Page 1

185–200 NET HORSEPOWER

DOZER

J

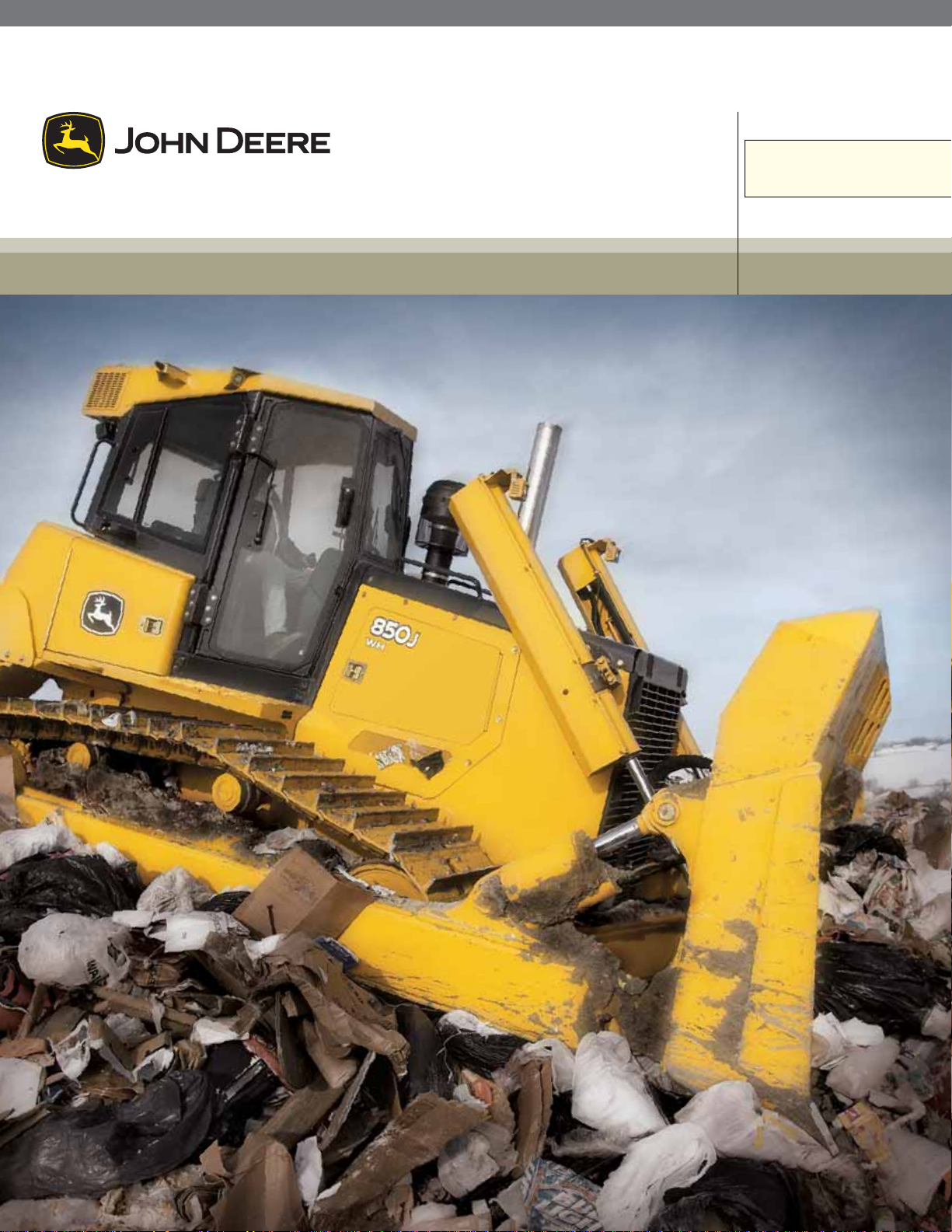

850J WASTE HANDLER

Page 2

Pur pose-built f or

Pur pose-built f or

Pur pose-built f or

handling waste.

handling waste.

handling waste.

850J Waste Handler Outside Dozer

with Semi-U Blade

WT undercarriage

185 hp net horsepower

7.62-cu.-yd. capacity

14.5-cu.-yd. capacity with trash rack

44,261-lb. operating weight

LGP undercarriage

200 hp net horsepower

7.8-cu.-yd. capacity

15.2-cu.-yd. capacity with trash rack

48,263-lb. operating weight

PAGES

2–3

Page 3

With their full-featured hydrostatic drive-

also have what they need to keep their cool

trains, 850J Waste Handlers deliver

production-boosting advantages you just

don’t get with other crawlers in this class.

