Page 1

Page 2

Handbook of Instructions

FOR

THE

JENSEN

MODEL

This handbook is published for the use and

assistance of owners of JENSEN CARS. It

embodies in a concise form the advice and

suggestions of the Company's Technical Staff

in regard to lubrication, general care, and

maintenance, together with supplementary

information regarding the necessary adjustments

which may be required from time to time.

PRICE

1216

NETT

Compiled

and

Published by

JENSEN

MOTORS LTD.

WEST BROMWICH

ENGLAND

Telephones

:

W.B.

1112-2-3

Telegrams

:

"

Expert

"

PAGE

ONE

Page 3

................................................................................................................................................

Chassis No

...................................................................................................................................................

Engine No

........................................................................

Registration No

............................................

..

Original date of

delivery from Works

...........................................................

....

...........................................

PAGE

TWO

Page 4

Foreword

I

N

COMPILING THIS BOOK some knowledge

of the operation and care of a Motor Car has

been pre-supposed, and the instructions

contained herein, will, if followed with reasonable

care, enable you to obtain the maximum enjoy-

ment and satisfaction from your JENSEN Car.

Illustrations are provided to give useful

information in the simplest form, and a lubrica-

tion chart will be found on page

11.

In the rare event of any unforeseen defect or

unusual trouble developing,

it

is requested that

the matter be at once brought to our notice.

The interest of Jensen Motors Ltd. in their

productions does not end with the delivery of

the Car; on the contrary,

it

is the Company's

desire to keep in close touch with all Jensen

owners, and to provide for their convenience,

a

Service after sales second to none.

JENSEN MOTORS LIMITED

PAGE

THREE

Page 5

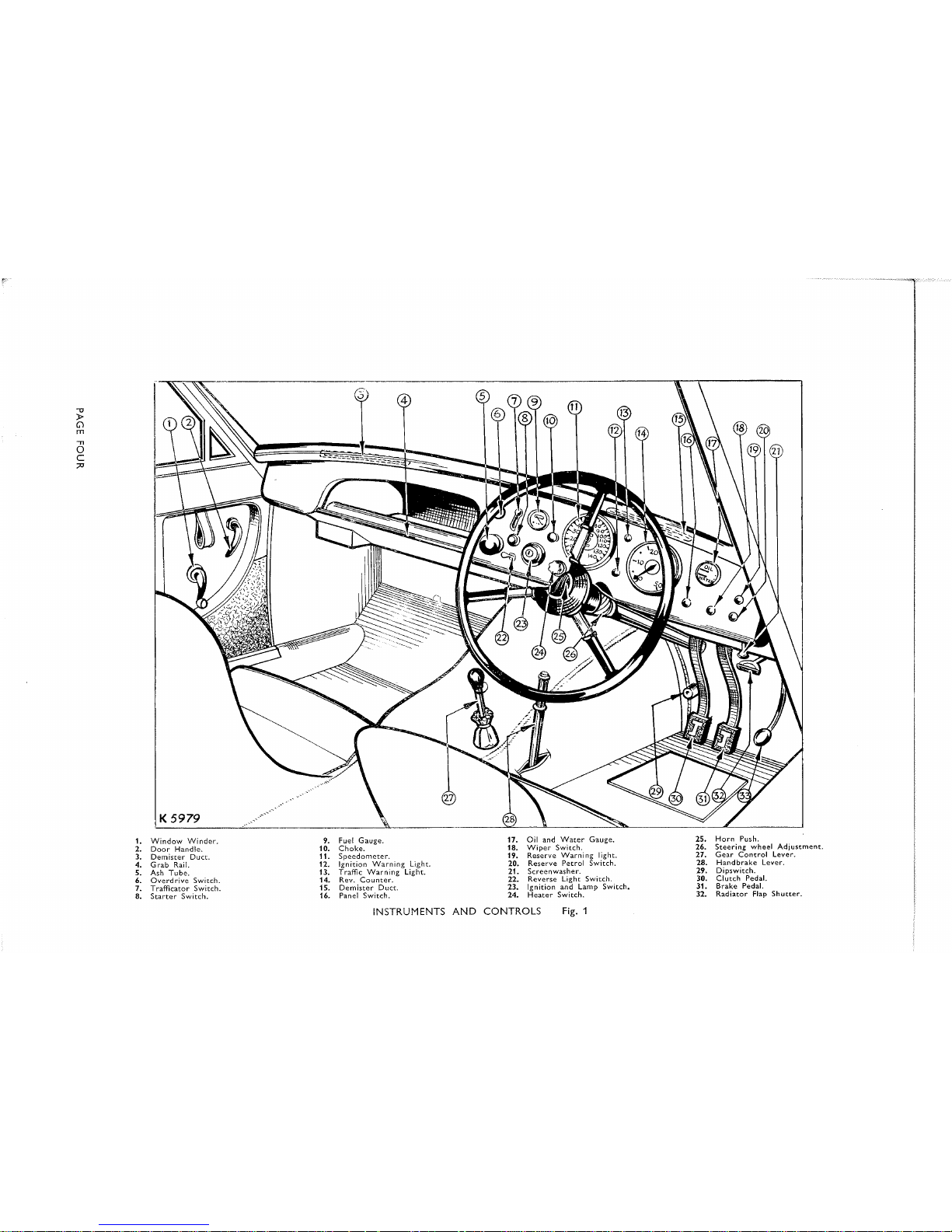

1.

Window Winder.

2.

Door Handle.

3.

Demister Duct.

4.

Grab Ra~l.

5.

Ash Tube.

6.

Overdrive Switch.

7.

Trafficator Switch.

8.

Starter Sw~tch.

9.

Fuel Gauge.

10.

Choke.

11.

Speedometer.

12.

lgnition Warning Light.

13.

Traffic Warn~ng Light.

14.

Rev. Counter.

15.

Demister Duct.

16.

Panel Switch.

17.

Oil and Water Gauge.

18.

Wiper Switch.

19.

Reserve Warning light.

20.

Reserve Petrol Switch.

21.

Screenwasher.

22.

Reverse Light Switch.

23.

Ignition and Lamp Switch.

24.

Heater Switch.

25.

Horn

Push.

26.

Steering wheel Adiustment.

27.

Gear Control Lever.

28.

Handbrake Lever.

29.

Dipswitch.

30. Clutch Pedal.

31.

Brake Pedal.

32.

Radiator Flap Shutter

INSTRUMENTS AND CONTROLS

Fig.

