Page 1

AT-3306-J STRAIGHT

LINE SINGLE

PISTON SANDER

CAUTION

RISK OF INJURY!

THIS MANUAL IS AN IMPORTANT PART OF THE SANDER

AND SHOULD REMAIN WITH THIS UNIT WHEN YOU SELL OR RENT IT.

Straight Line Single Piston Sander Operator's Manual 1

READ MANUAL BEFORE OPERATING!

Page 2

Introduction

Congratulations on the purchase of your new John Deere Straight Line Single Piston

Sander! You can be assured your straight line single piston sander was constructed and

designed with quality and performance in mind. Each component has been rigorously

tested to ensure the highest level of acceptance.

John Deere Straight Line Single Piston Sander is designed for various applications

requiring a more compact tool. Used for sanding, polishing, and finishing on a variety of

surfaces including woods, metals and fiberglass. This tool features a powerful piston drive

motor driving a sanding pad with over 29 square inches of surface. The 211/16 X11" sanding

pad accepts standard pressure sensitive adhesive (PSA) paper.

This operator's manual was compiled for your benefit. By reading and following the simple

safety, installation, operation, maintenance and troubleshooting steps described in this

manual, you will receive years of trouble-free operation from your new straight line single

piston sander. The contents of this manual are based on the latest product information

available at the time of publication. The manufacturer reserves the right to make changes

in price, color, materials, equipment, specifications or models at any time without notice.

Once the unit has been removed from the box, immediately write in the serial number of your

unit in the space provided below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim

with the transportation company immediately. Be sure that all damaged parts are replaced and

that the mechanical problems are corrected prior to operation of the unit. If you require service,

contact your Customer Service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Please have the following information available for all service calls:

2 Straight Line Single Piston Sander Operator's Manual

1. Model Number

2. Serial Number

3. Date and Place of Purchase

Page 3

Table of Content

INTRODUCTION .................................................................................................... 2

TABLE OF CONTENTS ......................................................................................... 3

SAFETY .................................................................................................................. 4-6

RECOGNIZE SAFETY INFORMATION ................................................ 4

UNDERSTAND SIGNAL WORDS......................................................... 4

READ OPERATING INSTRUCTIONS................................................... 4

ALWAYS WEAR APPROVED EYE PROTECTION ............................. 5

HEARING PROTECTION IS RECOMMENDED ................................... 5

WEAR RESPIRATORY PROTECTION ................................................ 5

AVOID PROLONGED EXPOSURE TO VIBRATION............................ 6

90 PSIG MAXIMUM ............................................................................... 6

INSTALLATION...................................................................................................... 7

RECOMMENDED AIR LINE SET-UP.................................................... 7

OPERATION........................................................................................................... 8

MAINTENANCE ..................................................................................................... 8

TROUBLESHOOTING ........................................................................................... 9

SPECIFICATIONS.................................................................................................. 9

STATEMENT OF WARRANTY .............................................................................. 10-11

FRENCH ................................................................................................................. 12-21

SPANISH ................................................................................................................ 22-31

Straight Line Single Piston Sander Operator's Manual 3

Page 4

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on

your pneumatic tool or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A "DANGER, WARNING or CAUTION" safety warning will be

surrounded by a "SAFETY ALERT BOX." This box is used to

designate and emphasize Safety Warnings that must be

followed when operating this tool.

Accompanying the Safety Warnings are "signal words" which

designate the degree or level of hazard seriousness. The

"signal words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided MAY result in minor or

moderate injury.

READ OPERATING INSTRUCTIONS

Always become familiar with all the instructions and

warnings before operating any pneumatic tool.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO

ANYONE USING THIS EQUIPMENT. READ ALL

INSTRUCTIONS BEFORE OPERATING THIS TOOL

AND ESPECIALLY POINT OUT THE "SAFETY

WARNINGS" TO PREVENT THE POSSIBILITY OF

PERSONAL INJURY TO THE OPERATOR.

4 Straight Line Single Piston Sander Operator's Manual

Page 5

WARNING

ALWAYS WEAR APPROVED EYE PROTECTION

Impact resistant eye protection should meet or

exceed the standards as set forth in the United

States ANSI Z87.1, Occupational and Educational

Eye and Face Protection. Look for the marking

Z87.1 on your eye protection to insure that it is an

approved style. For further information, ANSI Z87.1,

Occupational and Educational Eye and Face

Protection, is available from the American National

Standards Institute, Inc., 11 West 42nd Street, New

York, NY 10036.

HEARING PROTECTION IS RECOMMENDED

Hearing protection should be used when the noise

level exposure equals or exceeds an 8 hour timeweighted average sound level of 85 dBA. Process

noise, reflective surfaces, other tools being operated

nearby, all add to the noise level present in your

work area. If you are unable to determine your noise

level exposure, we recommend the use of hearing

protection.

WEAR RESPIRAT ORY PROTECTION

It is advisable, when using this tool for extended

periods of time, to wear a protective mask. This will

help prevent the inhalation of the fine dust produced

while using this tool. Prolonged breathing of dust

particles may lead to future respiratory problems.

Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth

defects or reproductive harm. Some examples of

these chemicals are:

• Lead from lead-base paints

• Crystalline Silica from bricks, cement and other

masonry products.

• Arsenic and Chromium from chemically treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well

ventilated area and work with approved safety

equipment such as those dust masks that are

specially designed to filter out microscopic particles.

Straight Line Single Piston Sander Operator's Manual 5

Page 6

WARNING

AVOID PROLONGED EXPOSURE TO VIBRATION

Pneumatic tools can vibrate during use. Prolonged exposure

to vibration or very repetitive hand and arm movements, can

cause injury. Stop using any tool if discomfort, tingling feeling

or pain occurs. You should consult your physician before

resuming use of the tool.

CAUTION

90 PSIG MAXIMUM

Designed to operate at an air pressure of 90 pounds per square

inch gauge pressure (90 PSIG) maximum, at the tool. Use of

higher air pressure can, and may cause injury. Also use of

higher air pressure places the internal components under loads

and stresses they were not designed for, causing premature

tool failure.

NOTE: The air supply should be clean and dry, preferably

lubricated. For best results drain the moisture from your

compressor daily.

