Jenn-Air JGR8885RDP Installation Instruction

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

INSTALLATION MANUAL

Gas 30-inch Wide Free-Standing Range

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

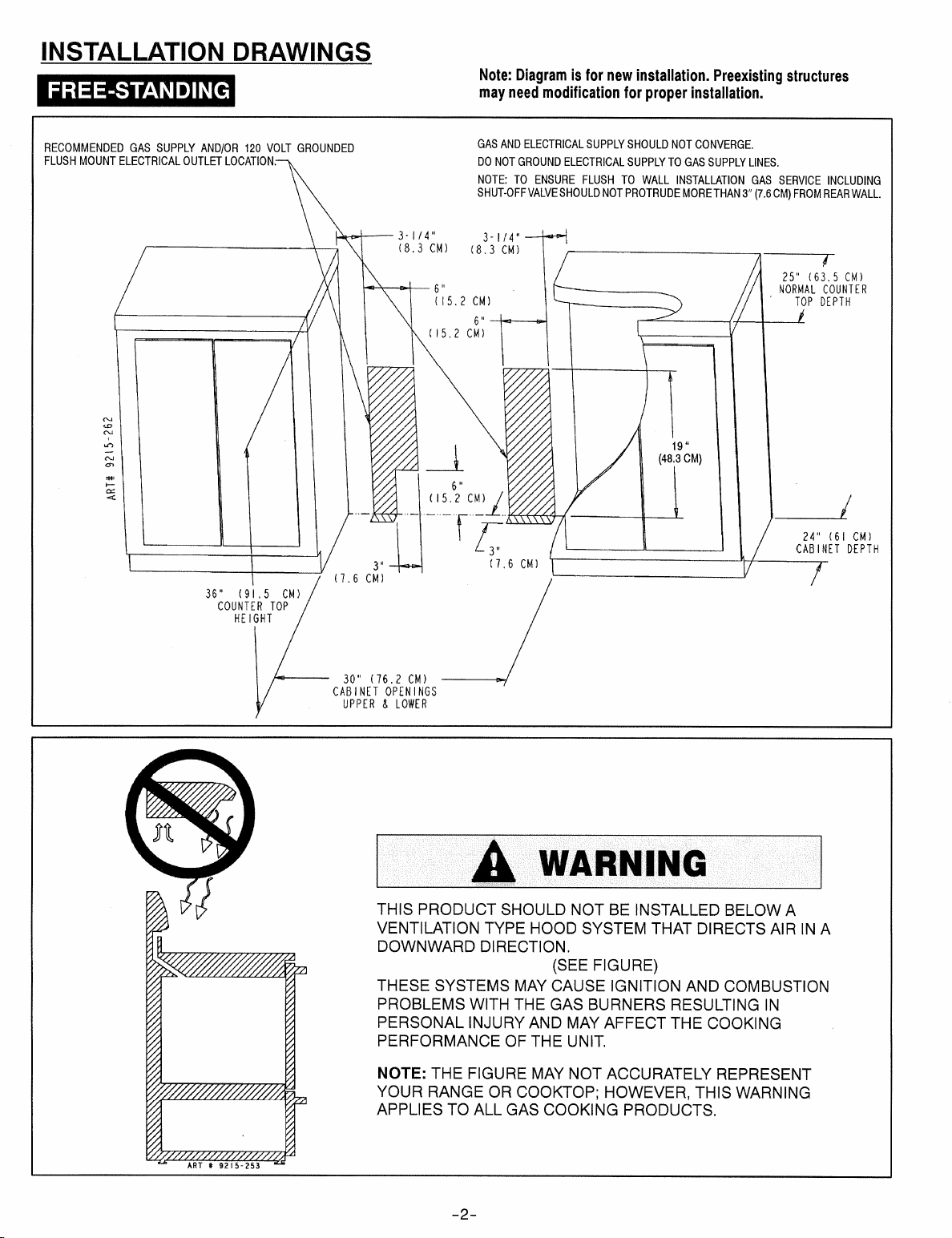

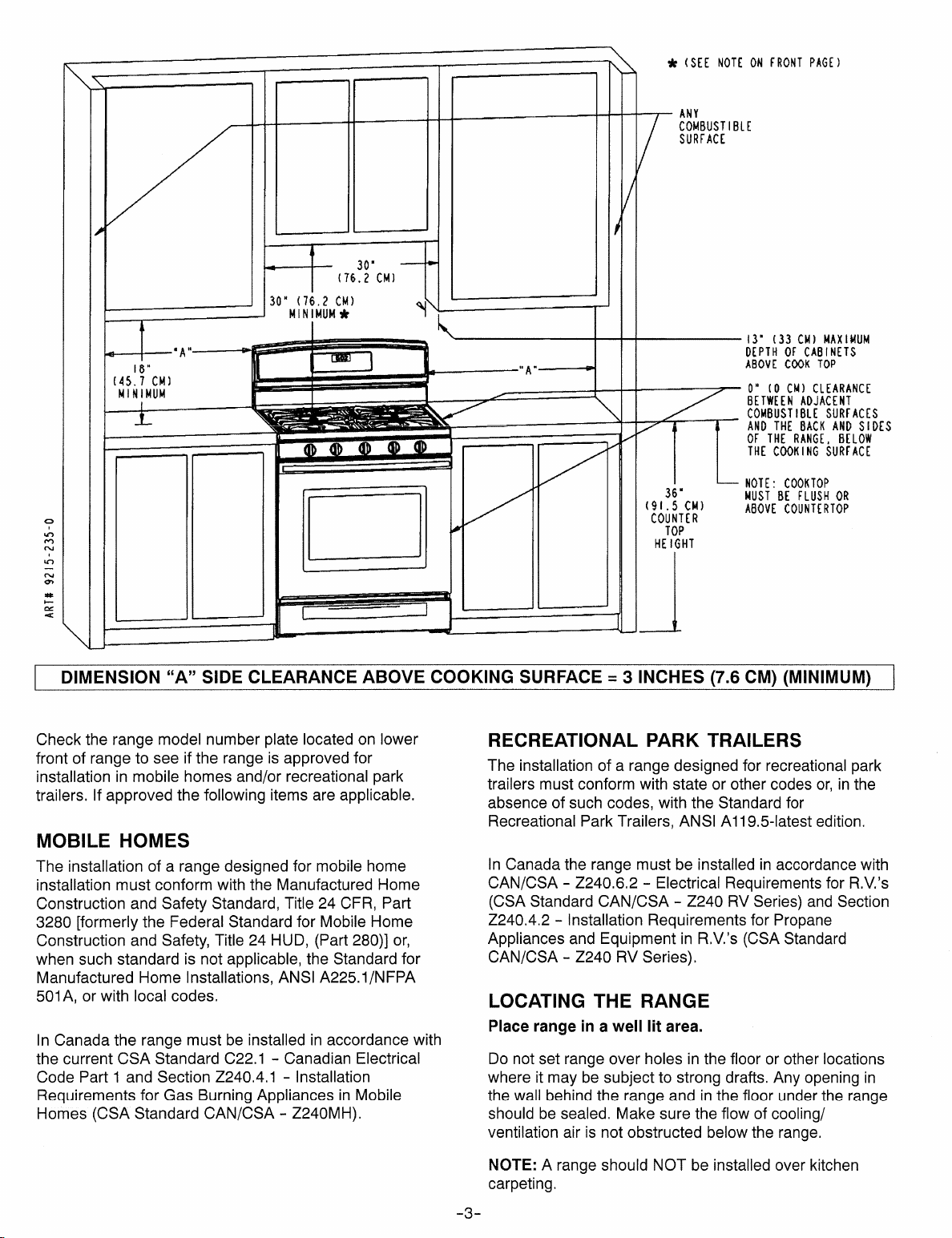

CLEARANCE DIMENSIONS

SPECIAL WARNING

Only qualified personnel should

install or service this range.

