Page 1

John Deere Agriculture

7200R, 7215R, 7230R, 7260R and 7280R

Tractors

REPAIR TECHNICAL MANUAL

(SN: 000101-080000) models 7200R, 7215R,

7230R, 7260R, 7280R

TM110119, May 2013

Page 2

TM110119-REPAIR TECHNICAL MANUAL

Table of contents

FOREWORD

DEALER PREDELIVERY INFORMATION FORM

Section 10 - GENERAL INFORMATION

Group 05 - Safety

Group 10 - General Information

Section 20 - ENGINE

Group 00 - Component Removal and Installation

Group 05 - Engine Repair

Section 30 - FUEL AND COOLING SYSTEMS

Group 10 - Diesel Fuel System

Group 15 - Air Intake System

Group 20 - Auxiliary Drive System

Group 25 - Radiator and Coolers

Group 30 - Exhaust System

Section 40 - ELECTRICAL

Group 05 - Connectors

Group 10 - Wiring Harness Routings

Group 15 - Charging Circuit

Group 20 - Starting Circuit

Group 25 - Relays, Fuses, Solenoids, and Switches

Group 30 - Monitoring System

Group 35 - Armrest Control

Group 40 - Implement and Accessory Connectors

Group 45 - Convenience and Accessory Components

Section 50 - AUTOQUAD/COMMANDQUAD TRANSMISSION

Group 00 - Component Removal and Installation

Group 05 - Transmission Shifting Mechanisms

Group 10 - PowrQuad-Plus™ Module

Group 20 - Range Box (PowrQuad™ and AutoQuad™)

Group 30 - Range Box (CommandQuad™)

Section 51 - AUTOPOWR/IVT TRANSMISSION

Group 00 - Component Removal and Installation

Group 05 - General Repair Procedures

Group 20 - Transmission Repair

Group 30 - Assemble Transmission

Section 56 - DRIVE SYSTEMS

Group 00 - Component Removal and Installation

Group 10 - Rear Differential

Group 20 - Final Drive

Group 30 - Rear PTO

Group 35 - Front PTO

Group 40 - Primary Brakes

Group 45 - Pump Drive Housing

Section 57 - 1100 SERIES MFWD AXLE

Group 00 - Component Removal And Installation

Group 05 - Final Drives

Group 10 - Axle Housing

Group 15 - Differential

(g) by Belgreen

<- Go to Global Table of contents TM110119-REPAIR TECHNICAL MANUAL

Page 3

TM110119-REPAIR TECHNICAL MANUAL

Section 58 - 1300 SERIES MFWD AXLE

Group 00 - Component Removal And Installation

Group 05 - Final Drives

Group 10 - Axle Housing

Group 15 - Differential

Section 59 - SUSPENDED MFWD AXLE

Group 00 - Component Removal And Installation

Group 05 - Final Drives

Group 10 - Axle Housing

Group 15 - Differential

Group 20 - Suspension Components

Section 60 - STEERING AND BRAKES

Group 05 - Steering Column

Group 10 - Steering Control Assembly

Group 15 - Steering Cylinders

Group 20 - Service Brakes

Group 30 - Hydraulic Trailer Brake

Group 35 - Air Trailer Brake

Section 70 - HYDRAULICS

Group 00 - Component Removal and Installation

Group 05 - General Repair Procedures

Group 15 - Integrated Hydraulic Pump

Group 25 - Hitch Valve, Selective Control Valves and Couplers

Group 30 - Rear Hitch

Group 35 - Front Hitch

Section 80 - MISCELLANEOUS

Group 05 - Hood

Group 10 - Front Axle (Two-Wheel Drive)

Group 20 - Rear Wheels

Group 25 - Wagon And Pick-Up Hitch

Section 90 - OPERATOR STATION

Group 00 - Component Removal and Installation

Group 05 - Heating, Ventilating, and Air Conditioning (HVAC)

Group 10 - Air Conditioning System

Group 15 - Air Suspension Seat

Group 16 - ComfortCommand™ Seat

Group 20 - ActiveSeat™

Group 25 - Armrest

Group 30 - Cab Door and Windshield

Group 35 - Cab Suspension

Section 99 - DEALER TOOLS

Group 05 - Dealer Fabricated Tools

Group 10 - Essential And Recommended Tools

(g) by Belgreen

<- Go to Global Table of contents TM110119-REPAIR TECHNICAL MANUAL

Page 4

<- Go to Global Table of contents TM110119-REPAIR TECHNICAL MANUAL

Page 5

TM110119-REPAIR TECHNICAL MANUAL

(g) by Belgreen

Foreword

This manual is written for an experienced technician. Essential and recommended tools

required in performing certain service work are identified in this manual.

Live with safety: Read the safety messages in the introduction of this manual and the

cautions presented throughout the text of the manual.

CAUTION:

This is the safety-alert symbol. When you see this symbol on the machine or in this manual,

be alert to the potential for personal injury.

Technical manuals are used to provide service information. The Repair Technical Manual tells

how to repair the components. The Operation and Test Technical Manual helps you quickly

identify the majority of failures.

Information is organized in groups for the various components requiring service instruction.

At the beginning of each group are summary listings of all applicable essential and

recommended tools, other material needed to do the job, service parts kits, specifications,

wear tolerances, and torque values.

Technical manuals are concise guides for specific machines. They are on-the-job guides

containing only the vital information needed for diagnosis, analysis, testing, and repair.

Fundamental service information is available from other sources covering basic theory of

operation, fundamentals of troubleshooting, general maintenance, and basic type of failures

and their causes.

<- Go to Global Table of contents TM110119-REPAIR TECHNICAL MANUAL

Page 6

GENERAL INFORMATION

(g) by Belgreen

Dealer Predelivery Information Form

The John Deere Predelivery Form, when properly filled out and signed by dealer, verifies

predelivery and delivery services were satisfactorily performed.

Because of the shipping factors involved, plus extra finishing touches necessary to promote

customer satisfaction, there are certain predelivery services that must be performed by the

dealer. These services are listed on the predelivery form with the tractor.

Perform all services listed and check each job off as it is completed. Fill form out completely

and sign it.

<- Go to Global Table of contents TM110119-REPAIR TECHNICAL MANUAL

Page 7

TM110119-REPAIR TECHNICAL MANUAL

Section 10 - GENERAL INFORMATION

Table of contents

Group 05 - Safety 1 ......................................................................................................................

Recognize Safety Information 1 ................................................................................................

Understand Signal Words 1 .......................................................................................................

Follow Safety Instructions 2 ......................................................................................................

Wear Protective Clothing 2 .......................................................................................................

Service Machines Safely 3 .........................................................................................................

Stay Clear of Rotating Drivelines 4 ...........................................................................................

Handle Fluids Safely—Avoid Fires 5 ..........................................................................................

Prevent Battery Explosions 5 ....................................................................................................

Prepare for Emergencies 6 ........................................................................................................

Remove Paint Before Welding or Heating 6 ..............................................................................

Avoid Heating Near Pressurized Fluid Lines 7 ...........................................................................

Handle Starting Fluid Safely 8 ...................................................................................................

Avoid Hot Exhaust 8 ..................................................................................................................

Clean Exhaust Filter Safely 10 ..................................................................................................

Prevent Acid Burns 13 ...............................................................................................................

Handle Agricultural Chemicals Safely 15 ..................................................................................

Clean Vehicle of Hazardous Pesticides 16 .................................................................................

Handling Batteries Safely 17 .....................................................................................................

Avoid Harmful Asbestos Dust 19 ...............................................................................................

Dispose of Waste Properly 20 ...................................................................................................

Avoid High-Pressure Fluids 21 ...................................................................................................

Wait Before Opening High-Pressure Fuel System 21 .................................................................

Service Accumulator Systems Safely 22 ...................................................................................

Protect Against High Pressure Spray 23 ....................................................................................

Service Cooling System Safely 23 .............................................................................................

Prevent Machine Runaway 24 ...................................................................................................

Keep ROPS Installed Properly 24 ...............................................................................................

Avoid Backover Accidents 25 ....................................................................................................

Park Machine Safely 25 .............................................................................................................

Support Machine Properly 26 ....................................................................................................

Work in Clean Area 27 ..............................................................................................................

Work In Ventilated Area 27 .......................................................................................................

Illuminate Work Area Safely 28 .................................................................................................

Use Proper Lifting Equipment 28 ...............................................................................................

Service Tires Safely 28 ..............................................................................................................

Instructional Seat 30 .................................................................................................................

Service Front-Wheel Drive Tractor Safely 30 ............................................................................

Use Steps and Handholds Correctly 31 .....................................................................................

Transport Tractor Safely 31 ......................................................................................................

Practice Safe Maintenance 32 ...................................................................................................

Use Proper Tools 33 ..................................................................................................................

Construct Dealer-Made Tools Safely 33 ....................................................................................

Replace Safety Signs 34 ............................................................................................................

Install All Guards 34 ..................................................................................................................

Live With Safety 35 ...................................................................................................................

(g) by Belgreen

<- Go to Global Table of contents TM110119-REPAIR TECHNICAL MANUAL

Page 8

TM110119-REPAIR TECHNICAL MANUAL

Group 10 - General Information 36 ............................................................................................

List of References 36 ................................................................................................................

Trademarks 37 ..........................................................................................................................

Sealants and Adhesives Cross-Reference Chart 40 ...................................................................

Metric Bolt and Screw Torque Values 42 ...................................................................................

Unified Inch Bolt and Screw Torque Values 43 ..........................................................................

Face Seal Fittings Assembly and Installation—All Pressure Applications 45 ..............................

Metric Face Seal And O-Ring Stud End Fitting Torque Chart—Standard Pressures 46 ..............

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—High Pressure Applications

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures 50 ..................

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—High Pressure Applications 51 .......

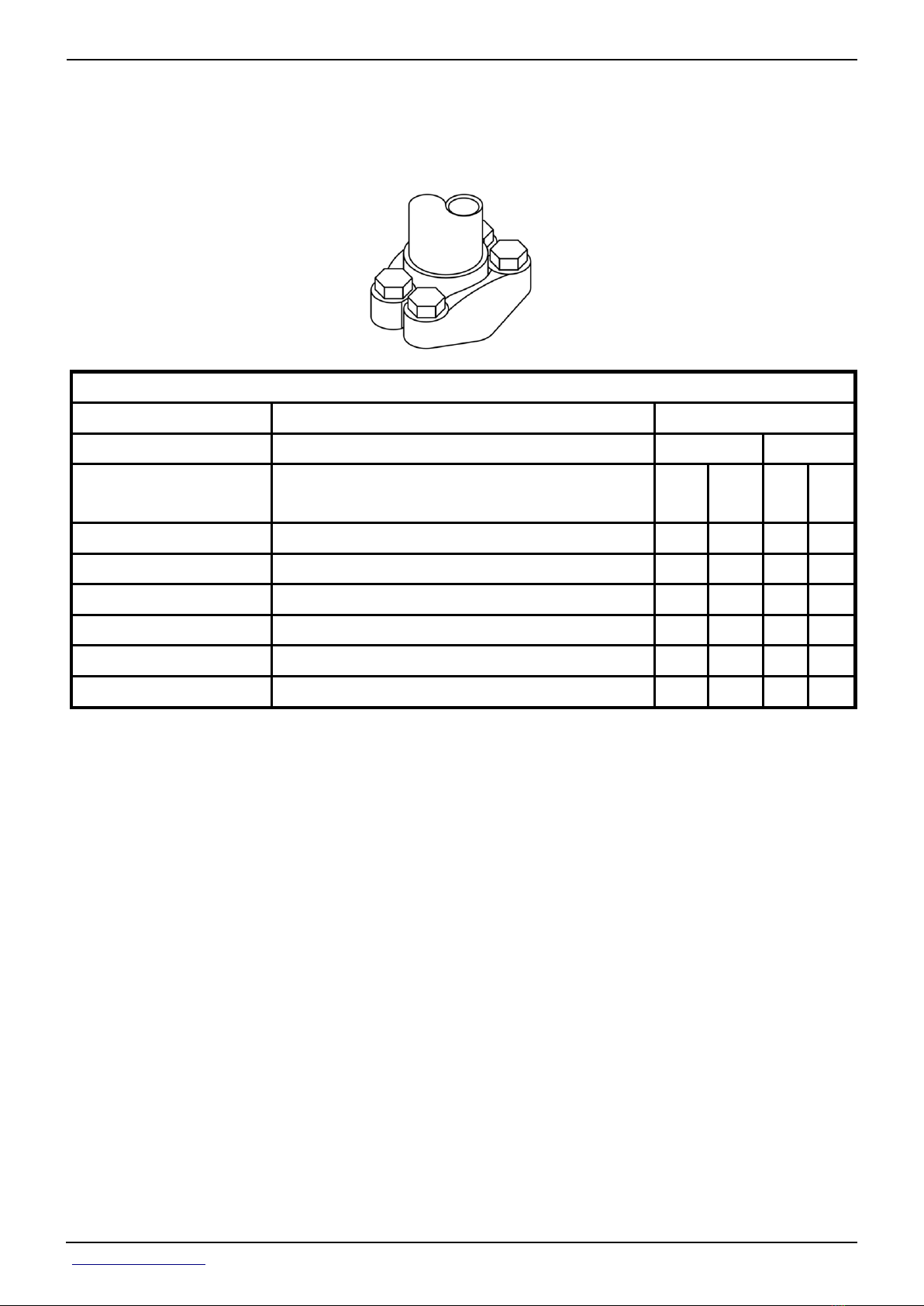

Four Bolt Flange Fittings Assembly and Installation—All Pressure Applications 52 ...................

