Operating Instructions and Parts Manual

Bench Top Edge Bander

Model JEB-1

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-708000

Ph.: 800-274-6848 Revision B 12/04

www.wmhtoolgroup.com Copyright © WMH Tool Group

(veneer banding not included)

This manual has been prepared for t he owner and operators of a J ET Model JEB-1 Edge Bander. Its

purpose, aside f rom machine oper ation, is to promot e safety using acc epted operati ng and maint enance

procedures. To obtain maxim um life and effi ciency from y our Edge Bander and to ai d in usi ng it safel y,

please read this manual thoroughly and follow the instructions carefully.

Warranty and Service

WMH Tool Gr oup warrants ever y product it sell s. If one of our tools needs s ervice or repai r, one of our

Authorized Repair St ations located thr oughout the United States can provi de quic k servi c e or information.

In most cases, a WM H Tool Group Repair Station c an as sist in authorizing repair work, obtaining parts, or

perform routi ne or m ajor maintenance repair on your JET pr oduc t.

For the nam e of an A uthoriz ed Repair St ation in your area, pl ease call 1-800-274-6848, or v isit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group i s consistently adding new products to the li ne. For complete, up-to-dat e

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in mat erials and workmanship as foll ows: 1 YEAR LI MITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or i ndirectly to

misuse, abuse, negl igence or acc idents, norm al wear-and-tear , repair or alterati ons outside our f aciliti es,

or to a lack of maintenanc e.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanati on of the complaint m ust accompany the merchandi se. If our inspecti on discloses a defec t, we

will either repair or replace the produc t at our discret ion, or r efund t he purchase pri ce if we cannot readi l y

and quickly provide a repai r or replac ement. We will return the repai red product or replacem ent at WMH

Tool Group’s ex pense, but if it is determ ined there i s no defect, or that the def ect resulted f rom causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning t he product . This warranty gives you specif i c legal rights; y ou may also hav e other rights, whic h

vary from state t o state.

WMH Tool Group sells through distributor s only. Members of the WMH Tool Group reserve the right to

effect at any time, wit hout prior notice, alter ations to parts, fittings and accessory equi pment, which they

may deem necessary for any reason whatsoever.

2

Table of Contents

Warranty and Servic e ..............................................................................................................................2

Warning...................................................................................................................................................4

Introduction.............................................................................................................................................. 6

Description..............................................................................................................................................6

Specifications..........................................................................................................................................6

Unpacking...............................................................................................................................................7

Contents of the Shipping Container......................................................................................................7

Assembly.................................................................................................................................................8

Installing S upport Table........................................................................................................................ 8

Grounding Instructions.............................................................................................................................8

Extension Cords...................................................................................................................................8

Adjustments.............................................................................................................................................9

Upper and Lower Guides...................................................................................................................... 9

Infeed and Outfeed F ences..................................................................................................................9

Operating Controls.................................................................................................................................10

Operation...............................................................................................................................................10

Selection of Banding Material............................................................................................................. 10

Basic Procedure............................................................................................................................... ..10

Maintenance..........................................................................................................................................13

Main Table Replacement....................................................................................................................13

Troubleshooting the JEB-1 Edge Bander ............................................................................................... 14

Replacement Parts................................................................................................................................15

Parts List: JEB- 1 E dge Bander ...........................................................................................................16

JEB-1 Edge Bander............................................................................................................................17

3

Warning

1. Read and understand the entire owners manual before attempting assembly or operat ion.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This edge bander i s designed and intended for use by properl y trained and ex perienced personnel

only. If you ar e not familiar with t he proper and safe operat ion of an edge bander, do not use until

proper trai ning and k nowledge have been obtai ned.

5. Do not use this edge bander for other t han its intended use. If used for other purposes, WMH Tool

Group discl aims any real or im plied warranty and holds itself harmless from any i njur y or tool damage

that may result from that use.

6. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

7. Do not operate this machine while tired or under the influence of dr ugs, alcohol or any medication.

8. Make certain t he switc h is i n the OFF position before connecting the machine to t he power supply.

9. Make all machine adjustments or maintenance with the machine unplugged from the power source.

10. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

11. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately.

12. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

13. Provide f or adequate space surrounding work area and non- glare, overhead lighting.

14. Keep the floor around the tool clean and free of scrap material, oil and grease.

15. Keep visit ors a safe distance from the work area. Keep children away.

ah

16. Make your workshop child proof with padlocks, m aster switc hes or by r em ov ing starter keys.

17. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

18. M aintain a balanc ed stance at all times so that y ou do not f all or l ean against the heat g un. Do not

overreach or use exc essive force to perform any tool operat ion.

4

19. Use the ri ght t ool at the cor rect speed and f eed rate. Do not for ce a tool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

20. Use recommended acc essories; improper accessories may be hazardous.

21. Mai ntain tools with care. Keep cutting bl ades sharp and clean for the best and safest perf ormance.

Follow instructions for lubricating and changing accessories.