Read “Safety Instructions” in the

Use & Care book before using

range.

Range may be installed with zero inches clearance

adjacent to (against) combustible construction at the rear

and on the sides below the cooktop. For complete

information in regard to the installation of wall cabinets

above the range and clearances to combustible wall

above the cooking top see the installation drawings. For

SAFETY CONSIDERATIONS do not install a range in any

combustible cabinetry which is not in accord with the

installation drawings.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage.

• ALL RANGES CAN TIP AND

CAUSE INJURIES TO PERSONS.

• INSTALL ANTI-TIP DEVICES

PACKED WITH RANGE.

• FOLLOW ALL INSTALLATION

INSTRUCTIONS.

Your range may not be equipped with

some of the features referred to in this

manual.

* NOTE: The 30 inch (76.2 cm) dimension may be

reduced to not less than 24 inches (61 cm) when the wall

cabinets in a domestic home are protected with fireproof

materials in accordance with American National

Standards -- National Fuel Gas Code or in mobile homes

when they are protected with fireproof materials in

accordance with the Federal Standard for Mobile Home

Construction and Safety.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches (13 cm) beyond the bottom of the

cabinets.

CAUTION: This range has been designed in

accordance with the requirements of various safety

agencies and complies with the maximum allowable

wood cabinet temperatures of 194°F. If this range is

installed with cabinets that have a lower working

temperature than 194°F, discoloration, delamination

or melting may occur. Contact Customer Service

for associated cabinet dimensions and installation

accessories.

8101P571-60

(02-06-02)

