Page 1

D

450D LC

45 METRIC TON

EXCAVATOR

Page 2

One of a kind.

One of a kind.

One of a kind.

Often imitated but never duplicated, the

John Deere 450D LC once again sets the

standard for power, smoothness, ease of

operation, and comfort. Like its predecessor,

the highly popular and productive 450C LC,

the D-Series boasts more of everything.

A larger, slower-running engine and even

more effi cient cooling system for long-lasting

durability. Quieter, more spacious, and comfortable cab with even better visibility. And

more operating weight, arm force, and lift

capacity. Read on to learn more about how

the 450D LC is well-armed to deliver maximum productivity and uptime.

PAGES

2–3

Page 3

Extended engine and hydraulic fl uid service intervals simplify

maintenance and reduce daily operating costs.

Redesigned cab combines more legroom and 47-percent more

glass for unsurpassed comfort and visibilit y.

Powerwise™ III engine/hydraulic management system

maximizes power output, saves fuel, and delivers smooth

multifunction hydraulic operation.

Hydraulically driven fan runs only as needed, reducing noise,

fuel consumption, and operating costs.

Fuel-effi cient Tier III emission-certifi ed 15.7-L diesel delivers

power without compromise in all conditions.

Specifi cations 450D LC

SAE Net Horsepower ................................. 348 hp

Operating Weight ...................................... 106,180 lb.

Lift Capacity .............................................. 29,900 lb.

Digging Depth ........................................... 27 ft. 2 in.

Arm Breakout Force ................................. 43,028 lb.

Page 4

Variable-speed fan, noise-reducing muffl er, and

isochronous high-idle speed help quiet things down.

Machine Information Center ( MIC ) captures and

stores vital machine performance and utilization

data to help improve uptime, productivity, and profi t.

Choose from a variety of track widths, booms, arms,

buckets, and other options.

Additional hydraulic capability a necessity?

Dealer-installed high-pressure, high-fl ow

auxiliary hydraulic packages meet the need.

1

1. Generous hydraulic fl ow and best-in-class

metering ensure powerful digging force

and superb multifunction operation.

When extra hydraulic muscle is needed,

simply press the power-boost button to

2

break through.

2. Powerwise III perfectly balances engine

performance and hydraulic fl ow for smooth

fi nesse and predictable operation. One

work mode makes it easy to be productive

in any application.

3. With more horsepower, weight, lift

capacity, swing torque, arm force, bucket

force, and drawbar pull than the model it

replaces, you can expect big productivity

from the 450D LC.

3

Page 5

The strong,

The strong,

The strong,

silent type.

silent type.

silent type.

Other excavators may talk the talk, but the

450D LC walks the walk. Combining faster

hydraulics with exceptional reach, lift capacity,

and arm force, this new Deere provides the

muscle and fi nesse for everything from mass

excavation to utility work. Control is smooth and

effortless, with the Powerwise III management

system delivering pinpoint metering. And

with several new noise-reducing features,

the 450D LC quietly goes about its business,

with less operator fatigue. Plus numerous

options are available, so you can equip the

450D LC exactly the way you need to

maximize your efforts.

PAGES

4–5

Page 6

More room for

More room for

More room for

more productivity.

more productivity.

more productivity.

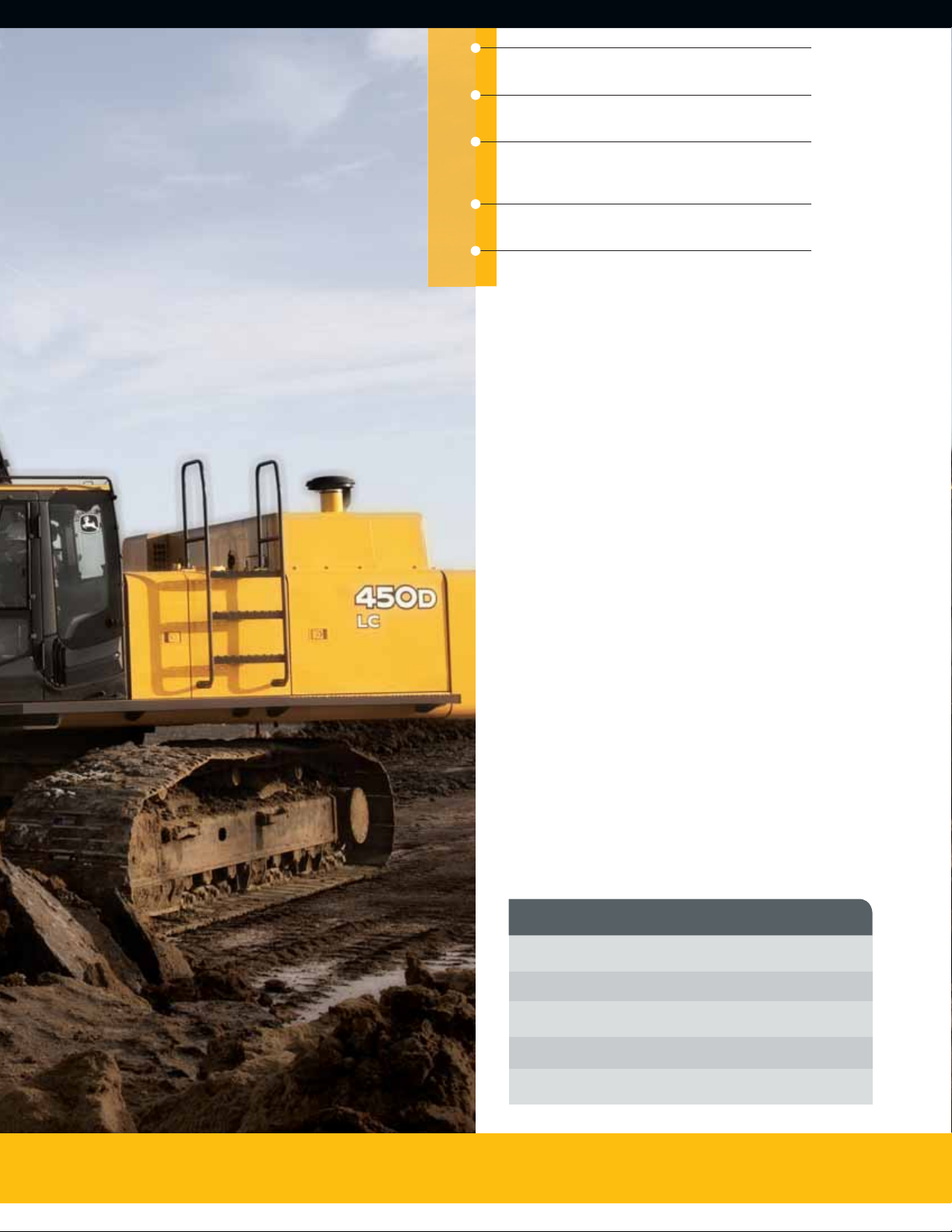

It’s hard not to be productive working from the

air-suspension heated seat in this spacious,

sound-suppressed operating environment. The

well-appointed cab offers more of everything

operators need to do their best. Forty-sevenpercent more glass for better visibility. Substantially more legroom and generous storage.

