Page 1

LOADERS

160–180 SAE NET HORSEPOWER

H

624H WH 644H WH

Page 2

The trash deflector helps

protect the rear axles from

the impact shock caused by

backing into a solid object.

It also provides access to

the engine compartment.

When you’re talking trash,

When you’re talking trash,

When you’re talking trash,

we’re listening.

we’re listening.

we’re listening.

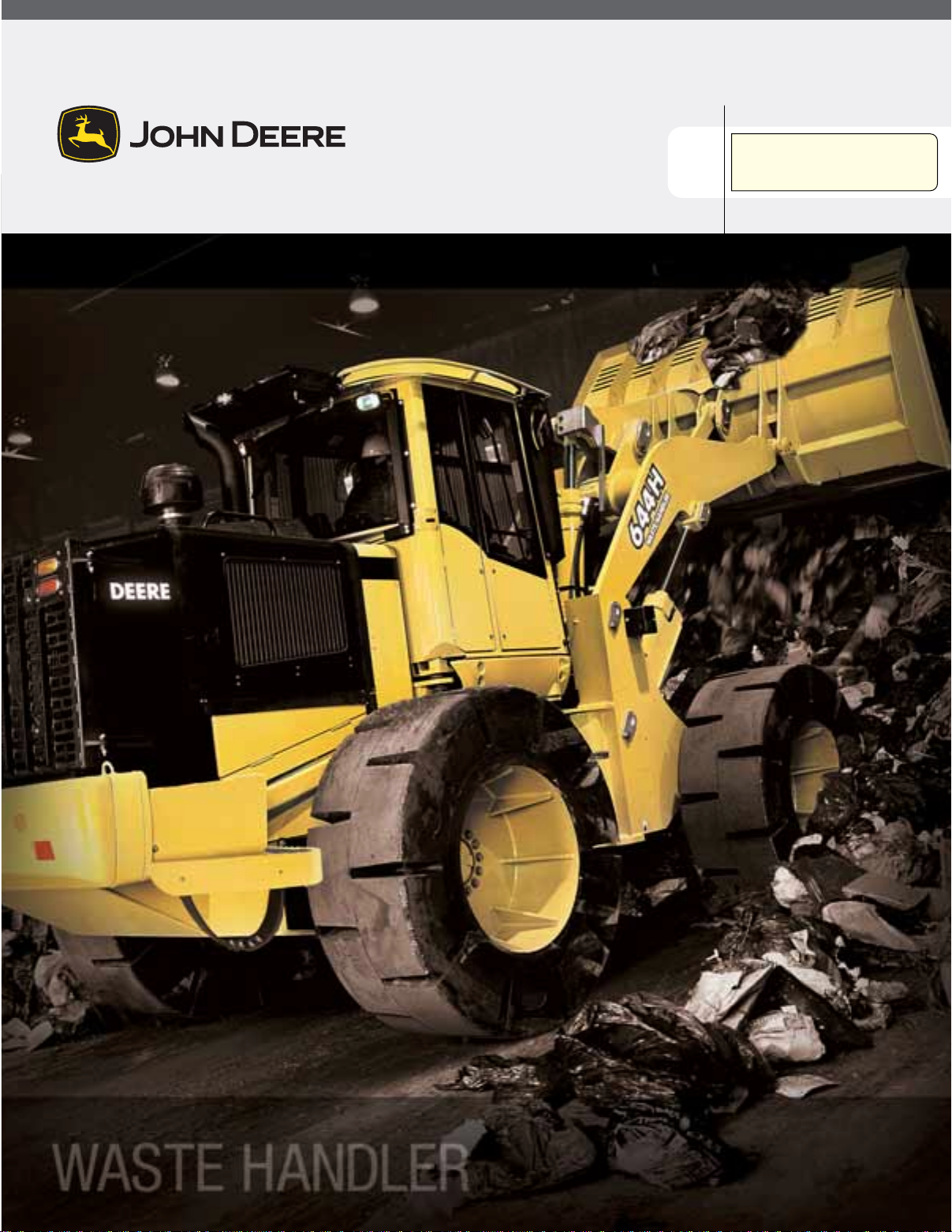

You know waste. We know loaders. Combine that

knowledge and you get the remarkably durable 600

H-Series Waste Handlers from John Deere. These

machines weren’t only built with you in mind, they

were designed with your input. The final product

delivers all of the outstanding performance charac-

teristics of our standard loader, as well as plenty of

special integrated features to maximize productivity

in the harshest waste environments. Everything

from the high-lift option for that extra lift to reach up

and over high-sided trucks to the component pro-

tection guards to keep debris out of areas where

you don’t want it, these machines are ready to han-

dle even the harshest waste environments. You’ve

never seen waste loaders perform like this. And

that’s not just talkin’ trash.