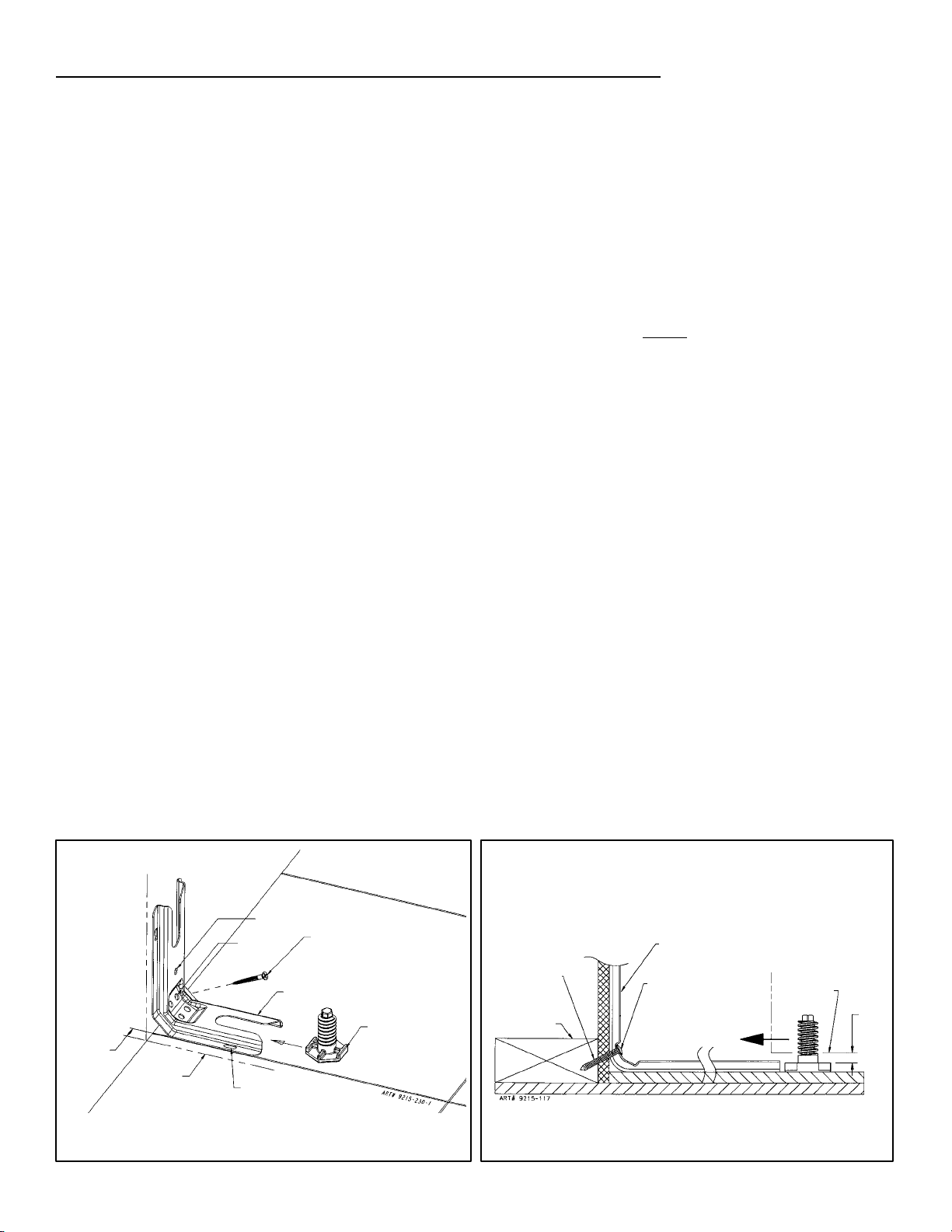

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

NOTE: A risk of range tip over exists if the appliance is

not installed in accordance with the installation

instructions provided. The proper use of this device

minimizes the risk of TIP-OVER. In using this device the

consumer must still observe the safety precautions as

stated in the USE and CARE MANUAL and avoid using

the oven door and/or lower drawer as a step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall.

STEP 1 -- Locating The Bracket (see figure 1)

A. Determine where either the right or left rear “edge” of

the range will be located and mark the floor or wall.

B. Place the BRACKET 9/16″ (14.5 mm) from the

marked “EDGE” toward center of opening and against

the back wall as shown in figure 1, with orientation

hole against wall.

C. Use the bracket as a template and mark the required

holes, as shown in figure 1 for the type of construction

you will be using.

STEP 2 -- Anti-Tip Bracket Installation

A. Wood Construction:

1. Floor: Locate the center of the two holes identified

in figure 1 as “HOLES FOR FLOOR”. Drill a 1/8″

(3 mm) pilot hole in the center of each hole (a nail

or awl may be used if a drill is not available).

Secure the ANTI-TIP bracket to the floor with the

two screws provided. Proceed to STEP 3.

2. Wall: Locate the center of the two holes identified

in figure 1 as “HOLES FOR WALL. Drill an angled

1/8″ (3 mm) pilot hole in the center of each hole

as shown in figure 2. (A nail or awl may be used if

a drill is not available). Secure the ANTI-TIP

bracket to the wall with the two screws provided

as shown in figure 2. Proceed to STEP 3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can be

obtained at a hardware store. Drill the required

size hole for the screws obtained into the

concrete at the center of the holes identified in

figure 1 as “HOLES FOR FLOOR”. Secure the

ANTI-TIP bracket to the floor. Proceed to STEP 3.

STEP 3 -- Range Installation

A. For safety considerations as well as optimum

performance, adjust the range so it is level and to

desired height prior to installing in cabinet opening.

NOTE: Cooktop MUST

be flush or above

countertop.

Levelness may be checked by placing a spirit level or

a large pan of water on the cooktop or oven rack.

Adjust the range by tipping it forward or back and

rotate the leveling feet as required.

NOTE: A minimum clearance of 1/4″ (6 mm) is

required between the range and the leveling foot that

will engage the anti-tip bracket, (see figure 2).

CAUTION: Damage to the range may occur if range

is moved or lifted by grasping the main top, backguard

or door handles.

