Page 1

,.

w

6300 BULLDOZER

-- --- ---

FEATURES

Inside-mounted with one-lever hydraulic

control.

Walk-through compartment.

Excellent visibility.

Choice of gO-inch or 72-inch blade.

3-piece, reversible, replaceable cutting edge.

High, fast-acting lift.

Positive down pressure.

Float position.

Right and left manual angling.

Right and left manual tilt.

Load-shaped blade provides maximum roil-

ing action.

Available in combination with Rotoboom,

winch, log arch,

SPECIFICATIONS

(Specifications and design are subject to change

without notice. Wherever applicable, specifica-

tions are in accordance with fEMC and SAE

Standards.)

Crawler.. .JD350 (gasoline or Diesel) with 46

gross flywheel and 42 net flywheel h.p. (at 500 ft.

altitude and 85° F. temp.). Engine equipped with

fan, air cleaner, water pump, lubricating oil pump,

fuel pump, and alternator.

Lift height above ground level .37-1/4 in.

Cutting depth below ground leveL.. .11-1/2 in.

Angle positions. .. Straight or 25 degrees left or

right (set manually).

Tilt positions 72-in. blade 90-in. blade

Right end down (set man-

ually) 12-1/2in. 16-1/2 in.

Left end down (set manu-

ally) 8-1/8 in. 10-3/16 in.

Blade. .. Reinforced, box-welded, 72 or 90in. long.

Cutting edge .3-piece, reversible replaceable,

heat-treated, high-carbon steel; center section

1/2 in.; end bits 5/8 in.

Bladeheight 23in.

Boom Reinforced box-welded.

Hydraulic system:

Control. . . Single-lever, 2-spool valve (1 for bull-

dozer, 1 for ripper).

Reservoir capacity 4 U.S. gal.

System capacity . . .6-3/4 U.S. gal.

Pump. . .Gear type, 15 or 23 gpm, 2,500 rpm (1,750

Cylinders. .. ..Two, double-acting, 3 in. x 12-1/8 in.

Cylinder rods Ground heat-treated, chrome-

Cylinder pivot pins.. .Hardened steel (replaceable

Shipping weight (Approximate):

Bulldozer and Crawler: Gasoline Diesel

with72-inblade 9,140 lb. 9,210 lb.

Bulldozer only:

with 72-in. blade 1,315 lb.

with 90-in. blade 1,440 lb.

plated polished.

Special equipment... Six 100-lb. front counter-

weights and brackets; for use in conjunction with

93 Series-A Backhoe. Adjustable depth shoes.

psi).

bushings).

132 in.

12-1/2 in. (72-in. BL~,DE)-'

16_1/2

in. (9~-~n~_BLADE) \

! - --------------

I i

I I

I I

L- :

- -- r-

L

- 8-1/8 in. (7;~i~~B-LAD~

10-3/16 in. (90-in. BLADE)

