Page 1

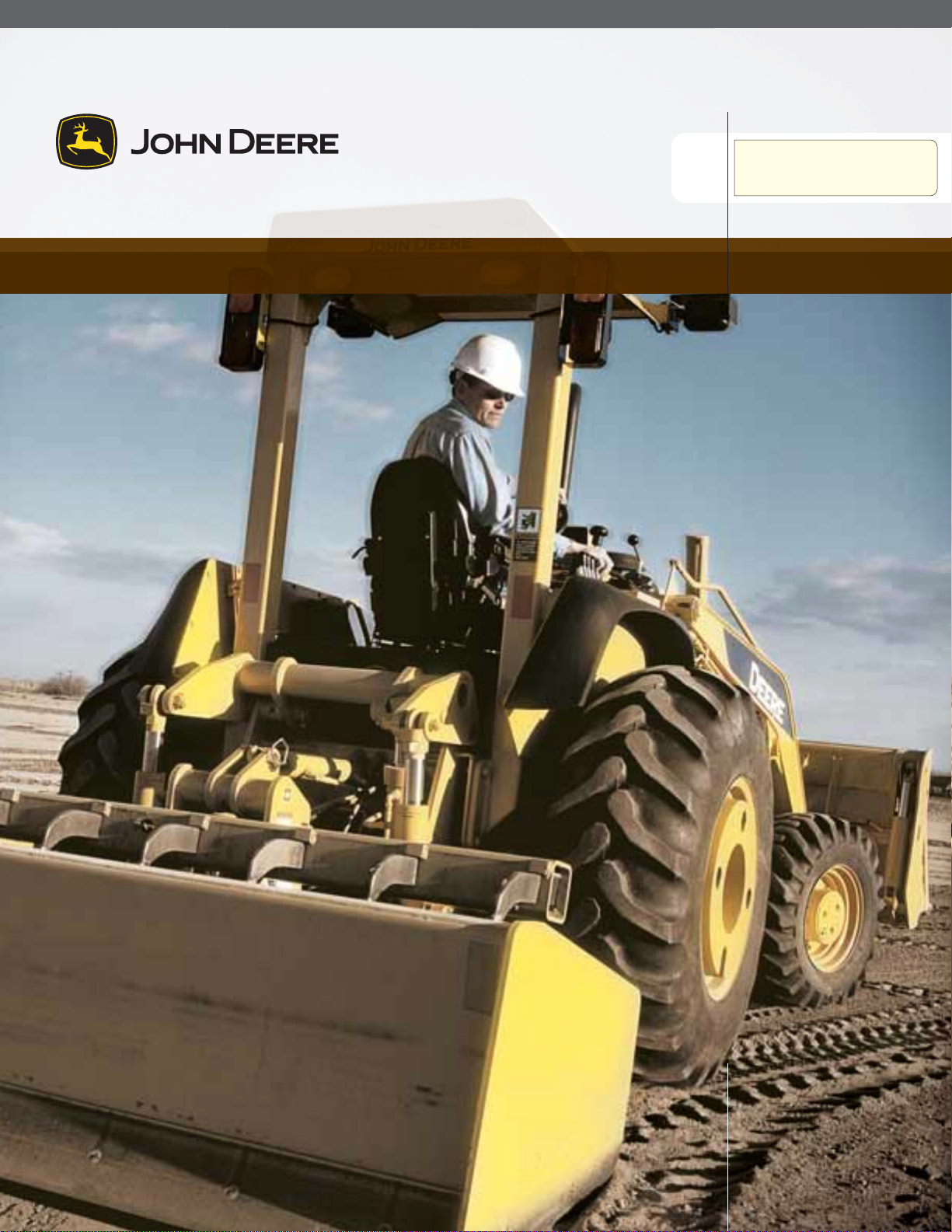

73 SAE NET HORSEPOWER

LOADERS

LE

210LE

ALL-WHEEL-DRIVE

Page 2

Not your “garden-variety”

loader tractor

Not your “garden-variety”

loader tractor

Not your “garden-variety”

loader tractor

If you think the 210LE is just another tractor with

yellow paint, think again. With heavy-duty unitized

mainframe, integral three-point hitch, and

industrial-strength loader, the 210LE is all

business. Its high-torque John Deere diesel,

four-speed torque-converter transmission, and

mechanical front-wheel drive deliver plenty of pull

with a box scraper. And more than enough muscle

for powering through piles and heaping the bucket.