22. Never leav e the t ool running unattended.

23. Remove loose items and unnecessary work pieces from the area before starti ng the t ool.

Familiarize you r self with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Introduction

This manual i s provided by J ET covering the safe operati on and maintenance procedures for a Model

JEB-1 Edge Bander. This manual contains instructions on installation, safety precautions, general

operating proc edures, mai ntenance instructi ons and parts breakdo wn. This tool has been desi gned and

constructed to pr ovide years of troubl e free operation if used in accordance with i nstructions set for th in

this manual. If there are any questions or com ments, please contact ei ther your local suppl ier or WMH

Tool Group. WMH Tool Group can also be reached at our web site: www.wmhtoolgroup.com.

Description

The Edge Bander is simple to operate and is designed to handle wood and polyester edge banding

materials that are backed by a hot melt adhesive. It has non-skid rubber feet, a built-i n plunge cutti ng

knife and wide support t able for the banding mat erial roll. The heati ng element has infinite adj ustment

within the 100 t o 200 degree heati ng range. The adj ust abl e guides will accomodate banding mat erial s as

wide as 2-1/4”.

Specifications

Model Number.................................................................................................................................JEB-1

Stock Number................................................................................................................................ 708000

Laminated Table Size (L x W)(in.)...................................................................................... 26-3/4 x 7-9/16

Fence Height (in.)............................................................................................................................2-3/16

Overall Size (L x W x H)(in.)....................................................................................26-3/4 x 26-1/4 x 9-3/8

Banding Material Maximum Width (in.)...............................................................................................2-1/4

Operating Tem per ature Range (deg.) ....................................................................................... 100 to 200

Hot Air Gun.....................................................................................Double Insulated, 1500W, 120V, 60Hz

Approximate Net Weight (lbs.) ...............................................................................................................26

The above specifications were current at the time this manual was published, but bec ause of our policy of

continuous im provement, WMH Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurri ng obligations.

6

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Edge

Bander is assembled and running properly.

Compare the cont ent s of y our cont ainer wit h the

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

1 Edge Bander

1 Support Table

1 Stud

1 Hex Cap Screw, M8 x 100 (with hex nut )

2 Socket Head Cap Screws, M6 x 10

2 Flat Washers, M6

1 Hex Wrench, 5mm

1 Double Edge Trimmer

1 Owner's Manual

1 Warranty Card

Read and understand the en t ire contents o f this manual before att empting set-up

or operation! Failure t o co mpl y may cause injury.

7

Assembly

Tools required for assembly:

5mm hex wrench (provi ded)

