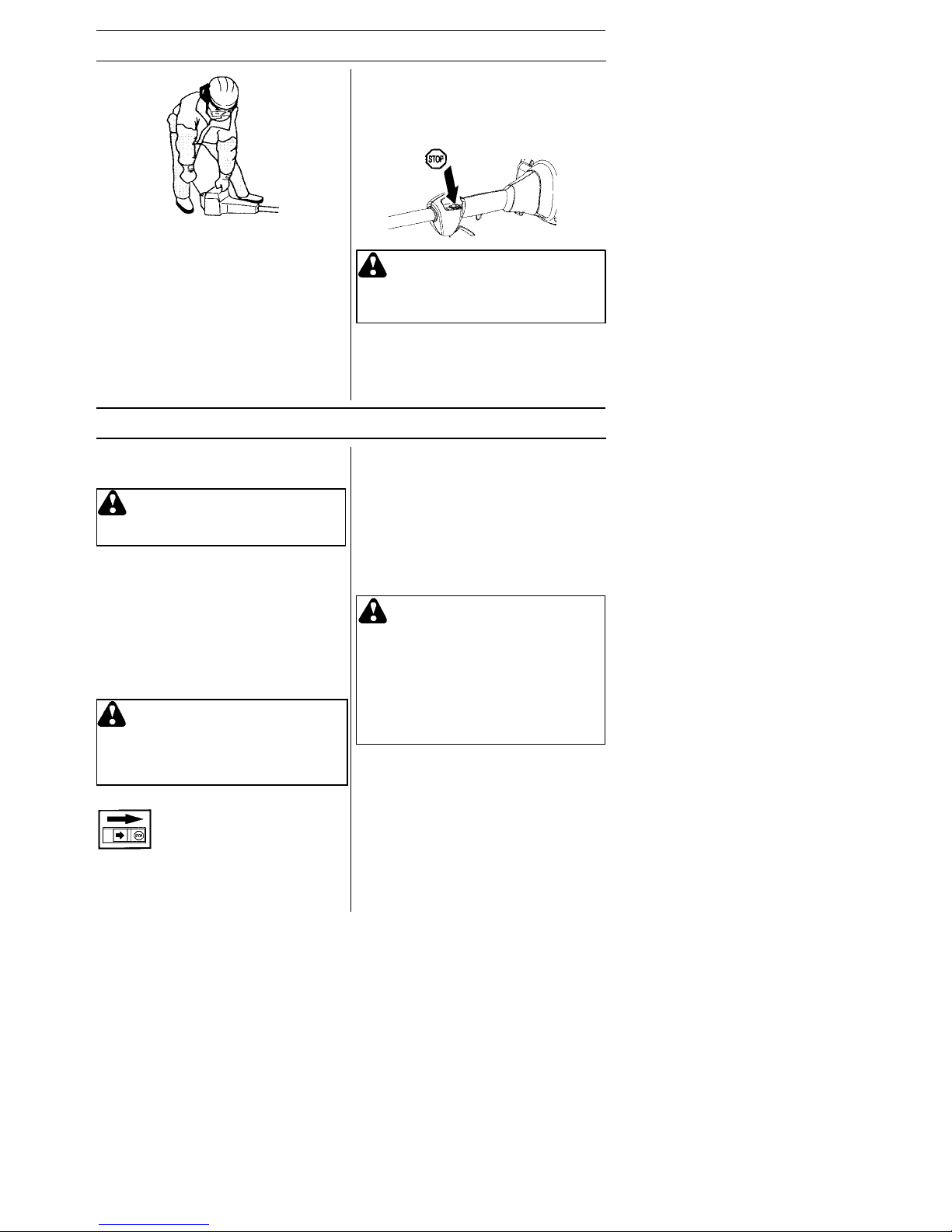

Stop the engine by pushing

and holding the stop switch

in the STOP position until the

engine stops before carrying

out any checks or maintenance.

Regular cleaning is required.

Visual check.

Approved eye protection must

always be used.

Symbols

WARNING: Clearing saws, brush-

cutters and trimmers can be dangerous! Careless or incorrect use

can result in serious or fatal

injury to the operator or others.

WARNING: Read the operator’s

manual before use. Failure to follow

instructions could result in serious

injury to the operator and/or

bystanders. Save operator’ s manual.

Always wear:

S Hearing protection

S Approved eye protection

Max. speed of output shaft, rpm

Watch out for thrown objects and

ricochets.

The operator of the machine

must ensure, while working,

that no persons or animals

come closer than 50 feet

(15 meters).

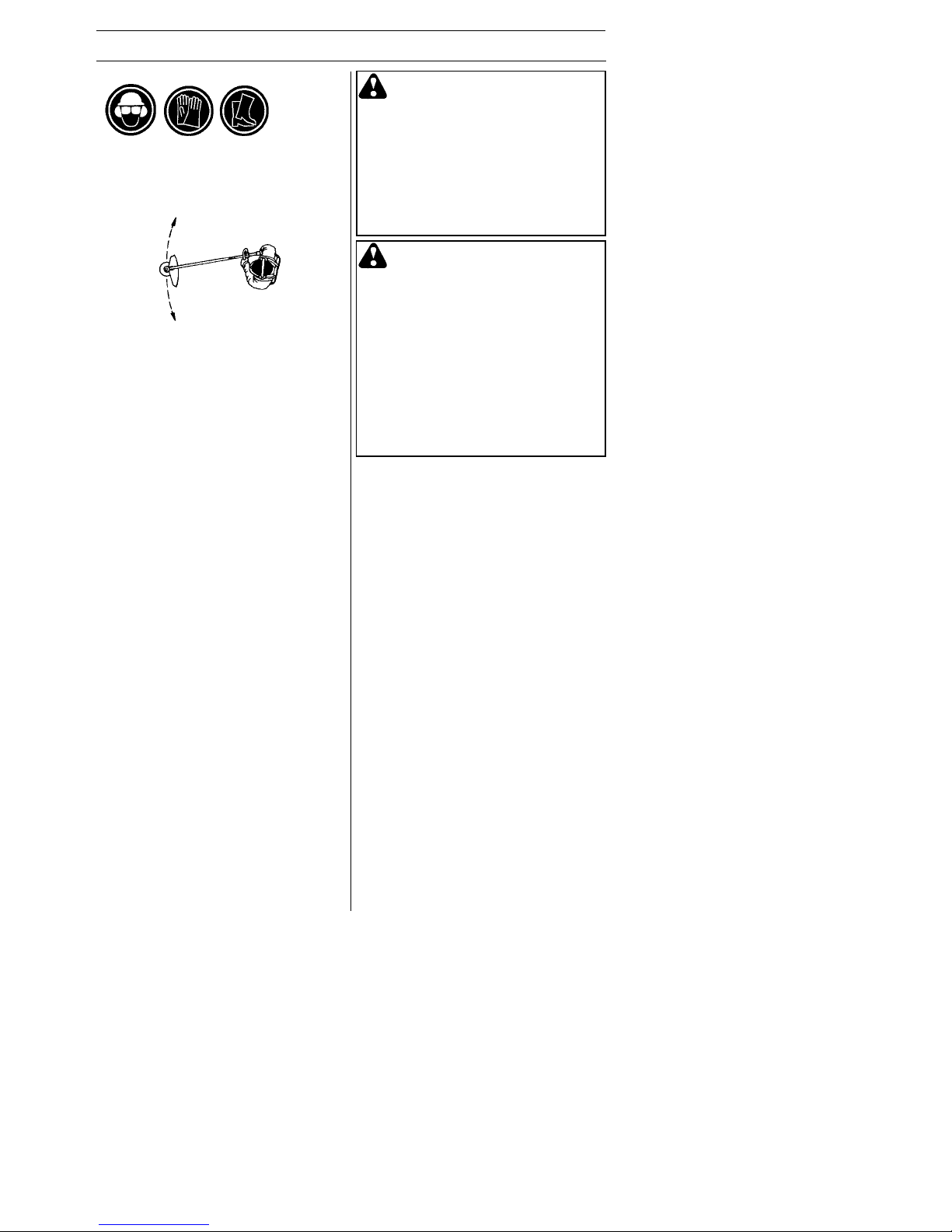

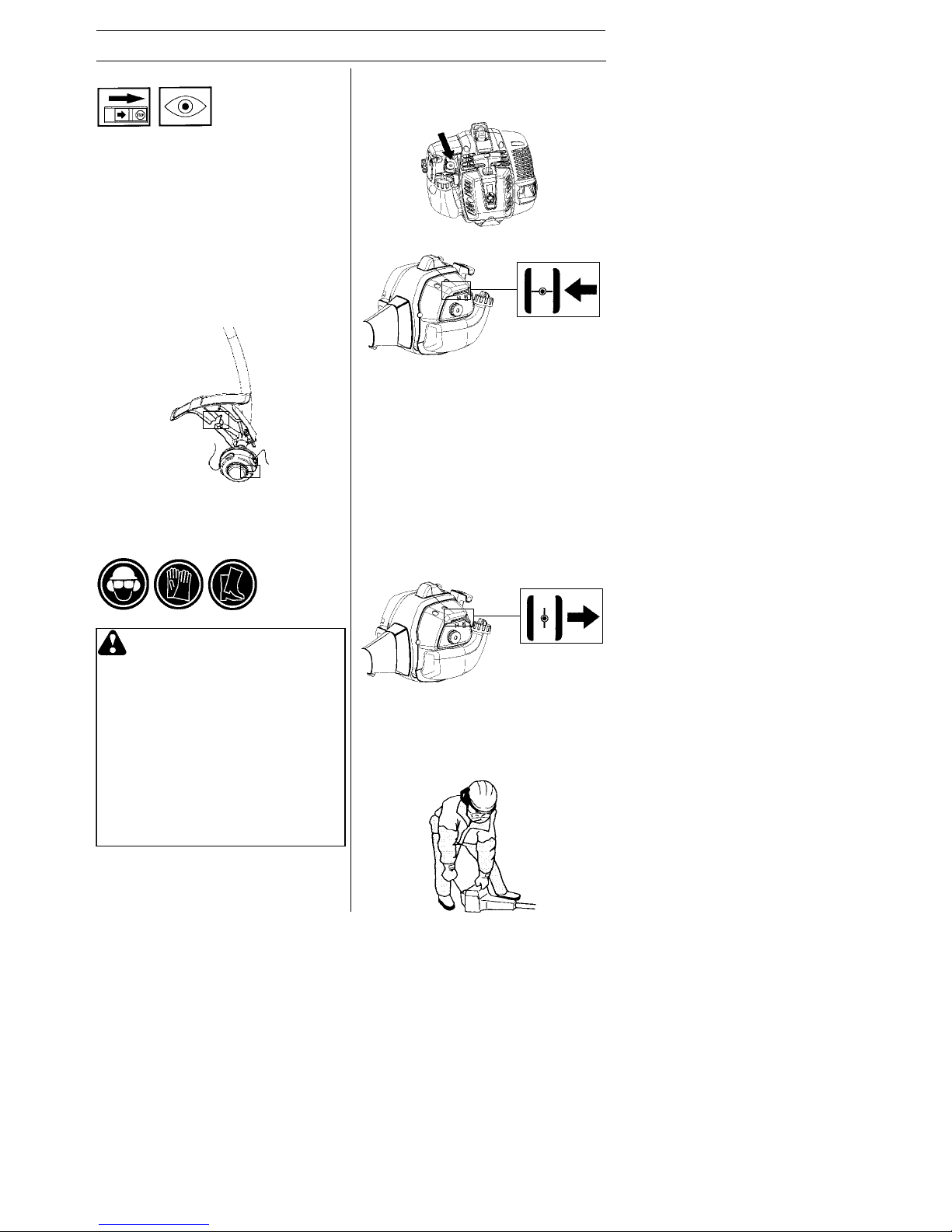

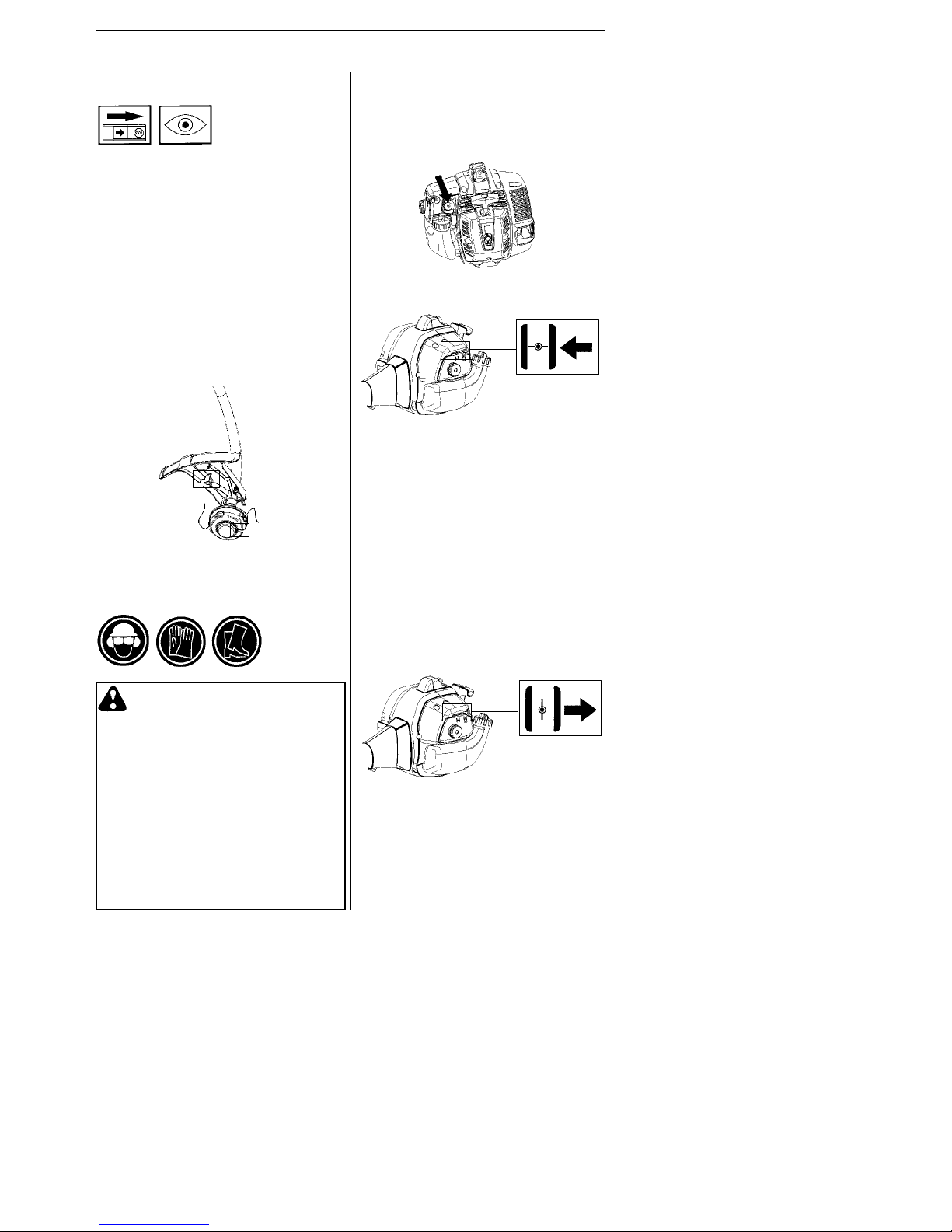

Arrows which show limits for

handle positioning.

Always wear approved protective

gloves.

Wear sturdy, non--slip boots.

Only use non--metallic, flexible

cutting attachments, i.e. trimmer

heads with trimmer line.

