Page 1

TECHNICAL MANUAL

TM 5-3805-280-10

OPERATOR’S MANU

AL

HYDRAULIC EXCAVATOR

JOHN DEERE

MODEL 230LCR

NSN 3805-01-463-0804

AND

MODEL 230LCRD WITH ROCK DRILL

NSN 3805-01-463-0806

DISTRIBUTION STATEMENT A - Approved for public release; distribution is unlimited.

Reproduced by permi

All rights reserved.

ssion of Deere & Company, Moline, IL © 2000.

HEADQUARTERS, DEPARTMENT OF THE ARMY

15 FEBRUARY 2000

Page 2

TM 5-3805-280-10

INSERT LATEST UPDATED PAGES. DESTROY SUPERSEDED DATA.

LIST OF EFFECTIVE PAGES

Note: The portion of text or illustration affected by the updates is indicated by a vertical line in the outer margins of

the page. Updates to wiring diagrams are indicated by shaded areas.

Dates of issue for original and updated pages are:

Original .. 0 .. 15 February 2000

TOTAL NUMBER OF PAGES IS 397 CONSISTING OF THE FOLLOWING:

Page *Revision

No. No.

Cover................................... 0

A.......................................... 0

B blank ................................ 0

i — xi ................................... 0

xii blank ............................... 0

1-1 — 1-37.......................... 0

1-38 blank ........................... 0

2-1 — 2-30.......................... 0

3-1 — 3-3............................ 0

3-4 blank ............................. 0

4-1.......................................0

4-2 blank ............................. 0

5-1 — 5-11.......................... 0

5-12 blank ........................... 0

6-1 — 6-8............................ 0

7-1 — 7-55.......................... 0

7-56 blank ........................... 0

8-1 — 8-14.......................... 0

9-1 — 9-12.......................... 0

10-1 — 10-4........................ 0

11-1 — 11-7........................ 0

11-8 blank ........................... 0

12-1 — 12-5........................ 0

Page *Revision

No. No.

12-6 blank............................0

13-1 — 13-3.........................0

13-4 blank............................0

14-1 — 14-10 ......................0

15-1 — 15-8.........................0

16-1 — 16-8.........................0

17-1 — 17-8.........................0

18-1 — 18-11 ......................0

18-12 blank.......................... 0

19-1 — 19-12 ......................0

20-1 — 20-28 ......................0

21-1 — 21-31 ......................0

21-32 blank.......................... 0

22-1 — 22-18 ......................0

23-1 — 23-5.........................0

23-6 blank............................0

24-1 — 24-8.........................0

A-1 — A-25..........................0

A-26 blank ...........................0

B-1 — B-4............................0

C-1 — C-3 ...........................0

C-4 blank.............................0

Page *Revision

No. No.

*Zero in this column indicates an original page.

A

Page 3

TM 5-3805-280-10

BLANK

B

Page 4

TM 5-3805-280-10

Technical Manual

No. 5-3805-280-10 HEADQUARTERS,

DEPARTMENT OF THE ARMY

Washington, DC,

OPERATOR’S MANUAL

HYDRAULIC EXCAVATOR

JOHN DEERE

MODEL 230LCR

NSN 3805-01-463-0804

AND

MODEL 230LCRD WITH ROCK DRILL

NSN 3805-01-463-0806

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

15 February 2000

You can help improve this publication. If you find any mistakes or if you know of a way to improve the procedures,

please let us know. Submit your DA Form 2028-2 (Recommended Changes to Equipment Technical Publications),

through the Internet, on the Army Electronic Product Support (AEPS) website. The Internet address is

http://aeps.ria.army.mil. If you need a password, scroll down and click on “ACCESS REQUEST FORM”. The DA

Form 2028 is located in the ONLINE FORMS PROCESSING section of the AEPS. Fill out the form and click on

SUBMIT. Using this form on the AEPS will enab le us to respond quicker to your comments and better manage the

DA Form 2028 program. You may also mail, fax or email your letter, DA Form 2028, or DA Form 2028-2 direct

to: Commander, U.S. Army Tank-aut omotive and Armaments Command, ATTN: AMSTA-LC-CI, Rock Island, IL

61299-7630. The email address is AMSTA-LC-CI@ria.army.mil. The fax number is DSN 793-0726 or

Commercial (309) 782-0726.

DISTRIBUTION STATEMENT A - Approved for public release; distribution is unlimited.

NOTE

As this operator manual is a commercial product supplemented to include Army specific

procedures, the manual may advise the operator to perform tasks that would normally not be

assigned to the operator level in a DATM. Always follow the limits established in the PMCS.

Also, references are made throughout the manual to see your authorized dealer or John Deere

dealer for repair or information. In those instances, notify your supervisor or next higher

maintenance level.

TABLE OF CONTENTS

Page

Introduction

Chapter 1 Safety and Safety Signs

John Deere Excavator Safety Features.......................................................................................1-1

Recognize Safety Information....................................................................................................1-2

Understand Signal Words...........................................................................................................1-2

Follow Safety Instructions .........................................................................................................1-2

Avoid Injury From: Loading Machine on a Trailer, Fastening Machine to

Trailer, and Unloading Machine From Trailer......................................................................1-3

i

Page 5

TM 5-3805-280-10

TABLE OF CONTENTS (Continued)

Page

Avoid Injury From Backover Accidents....................................................................................1-4

Avoid Injury From Rollaway Accidents....................................................................................1-5

Inspect Machine.........................................................................................................................1-5

Use Handholds and Steps ...........................................................................................................1-6

Use Seat Belt..............................................................................................................................1-6

Maintain Seat Belt......................................................................................................................1-7

Move and Operate Machine Safely............................................................................................1-7

Operate Only From Operator’s Seat...........................................................................................1-8

Secondary Exits..........................................................................................................................1-8

Operate Machine Safely.............................................................................................................1-8

Dig With Caution.......................................................................................................................1-9

Operate With Caution.................................................................................................................1-9

Avoid Tipping............................................................................................................................1-9

Avoid Power Lines.....................................................................................................................1-10

Drive Machine Safely.................................................................................................................1-10

Beware of Exhaust Fumes..........................................................................................................1-10

Park Machine Safely..................................................................................................................1-11

Keep Riders Off Machine ..........................................................................................................1-11

Operate Attachment Safely ........................................................................................................1-12

Handle Fluids Safely—Avoid Fires...........................................................................................1-12

Prepare for Emergencies............................................................................................................ 1-13

Handle Starting Fluid Safely......................................................................................................1-13

Clean Trash From Machine........................................................................................................1-14

Protect Against Flying Debris....................................................................................................1-14

Wear Protective Clothing...........................................................................................................1-14

Protect Against Noise.................................................................................................................1-15

Handle Chemical Products Safely..............................................................................................1-15

Warn Others of Service Work....................................................................................................1-16

Stay Clear of Moving Parts........................................................................................................1-16

Support Machine Properly .........................................................................................................1-17

Service Cooling System Safely.................................................................................................. 1-17

Practice Safe Maintenance.........................................................................................................1-18

Remove Paint Before Welding or Heating.................................................................................1-19

Avoid Heating Near Pressurized Fluid Lines.............................................................................1-19

Avoid High-Pressure Fluids.......................................................................................................1-20

Prevent Battery Explosions........................................................................................................1-20

Clean the Machine Regularly.....................................................................................................1-21

Store Attachments Safely...........................................................................................................1-21

Battery Terminals, Lifting Equipment, Dry Cleaning Solvent and Compressed Air.................1-22

