Assembly Instructions

JRBG-14 Roller Bearing Guides

Pre-Assembly

1. Disconnect the saw from the power source,

unplug.

2. It is easier to install the new guides if you

remove the band saw’s table.

3. Remove the circular table insert found on

the top of the table, and also the table pin

found on the side of the table. The table can

be removed by unscrewing the lock knobs

found below the table trunnion.

4. Remove the existing blade guides.

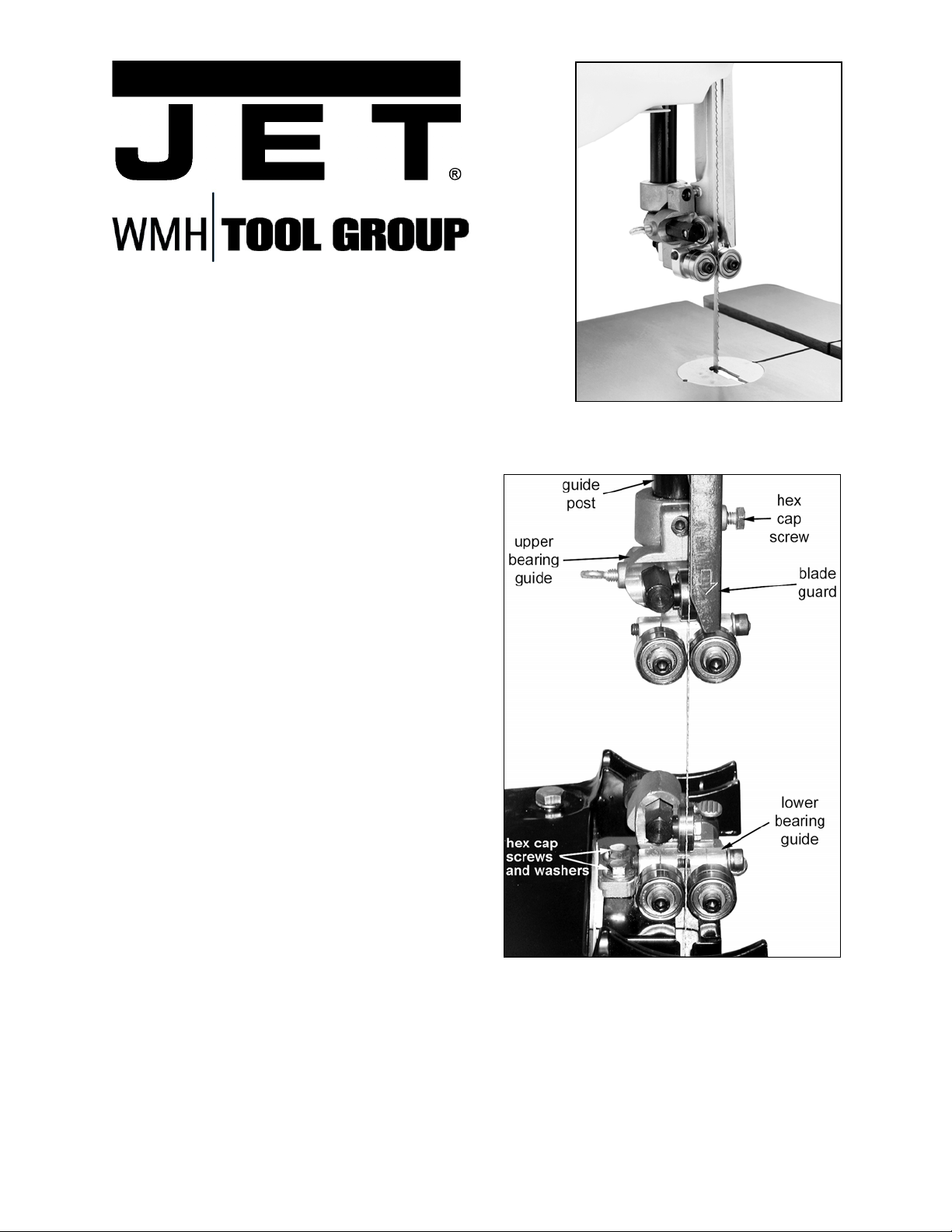

Upper Bearing Guide

Referring to Figure 1:

1. Fit the upper bearing guide onto the guide

post and tighten the hex cap screw.

Note: Model JWBS-14OS Band Saw

requires bushing (Part No. 150214) shown

in G, Fig. 2.

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-708127

Ph.: 800-274-6848 Revision B 03/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

Figure 1

Referring to Figure 2:

2. Adjust the back-up bearing (Fig. 2) so that it

is 0.003” away from the back of the blade,

about the thickness of a piece of paper. To

make this adjustment loosen thumb screw

(F, Fig. 2) and turn the adjusting screw

(E, Fig. 2) until the adjustment is correct.

Tighten thumb screw (F, Fig. 2).

3. Loosen the thumb screw (C, Fig. 2) and turn

the adjusting screw (D, Fig. 2) until the

bearing guides rest just behind the gullet of

the blade teeth.

4. Loosen the socket head cap screw

(A, Fig. 2) and turn the screw (B, Fig. 2)

clockwise or counter-clockwise until the

side-bearing (Fig. 2) is 0.003” away from the

side of the bearing, about the thickness of a

piece of paper.

5. Adjust the opposite side bearing.

6. Tighten socket head cap screw (A, Fig. 2).

Check to make sure the adjustments have

not changed and the bearing guides do not

pinch the blade.

7. Attach the blade guard.

Lower Bearing Guide

1. Attach the lower bearing guide (Fig. 1) with

two hex cap screws and washers (Fig. 1).

Referring to Figure 3:

2. Adjust the back-up bearing so that it is

0.003” away from the back of the blade,

about the thickness of a piece of paper. To

make this adjustment loosen thumb screw

(A, Fig. 3) and turn the adjusting screw

(B, Fig. 3) until the adjustment is correct.

Tighten thumb screw (A, Fig. 3).

3. Loosen the thumb screw (C, Fig. 3) and turn

the adjusting screw (D, Fig. 3) until the

bearing guides rest just behind the gullet of

the blade teeth.

4. Loosen the socket head cap screw

(E, Fig. 3) and turn the screw (F, Fig. 3)

clockwise or counter-clockwise until the

bearing is 0.003” away from the side of the

bearing, about the thickness of a piece of

paper.

5. Adjust the opposite side bearing.

6. Tighten socket head cap screw (E, Fig. 3).

Check to make sure the adjustments have

not changed and the bearing guides do not

pinch the blade.

Figure 2

Figure 3

Loading...

Loading...