Page 4

E n g l i s h --- 4

545186855 Rev. 8 5/15/12

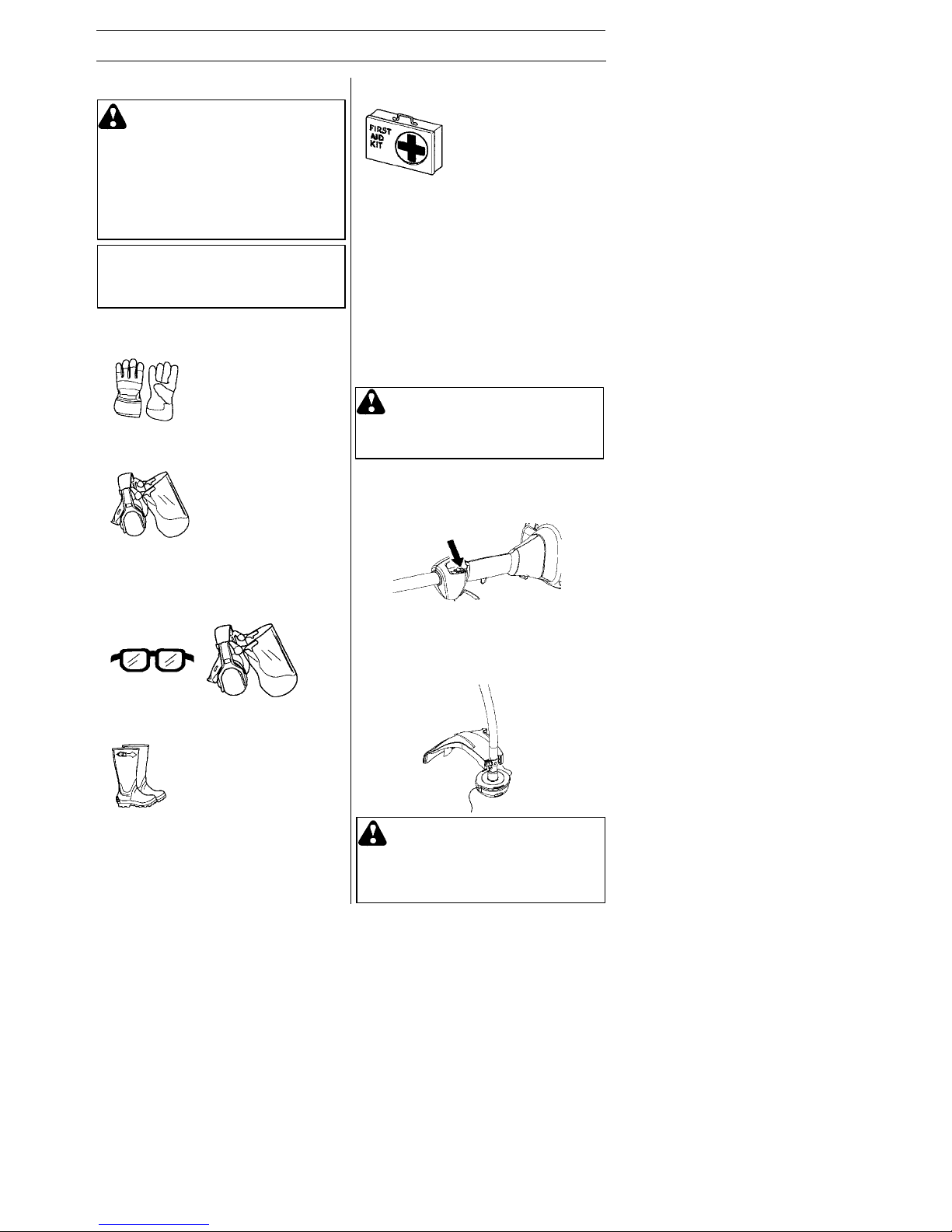

SAFETY INSTRUCTIONS

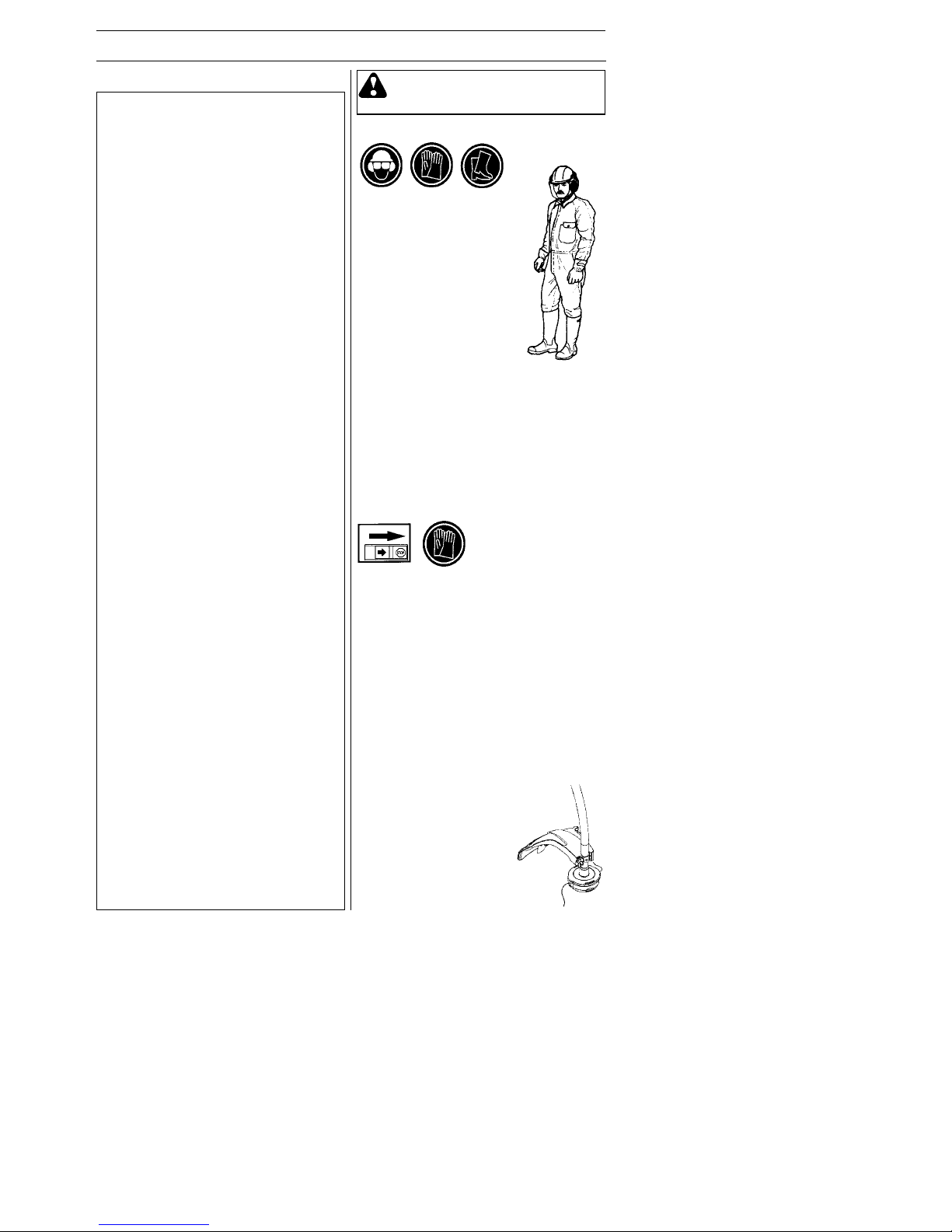

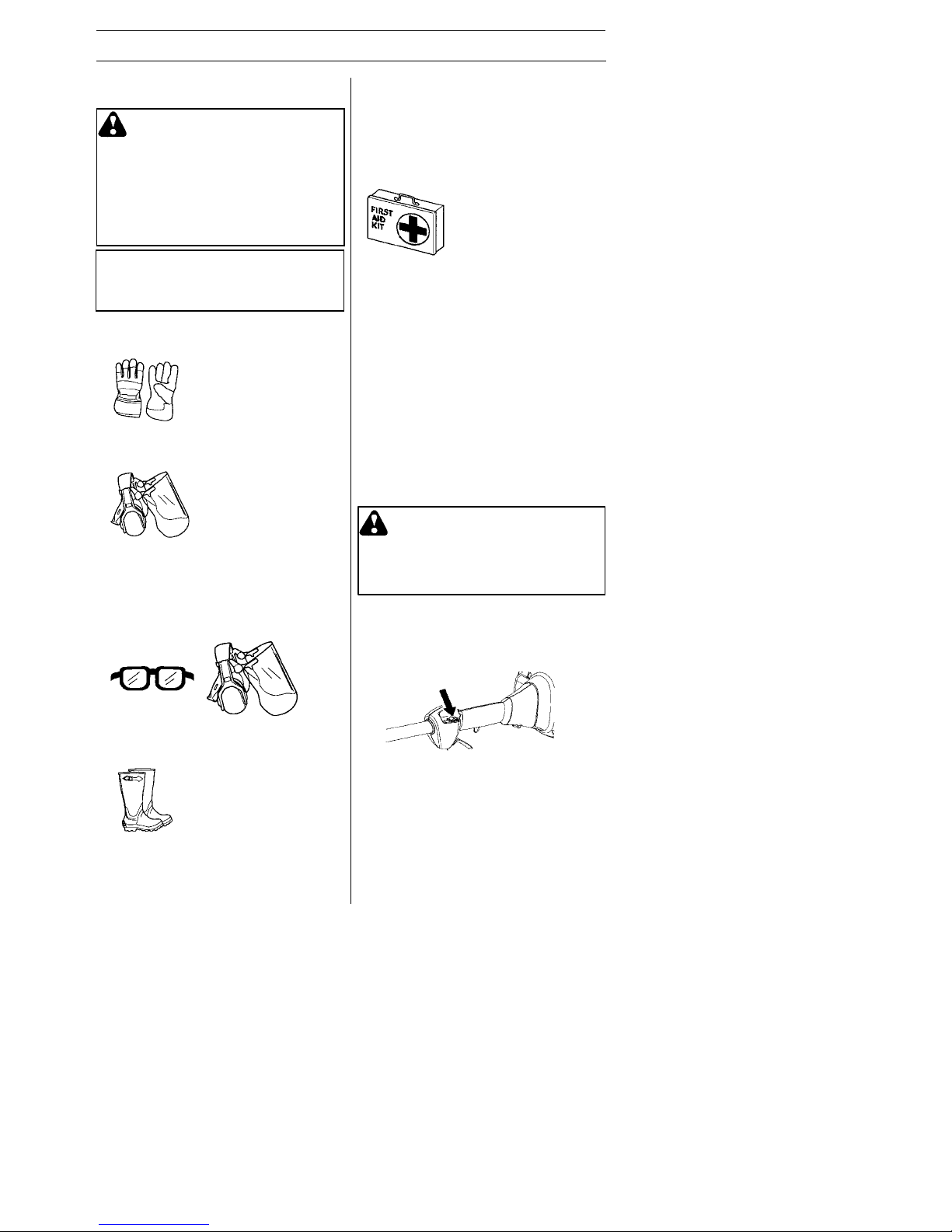

GLOVES

Gloves should be worn when necessary,

e.g., when fitting cutting attachments.

HEARING PROTECTION

Wear hearing protection that provides

adequate noise reduction.

EYE PROTECTION

Always wear approved eye protection. If

you use a visor then you must also wear

approved protective goggles. Approved

protective goggles must comply with

standard ANSI Z87.1.

BOOTS

Wear sturdy, non--slip boots.

CLOTHING

Wear clothes made of a strong fabric and

avoid loose clothing that can catch on

twigs and branches. Always wear heavy,

long pants. Do not wear jewelry , shorts

sandals or go barefoot. Secure hair so it is

above shoulder level.

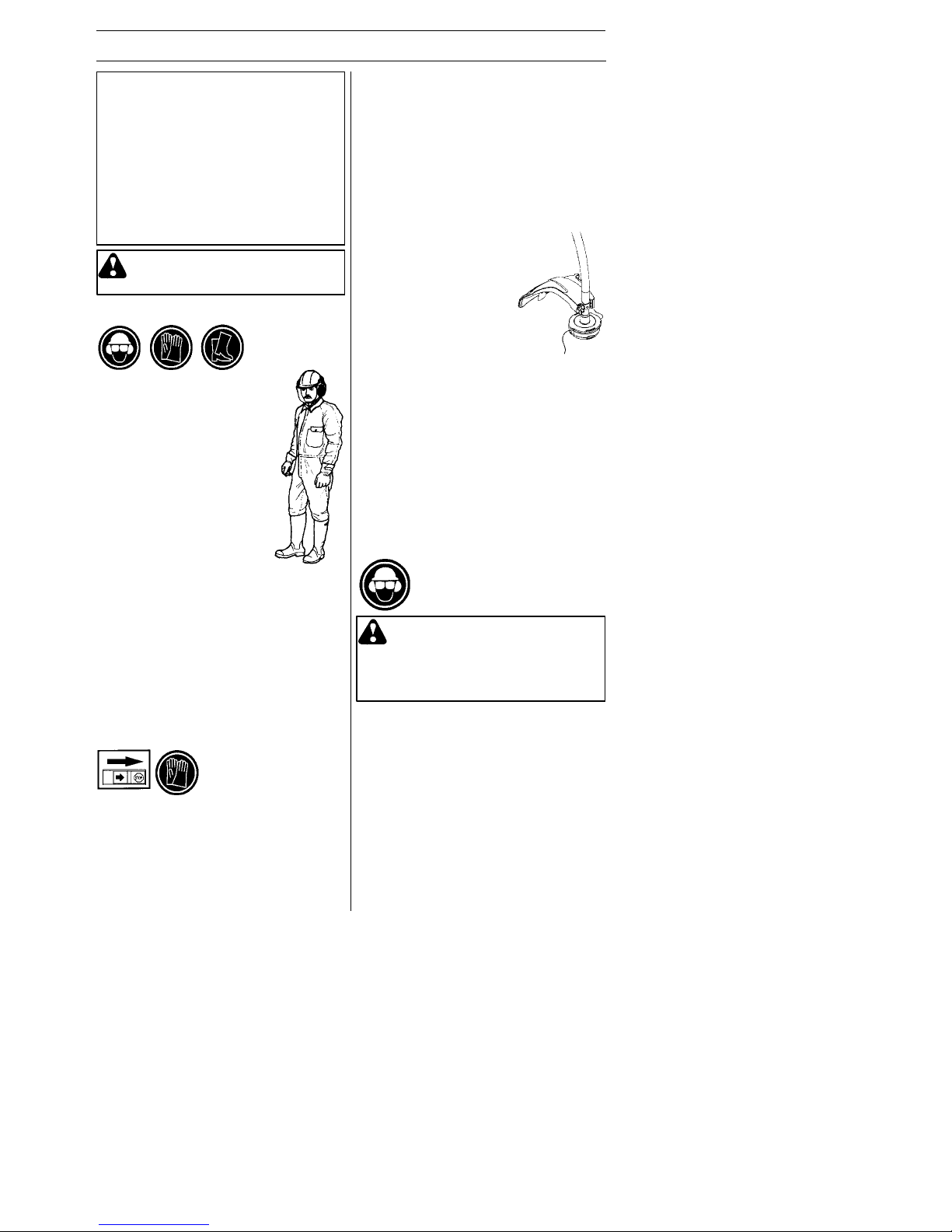

Personal protective equipment

FIRST AID KIT

Always have a first aid kit nearby.

Machine’ s safety equipment

This section describes the machine’s safety equipment, its purpose, and how checks

and maintenance should be carried out to

ensure that it operates correctly. See the

“Know your trimmer ” section to locate

where this equipment is positioned on your

machine.

The life span of the machine can be reduced

and the risk of accidents can increase if

machine maintenance is not carried out

correctly and if service and/or repairs are not

carried out professionally. If you need further

information please contact your nearest servicing dealer.

Stop switch

Make sure the engine stops when you push

and hold the stop switch.

WARNING: Never use a machine

that has faulty safety equipment!

Carry out the inspection, maintenance and service routines listed in

this section.

Cutting attachment guard

This guard is intended to prevent loose objects from being thrown towards the operator. The guard also protects the operator

from accidental contact with the cutting attachment.

WARNING: Never use a cutting

attachment without an approved

guard. See the section on “Technical

data”. If an incorrect or faulty guard

is fitted this can cause serious

personal injury.

WARNING: Whenever you use a

clearing saw, brushcutter or trimmer

you must wear personal protective

equipment that is approved by the

authorities. Personal protective

equipment does not eliminate the risk

of accidents, but it can reduce the ef fects of an injury in the event of an

accident. Ask your dealer for help

when choosing protective equipment.

IMPORTANT! Listen for warning signals

or shouts when you are wearing hearing

protection. Always remove your hearing

protection as soon as the engine stops.

Page 5

E n g l i s h --- 5

545186855 Rev. 8 5/15/12

SAFETY INSTRUCTIONS

Use ofincorrectly wound trimmer line or an

incorrect cutting attachment increases the

level of vibration.

Muffler

The muffler is designed to reduce the noise

level and to direct the exhaust gases away

from the operator.

CAUTION! Muffler is fitted with a catalytic

converter designed to reduce exhaust gas

emissions.

For mufflers, it is very important that you follow the instructions on checking, maintaining, and servicing your machine.

See Checking, maintaining and servicing the

machine’s safety equipment section.

WARNING: Overexposure to

vibration can lead to circulatory

damage or nerve damage in people

who have impaired circulation.

Contact your doctor if you experience symptoms of overexposure to

vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength,

changes in skin color or condition.

Thesesymptomsnormallyappear

in the fingers, hands or wrists. The

risk increases at low temperatures.

Cutting equipment

A trimmer head is intended for trimming

grass.

Checking, maintaining and

servicing the machine’s

safety equipment

IMPORTANT!

All servicing and repair work on the machine

requires special training. This is especially

true of the machine’s safety equipment. If

your machine fails any of the checks described below you must contact your service

agent. When you buy any of our products we

guarantee the availability of professional repairs and service. If the retailer who sells

your machine is not a servicing dealer, ask

him for the address of your nearest service

agent.

Stop switch

S Start the engine and make sure the engine

stops when you push and hold the stop

switch.

Cutting attachment guard

S Ensure that the guard is undamaged and

is not cracked.

S Replace the guard if it has been exposed

to impact or is cracked.

S Always use the recommended guard for

the cutting attachment you are using. See

section on “Technical data”.

WARNING: The inside of the

muffler contain chemicals that may

be carcinogenic. Avoid contact

with these elements in the event of

a damaged muffler.

CAUTION: Mufflers fitted with cata -

lytic converters get very hot during use

and remain so for some time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remembertheriskoffire!

WARNING: Engine exhaust

fumes contain carbon monoxide,

which can cause carbon monoxide

poisoning. DO NOT

start or run the

machine indoors, or anywhere that

is poorly ventilated. The exhaust

fumes from the engine are hot and

may contain sparks which can start

a fire. Never start the machine in doors or near combustible material!

Page 6

E n g l i s h --- 6

545186855 Rev. 8 5/15/12

SAFETY INSTRUCTIONS

Muffler

S Never use a machine that has a faulty

muffler.

S Regularly check that the muffler is securely

attached to the machine.

S The muffler on this unit is equipped with a

special spark arrestor mesh. The mesh

should be checked and, if necessary.

cleaned by a servicing dealer. A blocked

mesh will cause the machine to overheat,

which can lead to serious damage. Never

use a muffler with a defective spark arrestor mesh. See the Maintenance section.

Cutting equipment

This section describes how to choose and

maintain your cutting equipment in order to:

S Obtain maximum cutting performance.

S Extend the life of cutting equipment.

General rules

:

1. Only use cutting attachments with the

guards we recommend! See the section

on “Technical Data”.

2. Check the cutting attachment for damage

or cracks. A damaged cutting attachment

should always be replaced.

WARNING: Never use a machine

with faulty safety equipment. The

machine’s safety equipment must be

checked and maintained as

described in this section.

If your machine fails any of these

checks contact your service agent to

getitrepaired.Useofamachine

with faulty safety equipment increases the risk of serious personal

injury to the operator or others.

IMPORTANT!

This section describes how to choose and

maintain your cutting equipment in order to:

Obtain maximum cutting performance.

Extend the life of cutting equipment.

Only use cutting attachments with the guards

we recommend! See the section on

“T echnical data”.

Refer to the instructions for the cutting attachment to check the correct way to load the

trimmer line and the correct line diameter.

Trimmer head

S Only use the recommended cutting at-

tachments. See the section on “T echnical

data”.

S Smaller machines generally require small

trimmer heads and vice versa. This is because when clearing using trimmer line the

engine must throw out the trimmer line radially from the trimmer head and overcome

the resistance of the grass being cleared.

S The length of the trimmer line is also im-

portant. A longer trimmer line requires

greater engine power than a shorter

trimmer line of the same diameter.

S Make sure that the cutter on the trimmer

guard is intact. This is used to cut the

trimmer line to the correct length.

S To increase the life of the trimmer line it

can be soaked in water for a couple of

days. This will make the line tougher so

that it lasts longer.

IMPORTANT!

Always ensure the trimmer line is wound

tightly and evenly around the drum, otherwise the machine will generate harmful

vibration.

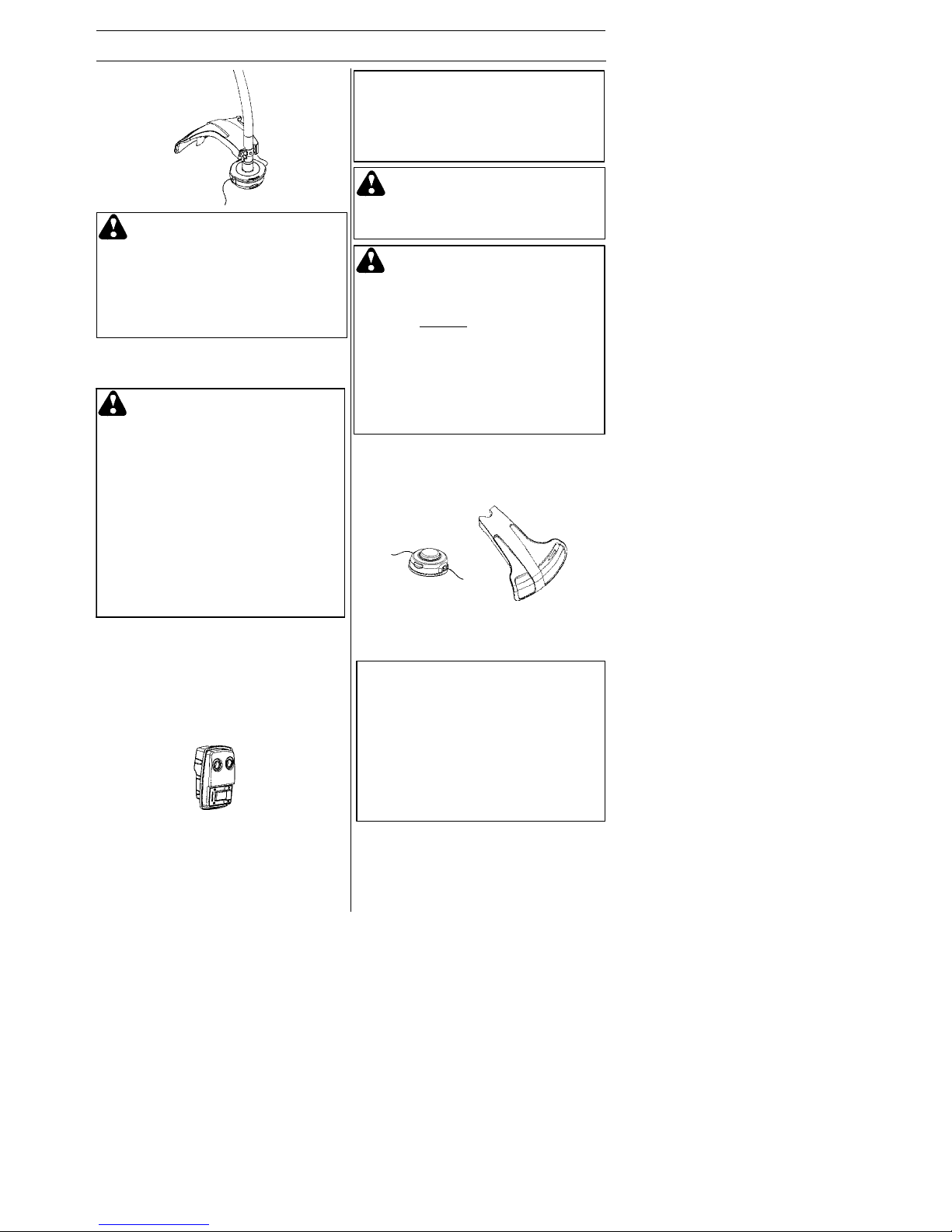

WARNING: Always stop the en-

gine before doing any work on the

cutting attachment. This continues

to rotate even after the throttle has

been released. Ensure that the

cutting attachment has stopped

completely and disconnect the

lead from the spark plug before

you start to work on it.