Dispose of Waste Properly.........................................................................................................1-23

Drilling.......................................................................................................................................1-24

Rock Drill Maintenance.............................................................................................................1-24

Emergency Stops........................................................................................................................1-25

Safety Signs................................................................................................................................1-27

Chapter 2 Operator’s Station

Pedal, Levers and Panels............................................................................................................2-1

Right Front Panel and Right Console Panel............................................................................... 2-2

Monitor Panel.............................................................................................................................2-3

Engine Coolant Temperature Gauge..........................................................................................2-4

Warm-Up Indicator....................................................................................................................2-4

Fuel Gauge.................................................................................................................................2-4

H/P (High Power) Mode Indicator.............................................................................................2-4

E (Economy) Mode Indicator.....................................................................................................2-5

Auto-Idle Indicator.....................................................................................................................2-5

ii

Page 6

TM 5-3805-280-10

TABLE OF CONTENTS (Continued)

Page

Hydraulic Oil Level Indicator....................................................................................................2-5

Hydraulic Oil Filter Restriction Indicator (Model 230LCRD)...................................................2-6

Fuel Level Indicator...................................................................................................................2-6

Air Filter Restriction Indicator...................................................................................................2-6

Engine Coolant Temperature Indicator......................................................................................2-7

Charge Air Temperature Indicator.............................................................................................2-7

Engine Oil Pressure Indicator.....................................................................................................2-8

Alternator Voltage Indicator......................................................................................................2-8

Engine Oil Level Indicator.........................................................................................................2-8

Coolant Level Indicator..............................................................................................................2-9

Switch Panel...............................................................................................................................2-10

Buzzer and Buzzer Stop Switch.................................................................................................2-11

Wiper Switch..............................................................................................................................2-11

Washer Switch............................................................................................................................2-12

Operating Lights Switch.............................................................................................................2-12

Operating Rear Lights Switch....................................................................................................2-13

Cab Light....................................................................................................................................2-13

Overload Alarm and Indicator....................................................................................................2-13

Key Switch.................................................................................................................................2-14

Engine RPM Dial.......................................................................................................................2-14

Power Boost Switch...................................................................................................................2-14

Horn...........................................................................................................................................2-15

Hour Meter.................................................................................................................................2-15

Cab Heater and Air Conditioner.................................................................................................2-16

Control Panel Switches..............................................................................................................2-17

Cab Heater Operation.................................................................................................................2-18

Air Conditioner Operation..........................................................................................................2-18

Defroster Operation....................................................................................................................2-19

Front Console.............................................................................................................................2-19

Operating the AM/FM Radio.....................................................................................................2-20

Setting the Clock........................................................................................................................2-20

Cab Door Release Lever.............................................................................................................2-21

Secondary Exit Tool...................................................................................................................2-21

Opening Upper Front (Secondary Exit) Window.......................................................................2-21

Closing Upper Front Window....................................................................................................2-22

Removing and Storing the Lower Front Window......................................................................2-23

Opening Side Windows..............................................................................................................2-23

Opening and Closing the Roof Exit Cover.................................................................................2-24

Removing and Storing Fire Extinguisher (Model 230LCR)......................................................2-24

Rock Drill Start—Stop Selection Control Box (Model 230LCRD)..........................................2-25

Compressor Remote Instrument Control Panel (Model 230LCRD)..........................................2-26

Removing and Storing Rifle.......................................................................................................2-26

J-Hooks......................................................................................................................................2-27

Toolbox Security Hasp...............................................................................................................2-27

Decontamination Kit Bracket.....................................................................................................2-28

Vandal Protection Panel Storage................................................................................................2-28

Adjusting the Seat......................................................................................................................2-29

Adjusting the Armrest................................................................................................................2-30

Seat Belt.....................................................................................................................................2-30

Operator’s Manual Compartment...............................................................................................2-30

Chapter 3 Break-In

Engine Break-In Oil...................................................................................................................3-1

Every 4 Hours.............................................................................................................................3-1

iii

Page 7

Every 10 Hours or Daily ............................................................................................................3-2

After the First 50 Hours..............................................................................................................3-2

After the First 100 Hours............................................................................................................3-3

Chapter 4 Pre-Start Inspection

Inspect Machine Daily Before Starting......................................................................................4-1

Chapter 5 Operating the Engine

Check Instruments Before Starting............................................................................................5-1

Level Check................................................................................................................................5-1

Starting the Engine.....................................................................................................................5-2

Using Booster Batteries—24 Volt System................................................................................. 5-3

Slave Receptacle—24 Volt System............................................................................................5-4

Starting Fluid (Cold Weather Starting Aid) ...............................................................................5-5

Using the Arctic Starter ..............................................................................................................5-7

Starting the Arctic Starter...........................................................................................................5-8

Check Instruments After Starting...............................................................................................5-8

Warming the Machine................................................................................................................5-9

Cold Weather Warm-Up ............................................................................................................5-10

Stopping the Engine...................................................................................................................5-11

TM 5-3805-280-10

TABLE OF CONTENTS (Continued)

Page

Chapter 6 Driving the Machine

Steering the Machine Using Pedals....................................................................................6-1

Steering the Machine Using Levers ...........................................................................................6-3

Removing Propel Levers............................................................................................................6-5

Propel Speed Switch...................................................................................................................6-6

Travel Alarm and Travel Alarm Cancel Switch.........................................................................6-6

Parking the Machine...................................................................................................................6-7

Parking Machine During Freezing Weather...............................................................................6-8

Lock All Compartments.............................................................................................................6-8

Chapter 7 Operating the Machine

Control Levers............................................................................................................................7-1

Control Lever Pattern Conversion..............................................................................................7-3

Control Levers John Deere Pattern.............................................................................................7-5

Pilot Control Shut-Off Lever......................................................................................................7-6

Auto-Idle Switch........................................................................................................................7-7

Mode Selection Switch...............................................................................................................7-8

Power Boost Switch...................................................................................................................7-8

E (Economy) Mode....................................................................................................................7-9

H/P (High Power) Mode ............................................................................................................7-10

Standard Mode...........................................................................................................................7-10

Operating Tips............................................................................................................................7-11

Driving Machine ........................................................................................................................7-11

Driving on Slopes.......................................................................................................................7-12

Driving Down a Slope................................................................................................................7-12

Driving Up a Slope.....................................................................................................................7-12

Driving Up a Steep or Slippery Slope—Boom on Uphill End of Machine................................7-13

Driving Up a Steep or Slippery Slope—Boom on Downhill End of Machine...........................7-13

Moving Machine off an Embankment........................................................................................7-14

Leveling Machine.......................................................................................................................7-15

Using Quick-Disconnect Hitch...................................................................................................7-16

Two Way Hydraulic Thumb Foot Pedal (Model 230LCR)........................................................7-20

Using Hydraulic Thumb.............................................................................................................7-21

Using Bucket..............................................................................................................................7-23

iv

Page 8

TM 5-3805-280-10

TABLE OF CONTENTS (Continued)

Page

Planning Spoil Piles ................................................................................................................... 7-25

Trenching ...................................................................................................................................7-25

Backfilling..................................................................................................................................7-27

Truck Loading............................................................................................................................7-28

Operating in Water and Mud......................................................................................................7-29

Clean Track Frame Area............................................................................................................ 7-29

Lifting.........................................................................................................................................7-30

Air Compressor - Operating Instructions...................................................................................7-32

