Page 1

145–200 NET HORSEPOWER

DOZERS

DOZERS

J

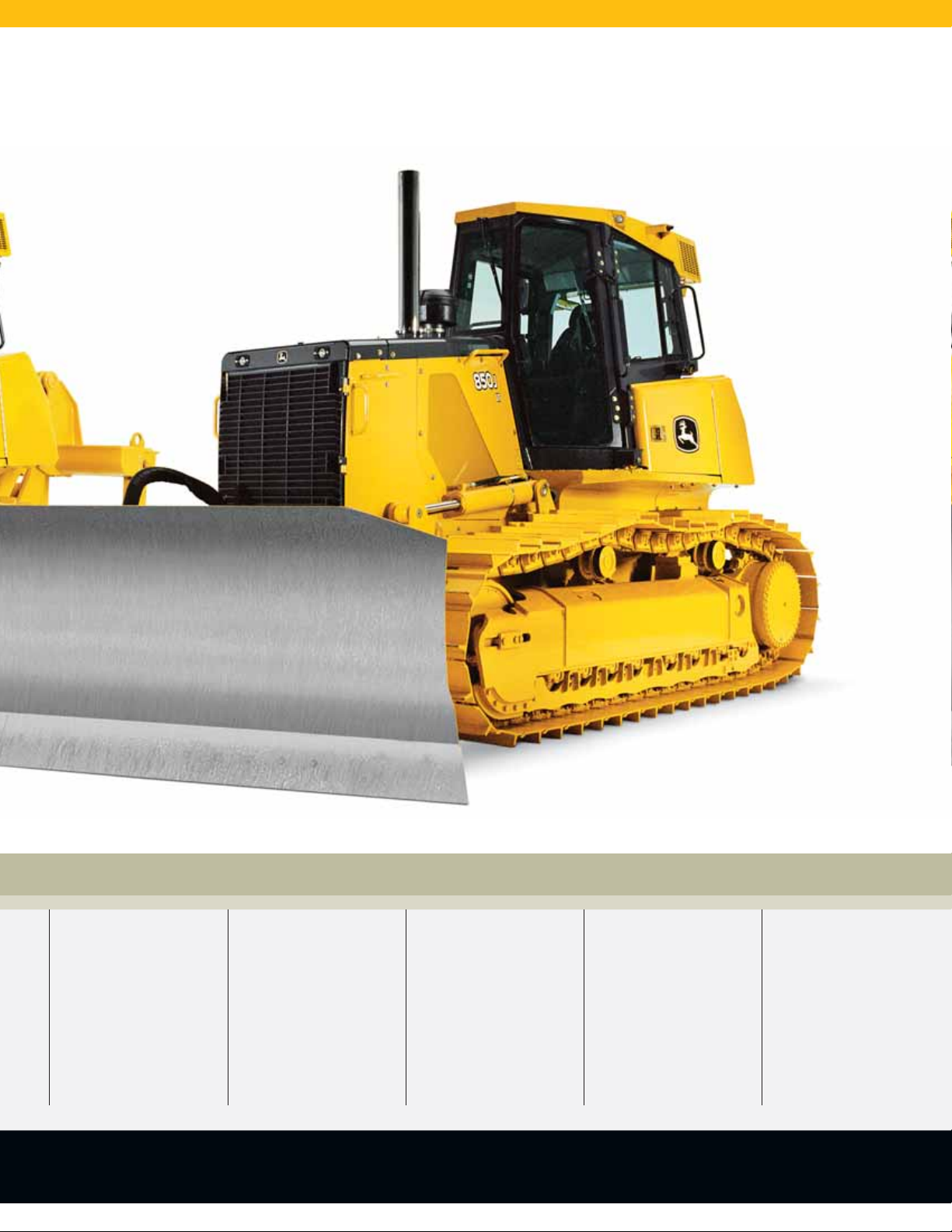

750J | 850J

Page 2

750J

145 hp Standard, LT

155 hp LGP

32,585 lb. Standard

34,395 lb. LT

36,725 lb. LGP

22-, 24-, 28-, and 34-in. grousers

128-, 130-, and 156-in. blades

Simply advanced.

Simply advanced.

Built with the same kind of forward thinking as

our first hydrostatic dozer more than 30 years

ago, 750J and 850J Dozers continue to define

the way earthwork gets done. Their unique state-

of-the-art Total Machine Control (TMC) enables

an operator to customize machine operation and

response to personal preferences. Coupled with

an uncommonly smooth full-featured hydrostatic

drivetrain, the John Deere J-Series Dozers deliver

unsurpassed power, control, and results. Again.

PAGES

2–3

Page 3

850J

185 hp Standard, LT, WT, WLT

200 hp LGP

40,165 lb. Standard

43,015 lb. LT

41,285 lb. WT

44,225 lb. WLT

45,375 lb. LGP

22-, 24-, 30-, and 36-in. grousers

128-, 140-, 146-, 152-,

158-, and 168-in. blades

Eleven track frames, four

mainframes, and a variety

of blades let you choose the

right crawler confi guration

for your kind of work.

Tier 3-certifi ed John Deere

diesels deliver power

without compromise in

all conditions.

Deere’s unique Total Machine

Control lets an operator

customize the crawler’s

operational characteristics

and response, and even

records machine usage.

Power turns, power management, infi nite speed control –– we introduced

them all more than 30 years ago. And today’s 750J and 850J are loaded

with even more productivity- and uptime-boosting enhancements.

Standard equipped with

JDLink™ Ultimate, you have

24/7 anywhere access to your

dozer’s location, utilization,

dashboard alerts, fuel con-

sumption, diagnostic codes,

and hours. Plus geofencing,

curfew, and numerous other

capabilities.

Best-in-class service access,

same-side daily servicing,

and extended engine,

hydraulic, and transmission

oil and fi lter service intervals

help keep downtime to a

minimum.

Page 4

Equipped with optional Integrated Grade Con-

trol (IGC), adding your preferred grade-control

system is “plug-and-play” easy.

Maximize productivity

Maximize productivity

with minimal effort.

with minimal effort.

Independent track control speeds up or slows

down each side – for smooth, full-power turns.

An automatic 10-percent power boost helps

carry more material in a turn.

No need to cross-steer or ride a brake. These

dozers steer the same and maintain their

preset speed whether working on level ground

or a 2-to-1 slope.

All dozers move the earth. But if you want one that does

more with a lot less effort, you’ll choose a John Deere

J-Series. State-of-the-art electronic controls put you in

complete command of a whole arsenal of hydrostatic

advantages, including power turns, counterrotation, and

infi nitely variable travel speeds. What’s more, Total

Machine Control lets an operator customize decelerator

mode and response, forward/reverse ground-speed

ranges, steering modulation, and forward/reverse

speed ratios. Nothing else even comes close.

PAGES

4–5

Page 5

Low-effort controls command

the blade and a full-featured

hydrostatic drivetrain, ensuring

predictable response at all

times in all conditions.

Counterrotation is a productivity-boosting feature

that enables an operator to overcome heavy

corner loads and quickly reposition the blade on

the go. Provides space-saving spot turns, too.

Simply set the maximum desired

ground speed and the power-

management system automati-

c ally maintains peak engine rpm

and power effi ciency without

stalling or shifting.

Infi nitely variable range to 6.8

mph gives total fl exibility to

match ground speed to the load.

Travel can also be varied to fi t

specifi c applications, terrain, or

operating preferences — and

even limited to maximize under-

carriage life.

Purpose-built mainframes for

power-angle-tilt and outside-

mount blades allow optimized

component placement for

uncompromised grading ability.

Fully modulated drivetrain

ensures smooth starts and

direction changes, while

virtually eliminating jerky or

abrupt movements.