1

Page 6

STARTING

UP

AND GENERAL RUNNING HINTS

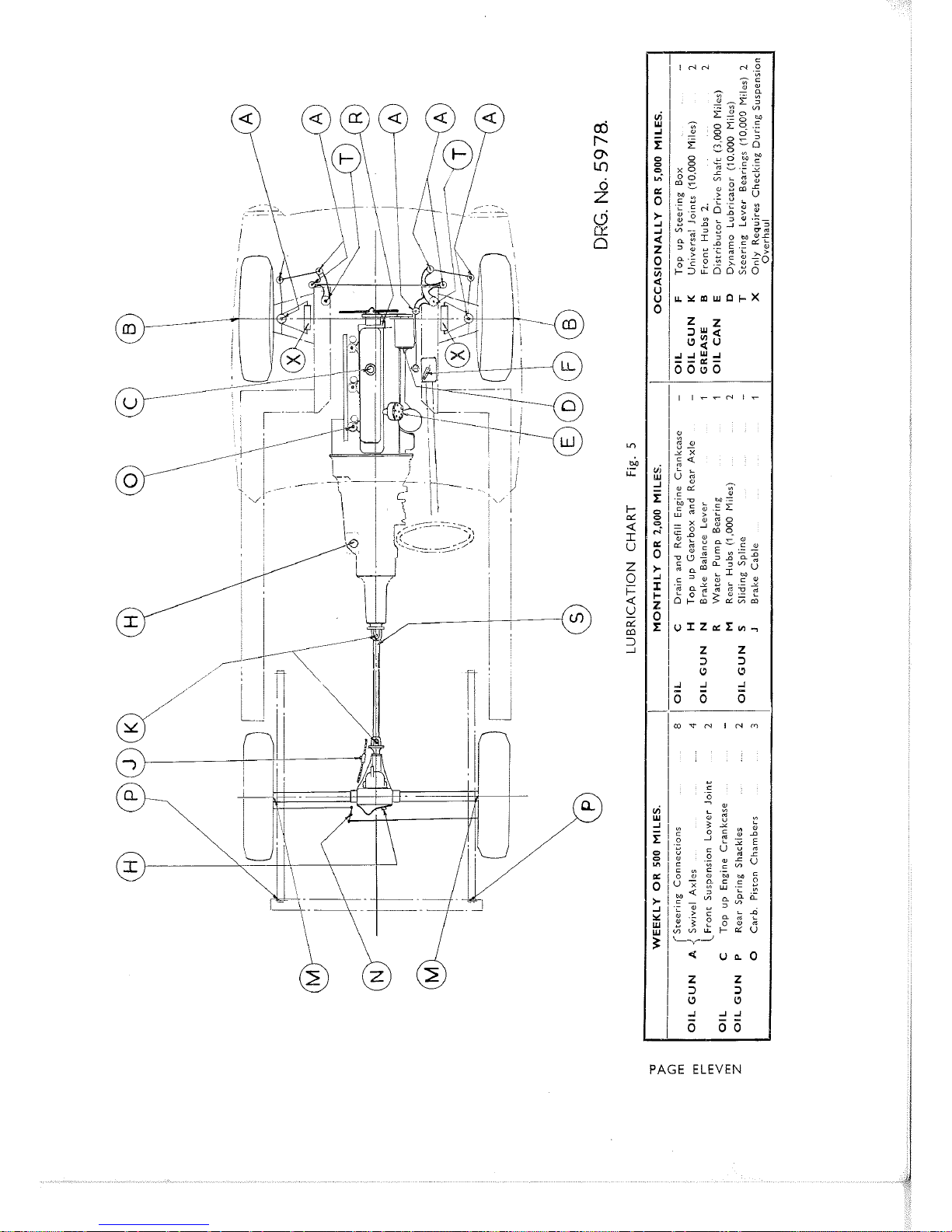

Treat the new car with consideration. Although every JENSEN car

is thoroughly tested on the road, the first few hundred miles should be done at a

moderate speed. We do not tie

JENSEN

owners to the monotonous observance

of an arbitrary maximum speed for a given distance, but we recommend that sustained high speeds in excess of say

60

miles per hour be avoided until the car has had

reasonable time to settle down and all moving parts are freed from their

initial stiffness. The observance of these precautions will be reflected later on in

the prolonged life of the car. Under this heading, lubrication

is

by far the most

important item. Many troubles are directly traceable to lack of proper lubrication

and owners will be well repaid by giving careful attention to the lubrication diagram

Page

11.

The engine attains maximum power at

3700

r.p.m. and

4000

r.p.m. should not

be exceeded.

We strongly recommend owners who do not wish to carry out their own oiling

and greasing to take advantage, where possible, of the facilities offered by service

stations with modern lubrication equipment.

The illustration on page four shows the general arrangement of controls and

the following points should be observed in starting the engine.

(a) Ensure that the gear control lever is in neutral.

(b) Switch on the ignition and

if

starting from cold, pull out switch on facia

marked

C.

This operates a small electric starting carburetter which feeds

a rich mixture to all the cylinders. Press starting switch firmly.

The engine

should then start immediately.

Never Race the Engine from a cold

start-this

is

most injurious.

The starting carburetter must be switched off when the engine has warmed

up. As a general guide, this will take place after

+

to

74

miles have been

covered, depending on the ambient temperature.

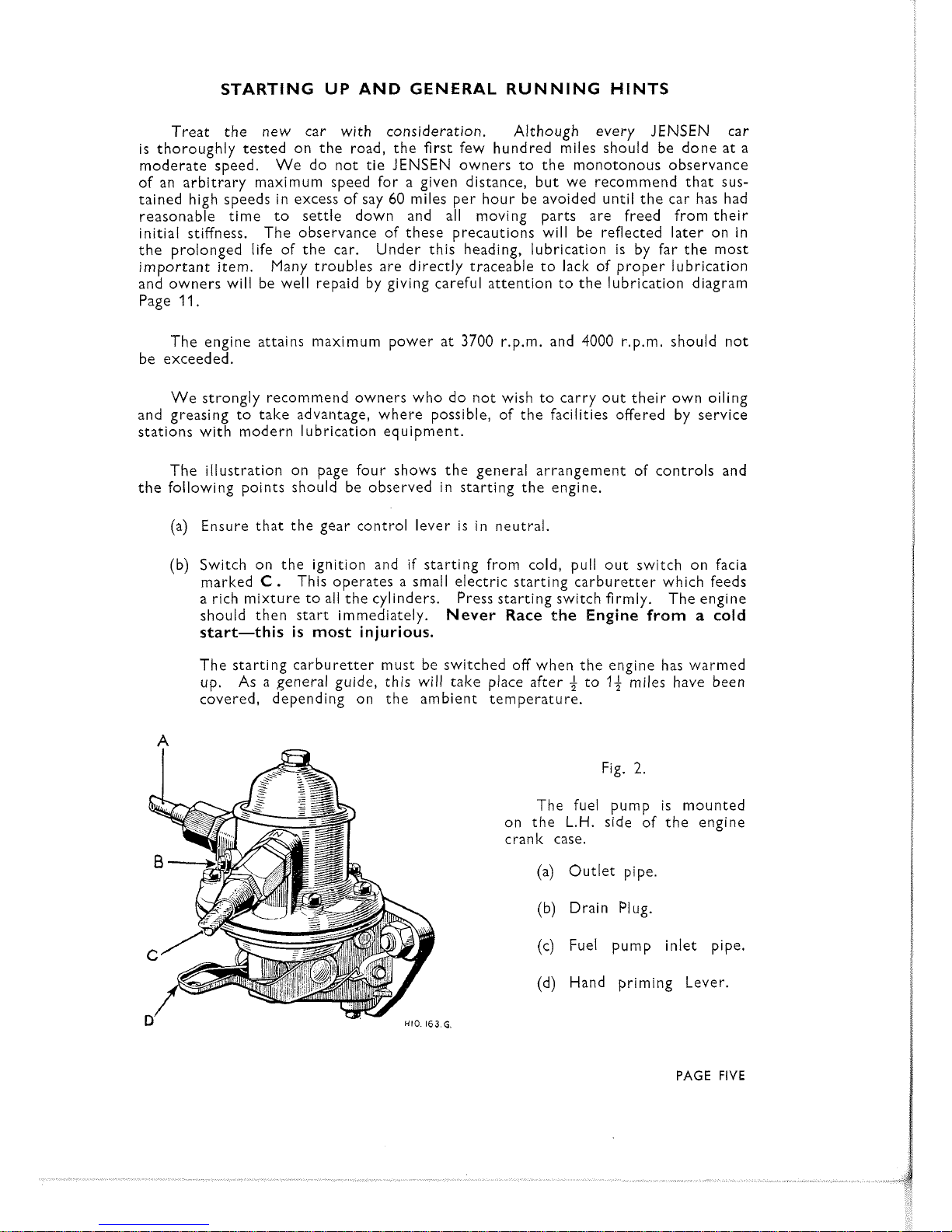

Fig.

2.

The fuel pump is mounted

on the

L.H.

side of the engine

crank case.

(a) Outlet pipe.

(b) Drain Plug.

(c) Fuel pump inlet pipe.

(d) Hand priming Lever.

PAGE

FIVE

Page 7

(c) When the car has been parked for some time or if the carburetter float

chambers have been dismantled for cleaning, fuel will have to be pumped

to the carburetter before the engine can be started. In these circumstances

operate the fuel pump hand priming lever.

(Fig.

2).

Fig.

3.

The full flow oil filter should

only be dismantled when the

filter element is to be renewed.

(a) Centre fixing bolt.

(b)

Filter casing drain plug.

(c) Filter element.

(d) Oil sump Drain plug.

The change speed arrangement being conventional,

we do not propose to describe the method of engaging

and changing gear, but we give here a plan showing the

gear lever positions.

(Fig.

4.)

Fig.

'4.

Overdrive.

The overdrive

is

an optional extra.

To engage overdrive, which can only be

operated from fourth speed position, all that

is

required

is

to pull switch on facia

marked

overdrive.

No movement of the clutch or alteration of accelerator pedal

is

necessary. Reverse process to return to fourth speed position.

PAGE

SIX

Page 8

CARE AND MAINTENANCE.

For correct lubrication of all engine parts, it is only necessary to maintain the

correct oil level in the sump.

This

is

ascertained by a Dipstick located on the right

hand side of the engine.

