Page 1

OPERATOR’S MANUAL

OMM144042

Issue D0

Lawn and Garden Tractors

425 and 445

Serial No. (070001 -)

Page 2

Introduction........................................................................................................................... 6

Thank You for Purchasing a John Deere Product............................................................. 6

Using Your Operator's Manual......................................................................................... 6

CALIFORNIA Proposition 65 Warning...........................................................................7

Product Identification............................................................................................................ 8

Record Identification Numbers......................................................................................... 8

Safety .................................................................................................................................... 9

Safety-Alert Symbol ......................................................................................................... 9

WARNING: AVOID SERIOUS INJURY OR DEATH .................................................. 9

DANGER: ROTATING BLADES CUT OFF ARMS AND LEGS .............................. 10

DANGER: EXPLOSIVE GASES .................................................................................. 10

HOT SURFACE ............................................................................................................. 11

CAUTION: PRESSURIZED LINE................................................................................ 11

Emission Control System Certification Label ................................................................ 11

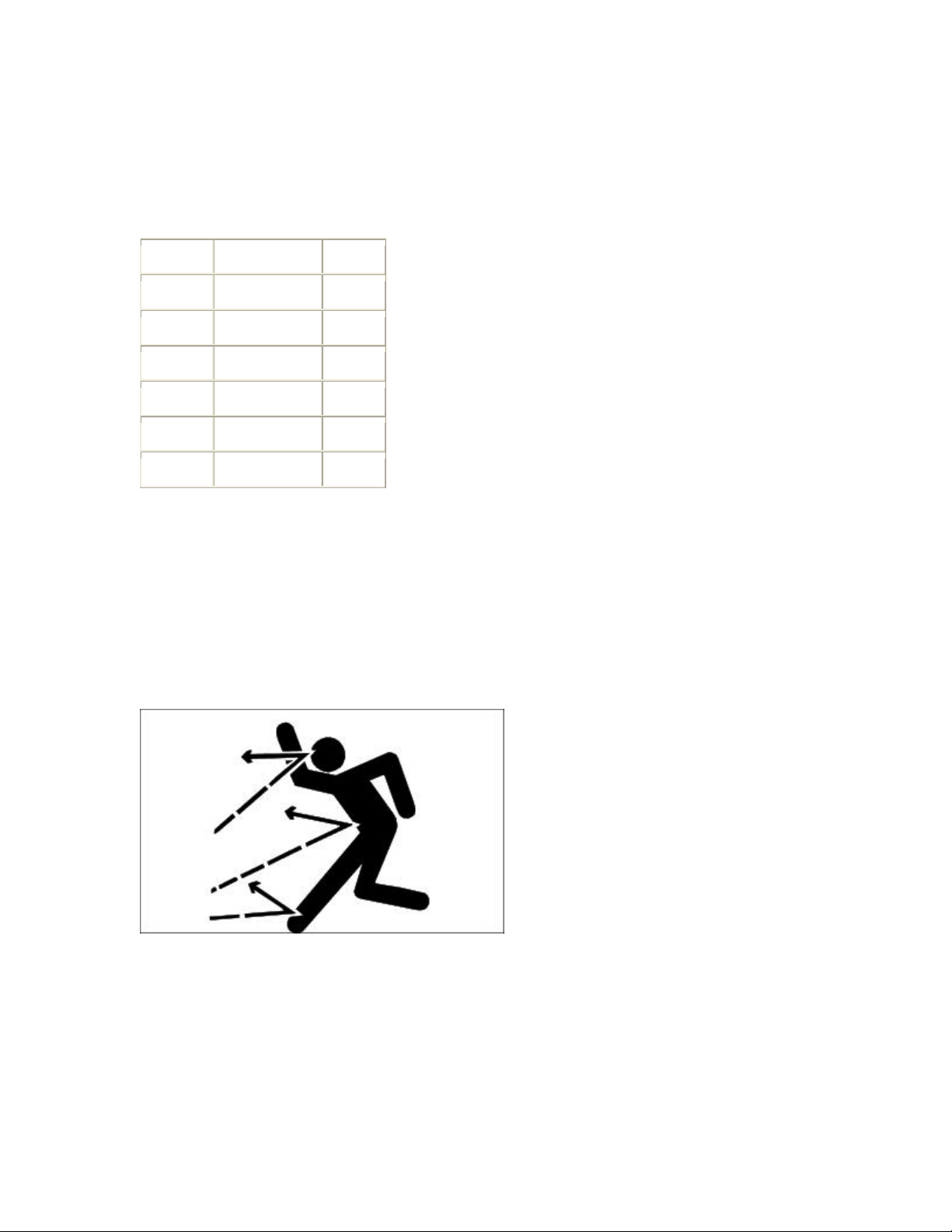

Emission Compliance Period.......................................................................................... 12

Certification .................................................................................................................... 12

Operate Safely................................................................................................................. 12

Park Safely...................................................................................................................... 13

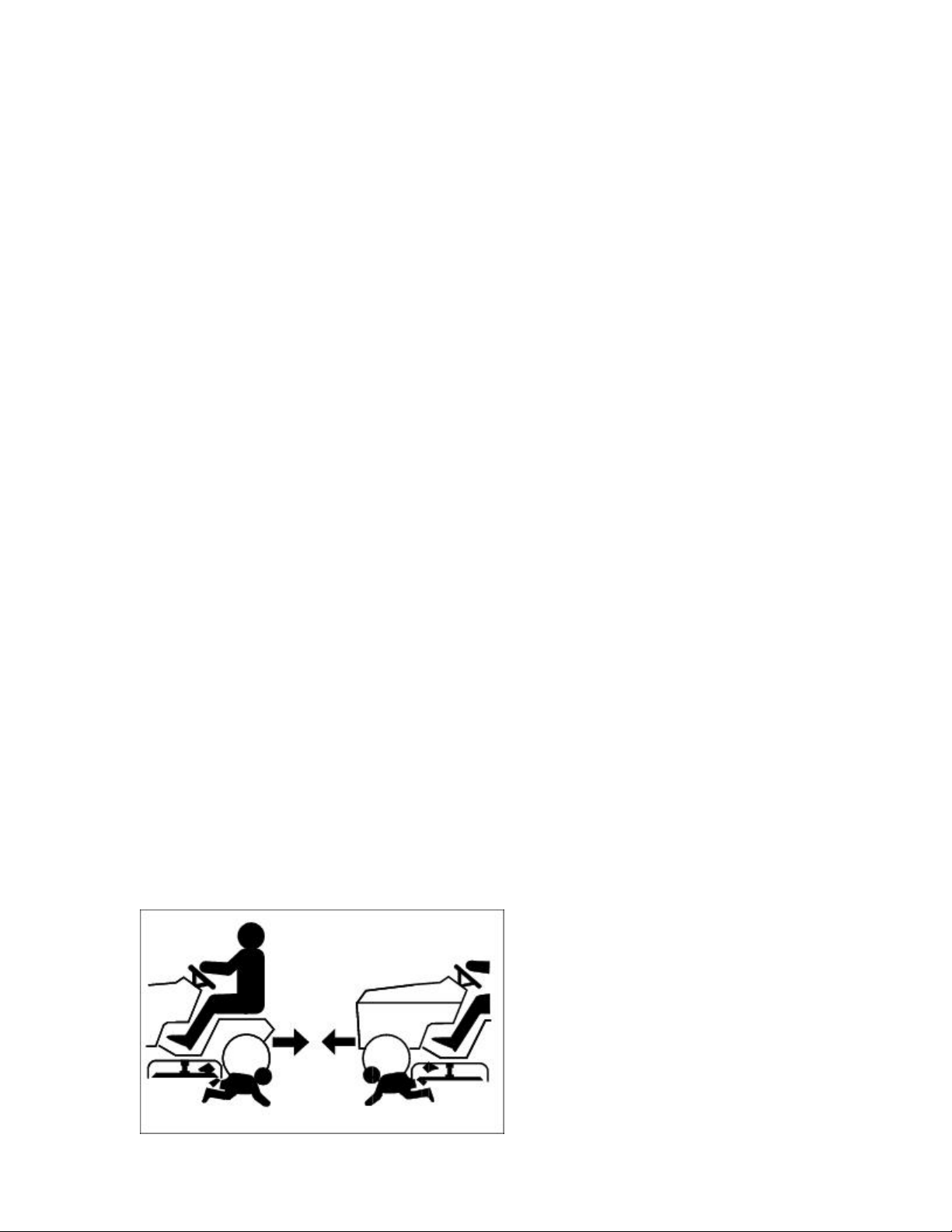

Rotating Blades are Dangerous - Protect Children and Prevent Accidents.................... 13

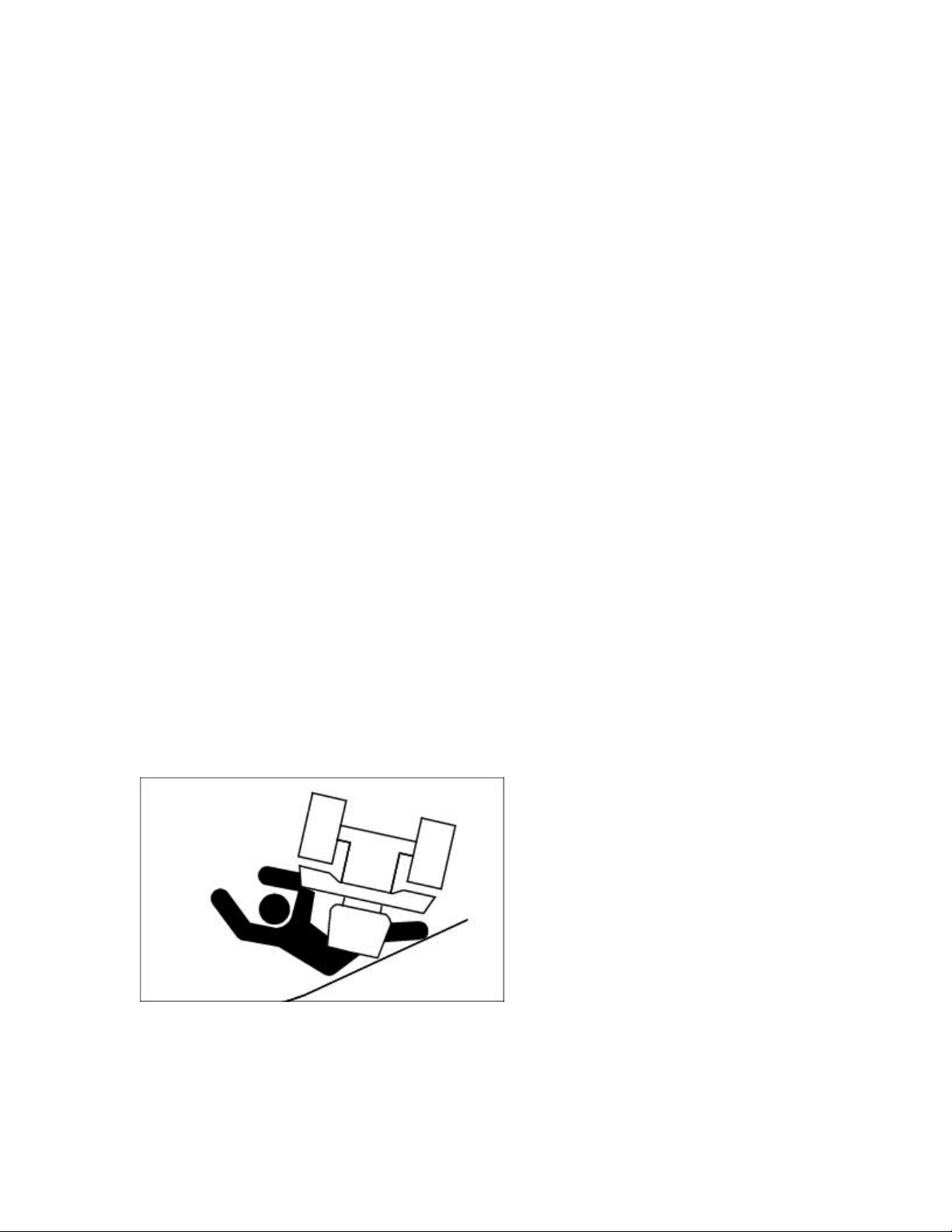

Avoid Tipping................................................................................................................. 14