Using Quick-Coupler Type Attachments...................................................................................7-37

Rock Drill Attachment (Model 230LCRD)................................................................................ 7-38

Install Rock Drill........................................................................................................................ 7-38

Remove Rock Drill.....................................................................................................................7-41

Operating the Rock Drill Attachment.........................................................................................7-43

Remote Control Operator’s Panel ..............................................................................................7-43

Rod Changer...............................................................................................................................7-45

Start Up ......................................................................................................................................7-49

Travelling...................................................................................................................................7-50

Drilling.......................................................................................................................................7-51

Shut Down..................................................................................................................................7-53

Lower Boom With Engine Stopped...........................................................................................7-54

Using Hydraulic Hand Tools Hose Reel....................................................................................7-55

Using Hydraulic Hand Tools Flow Rate Valve and Switch.......................................................7-55

Using Hand Held Air Tools........................................................................................................7-55

Chapter 8 Transporting

Loading Machine on a Trailer....................................................................................................8-1

Tiedowns....................................................................................................................................8-2

Fasten Machine to Trailer ..........................................................................................................8-3

Loading and Fastening Rock Drill on a Trailer..........................................................................8-6

Fasten Machine to Rail Car (Model 230LCR) ...........................................................................8-8

Fasten Machine and Rock Drill to Rail Car (Model 230LCRD)................................................8-10

Unloading Machine From Trailer...............................................................................................8-12

Towing Machine ........................................................................................................................8-13

Lifting the Machine....................................................................................................................8-14

Chapter 9 Fuels and Lubricants

Diesel Fuel .................................................................................................................................9-1

Lubricity of Diesel Fuels............................................................................................................9-1

Low Sulfur Diesel Fuel Conditioner..........................................................................................9-2

Diesel Fuel Storage ....................................................................................................................9-2

Fuel Tank ...................................................................................................................................9-3

Do Not Use Galvanized Containers ...........................................................................................9-3

Diesel Engine and Pump Gearbox Oils......................................................................................9-4

Hydraulic Oil..............................................................................................................................9-5

Swing Gearbox and Propel Gearbox Oils...................................................................................9-6

Track Roller, Front Idler, and Carrier Roller Oil .......................................................................9-6

Track Adjuster, Working Tool Pivot, Swing Bearing, and Swing Bearing Gear Grease...........9-7

Oil Filters ...................................................................................................................................9-7

Rock Drill Lubricants Specifications.........................................................................................9-8

Air Compressor Lubricants........................................................................................................9-10

Lubricant Storage.......................................................................................................................9-11

Alternative and Synthetic Lubricants.........................................................................................9-11

Mixing of Lubricants..................................................................................................................9-12

Factory/Initial Fill Lubricants ....................................................................................................9-12

v

Page 9

TABLE OF CONTENTS (Continued)

Chapter 10 Periodic Maintenance—Excavator

Service Your Machine at Specified Intervals...........................................................................10-1

Check the Hour Meter Regularly .............................................................................................10-1

Use Correct Fuels and Lubricants............................................................................................10-1

Prepare Machine for Maintenance............................................................................................10-2

Open Access Doors for Service................................................................................................10-3

Open Hood for Service.............................................................................................................10-4

Chapter 11 Maintenance—As Required

Sampling Engine Oil (GRP NO. 0400)....................................................................................11-1

Sampling Hydraulic Oil (GRP NO. 3360) ...............................................................................11-2

Clean Fuel Tank Inlet Screen (GRP NO. 0560).......................................................................11-3

Drain Fuel Tank Sump (GRP NO. 0560).................................................................................11-3

Clean Radiator Air Inlet Screens (GRP NO. 0511) ..................................................................11-4

Drain Water Separator (GRP NO. 0560)..................................................................................11-4

Clean Air Cleaner Dust Unloader Valve (GRP NO. 0521)......................................................11-5

Check Track Sag (GRP NO. 0132)..........................................................................................11-5

Adjusting Track Sag (GRP NO. 0132).....................................................................................11-6

Windshield Washer Fluid Level...............................................................................................11-7

TM 5-3805-280-10

Page

Chapter 12 Maintenance—Every 10 Hours or Daily

Check Engine Oil Level (GRP NO. 0400)...............................................................................12-1

Check Recovery Tank Coolant Level (GRP NO. 0510)...........................................................12-2

Check Hydraulic Oil Level (GRP NO. 3360) ..........................................................................12-3

Chapter 13 Maintenance—Every 50 Hours

Grease Working Tool Pivots (GRP NO. 3302)........................................................................13-1

Chapter 14 Maintenance—Every 250 Hours

Check Swing Gearbox Oil Level (GRP NO. 4351)..................................................................14-1

Drain Hydraulic Tank Sump (GRP NO. 3364)........................................................................14-1

Check Pump Drive Gearbox Oil Level (GRP NO. 3361)........................................................14-2

Change Engine Oil and Replace Filter (GRP NO. 0407).........................................................14-3

Check Radiator Coolant Level.................................................................................................14-5

Check Battery Electrolyte Level and Terminals (GRP NO. 1671)...........................................14-6

Check Propel Gearbox Oil Level (GRP NO. 0250).................................................................14-8

Clean Dusty Primary Element (GRP NO. 0521)......................................................................14-9

Inspect Element (GRP NO. 0521)............................................................................................14-10

Chapter 15 Maintenance—Every 500 Hours

Grease Swing Bearing (GRP NO. 4353)..................................................................................15-1

Grease Swing Bearing Gear (GRP NO. 4353).........................................................................15-2

Replace Final Fuel Filter (GRP NO. 0420)..............................................................................15-3

Replace Primary Fuel Filter (Water Separator) (GRP NO. 0560)............................................15-4

Check Air Intake Hoses (GRP NO. 0521)................................................................................15-5

Replace Hydraulic Oil Filter (GRP NO. 3360) ........................................................................15-6

Add Coolant Conditioner to Radiator (GRP NO. 0510) ..........................................................15-8

Chapter 16 Maintenance—Every 1000 Hours

Change Swing Gearbox Oil (GRP NO. 4351)..........................................................................16-1

Change Pilot Control Oil Filter (GRP NO. 3362)....................................................................16-1

Change Pump Drive Gearbox Oil (GRP NO. 3360) ................................................................16-2

Clean the Engine Crankcase Ventilation Tube.........................................................................16-3

Check and Adjust Engine Valve Lash (Clearance)..................................................................16-3

Firing Order 6-Cylinder Engine...............................................................................................16-5

vi

Page 10

TABLE OF CONTENTS (Continued)

Check Engine Speeds...............................................................................................................16-6

Engine Speed Learning Procedure...........................................................................................16-7

Change Air Cleaner Elements (GRP NO. 0521)......................................................................16-7

Inspect Fan Belt (GRP NO. 0429)............................................................................................16-8

Replace Air Cleaner Dust Valve (GRP NO. 0521)..................................................................16-8

Chapter 17 Maintenance—Every 2000 Hours

Drain Cooling System (GRP NO. 0510)..................................................................................17-1

Diesel Engine Coolant (GRP NO. 0510)..................................................................................17-2

Cooling System Fill and Deaeration Procedure (GRP NO. 0510) ...........................................17-3

Change Propel Gearbox Oil .....................................................................................................17-4

Change Hydraulic Oil...............................................................................................................17-5

Chapter 18 Maintenance—Air Compressor

General.....................................................................................................................................18-1

Scheduled Maintenance............................................................................................................18-1