But powerful performance is just the start of

the 850J WH story .These 24-ton workhorses

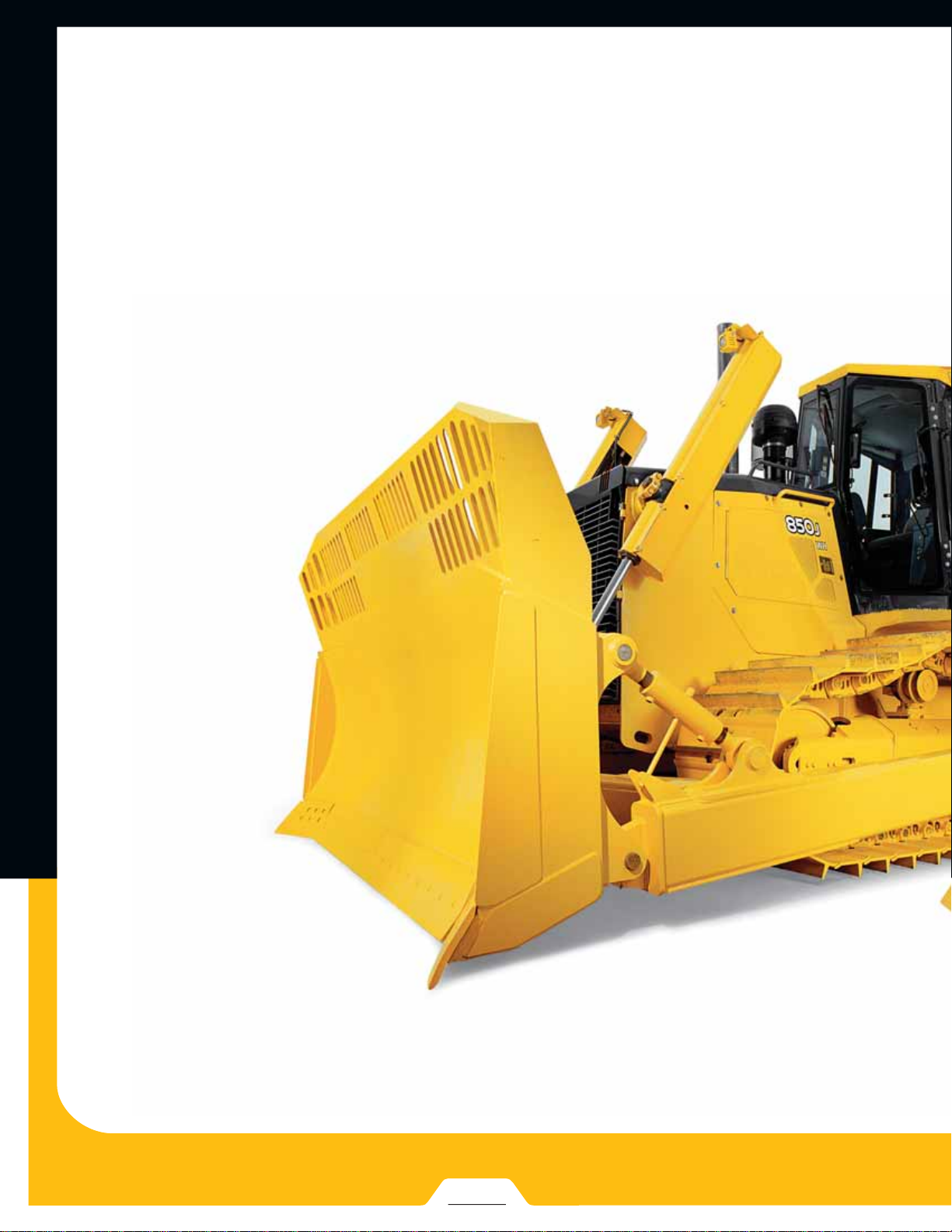

850J Waste Handler with PAT Blade

WLT undercarriage

185 hp net horsepower

5.57-cu.-yd. capacity

12.7-cu.-yd. capacity with trash rack

47,182-lb. operating weight

LGP undercarriage

200 hp net horsepower

5.87-cu.-yd. capacity

12.9-cu.-yd. capacity with trash rack

48,527-lb. operating weight

in a hostile world.They’re purpose-built to

be as waste-proof and easy to maintain as

possible.With the 850J Waste Handler,you

get the productivity and uptime you need

for landfill work.

Designed and built with extensive input from solid-waste professionals

like you, these crawlers are rugged and reliable performers.

For work in the waste pile, equip your 850J WH with an outside-mount

semi-U blade and optional trash rack.

For cover and slope work with occasional waste-pile use, opt for the

inside-mount PAT blade with optional trash rack.

