Page 1

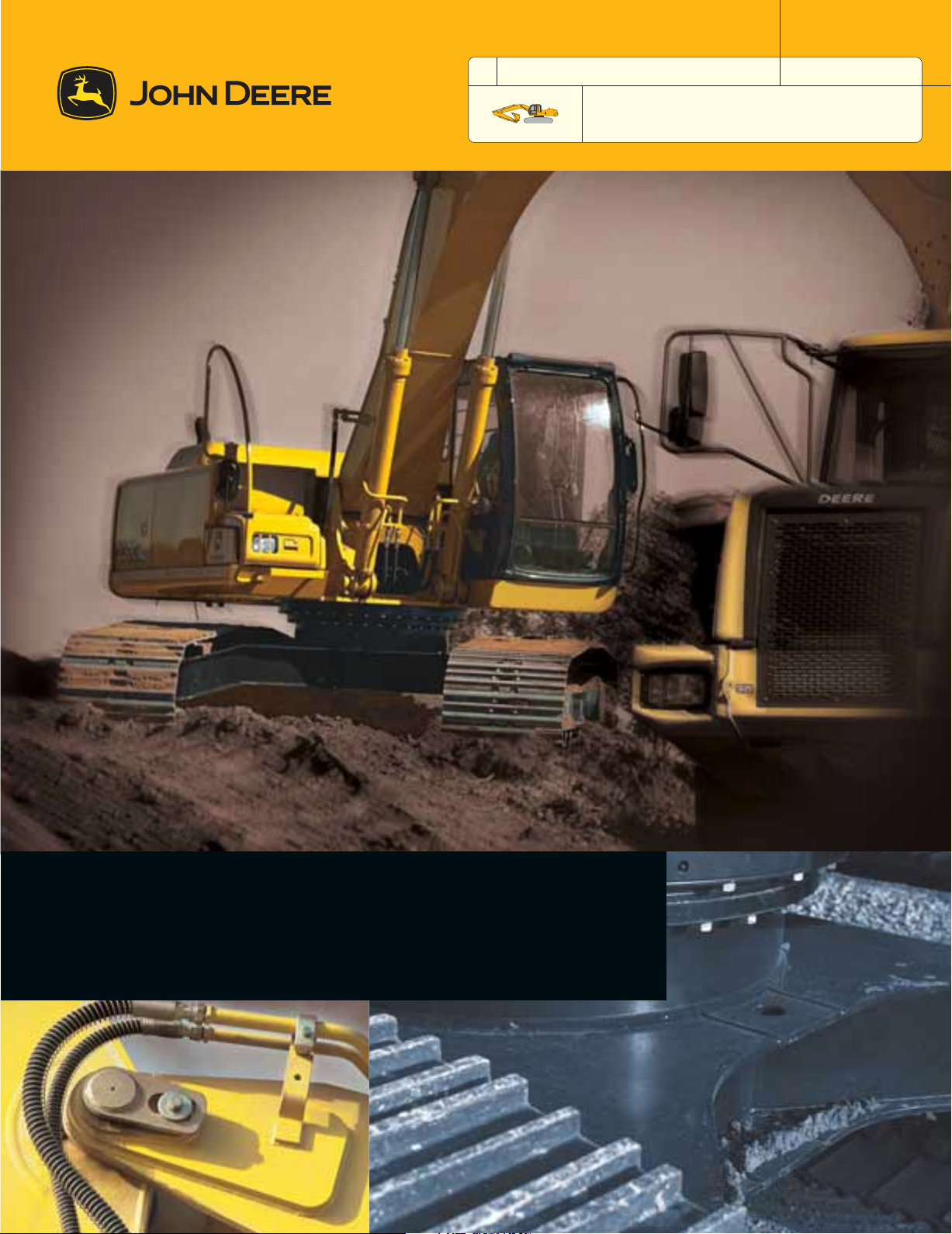

> 20- to 27-metric ton

> 141 to 177 horsepower

> 19-ft. 7-in. to 23-ft. 9-in. digging depth with standard arm

CONSTRUCTION EQUIPMENT

MODEL NO.

200C LC 230C LC 270C LC

EXCAVATORS

20-27 Metric Ton

Page 2

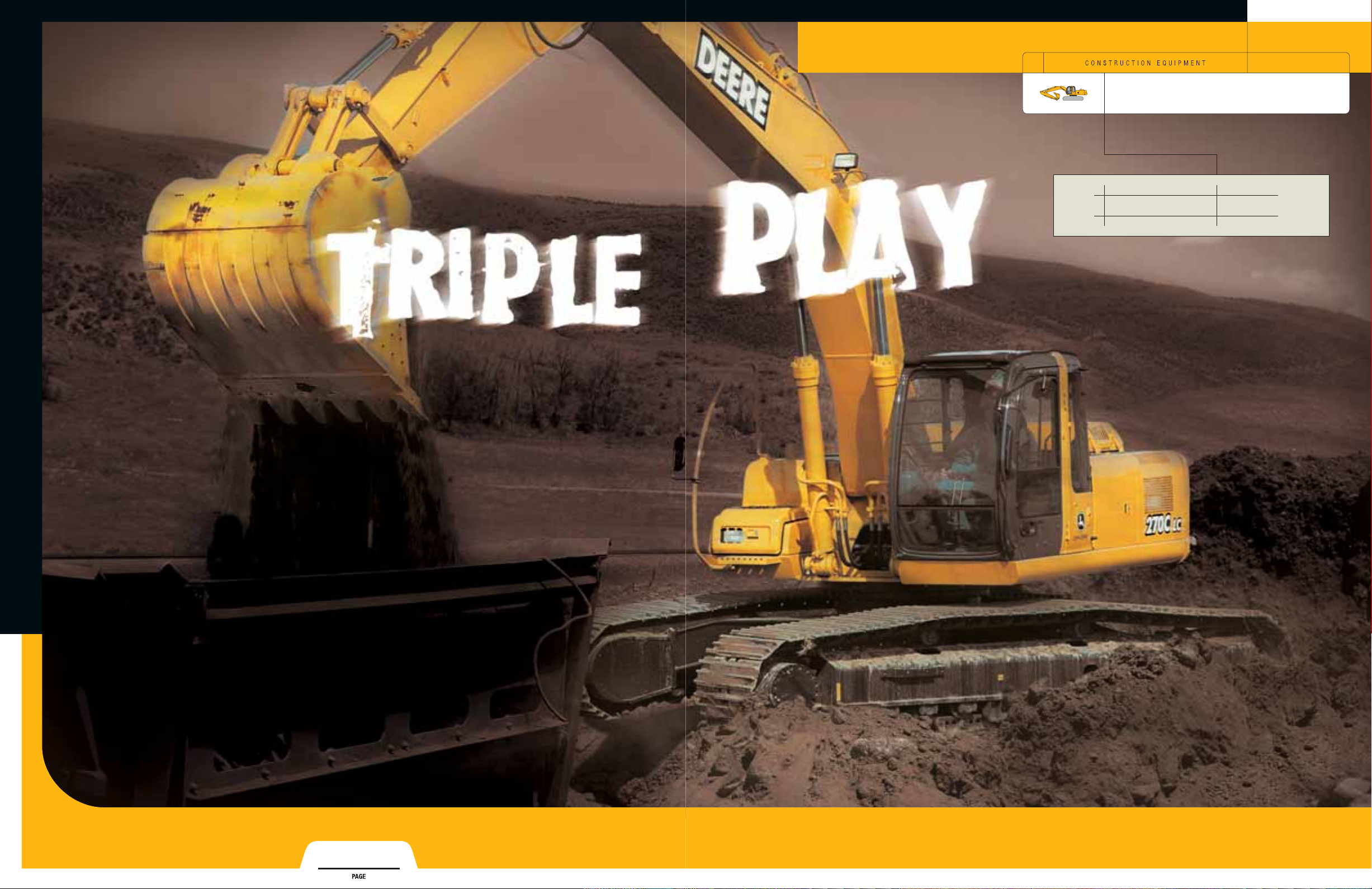

Reach for the stars…at ground level, the

200C LC has a 32-foot reach; the 230C LC

has a 34-foot, 10-inch reach; and the

270C LC has a 36-foot, 6-inch reach.

EXCAVATORS

SUBJECT:

PERFORMANCE

ARM OPTIONS:

You may feel like you’re at play instead of at work when you climb into the cab of one of our

new excavators. Whether you choose the 200C LC, the 230C LC, or the 270C LC, you’re sure

to feel the power, precision, and practicality we’ve packed into these 20–27-metric-ton machines.

TM

It’s all there: beefy Deere PowerTech

engines that meet the Environmental Protection Agency’s

“Tier II” emissions regulations without bashing your fuel budget; pinpoint metering and control

®

for your tightest tasks thanks to the Powerwize II

engine/hydraulic management system;

a sumptuous operator’s station with more visibility and ventilation; and serviceability features

200C LC

230C LC

270C LC

7 foot 3 inch (2.22 m)

9 foot 9 inch (2.96 m)

10 foot 2 inch (3.10 m)

What’s your game? These new excavators from Deere

are sized and powered to do just about everything.

Trenching? Site development? Dig basements? Bury

underground utilities? Aboveground applications?

Knock yourself out.

The Deere PowerTech 6.8-L, 414-cubic-inch engine

is turbocharged, air-cooled, and designed to give

you thousands of hours of efficient power.

9 foot 7 inch (2.91 m)

11 foot 10 inch (3.61 m)

12 foot 4 inch (3.75 m)

With Deere’s PowerTech engine

and efficient, gutsy hydraulics,

these excavators dig deep and

come up asking for more. The

20-metric-ton 200C LC boasts a

maximum digging depth of 21

feet, 11 inches. The 230C LC digs

down to 24 feet, 6 inches, while

the 270C LC maxes at 25 feet,

11 inches.

that make routine maintenance a stroll in the park.

You’ll find it so easy to be comfortable and productive in these excavators that by the end

of the day you might well hear someone calling you away from “play” — just like Mom used to.

But the first call has to be yours. Contact your dealer today and demo the model with the

right reach, horsepower, and lift capacity for you.

2-3

These “Cs” are easy to transport — usually without

permits — which means your customers won’t have

to play a “waiting game.” Just load and go!

Page 3

SUBJECT:

EXCAVATORS

There’s more joy

ENGINE & SYSTEMS

in our sticks.

Now this is cool: Deere’s cooling system

features a new airfoil fan that gives you

13 percent more cooling performance

while using 4 percent less horsepower.

The new fan also lowers noise level by

a significant 4 d(B)a.

The cooling system’s radiator is completely

welded from the tube to the header joint,

with a “square-wave” fin design to increase

heat transfer by 18 percent.

Deere PowerTech engines retain all the features

you’ve come to expect from Deere, and more.

Our wet-sleeve, individually replaceable cylinder

liners are admired throughout the industry for

their ability to eliminate hot spots.

Precision digging or laying pipe in just the right place shouldn’t be taxing. It should be

smooth and easy. Jerky controls, uneven bursts of power, or fatigue won’t be parts of your

workday due to Deere’s exclusive Powerwize II engine/hydraulic management system.

Powerwize technology lets the excavator arm be your “bionic” arm — an extension of your

own, only with a lot more muscle. It lets operators do precise work with a minimum of

effort — 10 percent less lever effort to be exact. There’s only one hydraulic mode, so just

select the desired engine mode, adjust the engine speed knob, and “go.”

We’ve increased hydraulic flow and

pressure to give you more

power and precision

at the end of the

boom. The new

design is very

“attachment

friendly.”

Each Deere engine has an Electronic Control Unit (ECU) that

serves as an electronic “brain.” By regulating the fuel-injection

process, the ECU ensures smooth, safe effort without wasting

fuel. It also acts like a safety net by decreasing engine power

and speed automatically if key readings like fuel pressure or

temperature drift into the red zone.