SAE Four Bolt Flange Cap Screw Torque Values—Standard Pressure Applications 53 ..............

SAE Four Bolt Flange Cap Screw Torque Values—High Pressure Applications 54 .....................

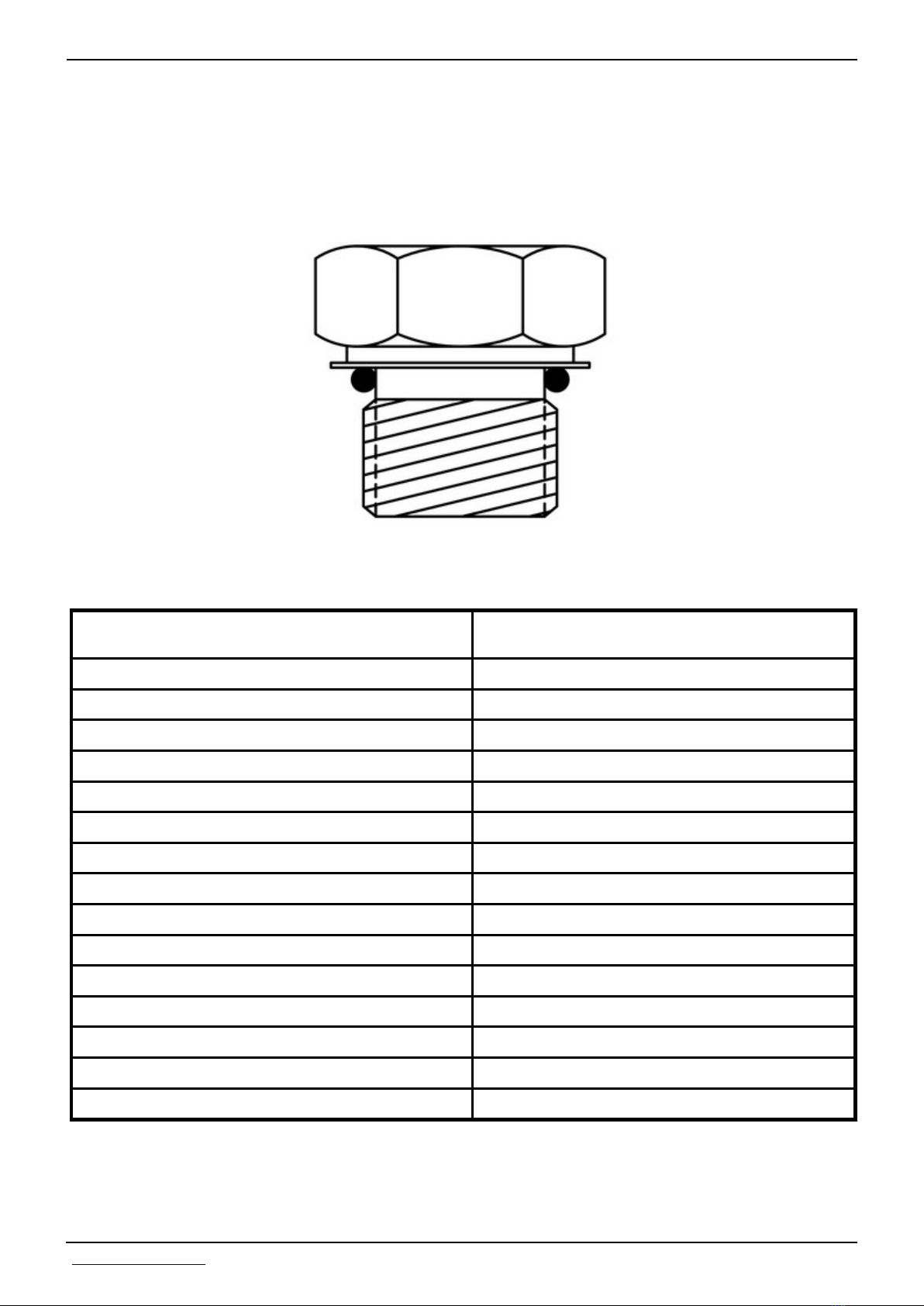

External Hexagon Port Plug Torque Chart 55 ............................................................................

Prevent Hydraulic System Contamination 55 ............................................................................

Check Oil Lines and Fittings 57 .................................................................................................

Basic Electrical Component Handling / Precautions For Vehicles Equipped With Computer

Controlled Systems 59 .......................................................................................................

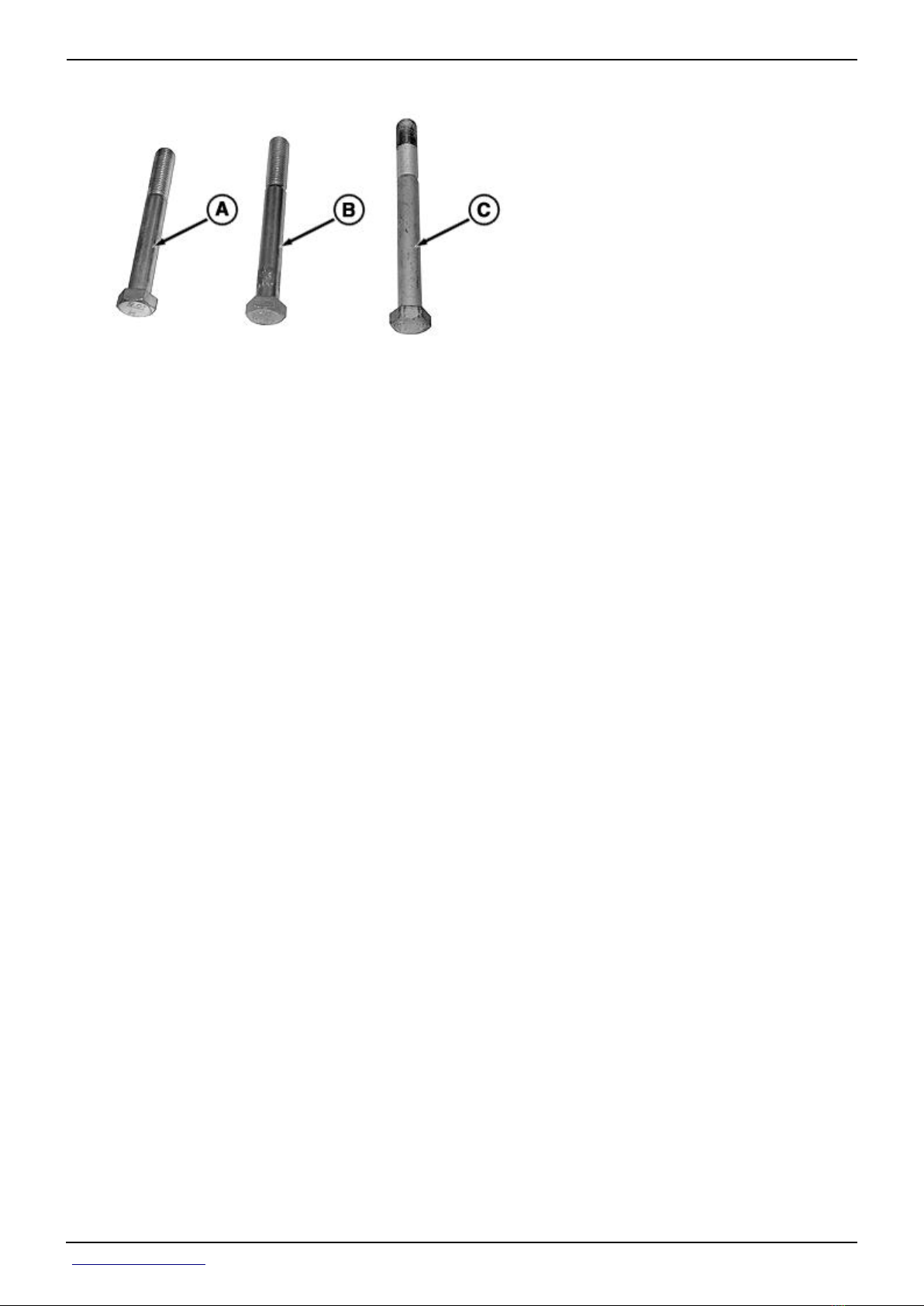

Identify Zinc-Flake Coated Fasteners 59 ...................................................................................

Use Torque Wrench Adapter 61 ................................................................................................

Servicing and Connecting Snap to Connect STC™ Fittings 62 ..................................................

Glossary of Terms 64 ................................................................................................................

(g) by Belgreen

48 .......................................................................................................................................

<- Go to Global Table of contents TM110119-REPAIR TECHNICAL MANUAL

Page 9

Section 10 - GENERAL INFORMATION Group 05: Safety

Group 05 - Safety

Recognize Safety Information

This is a safety-alert symbol. When you see this symbol on your machine or in this manual,

be alert to the potential for personal injury.

Follow recommended precautions and safe operating practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is used with the safety-alert symbol.

DANGER identifies the most serious hazards.

DANGER or WARNING safety signs are located near specific hazards. General precautions are

listed on CAUTION safety signs. CAUTION also calls attention to safety messages in this

<- Go to Section TOC

Section 10 page 1

TM110119-REPAIR TECHNICAL MANUAL

Page 10

Section 10 - GENERAL INFORMATION Group 05: Safety

manual.

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep

safety signs in good condition. Replace missing or damaged safety signs. Be sure new

equipment components and repair parts include the current safety signs. Replacement safety

signs are available from your John Deere dealer.

There can be additional safety information contained on parts and components sourced from

suppliers that is not reproduced in this operator′s manual.

Learn how to operate the machine and how to use controls properly. Do not let anyone

operate without instruction.

Keep your machine in proper working condition. Unauthorized modifications to the machine

may impair the function and/or safety and affect machine life.

If you do not understand any part of this manual and need assistance, contact your John

Deere dealer.

Wear Protective Clothing

<- Go to Section TOC

Section 10 page 2

TM110119-REPAIR TECHNICAL MANUAL

Page 11

Section 10 - GENERAL INFORMATION Group 05: Safety

Wear close fitting clothing and safety equipment appropriate to the job.

Prolonged exposure to loud noise can cause impairment or loss of hearing.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against

objectionable or uncomfortable loud noises.

Operating equipment safely requires the full attention of the operator. Do not wear radio or

music headphones while operating machine.

Service Machines Safely

<- Go to Section TOC

Section 10 page 3

TM110119-REPAIR TECHNICAL MANUAL

Page 12

Section 10 - GENERAL INFORMATION Group 05: Safety

Tie long hair behind your head. Do not wear a necktie, scarf, loose clothing, or necklace when

you work near machine tools or moving parts. If these items were to get caught, severe injury

could result.

Remove rings and other jewelry to prevent electrical shorts and entanglement in moving

parts.

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death.

Keep all shields in place at all times. Make sure rotating shields turn freely.

Wear close-fitting clothing. Stop the engine and be sure that all rotating parts and drivelines

are stopped before making adjustments, connections, or performing any type of service on

engine or machine driven equipment.

<- Go to Section TOC

Section 10 page 4

TM110119-REPAIR TECHNICAL MANUAL

Page 13

Section 10 - GENERAL INFORMATION Group 05: Safety

Handle Fluids Safely—Avoid Fires

When you work around fuel, do not smoke or work near heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized

containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn spontaneously.

Prevent Battery Explosions

Keep sparks, lighted matches, and open flame away from the top of battery. Battery gas can

explode.

<- Go to Section TOC

Section 10 page 5

TM110119-REPAIR TECHNICAL MANUAL

Page 14

Section 10 - GENERAL INFORMATION Group 05: Safety

Never check battery charge by placing a metal object across the posts. Use a volt-meter or

hydrometer.

Do not charge a frozen battery; it may explode. Warm battery to 16°C (60°F).

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near

your telephone.

Remove Paint Before Welding or Heating

<- Go to Section TOC

Section 10 page 6

TM110119-REPAIR TECHNICAL MANUAL

Page 15

Section 10 - GENERAL INFORMATION Group 05: Safety

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated by welding, soldering, or using a

torch.

Remove paint before heating:

Remove paint a minimum of 100 mm (4 in.) from area to be affected by heating. If paint

cannot be removed, wear an approved respirator before heating or welding.

If you sand or grind paint, avoid breathing the dust. Wear an approved respirator.

If you use solvent or paint stripper, remove stripper with soap and water before

welding. Remove solvent or paint stripper containers and other flammable material

from area. Allow fumes to disperse at least 15 minutes before welding or heating.

Do not use a chlorinated solvent in areas where welding will take place.

Do all work in an area that is well ventilated to carry toxic fumes and dust away.