Page 7

E n g l i s h --- 7

545186855 Rev. 8 5/15/12

SAFETY INSTRUCTIONS

Safety instructions regarding the

surroundings

S Never allow children to use the machine.

S Ensure no one comes closer than 50 feet

(15 meters) when working.

S Never allow anyone else to use the

machine without first ensuring that they

have understood the contents of the

operator’s manual.

Safety instructions before starting

work

S Inspect the working area. Remove any

objects such as stones, broken glass,

nails, steel wire, string, etc. that can be

thrown or can wrap around the cutting

head or shaft.

S Keep others at a safe distance. Children,

animals, onlookers and helpers should

stand outside of the safety zone of 50

feet (15 meters). Bystanders should be

encouraged to wear safety glasses. Stop

the machine immediately if anyone

should approach.

S Check the entire machine before starting

work. Replace damaged parts. Check for

fuel leakage and that all safety guards

and covers are complete and fastened

securely. Check all nuts and bolts.

S Check the cutting head

for cracks or any other

damage.

S Ensure the trimmer guard

is mounted and not

damaged.

Personal protection

S Always wear boots and

other equipment described

in the “Personal protective

equipment” section.

S Always wear working

clothes and heavy--duty

long pants.

S Never wear loose fitting

clothes or jewelry.

S Persons with long hair

should (for personal safety)

put their hair up.

General safety preca utions

IMPORTANT!

S The machine is only designed for trimming

grass.

S The only accessories you can operate

with this engine unit are the cutting attachments we recommend in the “Technical data” section.

S Never use wire, rope, string, etc.

S Never use the machine if you are tired, if

you have drunk alcohol, or if you are taking medication that could affect your vision, your judgment or your coordination.

S Never use the machine in extreme weath-

er conditions such as severe cold , very hot

and/or humid climates.

S Never use a machine that has been modi-

fied in any way from its original specification.

S Wear personal protective equipment. See

instructions in the “Personal protective

equipment” section.

S Never use a machine that is faulty . Carry

out the checks, maintenance and service

instructions described in this manual.

Some maintenance and service measures

must be carried out by trained and qualified specialists. See instructions in the

“Maintenance” section.

S All covers and guards must be fitted before

starting. Make sure the spark plug cap and

lead are not damaged. Otherwise you

could get an electric shock.

S The machine operator must ensure that

no people or animals come closer than

50 feet (15 meters) while working.

S Stay clear of spinning line.

S Secure or remove loose clothing or cloth-

ing with loosely hanging ties, straps, tassels, etc. They can be caught in moving

parts.

S Being fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning line.

S Keep handles free of oil and fuel.

S Always keep the engine on the right hand

side of your body .

S Hold the unit firmly with both hands.

S Keep trimmer head below waist level and

away from all parts of your body. Do not

raise engine above your waist.

S Keep all parts of your body away from

muffler and spinning line. Keep engine below waist level. A hot muffler can cause

serious burns.

S Keep firm footing and balance. Do not

overreach or use from unstable surfaces

such as ladders, trees, steep slopes, rooftops, etc.

S Use only in daylight or good artificial light.

S Use only for jobs explained in this manual.

WARNING: A faulty cutting at-

tachment may increase the risk of

accidents.

Page 8

E n g l i s h --- 8

545186855 Rev. 8 5/15/12

SAFETY INSTRUCTIONS

S Check that the trimmer head and guard

are correctly secured.

S When adjusting the carburetor, make sure

the lower end is supported and that no one

is in the immediate vicinity.

S Make sure the cutting head does not rotate

when idling.

S Make sure the handle and safety features

are in order. Never use a machine that has

parts missing or has been changed in

relation to the specification.

S Only use the machine for the purpose for

which it was intended.

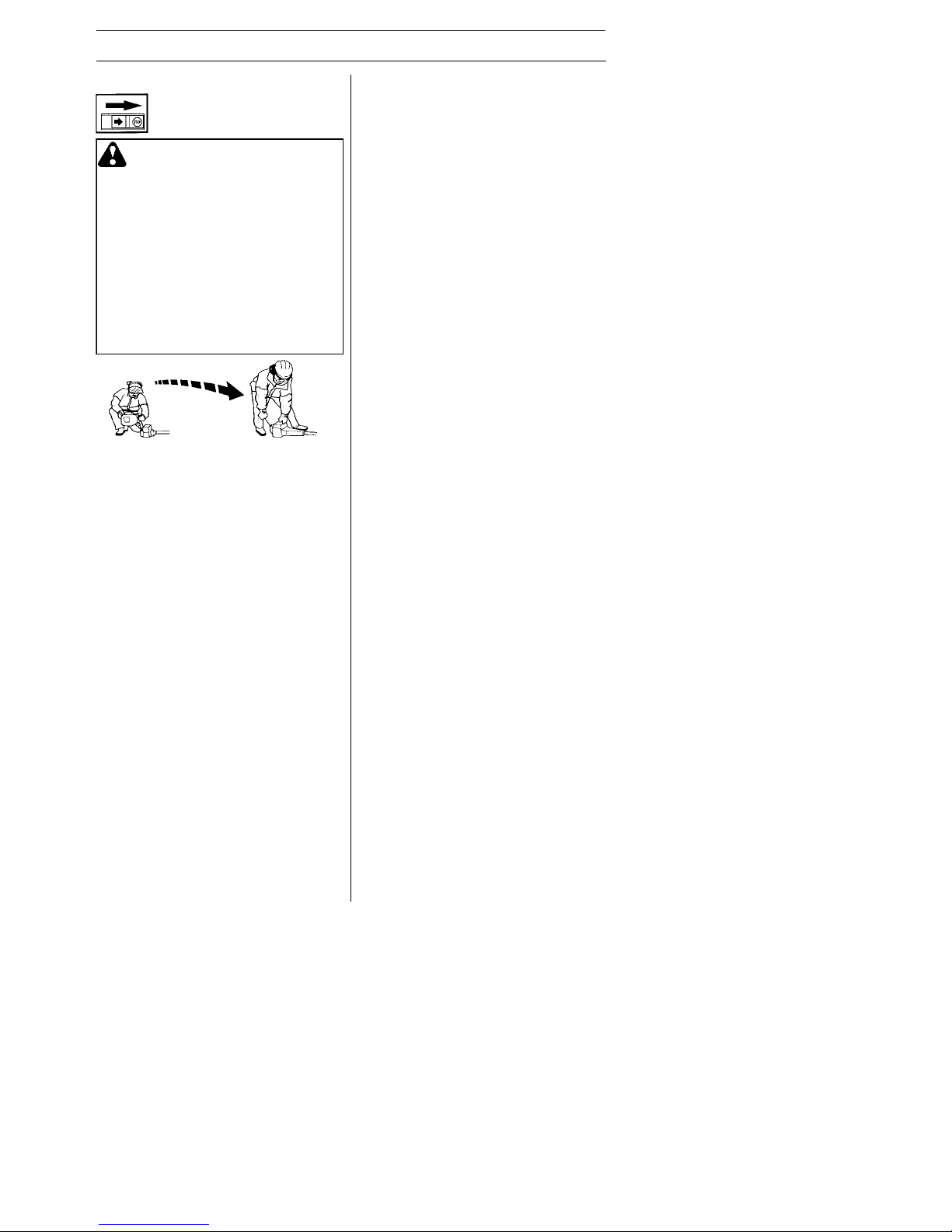

Starting

S Ensure that all of the engine covers and

housings are properly fitted before the unit

is started.

S Never start or attempt to run the unit with

the clutch, clutch drum, clutch cover, or

driveshaft removed.

S Never start the machine indoors. Exhaust

fumes can be dangerous if inhaled.

S Observe your surroundings and make sure

that there is no risk of people or animals

coming into contact with the cutting equipment.

S See the “Starting and Stopping” section for

complete instructions.

Fuel safety

S Always use a fuel container with an anti--

spill valve.

S Never refuel the machine while the engine

is running.

S Always stop the engine and let it cool for a

few minutes before refueling.

S Make sure there is plenty of ventilation

when refueling or mixing fuel (gasoline and

2--stroke oil).

S Move the machine at least 10 feet (3 me-

ters) from the refueling point before starting it.

S Never start the machine:

S If you have spilled fuel on it. Wipe off

the spillage and allow remaining fuel to

evaporate.

S If you have spilled fuel on yourself or

your clothes, change your clothes. Was

h

any part of your body that has come in

contact with fuel. Use soap and water.

WARNING: When the engine is

startedwiththechokeineitherthe

choke or start throttle positions the

cutting attachment will start to

rotate immediately.

Min. 10 ft.

(3 m)

S If the machine is leaking fuel. Check

regularly for leaks from the fuel cap

and fuel lines.

S Avoid all skin contact with fuel. Fuel is

a skin irritant and may even cause

skin changes.

Transporting and storage

S Store and transport the machine and fuel

so that there is no risk of any leakage or

fumes coming into contact with sparks or

naked flames, for example, from electrical machinery, electric motors, electrical

relays/switches or boilers.

S When storing and transporting fuel al-

ways use approved containers intended

for this purpose.

S When storing the machine for long peri-

ods the fuel tank must be emptied. Contact your local gas station to find out

where to dispose of excess fuel.

S Ensure the machine is cleaned and that

a complete service is carried out before

long--term storage.

General working instructions

IMPORTANT!

This section describes the basic safety precautions for working with trimmers. If you

encounter a situation where you are uncertain how to proceed you should ask an expert. Contact your servicing dealer.

Avoid all usage which you consider to be

beyond your capability.

You must understand the difference between

forestry cle aring, grass clearing and grass

trimming before use.

Basic safety rules

1. Look around you:

S To ensure that people, animals or other

things cannot affect your control of the

machine.

S To ensure that people, animals, etc.,

do not come into contact with the cutting attachment or loose objects that

are thrown out by the cutting attachment.

WARNING: Take care when han-

dling fuel. Bear in mind the risk of

fire, explosion and inhaling fumes.

Page 9

E n g l i s h --- 9

545186855 Rev. 8 5/15/12

SAFETY INSTRUCTIONS

3. Make sure you can move and stand safely.

Check the area around you for possible obstacles (roots, rocks, branches, ditches, etc.)

in case you have to move suddenly. T ake

great care when working on sloping ground.

4. Switch off the engine before moving to

another area.

5. Never put the machine down with the engine

running or while the cutting attachment is

rotating.

Basic working techniques

S Always slow the engine to idle speed after

each working operation. Long periods at

full throttle without any load on the engine

can lead to serious engine damage.

S It is recommended that the engine not

be operated for longer than 1 minute at

full throttle.

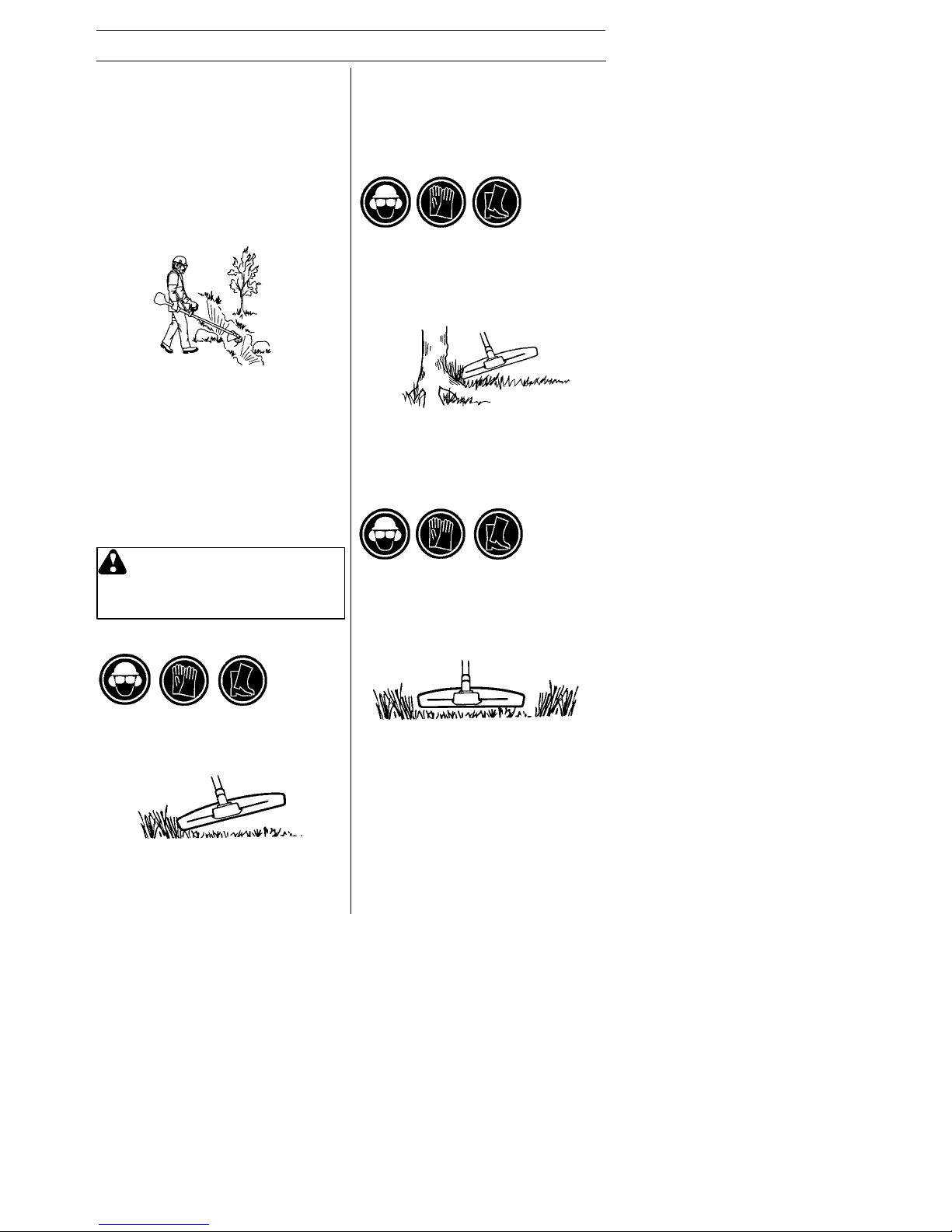

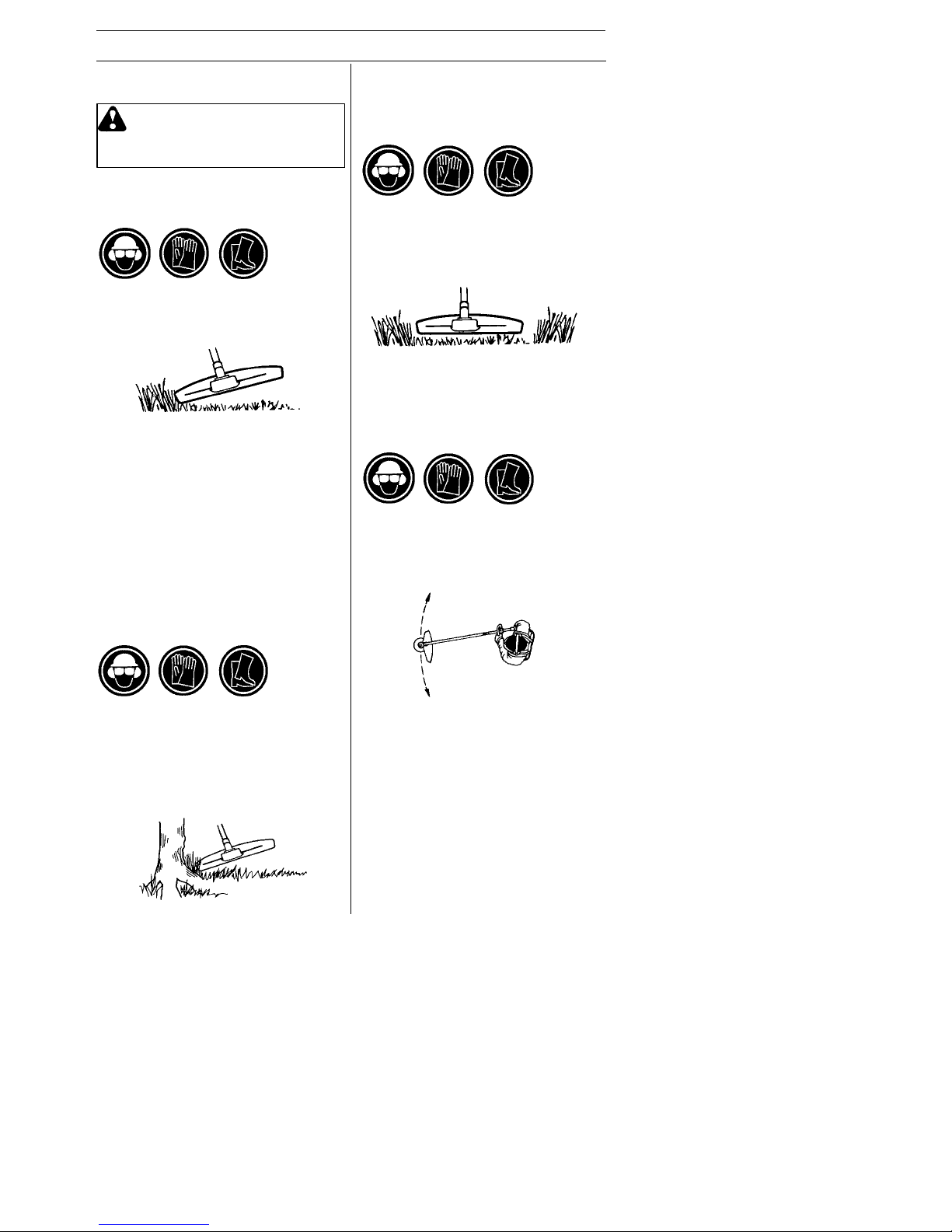

Grass trimming using a trimmer head

Tri mmi ng

S Hold the trimmer head just above the

ground at an angle. It is the end of the trimmer line that does the work. Let the trimmer line work at its own pace. Never press

the trimmer line into the area to be cut.