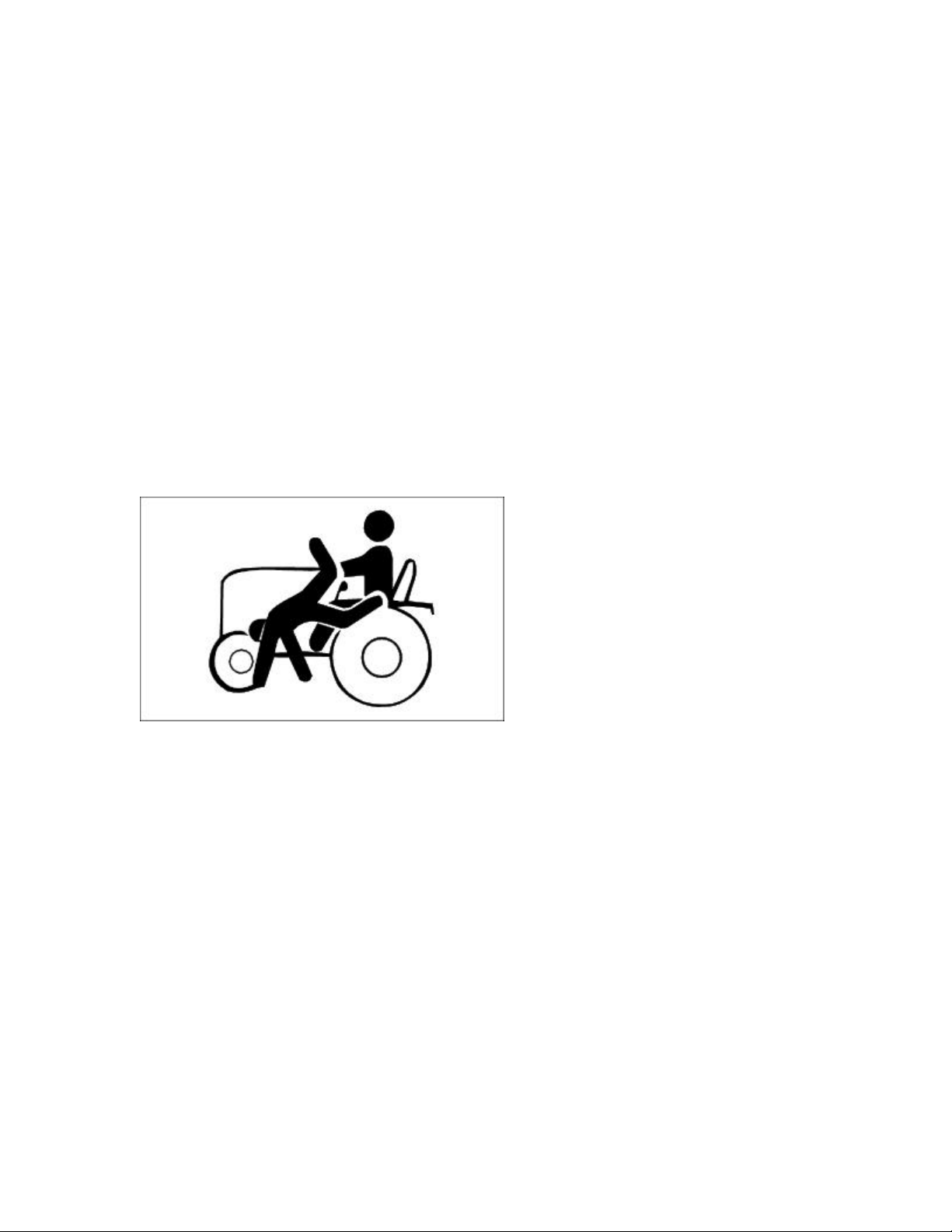

Keep Riders Off.............................................................................................................. 15

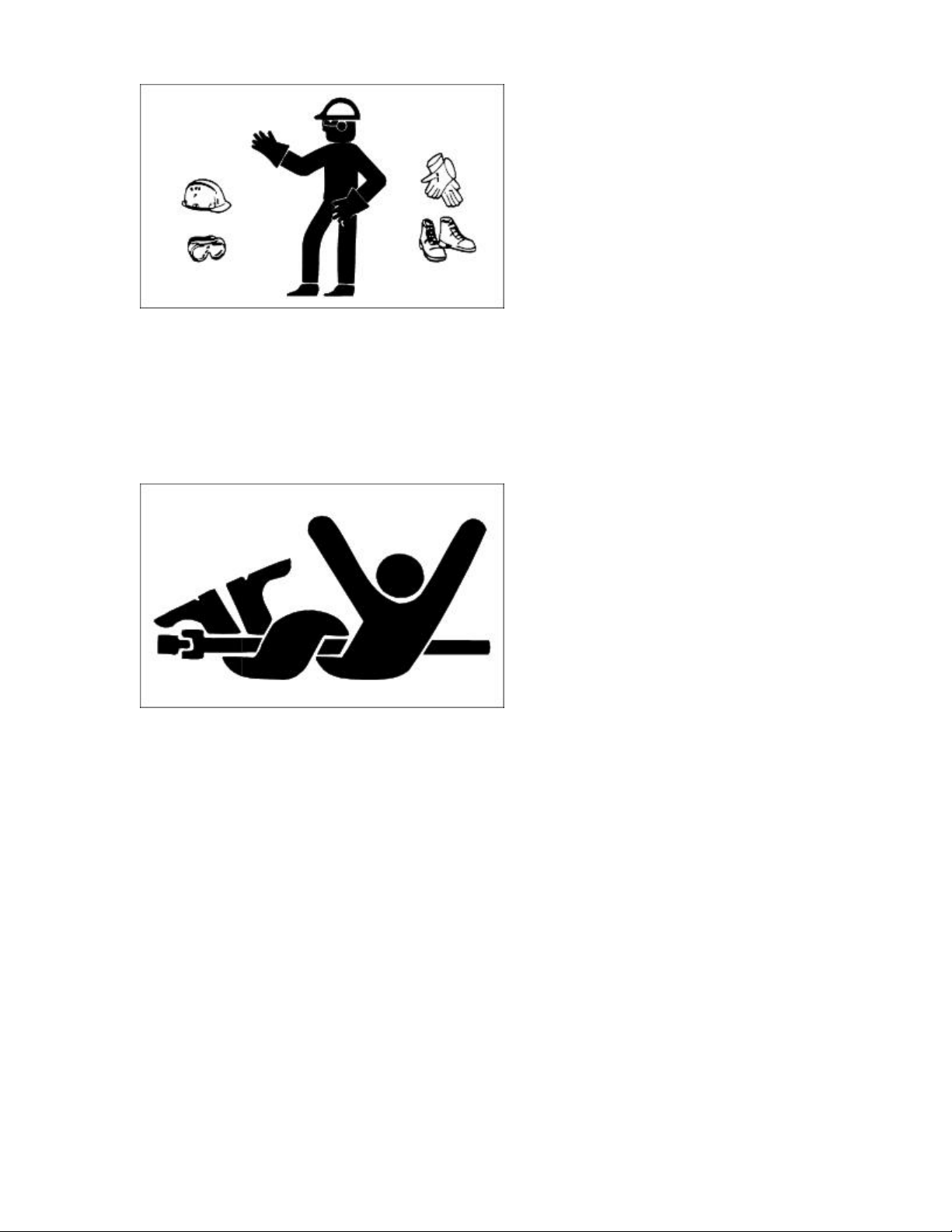

Wear Appropriate Clothing............................................................................................. 15

Stay Clear of Rotating Drivelines................................................................................... 16

Check Wheel Bolts ......................................................................................................... 16

Transport Safely.............................................................................................................. 16

Practice Safe Maintenance.............................................................................................. 17

Wear Appropriate Clothing............................................................................................. 18

Stay Clear of Rotating Drivelines................................................................................... 18

Handling Waste Product and Chemicals......................................................................... 18

Avoid High Pressure Fluids............................................................................................ 19

Operating............................................................................................................................. 21

Daily Operating Checklist............................................................................................... 21

Dash Controls.................................................................................................................. 21

Foot/Platform Controls ................................................................................................... 22

Miscellaneous Controls................................................................................................... 23

Adjusting Steering Wheel............................................................................................... 24

Adjusting Seat (425)....................................................................................................... 24

Adjusting Seat (445)....................................................................................................... 25

Rear Wheel Spacing (Two Wheel Steer Models With 23 x 10.50-12 Tires) ................. 26

Testing Safety Systems................................................................................................... 27

Test 1............................................................................................................................... 27

Test 2............................................................................................................................... 28

Test 3............................................................................................................................... 28

Test 4............................................................................................................................... 29

Test 5............................................................................................................................... 29

Test 6............................................................................................................................... 30

Using the Park Brake...................................................................................................... 31

Indicator Lights and Gauges........................................................................................... 31

2

Page 3

Starting the Engine.......................................................................................................... 33

Stopping the Engine........................................................................................................ 35

Using Travel Controls..................................................................................................... 36

Using Cruise Control ...................................................................................................... 37

Using The Reverse Implement Option ........................................................................... 38

Using Differential Lock.................................................................................................. 39

Using Hydraulic Control Levers..................................................................................... 40

Using PTO (Power Take-Off)......................................................................................... 41

Using Mower Height Control ......................................................................................... 42

Mower Lift Arms............................................................................................................ 43

Using Free-Wheeling Lever............................................................................................ 43

Using Engine Air Restriction Indicator (Optional Equipment)...................................... 44

Using Weights And Tire Chains..................................................................................... 45

Rear Weights................................................................................................................... 45

Installing Rear Wheel Weights (Two-Wheel Steer Tractors)......................................... 45

Installing Rear Wheel Weights (All-Wheel Steer Tractors)........................................... 49

Using Tire Chains........................................................................................................... 50

Installing the Chains ....................................................................................................... 50

Transporting Tractor....................................................................................................... 52

Mowing Tips................................................................................................................... 53

Trimming Tips................................................................................................................ 54

To Avoid Scalping.......................................................................................................... 54

After Mowing.................................................................................................................. 54

Bagging Tips................................................................................................................... 55

Bagging and Composting................................................................................................ 55

Mulching Tips................................................................................................................. 56

Replacement Parts............................................................................................................... 57

Service Literature............................................................................................................ 57

Parts................................................................................................................................. 57

Part Numbers .................................................................................................................. 57

Service Interval Chart......................................................................................................... 59

After First 5 Hours.......................................................................................................... 59

Break In (After First 50 Hours of Operation)................................................................. 59

50 Hours.......................................................................................................................... 59

100 Hours or Annually (whichever comes first)............................................................. 59

200 Hours........................................................................................................................ 59

200 Hours or Annually (whichever comes first)............................................................. 59

250 Hours or Annually (whichever comes first)............................................................. 60

500 Hours........................................................................................................................ 60

500 Hours or Every Two Years (whichever comes first)............................................... 60

Service Lubrication............................................................................................................. 61

Grease ............................................................................................................................. 61

Lubricating Rear Steering Pivot (All Wheel Steer)........................................................ 61

Lubricating Steering Cylinder Ball Joints (All Tractors) ............................................... 62

Lubricating Front Axle ................................................................................................... 63

Service Engine.................................................................................................................... 65

Engine Warranty Maintenance Statement ...................................................................... 65

Adjusting Carburetor ...................................................................................................... 65

Avoid Fumes................................................................................................................... 65

Engine Oil....................................................................................................................... 65

3

Page 4

Changing Engine Oil and Filter...................................................................................... 68

Cleaning Air Intake Screens ........................................................................................... 70

Checking Air Restriction Indicator (Optional Equipment)............................................. 71

Cleaning Radiator Screen and Fins................................................................................. 71

Servicing Air Cleaner Elements...................................................................................... 72

Recommended Engine Coolant....................................................................................... 75

Engine Coolant Drain Interval........................................................................................ 75

Engine Coolant Drain Interval........................................................................................ 76

Checking Coolant Level ................................................................................................. 76

Servicing Cooling System............................................................................................... 77

Replacing Fuel Filter (425)............................................................................................. 82

Relieving Fuel System Pressure (445)............................................................................ 82

Replacing Fuel Filter (445)............................................................................................. 83

Servicing Fan Belt........................................................................................................... 84

Service Transmission.......................................................................................................... 87

Anti-Chatter Transmission Oil........................................................................................ 87

Checking Transaxle Oil Level........................................................................................ 87

Changing Transaxle Oil and Filter.................................................................................. 88

Service Electrical................................................................................................................ 91

Cleaning or Replacing Battery........................................................................................ 91

Checking Battery Electrolyte Level................................................................................ 93

Charging the Battery....................................................................................................... 94

Using Booster Battery..................................................................................................... 96

Cleaning and Gapping Spark Plugs ................................................................................ 97

Replacing Fuses.............................................................................................................. 99

Replacing Headlight Bulb............................................................................................. 100

Replacing Taillight Bulb............................................................................................... 100

Replacing Indicator Light Bulb .................................................................................... 101

Service Miscellaneous ...................................................................................................... 104

Checking Tire Pressure................................................................................................. 104

Checking Tightness of Wheel Bolts ............................................................................. 105

Raising Hood ................................................................................................................ 105

Removing Grille............................................................................................................ 106

Removing and Cleaning Side Panels............................................................................ 106

Refueling Machine........................................................................................................ 108

Filling Fuel Tank........................................................................................................... 109

Cleaning and Repairing Plastic Surfaces...................................................................... 110

Cleaning and Repairing Metal Surfaces ....................................................................... 110

Troubleshooting................................................................................................................ 112

Using Troubleshooting Chart........................................................................................ 112

Engine........................................................................................................................... 112

Tractor........................................................................................................................... 113

Steering......................................................................................................................... 114

Mower........................................................................................................................... 114

Electrical....................................................................................................................... 114

Storing Machine................................................................................................................ 116

Storage Safety............................................................................................................... 116

Preparing Engine for Storage........................................................................................ 116

Storing the Tractor........................................................................................................ 116

Removing the Vehicle From Storage............................................................................ 117

4

Page 5

Assembly........................................................................................................................... 119

Remove Bracing............................................................................................................ 119

Fill Fuel Tank Safely .................................................................................................... 119

Fill Fuel Tank................................................................................................................ 119

Activate Battery (Early Model Dry Batteries).............................................................. 120

Check Battery Voltage (Late Model "Moist" Batteries)............................................... 122

Install Battery................................................................................................................ 123

Install the Steering Wheel............................................................................................. 124

Install Seat (425)........................................................................................................... 124

Install Seat (445)........................................................................................................... 125

Checking Tire Pressure................................................................................................. 126

Specifications.................................................................................................................... 128

Engine........................................................................................................................... 128

Engine........................................................................................................................... 128

Fuel System................................................................................................................... 129

Electrical System .......................................................................................................... 129

Capacities...................................................................................................................... 129

Drive Train.................................................................................................................... 130

Travel Speeds................................................................................................................ 130

Steering and Brakes ...................................................................................................... 130

Dimensions - 425.......................................................................................................... 130

Dimensions - 445.......................................................................................................... 131

Tires - 425..................................................................................................................... 132

Tires - 445..................................................................................................................... 132

Recommended Lubricants ............................................................................................ 132

Warranty ........................................................................................................................... 133

Product Warranty.......................................................................................................... 133

Tire Warranty................................................................................................................ 133

John Deere, Federal and California Emission Control System Warranty (Small Off-

Road Gas Engines)........................................................................................................ 133

Limited Battery Warranty............................................................................................. 137

John Deere Quality Statement .......................................................................................... 139

John Deere Quality ....................................................................................................... 139

Service Record.................................................................................................................. 141

Record Service Dates.................................................................................................... 141

5

Page 6

Introduction

Thank You for Purchasing a John Deere Product

We appreciate your business and wish you many years of safe and satisfied use of your machine.