Page 3

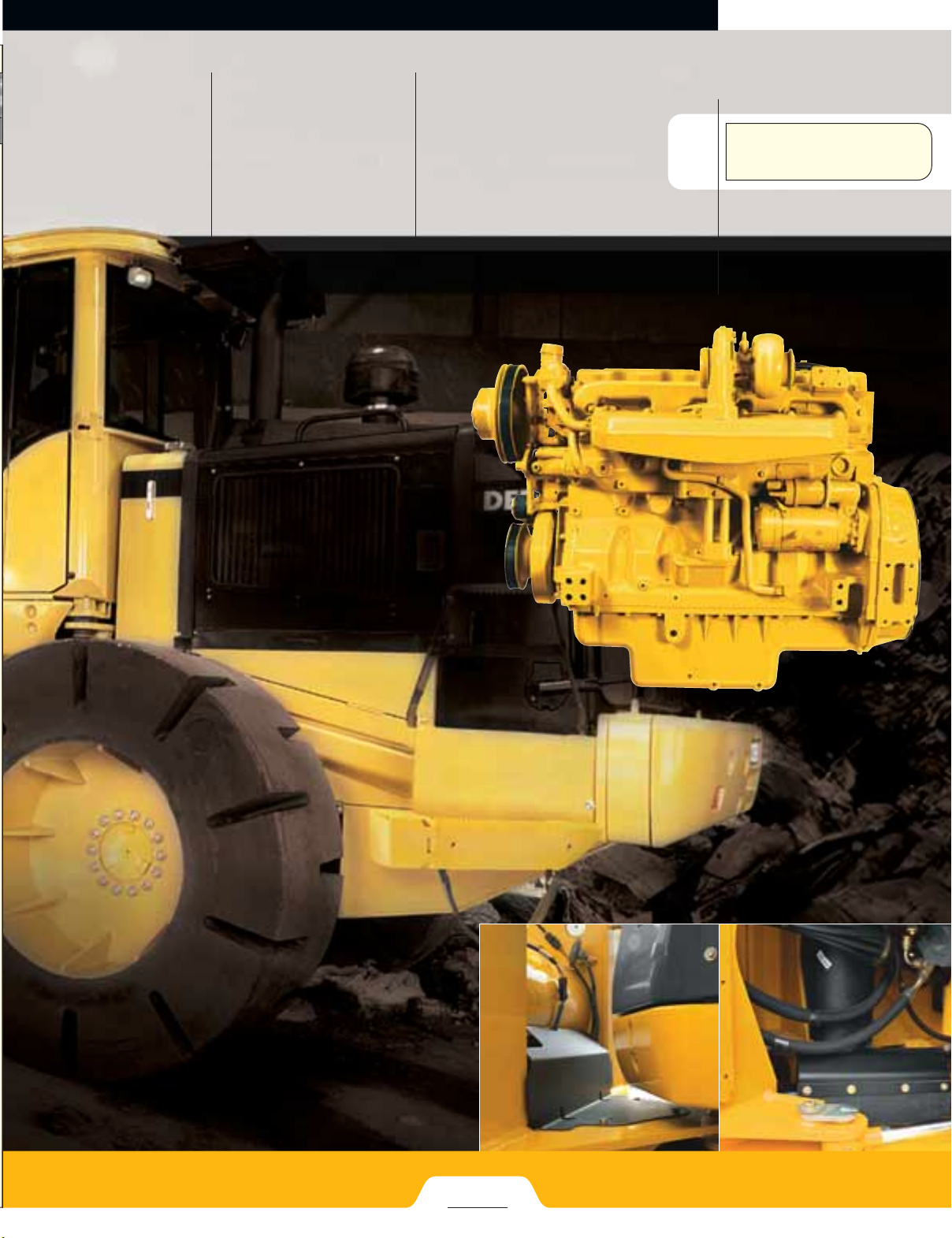

The optional roof-mounted

H

LOADERS

624H WH 644H WH

air-conditioning condenser

has no stacked cores and

provides easy daily cleanout.

Our performance edge starts

at the engine with power

bulge – the availability of

Deere PowerTech™diesels to

generate extra horsepower

when the going gets tough.

That means you can power

through challenging situations

without downshifting.

Articulation guards, driveshaft guard, and transmission

side guards provide extra

protection on the work site.

The rear of the loader frame

is guarded to protect it from

destructive waste.

Both the articulation joint and

drive shaft are protected from

corrosion and trash by guards.