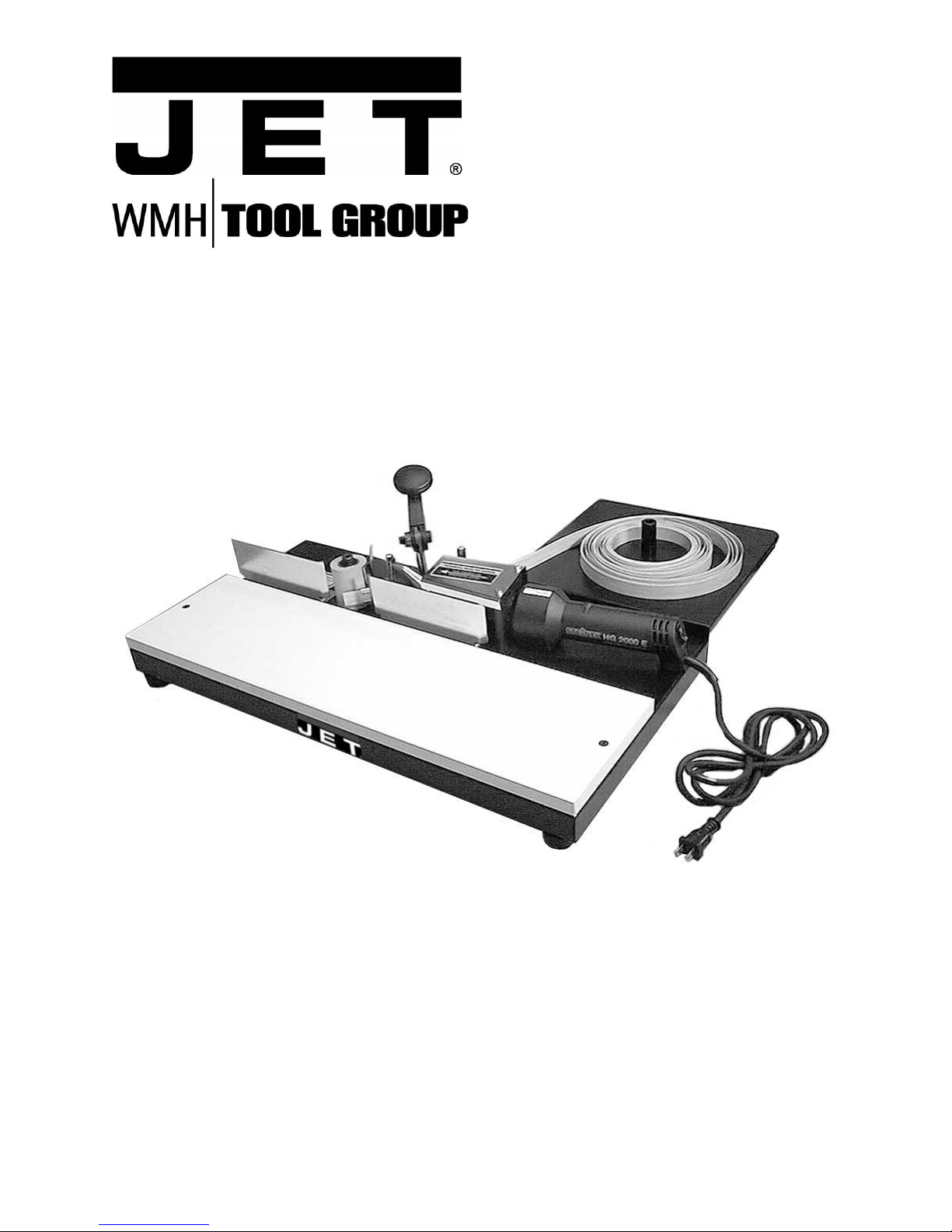

Installing Support Table

1. Tilt the Edge Bander up and attach the

support tabl e to the two holes at the rear of

the Edge Bander, wit h two M6 x 10 socket

head cap screws and two M6 f lat washers.

See Figure 1. Tighten with the 5mm hex

wrench.

2. Fr om below the support table, insert t he M8

x 100 hex cap screw up through the hol e in

the center of the support table as sho wn in

Figure 2. ( The hex nut on t he screw should

be below the support tabl e.)

3. Place the stud, with its threaded opening

facing down, over the hex cap screw and

thread it down ont o the hex cap screw. See

Figure 2.

4. Adjust the M8 x 100 screw until its head

contacts the surf ace of your table or bench.

This enables the scre w to act as a support

for the support t able.

Figure 1

5. Secure the positi on of the M8 x 100 screw

by tightening the hex nut up against the

bottom of the support table.

Grounding Instructions

Make sure the voltage of your power supply

matches the specif ications on the label aff ix ed to

the heat gun. The Edge Bander is de signed to

run on standard 120 volt “ househol d” c ur r ent.

Extens ion Cords

If an extension cord is necessary, make sure the

cord rating i s suitable for the am perage listed on

the machine's motor plate. An undersize cord

will cause a drop in line voltage resulting in loss

of power and overheating.

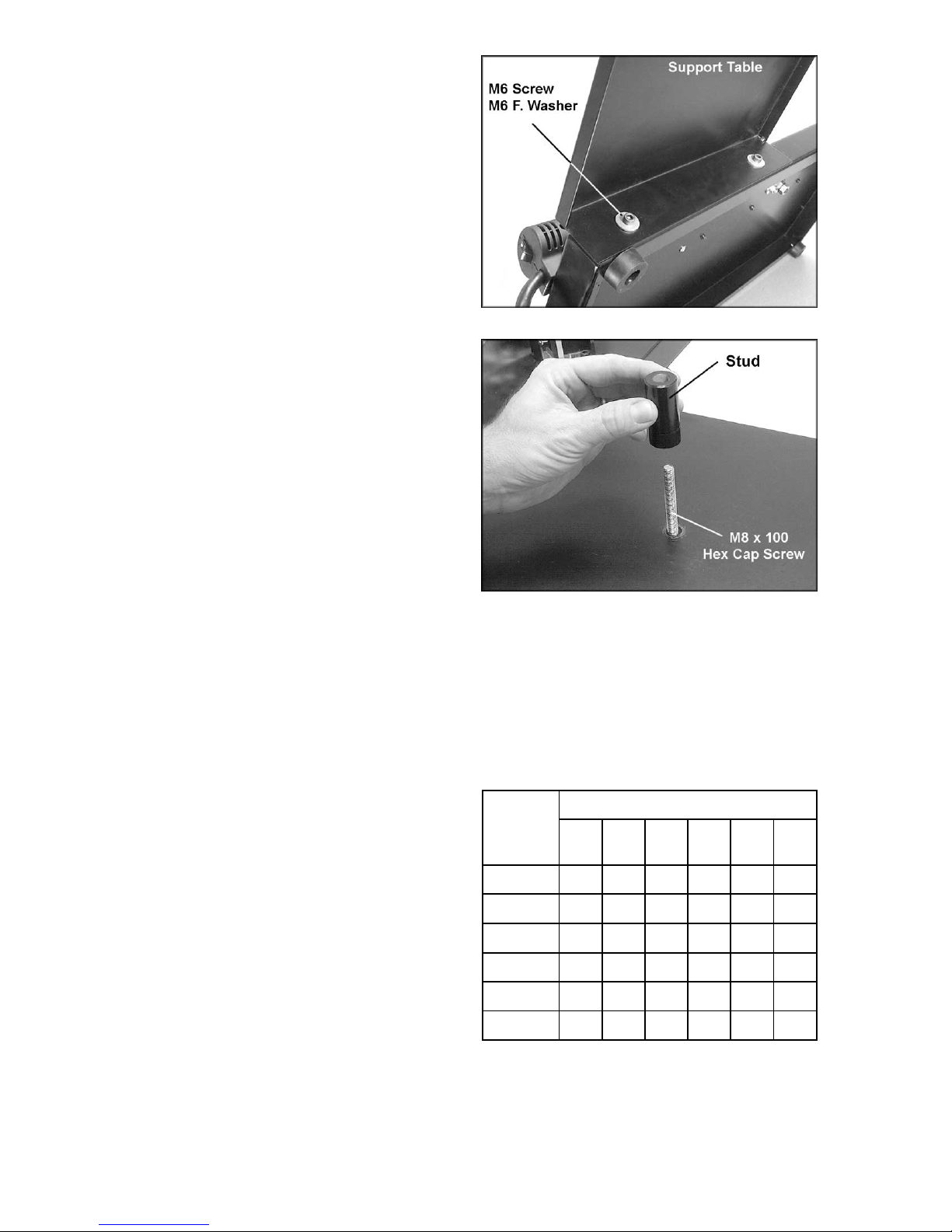

The chart in Figure 3 shows the correct size

cord to use based on cord length and motor

plate amp rating. If in doubt, use the next

heavier gauge. The smaller the gauge number

the heavier the cor d.