I

12

Page 2

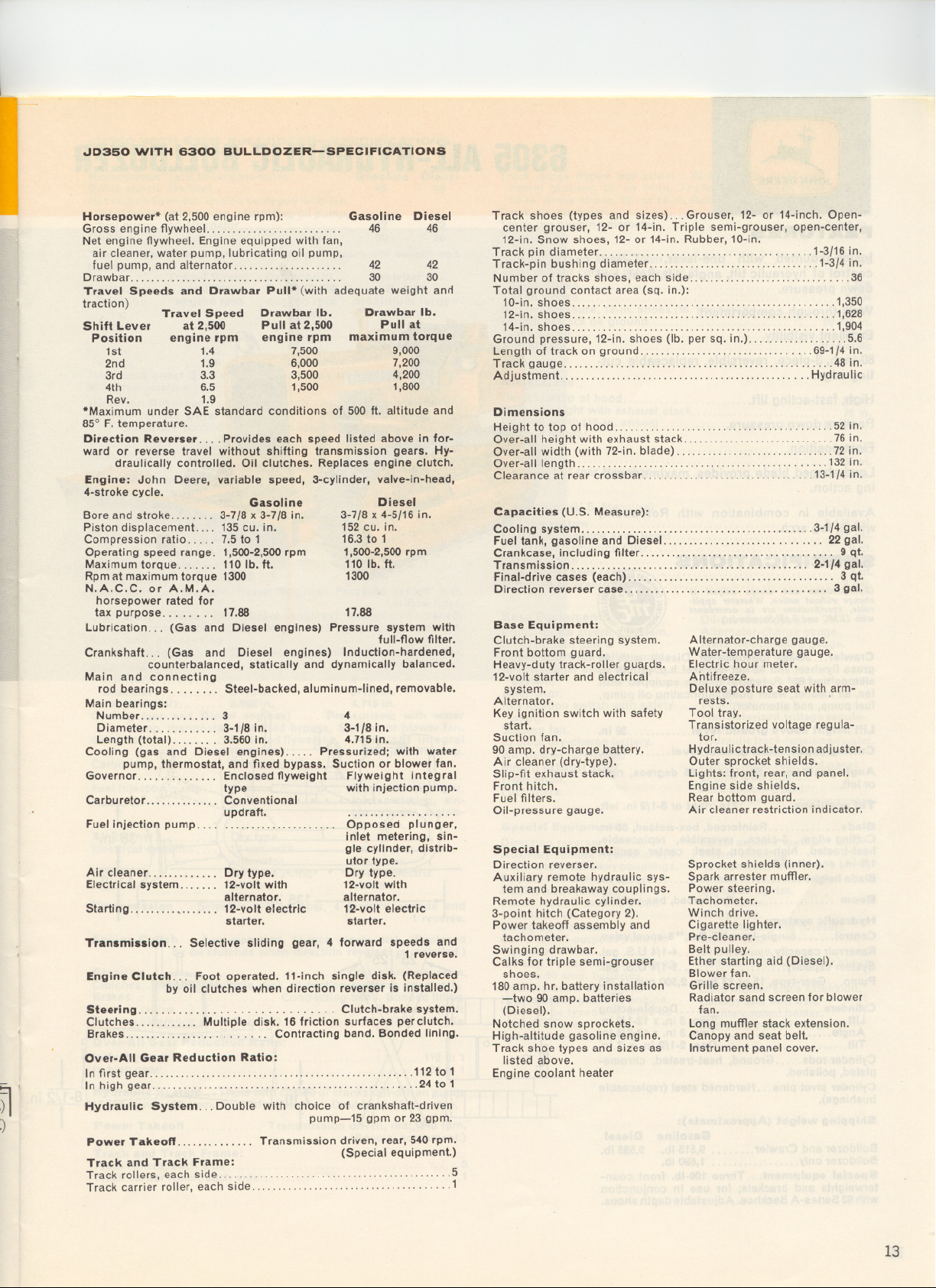

.JD350 WITH 6300 BULLDOZER-SPECIFICATIONS

_. ----

Horsepower* (at 2,500 engine rpm):

Grossengineflywheel..........................

Net engine flywheel. Engine equipped with fan,

air cleaner, water pump, lubricating oil pump,

fuel pump, and alternator 42 42

Drawbar 30 30

Gasoline Diesel

46 46

Travel Speeds and Drawbar Pull* (with adequate weight anrl

traction)

Shift

Position engine rpm

1st 1.4

2nd 1.9

3rd 3.3

4th 6.5

Rev. 1.9

*Maximum under SAE standard conditions of 500 ft. altitude and

85° F. temperature.

Direction Reverser. .. . Provides each speed listed above in for-

ward or reverse travel without shifting transmission gears. Hy-

draulically controlled. Oil clutches. Replaces engine clutch.

Engine: John Deere, variable speed, 3-cylinder, valve-in-head,

4-stroke cycle.

Travel Speed

Lever at 2,500

Drawbar lb.

Pull at 2,500

engine rpm

7,500

6,000

3,500

1,500

Gasoline

Bore and stroke 3-7/8x 3-7/8 in.

displacement 135cu. in.

Piston

Compression ratio.. ... 7.5 to 1

Operating speed range. 1,500-2,500 rpm

Maximum torque 110 lb. ft.

Rpm at maximum torque 1300

N.A.C.C. or A.M.A.

horsepower rated for

tax purpose. .. . . . .. 17.88

Lubrication... (Gas and Diesel engines)

Crankshaft. .. (Gas and Diesel engines) Induction-hardened,

Main and connecting

rod bearings. . . . . . .. Steel-backed, aluminum-lined, removable.

Main bearings:

Number 3 4

Diameter

Length(total) 3.560in. 4.715 in.

counterbalanced, statically and dynamically balanced.

3-1/8 in. 3-1/8 in.

Drawbar lb.

Pull at

maximum torque

9,000

7,200

4,200

1,800

Diesel

3-7/8 x 4-5/16 in.

152 cu. in.

16.3 to 1

1,500-2,500 rpm

110 lb. ft.