S The trimmer line can easily remove grass

and weeds up against walls, fences, trees

and borders, however it can also damage

sensitive bark on trees and bushes, and

damage fence posts.

WARNING: Sometimes branches

or grass get caught between the

guard and cutting attachment.

Always stop the engine before

cleaning.

S CAUTION! Do not use the machine

unless you are able to call for help in

the event of an accident.

2. Do not use the machine in bad weather,

such as dense fog, heavy rain, strong

wind, intense cold, etc. Working in bad

weather is tiring and often brings added

risks, such as icy ground, unpredictable

felling direction, etc.

S Reduce the risk ofdamaging plants by

shortening the trimmer line to 4- -4 1/2 inches

(10--12 cm) and reducing the engine speed.

S When trimming you should use less than

full throttle so that the trimmer line lasts

longer and to reduce the wear on the

trimmer head.

Clearing

S The clearing technique removes all un-

wanted vegetation. Keep the trimmer

head just above the ground and tilt it. Let

the end of the trimmer line strike the

ground around trees, posts, statues and

the like. IMPORTANT! This technique

increases the wear on the trimmer line.

S The trimmer line wears quicker and must

be fed forward more often when working

against stones, brick, concrete, metal

fences, etc., than when coming into contact with trees and wooden fences.

Cutting

S The trimmer is ideal for cutting grass that

is difficult to reach using a normal lawn

mower. Keep the trimmer line parallel to

the ground when cutting. Avoid pressing

the trimmer head against the ground as

this can ruin the lawn and damage the

tool.

S Do not allow the trimmer head to con--

stantly come into contact with the ground

during normal cutting. Constant contact

of this type can cause damage and wear

to the trimmer head.

Page 10

E n g l i s h --- 1 0

545186855 Rev. 8 5/15/12

SAFETY INSTRUCTIONS

Sweeping

S The fan effect of the rotating line can be

used for quick and easy clearing up.

Hold the trimmer line parallel to and

above the area to be swept and move

the tool to and fro.

S When cutting and sweeping you should

use full throttle to obtain the best results.

WARNING: Watch out for

thrown objects. Always wear

approved eye protection. Never

lean over the cutting attachment

guard. Stones, rubbish, etc. can be

thrown up into the eyes causing

blindness or serious injury. Keep

unauthorised persons at a distance. Children, animals, onlookers

and helpers should be kept outside

the safety zone of 15 m. Stop the

machine immediately if anyone

approaches. Never swing the machine around without first checking

behind you t o make sure no one is

within the safety zone.

WARNING: Sometimes

branches or grass get caught

between the guard and cutting

attachment or wrapped around the

shaft. Neither the operator of the

machine nor anyone else may attempt to remove the cut material

while the engine is running or the

cutting equipment is rotating,

as this can result in serious injury.

Stop the engine and cutting equipment before you remove material.

Page 11

E n g l i s h --- 1 1

545186855 Rev. 8 5/15/12

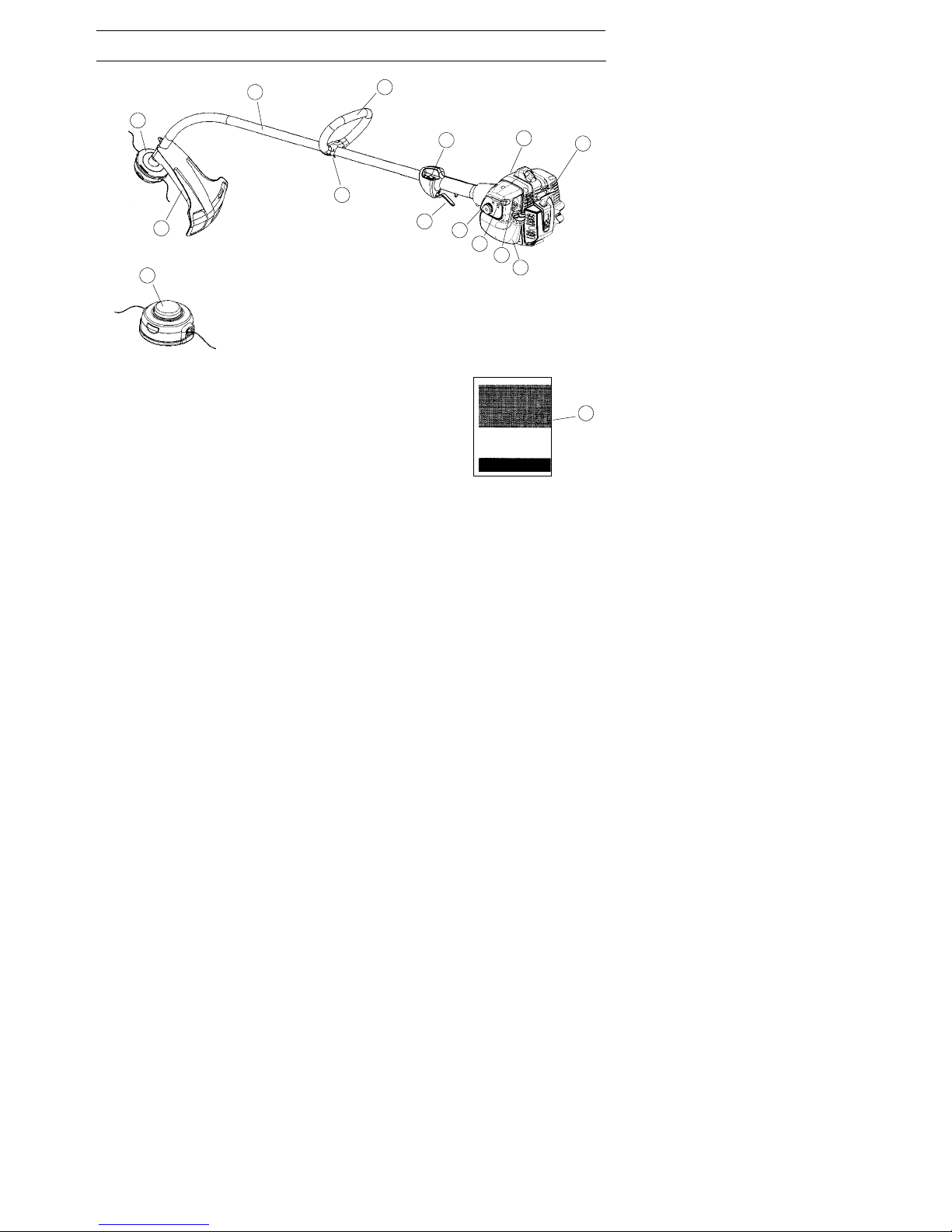

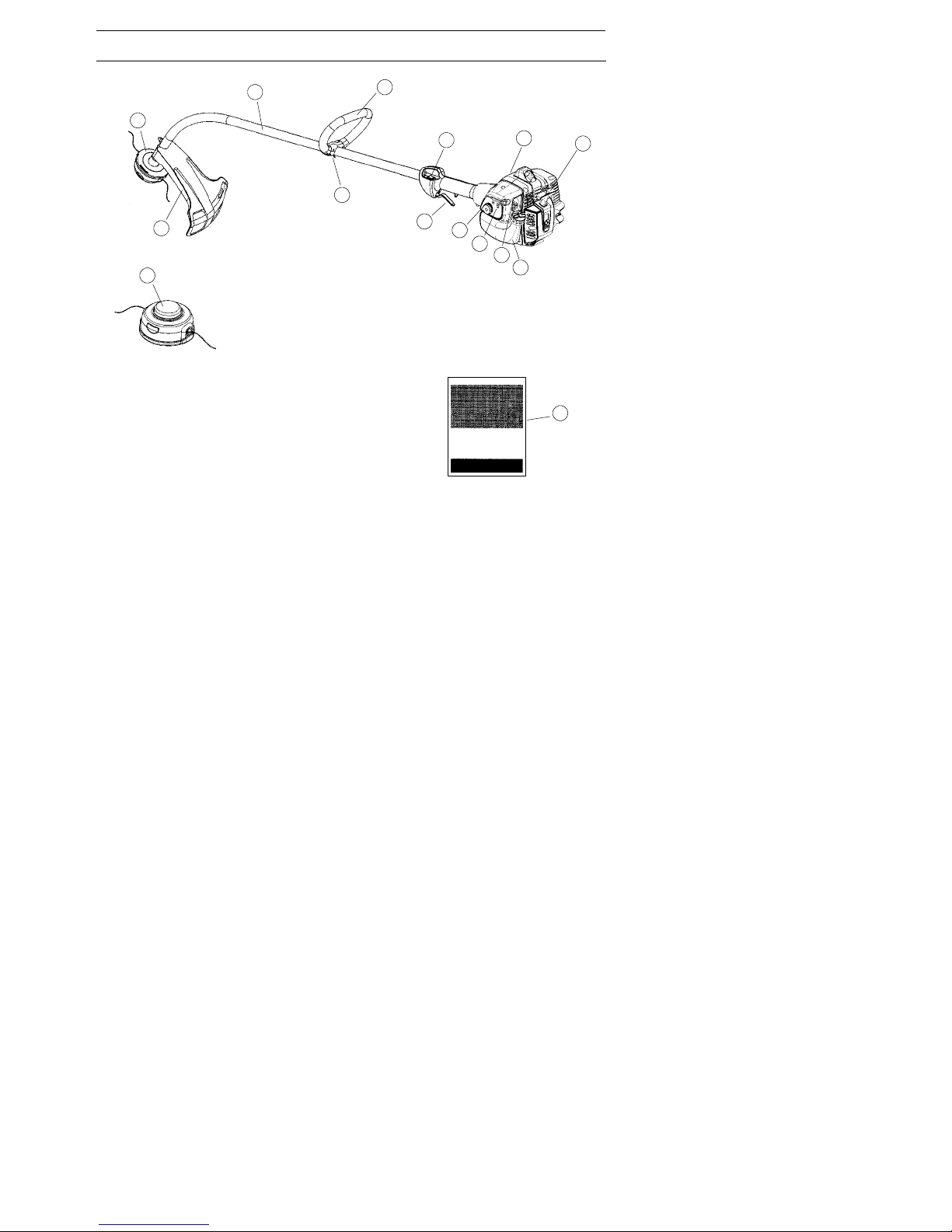

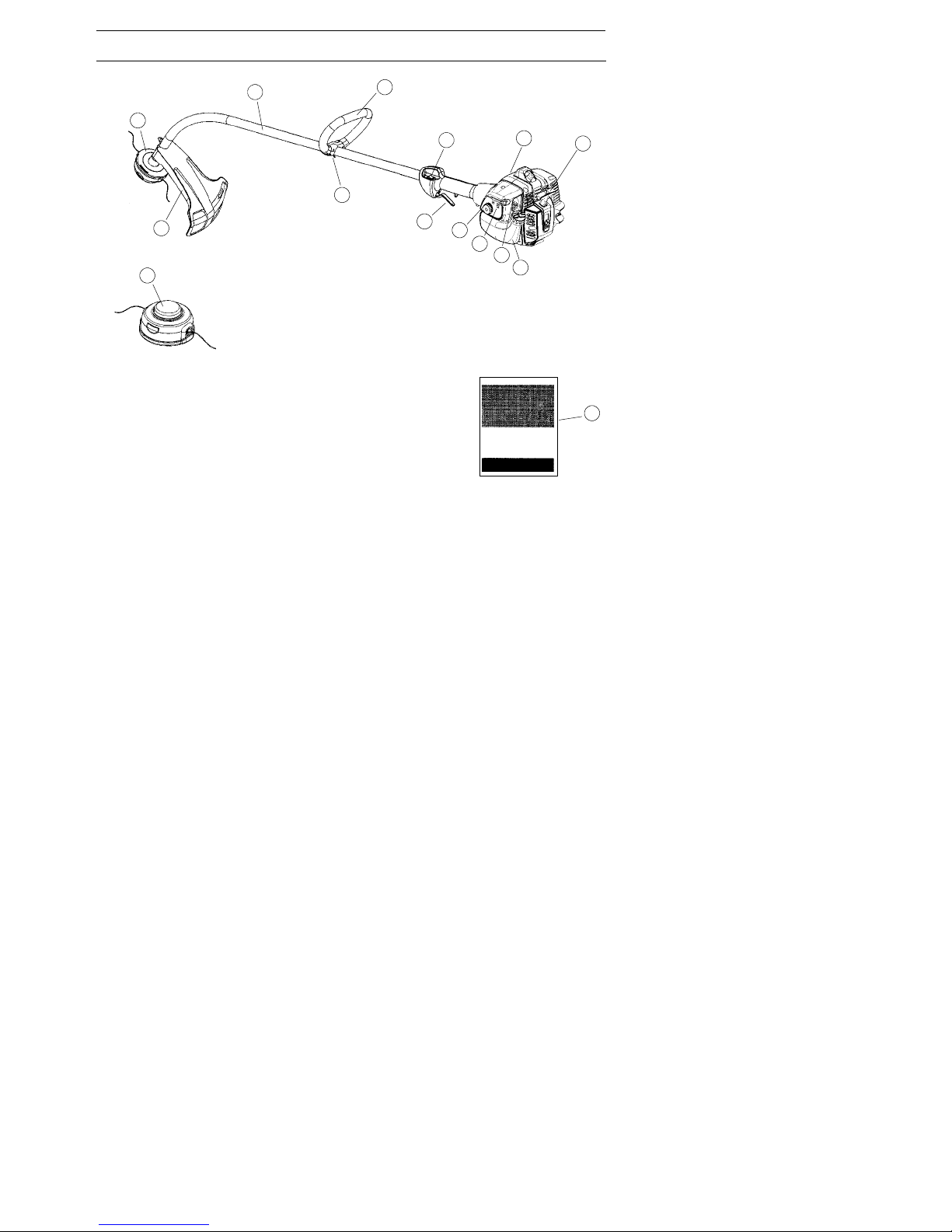

WHAT IS WHAT?

1. Trimmer head 8. Starter handle

2. Cutting attachment guard 9. Fuel tank

3. Shaft 10. Choke control

4. Loop handle 11. Air purge

5. Throttle control 12. Air filter cover

6. Stop switch 13. Handle adjustment

7. Cylinder cover 14. Operator’s manual

What is what?

3

7

4

1

2

12

1

6

8

11

10

5

9

14

13

Page 12

E n g l i s h --- 1 2

545186855 Rev. 8 5/15/12

ASSEMBLY

NOTE: Make sure unit is assembled cor-

rectly as shown in this manual.