Figure 2

Reco m me n de d G au g es (AWG) of Ext e ns io n C or d s

Extension Cord Length *

25

50

75

100

150

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting th e lin e voltag e drop to 5V at 150% of th e

rated amp eres.

NR: Not Recommended.

feet

feet

feet

feet

feet

200

feet

Figure 3

8

Adjustments

Upper and Lower Guides

The upper and lower gui des can be adj usted by

loosening the socket head cap screws with a

5mm hex wrench (provi ded). S ee Figure 4. Aft er

adjustment, re-tighten the screws.

The lower guides should be set slightly below

the work table, after which no further

adjustments will be necessary for the lower

guides.

Adjust the upper gui des to suit the width of your

banding material. NOTE: The banding material

must move freely through the guides.

Infeed and Outfeed Fences

The infeed and outfeed fences are used to

support the edge of the workpi ece. Both f ences

should be positioned in relation to the pinch

roller to allow for the thickness of the edge

banding material being used. Normally, the

fences will be recessed about 1/32” to 3/64”

from the crown of t he pinch roller, as shown in

Figure 5. This setting has already been made

before the Edge Bander wa s shipped; howev er

you may wish to d ouble-check it . It should also

be checked occasionally as the Edge Bander

receives use.

If a fence requires adjustment, loosen the two

socket head cap screws (Fi gure 5) and shi ft the

fence forward or backward as needed.

NOTE: To adjust the infeed fence, you must f irst

remove the hot air gun fr om the table as follows:

Figure 4

Figure 5

The hot air gun should be

disconnect ed from power. If the hot ai r gun

has just been used in an edge banding

operation, allow it to cool sufficiently before

attempting to remove it.

1. On the undersi de of the Edge B ander , use a

Phillips screwdriver to remove the two

screws which secure the hot air gun (F igure

6).

2. Carefully remove the hot air gun from the

table. The socket head cap screws on the

infeed fence will now be accessible; adjust

the infeed fence as needed.

