KNUCKLEBOOM LOG LOADERS

335C 435C 437C

335C 435C 437C

K N U C K L E B O O M L O G L O A D E R S

PAGES

2–3

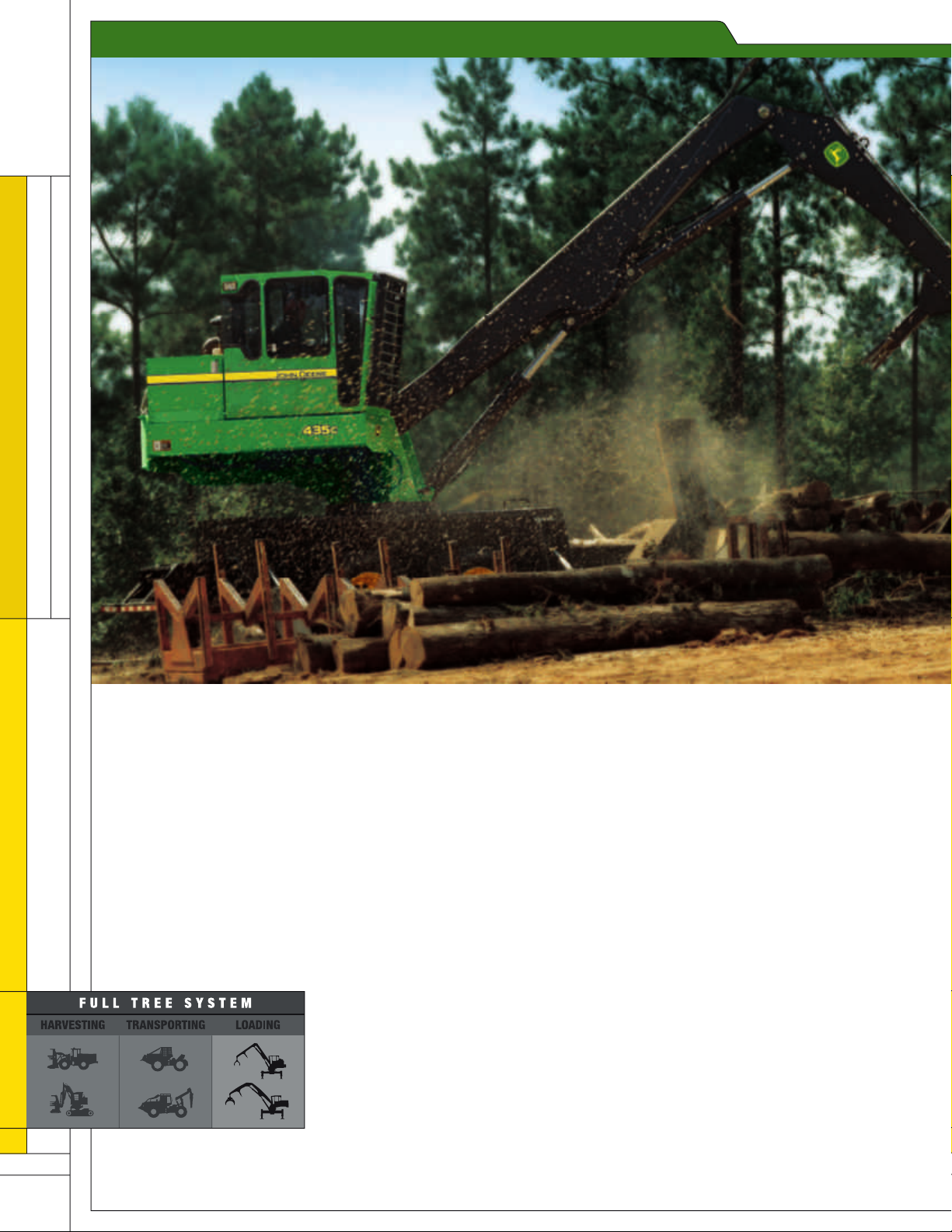

MORE UPTIME. MORE PRODUCTIVITY.

C-SERIES LOADERS ARE BUILT FOR

THE LONG HAUL.

