JENN-AIR jed7430aab, jed4536ws, jed4430ws, jed3536ws, jed3430ws Installation Instructions

...Page 1

DUCTLESS INSTALLATION INSTRUCTIONS

SLIDE-IN DOWNDRAFT RANGES

INSTRUCTIONS D’INSTALLATION SANS CONDUIT

DES CUISINIÈRES À ÉVACUATION PAR LE BAS

ENCASTRABLES

Table of Contents/Table des matières

RANGE SAFETY ....................................................................... 2

INSTALLATION REQUIREMENTS .......................................... 4

Tools and Parts .................................................................... 4

Location Requirements ....................................................... 5

Electrical Requirements – U.S.A. Only ................................ 7

Electrical Requirements – Canada Only .............................. 8

Gas Supply Requirements ................................................. . 8

INSTALLATION INSTRUCTIONS ........................................... 9

Unpack Range ..................................................................... 9

Adjust Leveling Legs ......................................................... 10

Install Anti-Tip Bracket ....................................................... 10

Install Recirculation Blower Assembly .............................. 11

Install Blower ...................................................................... 13

Make Utility Connections ................................................... 14

Complete Filter Assembly ................................................. 16

Verify Anti-Tip Bracket Is Installed and Engaged ............... 17

Oven Door ......................................................................... 17

Complete Installation .......................................................... 18

Electronic Ignition System .................................................. 19

GAS CONVERSIONS ............................................................ 19

LP Gas Conversion ............................................................ 19

Natural Gas Conversion ..................................................... 21

Adjust Flame Height ........................................................... 23

REPLACING AIR FILTER ...................................................... 24

SÉCURITÉ DE LA CUISINIÈRE ........................................... 25

EXIGENCES D’INSTALLATION ........................................... 26

Outillage et pièces ............................................................. 26

Exigences d’emplacement ................................................ 28

Spécifications électriques – Canada seulement ................ 30

Spécifications de l’alimentation en gaz .............................. 30

INSTRUCTIONS D’INSTALLATION ..................................... 32

Déballage de la cuisinière ................................................... 32

Réglage des pieds de nivellement .................................... 32

Installation de la bride antibasculement ............................. 33

Installation du ventilateur de recirculation ......................... 33

Installation du ventilateur ................................................... 35

Effectuer les raccords ......................................................... 36

Achever l’installation du filtre ............................................ 39

Vérifier que la bride antibasculement est bien installée

et engagée ........................................................................... 40

Porte du four ....................................................................... 40

Achever l’installation .......................................................... 40

Système d’allumage électronique ...................................... 41

CONVERSIONS POUR CHANGEMENT DE GAZ ................ 42

Conversion pour l’alimentation au propane ....................... 42

Conversion pour l’alimentation au gaz naturel ................... 44

Réglage de la taille des flammes ........................................ 46

REMPLACEMENT DU FILTRE À AIR ................................... 47

IMPORTANT:

Save for local electrical inspector’s use.

IMPORTANT :

À conserver pour consultation par l’inspecteur local des installations électriques.

W10794411B

W10787399 – SP

Page 2

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

IMPORTANT: Do not install a ventilation system that blows air downward toward this gas cooking appliance. This type of

ventilation system may cause ignition and combustion problems with this gas cooking appliance resulting in personal injury or

unintended operation.