PAGES

6–7

More creature comforts, too, including highvelocity automatic climate control, AM/FM

radio, 12-volt power port, and hot/cold box

for storage, to list just a few. Operators will

also appreciate what the 450D LC delivers

less of — like reduced noise levels, lower lever

efforts, and productivity-robbing fatigue.

Page 7

Wide expanse of glass, narrower front cab posts, large

overhead hatch, and numerous mirrors provide virtually

unobstructed all-around visibility.

Ergonomically designed short-throw pilot levers provide

smooth, predictable fi ngertip control with less movement

and effort.

Convenient 12-volt port powers cell phones and other

electronic devices.

Redesigned cab isn’t just roomier, it’s also noticeably quieter

and more comfortable. Silicone-fi lled mounts effectively

isolate operators from noise and vibration.

Automatic, high-velocity bi-level climate-control system with

automotive-style adjustable louvers helps keep the glass clear

and the cab comfortable.

1. Multi-position air-suspension seat has

10½ inches of travel, sliding together

or independently of the control console.

So it won’t cramp an operator’s style.

2. No shortage of storage in here. There’s a

place for a cooler, cup holders, and even

a hot/cold beverage box that keeps drinks

at just the right temperature.

3. Intuitive, multi-language monitor provides

a wealth of machine info and control. Its

LCD four-color screen displays operating,

diagnostic, and maintenance info with

easy-on-the-eyes clarity.

1

3

2

Page 8

Three welded bulkheads in the heavy-duty boom

resist torsional stress. Rigid, reinforced D-channel

side frames resist impacts, providing maximum

cab and component protection.

Highly effi cient, heavy-duty cooling system keeps

things cool. Reversing fan back-blows cooler cores

to reduce debris buildup. It’s a welcome addition

that will increase uptime.

Perforated screens behind the side shields

serve as a “fi rst fi lter,” helping prevent trash

entry. Anything that passes through will also

clear the cooler cores.

Large box-section track frames, thick-plate

single-sheet mainframe, and massive swing

bearing deliver rock-solid durability.

Boom, arm, and mainframe are so tough, they’re

warranted for three years or 10,000 hours.

1. Heavy-duty, slow-running sleeved diesel

1

delivers long-term engine durability.

2. Compare the size of the 450D LC’s carrier

and bottom rollers, idlers, and sealed and

lubricated chain. This is one heavy-duty

undercarriage.

3. Hydraulically driven fan runs only as

needed, reducing fuel consumption and

debris fl ow through the coolers.

4. State-of-the-art multifunction diagnostic

monitor helps troubleshoot problems and

defeat downtime.

2

3 4

Page 9

Nothing runs like a

Nothing runs like a

Nothing runs like a

Deere because nothing

Deere because nothing

Deere because nothing

is built like one.

is built like one.

is built like one.

Uptime makes the difference between a job

well done and a job gone wrong. That’s why

the 450D LC is built tough for maximum

reliability — from its rugged D-channel mainframe to its heavy-duty fuel-sipping diesel.

The signifi cantly beefed-up undercarriage

delivers long and reliable performance. Other

durability-boosting features such as a sleeved

engine, heavy-duty boom, and extended

engine and hydraulic oil change intervals help

keep downtime to a minimum. When you

know how they’re built, you’ll run a Deere.

PAGES

8–9

Page 10

Machine Information

Center, remote

diagnostics, and fl uidsample ports help

speed preventative

maintenance and

troubleshooting.

Auto-idle reduces engine

speed when hydraulics

aren’t in use, helping

make the most of every

precious drop of fuel.

Larger fuel tank and

500- and 5,000-hour

engine and hydraulic oil

service intervals enable

the 450D LC to work

longer between stops

for service.

Conveniently located

sight gauges let you

check coolant and

hydraulic fl uid levels

at a glance.

Wide, slip-resistant

“Deere walk,” sturdy

handrails, and selfcleaning steps provide

convenient one-side

access to the engine

service area.

Nobody backs you

better than the 500plus John Deere

dealers throughout

North America.

PAGES

10–11

Page 11

Minimize maintenance,

Minimize maintenance,

Minimize maintenance,

maximize results.

maximize results.

maximize results.

Increasing uptime and lowering daily operating

costs shouldn’t be a reach — and it’s not with

the 450D LC. Wide, slip-resistant steps and large,

easy-to-open service doors provide easy access

to conveniently grouped service points and major

components. Remote-mounted oil and fuel fi lters

1. Easy-to-navigate monitor enables you to

reference maintenance intervals and check

engine oil and coolant levels at the touch

of a button.

4. Easy-to-open hinged doors provide quick

access to service items. Filters and check

points are grouped for added convenience.

2. Vertical spin-on engine, hydraulic, and

fuel fi lters simplify service and help

minimize messes.

5. Fresh-air cab fi lter is quickly serviced

from outside the cab where it’s more

likely to get done.

and extended engine and hydraulic oil service

intervals minimize periodic maintenance. Plus a

Machine Information Center, diagnostic monitor,

and available fl uid-sample ports help you make

timely decisions about machine upkeep —

and improve uptime, productivity, and profi t.

3. Wide fi n spacing lets trash easily pass through

cores to resist plugging. Hinged swing-out

coolers allow additional access to the cores

for easier cleanout, if necessary.

6. Centralized lube banks place diffi cult-tolube zerks within easy reach. Prominently

posted lube chart helps ensure that nothing

gets overlooked.

1

4

2 3

5 6

Page 12

Specifications

Specifications

Specifications

Engine 450D LC

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Isuzu AH-6WG1XYSA-01 with turbocharger and air-to-air charge air cooler; meets EPA and CARB emission non-road regulations

Rated Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348 SAE net hp (260 kW) @ 1,800 rpm

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 957 cu. in. (15.681 L)

Maximum Net Torque . . . . . . . . . . . . . . . . . . . . . . 1,164 lb.-ft. (1580 Nm) @ 1,500 rpm

Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . suction-type, hydraulic-driven, remote-mounted drive

Electrical System. . . . . . . . . . . . . . . . . . . . . . . . . . 24 volt with 50-amp alternator

Batteries (two 12 volt) . . . . . . . . . . . . . . . . . . . . . . reserve capacity: 280 min.

Off-level capacity . . . . . . . . . . . . . . . . . . . . . . . . . 70% (35 deg.)

Hydraulic System

Main Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . two variable-displacement axial-piston

Maximum Flow . . . . . . . . . . . . . . . . . . . . . . . . 2 x 100 gpm (2 x 379 L/min.)

Pilot Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . one gear

Maximum Flow . . . . . . . . . . . . . . . . . . . . . . . . 7.9 gpm (30 L/min.)