Dispose of paint and solvent properly.

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near pressurized fluid lines, resulting in

severe burns to yourself and bystanders. Do not heat by welding, soldering, or using a torch

near pressurized fluid lines or other flammable materials. Pressurized lines can accidentally

burst when heat goes beyond the immediate flame area.

<- Go to Section TOC

Section 10 page 7

TM110119-REPAIR TECHNICAL MANUAL

Page 16

Section 10 - GENERAL INFORMATION Group 05: Safety

Handle Starting Fluid Safely

Starting fluid is highly flammable.

Keep all sparks and flame away when using it. Keep starting fluid away from batteries and

cables.

To prevent accidental discharge when storing the pressurized can, keep the cap on the

container, and store in a cool, protected location.

Do not incinerate or puncture a starting fluid container.

Avoid Hot Exhaust

<- Go to Section TOC

Section 10 page 8

TM110119-REPAIR TECHNICAL MANUAL

Page 17

Section 10 - GENERAL INFORMATION Group 05: Safety

Servicing machine or attachments with engine running can result in serious personal injury.

Avoid exposure and skin contact with hot exhaust gases and components.

Exhaust parts and streams become very hot during operation. Exhaust gases and

components reach temperatures hot enough to burn people, ignite, or melt common

materials.

<- Go to Section TOC

Section 10 page 9

TM110119-REPAIR TECHNICAL MANUAL

Page 18

Section 10 - GENERAL INFORMATION Group 05: Safety

Clean Exhaust Filter Safely

<- Go to Section TOC

Section 10 page 10

TM110119-REPAIR TECHNICAL MANUAL

Page 19

Section 10 - GENERAL INFORMATION Group 05: Safety

During exhaust filter cleaning operations, the engine may run at elevated idle and hot

temperatures for an extended period of time. Exhaust gases and exhaust filter components

reach temperatures hot enough to burn people, or ignite or melt common materials.

Keep machine away from people, animals, or structures which may be susceptible to harm or

damage from hot exhaust gases or components. Avoid potential fire or explosion hazards

from flammable materials and vapors near the exhaust. Keep exhaust outlet away from

<- Go to Section TOC

Section 10 page 11

TM110119-REPAIR TECHNICAL MANUAL

Page 20

Section 10 - GENERAL INFORMATION Group 05: Safety

people and anything that can melt, burn, or explode.

Closely monitor machine and surrounding area for smoldering debris during and after

exhaust filter cleaning.

Adding fuel while an engine is running can create a fire or explosion hazard. Always stop

engine before refueling machine and clean up any spilled fuel.

Always make sure that engine is stopped while hauling machine on a truck or trailer.

Contact with exhaust components while still hot can result in serious personal injury.

Avoid contact with these components until cooled to safe temperatures.

If service procedure requires engine to be running:

Only engage power-driven parts required by service procedure

Ensure that other people are clear of operator station and machine

Keep hands, feet, and clothing away from power-driven parts.

Always disable movement (neutral), set the parking brake or mechanism and disconnect

power to attachments or tools before leaving the operator’s station.

Shut off engine and remove key (if equipped) before leaving the machine unattended.

<- Go to Section TOC

Section 10 page 12

TM110119-REPAIR TECHNICAL MANUAL

Page 21

Section 10 - GENERAL INFORMATION Group 05: Safety

Prevent Acid Burns

Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin, eat holes in

clothing, and cause blindness if splashed into eyes.

Avoid the hazard by:

Filling batteries in a well-ventilated area.1.

Wearing eye protection and rubber gloves.2.

Avoiding breathing fumes when electrolyte is added.3.

Avoiding spilling or dripping electrolyte.4.

Use proper jump start procedure.5.

If you spill acid on yourself:

<- Go to Section TOC

Section 10 page 13

TM110119-REPAIR TECHNICAL MANUAL

Page 22

Section 10 - GENERAL INFORMATION Group 05: Safety

Flush your skin with water.1.

Apply baking soda or lime to help neutralize the acid.2.

Flush your eyes with water for 15—30 minutes. Get medical attention immediately.3.

If acid is swallowed:

Do not induce vomiting.1.

Drink large amounts of water or milk, but do not exceed 2 L (2 quarts).2.

Get medical attention immediately.3.

<- Go to Section TOC

Section 10 page 14

TM110119-REPAIR TECHNICAL MANUAL

Page 23

Section 10 - GENERAL INFORMATION Group 05: Safety

Handle Agricultural Chemicals Safely

Chemicals used in agricultural applications such as fungicides, herbicides, insecticides,

pesticides, rodenticides, and fertilizers can be harmful to your health or the environment if

not used carefully.

Always follow all label directions for effective, safe, and legal use of agricultural chemicals.

Reduce risk of exposure and injury:

Wear appropriate personal protective equipment as recommended by the

manufacturer. In the absence of manufacturer′s instructions, follow these general

guidelines:

Chemicals labeled′Danger′ : Most toxic. Generally require use of goggles,

respirator, gloves, and skin protection.

Chemicals labeled′Warning′ : Less toxic. Generally require use of goggles, gloves,

and skin protections.

<- Go to Section TOC

Section 10 page 15

TM110119-REPAIR TECHNICAL MANUAL

Page 24

Section 10 - GENERAL INFORMATION Group 05: Safety

Chemicals labeled′Caution′ : Least toxic. Generally require use of gloves and skin

protection.

Avoid inhaling vapor, aerosol or dust.

Always have soap, water, and towel available when working with chemicals. If chemical

contacts skin, hands, or face, wash immediately with soap and water. If chemical gets

into eyes, flush immediately with water.

Wash hands and face after using chemicals and before eating, drinking, smoking, or

urination.

Do not smoke or eat while applying chemicals.

After handling chemicals, always bathe or shower and change clothes. Wash clothing

before wearing again.

Seek medical attention immediately if illness occurs during or shortly after use of

chemicals.

Keep chemicals in original containers. Do not transfer chemicals to unmarked

containers or to containers used for food or drink.

Store chemicals in a secure, locked area away from human or livestock food. Keep

children away.

Always dispose of containers properly. Triple rinse empty containers and puncture or

crush containers and dispose of properly.

Clean Vehicle of Hazardous Pesticides

CAUTION:

During application of hazardous pesticides, pesticide residue can build up

on the inside or outside of the vehicle. Clean vehicle according to use

instructions of hazardous pesticides.

When exposed to hazardous pesticides, clean exterior and interior of vehicle daily to keep

free of the accumulation of visible dirt and contamination.

[1] - Sweep or vacuum the floor of cab.

[2] - Clean headliners and inside cowlings of cab.

[3] - Wash entire exterior of vehicle.

[4] - Dispose of any wash water with hazardous concentrations of active or non-active

ingredients according to published regulations or directives.

<- Go to Section TOC

Section 10 page 16

TM110119-REPAIR TECHNICAL MANUAL

Page 25

Section 10 - GENERAL INFORMATION Group 05: Safety

Handling Batteries Safely

<- Go to Section TOC

Section 10 page 17

TM110119-REPAIR TECHNICAL MANUAL

Page 26

Section 10 - GENERAL INFORMATION Group 05: Safety

Battery gas can explode. Keep sparks and flames away from batteries. Use a flashlight to

check battery electrolyte level.

Never check battery charge by placing a metal object across the posts. Use a voltmeter or

hydrometer.

Always remove grounded (-) battery clamp first and replace grounded clamp last.

Sulfuric acid in battery electrolyte is poisonous and strong enough to burn skin, eat holes in

clothing, and cause blindness if splashed into eyes.

Avoid hazards by:

Filling batteries in a well-ventilated area

Wearing eye protection and rubber gloves

<- Go to Section TOC

Section 10 page 18

TM110119-REPAIR TECHNICAL MANUAL

Page 27

Section 10 - GENERAL INFORMATION Group 05: Safety

Avoiding use of air pressure to clean batteries

Avoiding breathing fumes when electrolyte is added

Avoiding spilling or dripping electrolyte

Using correct battery booster or charger procedure.

If acid is spilled on skin or in eyes:

Flush skin with water.1.

Apply baking soda or lime to help neutralize the acid.2.

Flush eyes with water for 15—30 minutes. Get medical attention immediately.3.

If acid is swallowed:

Do not induce vomiting.1.

Drink large amounts of water or milk, but do not exceed 2 L (2 qt.).2.

Get medical attention immediately.3.

WARNING: Battery posts, terminals, and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer and reproductive

harm.Wash hands after handling.

Avoid Harmful Asbestos Dust

Avoid breathing dust that may be generated when handling components containing asbestos

fibers. Inhaled asbestos fibers may cause lung cancer.

Components in products that may contain asbestos fibers are brake pads, brake band and

lining assemblies, clutch plates, and some gaskets. The asbestos used in these components

is usually found in a resin or sealed in some way. Normal handling is not hazardous as long as

airborne dust containing asbestos is not generated.

Avoid creating dust. Never use compressed air for cleaning. Avoid brushing or grinding

<- Go to Section TOC

Section 10 page 19

TM110119-REPAIR TECHNICAL MANUAL

Page 28

Section 10 - GENERAL INFORMATION Group 05: Safety

material containing asbestos. When servicing, wear an approved respirator. A special vacuum

cleaner is recommended to clean asbestos. If not available, apply a mist of oil or water on the

material containing asbestos.

Keep bystanders away from the area.

Dispose of Waste Properly

Improperly disposing of waste can threaten the environment and ecology. Potentially harmful

waste used with John Deere equipment include such items as oil, fuel, coolant, brake fluid,

filters, and batteries.

Use leakproof containers when draining fluids. Do not use food or beverage containers that

may mislead someone into drinking from them.

Do not pour waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth’s atmosphere.

Government regulations may require a certified air conditioning service center to recover and

recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste from your local environmental or

recycling center, or from your John Deere dealer.

<- Go to Section TOC

Section 10 page 20

TM110119-REPAIR TECHNICAL MANUAL

Page 29

Section 10 - GENERAL INFORMATION Group 05: Safety

Avoid High-Pressure Fluids

Inspect hydraulic hoses periodically – at least once per year – for leakage, kinking, cuts,

cracks, abrasion, blisters, corrosion, exposed wire braid or any other signs of wear or

damage.

Replace worn or damaged hose assemblies immediately with John Deere approved

replacement parts.

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten

all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and body from high-pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this

type of injury should reference a knowledgeable medical source. Such information is

available in English from Deere & Company Medical Department in Moline, Illinois, U.S.A., by

calling 1-800-822-8262 or +1 309-748-5636.

Wait Before Opening High-Pressure Fuel System

<- Go to Section TOC

Section 10 page 21

TM110119-REPAIR TECHNICAL MANUAL

Page 30

Section 10 - GENERAL INFORMATION Group 05: Safety

High-pressure fluid remaining in fuel lines can cause serious injury. Only technicians familiar

with this type of system should perform repairs. Before disconnecting fuel lines, sensors, or

any other components between the high-pressure fuel pump and nozzles on engines with

High Pressure Common Rail (HPCR) fuel system, wait a minimum of 15 minutes after engine

is stopped.

Service Accumulator Systems Safely

Escaping fluid or gas from systems with pressurized accumulators that are used in air

conditioning, hydraulic, and air brake systems can cause serious injury. Extreme heat can

cause the accumulator to burst, and pressurized lines can be accidentally cut. Do not weld or

use a torch near a pressurized accumulator or pressurized line.

Relieve pressure from the pressurized system before removing accumulator.

Relieve pressure from the hydraulic system before removing accumulator. Never attempt to

<- Go to Section TOC

Section 10 page 22

TM110119-REPAIR TECHNICAL MANUAL

Page 31

Section 10 - GENERAL INFORMATION Group 05: Safety

relieve hydraulic system or accumulator pressure by loosening a fitting.

Accumulators cannot be repaired.

Protect Against High Pressure Spray

Spray from high pressure nozzles can penetrate the skin and cause serious injury. Keep spray

from contacting hands or body.

If an accident occurs, see a doctor immediately. Any high pressure spray injected into the

skin must be surgically removed within a few hours or gangrene may result. Doctors

unfamiliar with this type of injury should reference a knowledgeable medical source. Such

information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

Service Cooling System Safely

<- Go to Section TOC

Section 10 page 23

TM110119-REPAIR TECHNICAL MANUAL

Page 32

Section 10 - GENERAL INFORMATION Group 05: Safety

Explosive release of fluids from pressurized cooling system can cause serious burns.

Shut off engine. Only remove filler cap when cool enough to touch with bare hands. Slowly

loosen cap to first stop to relieve pressure before removing completely.

Prevent Machine Runaway

Avoid possible injury or death from machinery runaway.

Do not start engine by shorting across starter terminals. Machine will start in gear if normal

circuitry is bypassed.

NEVER start engine while standing on ground. Start engine only from operator’s seat, with

transmission in neutral or park.

Keep ROPS Installed Properly

<- Go to Section TOC

Section 10 page 24

TM110119-REPAIR TECHNICAL MANUAL

Page 33

Section 10 - GENERAL INFORMATION Group 05: Safety

Make certain all parts are reinstalled correctly if the roll-over protective structure (ROPS) is

loosened or removed for any reason. Tighten mounting bolts to proper torque.