PAGES

2–3

Page 4

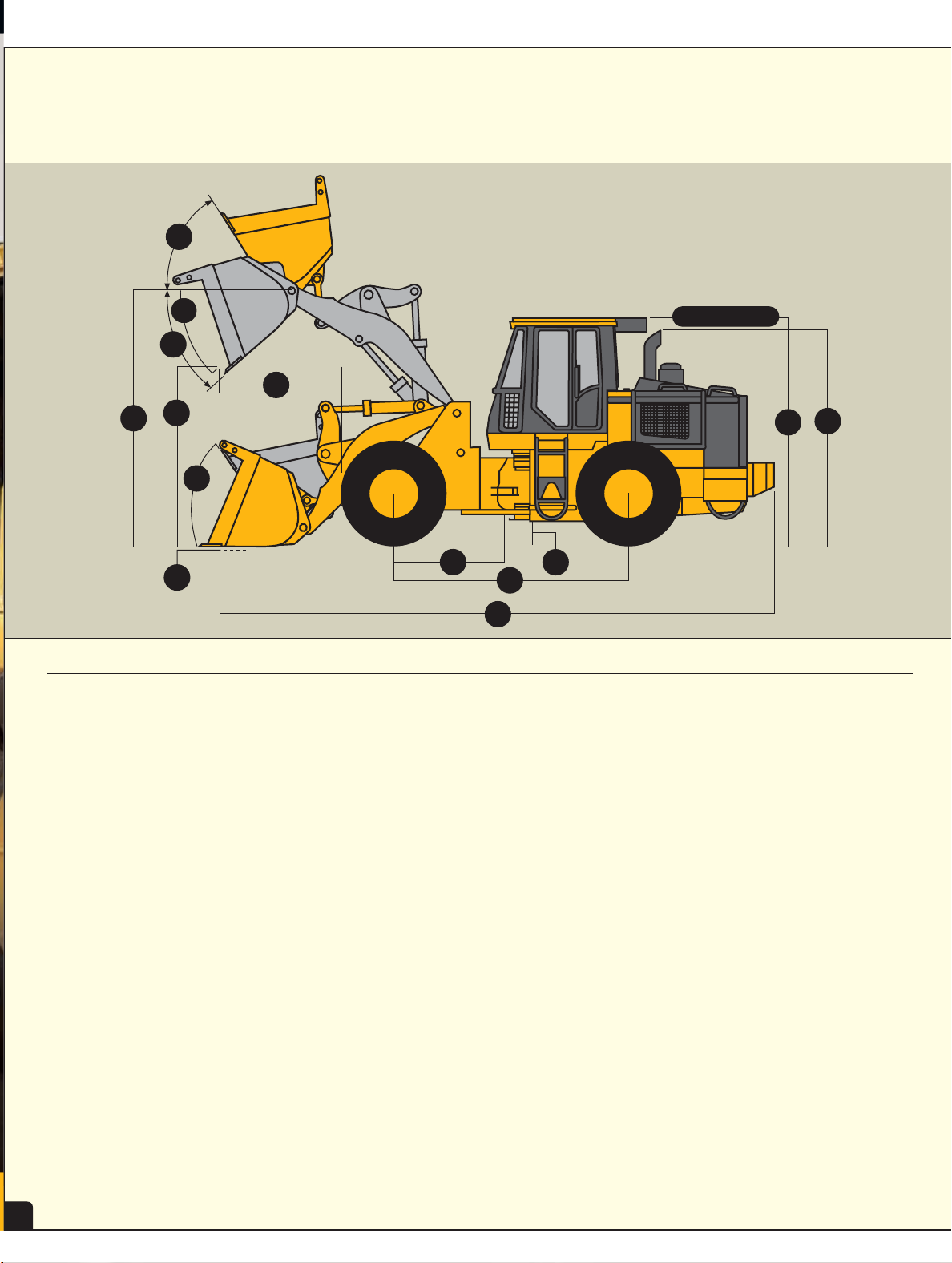

Strategically placed guards

protect axle seals and help

insulate the heavy-duty

axles from harmful trash

and contamination.

The excellent balance

of operator protection

and visibility is obvious

the moment you take

the seat.

The unique low-profile,

hood-mounted trapezoidal air-inlet screen

protects the engine and

cooling system.

High-intensity, guarded,

halogen driving lights

help keep the work

area illuminated.

Service access is

convenient, including

wide, easy-to-open

access doors.

With six fins per inch,

the wide-open spacing

allows debris to easily

exit the radiator, keeping

it clean and running

efficiently.

No vulnerable underbelly

here. A set of optional

hydraulic-actuated

bottom guards protect

the frame, engine area,

and fuel tank.

PAGES

4–5

The high-lift option adds

more than a foot to the

boom, providing the extra

lift needed to reach up

and over high-sided

trucks/trailers.

Page 5

Self-cleaning shields

protect the boom and

bucket cylinders by

automatically ejecting

corrosive waste every

time you raise the bucket.

Cool to operate…

Cool to operate…

Cool to operate…

in more ways than one.

in more ways than one.

in more ways than one.

Maybe this is what they mean by

“the perks of the job.” Comfort. Con-

venience. Excellent controls. Great vis-

ibility. You simply won’t find a more

operator-friendly loader than the 624H

or 644H Waste Handler. They keep their

cool even when the going gets tough,

thanks to a remarkable air-screen

group that

effectively

blocks trash and other airborne debris.

And, the reversing fan uses a timer to

routinely eject debris from the engine

shield as you work. As an added pre-

caution, the operator can reverse the

fan at any time by depressing a button

conveniently located in the cab. This

unique feature allows you to keep

working with less downtime and

machine maintenance.

Optional swing-out cooling fan makes cleanout

fast and easy. The hydraulically powered unit is

also reversible, so it can be used to blow debris

off the screens.

The standard, eight-cubic-yard

bucket comes equipped with

a trash guard. Other bucket

options are available to meet

your customized needs.

Page 6

LOADERS

SPECIFICATIONS

WASTE

624H 644H

E

ngine 624H 644H

Type .......................................................................John Deere P

Rated power ...........................................................160 SAE net hp (119 kW) / 172 SAE gross hp (128 kW) @ 2,200 rpm 180 SAE net hp (134 kW) / 205 SAE gross hp (153 kW) @ 2,200 rpm

Cylinders ................................................................6 6

Displacement..........................................................414 cu. in. (6.8 L) 496 cu. in. (8.1 L)

Maximum net torque ..............................................575 lb.-ft. (720 Nm) @ 1,400 rpm 745 lb.-ft. (1010 Nm) @ 1,300 rpm

The trash deflector helps

Lubrication .............................................................pressure system with full-flow spin-on filter and cooler pressure system with full-flow spin-on filter and cooler

protect the rear axles from

Fuel consumption, typical .......................................2.9 to 5.8 gal./hr. (10.9 to 21.8 L/h) 2.9 to 5.0 gal./hr. (10.9 to 18.8 L/h)

the impact shock caused by

Cooling fan .............................................................blower type, hydraulically driven, reversible swing out blower type, hydraulically driven, reversible swing out

backing into a solid object.

Electrical system ....................................................24 volt with 55-amp alternator 24 volt with 55-amp alternator

Batteries (two 12 volt).............................................625 CCA; reserve capacity: 160 min. – standard / 950 CCA; reserve 750 CCA; reserve capacity: 150 min. – standard / 950 CCA; reserve

It also provides access to

the engine compartment.