Page 6

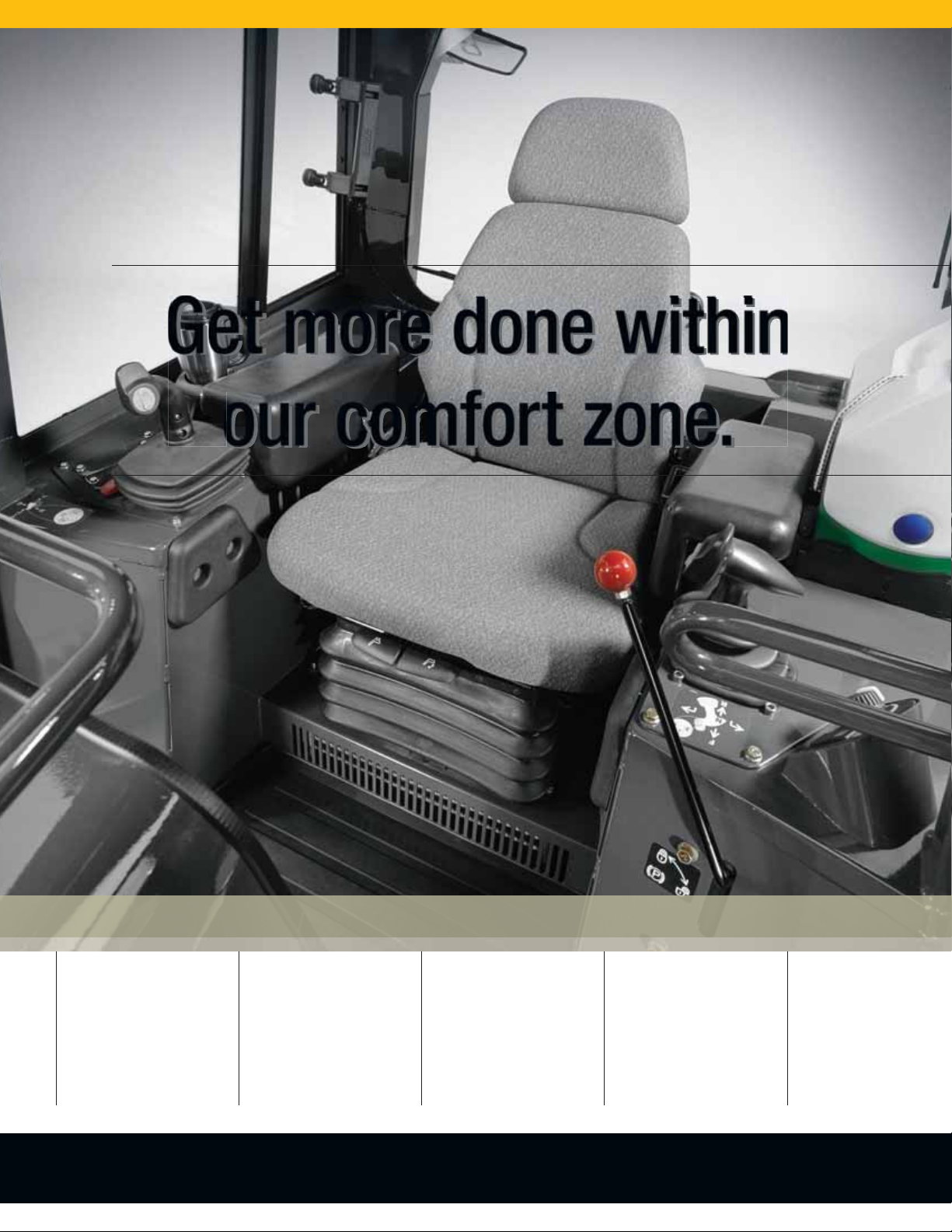

Get more done within

Get more done within

our comfort zone.

our comfort zone.

Generous hydraulic fl ow and

precise metering ensure

powerful and quick blade

response, while providing a

natural “feel” that will enhance

any operator’s grading skills.

A thumb-actuated switch pro-

vides low-effort angle control.

Retractable seat belt,

slip-resistant fl oor mat,

convenient grab bars,

neutral-start lever, and

automatic park brake

help keep the operator

out of harm’s way.

Deluxe suspension armchair

won’t cramp your operator’s

style. Seven-way adjustable

seat provides plenty of legroom

and daylong comfort. Arm- and

footrests also adjust.

Ergonomically correct joystick

provides intuitive, low-effort

control of steering, forward/

reverse travel, and ground speed.

It’s detented so it doesn’t require

an operator’s constant touch or

attention, and employs a thumb-

actuated travel-speed switch.

Convenient 12-volt port pro-

vides power for accessories

such as cell phones.

Page 7

Want your operators to be more productive? Put them

in the seat of this spacious air-conditioned modular cab.

From their ergonomically designed fully customizable

controls to best-in-class visibility, J-Series Dozers

are loaded with everything you need to keep your

operators cool, calm, productive – and on your payroll.

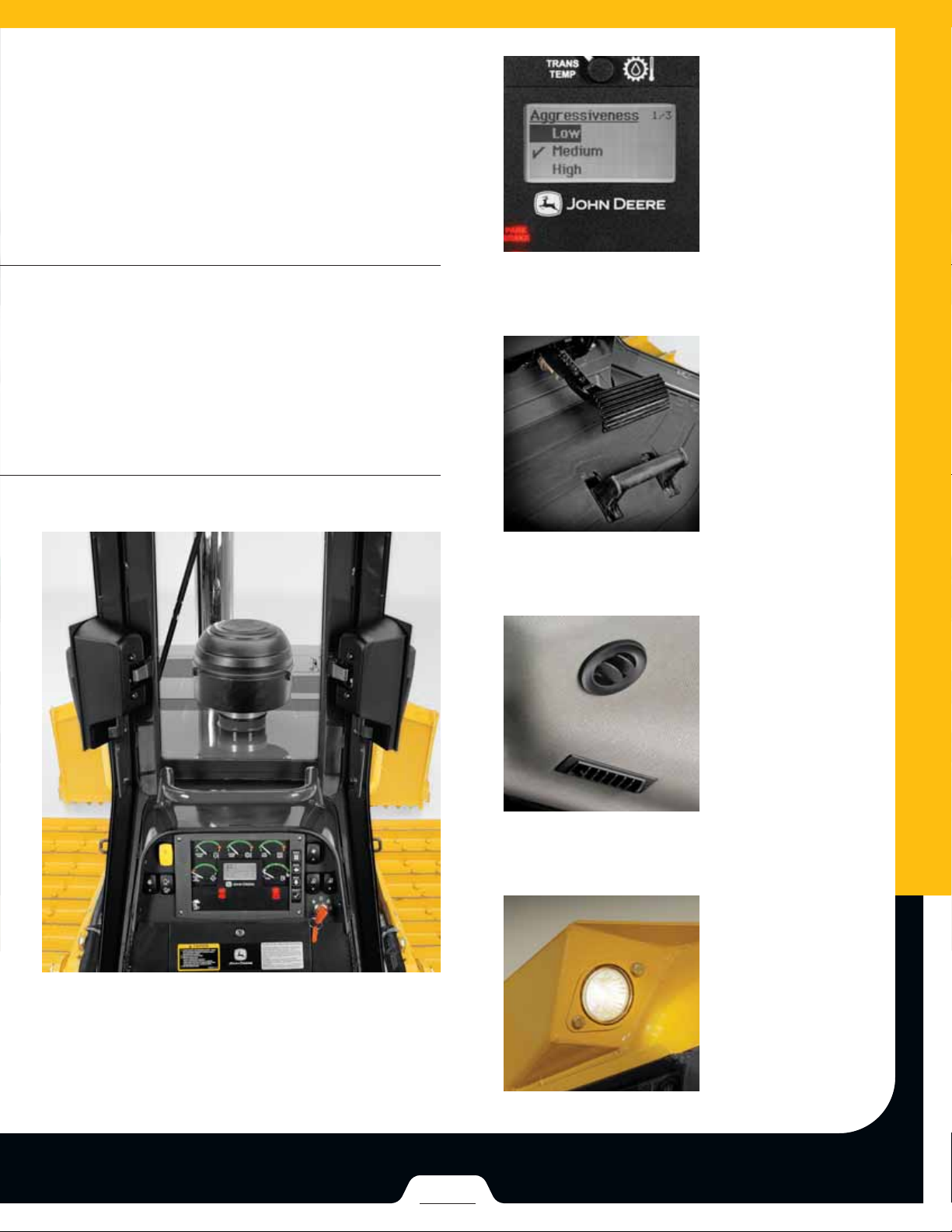

Exclusive TMC lets you

customize decelerator mode

and response, forward/

reverse ground-speed

ranges, steering modulation,

FNR shift rate, and forward/

reverse speed ratios, for

unsurpassed one-of-a-kind

control.

Choose the decelerator

function that’s right for the

job. Slow both ground speed

and engine rpm, or ground

speed only to help maintain

traction without affecting

engine power and hydraulic

response. Fully depressing

the pedal applies the brakes.

Cab-forward design positions the operator for a more stable ride and a commanding

view behind, below, and beyond the blade. Side and rear visibility is equally unobstructed.

Monitor keeps a vigilant watch on vital machine functions with warnings you can see and hear.

Automotive-style

directional vents deliver

effective airfl ow to keep

the glass clear and the

cab comfortable. Air

conditioning is standard

on all cabs. For ROPS-only

crawlers, an optional under-

seat heater helps warm the

operator.

High-intensity halogen

driving lights are standard.

Or opt for the factory-

installed 360-degree light

package and extend your

workday beyond normal

daylight hours.

PAGES

6–7

Page 8

One-piece welded main-

frame resists torsional

stress, absorbs shock loads,

and delivers maximum

strength while allowing easy

service access to major

components.

Individually replaceable wet-

sleeve cylinder liners provide

uniform engine cooling and

long-term durability.

Sealed transmission connec-

tors prevent moisture and

contaminants from entering

terminals: gold pins resist

corrosion for increased

reliability.

Nothing lasts like a

Nothing lasts like a

Deere, either.

Deere, either.

Designed and built with state-of-the-art tools and

techniques by a quality-conscious workforce at our

world-class facility in Dubuque, Iowa, the J-Series are

loaded with uptime-boosting features. Enhancements

include a variable-speed hydraulic-driven cooling

system fan, gold-plated electrical connectors, and

extended service intervals. These, plus traditional

Deere durability features such as one-piece unitized

mainframes, Dura-Trax

engine liners, O-ring face-seal hose couplers, and

isolated planetary fi nal drives keep them keeping on.

When you know how they’re built, you’ll run a Deere.

PAGES

8–9

™

undercarriage, wet-sleeve

Page 9

No need for elevated

sprockets. Heavy-duty

double-reduction planetary

fi nal drives are mounted

independent of the track

frames, where they’re

effectively protected from

shock loads.

One-piece rigid track frames

ensure long-term track

alignment. Smooth idler-

to-sprocket covers shed

material buildup for easy

clean-out.