The protection offered by ROPS will be impaired if ROPS is subjected to structural damage, is

involved in an overturn incident, or is in any way altered by welding, bending, drilling, or

cutting. A damaged ROPS should be replaced, not reused.

The seat is part of the ROPS safety zone. Replace only with John Deere seat approved for

your tractor.

Any alteration of the ROPS must be approved by the manufacturer.

Avoid Backover Accidents

Before moving machine, be sure that all persons are clear of machine path. Turn around and

look directly for best visibility. Use a signal person when backing if view is obstructed or when

in close quarters.

Do not rely on a camera to determine if personnel or obstacles are behind the machine. The

system can be limited by many factors including maintenance practices, environmental

conditions, and operating range.

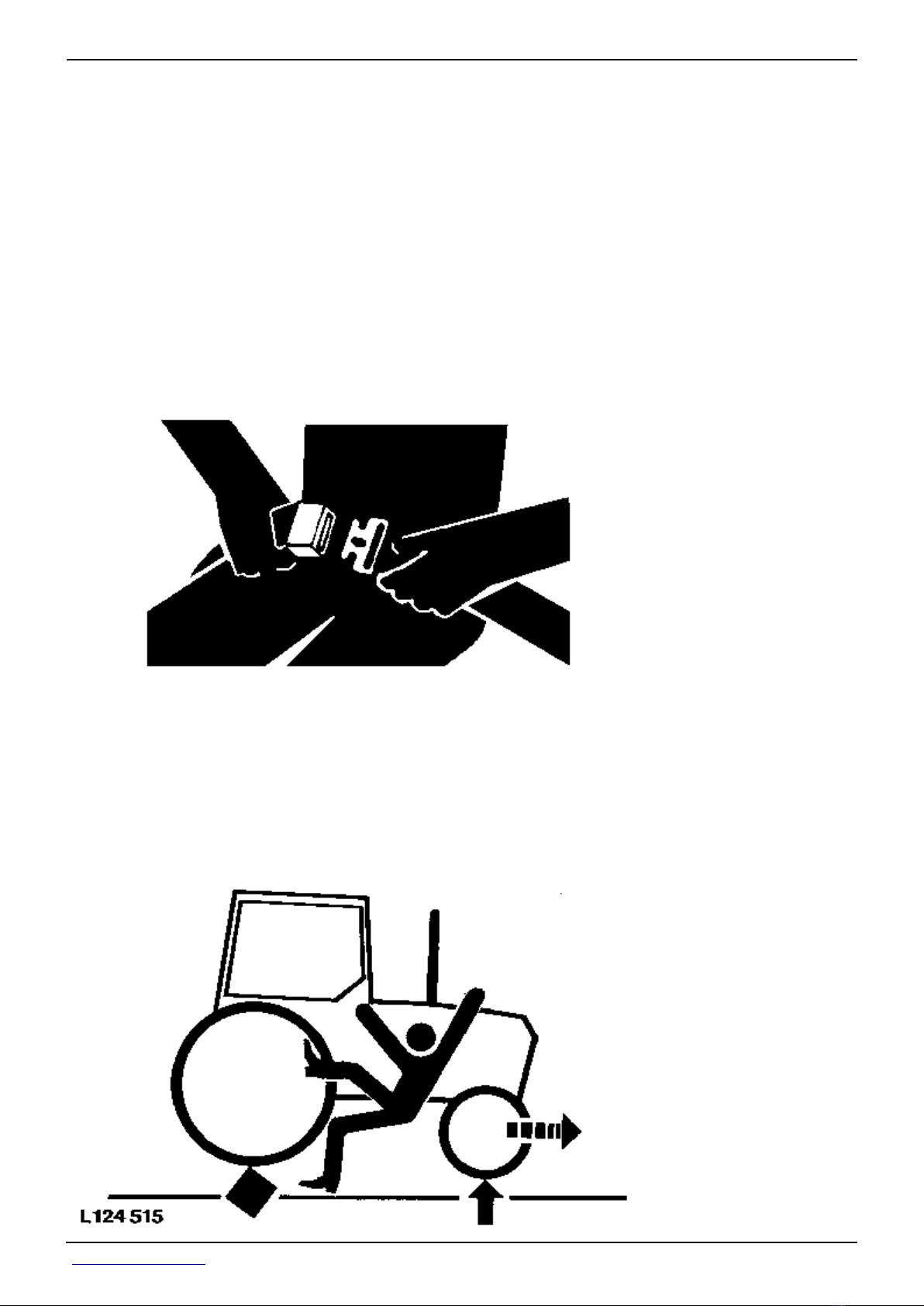

Park Machine Safely

<- Go to Section TOC

Section 10 page 25

TM110119-REPAIR TECHNICAL MANUAL

Page 34

Section 10 - GENERAL INFORMATION Group 05: Safety

Before working on the machine:

Lower all equipment to the ground.

Stop the engine and remove the key.

Disconnect the battery ground strap.

Hang a "DO NOT OPERATE" tag in operator station.

Support Machine Properly

Always lower the attachment or implement to the ground before you work on the machine. If

the work requires that the machine or attachment be lifted, provide secure support for them.

If left in a raised position, hydraulically supported devices can settle or leak down.

Do not support the machine on cinder blocks, hollow tiles, or props that may crumble under

continuous load. Do not work under a machine that is supported solely by a jack. Follow

recommended procedures in this manual.

<- Go to Section TOC

Section 10 page 26

TM110119-REPAIR TECHNICAL MANUAL

Page 35

Section 10 - GENERAL INFORMATION Group 05: Safety

When implements or attachments are used with a machine, always follow safety precautions

listed in the implement or attachment operator′s manual.

Work in Clean Area

Before starting a job:

Clean work area and machine.

Make sure you have all necessary tools to do your job.

Have the right parts on hand.

Read all instructions thoroughly; do not attempt shortcuts.

Work In Ventilated Area

Engine exhaust fumes can cause sickness or death. If it is necessary to run an engine in an

enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension.

<- Go to Section TOC

Section 10 page 27

TM110119-REPAIR TECHNICAL MANUAL

Page 36

Section 10 - GENERAL INFORMATION Group 05: Safety

If you do not have an exhaust pipe extension, open the doors and get outside air into the

area.

Illuminate Work Area Safely

Illuminate your work area adequately but safely. Use a portable safety light for working inside

or under the machine. Make sure the bulb is enclosed by a wire cage. The hot filament of an

accidentally broken bulb can ignite spilled fuel or oil.

Use Proper Lifting Equipment

Lifting heavy components incorrectly can cause severe injury or machine damage.

Follow recommended procedure for removal and installation of components in the manual.

<- Go to Section TOC

Section 10 page 28

TM110119-REPAIR TECHNICAL MANUAL

Page 37

Section 10 - GENERAL INFORMATION Group 05: Safety

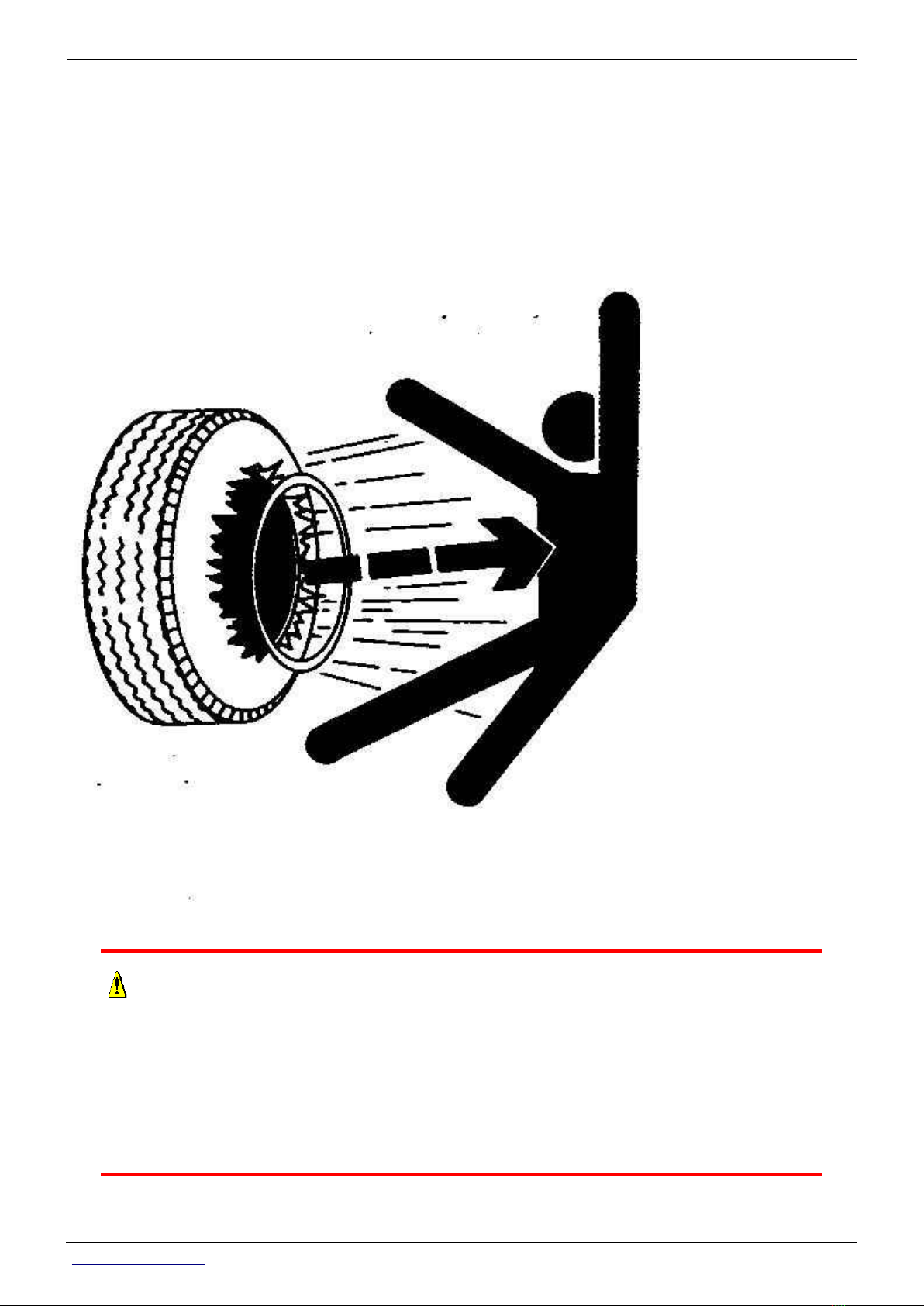

Service Tires Safely

CAUTION:

Explosive separation of a tire and rim parts can cause serious injury or

death.

Do not attempt to mount a tire unless you have the proper equipment and

experience to perform the job.

Always maintain the correct tire pressure. Do not inflate the tires above the recommended

<- Go to Section TOC

Section 10 page 29

TM110119-REPAIR TECHNICAL MANUAL

Page 38

Section 10 - GENERAL INFORMATION Group 05: Safety

pressure.

Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure

resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and extension hose long enough to allow you to

stand to one side and NOT in front of or over the tire assembly. Use a safety cage if available.

Check wheels for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

Instructional Seat

The instructional seat, if so equipped, has been provided only for training operators or

diagnosing machine problems.

Service Front-Wheel Drive Tractor Safely

<- Go to Section TOC

Section 10 page 30

TM110119-REPAIR TECHNICAL MANUAL

Page 39

Section 10 - GENERAL INFORMATION Group 05: Safety

When servicing front-wheel drive tractor with the rear wheels supported off the ground and

rotating wheels by engine power, always support front wheels in a similar manner. Loss of

electrical power or transmission hydraulic system pressure will engage the front driving

wheels, pulling the rear wheels off the support if front wheels are not raised. Under these

conditions, front drive wheels can engage even with switch in disengaged position.

Use Steps and Handholds Correctly

Prevent falls by facing the machine when getting on and off. Maintain 3-point contact with

steps, handholds, and handrails.

Use extra care when mud, snow, or moisture present slippery conditions. Keep steps clean

and free of grease or oil. Never jump when exiting machine. Never mount or dismount a

moving machine.

Transport Tractor Safely

A disabled tractor is best transported on a flatbed carrier. Use chains to secure the tractor to

the carrier. The axles and tractor frame are suitable attachment points.

<- Go to Section TOC

Section 10 page 31

TM110119-REPAIR TECHNICAL MANUAL

Page 40

Section 10 - GENERAL INFORMATION Group 05: Safety

Before transporting the tractor on a low-loader truck or flatbed rail wagon, make sure that

the hood is secured over the tractor engine and that doors, roof hatch (if equipped) and

windows are properly closed.

Never tow a tractor at a speed greater than 10 km/h (6 mph). An operator must steer and

brake the tractor under tow.

Practice Safe Maintenance

Understand service procedure before doing work. Keep area clean and dry.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet , and clothing

from power-driven parts. Disengage all power and operate controls to relieve pressure. Lower

equipment to the ground. Stop the engine. Remove the key. Allow machine to cool.