Air cleaner ..............................................................dual safety element dry type; restriction indicator for service dual safety element dry type; restriction indicator for service

Transmission

Type .......................................................................single-stage, single-phase torque converter; countershaft-type single-stage, single-phase torque converter; countershaft-type

Controls ..................................................................smooth shifts under any power condition provided by computer- smooth shifts under any power condition provided by computer-

Travel speeds* Forward Reverse Forward Reverse

Gear 1..............................................................5.1 mph (8.2 km/h) 5.4 mph (8.7 km/h) 5.3 mph (8.5 km/h) 5.5 mph (8.9 km/h)

Gear 2..............................................................8.1 mph (13.0 km/h) 8.6 mph (13.8 km/h) 9.1 mph (14.6 km/h) 9.6 mph (15.4 km/h)

Gear 3..............................................................15.0 mph (24.1 km/h) 16.0 mph (25.8 km/h) 17.1 mph (27.5 km/h) 17.8 mph (28.6 km/h)

*624H equipped with 20.5-25 solid rubber tires; 644H equipped with 23.5-25 solid rubber tires.

HANDLERS

charger and aftercooler; meets North American EPA and CARB non- charger and aftercooler; meets North American EPA and CARB nonroad diesel engine emission regulations effective January 1, 1997; road diesel engine emission regulations effective January 1, 1997;

also is certifiable to proposed E.U. (European Union) regulations, also is certifiable to proposed E.U. (European Union) regulations,

which are not yet effective which are not yet effective

capacity; 200 min. – optional capacity; 200 min. – optional

powershift with computer control powershift with computer control

controlled electronic shift with individual electronic control over controlled electronic shift with individual electronic control over

each clutch pack, one low-effort twist-grip shift lever, quick-shift each clutch pack, one low-effort twist-grip shift lever, quick-shift

button on hydraulic lever, automatic shift feature is selectable to button on hydraulic lever, automatic shift feature is selectable to

shift between gears 1–3 or 2–3 shift between gears 1–3 or 2–3

When you’re talking tra

When you’re talking tra

When you’re talking tra

TM

OWERTECH

6068H with altitude-compensating turbo- John Deere P

we’re listening.

we’re listening.

we’re listening.

CONSTRUCTION EQUIPMENT

CONSTRUCTION EQUIPMENT

OWERTECH

6081H with altitude-compensating turbo-

Axles

Final drives.............................................................heavy-duty planetary, mounted inboard heavy-duty planetary, mounted inboard

Differentials ............................................................conventional front and rear – standard; hydraulic locking front, conventional front and rear – standard; hydraulic locking front,

conventional rear – optional; dual locking front and rear – optional; conventional rear – optional; dual locking front and rear – optional;

limited-slip front and rear – optional limited-slip front and rear – optional

Rear axle oscillation, stop to stop ...........................18 degrees 18 degrees

Maximum rise and fall, single wheel.......................12.6 in. (320 mm) 13.4 in. (340 mm)

Brakes (conform to SAE J1473, ISO3450) 624H / 644H

Service brakes........................................................inboard-mounted hydraulic wet disc, bathed in cooling oil, long life self-adjusting

Parking brake .........................................................automatically spring applied, hydraulically released, wet disc bathed in cooling oil

Hydraulic System 624H 644H

Pump (loader and steering).....................................variable-displacement, axial piston pump; closed-center, pressure variable-displacement, axial piston pump; closed-center, pressure

compensating system compensating system

Maximum flow .................................................55 gpm (200 L/min.) @ 1,000 psi (6895 kPa) and 2,200 rpm 68 gpm (257 L/min.) @ 1,000 psi (6895 kPa) and 2,200 rpm

Pressure ..........................................................loader and steering relief 3,600 psi (24 850 kPa) loader and steering relief 3,600 psi (24 850 kPa)

Loader controls.......................................................two-function valve; single- or dual-lever controls; control lever two-function valve; single- or dual-lever controls; control lever

lockout feature; optional third- and fourth-function valve with lockout feature; optional third- and fourth-function valve with

auxiliary lever auxiliary lever

6

Page 7

LOADERS

160–180 SAE NET HORSEPOWER

H

624H WH 644H WH

Hydraulic System

Hydraulic cycle times

Raise ............................................................5.8 sec. 6.2 sec.

Dump ...........................................................1.4 sec. 1.4 sec.

Lower ...........................................................3.0 sec. (float down) / 3.5 sec. (power down) 3.0 sec. (float down) / 3.5 sec. (power down)

Total.............................................................10.2 sec. 10.6 sec.

(continued)

624H 644H

624H Maximum Lift Capacity

SAE heaped capacity...........................................4.0-cu. yd. 4.0-cu. yd. (3.06 m3) 5.0-cu. yd. 5.0-cu. yd. (3.8 m3) 6.0-cu. yd. 6.0-cu. yd. (4.6 m3)

Lift at ground level........................................25,309 lb. 25,018 lb. 24,826 lb. 24,149 lb. 24,098 lb. 23,834 lb.

Lift at maximum height ................................14,282 lb. 14,710 lb. 13,914 lb. 14,344 lb. 13,393 lb. 13,819 lb.

3

(3.06 m

) short lip standard lip (3.8 m3) short lip standard lip (4.6 m3) short lip standard lip

(11 478 kg) (11 346 kg) (11 259 kg) (10 952 kg) (10 929 kg) (10 809 kg)

(6477 kg) (6671 kg) (6310 kg) (6505 kg) (6074 kg) (6267 kg)

644H Maximum Lift Capacity

SAE heaped capacity...........................................5.0-cu. yd. 5.0-cu. yd. (3.8 m3) 6.0-cu. yd. 6.0-cu. yd. (4.6 m3) 7.0-cu. yd. 7.0-cu. yd. (5.4 m3)

Lift at ground level........................................31,922 lb. 30,813 lb. 31,119 lb. 29,626 lb. 30,458 lb. 28,475 lb.

Lift at maximum height ................................15,386 lb. 15,993 lb. 14,877 lb. 15,435 lb. 14,555 lb. 15,124 lb.