Page 4

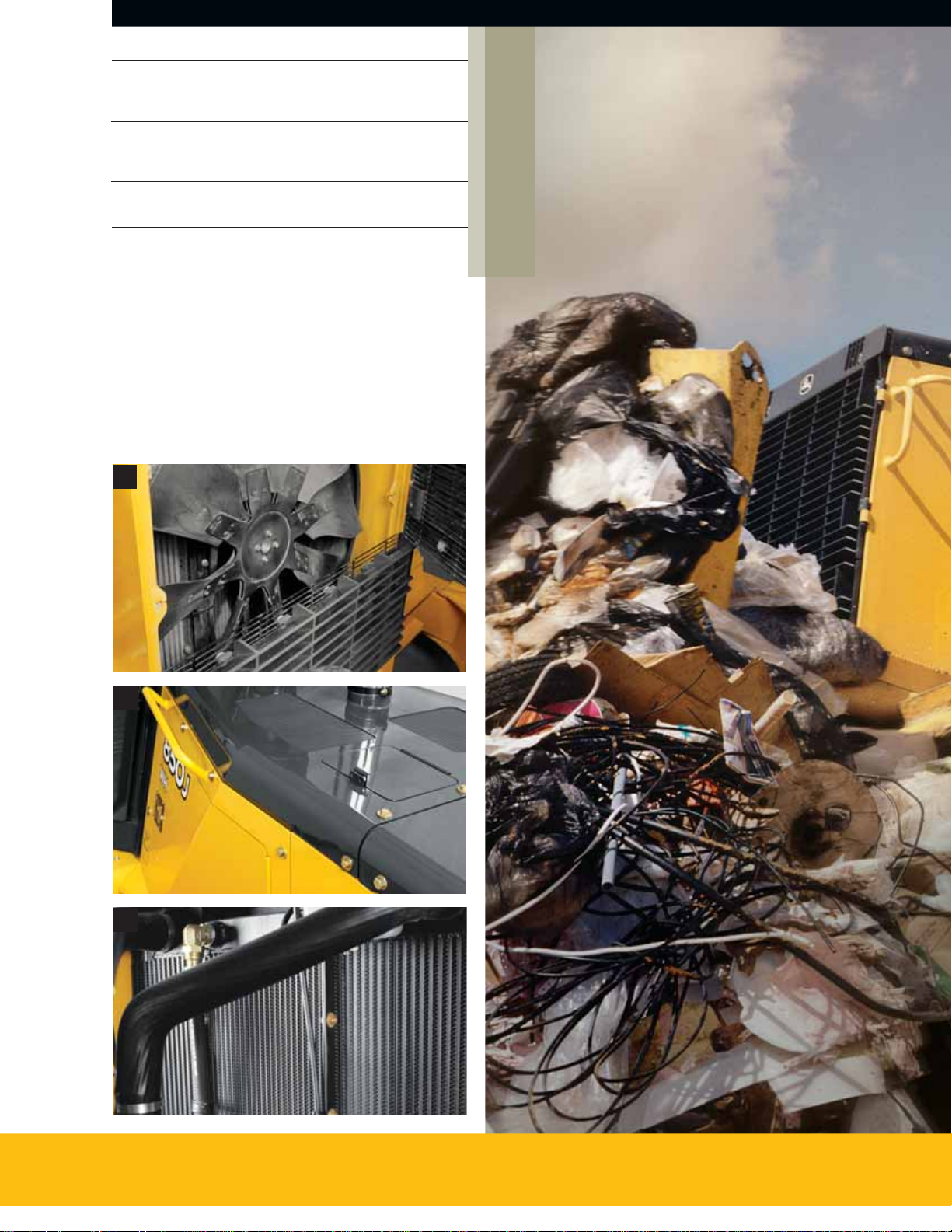

The reversing fan can be set to change direction every 30, 60, or 90

minutes, or activated from the seat as needed. Keeps the engine running

cool and increases productivity.

Variable-speed fan automatically speeds up or slows down,running only

as needed to keep things cool. Improves fuel efficiency and decreases

noise levels, too.

Unitized mainframe with flush-fit bottom guards combines with tight-fitting

side shields to prevent debris from being drawn into the engine compartment.

Generous air intake through the engine compartment slows the velocity

and reduces vacuuming of debris. Right and left side shields open wide

for easy access.

1. With the fan positioned just behind the heavy-duty grille, coolers are less

vulnerable to damage. Split-hinged grille opens wide for convenient clean out.

2. Five-millimeter perforations in the hood and side shields act as a “first

filter,”preventing entr y of most airborne debris.

3. Six-fin-per-inch side-by-side radiator and coolers resist clogging and are

easy to clean.

1

2

3

Page 5

Cool productivit y.

Cool productivit y.

Cool productivit y.

These waste handlers are built to run

cool regardless of what’s in the air or

underfoot.Their highly effective cooling

system design employs a hydraulicdriven variable-speed fan that helps

preserve power and precious fuel. The

fan automatically reverses to help shed

waste and debris from cooler cores and

side screens. So your operators can

work hard without breaking a sweat.

PAGES

4–5

Page 6

Unyielding .

Unyielding .

Unyielding .

You won’t have to worry about these waste

handlers getting trashed too soon. Engineers

started with highly reliable 850J Dozers, then

added what was needed to help them survive,

even thrive in, the daily grind of landfill work.

Anything that was susceptible to damage has

been sealed, rerouted, or re-engineered all in

the name of uptime.

PAGES

6–7

Page 7

Four forward and three rear high-intensity halogen work lights are

positioned high for superior illumination.

Lift-cylinder guards keep hydraulic hoses and cylinders out of danger.Blade

hoses are steel-cable supported and Cordura covered for extra protection.

Semi-U blade hoses are routed internally for extra protection and to

prevent snagging.

Air-conditioning condenser is mounted up and away behind the cab for

extra protection and dust reduction.

Cantilevered carrier rollers, recessed segmented sprockets, and trapezoidal openings in extreme-duty track shoes help prevent refuse packing.

Uni-body track frames ensure durability.Smooth idler-to-sprocket covers

shed material build-up for easier clean-out.

Sealed electrical center protects fuses, relays, and connections from dirt,

debris, and moisture, ensuring maximum reliability and uptime.

Optional full-width trash rack reduces front-end damage and increases

blade capacity for extra production.

Cab-mounted strobe light is activated whenever the electrical system is

switched on.

The curved shape of the final drive housings resists wrapping and sawing

action of debris.

1. Heavy-duty tank guards help protect the hydraulic, hydrostatic, and

fuel reservoirs. Optional front and rear striker bars help shed material

from the tracks.

2. Unitized mainframe with flush-fit bottom guards forms a smooth

underbelly that doesn’t accumulate or drag trash.