Powerful, durable, affordable — that’s the 210LE.

PAGES

2–3

Page 3

> 73 SAE net hp; 80 SAE net hp with turbocharger

> 1–1.25 cu.-yd. bucket

> 5,280-lb. lift capacity

> 7,900-lb. breakout force

> 9,130-lb. operating weight

Page 4

PAGES

4–5

The 210LE is widely regarded as the best

grading tractor available. And for good reason.

Its responsive, heavy-duty integral three-point

hitch and rugged multi-position box scraper

make the fine art of grading easy to master. But

when the work takes you outside the box, the

210LE is up to those tasks, too. Its industrial-

strength loader with your choice of heavy-duty

general-purpose or multipurpose bucket puts

a variety of work within reach. Demo one and

find out for yourself why the versatile 210LE is

the most popular loader tractor in its class.

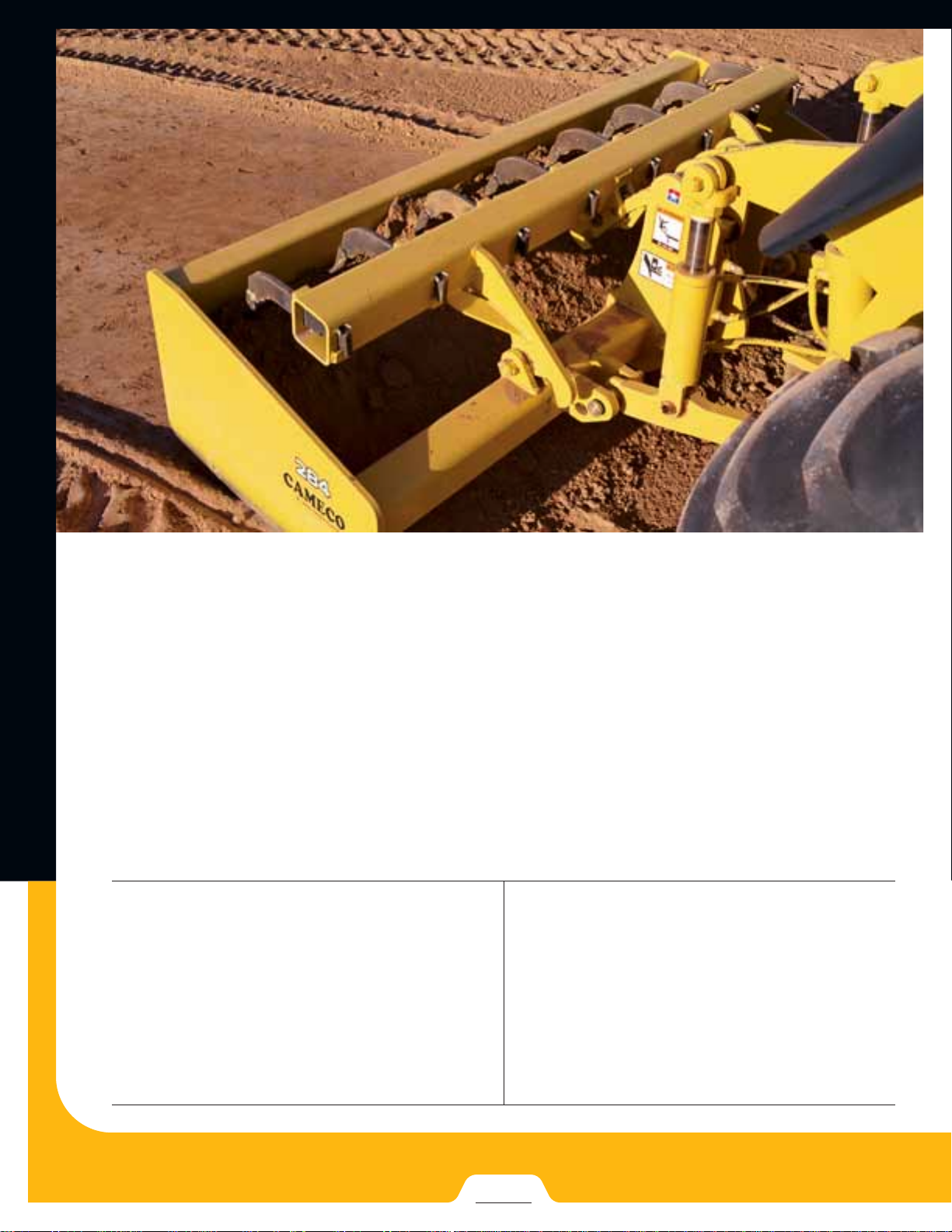

84-inch Cameco box scraper

employs a high-volume back,

double-beveled reversible

cutting edge, and high-lift

scarifier with heat-treated

replaceable teeth.