6 Straight Line Single Piston Sander Operator's Manual

Page 7

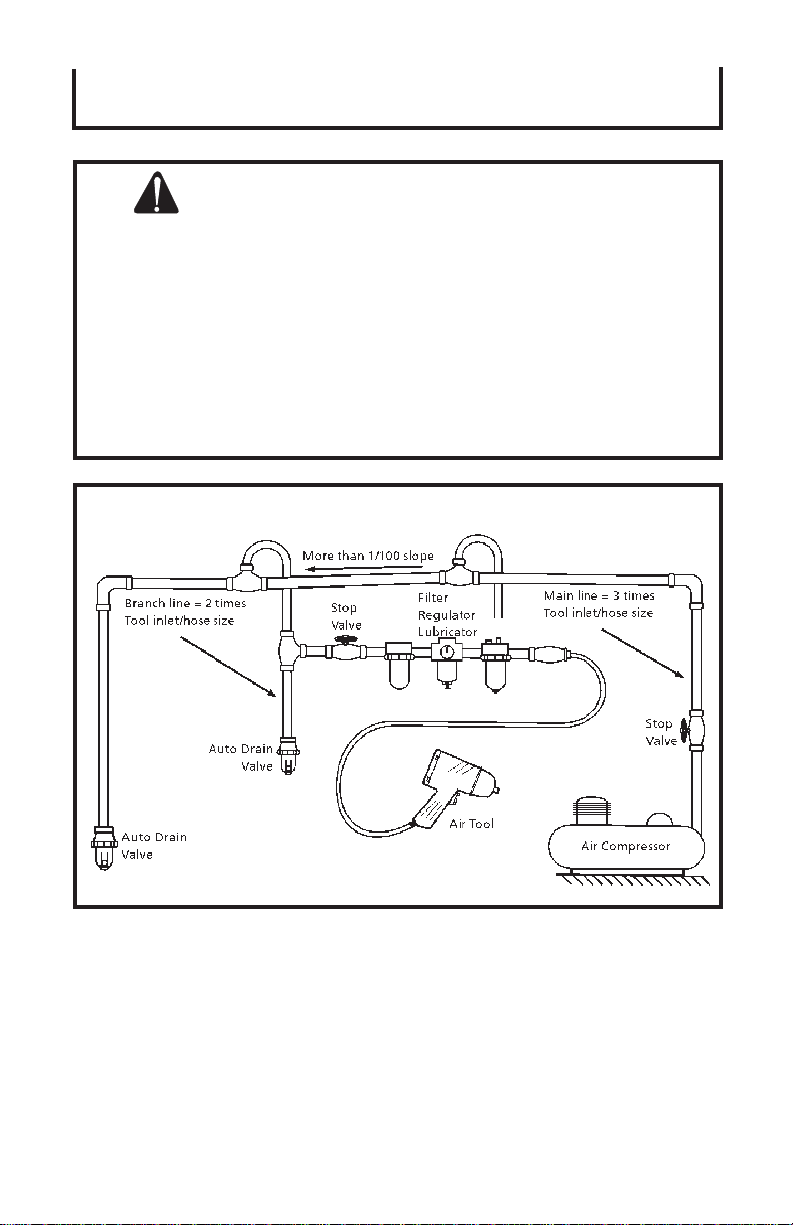

Installation

Designed to operate on 90 PSIG, lower pressure (below

90 PSIG) will reduce performance of the tool while higher air

pressure (over 90 PSIG) raises the performance of the tool

beyond its rated capacity and could cause serious damage to

tool and user.

Always use clean dry air. Excessive moisture and dirt will greatly reduce the life of any

air motor. We recommend the installation of an in-line filter-regulator-lubricator as

close to the tool as possible.

A 3/8" air hose is required up to a length of 8 ft. If more length is required a 1/2" air

hose should be connected to the 3/8" hose to ensure the tool has the necessary air

supply. Be sure all hoses and fittings are the correct size and tightly secured.

RECOMMENDED AIR LINE SET-UP

Straight Line Single Piston Sander Operator's Manual 7

Page 8

Operation

PRE-OPERATION:

Before the tool is connected to the air supply, clear the air hose of accumulated dust

and moisture. Before removing a tool for service or changing accessories, make sure

the air line is shut-off and drained of air. This will prevent the tool from operating if the

throttle is accidentally engaged.

OPERATION:

This tool is designed to use pressure sensitive adhesive (PSA) sanding paper. Trim

sanding paper to match size of pad assembly and apply to pad per manufacturers

instructions.

Let the sander do the work. Do not put excessive pressure on the tool. This will only

slow down the speed of the pad, reduce sanding efficiency and put an additional

burden on the motor. Start the sander off the work, set it down on the work evenly and

move it back and forth in wide, overlapping areas. When finished sanding, lift the

sander off the work before stopping motor.

Start the work with an abrasive grit just coarse enough to remove high spots and

roughness. Follow by using finer grits until the desired finish is obtained. Never go

from a coarse grit to a fine grit in one step. It may be difficult to remove swirl marks.

Use the finest grits practical for roughing operations and finish by using progressively

finer grits.

Maintenance

LUBRICATION:

An automatic in-line filter-regulator-lubricator is recommended as it increases tool life

and keeps the tool in sustained operation. The in-line lubricator should be regularly

checked and filled with air tool oil. Proper adjustment of the in-line lubricator is

performed by placing a sheet of paper next to the exhaust ports and holding the throttle

open approximately 30 seconds. The lubricator is properly set when a light stain of oil

collects on the paper. Excessive amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for an extended period of time

(overnight, weekend, etc.), it should receive a generous amount of lubrication at that

time. The tool should be run for approximately 30 seconds to ensure oil has been

evenly distributed throughout the tool. The tool should be stored in a clean and dry

environment.

Recommended lubricants: Use John Deere AT-4003 air tool oil or any other high

grade turbine oil containing moisture absorbent, rust inhibitors, metal wetting agents

and an EP (extreme pressure) additive.

8 Straight Line Single Piston Sander Operator's Manual

Page 9

Troubleshooting

Symptom

Loss of Power

Problem Solution

1. Low air pressure

2. Improper lubrication or

dirt build up

3. Worn motor parts, or

other problems

Specifications

Pad size ----------------------------------------211/16"X11"

Strokes per minute --------------------------2,600

Stroke length ----------------------------------1"

Weight------------------------------------------- 5¼ lbs.

Length -------------------------------------------12"

Average air consumption ------------------5 CFM

Recommended hose size------------------ 3/8" I.D.

Air inlet size------------------------------------ 1/4" NPT

Maximum operating pressure -------------90 PSI

1. Check air supply. For

rated performance, 90

PSI air pressure is

required at the tool, with

tool operating.

2. Check for wet or dirty

air. Wet air tends to

wash lubricant away.

Dirt or foreign matter will

impede the action of the

motor. If dirt or water

has entered the tool,

flush with John Deere

AT-4003.

3. Contact your customer

service.

Straight Line Single Piston Sander Operator's Manual 9

Page 10

Limited Warranty

John Deere Two-Year Limited Warranty. John Deere Straight

Line Single Piston Sander, Models covered in this manual, are

warranted by John Deere to the original user against defects in

workmanship or materials under normal use for two years after date

of purchase. Any part which is determined to be defective in

material or workmanship and returned to an authorized service

location, as John Deere designates, shipping costs prepaid, will be,

as the exclusive remedy, repaired or replaced at John Deere’s

option. For limited warranty claim procedures, see PROMPT

DISPOSITION below. This limited warranty gives purchasers

specific legal rights which may vary from jurisdiction to jurisdiction.