1

Final Drive Protection:

A) Final drive seal guard

B) Final drive seal guard

C) Stepped labyrinth protection

D) Protected final drive seals

C

Bolt-on seal guards and

A

B

stepped labyrinth housings

make the final drives virtually

impenetrable.They help minimize downtime and expense

by keeping wire, strapping

tape, metal springs, and other

intrusive contaminants away

2

from final drive seals.

D

Page 8

Unc over new ways to

Unc over new ways to

Unc over new ways to

keep cost s down.

keep cost s down.

keep cost s down.

Swing open their hinged side shields and you’ll

uncover lots of ways these crawlers help keep

maintenance and daily operating costs to a minimum.

Same-side daily service points make quick work

of the daily routine, and extended engine oil and

1 2 3

drivetrain service intervals let you work longer

between changes. Other uptime-enhancing features

include an easy-to-clean undercarriage, quick-toreplace hydraulic hoses,and designed-in diagnostics,

to list just a few.

4 5 6

1. Operator station tilts a full 70 degrees in only

minutes for wide-open access to internal

components.

4. Advanced in-cab monitor gives easy-tounderstand diagnostic messages for quick

and easy troubleshooting without special tools.

2. Common hydraulic and hydrostatic filters

and engine, hydraulic, and transmission oil

simplify service and minimize expense.

5. Rotar y air pre-cleaner ejects dust to

maximize filter life and includes a trash

guard to prevent debris entry.

3. Fluid sample and remote drive-system test

ports simplify preventative maintenance and

troubleshooting for increased uptime.

6. Convenient maintenance and lube chart

provides a quick reference to help ensure

that nothing gets overlooked.

Page 9

Five-hundred-hour engine oil and

2,000-hour transmission and

hydraulic fluid levels increase

uptime, decrease expense.

Hinged bottom guard opens

easily for quick and convenient

clean out.

Greaseless center crossbar pin

joint provides long life with less

maintenance.Lube bank provides

easy access to C-frame pivots.

Separate hydraulic and hydrostatic reservoirs eliminate the

possibility of cross-contamination. Sight gauges reveal fluid

levels at a glance.

Unlike elevated tracks, Deere’s

heavy-duty sealed and lubricated

™

Dura-Trax

undercarriage has

only one wear-causing forwardtravel flex point — for longer life.

Same-side daily service

points make quick work

of the daily routine.

PAGES

8–9

Page 10

Tireless perfor mer.

Tireless perfor mer.

Tireless perfor mer.

If you’re looking for a crawler that does more

with less effort, you’ll choose a John Deere.

The 850J’s hydrostatic system goes beyond the

limits of other drivetrains, delivering infinite

speed control, power management, and full

PAGES

10–11

power turns. What’s more, Total Machine

Control lets an operator customize machine

operation and response to personal preferences.

For nearly tireless operating ease that helps

make big productivity possible.

Page 11

Generous hydraulic

flow and precise

metering ensure

powerful and quick

blade response.

Power management

takes the work out

of efficient operation,

automatically powering

up or down as loads

change to maintain

peak engine efficiency.

Spacious, pressurized,

air-conditioned cab

employs two easyto-service filters and

numerous directional

vents to deliver a

comfortable work

environment.

Seven-way adjustable

deluxe suspension

armchair provides

plenty of legroom and

daylong comfort.

A convenient 12-volt

port powers cell

phones and other

accessories.

Ergonomically correct joystick provides intuitive, low-effort

control of steering, forward/reverse travel, and ground speed.

Exclusive TMC lets an operator select decelerator mode and

response, forward/reverse ground-speed ranges, steering

modulation, F-N-R shift rate, and forward/reverse ratios for

one-of-a-kind control.

Page 12

Specifications

Specifications

Specifications

Engine 850J WH WT w/Semi-U Blade / WLT w/PAT Blade 850J WH LGP w/PAT or Semi-U Blade

Manufacturer and Model. . . . . . . . . . . . . . . . . . John Deere PowerTech PlusTM6090HT John Deere PowerTech Plus 6090HT

Non-Road Emission Standards . . . . . . . . . . . . . complies with EPA Tier 3 regulations complies with EPA Tier 3 regulations

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 6

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . 550 cu.in. (9.0 L) 550 cu. in. (9.0 L)

Net Power (ISO9249) . . . . . . . . . . . . . . . . . . . . 185 hp (137 kW) @ 1,800 rpm 200 hp (151 kW) @ 1,800 rpm

Net Peak Torque (ISO9249). . . . . . . . . . . . . . . . 611 lb.-ft. (831 Nm) @ 1,500 rpm 675 lb.-ft. (915 Nm) @ 1,500 rpm

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . pressure system with full-flow spin-on filter and oil-to-water pressure system with full-flow spin-on filter and oil-to-water

cooler cooler

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual-stage dry type with tangential unloader dual-stage dry type with tangential unloader

Cooling

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . variable-speed, thermostatically controlled; hydraulically driven with auto reverser on selectable timer or activated by a switch

in the cab

Engine Coolant Rating. . . . . . . . . . . . . . . . . . . . – 34 deg. F (– 37 deg.C) – 34 deg. F (– 37 deg. C)

Powertrain

Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . automatic,dual-path,hydrostatic drive; load-sensing feature automatically adjusts speed and power to match changing load

conditions; each individually controlled track is powered by a variable-displacement piston pump and motor combination;

ground-speed selection buttons on single-lever steering and direction control; independently selectable reverse speed ratios