Maximum productivity

end to end

Maximum productivity

end to end

Maximum productivity

end to end

Page 5

Curved knee provides

exceptional reach, easily

dumping to the center

of most trucks for fast

loading cycles.

Tight torque converter

match, high torque reserve,

and optimum lift-to-crowd

match make the 210LE a

very capable loading tractor.

Integral category II three-point hitch

gives hydraulic control of lift and

lower with down-pressure and float,

tilt, pitch, and auxiliary functions.

Lower-link sway blocks and single tilt

cylinder are standard; dual cylinders,

fixed drawbar, and 540-rpm PTO

drive are available.

Choose either a 1-cu. -yd. general-

purpose or 1.12-cu. -yd. multipurpose

bucket. The “four-in-one” version

works well for a wide variety of tasks

such as spreading gravel, grading,

carrying cumbersome objects, or

loading trucks.

Page 6

Comes equipped,

not stripped

Comes equipped,

not stripped

Comes equipped,

not stripped

PAGES

6–7

No, the LE in this tractor’s model number

doesn’t stand for “lots of extras”. But it should.

Because this durable Deere utilizes several of

the same drivetrain components and structures

found in our highly reliable 310G Backhoe.

It’s no wonder the 210LE has carved out such a

loyal following among asphalt contractors, site

developers, and rental yards. And why it returns

such outstanding value at trade-in time. When

you know how it’s built, you’ll opt for the 210LE.

Unlike the “throwaway” engines employed

by others, the 210LE utilizes the same

heavy-duty wet-sleeve 4.5-L John diesels

found in our highly reliable backhoes.

Page 7

Mechanical front-wheel

drive delivers extra traction

for increased productivity

with heavy loads or on

marginal jobsites.

One-piece high-strength

unitized mainframe is

purpose-built to provide a

solid working base for

grading applications.

Isolates components from

shock-load stress, too.

Nothing light-duty here. This

is one category II three-point

hitch that can endure the

rigors of everyday use.

Box-constructed high-

tensile steel loader arms

provide superior strength

and durability.

Inboard-mounted multiple-disc brakes are sealed in a cooling oil bath for long, trouble-free life.

Page 8

Easy to operate

Easy to operate

Easy to operate

Electronic control unit lets

service technicians easily

retrieve vital operating

information and helps

diagnose problems more

quickly.

PAGES

8–9

Choose the four-speed trans-

mission that’s right for you —

a synchroshift with hydraulic

reverser is standard; powershift

is available. Either way, you get

smooth, no-clutch fingertip

direction changes for fast

work cycles.

FNR neutral safety switch

and automatic park brake

help prevent accidental

machine movement.

Doesn’t allow park-brake

drive through, either.

Low-profile sloped hood,

compact forward console,

loader arms that angle

outward, and two-post ROPS

allow unobstructed visibility.

Suspension seat swivels

15 degrees to the right for

extra visibility of rear tools.

Mechanical front-wheel drive and

a differential lock that engages

on-the-go give extra traction in

poor underfoot conditions or for

moving heavy loads. Limited-slip

MFWD is optional.

Transmission disconnect,

automatic return-to-dig,

bucket self-leveling, and

float make an operator more

efficient and help speed

repetitive loading cycles.

Three-point hitch controls

are conveniently positioned,

and hydraulic response is

consistent and quick.

Page 9

Easy to maintain

Easy to maintain

Easy to maintain

Expect low daily owning and

operating costs with the 210LE.

Its fuel-efficient Deere diesel runs

500 hours between oil changes.

Vertical spin-on filters simplify

fluid changes. Poly-V belt needs

no adjustment.

Two-position tilt hood

provides quick ground-level

access to engine and

transmission dipsticks,

engine oil fill, fuel filter, and

coolant reservoir.