Compressor Oil Maintenance...................................................................................................18-1

Air Cleaner...............................................................................................................................18-2

Gauges......................................................................................................................................18-3

Fuel Tank .................................................................................................................................18-3

Battery......................................................................................................................................18-3

Automatic Shutdown System...................................................................................................18-3

Compressor Oil Cooler.............................................................................................................18-4

Radiator....................................................................................................................................18-4

Hoses........................................................................................................................................18-4

Compressor Oil Filters.............................................................................................................18-5

Fasteners...................................................................................................................................18-6

Compressor Oil ........................................................................................................................18-6

Receiver-Separator Systems.....................................................................................................18-6

Scavenge Line..........................................................................................................................18-6

Cooling Fan Drive ....................................................................................................................18-6

Oil Separator Element..............................................................................................................18-7

Exterior Finish Care.................................................................................................................18-8

Lubrication...............................................................................................................................18-10

TM 5-3805-280-10

Page

Chapter 19 Maintenance—Rock Drill Attachment

First Oil Change.......................................................................................................................19-1

When Required.........................................................................................................................19-3

Adjustment of Drilling Automatisms.......................................................................................19-4

Replacing Rock Drill Dust Collector Filters ............................................................................19-8

Daily Maintenance Hydraulic Dust Collector..........................................................................19-9

Daily.........................................................................................................................................19-10

Every 50 Hours.........................................................................................................................19-10

Every 1000 Hours.....................................................................................................................19-11

Every 2000 Hours.....................................................................................................................19-11

Drifter Maintenance .................................................................................................................19-12

Chapter 20 Maintenance

Do Not Service Injection Nozzles............................................................................................20-1

Do Not Change Injection Pump ...............................................................................................20-1

Bleeding the Fuel System.........................................................................................................20-2

Precautions for Alternator and Regulator.................................................................................20-2

Service Batteries Carefully.......................................................................................................20-3

Checking Electrolyte Specific Gravity.....................................................................................20-5

Using Battery Charger..............................................................................................................20-6

vii

Page 11

TM 5-3805-280-10

TABLE OF CONTENTS (Continued)

Page

Replacing Batteries (GRP NO. 1671)......................................................................................20-7

Removing Batteries (GRP NO. 1671)......................................................................................20-7

Welding on Machine................................................................................................................20-8

Adding 12-Volt Accessories ....................................................................................................20-9

Replacing Fuses........................................................................................................................20-9

Fuse (Blade-Type) Color Codes...............................................................................................20-11

Checking Travel Alarm System (GRP NO. 1671)...................................................................20-11

Replacing Bucket Teeth (GRP NO. 3302)...............................................................................20-12

Removing the Bucket (GRP NO. 3302)...................................................................................20-13

Replacing Bucket Tooth Tip—Heavy-Duty Bucket (GRP NO. 3302) ....................................20-14

Do Not Service Control Valves, Cylinders, Pumps or Motors.................................................20-14

Track Sag General Information................................................................................................20-15

Hardware Torque Specifications..............................................................................................20-15

Check Track Shoe Torque........................................................................................................20-16

Unified Inch Bolt and Cap Screw Torque Values....................................................................20-17

Metric Bolt and Cap Screw Torque Values..............................................................................20-18

Additional Metric Cap Screw Torque Values..........................................................................20-19

Check Oil Lines and Fittings....................................................................................................20-20

Service Recommendations for O-Ring Boss Fittings...............................................................20-21

Service Recommendations for Flat Face O-Ring Seal Fittings................................................20-23

Service Recommendations for 37° Flare and 30° Cone Seat Connectors................................20-24

Service Recommendations for Flared Connections—Straight or Tapered Threads.................20-25

Service Recommendations for Inch Series Four Bolt Flange Fittings......................................20-26

Service Recommendations for Metric Series Four Bolt Flange Fitting....................................20-28

Chapter 21 Operational Checkout

Operational Checkout...............................................................................................................21-1

Operator Station Checks—Key Switch On, Engine Off ..........................................................21-2

Operator Station Checks—Engine On......................................................................................21-4

Hydraulic System Checks ........................................................................................................21-8

Undercarriage Checks..............................................................................................................21-15

Hydraulic Thumb Check..........................................................................................................21-17

Quick-Disconnect Hitch Checks..............................................................................................21-17

Accessories Checks..................................................................................................................21-18

Air Conditioning Checks..........................................................................................................21-20

Seat, Doors, Windows, Latches, and Locks Checks.................................................................21-23

Coolant Checks ........................................................................................................................21-29

Chapter 22 Troubleshooting

Using Troubleshooting Charts..................................................................................................22-1

Engine ......................................................................................................................................22-2

Electrical System......................................................................................................................22-8

Hydraulic System.....................................................................................................................22-14

Chapter 23 Storage

Prepare Machine for Storage ....................................................................................................23-1

Quick-Disconnect Hitch Storage Procedure.............................................................................23-2

Monthly Storage Procedure......................................................................................................23-3

Chapter 24 Specifications

230LCR/LCRD........................................................................................................................24-1

230LCR/LCRD Working Ranges.............................................................................................24-3

230LCR/LCRD........................................................................................................................24-4

230LCR/LCRD Drain and Refill Capacities............................................................................24-5

viii

Page 12

TM 5-3805-280-10

TABLE OF CONTENTS (Continued)

Page

230LCR/LCRD Lift Capacity—KG (LB)................................................................................24-6

Rock Drill Attachment - Technical Specifications...................................................................24-7

Air Compressor General Data..................................................................................................24-8

Appendix A Operator Preventive Maintenance Checks and Services (PMCS) .......................................A-1

Appendix B Components of End Item and Basic Issue Items List............................................................ B-1

Appendix C References.................................................................................................................................C-1

ix

Page 13

TM 5-3805-280-10

WARRANTY

1. General. This sectio n explains the contractor’s warranty for the Hydraulic Excavator (HYEX),

including all of its components and subassemblies. It also contains information, instructions, methods

and forms required to obtain services and/or supplies and for processing claims for items covered

under warranty for the HYEX. If additional warranty i nformation is required for the HYEX, contact

your local Warranty Control Office/Officer (WARCO) or TACOM-WRN Logistics Assistance

Representative (LAR). If your WARCO or TACOM LAR is not available, contact TACOM-WRN.

The numbers at TACOM to call are DSN 786-7215/(810) 574-7215, DSN 786-7420/(810) 574-7420,

or DSN 786-8297/(810) 574-8297. The caller should be prepared to provide: (1) name, (2) telephone

number and/or electronic address, (3) complete unit designation, (4) identification of the vehicle to

include serial number(s) and (5) a brief description of the problem.

2. Coverage Specific. The information and data contained in this Technical Manual applies to the U.S.

Army’s Hydraulic Excavator (HYEX), model number 230LCR, NSN 3805-01-463-0804 and model

number 230LCRD, NSN 3805-01-463-0806. The HYEX is manufactured by Deere & Company,

Moline, IL under contract number DAAE07-98-D-S009.

3. Claim Procedures. DA Form 2407, along with information and instructions provided by the

contractor at time of delivery of the HYEX, shall be used to process warranty claims.