4-5

Page 4

SUBJECT:

EXCAVATORS

OPERATOR STATION

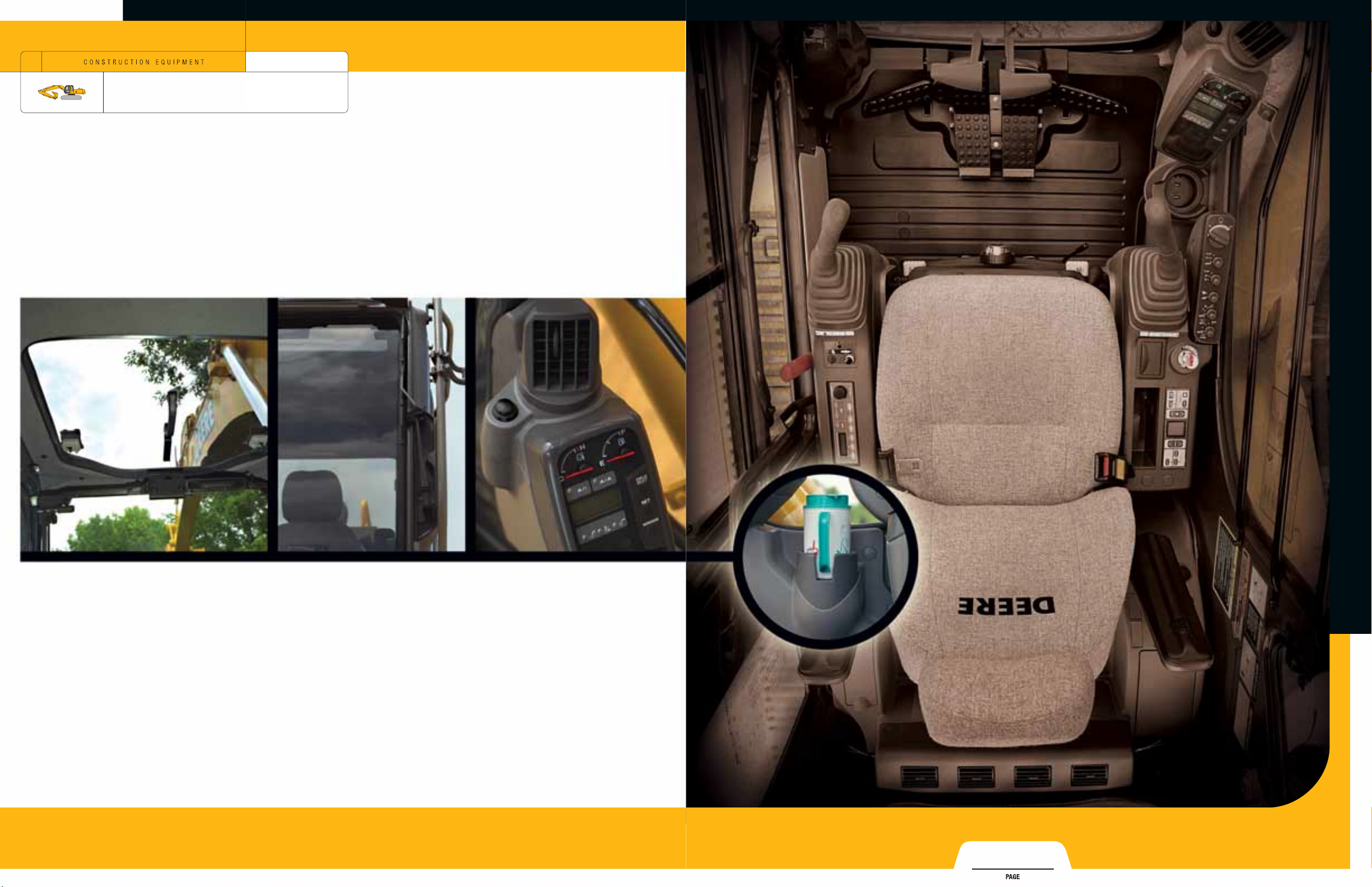

Windows to your world

Let the sunshine in — and the fresh air flow

freely — with the tinted sunroof hatch.

The windshield wiper cleans 25 percent

more glass for an even clearer look.

Then it disappears from view.

All the controls are within easy reach, and their

arrangement makes perfect ergonomic sense.

No stretching. No fatigue.

Adjustable vents are everywhere. You’ll

never have trouble setting and maintaining a comfortable temperature. All shift,

all week.

Seeing is indeed believing. Sit in the cab and take a good look around. Deere’s designed an operator’s

station with the ultimate view. There’s 28 percent more glass to look through, so you can see every

angle of the task at hand. Or at arm. Or at bucket. You get the picture.

And because your world can consist of tough 12-hour-days, we’ve made the cab a pleasant and

comfortable place to work. The new seat features adjustable lumbar support like you’d expect to

find in a best-in-class luxury car, and a “blend-air” automatic climate-control system keeps the

temperature just right. You might even start feeling a little self-indulgent when you see the built-in

beverage cooler, the “big-gulp” cupholder, and the 12-volt cellular phone jack. So, go ahead and

live a little. Why should work always have to feel like work?

Even the biggest coffee mugs fit

the new cupholder. We challenge

any convenience store to produce

something too big.

6-7

Page 5

Get to the point(s)!

EXCAVATORS

SUBJECT:

SERVICE

John Deere’s Customer Personal Service

(CPS) features a line-up of programs and

tools that can be customized to fit your

business. Whether it’s maintenance

programs, extended warranties, or

parts availability programs, CPS is a

one-on-one service that can bring

uptime to an all-new level. Talk to your

dealer about CPS today.

We stand behind these new excavators.

Want proof? Check out our StructurAll

warranty. It adds three years of coverage

on major structures as installed at the time

your excavator is manufactured. It’s free of

charge, for unlimited hours, on important

stuff like booms, arms, and mainframes.

™

The first hydraulic filter-change interval

is not until 4,000 hours, then every 2,000

hours after that. That’s time and money

better spent elsewhere.

Servicing the cooling system is a snap. The cooling cores

feature wide-fin spacing so that trash will pass through

the system without clogging it, reducing cleaning time.

We don’t think there’s ever been a job site where

there’s never mud, rain, or snow. That’s why we

strategically fastened bolt-on skid plates where

you step or stand during routine service.

Routine service is a lot like those childhood commands you used to get from

Mom — “Wash up before dinner,” or “Put on that jacket before you go out!” You

know it’s necessary, but it can delay the fun. That’s why we made daily service

quick and easy.

8-9

Look what’s behind those big, easy-to-open service doors. Checking filters and

fluid levels has never been faster. We’ve even extended some routine service intervals,

such as the engine oil-change interval. It’s been doubled from 250 to 500 hours.

We simply want you to get to the job you love. (Mom would be so proud!)

Page 6

EXCAVATORS

SPECIFICATIONS

200C

LC

230C

LC

270C

LC

CONSTRUCTION EQUIPMENT

CONSTRUCTION EQUIPMENT

Engine 200C LC 230C LC 270C LC

Type ......................................................................John Deere 6068H with turbocharger and air- John Deere 6068H with turbocharger and air- John Deere 6068H with turbocharger and air-

Rated power ..........................................................141 SAE net hp (105 kW) @ 2,150 rpm 169 SAE net hp (126 kW) @ 2,100 rpm 177 SAE net hp (132 kW) @ 2,150 rpm

Cylinders ...............................................................6 6 6

Displacement.........................................................414 cu. in. (6.8 L) 414 cu. in. (6.8 L) 414 cu. in. (6.8 L)

Maximum net torque .............................................427 lb.-ft. (579 Nm) @ 1,300 rpm 516 lb.-ft. (700 Nm) @ 1,400 rpm 540 lb.-ft. (733 Nm) @ 1,400 rpm

Fuel consumption, typical ......................................4.0 to 6.0 gal./hr. (15.1 to 22.7 L/h) 5.0 to 7.5 gal./hr. (19.0 to 28.0 L/h) 5.5 to 8.5 gal./hr. (21.0 to 32.0 L/h)

Cooling fan ............................................................suction-type drive suction-type drive suction-type drive

Electrical system ...................................................24 volt with 45-amp alternator 24 volt with 45-amp alternator 24 volt with 45-amp alternator

Batteries (two 12 volt)............................................reserve capacity: 180 min. reserve capacity: 180 min. reserve capacity: 180 min.

Off-level capacity...................................................100% (45 deg.) 100% (45 deg.) 100% (45 deg.)

to-air charge air cooler; meets EPA Tier II non- to-air charge air cooler; meets EPA Tier II non- to-air charge air cooler; meets EPA Tier II nonroad emissions regulations road emissions regulations road emissions regulations

Hydraulic System

Main pumps ..........................................................two variable-displacement axial-piston two variable-displacement axial-piston two variable-displacement axial-piston

Minimum flow.................................................2 x 21.5 gpm (2 x 82 L/min.) 2 x 32.0 gpm (2 x 121 L/min.) 2 x 34.9 gpm (2 x 132 L/min.)

Maximum flow................................................2 x 57.9 gpm (2 x 219 L/min.) 2 x 56.5 gpm (2 x 214 L/min.) 2 x 57.9 gpm (2 x 219 L/min.)

Pilot pump .............................................................one gear one gear one gear

Maximum flow................................................9.5 gpm (36 L/min.) 8.9 gpm (34 L/min.) 9.5 gpm (36 L/min.)

Pressure setting..............................................580 psi (3999 kPa) 580 psi (3999 kPa) 580 psi (3999 kPa)

System operating pressure

Implement circuits ..........................................4,980 psi (34 336 kPa) 4,980 psi (34 336 kPa) 4,980 psi (34 336 kPa)

Travel circuits .................................................4,980 psi (34 336 kPa) 4,980 psi (34 336 kPa) 5,050 psi (34 819 kPa)

Swing circuits.................................................4,480 psi (30 888 kPa) 4,270 psi (29 441 kPa) 4,380 psi (30 199 kPa)

Power boost....................................................5,270 psi (36 336 kPa) 5,270 psi (36 336 kPa) 5,270 psi (36 336 kPa)

Oil filtration............................................................one 10-micron full-flow return filter with by- one 10-micron full-flow return filter with by- one 10-micron full-flow return filter with by-

pass / one pilot oil filter pass / one pilot oil filter / one suction filter pass / one pilot oil filter / one suction filter

Cylinders

Boom (2)

Bore................................................................4.72 in. (120 mm) 4.90 in. (125 mm) 5.31 in. (135 mm)

Rod diameter ..................................................3.35 in. (85 mm) 3.50 in. (90 mm) 3.74 in. (95 mm)

Stroke.............................................................48.03 in. (1220 mm) 53.15 in. (1350 mm) 52.76 in. (1340 mm)

Arm (1)

Bore................................................................5.31 in. (135 mm) 5.51 in. (140 mm) 5.71 in. (145 mm)

Rod diameter ..................................................3.74 in. (95 mm) 4.13 in. (105 mm) 3.90 in. (100 mm)

Stroke.............................................................58.07 in. (1475 mm) 63.38 in. (1610 mm) 61.22 in. (1555 mm)

Bucket (1)

Bore................................................................4.53 in. (115 mm) 5.11 in. (130 mm) 5.31 in. (135 mm)

Rod diameter ..................................................3.15 in. (80 mm) 3.54 in. (90 mm) 3.74 in. (95 mm)

Stroke.............................................................41.73 in. (1060 mm) 42.32 in. (1075 mm) 42.13 in. (1070 mm)

Swing Mechanism

Swing speed..........................................................0–13.3 rpm 0–14.3 rpm 0–12.1 rpm

Swing torque .........................................................43,218 lb.-ft. (58 640 Nm) 49,915 lb.-ft. (67 725 Nm) 51,622 lb.-ft. (70 619 Nm)