Wet-disc brakes are fully

modulated and self-

adjusting so they require

little effort or maintenance.

Periodic maintenance chart

helps ensure that nothing

gets overlooked.

Page 10

Specifications

Specifications

Specifications

Engine 210LE

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . John Deere 4045D, naturally aspirated standard / John Deere 4045T, turbocharged optional; meets EPA and CARB emission non-road regulations

Rated power @ 2,200 rpm. . . . . . . . . . . . . . . . . . . . . . . . . 78 SAE gross hp (58.2 kW) / 73 SAE net hp (54.4 kW)

John Deere 4045T with turbocharger . . . . . . . . . . . . .

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276 cu. in. (4.524 L)

Fuel consumption, typical . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 to 1.9 gal./hr. (4.2 to 7.2 L/h)

Torque rise, net. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 percent

Maximum net torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220 lb.-ft. (298 Nm)

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pressure system with spin-on filter and cooler

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual stage dry type with safety element, evacuator valve, and prescreener

Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volt with 65-amp alternator

Cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . sucker type, 1:1 speed ratio

Transmission

Four-speed, helical-cut gear, collar-shift transmission synchronized in all gears with hydraulic reverser (optional full-power-shifted transmission)

Torque converter, single stage, dual phase with 2.63:1

stall ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 in. (280 mm) diameter

Tra vel speeds (maximum) with 16.9-24, 8 PR R4 rear

and 12-16.5, 8 PR NHS front tires

Gear 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 mph (5.8 km/h) 4.0 mph (6.4 km/h)

Powershift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 mph (5.8 km/h) 4.0 mph (6.4 km/h)

Gear 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.9 mph (9.5 km/h) 6.6 mph (10.6 km/h)

Powershift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.8 mph (9.3 km/h) 6.7 mph (10.8 km/h)

Gear 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.9 mph (22.4 km/h) 13.9 mph (22.4 km/h)

Powershift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.9 mph (22.4 km/h) 16.1 mph (25.9 km/h)

Gear 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.5 mph (33.0 km/h) 20.5 mph (33.0 km/h)

Powershift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.5 mph (33.0 km/h) N/A

Final Drives

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . heavy-duty, inboard planetary final drives evenly distribute shock loads over three gears

(conform to SAE J1473)

Brakes

Service brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic multi wet disc, mounted inboard, self adjusting and self equalizing

Parking and secondary brake . . . . . . . . . . . . . . . . . . . . . . . spring applied, hydraulically released multi wet disc, independent of service brakes, switch-operated electrical control, self engaging with engine shutdown

Capacities

Fuel tank (with ground level fueling). . . . . . . . . . . . . . . . . . 26 gal. (98 L)

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 gal. (16 L)

Engine oil including filter . . . . . . . . . . . . . . . . . . . . . . . . . . 9 qt. (8.5 L)

Torque converter and transmission. . . . . . . . . . . . . . . . . . . 15 qt. (14 L)

Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.4 gal. (54.5 L)

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 gal. (13 L)

Mechanical-front-wheel-drive axle . . . . . . . . . . . . . . . . . . . 2.3 gal. (8.5 L)

Steering

Typehydrostatic power steering conforms to SAE J1151, emergency steering to SAE J53

Mechanical-front-wheel-drive

Curb turning radius with brakes . . . . . . . . . . . . . . . . . 10 ft. 11 in. (3.34 m)

Without brakes . . . . . . . . . . . . . . . . . . . . . . . . . . 13 ft. 8 in. (4.17 m)

Bucket clearance circle with brakes . . . . . . . . . . . . . . 29 ft. 9 in. (9.07 m)

Without brakes . . . . . . . . . . . . . . . . . . . . . . . . . . 35 ft. 3 in. (10.74 m)

Steering wheel turns, stop to stop. . . . . . . . . . . . . . . . 3

Axle oscillations stop to stop, both axles. . . . . . . . . . . . . . . 22 degrees

Axle ratings (SAE J43) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17,340 lb. (7865 kg) front / 12,610 lb. (5720 kg) rear

Hydraulic System

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . open center

Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,750 psi (19 000 kPa)

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . gear type with integral priority valve

Flow @ 2,200 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 gpm (94.5 L/min.)