On all new or reconditioned engines, the sump and full flow oil filter should be

drained and refilled with new oil after the first 500, 1,000 and 2,000 miles.

After

this the operation should be repeated every 2,000 miles to provide the best running

conditions.

There

is

one drain plug in the sump and one near the bottom of the oil filter

reservoir (See (b) Fig. 3).

The capacity of the engine lubrication system is 15 pints

(8.4

litres), plus 2 pints (1.13 litres) for full flow Tecalemit Filter.

Cylinder Head Nuts

After the first 500 and 2,000 miles of running, the cylinder head nuts should be

tightened.

Tighten each nut a little at a time, working from the centre outwards.

This operation should be carried out when the engine

is

hot.

Tappets must be

checked after this operation and readjusted if necessary.

Oil Pressure.

The oil pressure gauge indicates whether the oiling system is working correctly

and

it

should be looked at occasionally while the engine

is

running.

The normal working pressure

is

55 p.s.i. and the idling pressure

is

26 p.s.i.

Should the normal oil pressure appear low, then

it

is

possible that the full flow Tecal-

emit oil filter

is

choked and in need of renewal. Never run the engine if the oil

gauge does not register pressure as serious damage may result.

Chassis Lubrication.

The various points of the chassis should receive periodical attention as indicated

in the Lubrication Chart on Page 11.

It

is

of

vital importance

that the rear hubs

receive attention at the periods recommended, as the rear hub bearings are actually

sealed from the oil circulating in the main casing.

Rear Axle Lubrication.

The standard rear axle for this model is a Hypoid Bevel type with a ratio of

2.93

:

l.

After the first 2,000 miles, drain the rear axle and refill with a recommended

type of new oil to the level of the combined oil filler and level plug.

The oil level

should be checked every further 2,000 miles and topped up when necessary.

It is extremely important that only approved Hypoid oils be used with

this axle, without the use

of

additives

of

any kind.

Gearbox Lubrication.

Drain gearbox and refill with new oil to the top level on the dipstick after the

first 2,000 miles.

Access to the dipstick and oil filler plug is gained by lifting the

rubber plug in Tunnel.

The capacity of the gearbox is 63 pints and if Overdrive

is fitted the combined capacity of Gearbox and Overdrive

is

8

pints, the oil level on

the gearbox dipstick remaining the same. Thz oil level should be checked every

further 2,000 miles and topped up when necessary.

PAGE

SEVEN

Page 9

RECOMMENDED LUBRICANTS FOR JENSEN

'541'

WAKEFIELD

Engine Summer

......

......

......

......

Winter

......

.....

Gearbox & Overdrive

...........

......

Rear Axle (Hypoid) & Steering Box

Chassis Lubrication

&

Wheel Hubs

....

(Grease Gun.)

......

Oil Can

...... ......

......

......

VACUUM

....

Engine Summer

....

......

......

Winter

......

......

Gearbox & Overdrive

........

.....

Rear Axle (Hypoid) & Steering Box

Chassis Lubrication

&

Wheel Hubs

(Grease G

U

n

.)

...... ...... ..... ......

Oil Can

......

......

.....

....

B.P.

Engine Summer

...... ......

......

......

Winter ......

......

Gearbox & Overdrive

............

......

Rear Axle (Hypoid) & Steering Box

Chassis Lubrication

&

Wheel Hubs

(Grease Gun.)

...... ......

Oil Can

......

......

......

.....

SHELL

......

....

Engine Summer

......

......

Winter

.... .....

............

Gearbox & Overdrive

......

Rear Axle (Hypoid) & Steering Box

Chassis Lubrication

&

Wheel Hubs

......

(Grease Gun.)

......

......

......

.....

Oil Can

...... .....

......

ESSO

Engine Summer

......

......

......

......

Winter

......

......

............

Gearbox & Overdrive

......

Rear Axle (Hypoid) & Steering Box

Chassis Lubrication

&

Wheel Hubs

(Grease Gun.)

...... ...... ...... ......

Oil Can

......

......

......

......

.....

Castrol

XL.

.....

Castrolite.

......

Castrol

XL.

......

Cast rol H y poy

......

Castrolrase Heavy.

......

Castrol

XL.

.....

Mobiloil "A".

......

Mobiloil Arctic.

......

Mobiloil "A".

....

Mobilube

GX90.

......

Mobilgrease No.

4.

......

Mobiloil "A".

......

Energol SAE.

30.

......

Energol SAE.

20.

......

Energol SAE.

30.

......

Energol EP SAE.

90.

.....

Energrease

C3.

.....

Energol SAE.

30.

....

X-100 30

......

X-100 20/20W

......

X-100 30

.....

Spirax

90

EP.

......

Retinax "A"

......

X-100 30.

......

Essolube

30.

......

Essolube

20.

......

Essolube

30.

....

Esso Expee Compound

90.

....

Esso

pressure Gun grease.

Essolube

30.

.....

PAGE

EIGHT

Page 10

ADJUSTMENTS.

The engine should not require any major adjustments for at least 20,000 miles.

After this distance, should there be any falling off in efficiency,

it

may be advisable

to have the cylinder head removed for decarbonising, valve grinding and tappet

adjustment.

The correct tappet clearance

is

.012" when the valve is closed.

(Hot

or cold).

Sparking

Plugs.

Sparking plugs should be removed and cleaned in a special plug cleaning machine.

After cleaning, the points should be checked and reset if necessary to the correct

gap of .035".

The carburetters should be checked and cleaned. (See carburetter

section Page

19).

PAGE NINE

Page 11

GENERAL DIMENSIONS AND DATA FOR

QUICK

REFERENCE.

The car number will be found stamped on a plate secured to the bulkhead.

This number

is

also stamped on the top of the

L.H.

chassis frame side member im-

mediately aft of the front suspension.

The engine number is stamped on the R.H.

side of the Cylinder Block immediately below number 2 Spark Plug.

Bore

.....

......

Stroke

.....

......

......

Cubic Capacity

.....

R.A.C. Rating

Compression Ratio

...

Firing Order

Coolant Capacity

Oil Sump Capacity

Gearbox Capacity

Rear axle capacity

Fuel Tank Capacity

Overall Gear Ratios.

I

st

...... ......

9.9

:

1

2nd

......

....

6.70 : 1

3rd

......

.....

4.18 : 1

4th

...... ....

2.93

:

1

Reverse

....

12.0

Tyres

......

....

...

Tyre pressure

Wheel base

...

...

Track

......

Toe-I n

Camber

Caster Angle

K~ng

Pin

lncl~nat~on

Overall W~dth

Overall He~ght

Overall Length

Ground Clearance

Turn~ng C~rcle

Clutch Pedal

Welght (Dry)

Centre of

Grav~ty

Steer~ng ratio

87 m.m. (3.4 ins.).

111

m.m. (4.37 ins.).

3,993

C.C.

(243 cub. ins.).

28.2 H.P.

6.8

:

1 (Special Head 7.4 : I).

1, 5,

3,

6, 2, 4.

31 Pints.

15 Pints plus 2 Pints for full flow filter.

66 Pints (8 Pints with Overdrive).

3 Pints.

15 Gallons (12 Main

-

3 Reserve).

With Overdrive.

....

...

....

11.98 : 1

......

....

.....

8.14 : 1

.....

....

...

5.06 : 1

....

....

3.54 : 1

Overdrive

...

2.75

:

1

Reverse

....

14.5 : 1

Dunlop 5.50-16 (6.40~15 with wire wheels).

28 p.s.i. all round. (6.40~15-24. p.s.i.).

8

ft. 9 ins.

Front

-

4

ft.

36

ins.

Rear

-

4 ft.

34

ins.

0 ins. to ins.

1"

2

2"

6;

O

5 ft. 3 ins.

4 ft. 5 ins.

14 ft.

'10

ins.

7 ins.

34 ft.

4

ins. free movement.

26 Cwts.

49 ins. aft

cf Front axle.

16

:

1.

2; turns lock to lock.

PAGE

TEN

Page 12

INN

NO

PAGE

ELEVEN

Page 13

Ignition.

Lucas Coil and Distributor. Automatic advance and retard.

Direction of rotation

-

anti-clockwise. Contact Breaker Gap .012 ins.

Spark Plugs.

Champion N.8.B. Gap ,035 ins.

Valve Clearances.

.012 ins. hot or cold.

ELECTRICAL EQUIPMENT.

Lamp Bulbs.

....

Headlamps

......

......

Side Lamps

.....