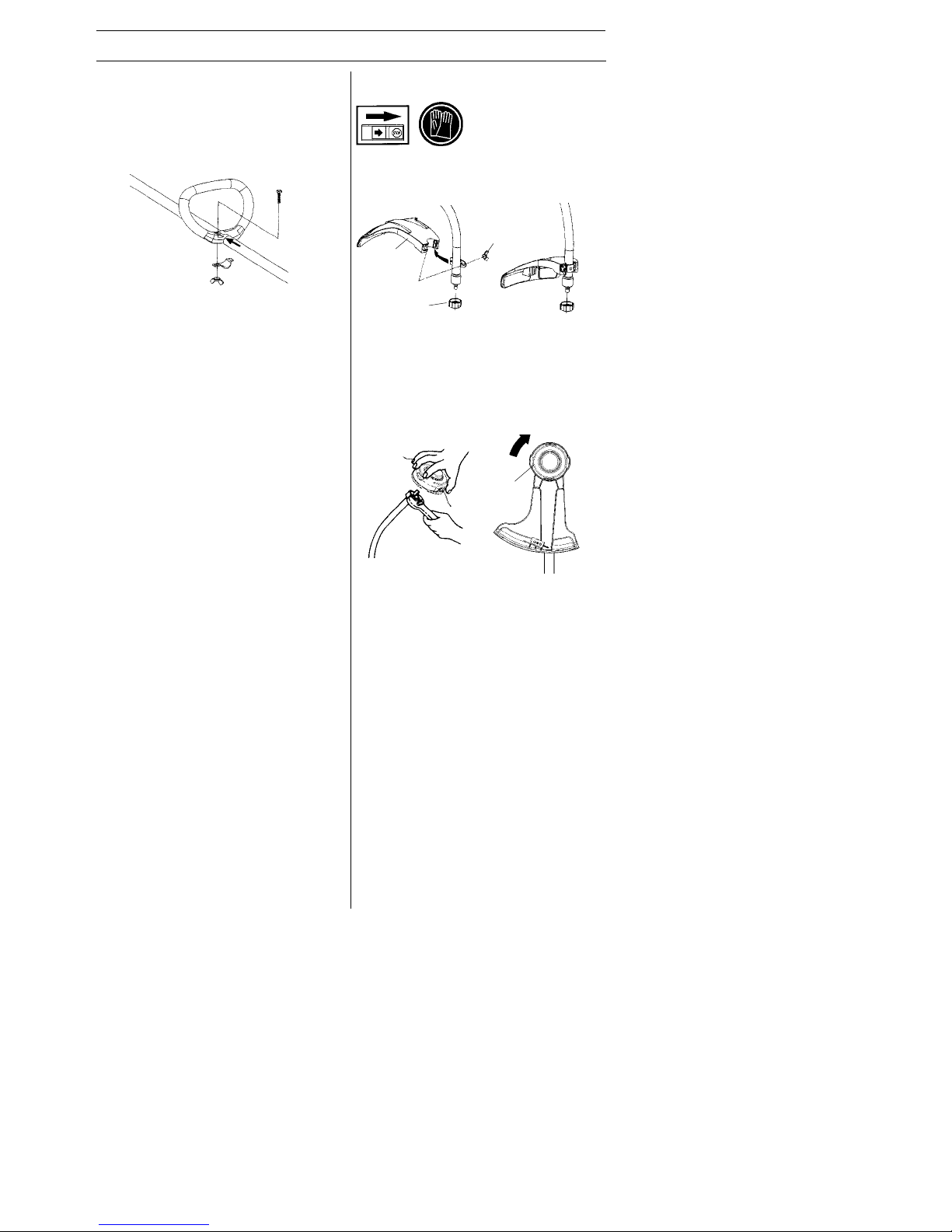

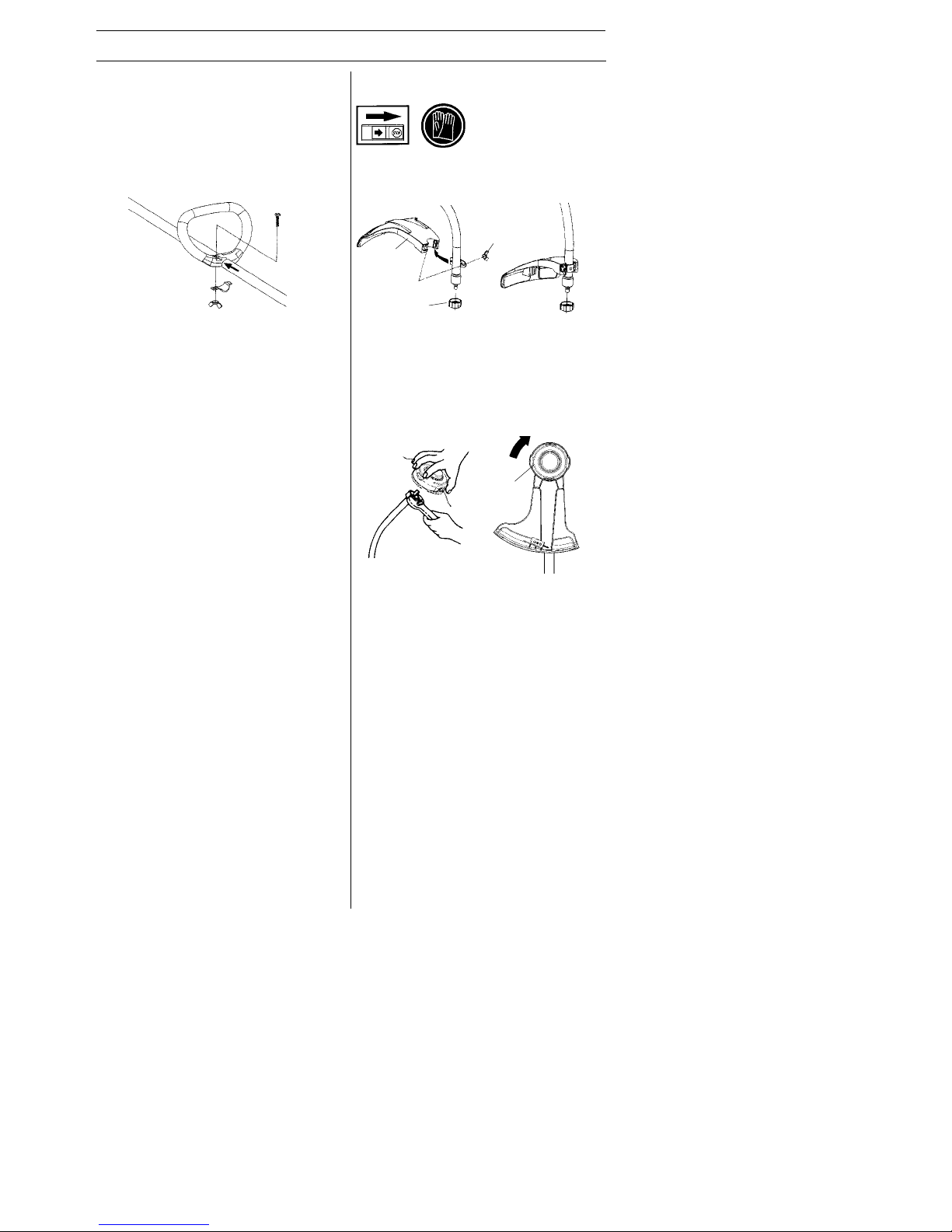

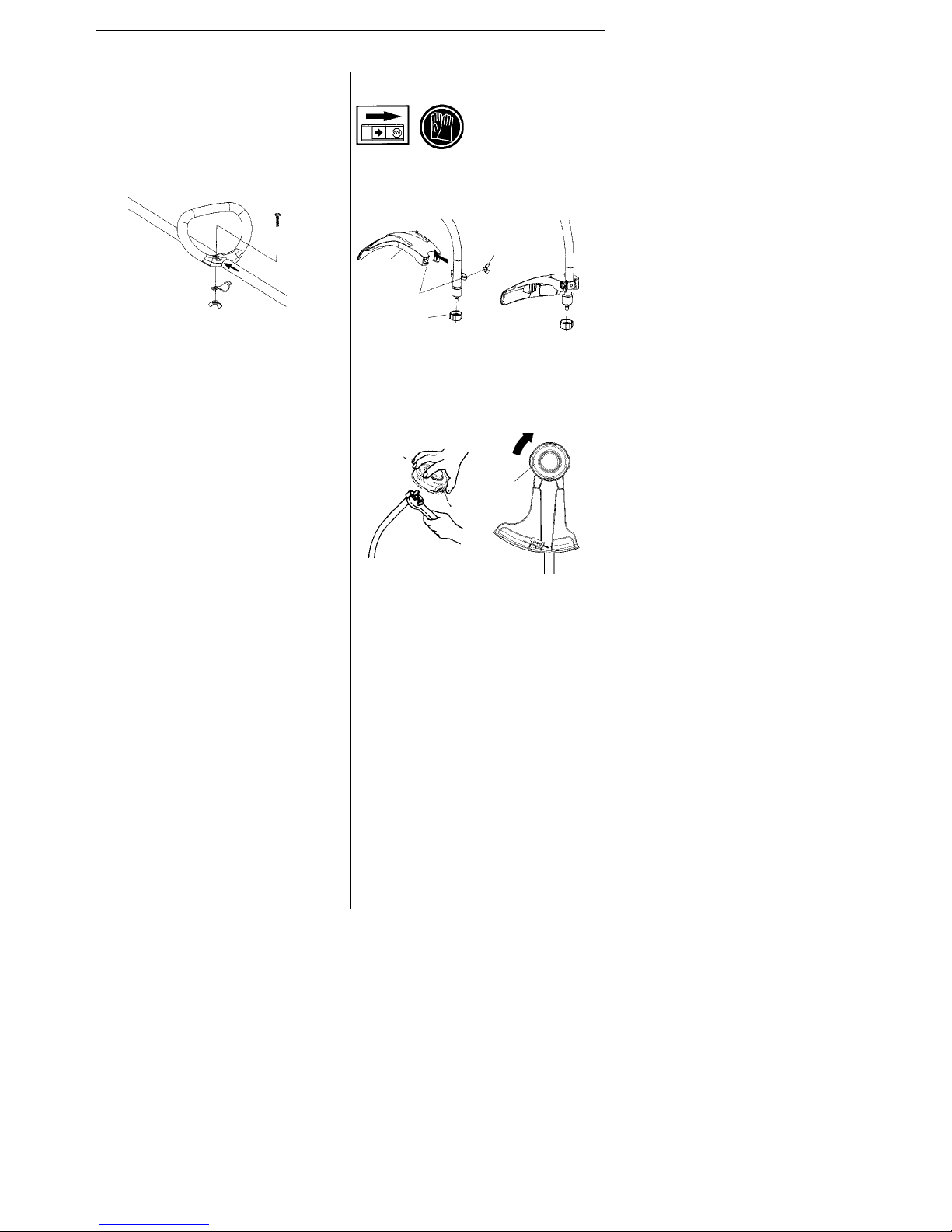

Fitting the loop handle

S Position the handle on the shaft. Note

that the handle must be mounted between the two arrows on the shaft.

S Fit the screw, securing plate and wing

nut as shown in the diagram.

S Tighten the wing nut.

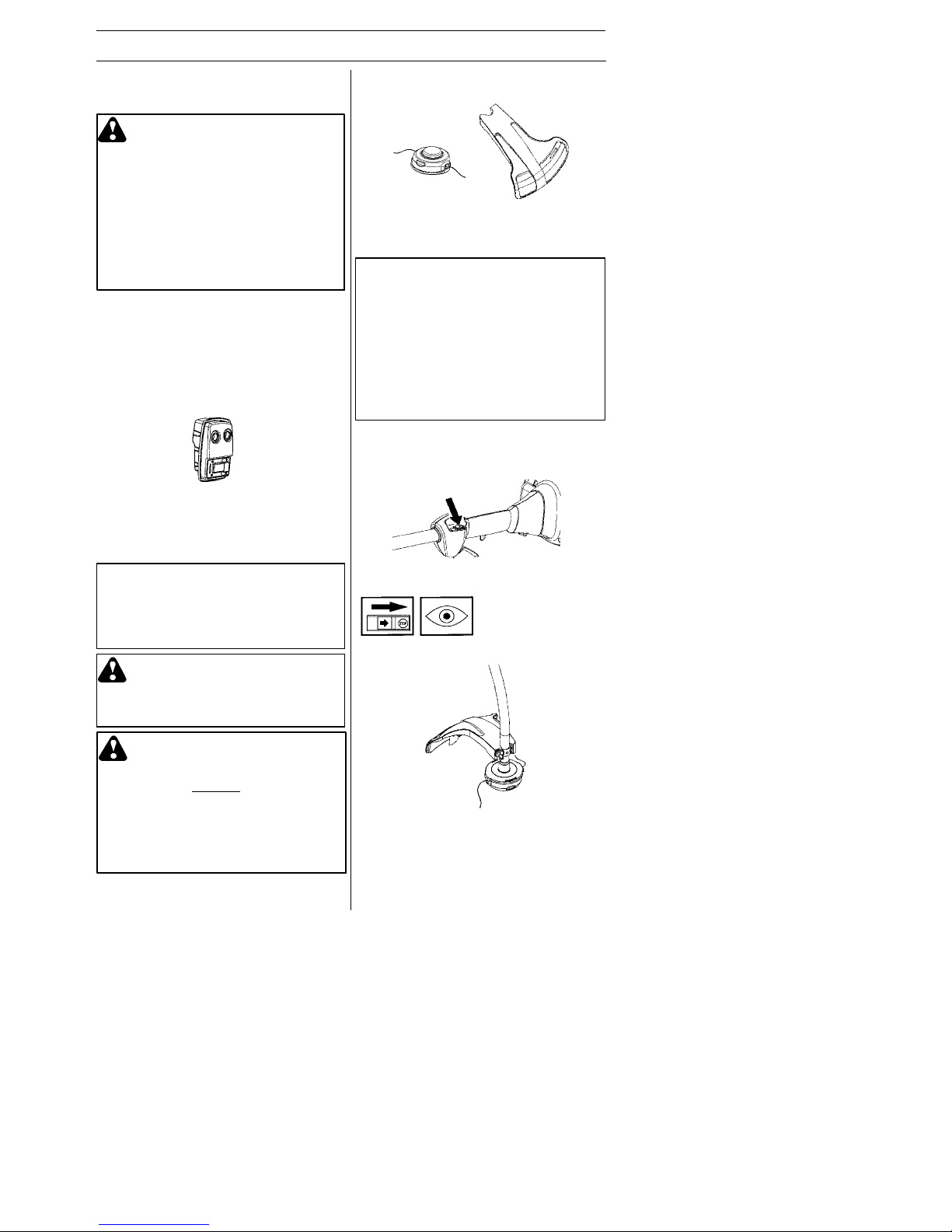

Fitting the trimmer guard and

trimmer head

S Fit the correct trimmer guard (A) for use

with the trimmer head. Hook the trimmer

guard/combination guard onto the fitting on

the shaft and secure with the wing nut (B).

A

C

B

S Fit the dust cup (C) on the shaft. The nut

must be completely covered by the dust

cup.

S Hold the dust cup with a wrench to pre-

vent the shaft from rotating.

S Screw the trimmer head (D) onto the

shaft.

S To dismantle, follow the instructions in

the reverse order.

D

Page 13

E n g l i s h --- 1 3

545186855 Rev. 8 5/15/12

FUEL HANDLING

Fuel mixture

CAUTION! The machine is equipped with

a two--stroke engine and must always be

run using a mixture of gasoline and two-stroke engine oil. It is important to accurately measure the amount of oil to be

mixed to ensure that the correct mixture is

obtained. When mixing small amounts of

fuel, even small inaccuracies can drastically affect the ratio of the mixture.

Gasoline

CAUTION! Always use high quality

unleaded gasoline.

S This engine is certified to operate on

unleaded gasoline.

S The lowest recommended octane rating

is 87. If you run the engine on lower octane rating than 87, “knocking” can occur. This leads to an increased engine

temperature, which can result in a serious engine breakdown.

S When working at continuous high revs a

higher octane rating is recommended.

Two-- s trok e o il

S For great results and performance use

JONSERED two--stroke oil, which is

specially formulated for our two--stroke

engines. Mixture 1:50 (2%).

S To maximize the life of your trimmer, you

may choose to use a high quality synthetic oil formulated for two--stroke

engines. Mixture 1:50 (2%).

S Never use two--stroke oil intended for

water--cooled outboard engines,

sometimes referred to as outboard oil.

S Never use oil intended for four --stroke

engines.

WARNING: Fuel and fuel fumes

are highly flammable and can cause

serious injury when inhaled or al lowed to come in contact with the

skin. For this reason, observe caution when handling fuel and make

sure there is adequate ventilation.

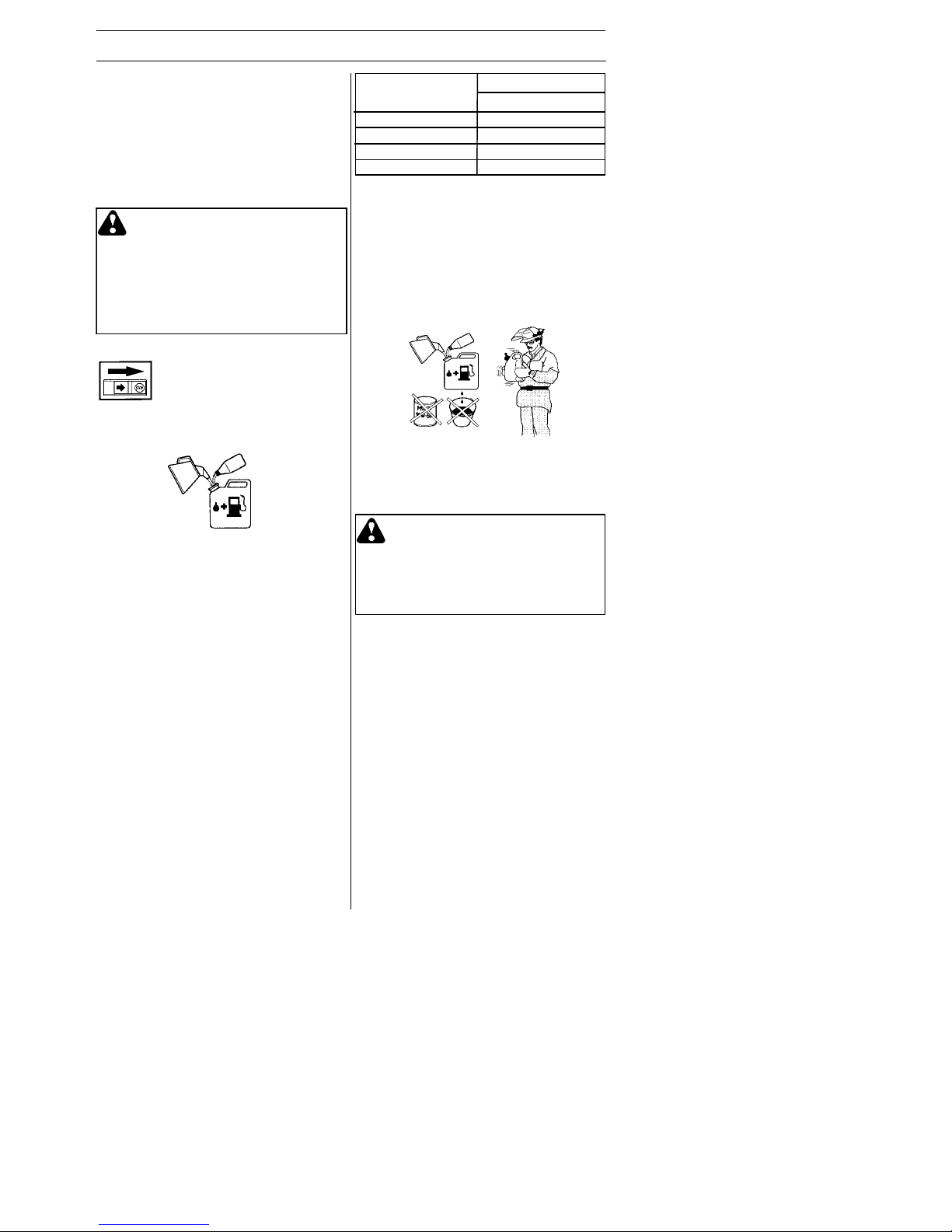

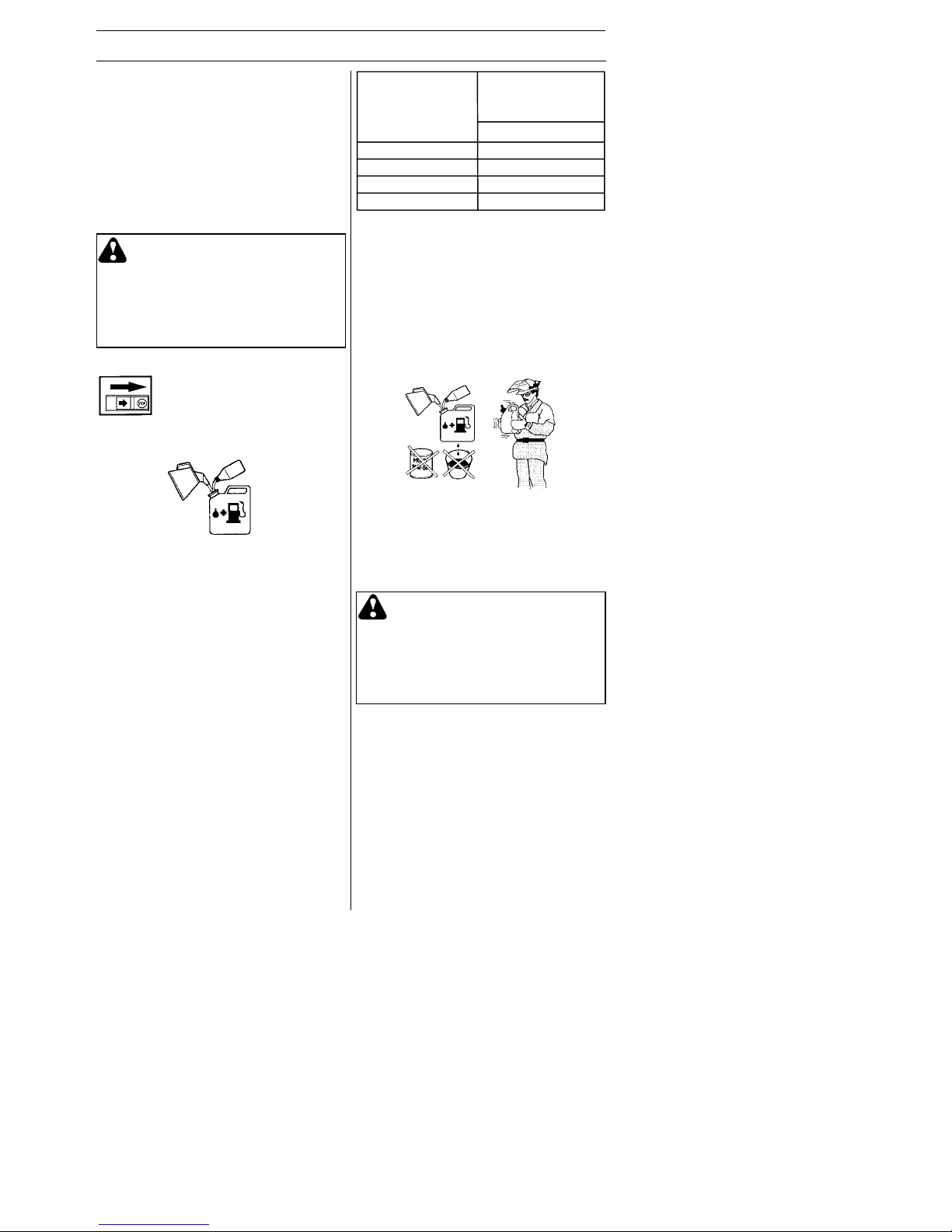

U.S. gallon U.S. fl. oz.

121/2

2 1/2 6 1/2

5127/8

Gasoline

Two - -stroke oil

2% (1:50)

S Always start by flling half the amount of the

gasoline to be used. Then add the entire

amount of oil. Mix (shake) the fuel mixture.