Using Your Operator's Manual

This manual is an important part of your machine and should remain with the machine when you sell

it.

Reading your operator's manual will help you and others avoid personal injury or damage to the

machine. Information given in this manual will provide the operator with the safest and m ost effective

use of the machine. Knowing how to operate this machine safely and correctly will allow you to train

others who may operate this machine.

Section in your operator's manual are placed in a specific order to help you understand all the safety

messages and learn the controls so you can operate this machine safely. YOu can also use this manual

to answer any specific operating or servicing questions. A convenient index located at the end of this

book will help you to find needed information quickly.

The machine shown in this manual may differ slightly from your machine, but will be similar enough

to help you understand our instructions.

RIGHT-HAND and LEFT-HAND sides are determined by facing in the direction the machine will

travel when going forward. When you see a broken line arrow (------>), the item referred to is hidden

from view.

Special Messages

Your manual contains special messages to bring attention to potential safety concerns, m achine

damage as well as helpful operating and servicing information. Please read all the highlighted

information carefully to avoid injury and machine damage.

6

Page 7

c CAUTION: Avoid injury!

This symbol and text highlight potential hazards or death to the operator or bystanders may occur if

the hazards or procedures are ignored.

IMPORTANT: Avoid damage!

This text is used to tell the operator of actions or conditions that might result in damage to the

machine.

NOTE: General information is given throughout the manual that may help the operator in the

operation of the machine.

CALIFORNIA Proposition 65 Warning

WARNING: The Engine Exhaust from this product contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive harm.

California Proposition 65 Warning

7

Page 8

Product Identification

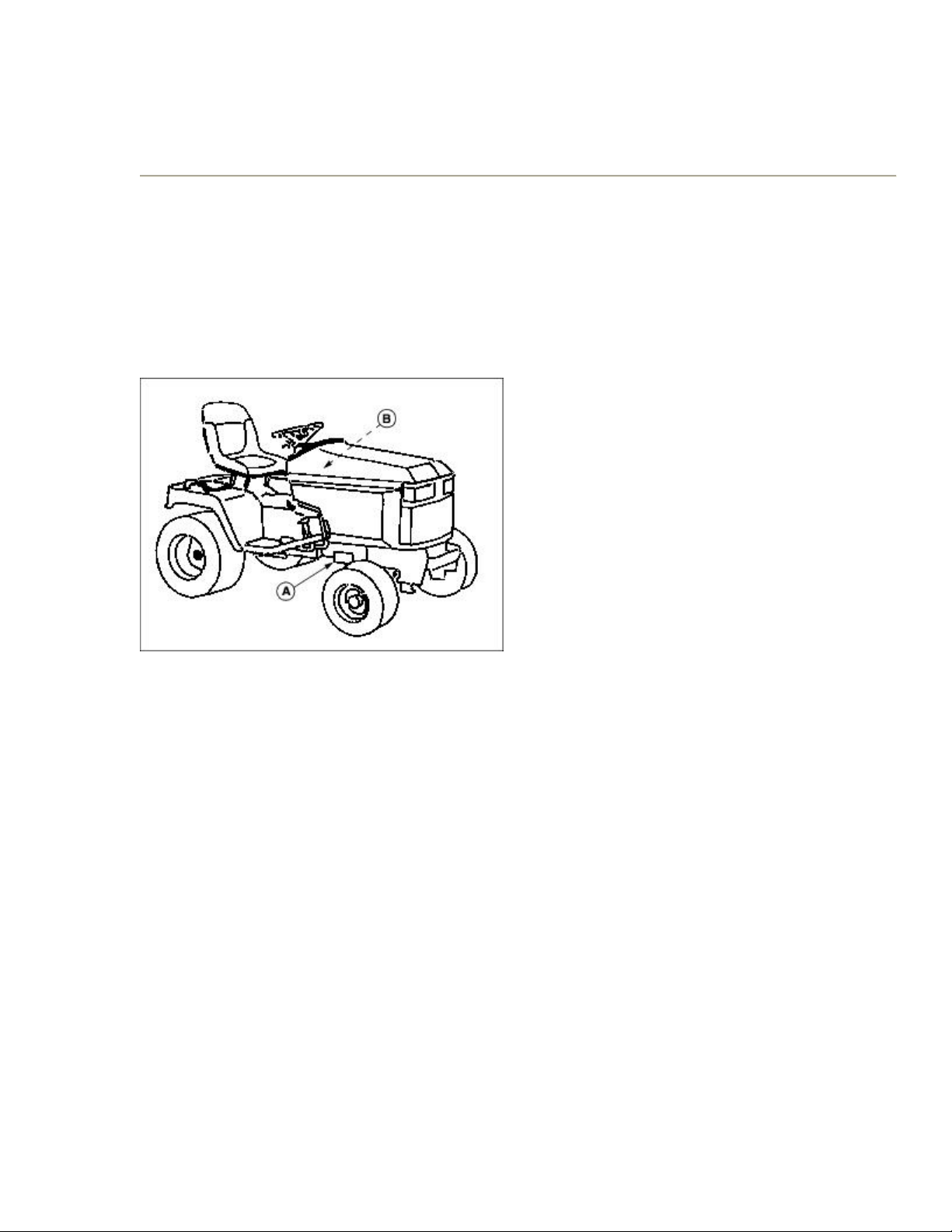

Record Identification Numbers

If you need to contact an Authorized Service Center for information on servicing, always provide the

product model and serial number.

You will need to locate the model and serial number for the machine and for the engine of your

machine and record the information in the spaces provided below.

M71459A

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

PRODUCT IDENTIFICATION NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

8

Page 9

Safety

Safety-Alert Symbol

Read and recognize safety information. Be alert to the potential for personal injury when you see this

safety-alert symbol.

On your machine safety labels, the words DANGER, WARNING, and CAUTION are used with this

safety-alert symbol. DANGER identifies the most serious hazards. In this manual, the word

CAUTION and this symbol call attention to safety messages.

WARNING: AVOID SERIOUS INJURY OR DEATH

m40180A

· Drive up and down slopes, not across.

· Avoid sudden turns.

· If machine stops going uphill, stop blade and back down slowly.

· Keep safety devices (guards, shields, and switches) in place and working.

9

Page 10

· Read Operator's Manual.

· When leaving machine: Stop engine, Set park brake, Remove key.

DANGER: ROTATING BLADES CUT OFF ARMS AND LEGS

M140180B

· Do not mow when children or others are around.

· Do not mow in reverse.

· Look down and behind before and while backing.

· Never carry children even with the blades off.

DANGER: EXPLOSIVE GASES

M74408

Cigarettes, flames or sparks could cause battery to explode. Always shield eyes and face from battery.

Don not charge or use booster cables or adjust post connections without proper instruction and

training. Keep vent caps tight and level.

POISON: CAUSES SEVERE BURNS

10

Page 11

Contains sulfuric acid. Avoid contact with skin, eyes or clothing. In event of accident, flush with

water and call a physician immediately. Keep out of reach of children.

HOT SURFACE

CAUTION: PRESSURIZED LINE

M71542 M71535

See operator's manual for instructions to remove.

Emission Control System Certification Label

NOTE: Tampering with emission controls and components by unauthorized personnel may result in

severe fines or penalties. Emission controls and components can only be adjusted by EPA and/or

CARB authorized service centers. Contact your John Deere Commercial and Consumer Equipment

Retailer concerning emission controls and component questions.

The presence of an emissions label signifies that the engine has been certified with the United States

Environmental Protection Agency (EPA) and/or California Air Resources Board (CARB).

The emissions warranty applies only to those engines marketed by John Deere that have been

certified by the EPA and/or CARB; and used in the United States and Canada in off-road mobile

equipment.

11

Page 12

Emission Compliance Period

If your engine has the emission compliance category listed on the emission control system

certification or air index label, this indicates the number of operating hours for which the engine has

been certified to meet EPA and/or CARB emission requirements. The following table provides the

engine compliance period in hours associated with the category found on the certification label.

Agency Category Hours

EPA C 250

EPA B 500

EPA A 1000

CARB Moderate 125

CARB Intermediate 250

CARB Extended 500

Certification

Your mower has been certified by an independent laboratory for compliance with American National

Standard B-71.1, "Safety Specifications" for Power Lawn Mowers, Lawn and Garden Tractors, and

Lawn Tractors.

Operate Safely

· Check brake action before you operate. Adjust or service brakes as necessary.

· Inspect machine before you operate. Be sure hardware is tight. Repair or replace damaged, badly

worn, or missing parts. Be sure guards and shields are in good condition and fastened in place. Make

any necessary adjustments before you operate.

· Clear work area of objects that might be thrown. Keep people and pets out of the work area. Stop

12

Page 13

machine if anyone enters the area.

· If you hit an object, stop the machine and inspect it. Make repairs before you operate. Keep machine

and attachments properly maintained and in good working order.

· DO NOT leave machine unattended when it is running.

· Only operate during daylight or with good artificial light.

· Be careful of traffic when operating near or crossing roadways.

· Do not wear radio or music headphones while operating the machine. Safe operation requires your

full attention.

· Older adults are involved in a large percentage of riding mower accidents involving injury. These

operators should evaluate their ability to operate a mower safely enough to protect the operator and

others from serious injury.

Park Safely

· Stop machine on a level surface, not on a slope.

· Disengage PTO.

· Lower attachments to the ground.

· Engage park brake.

· STOP engine.

· Remove key.

· Before you leave the operator's seat, wait for engine and all moving parts to STOP.

Rotating Blades are Dangerous - Protect Children and Prevent Accidents

Protect Children

13

Page 14

· Never assume that children will remain where you last saw them. Children are attracted to mowing

activity, stay alert to the presence of children.

· Keep children in the house when you are operating the machine.

· Turn machine off if a child enters the mowing area.

· Use extra care when you come to blind corners, shrubs, trees, or other objects that may block your

vision.

· DO NOT let children or an untrained person operate the machine.

· DO NOT carry or let children ride on machine or any attachment even with blades off. DO NOT tow

children in a cart or trailer.

Help Prevent Serious Or Fatal Accidents:

· Be alert at all times, drive forward carefully. People ESPECIALLY CHILDREN can move quickly

into the mowing area before you know it.

· Back carefully. Shut off PTO and look behind the machine carefully, ESPECIALLY FOR

CHILDREN, before you back up.

· DO NOT mow in reverse unless it is absolutely necessary.

· Shut off PTO when you are not mowing.

· DO NOT operate machine if you are under the influence of drugs or alcohol.

Avoid Tipping

· DO NOT drive where machine could slip or tip.

· Stay alert for holes and other hidden hazards in the terrain.

14

Page 15

· Keep away from drop-offs.

· Slow down before you make a sharp turn or operate on a slope.

· When pulling loads or using heavy equipment, use only approved hitches, limit loads to those you

can safely control, and use counterweights or wheel weights when required per this manual or your

attachment manual.

· Drive up and down a hill - not across. Be careful when you change direction on a slope.

· DO NOT stop when going up hill or down hill. If machine stops going up hill, STOP PTO and back

down slowly.

· DO NOT mow wet grass. Reduced traction could cause sliding.

· DO NOT try to stabilize the machine by putting your foot on the ground.

Keep Riders Off

· Only allow the operator on the machine. Keep riders off.

· Riders on the machine or attachment may be struck by foreign objects or thrown off the machine

causing serious injury.

· Riders obstruct the operator's view resulting in the machine being operated in an unsafe manner.