3

(3.8 m

) short lip standard lip (4.6 m3) short lip standard lip (5.4 m3) short lip standard lip

(14 477 kg) (13 974 kg) (14 113 kg) (13 436 kg) (13 813 kg) (12 914 kg)

(6978 kg) (7253 kg) (6747 kg) (7000 kg) (6601 kg) (6859 kg)

Steering

(conforms to SAE J1511)

Type....................................................................power, fully hydraulic power, fully hydraulic

Pressure..............................................................3,600 psi (24 850 kPa) relief 3,600 psi (24 850 kPa) relief

Articulation angle ................................................80-degree arc (40 degrees each direction) 80-degree arc (40 degrees each direction)

Turning radius (measured to centerline of

outside tire) ..................................................17 ft. 0 in. (5187 mm) 18 ft. 0 in. (5500 mm)

624H 644H

Tires

Standard Change In Change In

Tread Width Width Over Tires Vertical Height Tread Width Width Over Tires Vertical Height

20.5-25 solid rubber tires.............................80.7 in. (2050 mm) 101.3 in. (2572 mm) 0 in. (0 mm)

23.5-25 solid rubber tires.............................85.4 in. (2170 mm) 113.1 in. (2874 mm) 0 in. (0 mm)

L-5 radial or bias ply tires available.

Both tire types require 9-degree axle stops.

Capacities

Fuel tank (with ground level fueling)....................70 gal. (265 L) 90 gal. (341 L)

Cooling system....................................................23 qt. (22 L) 31 qt. (29 L)

Engine lubrication, including full-flow spin-

Powershift transmission, including vertical

Differential (each axle)

Loader hydraulic reservoir and filters ..................31 gal. (117 L) 31 gal. (117 L)

Parking brake......................................................0.31 qt. (0.3 L) 0.63 qt. (0.6 L)

(U.S.)

on filter.........................................................21 qt. (20 L) 26 qt. (25 L)

cartridge filter...............................................29 qt. (27 L) 27 qt. (26 L)

Front.............................................................30 qt. (28 L) 29 qt. (27 L)

Rear .............................................................19 qt. (20 L) 29 qt. (27 L)

7

Page 8

L

45˚

Cab and Canopy

M

H

F

G

B

A

K

I

D

C

E

J

624H Dimensions with Pin-on Type Waste Buckets

Bucket lip capacity (equipped with bolt-on

cutting edges)

Capacity, heaped SAE ......................................4.0-cu. yd. 4.0-cu. yd. (3.06 m

Capacity, struck SAE ........................................3.1-cu. yd. 3.5-cu. yd. (2.68 m

3

(3.06 m

) short lip standard lip (3.8 m3) short lip standard lip (4.6 m3) short lip standard lip

3

(2.37 m

) short lip standard lip (3.06 m3) short lip standard lip (3.82 m3) short lip standard lip

3

) 5.0-cu. yd. 5.0-cu. yd. (3.8 m3) 6.0-cu. yd. 6.0-cu. yd. (4.6 m3)

3

) 4.0-cu. yd. 4.3-cu. yd. (3.29 m3) 5.0-cu. yd. 5.2-cu. yd. (3.98 m3)

A Height to top of cab and canopy ......................11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in.

(3351 mm) (3351 mm) (3351 mm) (3351 mm) (3351 mm) (3351 mm)

B Height to top of exhaust ...................................11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in. 11 ft. 0 in.

(3356 mm) (3356 mm) (3356 mm) (3356 mm) (3356 mm) (3356 mm)

C Ground clearance .............................................18 in. (457 mm) 18 in. (457 mm) 18 in. (457 mm) 18 in. (457 mm) 18 in. (457 mm) 18 in. (457 mm)

D Length from centerline to front axle .................60 in. (1515 mm) 60 in. (1515 mm) 60 in. (1515 mm) 60 in. (1515 mm) 60 in. (1515 mm) 60 in. (1515 mm)

E Wheelbase .......................................................119 in. (3030 mm) 119 in. (3030 mm) 119 in. (3030 mm) 119 in. (3030 mm) 119 in. (3030 mm) 119 in. (3030 mm)

F Dump height ....................................................11 ft. 1.8 in. 10 ft. 10.4 in. 10 ft. 11.8 in. 10 ft. 5.9 in. 10 ft. 9.8 in. 10 ft. 0 in.

(3399 mm) (3312 mm) (3348 mm) (3199 mm) (3297 mm) (3048 mm)

G Height to hinge pin, fully raised........................14 ft. 4 in. 14 ft. 4 in. 14 ft. 4 in. 14 ft. 4 in. 14 ft. 4 in. 14 ft. 4 in.

(4379 mm) (4379 mm) (4379 mm) (4379 mm) (4379 mm) (4379 mm)

H Dump reach .....................................................36.1 in. (917 mm) 41.2 in. (1047 mm) 38.3 in. (974 mm) 46.3 in. (1176 mm) 40.6 in. (1030 mm) 53.1 in. (1349 mm)

I Maximum digging depth ..................................5.3 in. (135 mm) 5.3 in. (135 mm) 5.3 in. (135 mm) 5.3 in. (135 mm) 5.3 in. (135 mm) 5.3 in. (135 mm)

J Overall length...................................................25 ft. 2 in. 25 ft. 8 in. 25 ft. 5 in. 26 ft. 3 in. 25 ft. 8 in. 27 ft. 0 in.