80%, 100%, 115%, or 130% of forward ground speed; decelera tor pedal controls ground speed to stop

System Relief Pressure. . . . . . . . . . . . . . . . . . . 6,650 psi (45 850 kPa) 6,650 psi (45 850 kPa)

Filter, Charge Oil . . . . . . . . . . . . . . . . . . . . . . . . 10 micron 10 micron

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . oil-to-air

Travel Speeds (forward and reverse). . . . . . . . . 6.3 mph (10 km/h) 6.3 mph (10 km/h)

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . single-lever steering,speed, direction control, and counterrotation; full power turns and infinitely variable track speeds provide

unlimited maneuverability and optimum control; hydrostatic steering eliminates steering clutches and brakes

Final Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . double-reduction planetary final drives transfer torque loads over three gear sets; mounted independently of track frames and

dozer push frames for isolation from shock loads

Total Ratio . . . . . . . . . . . . . . . . . . . . . . . . . 44.7483 to 1 44.7483 to 1

Drawbar Pull

Maximum. . . . . . . . . . . . . . . . . . . . . . . 77,300 lb. (344 kN) 77,300 lb. (344 kN)

@ 1.2 mph (1.9 km/h) . . . . . . . . . . . . . 37,500 lb. (167 kN) 40,000 lb. (178 kN)

@ 2.0 mph (3.2 km/h) . . . . . . . . . . . . . 27,000 lb. (120 kN) 29,500 lb. (131 kN)

Service Brakes . . . . . . . . . . . . . . . . . . . . . . . . hydrostatic (dynamic) braking stops the machine when the direction/steering control lever is moved to neutral or the decelerator

is depressed to the end of travel

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic

Parking Brakes. . . . . . . . . . . . . . . . . . . . . . . . exclusive safety feature engages wet, multiple-disc brakes whenever the engine stops, the decelerator is depressed to the end

of travel, or the park lock lever is placed in the start or neutral positions and motion is detected; machine cannot be driven with

brake applied, reducing wear-out or need for adjustment; spring-applied, hydraulic release

PAGES

12–13

Page 13

Hydraulics 850J WH WT w/Semi-U Blade / WLT w/PAT Blade / LGP w/PAT or Semi-U Blade

Load sense, piston pump

Pump (74 cc) . . . . . . . . . . . . . . . . . . . . . . . . . . 46 gpm (174 L/min.)

System Relief Pressure. . . . . . . . . . . . . . . . . . . 3,625 psi (24 993 kPa)

Differential Pressure. . . . . . . . . . . . . . . . . . . . . 275 psi (1896 kPa)

Filter, Return Oil . . . . . . . . . . . . . . . . . . . . . . . . 10 micron

Maximum Flow @ Unloaded High Idle . . . . . . . 43 gpm (163 L/min.)

Control

Outside Dozer. . . . . . . . . . . . . . . . . . . . . . . T-bar hydraulic-pilot two-function joystick

PAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-bar hydraulic pilot two-function joystick with push-button angle function

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . convective oil sump

Electrical

Battery Capacity . . . . . . . . . . . . . . . . . . . . . . . . 950 CCA

Reserve Capacity . . . . . . . . . . . . . . . . . . . . . . . 190 min.

Alternator Rating (cab) . . . . . . . . . . . . . . . . . . . 80 amp

Waste-Handler Dozer Lights . . . . . . . . . . . . .

7 total: cab roof mounted (4), cab rear mounted (1), grille or lift cylinder mounted (2), and rear reflectors (2)

Undercarriage 850J WH WT w/Semi-U Blade / WLT w/PAT Blade 850J WH LGP w/PAT or Semi-U Blade

Tracks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . John Deere Dura-Trax™ features deep-heat-treated,sealed, and lubricated track links and through-hardened, sealed, and

lubricated rollers for maximum wear resistance; sprockets are segmented

WT with semi-U blade WLT with PAT blade LGP with PAT blade LGP with semi-U blade

Track Gauge for WT Waste Handler . . . . . . . . . . 6 ft. 8 in. (2032 mm) 7 ft. 4 in. (2235 mm) 7 ft. 10 in. (2388 mm) 7 ft. 2 in. (2184 mm)

Grouser Width (single bar,open center) . . . 30 in.(762 mm) 30 in. (762 mm) 36 in. (914 mm) 36 in.(914 mm)

Shoes (each side). . . . . . . . . . . . . . . . . . . . 40 45 45 45

Track Rollers (single flange,each side). . . . 7 8 8 8

Track Length on Ground. . . . . . . . . . . . . . . 9 ft.1 in.(2769 mm) 10 ft.9 in.(3284 mm) 10 ft. 9 in. (3284 mm) 10 ft. 9 in. (3284 mm)

Ground Contact Area. . . . . . . . . . . . . . . . . . 6,540 sq. in. (42 193 cm

Ground Pressure. . . . . . . . . . . . . . . . . . . . . 6.83 psi (47.1 kPa) 6.11 psi (42.2 kPa) 5.15 psi (35.5 kPa) 5.16 psi (35.6 kPa)

Track Pitch . . . . . . . . . . . . . . . . . . . . . . . . . 8 in. (203 mm) 8 in. (203 mm) 8 in. (203 mm) 8 in.(203 mm)

Oscillation at Front Roller . . . . . . . . . . . . . . ± 4.5 in. (± 114 mm) ± 6.5 in.(± 166.5 mm) ± 6.6 in. (± 168 mm) ± 6.6 in. (± 168 mm)