Wear Appropriate Clothing

15

Page 16

· Wear close fitting clothing and safety equipment appropriate for the job.

· Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as

earplugs.

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death:

· Wear close fitting clothing.

· STOP the engine and be sure PTO driveline is stopped before getting near it.

Check Wheel Bolts

· A serious accident could occur causing serious injury if wheel bolts are not tight.

· Check wheel bolt tightness often during the first 100 hours of operation.

Transport Safely

16

Page 17

· Use safety lights and devices. Slow moving machines when driven on public roads are hard to see,

especially at night. Avoid personal injury or death resulting from a collision with a vehicle.

· Whenever driving on public roads, use flashing warning lights and turn signals according to local

regulations. Extra flashing warning lights may need to be installed.

Practice Safe Maintenance

· Understand service procedure before doing work. Keep area clean and dry.

· Never lubricate, service, or adjust machine while it is moving. Keep safety devices in place and in

working condition. Keep hardware tight.

· To prevent them from getting caught, keep hands, feet, clothing, jewelry, and long hair away from

any moving parts.

· Before servicing machine, lower attachments to the ground. Disengage all power and stop the

engine. Move hydraulic lift levers back and forth to relieve pressure. Lock park brake and remove the

key. Let tractor cool.

· Securely support any machine elements that must be raised for service work.

· Never run engine unless park brake is locked.

· Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or

17

Page 18

broken parts. Remove any buildup of grease, oil, or debris.

· Disconnect battery ground cable (-) before making adjustments on electrical systems or welding on

tractor.

· Unauthorized modifications to the tractor may impair its function and safety.

Wear Appropriate Clothing

· Wear close fitting clothing and safety equipment appropriate for the job.

· Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as

earplugs.

· Do not wear radio or music headphones while servicing the machine. Safe service requires your full

attention.

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death:

· STOP the engine and be sure PTO driveline is stopped before getting near it.

Handling Waste Product and Chemicals

18

Page 19

· Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries, can harm the environment

and people.

· DO NOT use beverage containers for waste fluids-someone may drink from them.

· See your local Recycling Center or John Deere dealer to learn how to recycle or get rid of waste

products.

· A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and

health hazards, safety procedures, and emergency response techniques. See your John Deere dealer

for the MSDS on chemical products used with your machine.

Avoid High Pressure Fluids

· Hydraulic hoses can fail due to physical damage, kinks, age, and exposure. Check hoses regularly.

Replace damaged hoses.

· Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before

applying pressure.

· Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

· If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury

should reference a knowledgeable medical source. Such information is available from Deere &

19

Page 20

Company Medical Department in Moline, Illinois, U.S.A.

20

Page 21

Operating

Daily Operating Checklist

o Test safety systems.

o Check tire pressure.

o Check fuel level.

o Check engine oil level.

o Check transaxle oil level.

o Check coolanat level.

o Check Air Restriction Indicator (if so equipped).

o Clean air intake screens.

o Remove grass and debris from machine.

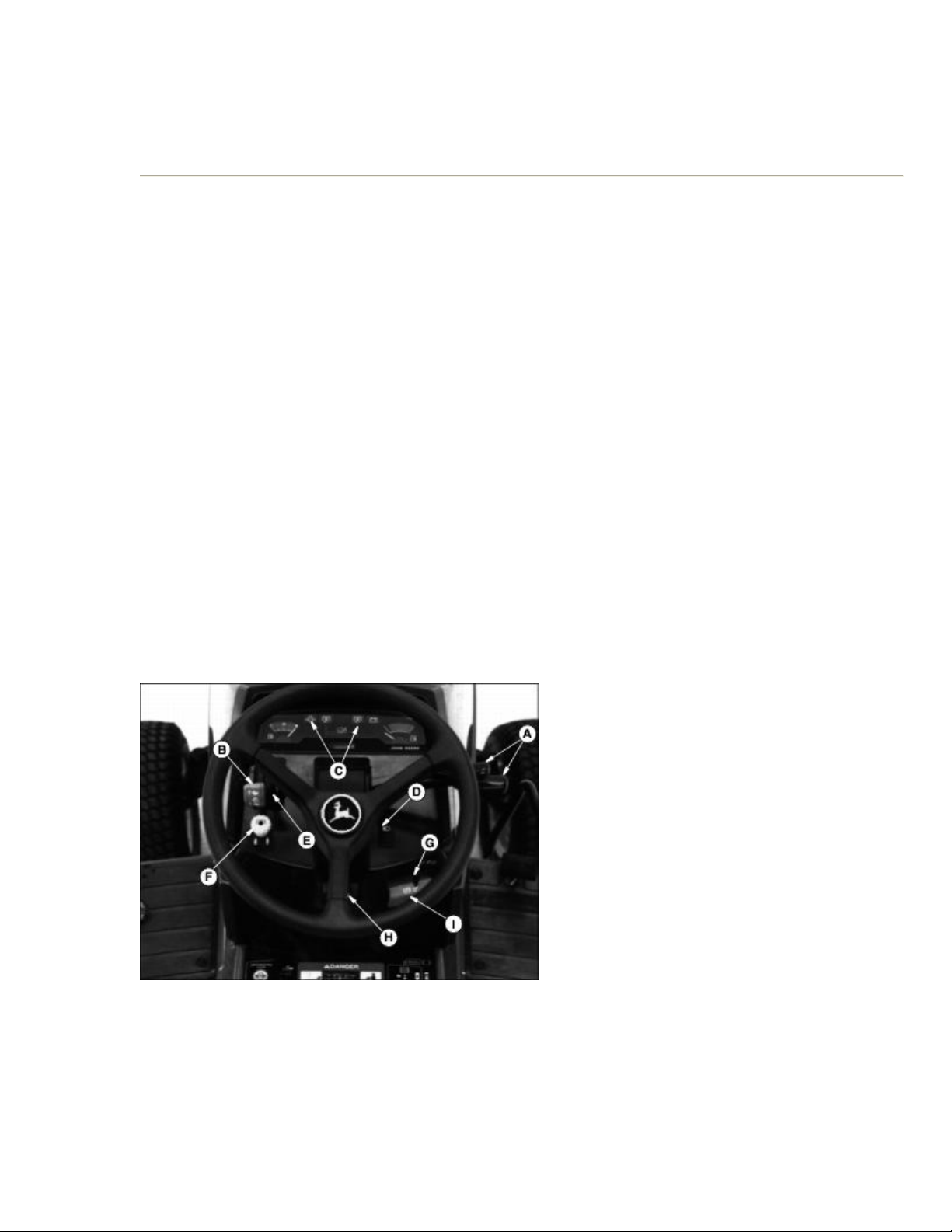

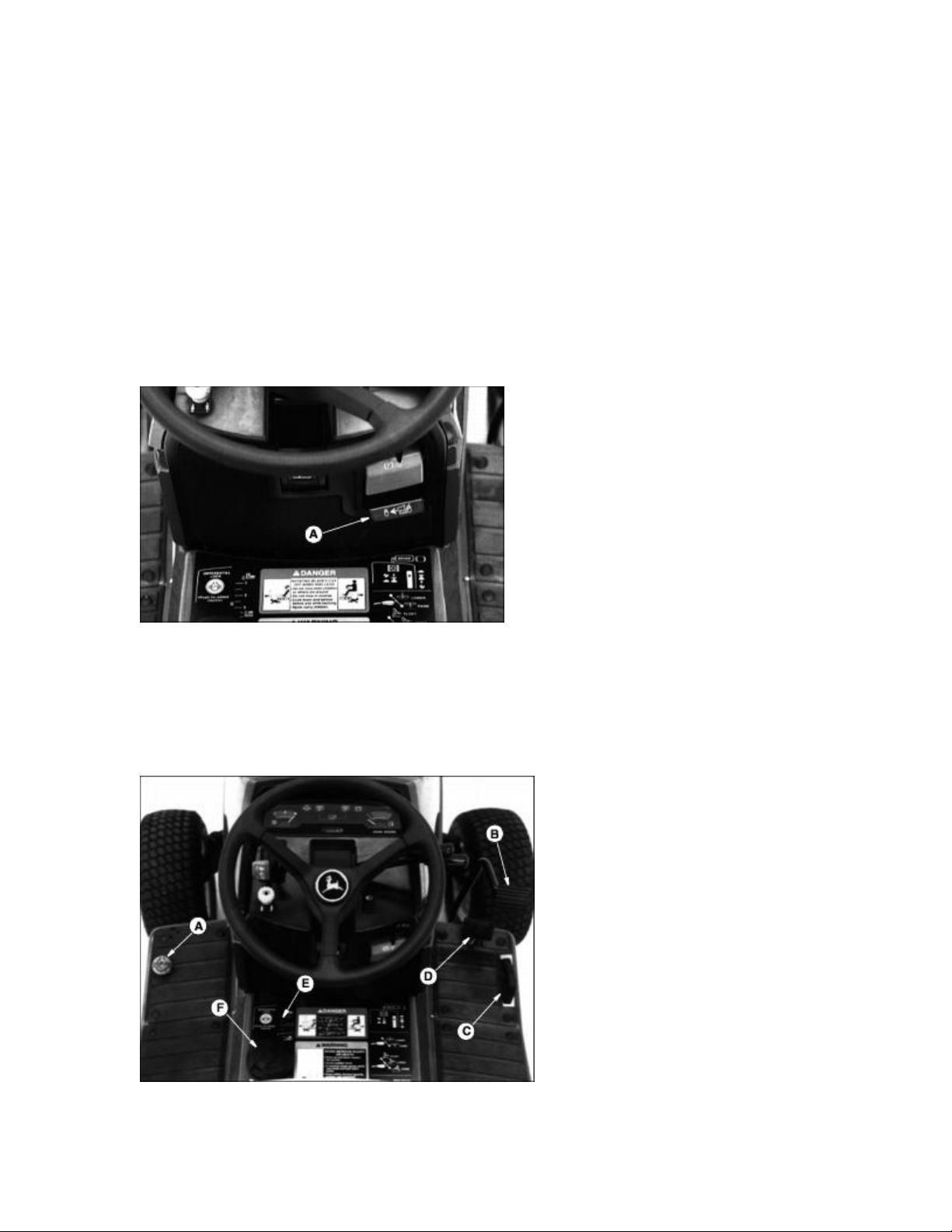

Dash Controls

M71462

A - Hydraulic Control Levers

B - Throttle Lever

21

Page 22

C - Indicator Lights

D - LIght Switch

E - Choke Lever (425)

F - PTO Switch

G - Key

H - Tilt Steering Wheel Button

I - Park Brake Lever

M71463

A - Cruise Control Lever

Foot/Platform Controls

M71462

22

Page 23

A - Differential Lock Pedal

B - Brake Pedal

C - Reverse Travel Pedal

D - Forward Travel Pedal

E - Mower Height Indicator

F - Mower Height Crank

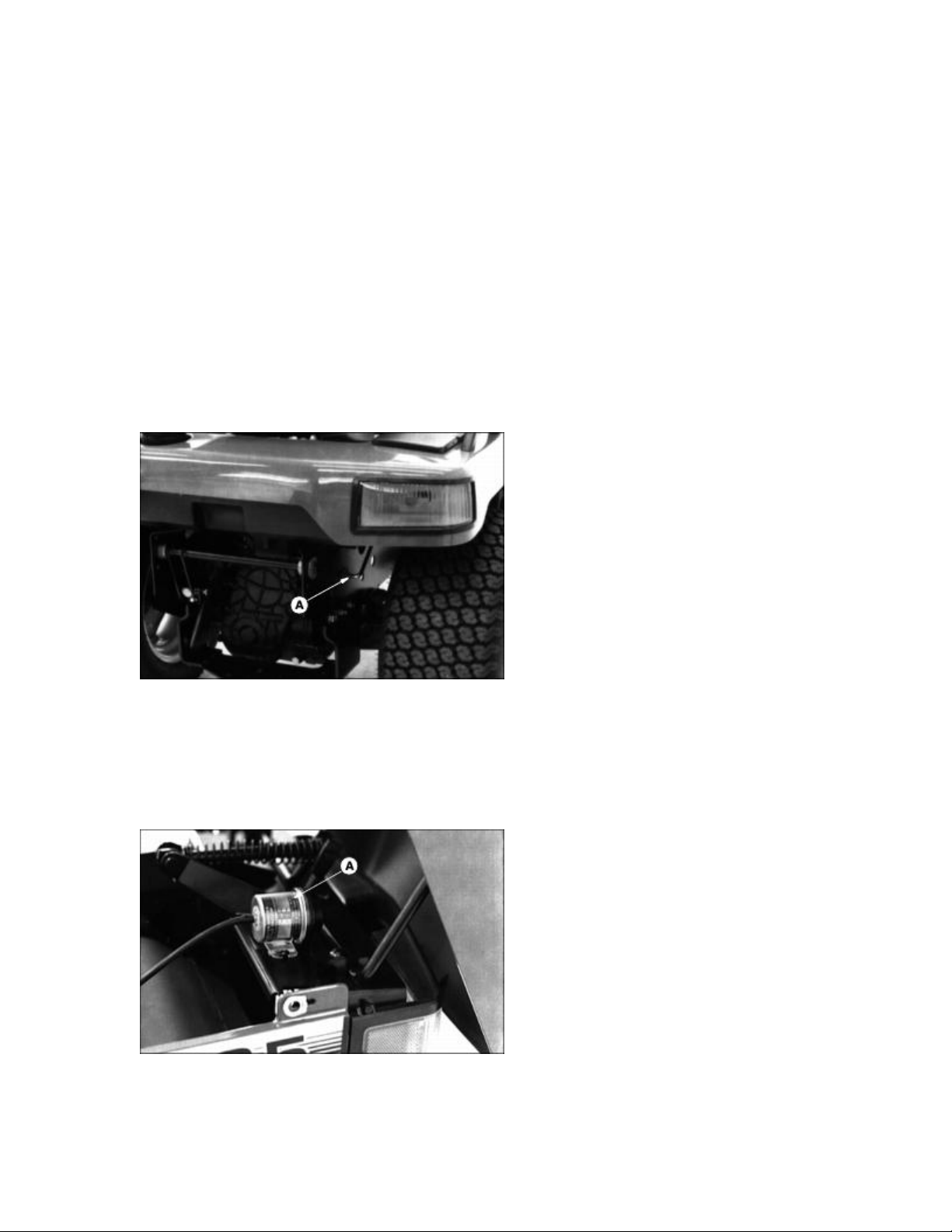

Miscellaneous Controls

Free Wheeling Lever

M71465

A - Free-Wheeling Lever

Air Restriction Indicator

M71510

A - Air Restriction Indicator (Optional)