<- Go to Section TOC

Section 10 page 32

TM110119-REPAIR TECHNICAL MANUAL

Page 41

Section 10 - GENERAL INFORMATION Group 05: Safety

Securely support any machine elements that must be raised for service work.

Keep all parts in good condition and properly installed. Fix damage immediately. Replace

worn or broken parts. Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground cable (-) before making adjustments

on electrical systems or welding on machine.

On towed implements, disconnect wiring harnesses from tractor before servicing electrical

system components or welding on machine.

Use Proper Tools

Use tools appropriate to the work. Makeshift tools and procedures can create safety hazards.

Use power tools only to loosen threaded parts and fasteners.

For loosening and tightening hardware, use the correct size tools. DO NOT use U.S.

measurement tools on metric fasteners. Avoid bodily injury caused by slipping wrenches.

Use only service parts meeting John Deere specifications.

Construct Dealer-Made Tools Safely

<- Go to Section TOC

Section 10 page 33

TM110119-REPAIR TECHNICAL MANUAL

Page 42

Section 10 - GENERAL INFORMATION Group 05: Safety

Faulty or broken tools can result in serious injury. When constructing tools, use proper,

quality materials, and good workmanship.

Do not weld tools unless you have the proper equipment and experience to perform the job.

Replace Safety Signs

Replace missing or damaged safety signs. See the machine operator’s manual for correct

safety sign placement.

Install All Guards

<- Go to Section TOC

Section 10 page 34

TM110119-REPAIR TECHNICAL MANUAL

Page 43

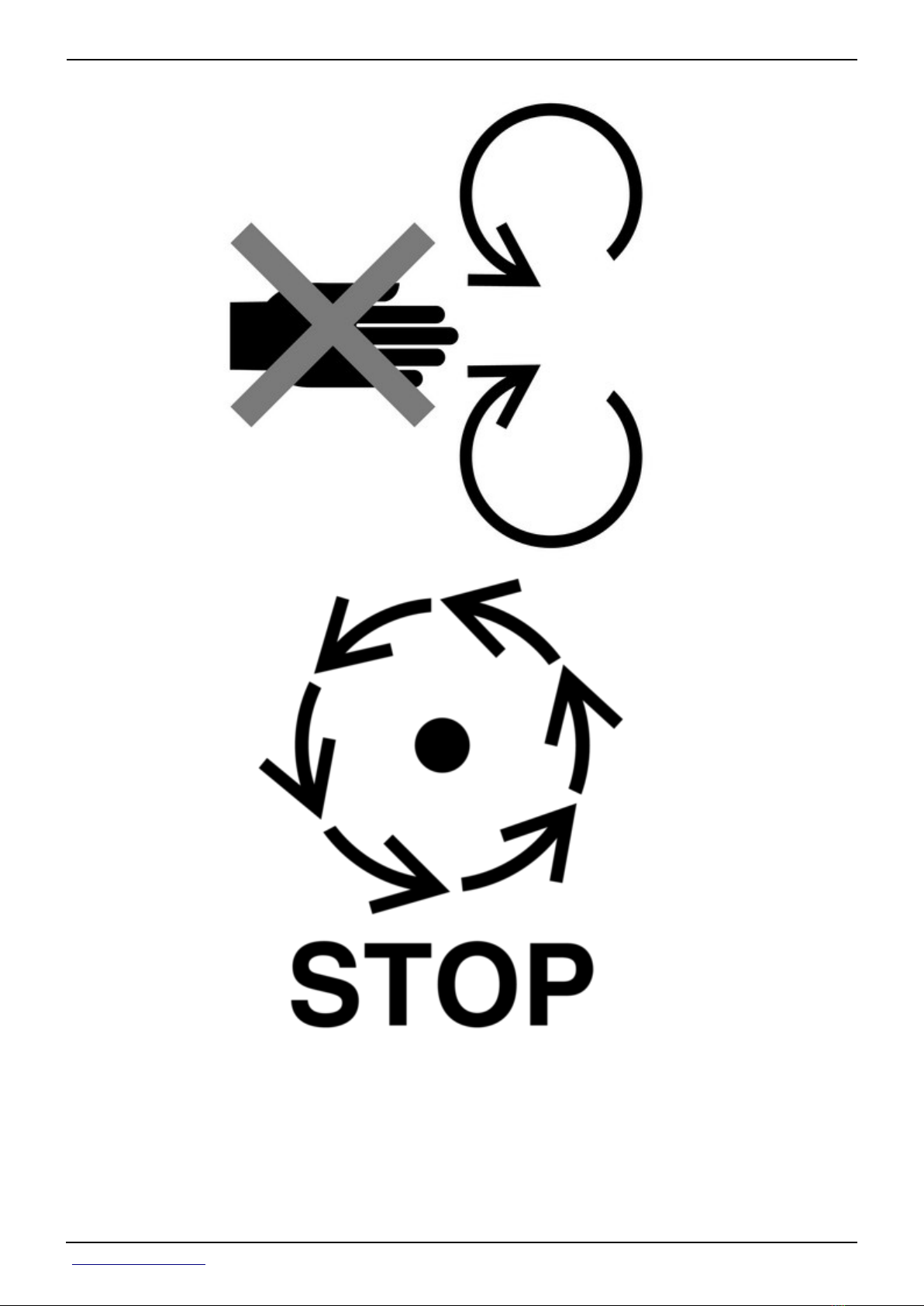

Section 10 - GENERAL INFORMATION Group 10: General Information

Rotating cooling system fans, belts, pulleys, and drives can cause serious injury.

Keep all guards in place at all times during engine operation.

Wear close-fitting clothes. Stop the engine and be sure fans, belts, pulleys, and drives are

stopped before making adjustments, connections, or cleaning near fans and their drive

components.

Live With Safety

Before returning machine to customer, make sure machine is functioning properly, especially

the safety systems. Install all guards and shields.

<- Go to Section TOC

Section 10 page 35

TM110119-REPAIR TECHNICAL MANUAL

Page 44

Section 10 - GENERAL INFORMATION Group 10: General Information

Group 10 - General Information

List of References

Below is a list of all items within this group.

Trademarks

Sealants and Adhesives Cross-Reference Chart

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Face Seal Fittings Assembly and Installation—All Pressure Applications

Metric Face Seal And O-Ring Stud End Fitting Torque Chart—Standard Pressures

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—High Pressure Applications

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—High Pressure Applications

Four Bolt Flange Fittings Assembly and Installation—All Pressure Applications

SAE Four Bolt Flange Cap Screw Torque Values—Standard Pressure Applications

SAE Four Bolt Flange Cap Screw Torque Values—High Pressure Applications

External Hexagon Port Plug Torque Chart

Prevent Hydraulic System Contamination

Check Oil Lines and Fittings

Basic Electrical Component Handling / Precautions For Vehicles Equipped With Computer

Controlled Systems

Identify Zinc-Flake Coated Fasteners

Use Torque Wrench Adapter

Servicing and Connecting Snap to Connect STC™ Fittings

Glossary of Terms

<- Go to Section TOC

Section 10 page 36

TM110119-REPAIR TECHNICAL MANUAL

Page 45

Section 10 - GENERAL INFORMATION Group 10: General Information

Trademarks

Trademarks

AccuDepth™ Trademark of Deere and Company

ACS™ Trademark of Deere and Company

ActiveSeat™ Trademark of Deere and Company

AMBLYGON™ Trademark of Kluber Lubrication

AMPSEAL 16™ Trademark of Tyco Electronics

AutoLoad™ Trademark of Deere and Company

AutoPowr™ Trademark of Deere and Company

AutoPowr™/IVT™ Trademark of Deere and Company

AutoQuad™ II Trademark of Deere and Company

AutoQuad™ PLUS Trademark of Deere and Company

AutoTrac™ Trademark of Deere and Company

Avdel™ Trademark of Avdel UK Limited

Bio Hy-Guard™ Trademark of Deere and Company

Break-In™ Trademark of Deere and Company

Break-In PLUS™ Trademark of Deere and Company

CINCH™ Trademark of Cinch Inc.

ClimaTrak™ Trademark of Deere and Company

ComfortCommand™ Trademark of Deere and Company

ComfortGard™ Trademark of Deere and Company

ComfortGard Deluxe™ Trademark of Deere and Company

CommandARM™ Trademark of Deere and Company

CommandCenter™ Trademark of Deere and Company

CommandQuad™ Trademark of Deere and Company

CommandView™ Trademark of Deere and Company

COOL-GUARD™ II Trademark of Deere and Company

CoolScan™ Trademark of Deere and Company

CPC™ Trademark of AMP Incorporated

Deere™ Trademark of Deere and Company

DEUTSCH™ Trademark of Deutsch Company

DURABUILT™ Trademark of Camoplast Inc.

Efficiency Manager™ Trademark of Deere and Company

FieldCruise™ Trademark of Deere and Company

Field Doc™ Trademark of Deere and Company

Field Office™ Trademark of Deere and Company

<- Go to Section TOC

Section 10 page 37

TM110119-REPAIR TECHNICAL MANUAL

Page 46

Section 10 - GENERAL INFORMATION Group 10: General Information

Trademarks

GreenStar™ Trademark of Deere and Company

HY-GARD™ Trademark of Deere and Company

ILS™ Trademark of Deere and Company

iPhone® Trademark of Apple, Inc.

iPod® Trademark of Apple, Inc.

iPod Touch® Trademark of Apple, Inc.

iTEC™ Trademark of Deere and Company

iTEC™ Pro Trademark of Deere and Company

IVT™ Trademark of Deere and Company

IVT Selector™ Trademark of Deere and Company

JDLink™ Trademark of Deere and Company

JDOffice™ Trademark of Deere and Company

John Deere™ Trademark of Deere and Company

Loctite™ Trademark of Henkel Corporation

MATE-N-LOC™ Trademark of AMP Incorporated

METRIMATE™ Trademark of AMP Incorporated

METRI-PACK™ Trademark of Delphi Packard Electric Systems

NEVER-SEEZ™ Trademark of Bostik-Findley Inc.

Oilscan™ Trademark of Deere and Company

Parallel Tracking™ Trademark of Deere and Company

PLUS-50™ II Trademark of Deere and Company

PowrQuad™ Trademark of Deere and Company

PowrQuad™ PLUS Trademark of Deere and Company

PowerTech™ Trademark of Deere and Company

PowerTech™ Plus Trademark of Deere and Company

Power Zero™ Trademark of Deere and Company

QUICK METAL™ Trademark of Henkel Corporation

QuickTatch™ Trademark of Deere and Company

Row-Trak™ Trademark of Deere and Company

ServiceADVISOR™ Trademark of Deere and Company

SERVICEGARD™ Trademark of Deere and Company

StarFire™ Trademark of Deere and Company

StarFire™ iTC Trademark of Deere and Company

STC™ Trademark of Aeroquip Corporation

StellarSupport™ Trademark of Deere and Company

SUMITOMO™ Trademark of Sumitomo Corporation

<- Go to Section TOC

Section 10 page 38

TM110119-REPAIR TECHNICAL MANUAL

Page 47

Section 10 - GENERAL INFORMATION Group 10: General Information

Trademarks

TEFLON™ Trademark of DuPont Co.