Add the remaining amount of gasoline.

S Mix (shake) the fuel mixture thoroughly

before filling the machine’s fuel tank.

S Do not mix more than one month’s sup-

ply of fuel at a time.

S If the machine is not used for some time,

the fuel tank should be emptied and

cleaned.

WARNING: The catalytic convert-

er muffler gets very hot during and

after use. This also applies during

idling.Beawareofthefirehazard,

especially when working near flammable substances and/or vapors.

Fueling

WARNING: Taking the following

precautions, will lessen the risk of

fire:

Do not smoke or place hot objects

near fuel.

Always shut off the engine before

refueling.

Always stop the engine and let it

cool for a few minutes before refueling.

When refueling, open the fuel cap

slowly so that any excess pressure

is released gently.

Tighten the fuel cap carefully after

refueling.

Always move the machine away

from the refueling area before

starting.

Min. 10 ft.

(3 m)

S Clean the area around the fuel cap.

Contamination in the tank can cause

operating problems.

S Ensure that the fuel is well mixed by shak-

ing the container before filling the tank.

Mixing

S Always mix the gasoline and oil in a

clean container intended for fuel.

Page 14

E n g l i s h --- 1 4

545186855 Rev. 8 5/15/12

STARTING AND STOPPING

Check before starting

S Inspect the unit before each use. Re-

place damaged parts. Check for fuel

leaks. Make sure all fasteners are in

place and secure. Make sure the cutting

attachment is properly installed and securely fastened. Use only flexible, nonmetallic line recommended by the

manufacturer. Never use, for example,

wire or wire rope, which can break off

and become a dangerous projectile.

S Check that the trimmer head and trimmer

guard are not damaged or cracked.

Replace the trimmer head or trimmer

guard if they have been exposed to

impact or are cracked.

S Never use the machine without a guard

nor with a defective guard.

Starting and stopping

WARNING: The complete clutch,

clutch cover, and shaft must be

fitted before the machine is started,

otherwise parts could come loose

and cause personal injury.

Always move the machine away

from the refueling area before

starting. Place the machine on a

flat surface. Ensure the cutting attachment cannot come into contact

with any object.

Make sure no unauthorized persons

are in the working area, otherwise

there is a risk of serious personal

injury. The safety distance is 50 feet

(15 meters).

Cold engine

Primer bulb: Press the primer bulb 10

times until fuel begins to fill the bulb. The

primer bulb need not be completely filled.

Choke: Move the blue engine choke lever

to the closed position.

Starting

Hold the body of the machine on the

ground using your left hand (CAUTION!

Not with your foot!).

Firmly grip the starter rope handle with

your right hand. DO NOT squeeze

throttle trigger. Slowly pull out the cord

until you feel some resistance (the starter

pawls grip); then quickly and powerfully

pull the cord.

Never wrap the starter cord around

your hand.

Repeat pulling the cord until the engine

attempts to start. Move the blue engine

choke lever to the ½ position. Pull starter

rope until engine runs. Move the blue engine choke lever to the opened position.

NOTE: If engine dies, return blue engine

choke lever to the closed position and

repeat starting steps.

CAUTION! Do not pull the starter cord all

the way out and do not let go of the starter

handle when the cord is fully extended.

This can damage the machine.

Page 15

E n g l i s h --- 1 5

545186855 Rev. 8 5/15/12

STARTING AND STOPPING

Warm engine

With a warm engine, move the blue engine

choke lever to the ½ position. Pull starter

rope until engine runs. Move the blue

engine choke lever to the opened position.

WARNING: When the engine is

started with the choke in the closed

position the cutting attachment will

start to rotate immediately.

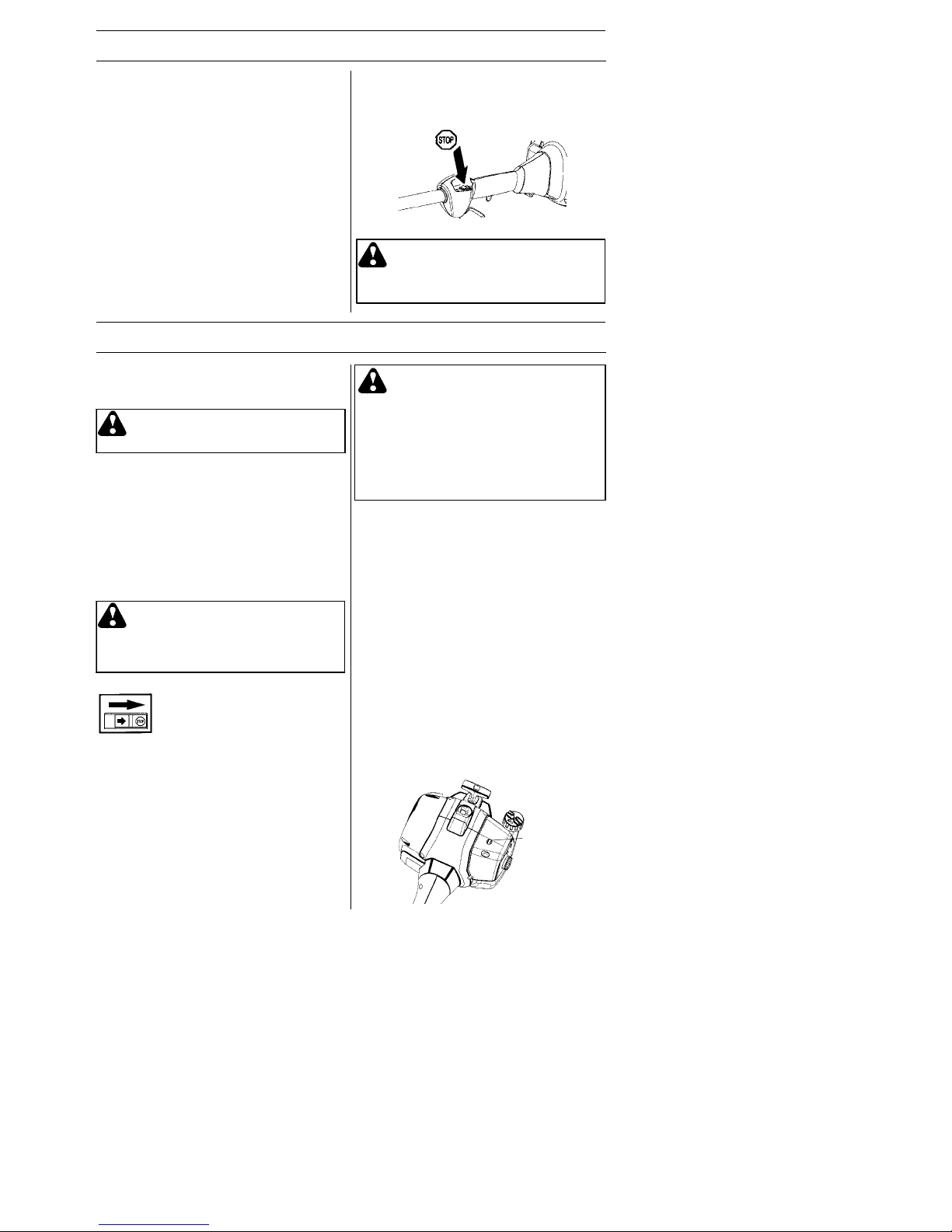

Stopping

Stop the engine by pushing and holding

the stop switch in the STOP position until

the engine stops.

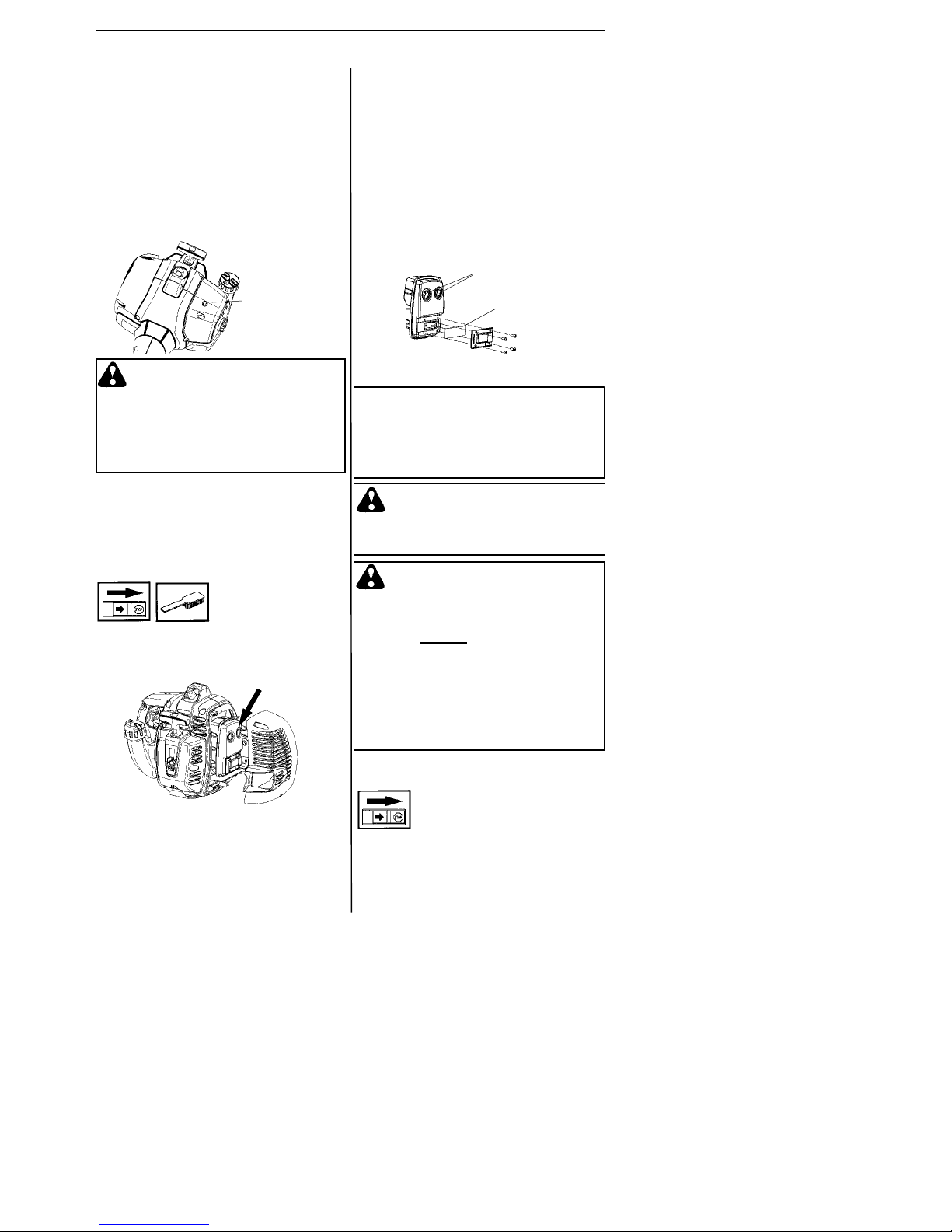

MAINTENANCE

Carburetor

Y our Jonsered product has been designed

and manufactured to specifications that reduce harmful emissions. After the engine

has used 8--10 tanks of fuel, the engine will

be run--in. To ensure that it continues to run

at peak performance and to minimize harmful exhaust emissions after the run--in period, ask your servicing dealer to adjust your

carburetor.

The owner is responsible for the per

f

ormance of all required maintenance as

defined in the operator’s manual.

WARNING: The complete clutch,

clutch cover , and shaft must be

fitted before the machine is started,

otherwise parts could come loose

and cause personal injury.

Function

S The carburetor governs the engine’s

speed via the throttle control. Air and fuel

are mixed in the carburetor.

S The T--screw regulates the throttle setting

at idle speed. If the T--screw is turned

clockwise this gives a higher idle speed;

turning it counterclockwise gives a lower

idle speed.

Basic setting

S The basic carburetor settings are ad-

justed during testing at the factory. Fine

adjustment should be carried out by a

skilled technician.

CAUTION! If the cutting attachment rotates

when the engine is idling the idle adjustment

screw T should be turned counterclockwise

until the cutting attachment stops.

WARNING: The cutting attach-

ment may be spinning during carburetor adjustments. Wear your protective equipment and observe all safety instructions. Be sure the cutting

attachment stops turning when the

engine idles. When the unit is turned

off, make sure the cutting attach ments has stopped before the unit is

set down.

Rec. idle speed:

See “Te chnical data” section.

Recommended max. speed:

See “Te chnical data” section.

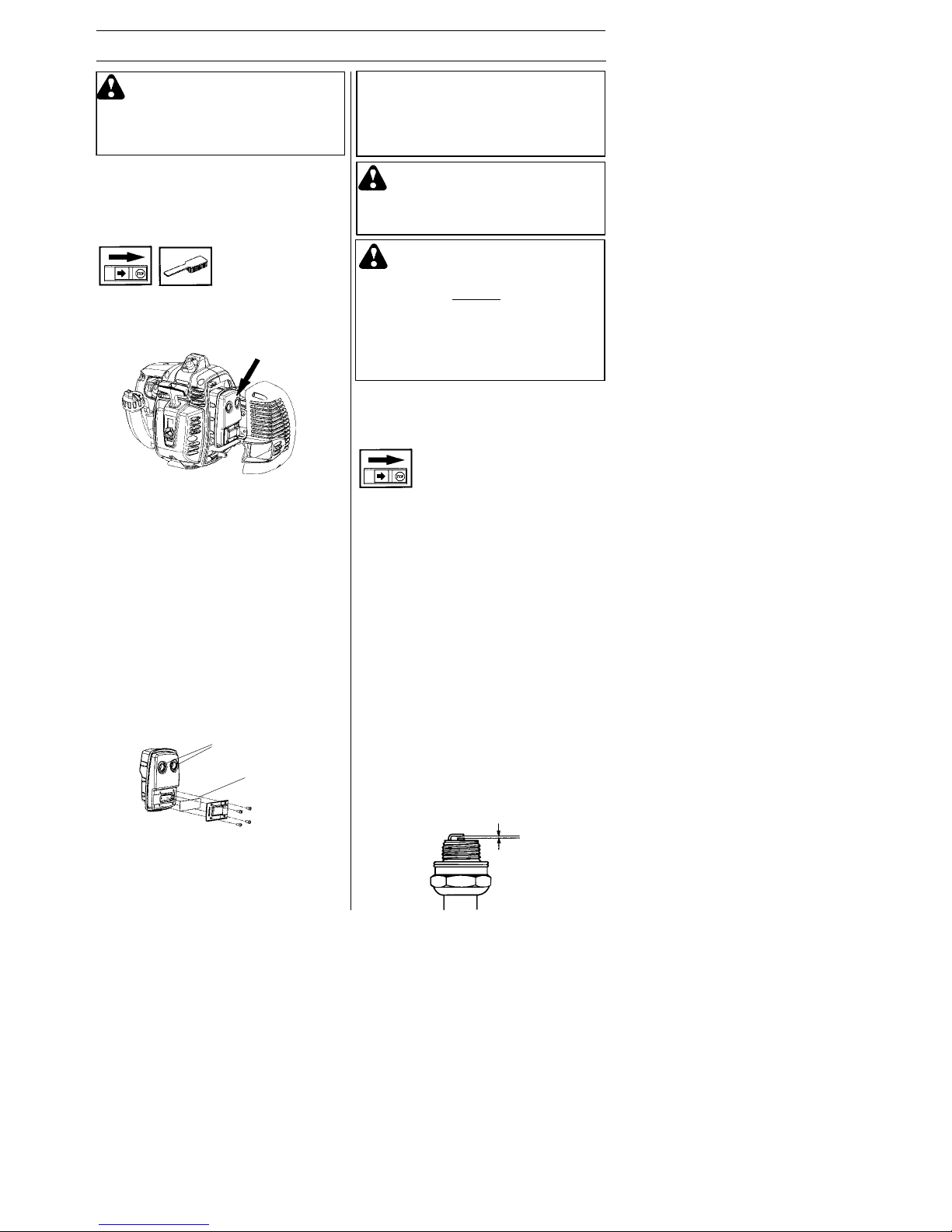

Fine adjustment of the idle speed--T

Adjust the idle speed using the idle adjustment screw --T if it is necessary to readjust.

First, turn the idle adjustment screw--T

clockwise until the cutting attachment starts

to rotate. Then, turn the screw counterclockwise until the cutting attachment stops.

The idle speed is correctly adjusted when

the engine will run smoothly in every position. The idle speed should also be well

below the speed at which the cutting attachment starts to rotate.

Idle Speed

Screw--T

WARNING: Improper mainte-

nance could result in serious engine

damage or in serious injury.

Page 16

E n g l i s h --- 1 6

545186855 Rev. 8 5/15/12

MAINTENANCE

WARNING: If the idle speed can-

not be adjusted so that the cutting

attachment stops, contact your servicing dealer. Do not use the machine until it has been correctly adjusted or repa ired.

Unit/Maintenance Safety

Disconnect the spark plug before performing maintenance, except carburetor adjustments.

Muffler

CAUTION! Muffler is fitted with a catalytic

converter designed to reduce harmful exhaust gases.

The muffler is designed to reduce the noise

level and to direct the exhaust gases away

from the operator. The exhaust gases are

hot and can contain sparks, which may

cause fire if directed against dry and combustible material.

Mufflers are equipped with a special spark

arrestor mesh. The mesh should be

checked and, if necessary. cleaned by a

servicing dealer. If the mesh is damaged,

it should be replaced. Ifthemeshisfrequently blocked, this can be a sign that the

performance of the catalytic converter is

impaired. Contact your servicing dealer to

inspect the muffler. A blocked mesh will

cause the machine to overheat and result

in damage to the cylinder and piston.

CAUTION! Never use a machine that has

a faulty or loose muffler. Ensure the muffler

bolts are tight.