4. Clai m Denial/Disputes. All denials or disputes will be handled by TACOM. The contact point for

warranty claim denials or disputes is:

Commander

U.S. Army T ank-Automo t i ve and Armaments Command

ATTN: AMSTA-LC-CJBB

Warren, MI 48397-5000

Telephone: DSN 786-5314

Commercial: (810) 574-5314

5. Local WARCO. Upo n completion of warranty actions by the contractor, the WARCO shall complete

and provide a copy of DA Form 2407 to TACOM for information and warranty tracking purposes

only. NOTE: The DA Form 2407 shall be stamped or otherwise clearly marked "FOR

INFORMATION ONLY". Send the completed DA Form 2407 to:

Commander

U.S. Army T ank-Automo tive and Armaments Command

ATTN: AMSTA-LC-CJCB

Warren, MI 48397-5000

Telephone: DSN 786-7215

Commercial: (810) 574-7215

Forms may also be faxed to TACOM. Fax the forms to: DSN 786-5605, Commercial - (810) 574-

5605. Include ATTN: AMSTA-LC-CJCB on all related materials being faxed to TACOM.

x

Page 14

INTRODUCTION

TM 5-3805-280-10

READ THIS MANUAL carefully to learn how

to operate and service your machine

correctly. Failure to do so could result in

personal injury or equipment damage. This

manual and safety signs on your machine

may also be available in other languages.

(See your John Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED

a permanent part of your machine and

should remain with the machine when you

sell it.

MEASUREMENTS in this manual are given

in both metric and customary U.S. unit

equivalents. Use only correct replacement

parts and fasteners. Metric and inch

fasteners may require a specific metric or

inch wrench.

RIGHT-HAND AND LEFT-HAND sides are

determined by facing in the direction of

forward travel.

GROUP NUMBERS (e.g., GRP NO. XXXX)

following maintenance task titles in the

Table of Contents refer to the John Deere

Functional Group Coding system.

WARRANTY is provided as part of John

Deere’s support program for customers who

operate and maintain their equipment as

described in this manual. The warranty is

explained on the warranty certificate, which

you should have received from your dealer .

This warranty provides you the assurance

that John Deere will back its products where

defects appear within the warranty period. In

some circumstances, John Deere also

provides field improvements, often without

charge to the customer, even if the product

is out of warranty. Should the equipment be

abused, or modified to change its

performance beyond the original factory

specifications, the warranty will become void

and field improvements may be denied.

Setting fuel delivery above specifications or

otherwise overpowering machines will result

in such action.

CALIFORNIA PROPOSITION 65 WARNING

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects and

other reproductive harm.

xi

Page 15

TM 5-3805-280-10

BLANK

xii

Page 16

TM 5-3805-280-10

CHAPTER 1

SAFETY AND SAFETY SIGNS

Page 17

TM 5-3805-280-10

BLANK

Page 18

1-1

JOHNDEEREEXCAVATORSAFETYFEATURES

Safety

TM 5-3805-280-10

TX,05,DH5854 –19–15AUG97–1/1

T111123 –19–14AUG97

Page 19

TM 5-3805-280-10

Safety

RECOGNIZESAFETYINFORMATION

Thisisthesafety-alertsymbol.Whenyouseethissymbol

onyourmachineorinthismanual,bealerttothe

potentialforpersonalinjury.

Followrecommendedprecautionsandsafeoperating

practices.

UNDERSTANDSIGNALWORDS

Asignalword—DANGER,WARNING,orCAUTION—is

usedwiththesafety-alertsymbol.DANGERidentifiesthe

mostserioushazards.

DANGERorWARNINGsafetysignsarelocatednear

specifichazards.Generalprecautionsarelistedon

CAUTIONsafetysigns.CAUTIONalsocallsattentionto

safetymessagesinthismanual.

DX,ALERT –19–03MAR93–1/1

T81389 –UN–07DEC88

TS187 –19–30SEP88

DX,SIGNAL–19–03MAR93–1/1

FOLLOWSAFETYINSTRUCTIONS

Carefullyreadallsafetymessagesinthismanualandon

yourmachinesafetysigns.Keepsafetysignsingood

condition.Replacemissingordamagedsafetysigns.Be

surenewequipmentcomponentsandrepairpartsinclude

thecurrentsafetysigns.

Learnhowtooperatethemachineandhowtouse

controlsproperly.Donotletanyoneoperatewithout

instruction.

Keepyourmachineinproperworkingcondition.

Unauthorizedmodificationstothemachinemayimpairthe

functionand/orsafetyandaffectmachinelife.

TS201 –UN–23AUG88

TX,05,DY336–19–15MAY96–1/1

1-2

Page 20

TM 5-3805-280-10

Safety

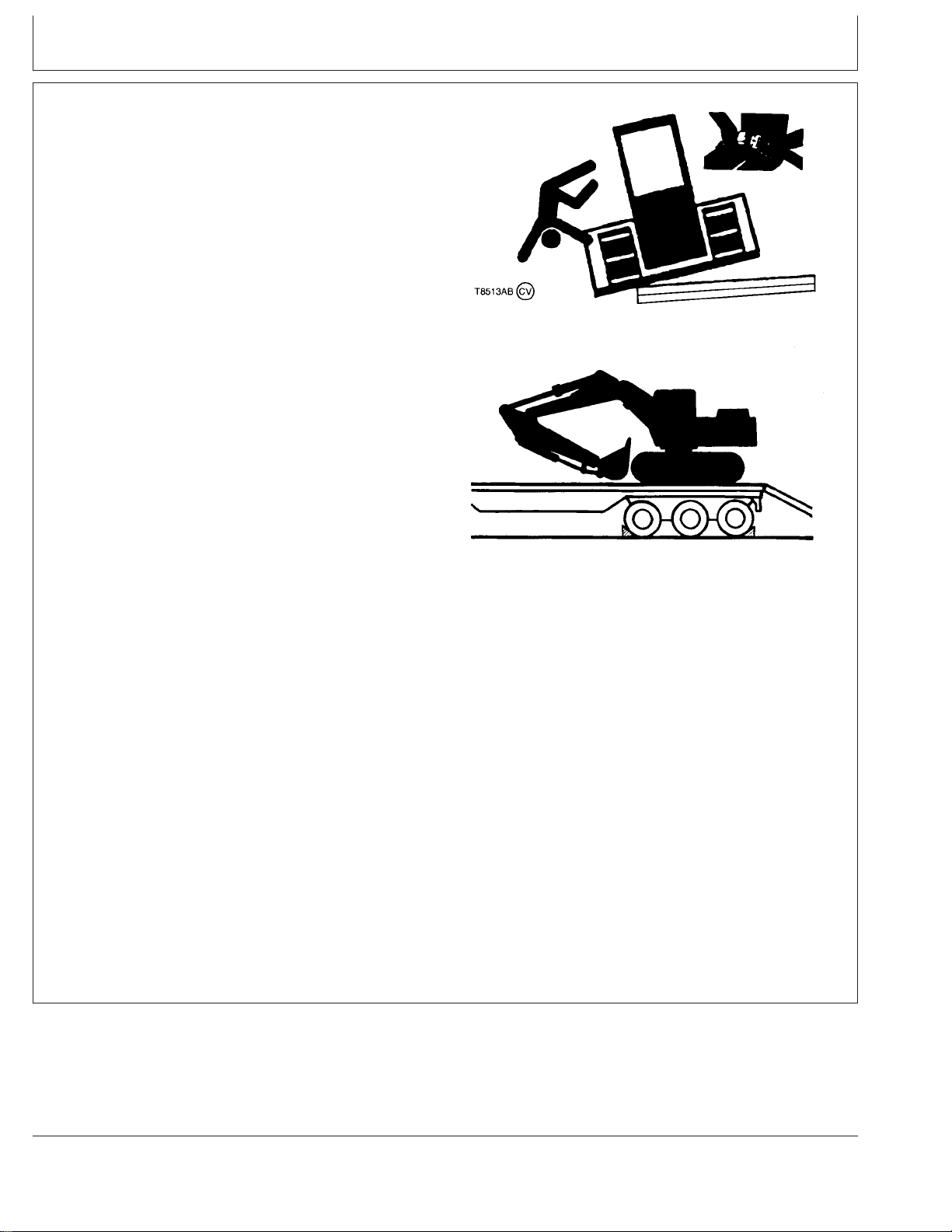

AVOIDINJURYFROM:

LOADINGMACHINEONATRAILER,

FASTENINGMACHINETOTRAILER,

UNLOADINGMACHINEFROMTRAILER

---------------------------------ALWAYSUSECAUTIONWHENLOADING

ANDUNLOADINGMACHINESONATRAILER

---------------------------------ALWAYSKNOWANDFOLLOWTHE

RECOMMENDEDPROCEDURESFORTHE

MACHINE,BECAUSEALLMACHINESARE

NOTLOADED,FASTENED,ANDUNLOADED

THESAMEWAY

---------------------------------ALWAYSKEEPBYSTANDERSCLEAROF

THEAREA

T8513AB –UN–28JUN95T7405BJ –UN–29NOV90

Toavoidinjury:

Keepthetrailerbedclean.

Parkthetraileronafirm,hard,levelsurfacethatwillnot

givewaywhentheweightofthemachineisonthetrailer.

Putchockblocksagainsttruckwheels.

Usearamporloadingdock.Rampsmustbestrong

enoughtoadequatelyhandletheloadandhavealow

angleandcorrectheight.

Ifmachineisequippedwithaseatbelt,fastenitbefore

startingtheengine.

Drivemachineonorofftherampslowly.

fastenchainsorcablestomachinetracksortrackchain

links.Donotplacechainsorcableoveroragainst

hydrauliclinesorhoses.

1-3

TX,05,FF1808 –19–28JUN90–1/1

Page 21

TM 5-3805-280-10

Safety

AVOIDINJURYFROMBACKOVER

ACCIDENTS

---------------------------------BEFOREMOVINGMACHINE,BESUREALL

PERSONSARECLEAROFAREA

---------------------------------ALWAYSBEALERTFORBYSTANDERS

MOVINGINTOTHEWORKAREA.USEHORN

OROTHERSIGNALTOWARNBYSTANDERS

BEFOREMOVINGMACHINE

---------------------------------WHENUSINGASIGNALPERSON,KEEP

PERSONINVIEWATALLTIMES,BESURE

SIGNALPERSONISCLEARBEFORE

BACKINGUP

Toavoidbackoveraccidents:

T7241AY –UN–21FEB90

Alwayslookaroundbeforeyoubackup.Besurethat

everyoneisintheclear.

Keeptravelalarminworkingcondition.

Useasignalpersonwhenbackingupifviewis

obstructed.Alwayskeepsignalpersoninview.

Learnthemeaningofallflags,signs,andmarkingsused

onthejobandwhohastheresponsibilityforsignaling.

Keepwindows,mirrors,andlightscleanandingood

condition.

Dust,heavyrain,fog,etc.,canreducevisibility.As

visibilitydecreases,reducespeedanduseproperlighting.

Readandunderstandtheoperatinginstructionsinthis

operator’smanual.

1-4

TX,05,DY337–19–15MAY96–1/1

Page 22

TM 5-3805-280-10

AVOIDINJURYFROMROLLAWAY

ACCIDENTS

-------------------------------TOPREVENTROLLAWAY,ALWAYSMAKE

SUREMACHINEISPROPERLYSECURED

BEFORELEAVINGOPERATOR’SSEAT

-------------------------------DEATHORSERIOUSINJURYMAYRESULT

IFYOUATTEMPTTOMOUNTORSTOPA

MOVINGMACHINE

Toavoidrollaways:

Selectlevelgroundwhenpossibletoparkmachine.

Pullpilotcontrolshut-offlevertolockedposition.

Lowerallequipmenttoground.

Safety

T7241AZ –UN–21FEB90

Stoptheengine.

Blockalltracksifyoumustparkonagrade.Position

machinetopreventrolling.

Parkareasonabledistancefromothermachines.

Readandunderstandtheoperatinginstructionsinthis

operator’smanual.

INSPECTMACHINE

TX,05,FF2433–19–22MAY91–1/1

Inspectyourmachinecarefullyeachdaybywalking

arounditbeforeyoustartit.(SeePre-StartInspection

Chapter.)

T82,BHSA,CL–19–14MAR90–1/1

T6607AQ –UN–18OCT88

1-5

Page 23

TM 5-3805-280-10

Safety

USEHANDHOLDSANDSTEPS

Fallingisoneofthemajorcausesofpersonalinjury.

Whenyougetonandoffthemachine,alwaysmaintaina

threepointcontactwiththestepsandhandrailsandface

themachine.Donotuseanycontrolsashandholds.

Neverjumponoroffthemachine.Nevermountor

dismountamovingmachine.

Becarefulofslipperyconditionsonplatforms,steps,and

handrailswhenleavingthemachine.

USESEATBELT

Alwaysusetheseatbeltwhenoperatingyourmachine.

T6981AN –UN–15JUN89

TX,05,DH832–19–16MAR92–1/1

TS175 –UN–23AUG88

TX,05,DH3732 –19–18AUG95–1/1

1-6

Page 24

TM 5-3805-280-10

Safety

MAINTAINSEATBELT

Keeptheseatbeltingoodcondition.

Thecompleteseatbeltassemblyshouldbereplaced

afterthreeyearsofusage,regardlessofappearance.

Betweenreplacementintervals:

Carefullyexaminebuckle,webbing,andattaching

hardware.

Besurethattheretractor,ifequipped,lockstoprevent

beltextensionafterlatchingbuckle.

Besurethatattachinghardwareisinplace.Tighten,if

necessary.

Replacetheseatbeltifitdoesnotoperateproperly,orifit

isdamaged,worn,ordeteriorated.

MOVEANDOPERATEMACHINESAFELY

Bystanderscanberunover.Knowthelocationof

bystandersbeforemoving,swinging,oroperatingthe

machine.

Alwayskeepthetravelalarminworkingcondition.It

warnspeoplewhenthemachinestartstomove.

Useasignalpersonwhenmoving,swinging,oroperating

themachineincongestedareas.Coordinatehandsignals

beforestartingthemachine.

TX,05,DH3729 –19–09AUG95–1/1

T7273AL –UN–08JUN90

TX,05,FF1806 –19–05OCT90–1/1

1-7

Page 25

TM 5-3805-280-10

Safety

OPERATEONLYFROMOPERATOR’SSEAT

Avoidpossibleinjuryormachinedamage.Donotstart

enginebyshortingacrossstarterterminals.

NEVERstartenginewhilestandingonground.Start

engineonlyfromoperator’sseat.

SECONDARYEXITS

Machinesequippedwithcabsareequippedwith

secondaryexits.Foradditionalsecondaryexitinformation,

seethetopics”SecondaryExitTool”and’OpeningUpper

Front(SecondaryExit)Window’inchapter10ofthis

manual.

OPERATEMACHINESAFELY

Clearallpersonsfromareaofoperationandmachine

movement.

Useyourseatbelt.