Bolt-on wear parts for the

chain guides and push-beam

mounts virtually eliminate

diffi cult and time-consuming

cut-and-weld repairs.

The PAT dozer’s closed-

cell blade design and

box-section C-frame deliver

exceptional strength and

durability. Outside-mounted

dozer push beams are

equally durable.

Bypass start protection, automatic park

brake, convenient handholds, and slip-

resistant steps help keep the operator

out of harm’s way.

Available extended life tracks deliver twice the

bushing life, for extra durability in extremely

abrasive conditions. If you’re looking to further

reduce maintenance and operating costs, the

SC-2™ option is for you.

Blade hoses are steel-cable

supported and Cordura covered

for extra protection.

Page 10

Perforations act as a “fi rst fi lter,” preventing entry

of most debris. Anything that gets past the fi ve-mm

holes also easily passes through the cooler cores.

Keep your cool and

Keep your cool and

burn less fuel.

burn less fuel.

Unitized mainframe with fl ush-fi t bottom guards combines

with tight-fi tting side shields to prevent debris from being

drawn into the engine compartment.

No stacked coolers in these crawlers. Side-by-side

cores with wide fi n spacing reduce clogging and are

easy to clean.

J-Series Dozers are designed to run cool regardless

of what’s in the air or underfoot. Their highly

effective cooling system employs a hydraulic-

driven variable-speed suction fan that operates

only as needed for maximum power and efficiency.

For work in environments with lots of airborne

debris, an optional reversing fan automatically

back-blows to help shed debris from cooler cores

and side screens. So your 750J or 850J can work

long and hard without breaking a sweat.

PAGES

10–11

Page 11

Variable-speed fan automati-

cally speeds up or slows down,

operating only as needed

to keep things cool. Helps

conserve power and fuel,

while reducing noise.

Air isn’t blown into the coolers,

so engine and transmission

reach operating temperatures

more quickly in cold weather.

Warm fl uids fl ow easier, helping

extend component life, too.

Programmable fan automati-

cally reverses to help eliminate

cooler-clogging buildup. Or

press a button on the dash

to actuate cleaning cycles as

needed.

With the fan positioned just

behind the grille, coolers are

less vulnerable to damage.

Hinged grille opens wide for

convenient clean-out.

Suction fan is more effi cient

than blower designs, eliminat-

ing the need for oversize

coolers. There’s no need for

a radiator screen to decrease

tube erosion, either.

Page 12

The J-Series’ highly adaptable drivetrain makes

them ideal for work with rear-mount attachments

such as rippers and cable plows.

Built to do one job

Built to do one job

Forestry-protection packages and waste-

handler confi gurations help these machines

survive and thrive in tough applications.

extremely well – yours.

extremely well – yours.

Yours isn’t just any business. Why settle for just any

crawler? Choose a J-Series Dozer in standard, long-

track, wide-track, wide-long track, and low ground-

pressure confi gurations with inside-mounted PAT or

outside-mounted straight or semi-U blades. What’s

more, these highly productive and uniquely versatile

machines can be equipped with a variety of special-

duty and severe-application packages to help them

thrive in a wide variety of work. And tackle tasks

that other crawlers can’t. Ask your dealer for details.

PAGES

12–13

Page 13

With optional Integrated Grade

Control, wiring harnesses, sensor

mounts, control valves, and monitor

bracket are factory installed. So

adding a Trimble®, TOPCON, or

other electronic grade-control

system is “plug-and-play” easy.

Choose the blade that’s best for

your kind of work. Purpose-built

mainframes allow optimized

component placement — for

uncompromised grading ability,

regardless of which confi guration

you prefer.

BLADE CONFIGURATIONS

750J 750J LT 750J LGP

PAT

Semi-U

Straight

PAT

Semi-U

Straight

•••

•

850J 850J LT 850J WT 850J WLT 850J LGP

•••

•••

•

Page 14

Uncover new ways

Uncover new ways

to keep costs down.

to keep costs down.

Vertical fi lters allow quick, no-spill

changes. Engine, hydraulics, and

transmission utilize a common oil,

further simplifying service.

Swing open their hinged doors and you’ll uncover lots

of the ways these crawlers help keep maintenance to a

minimum. Same-side daily service points make quick

work of the daily routine, and extended engine oil and

Advanced in-cab monitor gives easy-

to-understand messages for quick

and easy troubleshooting without

special tools.

Operator station tilts a full 70 degrees

in only minutes, for wide-open access

to internal components. Unlike other

crawlers, there’s no need to disconnect

linkages, hydraulics, or wiring.

drivetrain service intervals let you work longer between

changes. Other timesaving features include an easy-to-

clean undercarriage, quick-to-replace hydraulic hoses,

and designed-in diagnostics, to list just a few.

PAGES

14–15

Page 15

Separate hydraulic and

hydrostatic reservoirs

eliminate any possibility of

cross-contamination. Sight

gauges give fl uid levels

at a glance.

Hinged side shields open

wide for ground-level

access to dipsticks, fi ll

tubes, batteries, master

electrical shutoff, and

engine, transmission,

and hydraulic fi lters.

Fluid sample ports and remote

drive system test ports simplify

preventative maintenance

work and troubleshooting for

increased uptime.

Remote lube banks provide

easy access to diffi cult-to-

reach crossbar and C-frame

pivots. Convenient lube chart

ensures that nothing gets

overlooked.

Five-hundred-hour engine oil

and 2,000-hour transmission

and hydraulic fl uid intervals

decrease downtime and

expense.

Page 16

Specifications

Specifications

Specifications

Engine 750J 750J LT 750J LGP

Manufacturer and Model .............. John Deere PowerTechTM 6068H John Deere PowerTech 6068H John Deere PowerTech 6068H

Non-Road Emission Standards .......... certified to EPA Tier 3 emissions certified to EPA Tier 3 emissions certified to EPA Tier 3 emissions

Cylinders .......................... 6 6 6

Displacement ....................... 414 cu. in. (6.8 L) 414 cu. in. (6.8 L) 414 cu. in. (6.8 L)

Net Peak Power (ISO9249) ............. 145 hp (108 kW) @ 2,100 rpm 145 hp (108 kW) @ 2,100 rpm 155 hp (116 kW) @ 2,100 rpm

Net Peak Torque (ISO9249) ............ 494 lb.-ft. (670 Nm) @ 1,400 rpm 494 lb.-ft. (670 Nm) @ 1,400 rpm 548 lb.-ft. (742 Nm) @ 1,400 rpm

Aspiration ......................... turbocharger air-to-air aftercooler air-to-air aftercooler

Air Cleaner ......................... dual-stage dry type with safety element, pre- dual-stage dry type with safety element, pre- dual-stage dry type with safety element, pre-

cleaner, and underhood restriction indicator cleaner, and underhood restriction indicator cleaner, and underhood restriction indicator

Slope Operation (maximum angle) ....... 45 deg. 45 deg. 45 deg.

Cooling 750J / 750J LT / 750J LGP

Variable-speed suction fan

Engine Coolant Rating ................ –34 deg. F (–37 deg. C)

Powertrain

Transmission ...................... automatic, dual-path, hydrostatic drive; load-sensing feature automatically adjusts speed and power to match changing load conditions; each individually

controlled track is powered by a variable-displacement piston pump and motor combination; ground-speed selection buttons on single-lever steering and

direction control; independently selectable reverse speed ratios 80%, 100%, 115%, or 130% of forward ground speed; decelerator pedal controls ground

speed to stop

System Relief Pressure ............ 6,650 psi (45 850 kPa)

Travel Speeds

Forward and Reverse .......... 6.3 mph (10.1 km/h)

Maximum (optional) ........... 6.8 mph (10.9 km/h)

Steering .......................... single-lever steering, speed, direction control, and counterrotation; full power turns and infinitely variable track speeds provide unlimited maneuverability

and optimum control; hydrostatic steering eliminates steering clutches and brakes

Final Drives ....................... double-reduction, planetary final drives transfer torque loads over three gear sets; mounted independently of track frames and dozer push frames for

isolation from shock loads

Total Ratio ..................... 46.4056 to 1

Drawbar Pull

Maximum .................. 55,000 lb. (244.6 kN)

@ 1.2 mph (1.9 km/h) ......... 33,000 lb. (146.8 kN)

@ 2.0 mph (3.2 km/h) ......... 22,000 lb. (97.9 kN)

Brakes ........................... decelerator/brake pedal; automatic power management with manual override for matching ground speed

Service Brakes ..................... hydrostatic (dynamic) braking stops machine when the direction/steering control lever is moved to neutral or the decelerator is depressed to the end of travel

Type .......................... hydraulic

Parking Brakes .................... exclusive park brake feature engages wet, multiple-disc brakes whenever the engine stops, whenever the combined decelerator/brake pedal is fully

depressed, whenever the unit is in neutral for three seconds (with detected motion), or whenever the park lock lever is in the park position; machine

cannot be driven with brake applied, reducing wear-out or need for adjustments; spring-applied, hydraulic release

Hydraulics 750J 750J LT 750J LGP

Load sense, piston pump

Blade Type ........................ PAT Outside dozer PAT PAT

Pump (63 cc) ....................... 38 gpm (144 L/m) 38 gpm (144 L/m) 38 gpm (144 L/m) 38 gpm (144 L/m)

System Relief Pressure ............... 3,625 psi 3,625 psi 3,625 psi (24 993 kPa) 3,625 psi (24 993 kPa)

(24 993 kPa) (24 993 kPa)

Differential Pressure ................. 275 psi (1896 kPa) 275 psi (1896 kPa) 275 psi (1896 kPa) 275 psi (1896 kPa)

Maximum Flow @ Unloaded High Idle ..... 37 gpm (140 L/m) 37 gpm (140 L/m) 37 gpm (140 L/m) 37 gpm (140 L/m)

Control ............................ T-bar hydraulic-pilot T-bar hydraulic-pilot T-bar hydraulic-pilot two-function joystick T-bar hydraulic-pilot two-function joystick

two-function joystick two-function joystick with push-button angle function with push-button angle function

with push-button

angle function

Cooling ........................... convective oil sump convective oil sump convective oil sump convective oil sump

PAGES

16–17

Page 17

Cylinders 750J / 750J LT / 750J LGP

Heat-treated, chrome-plated, polished cylinder rods, hardened steel (replaceable bushings) pivot pins

Electrical

Voltage ........................... 24 volt

Battery Capacity .................... 950 CCA

Reserve Capacity .................... 190 min.