Pressure Setting . . . . . . . . . . . . . . . . . . . . . . . 566 psi (3900 kPa)

System Operating Pressure

Implement Circuits . . . . . . . . . . . . . . . . . . . . . 4,625 psi (31 900 kPa)

Travel Circuits . . . . . . . . . . . . . . . . . . . . . . . . . 4,980 psi (34 300 kPa)

Swing Circuits. . . . . . . . . . . . . . . . . . . . . . . . . 4,045 psi (27 900 kPa)

Power Boost . . . . . . . . . . . . . . . . . . . . . . . . . . 4,980 psi (34 300 kPa)

Oil Filtration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . one 10-micron full-flow return filter with by-pass / one pilot oil filter

Cylinders

Bore Rod Diameter Stroke

Boom (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 in. (170 mm) 4.5 in. (115 mm) 62.6 in. (1590 mm)

Arm (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5 in. (190 mm) 5.1 in. (130 mm) 76.4 in. (1940 mm)

Bucket (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 in. (170 mm) 4.7 in. (120 mm) 52.2 in. (1325 mm)

Swing Mechanism

Swing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0–9 rpm

Swing Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107,004 lb.-ft. (145 189 Nm)

Undercarriage

Carrier Rollers (per side) . . . . . . . . . . . . . . . . . . . . 3

Track Rollers (per side) . . . . . . . . . . . . . . . . . . . . . 9

Shoes, Triple Semi-Grouser (per side) . . . . . . . . . . 53

Track Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . front and center

Track Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic

Travel Speed

Low. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0–2.1 mph (0–3.4 km/h)

High . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0–3.4 mph (0–5.5 km/h)

Drawbar Pull . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79,590 lb. (36 100 kg)

Ground Pressure Data

Average Ground Pressure

30-in. (750 mm) Triple Semi-Grouser Shoes

(recommended for rocky terrain/stumps) . . . 8.81 psi (60.7 kPa)

36-in. (900 mm) Triple Semi-Grouser Shoes

(recommended for general/soft terrain) . . . 7.45 psi (51.4 kPa)

PAGES

12–13

Page 13

Capacities (U.S.) 450D LC

E

GROUND LINE

B

C

D

F

G

CENTERLINE OF SWING

B'

A'

A

Fuel Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192 gal. (725 L)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . 50.7 qt. (48 L)

Engine Lubrication, Including Filter . . . . . . . . . . . . 59 qt. (55.8 L)

Hydraulic Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 gal. (322 L)

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . 148 gal. (560 L)

Propel Gearbox (each) . . . . . . . . . . . . . . . . . . . . . . 9 qt. (8.5 L)

Swing Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 qt. (4.7 L)

SAE Operating Weights

With Full Fuel Tank; 175-lb. (79 kg) Operator;

3.06-cu.-yd. (2.34 m

4,478-lb. (2031 kg) Bucket; 12-ft. 10-in.

(3.9 m) Arm; 20,172-lb. (9150 kg) Counterweight; and 36-in. (900 mm) Triple Semi-

Grouser Shoes. . . . . . . . . . . . . . . . . . . . . . . . . 106,180 lb. (48 163 kg)

3

), 54-in. (1370 mm),

Component Weights

Undercarriage

30-in. (750 mm) Triple Semi-Grouser Shoes . . . 40,227 lb. (18 247 kg)

36-in. (900 mm) Triple Semi-Grouser Shoes . . . 41,726 lb. (18 927 kg)

One-Piece Boom (with arm cylinder) . . . . . . . . . . . 9,458 lb. (4290 kg)

Arm with Bucket Cylinder and Linkage

9 ft. 6 in. (2.9 m) . . . . . . . . . . . . . . . . . . . . . . . 5,291 lb. (2400 kg)

With 20-ft. 7-in. (6.3 m) Mass-Excavat-

ing Boom . . . . . . . . . . . . . . . . . . . . . . 5,291 lb. (2400 kg)

11 ft. 2 in. (3.4 m) . . . . . . . . . . . . . . . . . . . . . . 5,137 lb. (2330 kg)

12 ft. 10 in. (3.9 m) . . . . . . . . . . . . . . . . . . . . . 5,820 lb. (2640 kg)

16 ft. 1 in. (4.9 m) . . . . . . . . . . . . . . . . . . . . . . 4,078 lb. (1850 kg)

Boom Lift Cylinders (2) Total Weight . . . . . . . . . . . 1,851 lb. (840 kg)

3.06-cu.-yd. (2.34 m

General-Purpose Bucket . . . . . . . . . . . . . . . . . 4,478 lb. (2031 kg)

Counterweight. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20,172 lb. (9150 kg)

3

), 54-in. (1370 mm)

Operating Information

Arm Force with 36-in. (900 mm) Triple Semi-

Grouser Shoes* . . . . . . . . . . . . . . . . . . . . . . . . 51,014 lb. 51,014 lb. (227 kN) 47,321 lb. 43,028 lb. 37,560 lb.

Bucket Digging Force with 36-in. (900 mm)

Triple Semi-Grouser Shoes* . . . . . . . . . . . . . . 57,111 lb. 57,111 lb. (254 kN) 57,111 lb. 57,111 lb. 43,624 lb.

Lifting Capacity Over Front @ Ground Level

20-ft. (6.1 m) Reach* . . . . . . . . . . . . . . . . . . . 40,000 lb. 39,900 lb. (18 099 kg) 40,200 lb. 39,200 lb. 38,600 lb.

A Maximum Reach . . . . . . . . . . . . . . . . . . . . . . 37 ft. 5 in. 35 ft. 8 in. (10.86 m) 39 ft. 7 in. 41 ft. 0 in. 43 ft. 9 in.

A' Maximum Reach @ Ground Level . . . . . . . . . 36 ft. 8 in. 34 ft. 10 in. (10.61 m) 38 ft. 10 in. 40 ft. 3 in. 43 ft. 1 in.

B Maximum Digging Depth . . . . . . . . . . . . . . . . 23 ft. 11 in. 20 ft. 5 in. (6.23 m) 25 ft. 6 in. 27 ft. 2 in. 29 ft. 11 in.

B' Maximum Digging Depth @ 8-ft. (2.44 m)

Flat Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . 23 ft. 3 in. 19 ft. 11 in. (6.08 m) 25 ft. 0 in. 26 ft. 8 in. 29 ft. 6 in.

C Maximum Cutting Height . . . . . . . . . . . . . . . . 33 ft. 8 in. 35 ft. 8 in. (10.88 m) 36 ft. 3 in. 36 ft. 7 in. 38 ft. 6 in.

D Maximum Dumping Height . . . . . . . . . . . . . . 23 ft. 1 in. 24 ft. 1 in. (7.33 m) 25 ft. 1 in. 25 ft. 6 in. 28 ft. 5 in.

E Minimum Swing Radius. . . . . . . . . . . . . . . . . 16 ft. 6 in. 12 ft. 11 in. (3.93 m) 15 ft. 10 in. 15 ft. 9 in. 15 ft. 11 in.

F Maximum Vertical Wall. . . . . . . . . . . . . . . . . . 17 ft. 3 in. 16 ft. 6 in. (5.02 m) 21 ft. 7 in. 22 ft. 11 in. 27 ft. 7 in.

G Tail Swing Radius . . . . . . . . . . . . . . . . . . . . . 12 ft. 0 in. 12 ft. 0 in. (3.65 m) 12 ft. 0 in. 12 ft. 0 in. 12 ft. 0 in.