TIA™ Trademark of Deere and Company

TLS™ Trademark of Deere and Company

TLS™ Plus Trademark of Deere and Company

TouchSet™ Trademark of Deere and Company

Tractor-Implement Automation™ Trademark of Deere and Company

Vari-Cool™ Trademark of Deere and Company

Weather Pack™ Trademark of Packard Electric

YAZAKI™ Trademark of Yazaki Corporation

<- Go to Section TOC

Section 10 page 39

TM110119-REPAIR TECHNICAL MANUAL

Page 48

Section 10 - GENERAL INFORMATION Group 10: General Information

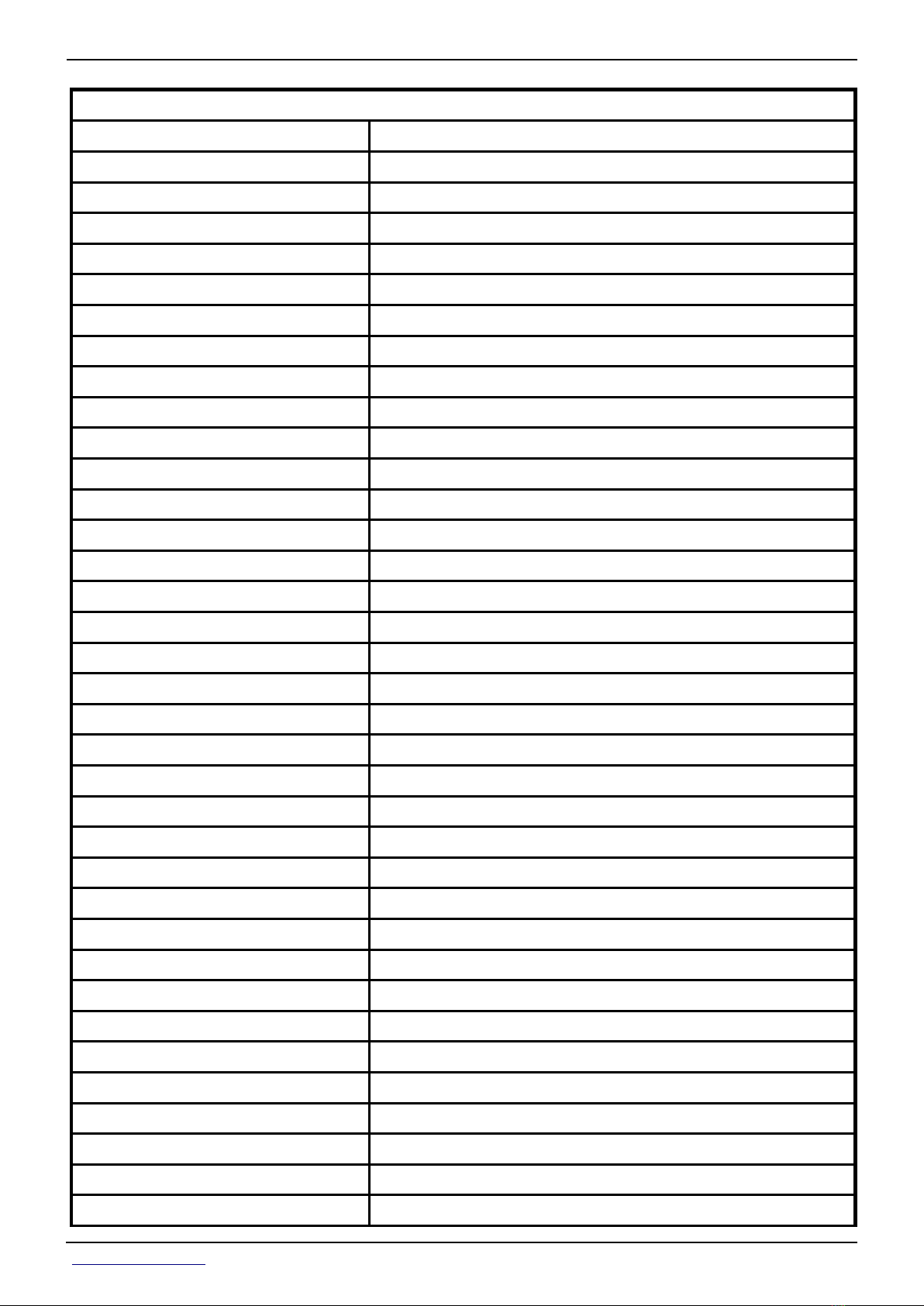

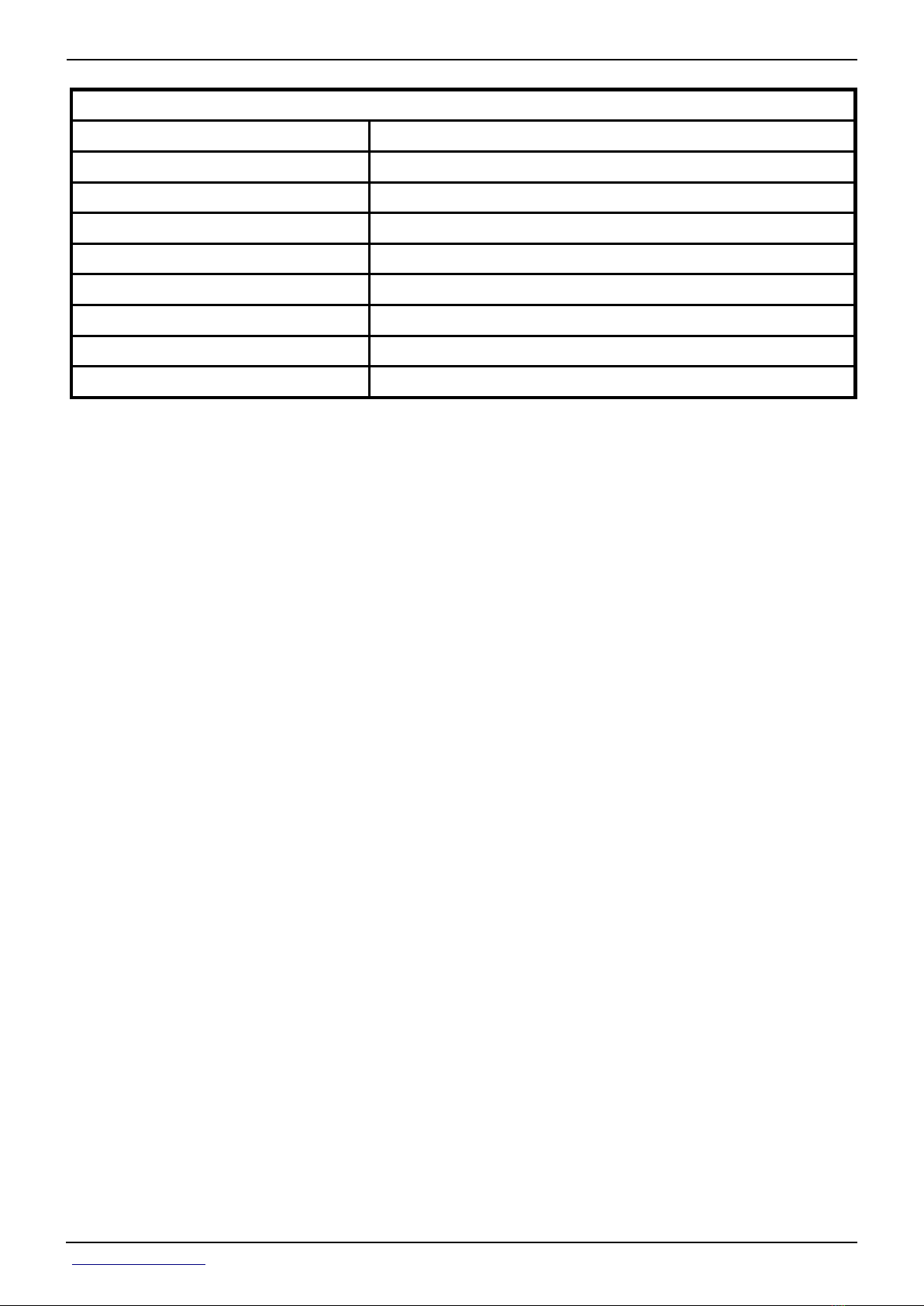

Sealants and Adhesives Cross-Reference Chart

<- Go to Section TOC

Section 10 page 40

TM110119-REPAIR TECHNICAL MANUAL

Page 49

Section 10 - GENERAL INFORMATION Group 10: General Information

U.S. Part Number

Bonding

PM37513 PM38606 BLACK AND WHITE 4 g Epoxy Adhesive 21425

PM37391 PM38615 CLEAR 2 g Gel Super Glue 454

PM37532 — BLACK 5 oz Weatherstrip Adhesive 30540

— PM38603 YELLOW 147 ml Weatherstrip Adhesive 30537

Gasketing

PM38655 PM38625 PURPLE 50 ml Flexible Form-in-Place Gasket 515

— PM38600 BROWN 118 ml Liquid Gasket Maker 30524

PM37559 PM38600 BROWN 4 oz

PM38657 PM38628 BLUE 50 ml High-Flex Form-in-Place Gasket 17430

PM37463 PM37463 CLEAR 80 g RTV Clear Silicone 59530

PM37521 CLEAR 30 g RTV Clear Silicone 59575

— PM38618 CLEAR 300 g RTV Clear Silicone

PM37465 PM38616 METALLIC BLUE 80 ml Ultra Blue RTV Silicone 58730

PM37553 PM37553 BURGUNDY 16 oz High Tack Gasket Dressing 30525

PM37555 PM38607 BURGUNDY 9 oz aerosol Hi-Tack Gasket Sealant 30524

PM37469 PM38609 RED 80 g Hi-Temp RTV Silicone 59630

PM37529 — RED 7.25 aerosol Hi-Temp RTV Silicone 30541

PM37512 PM37512 — — Flexible Flange Sealant 5900

PM37616 — — 20 g Stick Copper Anti-Seize Stick —

PM37617 — — 20 g Stick Silver-Grade Anti-Seize Stick —

TY24810 TY24810 — 12.5 aerosol NEVER-SEEZ ™ —

TY24811 TY24811 — 8 oz can with brush NEVER-SEEZ ™ —

H154379 — GREEN Sealant —

Canadian Part

Number

Color Size Description

General Purpose Gasket Dressing (Aviation Gasket

Sealant)

LOCTITE ™

/Permatex Number

30517

Priming

PM37509 PM38611 GREEN 4.5 oz Cure Primer 7649

Retaining

PM38651 PM38612 SILVER 50 ml QUICK METAL ™ 660

PM37485 — GREEN 36 ml Maximum Strength 680

— PM38626 GREEN 50 ml Maximum Strength 62083

PM38652 — GREEN 36 ml High-Temperature 620

Thread Locking and Sealing

PM38653 — PURPLE 6 ml Low Strength 222

— PM38645 PURPLE 2 g Superglue Instant Adhesive 22200

PM37418 PM38621 BLUE 6 ml Medium Strength 242

PM37477 PM38622 BLUE 36 ml Medium Strength 242

PM37643 — BLUE 9 g Stick Blue Stick Threadlocker (medium-strength) —

PM37614 — BLUE 19 g Stick Blue Stick Threadlocker (medium-strength) —

PM37615 — — 19 g Stick PST Thread Sealant Stick —

PM37421 PM38623 RED 6 ml High Strength

PM38654 PM38623 RED 36 ml High Strength 271

— PM38624 RED 50 ml High Strength 27140

PM38656 PM38627 RED 36 ml High Strength 277

PM37700 — RED 19 g Stick Red Stick Threadlocker (High-Strength) —

PM37701 — RED 9 g Stick Red Stick Threadlocker (High-Strength) —

PM37398 PM38613 WHITE 6 ml Pipe Sealant with TEFLON ™ 592

PM37397 PM38613 WHITE 50 ml Pipe Sealant with TEFLON 592

271 (usually red in

color)

<- Go to Section TOC

Section 10 page 41

TM110119-REPAIR TECHNICAL MANUAL

Page 50

Section 10 - GENERAL INFORMATION Group 10: General Information

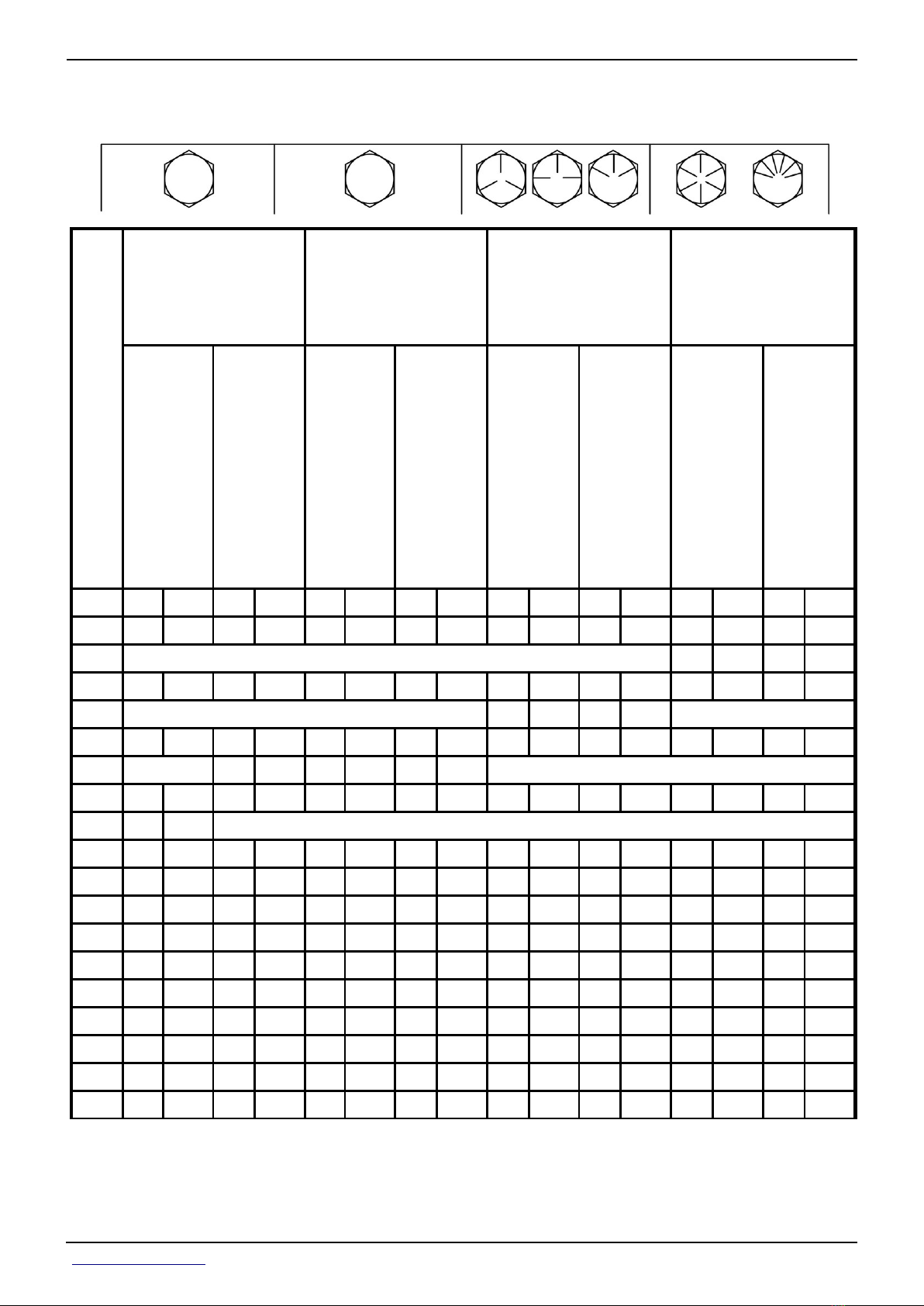

Metric Bolt and Screw Torque Values

Class 4.8 Class 8.8 or 9.8 Class 10.9 Class 12.9

Bolt

or

Screw

Size

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

M20 and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

M6 to M18

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

M20 and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

M6 to M18

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

M20 and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

M6 to M18

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

M20 and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

M6 to M18

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in.