2

) 7,758 sq. in. (50 052 cm2) 9,310 sq. in. (60 064 cm2) 9,310 sq. in. (60 064 cm2)

Serviceability 850J WH WT w/Semi-U Blade / WLT w/PAT Blade / LGP w/PAT or Semi-U Blade

Refill Capacities*

Fuel Tank with Lockable Cap . . . . . . . . . . . 98 gal. (371 L)

Cooling System with Recovery Tank. . . . . . 9.2 gal. (35 L)

Engine Oil with Filter . . . . . . . . . . . . . . . . . 7 gal.(26 L)

Transmission Reservoir with Filter . . . . . . . 27.9 gal. (106 L)

Hydrostatic Reservoir and Filter . . . . . . . . . 27.9 gal. (106 L)

*Please follow drain and refill procedures and volumes listed in the operator’s manual.

Operating Weights 850J WH WT w/Semi-U Blade / WLT w/PAT Blade 850J WH LGP w/PAT or Semi-U Blade

With Waste-Handling Package, Blade with

Trash Rack,Full Fuel Tank, and 175-lb.

(79 kg) Operator

With Extreme-Duty Shoes With Trape-

zoidal Holes

30 in. (762 mm) . . . . . . . . . . . . . . . . . . 44,665 lb.(20 260 kg) 47,432 lb. (21 515 kg)

36 in. (914 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48,906 lb. (22 183 kg) 48,796 lb. (22 133 kg)

Blade With Trash Rack and Push-

. . . . . . . . . . . . . . . . . . . . . WT with semi-U blade WLT with PAT blade LGP with PAT blade LGP with semi-U blade

Beam Weights

Including Straight End Bits . . . . . . . 7,486 lb. (3396 kg) N/A N/A 7,644 lb. (3467 kg)

C-Frame Assembly with Cylinder. . . N/A 7,024 lb.(3186 kg) 7,198 lb.(3265 kg) N/A

Page 14

Operating Weights

Optional Components

from base weight) WT with semi-U blade WLT with PAT blade LGP with PAT blade LGP with semi-U blade

22-in. (560 mm) Extreme-Duty. . . . . . . . . . . . . – 482 lb. (– 218.6 kg) – 482 lb. (– 218.6 kg)

24-in. (610 mm) Extreme-Duty. . . . . . . . . . . . . – 148 lb. (– 67.1 kg) – 148 lb. (– 67.1 kg)

30-in. (760 mm) Extreme-Duty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 1,102 lb.(– 500 kg) – 1,102 lb. (– 500 kg)

Trash Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455 lb.(206.4 kg) 436 lb. (197.8 kg) 462 lb. (209.6 kg) 498 lb. (225.9 kg)

Striker Bars

Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245 lb. (111.1 kg) 160 lb. (72.6 kg) 160 lb. (72.6 kg) 325 lb. (147.4 kg)

Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366 lb.(166 kg) 171 lb.(77.6 kg) 171 lb. (77.6 kg) 171 lb. (77.6 kg)

Air Pre-Cleaner

Powered Cab . . . . . . . . . . . . . . . . . . . . . . . 47 lb.(21.3 kg) 47 lb. (21.3 kg) 47 lb. (21.3 kg) 47 lb. (21.3 kg)

Dual-Stage Engine . . . . . . . . . . . . . . . . . . . 13 lb. (5.9 kg) 13 lb. (5.9 kg) 13 lb. (5.9 kg) 13 lb. (5.9 kg)

Retrieval Hitch . . . . . . . . . . . . . . . . . . . . . . . . . 114 lb. (52 kg) 114 lb.(52 kg) 114 lb.(52 kg) 114 lb. (52 kg)

Drawbar (extended rigid) . . . . . . . . . . . . . . . . . 286 lb. (130 kg) 286 lb.(130 kg) 286 lb.(130 kg) 286 lb.(130 kg)

Screens

Front and Door . . . . . . . . . . . . . . . . . . . . . . 175 lb. (79 kg) 175 lb.(79 kg) 175 lb.(79 kg) 175 lb.(79 kg)

Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 lb.(34 kg) 75 lb. (34 kg) 75 lb. (34 kg) 75 lb. (34 kg)

Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg) 120 lb. (54 kg)

Condenser Guard . . . . . . . . . . . . . . . . . . . . . . . 121 lb. (55 kg) 121 lb.(55 kg) 121 lb.(55 kg) 121 lb. (55 kg)

Limb Risers . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 lb.(272 kg) 600 lb. (272 kg) 600 lb.(272 kg) 600 lb. (272 kg)

Counterweight

Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 875 lb. (397 kg) 875 lb.(397 kg) 875 lb. (397 kg) 875 lb.(397 kg)

Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 990 lb.(449 kg) 990 lb.(449 kg) 990 lb.(449 kg) 990 lb.(449 kg)

(continued)

(add or subtract

850J WH WT w/Semi-U Blade / WLT w/PAT Blade 850J WH LGP w/PAT or Semi-U Blade

Machine Dimensions

WT with semi-U blade WLT with PAT blade LGP with PAT blade LGP with semi-U blade

A Overall Height to Roof. . . . . . . . . . . . . . . . . 10 ft. 5 in.(3175 mm) 10 ft. 5 in. (3175 mm) 10 ft.5 in.(3175 mm) 10 ft. 5 in. (3175 mm)