B. Align the range to its designated location and prepare

to slide it back into position. Connect gas line and

plug in power cord to outlet following guidelines

outlined in connecting the range and remainder of

installation instructions.

C. Slide range in place visually inspecting to verify that

power cord and gas line are freely routed and

contained within recessed area of back panel.

D. To check the range for proper installation of the

anti-tip bracket, use a flashlight and look underneath

the bottom of the range to see that one of the rear

leveling feet is engaged in the bracket slot.

9/16”

(14.5 mm)

FROM EDGE

OF RANGE

MARKED EDGE

OF RANGE

NOTE: USE A MINIMUM OF (2) SCREWS

TO INSTALL ANTI-TIP BRACKET

TO THE WALL OR FLOOR.

ORIENTATION

HOLE

HOLES FOR

WALL

HOLES FOR

FLOOR

(EACH SIDE)

ATTACH ANTI-TIP BRACKET WITH A

MINIMUM OF TWO (2) LONG SCREWS

TO THE WALL OR FLOOR.

ANTI-TIP

BRACKET

LEVELING

FOOT

SCREWS MUST

ENTER WOOD

OR METAL.

WALL PLATE

ANTI-TIP

BRACKET

SCREW BRACKET

TO WALL

SLIDE IN

TO SECURE

FIGURE 1 FIGURE 2

-- 4 --

RANGE

BOTTOM

1/4”

(6mm)

MIN.

CONNECTING THE RANGE

Electric Supply

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code,

ANSI/NFPA 70.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 -- Canadian Electrical

Code Part 1.

Electrical Supply Connection

The range requires 120 volts, 60 cycle alternating current

from a grounded outlet with a 15 amp circuit breaker. See

serial plate for rating, located on lower surface of front

frame.

User may experience occasional circuit tripping if Ground

Fault Circuit Interrupter (GFCI) outlet or breaker is in use.

Electrical Grounding Instructions

This appliance is equipped with a (three-prong)

grounding plug for your protection against shock

hazard and should be plugged directly into a properly

grounded receptacle. Do not cut or remove the

grounding prong from this plug.

DISCONNECT ELECTRICAL SUPPLY

BEFORE SERVICING THE APPLIANCE.

Gas Supply

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition.

In The Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or

gas fitter when installed within the Commonwealth of

Massachusetts.

A “T” handle type manual gas valve must be installed in

the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a

length of three (3) feet / 36 inches.

In Canada the range must be installed in accordance with

the current CGA Standard CAN/CGA--B149 -- Installation

Codes for Gas Burning Appliances and Equipment and/or

local codes.

Gas leaks may occur in your system and result in a

dangerous situation. Gas leaks may not be detected

by smell alone. Gas suppliers recommend you

purchase and install an UL approved gas detector.

Install and use in accordance with the manufacturer’s

instructions.

Checking Pressure Of House Piping

System

1. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water

column).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water column).