(7682 mm) (7832 mm) (7758 mm) (8003 mm) (7835 mm) (8233 mm)

K Maximum rollback at ground level ...................33.7 degrees 34.7 degrees 33.7 degrees 34.7 degrees 33.7 degrees 34.7 degrees

L Maximum rollback at full height.......................43.7 degrees 44.7 degrees 43.7 degrees 44.7 degrees 43.7 degrees 44.7 degrees

M Maximum dump angle, full height....................46.2 degrees 45.2 degrees 46.2 degrees 45.2 degrees 46.2 degrees 45.2 degrees

Bucket width ..........................................................128.0 in. (3251 mm) 114.7 in. (2913 mm) 128.0 in. (3251 mm) 114.7 in. (2913 mm) 128.0 in. (3251 mm) 114.7 in. (2913 mm)

Breakout force, SAE J732C.....................................30,312 lb. 26,411 lb. 27,787 lb. 22,632 lb. 25,516 lb. 18,791 lb.

(13 747 kg) (11 978 kg) (12 602 kg) (10 264 kg) (11 572 kg) (8522 kg)

Tipping load, straight..............................................23,860 lb. 23,552 lb. 23,750 lb. 22,791 lb. 23,342 lb. 22,456 lb.

(10 821 kg) (10 681 kg) (10 771 kg) (10 336 kg) (10 586 kg) (10 184 kg)

8

Page 9

624H Dimensions with Pin-on Type Waste Buckets

Tipping load, 40-degree full turn, SAE.....................20,125 lb. 19,900 lb. 19,988 lb. 19,199 lb. 19,583 lb. 18,840 lb.

(9127 kg) (9025 kg) (9065 kg) (8707 kg) (8881 kg) (8544 kg)

Reach, 45-degree dump, 7-ft. (2.13 m)

clearance.........................................................68.8 in. (1748 mm) 71.3 in. (1811 mm) 70.1 in. (1781 mm) 73.9 in. (1877 mm) 71.4 in. (1812 mm) 77.0 in. (1956 mm)

Loader clearance circle, bucket in carry

position............................................................42 ft. 0 in. 41 ft. 4 in. 42 ft. 2 in. 41 ft. 8 in. 42 ft. 4 in. 42 ft. 2 in.

(12 804 mm) (12 585 mm) (12 852 mm) (12 698 mm) (12 900 mm) (12 852 mm)

Operating weight ....................................................38,859 lb. 38,477 lb. 39,227 lb. 38,894 lb. 39,763 lb. 39,447 lb.

(17 623 kg) (17 450 kg) (17 790 kg) (17 639 kg) (18 033 kg) (17 890 kg)

Loader operating information is based on a machine with all standard equipment; waste handler complete protection package; 20.5-25 solid rubber tires; high-lift boom; ROPS cab; differential

lock front axle with standard rear axle; two-spool valve with two-lever control; heater and defroster; 175-lb. (79 kg) operator; and full fuel tank. This information is affected by tire size,

ballast, and different attachments.

(continued)

644H Dimensions with Pin-on Type Waste Buckets

Bucket lip capacity (equipped with bolt-on

cutting edges)

Capacity, heaped SAE ......................................5.0-cu. yd. 5.0-cu. yd. (3.8 m

Capacity, struck SAE ........................................4.4-cu. yd. 4.0-cu. yd. (3.1 m

3

(3.8 m

) short lip standard lip (4.6 m3) short lip standard lip (5.4 m3) short lip standard lip

3

(3.4 m

) short lip standard lip (4.2 m3) short lip standard lip (4.7 m3) short lip standard lip

3

) 6.0-cu. yd. 6.0-cu. yd. (4.6 m3) 7.0-cu. yd. 7.0-cu. yd. (5.4 m3)

3

) 5.5-cu. yd. 5.0-cu. yd. (3.8 m3) 6.2-cu. yd. 5.7-cu. yd. (4.4 m3)

A Height to top of cab and canopy ......................11 ft. 5 in. 11 ft. 5 in. 11 ft. 5 in. 11 ft. 5 in. 11 ft. 5 in. 11 ft. 5 in.

(3467 mm) (3467 mm) (3467 mm) (3467 mm) (3467 mm) (3467 mm)

B Height to top of exhaust ...................................11 ft. 3 in. 11 ft. 3 in. 11 ft. 3 in. 11 ft. 3 in. 11 ft. 3 in. 11 ft. 3 in.

(3417 mm) (3417 mm) (3417 mm) (3417 mm) (3417 mm) (3417 mm)

C Ground clearance .............................................20.8 in. (528 mm) 20.8 in. (528 mm) 20.8 in. (528 mm) 20.8 in. (528 mm) 20.8 in. (528 mm) 20.8 in. (528 mm)

D Length from centerline to front axle .................63 in. (1600 mm) 63 in. (1600 mm) 63 in. (1600 mm) 63 in. (1600 mm) 63 in. (1600 mm) 63 in. (1600 mm)

E Wheelbase .......................................................126 in. (3200 mm) 126 in. (3200 mm) 126 in. (3200 mm) 126 in. (3200 mm) 126 in. (3200 mm) 126 in. (3200 mm)

F Dump height ....................................................12 ft. 7 in. 11 ft. 5 in. 11 ft. 9 in. 10 ft. 11 in. 11 ft. 7 in. 10 ft. 7.5 in.

(3838 mm) (3479 mm) (3589 mm) (3331 mm) (3532 mm) (3237 mm)

G Height to hinge pin, fully raised........................15 ft. 4 in. 15 ft. 4 in. 15 ft. 4 in. 15 ft. 4 in. 15 ft. 4 in. 15 ft. 4 in.