23

Page 24

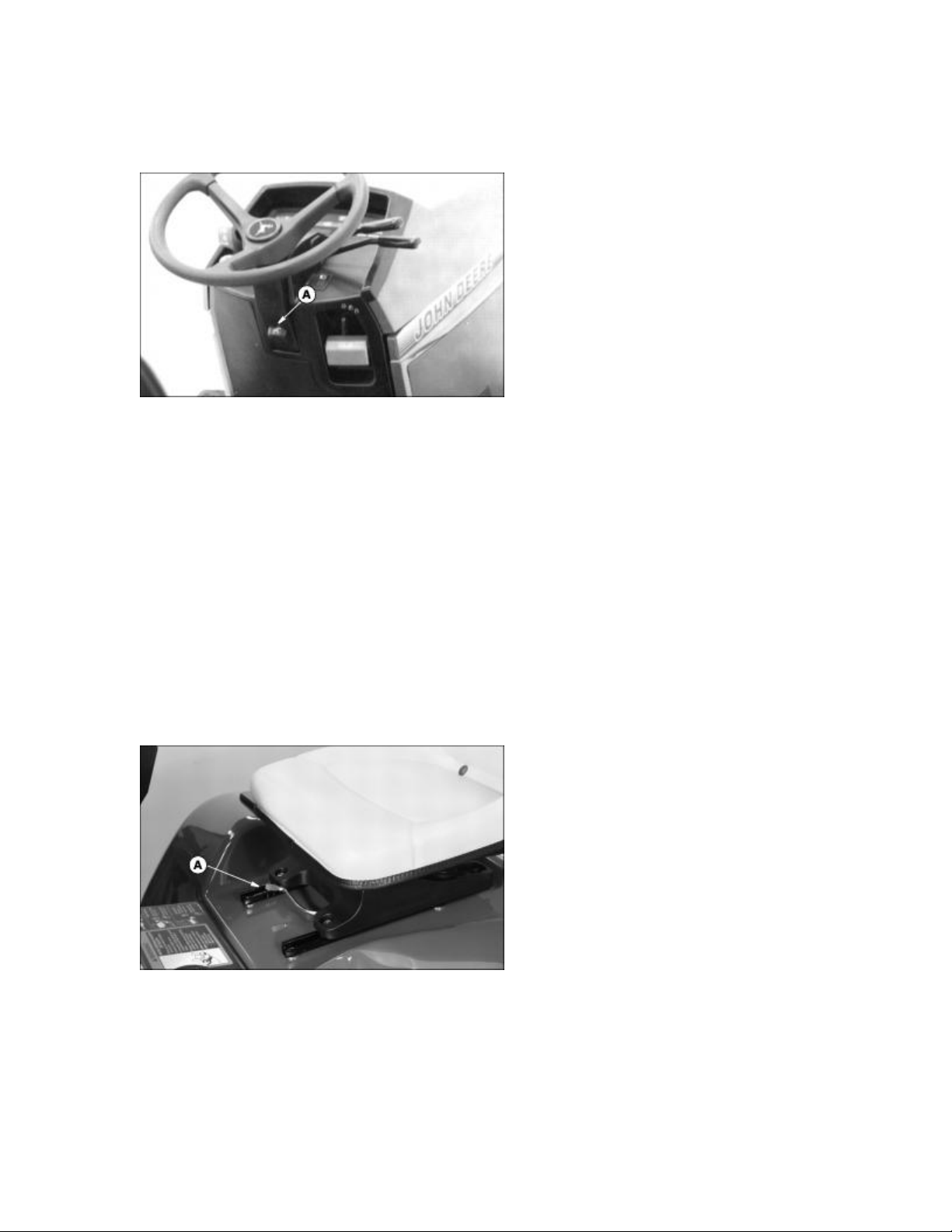

Adjusting Steering Wheel

NOTE: Steering wheel has four tilt positions.

M71475

1. Push in button (A) and push or pull wheel to a comfortable operating position.

2. Release button.

NOTE: Before operating, be sure steering wheel is locked in position.

Adjusting Seat (425)

Adjust Forward / Rearward

NOTE: This tractor is equipped with a fourteen position slide rail seat. Be sure seat is locked in

position before operating.

M96042

1. Push lever (A) to the left.

2. Slide seat forward or backward to desired position.

3. Release lever.

24

Page 25

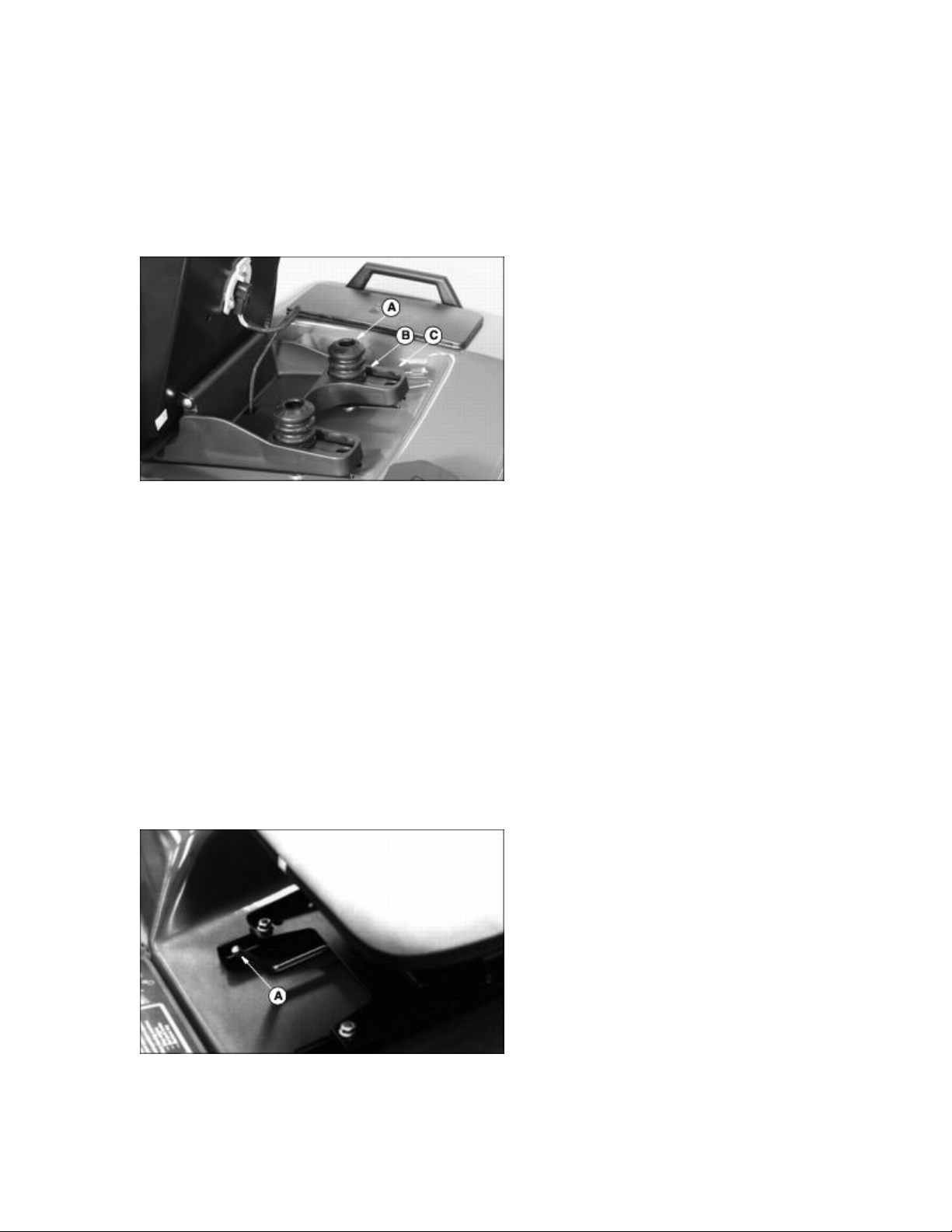

Adjust Seat Suspension

NOTE: Seat suspension can be adjusted to better match the weight of the operator.

1. Lift operators seat.

2. Suspension coils can be moved to three different settings:

M96043

· Soft Ride (A)

· Average Ride (B)

· Firm Ride (C)

3. Make sure suspension coils are in the same ride setting for each side.

Adjusting Seat (445)

NOTE: This tractor is equipped with a fourteen position slide rail seat. Be sure seat is locked in

position before operating.

M71483

1. Push lever (A) to the left.

25

Page 26

2. Slide seat forward or backward to desired position.

3. Release lever.

Rear Wheel Spacing (Two Wheel Steer Models With 23 x 10.50-12 Tires)

IMPORTANT: Avoid damage! On 26 x 12.00-12 tire option, wheels should always be in the wide

position.

c CAUTION: Avoid injury! Do not work under a raised tractor unless it is safely supported. A tractor

that slips and falls off a jack could cause serious injury or death.

1. Park tractor on level surface. STOP engine. LOCK park brake. Put blocks in front and back of front

wheels.

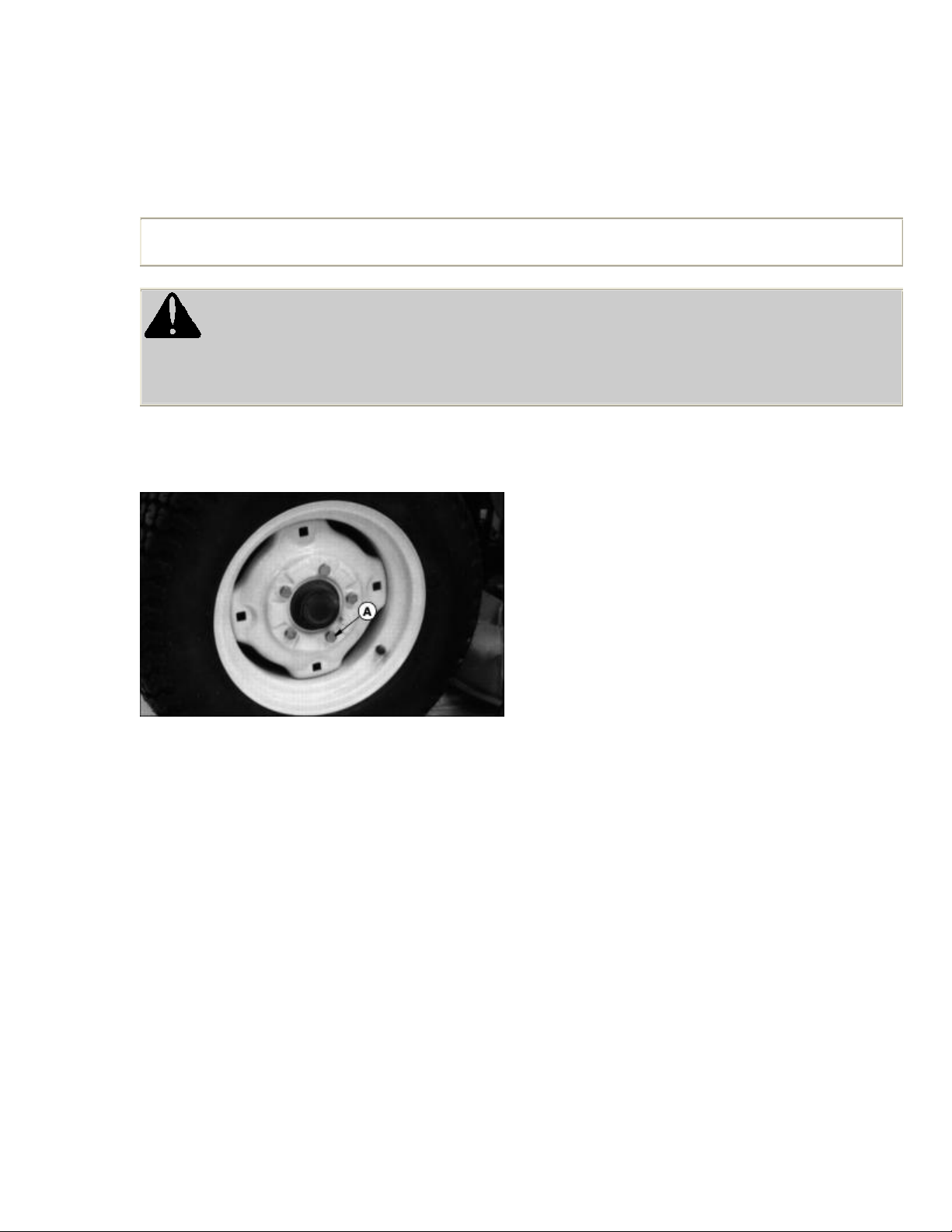

M71459

2. Loosen five rear wheel bolts (A). Lift rear wheels off the ground with floor jack or hoist.

3. Remove wheel bolts.

4. Install wheels as follows:

· Turf tires: Install wheel on same side of tractor with valve stem inside.