Limitation of Liability. To the extent allowable under applicable

law, John Deere’s liability for consequential and incidental damages

is expressly disclaimed. John Deere’s liability in all events is limited

to and shall not exceed the purchase price paid.

Warranty Disclaimer. John Deere has made a diligent effort to

provide product information and illustrate the products in this

literature accurately; however, such information and illustrations are

for the sole purpose of identification, and do not express or imply a

warranty that the products are merchantable, or fit for a particular

purpose, or that the products will necessarily conform to the

illustrations or descriptions.

Except as provided below, no warranty or affirmation of fact,

expressed or implied, other than as stated in the “LIMITED

WARRANTY” above is made or authorized by John Deere.

10 Straight Line Single Piston Sander Operator's Manual

Page 11

Product Suitability. Many jurisdictions have codes and regulations

governing sales, construction, installation, and/or use of products for

certain purposes, which may vary from those in neighboring areas.

While John Deere attempts to assure that its products comply with

such codes, it cannot guarantee compliance, and cannot be

responsible for how the product is installed or used. Before

purchase and use of a product, review the product applications,

and all applicable national and local codes and regulations, and be

sure that the product, installation, and use will comply with them.

Certain aspects of disclaimers are not applicable to consumer

products: e.g., (a) some jurisdictions do not allow the exclusion or

limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you; (b) also, some

jurisdictions do not allow a limitation on how long an implied

warranty lasts, consequentially the above limitation may not apply to

you; and (c) by law, during the period of this limited warranty, any

implied warranties of implied merchantability or fitness for a

particular purpose applicable to consumer products purchased by

consumers, may not be excluded or otherwise disclaimed.

Prompt Disposition. John Deere will make a good faith effort for

prompt correction or other adjustment with respect to any product

which proves to be defective within limited warranty. For any

product believed to be defective within limited warranty, first write or

call dealer from whom the product was purchased. Dealer will give

additional directions. If unable to resolve satisfactorily, write to the

Mi-T-M® Corporation at address below, giving dealer’s name,

address, date, and number of dealer’s invoice, and describing the

nature of the defect. Title and risk of loss pass to buyer on delivery

to common carrier. If product was damaged in transit to you, file

claim with carrier.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Straight Line Single Piston Sander Operator's Manual 11

Page 12

Introduction

Félicitations de l'achat de votre nouveau la ponceuse en ligne droite à seule piston! Vous

pouvez être assuré que votre nouveau la ponceuse à seule effet a été construit avec le

plus haut niveau la ponceuse en ligne droite à double piston. Chaque composant a été

rigoureusement testé par des techniciens pour assurer la qualité, la durabilité et la

performance de ce outil pneumatique.

La ponceuse en ligne droite à seule piston de John Deere est conçue pour des applications diverses demandant un outil plus petit. Cet outil est utilisé pour poncer, polir et finir

une variété de surfaces incluant le bois, le métal et la fibre de verre. Il est équipé d’un

puissant moteur d’entraînement à piston qui actionne un tampon de ponçage d’une

surface de plus de 29 po. carrés (187 cm²). Le tampon de ponçage de 6,8 x 27,9 cm (2 11/

16 x 11") accepte le papier adhésif sensible à la pression (ASP) standard.

Ce manuel opérateur a été dressé pour que vous en retiriez le meilleur parti. Par la lecture

et l'application des mesures simples de sécurité, d'installation et d'opération, d'entretien et

de dépannage décrites dans ce manuel, votre nouveau la ponceuse en ligne droite à seule

piston. Fonctionnera sans faille pendant de nombreuses années. Le contenu de ce

manuel est basé sur la dernière information disponible du produit au moment de la

publication. Félicitations se réserve le droit d'effectuer des changements de prix, de

couleur, de matériaux, d'équipement, de caractéristiques ou de modèles à tout moment

sans communication préalable.

Une fois l'appareil déballé, écrivez immédiatement le numéro de série de votre appareil dans

l'espace çi-dessous.

NUMERO DE SERIE_________________________________

Assurez-vous qu'il n'y a pas de signes de dommages évidents ou cachés suite au transport.

En cas de dommage, remplissez immédiatement une réclamation avec la compagnie de

transport. Assurezvous que toutes les pièces endommagées sont remplacees et les

problémes mécaniques et électriques corrigés avant l'utilisation de l'appareil. Si vous avez

besoin d'assistance, entrez en contact avec votre service clientèle.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068-0050

Tél.: JD-KLEEN (1-877-535-5336) Fax 563-556-1235

du lundi au vendredi de 8h00 à 17h, CST (heure centrale)

Veuillez avoir les informations suivantes disponibles pour toute intervention:

1. Numéro de modèle

12 Straight Line Single Piston Sander Operator's Manual

2. Numéro de série

3. Date et lieu d'achat

Page 13

Table Des Matieres

INTRODUCTION .................................................................................................... 12

TABLE DES MATIERESRE................................................................................... 13

SÉCURITÉ.............................................................................................................. 14-16

RECONNAÎTRE LES SYMBOLES DE MISE EN GARDE.................... 14

COMPRENDRE LES TERMES DE MISE EN GARDE ......................... 14

LISEZ LES INSTRUCTIONS D’UTILISATION ...................................... 14

PORTEZ TOUJOURS DES LUNETTES DE PROTECTION

HOMOLOGUÉES................................................................................... 15

LE PORT D’UN CASQUE EST RECOMMANDÉ .................................. 15

LE PORT D’UNE PROTECTION RESPIRATOIRE EST

RECOMMANDÉ ..................................................................................... 15

ÉVITEZ UNE EXPOSITION PROLONGÉE AUX VIBRATIONS ........... 16

PRESSION MAXIMUM DE 620 KPA..................................................... 16

INSTALLATION...................................................................................................... 17

CONFIGURATION RECOMMANDÉE DE LA CONDUITE

D’ALIMENTATION EN AIR .................................................................... 17

FONCTIONNEMENT.............................................................................................. 18

ENTRETIEN ........................................................................................................... 18

DÉPANNAGE ......................................................................................................... 19

SPÉCIFICATIONS.................................................................................................. 19

CONDITIONS DE LA GARANTIE.......................................................................... 20-21

Straight Line Single Piston Sander Operator's Manual 13

Page 14

Sécurité

RECONNAÎTRE LES SYMBOLES DE MISE EN GARDE

Voici le symbole de mise en garde. Lorsqu'il apparaît sur la

outil pneumatique ou dans la présente publication, c'est pour

prévenir d'un risque potentiel de blessure.

Respecter tous les conseil de sécurité ainsi que les

consignes générales de prévention des accidents.