3. When finished, re-i nstall the hot air gun. Reinstall and tighten the two screws (Figure 6).

Figure 6

9

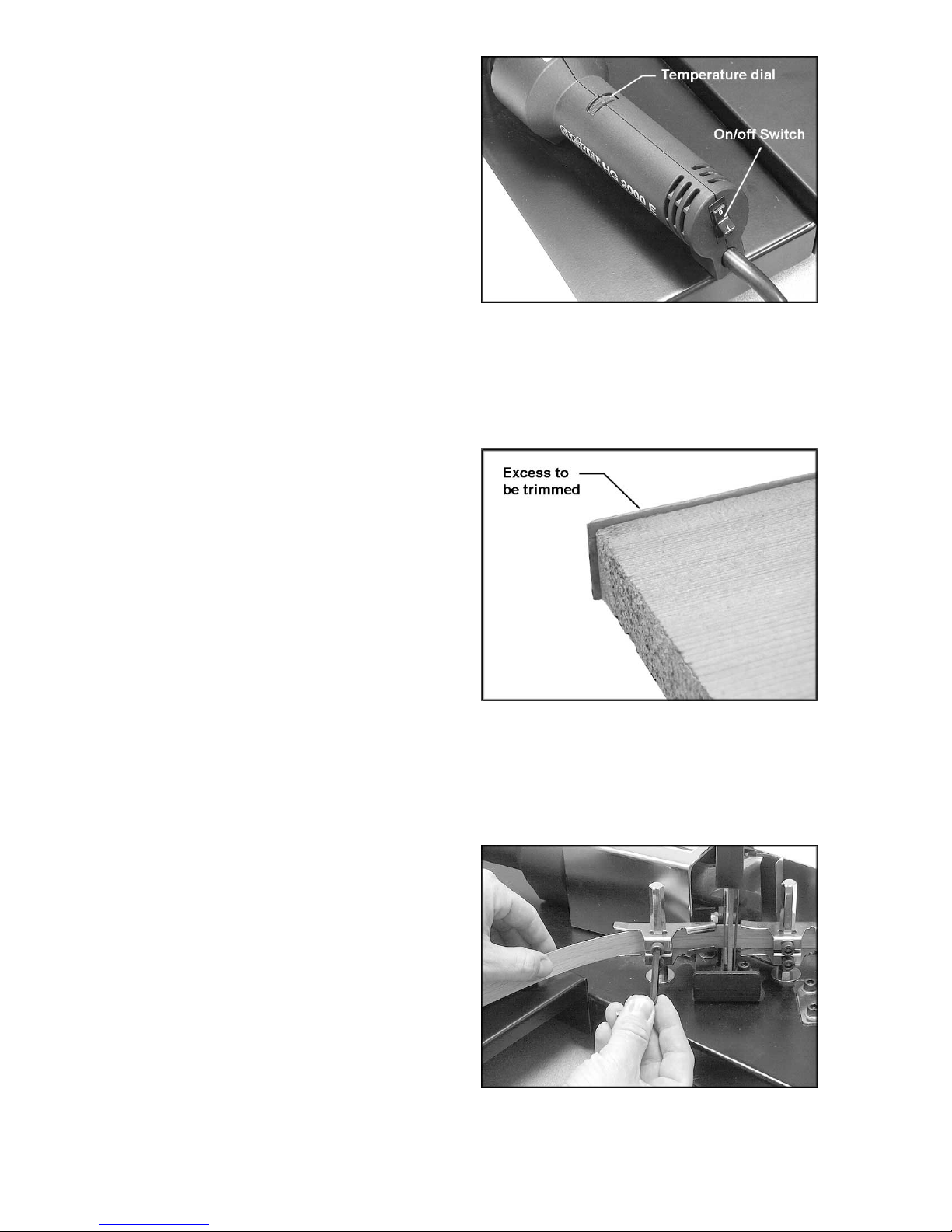

Operating Controls

The main on-off switch is on the handle of the

hot air gun (Figure 7) .

The temper ature of t he heat is cont rolled by t he

dial (Fi gure 7); hotter toward the red part of the

dial, cooler toward the blue part of the dial.

NOTE: The heat sett ing is arbitrary. The hotter

the gun, the f aster you must f eed the work. For

best results, start with a low heat and make

adjustments according to your experience with

the edge bander and the material you are using.

Operation

Figure 7

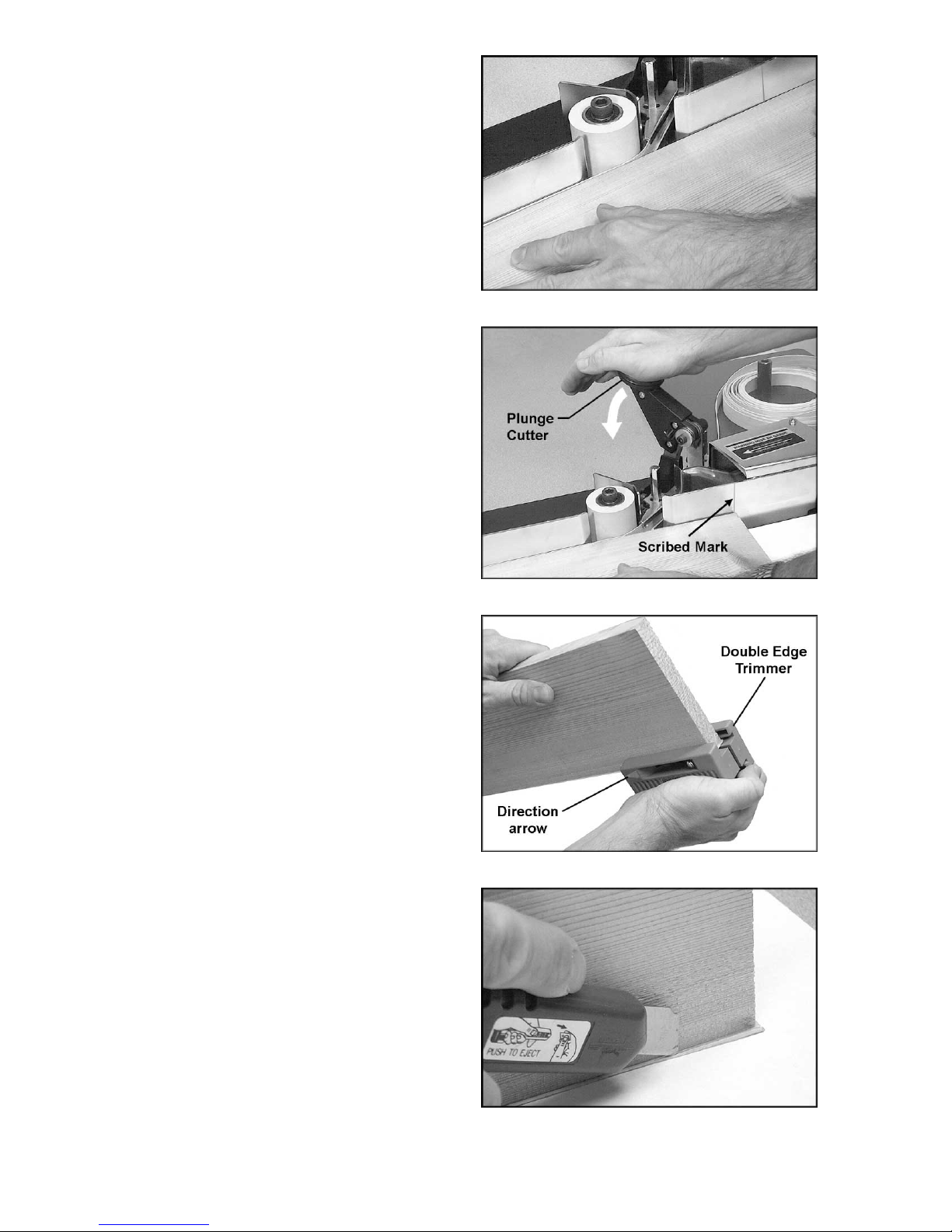

Selection of Banding Material

The edge banding m aterial must hav e a hot melt

adhesive backing.