26

Page 27

M71484

· Bar tires: Install each wheel on opposite side of tractor. Bars on tires must point forward.

· Tighten wheel bolts to 88 N·lm (65 lb-ft).

· Lower rear wheels to the ground. Remove blocks from front wheels.

Testing Safety Systems

c CAUTION: Avoid injury! Engine exhaust fumes can cause sickness or death.

· If it is necessary to run an engine in an enclosed area, remove the exhaust fumes for the area with

an exhaust pipe extension.

· If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

Use the following checkout procedure to check for normal operation of tractor.

If there is a malfunction during one of these procedures, DO NOT operate tractor. (See your John

Deere dealer for service.)

IMPORTANT: Avoid damage! Tests 1, 2 and 3 are performed WITHOUT the engine running.

Perform these tests in a clear open area. Keep bystanders away.

Test 1

27

Page 28

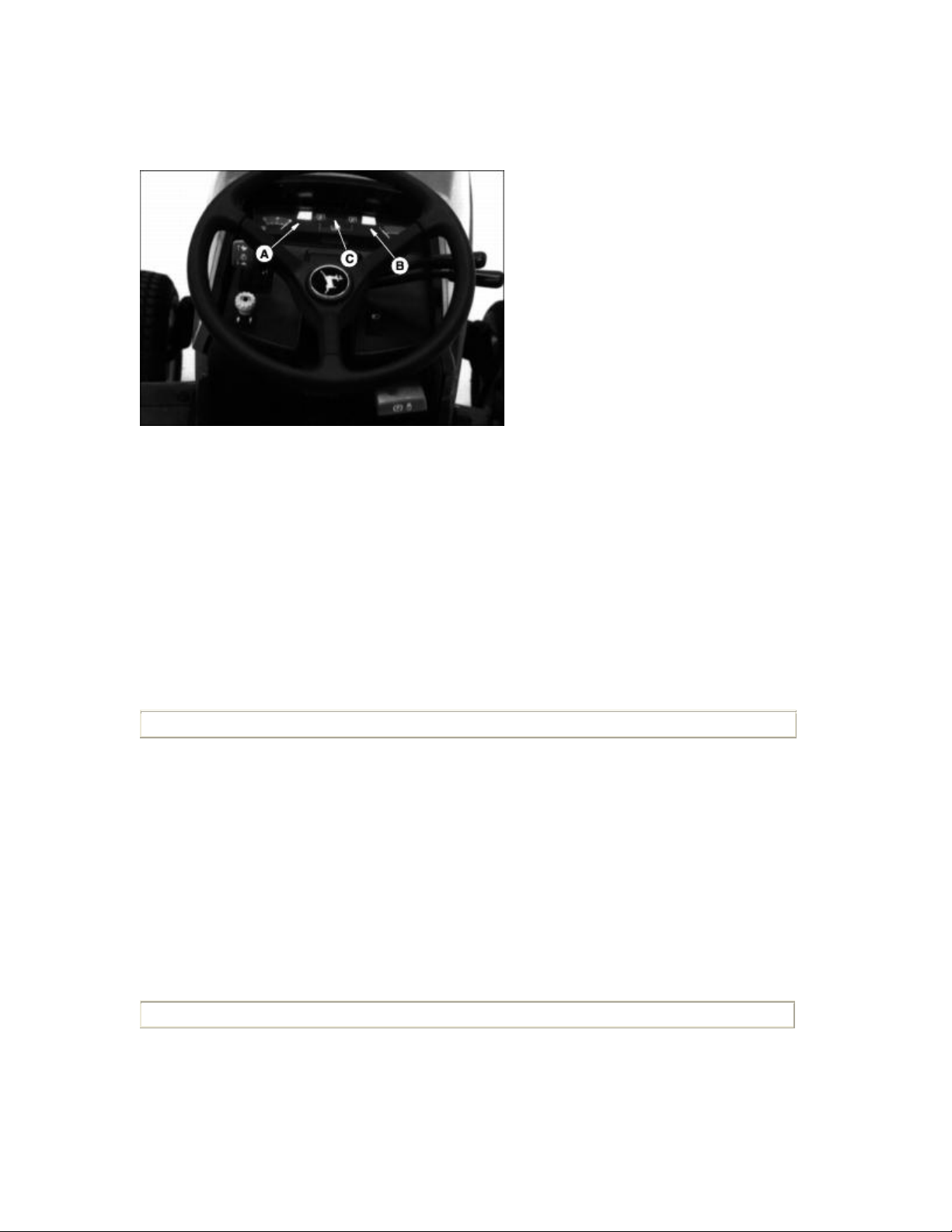

Check operation of indicator lights:

· Turn key to RUN position.

M71630

· LOOK: Indicator lights (A) and (B) must light.

· LOOK: On Model 445, indicator light (C) will come on and go out in two to three seconds.

· If one indicator does not light, see Replacing Indicator Light Bulb in Service-Electrical section.

· If new indicator bulb does not light or no indicators work, see your John Deere dealer.

Test 2

IMPORTANT: Avoid damage! If test fails, the engine may start and tractor may move.

Test brake switch:

1. Unlock park brake and release brake pedal.

2. Turn key to START position.

3. Engine must not crank.

Test 3

IMPORTANT: Avoid damage! If test fails, the engine may start and PTO may engage.

Test PTO switch:

1. Depress brake pedal, or lock park brake.

28

Page 29

2. Put PTO switch lever in ON position.

3. Turn key to START position.

4. Engine must not crank.

Test 4

Test seat switch:

1. First part of test:

· Start engine. Run engine at MAXIMUM engine speed. Unlock park brake and release brake pedal.

· Put PTO switch lever in ON position.

· Raise up off seat. DO NOT get off tractor.

· Engine should begin to die. PTO should immediately SHUT OFF and mower blades should STOP.

2. Second part of test

· DISENGAGE PTO.

· Start engine.

· UNLOCK brake.

· Raise up off seat. DO NOT get off tractor.

· Engine should STOP.

3. Third part of test:

· DISENGAGE PTO.

· Start engine.

· LOCK park brake

· Raise up off seat. DO NOT get off tractor.

· Engine should continue to run.

Test 5

NOTE: This test should be performed once a year or every 100 hours.

29

Page 30

Check mower blade stop time.

Perform this test while sitting on the tractor.

1. Start engine.

2. ENGAGE PTO.

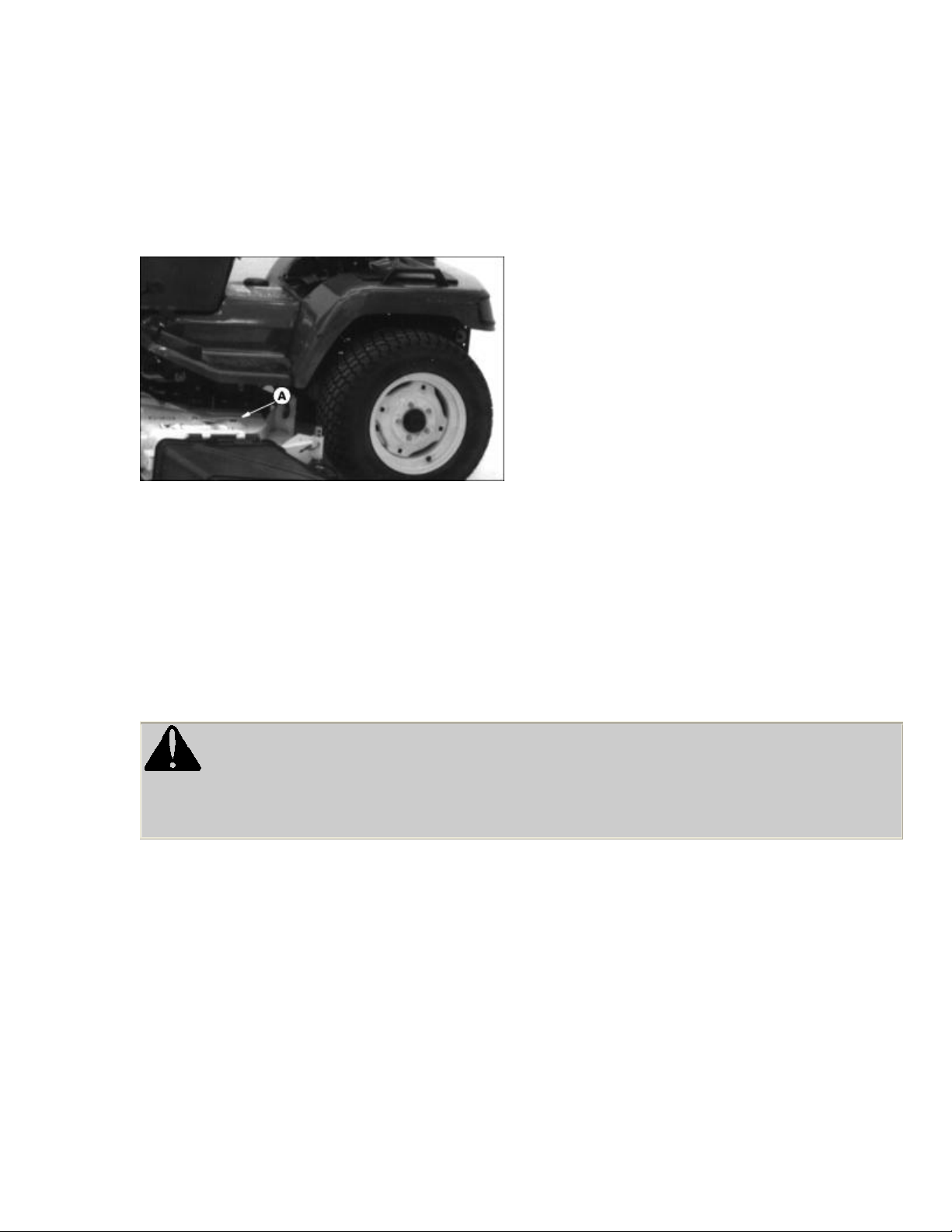

M47474

3. Watch left-hand side mower spindle (A). DISENGAGE PTO, mower spindle should stop turning

within 5 seconds.

4. If spindle does not stop within 5 seconds, the PTO brake needs servicing. (See your John Deere

dealer for service.)

Test 6

c CAUTION: Avoid injury! Before moving rearward, make sure area is clear of bystanders,

especially children.

Test Reverse Implement Option:

1. Start engine.

2. Engage PTO to start attachment.

3. Look behind the vehicle to be sure there are no bystanders.

4. Begin REVERSE travel by depressing REVERSE foot pedal.

5. Attachment should stop operation. If attachment continues to operate while tractor travels in

REVERSE, do not continue to operate attachment. See your John Deere dealer for service.

30

Page 31

Using the Park Brake

Lock Park Brake:

c CAUTION: Avoid injury!

Always LOCK park brake before getting off tractor or leaving tractor unattended.

M71468

1. Push down on brake pedal (A) and hold pedal all the way down.

2. Pull park brake lever (B) up to LOCK park brake.

3. Release pedal and then park brake lever. Pedal should stay down and park brake lever should stay

up in LOCKED position.

Unlock Park Brake:

1. Push down on brake pedal and hold pedal all the way down.

2. Push park brake lever down.

3. Release pedal. Pedal should come up to operating position.

Indicator Lights and Gauges

31

Page 32

M71629

A - Fuel Gauge - indicates fuel level.

B - Oil Pressure Indicator Light - will come on when engine oil pressure is too low. If indicator

comes on during operation, stop engine and perform appropriate service. This is an indication that

the engine is low on oil.

C and D - PTO Indicator Lights - will come on when mid/front or rear PTO is engaged.

E - Battery Discharge Indicator Light - will come on when output is too low. If indicator comes on

during operation, stop engine and perform appropriate service.

F - Coolant Temperature Gauge - indicates temperature of the cooling system.

G - Hour Meter - shows the number of hours the engine has run. Check the hour meter daily to see

what services from the Service Interval Chart in Service section need to be done.

M71629

H - Injection System Failure indicator (Model 445 Only) - will come on for a few seconds when

you turn key to the RUN position.