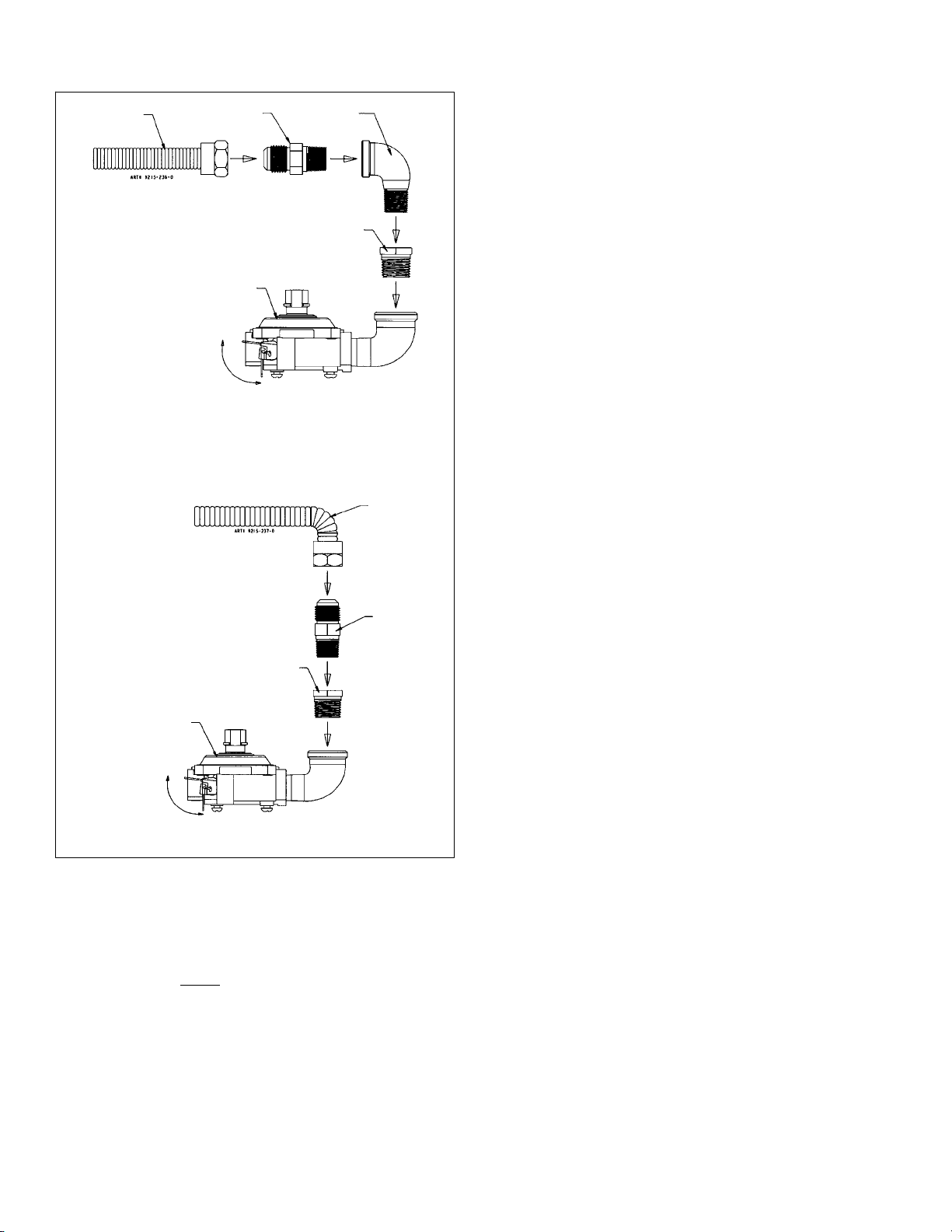

Gas Supply Connection (See figure 3)

A QUALIFIED SERVICEMAN OR GAS APPLIANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the

instructions given in section h.

NATURAL GAS SUPPLY LINE MUST HAVE A NATURAL

GAS SERVICE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

POUNDS PER SQUARE INCH (P.S.I.). LIQUEFIED

PETROLEUM (L.P.)

MUST HAVE A L.P. GAS PRESSURE REGULATOR.

INLET PRESSURE TO THIS APPLIANCE SHOULD BE

REDUCED TO A MAXIMUM OF 14 INCHES WATER

COLUMN (0.5 P.S.I.). INLET PRESSURES IN EXCESS

OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE

PRESSURE REGULATOR AND OTHER GAS

COMPONENTS IN THIS APPLIANCE AND CAN RESULT

IN A GAS LEAK.

NOTE: This range is shipped from the factory set for

Natural Gas at 4″ water column pressure.

Gas supply pressure for testing regulator must be at

least 1″ water column pressure above manifold

pressure shown on serial plate.

If conversion to LP Gas is required, convert appliance

before installation.