(4661 mm) (4661 mm) (4661 mm) (4661 mm) (4661 mm) (4661 mm)

H Dump reach .....................................................38.1 in. (968 mm) 46.0 in. (1167 mm) 40.4 in. (1026 mm) 52.9 in. (1343 mm) 43.1 in. (1094 mm) 57.3 in. (1455 mm)

I Maximum digging depth ..................................7.5 in. (190 mm) 7.5 in. (190 mm) 7.5 in. (190 mm) 7.5 in. (190 mm) 7.5 in. (190 mm) 7.5 in. (190 mm)

J Overall length...................................................26 ft. 8 in. 27 ft. 6 in. 26 ft. 10 in. 28 ft. 3 in. 27 ft. 2 in. 28 ft. 8 in.

(8121 mm) (8372 mm) (8189 mm) (8601 mm) (8286 mm) (8747 mm)

K Maximum rollback at ground level ...................35 degrees 35 degrees 35 degrees 35 degrees 35 degrees 35 degrees

L Maximum rollback at full height.......................40.8 degrees 40.8 degrees 40.8 degrees 40.8 degrees 40.8 degrees 40.8 degrees

M Maximum dump angle, full height....................44 degrees 44 degrees 44 degrees 44 degrees 44 degrees 44 degrees

Bucket width ..........................................................128.0 in. (3251 mm) 114.2 in. (2900 mm) 128.0 in. (3251 mm) 114.2 in. (2900 mm) 128.0 in. (3251 mm) 114.2 in. (2900 mm)

Breakout force, SAE J732C.....................................37,606 lb. 30,270 lb. 34,665 lb. 25,258 lb. 31,836 lb. 22,760 lb.

(17 055 kg) (13 728 kg) (15 721 kg) (11 455 kg) (14 438 kg) (10 322 kg)

Tipping load, straight..............................................32,857 lb. 31,434 lb. 31,950 lb. 30,420 lb. 31,988 lb. 29,307 lb.

(14 901 kg) (14 256 kg) (14 490 kg) (13 796 kg) (14 507 kg) (13 291 kg)

Tipping load, 40-degree full turn, SAE.....................27,728 lb. 26,553 lb. 26,892 lb. 25,607 lb. 26,888 lb. 24,610 lb.

(12 575 kg) (12 042 kg) (12 196 kg) (11 613 kg) (12 194 kg) (11 161 kg)

Reach, 45-degree dump, 7-ft. (2.13 m)

clearance.........................................................73.9 in. (1878 mm) 78.6 in. (1996 mm) 75.3 in. (1913 mm) 82.1 in. (2086 mm) 76.8 in. (1952 mm) 84.2 in. (2138 mm)

Loader clearance circle, bucket in carry

position............................................................44 ft. 2 in. 43 ft. 8 in. 44 ft. 4 in. 44 ft. 3 in. 44 ft. 7 in. 44 ft. 7 in.

(13 470 mm) (13 321 mm) (13 518 mm) (13 479 mm) (13 589 mm) (13 582 mm)

Operating weight ....................................................50,627 lb. 50,223 lb. 50,391 lb. 50,874 lb. 51,522 lb. 51,304 lb.

(22 960 kg) (22 777 kg) (22 853 kg) (23 072 kg) (23 366 kg) (23 267 kg)

Loader operating information is based on a machine with all standard equipment; waste handler complete protection package; 23.5-25 solid rubber tires; high-lift boom; ROPS cab; differential

lock front axle with standard rear axle; two-spool valve with two-lever control; heater and defroster; 175-lb. (79 kg) operator; and full fuel tank. This information is affected by tire size,

ballast, and different attachments.

9

Page 10

LOADERS

160–180 SAE NET HORSEPOWER

H

624H WH 644H WH

624H / 644H Waste Handlers

Key: ● Standard equipment ▲ Optional or special equipment *See your John Deere dealer for further information.

624H 644H

Engine

●●

Antifreeze, –34°F (–37°C)

●●Coolant recovery tank

●●Engine oil cooler

●●Environmentally friendly engine oil drain

●●Fan safety guard

●●Muffler, under hood with large exhaust stack

▲▲Chrome exhaust stack

●●Quick-release fuel filter and water separator

▲▲Engine air heater (for cold starts)

▲▲Ether start aid (for cold starts)

Power Train

●●

TC/PS transmission, computer-controlled

electronic soft shift, automatic shift and

quick-shift features included

●●Conventional-type differentials, front and rear

▲▲Front and rear axles with hydraulic locking

differentials

▲▲Front and rear axles with limited-slip differ-

entials

▲▲Front axle with hydraulic locking differential

▲▲Front axle disconnect

Hydraulic System

●●

Automatic boom height kickout control

▲▲Automatic boom return-to-carry control

●●Automatic bucket return-to-dig control

●●Hydraulic lever lockout

●●Hydraulic system oil cooler (for continuous

running attachments and extreme temperatures)

●●Reservoir sight gauge

●●Spin-on hydraulic filters, vertical mounting

●●Two-function hydraulic valve with joystick

control

▲▲Two-function hydraulic valve with two levers

and adjustable wristrest

▲▲Three-function hydraulic valve with joystick

control and auxiliary lever for third function

▲▲Three-function hydraulic valve with two

levers and adjustable wristrest and auxiliary

lever for third function

▲▲Four-function hydraulic valve with dual joy-

stick controls

▲▲Two- to three-function valve hydraulic con-

version kit

▲▲Three- to four-function valve hydraulic con-

version kit

▲▲Ride control, automatic type

Electrical

●●

24-volt electrical system

●●Alternator, high capacity, 80 amps and 24 volts

●●Alternator trash covers

●●Batteries, standard (2), 12 volt with 750 CCA,

150-min. rated reserve

▲▲Batteries, high capacity (2), 12 volt with 950

CCA, 200-min. rated reserve

●●Deluxe monitor and alarm system, multifunc-

tion computerized electronic: Audible and

visual warnings include: Message center display (12-character message board) / Analog

instruments (engine coolant temperature,

transmission oil temperature, fuel level,

speedometer, engine oil pressure, hydraulic

oil temperature) / Digital instruments (engine

624H 644H

Electrical (cont.)