COMPRENDRE LES TERMES DE MISE EN GARDE

Les avertissements de sécurité "DANGER,

AVERTISSEMENT ou ATTENTION" seront entourés par

un "ENCADRE ALERTE SECURITE".Cet encadré est utilisé

pour indiquer et souligner les avertissements de sécurité qui

doivent être suivis en actionnant d'outils. En plus des

avertissements de sécurité, des "mots d'alerte" sont utilisés

pour indiquer le degré ou niveau de risque. Les "mots

d'alerte" utilisés dans ce manuel sont comme suit:

DANGER: Indique une situation au danger

imminent qui, si elle n'est pas évitée,

ENTRAINERA la mort ou des blessures

graves.

AVERTISSEMENT: Indique une situation

potentiellement dangereuse qui, si elle

n'est pas évitée, POURRAIT entraîner la

mort ou des blessures graves.

ATTENTION: Indique une situation

potentiellement dangereuse, qui, si elle

n'est pas évitée, PEUT entraîner des

blessures mineures ou peu graves et des

dégats au compresseur.

LISEZ LES INSTRUCTIONS D’UTILISATION

Familiarisez vous toujours avec l’ensemble des

instructions et avertissements avant de faire

fonctionner tout outil pneumatique

DANGER

AVERTISSEMENT

ATTENTION

Fournissez toujours une copie de ce manuel à toute

personne utilisant cet équipement. Lisez toutes les

instructions dans ce manuel et toutes instructions

fournies par les fabricants d'équipement de support

avant d'utiliser d'outils et attirer spécialement

l'attention aux "Avertissements de Sécurité" pour

éviter la possibilité de blessures pour l'utilisateur.

14 Straight Line Single Piston Sander Operator's Manual

Page 15

AVERTISSEMENT

PORTEZ TOUJOURS DES LUNETTES DE PROTECTION HOMOLOGUÉES

Les lunettes de protection antichoc doivent être au moins

conformes à la norme ANSI Z87.1 relative à la protection

des yeux et du visage sur les lieux de travail et d’apprentissage. Recherchez l’indication Z87.1 sur vos lunettes

de protection pour vous assurer qu’elles sont d’un type

homologué. Pour des informations complémentaires,

vous pouvez vous procurer le texte de la norme ANSI

Z87.1 précitée auprès de l’American National Standards

Institute, Inc., 11 West 42nd Street, New York, NY

10036.

LE PORT D’UN CASQUE EST RECOMMANDÉ

Il convient de porter un casque en cas d’exposition à un

niveau de bruit pondéré d’au moins 85 dBA pendant 8

heures. Le bruit d’usinage, les surfaces réfléchissantes,

l’utilisation d’autres outils à proximité ajoutent tous au

niveau de bruit régnant dans la zone de travail. Nous

vous recommandons de porter un casque si vous n’êtes

pas en mesure de déterminer le niveau de bruit auquel

vous êtes exposé.

LE PORT D’UNE PROTECTION RESPIRATOIRE EST

RECOMMANDÉ

Il est recommandé, fonctionner tout outil pneumatique

pour des périodes de temps prolongées, de porter un

masque protecteur. Ceci vous empêchera d’inhaler la

poussière fine produite lors du ponçage. La respiration

prolongée de particules de poussière peut causer des

problèmes respiratoires dans le futur.

Certaines poussières produites par le sablage, le

sciage, le broyage, le perçage, et autres activités de

construction contiennent des produits chimiques connus

comme étant cause de cancer, de défauts de naissance

ou de problèmes de reproduction. Des exemples de ces

produits chimiques sont:

• Du plomb provenant de peintures à base de plomb.

• De la silice de Crystalline provenant de briques, de

ciment et d’autres produits de maçonnerie.

• De l’arsenic et du chrome provenant de bois de

charpente traité chimiquement.

Votre risque de ces contacts varie selon le temps passé

à faire ce genre de travail. Pour réduire votre exposition

à ces produits chimiques, travailler dans un endroit bien

aéré et avec un équipement de sécurité approuvé tels

que les masques de poussière conçus spécialement

pour filtrer les particules microscopiques.

Straight Line Single Piston Sander Operator's Manual 15

Page 16

AVERTISSEMENT

ÉVITEZ UNE EXPOSITION PROLONGÉE AUX VIBRATIONS

Les outils pneumatiques peuvent vibrer en cours de fonctionnement.

Une exposition prolongée aux vibrations ou des mouvements très

répétitifs de la main et du bras peuvent provoquer des blessures.

Arrêtez de vous servir d’un outil quelconque en cas de gêne, de

picotements ou de douleur. Vous devez consulter votre médecin avant

de vous resservir de l’outil.

ATTENTION

PRESSION MAXIMUM DE 620 kPa

L’outil est conçu pour fonctionner à une pression maximum de 620 kPa

au manomètre. Le fonctionnement à une pression pneuma-tique plus

élevée peut faire courir des risques de blessures. Il fait également subir

aux composants intérieurs des charges et des contraintes pour

lesquelles ils ne sont pas conçus, provoquant ainsi une défaillance

prématurée de l’outil.

NOTE: Celuici doit être alimenté en air propre et sec, lubrifié de

préférence. Pour obtenir les meilleurs résultats, purgez

quotidiennement votre compresseur de l’eau qu’il contient.

16 Straight Line Single Piston Sander Operator's Manual

Page 17

Installation

L’outil est conçu pour fonctionner à une pression de

620 kPa. Son fonctionnement à une pression

inférieure rend l’outil moins performant, alors que

son fonctionnement à une pression supérieure

accroît ses performances audelà de sa capacité

nominale et risque d’endommager l’outil et de blesser

l’utilisateur.

Alimentez toujours l’outil en air propre et sec. Une humidité et une saleté excessives

réduisent grandement la durée de service de tout moteur pneumatique. Nous

recommandons la pose d’un filtre régulateur lubrificateur sur la conduite, aussi près de

l’outil que possible.

Il est nécessaire d’utiliser un tuyau de 3/8 po si sa longueur ne dépasse pas 2,44 m. Si

une plus grande longueur de tuyau s’avère nécessaire, il convient de raccorder un

tuyau de 1/2 po à celui de 3/8 po pour garantir que l’alimentation en air de l’outil est

suffisante. Veillez à ce que tous les tuyaux et raccords soient de la bonne taille

et bien serrés.

Configuration recommandée de la conduite d’alimentation en air

Pente de plus de 1/100

Branchement = 2 fois le

diamètre d’arrivée d’air

d’outil/tuyau

Vanne de

purge

automatique

Vanne de

purge

automatique

Vanne

d’arrêt

Filtrerégulateurlubrificateur

Outil

pneumatique

Conduite principale = 3 fois

le diamètre d’arrivée d’air

d’outil/tuyau

Vanne

d’arrêt

Compresseur

Straight Line Single Piston Sander Operator's Manual 17

Page 18

Fonctionnement

AVANT UTILISATION

Avant de raccorder l’outil à l’alimentation en air, nettoyez le tuyau d’air pour le

débarrasser de la poussière et de l’eau. Avant de débrancher un outil pour entretien ou

changement d’accessoire, veillez à couper l’alimentation en air et à purger le tuyau de

l’air qu’il contient. Cela empêche l’outil de se mettre en marche si sa commande est

actionnée accidentellement.