B Tread Depth with Extreme-Duty Single-

Bar Grousers . . . . . . . . . . . . . . . . . . . . 2.8 in. (71 mm) 2.8 in.(71 mm) 2.8 in.(71 mm) 2.8 in. (71 mm)

C Ground Clearance with Grousers

(excludes grouser height). . . . . . . . . . . 16.1 in. (409 mm) 16.1 in. (409 mm) 16.1 in. (409 mm) 16.1 in. (409 mm)

With Trash Rack

D Blade Width . . . . . . . . . . . . . . . . . . . . . . . . 11 ft.8 in.(3556 mm) 13 ft. 2 in.(4013 mm) 14 ft. 0 in.(4267 mm) 12 ft. 8 in. (3861 mm)

E Blade Height

With Trash Rack . . . . . . . . . . . . . . . . . . . . . 6 ft.6 in.(1981 mm) 6 ft. 0 in. (1829 mm) 6 ft. 0 in. (1829 mm) 6 ft. 4 in. (1930 mm)

Without Trash Rack. . . . . . . . . . . . . . . . . . . 4 ft.6 in.(1374 mm) 4 ft. 0 in. (1229 mm) 4 ft. 0 in. (1229 mm) 4 ft. 4 in. (1321 mm)

F Blade Lift Height. . . . . . . . . . . . . . . . . . . . . 3 ft. 9 in.(1151 mm) 3 ft. 6 in.(1072 mm) 3 ft. 6 in. (1072 mm) 3 ft.9 in.(1151 mm)

G Blade Digging Depth. . . . . . . . . . . . . . . . . . 23.6 in. (599 mm) 27.7 in. (704 mm) 28 in. (704 mm) 24 in. (599 mm)

H Blade Tilt (uses tilt jack) . . . . . . . . . . . . . . . 29.6 in. (752 mm) 21.2 in. (538 mm) 23 in. (572 mm) 34 in.(853 mm)

I Overall Length with Blade. . . . . . . . . . . . . . 17 ft. 8 in. (5385 mm) 18 ft. 10 in. (5728 mm) 18 ft.10 in.(5728 mm) 19 ft. 6 in. (5944 mm)

J Overall Width with Blade Angled. . . . . . . . . N/A 9 ft.6 in.(2896 mm) 12 ft. 10 in.(3901 mm) N/A

K Blade Angle . . . . . . . . . . . . . . . . . . . . . . . . N/A 23.8 deg. 23.8 deg. N/A

L Cut Reach. . . . . . . . . . . . . . . . . . . . . . . . . . N/A 5.7 in.(145 mm) 4.3 in. (158 mm) N/A

M Width Over Track . . . . . . . . . . . . . . . . . . . . 9 ft.2 in.(2794 mm) 9 ft. 10 in. (2997 mm) 10 ft.10 in.(3302 mm) 10 ft. 2 in. (3099 mm)

Blade Capacity

With Trash Rack . . . . . . . . . . . . . . . . . . . . . 14.5 cu.yd. (11.09 m3) 12.7 cu. yd. (9.71 m3) 12.9 cu. yd. (9.86 m3) 15.2 cu.yd. (11.62 m3)

Without Trash Rack. . . . . . . . . . . . . . . . . . . 7.62 cu.yd. (5.82 m

3

) 5.57 cu.yd. (4.26 m3) 5.87 cu. yd. (4.49 m3) 7.8 cu.yd. (5.96 m3)

PAGES

14–15

Page 15

D

H

Standard Drawbar

E

F

G

I

Extended Drawbar

B

C

A

K

J

L

M

Cast Reach

Rear Ripper 850J WH WT w/Semi-U Blade / WLT w/PAT Blade / LGP w/PAT or Semi-U Blade

T

S Q

T

R

O

N

P

'

P

Parallelogram ripper with hydraulic pitch adjustment and ESCO ripper tips, multi-shank (3)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,480 lb. (2032 kg)

N Maximum Penetration . . . . . . . . . . . . . . . . . 28.5 in.(724 mm)

O Maximum Clearance Under Tip . . . . . . . . . . 24 in. (610 mm)

P Overall Length (lowered position). . . . . . . . . 5 ft. 4 in.(1626 mm)

P'Overall length (raised position). . . . . . . . . . . 5 ft.0 in.(1524 mm)

Q Overall Beam Width . . . . . . . . . . . . . . . . . . . 7 ft. 10.5 in.(2400 mm)

R Slope Angle (full raise). . . . . . . . . . . . . . . . . 24 deg.

S Ripping Width. . . . . . . . . . . . . . . . . . . . . . . . 7 ft. 0.5 in. (2146 mm)

T Distance Between Shanks . . . . . . . . . . . . . . 3 ft. 5 in. (1041 mm)

Number of Teeth. . . . . . . . . . . . . . . . . . . . . . . . 3

Page 16

850J WH WASTE HANDLER

Key: ● Standard equipment ▲ Optional or special equipment *See your John Deere dealer for further information.

Base Landfill

850J Package Engine

●●

Certified to EPA Tier 3 emissions

●●Electronic control with automatic engine protection

●●Dual safety element dry-type air cleaner,evacuator valve

●●Muffler,self draining, under hood, with vertical stack

●●Environmental service drains

▲▲Ether start aid

▲▲Chrome exhaust

▲ ● Rotary ejector engine air precleaner

Cooling

▲ ● Cooling fan, suction type, programmable reversing

●●Engine coolant radiator (6 fins per in.)