Filter, return oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-micron, spin-on enclosed replaceable element

Cylinders

Loader boom (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.15 in. (80 mm) 31.1 in. (790 mm) 1.97 in. (50 mm)

Loader bucket (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.54 in. (90 mm) 29.3 in. (744 mm) 1.97 in. (50 mm)

Steering (1) standard axle. . . . . . . . . . . . . . . . . . . . . . . . . . 1.97 in. (50 mm) 9.49 in. (241 mm) 0.98 in. (25 mm)

Steering (1) MFWD axle . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.56 in. (65 mm) 8.27 in. (210 mm) 1.42 in. (36 mm)

84.5 SAE gross hp (63 kW) / 80 SAE net hp (60 kW)

Forward Reverse

Fill / Change

Bore Stroke Rod

PAGES

10–11

Page 11

Three-Point Hitch 210LE

B

G

C

M

D

E

K

I

N

F

H

L

A

J

b

a

j

d

e

k

g

i

h

f

c

Lift (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.00 in. (76.2 mm) 8.00 in. (203.0 mm) 2.00 in. (50.8 mm)

Pitch (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.50 in. (63.5 mm) 8.50 in. (215.9 mm) 1.25 in. (31.8 mm)

Tilt (1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.00 in. (76.2 mm) 4.75 in. (120.7 mm) 2.00 in. (50.8 mm)

Bore Stroke Rod

Tires

With mechanical-front-wheel-drive. . . . . . . . . . . . . . . . . . . 16.9-24, 8 PR R4 12-16.5, 8 PR NHS

Rear Front

Category II Three-Point Hitch

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . heavy duty, integral to vehicle mainframe, with individual lever control of the lift, tilt, pitch, and auxiliary functions and with down force and float on the lift circuit

Static lift at lower link, ends horizontal. . . . . . . . . . . . . . . . 6,870 lbf (30.57 kN)

Static lift 24 in. (610 mm) behind lift points . . . . . . . . . . . . 3,790 lbf (16.85 kN)

Controlled hydraulic flow rate, maximum . . . . . . . . . . . . . . 10 gpm (37.9 L/min.)

SAE J/ISO 6016.3.2.1 Operating Weights

Base tractor with full fuel tank and 165-lb. (75 kg)

operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9,130 lb. (4141 kg)

Hitch weight / drawbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535 lb. (243 kg)

Wheel weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,100 lb. (499 kg)

1.00-cu.-yd. (0.76 m

1.12-cu.-yd. (0.86 m

1.25-cu.-yd. (0.96 m

3

) bucket. . . . . . . . . . . . . . . . . . . . . . . 740 lb. (336 kg)

3

) bucket. . . . . . . . . . . . . . . . . . . . . . . 940 lb. (426 kg)

3

) multipurpose bucket . . . . . . . . . . . . 1,640 lb. (744 kg)

88-in.-wide Cameco-brand box blade . . . . . . . . . . . . . . . . 1,650 lb. (748 kg)

84-in.-wide Cameco-brand box blade . . . . . . . . . . . . . . . . 1,620 lb. (735 kg)

Maximum allowable operating weight . . . . . . . . . . . . . . . . 16,000 lb. (7257 kg)

Loader Buckets

Heavy-duty long lip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86 in. (2180 mm) 1.00 cu. yd. (0.76 m3) 710 lb. (322 kg)

Multipurpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86 in. (2180 mm) 1.12 cu. yd. (0.86 m

Width Heaped Capacity Weight

86 in. (2180 mm) 1.12 cu. yd. (0.86 m

3

) 940 lb. (426 kg)

3

)1,450 lb. (658 kg)

Loader Performance

with 1.00-cu. yd. (0.76 m3) with 1.12-cu. yd. (0.86 m3) with 1.25-cu. yd. (0.96 m3)

Heavy-Duty Long Lip Bucket Heavy-Duty Long Lip Bucket Multipurpose Bucket

Operator control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . single lever single lever single lever

Breakout force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,900 lbf (35.14 kN) 7,750 lbf (34.47 kN) 6,900 lbf (30.69 kN)

Lifting capacity, full height . . . . . . . . . . . . . . . . . . . . . . . . . 5,280 lb. (2395 kg) 5,100 lb. (2313 kg) 4,600 lb. (2086 kg)

Height to bucket hinge pin, maximum . . . . . . . . . . . . . . . . 11 ft. 4.7 in. (3.47 m) 11 ft. 4.7 in. (3.47 m) 11 ft. 4.7 in. (3.47 m)