Muffler bolts

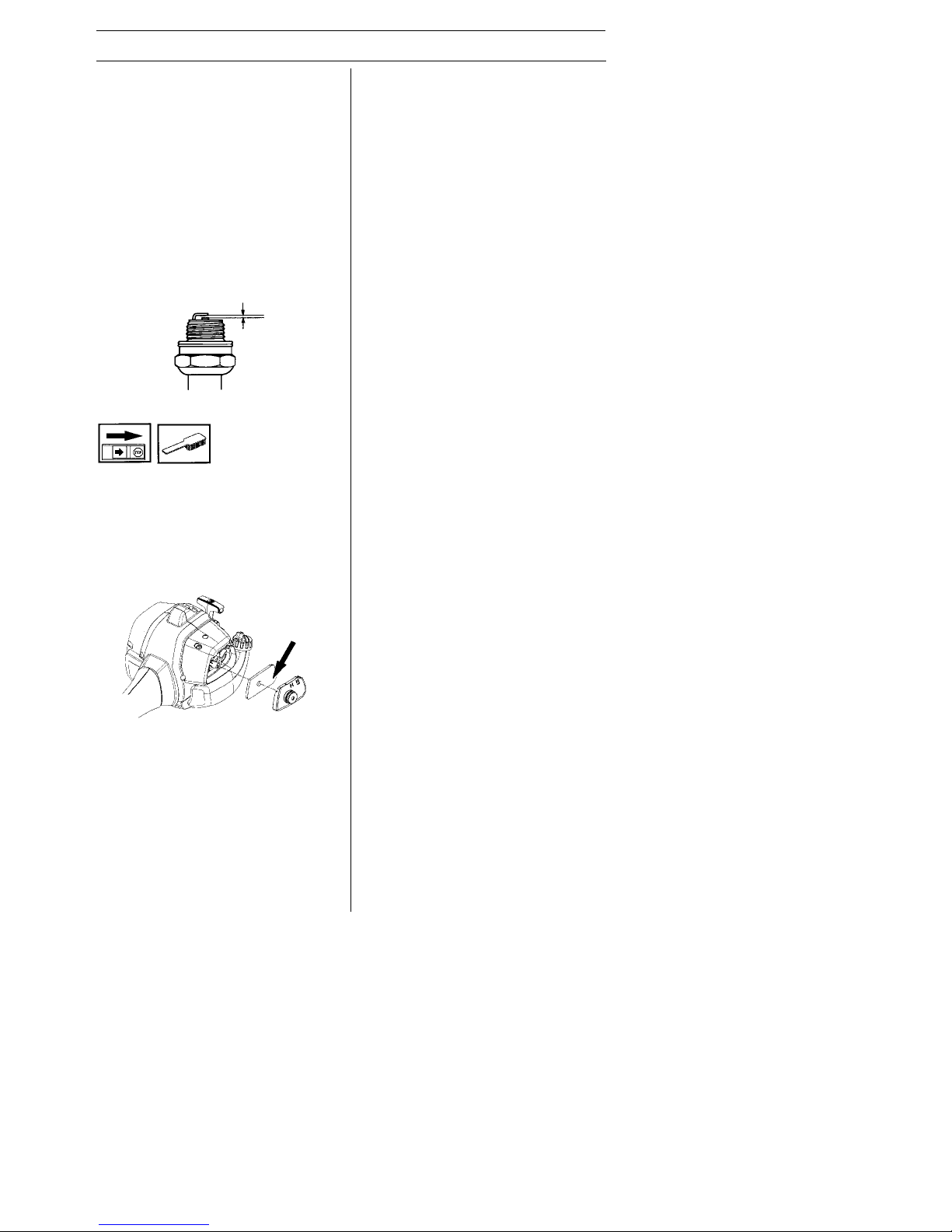

Spark plug

The spark plug condition is influenced by:

S Incorrect carburetor adjustment.

S An incorrect fuel mixture (too much or in-

correct type of oil).

S A dirty air filter.

These factors cause deposits on the spark

plug electrodes, which may result in operating problems and starting difficulties.

If the machine is low on power, difficult to

start or runs poorly at idle speed: always

check the spark plug first before taking

any further action. If the spark plug is dirty,

clean it and check that the electrode gap is

0.024″ (0.6 mm). The spark plug should be

replaced after about a month in operation or

earlier if necessary.

CAUTION! Always use the recommended

spark plug type! Use of the wrong spark

plug can damage the piston/cylinder.

0.024″ (0.6 mm)

Spark arrestor mesh

WARNING: The inside of the

muffler contain chemicals that may

be carcinogenic. Avoid contact

with these elements in the event of

a damaged muffler.

CAUTION: Mufflers fitted with cata-

lytic converters get very hot during use

and remain so for some time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remember the risk of fire!

WARNING: Engine exhaust

fumes contain carbon monoxide,

which can cause carbon monoxide

poisoning. DO NOT

start or run the

machine indoors, or anywhere that

is poorly ventilated. The exhaust

fumes from the engine are hot and

may contain sparks which can start

a fire. Never start the machine in doors or near combustible material!

Page 17

E n g l i s h --- 1 7

545186855 Rev. 8 5/15/12

MAINTENANCE

Air filter

The air filter must be regularly cleaned to

remove dust and dirt in order to avoid:

S Carburetor malfunctions

S Starting problems

S Loss of engine power

S Unnecessary wear to engine parts

S Excessive fuel consumption

Clean the filter every 25 hours, or more

regularly if conditions are exceptionally

dusty.

Cleaning the air filter

Remove the air filter cover and take out the

filter. Wash it clean in warm, soapy water.

Rinse thoroughly. Ensure that the filter is dry

before refitting it.

An air filter that has been in use for a long

time cannot be cleaned completely. The

filter must therefore be replaced with a new

one at regular intervals. A damaged air

filter must always be replaced.

Maintenance schedule

Below you will find some general maintenance instructions.

Daily maintenance

S Check throttle trigger and throttle trigger

lockout function.

S Check that the stop switch works

correctly.

S Check that there are no fuel leaks from

the engine, tank or fuel lines.

S Check that the cutter does not rotate

when the engine is idling.

S Clean the outside of the machine.

S Check that the harness is not damaged.

S Check that the blade guard is not dam-

aged or cracked.

S Replace the blade guard if it is exposed to

impact or is cracked.

S A non--balanced trimmer head induces

heavy vibrations that may damage the

machine.

S Check that nuts and screws are tight.

S Check that the trimmer head is tight.

Weekly maintenance

S Check the starter and starter cord.

S Clean the carburetor area.

S Clean the outside of the spark plug. Re-

move it and check the electrode gap. Adjust the gap to 0.024″ (0.6 mm), or

replace the spark plug. Use resistor spark

plug Champion RCJ --8Y or equivalent.

S Clean the cooling fins on the cylinder and

check that the air intake near the starter

is not blocked.

S Clean the air filter.

Monthly maintenance

S Clean the fuel tank.

S Clean the outside of the carburetor and

the space around it.

S Clean the fan and the area around it.

S Check fuel lines for cracks or other dam-

age. Change if necessary.

S Change the fuel filter in fuel tank.

S Check the clutch, clutch springs and the

clutch drum for wear. Replace if necessary.

S Check electrical wires and connections.

S Replace the spark plug. Use resistor

spark plug Champion RCJ --8Y or equivalent.

S Change the air filter.

Page 18

E n g l i s h --- 1 8

545186855 Rev. 8 5/15/12

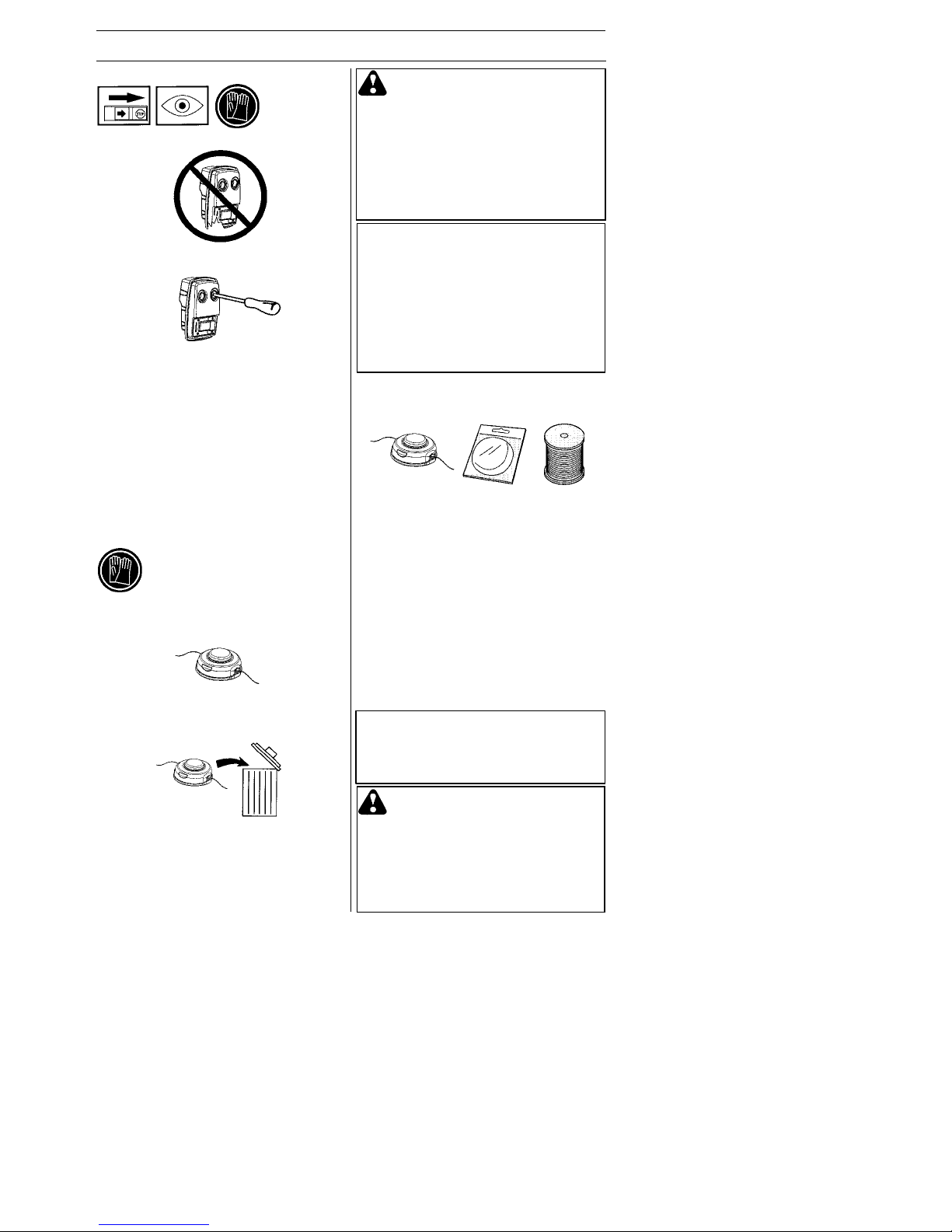

Trimmer Head Line Loading Instructions

20i

10i

3m

6m

1

23

45

6

78

9

Page 19

E n g l i s h --- 1 9

545186855 Rev. 8 5/15/12

TECHNICAL DATA

Technical data

GT 2128

Engine

Cylinder volume, cu.in./cm

3

1.7/28

Cylinder bore, inch/mm 1.4/35

Stroke, inch/mm 1.130/28.7

Idle speed, rpm 2,800--3,200

Recommended max. speed, rpm 10,000

Speed of output shaft, rpm 8,000

Max. engine output, acc. to ISO 8893, hp/kW 1.1/0.8

Catalytic converter muffler Yes

Speed--regulated ignition system Yes

Ignition system

Manufacturer/type of ignition system Walbro/CD

Spark plug Champion RCJ --8Y

Electrode gap, inch/mm 0.024/0.6

Fuel and lubrication system

Manufacturer/type of carburetor Zama

Fuel tank capacity, US pint/liter 0.85/0.4

Weight

Weight without fuel, cutting attachment and guard, lbs/kg 10/4.4

Sound levels

(see note 1)

Equivalent sound pressure level at the user’s ear,

measured according to ANSI B175.3--1997, dB(A),

min/max: 94/97

Vibration levels

Vibration levels at handles, measured according to

ANSIB175.3--1997, m/s

2

At idle, left/right handles: 3/5

At max. speed, left/right handles: 9/8

NOTE! This spark ignition system complies with the Canadian standard ICES- -002.

Note 1: Equivalent noise pressure level is calculated as the time--weighted energy total for

noise pressure levels under various working conditions with the following time distribution:

1/2 idle and 1/2 max. speed.

NOTE! Noise pressure at the user’s ear and vibration on the handles are measured with all

the machine’s approved cutting equipment fitted. The table indicates the highest and lowest

values.

Model GT 2128 (3/8 RH arbor shaft thread)

Approved accessories Type Cutting attachment / guard, part. no.

Trimmer head T25 537 33 83--07 / 545 006 049

Page 20

E n g l i s h --- 2 0

545186855 Rev. 8 5/15/12

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

IMPORTANT: This product is compliant

with U.S. EPA Phase 3 regulations for

exhaust and evaporative emissions. To

ensure EPA Phase 3 compliance, we

recommend using only genuine Jonsered

brand replacement parts. Use of noncompliant replacements parts is a

violation of federal law.

YOUR WARRANTY RIGHTS AND

OBLIGATIONS:

The U.S. Environmental Protection Agency ,

California Air Resources Board, Environment

Canada and Jonsered are pleased to explain

the emissions control system warranty on

your year 2012 and later small off--road engine. In California, all small off--road engines

must be designed, built, and equipped to meet

the State’s stringent anti--smog standards.

Jonsered must warrant the emission control

system on your small off- -road engine for the

periods of time listed below provided there

has been no abuse, neglect, or improper

maintenance of your small off--road engine.

Your emission control system includes parts

such as the carburet or, the ignition system

and the fuel tank. Where a warrantable condition exists, Jonsered will repair your small off-road engine at no cost to you. Expenses

covered under warranty include diagnosis,

parts and labor.

MANUFACTURER’S WARRANTY

COVERAGE:

If any emissions related part on your engine

(as listed under Emissions Control Warranty Parts List) is defective or a defect in the

materials or workmanship of the engine

causes the failure of such an emission related part, the part will be repaired or replaced by Jonsered.

OWNER’S WARRANTY RESPONSIBILITIES:

As the small off--road engine owner, you are

responsible for the performance of the required maintenance listed in your operator’s

manual. Jonsered recommends that you

retain all receipts covering maintenance on

your small off-- road engine, but Jonsered

cannot deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all scheduled maintenance. As

the small off--road engine owner, you should

be aware that Jonsered may deny you warranty coverage if your small off--road engine

or a part of it has failed due to abuse, neglect, improper maintenance, unapproved

modifications, or the use of parts not made

or approved by the original equipment

manufacturer.

WARRANTY COMMENCEMENT

DATE:

The warranty period begins on the date the

small off--road engine is purchased.

LENGTH OF COVERAGE:

This warranty shall be for a period of two

years from the initial date of purchase, or

until the end of the product warranty (whichever is longer).

WHAT IS COVERED: REPAIR OR

REPLACEMENT OF PARTS.

Repair or replacement of any warranted

part will be performed at no charge to the

owner at an approved Jonsered servicing

center. If you have any questions regarding

your warranty rights and responsibilities,

you should contact your nearest authorized

service center, call Jonsered at

1--800-- 487--5951, or visit

www.charlotte.usa.jonsered.com

.

WARRANTY PERIOD:

Any warranted part which is not scheduled

for replacement as required maintenance,

or which is scheduled only for regular inspection to the effect of “repair or replace

as necessary” shall be warranted for 2

years. Any warranted part which is scheduled for replacement as required maintenance shall be warranted for the period of

time up to the first scheduled replacement

point for that part.

DIAGNOSIS:

The owner shall not be charged for diagnostic labor which leads to the determination that a warranted part is defective if the

diagnostic work is performed at an approved Jonsered servicing center.

CONSEQUENTIAL DAMAGES:

Jonsered may be liable for damages to other

engine components caused by the failure of a

warranted part still under warranty.

WHAT IS NOT COVERED:

All failures caused by abuse, neglect, or

improper maintenance are not covered.

Y

ou are responsiblefor presenting your

small off--road engine to a Jonsered authorized repair center as soon as a problem

exists . Warranty repairs should be completed

in a reasonable amount of time, not to exceed

30 days. If you have any questions regarding

your warranty rights and responsibilities,

you should contact your nearest authorized

service center, call Jonsered at

1--800-- 487--5951, or visit

www.charlotte.usa.jonsered.com

.

Page 21

E n g l i s h --- 2 1

545186855 Rev. 8 5/15/12

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

EMISSION CONTROL WARRANTY

PARTS LIST:

Carburetor, Air Filter (covered up to maintenance schedule), Ignition System: Spark

Plug (covered up to maintenance schedule), Ignition Module, Muffler including Catalyst (if equipped), Fuel Tank, Line and Cap.

MAINTENANCE STATEMENT:

The owner is responsible for the performance of all required maintenance as defined in the operator’s manual.

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RELATED PARTS:

Any Jonsered approved replacement part

used in the performance of any warranty

maintenance or repair on emission related

parts will be provided without charge to the

owner if the part is under warranty.

ADD-- ON OR MODIFIED PARTS:

The use of add--on or modified parts can be

grounds for disallowing a warranty claim.

Jonsered is not liable to cover failures of

warranted parts caused by the use of add-on or modified parts.

HOW TO FILE A CLAIM:

If you have any questions regarding your warranty rights and responsibilities, you should

contact your nearest authorized service center, call Jonsered at 1--800-- 487--5951,

or visit www.charlotte.usa.jonsered.com

.

WHERE TO GET WARRANTY SERVICE:

Warranty services or repairs shall be

provided at all Jonsered service centers.

Call 1- -800--487--5951 or visit

www.charlotte.usa.jonsered.com

.

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

Page 22

F r e n c h --- 2 2

545186855 Rev. 8 5/15/12

CONTENU

Contenu

CONTENU

Contenu 22.........................

Contrôler les points suivants avant

la mise en marche 22................

EXPLICATION DES SYMBOLES

Symboles 23........................

INSTRUCTIONS DE SÉCURITÉ

Équipement de protection personnelle 24..

Équipement de sécurité de la machine 24.

Equipement de coupe 25..............

Contrôle, maintenance, et entretien des

équipements de sécurité de la machine 25

Instructions générales de sécurité 27.....

Sécurité du mise en marche 28.........

Sécurité carburant 29.................

Transport et entreposage 29............

Méthodes de travail 29................

Règles élémentaires de sécurité 29......

T echniques de travail de base 30........

QUELS SONT LES COMPOSANTS?

Quels sont les composants? 32.........

MONTAGE

Montage de la poignée en boucle 33....

Montage de la protectuer et de la

tête de coupe 33....................

MANIPULATION DU CARBURANT

Carburant 34........................

Remplissage de carburant 35..........

DÉMARRAGE ET ARRÊT

Contrôles avant la mise en marche 36..

Démarrage et arrêt 36................

ENTRETIEN

Carburateur 37......................

Silencieux 38.......................

Bougie 38..........................

Filtre à air 39........................

Schéma d’entretien 39................

Remplacement du fil dans la tête de

coupe 40...........................

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques techniques 41........

DÉCLARATION DE GARANTIE

DE LUTTE AN MISSIONS 42.........

Contrôler les points suivants

avant la mise en marche:

Jonsered travaille continuellement au développement de ses produits et se réserve

le droit d’en modifier, entre autres, la conception et l’aspect sans préavis. Une exposition prolongée au bruit risque de causer des lésions auditives permanentes.

Toujours utiliser des protecteurs d’oreille

agréés. L’entretien, le remplacement, ou la

réparation des dispositifs d’émission et le

système peuvent être exécutés par n’importe quel distributeur ou individu de réparation de moteur tout--terrain.

Pour la référence, veuillez enregistrer l’information suivante qui sera nécessaire

pour le futur entretien de votre appareil :

Numéro de Modèle :

Numéro de série:

Date d’achat:

Distributeur:

AVERTISSEMENT: Utilisés de

manière négligente ou erronée, les

débroussailleuses et les coupe-herbes peuvent devenir des outils

dangereux pouvant occasionner

des blessures graves, voire mortelles pour l’utilisateur ou d’autres.

Il est très important de lire attentivement et de bien comprendre les

instructions contenues dans ce

mode d’emploi.

AVERTISSEMENT: Ne jamais

modifier sous aucun prétexte la machine sans l’autorisation du fabricant. N’utiliser que des accessoires

et des pièces d’origine. Des modifications non--autorisées et l’emploi

d’accessoires non--homologués

peuvent provoquer des accidents

graves et même mortels, à l’utilisateur ou d’autres personnes. Votre

garantie peut ne pas couvrir des

dommages ou la respons abilité

provoqués par l’utilisation des

accessoires ou des pièces de

rechange non--autorisés.

L

a période de conformité d’émissions énuméré sur l’étiquette de conformité d’émissions indique le nombre de temps d’exploitation l’où le moteur a été montré pour

répondre à des exigences fédérales d’émissions. Catégorie C = 50 heures, B = 125

heures, et A = 300 heures.