Alternator Rating

Cab ........................... 80 amp

Canopy ........................ 55 amp

Lights ............................ 3 total: grille mounted (2) and rear mounted (1), and rear reflectors (2)

Undercarriage 750J 750J LT 750J LGP

Tracks ........................... track frame with front and rear track guides and sprocket guard; John Deere Dura-TraxTM features deep-heat-treated, sealed, and lubricated track links

and through-hardened, sealed, and lubricated rollers for maximum wear resistance; sprockets are segmented; extreme-duty shoes are available (on some

models) for severe applications

Blade Type ........................ PAT Outside dozer PAT PAT

Track Gauge (standard) ............... 6 ft. 2 in. (1880 mm) 6 ft. 2 in. (1880 mm) 6 ft. 2 in. (1880 mm) 7 ft. 0 in. (2134 mm)

Grouser Width (closed center,

single bar) ..................... 22 in. (559 mm) 22 in. (559 mm) 22 in. (559 mm) 34 in. (864 mm)

Chain ............................. sealed and lubricated sealed and lubricated sealed and lubricated sealed and lubricated

Shoes (each side) ................... 40 40 45 45

Track Rollers (single flange, each side) ... 7 7 8 8

Track Length on Ground .............. 8 ft. 6 in. (2591 mm) 8 ft. 6 in. (2591 mm) 10 ft. 1 in. (3073 mm) 10 ft. 1 in. (3073 mm)

Ground Contact Area ................. 4,488 sq. in. 4,488 sq. in. 5,324 sq. in. (34 348 cm

(28 955 cm

2

) (28 955 cm2)

Ground Pressure .................... 7.24 psi (49.9 kPa) 7.53 psi (51.9 kPa) 6.45 psi (44.5 kPa) 4.45 psi (30.7 kPa)

Track Pitch ........................ 7.5 in. (191 mm) 7.5 in. (191 mm) 7.5 in. (191 mm) 7.5 in. (191 mm)

Oscillation at Front Roller .............. ±4.3 in. (±110 mm) ±4.3 in. (±110 mm) ±5.3 in. (±135 mm) ±5.0 in. (±127 mm)

2

) 8,228 sq. in. (53 084 cm2)

Serviceability

Refill Capacities

Blade Type ........................ PAT Outside dozer PAT PAT

Fuel Tank with Lockable Cap ....... 98 gal. (371 L) 98 gal. (371 L) 98 gal. (371 L) 98 gal. (371 L)

Cooling System with Recovery

Tank ...................... 5.7 gal. (21.6 L) 5.7 gal. (21.6 L) 5.7 gal. (21.6 L) 5.7 gal. (21.6 L)

Engine Oil with Filter .............. 7.0 gal. (26.5 L) 7.0 gal. (26.5 L) 7.0 gal. (26.5 L) 7.0 gal. (26.5 L)

Transmission Reservoir with Filter .... 28 gal. (105.6 L) 28 gal. (105.6 L) 27.9 gal. (105.6 L) 28 gal. (106 L)

Hydraulic Reservoir and Filter ....... 28 gal. (105.6 L) 28 gal. (105.6 L) 27.9 gal. (105.6 L) 28 gal. (106 L)

Operating Weights

Base weights were computed for units with standard equipment, rollover protective structures, full fuel tanks, and 175-lb. (79 kg) operators.

Blade Type ........................ PAT Outside dozer PAT PAT

Base Weight .................... 32,585 lb. 33,865 lb. 34,395 lb. (15 599 kg) 36,725 lb. (16 655 kg)

(14 778 kg) (15 358 kg)

Refer to the Attachment Guide or see your dealer for details regarding Mechanical Angle blades for the 750J LT.

Blade, C-Frame, and Push-Beam Weights

Includes straight end bits.

Blade Type ........................ PAT Outside dozer PAT PAT

PAT ........................... 2,066 lb. (937 kg)* N/A 2,066 lb. (937 kg)* 2,383 lb. (1081 kg)*

Semi-U ........................ N/A 2,564 lb. (1163 kg)* N/A N/A

Straight ........................ N/A N/A N/A N/A

Push Beam Assemblies for Straight

or Semi-U Blades (without blade) .... N/A 3,242 lb. (1470 kg)* N/A N/A

PAT Dozer C-Frame Assemblies In-

cluding Cylinder (without blade) ..... 2,829 lb. (1283 kg)* N/A 2,905 lb. (1318 kg)* 2,905 lb. (1318 kg)*

*Included in SAE operating weight.

Refer to the Attachment Guide or see your dealer for details regarding Mechanical Angle blades for the 750J LT.

Blade Capacities

Blade Type ........................ PAT Outside dozer PAT PAT

PAT ........................... 130 in. (3295 mm) N/A 130 in. (3295 mm) 156 in. (3962 mm)

4.23 cu. yd. (3.23 m

Semi-U ........................ N/A 128 in. (3251 mm) N/A N/A

5.58 cu. yd. (4.27 m

Straight ........................ N/A N/A N/A N/A

Refer to the Attachment Guide or see your dealer for details regarding Mechanical Angle blades for the 750J LT.

3

) 4.23 cu. yd. (3.23 m3) 4.98 cu. yd. (3.81 m3)

3

)

Page 18

Optional or Special Equipment 750J 750J LT 750J LGP

Blade Type ........................ PAT Outside dozer PAT PAT

Tracks – Dura-Trax™ Lubricated

Chain with Split Master Link,

Single-Bar Grousers, and

Extended Life Undercarriage

22-in. (560 mm) Moderate

Duty ................... in base* in base* in base* N/A

22-in. (560 mm) Extreme

Duty ................... 263 lb. (119 kg) 263 lb. (119 kg) 296 lb. (134 kg) N/A

24-in. (610 mm) Moderate

Duty ................... 275 lb. (125 kg) 275 lb. (125 kg) 309 lb. (140 kg) N/A

24-in. (610 mm) Extreme

Duty ................... 566 lb. (257 kg) 566 lb. (257 kg) 637 lb. (289 kg) N/A

28-in. (710 mm) Moderate

Duty ................... N/A N/A N/A – 922 lb. (– 418 kg)

34-in. (865 mm) Moderate

Duty ................... N/A N/A N/A in base*

Cab with Pressurizer and Heater/

Air Conditioner .................. 743 lb. (337 kg) 743 lb. (337 kg) 743 lb. (337 kg) 743 lb. (337 kg)

Heater (ROPS canopy) ................ 85 lb. (39 kg) 85 lb. (39 kg) 85 lb. (39 kg) 85 lb. (39 kg)

Full-Length Rock Guard ............... 384 lb. (174 kg) 384 lb. (174 kg) 340 lb. (154 kg) 340 lb. (154 kg)

Final Drive Seal Guard ................ 155 lb. (70 kg) 155 lb. (70 kg) 155 lb. (70 kg) 155 lb. (70 kg)

Retrieval Hitch* ..................... 81 lb. (37 kg) 81 lb. (37 kg) 81 lb. (37 kg) 81 lb. (37 kg)

Drawbar, Extended Rigid .............. 286 lb. (130 kg) 286 lb. (130 kg) 286 lb. (130 kg) 286 lb. (130 kg)

Heavy-Duty Grille .................... 62 lb. (28 kg) 62 lb. (28 kg) 62 lb. (28 kg) 62 lb. (28 kg)

Front and Door Screens

ROPS Canopy ................... 186 lb. (84 kg) 186 lb. (84 kg) 186 lb. (84 kg) 186 lb. (84 kg)

Cab with Air Conditioner ........... 175 lb. (79 kg) 175 lb. (79 kg) 175 lb. (79 kg) 175 lb. (79 kg)

Rear Screen

ROPS Canopy ................... 50 lb. (23 kg) 50 lb. (23 kg) 50 lb. (23 kg) 50 lb. (23 kg)

Cab with Air Conditioner ........... 75 lb. (34 kg) 75 lb. (34 kg) 75 lb. (34 kg) 75 lb. (34 kg)

Side Screens

ROPS Canopy ................... 98 lb. (44 kg) 98 lb. (44 kg) 98 lb. (44 kg) 98 lb. (44 kg)

Cab with Air Conditioner ........... 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg)

Condenser Guard (cab with air

conditioner). . . . . . . . . . . . . . . . . . . . . 121 lb. (55 kg) 121 lb. (55 kg) 121 lb. (55 kg) 121 lb. (55 kg)

Limb Risers (ROPS canopy and cab) ..... 575 lb. (261 kg) 575 lb. (261 kg) 575 lb. (261 kg) 575 lb. (261 kg)

Lift-Cylinder Guards .................. 93 lb. (42 kg) 170 lb. (77 kg) 93 lb. (42 kg) 93 lb. (42 kg)

Blade Brush Guard ................... 192 lb. (87 kg) 192 lb. (87 kg) 192 lb. (87 kg) 192 lb. (87 kg)

Tank Guard ........................ 712 lb. (323 kg) 712 lb. (323 kg) 712 lb. (323 kg) 712 lb. (323 kg)

Counterweight

Front .......................... 550 lb. (249 kg) 550 lb. (249 kg) 550 lb. (249 kg) 550 lb. (249 kg)

Rear .......................... 720 lb. (326 kg) 720 lb. (326 kg) 720 lb. (326 kg) 720 lb. (326 kg)

*Included in SAE operating weight.