Number Plate

..........

.........

Reverse Lamp

....

Instrument

......

......

Warning Lamps

......

Stop & Tail

......

Flashers

.... .....

Boot & Bonnet Light

60136

6w.

6w.

24w.

18 amps.

18 amps.

1816~.

24w.

6w.

Lucas No. 404.

,,

,,

989.

,,

,,

989.

P,

,,

199.

,,

,,

987.

,,

,,

987.

,, ,,

361.

,,

,,

199.

,p

,,

989.

Battery.

The Lucas 12 volt Battery Type GTWllA 64 amp. hrs. is situated below R.H.

rear seat.

This location is preferable to under Bonnet fixing as fluid evaporation

is far less rapid and consequently the "topping up" operation is less frequently

required. When the acid level falls below the top of the plates, distilled water should

be added until the plates are again covered. Keep the battery terminals clean and

tight and well smeared with petroleum jelly. This will protect the terminals from

corrosion, which if allowed to continue unchecked, will result in a break in the

battery circuit.

It is important that the battery be firmly secured in its supporting brackets at

all times.

When removing or replacing battery, remove clamp bar and bolts away

from well, otherwise bolts may be bent by the weight of the battery.

Headlamps.

Each headlamp incorporates a Lucas light unit which consists essentially of a

combined reflector and front glass assembly provided with a mounting flange by

means of which it is secured to the body housing. The bulb which is a Lucas Prefocus

type is located accurately in the reflector and is secured by a bayonet fixed

bacl<shell,

which also provides the contact to the bulb. The design of the bulb is such that

it

is correctly positioned in relation to the reflector and no focusing

is

required when

a replacement bulb is fitted.

Fig.

6.

Headlight Adjusting.

A.

C

and E are Reflector adjusting

screws, B

is

a slotted way, and D the

Bayonet catched backshell.

PAGE

TWELVE

Page 14

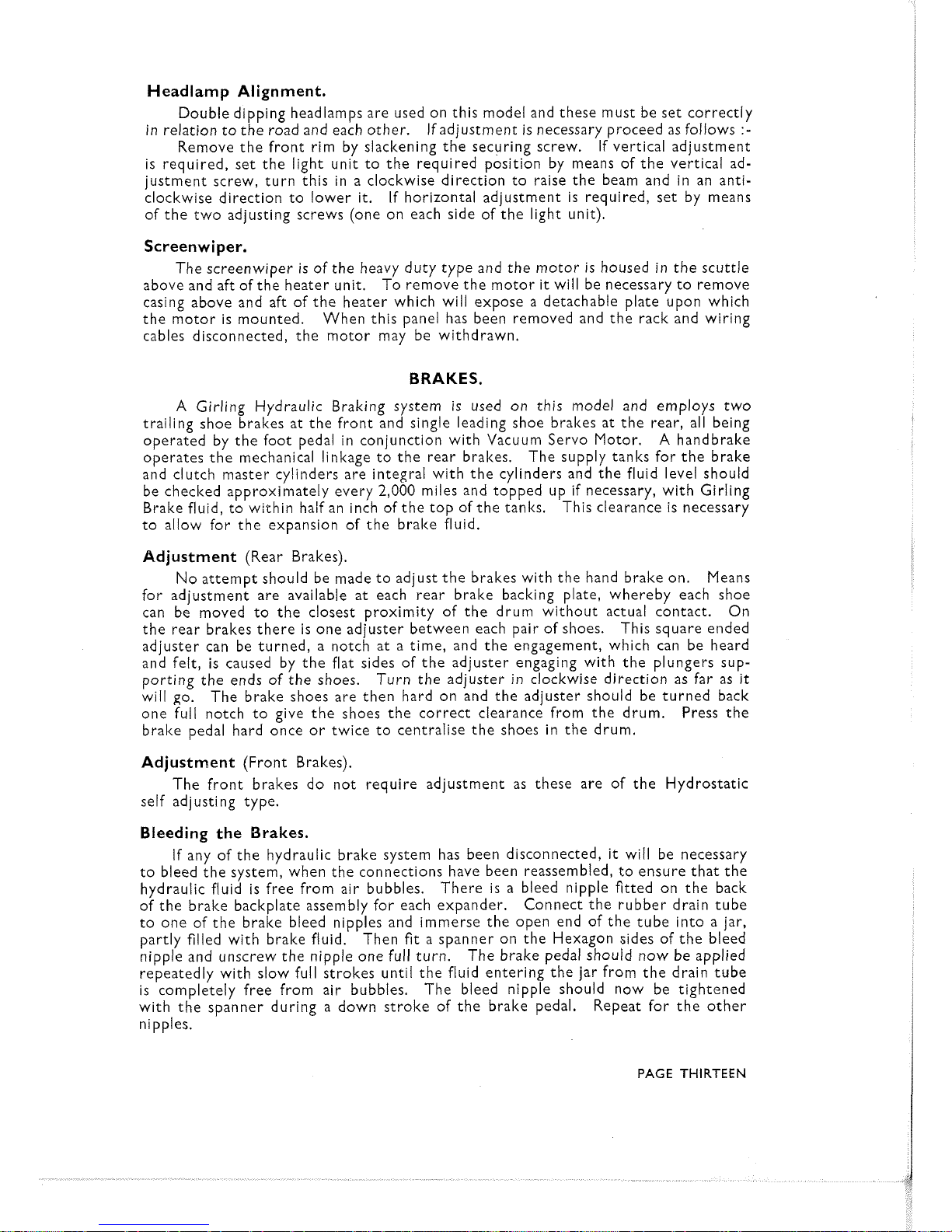

Headlamp Alignment.

Double dipping headlamps are used on this model and these must be set correctly

in relation to the road and each other.

If adjustment is necessary proceed as follows

:-

Remove the front rim by slackening the securing screw.

If vertical adjustment

is required, set the light unit to the required position by means of the vertical adjustment screw, turn this in a clockwise direction to raise the beam and in an anticlockwise direction to lower it. If horizontal adjustment is required, set by means

of the two adjusting screws (one on each side of the light unit).

Screenwiper.

The screenwiper is of the heavy duty type and the motor is housed in the scuttle

above and aft of the heater unit.

To remove the motor it will be necessary to remove

casing above and aft of the heater which will expose a detachable plate upon which

the motor is mounted. When this panel has been removed and the rack and wiring

cables disconnected, the motor may be withdrawn.

BRAKES.

A

Girling Hydraulic Braking system is used on this model and employs two

trailing shoe brakes at the front and single leading shoe brakes at the rear, all being

operated by the foot pedal in conjunction with Vacuum Servo Motor.

A

handbrake

operates the mechanical linkage to the rear brakes. The supply tanks for the brake

and clutch master cylinders are integral with the cylinders and the fluid level should

be checked approximately every

2,000

miles and topped up if necessary, with Girling

Brake fluid, to within half an inch of the top of the tanks. This clearance is necessary

to allow for the expansion of the brake fluid.

Adjustment

(Rear Brakes).

No attempt should be made to adjust the brakes with the hand brake on.

Means

for adjustment are available at each rear brake backing plate, whereby each shoe

can be moved to the closest proximity of the drum without actual contact. On

the rear brakes there is one adjuster between each pair of shoes. This square ended

adjuster can be turned, a notch at a time, and the engagement, which can be heard

and felt, is caused by the flat sides of the adjuster engaging with the plungers supporting the ends of the shoes. Turn the adjuster in clockwise direction as far as

it

will go. The brake shoes are then hard on and the adjuster should be turned back

one full notch to give the shoes the correct clearance from the drum. Press the

brake pedal hard once or twice to centralise the shoes in the drum.

Adjustment

(Front Brakes).

The front brakes do not require adjustment as these are of the Hydrostatic

self adjusting type.

Bleeding the Brakes.

If any of the hydraulic brake system has been disconnected,

it

will be necessary

to bleed the system, when the connections have been reassembled, to ensure that the

hydraulic fluid is free from air bubbles. There is a bleed nipple fitted on the back

of the brake backplate assembly for each expander. Connect the rubber drain tube

to one of the brake bleed nipples and immerse the open end of the tube into a jar,

partly filled with brake fluid. Then

fit

a spanner on the Hexagon sides of the bleed

nipple and unscrew the nipple one full turn. The brake pedal should now be applied

repeatedly with slow full strokes until the fluid entering the jar from the drain tube

is completely free from air bubbles. The bleed nipple should now be tightened

with the spanner during a down stroke of the brake pedal. Repeat for the other

nipples.