M6 4.7 42 6 53 8.9 79 11.3 100 13 115 16.5 146 15.5 137 19.5 172

N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft.

M8 11.5 102 14.5 128 22 194 27.5 243 32 23.5 40 29.5 37 27.5 47 35

N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft.

M10 23 204 29 21 43 32 55 40 63 46 80 59 75 55 95 70

N˙m lb.-ft.

M12 40 29.5 50 37 75 55 95 70 110 80 140 105 130 95 165 120

M14 63 46 80 59 120 88 150 110 175 130 220 165 205 150 260 190

M16 100 74 125 92 190 140 240 175 275 200 350 255 320 235 400 300

M18 135 100 170 125 265 195 330 245 375 275 475 350 440 325 560 410

M20 190 140 245 180 375 275 475 350 530 390 675 500 625 460 790 580

M22 265 195 330 245 510 375 650 480 725 535 920 680 850 625 1080 800

M24 330 245 425 315 650 480 820 600 920 680 1150 850 1080 800 1350 1000

M27 490 360 625 460 950 700 1200 885 1350 1000 1700 1250 1580 1160 2000 1475

M30 660 490 850 625 1290 950 1630 1200 1850 1350 2300 1700 2140 1580 2700 2000

M33 900 665 1150 850 1750 1300 2200 1625 2500 1850 3150 2325 2900 2150 3700 2730

M36 1150 850 1450 1075 2250 1650 2850 2100 3200 2350 4050 3000 3750 2770 4750 3500

Torque values listed are for general use only, based on the

strength of the bolt or screw. DO NOT use these values if a

different torque value or tightening procedure is given for a

specific application. For stainless steel fasteners or for nuts

on U-bolts, see the tightening instructions for the specific

application. Tighten plastic insert or crimped steel type lock

nuts by turning the nut to the dry torque shown in the chart,

unless different instructions are given for the specific

application.

Shear bolts are designed to fail under predetermined loads. Always

replace shear bolts with identical property class. Replace fasteners

with the same or higher property class. If higher property class

fasteners are used, tighten these to the strength of the original. Make

sure fastener threads are clean and that you properly start thread

engagement. When possible, lubricate plain or zinc plated fasteners

other than lock nuts, wheel bolts or wheel nuts, unless different

instructions are given for the specific application.

<- Go to Section TOC

Section 10 page 42

TM110119-REPAIR TECHNICAL MANUAL

Page 51

Section 10 - GENERAL INFORMATION Group 10: General Information

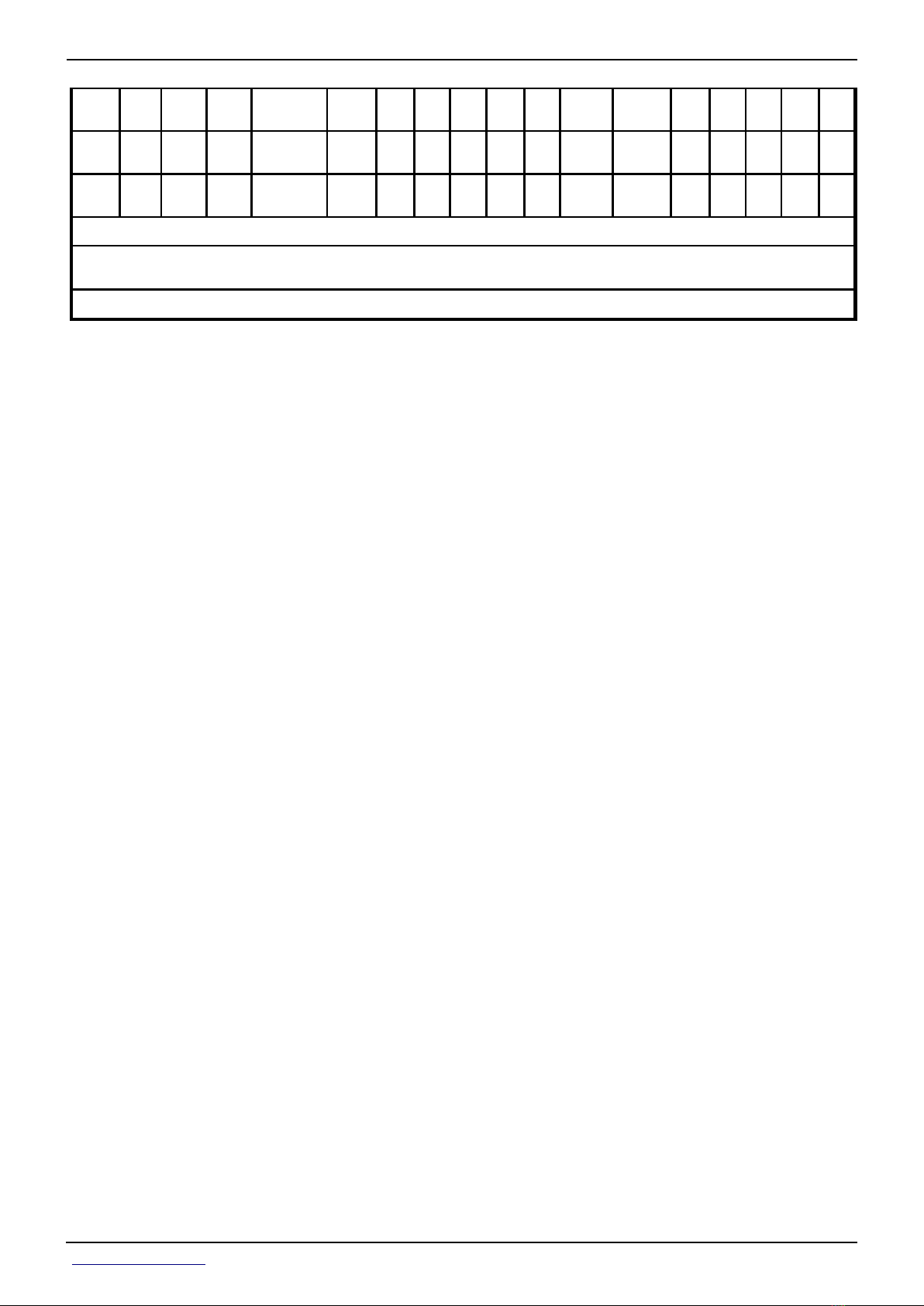

Unified Inch Bolt and Screw Torque Values

SAE Grade 2

[ Grade 2 applies for hex cap

screws (not hex bolts) up to 6

SAE Grade 1

in. (152 mm) long. Grade 1

applies for hex cap screws

over 6 in. (152 mm) long, and

for all other types of bolts and

screws of any length. ]

SAE Grade 5, 5.1 or 5.2 SAE Grade 8 or 8.2

Bolt

or

Screw

Size

Lubricated

[

“Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[

“Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in.

1/4 3.7 33 4.7 42 6 53 7.5 66 9.5 84 12 106 13.5 120 17 150

N˙m lb.-ft. N˙m lb.-ft.

5/16 7.7 68 9.8 86 12 106 15.5 137 19.5 172 25 221 28 20.5 35 26

N˙m lb.-ft. N˙m lb.-ft.

3/8 13.5 120 17.5 155 22 194 27 240 35 26 44 32.5 49 36 63 46

N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft.

7/16 22 194 28 20.5 35 26 44 32.5 56 41 70 52 80 59 100 74

N˙m lb.-ft.

1/2 34 25 42 31 53 39 67 49 85 63 110 80 120 88 155 115

9/16 48 35.5 60 45 76 56 95 70 125 92 155 115 175 130 220 165

5/8 67 49 85 63 105 77 135 100 170 125 215 160 240 175 305 225

3/4 120 88 150 110 190 140 240 175 300 220 380 280 425 315 540 400

7/8 190 140 240 175 190 140 240 175 490 360 615 455 690 510 870 640

1 285 210 360 265 285 210 360 265 730 540 920 680 1030 760 1300 960

1-1/8 400 300 510 375 400 300 510 375 910 670 1150 850 1450 1075 1850 1350

1-1/4 570 420 725 535 570 420 725 535 1280 945 1630 1200 2050 1500 2600 1920

1-3/8 750 550 950 700 750 550 950 700 1700 1250 2140 1580 2700 2000 3400 2500

1-1/2 990 730 1250 930 990 730 1250 930 2250 1650 2850 2100 3600 2650 4550 3350

<- Go to Section TOC

Section 10 page 43

TM110119-REPAIR TECHNICAL MANUAL

Page 52

Section 10 - GENERAL INFORMATION Group 10: General Information

SAE Grade 2

[ Grade 2 applies for hex cap

screws (not hex bolts) up to 6

SAE Grade 1

in. (152 mm) long. Grade 1

applies for hex cap screws

over 6 in. (152 mm) long, and

for all other types of bolts and

screws of any length. ]

SAE Grade 5, 5.1 or 5.2 SAE Grade 8 or 8.2

Bolt

or

Screw

Size

Lubricated

[

“Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[

“Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Torque values listed are for general use only, based on the strength

of the bolt or screw. DO NOT use these values if a different torque

value or tightening procedure is given for a specific application. For

plastic insert or crimped steel type lock nuts, for stainless steel

fasteners, or for nuts on U-bolts, see the tightening instructions for

the specific application. Shear bolts are designed to fail under

predetermined loads. Always replace shear bolts with identical grade.

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Lubricated

[ “Lubricated”

means coated

with a

lubricant such

as engine oil,

fasteners with

phosphate

and oil

coatings, or

7/8 in. and

larger

fasteners with

JDM F13C,

F13F or F13J

zinc flake

coating. ]

Dry

[ “Dry” means

plain or zinc

plated without

any

lubrication, or

1/4 to 3/4 in.

fasteners with

JDM F13B,

F13E or F13H

zinc flake

coating. ]

Replace fasteners with the same or higher grade. If higher

grade fasteners are used, tighten these to the strength of the

original. Make sure fastener threads are clean and that you

properly start thread engagement. When possible, lubricate

plain or zinc plated fasteners other than lock nuts, wheel

bolts or wheel nuts, unless different instructions are given for

the specific application.