Machine Dimensions

Blade Type ........................ PAT Outside dozer PAT PAT

A Overall Height to Roof .............. 10 ft. 2 in. 10 ft. 2 in. 10 ft. 2 in. (3095 mm) 10 ft. 2 in. (3095 mm)

(3095 mm) (3095 mm)

Overall Height to Exhaust Stack ...... 9 ft. 11 in. 9 ft. 11 in. 9 ft. 11 in. (3020 mm) 9 ft. 11 in. (3020 mm)

(3020 mm) (3020 mm)

B Tread Depth with Single-Bar

Grouser

Moderate Duty .................. 2.2 in. (56 mm) 2.2 in. (56 mm) 2.2 in. (56 mm) 2.2 in. (56 mm)

Extreme Duty ................... 2.7 in. (68 mm) 2.7 in. (68 mm) 2.7 in. (68 mm) 2.7 in. (68 mm)

C Ground Clearance with Grousers

(excludes grouser height) ........... 14 in. (356.9 mm) 14 in. (356.9 mm) 14 in. (356.9 mm) 14 in. (356.9 mm)

D Blade Width ..................... 10 ft. 9.75 in. 10 ft. 8 in. 10 ft. 9.75 in. (3296 mm) 13 ft. 0 in. (3962 mm)

(3296 mm) (3251 mm)

E Blade Height ..................... 3 ft. 11 in. 4 ft. 0.8 in. 3 ft. 11 in. (1194 mm) 3 ft. 10.1 in. (1170 mm)

(1194 mm) (1240 mm)

F Blade Lift Height .................. 3 ft. 2.5 in. 3 ft. 5.3 in. 3 ft. 4.3 in. (1025 mm) 3 ft. 4.3 in. (1025 mm)

(979 mm) (1050 mm)

G Blade Digging Depth ............... 24.4 in. (620 mm) 22.6 in. (575 mm) 25.6 in. (650 mm) 25.6 in. (650 mm)

H Blade Tilt (uses tilt jack) ............ 17.2 in. (437 mm) 28.4 in. (722 mm) 17.2 in. (437 mm) 20.6 in. (524 mm)

I Overall Length with Blade* .......... 16 ft. 4.5 in. 17 ft. 1 in. 17 ft. 4.5 in. (5300 mm) 17 ft. 4.5 in. (5300 mm)

(4990 mm) (5205 mm)

*Optional extended drawbar adds 11 in. (279.5 mm).

PAGES

18–19

Page 19

G

Extended Drawbar

I

Standard Drawbar

A

B

C

EOF

SPEED

DRAWBAR PULL X 1000 lb. (N) (kg)

lb.

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

N

40

80

120

160

200

240

280

320

750J / LT

750J LGP

km/h 024 6 8 10 12

0 1 2 3 4 5 6 7 8

32

28

24

20

16

12

8

4

CRAWLER SPEED

VS

GROUND PULL

Usable pull will depend

on traction and weight of tractor.

mph

kg

Machine Dimensions

H

D

M

N

L

K

J

Width Over Track

Cut Reach

Cast Reach

T

Q

P

R

|

R

V

U S

V

(continued)

750J 750J LT 750J LGP

Blade Type ........................ PAT Outside dozer PAT PAT

J Overall Width with Blade Angled ...... 9 ft. 10.9 in. N/A 9 ft. 10.9 in. (3020 mm) 11 ft. 10.9 in. (3631 mm)

(3020 mm)

K Blade Angle ..................... 23.5 deg. N/A 23.5 deg. 23.5 deg.

L Cut Reach ....................... 4.3 in. (108 mm) N/A 4.3 in. (108 mm) 3.3 in. (84 mm)

M Width Over Track ................. 8 ft. 0 in. (2438 mm) 8 ft. 0 in. (2438 mm) 8 ft. 0 in. (2438 mm) 9 ft. 10 in. (2997 mm)

N Cast Reach ...................... 8.8 in. (224 mm) N/A 8.8 in. (224 mm) 11.7 in. (297 mm)

O Cutting Edge Angle ................ 55.2–60.1 deg. 50.5–60.0 deg. 55.2–60.1 deg. 55.2–60.1 deg.

Rear Ripper 750J / 750J LT / 750J LGP

Multi-shank (3) parallelogram ripper with hydraulic pitch adjustment and ESCO ripper tips

Weight ......................... 3,725 lb. (1690 kg)

P Maximum Penetration. . . . . . . . . . . . . . 27 in. (686 mm)

Q Maximum Clearance Under Tip ....... 27 in. (686 mm)

R Overall Length (lowered position) ..... 5 ft. 7 in. (1689 mm)

|

R

Overall Length (raised position) ...... 4 ft. 9 in. (1448 mm)

S Overall Beam Width ............... 7 ft. 0 in. (2134 mm)

T Slope Angle (full raise) ............. 22 deg.

U Ripping Width .................... 6 ft. 2 in. (1880 mm)

V Distance Between Shanks .......... 35.5 in. (902 mm)

Page 20

Specifications

Specifications

Specifications

Engine 850J / 850J LT / 850J WT / 850J WLT 850J LGP

For use in U.S., For use outside U.S., For use in U.S., For use outside U.S.,

Canada, and Europe Canada, and Europe Canada, and Europe Canada, and Europe

Manufacturer and Model ..............John Deere PowerTech

Non-Road Emissions Standards. . . . . . . . . EPA Tier 3 / EU Stage IIIA EPA Tier 2 / EU Stage II EPA Tier 3 / EU Stage IIIA EPA Tier 2 / EU Stage II

Cylinders ..........................6 6 6 6

Displacement . . . . . . . . . . . . . . . . . . . . . . 550 cu. in. (9.0 L) 496 cu. in. (8.1 L) 550 cu. in. (9.0 L) 496 cu. in. (8.1 L)

Net Peak Power (ISO9249) . . . . . . . . . . . . 185 hp (137 kW) @ 1,800 rpm 185 hp (137 kW) @ 1,800 rpm 200 hp (152 kW) @ 1,800 rpm 200 hp (151 kW) @ 1,800 rpm

Net Peak Torque (ISO9249) ............611 lb.-ft. (828 Nm) @ 1,500 rpm 590 lb.-ft. (800 Nm) @ 1,400 rpm 675 lb.-ft. (915 Nm) @ 1,500 rpm 650 lb.-ft. (880 Nm) @ 1,400 rpm

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . turbocharger and air-to-air aftercooler turbocharger and air-to-air aftercooler turbocharger and air-to-air aftercooler turbocharger and air-to-air aftercooler

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . dual-stage dry type with tangential dual-stage dry type with tangential dual-stage dry type with tangential dual-stage dry type with tangential

unloader unloader unloader unloader

Slope Operation (maximum angle) .......45 deg. 45 deg. 45 deg. 45 deg.

Cooling 850J / 850J LT / 850J WT / 850J WLT / 850J LGP

Variable-speed suction fan

Engine Coolant Rating ................–34 deg. F (–37 deg. C)

Powertrain 850J 850J LT 850J WT 850J WLT 850J LGP

Transmission ......................automatic, dual-path, hydrostatic drive; load-sensing feature automatically adjusts speed and power to match changing load conditions; each individually controlled

track is powered by a variable-displacement piston pump and motor combination; ground-speed selection buttons on single-lever steering and direction control; inde pendently selectable reverse speed ratios 80%, 100%, 115%, or 130% of forward ground speed; decelerator pedal controls ground speed to stop

System Relief Pressure . . . . . . . . . . . 6,650 psi (45 850 kPa)

Travel Speeds

Forward and Reverse .........6.3 mph (10.1 km/h)

Maximum (optional) . . . . . . . . . . 6.8 mph (10.9 km/h)

Steering ..........................single-lever steering, speed, direction control, and counterrotation; full power turns and infinitely variable track speeds provide unlimited maneuverability and optimum

control; hydrostatic steering eliminates steering clutches and brakes

Final Drives . . . . . . . . . . . . . . . . . . . . . . . double-reduction, planetary final drives transfer torque loads over three gear sets; mounted independently of track frames double-reduction (spur gear set and

and dozer push frames for isolation from shock loads planetary) transfer shock loads; mounted

independently of track frames and dozer

push frames for isolation from shock loads

Total Ratio .....................44.7483 to 1 44.7483 to 1

Drawbar Pull

Maximum ..................77,300 lb. (344 kN) 77,300 lb. (344 kN)