1300

17.88

Pressure system with

full-flow filter.

Cooling (gas and Diesel engines) Pressurized; with water

pump, thermostat, and fixed bypass. Suction or blower fan.

Governor Enclosed

Carburetor Conventional

Fuel injection pump. ... ..................... Opposed plunger,

type with injection pump.

updraft.

flyweight Flyweight integral

....................

inlet metering, sin-

gle cylinder, distrib-

Air cleaner.............

Electrical system... .. . .

Starting.................

Drytype.

12-volt with

alternator.

12-volt electric

starter.

Transmission... Selective sliding gear, 4 forward speeds and

utor type.

Dry type.

12-volt with

alternator.

12-volt electric

starter.

1 reverse.

Engine Clutch... Foot operated. 11-inch single disk. (Replaced

by oil clutches when direction reverser is installed.)

Steering Clutch-brake system.

Clutches Multiple disk. 16 friction surfaces perclutch.

Brakes

Over-All Gear Reduction Ratio:

. . . . . ." Contracting band. Bonded lining.

In first gear 112t01

In high gear

~.

Hydraulic System... Double with choice of crankshaft-driven

:)

Power Takeoff . Transmission driven, rear, 540 rpm.

Track and Track Frame:

Track rollers, each side .. ... .. .. ....... ... .. .. ... ... ... .. ... .. .5

Track carrier roller, each side 1

.. .... .. ...... ... .. .. .. ... .. .. .. . . . .. ..24 to 1

pump-15 gpm or 23 gpm.

(Special equipment.)

Track shoes (types and sizes)... Grouser, 12- or 14-inch. Open-

center grouser, 12- or 14-in. Triple semi-grouser, open-center,

12-in. Snow shoes, 12- or 14-in. Rubber, 10-in.

Trackpindiameter 1-3/16in.

Track-pin bushing diameter .1-3/4 in.

Number of tracks shoes, each side .36

Total ground contact area (sq. in.):

10-in. shoes .1,350

12-in. shoes ,... .1,628

14-in. shoes .1,904

Ground pressure, 12-in. shoes (lb. per sq. in.) ... . .5.6

Length of track on ground ...69-1/4 in.

Trackgauge 48in.

Adjustment . . . .Hydraulic

Dimensions

Heighttotopofhood 52in.

Over-allheightwithexhauststack 76in.

Over-all width (with 72-in. blade) 72in.

Over-all length . .. .. .132in.

Clearance at rear crossbar 13-1/4in.

Capacities (U.S. Measure):

Cooling system .................3-114gal.

Fuel tank, gasoline and Diesel .. .. .. .. .. .. .. .. 22gal.

Crankcase, including filter 9 qt.

Transmission 2-1/4gal.

Final-drivecases(each) ................ 3 qt.

Direction reverser case 3 gal.

Base Equipment:

Clutch-brake steering system.

Front bottom guard.

Heavy-duty track-roller guards.

12-volt starter and electrical

system.

Alternator.

Key ignition switch with safety

start.

Suction fan.

90 amp. dry-charge battery.

Air cleaner (dry-type).

Slip-fit exhaust stack.

Front hitch.

Fuel filters.

Oil-pressure gauge.

Special Equipment:

Direction reverser.

Auxiliary remote hydraulic sys-

tem and breakaway couplings.

Remote hydraulic cylinder.

3-point hitch (Category 2).

Power takeoff assembly and

tachometer.

Swinging drawbar.

Calks for triple semi-grouser

shoes.

180 amp. hr. battery installation

-two 90 amp. batteries

(Diesel).

Notched snow sprockets.

High-altitude gasoline engine.

Track shoe types and sizes as

listed above.

Engine coolant heater

Alternator-charge gauge.

Water-temperature gauge.

Electric hour meter.

Antifreeze.

Deluxe posture seat with arm-

rests. .

Tool tray.

Transistorized voltage regula-

tor.

Hydraulictrack-tension adjuster.

Outer sprocket shields.

Lights:front, rear, and panel.

Engine side shields.

Rear bottom guard.

Air cleaner restriction indicator.

Sprocket shields (inner).

Spark arrester muffler.

Power steering.

Tachometer.

Winch drive.

Cigarette lighter.

Pre-cleaner.

Belt pulley.

Ether starting aid (Diesel).

Blower fan.

Grille screen.

Radiator sand screen for blower

fan.

Long muffler stack extension.

Canopy and seat belt.

Instrument panel cover.

13

Loading...

Loading...