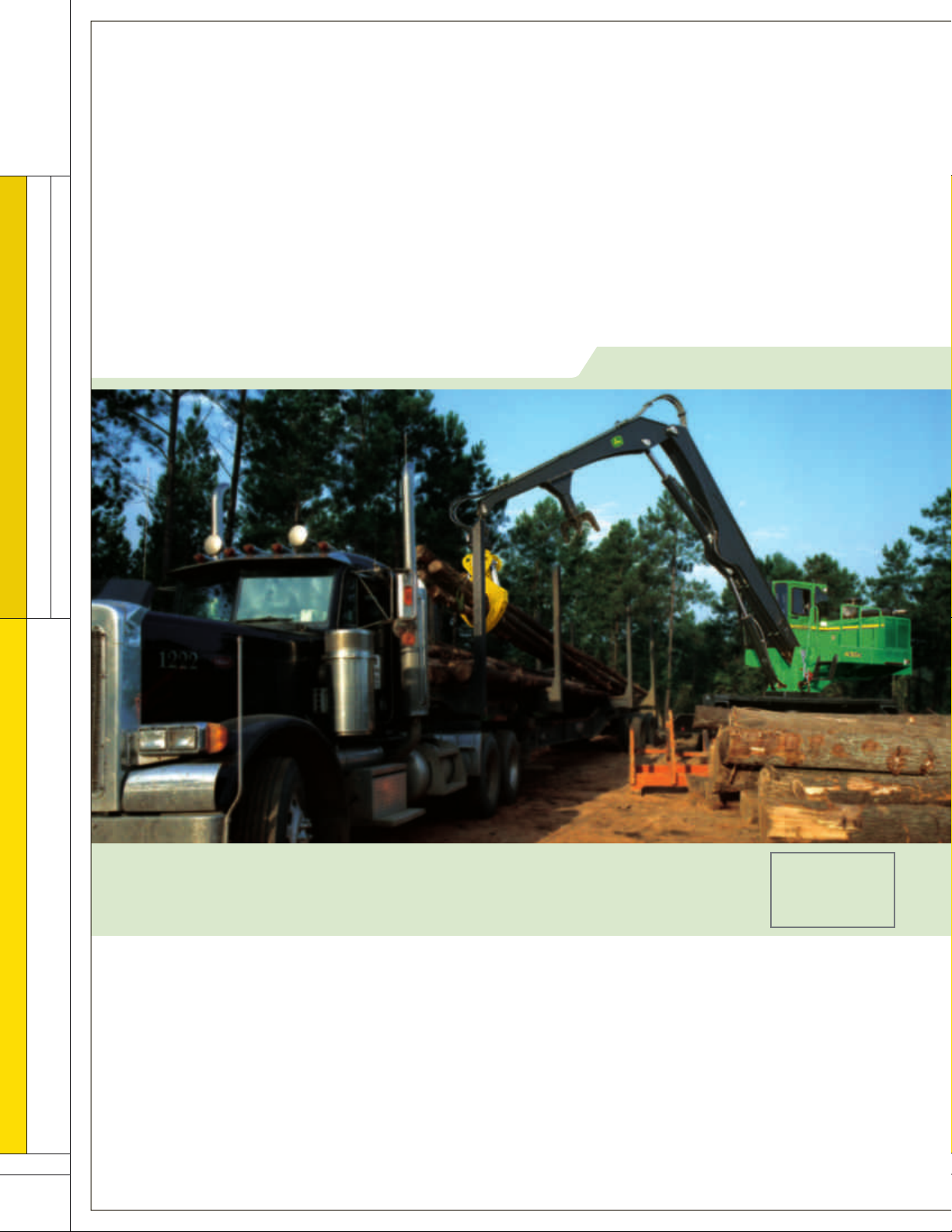

Keep your landing busier than ever with the highly reliable, highly productive

C-Series Knuckleboom Loaders.

Full Tree System—No one offers the

extensive product line,dealer network

and tough, purpose-built machines

of John Deere.

335C 435C 437C

John Deere 6068T Engine Power 170 gross hp 127 kW 170 gross hp 127 kW 170 gross hp 127 kW

Reach 30 ft. 9.1 m 32 ft. 9.7 m 32 ft. 9.7 m

Standard Operating Weight 26,500 lb. 12 020 kg 29,500 lb. 13 381 kg 29,500 lb. 13 381 kg

Lift Capacity @ 10 ft. 12,916 lb. 5859 kg 26,100 lb. 11 838 kg 26,100 lb. 11 838 kg

Your log loader is the key to productivity. It must be strong, fast and

able to endure a steady pace, day after day. That punishing logging

environment is exactly what the C-Series Knuckleboom Loaders

were designed to handle.

Integrating woods-tested John Deere parts and rigorous quality

control, these industry-leading machines have many new features

that directly impact your bottom line. For better productivity, we

increased swing torque, horsepower, hydraulic pump flow and lift

capacity. For maximum durability and stability, the box section on

the booms has been designed for optimum strength. And we’re

keeping your operating costs low with serviceability and a high

degree of common parts for the entire line. Add in the 437C with

load-sensing hydraulics for a complete line of tough, woods-ready

loaders that are built to stand the test of time, and whatever else

you throw their way.

PRO DUC TIV ITY UPT IME LOW DAI LY OPE RAT I NG COS T S

Keep your work area in sight with bestin-class visibility featuring a wraparound

Our isolation-mounted

cab is the industry

leader in both size and

noise level. It features

335C 435C 437C

A John Deere 6068T

K N U C K L E B O O M L O G L O A D E R S

turbocharged diesel

has the high torque

rise you need.

insulated all-weather

protection, comfortable

pilot-operated joystick

controls and a deluxe

adjustable cloth seat

with lumbar support.

rear window, polycarbonate skylight and

industry-first hinged side window that

serves as a second exit.