The width of the edge banding material you

select is dependent upon the thickness of the

stock you are banding. The Edge Bander will

accept banding material up to 2-1/4” wide.

The banding material is usually no more than

1/16” wider than t he thick ness of the workpiece.

This means there i s only about 1/32” of ex cess

to remove from eit her si de of t he workpiece. See

Figure 8. This al lows the excess to be remov ed

with a knife (not provided) or the double edge

trimmer. The excess may also be removed by

sanding.

When the edge banding materi al is too wide, the

clean-up job becomes difficult and edge banding

materia l is w a sted.

Basic Procedure

1. Set the r oll of edge banding materi al on the

support table. The banding material should

be oriented so the adhesiv e backed side will

face the heat gun as it moves through the

guides.

Figure 8

(banding shown is 13/16” wide oak veneer)

2. Make sure the lower guide s have been set

slightly below the work tabl e. This will place

the bottom edge of the banding material

slightly below the edge of the workpiece.

3. Slide the leading end of the banding

material t hrough the guides, and adjust the

upper guides to the width of the banding

material. See Fi gure 9. NOTE: The banding

material must move freely through the

guides.

Figure 9

10

4. Position the leading end of the banding

material i n front of the nozz le of the hot air

gun, as shown in Figure 10.

5. Choose the desired heat setting on the

temperature dial.

6. Plug the Edge Bander into the power source

and turn on the s witch. Allow approxim ately

30 seconds for the hot air gun to reach

operating temperature. Adjust the

temperature dial again if necessary.

The hot air gun generates

sufficient heat to burn flesh and ignite

combustibles. Work with extreme caution.

Do not touch metal areas around hot air gun

while it is t ur ne d on.

7. As the hot melt adhesive soft ens at t he front

end of the bandi ng material, hand feed the

banding material up to the crown of the

pinch roll er, as shown in Fi gur e 11.

NOTE: A general indi cat or that the adhesiv e

is hot enough is when it begins to bubble

slightly.

8. Place the workpiece on the table and

against the infeed fence. See Figure 12.

9. Push the edge of the workpiece along the

infeed fence and agai nst the edge banding

material (Figure 12). The edge banding

material will be trapped between the pinch

roller and the workpiece. The edge bandi ng

material will bond to the workpiece.

Figure 10

Figure 11

10. Guide the workpiece along the pinch roller

at a steady, moderate speed. The edge

banding mat erial will conti nue to bond t o the

edge of the workpiece and will be pulled

through the guides by t he movement of the

workpiece.

NOTE: Be sure the hot melt adhesive is

bonding to the workpiece. If you feed the

workpiece too fast, or the hot air gun

temperature is set too l ow, the bond will be

poor. Make adjustments as needed to

obtain a good bond.

Figure 12

11

11. As the workpiece is advanced (Figure 13),

the leading edge of the workpiece may be

rested against t he outfeed fence as well as

the pinch roll er. Always main tain pressure

on the pinch roller while you are edge

banding.

12. W hen the trailing end of the workpiece li nes

up with the scribed mark on the infeed

fence, push do wn on the plunge cutter firmly

and rapidly to sever the edge banding

material. See Figure 14.

13. Continue to push the workpiece forward

until the entire edge of the workpiece has

been banded. The end of the banding

material will extend slightly beyond the

trailing end of the workpiece.

14. Shut of f the hot air gun and al low it to cool

completely before storing the Edge Bander.

When the Edge Bander is not being used,

unplug it from t he power source.

Figure 13

15. Trim the excess banding material from the

workpiece. Thi s can be done ea sily wit h the

Double Edge Trimmer provided with your

Edge Bander. See Fi gur e 15.

16. The Double Edge Trimmer will work on

materials 1/2” to 1” thick. Simply place the

Trimmer over the banded edge of the

workpiece and squeeze the Trimmer firmly

to clamp it against the workpiece edge.

Continue to squeeze i t firmly, and slide the

Trimmer down the edge of the workpiece i n

the direction of the arrows, as shown in

Figure 15. Use steady, even pressure for

best results.

17. Replacement knives (Stock No. JEB-151)

are available f or the Double Edge Trimmer.

To order, contact your local distributor or

call customer service at 1-800-274-6848.

Figure 14

Figure 15

18. A sharp knife (not provided), as shown in

Figure 16, is an alternative method for

trimming the excess banding material. The

excess may also be sanded off in some

cases.

Figure 16

12

Maintenance

Before doing maintenance

on the Edge Bander, unplug it from the

power source, unless sp ecified otherwise.

Prolonged use of the Edge Bander may cause

accumulation of hot melt adhesive on the

guides, which can block free movement of the

edge banding material. To remove this

adhesive, pl ug in t he tool and tur n it on, with t he

heat gun at a medium setting. Keep hands

away from hot air gun. As the heat gun softens

the hot melt adhesive, peel the adhesive from

the guides with a putty knife. Be careful not to

scratch the gui des; they m ust remain sm ooth for

best results.

If the pinch roller needs cleaning, wipe it with

soap and water. Do not use solvents on the

pinch roll er.

If the power cord is worn, cut, or damaged in

any way, have it repl ac ed immediately.