Undercarriage

Carrier rollers (per side) .........................................2 2 2

Track rollers (per side)...........................................8 9 9

Shoes, triple semi-grouser (per side) .....................49 51 48

Track guides..........................................................front and center front and center front and center

Track adjustment...................................................hydraulic hydraulic hydraulic

Travel speed

Low ................................................................0–2.2 mph (0–3.6 km/h) 0–2.1 mph (0–3.4 km/h) 0–1.8 mph (0–2.9 km/h)

High................................................................0–3.4 mph (0–5.5 km/h) 0–3.4 mph (0–5.5 km/h) 0–3.0 mph (0–4.9 km/h)

Drawbar pull..........................................................42,420 lb. (19 240 kg) 44,420 lb. (20 150 kg) 56,074 lb. (25 435 kg)

Ground Pressure Data 200C LC 230C LC 270C LC

Average ground pressure

24-in. (600 mm) triple semi-grouser

shoes (recommended for rocky

terrain/stumps) ........................................6.08 psi (41.9 kPa) 6.84 psi (47.2 kPa) 7.50 psi (51.7 kPa)

28-in. (700 mm) triple semi-grouser

shoes (recommended for general/

soft terrain)..............................................5.32 psi (36.7 kPa) 5.97 psi (41.2 kPa)

32-in. (800 mm) triple semi-grouser

shoes (recommended for extremely

soft terrain)..............................................4.72 psi (32.5 kPa) 5.29 psi (36.5 kPa) 5.83 psi (40.2 kPa)

Capacities

Fuel tank ...............................................................95 gal. (360 L) 100 gal. (380 L) 100 gal. (380 L)

Cooling system ......................................................24.4 qt. (23 L) 24.4 qt. (23 L) 24.4 qt. (23 L)

Engine lubrication, including filter..........................20 qt. (19 L) 26 qt. (24.5 L) 26 qt. (24.5 L)

Hydraulic tank .......................................................34 gal. (130 L) 39 gal. (148 L) 39 gal. (148 L)

Hydraulic system ...................................................52.8 gal. (200 L) 66 gal. (250 L) 66 gal. (250 L)

Propel gearbox (each) ............................................5.5 qt. (5.2 L) 5.5 qt. (5.2 L) 5.5 qt. (5.2 L)

Swing drive ...........................................................5 qt. (4.7 L) 8 qt. (7.6 L) 8 qt. (7.6 L)

Operating Weights

With full fuel tank; 175-lb. (79 kg) operator; and 32-in. (800 mm) triple semi-grouser shoes

With 1.12-cu. yd. (0.86 m3), 42-in.

(1065 mm), 1,590-lb. (723 kg)

general-purpose bucket; 9-ft.

7-in. (2.91 m) arm; and 10,270-lb.

(4658 kg) counterweight..........................46,130 lb. (20 925 kg)

With 1.38-cu. yd. (1.06 m3), 42-in.

(1065 mm), 1,785-lb. (810 kg)

general-purpose bucket; 11-ft.

10-in. (3.61 m) arm; and 11,265-lb.

(5110 kg) counterweight........................................................................................................54,020 lb. (24 503 kg)

With 1.75-cu. yd. (1.34 m3), 42-in.

(1065 mm), 1,966-lb. (892 kg)

general-purpose bucket; 12-ft.

4-in. (3.75 m) arm; and 13,468-lb.

(6109 kg) counterweight ......................................................................................................................................................................................62,870 lb. (28 518 kg)

Component Weights

Undercarriage

24-in. (600 mm) triple semi-grouser shoes ......15,794 lb. (7164 kg) 17,685 lb. (8022 kg) 23,732 lb. (10 765 kg)

28-in. (700 mm) triple semi-grouser shoes ......16,702 lb. (7576 kg) 18,629 lb. (8450 kg)

32-in. (800 mm) triple semi-grouser shoes ......17,328 lb. (7860 kg) 19,259 lb. (8736 kg) 25,915 lb. (11 755 kg)

Upperstructure with full fuel tank (less front

attachments and boom lift cylinders [2])

Less 10,270-lb. (4658 kg) counterweight .......10,174 lb. (4615 kg)

Less 11,265-lb. (5110 kg) counterweight .....................................................................................11,973 lb. (5431 kg)

Less 13,468-lb. (6109 kg) counterweight....................................................................................................................................................................11,720 lb. (5316 kg)

One-piece boom (with arm cylinder) ......................3,717 lb. (1686 kg) 4,868 lb. (2208 kg) 5,086 lb. (2307 kg)

Arm with bucket cylinder and linkage

7 ft. 3 in. (2.22 m)...........................................1,936 lb. (878 kg)

9 ft. 7 in. (2.91 m)...........................................2,125 lb. (964 kg)

9 ft. 9 in. (2.96 m).........................................................................................................................2,855 lb. (1295 kg)

11 ft. 10 in. (3.61 m).....................................................................................................................3,075 lb. (1395 kg)

10 ft. 2 in. (3.10 m).....................................................................................................................................................................................................3,102 lb. (1407 kg)

12 ft. 4 in. (3.75 m).....................................................................................................................................................................................................3,298 lb. (1496 kg)

Boom lift cylinders (2) total weight.........................750 lb. (340 kg) 957 lb. (434 kg) 1,089 lb. (494 kg)

42-in. (1065 mm), 1.12-cu.-yd. (0.86 m3)

general-purpose bucket..................................1,590 lb. (723 kg)

42-in. (1065 mm), 1.38-cu.-yd. (1.06 m3)

general-purpose bucket................................................................................................................1,785 lb. (810 kg)

42-in. (1065 mm), 1.75-cu.-yd. (1.34 m3)

general-purpose bucket ..............................................................................................................................................................................................1,966 lb. (892 kg)

Counterweight .......................................................10,270 lb. (4658 kg) 11,925 lb. (5409 kg) 13,468 lb. (6109 kg)

10 11

Page 7

200C LC Operating Information

CENTERLINE OF SWING

GROUND LINE

G

E

C D

B

B'

A'

A

F

Arm Length Arm Length

Arm force with 42-in. (1065 mm) general-

purpose bucket* .............................................29,946 lb. (131 kN) 23,250 lb. (103.5 kN)

Bucket digging force with 42-in. (1065 mm),

1.12-cu. yd. (0.86 m3) general-purpose

bucket*...........................................................30,410 lb. (135.3 kN) 30,410 lb. (135.3 kN)

Lifting capacity over front @ ground level

20-ft. (6.1 m) reach*.......................................14,737 lb. (6685 kg) 14,764 lb. (6697 kg)

7 ft. 3 in. (2.22 m) 9 ft. 7 in. (2.91 m)

A Maximum reach..............................................30 ft. 4 in. (9.25 m) 32 ft. 6 in. (9.91 m)

1

A

Maximum reach @ ground level .....................29 ft. 9 in. (9.08 m) 32 ft. (9.75 m)

B Maximum digging depth .................................19 ft. 7 in. (5.98 m) 21 ft. 11 in. (6.67 m)

1

B

Maximum digging depth @ 8-ft. (2.44 m)

flat bottom......................................................18 ft. 10 in. (5.74 m) 21 ft. 4 in. (6.49 m)

C Maximum cutting height .................................30 ft. 1 in. (9.17 m) 31 ft. 6 in. (9.60 m)

D Maximum dumping height ..............................21 ft. (6.39 m) 22 ft. 3 in. (6.78 m)

E Minimum swing radius ...................................11 ft. 7 in. (3.53 m) 11 ft. 7 in. (3.54 m)

F Maximum vertical wall....................................16 ft. 10 in. (5.14 m) 19 ft. 10 in. (6.05 m)

G Tail swing radius.............................................9 ft. (2.75 m) 9 ft. (2.75 m)

*Digging forces and lift capacities with power boost.

230C LC Operating Information

Arm Length Arm Length

Arm force with 42-in. (1065 mm) general-

purpose bucket* .............................................27,640 lb. (122.9 kN) 24,020 lb. (106.8 kN)

Bucket digging force with 42-in. (1065 mm),

1.38-cu. yd. (1.06 m3) general-purpose

bucket*...........................................................37,670 lb. (167 kN) 37,670 lb. (167 kN)

Lifting capacity over front @ ground level

20-ft. (6.1 m) reach*.......................................17,604 lb. (7985 kg) 16,672 lb. (7562 kg)

9 ft. 9 in. (2.96 m) 11 ft. 10 in. (3.61 m)

A Maximum reach..............................................33 ft. 4 in. (10.16 m) 35 ft. 5 in. (10.79 m)

1

A

Maximum reach @ ground level .....................32 ft. 9 in. (9.99 m) 34 ft. 10 in. (10.62 m)

B Maximum digging depth .................................22 ft. 5 in. (6.84 m) 24 ft. 6 in. (7.48 m)

1

B

Maximum digging depth @ 8-ft. (2.44 m)

flat bottom......................................................21 ft. 9 in. (6.63 m) 24 ft. (7.32 m)

C Maximum cutting height .................................31 ft. 7 in. (9.63 m) 32 ft. 9 in. (9.99 m)

D Maximum dumping height ..............................22 ft. 2 in. (6.76 m) 23 ft. 4 in. (7.10 m)

E Minimum swing radius ...................................12 ft. 8 in. (3.87 m) 12 ft. 9 in. (3.89 m)

F Maximum vertical wall....................................19 ft. 5 in. (5.91 m) 21 ft. 9 in. (6.63 m)

G Tail swing radius.............................................9 ft. 8 in. (2.94 m) 9 ft. 8 in. (2.94 m)

*Digging forces and lift capacities with power boost.

Dimensions 200C LC 230C LC 270C LC

A 7-ft. 3-in. (2.22 m) arm...................................31 ft. 7 in. (9.62 m)

9-ft. 7-in. (2.91 m) arm...................................31 ft. 2 in. (9.50 m)

9-ft. 9-in. (2.96 m) arm.................................................................................................................33 ft. 3 in. (10.14 m)

11-ft. 10-in. (3.61 m) arm.............................................................................................................33 ft. 6 in. (10.20 m)

10-ft. 2-in. (3.10 m) arm.............................................................................................................................................................................................33 ft. 9 in. (10.29 m)

12 ft. 4 in. (3.75 m) arm..............................................................................................................................................................................................33 ft. 11 in. (10.34 m)

B 7-ft. 3-in. (2.22 m) arm...................................10 ft. 3 in. (3.13 m)

9-ft. 7-in. (2.91 m) arm...................................9 ft. 9 in. (2.97 m)

9-ft. 9-in. (2.96 m) arm.................................................................................................................10 ft. 2 in. (3.10 m)

11-ft. 10-in. (3.61 m) arm.............................................................................................................10 ft. 11 in. (3.32 m)

10-ft. 2-in. (3.10 m) arm.............................................................................................................................................................................................10 ft. 5 in. (3.17 m)

12 ft. 4 in. (3.75 m) arm..............................................................................................................................................................................................11 ft. (3.35 m)

C With 24-in. (600 mm) semi-grouser shoes......9 ft. 10 in. (2.99 m) 10 ft. 6 in. (3.19 m) 10 ft. 6 in. (3.19 m)

With 28-in. (700 mm) semi-grouser shoes......10 ft. 2 in. (3.09 m) 10 ft. 10 in. (3.29 m)

With 32-in. (800 mm) semi-grouser shoes......10 ft. 6 in. (3.19 m) 11 ft. 2 in. (3.39 m) 11 ft. 2 in. (3.39 m)

9 ft. 8 in. (2.95 m)

1 ft. 6 in. (450 mm)

8 ft. 11 in. (2.71 m)

7 ft. 10 in. (2.39 m)

C

9 ft. 11 in. (3.02 m)