PAGE

THIRTEEN

Page 15

It

is important when bleeding the brakes to check the fluid level in the supply

tank at frequent intervals and to top up as necessary to ensure that the

master cylinders are never starved of fluid. Should air reach the master cylinders

it

will be necessary to bleed the whole system again.

Fluid which has just been bled from the system should never be used for topping

up the supply tank immediately, since it will be, to some extent, aerated. It must,

therefore, be allowed to stand for an hour or two before it can be safely used again.

Dirty fluid must be discarded since grit or other foreign matter in the system will

seriously effect braking efficiency and cause unnecessary wear.

Servs.

Under normal conditions the Servo motor should not require attention over

long periods. However, should any trouble be experienced with the Servo,

it

is

recommended that the unit be returned to the manufacturer for servicing.

(See

page

28).

Care should be taken to see that the breather pipe on the Servo unit is never

left disconnected from the breather valve situated on the front of the bulkhead in

the centre of the

R.H.

side, below the Servo.

FRONT

SUSPENSION.

The independent front suspension is of the 'Wishbone' type, the coil springs

being held in compression between the chassis frame and the lower Wishbone.

Damping is effected by telescopic hydraulic dampers (Girling BAS6). The dampers

are of the sealed type and no attention to them should be necessary. Suspension

lubrication points are shown in the lubrication chart (See Page

11).

Alignment

of

Front Wheels.

Alignment of the front wheels is an importmt factor in tyre economy and ease

of steering.

The front wheels should have a toe-in of between

0

ins. and &ins.

This measurement

is

taken between the wheel rims at the front and rear of the wheels

at a height equal to the centre of the wheel to the ground. The rear measurement

should be between

0

ins. and ins. greater than the front measurement. If the

difference between the two measurements is other than this, the wheels are out of

alignment and adjustment should be made immediately.

To carry out this adjustment, loosen the

lock nuts on the ends of the front crosstube and rotate the tube in the appropriate direction to give the correct toe-in.

To permit this adjustment the cross tube carries a right-hand thread at one end and

a left-hand thread at the other end. When the correct measurement has been

obtained, retighten the two

lock nuts. Do not alter setting of side tubes.

Adjusting Front Wheel Bearings.

If there is excessive play in the bearings, they can be adjusted as follows

:-

Jack up the front of the car and remove the nave plates and hub caps. Remove

cotter pins from bearing nuts and tighten bearing nuts with a suitable wrench. The

bearing spacer is of the non-collapsible type and provided the bearing nut

is

pulled

up tight, the correct bearing clearance will be obtained. Replace cotter pins. If

play

still

exists after tightening up the hub nuts,

it

is probable that the bearings will

need replacement.

Lubrication of Front Wheels.

Wheel bearings should be cleaned and repacked with grease every

5,000

miles

under normal conditions.

PAGE

FOURTEEN

Page 16

Centre Lock Wire Wheels.

Where centre lock wire wheels are fitted

it

is essential that the hubs, hub nuts

and inner portion of the wheel shell are kept clean and well lubricated.

Engine oil should be used for the latter purpose and not grease, particular atten-

tion being paid to the conical surfaces.

CARE

OF

TYRES.

Tyre Pressures.

The correct pressures are as follows

:-

5.50 X 16 :-28 p.s.i. all round.

6.40

x

15

:-24 p.s.i. all round.

For sustained high speed in excess of 90 miles per hour, the tyre pressures should

be increased to 34

p.s.i. all round for 5.50

x

16, and 30 p.s.i. for 6.40~ 15 tyres.

Pressures (including spare) should be checked and adjusted at least weekly.

This should be done when the tyres are cold and not when they have attained normal

running temperatures. Any unusual pressure loss should be investigated

and corrected.

Under-inflation has an adverse effect on the car and causes rapid and sometimes

irregular wear.

Also the casing may be damaged by excessive bending.

Changing Position of Tyres.

To obtain the best tyre mileage, equal wear, and to suppress the development

of irregular wear on front tyres, interchange front tyres with rear tyres at least

every 2,000 miles.

Tyre and Wheel Balance.

To provide smooth riding, precise steering and to avoid high speed steering

reaction, the tyres are balanced to predetermined limits.

By fitting the tyre so

that the white spots near the cover bead coincide with the black spots on the tube,

a high degree of balance is achieved.

If a higher degree of balance is required, the complete tyre and wheel assembly

should be balanced.

All wheel assemblies on JENSEN cars are balanced before leaving the factory

The original balance may be disturbed after a period of running.

It can be

checked, and,

if

necessary, corrected by any Service Station with tyre balance

equipment.

Factors Affecting Tyre Life.

The most important factors which have an adverse affect on tyre life are

:-

(l)

Incorrect tyre pressures.

(2)

Misalignment of wheels (See alignment of front wheels, Page 14).

(3)

High average speeds.

The rate of tread wear at 50 m.p.h. is nearly twice

as fast as at

30

m.p.h.

(4) Harsh acceleration.

(5) Frequent fierce braking.

(6) Warm dry weather.

The rate of tread wear in summer may be twice as

fast as during a cold and wet winter.

(7)

Bad road surfaces.

(8) Winding, cambered and abrasive roads.

Quite moderate speeds on such

roads will produce faster tread wear than much higher speeds on straight

flat roads.

PAGE

FIFTEEN

Page 17

TRANSMISSION.

Clutch.

The Borg and Beck loin. diameter dry, single plate clutch has a spring cushion

drive and a total frictional area of 88 sq. ins.

The clutch pedal

is

isolated from the

clutch housing by means of a flexible hydraulic control.

A

clearance of

-&

in. should

be maintained between the carbon release bearing and the pressure pad. This may

be checked by removing the

clevis pin connecting the clutch release arm and the

slave cylinder connecting arm and measuring the amount of free movement at this

connecting point.

This should be

$

in. If it is other than this, adjustment may be effected by slackening off clevis locknut and rotating clevis in the appropriate direction to obtain

the requisite free movement. When this has been obtained the pin should be re-

placed, split pinned and

clevis locknut fully tightened.

The method of bleeding is the same as that described for the brakes on Page 13.

The clutch release bearing requires no lubrication.

Gearbox.

The gearbox provides 4 speeds forward and reverse, with synchromesh 2nd,

3rd and top gears.

Ratios are as follows

:-

......

1st Gear

...........

......

3.07:l 2nd Gear

....

.....

1.88:l

......

3rd Gear

............

...

1.27:l 4th Gear

......

......

1.OO:l

Reverse

....

...... .....

3.07:l

Instructions for lubrication are given on Page

7.

The gearbox mainshaft is extended in a housing which allows the use of a short

propeller shaft and provides additional mainshaft bearings to give firmer positioning

for the gears.

Oil capacity

64

pints.

When Overdrive

is

fitted (optional extra) the combined

capacity of the gearbox and overdrive is eight pints.

Propeller Shaft.

The open propeller shaft has Hardy Spicer needle roller bearing universal joints.

Lubrication particulars for this will be found on the lubrication chart on Page 11.

Rear Axle.

The rear axle is of the semi-floating type with shim adjustment for all the

bearings and meshing of the Hypoid drive gear and pinion matched assembly.

The

axle shafts are

splined at the inner ends, which engage splines in the differential side

gears, while the outer ends have tapers and keys to

fit

the rear wheel hubs.

The hubs are supported by taper roller bearings pressed on to the axle shafts

and located in the ends of the axle tubes.

Outward thrust on either wheel is taken

by the adjacent hub bearing, whilst inward thrust is transmitted through the axle

shafts and slotted axle shaft spacer to the opposite bearing. Thus, each hub bearing

takes thrust in one direction only.

PAGE

SIXTEEN

Page 18

A

cover on the rear of the gear carrier housing permits the inspection and

flushing of the differential assembly without dismantling the axle.

The axle gear ratio is stamped on a tag attached to the assembly by one of the

rear cover screws. The axle serial number is stamped on the gear carrier housing

and should always be referred to when corresponding with reference to any

particulzr

unit.

In the event of trouble through any cause, wherever possible

it

is strongly

recommended that use should be made of the factory reconditioning service.

It should be clearly understood that the adjustment of the Hypoid Bevel axle

is more complex than that necessary for the satisfactory performance of the spiral

bevel.

For rear axle lubrication, see instructions on Page

7.

FUEL

SYSTEM.

Fuel Pump.