*Digging forces and lift capacities with power boost.

Arm Length 20-ft. 7-in. (6.3 m) Mass-Excavat- Arm Length Arm Length Arm Length

9 ft. 6 in. (2.9 m) ing Boom w/9-ft. 6-in. (2.9 m) Arm 11 ft. 2 in. (3.4 m) 12 ft. 10 in. (3.9 m) 16 ft. 1 in. (4.9 m)

(227 kN) (210 kN) (192 kN) (167 kN)

(254 kN) (254 kN) (254 kN) (194 kN)

(18 144 kg) (18 235 kg) (17 781 kg) (17 509 kg)

(11.40 m) (12.06 m) (12.49 m) (13.34 m)

(11.17 m) (11.84 m) (12.28 m) (13.14 m)

(7.28 m) (7.77 m) (8.27 m) (9.11 m)

(7.08 m) (7.63 m) (8.14 m) (9.00 m)

(10.25 m) (11.06 m) (11.16 m) (11.73 m)

(7.03 m) (7.65 m) (7.77 m) (8.67 m)

(5.02 m) (4.84 m) (4.81 m) (4.85 m)

(5.27 m) (6.59 m) (6.98 m) (8.42 m)

(3.65 m) (3.65 m) (3.65 m) (3.65 m)

Page 14

Dimensions

9-ft. 6-in. (2.9 m) Arm. . . . . . . . . . . . . . . . . . . 11 ft. 10 in. (3.60 m)

A

450D LC

11-ft. 2-in. (3.4 m) Arm. . . . . . . . . . . . . . . . . . 11 ft. 5 in. (3.48 m)

12-ft. 10-in. (3.9 m) Arm. . . . . . . . . . . . . . . . . 11 ft. 6 in. (3.50 m)

16-ft. 1-in. (4.9 m) Arm. . . . . . . . . . . . . . . . . . 14 ft. 11 in. (4.55 m)

20-ft. 7-in. (6.3 m) ME Boom with 9-ft. 6-in.

(2.9 m) Arm . . . . . . . . . . . . . . . . . . . . . . . 12 ft. 3 in. (3.74 m)

B 9-ft. 6-in. (2.9 m) Arm. . . . . . . . . . . . . . . . . . . 39 ft. 4 in. (12.0 m)

11-ft. 2-in. (3.4 m) Arm. . . . . . . . . . . . . . . . . . 39 ft. 1 in. (11.91 m)

12-ft. 10-in. (3.9 m) Arm. . . . . . . . . . . . . . . . . 39 ft. 1 in. (11.91 m)

16-ft. 1-in. (4.9 m) Arm. . . . . . . . . . . . . . . . . . 39 ft. 0 in. (11.9 m)

20-ft. 7-in. (6.3 m) ME Boom with 9-ft. 6-in.

(2.9 m) Arm . . . . . . . . . . . . . . . . . . . . . . . 36 ft. 10 in. (11.22 m)

C Operating Position. . . . . . . . . . . . . . . . . . . . . . 9 ft. 6 in. (2.89 m)

Transport Position . . . . . . . . . . . . . . . . . . . . . . 7 ft. 10 in. (2.39 m)

D 30-in. (750 mm) Triple Semi-Grouser Shoes

Operating Position. . . . . . . . . . . . . . . . . . . 11 ft. 11 in. (3.64 m)

Transport Position . . . . . . . . . . . . . . . . . . . 10 ft. 4 in. (3.14 m)

36-in. (900 mm) Triple Semi-Grouser Shoes

Operating Position. . . . . . . . . . . . . . . . . . . 12 ft. 5 in. (3.79 m)

Transport Position . . . . . . . . . . . . . . . . . . . 10 ft. 10 in. (3.29 m)

12 ft. 0 in. (3.645 m)

10 ft. 11 in. (3.33 m)

30 in. (750 mm)

36 in. (900 mm)

11 ft. 7 in. (3.53 m)

2 ft. 4 in. (723 mm)

C

D

A

14 ft. 8 in. (4.47 m)

17 ft. 11 in. (5.47 m)

B

Lift Capacities

Boldface italic

20,172-lb. (9150 kg) counterweight; standard gauge; and situated on firm, uniform supporting surface. Total load includes weight of cables, hook, etc. Figures do not exceed

87 percent of hydraulic capacities or 75 percent of weight needed to tip machine. All lift capacities are based on SAE J1097.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m) 30 ft. (9.15 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

With 23-ft. 0-in. (7.0 m) boom; 9-ft. 6-in. (2.9 m) arm; 3.0-cu.-yd. (2.3 m3), 3,924-lb. (1780 kg) bucket; and 30-in. (750 mm) triple semi-grouser shoes

25 ft. (7.62 m)

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings at bucket lift hook; machine equipped with

21,500 (9752) 21,500 (9752)

39,900 (18 099)39,900 (18 099)29,600 (13 426)29,600 (13 426) 24,700 (11 204)

49,400 (22 408)

47,900 (21 727) 47,900 (21 727) 44,300 (20 094)

36,500 (16 556)36,500 (16 556)29,900 (13 563)

40,500 (18 371)

41,000 (18 597)

34,800 (15 785)

38,700 (17 554)

40,000 (18 144)

39,000 (17 690)

35,900 (16 284)

28,000 (12 701)

26,300 (11 930)

25,500 (11 567)

25,200 (11 431)

25,400 (11 521)

26,000 (11 794)

22,600 (10 251)

27,300 (12 383)

29,500 (13 381)

30,800 (13 971)

30,500 (13 835)

28,300 (12 837)

22,600 (10 251)

21,700 (9843)

20,800 (9435)

19,800 (8981)

18,800 (8528) 23,800 (10 796) 14,000 (6350)

18,200 (8255) 23,300 (10 569) 13,600 (6169)

17,900 (8119) 23,100 (10 478) 13,400 (6078)

17,900 (8119)

18,400 (8346)

22,000 (9979)

22,100 (10 024)

15,000 (6804)

14,500 (6577)

4 ft. 6 in. (1.36 m)

PAGES

14–15

Page 15

Lift Capacities

Boldface italic

(continued)

450D LC

type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings at bucket lift hook; machine equipped with

20,172-lb. (9150 kg) counterweight; standard gauge; and situated on firm, uniform supporting surface. Total load includes weight of cables, hook, etc. Figures do not exceed

87 percent of hydraulic capacities or 75 percent of weight needed to tip machine. All lift capacities are based on SAE J1097.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m) 30 ft. (9.15 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

With 23-ft. 0-in. (7.0 m) boom; 11-ft. 2-in. (3.4 m) arm; 2.7-cu.-yd. (2.1 m3), 3,593-lb. (1630 kg) bucket; and 30-in. (750 mm) triple semi-grouser shoes

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

–20 ft. (–6.10 m)

28,000 (12 701) 28,000 (12 701) 23,700 (10 750)

33,400 (15 150)

37,900 (17 191)

25,400 (11 521) 25,400 (11 521) 40,200 (18 235)

43,200 (19 595)