TX,05,FF1615 –19–14JUN90–1/1

T6607AO –UN–18OCT88

TX,05,DH5848 –19–13AUG97–1/1

Makesuretheworksitefootinghassufficientstrengthto

firmlysupportthemachine.Whenworkingclosetoan

excavation,positionmachinewithpropelmotorsatthe

rear.

Becautiousoftippingwhenworkingonfrozenground.

Temperatureincreaseswillcausegroundtobecomesoft,

makinggroundunstable.

Whendiggingdeep,avoidhittingbottomofboomor

bucketcylinderhosesagainsttheground.

Usethebucketonlyfordigging.Donotuseitasajack

hammerorwreckingball.

T7252AL –UN–08JUN90

TX,05,DH3730 –19–09AUG95–1/1

1-8

Page 26

DIGWITHCAUTION

Beforedigging,checkthelocationofcables,gaslines,

andwaterlines.

TM 5-3805-280-10

Safety

OPERATEWITHCAUTION

Avoidcontactofboomorarmandoverheadobstacles

whenyouoperatethemachine.

AVOIDTIPPING

Useyourseatbelt.

Whenoperatingonaslope,keepbucketlowtoground

andclosetomachine.Pointtracksuphill.

05,RR,592–19–12JUN90–1/1

T7252AJ –UN–08JUN90

T7286AJ –UN–08JUN90

TX,05,RR,602 –19–26FEB91–1/1

Avoidtippingthemachinewhenswingingheavyloads.

Reduceswingspeedasnecessary.

Becautiousoftippingwhenworkingonfrozenground.

Temperatureincreaseswillcausegroundtobecomesoft

andmakegroundtravelunstable.

T7273AE –UN–08JUN90

TX,05,DH3731 –19–09AUG95–1/1

1-9

Page 27

TM 5-3805-280-10

AVOIDPOWERLINES

Seriousinjuryordeathcanresultfromcontactwith

electriclines.

Nevermoveanypartofthemachineorloadcloserto

electriclinethan3m(10ft)plustwicethelineinsulator

length.

Safety

DRIVEMACHINESAFELY

Useyourseatbelt.

Beforemovingmachine,findoutwhichwaytomove

propelpedals/leversforthedirectionyouwanttogo.

Pushingdownonthefrontofthepropelpedalsorpushing

theleversmovesthemachinetowardstheidlers.

Keepthebucketontheuphillside,approximately30cm

(12in.)(A)aboveground,whengoingupordownhill.If

machinestartstosliporbecomeunstable,lowerthe

bucketimmediately.

TX,05,RR,594 –19–12JUN90–1/1

T7273AD –UN–08JUN90

T7273AG –UN–08JUN90

TX,05,DH3733 –19–09AUG95–1/1

BEWAREOFEXHAUSTFUMES

Preventasphyxiation.Engineexhaustfumescancause

sicknessordeath.

Ifyoumustoperateinabuilding,bepositivethereis

adequateventilation.Eitheruseanexhaustpipeextension

toremovetheexhaustfumesoropendoorsandwindows

tobringenoughoutsideairintothearea.

02T,05,J9 –19–07JAN91–1/1

T6458AO –UN–18OCT88

1-10

Page 28

PARKMACHINESAFELY

Beforeworkingonthemachine:

•Parkmachineonalevelsurface.

•Lowerbuckettotheground.

•Turnauto-idleswitchoff.

•Runenginewithenginerpmdialat1/3positionfor2

minutes.

•Moveenginerpmdialtoslowidleposition.

•TurnkeyswitchtoOFF.Removekeyfromswitch.

•Pullpilotcontrolshut-offlevertolockedposition.

•Allowenginetocool.

TM 5-3805-280-10

Safety

TX,05,DH5002 –19–28MAY96–1/1

KEEPRIDERSOFFMACHINE

Onlyallowtheoperatoronthemachine.Keepridersoff.

Ridersonmachinearesubjecttoinjurysuchasbeing

struckbyforeignobjectsandbeingthrownoffthe

machine.Ridersalsoobstructtheoperator’sviewresulting

inthemachinebeingoperatedinanunsafemanner.

TX,05,RR,560–19–05OCT90–1/1

T7273AH –UN–08JUN90

1-11

Page 29

TM 5-3805-280-10

Safety

OPERATEATTACHMENTSAFELY

Anattachmentmaychangethecapabilitiesofyour

machineinanyoralloftheseways:

•Saferangeofmotion

•Machinestability

•Hydraulicperformance

•Engineperformance

Readtheattachmentmanualtolearnhowtheattachment

works.

Inanareafreeofbystandersandobstructions,carefully

operatetheattachmenttolearntheavailablerangeof

motion.Anticipatehowobjectsmanipulatedbythe

attachment,ortheattachmentitself,maycontactthe

machine,especiallytheoperator’sstation.Consider

addingguardstothemachinetoprotecttheoperator,and

ifnecessary,topreventdamagetomachine.

Seeyourdealertomatchattachmentdemandsto

machineperformance.

HANDLEFLUIDSSAFELY—AVOIDFIRES

Handlefuelwithcare;itishighlyflammable.Donotrefuel

themachinewhilesmokingorwhennearopenflameor

sparks.Alwaysstopenginebeforerefuelingmachine.Fill

fueltankoutdoors.

TX,05,FF2883 –19–29OCT92–1/1

Continuedonnextpage

1-12

TX,05,FF1622 –19–14JUN90–1/2

TS202 –UN–23AUG88

Page 30

TM 5-3805-280-10

Safety

Storeflammablefluidsawayfromfirehazards.Donot

incinerateorpuncturepressurizedcontainers.

Makesuremachineiscleanoftrash,grease,anddebris.

Donotstoreoilyrags;theycanigniteandburn

spontaneously.

PREPAREFOREMERGENCIES

Bepreparedifafirestarts.

Keepafirstaidkitandfireextinguisherhandy.

Keepemergencynumbersfordoctors,ambulanceservice,

hospital,andfiredepartmentnearyourtelephone.

HANDLESTARTINGFLUIDSAFELY

Startingfluidishighlyflammable.

Keepallsparksandflameawaywhenusingit.Keep

startingfluidawayfrombatteriesandcables.

TX,05,FF1622 –19–14JUN90–2/2

TS227 –UN–23AUG88

TS291 –UN–23AUG88

DX,FIRE2–19–03MAR93–1/1

Topreventaccidentaldischargewhenstoringthe

pressurizedcan,keepthecaponthecontainer,andstore

inacool,protectedlocation.

Donotincinerateorpunctureastartingfluidcontainer.

TS1356 –UN–18MAR92

DX,FIRE3 –19–16APR92–1/1

1-13

Page 31

TM 5-3805-280-10

Safety

CLEANTRASHFROMMACHINE

Keepenginecompartment,radiator,batteries,hydraulic

lines,fueltank,andoperator’sstationclean.

Temperatureinenginecompartmentmaygoup

immediatelyafterengineisstopped.BEONGUARDFOR

FIRESDURINGTHISPERIOD.

Openaccessdoor(s)tocooltheenginefaster,andclean

enginecompartment.

T6669AG –UN–18OCT88

02T,05,J33–19–14MAR90–1/1

PROTECTAGAINSTFLYINGDEBRIS

Guardagainstinjuryfromflyingpiecesofmetalordebris;

weargogglesorsafetyglasses.

WEARPROTECTIVECLOTHING

Wearclosefittingclothingandsafetyequipment

appropriatetothejob.