/PROPANE GAS SUPPLY LINE

-- 5 --

Recommended Gas Supply Connections

FLEXIBLE

SUPPLY

LINE

ADAPTER

1/2″ NPT MALE TO 3/8″ NPT FEMALE

ADAPTER BUSHING

REGULATOR

ON

REGULATOR

SHUT-OFF

VALVE

OFF

3/8″ NPT

STREET

ELBOW

FLEXIBLE

SUPPLY

LINE

a. A GAS CUTOFF VALVE SHOULD BE PUT IN AN

ACCESSIBLE LOCATION IN THE SUPPLY LINE

AHEAD OF THE RANGE, FOR TURNING ON AND

TURNING OFF GAS SUPPLY. If range is to be

connected to house piping with flexible or semi-rigid

metal connectors for gas appliances, CONNECTOR

NUTS MUST NOT BE CONNECTED DIRECTLY TO

PIPE THREADS. THE CONNECTORS MUST BE

INSTALLED WITH ADAPTORS PROVIDED WITH

THE CONNECTOR.

b. The house piping and/or range connector used to

connect the range to the main gas supply must be

clean, free of metal shavings, rust, dirt and liquids (oil

or water). Dirt, etc. in the supply lines can work its

way into the range manifold and in turn cause failure

of the gas valves or controls and clog burners and/or

pilot orifices.

CAUTION: DO NOT LIFT OR MOVE RANGE BY

DOOR HANDLES, OR BACKGUARD.

c. Turn off all pilots and main gas valve of other gas

appliances.

d. Turn off main gas valve at meter.

ADAPTER

1/2″ NPT MALE TO 3/8″ NPT FEMALE

REGULATOR

ON

REGULATOR

SHUT-OFF

VALVE

ADAPTER BUSHING

OFF

FIGURE 3

WHEN THE INSTALLER HAS COMPLETED

INSTALLATION OF THE APPLIANCE, LEAVE THE

APPLIANCE PRESSURE REGULATOR SHUT-OFF

VALVE IN THE “ON” POSITION.

e. Before connecting range, apply pipe thread

compound approved for LPG to all threads.

f. Use only a flexible connector to connect range to gas

supply at appliance pressure regulator using adaptors

supplied with connector. Regulator supplied with

range has 1/2″ NPT female connection.

NOTE: It is recommended to use a CSA certified

flexible connector no longer than 36″ (91.4 cm)

with a minimum BTU/HR rating of 88,200, and in

accordance with local codes.

See serial plate for type of gas range has been

manufactured for.

g. Turn on main gas valve at meter, and relight pilots at

other gas appliances.

h. Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the supply

line shut-off valve and the range. Include gas fittings

and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles

appearing around fittings and connections will indicate

a leak. If a leak appears, turn off supply line gas

shut-off valve, tighten connections, turn on the supply

line gas shut off valve, and retest for leaks.

-- 6 --

CAUTION: NEVER CHECK FOR LEAKS WITH A

FLAME.

WHEN LEAK CHECK IS COMPLETE, WIPE OFF

ALL RESIDUE.

RANGE ADJUSTMENTS

Top Section -- Electric Ignition

To operate, push and turn top burner knob to the LITE

position. The top burner will light. To turn OFF spark after

the top burner has ignited, turn knob to HI setting.

NOTE: Top burners are not adjustable.