9 ft. 6 in. (2.89 m)

28 in. (700 mm)

24 in. (600 mm)

32 in. (800 mm)

B

B

12 ft. (3.66 m)

14 ft. 8 in. (4.46 m)

A

200C LC EXCAVATOR

9 ft. 8 in. (2.94 m)

9 ft. (2.75 m)

3 ft. 5 in. (1030 mm)

270C LC Operating Information

Arm force with 42-in. (1065 mm) general-

purpose bucket* .............................................26,076 lb. (116 kN) 22,950 lb. (101.5 kN)

Bucket digging force with 42-in. (1065 mm),

1.75-cu. yd. (1.34 m3) general-purpose

bucket*...........................................................37,480 lb. (166.7 kN) 37,480 lb. (166.7 kN)

Lifting capacity over front @ ground level

20-ft. (6.1 m) reach*.......................................20,643 lb. (9364 kg) 19,537 lb. (8862 kg)

A Maximum reach..............................................35 ft. 3 in. (10.74 m) 37 ft. 1 in. (11.30 m)

1

A

Maximum reach @ ground level .....................34 ft. 7 in. (10.55 m) 36 ft. 6 in. (11.12 m)

B Maximum digging depth .................................23 ft. 10 in. (7.26 m) 25 ft. 11 in. (7.91 m)

1

B

Maximum digging depth @ 8-ft. (2.44 m)

flat bottom......................................................23 ft. 2 in. (7.05 m) 25 ft. 8 in. (7.72 m)

C Maximum cutting height .................................32 ft. 10 in. (10.01 m) 33 ft. 5 in. (10.18 m)

D Maximum dumping height ..............................23 ft. 2 in. (7.07 m) 23 ft. 9 in. (7.25 m)

E Minimum swing radius ...................................13 ft. 7 in. (4.41 m) 13 ft. 6 in. (4.12 m)

F Maximum vertical wall....................................20 ft. 1 in. (6.11 m) 21 ft. 10 in. (6.66 m)

G Tail swing radius.............................................9 ft. 8 in. (2.94 m) 9 ft. 8 in. (2.94 m)

*Digging forces and lift capacities with power boost.

12

Arm Length Arm Length

10 ft. 2 in. (3.10 m) 12 ft. 4 in. (3.75 m)

24 in. (600 mm)

10 ft. 2 in. (3.11 m)

24 in. (600 mm)

32 in. (800 mm)

32 in. (800 mm)

28 in. (700 mm)

8 ft. 6 in. (2.59 m)

9 ft. 6 in. (2.89 m)

1 ft. 8 in. (510 mm)

8 ft. 6 in. (2.59 m)

C

1 ft. 6 in. (460 mm)

C

12 ft. 7 in. (3.84 m)

15 ft. 3 in. (4.64 m)

A

230C LC EXCAVATOR

9 ft. 8 in. (2.94 m)

B

13 ft. 3 in. (4.05 m)

16 ft. 2 in. (4.94 m)

A

270C LC EXCAVATOR

3 ft. 7 in. (1090 mm)

3 ft. 10 in. (1180 mm)

13

Page 8

200C LC Lift Capacities

Boldface italic type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings at bucket lift hook; machine equipped with 1.12-cu. yd. (0.86 m3),

42-in. (1065 mm) wide, 1,590-lb. (723 kg) bucket; and situated on firm, uniform supporting surface. Total load includes weight of cables, hook, etc. Figures do not exceed 87 percent of hydraulic

capacities or 75 percent of weight needed to tip machine. All lift capacities are with power boost and are based on SAE J1097.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m) 30 ft. (9.15 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

With 7-ft. 3-in. (2.22 m) arm and 24-in. (600 mm) shoes

20 ft. (6.10 m) 9,485 (4302) 9,485 (4302)

15 ft. (4.57 m) 10,318 (4680) 10,023 (4546)

10 ft. (3.05 m) 16,159 (7330) 14,860 (6740) 12,133 (5503) 9,519 (4318) 10,513 (4769) 6,574 (2982)

5 ft. (1.52 m) 14,181 (6432) 8,989 (4077) 10,252 (4650) 6,336 (2874)

Ground Line 14,243 (6461) 8,632 (3915) 10,048 (4558) 6,150 (2790)

–5 ft. (–1.52 m) 21,774 (9877) 13,231 (6001) 14,099 (6395) 8,505 (3858) 9,992 (4532) 6,098 (2766)

–10 ft. (–3.05 m) 19,899 (9026) 19,899 (9026) 19,972 (9059) 13,419 (6087) 14,209 (6445) 8,601 (3901)

–15 ft. (–4.57 m) 15,778 (7157) 13,891 (6301)

With 9-ft. 7-in. (2.91 m) arm and 24-in. (600 mm) shoes

15 ft. (4.57 m) 8,883 (4029) 8,883 (4029) 8,724 (3957) 6,856 (3110)

10 ft. (3.05 m) 13,702 (6215) 13,702 (6215) 10,818 (4907) 9,684 (4393) 9,551 (4332) 6,629 (3007)

5 ft. (1.52 m) 18,545 (8412) 14,058 (6377) 13,097 (5941) 9,094 (4125) 10,272 (4659) 6,342 (2877)

Ground Line 21,407 (9710) 13,309 (6037) 14,271 (6473) 8,640 (3919) 10,004 (4538) 6,097 (2766)

–5 ft. (–1.52 m) 13,714 (6221) 13,714 (6221) 22,036 (9995) 13,091 (5938) 14,012 (6356) 8,411 (3815) 9,857 (4471) 5,963 (2705)

–10 ft. (–3.05 m) 23,423 (10 624) 23,423 (10 624) 21,039 (9543) 13,167 (5972) 14,001 (6351) 8,402 (3811) 9,902 (4491) 6,004 (2723)

–15 ft. (–4.57 m) 24,915 (11 301) 24,915 (11 301) 18,123 (8220) 13,497 (6122) 13,140 (5960) 8,651 (3924)

With 7-ft. 3-in. (2.22 m) arm and 28-in. (700 mm) shoes

20 ft. (6.10 m) 9,485 (4302) 9,485 (4302)

15 ft. (4.57 m) 10,318 (4680) 10,204 (4628)

10 ft. (3.05 m) 16,159 (7330) 15,124 (6860) 12,133 (5503) 9,700 (4400) 10,563 (4791) 6,711 (3044)

5 ft. (1.52 m) 14,181 (6432) 9,170 (4159) 10,467 (4748) 6,473 (2936)

Ground Line 14,535 (6593) 8,813 (3998) 10,264 (4656) 6,287 (2852)

–5 ft. (–1.52 m) 21,774 (9877) 13,496 (6122) 14,391 (6528) 8,685 (3939) 10,207 (4630) 6,235 (2828)

–10 ft. (–3.05 m) 19,899 (9026) 19,899 (9026) 19,972 (9059) 13,684 (6207) 14,501 (6578) 8,782 (3983)

–15 ft. (–4.57 m) 15,778 (7157) 14,155 (6420)

With 9-ft. 7-in. (2.91 m) arm and 28-in. (700 mm) shoes

15 ft. (4.57 m) 8,883 (4029) 8,883 (4029) 8,724 (3957) 6,856 (3110)

10 ft. (3.05 m) 13,702 (6215) 13,702 (6215) 10,818 (4907) 9,684 (4393) 9,551 (4332) 6,629 (3007)

5 ft. (1.52 m) 18,545 (8412) 14,058 (6377) 13,097 (5941) 9,094 (4125) 10,272 (4659) 6,342 (2877)

Ground Line 21,407 (9710) 13,309 (6037) 14,271 (6473) 8,640 (3919) 10,004 (4538) 6,097 (2766)

–5 ft. (–1.52 m) 13,714 (6221) 13,714 (6221) 22,036 (9995) 13,091 (5938) 14,012 (6356) 8,411 (3815) 9,857 (4471) 5,963 (2705)

–10 ft. (–3.05 m) 23,423 (10 624) 23,423 (10 624) 21,039 (9543) 13,167 (5972) 14,001 (6351) 8,402 (3811) 9,902 (4491) 6,004 (2723)

–15 ft. (–4.57 m) 24,915 (11 301) 24,915 (11 301) 18,123 (8220) 13,497 (6122) 13,140 (5960) 8,651 (3924)

With 7-ft. 3-in. (2.22 m) arm and 32-in. (800 mm) shoes

20 ft. (6.10 m) 9,485 (4302) 9,485 (4302)

15 ft. (4.57 m) 10,318 (4680) 10,318 (4680)

10 ft. (3.05 m) 16,159 (7330) 15,306 (6942) 12,133 (5503) 9,824 (4456) 10,563 (4791) 6,806 (3087)

5 ft. (1.52 m) 14,181 (6432) 9,294 (4216) 10,616 (4815) 6,568 (2979)

Ground Line 14,737 (6685) 8,937 (4054) 10,412 (4723) 6,382 (2894)

–5 ft. (–1.52 m) 21,774 (9877) 13,678 (6204) 14,593 (6619) 8,810 (3996) 10,355 (4697) 6,330 (2871)

–10 ft. (–3.05 m) 19,899 (9026) 19,899 (9026) 19,972 (9059) 13,866 (6290) 14,702 (6669) 8,907 (4040)

–15 ft. (–4.57 m) 15,778 (7157) 14,337 (6503)

With 9-ft. 7-in. (2.91 m) arm and 32-in. (800 mm) shoes

15 ft. (4.57 m) 8,883 (4029) 8,883 (4029) 8,724 (3957) 7,088 (3215)

10 ft. (3.05 m) 13,702 (6215) 13,702 (6215) 10,818 (4907) 9,990 (4531) 9,551 (4332) 6,861 (3112)

5 ft. (1.52 m) 18,545 (8412) 14,504 (6579) 13,097 (5941) 9,399 (4263) 10,636 (4824) 6,574 (2982)

Ground Line 21,407 (9710) 13,755 (6239) 14,764 (6697) 8,945 (4057) 10,367 (4702) 6,329 (2871)

–5 ft. (–1.52 m) 13,714 (6221) 13,714 (6221) 22,036 (9995) 13,538 (6141) 14,505 (6579) 8,716 (3954) 10,220 (4636) 6,195 (2810)

–10 ft. (–3.05 m) 23,423 (10 624) 23,423 (10 624) 21,039 (9543) 13,614 (6175) 14,495 (6575) 8,707 (3949) 10,266 (4657) 6,236 (2829)

–15 ft. (–4.57 m) 24,915 (11 301) 24,915 (11 301) 18,123 (8220) 13,943 (6324) 13,140 (5960) 8,957 (4063)

230C LC Lift Capacities

Boldface italic type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings at bucket lift hook; machine equipped with 1.38-cu. yd. (1.06 m3),

42-in. (1065 mm) wide, 1,785-lb. (810 kg) bucket; and situated on firm, uniform supporting surface. Total load includes weight of cables, hook, etc. Figures do not exceed 87 percent of hydraulic

capacities or 75 percent of weight needed to tip machine. All lift capacities are with power boost and are based on SAE J1097.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m) 30 ft. (9.15 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

With 9-ft. 9-in. (2.96 m) arm and 24-in. (600 mm) shoes

20 ft. (6.10 m) 8,174 (3708) 8,174 (3708)

15 ft. (4.57 m) 10,321 (4682) 10,321 (4682) 9,733 (4415) 8,581 (3892)

10 ft. (3.05 m) 17,171 (7789) 17,171 (7789) 12,827 (5818) 12,029 (5456) 10,925 (4955) 8,194 (3717) 6,996 (3173) 5,760 (2613)

5 ft. (1.52 m) 22,872 (10 375) 17,272 (7834) 15,563 (7059) 11,169 (5066) 12,355 (5604) 7,759 (3519) 9,044 (4102) 5,572 (2527)