FONCTIONNEMENT

Cet outil est conçu pour utiliser du papier de verre adhésif sensible à la pression (ASP).

Tailler le papier de verre à la grandeur du montage du tampon et appliquer au tampon

selon les instructions du fabriquant.

Laissez la ponceuse faire le travail. N’exercez pas une pression excessive sur l’outil.

Cela ne fera que ralentir la vitesse du plateau, réduire l’efficacité du ponçage et

imposer des contraintes supplémentaires au moteur. Écartez la ponçeuse de la pièce

pour la faire démarrer, abaissez la uniformément sur la pièce et déplacez la d’avant en

arrière dans des zones qui se chevauchent. Une fois le ponçage terminé, soulevez la

ponçeuse pour l’écarter de la pièce avant d’arrêter le moteur.

Commencez à travailler avec un abrasif à grain juste assez gros pour supprimer les

saillies importantes et la rugosité. Servez vous ensuite d’abrasifs à grain de plus en

plus fin jusqu’à ce que vous obteniez le fini que vous désirez. Ne passez jamais

directement d’un gros grain à un grain fin, ce qui pourrait rendre difficile l’élimination

des marques de rotation. Utilisez des abrasifs au grain le plus fin possible pour

effectuer le dégrossissage et finissez en utilisant des abrasifs à grain de plus en plus

fin.

Entretien

GRAISSAGE:

Il est recommandé d’installer un filtre régulateur graisseur sur la conduite

d’alimentation d’air pour prolonger la durée de vie de l’outil et assurer un bon

fonctionnement continu de celuici. Le graisseur sur conduite devrait être vérifié

régulièrement et rempli d’huile pour outil pneumatique. Le réglage du graisseur sur

conduite est effectué en plaçant une feuille de papier près des orifices

d’échappement et en gardant l’obturateur ouvert pendant environ 30 secondes. Le

graisseur est correctement réglé lorsqu’une petite tache d’huile se forme sur le papier.

Éviter les quantités d’huiles excessives.

S’il s’avère nécessaire de ranger l’outil pendant une période de temps prolongée

(pendant la nuit, la fin de semaine, etc.), il convient alors de le graisser

généreusement et de le faire fonctionner pendant environ 30 secondes pour garantir

une répartition uniforme de l’huile dans l’outil. L’outil devrait être rangé dans un

endroit propre et sec.

Lubrifiants recommandés: Utiliser John Deere AT-4003 de l’huile à outil

pneumatique ou toute autre huile à turbine de hautequalité contenant des absorbants

d’humidité, des inhibiteurs de rouille, des agents d’arrosage de métal et un additif de

pression extrême.

18 Straight Line Single Piston Sander Operator's Manual

Page 19

Dépannage

Perte de puissance

Cause(s) Possible(s)

1. Pression d’air trop

basse

2. Mauvaise

lubrification ou

encrassement

3. Usure de pièces du

moteur ou autres

problèmes

Spécifications

SolucionSymptôme

1. Vérifiez l’alimentation en air.

Pour obtenir le rendement

prévu, l’outil en marche doit

être alimenté en air comprimé

à 620 kPa.

2. Vérifiez l’air pour voir s’il est

humide ou sale. Un air humide

tend à entraîner le lubrifiant. La

crasse ou tout autre corps

étranger gêne le

fonctionnement du moteur. Si

de la crasse ou de l’eau a

pénétré dans l’outil, rincez

celuici à l’huile John Deere AT-

4003.

3. Entrez en contact avec botre

service clientéle.

Grandeur du tampon ------------------------------- 6,8 x 27,9 cm (2 11/16 x 11")

Cadence d'impact ----------------------------------- 2600cps/min

Longueur des coups-------------------------------- 2,5 cm

Poids --------------------------------------------------- 2,38 kg

Longueur totale -------------------------------------- 30,48 cm

Consommation d’air moyenne------------------- 0,14 m3/min

Diam. int. de boyau recommandé -------------- 3/8 po

Arrivée d’air ------------------------------------------- 1/4 po NPT

Pression de service maximale------------------- 620 kPa

Straight Line Single Piston Sander Operator's Manual 19

Page 20

Garantie limitée

Garantie limitée deux John Deere. Les modèles de mini-

ponceuse droite John Deere, traités dans ce manuel sont garantis

par John Deere contre tout vice de matériau et de fabrication

pendant deux an à compter de la date d’achat par l’acheteur

d’origine et si utilisés selon les normes indiquées. Toute pièce

s’avérant défectueuse en matières premières et/ou en fabrication

et ayant été renvoyée port payé à une centrale de service aprèsvente comme recours exclusif, sera remplacée ou réparée

gratuitement au choix de John Deere. Pour les procédures de

recours de garantie limitée, voir “DISPOSITIONS RAPIDES” cidessous. Cette garantie limitée donne à l'acheteur des droits

juridiques spécifiques qui varient d’une juridiction à l’autre.

Limitations de responsabilités. Conformément au droit

applicable, John Deere décline toute responsabilité en cas de

dommages directs ou indirects. La responsabilité de John Deere

se limitera à et en aucun cas ne dépassera le prix d’achat du

produit.

Dénégation de garantie. John Deere s’est efforcé d’illustrer et de

décrire avec précision le produit dans cette brochure. Cependant,

ces illustrations et ces descriptions ont pour seul et unique but

d’aider à une identification. Ces dernières ne doivent en aucun cas

être interprétées en tant que garanties expresses ou implicites

d’aptitude à la commercialisation ou d’aptitude à une utilisation

particulière ou encore que ces produits devront nécessairement

être conformes aux illustrations ou aux descriptions.

Hormis les informations indiquées cidessous, John Deere décline

toute autre garantie ou accord, explicite ou implicite autre que

celui décrit au paragraphe ci dessus “GARANTIE LIMITÉE”.

20 Straight Line Single Piston Sander Operator's Manual

Page 21

Appropriation du produit. De nombreuses juridictions possèdent

des codes et une législation concernant la vente, la construction,

l’installation et/ou l’utilisation particulière de produits pouvant

différer de celles en vigueur dans les régions voisines. Bien que

John Deere fait de son mieux afin que ses produits soient

conformes à la dite législation, John Deere ne peut garantir cette

conformité et ne saurait être responsable de la façon dont ce

produit a été installé ou utilisé. Avant l'achat et l'utilisation du

produit, consultez les indications consacrées à l’usage de ce

dernier, ainsi que les codes et la législation locale et nationale

applicables et assurezvous que l’installation et l’usage du produit

sont conformes à ces derniers.