●●Hydrostatic cooler (oil/air – 6 fins per in.)

●●Hydraulic cooler (oil/air – 6 fins per in.)

●●Enclosed safety fan guard (conforms to SAE J1308 and ISO3457)

●●Perforated engine side shields

●●Split-hinge bar-type grille

▲

Extreme-duty grille

●

Transmission

●●

Diagnostic test ports

●●Environmental service drains

▲

Final-drive seal guards

●

●●Onboard diagnostics

Hydraulic System

●●

Two-function hydraulics

▲▲Three-function hydraulics

▲▲Four-function hydraulics with rear plumbing

Electrical

●●

Sealed alternator,80 amps

●●Master electrical disconnect switch

●●Lights, grille or lift cylinder mounted (2) and rear mounted (1)

▲ ● Work lights (4),cab roof mounted

Mainframe, Access Panels

●●

Tilt operator station transmission access

●●Front tow loop

●●Integral bottom protection

●●Bottom access covers (bolt-on, 6 total, 5 swing away)

●●Vandal protection:Engine access door / Side tank access doors / Fuel

tank / Instrument panel / Transmission reservoir / Hydraulic reservoir

Base Landfill

850J Package Attachments

▲▲Retrieval hitch with pin

▲▲Extended rigid drawbar with pin for pull-type implements

▲▲Counterweight, rear, 720 lb. (327 kg)

▲▲Counterweight, rear, 1,000 lb. (454 kg)

▲▲Ripper, rear, three shank

▲▲Cab screens

Undercarriage

●●

Oscillating undercarriage with remote lube

●●Full-length, smooth-surface track frame covers

●●Guides, front and rear,with bolt-on wear strips

●●Segmented sprockets

●●Double-flange rollers

●●Maintenance-free center crossbar pivot

Operator’s Station

▲

Cab with roof-mounted air conditioner (24,000 BTU) and heater

●

● Left and right quarter hinged windows

● Tinted safety glass

● Dome light

● Fresh-air-intake heater/defroster

● Windshield wiper/washers (3) for windshield and doors

● Mechanical suspension high-back fabric seat

▲▲Air suspension high-back fabric seat

●●3-in. (76 mm) retractable seat belt

●●Backrest tilt,thigh support, lumbar,height, weight,and fore-aft positioning

●●Power port, 12 volt

▲▲Second power port

●●Lockable dash-mounted storage compartment

▲▲Rear wiper, two speed

▲▲AM/FM weather-band radio and digital clock

▲▲External mounted attachment mirror

▲▲JDLink

TM

Landfill Configuration

▲ ● Tank guards

▲ ● Lift-cylinder hose guards

▲ Blade trash rack

▲ ● Beacon

▲▲30-in.(762 mm) extreme-service shoes with trapezoidal holes

▲▲36-in.(914 mm) extreme-service shoes with trapezoidal holes

CONTROL OWNING AND OPERATING COSTS

Customer Personal Service (CPS) is part of John Deere’s proactive,fix-before-fail

strategy on machine maintenance that will help control costs, increase profits, and

reduce stress. Included in this comprehensive lineup of ongoing programs and

services are:

Fluid analysis program

major components so you’ll know if there’s a problem

performance. Fluid analysis is included in most extended coverage and preventivemaintenance agreements.

Component life-cycle data

span of components and lets you make informed decisions on machine maintenance

by telling you approximately how many hours of use you can expect from an engine,

transmission, or hydraulic pump.This information can be used to preempt catastrophic

downtime by servicing major components at about 80 percent of their life cycle.

DKA850JWH Litho in U.S.A. (07-04)

– tells you what’s going on inside

– gives you vital information on the projected life

Net engine power is with standard equipment including air cleaner, exhaust system, alternator,and

cooling fan at test conditions per ISO9249. No derating is required up to 10,000-ft. (3050 m) altitude.

all

before

you see a decline in

of your machine’s

Preventive Maintenance (PM) agreements

ing a machine for a given period of time.They also help you avoid downtime by ensuring that critical maintenance work gets done right and on schedule. On-site preventive

maintenance service performed where and when you need it helps protect you from

the expense of catastrophic failures and lets you avoid waste-disposal hassles.

Extended coverage

of time so you can effectively manage costs.Whether you work in a severe-service

setting or just want to spread the risk of doing business, this is a great way to customfit coverage for your operation.And an extended covera ge contract also travels well

because it’s backed by John Deere and is honored by

Customer Support Advisors (CSAs)

personal

quality to Customer Personal Service (CPS). Certified CSAs ha ve the kno wledge

and skills for helping make important decisions on machine maintenance and repair.

Their mission is to help you implement a plan that’s right for

the burden of machine maintenance off your shoulders.

Specifications and design subject to change without notice.Wherever applicable, specifications are

in accordance with SAE standards. Except where otherwise noted, these specifications are based

on a unit with cab, waste-handling package, full fuel tank, 175-lb. (79 kg) operator, and standard

equipment; 140-in. (3556 mm) outside-mount semi-U blade or 158-in. (4013 mm) PAT blade.

– gives you a fixed cost for machine repairs for a given period

– give you a fixed cost for maintain-

all

– Deere believes the CSA program lends a

Deere construction dealers.

your

business and take

Loading...

Loading...