@ 1.2 mph (1.9 km/h) . . . . . . . . 37,500 lb. (167 kN) 40,000 lb. (178 kN)

@ 2.0 mph (3.2 km/h) . . . . . . . . 27,000 lb. (120 kN) 29,500 lb. (131 kN)

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . decelerator/brake pedal; automatic power management with manual override for matching ground speed

Service Brakes . . . . . . . . . . . . . . . . . . . . hydrostatic (dynamic) braking stops machine when the direction/steering control lever is moved to neutral or the decelerator is depressed to the end of travel

Type . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic

Parking Brakes . . . . . . . . . . . . . . . . . . . . exclusive safety feature engages wet, multiple-disc brakes whenever the engine stops, whenever the decelerator is depressed to the end of travel, or whenever the

park lock lever is placed in the start or neutral position and motion is detected; machine cannot be driven with brake applied, reducing wear-out or need for adjustment;

spring-applied, hydraulic release

TM

Plus 6090HT John Deere PowerTech 6081 John Deere PowerTech Plus 6090HT John Deere PowerTech 6081

Hydraulics

Load sense, piston pump

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

Pump (74 cc). . . . . . . . . . . . . . . . . . . . . . . 46 gpm (174 L/m) 46 gpm (174 L/m) 46 gpm (174 L/m) 46 gpm (174 L/m) 46 gpm (174 L/m) 46 gpm (174 L/m)

System Relief Pressure ...............3,625 psi (24 993 kPa) 3,625 psi (24 993 kPa) 3,625 psi (24 993 kPa) 3,625 psi (24 993 kPa) 3,625 psi 3,625 psi

(24 993 kPa) (24 993 kPa)

Differential Pressure . . . . . . . . . . . . . . . . . 275 psi (1896 kPa) 275 psi (1896 kPa) 275 psi (1896 kPa) 275 psi (1896 kPa) 275 psi (1896 kPa) 275 psi (1896 kPa)

Maximum Flow @ Unloaded High Idle ....43 gpm (163 L/m) 43 gpm (163 L/m) 43 gpm (163 L/m) 43 gpm (163 L/m) 43 gpm (163 L/m) 43 gpm (163 L/m)

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . T-bar hydraulic-pilot two- T-bar hydraulic-pilot two- T-bar hydraulic-pilot two- T-bar hydraulic-pilot two- T-bar hydraulic- T-bar hydraulic-

function joystick function joystick with push- function joystick function joystick with push- pilot two-function pilot two-function

button angle function button angle function joystick with joystick

push-button

angle function

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . convective oil sump convective oil sump convective oil sump convective oil sump convective convective

oil sump oil sump

PAGES

20–21

Page 21

Cylinders 850J / 850J LT / 850J WT / 850J WLT / 850J LGP

Heat-treated, chrome-plated, polished cylinder rods, hardened steel (replaceable bushings) pivot pins

Electrical

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 volt

Battery Capacity . . . . . . . . . . . . . . . . . . . . 950 CCA

Reserve Capacity. . . . . . . . . . . . . . . . . . . . 190 min.

Alternator Rating

Cab . . . . . . . . . . . . . . . . . . . . . . . . . . 80 amp

Canopy . . . . . . . . . . . . . . . . . . . . . . . 55 amp

Lights ............................3 total: grille mounted (2) and rear mounted (1), and rear reflectors (2)

Undercarriage 850J 850J LT 850J WT 850J WLT 850J LGP

Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . track frame with front and rear track guides and sprocket guard; John Deere Dura-TraxTM features deep-heat-treated, sealed, and lubricated track links and through-

hardened, sealed, and lubricated rollers for maximum wear resistance; sprockets are segmented; extreme-duty shoes are available (on some models) for severe applications

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

Track Gauge (standard) ...............6 ft. 2 in. (1880 mm) 6 ft. 10 in. (2083 mm) 6 ft. 8 in. (2032 mm) 7 ft. 4 in. (2235 mm) 7 ft. 10 in. 7 ft. 2 in.

(2388 mm) (2184 mm)

Grouser Width (closed center, single bar) ...24 in. (610 mm) 24 in. (610 mm) 30 in. (762 mm) 30 in. (762 mm) 36 in. (914 mm) 36 in. (914 mm)

Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . sealed and lubricated sealed and lubricated sealed and lubricated sealed and lubricated sealed and sealed and

lubricated lubricated

Shoes (each side) . . . . . . . . . . . . . . . . . . . 40 45 40 45 45 45

Track Rollers (single flange, each side) ...7 8 7 8 8 8

Track Length on Ground . . . . . . . . . . . . . . 9 ft. 1 in. (2769 mm) 10 ft. 9 in. (3284 mm) 9 ft. 1 in. (2769 mm) 10 ft. 9 in. (3284 mm) 10 ft. 9 in. 10 ft. 9 in.

(3284 mm) (3284 mm)

Ground Contact Area .................5,232 sq. in. (33 755 cm2) 6,206 sq. in. (40 039 cm2) 6,540 sq. in. (42 193 cm2) 7,758 sq. in. (50 052 cm2) 9,310 sq. in. 9,310 sq. in.

(60 064 cm2) (60 064 cm2)

Ground Pressure ....................7.61 psi (52.5 kPa) 6.87 psi (47.4 kPa) 6.26 psi (43.2 kPa) 5.65 psi (39.0 kPa) 4.83 psi (33.3 kPa) 4.80 psi (33.1 kPa)

Track Pitch . . . . . . . . . . . . . . . . . . . . . . . . 8 in. (203 mm) 8 in. (203 mm) 8 in. (203 mm) 8 in. (203 mm) 8 in. (203 mm) 8 in. (203 mm)

Oscillation at Front Roller . . . . . . . . . . . . . ±4.5 in. (±114 mm) ±6.6 in. (±168 mm) ±4.5 in. (±114 mm) ±6.5 in. (±166.5 mm) ±6.6 in. ±6.6 in.

(±168 mm) (±168 mm)

Serviceability

Refill Capacities

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

Fuel Tank with Lockable Cap .......98 gal. (371 L) 98 gal. (371 L) 98 gal. (371 L) 98 gal. (371 L) 98 gal. (371 L) 98 gal. (371 L)

Cooling System with Recovery Tank ...9.2 gal. (35 L) 9.2 gal. (35 L) 9.2 gal. (35 L) 9.2 gal. (35 L) 9.2 gal. (35 L) 9.2 gal. (35 L)

Engine Oil with Filter . . . . . . . . . . . . . 7 gal. (26 L) 7 gal. (26 L) 7 gal. (26 L) 7 gal. (26 L) 7 gal. (26 L) 7 gal. (26 L)

Transmission Reservoir with Filter ...28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L)

Hydraulic Reservoir and Filter . . . . . . 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L) 28 gal. (106 L)

Operating Weights

Base weights were computed for units with standard equipment, rollover protective structures, full fuel tanks, and 175-lb. (79 kg) operators.

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

Base Weight . . . . . . . . . . . . . . . . . . . 40,165 lb. (18 220 kg) 43,015 lb. (19 510 kg) 41,285 lb. (18 725 kg) 44,225 lb. (20 060 kg) 45,375 lb. 45,075 lb.

(20 580 kg) (20 445 kg)

Refer to the Attachment Guide or see your dealer for details regarding Mechanical Angle blades for the 850J LT.

Blade, C-Frame, and Push-Beam Weights

Includes straight end bits.

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

PAT . . . . . . . . . . . . . . . . . . . . . . . . . . N/A 2,758 lb. (1251 kg)* N/A 2,932 lb. (1330 kg)* 3,080 lb. N/A

(1397 kg)*

Semi-U . . . . . . . . . . . . . . . . . . . . . . . 2,923 lb. (1326 kg)* N/A 3,110 lb. (1411 kg)* N/A N/A 3,225 lb.

(1463 kg)*

Straight . . . . . . . . . . . . . . . . . . . . . . . N/A N/A N/A N/A N/A 2,846 lb.

(1291 kg)

Push Beam Assemblies for Straight or

Semi-U Blades (without blade) ......3,687 lb. (1672 kg)* N/A 3,757 lb. (1704 kg)* N/A N/A 4,196 lb.

(1903 kg)

PAT Dozer C-Frame Assemblies Includ-

ing Cylinder (without blade) ........N/A 3,631 lb. (1647 kg)* N/A 3,631 lb. (1647 kg)* 3,631 lb. N/A

(1647 kg)*

*Included in SAE operating weight.

Refer to the Attachment Guide or see your dealer for details regarding Mechanical Angle blades for the 850J LT.

Blade Capacities

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

PAT . . . . . . . . . . . . . . . . . . . . . . . . . . N/A 146 in. (3708 mm) N/A 158 in. (4013 mm) 168 in. (4267 mm) N/A

5.15 cu. yd. (3.94 m3) 5.57 cu. yd. (4.26 m3) 5.87 cu. yd.

(4.49 m3)

Semi-U . . . . . . . . . . . . . . . . . . . . . . . 128 in. (3251 mm) N/A 140 in. (3556 mm) N/A N/A 152 in. (3861 mm)

7.29 cu. yd. (5.57 m3) 7.62 cu. yd. (5.82 m3) 7.80 cu. yd.