Certains aspects de cette dénégation de responsabilité ne

peuvent être appliqués aux produits de consommation. En effet,

(a) certaines juridictions ne permettent pas l’exclusion ou la

limitation de dommages directs ou indirects. Par conséquent, les

exclusions ou limitations indiquées cidessus peuvent ne pas vous

être applicables; (b) certaines juridictions ne permettent pas de

limitation en durée d’une garantie implicite. Par conséquent, la

limitation indiquée cidessus peut ne pas vous être applicable; et

(c) en vertu de la loi, pendant la période couverte par la garantie

limitée, certaines garanties implicites de commercialisation ou

d’aptitude à une utilisation particulière applicables aux produits de

consommations achetés par les consommateurs, peuvent ne pas

être exclues ni déniées.

Dispositions rapides. John Deere fera preuve de bonne foi afin

de corriger ou de réparer rapidement tout produit défectueux dans

le cadre de la garantie limitée. Si un produit s’avère défectueux

pendant la période de couverture, écrivez tout d’abord ou appelez

le revendeur auprès duquel le produit a été acheté. Le revendeur

vous donnera des directives supplémentaires. Si votre cas ne

peut être résolu par l’intermédiaire du revendeur, écrivez à Mi-T-M

à l’adresse suivante, en indiquant le nom du revendeur, son

adresse et numéro de facture du revendeur et en décrivant la

nature du défaut. Le titre et le risque de perte passent à l’acheteur

au moment où le produit est remis au transporteur. En cas de

dommages lors du transport à votre domicile, déposer une plainte

auprés du transporteur.

8650 Enterprise Drive, Peosta, IA 52068-0050

Tél.: JD-KLEEN (1-877-535-5336) Fax 563-556-1235

du lundi au vendredi de 8h00 à 17h, CST (heure centrale)

Mi-T-M® Corporation

Straight Line Single Piston Sander Operator's Manual 21

Page 22

Introduccion

¡Felicitaciones por la compra de su nueva Lijadora Recta de Pistón Solo John Deere!

Puede estar seguro que su lijadora recta de pistón solo fue construida con el nivel más

alto de precisión y exactitud. Cada componente ha sido probado rigurosamente por

técnicos para asegurar la calidad, la resistencia y el rendimiento de esta unidad.

La lijadora recta de pistón solo John Deere está diseñada para varias aplicaciones que

requieren una herramienta más compacta. Se usa para lijado, lustrado y acabado en una

variedad de superficies incluyendo maderas, metales y fibra de vidrio. Esta herramienta

presenta un motor potente impulsor de pistón que impulsa a una almohadilla lijadora con

más de 29 pulgadas cuadradas de superficie. La almohadilla lijadora de 2 11/16 x 11"

acepta papel adhesivo sensible a la presión (PSA).

Este manual del operador fue compilado para su beneficio. Leyendo y siguiendo los pasos

simples de seguridad, instalación, operación, mantenimiento y localización de fallas

descritos en este manual ayudará a prolongar aun más la operación libre de fallas que

usted puede esperar de su nueva lijadora recta de pistón solo. El contenido de este

manual está basado en la información actualizada disponible al momento de la

publicación. Fabricante se reserva el derecho de efectuar cambios en precio, color,

materiales, equipo, especificaciones o modelos en cualquier momento sin previo aviso.

Escriba el número de serie de su unidad en el espacio provisto abajo, una vez que la

unidad haya sido desempacada.

NUMERO DE SERIE___________________________

Inspeccione por daño el contenido de la caja. Si algo parece dañado, NO LA DEVUELVA

AL LUGAR DE COMPRA. Llame a su representante de servicio al cliente.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

Telefone gratis en los EE. UU.: 877-535-5336 / Fax 563-556-1235

Por favor tenga disponible la información siguiente para todas las llamadas de servicio:

22 Straight Line Single Piston Sander Operator's Manual

Telefono: 1-877-JD-KLEEN

Lunes - Viernes 8:00 a.m. - 5:00 p.m. CST

1. Número de modelo

2. Número de serie

3. Fecha y lugar de compra

Page 23

Tabla de Materias

INTRODUCCION.................................................................................................... 22

TABLA DE MATERIAS .......................................................................................... 23

SEGURIDAD .......................................................................................................... 24-26

INFORMATION DE SÉCURITÉ RECONOCER.................................... 24

PALABRAS DE ALERTA QUE ENTIENDO .......................................... 24

LAS INSTRUCCIONES DE OPERACIÓN ............................................ 24

SIEMPRE USE PROTECCIÓN PARA LOS OJOS APROBADA ......... 25

SE RECOMIENDA LA PROTECCIÓN DE LOS OÍDOS....................... 25

USE SOLAMENTE ACCESORIOS Y CASQUILLOS DE IMPACTO ... 25

EVITE LA EXPOSICIÓN PROLONGADA A LA VIBRACIÓN............... 26

620 KPA PRESIÓN ATMOSFÉRICA, MÁXIMO ................................... 26

INSTALACIÓN ....................................................................................................... 27

PREPARACIÓN DE TUBERÍA DE AIRE RECOMENDADA................. 27

OPERACIÓN .......................................................................................................... 28

MANTENIMIENTO ................................................................................................. 28

LOCALIZACION DE FALLAS................................................................................ 29

ESPECIFICACIONES ............................................................................................ 29

DECLARACION DE GARANTIA............................................................................ 30-31

Straight Line Single Piston Sander Operator's Manual 23

Page 24

Seguridad

PELIGRO

ADVERTENCIA

PRECAUCION

INFORMATION DE SÉCURITÉ RECONOCER

El símbolo indicado a “Símbolo de Alerta de Seguridad”. Este

símbolo se usa para alertarlo acerca de artículos o

procedimientos que podrían ser peligrosos para usted u otras

personas usando este equipo.

PALABRAS DE ALERTA QUE ENTIENDO

Estos párrafos están rodeados por una “CASILLA DE

ALERTA DE SEGURIDAD”. Esta casilla se usa para

designar y enfatizar las Advertencias de Seguridad que

deben seguirse al operar esta herramienta.

Acompañando a las Advertencias de Seguridad están las

“palabras de alerta” que designan el grado o nivel de

seriedad de riesgo. Las “palabras de alerta” usadas en este

manual son las siguientes:

PELIGRO: Indica una situación inminente riesgosa la cual, si no se evita,

ADVERTENCIA: Indica una situación potencialmente riesgosa la cual, si no se

PRECAUCION: Indica una situación potencialmente riesgosa la cual, si no se

LAS INSTRUCCIONES DE OPERACIÓN

Siempre familiarícese con todas las instrucciones y

advertencias antes de operar cualquier herramienta

neumática.

Provea siempre una copia de este manual a

cualquier persona que use este equipo. Lea todas

las instrucciones antes de operar esta

herramienta, observando en particular las

"ADVERTENCIAS DE SEGURIDAD" para evitar la

posibildad de lesiones personales al operador.

24 Straight Line Single Piston Sander Operator's Manual

RESULTARA en la muerte o en lesiones graves.

evita, PODRIA resultar en la muerte o en lesiones graves.

evita PUEDE resultar en lesiones menores o moderadas.