The injection system failure indicator serves as an injection system diagnostic tool. When there is a

problem with one of the fuel injection sensors, the indicator will blink. This light has two signals, a

32

Page 33

long blink (-) and a short blink (·). Use the following to diagnose the indicator blinking:

· - · · Air Temperature Sensor problem.

· - · · · Water Temperature Sensor problem.

· - - · Air Pressure Sensor problem.

· - - · · Key switch was turned on too quickly.

· If light is blinking, see your John Deere dealer for service.

Starting the Engine

c CAUTION: Avoid injury! Engine exhaust fumes can cause sickness or death.

· If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with

an exhaust pipe extension.

· If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

NOTE: You must hold brake pedal down, or LOCK park brake, before you can start the engine. Be

sure PTO switch is off.

1. LOCK park brake or depress brake pedal.

M71469

2. Push throttle lever (A) up to 1/2 position.

NOTE: You may not need to choke a warm engine.

33

Page 34

3. Model 425: COLD engine: Choke engine by pushing choke lever (B) all the way up to CHOKE

(Closed) position.

M71641

4. Turn key (A) to the RUN position (C).

M71630

5. Check indicator lights:

· Oil Pressure indicator (E) will be ON.

IMPORTANT: Avoid damage! If indicator (F) blinks after engine is started, STOP engine. Be sure

to wait 1/2 second before cranking engine again.

· Battery Discharge indicator (G) will be ON.

· Model 425: Injection System Failure Indicator (F) will come on for a few seconds. WAIT for

approximately 1/2 second before cranking the engine.

6. Turn key to the START position (D):

· Crank engine.

34

Page 35

IMPORTANT: Avoid damage! Avoid unnecessary engine idling.

· Wastes fuel.

· Causes carbon build up.

· Can cause over heating.

· If engine does not start within 5 seconds, turn key to STOP position (B) and wait 10 seconds.

· Crank engine again for 5 seconds.

Repeat this procedure if necessary.

7. As soon as engine starts, release key. The key will return to the RUN position and all indicator

lights should be off. If a light does not go off, stop engine and perform appropriate service.

8. Model 425: Cold engine:

· After engine starts, gradually pull the choke lever back to the HALF-WAY position. You may have

to leave the choke lever at this position until the engine runs smoothly.

M71460

· When engine is running smoothly, gradually pull choke lever down to the NO CHOKE (Open)

position (A).

Stopping the Engine

1. STOP tractor.

35

Page 36

M71460

2. Pull throttle lever (A) down to the SLOW position.

IMPORTANT: Avoid damage! To avoid fuel pump damage, be sure key is in STOP (Off) position

whenever engine is not running.

NOTE: Model 425: Engine may run for a second after key is turned off to burn unused fuel in the

system.

3. Turn key (B) to STOP (Off) position.

4. LOCK park brake and remove key.

Using Travel Controls

c CAUTION: Avoid injury!

· Before moving forward or rearward, make sure area is clear of bystanders, especially children.

· Disengage mower before backing up.

TO TRAVEL FORWARD:

· UNLOCK park brake.

36

Page 37

M71644

· Slowly push down forward pedal (B). Tractor will travel faster the farther down you push the pedal.

· Release forward pedal, tractor will automatically return to neutral and STOP.

TO TRAVEL IN REVERSE:

NOTE: Any operating attachment will stop as the REVERSE foot pedal is depressed with attachment

engaged.

1. Bring the vehicle to a stop.

2. Push PTO knob down to the OFF position to disengage attachment.

3. Look behind the vehicle to be sure there are no bystanders nearby.

4. Slowly push down reverse pedal (C). Tractor will travel faster the farther down you push the pedal.

Release reverse pedal, tractor will automatically return to neutral and STOP.

FOR EMERGENCY STOPPING:

· Release either travel pedal, tractor will automatically return to neutral and STOP.

· Push down on brake pedal (A). Tractor brakes will be applied to assist in stopping.

Using Cruise Control

Use cruise control when you want to maintain travel speed without having to hold the forward travel

pedal down. Cruise control operates only for forward travel.

Operate tractor in a large, open area to learn how the cruise control works.

Engage Cruise Control

1. Push forward pedal down until you reach desired travel speed.

37

Page 38

M71463

2. Pull lever (A) up to lock the cruise control.

Disengage Cruise Control

1. Push brake pedal down.

Using The Reverse Implement Option

c CAUTION: Avoid injury!

· Before moving forward or rearward, make sure area is clear of bystanders, especially children.

NOTE: Operating the mower while backing up is strongly discouraged. The Reverse Implement

Option should be used ONLY when operating another attachment or when the operator deems it

necessary to reposition the machine with the mower engaged.

1. Stop the machine FORWARD travel with attachment engaged.

2. Look behind the vehicle to be sure there are no bystanders.

38

Page 39

M71469

3. Lift and hold the PTO knob (A) up past the PTO engagement position to activate the reverse

implement position while depressing REVERSE foot pedal slightly.

NOTE: If the attachment stops while repositioning the machine, return PTO knob to the OFF

position. Begin again with Step 2 in procedure.

4. As the machine begins to move backward, release the PTO knob and reposition the machine.

5. Resume FORWARD travel. The attachment should continue operating.

6. Repeat Steps 1 through 5 to reposition the machine again.

Using Differential Lock

c CAUTION: Avoid injury! To prevent tipping DO NOT attempt to turn on slopes and hills with

differential lock engaged.

IMPORTANT: Avoid damage! To prevent damage to differential, DO NOT engage differential lock

at high speeds.

The differential lock is used to provide better traction when rear wheels start to slip. Do not use

differential lock unless you are experiencing rear wheel slippage. Engaging differential lock will

cause both rear wheels to drive equally to improve traction.

Engage Differential Lock

1. STOP or slow tractor down.

M71462

39

Page 40

2. Push down on differential lock pedal (A). Lock will remain engaged as long as there is rear wheel

slippage or pedal is depressed.

NOTE: Turning radius is increased when differential is locked.

When brake pedal is depressed, differential lock will automatically engage.

Disengage Differential Lock

1. Release differential lock pedal. Differential lock will disengage when rear wheels are no longer

slipping.

Using Hydraulic Control Levers

Using Hydraulic Valve

NOTE: Only tractors equipped with the optional front hitch or loader will be equipped with a

hydraulic valve.

Hydraulic control levers operate differently depending on the attachment. When using an attachment

other than a mower deck, please see the ATTACHMENT OPERATOR'S MANUAL.

M55415

· When operating mower deck or rear implement lift - turn T-handle (A) counterclockwise until tight.

· When operating front hitch/attachments - turn T-handle (A) clockwise until it is bottomed out.

Using Control Levers

Using control lever (B) with a m

ower deck:

40

Page 41

M71478

· Pull and hold lever back until mower deck is raised.

· Push lever forward to lower the mower deck.

Using control lever (C):

M71478

· This control lever is used to raise and lower other attachments such as a snowthrower, rotary broom,

etc.

NOTE: If you are not using lever (C), periodically move lever back and forth to maintain lubrication.

Be sure lever is returned to the middle (NEUTRAL) position and not locked in the forward (FLOAT)

position.

Using PTO (Power Take-Off)

NOTE: Any operating attachment will stop as the REVERSE foot pedal is depressed with attachment

engaged. Prior to operating the PTO, see Reverse Implement Option in this section.

This tractor is equipped with a 2000 rpm mid PTO.

41

Page 42

Engage PTO

1. Reduce travel speed or stop tractor.

M71460

2. After engine has warmed, push throttle lever (B) all the way up to maximum engine speed position.

3. Pull PTO knob (A) up. PTO indicator light (C) will come on when PTO is engaged.

NOTE: Always operate engine at maximum speed when PTO is engaged.

Disengage PTO

1. Push knob down to disengage PTO. PTO indicator light will go out.

NOTE: If brake pedal is depressed, PTO will disengage.

Using Mower Height Control

IMPORTANT: Avoid damage! Use this procedure to determine cut height. Do not use hydraulic

control levers to determine cut height.

1. Park tractor on a hard, level surface.

42

Page 43

M71478

2. Pull back hydraulic control lever (A) and raise mower as high as it will go.

3. Adjust mower wheels.

M71481

4. Flip open crank handle (B). Crank height control counterclockwise far enough to permit mower to

be lowered to surface. Do not turn lever too far, height control may be damaged.

NOTE: NOTE: One full rotation of height control equals approximately 12.5 mm (1/2 in.) of height

adjustment.

5. Lower mower to desired cutting height with hydraulic control lever.

IMPORTANT: Avoid damage! Be sure to raise mower before changing height.

6. Crank height control clockwise until it is tight to lock mower in set cutting height. Close crank.

7. To LOCK mower in completely raised position:

· Raise mower as high as it will go using the hydraulic control lever.

· Crank height control clockwise until it is tight. Close crank.

Mower Lift Arms

IMPORTANT: Avoid damage! To avoid tractor damage: When operating without a mower deck,

lock mower lift arms into the UP position by turning height control crank clockwise until it is tight.

Close crank.

Using Free-Wheeling Lever

43

Page 44

IMPORTANT: Avoid damage! To prevent transaxle damage, NEVER tow the tractor. Only push

tractor by hand. Do not use another vehicle to push tractor.

When you need to move the tractor without starting the engine, use the free-wheeling lever:

M71465

· Pull free-wheeling control lever (A) up.

· Unlock park brake.

· Push tractor to desired location.

Lever will return to the operating position when tractor is started and driven.

Using Engine Air Restriction Indicator (Optional Equipment)

IMPORTANT: Avoid damage! Engine damage may occur if the air filter is not serviced properly.

This tractor can be equipped with an air restriction indicator. The indicator is designed to inform you

when it is time to service the air filter elements.

M71510

44

Page 45

The air restriction indicator (A) is numbered to measure air restriction. As the filter collects more dirt,

the restriction increases, raising the numbered reading on the indicator.

Using Weights And Tire Chains

Front Weights

c CAUTION: Avoid injury! Tractor front weights improve stability when operating on slopes.

To avoid injury, add front weights for better front-end stability and steering when using a rear

mounted attachment or pulling a cart.

There are two types of front weights available for your tractor, suitcase weights and wheel weights.

Suitcase weights can be mounted on the front bumper and wheel weights are mounted to the front

wheels.

Five suitcase weights can be mounted on the front bumper. An additional four weights can be added if

you have installed a "Front Weight Bracket Kit." Each suitcase weight weighs 19 kg (42 lbs).

NOTE: Before installing wheel weights on your tractor, MAKE SURE that the tire valve stems are

facing to the inside.

A front wheel weight weighs 16 kg (35 lbs). Two front wheel weights and mounting kit are required.

See your John Deere dealer for kits and weights to best fit your needs.

Rear Weights

There are two types of rear weights available for your tractor, suitcase weights and rear wheel

weights. The suitcase weights are mounted on a bracket on the back of the tractor and wheel weights

are mounted to the rear wheels.

To use rear suitcase weights, you need to order the "Rear Weight Bracket Kit". The rear weight

bracket holds up to six 19 kg (42 lb) suitcase weights. Use of these weights is required when an

attachment, such as snowthrower or snowblower is used.

To use rear wheel weights, you need to order the appropriate weight and in some cases the hardware

to attach the weights.

See your John Deere dealer for kits and weights to best fit your needs.

If you are installing rear wheel weights, please use the following instructions.

Installing Rear Wheel Weights (Two-Wheel Steer Tractors)

45

Page 46

23x10.50-12 Tires With BM17976 Weight

BM17976 is a 23 kg (50 lb) plastic coated weight and includes the necessary hardware.

Install weight as shown.

M71770

· Measurement (A) should be 160 mm (6.3 in.).

23x10.50-12 Tires With BM17972 Weight

BM17972 is a 23 kg (50 lb) Weight. You must also order BM18089 attaching hardware when using

one weight and BM17977 attaching hardware when using two weights.

Install weight(s) as shown:

m71770

A - One Weight

B - Two Weights

· Measurement (C) should be 200 mm (7.9 in.).

26x12.00-12 Tires With BM17976 Weight

46

Page 47

BM17976 is a 23 kg (50 lb) plastic coated weight and includes the necessary hardware.

Install weight as shown.

M71770

· Measurement (A) should be 210 mm (8.3 in.).

26x12.00-12 Tires With BM17972 Weight

BM17972 is a 23 kg (50 lb) Weight. You must also order BM17977 attaching hardware when using

one weight and BM18101 attaching hardware when using two weights.

Install weight(s) as shown:

M71770

A - One Weight

B - Two Weights

· Measurement (C) should be 195 mm (7.7 in.).

· Measurement (D) should be 250 mm (9.8 in.).

26x12.00-12 Tires With BM17973 Weight

47

Page 48

BM17973 is a 33 kg (72 lb) Weight. You must also order BM18089 attaching hardware.

M71770

Install weight as shown.

26x12.00-12 Tires With BM17973 Weight and BM17972 Weight

BM17973 is a 33 kg (72 lb) Weight.

BM17972 is a 23 kg (50 lb) Weight.

You must also order BM17977 attaching hardware when using one BM17973 and one BM17972

weight. Order BM18101 attaching hardware when using one BM17973 and two BM17972 weights.