The fuel tank is mounted aft of the rear axle and is of 15 gallons capacity-l2

gallons main,

3

gallons reserve.

The

3

gallons reserve are not metered on the gauge.

From this tank fuel is fed to the carburetter by an A.C. mechanical pump mounted

on the

L.H.

side of the engine crank case. A priming lever is fitted to enable the

carburetter to be primed by hand (See Fig.

2,

Page 5). This should be used if the

carburetter float chamber has just been replaced after cleaning, to save an excess of

strain on the battery through using the starter to pump fuel through the system.

Approximately every 5,000 miles the strainer gauze in the fuel pump should be re-

moved and cleaned.

Fig. 7.

This exploded view of the fuel pump,

shows the location of the strainer gauze.

A. Outlet pipe union.

B.

Drain Plug.

C.

Inlet pipe union.

D.

Strainer gauze.

E.

Cork washer.

F.

Cover securing screw.

Access to the strainer is gained by removing the pump top cover and at the same

time that the strainer gauze is removed, the pump drain plug should be unscrewed

and all sediment removed from the body of the Dump chamber. Use fuel and a non-

,

a

fluffy rag for cleaning the chamber2,;nd for the strainer gauze use fuel only.

(See Fig.

7,

Page 17).

PAGE SEVENTEEN

Page 19

CARBURETTERS.

Fig.

8.

(1) Filter.

(2) Float.

(3)

Float chamber secur-

ing. nut.

(4) Float needle.

(5) Air bleed.

(6) Bridge plate screw.

(7) Fast idling screw.

(8) Stop collar.

(9)

Terminal Itnob.

(10) Solenoid Case.

(11) Solenoid.

(12) Plunger.

(1 3) Control spring.

(14)

Plunger return spring.

(15) Valve flat.

(16) Valve seat insert.

(17) Olive union nut.

(18) Taper needle.

(19) Therrno jet.

(20) Fuel passage.

(21) Holding up bolt.

(22) Banjo union bolt.

(23)

Float tickler pin.

Fig.

9.

'

(1) Cork Gland Washer.

K(2) Slow running adjustment screw.

(3)

Throttle spindle.

(4) Vacuum Ignition Union.

(5) Holding up bolt.

(6) Nut cap.

(7) Jet adjusting screw.

(8) Fibre washer.

(9) Jet lower bearing.

(10) Jet head.

(11) Brass sealing ring.

(12) Cork sealing ring.

(13) Gland spring.

(14) Main jet.

(15) Needle.

(16) Needle

loclting screw.

(17) Piston.

(18) Piston spring.

(19) Suction chamber.

(20) Oil Cap,

PAGE EIGHTEEN

Page 20

Fig.

10.

(1) Upper jet bearing.

(2) Main jet.

(3)

Cork gland washer.

(4) Fuel Passage.

(5)

Gland washer.

(6)

Brass sealing ring.

(7) Jet head.

(8)

Nut cap.

(9)

Jet adjusting screw.

(10) Fibre washer.

(1 1) Jet lower bearing.

(12) Set screw.

(13)

Cork sealing ring.

(14) Gland spring.

('i

5)

Copper plug.

(16)

Float chamber body.

(17) Copper washer.

The model

'541'

has three S.U. carburetters, with a smal! electrically operated

carburetter for starting. This starting carburetter which

is

operated by a switch

on the facia panel marked

'C,'

supplies a rich mixture to the cylinders for easystarting.

This starting carburetter must be switched off as soon as possible after the motor

has warmed up.

The carburetters are carefully synchronised to ensure perfect running for the

engine and

it

is,

therefore, very important that the throttle linkage between the

carburetters is not interfered with in any way. The carburetters will also give the

best results if adjustments are only made when absolutely necessary.

Maintenance.

The only attention normally required

is

the monthly application of a few spots

of thin machine oil to each carburetter suction chamber oil cap.

This will ensure

that the taper needle and piston assembly are free to respond readily to changes in

engine speed.

The filter in the inlet unions to each carburetter should be cleaned occasionally.

Unscrew the unions, lift off the filter, rinse in clean fuel and replace.

Ensure that

the two fibre washers are in position on each side of the union.

If the running of the engine

is

poor, always make sure that the trouble does not

lie elsewhere than the carburetters.

Check the spark plugs and distributor contact

breaker points and see that the tappets are correctly set.

PAGE

NINETEEN

Page 21

Carburetter Pistons.

Sluggish and uneven running may be caused by sticking carburetter pistons.

When the engine is thoroughly warm, remove the air cleaner and connections,

switch off the engine and then check that the carburetter pistons fall freely when

lifted and released. If any of the pistons stick, the cause may be dirt in the suction

chamber or an incorrectly centred jet. To examine a suction chamber, remove its

three securing screws and lift off the cover, when the chamber and piston can be

cleaned with a non-fluffy rag. Do not use metal polish or emery cloth. If when the

piston is replaced

it

does not fall freely,

it

is probable that the jet is not correctly

centred or the jet needle is bent. In the latter case needle should be replaced.

To centre the jet, remove the nut cap, release the large hexagon screw half a

turn or so and then screw up the jet as far as it will go, noting the number of turns.

This procedure will centre the jet on

the needle and the large hexagon screw can

now be tightened. Finally, release the jet the same numbzr of turns as were needed

to screw it up fully.

Slow Running.

When the idling setting is correct, the carburetters will operate properly at

all speeds. The two adjustments on each carburetter effecting slow running are the

throttle stop screw and the jet adjustment screw. The jet adjustment screws weaken

the mixture when screwed up and enrich

it

when screwed down. When these

screws are correctly adjusted, lifting any of the pistons with a thin blade will slow

the engine down. If the lifting of the piston makes the engine go faster, it indicates

that the carburetter setting is too rich and must therefore be weakened. At the

same time

it

may be necessary to enrich the other two carburetters until a good

balance is obtained.

Starter Carburetter.

The only adjuster is the idling hexagon screw through which the needle passes.

When the engine is hot and the starter carburetter is switched on, the screw should

be adjusted upwards as far as possible without uneven running of the engine. If

next time a cold start is attempted, the engine starts and then stops, the adjusting

screw should be released another third of a turn.

Air Cleaner.

The three cleaner elements should be removed and cleaned every

5,000

miles.

To do this remove the air cleaner by unscrewing the three bolts which secure the

cover plate and the three elements to the back plate. Immerse the elements in

petrol and wash thoroughly.

Allow to dry and then dip in clean engine oil. Shake

out any surplus oil and reassemble.

When carrying out the above operation

it

is necessary to disconnect the rubber

Servo connection. Care must be taken to prevent dirt from entering the system

whilst the pipe is disconnected.

PAGE

TWENTY

Page 22

ENGINE.

Dimensions.

Bore

87

m.m. (3.43 ins.).

Stroke 111 m.m. (4.375 ins.).

Capacity 3993

C.C.

(243 cub ins.).

R.A.C. rating 28.2 h.p.

Compression ratio 6.8

:

1 (Standard) 7.4 : 1 (Special Head).

Cylinders.

Six cylinders, integral with crankcase. Special cast iron is used and there are

full length water jackets. The detachable cast iron cylinder head carries the valve

gear.

Maximum Rebore.

The maximum permissible rebore

is

bore diameter plus .040 ins.

Crankshaft.

The forged steel counterbalanced crankshaft has a torsional vibration damper

and

is

supported by four detachable "Thinwall" bearings.

Crankshaft Regrinding Sizes.

Undersize

CRANKPINS JOURNALS

Bearing

--p----

Minimum Maximum Minimum Maximum

-

----

---

.020 in.

2.1

048 in. 2.1053 in.

2.4590 in. 2.4594 in.

.040 in.

2.0848 in. 2.0853 in. 2.4390 in. 2.439; in.

1

Connecting Rods.

The connecting rods are of forged steel with detachable "Thinwall" bearings.

Pistons.

Aluminium alloy with Anodised surface.

Split skirt type with threecompression

rings and one scraper.

Piston Fitting.

.0012 ins, at top to .0018 at skirt.

Piston Rings.

Gap - .021 ins. to ,015 ins.

Groove width.

Compression

.0957 ins. to .0967 ins

Oil Control .l58 to .l59 ins.

Groove clearances

-

Compression .0017 to .0037.

Camshaft.

The forged steel camshaft is supported by four "Thinwall" bearings and driven

by a duplex roller chain.