Page 25

ADVERTENCIA

SIEMPRE USE PROTECCIÓN PARA LOS OJOS

APROBADA

La protección para los ojos, resistente al impacto,

tiene que cumplir o exceder los estándares establecidos en ANSI Z87.1 de Estados Uni-dos sobre la

Protección de los Ojos y de la Cara en el Trabajo y la

Educación. Mire la sección Z87.1 sobre la protección

para los ojos para asegurarse que está usando un

estilo aprobado. Para más información la publicación

de ANSI Z87.1 de Estados Unidos sobre la Protección

de los Ojos y de la Cara en el Trabajo y la Educación,

está disponible en el American National Standards

Institute, Inc., 11 West 42nd Street, New York, NY

10036.

SE RECOMIENDA LA PROTECCIÓN DE LOS OÍDOS

La protección de los oídos se tiene que usar cuando la

exposición al nivel del ruido es igual o excede un nivel de

ruido promedio de 85 dBA con la importancia del factor

de tiempo de 8 horas. El ruido del proceso, las superficies

reflectoras, las demás herramientas que están operando

cerca, aumentan el nivel del ruido en su área de trabajo.

Si no puede determinar su nivel de exposición al ruido, le

recomendamos que use protección para los oídos.

USE PROTECCIÓN RESPIRATORIA

Es aconsejable operar cualquier herramienta neumática

por períodos prolongados de tiempo, es aconsejable

usar una máscara protectora. Esto ayuda a impedir la

inhalación del polvo fino producido cuando se lija. La

respiración prolongada de las partículas de polvo puede

producir problemas respiratorios en el futuro.

Algún polvo hecho por enarenando, serrando,

moliendo, y taladrando de poder y otras actividades de

constucción contienen quimicos que puedan causar

Cáncer, defectos de nacimiento, o peligro reproductivo.

Algunos ejemplos de estos quimicos son:

• Plomo de pinturas con plomo

• Sílice de cristalino de los ladrillos, el cemento, y

otros productos de masonería

• Arsénico y chromo de madera con quimicos

Tu riesgo de estas cosas varia, depende de cuánto

tiempo hace usted este tipo de trabajo. Para reducir tu

peligro de estos quimicos, trabaja usted en un lugar

bien ventilado y trabaja con equipo aprobado y seguro,

como una mascarilla de polvo diseño especialmente

para filtrar las particulas microscopias.

Straight Line Single Piston Sander Operator's Manual 25

Page 26

ADVERTENCIA

EVITE LA EXPOSICIÓN PROLONGADA A LA VIBRACIÓN

Las herramientas neumáticas pueden vibrar durante el uso. La exposición

prolongada a la vibración o los movimientos de las manos o de los brazos muy

repetidos pueden producir lesiones. Deje de usar cualquier herramienta si siente

incomodidad, hormigueo o dolor. Debe consultar a su doctor antes de volver a usar

la herramienta.

PRECAUCION

620 KPA PRESIÓN ATMOSFÉRICA, MÁXIMO

Ha sido diseñada para operar a 620 kPa sobre la presión atmosférica, máximo, en

la herramienta. Si se usa una mayor presión de aire puede y de hecho producirá

lesiones. También la presión de aire mayor pone a los componentes internos bajo

cargas y esfuerzos para los cuales no habían sido diseñados produciendo fallas

prematuras en la herramienta.

NOTA: El abastecimiento de aire debe ser limpio y seco, preferiblemente lubricado.

Para lograr los mejores resultados drene la humedad de su compresor diariamente.

26 Straight Line Single Piston Sander Operator's Manual

Page 27

Instalación

La herramienta ha sido diseñada para operar a 620 kPa, por lo

tanto, la presión más baja (por debajo de 620 kPa) reducirá su

rendimiento y la presión de aire más alta (sobre 620 kPa) aumentará

el rendimiento de la herramienta por sobre su capacidad nominal,

lo que podría dañarla gravemente o lesionar al usuario.

Siempre use aire limpio y seco. La humedad excesiva y la mugre reducen

considerablemente la duración de cualquier motor de aire. Recomendamos la

instalación en línea de un filtro-regulador-lubricador, tan cerca de la herramienta

como sea posible.

Es necesario usar una manguera de 3/8" de hasta 2,44 m de largo. Si se necesita

una mayor longitud, se debe conectar una manguera de aire de 1/2" a la de 3/8",

para asegurarse que la herramienta cuente con el abastecimiento de aire

necesario. Asegúrese que todas las mangueras y los accesorios sean del tamaño

correcto y que queden firmemente asegurados.

PREPARACIÓN DE TUBERÍA DE AIRE RECOMENDADA

Inclinación más de 1/100

Tubería derivada = 2 veces la

entrada de la herramienta/

tamaño de la manguera

Válvula de

autodrenaje

Válvula de

autodrenaje

Válvula

de cierre

Filtro

Regulador

Lubricador

Tubería principal = 3 veces la

entrada de la herramienta/

tamaño de la manguera

Herramienta de

aire

Válvula

de cierre

Compresor de aire

Straight Line Single Piston Sander Operator's Manual 27

Page 28

Operación

ANTES DE LA OPERACIÓN:

Antes de que se conecte la herramienta al abastecimiento de aire, despeje la

acumulación de polvo y de humedad de la manguera de aire. Antes de remover una

herramienta para darle servicio o de cambiar accesorios, asegúrese que la tubería

de aire esté cerrada y sin aire. Esto impedirá que la herramienta funcione si se

engancha el mando por accidente.

OPERACIÓN:

Esta herramienta está diseñada para usar papel de lija adhesivo sensible a la

presión (PSA). Corte el papel de lija para corresponder con el tamaño del conjunto

de la almohadilla y aplique a la misma según las instrucciones del fabricante.

Permita que la lijadora haga el trabajo. No ponga una presión excesiva en la

herramienta. Esto sólo retardará la velocidad de la base, reducirá la eficiencia del

lijado y pondrá una carga adicional en el motor. Haga arrancar la lijadora fuera del

trabajo, póngala en el trabajo en forma pareja y muévala de atrás para adelante en

áreas amplias que se solapen. Cuando termine de lijar, levante la lijadora del trabajo

antes de parar el motor.

Empiece el trabajo con una arenilla abrasiva justo lo suficientemente gruesa como

para remover los puntos altos y las asperezas. Luego use arenilla más fina hasta

que se obtenga el acabado deseado. Nunca pase de una arenilla gruesa a una fina

en un paso. Puede que sea difícil remover las marcas de remolino. Use la arenilla

más fina que sea práctico para las operaciones de reducción de asperezas y acabe

usando arenillas cada vez más finas.