(5.96 m3)

Straight . . . . . . . . . . . . . . . . . . . . . . . N/A N/A N/A N/A N/A 154 in. (3912 mm)

5.35 cu. yd.

(4.09 m3)

Refer to the Attachment Guide or see your dealer for details regarding Mechanical Angle blades for the 850J LT.

Page 22

Optional or Special Equipment 850J 850J LT 850J WT 850J WLT 850J LGP

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

Tracks – Dura-Trax™ Lubricated

Chain with Split Master Link,

Single-Bar Grousers, and Extended

Life Undercarriage

22-in. (560 mm) Extreme Duty. . . . 341 lb. (155 kg) 384 lb. (174 kg) – 482 lb. (– 219 kg) N/A N/A N/A

24-in. (610 mm) Moderate Duty . . . in base* in base* – 823 lb. (– 374 kg) N/A – 1,868 lb. – 1,868 lb.

(– 847 kg) (– 847 kg)

24-in. (610 mm) Extreme Duty. . . . 676 lb. (307 kg) 760 lb. (345 kg) – 148 lb. (– 67 kg) N/A – 1,108 lb. – 1,108 lb.

(– 503 kg) (– 503 kg)

30-in. (760 mm) Moderate Duty . . . N/A N/A in base* in base* – 942 lb. N/A

(– 427 kg)

30-in. (760 mm) Extreme Duty. . . . N/A N/A 855 lb. (388 kg) 961 lb. (436 kg) 20 lb. (9 kg) N/A

36-in. (910 mm) Moderate Duty . . . N/A N/A N/A N/A in base* in base*

36-in. (910 mm) Extreme Duty. . . . N/A N/A N/A N/A 1,153 lb. (523 kg) 1,153 lb. (523 kg)

Cab with Pressurizer and Heater/Air

Conditioner . . . . . . . . . . . . . . . . . . . . 743 lb. (337 kg) 743 lb. (337 kg) 743 lb. (337 kg) 743 lb. (337 kg) 743 lb. (337 kg) 743 lb. (337 kg)

Heater (ROPS canopy) ................85 lb. (39 kg) 85 lb. (39 kg) 85 lb. (39 kg) 85 lb. (39 kg) 85 lb. (39 kg) 85 lb. (39 kg)

Full-Length Rock Guard ...............534 lb. (224 kg) 490 lb. (222 kg) 534 lb. (224 kg) 490 lb. (222 kg) 490 lb. 490 lb.

(222 kg) (222 kg)

Final Drive Seal Guard ................155 lb. (70 kg) 155 lb. (70 kg) 155 lb. (70 kg) 155 lb. (70 kg) 155 lb. (70 kg) 155 lb. (70 kg)

Retrieval Hitch* .....................114 lb. (52 kg) 114 lb. (52 kg) 114 lb. (52 kg) 114 lb. (52 kg) 114 lb. (52 kg) 114 lb. (52 kg)

Drawbar, Extended Rigid ..............286 lb. (130 kg) 286 lb. (130 kg) 286 lb. (130 kg) 286 lb. (130 kg) 286 lb. (130 kg) 286 lb. (130 kg)

Heavy-Duty Grille . . . . . . . . . . . . . . . . . . . 86 lb. (39 kg) 86 lb. (39 kg) 86 lb. (39 kg) 86 lb. (39 kg) 86 lb. (39 kg) 86 lb. (39 kg)

Front and Door Screens

ROPS Canopy ...................186 lb. (84 kg) 186 lb. (84 kg) 186 lb. (84 kg) 186 lb. (84 kg) 186 lb. (84 kg) 186 lb. (84 kg)

Cab with Air Conditioner . . . . . . . . . . 175 lb. (79 kg) 175 lb. (79 kg) 175 lb. (79 kg) 175 lb. (79 kg) 175 lb. (79 kg) 175 lb. (79 kg)

Rear Screen

ROPS Canopy ...................50 lb. (23 kg) 50 lb. (23 kg) 50 lb. (23 kg) 50 lb. (23 kg) 50 lb. (23 kg) 50 lb. (23 kg)

Cab with Air Conditioner . . . . . . . . . . 75 lb. (34 kg) 75 lb. (34 kg) 75 lb. (34 kg) 75 lb. (34 kg) 75 lb. (34 kg) 75 lb. (34 kg)

Side Screens

ROPS canopy ...................98 lb. (44 kg) 98 lb. (44 kg) 98 lb. (44 kg) 98 lb. (44 kg) 98 lb. (44 kg) 98 lb. (44 kg)

Cab with Air Conditioner . . . . . . . . . . 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg)

Condenser Guard (cab with air

conditioner) . . . . . . . . . . . . . . . . . . . . 121 lb. (55 kg) 121 lb. (55 kg) 121 lb. (55 kg) 121 lb. (55 kg) 121 lb. (55 kg) 121 lb. (55 kg)

Limb Risers (ROPS canopy and cab) . . . . . 600 lb. (272 kg) 600 lb. (272 kg) 600 lb. (272 kg) 600 lb. (272 kg) 600 lb. (272 kg) 600 lb. (272 kg)

Lift-Cylinder Guards . . . . . . . . . . . . . . . . . 176 lb. (80 kg) 93 lb. (42 kg) 176 lb. (80 kg) 93 lb. (42 kg) 93 lb. (42 kg) 176 lb. (80 kg)

Blade Brush Guard . . . . . . . . . . . . . . . . . . 192 lb. (87 kg) 192 lb. (87 kg) 192 lb. (87 kg) 192 lb. (87 kg) 192 lb. (87 kg) 192 lb. (87 kg)

Tank Guard ........................712 lb. (323 kg) 712 lb. (323 kg) 712 lb. (323 kg) 712 lb. (323 kg) 712 lb. (323 kg) 712 lb. (323 kg)

Counterweight

Front . . . . . . . . . . . . . . . . . . . . . . . . . 875 lb. (397 kg) 875 lb. (397 kg) 875 lb. (397 kg) 875 lb. (397 kg) 875 lb. (397 kg) 875 lb. (397 kg)

Rear ..........................990 lb. (449 kg) 990 lb. (449 kg) 990 lb. (449 kg) 990 lb. (449 kg) 990 lb. (449 kg) 990 lb. (449 kg)

*Included in SAE operating weight.

Machine Dimensions

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

A Overall Height to Roof . . . . . . . . . . . . . 10 ft. 5 in. (3180 mm) 10 ft. 5 in. (3180 mm) 10 ft. 5 in. (3180 mm) 10 ft. 5 in. (3180 mm) 10 ft. 5 in. 10 ft. 5 in.

(3180 mm) (3180 mm)

Overall Height to Exhaust Stack ......10 ft. 5.5 in. (3190 mm) 10 ft. 5.5 in. (3190 mm) 10 ft. 5.5 in. (3190 mm) 10 ft. 5.5 in. (3190 mm) 10 ft. 5.5 in. 10 ft. 5.5 in.

(3190 mm) (3190 mm)

B Tread Depth with Single-Bar Grouser

Moderate Duty ...............2.6 in. (65 mm) 2.6 in. (65 mm) 2.6 in. (65 mm) 2.6 in. (65 mm) 2.6 in. (65 mm) 2.6 in. (65 mm)

Extreme Duty ................2.8 in. (72 mm) 2.8 in. (72 mm) 2.8 in. (72 mm) 2.8 in. (72 mm) 2.8 in. (72 mm) 2.8 in. (72 mm)

C Ground Clearance with Grousers

(excludes grouser height). . . . . . . . . . . 16.1 in. (408.5 mm) 16.1 in. (408.5 mm) 16.1 in. (408.5 mm) 16.1 in. (408.5 mm) 16.1 in. 16.1 in.

(408.5 mm) (408.5 mm)

D Blade Width .....................10 ft. 8 in. (3251 mm) 12 ft. 2 in. (3708 mm) 11 ft. 8 in. (3556 mm) 13 ft. 2 in. (4013 mm) 14 ft. 0 in. 12 ft 8 in.

(4267 mm) (3861 mm)

E Blade Height . . . . . . . . . . . . . . . . . . . . 4 ft. 8 in. (1422 mm) 4 ft. 0.4 in. (1230 mm) 4 ft. 6.1 in. (1375 mm) 4 ft. 0.4 in. (1230 mm) 4 ft. 0.4 in. 4 ft. 4 in.

(1230 mm) (1320 mm)

F Blade Lift Height . . . . . . . . . . . . . . . . . 3 ft. 9.3 in. (1150 mm) 3 ft. 6.2 in. (1071 mm) 3 ft. 9.3 in. (1150 mm) 3 ft. 6.2 in. (1071 mm) 3 ft. 6.2 in. 3 ft. 9.3 in.

(1071 mm) (1150 mm)

G Blade Digging Depth . . . . . . . . . . . . . . 23.6 in. (600 mm) 27.7 in. (703 mm) 23.6 in. (600 mm) 27.7 in. (703 mm) 27.7 in. (703 mm) 23.6 in. (600 mm)

H Blade Tilt (uses tilt jack) . . . . . . . . . . . 29.6 in. (753 mm) 19.6 in. (498 mm) 29.6 in. (753 mm) 21.2 in. (538 mm) 22.5 in. (572 mm) 33.6 in. (854 mm)

I Overall Length with Blade* . . . . . . . . . 17 ft. 8 in. (5377 mm) 18 ft. 9.5 in. (5726 mm) 17 ft. 8 in. (5377 mm) 18 ft. 9.5 in. (5726 mm) 18 ft. 9.5 in. 19 ft. 6 in.