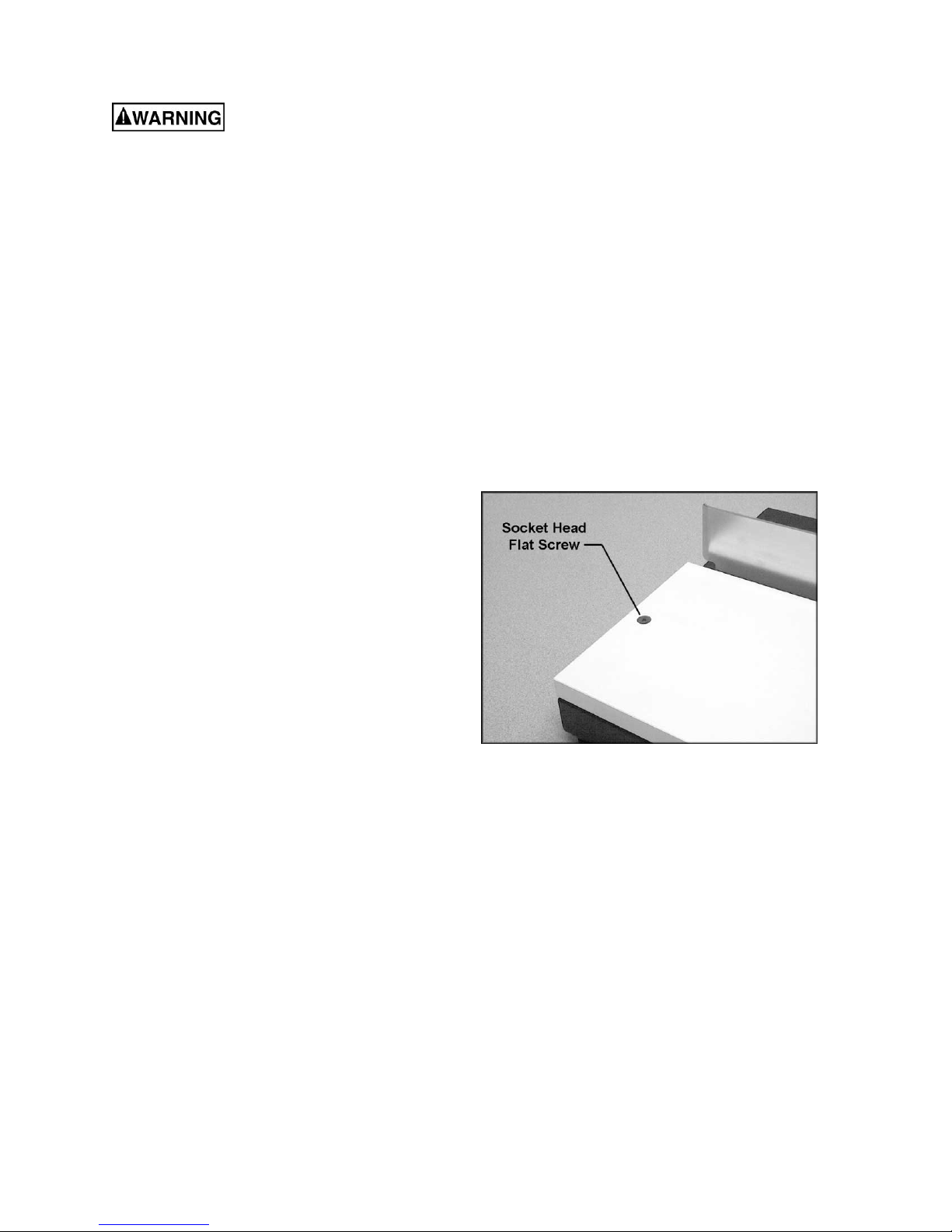

Main Table Replacement

The laminated front table may eventually

become scuffed with use. It can be replaced

with any smooth faced stock. Remove the old

table by unscrewing and removing the two

socket head flat screws, shown in Figure 16,

with a 5/32” (or 4mm) hex wrench (not

provided). Use the old table as a pattern for

cutting the new one.

A plastic lami nate f ace may be gl ued t o the new

table. This will i ncrease its durabili ty and reduce

friction bet ween the tabl e and the workpiec e. Be

sure the new table i s the same t hickness as the

original. Make an allowance for the plastic

laminate if y ou plan to laminate your new work

table.

Figure 16

13

Troubleshooting the JEB-1 Edge Bander

Trouble Probable Cause Remedy

Edge Bander will not

turn on.

Edge Bander will not

heat.

Edge banding

material does not

feed smoothly

through guides.

Edge banding

material will not bond

to workpiece.

Not connected to power source. Check plug connection.

Fuse blown, or cir c uit break er tr ipped. Replace fuse, or reset circuit break er .

Cord damaged. Replace cord.

Hot air gun motor damaged. Have hot air gun repai r ed or replaced.

Temperature dial not set properly. Turn temperature dial toward the red.

Hot air gun motor damaged. Have hot air gun repai r ed or replaced.

Guides not adjust ed pr oper ly.

Guides need cleaning.

Hot air gun not hot enough.

Feed rate too fast for heat level.

Infeed and/or outfeed fence not set

properly.