A synthetic rubber tensioner ring for the timing chain,

and

a

sound insulated timing gear cover combine to ensure quiet operation.

Valves.

Heat and corrosion resisting steel is used for the exhaust valves and silicon

chrome steel for the inlet valves, while twin exhaust down-pipes permit the unrestricted escape of the exhaust gases from the cylinders.

PAGE TWENTY-ONE

Page 23

Valve Timing.

Both the camshaft gear and the crankshaft gear are spot marked for valvesetting;

the inlet valve opens at

5"

B.T.D.C.

Ignition.

Ignition coil with automatic advance and retard assisted by vacuum control.

Ignition Timing.

In order to reset the ignition timing, remove all spark plugs except that from

No.

1

cylinder and using the starting handle rotate the engine until No. 1 piston

is at T.D.C. before firing stroke. The compression felt at the handle will denote

the correct stroke. T.D.C. of No.

1

piston is marked on the flywheel

(116).

Set Micrometer adjustment to zero.

Remove the distributor cap and slacken pinch bolt of the distributor clamp.

Turn distributor casing until the contact breaker points just begin to open,

with the rotor arm pointing to the relative position of No.

1

cylinder electrode

in the distributor cap. The spark is then correctiy timed.

Finally, retighten the pinch bolt in the clamping plate and refit the distributor cap.

Finer adjustment can be obtained under road conditions by means of

the micrometer adjustment.

Lubrication.

A

pressure gear pump forces oil from a fin cooled cast aluminium sump to all

main, big end and camshaft bearings.

Each main bearing oil feed is supplied from a

circular channel cut in the bearing housing which provides a uniform feed of oil

between the bearing surfaces.

Big end bearing lubrication, controlled by a special oil feed in the crankshaft

also provides for jet lubrication of the cylinder walls, while oil from the camshaft

front bearing

is

guided by deflectors fitted to the camshaft gear on the timing chain.

The valve rocker shaft

is

fed by oil on the camshaft rear centre bearing.

Oil

capacity

15

pints plus 2 pints for full flow Tecalemit filter.

COOLING

SYSTEM.

Cooling.

Circulation of the coolant is by a large outlet centrifugal pump with athermostat

to assist rapid warming from cold.

The system is pressurised

andda spring loaded flap is provided to give further

control, should this be necessary. "The flap control is situated above the brake

pedal and should be used in

conjuoction with the coolant thermometer. To close

the flap, it is necessary to pull the control handle and vice versa. Capacity of the

cooling system

is

31

pints.

Topping Up.

Coolant level should be checked weekly.

Top up when necessary to replace

coolant lost through evaporation. Use only rainwater, if available, and

fill

to approximately 4 in. below the top of the header tank when engine is cold.

PAGE

TWENTY-TWO

Page 24

Winter Precautions.

In winter, an anti-freezing mixture should be added to the cooling water as a

safeguard against freezing and damage to the cylinder block or the radiator.

Care-

fully follow the maker's instructions when preparing the mixture, and when topping

up

it

will be necessary to maintain this mixture.

A satisfactory anti-freezing mixture

is

Smiths "Bluecol", and in this case the

correct mixture for the coolant is

20%

Bluecol and

80%

water.

Bluecol does not evaporate and provided there are no leaks in the cooling system

it

is

only necessary to top up with water.

The boiling point of this solution is

103"

centigrade.

Before adding the anti-freeze mixture it is always advisable to check the security

of the hose connection between the engine and the radiator and other water joints.

Anti-freeze %as a very searching action and soon reveals any joint weaknesses

which unless remedied will give rise to a serious loss of coolant.

When anti-freeze has been added

it

is

a good plan to tie an anti-freeze label to

the radiator drain tap to prevent a garage employee from inadvertently draining the

solution.

If

anti-freeze is not used and no other precaution is taken, the.water should be

drained off completely when garaging the car at night during frosty weather.

There are two drain taps ; one

is

at the bottom of the radiator and one

on the engine crankcase forward of the distributor.

When all the water has been drained the engine should be run for not more

than one minute at tick-over speed to ensure complete elimination of water from

the cyiina'er block.

It is advisable occasionally to clean out the tap apertures with a strong piece of

wire since the drain taps may become choked with sediment which will prevent

effective draining.

When the system has been drained it is

a

good plan to leave the radiator filler

cap on the driving seat as a reminder to refill the cooling system before using the

car again.

Flushing.

To ensure eficient circulation of the coolant and to reduce formation of chemical

deposits within the cooling passages, the system should be thoroughly flushed with

clean running water every

5,000

miles.

Cabin Cooling.

Sliding doors are provided on each side of the scuttle to permit cool air

to

be

admitted to the car interior.

Where temperature control unit (optional extra)

is fitted, please refer to Page

29

for instructions.

PAGE

TWENTY-THREE

Page 25

PAGE

TWENTY-FOUR

Page 26

ENGINE

IGNITION

MISFIRES.

-High tension leads to spark

plugs shorting.

-Incorrect spacing of sparlc

plug points.

-Cracked sparlc plug porcelain.

-Battery Connection loose.

--

Faulty or damp cap.

ENGINE STARTS

AND STOPS.

IGNITION

CARBURETTER

Water in Carburetter.

-Petrol line partly cholted.

-Fuel pump pressure low.

-Fuel pump filter cholted.

-Needle valve faulty or dirty.

LOW tension connection loose.

-Faulty switch contact.

-Dirty contact points.

MECHANICAL

-Valves sticking.

Valves burnt or

broken.

-Valve spring broken

Incorrect valve

clearance.

__

I

-

I

CARBURETTOR.

-Petrol line blocked.

-Water in petrol.

---Needle valve sticlting.

-Fuel pump faulty.

--Petrol exhausted.

--Air

lealts.

ENGINE RUNS ON WIDE

THROTTLE ONLY.

I

CARBURETTER

MECHANICAL.

1

-Slow running adjusting screw

--Valve sticking.

incorrectly adjusted.

IZvalve burnt or broken.

Valve spring broken.

--P---------------

MECHANICAL and IGNITION

ENGINE DOES NOT GIVE

CARBURETTER

FULL POWER.

-Ignition retarded.

--Timing too far advanced.

--Excessive carbon deposit.

C

Loose bearing or pistons.

2

I---

+

;<

--

High tension lead shorting.

--Valve burnt or bad seating.

--Incorrect valve clearance.

--Plug leads crossed.

--

Faulty cap.

--Petrol supply faulty.

.

..

-

-Petrol feed faulty.

--Inlet valve not closing.

-Ignition timing incorrect.

-Carburetter flooding.

ENGINE RUNS

-I

IMPERFECTLY.

,-Weak mixture. ENGINE KNOCKS.

9

-Air leaks in induction pipe.

-Jet partly choked.

Page 27

STEERING.

The cam gear steering box has a ratio of

l6:l

and has provision for taking up wear.

The height of the wheel is adjustable so that the driver may obtain the most

comfortable position. Immediately below the wheel boss there is a knurled nut.

To raise or lower the steering wheel

it

is necessary to release this nut - slide the

wheel into the required position and lock knurled nut.

The oil filler cap should occasionally be removed and the oil level inspected.

It is important that the oil level should be maintained at approximately +in. from

the top of the filler tube.

Fan Belt Adjustment.

The fan belt must be sufficiently tight to prevent slip at the Dynamo and Water

Pump, yet there should be sufficient slack to move the centre of the belt sideways

about lin.

Fig.

11.

Dynamo adjustment.

Slacken at 'A' and swing up Dynamo to

tighten the fan belt.

H.25.

162.A.

To make any necessary adjustments, slacken the bolts and raise or lower the

Dynamo until the desired tension of the belt is obtained, then securely lock the

Dynamo in position again.

BODYWORK.

Dust on the car may be lightly flicked off with a duster, but on all other occasions

the car must thoroughly washed and dried before a cellulose polish is used.

Any

attempt to rub dirt off the car will result in a severe scratching of the smooth surface

of the cellulose.

Grease and tar splashes must be very carefully removed with a soft rag dipped

in petrol.

Washing and Polishing.

When washing the car, commence from the top and worlc downwards, using

a slow flood of water and then leather off all the surplus moisture.

After washing

and drying, use a good quality cellulose polish which will not only impart a brilliant

lustre to the surface of the cellulose but will help to preserve it from atmospheric

corrosion. An occasional application of a good class wax polish will also help considerably in maintaining a smooth finish.

PAGE

TWENTY-SIX

Page 28

Seats.