(5726 mm) (5940 mm)

J Overall Width with Blade Angled . . . . . N/A 11 ft. 1.5 in. (3390 mm) N/A 12 ft. 0 in. (3658 mm) 12 ft. 9.6 in. N/A

(3901 mm)

K Blade Angle .....................N/A 23.8 deg. N/A 23.8 deg. 23.8 deg. N/A

L Cut Reach . . . . . . . . . . . . . . . . . . . . . . N/A 6.2 in. (158 mm) N/A 5.7 in. (145 mm) 4.3 in. (109 mm) N/A

*Optional extended drawbar adds 9.5 in. (241.5 mm).

PAGES

22–23

Page 23

SPEED

DRAWBAR PULL X 1000 lb. (N) (kg)

lb.

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

N

40

80

120

160

200

240

280

320

850J / LT / WT / WLT

850J LGP

km/h 024 6 8 10 12

0 1 2 3 4 5 6 7 8

32

28

24

20

16

12

8

4

CRAWLER SPEED

VS

GROUND PULL

Usable pull will depend

on traction and weight of tractor.

mph

kg

80

Machine Dimensions

T

Q

P

R

|

R

V

U S

V

G

Extended Drawbar

I

Standard Drawbar

A

B

C

EOF

D

H

M

N

L

K

J

Width Over Track

Cut Reach

Cast Reach

(continued)

850J 850J LT 850J WT 850J WLT 850J LGP

Blade Type . . . . . . . . . . . . . . . . . . . . . . . . Outside dozer PAT Outside dozer PAT PAT Outside dozer

M Width Over Track .................8 ft. 2 in. (2489.2 mm) 8 ft. 10 in. (2692.4 mm) 9 ft. 2 in. (2794 mm) 9 ft. 10 in. (2997.2 mm) 10 ft. 10 in. 10 in. 2 in.

(3302 mm) (3098.8 mm)

N Cast Reach . . . . . . . . . . . . . . . . . . . . . N/A 11.2 in. (284 mm) N/A 10.7 in. (271 mm) 9.2 in. (234 mm) N/A

O Cutting Edge Angle . . . . . . . . . . . . . . . 51.5–61.0 deg. 55.1–60.2 deg. 51.5–61.0 deg. 55.1–60.2 deg. 55.1–60.2 deg. 51.5–61.0 deg.

Rear Ripper

850J / 850J LT / 850J WT / 850J WLT / 850J LGP

Multi-shank (3) parallelogram ripper with hydraulic pitch adjustment and ESCO ripper tips

Weight .........................4,480 lb. (2032 kg)

P Maximum Penetration . . . . . . . . . . . . . 28.5 in. (724 mm)

Q Maximum Clearance Under Tip . . . . . . 24 in. (610 mm)

R Overall Length (lowered position) .....5 ft. 4 in. (1626 mm)

|

R

Overall Length (raised position) . . . . . . 5 ft. 0 in. (1524 mm)

S Overall Beam Width ...............7 ft. 11 in. (2400 mm)

T Slope Angle (full raise) .............24 deg.

U Ripping Width . . . . . . . . . . . . . . . . . . . 7 ft. 1 in. (2146 mm)

V Distance Between Shanks ..........3 ft. 5 in. (1041 mm)

Page 24

750J / 850J CRAWLER DOZERS

Key: l Standard equipment s Optional or special equipment *See your John Deere dealer for further information.

750J 850J Engine

lCertified to EPA Tier 3 emissions

l Certified to EPA Tier 3 and EU Stage IIIA emissions

s Certified to EPA Tier 2 and EU Stage II emissions

l l Electronic control with automatic engine protection

l l Dual safety element dry-type air cleaner, evacuator valve

l l Muffler, self draining, under hood, with vertical stack

l l Environmental service drains

s s Ether start aid

s s Chrome exhaust

s s Rotary ejector engine air precleaner

Cooling

l l Cooling fan, suction type, programmable reversing

lEngine coolant radiator (10 fins per in.)

l Engine coolant radiator (6 fins per in.)

lHydrostatic cooler (oil/air – 10 fins per in.)

l Hydrostatic cooler (oil/air – 6 fins per in.)

l l Hydraulic cooler (oil/air – 6 fins per in.)

l l Enclosed safety fan guard (conforms to SAE J1308 and ISO3457)

l l Perforated engine side shields

l l Split-hinge bar-type grille

s s Extreme-duty grille

Transmission

l l Diagnostic test ports

l l Environmental service drains

s s Final-drive seal guards

Hydraulic System

l l Two-function hydraulics

s s Three-function hydraulics

s s Four-function hydraulics with rear plumbing

s s High-flow hydraulic pump and hydraulic cooler for use with winch

s s Integrated Grade Control (IGC)

Mainframe, Access Panels

l l Tilt operator station transmission access

l l Front tow loop (bolt-on)

l l Integral bottom protection

l l Hinged bottom access covers (bolt-on)

l l Vandal protection: Engine access door / Side tank access doors / Fuel

tank / Instrument panel / Transmission reservoir / Hydraulic reservoir

l l Maintenance-free center crossbar pivot

750J 850J Attachments

s s Retrieval hitch with pin

s s Extended rigid drawbar with pin for pull-type implements

s s Counterweight, rear, 720 lb. (327 kg)

s s Counterweight, rear, 1,000 lb. (454 kg)

s s Ripper, rear, three shank

s s Winch, hydrostatically driven*

s s Forestry screens*

Undercarriage

l l Oscillating undercarriage with remote lube

l l Full-length, smooth-surface track frame covers

l l Guides, front and rear, with bolt-on wear strips

l l Segmented sprockets

l l Double-flange rollers

s s Extended life undercarriage SC-2

TM

bushings

s s Full-length rock guards

Canopy Cab

Operator’s Station / Electrical

l l Retractable seat belts, 3 in. (76 mm) (conforms to SAE J386)

l l Convex interior rearview mirror, 4-in. (102 mm) tall, 8-in. (203 mm)

wide (conforms to SAE J985)

l l Power port, 12 volts

s s Second power port, 12 volts

l l Lockable dash-mounted storage compartment

l Air conditioner, 24,000 Btu

l Tinted glass

l Dome light

l Heater (roof mount)

l Front and door wipers

l Mechanical suspension vinyl seat

l Mechanical suspension fabric seat

s Air suspension vinyl seat

s Air suspension fabric seat

s Under-seat heater

s Rear wiper, two speed

s AM/FM, weather-band radio, clock

s External-mounted attachment mirror

l l Sealed alternator, 55 amps

l l Master electrical disconnect switch

l l Lights, grille mounted (2), rear mounted (1)

s s Work lights (4), roof mounted

l l JDLink

TM

Ultimate wireless communication system

CONTROL OWNING AND OPERATING COSTS

Customer Personal Service (CPS) is part of John Deere’s proactive, fix-before-fail

strategy on machine maintenance that will help control costs, increase profits, and

reduce stress. Included in this comprehensive lineup of ongoing programs and services are:

Fluid analysis program – tells you what’s going on inside all of your machine’s

major components so you’ll know if there’s a problem before you see a decline in

performance. Fluid analysis is included in most extended coverage and preventivemaintenance agreements.

Component life-cycle data – gives you vital information on the projected life

span of components and lets you make informed decisions on machine maintenance

by telling you approximately how many hours of use you can expect from an

engine, transmission, or hydraulic pump. This information can be used to preempt

catastrophic downtime by servicing major components at about 80 percent of

their life cycle.

Preventive Maintenance (PM) agreements – give you a fixed cost for maintaining a machine for a given period of time. They also help you avoid downtime

Net engine power is with standard equipment including air cleaner, exhaust system, alternator, and

cooling fan at test conditions per ISO9249. No derating is required up to 10,000-ft. (3050 m) altitude.

Also available: winches, fair-leads, log arches, skidding grapples, trash packages, landfill protection

packages, cable plows, side booms, field-installed cab for canopy, canopy heater, and fire suppression systems.

10-05-09

by ensuring that critical maintenance work gets done right and on schedule. Onsite preventive maintenance service performed where and when you need it helps

protect you from the expense of catastrophic failures and lets you avoid wastedisposal hassles.

Extended coverage – gives you a fixed cost for machine repairs for a given

period of time so you can effectively manage costs. Whether you work in a severeservice setting or just want to spread the risk of doing business, this is a great

way to custom-fit coverage for your operation. And an extended coverage contract

also travels well because it’s backed by John Deere and is honored by all Deere

construction dealers.

Customer Support Advisors (CSAs) – Deere believes the CSA program lends

a personal quality to Customer Personal Service (CPS). Certified CSAs have the

knowledge and skills for helping make important decisions on machine maintenance and repair. Their mission is to help you implement a plan that’s right for

your business and take the burden of machine maintenance off your shoulders.

Specifications and design subject to change without notice. Wherever applicable, specifications are

in accordance with SAE standards. Except where otherwise noted, these specifications are based

on units with rollover protective structures, full fuel tanks, 175-lb. (79 kg) operators, and standard

equipment; 750J LT unit with 22-in. (560 mm) moderate-duty grousers, rigid drawbar, and Semi-U

(High-Production) blade; and 750J WT and LGP units with 34-in. (865 mm) single-bar grousers and

rigid drawbars.

Loading...

Loading...