Dump clearance, bucket at 45 degrees . . . . . . . . . . . . . . . 8 ft. 4.6 in. (2.56 m) 8 ft. 4.4 in. (2.55 m) 8 ft. 0.5 in. (2.45 m)

Reach at full height, bucket at 41.6 degrees . . . . . . . . . . . 34.4 in. (875 mm) 33.8 in. (858 mm) 35.4 in. (899 mm)

Rollback angle at ground level . . . . . . . . . . . . . . . . . . . . . . 44 degrees 44 degrees 44 degrees

Digging depth below ground, bucket level . . . . . . . . . . . . . 9.6 in. (245 mm) 10.2 in. (259 mm) 11.8 in. (300 mm)

Raising time to full height. . . . . . . . . . . . . . . . . . . . . . . . . . 5.2 sec. 5.2 sec. 5.2 sec.

Bucket dump time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 sec. 1.5 sec. 1.5 sec.

Bucket lowering time (power down) . . . . . . . . . . . . . . . . . . 2.4 sec. 2.4 sec. 2.4 sec.

Tractor Loader Dimensions

At 45-degree dump angle . . . . . . . . . . . . . . . . . . . . 10 ft. 10.9 in. (3.33 m)

A

At full height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 ft. 4.7 in. (3.47 m)

B At 45-degree dump angle . . . . . . . . . . . . . . . . . . . . 8 ft. 4.6 in. (2.56 m)

At full height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 ft. 9.7 in. (2.69 m)

C Bucket pin 11 in. (280 mm) off ground . . . . . . . . . . 44 degrees

D At full height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.6 degrees

E At 45-degree dump angle . . . . . . . . . . . . . . . . . . . . 37.0 in. (940 mm)

At full height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.4 in. (874 mm)

F Lower link horizontal. . . . . . . . . . . . . . . . . . . . . . . . 45.0 in. (1143 mm)

G Bucket level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.6 in. (244 mm)

H Bucket level on ground . . . . . . . . . . . . . . . . . . . . . . 78.1 in. (1984 mm)

Bucket rolled back, pin 11 in. (280 mm) off ground . . . 76.6 in. (1946 mm)

I Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.3 in. (2116 mm)

J Transport height . . . . . . . . . . . . . . . . . . . . . . . . . . . 97.6 in. (2479 mm)

K Bucket level on ground . . . . . . . . . . . . . . . . . . . . . . 17 ft. 2 in. (5.2 m)

L Lower link pin center . . . . . . . . . . . . . . . . . . . . . . . 1.6 in. (40 mm)

M Static loaded radius . . . . . . . . . . . . . . . . . . . . . . . . 23.0 in. (584 mm)

N Ground clearance

Under MFWD axle . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3 in. (287 mm)

Under transmission . . . . . . . . . . . . . . . . . . . . . . . . . 12.3 in. (312 mm)

Width over rear tires . . . . . . . . . . . . . . . . . . . . . . . . 84.0 in. (2134 mm)

Three-Point Hitch Dimensions

Height of hole for top link . . . . . . . . . . . . . . . . . . . . 30.8 in. (783 mm)

a

b Height of rear axle center . . . . . . . . . . . . . . . . . . . . 23.0 in. (584 mm)

c Top link hole distance from rear axle center . . . . . . 17.7 in. (450 mm)

d Height of lower link point . . . . . . . . . . . . . . . . . . . . 18.3 in. (465 mm)

e Lower link point distance from rear axle center . . . 14.0 in. (356 mm)

f Pitch cylinder (top link)

Retracted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.5 in. (572 mm) min.

Extended. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.0 in. (788 mm) max.

g Lower link length . . . . . . . . . . . . . . . . . . . . . . . . . . 29.5 in. (749 mm)

h Maximum height of lower link. . . . . . . . . . . . . . . . . 28.1 in. (714 mm)

i Minimum height of lower link . . . . . . . . . . . . . . . . . 7.7 in. (196 mm)

j Height of drawbar . . . . . . . . . . . . . . . . . . . . . . . . . . 12.8 in. (325 mm)

k Hitch pin from rear axle center . . . . . . . . . . . . . . . . 33.2 in. (843 mm)

Page 12

210LE LANDSCAPE LOADER

Key: ● Standard equipment ▲ Optional or special equipment *See your John Deere dealer for further information.