Install weight(s) as shown:

M71770

A - One BM17973 weight and one BM17972 weight

B - One BM17973 weight and two BM17972 weights

· Measurement (C) should be 200 mm (7.9 in.).

· Measurement (D) should be 260 mm (10.2 in.).

48

Page 49

Installing Rear Wheel Weights (All-Wheel Steer Tractors)

IMPORTANT: Avoid damage! To avoid damage to axle, be sure to install weight mounting

hardware as shown.

23x10.50-12 Tires With BM17972 Weight

BM17972 is a 23 kg (50 lb) Weight. You must also order BM18094 attaching hardware when using

one weight and BM18089 attaching hardware when using two weights.

M71771

A - One Weight

B - Two Weights

Install weight(s) as shown. Cut off any excess threads on bolts.

23x8.50-12 Tires With BM17972 Weight

BM17972 is a 23 kg (50 lb) W

one weight and BM18089 attaching hardware when using two weights.

eight. You must also order BM18094 attaching hardware when using

M71771

49

Page 50

A - One Weight

B - Two Weights

Install weight(s) as shown. Cut off any excess threads on bolts.

Using Tire Chains

Tire Size Tire Chains Available Requires Optional Wheel Spacer Kit

All-wheel steer:

Yes

23 x 8.50-12

Yes

23 x 10.50-12

Two-wheel steer:

Yes

23 x 10.50-12

Yes

26 x 12.00-12

No

Yes

No

No

Tire chains are recommended for use with a snowthrower and, under certain conditions; the front

blade. (See your John Deere dealer for tire chains).

Installing the Chains

1. Park the tractor on a level surface.

2. Lock the park brake.

3. STOP the engine.

4. Remove the key.

5. Remove chains from bag and lay out flat with the cross chain hook ends facing upward. Remove

any twists and tangles from cross chain and rim chain.

50

Page 51

M73743

6. Drape chain over tire with the lever fastener on outside of tire and cross link hooks (A) facing

upward and away from tire.

7. Adjust chain for straightness and an even amount of cross chain links on each side of tire.

8. Place the first cross chain (opposite the end with fastener and inside hook) under tire.

M73744

9. Pull the inside rim chain tight and hook the inside hook. Pull the outside rim chain tight and hook

the outside lever fastener (B) by running the end through a free link (C). Close the fastener by rotating

it back 180 degrees and engaging the hook (D) on the end of the fastener into a rim chain link (E).

Make sure the chain is centered on the tire with approximately the same number of free rim links (F)

on the inside and outside.

51

Page 52

M73745

M73746

10. Tie excess rim chain links (G) back to the rim chain.

11. The chain should be as tight as possible by hand. Unhook the fastener and repeat Step 5 if the

chain is loose.

IMPORTANT: Avoid damage!

· Periodically check chains for looseness and adjust when necessary.

· Maintain proper air pressure in tires.

12. Drive forward on chains 30' - 40' and recheck for tightness. Adjust as necessary.

Transporting Tractor

52

Page 53

M34229

Use a heavy-duty trailer to transport your tractor.

Drive tractor forward onto a trailer. Lower any attachments to trailer deck.

Lock park brake.

Fasten tractor to trailer with heavy-duty straps, chains, or cables. Both front and rear straps must be

directed down and outward from tractor.

Trailer must have signs and lights required by law.

Mowing Tips

Before mowing, be sure deck is leveled and mower wheels are in the proper position.

When you mow an area for the first time, travel SLOW and cut HIGH so you can:

· Learn the terrain.

· Learn the best mowing pattern.

· Help prevent hitting objects hidden in the grass.

Mow grass only when it is dry: Wet grass may plug mower and leave a trail of grass clumps.

Mow grass often: Short grass clippings will decay quickly.

Mow at full throttle for best performance.

Use travel speed that fits conditions:

· Travel SLOW when you mow thick, tall grass.

· FAST travel or sharp turns may produce stripes or uneven cut: slow down.

53

Page 54

· Travel at MODERATE speed when you mow a thin stand of grass.

Mow often enough so you cut only 1/3 of grass blade in one mowing. Cutting grass too short may kill

grass and let weeds grow easily.

See your John Deere dealer for blades that will best fit your mowing conditions.

Aerate lawn to help stimulate soil organisms and root growth.

Trimming Tips

· Turn to left around trees, bushes, etc.

· Drive slowly. Avoid hitting trees, bushes, etc.

· If ground slopes up to a tree or bush, you may have to approach the tree or bush straight-on to avoid

scalping.

To Avoid Scalping

· Pay attention to the way you drive: you can eliminate scalping.

· If mower scalps easily, cutting height may be too low for ground conditions-especially on lawns

with many small mounds and ridges.

· Rear gauge wheels must be adjusted correctly.

· Drive over ridges and through shallow ditches straight-on, not at an angle.

Keep blades sharp: Dull blades will tear grass; tips of grass will then turn brown.

Check lawn regularly for uneven cut. If cut is uneven:

· LOOK: Mower may not be level.

· Slow down before you make a turn.

· Sharpen blades often.

Use thatcher (available from John Deere dealer) in late spring or summer to pull up dead grass and

aerate ground.

For bagging information, see your Bagger Operator's Manual.

After Mowing

· Let engine cool-to prevent fire when you store mower.

54

Page 55

· Clean top of deck, engine, and chute with compressed air, if possible-to help prevent buildup and

fire.

· Clean under deck with water under pressure-to prevent buildup and remove corrosive lawn

chemicals.

Bagging Tips

For best performance, bagger needs good airflow. To help increase airflow:

· Keep underside of deck and chute clean.

· Cut grass high.

· Mow at full throttle.

IMPORTANT: Avoid damage! Don't leave clippings in bag(s):

· Moisture may damage bag(s).

· Damp clippings are fire hazard.

· Clean bag(s) often with water from garden hose, from outside to inside of bag. Let bag(s) dry before

use.

LOOK: Check level of clippings in bags often. When bag(s) are full:

· Mower may leave a trail of clippings.

· Clippings may blow to side.

Bagging and Composting

Many communities will no longer haul lawn clippings and leaves to landfills. Bagging and

composting clippings and leaves is one way to solve this problem.

Clippings from grass bag may also be used as mulch, or sheet compost, between garden rows and

around trees and shrubs. This mulch will:

· Keep weeds from growing.

· Help soil keep moisture.

· Add nutrients to soil as it decays.

· Help keep soil temperature down during hot weather.

55

Page 56

You may compost clippings and leaves in various ways. See garden magazines or clubs for

information, or go to your local library for help.

Finished compost is crumbly. It is rich in soil nutrients, and can be spread on your lawn. Compost

may also be worked into soil. It adds humus to soil and improves soil texture, making soil looser and

easier to work.

Mulching Tips

Advantages:

· You do not have to rake or bag grass or leaves.

· Lawn holds moisture better during dry weather.

· Soil temperatures stay down during hot weather.

· Mulch adds nutrients to soil, and reduces need for fertilizer.

Mulching does not make thatch. Frequent shallow watering and fertilizer application produce thatch

from roots that grow close to surface.

Be careful when you mulch leaves in Fall. Grass needs sunlight in Fall to help store food for Winter.

A thick layer of mulched leaves can prevent sunlight from getting to grass and smother it. You may

have to mow with grass bag to remove this layer.

Mulch only when the grass and leaves are dry.

Mulching wet or damp grass or leaves may cause problems:

· Clippings and leaves may build up on the underside of the mower deck.

· Cut grass and leaves may form clumps.

· Clippings and leaves may not be cut into small bits.

· Engine may work harder and use more fuel.

Cut only top 1/3 of grass at a time.

Use a different mowing pattern each time you mow. Overlap mowing paths 50-100 mm (2-4 in.).

Slow down. Mulching takes more power.

Keep blades sharp. Check them often.

Clean underside of deck after each use.

56

Page 57

Replacement Parts

Service Literature

If you would like a copy of the Parts Catalog or Technical Manual for this machine call:

· U.S. & Canada: 1-800-522-7448.

· All Other Regions: Your John Deere dealer.

Parts

We recommend John Deere quality parts and lubricants, available at your John Deere dealer.

Part numbers may change, use part numbers listed below when you order. If a number changes, your

dealer will have the latest number.

When you order parts, your John Deere dealer needs your machine serial number and engine serial

number. These are the numbers that you recorded in the Product Identification section of this manual.

Part Numbers

Item Part Number

Air Cleaner Element:

M76076

· Foam Element

M117254

· Paper Element

Battery TY6182

Fuel Filter:

AM116304

· 425

AM118131

· 445

Fuse: 15 amp 99M7065

Fuse: 10 amp 57M7121

Engine Oil Filter AM107423

Hydraulic Oil Filter AM116156

Spark Plug:

57

AM101194

Page 58

· 425

· 445

(Part numbers are subject to change without notice. Part Numbers may be different outside the

U.S.A.)

M71939

58

Page 59

Service Interval Chart

After First 5 Hours

· Check/tighten hardware.

· Check wheel bolt torque.

Break In (After First 50 Hours of Operation)

· Check wheel bolt torque.

· Check/tighten air & cooling hose clamps.

· Change transaxle oil and filter.

· Change engine oil and filter.

50 Hours

· Check electrolyte level/clean battery.

· Lubricate front axle.

· Lubricate steering cylinder.

100 Hours or Annually (whichever comes first)

· Check/tighten hardware.

· Check tire pressure.

200 Hours

· Check fan belt tension.

· Change transaxle oil and filter.

· Clean radiator fins and screen.

200 Hours or Annually (whichever comes first)

· Change air filter/clean precleaner. (If not equipped with air restriction indicator)

59

Page 60

· Change engine oil and filter.

250 Hours or Annually (whichever comes first)

· Change fuel filter (425)

500 Hours

· Check wheel bolt torque.

· Check/tighten air & cooling hose clamps.

· Change fuel filter (445).

· Inspect spark plugs.

NOTE: See your John Deere dealer for the following services.

· Check engine idle speed.

· Adjust engine valve clearance.

500 Hours or Every Two Years (whichever comes first)

· Change radiator coolant.

60

Page 61

Service Lubrication

Grease

TS1417

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

· John Deere MOLY HIGH- TEMPERATURE EP GREASE - JDM J25C (NLGI Grade 2)

· John Deere HIGH-TEMPERATURE EP GREASE - JDM J13E4 (NLGI Grade 2)

Other greases may be used if the above recommended John Deere greases are not available, provided

they meet one of the following:

· SAE J310 Classification GC-LB

· NLGI Grade 2 Grease

Greases meeting Military Specification MIL-G-10924F may be used as arctic grease.

Lubricating Rear Steering Pivot (All Wheel Steer)

61

Page 62

M71527

Lubricate joint (A) with one or two shots of John Deere grease.

NOTE: Rear wheel removed for clarity of photo.

M94194

Lubricate king pin pivot (B) with John Deere grease.

Lubricating Steering Cylinder Ball Joints (All Tractors)

M88454

62

Page 63

Picture Note: Two Wheel Steer model shown - Left Side

Lubricate ball joints (A) and (B) with one or two shots of John Deere grease.

M66455

Picture Note: Two Wheel Steer model shown - Right Side

Lubricating Front Axle

All Wheel Steer

M71526

Lubricate axle points (A) with one or two shots of John Deere grease.

63

Page 64

M71525

Lubricate axle points (B), one on each side of axle, with one or two shots of John Deere grease.

Two Wheel Steer

M88456

Lubricate axle pivot point (A) with one or two shots of John Deere grease.

M88453

Lubricate axle points (B), one on each side of axle, with one or two shots of John Deere grease.

64

Page 65

Service Engine

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and systems on this engine,

which are being done at the customers expense, may be performed by any nonroad engine repair

establishment or individual. Warranty repairs must be performed by an authorized John Deere

dealer.

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine manufacturer and should not require any adjustments.

If engine is operated at altitudes above 1829 m (6,000 ft), some carburetors may require a special

high altitude main jet. See your John Deere dealer.

Possible engine surging will occur at high rpm with no load (with transmission in "N" neutral and

PTO switch in the OFF position. This is a normal condition due to the emission control system.

If engine is hard to start or runs rough, check the troubleshooting section of this manual.

After performing the checks in the troubleshooting section and your engine is still not performing

correctly, contact your John Deere dealer.

Avoid Fumes

c CAUTION: Avoid injury! Engine exhaust fumes can cause sickness or death:

· If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the

fumes.

· Always try to work in a well ventilated area.

Engine Oil

65

Page 66

TS1412

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere oil is preferred:

· TURF-GARD®-SAE 10W30

The following John Deere oils are also recommended if above preferred oil is not available:

· PLUS-4® - SAE 10W40

· PLUS-4® - SAE 10W30

· TORQ-GARD SUPREME® - SAE 5W30

Other oils may be used if all the above John Deere oils are not available and they meet one of the

following:

· API Service Classification SH and SG

· CCMC Specifications G5 and G4

· Military Specification MIL-L-2104F

Arctic oils (such as SAE 0W30 or Military Specification MIL-L-46167B) may be used if

66

Page 67

temperatures fall below 30°C (22°F), but reduce the oil change interval by 50%.

Checking Engine Oil Level

1. Park vehicle on a level surface.

2. Check engine oil when oil is cold.

3. Raise hood.

M71493