PAGES

4–5

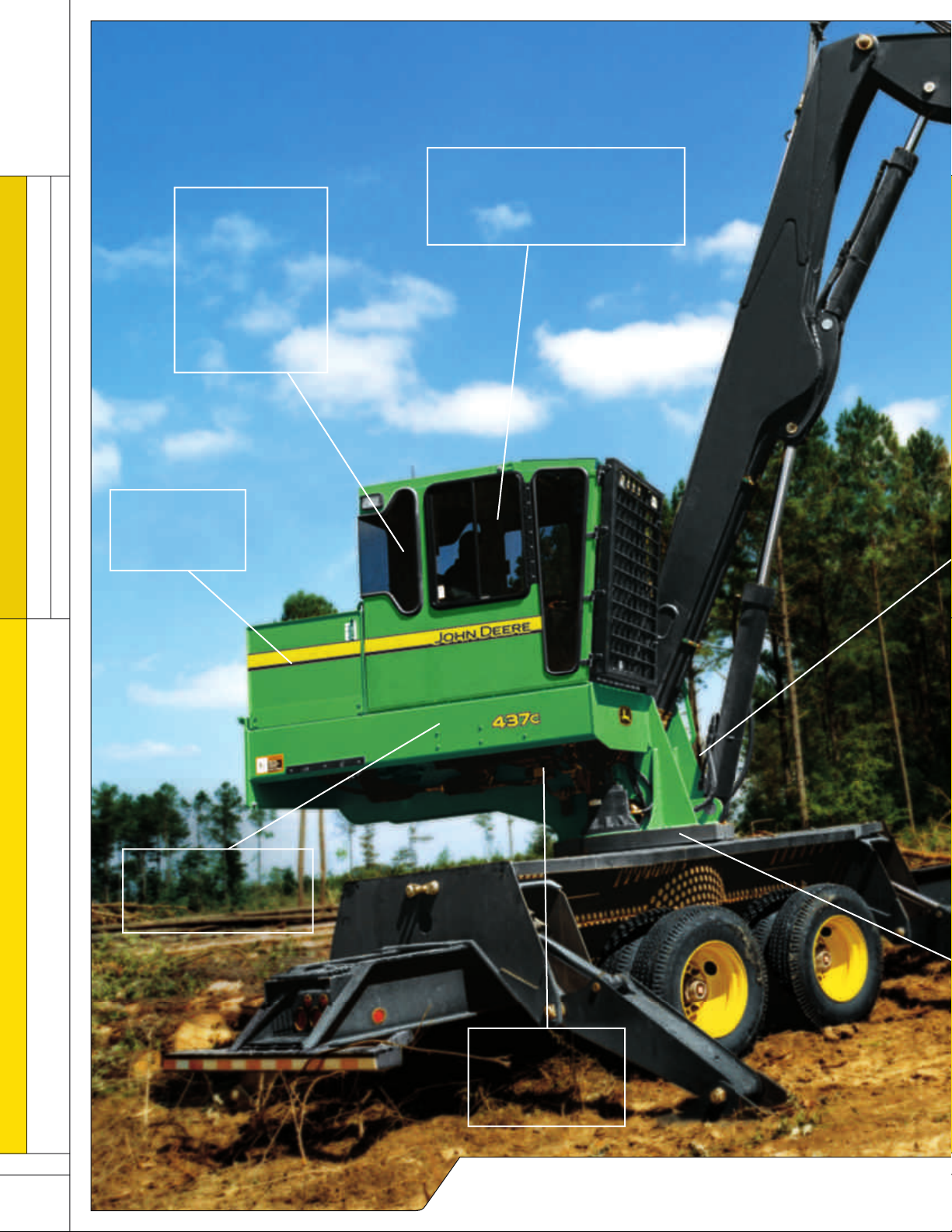

A dedicated swing circuit

gives you continuous power

for more productive delimbing

and loading.

Load-sensing hydraulic

system delivers power

on demand, reducing

fuel consumption and

parts wear.

C-SERIES LOADERS. T

A large 90-gallon fuel tank means

more productivity per fill up, while

quick, deck-level access to service

points speeds daily maintenance

for more time on the job.

Application-specific

boom design to ensure

greater reliability.

Strong swing-bearing

arrangement.

ORS fittings to keep

your machine dry.

Component commonality

among the C-Series

Knuckleboom Loaders

lowers your investment

in spare service parts.

MORE RELIABILITY MEANS

“LOADS” MORE PRODUCTIVITY.

From boom to bearing mount, hydraulics to hose routings, we toughened the

335C 435C 437C

K N U C K L E B O O M L O G L O A D E R S

C-Series Loaders with woods-tested John Deere parts and manufacturing

expertise to give you more uptime than ever.

PAGES

6–7

When it comes to uptime, we designed the C-Series Loaders

to not only set the pace for your landing, but also the pace

for the industry. Uptime on these machines has been increased

dramatically. Hydraulics include better hose routings and

ORS fittings. Faster boom and swing speeds pick up the

pace at your landing.

The larger 90-gallon

fuel tank will give

you more running

time than ever.

The lower structure has been designed, with the center tube

integrated into the lower main structure, load lock valves are

mounted directly to the outrigger cylinders. The many design

changes have strengthened the new C-Series Loaders making

them the toughest machines in the industry.

The dependable power—a John Deere 6068T,

6-cylinder, turbocharged diesel engine provides all

the power you need to keep loading, day after day.

A single main cylinder

means fewer parts

and improved visibility

to work area.

Boom cylinder hose bulkhead

has been relocated to the boom

base creating shorter hoses that

are easier to change.