rpm, selectable battery voltage or odometer,

transmission gear indicator, hourmeter) /

Operator warning lights (coolant level, engine

oil pressure, engine air filter, battery voltage,

transmission filter restriction, brake pressure, hydraulic oil temperature, hydraulic oil

filter, fasten seat belt, park brake actuated) /

Indicator lights (turn signals, warning flashers, work lights) / Built-in diagnostics (fault

code retrieval, message center) / Push-button

selection (three clutch cut-off adjustments,

two automatic transmission sequences, two

quick-shift button sequences)

●●Horn, with push button in center of steering

wheel (conforms to SAE J994, J1446)

●●Lights (conform to SAE J99): Driving with

guards / Turn signals and flashers / Stop and

taillights

●●Work lights, front (2) and rear (2)

●●Radio-ready cab: Fused 24-volt radio electri-

cal lead, and fused lead for optional Deere

5-amp and 10-amp voltage converters

▲▲Radio-ready cab: 24- to 12-volt radio con-

verter, 5 amp with receptacle / 24- to 12-volt

radio converter, 10 amp with receptacle /

24-volt AM/FM stereo radio with clock

▲▲Cab wired for rotating beacon

●●Reverse warning alarm, self-adjusting (con-

forms to SAE J994, J1446)

Operator’s Station

●●

Cab (conforms to SAE J1040 APR88): ROPS/

FOPS / Heater/Defroster / Multiplane isolation mounted for noise/vibration reduction /

Front and rear windshield washers and intermittent wipers / Tinted safety glass

●●Cup holder, personal cooler holder

●●Handholds and steps, ergonomically located

and slip resistant (conform to SAE J185)

●●Rearview mirrors, outside (2) and inside (2)

(conform to SAE J985)

●●Rubber floormat

●●Seat belt, 3 in. (76 mm), with retractor

●●Seat, deluxe cloth covered with deep foam,

high back, mechanical suspension, adjustable for weight-height, fore-aft position,

backrest tilt, and armrest angle

▲▲Seat, air suspension, deluxe cloth covered

▲▲Seat backrest extension

●●Steering wheel, textured with spinner knob

●●Storage compartment for operator’s manual

and other items

●●Tilt steering column

●●Air conditioning

▲▲Sun visor for cab

Complete Waste Handler Package

●●

Airscreen group: Low-profile perforated hoodmounted air-inlet screen / Engine side shield

inlet screens, perforated/corrugated / Engine

air-intake precleaner / Engine rubber baffle

●●Articulation guards

●●Axle seal guards

●●Boom cylinder and hydraulic lines guard

●●Boom lift cylinder head end debris deflector

624H 644H

Complete Waste Handler Package (cont.)

●●Bucket cylinder hydraulic lines, zerk, and

sensor guard

●●Cab floor-mounted lockable master electrical

disconnect switch

●●Drive-shaft guard

●●Extreme-duty cab entry steps

●●Extreme-duty front loader frame access

cover with handles

●●Extreme-duty hydraulic bottom guards (fuel

tank, loader frame, engine frame)

●●Extreme-duty transmission side guards

●●Full-frontal cab window guard (high-visibility

version not designed to SAE J1084)

●●Grease-fitting guards

●●Heavy-duty rear grille

●●High-intensity halogen driving lights with

heavy-duty guard

●●High-intensity halogen front cab work lights

with heavy-duty guard

●●Loader frame lower guard

●●Loader frame trash cover

●●Rear-access platforms with step and handhold

●●Rear roof-mounted air-conditioner condenser

with manually activated reversible electric

fans (requires air conditioning)

●●Strobe light wired to the master electrical

disconnect switch

●●Swing-out, manually activated, hydraulic

reversible engine cooling fan

Loader Linkage

▲▲

High-lift boom

●●Loader boom service locking bar (conforms

to SAE J38)

●●Z-bar loader linkage provides “high bucket

breakout”

Buckets and Attachments

▲▲

Full line of construction utility forks, pallet

forks, extendible boom with hook, and other

attachments for couplers*

▲▲Hydraulic control system for quick-coupler

locking pins, includes all controls in the cab,

lines, and valves

▲▲Loadrite

TM

weighing system*

▲▲Quick-coupler which accepts JRB attachments*

Tires

●

20.5-25 solid rubber

● 23.5-25 solid rubber

▲ 20.5 R 25

▲ 23.5 R 25

▲▲L-5 radial or bias ply tires

▲▲Less wheels and tires

▲▲Multi-piece rims

Other

●●

Articulation locking bar (conforms to SAE

J276)

●●Counterweight, built-in

●●Drawbar, with locking pin

●●Vandal protection, includes lockable engine

enclosure, rear grille, and fuel fill

▲▲License-plate bracket

▲▲Lift and tie-down hooks

▲▲Secondary steering

DKA624HWH Litho in U.S.A. (03-08)

Net engine power is with standard equipment including air cleaner, exhaust

system, alternator, and cooling fan, at standard conditions per SAE J1349

and DIN 70 020, using No. 2-D fuel at 35 API gravity. No derating is required

up to 10,000-ft. (3050 m) altitude. Gross power is without cooling fan.

Specifications and design subject to change without notice. Wherever applicable, specifications are in accordance with SAE standards. Except where otherwise noted, these specifications are based on units with all standard equipment, waste handler complete protection

package, high-lift booms, ROPS cabs, full fuel tanks, and 175-lb. (79 kg) operators; 624J unit

with 20.5-25 solid rubber tires; and 644J unit with 23.5-25 solid rubber tires.

Loading...

Loading...