210LE

Engine

●

Meets EPA and CARB emission non-road regulations

● John Deere Model 4045D – 4.5 liter, 73 SAE net hp

naturally aspirated, isolation mounted

▲ John Deere Model 4045T – 4.5 liter, 80 SAE net hp

turbocharged, isolation mounted

● Diagnostic capabilities with Tier-II engine

● Vertical spin-on engine oil filter

● Spin-on John Deere fuel filter

● Oil-to-water engine oil cooler

● Antifreeze, –34°F (–37°C)

● Coolant recovery tank

● Serpentine belt with automatic belt tensioner

● Sucker-type cooling fan

● Enclosed safety fan guard

● Dual element dry-type air cleaner with evacuator

valve and prescreener

● Muffler, underhood with curved-end exhaust stack

▲ Muffler, spark arrested, underhood with curved-end

exhaust stack

▲ Electric ether starting aid

▲ Engine coolant heater, 1,000 watts

Power Train

●

Transmission with powershift reverser and torque

converter: Fully synchronized four forward, four

reverse speeds / Isolation mounted to mainframe

▲ Powershift transmission: Torque converter with

electrically actuated twist grip F-N-R in 1st through

4th gears

● Transmission oil cooler

● Vertical spin-on transmission filter

● Electric forward-neutral-reverse control lever with

neutral safety switch interlock

● Electric clutch cutoff on gearshift and loader levers

● Differential lock, electric foot-actuated

● Planetary final drives

● Hydraulic service brakes (conform to SAE J1473):

Inboard, wet multi-disc, self adjusting and self equalizing

● Parking brake with electric switch control (conforms

to SAE J1473): Spring applied, hydraulically released

wet multi-disc / Independent of service brakes

● Hydrostatic power steering with emergency manual

mode

● MFWD axle

● Mechanical-front-wheel-drive, standard differential:

Electric on/off control / Driveshaft guard / Sealed axle

▲ Mechanical-front-wheel-drive, limited-slip differential:

Electric on/off control / Driveshaft guard / Sealed axle

▲ Transmission guard

▲ Rear wheel spacers for use with chains*

210LE

Three-Point Hitch

●

Integral Category II

● Four-function sectional hydraulic valve, 6 gpm: Lift,

with down-pressure and float / Tilt, single / Pitch /

Fourth function auxiliary with capped hoses

● Cylinders: Lift (1) / Tilt (1) / Pitch (1)

▲ Fifth-function auxiliary valve with control lever

▲ Hydraulic flow cartridge, 3 gpm*

▲ Second tilt cylinder

Loader

●

Hydraulic self leveling

● Return-to-dig feature

● Single-lever control with electric clutch cutoff switch

● Bucket-level indicator

● Loader boom service lock

▲ Loader front coupler

▲ Third-function valve and lever for auxiliary equipment

Hydraulic System

●

25 gpm (95 L/min.) gear pump, open center system

● Independent hydraulic reservoir

● Hydraulic oil cooler

● “O”-ring face seal connectors

● 10-micron vertical spin-on filter

Electrical

●

12-volt system

● 65-amp alternator

● Single battery with 180-min. reserve capacity and

925 CCA

▲ Dual batteries with 360-min. reserve capacity and

1,850 CCA

● Positive terminal battery cover

● Blade-type multi-fused circuits

● By-pass start safety cover on starter

Lights

●

Two front halogen driving/work lights, 32,500 candlepower each

▲ Deluxe electrical package with rear lights, light guards

for front and signal lights, two 12-volt convenience

outlets, and battery disconnect switch

● Two combination front/rear turn signal/flashing

● Two rear stop and tail

● Two rear reflectors

▲ Rotating beacon*

Operator’s Station

●

Two-post ROPS/FOPS canopy with steel roof (conforms

to SAE J1040): Isolation mounted

▲ Operator enclosure*

● Left front access

● Slip-resistant steps and ergonomically located

handholds

● Built-in Operator’s Manual storage compartment with

manual

210LE

Operator’s Station

(continued)