Ground Line 25,546 (11 587) 16,412 (7444) 17,281 (7839) 10,554 (4787) 12,029 (5456) 7,403 (3358) 8,907 (4040) 5,407 (2453)

–5 ft. (–1.52 m) 12,891 (5847) 12,891 (5847) 25,759 (11 684) 16,231 (7362) 16,953 (7690) 10,264 (4656) 11,814 (5359) 7,206 (3269)

–10 ft. (–3.05 m) 20,687 (9383) 20,687 (9383) 24,411 (11 073) 16,373 (7427) 16,946 (7687) 10,258 (4653) 11,830 (5366) 7,221 (3275)

–15 ft. (–4.57 m) 28,595 (12 970) 28,595 (12 970) 21,205 (9618) 16,803 (7622) 15,773 (7155) 10,546 (4784)

With 11-ft. 10-in. (3.61 m) arm and 24-in. (600 mm) shoes

20 ft. (6.10 m) 7,557 (3428) 7,557 (3428)

15 ft. (4.57 m) 8,534 (3871) 8,534 (3871) 6,161 (2795) 6,009 (2726)

10 ft. (3.05 m) 14,308 (6490) 14,308 (6490) 11,291 (5122) 11,291 (5122) 9,851 (4468) 8,315 (3772) 8,047 (3650) 5,826 (2643)

5 ft. (1.52 m) 20,379 (9244) 17,852 (8098) 14,230 (6455) 11,370 (5157) 11,438 (5188) 7,823 (3548) 9,101 (4128) 5,576 (2529)

Ground Line 24,314 (11 029) 16,560 (7511) 16,672 (7562) 10,616 (4815) 12,034 (5459) 7,393 (3353) 8,855 (4017) 5,347 (2425)

–5 ft. (–1.52 m) 13,152 (5966) 13,152 (5966) 25,636 (11 628) 16,090 (7298) 16,889 (7661) 10,188 (4621) 11,727 (5319) 7,113 (3226) 8,706 (3949) 5,209 (2363)

–10 ft. (–3.05 m) 24,308 (11 026) 24,308 (11 026) 25,121 (11 395) 16,073 (7291) 16,749 (7597) 10,064 (4565) 11,633 (5277) 7,027 (3187)

–15 ft. (–4.57 m) 32,401 (14 697) 32,401 (14 697) 22,854 (10 366) 16,375 (7428) 16,874 (7654) 10,219 (4635) 11,826 (5364) 7,203 (3267)

–20 ft. (–6.10 m) 17,802 (8075) 17,067 (7741)

With 9-ft. 9-in. (2.96 m) arm and 28-in. (700 mm) shoes

20 ft. (6.10 m) 8,174 (3708) 8,174 (3708)

15 ft. (4.57 m) 10,321 (4682) 10,321 (4682) 9,733 (4415) 8,738 (3963)

10 ft. (3.05 m) 17,171 (7789) 17,171 (7789) 12,827 (5818) 12,236 (5550) 10,925 (4955) 8,351 (3788) 6,996 (3173) 5,886 (2670)

5 ft. (1.52 m) 22,872 (10 375) 17,578 (7973) 15,563 (7059) 11,376 (5160) 12,355 (5604) 7,915 (3590) 9,044 (4102) 5,698 (2585)

Ground Line 25,546 (11 587) 16,718 (7583) 17,604 (7985) 10,761 (4881) 12,269 (5565) 7,559 (3429) 9,001 (4083) 5,533 (2510)

–5 ft. (–1.52 m) 12,891 (5847) 12,891 (5847) 25,759 (11 684) 16,537 (7501) 17,280 (7838) 10,471 (4750) 12,054 (5468) 7,363 (3340)

–10 ft. (–3.05 m) 20,687 (9383) 20,687 (9383) 24,411 (11 073) 16,679 (7565) 17,274 (7835) 10,465 (4747) 12,069 (5474) 7,377 (3346)

–15 ft. (–4.57 m) 28,595 (12 970) 28,595 (12 970) 21,205 (9618) 17,109 (7761) 15,773 (7155) 10,754 (4878)

With 11-ft. 10-in. (3.61 m) arm and 28-in. (700 mm) shoes

20 ft. (6.10 m) 7,557 (3428) 7,557 (3428)

15 ft. (4.57 m) 8,534 (3871) 8,534 (3871) 6,161 (2795) 6,135 (2783)

10 ft. (3.05 m) 14,308 (6490) 14,308 (6490) 11,291 (5122) 11,291 (5122) 9,851 (4468) 8,472 (3843) 8,047 (3650) 5,952 (2700)

5 ft. (1.52 m) 20,379 (9244) 18,158 (8236) 14,230 (6455) 11,577 (5251) 11,438 (5188) 7,979 (3619) 9,290 (4214) 5,702 (2586)

Ground Line 24,314 (11 029) 16,866 (7650) 16,672 (7562) 10,823 (4909) 12,274 (5567) 7,549 (3424) 9,044 (4102) 5,473 (2483)

–5 ft. (–1.52 m) 13,152 (5966) 13,152 (5966) 25,636 (11 628) 16,396 (7437) 17,216 (7809) 10,395 (4715) 11,967 (5428) 7,270 (3298) 8,895 (4035) 5,335 (2420)

–10 ft. (–3.05 m) 24,308 (11 026) 24,308 (11 026) 25,121 (11 395) 16,379 (7429) 17,076 (7746) 10,271 (4659) 11,873 (5386) 7,183 (3258)

–15 ft. (–4.57 m) 32,401 (14 697) 32,401 (14 697) 22,854 (10 366) 16,681 (7566) 16,874 (7654) 10,426 (4729) 12,065 (5473) 7,359 (3338)

–20 ft. (–6.10 m) 17,802 (8075) 17,373 (7880)

With 9-ft. 9-in. (2.96 m) arm and 32-in. (800 mm) shoes

20 ft. (6.10 m) 8,174 (3708) 8,174 (3708)

15 ft. (4.57 m) 10,321 (4682) 10,321 (4682) 9,733 (4415) 8,843 (4011)

10 ft. (3.05 m) 17,171 (7789) 17,171 (7789) 12,827 (5818) 12,375 (5613) 10,925 (4955) 8,456 (3836) 6,996 (3173) 5,970 (2708)

5 ft. (1.52 m) 22,872 (10 375) 17,783 (8066) 15,563 (7059) 11,515 (5223) 12,355 (5604) 8,020 (3638) 9,044 (4102) 5,782 (2623)

Ground Line 25,546 (11 587) 16,923 (7676) 17,604 (7985) 10,899 (4944) 12,428 (5637) 7,664 (3476) 9,001 (4083) 5,617 (2548)

–5 ft. (–1.52 m) 12,891 (5847) 12,891 (5847) 25,759 (11 684) 16,741 (7594) 17,498 (7937) 10,610 (4813) 12,213 (5540) 7,468 (3387)

–10 ft. (–3.05 m) 20,687 (9383) 20,687 (9383) 24,411 (11 073) 16,883 (7658) 17,492 (7934) 10,604 (4810) 12,229 (5547) 7,482 (3394)

–15 ft. (–4.57 m) 28,595 (12 970) 28,595 (12 970) 21,205 (9618) 17,314 (7853) 15,773 (7155) 10,892 (4941)

With 11-ft. 10-in. (3.61 m) arm and 32-in. (800 mm) shoes

20 ft. (6.10 m) 7,557 (3428) 7,557 (3428)

15 ft. (4.57 m) 8,534 (3871) 8,534 (3871) 6,161 (2795) 6,161 (2795)

10 ft. (3.05 m) 14,308 (6490) 14,308 (6490) 11,291 (5122) 11,291 (5122) 9,851 (4468) 8,576 (3890) 8,047 (3650) 6,036 (2738)

5 ft. (1.52 m) 20,379 (9244) 18,363 (8329) 14,230 (6455) 11,715 (5314) 11,438 (5188) 8,084 (3667) 9,416 (4271) 5,786 (2624)

Ground Line 24,314 (11 029) 17,070 (7743) 16,672 (7562) 10,962 (4972) 12,433 (5640) 7,654 (3472) 9,170 (4159) 5,557 (2521)

–5 ft. (–1.52 m) 13,152 (5966) 13,152 (5966) 25,636 (11 628) 16,600 (7530) 17,434 (7908) 10,534 (4778) 12,127 (5501) 7,374 (3345) 9,021 (4092) 5,419 (2458)

–10 ft. (–3.05 m) 24,308 (11 026) 24,308 (11 026) 25,121 (11 395) 16,584 (7522) 17,294 (7844) 10,410 (4722) 12,032 (5458) 7,288 (3306)

–15 ft. (–4.57 m) 32,401 (14 697) 32,401 (14 697) 22,854 (10 366) 16,885 (7659) 16,874 (7654) 10,565 (4792) 12,225 (5545) 7,464 (3386)

–20 ft. (–6.10 m) 17,802 (8075) 17,578 (7973)

14 15

Page 9

270C LC Lift Capacities

Boldface italic type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings at bucket lift hook; machine equipped with 1.75-cu. yd. (1.34 m3),

42-in. (1065 mm) wide, 1,966-lb. (892 kg) bucket; and situated on firm, uniform supporting surface. Total load includes weight of cables, hook, etc. Figures do not exceed 87 percent of hydraulic

capacities or 75 percent of weight needed to tip machine. All lift capacities are with power boost and are based on SAE J1097.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m) 30 ft. (9.15 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

With 10-ft. 2-in. (3.10 m) arm and 24-in. (600 mm) shoes

20 ft. (6.10 m) 9,998 (4535) 9,988 (4530)

15 ft. (4.57 m) 10,841 (4917) 10,238 (4644) 7,014 (3181) 7,014 (3181)

10 ft. (3.05 m) 19,987 (9066) 19,987 (9066) 14,695 (6666) 14,190 (6436) 12,438 (5642) 9,771 (4432) 10,732 (4868) 6,989 (3170)

5 ft. (1.52 m) 26,941 (12 220) 20,321 (9217) 18,092 (8206) 13,221 (5997) 14,278 (6476) 9,268 (4204) 11,565 (5246) 6,744 (2964)

Ground Line 24,266 (11 007) 19,439 (8817) 20,643 (9364) 12,543 (5689) 15,236 (6911) 8,862 (4020) 11,336 (5142) 6,534 (2786)

–5 ft. (–1.52 m) 11,720 (5316) 11,720 (5316) 30,593 (13 877) 19,266 (8739) 21,509 (9756) 12,226 (5546) 14,980 (6795) 8,632 (3915) 10,811 (4904) 6,439 (2921)

–10 ft. (–3.05 m) 22,082 (10 016) 22,082 (10 016) 29,398 (13 335) 19,416 (8807) 21,487 (9746) 12,207 (5537) 14,963 (6787) 8,617 (3909)

–15 ft. (–4.57 m) 34,463 (15 632) 34,463 (15 632) 26,341 (11 948) 19,850 (9004) 19,736 (8952) 12,476 (5659)

–20 ft. (–6.10 m) 19,690 (8931) 19,690 (8931)

With 12-ft. 4-in. (3.75 m) arm and 24-in. (600 mm) shoes

15 ft. (4.57 m) 9,499 (4309) 9,499 (4309) 8,346 (3786) 7,317 (3319)

10 ft. (3.05 m) 12,902 (5852) 12,902 (5852) 11,214 (5087) 9,931 (4505) 10,397 (4716) 7,072 (3208)

5 ft. (1.52 m) 23,934 (10 856) 21,010 (9530) 16,527 (7497) 13,480 (6114) 13,221 (5997) 9,371 (4251) 11,506 (5219) 6,774 (3073)

Ground Line 28,654 (12 997) 19,638 (8908) 19,537 (8862) 12,652 (5739) 15,055 (6829) 8,887 (4031) 11,317 (5133) 6,504 (2950)