We not only changed the machines, we changed the

plant in which they’re built. John Deere quality control

and assembly processes have been integrated into

every step of the C-Series Loader manufacturing.The

result is a loader that sets the pace for the industry.

Improved hose

routings and ORS

fittings keep

machine dry.

335C 435C 437C

K N U C K L E B O O M L O G L O A D E R S

PAGES

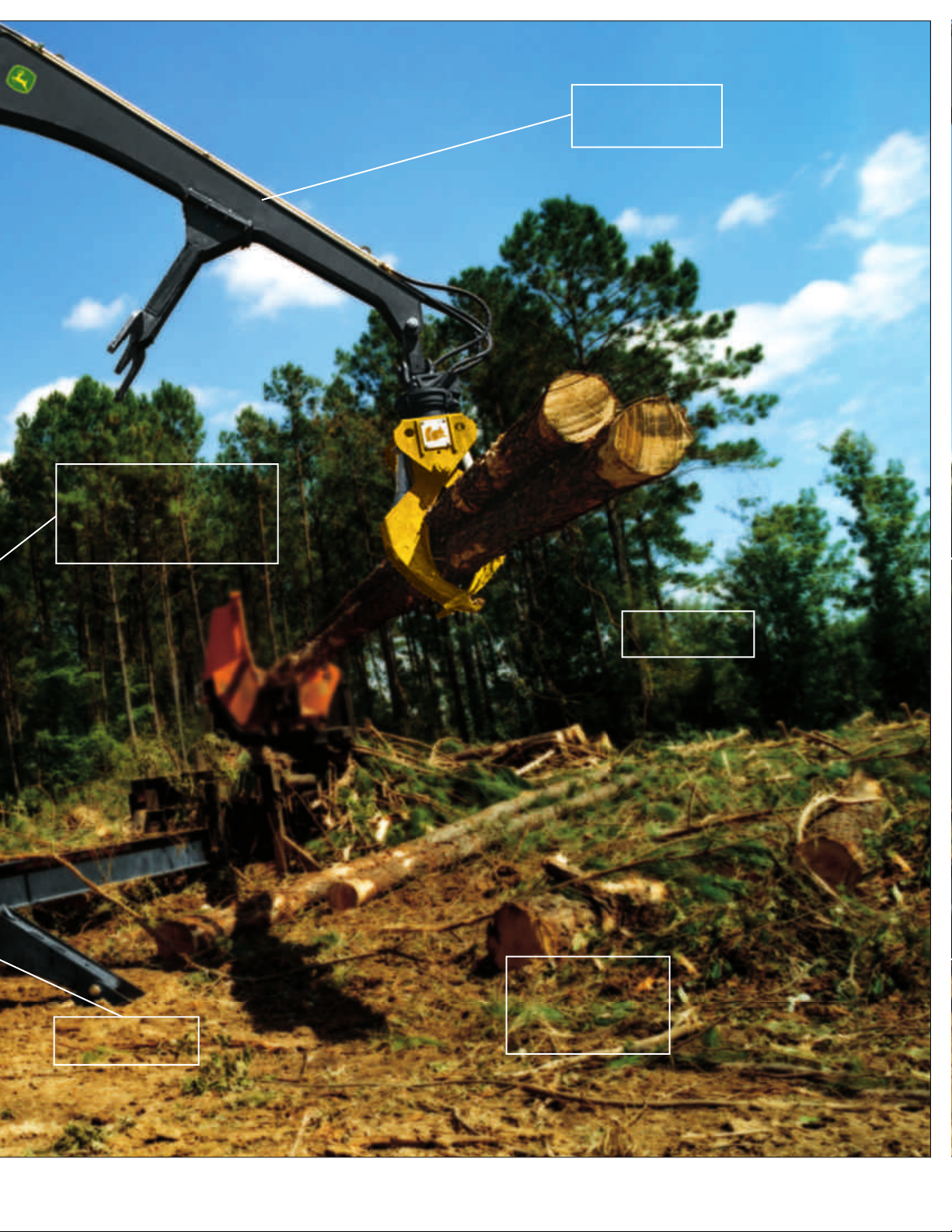

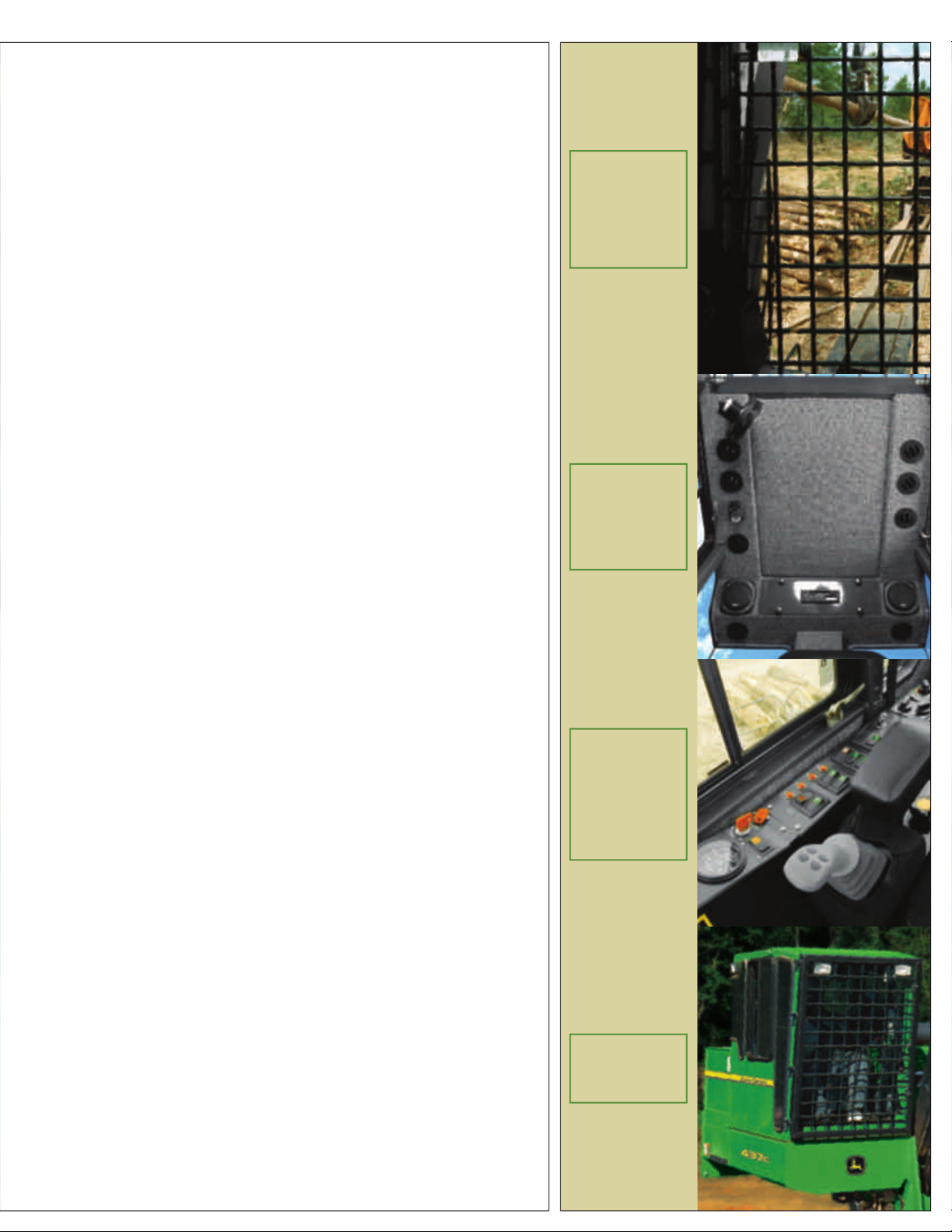

The largest cab in the industry

also allows the most visibility,

with a wraparound rear window,

polycarbonate skylight, and

hinged side window that serves

as a second exit.

8–9

A COMFORTABLE

OPERATOR

IS A PRODUCTIVE

OPERATOR.

With the new C-Series cabs, hard work

never felt this easy.

The C-Series Loaders feature an isolation-mounted, insulated,

all-weather cab that’s the largest and quietest in the industry. From

low idle to high idle, noise levels are dramatically lower than any

other machine in its class, allowing your operator to relax and be

more productive than ever. Visibility is optimum with wraparound

rear window and a polycarbonate skylight. At the operator station,

pilot-operated joystick controls, a deluxe adjustable cloth seat,

HVAC system and an AM/FM/CD stereo create a commanding

and comfortable position for the operator. Your operator will be

able to spend more time out in the woods doing what he does best.

Visibility was also

increased to the

front working area

by changing the

boom design to a

single cylinder.

Add the optional

HVAC package to

keep your operator

comfortable

year round.

Joy sticks are

ergonomic in

design with all

gauges and

switches located

with good sight

line to the console.

Cabs are isolated

mounted, reducing

noise and vibration.

335C 435C 437C

THE NEW 437C

LOAD SENSING THAT MAKES SENSE.

If you know the old saying, “work smarter not harder,” then you know

what the 437C Loader with load sensing is all about.

It’s a simple concept—use only as much power as you need.

The results, however, are remarkable. The 437C with load

sensing not only minimizes heat generation, reduces

hydraulic load, and improves fuel economy, it also gives

your operator better control with lower noise levels. The

K N U C K L E B O O M L O G L O A D E R S

joystick position determines your system speed, with the

system automatically adjusting the pressure.

And, while other machines share hydraulic flow with all

functions equally, the 437C offers multi-functioning with

main and stick functions as one section, and swing functions

as another. It’s load sensing that not only improves your

uptime and productivity, it just makes sense.