Position guides accor ding to width of

edge banding mat erial. [page 9]

Follow instructions for cleaning off old

adhesive from guides. [page 13]

Turn temperature dial toward the red

to increase heat.

Reduce feed rate, or increase heat

level.

Fences should be recessed 1/32” t o

3/64” from crown of pi nc h roll er .

[page 9]

Edge banding

materia l is di ffi cult to

cut.

Edge banding materi al does not have

hot melt backing, or has poor

adhesive or is defective.

Plunge cutter being pushed down too

lightly or slowly.

Knives in plunge cutter unit are dull. Replace kniv es in plunge cutter unit.

Replace edge banding material.

Push down plunge cutter r apidly and

firmly.

14

Replacement Parts

Replacement part s are li sted on the f ollowing page s. To order par ts or reac h our servi ce depar tment, call

1-800-274-6848 between 7:00 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you cal l will allow us to serv e y ou quickly and

accurately.

JEB-151.......Knives for Double Edge Trimmer (set of 4)

15

Parts List: JEB-1 Edge Bander

Index No. Part No. Description Size Qty

1...............JEB-101.................. Support Table.................................................... ...................................1

2...............JEB-102.................. Stud................................................................... ...................................1

3...............TS-1503021............Socket Head Cap Screw.................................... M6 × 10....................16

4...............JEB-104.................. Flat Washer....................................................... M6 × 20......................7

5...............JEB-105.................. Upper Edge Guide............................................. ...................................2

6...............JEB-106.................. Roller................................................................. ...................................1

7...............BB-6200ZZ.............. Ball Bearing....................................................... #6200ZZ.....................2

8...............TS-1505131............Socket Head Cap Screw.................................... M10 × 80....................1

9...............TS-1533052............Phillips Pan Head Machine Screw...................... M5 × 16......................3

10.............JEB-110.................. Handle (Right) ................................................... ...................................1

11.............JEB-111.................. Handle (Left) ...................................................... ...................................1

12.............TS-1541021............ Nylon Lock Hex Nut........................................... M6..............................2

13.............JEB-113.................. Retaining Clamp Screw......................................M5 × 60......................2

14.............TS-1550031............ Flat Washer....................................................... M5..............................2

15.............JEB-115.................. Heat Shield........................................................ ...................................1

16.............JEB-116.................. Top Retaining Clamp......................................... ...................................1

17.............JEB-117.................. Bottom Retaining Clamp.................................... ...................................1

18.............JEB-118.................. Nozzle............................................................... 070236 .......................1

19.............JEB-119.................. Hot Air Gun........................................................ ...................................1

20.............JEB-120.................. Electric Cord...................................................... ...................................1

21.............TS-1514031............ Socket Head Flat Screw.....................................M6 × 20......................2

22.............JEB-122.................. Work Tab le........................................................ ...................................1

23.............JEB-123.................. Rubber Foot ...................................................... ...................................4

24.............TS-1482031............ Hex Cap Screw..................................................M6 × 16......................4

25.............JEB-125.................. Base.................................................................. ...................................1

26.............JEB-126.................. Fence................................................................ ...................................2

27.............TS-1533052............ Phillips Pan Head Machine Screw...................... M5 × 16......................2

28.............TS-1550061............ Flat Washer....................................................... M8..............................4

29.............TS-1540061............ Hex Nut.............................................................M8..............................2

30.............TS-1540071............ Hex Nut.............................................................M10............................2

31.............TS-1550041............ Flat Washer....................................................... M6..............................1

32.............TS-1503031............ Socket Head Cap Screw .................................... M6 × 12......................1

33.............JEB-133.................. Heat Shield........................................................ ...................................1

34.............TS-1550041............ Flat Washer....................................................... M6..............................7

35.............JEB-135.................. Stud................................................................... ...................................2

36.............JEB-136.................. Lower Edge Guide............................................. ...................................2

37.............JEB-137.................. Hex Cap Screw (Full Thread)............................. M8 × 100....................1

38.............TS-1540061............ Hex Nut.............................................................M8..............................1

39.............TS-1503041............ Socket Head Cap Screw .................................... M6 × 16......................1

40.............TS-1540031............ Hex Nut.............................................................M5..............................3

41.............JEB-141.................. Spacer............................................................... ...................................1

42.............JEB-142.................. Knife Gua r d (R ig h t)............................................ ...................................1

43.............JEB-143.................. Knife Ba se......................................................... ...................................1

44.............TS-1503081............ Socket Head Cap Screw .................................... M6 × 35......................1

45.............JEB-145.................. Spring................................................................ ...................................1

46.............JEB-146.................. Upper Knife ....................................................... ...................................1

47.............JEB-147.................. Knife Gua r d (Left) .............................................. ...................................1

48.............JEB-148.................. Botto m Kn i fe...................................................... ...................................1

49.............JEB-149.................. Clamp Ring........................................................ ...................................1

50.............JEB-150.................. Double Edge Trimmer (not shown)..................... ...................................1

51.............JEB-151.................. Knives for Double Edge Trimmer, set of 4 (not shown)........................... 1

16

JEB-1 Edge Bander

17

NOTES

18

NOTES

19

WMH Tool Gr ou p

2420 Vantage Drive

Elgin, Illinois 60123

Phone: 800-274-6848

www.wmhtoolgroup.com

20

Loading...

Loading...