38,800 (17 600) 38,800 (17 600) 48,200 (21 863)

40,700 (18 461)

41,100 (18 643)

40,100 (18 189)

37,700 (17 101)

49,300 (22 362) 49,300 (22 362) 41,100 (18 643) 41,100 (18 643) 32,800 (14 878)

29,600 (13 426)29,600 (13 426) 23,400 (10 614) 23,400 (10 614)

29,000 (13 154)

27,200 (12 338)

26,100 (11 839)

25,600 (11 612)

25,600 (11 612)

26,100 (11 839)

21,500 (9752) 21,500 (9752) 18,500 (8392)

26,500 (12 020)

29,200 (13 245)

30,800 (13 971)

31,100 (14 107)

29,600 (13 426)

25,500 (11 567)

21,400 (9707)

20,400 (9253)

19,400 (8800)

18,600 (8437) 23,700 (10 750) 14,000 (6350)

18,200 (8255) 23,400 (10 614) 13,700 (6214)

18,100 (8210)

18,500 (8392)

21,300 (9662)

22,700 (10 297)

24,100 (10 932)

23,100 (10 478)

15,900 (7212)

15,500 (7031)

15,000 (6804)

14,400 (6532)

13,700 (6214)

With 23-ft. 0-in. (7.0 m) boom; 12-ft. 10-in. (3.9 m) arm; 2.5-cu.-yd. (1.9 m3), 5,434-lb. (1570 kg) bucket; and 30-in. (750 mm) triple semi-grouser shoes

25 ft. (7.62 m)

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

–20 ft. (–6.10 m)

43,900 (19 913) 43,900 (19 913) 31,100 (14 107)

35,100 (15 921) 35,100 (15 921) 36,100 (16 375)

32,500 (14 742) 32,500 (14 742) 39,200 (17 781)

19,400 (8800) 19,400 (8800) 44,000 (19 958)

36,700 (16 647) 36,700 (16 647) 50,200 (22 770)

56,100 (25 447) 56,100 (25 447) 43,900 (19 913)

33,900 (15 377) 33,900 (15 377) 26,800 (12 156)

40,000 (18 144)

40,200 (18 235)

40,800 (18 507)

39,800 (18 053)

38,300 (17 373)

34,300 (15 558)

29,300 (13 290)

27,300 (12 383)

25,900 (11 748)

25,200 (11 431)

25,100 (11 385)

25,400 (11 521)

26,200 (11 884)

22,100 (10 024)

25,000 (11 340)

27,900 (12 655)

29,900 (13 563)

30,700 (13 925)

29,800 (13 517)

26,800 (12 156)

19,200 (8709)

21,600 (9798)

20,400 (9253)

19,300 (8754)

18,400 (8346) 23,500 (10 660) 13,700 (6214)

17,900 (8119) 23,100 (10 478) 13,400 (6078)

17,700 (8029) 23,000 (10 433) 13,300 (6033)

17,900 (8119)

18,700 (8482)

11,200 (5080) 11,200 (5080)

17,900 (8119)

20,000 (9072)

21,500 (9752)

23,100 (10 478)

16,000 (7258)

15,600 (7076)

14,900 (6759)

14,300 (6486)

With 23-ft. 0-in. (7.0 m) boom; 16-ft. 1-in. (4.9 m) arm; 1.8-cu.-yd. (1.4 m3), 2,579-lb. (1170 kg) bucket; and 30-in. (750 mm) triple semi-grouser shoes

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

–20 ft. (–6.10 m)

–25 ft. (–7.62 m)

48,100 (21 818)

42,900 (19 459) 42,900 (19 459)38,600 (17 509)

19,100 (8664) 19,100 (8664) 43,400 (19 686)

30,000 (13 608) 30,000 (13 608) 53,900 (24 449)

43,500 (19 731) 43,500 (19 731) 51,200 (23 224)

58,800 (26 672) 58,800 (26 672) 44,000 (19 958)

31,900 (14 470) 31,900 (14 470) 24,700 (11 204) 24,700 (11 204)

46,000 (20 865)

41,600 (18 870)

41,200 (18 688)

41,500 (18 824)

42,200 (19 142)

34,000 (15 422)

40,900 (18 552)

41,100 (18 643)

38,900 (17 645)

34,100 (15 468)

23,600 (10 705)

29,800 (13 517)

28,000 (12 701)

26,900 (12 202)

26,400 (11 975) 32,000 (14 515) 18,900 (8573) 24,100 (10 932) 14,500 (6577)

26,300 (11 930)

26,700 (12 111)

27,000 (12 247)

29,900 (13 563)

31,700 (14 379)

30,600 (13 880)

26,600 (12 066)

22,500 (10 206)

21,200 (9616)

20,100 (9117)

19,400 (8800) 24,500 (11 113) 14,700 (6668)

18,900 (8573) 24,100 (10 932) 14,400 (6532)

19,200 (8709)

18,800 (8528)

20,900 (9480)

22,900 (10 387)

24,700 (11 204)

19,500 (8845)

With 20-ft. 8-in. (6.3 m) ME boom; 9-ft. 6-in. (2.9 m) ME arm; 3.3-cu.-yd. (2.5 m3), 4,123-lb. (1870 kg) bucket; and 30-in. (750 mm) triple semi-grouser shoes

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

36,200 (16 420) 36,200 (16 420) 28,900 (13 109)28,900 (13 109) 25,100 (11 385)

55,100 (24 993)

51,800 (23 496)

45,600 (20 684)

40,700 (18 461)

40,600 (18 416)

41,100 (18 643)

35,000 (15 876) 35,000 (15 876) 27,000 (12 247)

25,400 (11 521) 25,400 (11 521) 22,500 (10 206)

33,700 (15 286)

37,900 (17 191)

39,900 (18 099)

39,200 (17 781)

35,400 (16 057)

28,800 (13 064)

27,000 (12 247)

25,900 (11 748)

25,400 (11 521)

25,600 (11 612)

26,400 (11 975)

27,300 (12 383)

29,500 (13 381)

30,700 (13 925)

30,200 (13 699)

26,800 (12 156)

21,400 (9707)

20,800 (9435)

19,900 (9027)

19,000 (8618)

18,300 (8301)

18,000 (8165)

18,100 (8210)

17,700 (8029)

22,700 (10 297)

20,000 (9072)

With 23-ft. 0-in. (7.0 m) boom; 9-ft. 6-in. (2.9 m) arm; 3.0-cu.-yd. (2.3 m3), 3,924-lb. (1780 kg) bucket; and 36-in. (900 mm) triple semi-grouser shoes

25 ft. (7.62 m)

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

39,900 (18 099)39,900 (18 099)29,600 (13 426)29,600 (13 426) 24,700 (11 204)

49,400 (22 408)

47,900 (21 727) 47,900 (21 727) 44,300 (20 094)

36,500 (16 556)36,500 (16 556)29,900 (13 563)

41,100 (18 643)

41,500 (18 824)

34,800 (15 785)

38,700 (17 554)

40,000 (18 144)

39,000 (17 690)

35,900 (16 284)

28,400 (12 882)