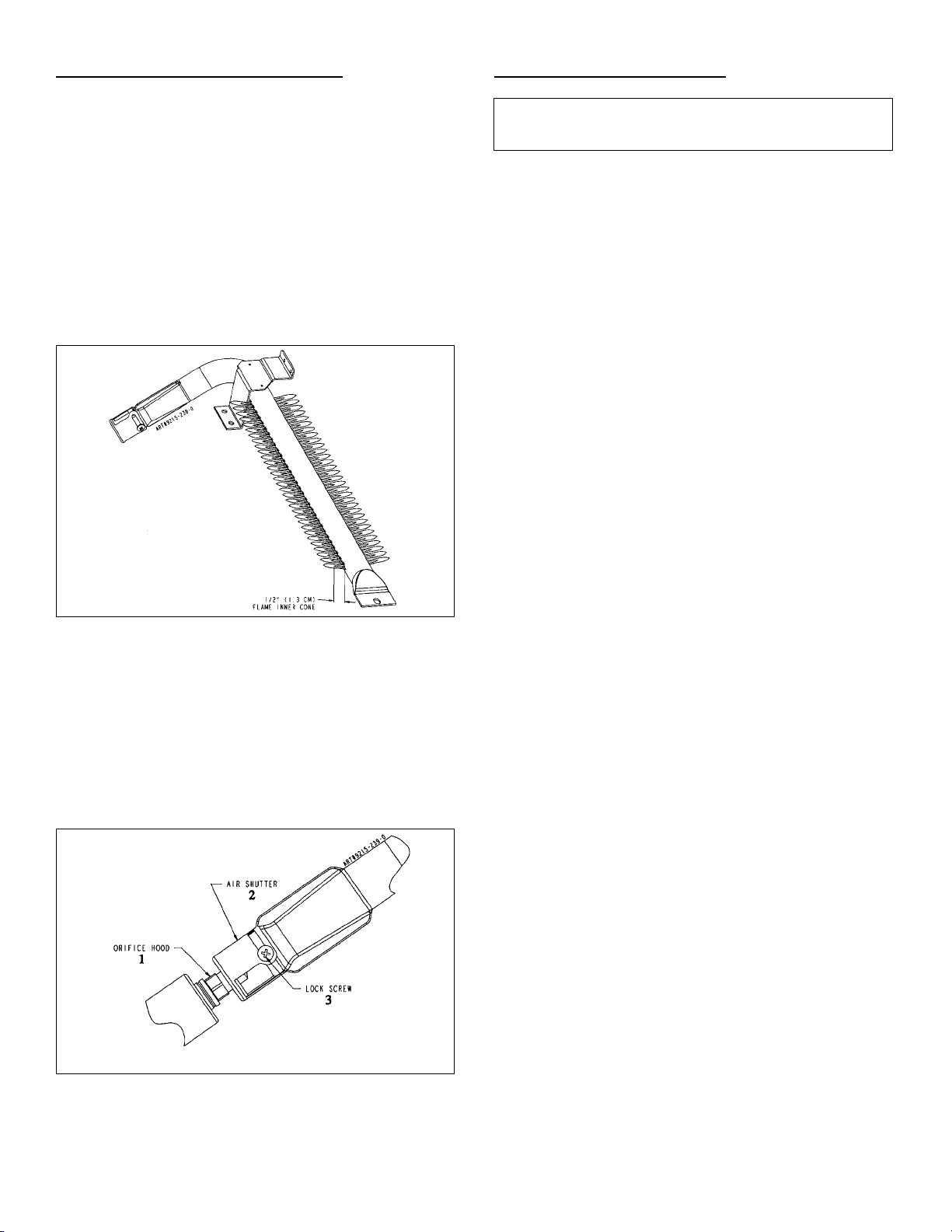

Air Shutter -- Bake/Broil Burner

NOTE: If oven burner does not ignite, check oven gas

shut-off position at the regulator.

a. The approximate length of the flame of oven burner is

a 1/2 inch distinct inner blue flame, figure 4.

GAS CONVERSION

SEE INSTRUCTIONS FOR GAS CONVERSION

LOCATED ON THE BACK OF THE RANGE.

FIGURE 4

b. Bake/broil burner flame can be checked as follows:

1. Yellow flame on burner -- open burner air shutter

to the widest opening that will not cause the flame

to lift or blow off the burner when cold. (See #2 on

figure 5). Some yellow tipping on LP is normal.

2. Distinct blue flame but lifting -- close burner air

shutter to the point where it will not cause the

flame to lift or blow off the burner when cold. (See

#2 on figure 5).

FIGURE 5

-- 7 --

Loading...

Loading...