Operatingequipmentsafelyrequiresthefullattentionof

theoperator.Donotwearradioormusicheadphones

whileoperatingmachine.

TX,05,FF1613 –19–14JUN90–1/1

T6642DK –UN–18OCT88

1-14

DX,WEAR2 –19–03MAR93–1/1

TS206 –UN–23AUG88

Page 32

TM 5-3805-280-10

PROTECTAGAINSTNOISE

Prolongedexposuretoloudnoisecancauseimpairment

orlossofhearing.

Wearasuitablehearingprotectivedevicesuchas

earmuffsorearplugstoprotectagainstobjectionableor

uncomfortableloudnoises.

Safety

HANDLECHEMICALPRODUCTSSAFELY

Directexposuretohazardouschemicalscancause

seriousinjury.Potentiallyhazardouschemicalsusedwith

yourmachineincludesuchitemsaslubricants,coolants,

paints,andadhesives.

AMaterialSafetyDataSheet(MSDS)providesspecific

detailsonchemicalproducts:physicalandhealthhazards,

safetyprocedures,andemergencyresponsetechniques.

ChecktheMSDSbeforeyoustartanyjobusinga

hazardouschemical.Thatwayyouwillknowexactlywhat

therisksareandhowtodothejobsafely.Thenfollow

proceduresandrecommendedequipment.

SeeyourauthorizeddealerforMSDS’sonchemical

productsusedwithyourmachine.

DX,NOISE–19–03MAR93–1/1

TS207 –UN–23AUG88

TS1132 –UN–26NOV90

1-15

TX,05,DH2500 –19–02OCT92–1/1

Page 33

TM 5-3805-280-10

Safety

WARNOTHERSOFSERVICEWORK

Unexpectedmachinemovementcancauseseriousinjury.

Beforeperforminganyworkonthemachine,attacha’Do

NotOperate’tagontherightcontrollever.

STAYCLEAROFMOVINGPARTS

Entanglementsinmovingpartscancauseseriousinjury.

Topreventaccidents,usecarewhenworkingaround

rotatingparts.

TX,05,RR,566 –19–23JUL91–1/1

T7273AP –UN–08JUN90

T7273AS –UN–08JUN90

TX,05,RR,572 –19–12JUN90–1/1

1-16

Page 34

TM 5-3805-280-10

Safety

SUPPORTMACHINEPROPERLY

Alwayslowertheattachmentorimplementtotheground

beforeyouworkonthemachine.Ifyoumustworkona

liftedmachineorattachment,securelysupportthe

machineorattachment.

Donotsupportthemachineoncinderblocks,hollowtiles,

orpropsthatmaycrumbleundercontinuousload.Donot

workunderamachinethatissupportedsolelybyajack.

Followrecommendedproceduresinthismanual.

TS229 –UN–23AUG88

DX,LOWER–19–04JUN90–1/1

SERVICECOOLINGSYSTEMSAFELY

Explosivereleaseoffluidsfrompressurizedcooling

systemcancauseseriousburns.

Shutoffengine.Onlyremovefillercapwhencoolenough

totouchwithbarehands.Slowlyloosencaptofirststop

torelievepressurebeforeremovingcompletely.

DX,RCAP –19–04JUN90–1/1

TS281 –UN–23AUG88

1-17

Page 35

TM 5-3805-280-10

PRACTICESAFEMAINTENANCE

Understandserviceprocedurebeforedoingwork.Keep

areacleananddry.

Neverlubricateorservicemachinewhileitismoving.

Keephands,feetandclothingfrompower-drivenparts.

Beforeservicingmachine.

•Parkmachineonalevelsurface.

•Lowerbuckettotheground.

•Turnauto-idleswitchoff.

•Runenginewithenginerpmdialat1/3speedfor2

minutes.

•Moveenginerpmdialtoslowidleposition.

•TurnkeyswitchtoOFF.Removekeyfromswitch.

•Attacha’DoNotOperate’tagontherightside

controllerlever.

•Pullpilotcontrolshut-offlevertolockedposition.

•Allowenginetocool.

Safety

Ifmaintenanceproceduremustbeperformedwithengine

running,donotleavemachineunattended.

Securelysupportanymachineelementsthatmustbe

raisedforservicework.Neverworkunderamachine

raisedbytheboom.Ifthemachinemustberaised,keep

a90-110°anglebetweenboomandarm.

Keepallpartsingoodconditionandproperlyinstalled.Fix

damageimmediately.Replacewornorbrokenparts.

Removeanybuildupofgrease,oil,ordebris.

Disconnectbatterygroundcable(-)beforemaking

adjustmentsonelectricalsystemsorweldingonmachine.

TS218 –UN–23AUG88

1-18

TX,05,DH5001 –19–28MAY96–1/1

Page 36

TM 5-3805-280-10

Safety

REMOVEPAINTBEFOREWELDINGOR

HEATING

Avoidpotentiallytoxicfumesanddust.

Hazardousfumescanbegeneratedwhenpaintisheated

bywelding,soldering,orusingatorch.

Doallworkoutsideorinawellventilatedarea.Disposeof

paintandsolventproperly.

Removepaintbeforeweldingorheating:

•Ifyousandorgrindpaint,avoidbreathingthedust.

Wearanapprovedrespirator.

•Ifyouusesolventorpaintstripper,removestripperwith

soapandwaterbeforewelding.Removesolventor

paintstrippercontainersandotherflammablematerial

fromarea.Allowfumestodisperseatleast15minutes

beforeweldingorheating.

AVOIDHEATINGNEARPRESSURIZEDFLUID

LINES

Flammablespraycanbegeneratedbyheatingnear

pressurizedfluidlines,resultinginsevereburnsto

yourselfandbystanders.Donotheatbywelding,

soldering,orusingatorchnearpressurizedfluidlinesor

otherflammablematerials.Pressurizedlinescanbe

accidentallycutwhenheatgoesbeyondtheimmediate

flamearea.

TS220 –UN–23AUG88

DX,PAINT–19–03MAR93–1/1

1-19

TS953 –UN–15MAY90

DX,TORCH –19–03MAR93–1/1

Page 37

TM 5-3805-280-10

Safety

AVOIDHIGH-PRESSUREFLUIDS

Escapingfluidunderpressurecanpenetratetheskin

causingseriousinjury.

Avoidthehazardbyrelievingpressurebefore

disconnectinghydraulicorotherlines.Tightenall

connectionsbeforeapplyingpressure.

Searchforleakswithapieceofcardboard.Protecthands

andbodyfromhighpressurefluids.

Ifanaccidentoccurs,seeadoctorimmediately.Anyfluid

injectedintotheskinmustbesurgicallyremovedwithina

fewhoursorgangrenemayresult.Doctorsunfamiliarwith

thistypeofinjuryshouldreferenceaknowledgeable

medicalsource.SuchinformationisavailablefromDeere

&CompanyMedicalDepartmentinMoline,Illinois,U.S.A.

X9811 –UN–23AUG88

PREVENTBATTERYEXPLOSIONS

Keepsparks,lightedmatches,andopenflameawayfrom

thetopofbattery.Batterygascanexplode.

Nevercheckbatterychargebyplacingametalobject

acrosstheposts.Useavolt-meterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm

batteryto16°C(60°F).

DX,FLUID –19–03MAR93–1/1

TS204 –UN–23AUG88

DX,SPARKS –19–03MAR93–1/1

1-20

Page 38

TM 5-3805-280-10

Safety

CLEANTHEMACHINEREGULARLY