26,700 (12 111)

25,900 (11 748)

25,600 (11 612)

25,800 (11 703)

26,400 (11 975)

21,500 (9752) 21,500 (9752)

22,600 (10 251)

27,300 (12 383)

29,500 (13 381)

30,800 (13 971)

30,500 (13 835)

28,300 (12 837)

22,600 (10 251)

21,900 (9934)

21,100 (9571)

20,000 (9072)

19,100 (8664) 24,100 (10 932) 14,200 (6441)

18,400 (8346) 23,700 (10 750) 13,800 (6260)

18,100 (8210) 23,500 (10 660) 13,700 (6214)

18,200 (8255)

18,700 (8482)

22,000 (9979)

23,100 (10 478)

17,300 (7847)

16,700 (7575)

15,900 (7212)

15,200 (6895)

14,800 (6713)

14,300 (6486)

13,900 (6305)

13,600 (6169)

15,300 (6940)

14,700 (6668)

Page 16

Lift Capacities

Boldface italic

(continued)

450D LC

type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings at bucket lift hook; machine equipped with

20,172-lb. (9150 kg) counterweight; standard gauge; and situated on firm, uniform supporting surface. Total load includes weight of cables, hook, etc. Figures do not exceed

87 percent of hydraulic capacities or 75 percent of weight needed to tip machine. All lift capacities are based on SAE J1097.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m) 30 ft. (9.15 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

With 23-ft. 0-in. (7.0 m) boom; 11-ft. 2-in. (3.4 m) arm; 2.7-cu.-yd. (2.1 m3), 3,593-lb. (1630 kg) bucket; and 36-in. (900 mm) triple semi-grouser shoes

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

–20 ft. (–6.10 m)

28,000 (12 701) 28,000 (12 701) 23,700 (10 750)

33,400 (15 150)

37,900 (17 191)

25,400 (11 521) 25,400 (11 521) 40,200 (18 235)

43,200 (19 595)

38,800 (17 600) 38,800 (17 600) 48,200 (21 863)

41,300 (18 734)

41,600 (18 870)

40,100 (18 189)

37,700 (17 101)

49,300 (22 362) 49,300 (22 362) 41,100 (18 643) 41,100 (18 643) 32,800 (14 878)

29,600 (13 426)29,600 (13 426) 23,400 (10 614) 23,400 (10 614)

29,400 (13 336)

27,600 (12 519)

26,500 (12 020)

26,000 (11 794)

26,000 (11 794)

26,400 (11 975)

21,500 (9752) 21,500 (9752) 18,500 (8392)

26,500 (12 020)

29,200 (13 245)

30,800 (13 971)

31,100 (14 107)

29,600 (13 426)

25,500 (11 567)

21,700 (9843)

20,700 (9389)

19,700 (8936)

18,900 (8573) 24,100 (10 932) 14,200 (6441)

18,500 (8392) 23,800 (10 796) 13,900 (6305)

18,400 (8346)

18,700 (8482)

21,300 (9662)

22,700 (10 297)

24,100 (10 932)

23,100 (10 478)

16,100 (7303)

15,800 (7167)

15,200 (6895)

14,700 (6668)

14,000 (6350)

With 23-ft. 0-in. (7.0 m) boom; 12-ft. 10-in. (3.9 m) arm; 2.5-cu.-yd. (1.9 m3), 5,434-lb. (1570 kg) bucket; and 36-in. (900 mm) triple semi-grouser shoes

25 ft. (7.62 m)

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

–20 ft. (–6.10 m)

43,900 (19 913) 43,900 (19 913) 31,100 (14 107)

35,100 (15 921) 35,100 (15 921) 36,100 (16 375)

32,500 (14 742) 32,500 (14 742) 39,200 (17 781)

19,400 (8800) 19,400 (8800) 44,000 (19 958)

36,700 (16 647) 36,700 (16 647) 50,200 (22 770)

56,100 (25 447) 56,100 (25 447) 43,900 (19 913)

33,900 (15 377) 33,900 (15 377) 26,800 (12 156)

40,500 (18 371)

40,700 (18 461)

41,400 (18 779)

39,800 (18 053)

38,300 (17 373)

34,300 (15 558)

29,700 (13 472)

27,700 (12 565)

26,300 (11 930)

25,600 (11 612)

25,500 (11 567)

25,800 (11 703)

26,500 (12 020)

22,100 (10 024)

25,000 (11 340)

27,900 (12 655)

29,900 (13 563)

30,700 (13 925)

29,800 (13 517)

26,800 (12 156)

19,200 (8709)

21,900 (9934)

20,700 (9389)

19,600 (8891)

18,700 (8482) 23,900 (10 840) 14,000 (6350)

18,200 (8255) 23,500 (10 660) 13,600 (6169)

18,000 (8165) 23,400 (10 614) 13,500 (6124)

18,200 (8255)

18,900 (8573)

11,200 (5080) 11,200 (5080)

17,900 (8119)

20,000 (9072)

21,500 (9752)

23,100 (10 478)

16,200 (7348)

15,800 (7167)

15,200 (6895)

14,500 (6577)

With 23-ft. 0-in. (7.0 m) boom; 16-ft. 1-in. (4.9 m) arm; 1.8-cu.-yd. (1.4 m3), 2,579-lb. (1170 kg) bucket; and 36-in. (900 mm) triple semi-grouser shoes

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

–20 ft. (–6.10 m)

–25 ft. (–7.62 m)

48,100 (21 818)

42,900 (19 459) 42,900 (19 459)38,600 (17 509)

19,100 (8664) 19,100 (8664) 43,400 (19 686)

30,000 (13 608) 30,000 (13 608) 53,900 (24 449)

43,500 (19 731) 43,500 (19 731) 51,200 (23 224)

58,800 (26 672) 58,800 (26 672) 44,000 (19 958)

31,900 (14 470) 31,900 (14 470) 24,700 (11 204) 24,700 (11 204)

46,600 (21 138)

42,200 (19 142)

41,800 (18 960)

42,000 (19 051)

42,800 (19 414)

34,000 (15 422)

40,900 (18 552)

41,100 (18 643)

38,900 (17 645)

34,100 (15 468)

30,100 (13 653)

28,400 (12 882)

27,200 (12 338)

26,700 (12 111)

26,700 (12 111)

27,100 (12 292)

23,600 (10 705)

27,000 (12 247)

29,900 (13 563)

31,700 (14 379)

32,000 (14 515)

30,600 (13 880)

26,600 (12 066)

22,700 (10 297)

21,500 (9752)

20,400 (9253)

19,600 (8891) 24,800 (11 249) 15,000 (6804)

19,200 (8709) 24,500 (11 113) 14,700 (6668)

19,100 (8664)

19,400 (8800)

18,800 (8528)

20,900 (9480)

22,900 (10 387)

24,700 (11 204)

24,300 (11 022)

19,500 (8845)

With 20-ft. 8-in. (6.3 m) ME boom; 9-ft. 6-in. (2.9 m) ME arm; 3.3-cu.-yd. (2.5 m3), 4,123-lb. (1870 kg) bucket; and 36-in. (900 mm) triple semi-grouser shoes