PAGES

10–11

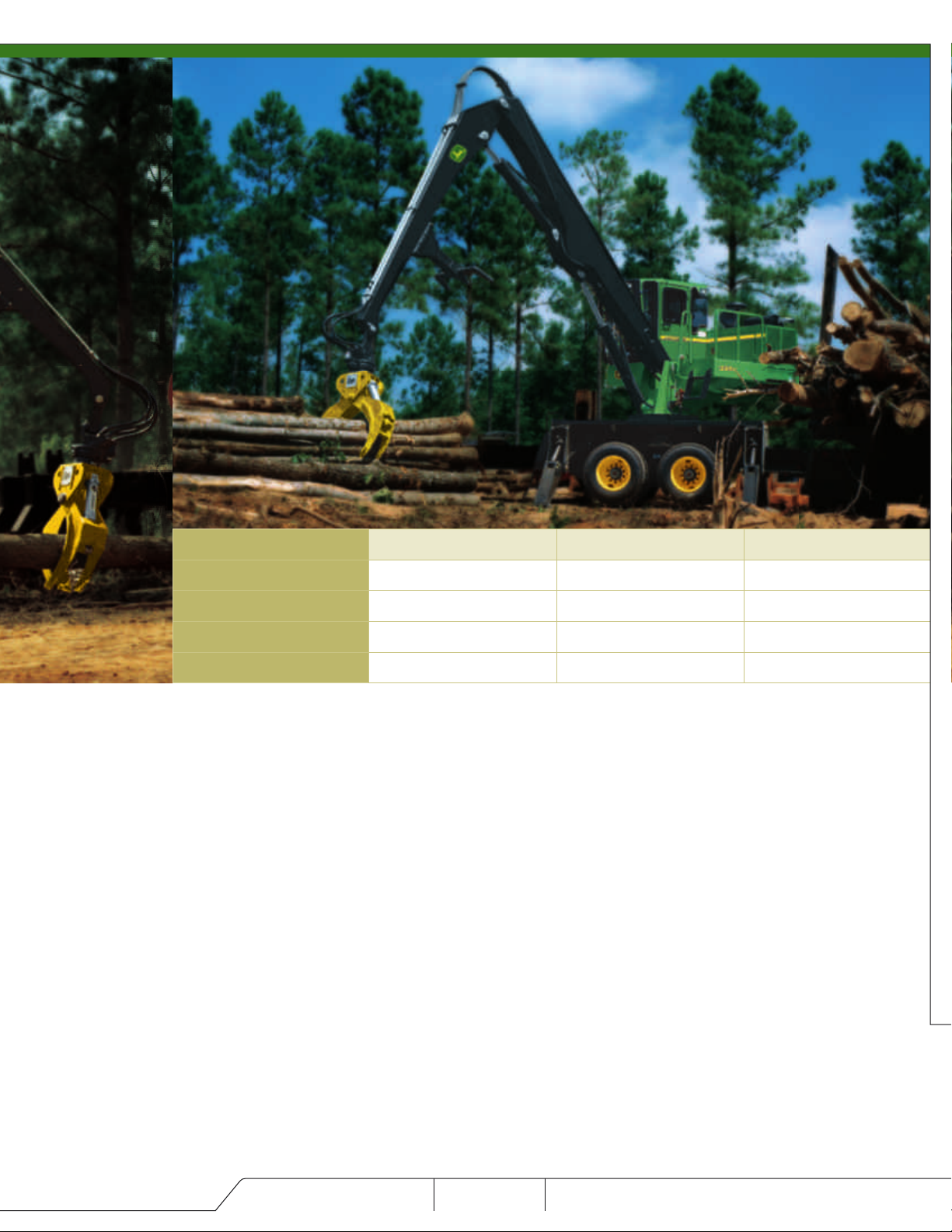

The437C load-sense system featurestwopump variable displacement with dedicated

swing pump for significant reduction in

fuel consumption and noise levels.

The 437C shares a common platform and

engine with the 335C and 435C creating

consistency across the line.

The combination of load-sensing hydraulics,

for reduced fuel consumption, and a larger

fuel tank, keeps your loader running longer

between fill-ups for greater productivity.

WHEN IT COMES TO KEEPING YOUR

COSTS LOW, WE’RE VERY ACCESSIBLE.

Loggers need machines that are easy to maintain, and easy to keep

335C 435C 437C

K N U C K L E B O O M L O G L O A D E R S

on the job. The C-Series Loaders are designed to be exactly that.

PAGES

• A clean and level lower deck offers a

better work platform for service.

• Lower platform redesign offers

improved access to the bearing bolts

and hydraulic manifold.

No one likes maintenance. But when it’s easy to do, it gets

done faster and more often. The C-Series Loaders are

designed to help you take care of daily maintenance quickly

so your operators can get back to more productive work. It’s

simple things like a fuel filler tube located off the deck for

convenient filling and less spill risk.

Rest assured that your purpose-built John Deere Forestry Equipment

is supported by the most extensive dealer network in the industry and

unsurpassed parts availability.That’s our promise.

• The C-Series Loaders also feature

improved hydraulic manifold mounting,

retention, and hydraulic hose access

from both upper and lower frame.

• All machines are backed by

John Deere parts and support

programs, and a dealer network

that’s second to none.

The C-Series Loaders also have more common parts, from

boom tubes and pins to hydraulic plumbing. This ensures

parts availability and familiarity. And of course, all C-Series

Loaders share the John Deere standard quick, deck-level

access to service points for faster servicing. It all translates

into less time doing the maintenance your machines require

and more time on the job building your logging business.