–5 ft. (–1.52 m) 13,075 (5931) 13,075 (5931) 30,367 (13 774) 19,155 (8689) 21,337 (9678) 12,185 (5527) 14,928 (6771) 8,571 (3888) 11,127 (5047) 6,329 (2871)

–10 ft. (–3.05 m) 23,260 (10 551) 23,260 (10 551) 30,084 (13 646) 19,140 (8682) 21,320 (9671) 12,043 (5463) 14,802 (6714) 8,457 (3836) 9,313 (4224) 6,321 (2867)

–15 ft. (–4.57 m) 35,784 (16 231) 35,784 (16 231) 27,986 (12 694) 19,445 (8820) 20,706 (9392) 12,184 (5527) 14,951 (6782) 8,591 (3897)

–20 ft. (–6.10 m) 32,182 (14 598) 32,182 (14 598) 23,188 (10 518) 20,123 (9128) 16,916 (7673) 12,693 (5757)

With 10-ft. 2-in. (3.10 m) arm and 32-in. (800 mm) shoes

20 ft. (6.10 m) 9,998 (4535) 9,988 (4530)

15 ft. (4.57 m) 10,841 (4917) 10,602 (4809) 7,014 (3181) 7,014 (3181)

10 ft. (3.05 m) 19,987 (9066) 19,987 (9066) 14,695 (6666) 14,671 (6655) 12,438 (5642) 10,135 (4597) 10,732 (4868) 7,282 (3303)

5 ft. (1.52 m) 26,941 (12 220) 21,033 (9540) 18,092 (8206) 13,703 (6216) 14,278 (6476) 9,631 (4369) 12,029 (5456) 7,036 (3191)

Ground Line 24,266 (11 007) 20,151 (9140) 20,643 (9364) 13,025 (5908) 15,286 (6934) 9,225 (4184) 11,800 (5352) 6,826 (3096)

–5 ft. (–1.52 m) 11,720 (5316) 11,720 (5316) 30,593 (13 877) 19,979 (9062) 21,872 (9921) 12,707 (5764) 15,571 (7063) 8,996 (4080) 10,811 (4904) 6,732 (3054)

–10 ft. (–3.05 m) 22,082 (10 016) 22,082 (10 016) 29,398 (13 335) 20,219 (9130) 21,704 (9845) 12,689 (5756) 15,554 (7055) 8,980 (4073)

–15 ft. (–4.57 m) 34,463 (15 632) 34,463 (15 632) 26,341 (11 948) 20,563 (9327) 19,736 (8952) 12,957 (5877)

–20 ft. (–6.10 m) 19,690 (8931) 19,690 (8931)

With 12-ft. 4-in. (3.75 m) arm and 32-in. (800 mm) shoes

15 ft. (4.57 m) 9,499 (4309) 9,499 (4309) 8,346 (3786) 7,609 (3451)

10 ft. (3.05 m) 12,902 (5852) 12,902 (5852) 11,214 (5087) 10,295 (4670) 10,397 (4716) 7,365 (3341)

5 ft. (1.52 m) 23,934 (10 856) 21,723 (9853) 16,527 (7497) 13,962 (6333) 13,221 (5997) 9,734 (4415) 11,506 (5219) 7,066 (3205)

Ground Line 28,654 (12 997) 20,351 (9231) 19,537 (8862) 13,133 (5957) 15,055 (6829) 9,251 (4196) 11,781 (5344) 6,796 (3083)

–5 ft. (–1.52 m) 13,075 (5931) 13,075 (5931) 30,367 (13 774) 19,868 (9012) 21,337 (9678) 12,667 (5746) 15,519 (7039) 8,934 (4052) 11,591 (5258) 6,621 (3003)

–10 ft. (–3.05 m) 23,260 (10 551) 23,260 (10 551) 30,084 (13 646) 19,852 (9005) 21,795 (9886) 12,524 (5681) 15,393 (6982) 8,821 (4001) 9,313 (4224) 6,613 (3000)

–15 ft. (–4.57 m) 35,784 (16 231) 35,784 (16 231) 27,986 (12 694) 20,157 (9143) 20,706 (9392) 12,665 (5745) 15,542 (7050) 8,955 (4062)

–20 ft. (–6.10 m) 32,182 (14 598) 32,182 (14 598) 23,188 (10 518) 20,835 (9451) 16,916 (7673) 13,174 (5976)

200C LC Buckets

A full line of buckets is offered to meet a wide variety of applications. Digging forces are with power boost. The buckets have an adjustable bushing for side clearance, with the exception of the

ditching bucket. Tooth selection includes either the John Deere Fanggs®, Standard, Tiger, Twin Tiger, Abrasion panel, or Flare tooth, or the ESCO (Vertalok) Standard, Tiger, Twin Tiger, or Flare tooth.

Replaceable cutting edges are available through John Deere parts. Optional side cutters add 6 inches (150 mm) to bucket widths.

Type Bucket Width Capacity* Weight Dig Force 7 ft. 3 in. (2.22 m) 9 ft. 7 in. (2.91 m) Tip Radius No. Teeth

General-Purpose 24 610 0.59 0.45 1,106 502 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

Plate Lip 30 760 0.77 0.59 1,182 536 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

General-Purpose 30 760 0.95 0.73 1,391 631 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 4

High Capacity 36 915 1.16 0.89 1,451 658 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 5

*All capacities are SAE heaped ratings and with side cutters.

Bucket Bucket Bucket Arm Dig Force Arm Dig Force Bucket

in. mm cu. yd. m

36 915 0.95 0.73 1,401 635 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 5

42 1065 1.12 0.86 1,590 721 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 5

48 1220 1.30 0.99 1,673 759 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 6

42 1065 1.38 1.06 1,596 724 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 5

48 1220 1.60 1.22 1,785 809 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 6

3

lb. kg lb. kN lb. kN lb. kN in. mm

200C LC Buckets

A full line of buckets is offered to meet a wide variety of applications. Digging forces are with power boost. The buckets have an adjustable bushing for side clearance, with the exception of the

ditching bucket. Tooth selection includes either the John Deere Fanggs®, Standard, Tiger, Twin Tiger, Abrasion panel, or Flare tooth, or the ESCO (Vertalok) Standard, Tiger, Twin Tiger, or Flare tooth.

Replaceable cutting edges are available through John Deere parts. Optional side cutters add 6 inches (150 mm) to bucket widths.

Type Bucket Width Capacity* Weight Dig Force 7 ft. 3 in. (2.22 m) 9 ft. 7 in. (2.91 m) Tip Radius No. Teeth

Heavy-Duty 24 610 0.59 0.45 1,358 616 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

Plate Lip 30 760 0.77 0.59 1,447 656 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

Heavy-Duty 24 610 0.73 0.56 1,401 635 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 4

High Capacity 30 760 0.95 0.73 1,528 693 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 4

Severe-Duty 24 610 0.59 0.45 1,439 653 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 3

Cast Lip 30 760 0.77 0.59 1,551 703 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

Severe-Duty 30 760 0.77 0.59 1,760 798 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

Plate Lip 36 915 0.95 0.73 1,859 843 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

Ditching 60 1500 0.90 0.69 1,121 508 45,615 202.9 34,400 153.0 24,881 110.7 37.0 940 0

*All capacities are SAE heaped ratings and with side cutters.

(cont.)

Bucket Bucket Bucket Arm Dig Force Arm Dig Force Bucket

in. mm cu. yd. m

36 915 0.95 0.73 1,567 711 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 5

42 1065 1.12 0.86 1,676 760 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 5

48 1220 1.30 0.99 1,759 798 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 6

36 915 1.16 0.89 1,629 739 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 5

42 1065 1.38 1.06 1,701 771 29,348 130.5 29,531 131.4 22,979 102.2 57.5 1461 5

36 915 0.95 0.73 1,629 739 30,410 135.3 29,946 133.2 23,250 103.4 55.5 1410 4

72 1800 1.06 0.81 1,244 564 45,615 202.9 34,400 153.0 24,881 110.7 37.0 940 0

3

lb. kg lb. kN lb. kN lb. kN in. mm

230C LC Buckets

A full line of buckets is offered to meet a wide variety of applications. Digging forces are with power boost. The buckets have an adjustable bushing for side clearance, with the exception of the

ditching bucket. Tooth selection includes either the John Deere Fanggs®, Standard, Tiger, Twin Tiger, Abrasion panel, or Flare tooth, or the ESCO (Vertalok) Standard, Tiger, Twin Tiger, or Flare tooth.

Replaceable cutting edges are available through John Deere parts. Optional side cutters add 6 inches (150 mm) to bucket widths.

Type Bucket Width Capacity* Weight Dig Force 9 ft. 9 in. (2.96 m) 11 ft. 10 in. (3.61 m) Tip Radius No. Teeth

General-Purpose 24 610 0.95 0.73 1,453 659 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 3

Plate Lip 30 760 1.20 0.92 1,731 785 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 4

Heavy-Duty 30 760 0.95 0.73 1,930 875 37,676 167.0 27,690 122.9 24,020 106.8 56.5 1435 4

Plate Lip 36 915 1.16 0.89 2,075 941 37,676 167.0 27,690 122.9 24,020 106.8 56.5 1435 4

Heavy-Duty 24 610 0.92 0.70 1,765 801 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 3

High Capacity 30 760 1.20 0.92 2,010 912 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 4

Severe-Duty 36 915 1.16 0.89 1,921 871 39,058 173.7 27,319 121.5 23,777 105.8 54.5 1384 4

Cast Lip 42 1065 1.38 1.06 2,119 961 39,058 173.7 27,319 121.5 23,777 105.8 54.5 1384 5

Severe-Duty 30 760 0.95 0.73 2,080 943 37,676 167.0 27,640 122.9 24,020 106.8 56.5 1435 4

Plate Lip 36 915 1.16 0.89 2,179 988 37,676 167.0 27,640 122.9 24,020 106.8 56.5 1435 4

Ditching 60 1525 1.34 1.02 1,562 709 45,273 201.4 29,244 130.1 25,225 112.2 47.0 1194 0

*All capacities are SAE heaped ratings and with side cutters.

Bucket Bucket Bucket Arm Dig Force Arm Dig Force Bucket

in. mm cu. yd. m

36 915 1.48 1.13 1,845 837 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 5

42 1065 1.38 1.06 1,785 810 37,670 167.0 27,690 122.9 24,020 106.8 56.5 1435 5

42 1065 1.75 1.34 1,966 892 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 5

48 1220 2.03 1.55 2,068 938 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 6

42 1065 1.38 1.06 2,195 996 37,676 167.0 27,690 122.9 24,020 106.8 56.5 1435 5

48 1220 1.60 1.22 2,359 1070 37,676 167.0 27,690 122.9 24,020 106.8 56.5 1435 6

54 1370 1.82 1.39 2,507 1137 37,676 167.0 27,690 122.9 24,020 106.8 56.5 1435 6

36 915 1.48 1.13 2,133 968 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 4

42 1065 1.75 1.34 2,279 1034 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 5

48 1200 2.03 1.55 2,505 1136 35,846 159.4 26,710 118.8 23,313 103.7 62.5 1588 6

42 1065 1.38 1.06 2,345 1064 37,676 167.0 27,640 122.9 24,020 106.8 56.5 1435 5

72 1830 1.66 1.27 1,759 798 45,273 201.4 29,244 130.1 25,225 112.2 47.0 1194 0

3

lb. kg lb. kN lb. kN lb. kN in. mm

14 1716

Page 10

270C LC Buckets

A full line of buckets is offered to meet a wide variety of applications. Digging forces are with power boost. The buckets have an adjustable bushing for side clearance, with the exception of the

ditching bucket. Tooth selection includes either the John Deere Fanggs®, Standard, Tiger, Twin Tiger, Abrasion panel, or Flare tooth, or the ESCO (Vertalok) Standard, Tiger, Twin Tiger, or Flare tooth.