20 ft. (6.10 m)

15 ft. (4.57 m)

10 ft. (3.05 m)

5 ft. (1.52 m)

Ground Line

–5 ft. (–1.52 m)

–10 ft. (–3.05 m)

–15 ft. (–4.57 m)

36,200 (16 420) 36,200 (16 420) 28,900 (13 109)28,900 (13 109) 25,100 (11 385)

55,100 (24 993)

51,800 (23 496)

45,600 (20 684)

41,200 (18 688)

41,200 (18 688)

41,700 (18 915)

35,000 (15 876) 35,000 (15 876) 27,000 (12 247)

25,400 (11 521) 25,400 (11 521) 22,500 (10 206)

33,700 (15 286)

37,900 (17 191)

39,900 (18 099)

39,200 (17 781)

35,400 (16 057)

29,100 (13 200)

27,400 (12 429)

26,200 (11 884)

25,800 (11 703)

26,000 (11 794)

26,700 (12 111)

27,300 (12 383)

29,500 (13 381)

30,700 (13 925)

30,200 (13 699)

26,800 (12 156)

21,700 (9843)

21,100 (9571)

20,200 (9163)

19,200 (8709)

18,600 (8437)

18,200 (8255)

18,400 (8346)

17,700 (8029)

22,700 (10 297)

20,000 (9072)

17,600 (7983)

16,900 (7666)

16,100 (7303)

15,500 (7031)

14,700 (6668)

15,100 (6849)

14,600 (6623)

14,100 (6396)

13,800 (6260)

PAGES

16–17

Page 17

Buckets

5.0

(3.8)

4.0

(3.0)

3.0

(2.3)

2,000 2,200 2,600 3,200

lb./cu. yd.

kg/m

3

BUCKET SIZE cu. yd. (m

3

)

1,600

6.0

(4.5)

3,400

2.0

(1.5)

2.5

(1.9)

3.5

(2.7)

4.5

(3.4)

5.5

(4.2)

1,200 1,400 1,800 2,400 2,800 3,000 3,600

Wet Peat

Topsoil

Coal

Caliche

Shale

Dry Sand

Dry Clay

Limestone

Wet Earth

Wet Clay, Granite

Moist Sand

Wet Sand

Wet Sand, Gravel

Contact your John Deere dealer for optimum bucket and attachment selections. These recommendations are for general conditions and average use. Does not include optional

equipment such as thumbs or couplers. Larger buckets may be possible when using light materials, for flat and level operations, less compacted materials, and volume loading

applications such as mass excavation applications in ideal conditions. Smaller buckets are recommended for adverse conditions such as off-level applications, rocks, and uneven

surfaces. Bucket capacity indicated is SAE heaped.

*

1300

700 800 900 1000 1100 1200

2000

1400 1500 1600 1700 1800 1900

2100

6.5

(5.0)

Deere 9-ft. 6-in. (2.9 m) Arm

Deere 11-ft. 2-in. (3.4 m) Arm

Deere 12-ft. 10-in. (3.9 m) Arm

Deere 16-ft. 1-in. (4.9 m) Arm

450D LC

A full line of buckets is offered to meet a wide variety of applications. Digging forces are with power boost. Tooth selection includes either the John Deere Fanggs®, Standard,

Tiger, Twin Tiger, Abrasion panel, or Flare tooth, or the ESCO (Vertalok) Standard, Tiger, Twin Tiger, or Flare tooth. Replaceable cutting edges are available through John Deere

parts. Optional side cutters add 6 inches (150 mm) to bucket widths.

Arm Dig Arm Dig Arm Dig Arm Dig

Bucket Bucket Bucket Force 9 ft. Force 11 ft. Force 12 ft. Force 16 ft. Bucket

Type Bucket Width Capacity* Weight Dig Force 6 in. (2.9 m) 2 in. (3.4 m) 10 in. (3.9 m) 1 in. (4.9 m) Tip Radius No. Teeth

in. mm cu. yd. m

3

lb. kg lb. kN lb. kN lb. kN lb. kN lb. kN in. mm

General-Purpose 54 1370 2.30 1.76 2,215 1005 40,505 180.2 34,778 155.0 69.5 1765 7

Plate Lip

Heavy-Duty 42 1065 1.85 1.41 3,124 1417 54,900 244.0 51,705 230.0 44,354 197.0 40,474 180.0 71.5 1816 5

Plate Lip 48 1220 2.15 1.64 3,320 1505 54,900 244.0 51,705 230.0 44,354 197.0 40,474 180.0 71.5 1816 6

54 1370 2.45 1.87 3,578 1623 54,900 244.0 51,705 230.0 44,354 197.0 40,474 180.0 71.5 1816 6

60 1525 2.74 2.10 3,771 1710 54,900 244.0 51,705 230.0 44,354 197.0 40,474 180.0 71.5 1816 7

66 1675 3.01 2.30 3,825 1735 54,900 244.0 51,705 230.0 44,354 197.0 40,474 180.0 71.5 1816 7

72 1830 3.29 2.52 4,061 1842 54,900 244.0 51,705 230.0 44,354 197.0 40,474 180.0 71.5 1816 8

Truck Loading 72 1830 4.18 3.20 4,340 2041 53,028 236.0 51,013 227.0 43,816 195.0 40,026 178.0 74.0 1880 6

Heavy-Duty 48 1220 2.69 2.06 3,969 1800 53,028 236.0 51,013 227.0 43,816 195.0 40,026 178.0 74.0 1880 5

High Capacity 54 1370 3.06 2.34 4,478 2031 53,028 236.0 51,013 227.0 43,816 195.0 40,026 178.0 74.0 1880 5

60 1525 3.43 2.62 5,131 2327 53,028 236.0 51,013 227.0 43,816 195.0 40,026 178.0 74.0 1880 6

66 1675 3.80 2.91 5,003 2269 53,028 236.0 51,013 227.0 43,816 195.0 40,026 178.0 74.0 1880 6

72 1830 4.18 3.20 5,865 2660 53,028 236.0 51,013 227.0 43,816 195.0 40,026 178.0 74.0 1880 7

*All capacities are SAE heaped ratings and with side cutters.

Bucket Selection Guide*

Page 18

450D LC EXCAVATOR

Key: ● Standard equipment ▲ Optional or special equipment *See your John Deere dealer for further information.