12–13

TECHNICAL DATA 335C 435C 437C

ENGINE 335C 435C 437C

Models/Cylinders .....................................Deere 6068T, 6-cylinder turbocharged diesel.... Deere 6068T, 6-cylinder turbocharged diesel...Deere 6068T, 6-cylinder turbocharged diesel

Maximum Horsepower @ 2,200 rpm .......170 hp (127 kW).............................................. 170 hp (127 kW).............................................170 hp (127 kW)

Fuel Tank Capacity....................................90 gal. (285 L)................................................. 90 gal. (285 L)................................................90 gal. (285 L)

HYDRAULIC SYSTEM

Pumps ......................................................Triple-gear pump assembly @ 2,200 rpm........ Triple-gear pump assembly @ 2,200 rpm.......Tandem variable displacement,

SYSTEM PRESSURE

Main..........................................................2,300 psi 158 bar............................................ 2,700 psi 186 bar...........................................3,625 psi 250 bar

Jib.............................................................2,300 psi 158 bar............................................ 2,950 psi 203 bar...........................................3,625 psi 250 bar

Swing........................................................2,400 psi 165 bar............................................ 3,300 psi 227 bar...........................................3,300 psi 227 bar

CYLINDERS

Boom (1)

Bore......................................................7.5 in. 190.5 mm............................................. 8 in.203 mm .................................................7 in. 178 mm

Rod.......................................................4 in. 101.6 mm................................................ 4 in.101 mm..................................................4 in. 101 mm

Jib

Bore......................................................7 in. 177 mm................................................... 6.5 in.165 mm...............................................6 in. 152 mm

Rod.......................................................3.5 in. 89 mm.................................................. 4 in.101 mm..................................................3.5 in. 89 mm

Stabilizer (4)

Bore......................................................6 in. 152 mm................................................... 6 in.152 mm..................................................6 in. 152 mm

Rod.......................................................3 in. 76 mm .................................................... 3 in.76 mm....................................................3 in. 76 mm

Filtration ...................................................10-micron return ............................................ 10-micron return ...........................................10-micron return

Fill System................................................Hand pump through return filters..................... Hand pump through return filters....................Hand pump through return filters

Reservoir ..................................................100 gal. 378 L................................................. 100 gal. 378 L................................................100 gal. 378 L

55–50–43 gpm 208–184–161 L/min 60–60–43 gpm 227–227–161 L/min load sensing @ 2,100 rpm

117 gpm 443 L/min

solid solid

solid solid

with integral lock valves solid, with integral lock valves solid, with integral lock valves

ELECTRICAL SYSTEM

Alternator..................................................12 volt, 95 amp, self-energizing ...................... 12 volt, 95 amp,self-energizing......................12 volt, 95 amp, self-energizing

Batteries...................................................Two 12 volt with master disconnect switch ..... Two 12 volt with master disconnect switch.....Two 12 volt with master disconnect switch

Lights (3)...................................................Two front,one side .......................................... Two front, one side .........................................Two front, one side

BOOM

Knuckleboom............................................30 ft. 9,1 m..................................................... 32 ft. 9,75 m ..................................................32 ft. 9,75 m

Boxed plate design with bolt-on heel bar Boxed plate design with bolt-on heel bar Boxed plate design with bolt-on heel bar

SWING SYSTEM

Rotation ....................................................360-degree continuous................................... 360-degree continuous ..................................360-degree continuous

Speed .......................................................9 rpm.............................................................. 10 rpm ...........................................................8.5 rpm

Drive .........................................................Two-stage planetary gearbox ........................ Two-stage planetary gearbox .........................Two-stage planetary gearbox

Bearing.....................................................42 in. 1067 mm O.D. hardened gear ............... 42 in. 1067 mm O.D. hardened gear...............42 in. 1067 mm O.D. hardened gear

Swing Torque............................................30,683 ft.-lb.41 600 Nm................................. 36,000 ft.-lb.48 809 Nm................................36,000 ft.-lb. 48 809 Nm

with gear motor with piston motor with piston motor

Greaseable from cab Greaseable from cab Greaseable from cab

OPERATING WEIGHTS

Standard Equipment.................................26,500 lb. 12 020 kg....................................... 29,500 lb. 13 381 kg......................................29,500 lb. 13 381 kg

TECHNICAL DATA 335C 435C 437C

335C MAXIMUM RATED LIFT CAPACITY

Lift capacities are limited by hydraulic relief and do not include grapple weight.The figures in the chart represent rated lift capacities; actual lift capacities are related to unit

stability,which will vary with choice of carrier, rotational attitude of turntable in relation to carrier, and terrain conditions on the worksite.

REACH

335C 435C 437C

ELEVATION

20 ft.

(6,10 m)

15 ft.

(4,57 m)

10 ft.

(3,05 m)

5 ft.

(1,52 m)

435C AND 437C MAXIMUM RATED LIFT CAPACITY

Lift capacities are limited by hydraulic relief and do not include grapple weight.The figures in the chart represent rated lift capacities; actual lift capacities are related to unit

stability,which will vary with choice of carrier, rotational attitude of turntable in relation to carrier, and terrain conditions on the worksite.

K N U C K L E B O O M L O G L O A D E R S

20 ft.

(6,10 m)

15 ft.

(4,57 m)

10 ft.

ELEVATION

(3,05 m)

5 ft.

(1,52 m)

10 ft. (3,05 m) 15 ft. (4,57 m) 20 ft. (6,10 m) 25 ft. (7,62 m) Maximum

N/A 10,125 lb.