<- Go to Section TOC

Section 10 page 44

TM110119-REPAIR TECHNICAL MANUAL

Page 53

Section 10 - GENERAL INFORMATION Group 10: General Information

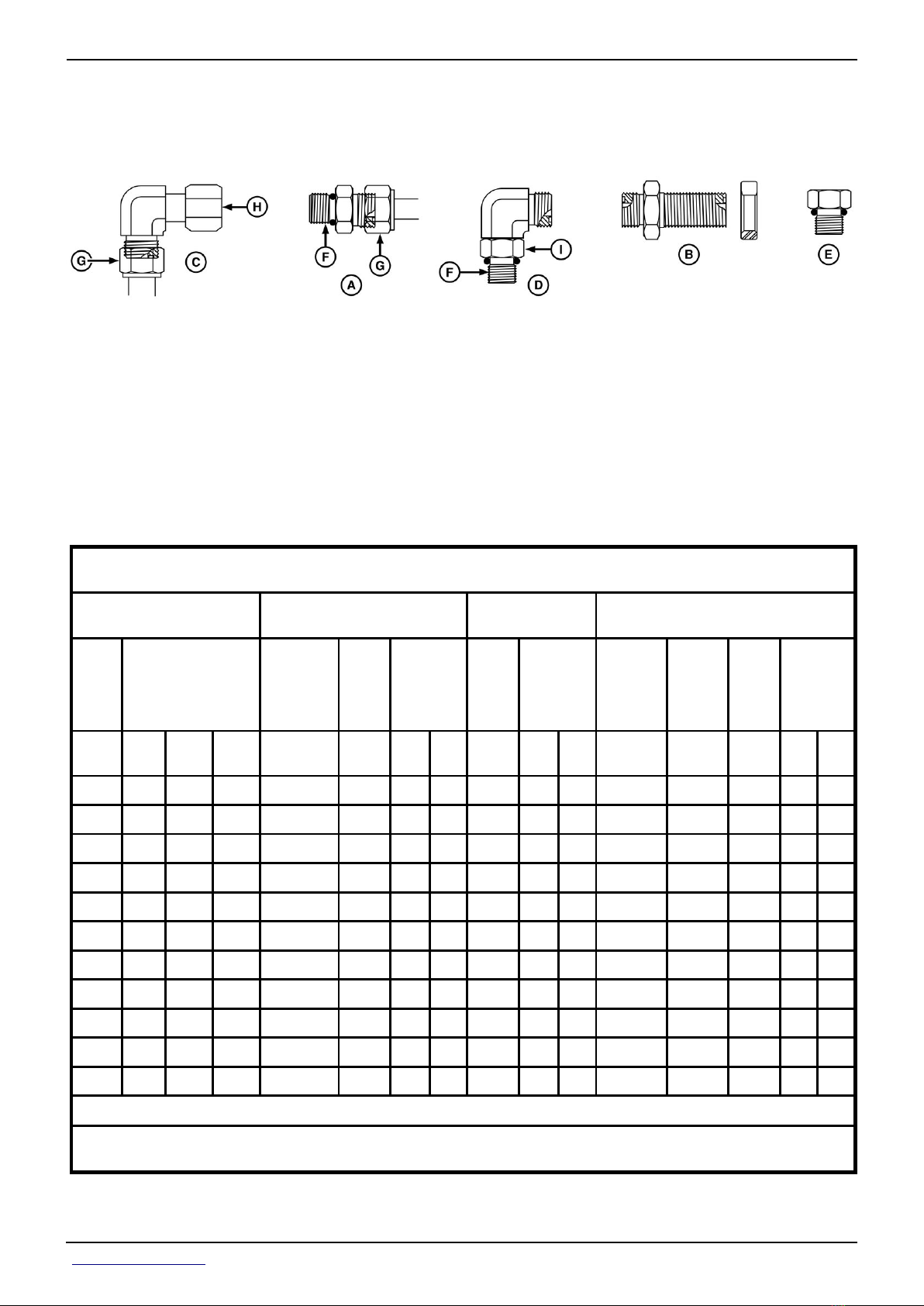

Face Seal Fittings Assembly and Installation—All

Pressure Applications

Face Seal O-Ring to Stud End Installation

[1] - Inspect the fitting surfaces. They must be free of dirt and/or defects.

[2] - Inspect the O-ring. It must be free of damage and/or defects.

[3] - Lubricate O-rings and install into groove using petroleum jelly to hold in place.

[4] - Push O-ring into groove with petroleum jelly so O-ring is not displaced during assembly.

[5] - Index angle fittings and tighten by hand pressing joint together to insure O-ring remains

in place.

[6] - Tighten fitting or nut to torque value shown on the chart per dash size stamped on the

fitting. DO NOT allow hoses to twist when tightening fittings.

Face Seal Adjustable Stud End O-Ring Installation

[1] - Back off lock nut (jam nut) and washer to full exposed turned down section of the

fitting.

[2] - Install a thimble over the fitting threads to protect the O-ring from nicks.

[3] - Slide the O-ring over the thimble into the turned down section of the fitting.

[4] - Remove thimble.

Face Seal Straight Stud End O-Ring Installation

[1] - Install a thimble over the fitting threads to protect the O-ring from nicks.

[2] - Slide the O-ring over the thimble into the turned down section of the fitting.

[3] - Remove thimble.

Fitting Installation

[1] - Install fitting by hand until snug.

[2] - Position adjustable fittings by unscrewing the fitting no more than one turn.

[3] - Apply assembly torque per table.

Assembly Torque

[1] - Use one wrench to hold the connector body and one wrench to tighten nut.

[2] - For a hydraulic hose, it may be necessary to use three wrenches to prevent twist; one

on the connector body, one on the nut, and one on the body of the hose fitting.

<- Go to Section TOC

Section 10 page 45

TM110119-REPAIR TECHNICAL MANUAL

Page 54

Section 10 - GENERAL INFORMATION Group 10: General Information

Metric Face Seal And O-Ring Stud End Fitting

Torque Chart—Standard Pressures

LEGEND:

A Straight Stud and Tube Nut

B Bulkhead Union and Bulkhead Jam Nut

C 90° Swivel Elbow and Tube Nut

D 90° Adjustable Stud Elbow

E Port Plug

F Stud End

G Tube Nut

H Swivel Nut

I Jam Nut

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressure-Below 27.6 MPA (4,000 PSI)

Nominal Tube OD

Hose ID

Metric

TubeODInch Tube OD

mm

4 -2 0.125 3.18 — — — — — — — M8 X 1 12 12 8 6 5 4

5 -3 0.188 4.76 — — — — — — —

6 -4 0.250 6.35 9/16-18 17 16 12 22 32 24

8 -5 0.312 7.92 — — — — — — —

10 -6 0.375 9.53 11/16-16 22 24 18 27 42 31

12 -8 0.500 12.70 13/16-16 24 50 37 30 93 69

16 -10 0.625 15.88 1-14 30 69 51 36 118 87

Dash

in. mm in. mm N˙m lb-ft mm N˙m lb-ft mm mm mm N·m lb-ft N˙m lb-ft

Size

O-Ring Face Seal/

Tube Swivel Nut

Thread

Size

Swivel

Nut

Hex

Size

Tube

Nut/Swivel

Nut

Torque

Bulkhead Jam

Nut Torque

Jam

Nut

Jam Nut

Hex

Torque

Size

O-Ring Straight, Adjustable, and External Port

A

Plug Stud Ends

Thread

Size

M10 X

1

M12 X

1.5

M14 X

1.5

M16 X

1.5

M18 X

1.5

M22 X

1.5

A

Adj

Straight

Hex

B

Size

14 14 15 11 10 7

17 17 25 18 17 12

19 19 40 30 27 20

22 22 45 33 30 22

24 24 50 37 33 25

27 27 69 51 46 34

Lock

Nut

Hex

Size

Steel

or

Gray Iron

Torque

Aluminum

or

Brass

Torque

C

20 -12 0.750 19.05 1-3/16-12 36 102 75 41 175 129

22 -14 0.875 22.23 1-3/16-12 36 102 75 41 175 129

25 -16 1.000 25.40 1-7/16-12 41 142 105 46 247 182

28 — — — — — — — — — —

<- Go to Section TOC

Section 10 page 46

M27 X

2

M30 X

2

M33 X

2

M38 x

2

32 32 100 74 67 49

36 36 130 96 87 64

41 41 160 118 107 79

46 46 176 130 117 87

TM110119-REPAIR TECHNICAL MANUAL

Page 55

Section 10 - GENERAL INFORMATION Group 10: General Information

32 -20 1.250 31.75 1-11/16-12 50 190 140 50 328 242

38 -24 1.500 38.10 2-12 60 217 160 60 374 276

50 -32 2.000 50.80 — — — — — — —

A

Tolerance is +15%, minus 20% of mean tightening torque unless otherwise specified.

B

The straight hex wrench sizes listed apply to connectors only and may not be the same as the corresponding plug of the same

M42 X

2

M48 X

2

M60 X

2

50 50 210 155 140 103

55 55 260 192 173 128

65 65 315 232 210 155

thread size.

C

These torques were established using steel plated connectors in aluminum and brass.

<- Go to Section TOC

Section 10 page 47

TM110119-REPAIR TECHNICAL MANUAL

Page 56

Section 10 - GENERAL INFORMATION Group 10: General Information

Metric Face Seal and O-Ring Stud End Fitting

Torque Chart—High Pressure Applications

LEGEND:

A Stud Straight and Tube Nut

B Bulkhead Union and Bulkhead Lock Nut

C 90° Swivel Elbow and Tube Nut

D 90° Adjustable Stud Elbow

E Port Plug

F Stud End

G Tube Nut

H Swivel Nut

I Lock Nut

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—High Pressure-Above 27.6 MPA (4,000 PSI),

Working Pressure-41.3 MPA (6,000 PSI)

Nominal Tube OD

Hose ID

Metric

TubeODInch Tube OD

mm

4 -2 0.125 3.18 — — — — — — — M8 X 1 12 12 8 6

5 -3 0.188 4.76 — — — — — — —

6 -4 0.250 6.35 9/16-18 17 24 18 22 32 24

8 -5 0.312 7.92 — — — — — — —

10 -6 0.375 9.53 11/16-16 22 37 27 27 42 31

Dash

in. mm in. mm N˙m lb-ft mm N˙m lb-ft mm. mm mm N·m lb-ft

Size

O-Ring Face Seal/

Tube Swivel Nut

Swivel

Thread

Size

Nut

Hex

Size

Tube

Nut/Swivel

Nut

Torque

Bulkhead Jam

Nut

A

Torque

Jam

Nut

Jam Nut

Hex

Torque

Size

O-Ring Straight, Adjustable, and

External Port Plug Stud Ends

Adj

Thread

Size

M10 X

1

M12 X

1.5

M14 X

1.5

M16 X

1.5

Straight

Hex

Size

14 14 15 11

17 17 35 26

19 19 45 33

22 22 55 41

Lock

Nut

B

Hex

Size

A

Steel

or

Gray Iron

Torque

12 -8 0.500 12.70 13/16-16 24 63 46 30 93 69

16 -10 0.625 15.88 1-14 30 103 76 36 118 87

20 -12 0.750 19.05 1-3/16-12 36 152 112 41 175 129

22 -14 0.875 22.23 1-3/16-12 36 152 112 41 175 129

<- Go to Section TOC

Section 10 page 48

M18 X

1.5

M22 X

1.5

M27 X

2

M30 X

2

TM110119-REPAIR TECHNICAL MANUAL

24 24 70 52

27 27 100 74

32 32 170 125

36 36 215 159

Page 57

Section 10 - GENERAL INFORMATION Group 10: General Information

25 -16 1.000 25.40 1-7/16-12 41 214 158 46 247 182

28 — — — — — — — — — —

32 -20 1.250 31.75 1-11/16-12 — 286 211 50 328 242

38 -24 1.500 38.10 2-12 — 326 240 60 374 276

A

Tolerance is +15%, minus 20% of mean tightening torque unless otherwise specified.

B

The straight hex wrench sizes listed apply to connectors only and may not be the same as the corresponding plug of the

M33 X

2

M38 x

2

M42 X

2

M48 X

2

41 41 260 192

46 46 320 236

50 50 360 266

55 55 420 310

same thread size.

<- Go to Section TOC

Section 10 page 49

TM110119-REPAIR TECHNICAL MANUAL

Page 58

Section 10 - GENERAL INFORMATION Group 10: General Information

SAE Face Seal and O-Ring Stud End Fitting Torque

Chart—Standard Pressures

LEGEND:

A Stud Straight and Tube Nut

B Bulkhead Union and Bulkhead Lock Nut

C 90° Swivel Elbow and Tube Nut

D 90° Adjustable Stud Elbow

E Port Plug

F Stud End

G Tube Nut

H Swivel Nut

I Lock Nut

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressure-Below 27.6 MPA (4,000 PSI)

Nominal Tube OD

Hose ID

Metric

TubeODInch Tube OD

mm

5 -3 0.188 4.78 — — — — — — — 3/8-24 5/8 9/16 12 9 8 6

6 -4 0.250 6.35 9/16-18 11/16 16 12 13/16 32 24 7/16-20 5/8 5/8 16 12 11 8

8 -5 0.312 7.92 — — — — — — — 1/2-20 3/4 11/16 24 18 16 12

10 -6 0.375 9.53 11/16-16 13/16 24 18 1 42 31 9/16-18 3/4 3/4 37 27 25 18

12 -8 0.500 12.70 13/16-16 15/16 50 37 1-1/8 93 69 3/4-16 7/8 15/16 50 37 33 25

16 -10 0.625 15.88 1-14 1-1/8 69 51 1-5/16 118 87 7/8-14 1-1/16 1-1/16 69 51 46 34

20 -12 0.750 19.05 1-3/16-12 1-3/8 102 75 1-1/2 175 129 1-1/16-12 1-1/4 1-3/8 102 75 68 50

22 -14 0.875 22.23 1-3/16-12 — 102 75 — 175 129 1-3/16-12 1-3/8 1-1/2 122 90 81 60

25 -16 1.000 25.40 1-7/16-12 1-5/8 142 105 1-3/4 247 182 1-5/16-12 1-1/2 1-5/8 142 105 95 70

32 -20 1.25 31.75 1-11/16-12 1-7/8 190 140 2 328 242 1-5/8-12 1-3/4 1-7/8 190 140 127 93

Dash

in. mm in. in. N˙m lb-ft N˙m lb-ft in. in. in. N·m lb-ft N˙m lb-ft

Size

O-Ring Face Seal/

Tube Swivel Nut

Thread

Size

Swivel

Nut

Hex

Size

Tube Nut

Swivel Nut

Torque

Bulkhead Jam Nut

A

Torque

Jam

Nut

Hex

Size

Jam Nut

Torque

O-Ring Straight, Adjustable, and External Port Plug

Stud Ends

Thread

Size

A

Straight

Hex

Size

Adj

Lock

Nut

B

Hex

Size

Steel

or

Gray Iron

Torque

Aluminum

or

Brass

Torque

C