450D Engine

●

Meets EPA and CARB emission non-road regulations

● Auto-idle system

● Batteries (two 12 volt), 280-min. reserve capacity

● Coolant recovery tank

● Dual-element dry-type air filter

● Electronic engine control

● Enclosed fan guard (conforms to SAE J1308)

● Engine coolant to –34°F (–37°C)

● Fuel filter with water separator

● Full-flow oil filter

● Turbocharger with charge air cooler

● Muffler, under hood, with vertical curved end

exhaust stack

● Cool-on-demand hydraulic-driven fan

● Glow-plug start aid

● 500-hour engine-oil-change interval

● 70% (35 deg.) off-level capability

▲ Engine-oil-sampling valve

● Hydraulic fan reverser

Hydraulic System

●

Reduced-drift valve for boom down, arm in

● Auxiliary hydraulic valve section

● Spring-applied, hydraulically released automatic

swing brake

● Auxiliary hydraulic-flow adjustments through monitor

● Auto power lift

● 5,000-hour hydraulic-oil-change interval

▲ Hydraulic-oil-sampling valve

▲ Auxiliary hydraulic lines

▲ Auxiliary pilot and electric controls

▲ Hydraulic filter restriction indicator kit

▲ Load-lowering control device

▲ Single-pedal propel control

▲ Pattern changer

Undercarriage

●

Planetary drive with axial piston motors

● Propel motor shields

● Spring-applied, hydraulically released automatic

propel brake

● Track guides, front idler and center

● Two-speed propel with automatic shift

● Upper carrier rollers (3)

● Sealed and lubricated track chain

▲ Triple semi-grouser shoes, 30 in. (750 mm)

▲ Triple semi-grouser shoes, 36 in. (900 mm)

450D Upperstructure

▲

Counterweight-removal system

● Right- and left-hand mirrors

● Vandal locks with ignition key: Cab door / Fuel cap /

Service doors / Toolbox

● Debris-screening side panel

● Service platform, left side

● Remote-mounted engine oil and fuel filters

Front Attachments

●

Centralized lubrication system

● Dirt seals on all bucket pins

● No-boom-arm option

▲ Boom, 23 ft. 0 in. (7.0 m)

▲ Boom, mass excavating, 20 ft. 8 in. (6.3 m)

▲ Arm, mass excavating, 9 ft. 6 in. (2.9 m)

▲ Arm, 9 ft. 6 in. (2.9 m)

▲ Arm, 11 ft. 2 in. (3.4 m)

▲ Arm, 12 ft. 10 in. (3.9 m)

▲ Arm, 16 ft. 1 in. (4.9 m)

▲ Attachment quick-couplers

▲ Boom cylinder with plumbing to mainframe for

no-boom-arm option

▲ Buckets: Heavy duty / Heavy-duty high capacity /

Side cutters and teeth

▲ Material clamps

▲ Super-long fronts

Operator’s Station

●

Adjustable independent control positions (leversto-seat, seat-to-pedals)

● AM/FM radio

● Auto climate control/air conditioner, 20,000 Btu/hr.

(5.9 kW) with heater and pressurizer

● Built-in Operator’s Manual storage compartment

and manual

● Cell-phone power outlet, 12 volt, 60 watt, 5 amp

● Coat hook

● Deluxe air-suspension heated cloth seat with 4-in.

(100 mm) adjustable armrests

● Floor mat

● Front windshield wiper with intermittent speeds

● Gauges (illuminated): Engine coolant / Fuel

● Horn, electric

● Hourmeter, electric

● Hydraulic shutoff lever, all controls

● Hydraulic warm-up control

450D Operator’s Station

(continued)

● Interior light

● Large cup holder

● Machine Information Center (MIC)

● Mode selectors (illuminated): Power modes – three /

Travel modes – two with automatic shift / Work

mode – one / Boom mode

● Multifunction, color LCD monitor with: Diagnostic

capability / Multiple-language capabilities / Maintenance tracking / Clock / System monitoring with

alarm features: Auto-idle, engine air cleaner

restriction indicator light, engine check, engine

coolant temperature indicator light with audible

alarm, engine oil pressure indicator light with

audible alarm, low-alternator-charge indicator light,

low-fuel indicator light, fault code alert indicator,

fuel-rate display, wiper-mode indicator, worklights-on indicator, and work-mode indicator

● Fluid-level switch and indicator light for engine

coolant and engine oil

▲ Monitor system with alarm features: Hydraulic oil

filter restriction indicator light

● Motion alarm with cancel switch (conforms to SAE

J994)

● Power-boost switch on right console lever

● Propel pedals and levers

● SAE two-lever control pattern

● Seat belt, 2 in. (51 mm), retractable

▲ Seat belt, 3 in. (76 mm), non-retractable

● Tinted glass

● Transparent tinted overhead hatch

● Hot/cold beverage compartment

▲ 24- to 12-volt D.C. radio convertors, 10 amp

▲ Circulation fan

▲ Protection screens for cab front, rear, and side

▲ Window vandal protection covers

Electrical

●

50-amp alternator

● Blade-type multi-fused circuits

● Positive terminal battery covers

▲ Cab extension wiring harness

● JDLink

● JDLink

™

Ultimate wireless communication

system with 3 years of service

™

wireless communication system

Lights

●

Work lights: Halogen / One mounted on boom /

One mounted on frame

CONTROL OWNING AND OPERATING COSTS

Customer Personal Service (CPS) is part of John Deere’s proactive, fix-before-fail strategy

on machine maintenance that will help control costs, increase profits, and reduce stress.

Included in this comprehensive lineup of ongoing programs and services are:

Fluid analysis program

components so you’ll know if there’s a problem

analysis is included in most extended coverage and preventive-maintenance agreements.

Component life-cycle data

components and lets you make informed decisions on machine maintenance by telling you

approximately how many hours of use you can expect from an engine, transmission, or

hydraulic pump. This information can be used to preempt catastrophic downtime by servicing major components at about 80 percent of their life cycle.

Preventive Maintenance (PM) agreements

machine for a given period of time. They also help you avoid downtime by ensuring that

DKAX450DLC Litho in U.S.A. (09-08)

– tells you what’s going on inside

– gives you vital information on the projected life span of

Net engine power is with standard equipment including air cleaner,

exhaust system, alternator, and cooling fan, at standard conditions

per SAE J1349 and DIN 6270B, using No. 2-D fuel at 35 API gravity.

No derating is required up to 10,000-ft. (3050 m) altitude. Gross

power is without cooling fan.

before

you see a decline in performance. Fluid

– give you a fixed cost for maintaining a

all

of your machine’s major

Specifications and design subject to change without notice. Wherever applicable, specifications are in accordance with SAE standards.

Except where otherwise noted, these specifications are based on a unit with 54-in. (1370 mm) bucket, 36-in. (900 mm) triple semigrouser shoes, 20,172-lb. (9150 kg) counterweight, full fuel tank, and 175-lb. (79 kg) operator.

critical maintenance work gets done right and on schedule. On-site preventive maintenance

service performed where and when you need it helps protect you from the expense of catastrophic failures and lets you avoid waste-disposal hassles.

Extended coverage

time so you can effectively manage costs. Whether you work in a severe-service setting or

just want to spread the risk of doing business, this is a great way to custom-fit coverage

for your operation. And an extended coverage contract also travels well because it’s backed

by John Deere and is honored by

Customer Support Advisors (CSAs)

quality to Customer Personal Service (CPS). Certified CSAs have the knowledge and skills

for helping make important decisions on machine maintenance and repair. Their mission is

to help you implement a plan that’s right for

maintenance off your shoulders.

– gives you a fixed cost for machine repairs for a given period of

all

Deere construction dealers.

– Deere believes the CSA program lends a

your

business and take the burden of machine

personal

Loading...

Loading...