● Interior rearview mirror

● Foot throttle

▲ Hand throttle

● Horn

● Key start switch with electric fuel shutoff

● Hourmeter, electric

● Fuel gauge, illuminated electric

● Hydraulic self leveling

● Monitor system with audible and visual warning: Engine

air filter restriction indicator / Alternator indicator /

Engine coolant temperature indicator with audible

warning / Engine oil pressure indicator with audible

warning / Hydraulic filter restriction indicator / Torque

converter oil temperature indicator / Parking brake

on/off indicator with audible warning / Seat belt indicator / Mechanical front-wheel-drive on/off indicator

● Suspension vinyl seat with flip-up armrests, backrest

angle adjustment, swivel base, 3-in. seat belt with

retractor

▲ Non-suspension vinyl seat without armrests, with

3-in. seat belt with retractor

Loader Buckets

●

Less bucket, with bucket pins

▲ Heavy-duty bucket with lift loops, prepunched for

bolt-on cutting edge

▲ Heavy-duty buckets with bolt-on cutting edge, skid

plates, and lift loops

▲ Multipurpose buckets with bolt-on cutting edge, skid

plates, and lift loops

Tires

▲

12-16.5, 8 PR NHS front tires

● 16.9-24, 8 PR R4 rear tires

Overall Vehicle

●

One-piece unitized construction mainframe with

integral front bumper

● Vehicle tiedowns, two front and two rear

● Fuel tank, 26 gal. (98 L), ground level fueling

● Vandal protection for instrument panel, access doors,

fuel tank, and hydraulic reservoir

● Reverse warning alarm

● Dent-resistant rear fenders

▲ Three-point hitch counterweight

▲ Wheel weights

▲ Hydrostatic PTO, 540 rpm

▲ Three-point hitch weight box*

▲ Drawbar, fixed single position

▲ Box scraper

information and factory installation)

(contact Cameco Industries for ordering

▲ SMV emblem*

▲ Brush guards*

▲ Fender extensions*

▲ Cab panels*

CONTROL OWNING AND OPERATING COSTS

Customer Personal Service (CPS) is part of John Deere’s proactive, fix-before-fail strategy on machine

maintenance that will help control costs, increase profits, and reduce stress. Included in this comprehensive lineup of ongoing programs and services are:

Fluid analysis program—

so you’ll know if there’s a problem

most extended coverage and preventive-maintenance agreements.

Component life-cycle data—

and lets you make informed decisions on machine maintenance by telling you approximately how many

hours of use you can expect from an engine, transmission, or hydraulic pump.This information can be used

to preempt catastrophic downtime by servicing major components at about 80 percent of their life cycle.

Preventive Maintenance (PM) agreements—

a given period of time. They also help you avoid downtime by ensuring that critical maintenance work gets

DKA210LE Litho in U.S.A. (05-08)

tells you what’s going on inside

before

you see a decline in performance. Fluid analysis is included in

gives you vital information on the projected life span of components

Net engine power is with standard equipment including air

cleaner, exhaust system, alternator, and cooling fan, at standard conditions per SAE J1349 and DIN 70 020, using No. 2-D

fuel at 35 API gravity. No derating is required up to 5,000-ft.

(1500 m) altitude. Gross power is without cooling fan.

all

of your machine’s major components

give you a fixed cost for maintaining a machine for

done right and on schedule. On-site preventive maintenance service performed where and when you need

it helps protect you from the expense of catastrophic failures and lets you avoid waste-disposal hassles.

Extended coverage—

can effectively manage costs. Whether you work in a severe-service setting or just want to spread the

risk of doing business, this is a great way to custom-fit coverage for your operation. And an extended

coverage contract also travels well because it’s backed by John Deere and is honored by

construction dealers.

Customer Support Advisors (CSAs)—

Customer Personal Service (CPS). Certified CSAs have the knowledge and skills for helping make important

decisions on machine maintenance and repair. Their mission is to help you implement a plan that’s right

for

your

business and take the burden of machine maintenance off your shoulders.

Specifications and design subject to change without notice. Wherever applicable, specifications are in accordance with SAE

and/or ISO standards. Except where otherwise noted, these specifications are based on a unit with 16.9-24, 8 PR R4 rear tires;

12-16.5, 8 PR NHS front tires; 1.00-cu. yd. (0.76 m

gives you a fixed cost for machine repairs for a given period of time so you

Deere believes the CSA program lends a

3

) loader bucket; full fuel tank; and 175-lb. (79 kg) operator.

all

Deere

personal

quality to

Loading...

Loading...