Mantenimiento

LUBRICACION

Se recomienda usar un filtro-regulador-lubricador en línea para prolongar la duración

de la herramienta y mantenerla funcionando correctamente. El lubricador en línea se

debe revisar regularmente y se debe llenar con aceite para herramientas de aire John

Deere AT-4003. El ajuste correcto del lubricador en línea se hace colocando una hoja

de papel próxima a los orificios de escape de la herramienta y sujetando el mando

abierto aproximadamente por 30 segundos. El lubricador ha quedado ajustado

correctamente cuando cae una mancha no viscosa de aceite en el papel. Se deben

evitar las cantidades excesivas del aceite pues se disminuye el rendimiento de la

herramienta.

En el caso que se haga necesario tener que guardar la herramienta por un período

prolongado de tiempo, (de un día para el otro, fin de semana, etc.) se le debe lubricar

abundantemente en ese momento. Se debe hacer funcionar por aproximadamente 30

segun-dos para asegurarse que el aceite se ha distribuido parejamente a través de la

herramienta. La herramienta se debe guardar en un ambiente limpio y seco.

Lubricantes recomendados: Use solamente aceite para herramientas de aire John

Deere AT-4003 o cualquier otro aceite de turbina de alta calidad que contenga

elementos absorbedores de humedad, inhibidores de óxido, agentes humedecedores

de metal y aditivos de presión extrema.

28 Straight Line Single Piston Sander Operator's Manual

Page 29

Localizacion de Fallas

Síntoma

Pérdida de energía

Causa(s) Posible(s)

1. Baja presión de aire.

2. Mala lubricación o

acumulación de mugre.

3. Las partes del motor

están desagastadas o hay

otros problemas.

Solucion

1. Revise el abastecimiento de

aire. Se necesita la presión

de aire de 620 kPa en la

herramienta cuando está

operando, para lograr el

rendimiento de capacidad

nominal.

2. Revise si hay aire mojado o

sucio. El aire mojado tiende a

lavar el lubricante. La mugre

o los materiales extraños

impiden el funcionamiento del

motor. Si la mugre o el agua

han entrado en la herramienta, lávelas con John

Deere AT-4003.

3. Llame al Servicio al Cliente.

Especificaciones

Tamaño de la almohadilla ------------------------ 6,8 x 27,9 cm (2 11/16 x 11")

Carreras por minuto -------------------------------- 2.600 cps/mir

Largo de la carrera --------------------------------- 2,5 cm

Peso ---------------------------------------------------- 2,38 kg

Largo --------------------------------------------------- 30,48 cm

Consumo neumático promedio------------------ 0,14 m3/mn

Tamaño recomendado de la manguera------- 3/8" de D.I..

Entrada de aire -------------------------------------- 1/4" NPT

Presión de operativa máxima-------------------- 620 kPa

Straight Line Single Piston Sander Operator's Manual 29

Page 30

Garantía Limitada

Garantía Limitada de John Deere por Dos Año. Minilijador recta

John Deere, y los Modelos tratados en este manual están

garantizados por John Deere para el comprador original contra

defectos en la fabricación o el material bajo uso normal por dos

año a partir de la fecha de compra. Cualquier pieza que se

determine como defectuosa, tanto en el material como en su

fabricación y sea devuelta a un centro autorizado de servicio de

John Deere, con los gastos de envió prepagados, será

reemplazada o reparada a la exclusiva discreción de John Deere.

Los procedimientos para resolver los casos de RECLAMOS DE

GARANTIAS se explican a continuación. Esta garantía limitada le

otorga al comprador derechos legales específicos que pueden

variar de jurisdicción a jurisdicción.

Límite de Responsabilidad. La responsabilidad civil de John

Deere por daños emergentes o incidentales y accidentes está

expresamente limitada y no podrá, en ningún caso, exceder el

precio de compra del artículo.

Renuncia a la Garantía. John Deere se ha esforzado en describir

sus productos con exactitud en este manual; sin embargo, la

información, las ilustraciones y descripciones tienen como único

propósito la identificación del producto y no expresan ni implican

garantías de que los productos descritos son adecuados para un

propósito en particular o que se ajustan necesariamente a las

ilustraciones o descripciones provistas. Con excepción de lo que

se establece a continuación, John Deere no reconocerá o

autorizará ninguna otra garantía o afirmación de hecho, expresa o

implícita, la cual no esté estipulada en la “GARANTIA LIMITADA”.

30 Straight Line Single Piston Sander Operator's Manual

Page 31

Uso adecuado del producto. Muchas jurisdicciones tienen

códigos o reglamentos que regulan las ventas, fabricación,

instalación y/o uso del producto para ciertos usos específicos, los

cuales pueden variar en áreas circunvecinas. John Deere trata de

que sus productos cumplan con dichos códigos o

reglamentaciones, sin embargo, el cumplimiento de los mismos no

se puede garantizar y la compañía no se hace responsable por la

forma en la cual el producto se instala o usa. Antes de la compra o

uso del producto, revise su aplicación y los códigos y

reglamentaciones nacionales y locales que sean aplicables y

cerciórese de que el producto, la instalación y el uso cumplan con

los mismos.

Ciertos aspectos de la renuncia a la garantía no se aplican a

productos para el consumidor, por ejemplo, (a) algunas

jurisdicciones no permiten la exclusión o limitación de daños

incidentales o emergentes, por lo tanto, estas podrían no ser

aplicables en su caso; (b) también, algunas jurisdicciones no

permiten limitar la duración de una garantía implícita, por lo tanto

estas podrían no ser aplicables en su caso; (c) según la ley y

durante la duración de esta garantía limitada, las garantías escritas

o implícitas relacionadas con el buen estado o posible uso del

producto por parte del consumidor, no podrán ser excluidas o

renunciadas en forma alguna.

Pronta Disposición. John Deere se compromete a resolver los

casos de los productos bajo garantía en forma diligente de acuerdo

a lo estipulado en esta garantía limitada. En el caso de que su

producto tenga algún defecto y que esté cubierto dentro de los

límites de esta garantía, diríjase por escrito o llame al distribuidor

autorizado donde compró el producto. El distribuidor le indicará los

pasos a seguir. Si no logra resolver el problema

satisfactoriamente, diríjase directamente por escrito a Mi-T-M a la

dirección dada a continuación, dando la siguiente información:

nombre del distribuidor, dirección del mismo, fecha de compra,

número de factura y descripción del defecto. La propiedad del

artículo y el riesgo de pérdida pasan al comprador en el momento

en el cual el producto es entregado a la compañía de transporte.

Si el daño ocurrió durante el transporte, deberá presentarse el

reclamo a la compañía de transporte.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

Telefone gratis en los EE. UU.: 877-535-5336 / Fax 563-556-1235

Telefono: 1-877-JD-KLEEN

Lunes - Viernes 8:00 a.m. - 5:00 p.m. CST

Straight Line Single Piston Sander Operator's Manual 31

Page 32

#37-0659-090403

32 Straight Line Single Piston Sander Operator's Manual

©

Copyright 2003, John Deere

Manufactured for Deere & Company

Moline, Illinois 61265

Straight Line Single Piston Sander

Loading...

Loading...