Both the front and rear seats are upholstered in best quality hide and will not

require any attention other than an occacional clean down with a cloth moistened

in water.

Chromium.

Wash chromium plating with soap and warm water. On no account use metal

polish.

Other attentions.

Door locks, hinges and other small working parts should be given a drop of

oil occasionally and be checked for security.

Sliding seat runners will benefit if

periodically smeared with grease.

Front Seat Adjustment.

Provision is made for 'fore and aft' adjustment of the front seats. Adjustment

is effected by pushing the control lever, located beneath the seat in a left handed

direction, easing the seat backward or forward as required. To ensure that the

seat is properly located, check that the trigger on the adjustment lever is located in

one of the adjustment apertures.

Spare Wheel Valve.

Access to spare wheel valve is obtained through hole in rear of boot floor

TOOL

KIT.

The following tool kit is supplied with the car

:-

+

in.

\c

&

in Whitworth

DIE

Spanner.

&

in.

,;

5

in.

g

in.

\*

in,

in.

X

$

in. Whitworth Box Spanner.

&in.

X

gin,

in.

X

4

in.

Tommy Bar.

Screw Driver.

Combination pliers.

4

in. Adjustable spanner.

Wheel brace.

Starting handle and bracket.

Bevelift Jack.

Tool Wrap.

Combination hammer is supplied when wire wheels are fitted.

N.B. When it is necessary to use the starting handle the bracket supplied

must be attached to the front bumper by means of the two innermost

bumper stud nuts.

PAGE

TWENTY-SEVEN

Page 29

EQUIPMENT.

JENSEN MOTORS LTD., accept no liability for tyres, instruments, electrical

equipment and any other accessories fitted to the car which are not of their manufacture. All claims relating to any of these parts, or orders for repair to them should

be addressed to their respective manufacturers from whom further information

may be obtained on application to the addresses quoted below.

Important.

When claims are being made under guarantee it is essential to quote the car

number which

is

stamped on a plate located under the bonnet on the side of the

scuttle and the date on which the car was commissioned.

Brakes and Dampers.

Messrs. Girling Ltd., Kings Road, Tyseley, Birmingham 11.

Brake Servo System.

Messrs. Clayton Dewandre Co. Ltd., Titanic Works, Lincoln.

Electrical Equipment.

Joseph Lucas (Electrical) Ltd., Great Hampton Street, Birmingham 18, and

Dordrecht Road, Acton Vale, London, W.3.

Engine Oil Filter.

Tecalemit Limited, Great West Road, Brentford, Middlesex.

Instruments.

S.

Smith & Sons (M.A.) Ltd., Cricklewood Works, London, N.W.2.

Tyres.

Dunlop Rubber Co. Ltd., Fort Dunlop, Birmingham, and

1, Albany Street, London, N.W.1.

Tools.

Abingdon King Dick Ltd., Abingdon Works, Kings Road, Tyseley, Birmingham 11.

Lift Jack.

Smiths Jacking Systems Ltd., Jackall Works, Edgware Road, London,

N.W.2.

Door Handles and Keys.

Willmot Breeden Ltd., Eastern Works, Camden Street, Birmingham 1.

Carburetters.

S.U. Carburetters Ltd., Erdington, Birmingham.

Air Filters and Exhaust Silencers.

Burgess Products Co. Ltd., Brookfield Road, Hinckley, Leics.

PAGE

TWENTY-EIGHT

Page 30

OPTIONAL EQUIPMENT.

Overdrive.

Special head and twin exhaust system.

Rev. Counter

Screenwasher.

Heater

15 in. Centre lock wire wheels with Dunlop road speed tyres 6.40~15.

Dunlop Road Speed tyres 5.50~16 on standard wheels.

AI-fin Drums.

CAB1

N

HEATER

(Optional

Extra).

The Smiths heater and defroster unit is of 3 kilowatts nominal output. This

unit utilises waste heat from the engine and

is

located under the facia on the L.H.

side of the car.

A resistance is fitted in the heater which

is

controlled by a 3 position switch on

the facia.

First pull of switch gives

3

speed, second pull and turn gives full speed,

at which maximum heat

is

obtained.

The heater unit draws fresh air from outside the car and this may be cut off by

closing sliding door on L.H. side of bulkhead.

Hot air is ducted from the heater to

the Drivers side of the car and

is

controlled by opening a door underneath the facia.

A

similar door is fitted to the heater unit itself which when open will permit hot air

to be directed into the vicinity of the passengers feet.

At speeds above

30

miles per hour the motor

is

not necessary owing to the ram

effect in the air intake.

In summer it

is

usually desirable to turn off the cylinder head valve to permit

the heating system to be used for the circulation of fresh unheated air throughout

the car interior. This valve is located

on

the right hand side of the cylinder head

and must be screwed fully home in a clockwise direction to shut off the supply of

water to the heater radiator.

PAGE

TWENTY-NINE

Page 31

Page

BODYWORK

Washing & Polrshrng 26

Seats 27

Chromrum 27

Other attentrons 27

Front seat

adlustment 27

BRAKES

Adjustment (Rear Brakes) 13

Adjustment (Front Braltes) 13

Bleeding the Brakes

Servo.

CARBURETTERS

Maintenance

Carburetter Pistons

Slow running

Starter Carburetter

CLUTCH

CONTROLS

COOLING SYSTEM

Topping up

Winter Precautrons

Flushing

Page

FRONT SUSPENSION

Alrgnment of front wheels 14

Adjusting front wheel bearings 14

Lubrication of front wheels 14

FUEL SYSTEM

Fuel pump 17

Carburetters

18-1

9

Maintenance 19

Carburetter Prstons 20

13

14

GEARBOX

HEATER

19

20

IGNITION

20

20

Spark Plugs

Valve Clearances

l6

INSTRUMENTS

LUBRICATION

Chart

Chassrs Lubr~catron

22 Rear Axle

,,

23 Gearbox

,,

23 Front Wheels

,,

Engrne Lubrication

ELECTRICAL EQUIPMENT

Lamp Bulbs 12

Battery 12

Headlamps 12

Headlamp Alignment 13

Screenwrper 13

ENGINE

Dimensrons 21

Cylinders 21

Crankshaft

21

Crankshaft regrrnding srzes 21

Connectrng rods 21

Pistons 21

Prston Rings 21

Camshaft 21

Valves 21

Valve

tlmrng 22

lgnrtron trming 22

Lubrrcatton 22

EQUIPMENT

..

28

FAN BELT ADJUSTMENT

.

.

26

FOREWORD

......

...

3

MAINTENANCE

7

OPTIONAL EQUIPMENT

29

REAR AXLE

16

STARTING, UP AND GENERAL

RUNNING HINTS

5

SPECIFICATION

l0

STEERING

26

TRANSMISSION

Clutch 16

Gearbox

..

.. .

16

Propeller shaft 16

Rear Axle 16

TYRES

Tyre Pressures 15

Changing posltlon of tyres 15

Tyre and wheel balance 15

Factors

affect~ng tyre l~fe 15

PAGE THIRTY

Page 32

JENSEN

'6541

"

SALOQN

CARS

(a

955)

HOME

AND

EXPORT

MODELS

xrnoi

REmbE

SWTCd

6

WARNlhYj

LIGHT

SWITCH

3H

-

---

COLOURS

i

iiiG

with

RED

rf

BLUE wlth YELLOW

4

BLUE with WHITE

S

BLUE with GREEN

6

BLUE with PURPLE

7

BLUE with BROWN

8

BLUE wlth BLACK

O

WHITF

25

YELLOW

26

YELLOW

wkh

RED

27

YELLOW

with BLUE

28

YELLOW with WHITE

29

YELLOW with GREEN

30

YELLOW wlth PURPLE

31 YELLOW wlth BROWN

32

YELLOW with BLACK

33

RROWN

49

PURPLE

50

PURPLE 4th

RED

38

BROWN

wlth

GREEN

39 BROWN with PURPLE

40

SROWN

with

RI

ArK

51

PURPLE

ki;h

YKLOW

52

PURPLE with BLUE

27

PI

IRPI

C

vrirh

WUlTC

ISSUED

:

i

355

L

MARCH

1955

NUMBERS INDICATE CABLE IDENJlFlCATlON COLOURS,

SEE

KEY

ABOVE

COPYRIG

HT

All

rights reserved.

No part

of

this

diagram

may

be

reproduced without permission.

Printed

in

Enpland

Loading...

Loading...