(4593 kg)

N/A 10,792 lb.

(4895 kg)

12,916 lb.

(5858 kg)

11,928 lb.

(5410 kg)

10 ft. (3,05 m) 15 ft. (4,57 m) 20 ft. (6,10 m) 25 ft. (7,62 m) 30 ft. (9,14 m) Maximum

N/A 13,422 lb.

N/A 15,785 lb.

26,100 lb.

(11 839 kg)

11,762 lb.

(5335 kg)

(6088 kg)

(7160 kg)

18,464 lb.

(8375 kg)

20,596 lb.

(9342 kg)

13,708 lb.

(6217 kg)

15,449 lb.

(7007 kg)

12,217 lb.

(5544 kg)

13,153 lb.

(5966 kg)

14,352 lb.

(6510 kg)

15,292 lb.

(6936 kg)

9,338 lb.

(4235 kg)

9,968 lb.

(4521 kg)

10,850 lb.

(4921 kg)

11,593 lb.

(5258 kg)

REACH

10,996 lb.

(4988 kg)

11,357 lb.

(5151 kg)

11,849 lb.

(5375 kg)

12,152 lb.

(5512 kg)

8,346 lb.

(3786 kg)

8,774 lb.

(3980 kg)

9,053 lb.

(4106 kg)

9,220 lb.

(4182 kg)

N/A 5,741 lb. @ 29.8 ft.

8,559 lb.

(3882 kg)

9,944 lb.

(4510 kg)

9,733 lb.

(4415 kg)

3,443 lb. @ 27.6 ft.

1562 kg @ 8,41 m

3,225 lb. @ 29.3 ft.

1463 kg @ 8,93 m

3,717 lb. @ 30 ft.

1686 kg @ 9,14 m

3,143 lb. @ 30 ft.

1426 kg @ 9,14 m

2604 kg @ 9,08 m

5,636 lb. @ 31.3 ft.

2556 kg @ 9,54 m

5,707 lb. @ 32.1 ft.

2589 kg @ 9.78 m

5,954 lb. @ 32 ft.

2700 kg @ 9,75 m

PAGES

14–15

OPERATOR’S STATION

Fully enclosed; isolated mounting; insulated;

40 in. (1016 mm) x 60 in.(1524 mm); two

sliding windows; tinted safety glass; dual front

windshield wiper; windshield washer; Lexan

skylight with integral guard; fan; horn; deluxe

cloth, fully adjustable suspension seat with lumbar

support, seat belt,and armrests; instrument/control

panel; with emergency exit window.

STANDARD EQUIPMENT

Hydraulic System

High-volume remote hydraulics

Knuckleboom

335C

30-ft. (9.1 m) knuckleboom with bolt-on heel bar

435C and 437C

32-ft. (9.8 m) knuckleboom with bolt-on heel bar

Operator’s Station

Cigarette lighter

Fire extinguisher

Grease gun

Heavy-duty front windshield guard

Parts, operator and maintenance manuals

Pilot-operated joystick controls

Powerpoint outlet

Sun visor

Air conditioning

AM/FM/CD stereo

Cobra 40-channel CB

OPTIONAL EQUIPMENT

Grapple

A variety of designs and sizes available

to match the application

Rotobec Heavy-Duty Log Grapples factory installed.

Grapple Rotator

4042HD RT252

4042HD RT504

4048HD RT504 (435C, 437C only)

4552HD RT504 (435C, 437C only)

A

335C, 435C AND 437C KNUCKLEBOOM LOADERS

A 101 in.2563.7 mm (435C/437C only)

B 87.4 in. 2220.6 mm

C 94 in.2392 mm

D 38.25 in. 971.5 mm

E 55 in. 1397 mm

F 22 in. 558.8 mm

G 164.4 in. 4176.5 mm

H 335C - 360 in. (30 ft.) 9144 mm

435C/437C - 384 in. (32 ft.) 9754 mm

J Varies with grapple option

K 120 in. 3048 mm

L 161 in. 4089 mm

M 34.75 in. 883 mm

N 93.7 in 2380 mm

P 98.14 in. 2493 mm

Q 173 in. 4397 mm

R 184.5 in. 4688 mm

S 213.66 in. 5427 mm

T 11.5 in. 292 mm

K N U C K L E B O O M L O G L O A D E R S

335C 435C 437C

NOTHING RUNS LIKE A DEERE.

™

Maybe those words are the reason why almost every

other professional logger is a John Deere customer.

They’re just five simple words. Yet they have profound

impact on your company. Because at their heart they

mean equipment that is built forest tough, with greater

productivity, more uptime and lower daily operating

costs. They mean a dealer network over 380 locations

strong, with immediate access to parts and experts that

understand your industry. They mean a dedicated lender

Your world is logging. So is ours. John Deere Forestry. Leading the way, worldwide.

in John Deere Credit, committed to helping loggerssucceed

with competitive financing to enhancecash flow. And they

mean a global forestry equipment leader that invests more

in R & D than any other manufacturer.

But most of all, thesewords represent the confidence that

comes with over 168 years of heavy equipment experience.

ww w.J o hn D ee r e .c o m

DKA335CKBL Litho in U.S.A. (05-06)

Loading...

Loading...