Replaceable cutting edges are available through John Deere parts. Optional side cutters add 6 inches (150 mm) to bucket widths.

Type Bucket Width Capacity* Weight Dig Force 10 ft. 2 in. (3.10 m) 12 ft. 4 in. (3.75 m) Tip Radius No. Teeth

General-Purpose 24 610 0.95 0.73 1,453 659 37,480 167.0 26,056 116.0 22,950 101.5 62.5 1588 3

Plate Lip 30 760 1.20 0.92 1,731 785 37,480 167.0 26,056 116.0 22,950 101.5 62.5 1588 4

Heavy-Duty 30 760 0.95 0.73 1,930 875 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 4

Plate Lip 36 915 1.16 0.89 2,075 941 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 4

Heavy-Duty 24 610 0.92 0.70 1,765 801 37,480 166.7 26,076 116.0 22,950 101.5 62.5 1588 3

High Capacity 30 760 1.20 0.92 2,010 912 37,480 166.7 26,076 116.0 22,950 101.5 62.5 1588 4

Severe-Duty 36 915 1.16 0.89 1,921 871 43,005 191.3 27,262 121.3 23,862 106.1 54.5 1384 4

Cast Lip 42 1065 1.38 1.06 2,119 961 43,005 191.3 27,262 121.3 23,862 106.1 54.5 1384 5

Severe-Duty 30 760 0.95 0.73 2,080 943 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 4

Plate Lip 36 915 1.16 0.89 2,179 988 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 4

Ditching 60 1525 1.34 1.02 1,562 709 49,848 221.7 28,469 126.6 24,779 110.2 47.0 1194 0

*All capacities are SAE heaped ratings.

Bucket Bucket Bucket Arm Dig Force Arm Dig Force Bucket

in. mm cu. yd. m

36 915 1.48 1.13 1,845 837 37,480 167.0 26,056 116.0 22,950 101.5 62.5 1588 5

42 1065 1.38 1.06 1,785 810 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 5

42 1065 1.75 1.34 1,966 892 37,480 167.0 26,056 116.0 22,950 101.5 62.5 1588 5

48 1220 2.03 1.55 2,068 938 37,480 167.0 26,056 116.0 22,950 101.5 62.5 1588 6

42 1065 1.38 1.06 2,195 996 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 5

48 1220 1.60 1.22 2,359 1070 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 6

54 1370 1.82 1.39 2,507 1137 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 6

36 915 1.48 1.13 2,133 968 37,480 166.7 26,076 116.0 22,950 101.5 62.5 1588 4

42 1065 1.75 1.34 2,279 1034 37,480 166.7 26,076 116.0 22,950 101.5 62.5 1588 5

48 1200 2.03 1.55 2,505 1136 37,480 166.7 26,076 116.0 22,950 101.5 62.5 1588 6

42 1065 1.38 1.06 2,345 1064 41,476 184.5 26,956 119.9 23,627 105.1 56.5 1435 5

72 1830 1.66 1.27 1,759 798 49,848 221.7 28,469 126.6 24,779 110.2 47.0 1194 0

3

lb. kg lb. kN lb. kN lb. kN in. mm

200C LC Bucket Selection Guide

Material (loose weight)

General-Purpose Bucket* Heavy-Duty Bucket*

Wood chips – 700 lb./cu. yd. (420 kg/m3) .........................6.50 cu. yd. (5.0 m3)—

Peat, dry – 750 lb./cu. yd. (440 kg/m3) .............................5.50 cu. yd. (4.2 m3)—

Cinders – 950 lb./cu. yd. (560 kg/m3) ...............................4.00 cu. yd. (3.1 m3)—

Peat, wet – 1,170 lb./cu. yd. (690 kg/m3)..........................3.50 cu. yd. (2.7 m3)—

Topsoil – 1,600 lb./cu. yd. (950 kg/m3) .............................2.50 cu. yd. (1.9 m3)—

Coal – 1,780 lb./cu. yd. (1050 kg/m3) ...............................2.25 cu. yd. (1.7 m3)—

Caliche – 2,100 lb./cu. yd. (1250 kg/m3)...........................1.38 to 1.75 cu. yd. (1.1 to 1.3 m3) 1.25 to 1.50 cu. yd. (1.0 to 1.2 m3)

Earth, loam – 2,100 lb./cu. yd. (1250 kg/m3) ....................1.75 cu. yd. (1.3 m3) 1.50 cu. yd. (1.2 m3)

Shale – 2,250 lb./cu. yd. (1330 kg/m3) .............................1.75 cu. yd. (1.3 m3) 1.50 cu. yd. (1.2 m3)

Sand, dry – 2,400 lb./cu. yd. (1420 kg/m3) .......................1.75 cu. yd. (1.3 m3) 1.50 cu. yd. (1.2 m3)

Clay, dry – 2,500 lb./cu. yd. (1480 kg/m3).........................1.12 to 1.50 cu. yd. (0.9 to 1.1 m3) 1.38 cu. yd. (1.1 m3)

Earth, dry – 2,550 lb./cu. yd. (1510 kg/m3).......................1.38 to 1.50 cu. yd. (1.1 to 1.2 m3) 1.38 cu. yd. (1.1 m3)

Limestone, broken or crushed – 2,600 lb./cu. yd.

(1540 kg/m3) .............................................................1.12 to 1.50 cu. yd. (0.9 to 1.2 m3) 1.00 to 1.38 cu. yd. (0.8 to 1.1 m3)

Earth, wet – 2,700 lb./cu. yd. (1600 kg/m3) ......................1.50 cu. yd. (1.2 m3) 1.38 cu. yd. (1.1 m3)

Clay, wet – 2,800 lb./cu. yd. (1660 kg/m3)........................1.50 cu. yd. (1.2 m3) 1.38 cu. yd. (1.1 m3)

Rock, granite, blasted and broken – 2,800 lb./cu. yd.

(1660 kg/m3) .............................................................1.38 to 1.75 cu. yd. (1.1 to 1.3 m3) 1.25 to 1.50 cu. yd. (1.0 to 1.2 m3)

Sand, moist – 2,850 lb./cu. yd. (1690 kg/m3)....................1.50 cu. yd. (1.2 m3) 1.38 cu. yd. (1.1 m3)

Sand and gravel, dry – 2,900 lb./cu. yd. (1720 kg/m3).......1.50 cu. yd. (1.2 m3) 1.38 cu. yd. (1.1 m3)

Sand, wet – 3,100 lb./cu. yd. (1840 kg/m3) ......................1.38 cu. yd. (1.1 m3) 1.25 cu. yd. (1.0 m3)

Sand and gravel, wet – 3,400 lb./cu. yd. (2020 kg/m3) ......1.38 cu. yd. (1.1 m3) 1.25 cu. yd. (1.0 m3)

*Contact your John Deere dealer for optimum bucket and attachment selections. These recommendations are for general conditions and average use. Larger buckets may be possible when using

light buckets, for flat and level operations, less compacted materials, and volume loading applications such as mass excavation applications in ideal conditions. Smaller buckets are recommended for

adverse conditions such as off-level applications and uneven surfaces. Bucket capacity indicated is SAE heaped.

Recommended Bucket Size

230C LC Bucket Selection Guide

Recommended Bucket Size

General-Purpose Bucket* Heavy-Duty Bucket*

Material (loose weight)

Wood chips – 700 lb./cu. yd. (420 kg/m3) .........................7.0 cu. yd. (5.4 m3)—

Peat, dry – 750 lb./cu. yd. (440 kg/m3) .............................6.0 cu. yd. (4.6 m3)—

Cinders – 950 lb./cu. yd. (560 kg/m3) ...............................4.25 cu. yd. (3.2 m3)—

Peat, wet – 1,170 lb./cu. yd. (690 kg/m3)..........................3.75 cu. yd. (2.9 m3)—

Topsoil – 1,600 lb./cu. yd. (950 kg/m3) .............................2.5 cu. yd. (1.9 m3)—

Coal – 1,780 lb./cu. yd. (1050 kg/m3) ...............................2.5 cu. yd. (1.9 m3)—

Caliche – 2,100 lb./cu. yd. (1250 kg/m3)...........................1.25–1.75 cu. yd. (1.0–1.3 m3) 1.13–1.50 cu. yd. (0.9–1.2 m3)

Earth, loam – 2,100 lb./cu. yd. (1250 kg/m3) ....................1.75 cu. yd. (1.3 m3) 1.50 cu. yd. (1.2 m3)

Shale – 2,250 lb./cu. yd. (1330 kg/m3) .............................1.75 cu. yd. (1.3 m3) 1.50 cu. yd. (1.2 m3)

Sand, dry – 2,400 lb./cu. yd. (1420 kg/m3) .......................1.75 cu. yd. (1.3 m3) 1.50 cu. yd. (1.2 m3)

Clay, dry – 2,500 lb./cu. yd. (1480 kg/m3).........................1.25–1.75 cu. yd. (1.0–1.3 m3) 1.38 cu. yd. (1.1 m3)

Earth, dry – 2,550 lb./cu. yd. (1510 kg/m3).......................1.25–1.63 cu. yd. (1.0–1.2 m3) 1.38 cu. yd. (1.1 m3)

Limestone, broken or crushed – 2,600 lb./cu. yd.

(1540 kg/m3) .............................................................1.13–1.63 cu. yd. (0.9–1.2 m3) 1.0–1.38 cu. yd. (0.8–1.0 m3)

Earth, wet – 2,700 lb./cu. yd. (1600 kg/m3) ......................1.75 cu. yd. (1.3 m3) 1.63 cu. yd. (1.2 m3)

Clay, wet – 2,800 lb./cu. yd. (1660 kg/m3)........................1.63 cu. yd. (1.2 m3) 1.50 cu. yd. (1.2 m3)

Rock, granite, blasted and broken – 2,800 lb./cu. yd.

(1660 kg/m3) .............................................................1.50–1.75 cu. yd. (1.2–1.3 m3) 1.25–1.50 cu. yd. (1.0–1.2 m3)

Sand, moist – 2,850 lb./cu. yd. (1690 kg/m3)....................1.63 cu. yd. (1.2 m3) 1.50 cu. yd. (1.2 m3)

Sand and gravel, dry – 2,900 lb./cu. yd. (1720 kg/m3).......1.63 cu. yd. (1.2 m3) 1.50 cu. yd. (1.2 m3)

Sand, wet – 3,100 lb./cu. yd. (1840 kg/m3) ......................1.50 cu. yd. (1.2 m3) 1.38 cu. yd. (1.0 m3)

Sand and gravel, wet – 3,400 lb./cu. yd. (2020 kg/m3) ......1.50 cu. yd. (1.2 m3) 1.38 cu. yd. (1.0 m3)

*Contact your John Deere dealer for optimum bucket and attachment selections. These recommendations are for general conditions and average use. Larger buckets may be possible when using

light buckets, for flat and level operations, less compacted materials, and volume loading applications such as mass excavation applications in ideal conditions. Smaller buckets are recommended for

adverse conditions such as off-level applications and uneven surfaces. Bucket capacity indicated is SAE heaped.