Page 23

F r e n c h --- 2 3

545186855 Rev. 8 5/15/12

EXPLICATION DES SYMBOLES

Destiné uniquement à des

équipements de coupe flexibles

et non métalliques, c’est--àdire

les têtes de coupe avec fil.

Destiné uniquement aux têtes

de coupe.

Utilisez de l’essence sans

plomb ou de l’essence avec

plomb de haute qualité et un

huile deux temps mélangée

dans un rapport de 2,5% (1:50).

Les autres symboles/autocollants présents sur la machine concernent des

exigences de certification spécifiques à

certains marchés.

Arrêt le moteur avant tout contrôle

ou réparation en poussant le

bouton d’arrêt et maintenez-- le

dans la position «STOP» jusqu’à

ce que le moteur soit completement

arrêté.

Un nettoyage régulier est

indispensable.

Examen visuel.

Le port de protège--yeux

homologués est obligatoire.

Symboles

AVERTISSEMENT: Les débrous-

sailleuses et les coupe- -herbes

peuvent être dangereux! Une utilisation erronée ou négligente peut

occasionner des blessures graves,

voire mortelles pour l’utilisateur ou

d’autres personnes.

AVERTISSEMENT: Lisez le manuel

d’instructions complètement avant

d’utiliser l’appareil. T out défaut

de respecter tous les instructions

peut entraîner des blessures graves

aux utilisateur et/ou spectateurs.

Conservez ces instructions.

Toujours utiliser:

S Protecteur d’oreilles

S Des protège--yeux homologués

Régime maxi. recommandé de

l’axe sortant, tr/min

Attention: projections et ricochets.

L’utilisateur de la machine doit

s’assurer qu’aucune personne

ou animal ne s’approche à moins

de 15 mètres (50 pieds)

pendant le travail.

Flèches indiquant les limites quant

à l’emplacement de la fixation de

la poignée.

Toujours porter des gants de

protection homologués.

Utiliser des bottes antidérapantes

et stables.

ADVERTENCIA

Los gases de escape del motor de este producto

contienen sustancias químicas conocidas en el

Estado de California como causantes d e cáncer,

defectos congénitos y otros daños reproductivos.

Page 24

F r e n c h --- 2 4

545186855 Rev. 8 5/15/12

INSTRUCTIONS DE SÉCURITÉ

GANTS

Au besoin, utiliser des gants, notamment lors

du montage de l’équipement de coupe.

PROTÈGE--OREILLES

Porter des protège--oreilles ayant un effet

atténuateur suffisant.

PROTÈGE--YEUX

T oujours porter des protège- -yeux homologués. L’usage d’une visière doit toujours

s’accompagner du port de lunettes de

protection homologuées. Par lunettes de

protection homologuées, on entend celles

qui sont en conformité avec les normes

ANSI Z87.1.

BOTTES

Utiliser des bottes antidéparapantes et

stables.

HABITS

Porter des vêtements fabriqués dans un matériau résistant à la déchirure, éviter les vêtements excessivement amples qui risqueraient de se

p

rendre dans les broussailles et

É

quipement de protection

personnelle

les branches. Toujours utiliser des pantalons

longs et robustes. Ne pas porter de bijoux,

de shorts ou de sandales, et ne pas marcher pieds--nus. Veiller à ce que les cheveux

ne tombent pas sur les épaules.

PREMIERS SECOURS

Une trousse de premiers secours doit toujours être disponible.

A VERTISSEMENT: Ne jamais

utiliser une machine dont les équipements de sécurité sont défectueux.

Suivre les directives de maintenance,

d’entretien et les instructions de réparation indiquées dans ce section.

Équipement de sécurité de la

machine

Ce section présente les équipements de

sécurité de la machine, leur fonction, comment les utiliser et les maintenir en bon

état. Voir la section ”Familiarisez--vous

avec votre appareil” sont les composants

pour trouver leur emplacement sur la machine.

La durée de vie de la machine risque d’être

écourtée et le risque d’accidents accru si la

maintenance de la machine n’est pas effectuée correctement et si les mesures d’entretien et/ou de réparation ne sont pas effectuées de manière professionnelle. Pour

obtenir de plus amples informations, contacter votre distributeur autorisé de service

le plus proche.

Bouton d’arrêt

Mettre le moteur en marche et s’assurer

qu’il s’arrête lorsque le boiuton d’arrêt est

amené den position d’arrêt.

Protecteur pour l’équipement de

coupe

Cette protecteur a pour but d’empêcher que

des objets ne soient projetés en direction

de l’utilisateur. La protecteur prévient aussi

le contact entre l’utilisateur et l’équipement

de coupe.

AVERTISSEMENT: Un équipe-

ment de protection personnelle

homologué doit impérativement être

utilisé lors de tout travail avec la machine. L’équipement de protection

personnelle n’élimine pas les risques

mais réduit la gravité des blessures

en cas d’accident. Demander conseil

au concessionnaire afin de choisir un

équipement adéquat.

IMPORTANT! .Soyez toujours attentifs

aux signaux d’alerte ou aux appels en

portant des protège--oreilles. Enlevez--les

sitôt le moteur arrêté.

Page 25

F r e n c h --- 2 5

545186855 Rev. 8 5/15/12

INSTRUCTIONS DE SÉCURITÉ

Silencieux

Le silencieux est conçu pour réduire au

maximum le niveau sonore et détourner

les gaz d’echappement loin de l’utilisateur.

ATTENTION! Votre silencieux est équipé

d’un pot catalytique conçu pour réduire la

teneur des gaz d’échappement.

En ce qui concerne le silencieux, il importe

de bien suivre les instructions de contrôle,

de maintenance et d’entretien. Voir les instructions au section Contrôle, maintenance et entretien des équipements de sécurité de la machine.

A V ER TISSEMEN T: Une ex-

position excessive aux vibrations

peut entraîner des troubles circulatoires ou nerveux chez les personnes sujettes à des troubles cardio--vasculaires. Consulter un médecin en cas de symptômes liés à une

exposition excessive aux vibrations.

De tels symptômes peuvent être:

engourdissement, perte de sensibilité, chatouillements, picotements,

douleur, faiblesse musculaire, décolorationoumodificationépidermique.

Ces symptômes affectent généralement les doigts, les mains ou les

poignets. Les risques peuvent

augmenter à basses températures.

A VERTISSEMENT: Un équipe-

ment de coupe ne peut en aucun

cas être utilisé si une protection

homologuée n’a pas été préalablement montée. Voir la section “Caractéristiques techniques”. La mise en

place d’une protection erronée ou

défectueuse peut provoquer des

blessures graves.

L’utilisation d’un fil mal enroulé ou d’un

équipement de coupe inadéquat augmente

le niveau de vibration.

Équipement de coupe

La tête de coupe est destinée au désherbage.

Contrôle, maintenance, et entretien des équipements de

sécurité de la machine

IMPORTANT!

L’entretien et la réparation de la machine

exigent une formation spéciale. Ceci concerne particulièrement l’équipement de sécurité de la machine. Si les contrôles suivants

ne donnent pas un résultat positif, s’adresser

à un distributeur autorisé. L’achat de l’un de

nos produits offre à l’acheteur la garantie

d’un service et de réparations qualifiés. Si le

point de vente n’assure pas ce service,

s’adresser un distributeur autorisé le plus

proche.

A VERTISSEMENT: L’intérieur

du silencieux contient des produits

chimiques pouvant être cancérigènes.

Eviter tout contact avec ces éléments

si le silencieux est endommagé.

A TTENTION: Un silencieux muni d’un

pot catalytique est très chaud aussi bien à

l’utilisation qu’après arrêt. Ceci est également vrai pour le régime au ralenti. Tout

contact peut causer des brûlures à la

peau. Attention au risque d’incendie!

A VERTISSEMENT: Les gaz

d’échappement du moteur

contiennent du monoxyde de

carbone, qui peut provoquer une

intoxication. Ne démarrez ou n’utilisez JAMAIS

l’appareil dans

un local fermé ou un lieu mal aéré.

Les gaz d’échappement du moteur

sont très chauds et peuvent

contenir des étincelles pouvant

provoquer un incendie. Ne jamais

démarrer l’appareil dans un local

ferméouàproximitédematériaux

inflammables !

Page 26

F r e n c h --- 2 6

545186855 Rev. 8 5/15/12

INSTRUCTIONS DE SÉCURITÉ

Bouton d’arrêt

S Mettre le moteur en marche et s’assurer

qu’il s’arrête lorsque le boiuton d’arrêt est

amené den position d’arrêt.

Protecteur pour l’équipement de

coupe

S S’assurer que la protecteur est intacte et

qu’elle ne présente pas de fissures.

S Remplacer la protecteur si elle a subi des

impacts ou si elle présente des fissures.

S Toujours utiliser la protecteur recomman-

dée prévue pour l’équipement de coupe

en question. Voir “Caractéristiques

techniques”.

Silencieux

S Ne jamais utiliser une machine dont le silen-

cieux est défectueux.

S Vérifier régulièrement la fixation du silen-

cieux dans la machine.

S

L

e silencieux de la machine est muni d’une

grille antiflamme, il faut le nettoyer régulièrement. Une grille antiflamme bouchéeentraîne

une surchauffe du moteur pouvant provoquer

des dommages graves. Ne jamais utiliser un

silencieux avec une grille antiflamme défectueuse. Voir la section Entretien.

Équipement de coupe

Cette section explique comment, grâce à

l’utilisation du bon équipement de coupe et

grâce à un entretien correct:

S Obtenir la meilleure coupe possible.

S Augmenter la durée de vie de l’équipement

de coupe.

Règles élémentaires

:

1. N’utiliser l’équipement de coupe qu’avec

la protecteur recommandée! Voir la section “Caractéristiques techniques”.

2. Inspecter l’équipement de coupe afin de

détecter d’éventuels dommages ou fissures. Toujours remplacer un équipement

de coupe endommagé.

A VERTISSEMENT: Ne jamais

utiliser une machine dont les

équipements de sécurité sont défectueux. Contrôler et entretenir

les équipements de sécurité de la

machine conformément aux instructions données dans ce chapitre. Si les contrôles ne donnent

pas de résultat positif, confier la

machine à un distributeur autorisé.

L’utilisa tion d’une machine dont les

équipements de sécurité sont défectueuxaugmentelerisquede

blessures graves pour l’opérateur

ou d’autres personnes.

IMPORTANT!

Cette section explique comment, grâce à

l’utilisation du bon équipement de coupe et

grâce à un entretien correct:

Réduire le risque de rebond de la machine.

Obtenir la meilleure coupe possible.

Augmenter la durée de vie de l’équipement

de coupe.

N’utiliser l’équipement de coupe qu’avec le

protecteur recommandée! Voir la section

“Caractéristiques techniques”.

Voir les instructions relatives à l’équipement

de coupe pour poser correctement le fil et

choisir le diamètre de fil approprié.

Page 27

F r e n c h --- 2 7

545186855 Rev. 8 5/15/12

INSTRUCTIONS DE SÉCURITÉ

Tête de coupe

S N’utiliser l’équipement de coupe qu’avec la

protecteur recommandée! Voir la section

“Caractéristiques techniques”.

S En général, les petites machines de-

mandent des petites têtes de désherbage, et vice versa. Cela vient du fait que

lors du désherbage au moyen de fils, le

moteur doit éjecter le fil radialement depuis la tête de désherbage tout en affrontant la résistance de l’herbe à couper.

S La longueur du fil est également impor-

tante. Un fil long demande un moteur

plus puissant qu’un fil court, même

en cas de diamètre égal de fil.

S S’assurer que le couteau monté sur le

carter de protection est intact. Il sert à

découper le fil à la bonne longueur.

S Pour améliorer la durée de vie du fil,

laisser le fil tremper dans de l’eau pendant quelques nuits. Le fil devient alors

plus résistant et dure plus longtemps.

IMPORTANT!

Veiller à ce que le fil du coupe--herbe soit

toujours enroulé de manière serrée et régulière autour du tambour, autrement la machine produit des vibrations dangereuses

pour la santé.

A V ER TISSEMEN T: Toujours

arrêter le moteur avant d’entamer

des travaux sur l’équipement de

coupe. Celui--ci continue de tourner

après qu’on a relâché l’accélérateur.

S’assurer que l’équipement de

coupe est complètement immobilisé

et débrancher le câble de la bougie

d’allumage avant de commencer

l’intervention sur l’équipement

de coupe.

Instructions générales de

sécurité

IMPORTANT!

S La machine est conçue uniquement pour

le désherbage.

S Les seuls accessoires pouvant utiliser le

moteurcommesourcemotricesontles

équipements de coupe que nous recommandons dans la section “Caractéristiques

techniques”.

S Ne utilisez pas jamais de broche, de

corde, de ficelle, etc.

S Éviter d’utiliser la machine en cas de fa-

tigue, d’absorption d’alcool ou de prise de

médicaments susceptib les d’affecter l’acuité visuelle, le jugement ou la maîtrise du

corps .

S Ne jamais utiliser la machine dans des

conditions climatiques extrêmes telles que

la froid intense ou climat très chaud et/ou

humide.

S Ne jamais utiliser une machine qui a été

modifiée au point de ne plus être conforme

au modèle original.

S Utiliser les équipements de protection per-

sonnelle. Voir la section “Équipement de

protection personnelle”.

S Ne jamais utiliser une machine qui n’est

pas en parfait état de marche. Suivre dans

ce manuel d’utilisation les instructions de

maintenance, de contrôle et d’entretien.

Certaines mesures de maintenance et

d’entretien doivent être confiées à un spécialiste dûment formé et qualifié. Voir la

section “Entretien”.

S Tous les carters et toutes les protections

doivent être montés avant le démarrage.

Vérifier que le chapeau de bougie et le

câble d’allumage ne sont pas endommagés. Risque de chocs électriques.

S L’utilisateur de la machine doit s’assurer

qu’aucune personne ou animal ne s’approche à moins de 15 mètres (50 pieds)

pendant le travail.

S Tenez--vous à l’écart du fil tournante.

S Attachez ou enlevez tous les vêtements

amples et les bijoux ou les vêtements qui

ont des attaches, des bretelles, des pompons, etc. qui pendent. Ils peuvent se

prendre dans les pieces mobiles.

S Si vous êtes bien couvert(e), cela vous

aidera à vous protéger contre les débris

et brins de plantes toxiques qui sont projetés par le fil qui tourne.

S Conservez les poignée libres d’huile et

de carburant.

S Maintenez le moteur toujours à votre

droite.

S Maintenez l’appareil fermement avec vos

deux mains.

S Maintenez la tête de coupe sous le niveau

de la ceinture. Ne soulevez pas lemoteur

au dessus de votre taille.

Page 28

F r e n c h --- 2 8

545186855 Rev. 8 5/15/12

INSTRUCTIONS DE SÉCURITÉ

Protection personnelle

S Toujours porter des bottes

ainsi que l’équipement de

protection indiqué au section

“Equipement de protection

personnelle”.

S Toujours porter des vêtements

de travail et des pantalons

longs résistants.

S Ne jamais porter des vêtements

amples ou des bijoux.

S La longueur des cheveux ne

doit pas dépasser les épaules.

Consignes de sécurité pour

l’entourage

S Ne jamais laisser un enfant utiliser la ma-

chine.

S S’assurer qu’aucune personne ne

s’approche à moins de 15 mètres (50

pieds) pendant le travail.

S Ne jamais laisser d’autres personnes

utiliser la machine avant d’avoir vérifié

que le contenu du manuel d’utilisation a

été assimilé par ces personnes.

S Eloignez toutes les parties de votre corps

de la tête de coupe et du silencieux lorsque le moteur est allumé.

S Tener les pieds toujours sur une surface

stable et maintenez l’équilibre. Ne vous

penchez pas excessivement.

S N’utilisez l’appareil que le jour ou sous

une bonne lumière artificielle.

S N’utilisez l’appareil que pour les travaux

indiqués dans ce manuel.

AVERTISSEMENT: Un équipe-

ment de coupe inadéquat peut augmenter les risques d’accidents.

Consignes de sécurité avant la mise

en ser vice

S Inspecter la zone de travail. Enlever tout

objet traînant par terre, tels que cailloux,

débris de verre, clous, fil de fer, ficelle

etc., pouvant être projetés ou s’enrouler

autour de la lame ou dans le protecteur.

S Maintenir les enfants, animaux, specta-

teurs et aides à 15 mètres (50 pieds) de

la zone de travail. Encouragez--les à

por ter des prot ection des yeux. Stopper la

machine immédiatement si quelqu’un

s’approche.

S Contrôler toute la machine avant de la

mettre en service. Remplacer les pièces

endommagées. S’assurer que le carburant ne fuit pas et que toutes les protections et carters ne sont pas endommagés et correctement fixés. Vérifier toutes

les vis et écrous.

S S’assurer que la tête

de coupe n’est pas

endommagée

ou fissurée.

S S’assurer que le

protecteur est monté

et en bon état.

S S’assurer que la tête de coupe et le pro-

tecteur sont correctement fixés.

S Pendant le réglage du carburateur, s’as-

surer que le bout inférieur supporté et

que personne ne se trouve à proximité.

S S’assurer que la tête de coupe s’arrête

toujours au ralenti.

S S’assurer que la poignée et le dispositif

de sécurité sont en bon état. Ne jamais

utiliser la machine avec une pièce manquante ou ayant été modifiée.

S Utiliser la machine uniquement pour les

travaux auxquels elle est destinée.

Sécurit é du mise en marche

S Un couvercle d’embrayage et boîtiers

complet doit être monté avant de démarrer

la machine.

S Ne démarrer jamais ou essayez pour

marcher l’appareil avec l’embrayage, le

tambour d’embrayage, la couvercle d’embrayage, ou l’axe étant enlevé.

S Ne jamais mettre la machine en marche à

l’intérieur. Les gaz d’échappement du moteur sont nocifs.

AVERTISSEMENT: Lorsque le

moteur est démarré avec la commande de starter en position starter/accélérateur, l’équipement

de coupe commence à tourner

immédiatement.

S S’assurer que la zone de travail est bien

dégagée et qu’aucune personne et aucun

animal ne risquent d’entrer en contact

avec l’équipement de coupe.

S Voir la section “Démarrage et arrêt” pour

des instructions complètes.

Page 29

F r e n c h --- 2 9

545186855 Rev. 8 5/15/12

INSTRUCTIONS DE SÉCURITÉ

Sécurité carburant

S Utiliser un bidon d’essence comportant un

dispositif d’arrêt de remplissage automatique.

S Ne jamais effectuer le remplissage de la

machine lorsque le moteur tourne.

S Arrêter le moteur et le laisser refroidir pen-

dant quelques minutes avant de faire le

plein.

S Veiller à une bonne aération lors du rem-

plissage et du mélange de carburant (essence et huile 2 temps).

S Avant de mettre la machine en marche, la

déplacer à au moins 3 mètres (10 pieds)

de l’endroit où a été fait le plein.

S Ne jamais démarrer la machine:

S Si du carburant a été renversé soig-

neusement. Essuyer toute trace et laisser les restes d’essence s’évaporer.

S Si vous avez renversé du carburant sur

vous ou sur vos vêtements, changez de

vêtements. Lavez les parties du corps

qui ont été en contact avec le carburant.

Utilisez de l’eau et du savon.

Min. 3 m

(10 ft.)

S S’il y a fuite de carburant. Vérifier ré-

gulièrement que le bouchon du réservoir et la conduite de carburant ne

fuient pas.

S Éviter tout contact de la peau avec du