270C LC Bucket Selection Guide

Recommended Bucket Size

General-Purpose Bucket* Heavy-Duty Bucket*

Material (loose weight)

Wood chips – 700 lb./cu. yd. (420 kg/m3) .........................8.0 cu. yd. (6.2 m3)—

Peat, dry – 750 lb./cu. yd. (440 kg/m3) .............................7.0 cu. yd. (5.4 m3)—

Cinders – 950 lb./cu. yd. (560 kg/m3) ...............................5.0 cu. yd. (3.9 m3)—

Peat, wet – 1,170 lb./cu. yd. (690 kg/m3)..........................4.5 cu. yd. (3.5 m3)—

Topsoil – 1,600 lb./cu. yd. (950 kg/m3) .............................3.25 cu. yd. (2.5 m3)—

Coal – 1,780 lb./cu. yd. (1050 kg/m3) ...............................3.25 cu. yd. (2.5 m3)—

Caliche – 2,100 lb./cu. yd. (1250 kg/m3)...........................1.50–2.0 cu. yd. (1.2–1.5 m3) 1.25–2.0 cu. yd. (1.0–1.5 m3)

Earth, loam – 2,100 lb./cu. yd. (1250 kg/m3) ....................2.25 cu. yd. (1.7 m3) 2.0 cu. yd. (1.5 m3)

Shale – 2,250 lb./cu. yd. (1330 kg/m3) .............................2.25 cu. yd. (1.7 m3) 2.0 cu. yd. (1.5 m3)

Sand, dry – 2,400 lb./cu. yd. (1420 kg/m3) .......................2.25 cu. yd. (1.7 m3) 2.0 cu. yd. (1.5 m3)

Clay, dry – 2,500 lb./cu. yd. (1480 kg/m3).........................1.50–2.0 cu. yd. (1.2–1.3 m3) 1.75 cu. yd. (1.3 m3)

Earth, dry – 2,550 lb./cu. yd. (1510 kg/m3).......................1.50–2.0 cu. yd. (1.2–1.3 m3) 1.75 cu. yd. (1.3 m3)

Limestone, broken or crushed – 2,600 lb./cu. yd.

(1540 kg/m3) .............................................................1.50–2.0 cu. yd. (1.2–1.5 m3) 1.38–1.75 cu. yd. (1.1–1.3 m3)

Earth, wet – 2,700 lb./cu. yd. (1600 kg/m3) ......................2.0 cu. yd. (1.5 m3) 1.75 cu. yd. (1.3 m3)

Clay, wet – 2,800 lb./cu. yd. (1660 kg/m3)........................2.0 cu. yd. (1.5 m3) 1.75 cu. yd. (1.3 m3)

Rock, granite, blasted and broken – 2,800 lb./cu. yd.

(1660 kg/m3) .............................................................1.75–2.0 cu. yd. (1.3–1.5 m3) 1.50–1.75 cu. yd. (1.2–1.3 m3)

Sand, moist – 2,850 lb./cu. yd. (1690 kg/m3)....................2.0 cu. yd. (1.5 m3) 1.75 cu. yd. (1.3 m3)

Sand and gravel, dry – 2,900 lb./cu. yd. (1720 kg/m3).......2.0 cu. yd. (1.5 m3) 1.75 cu. yd. (1.3 m3)

Sand, wet – 3,100 lb./cu. yd. (1840 kg/m3) ......................1.50 cu. yd. (1.2 m3) 1.63 cu. yd. (1.2 m3)

Sand and gravel, wet – 3,400 lb./cu. yd. (2020 kg/m3) ......1.75 cu. yd. (1.3 m3) 1.63 cu. yd. (1.2 m3)

*Contact your John Deere dealer for optimum bucket and attachment selections. These recommendations are for general conditions and average use. Larger buckets may be possible when using

light buckets, for flat and level operations, less compacted materials, and volume loading applications such as mass excavation applications in ideal conditions. Smaller buckets are recommended for

adverse conditions such as off-level applications and uneven surfaces. Bucket capacity indicated is SAE heaped.

18 19

Page 11

200C LC / 230C LC / 270C LC Excavators

Key: ● Standard equipment ▲ Optional or special equipment *See your John Deere dealer for further information.

200 230 270

●●●

●●●Auto-idle system

●●●Automatic belt tension device

●●●Batteries (two 12 volt), 180-min. reserve

●●●Coolant recovery tank

●●●Dual element dry-type air filter

●●●Electronic engine control with diagnostics

●●●Enclosed fan guard (conforms to SAE

●●●Engine coolant to –34°F (–37°C)

●●●Fuel filter with water separator

●●●Full-flow oil filter

●●●Radiator trash screen

●●●Tier II EPA off-road emission compliant

●●●Turbocharger with charge air cooler

●●●Underhood muffler with vertical curved

▲▲▲Electric ether starting aid

▲▲▲Engine coolant heater

●●●

●●●Auxiliary hydraulic valve section

●●●Spring-applied, hydraulically released

▲▲▲Auxiliary hydraulic lines

▲▲▲Auxiliary pilot and electric controls

▲▲▲Hydraulic filter restriction indicator kit

▲▲▲Load-lowering control device

▲▲▲Single pedal propel control

●●●

●●●Propel motor shields

●●●Track guides, front idler and center

●●●Triple semi-grouser shoes, 32 in. (800 mm)

▲▲▲Triple semi-grouser shoes, 24 in. (600 mm)

▲▲ Triple semi-grouser shoes, 28 in. (700 mm)

●●●Two-speed propel with automatic shift

●●●Upper carrier rollers (2)

●●●

●●●Vandal locks with ignition key: Cab door /

Engine

Meets EPA Tier II non-road emissions

regulations

capacity

capability

J1308)

end exhaust stack

Hydraulic System

Reduced-drift valve for boom down, arm in

automatic swing brake

Undercarriage

Planetary drive with axial piston motors

Upperstructure

Right- and left-hand mirrors

Fuel cap / Service doors

200 230 270

●●●

Front Attachments

Bucket-to-arm clearance adjustable

bushing (except ditching buckets)

●●●Centralized lubrication system

●●●Dirt seals on all bucket pins

●●●No-boom-arm option

▲ Arm, 7 ft. 3 in. (2.22 m)

▲ Arm, 9 ft. 7 in. (2.91 m)

▲ Arm, 9 ft. 9 in. (2.96 m)

▲ Arm, 10 ft. 2 in. (3.10 m)

▲ Arm, 11 ft. 10 in. (3.61 m)

▲ Arm, 12 ft. 4 in. (3.75 m)

▲▲▲Attachment quick couplers

▲▲▲Boom cylinder with plumbing to main-

▲▲▲Buckets: Ditching / General purpose /

frame for no-boom-arm option

General-purpose high capacity / Heavy

duty / Heavy-duty high capacity / Severeduty cast lip / Severe-duty plate lip /

Side cutters and teeth

▲▲▲Material clamps

▲▲▲Super-long fronts

Operator’s Station

●●●

Adjustable independent control positions

(levers-to-seat, seat-to-pedals)

●●●AM/FM radio

●●●Auto climate control/air conditioner,

20,000 Btu/hr. (5.9 kW) with heater and

pressurizer

●●●Built-in Operator’s Manual storage

●●●Cell-phone power outlet, 12 volt, 60 watt,

compartment and manual

●●●Coat hook

5 amp

●●●Deluxe suspension cloth seat with 4-in.

●●●Floor mat

(100 mm) adjustable armrests

●●●Front windshield wiper with intermittent

●●●Gauges (illuminated): Engine coolant /

speeds

●●●Horn, electric

Fuel

●●●Hourmeter, electric

●●●Hydraulic shutoff lever, all controls

●●●Hydraulic warm-up control

●●●Interior light

●●●Large cup holder

200 230 270

Operator’s Station (continued)

●●●Machine Information Center (MIC)

●●●Mode selectors (illuminated): Power

modes – three / Travel modes – two with

automatic shift / Work mode – one

●●●Monitor system with alarm features:

Auto-idle/auto-acceleration indicator

light / Engine air cleaner restriction

indicator light / Engine check / Engine

coolant temperature indicator light with

audible alarm / Engine oil pressure

indicator light with audible alarm / Fluid

level: Engine coolant level indicator

light, engine oil level indicator light,

and hydraulic oil level indicator light /

Low alternator charge indicator light /

Low fuel indicator light / Wiper mode

indicator / Work lights on indicator /

Work mode indicator

▲▲▲Monitor system with alarm features:

Hydraulic oil filter restriction indicator

light

●●●Motion alarm with cancel switch (con-

●●●Power boost switch on right control lever

forms to SAE J994)

●●●Propel pedals and levers

●●●SAE two-lever control pattern

●●●Seat belt, 2 in. (51 mm), retractable

▲▲▲Seat belt, 3 in. (76 mm), non-retractable

●●●Tinted glass

●●●Transparent tinted overhead hatch

▲▲▲24- to 12-volt D.C. radio convertors,

▲▲▲Alternate pilot control pattern

10 amp

▲▲▲Circulation fan

▲▲▲Protection screens for cab front, rear,

▲▲▲Window vandal protection covers

and side

Electrical

●●●

45-amp alternator

●●●Blade-type multi-fused circuits

●●●Positive terminal battery covers

▲▲▲Cab extension wiring harness

Lights

●●●

Work lights: Halogen / One mounted on

boom / One mounted on frame

Control Owning and Operating Costs

Total Repair Cost Management (TRCM) is part of John Deere’s proactive, fix-before-fail strategy on

machine maintenance that will help control costs, increase profits, and reduce stress. Included in this

comprehensive lineup of ongoing programs and services are:

OilScan®Plus program – tells you what’s going on inside all of your machine’s major compo-

nents so you’ll know if there’s a problem before you see a decline in performance. OilScan Plus oil

analysis is included in most SECURE®-Extended warranty and preventive-maintenance agreements.

Component life-cycle data – gives you vital information on the projected life span of components and lets you make informed decisions on machine maintenance by telling you approximately

how many hours of use you can expect from an engine, transmission, or hydraulic pump. This information can be used to preempt catastrophic downtime by servicing major components at about 80

percent of their life cycle.

Preventive Maintenance (PM) agreements – give you a fixed cost for maintaining a machine

for a given period of time. They also help you avoid downtime by ensuring that critical maintenance

Net engine power is with standard equipment including air cleaner, exhaust

system, alternator, and cooling fan, at standard conditions per SAE J1349 and

DIN 6270B, using No. 2-D fuel at 35 API gravity. No derating is required up to

10,000-ft. (3050 m) altitude. Gross power is without cooling fan.

DKAX200CLC Litho in U.S.A. (04-04)

work gets done right and on schedule. On-site preventive maintenance service performed where and

when you need it helps protect you from the expense of catastrophic failures and lets you avoid wastedisposal hassles.

SECURE-Extended warranty – gives you a fixed cost for machine repairs for a given period of

time so you can effectively manage costs. Whether you work in a severe-service setting or just want to

spread the risk of doing business, this is a great way to custom-fit coverage for your operation. And a

SECURE-Extended contract also travels well because it’s backed by John Deere and is honored by all

Deere construction dealers.

Customer Support Advisors (CSAs) – Deere believes the CSA program lends a personal qual-

ity to Total Repair Cost Management. Certified CSAs have the knowledge and skills for helping make

important decisions on machine maintenance and repair. Their mission is to help you implement a plan

that’s right for your business and take the burden of machine maintenance off your shoulders.

Specifications and design subject to change without notice. Wherever applicable, specifications

are in accordance with PCSA and SAE standards. Except where otherwise noted, these specifications are based on units with 32-in. (800 mm) triple semi-grouser shoes; full fuel tanks; and

175-lb. (79 kg) operators; 200C LC unit with 9-ft. 7-in. (2.91 m) arm, 42-in. (1065 mm) 1.12-cu.

3

) bucket, and 10,270-lb. (4658 kg) counterweight; 230C LC unit with 11-ft. 10 in.

yd. (0.86 m

(3.61 m) arm, 42-in. (1065 mm) 1.38-cu. yd.(1.06 m

terweight; and 270C LC unit with 12-ft. 4-in. (3.75 m) arm, 42-in. (1065 mm) 1.75-cu. yd. (1.34

3

) bucket, and 13,468-lb. (6109 kg) counterweight.

m

3

) bucket, and 11,265-lb. (5110 kg) coun-

Loading...

Loading...