2

Page 3

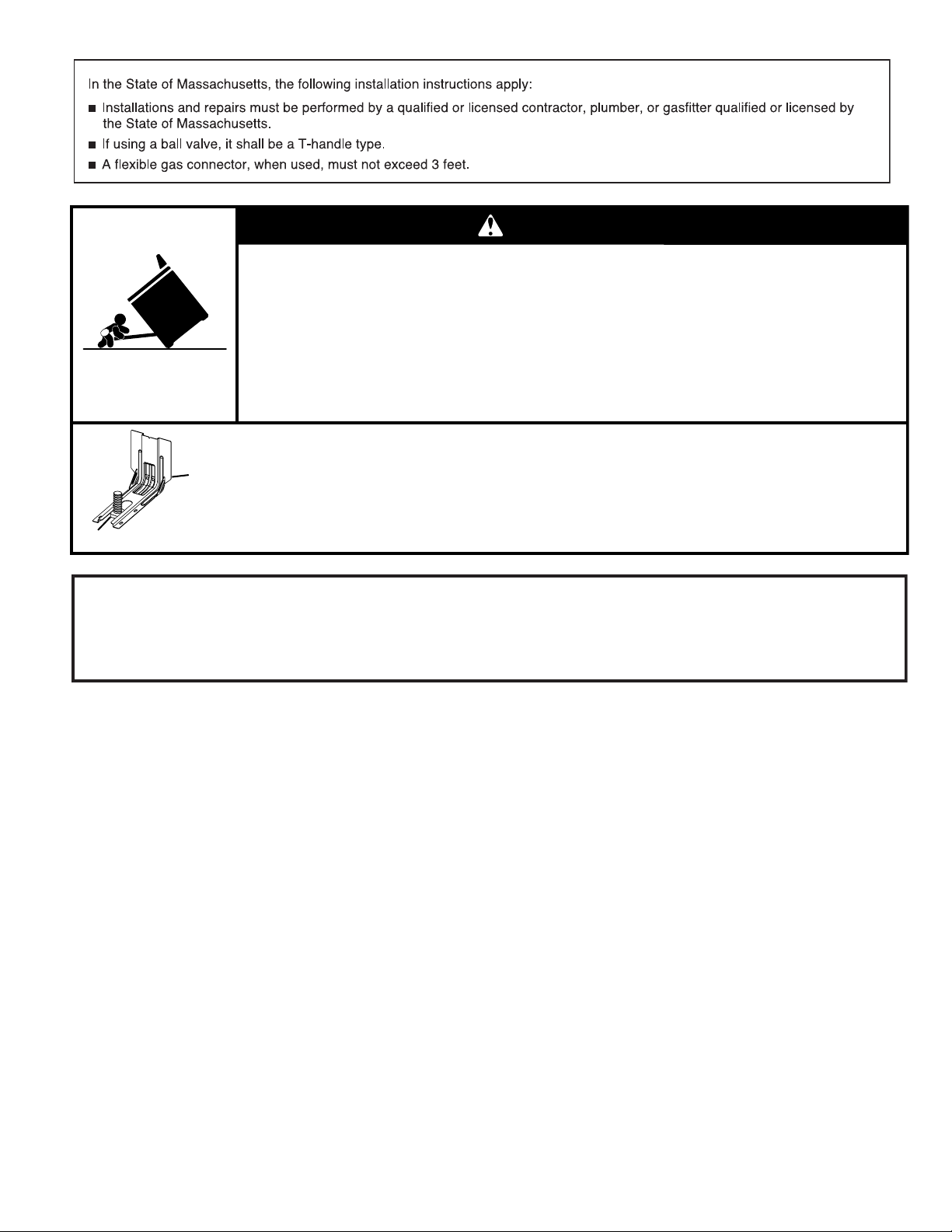

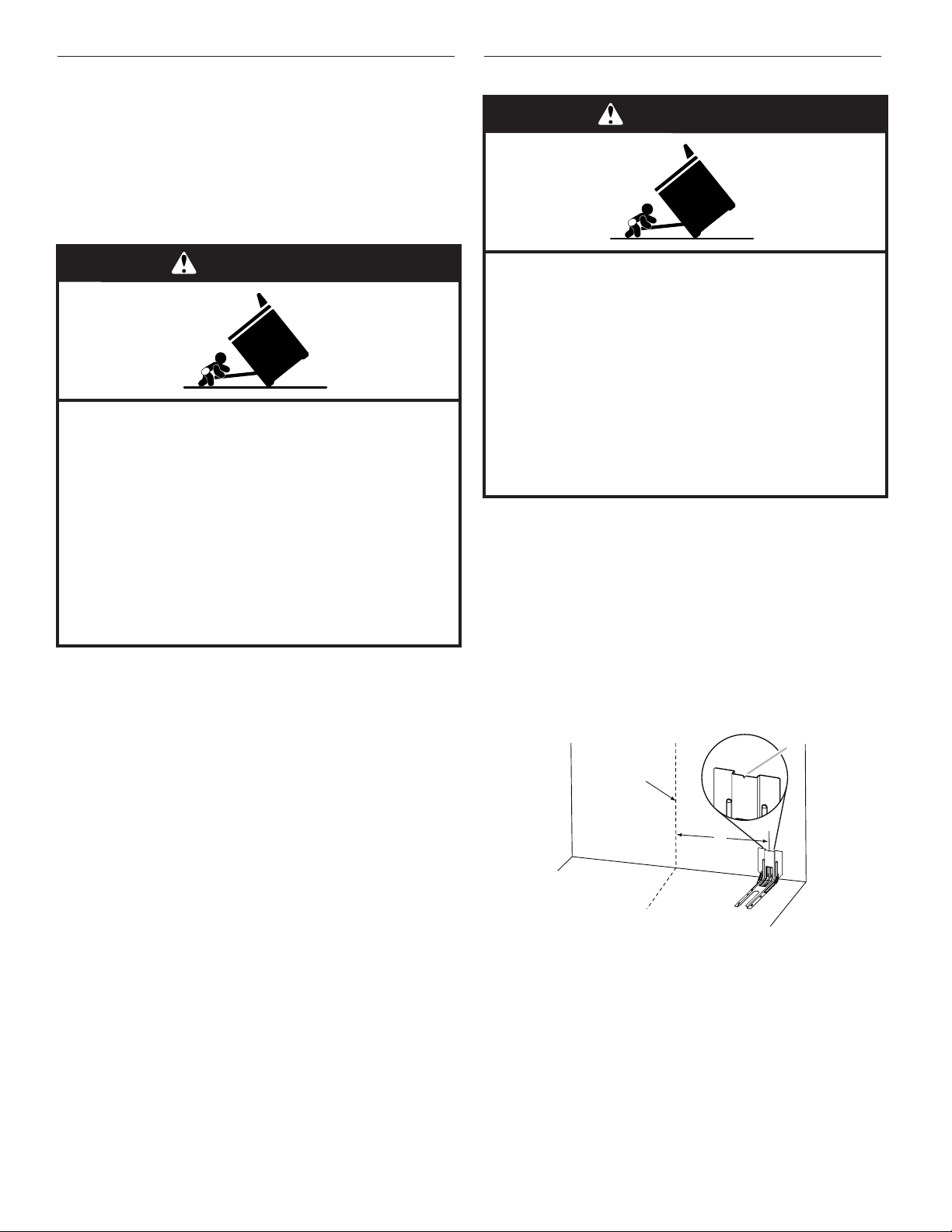

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

To verify the anti-tip bracket is installed and engaged:

Anti-Tip

Bracket

Range Foot

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

3

Page 4

INSTALLATION REQUIREMENTS

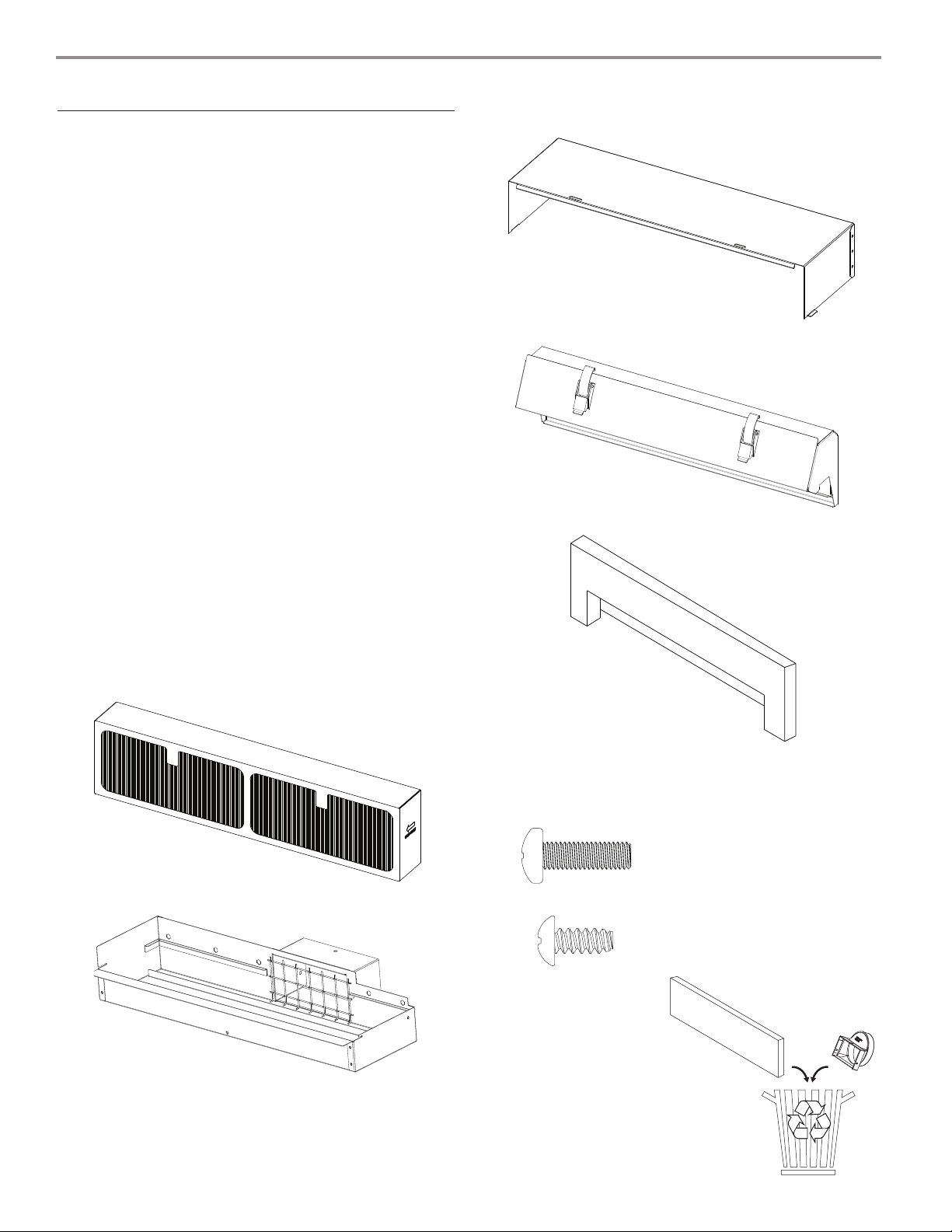

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools Needed

■ Tape measure

■ Phillips

screwdriver

■ Flat-blade

screwdriver

■ ¹⁄8" (3 mm) flat-

blade screwdriver

■ Level

■ Drill

■ Adjustable wrench

■ Slip joint pliers

■ Pipe wrench

15

■

⁄16" (2.4 cm)

combination

wrench

■ ¹⁄8" (3.2 mm) drill

bit (for wood

floors)

■ Marker or pencil

■ Flashlight

■ Masking tape

■ Pipe-joint compound resistant

to natural and LP gases

3

■

⁄16" (4.8 mm) carbide-tipped

masonry drill bit (for concrete/

ceramic floors)

■ Noncorrosive leak-detection

solution

■ Sheet metal aluminum tape

For LP/Natural Gas Conversions

■ ½" (13 mm) combination

wrench

■ ¼" (6 mm) nut driver

9

■

⁄32" (7 mm) nut driver

■ Upper Filter Enclosure

■ Enclosure Front

■ Front Lower Access Panel

Parts Supplied

Check that all parts are included. Some parts are assembled

for shipping and require disassembly.

■ Air Filter (PN# W10748931)

■ Lower Filter Enclosure

NOTE: This manual covers several models. Your product may

vary from this image.

■ (5) M5 x 15 mm screws and washer (disassemble upper

and lower filter enclosure)

■ (3) #8 – 3/8" screws (included in hardware bag with the kit)

NOTE: Exhaust adapter

from the blower mounting

kit and lower access panel

that shipped with the range

will not be needed.

4

Page 5

Parts Needed

A

To order, see the “Assistance or Service” section of the Use and

Care Guide:

– Aluminum foil tape

Check local codes and consult gas supplier. Check existing

gas supply and electrical supply. See the appropriate “Electrical

Requirements” and “Gas Supply Requirements” sections.

It is recommended that all electrical connections be made by

a licensed, qualified electrical installer.

Optional Parts

To purchase these or any other accessories, please reference

the “Accessories” section of the Use and Care Guide for

contact information.

■ Side Trim Kits:

5

⁄8" (1.7 cm) Black – Order Part Number W10675026

5

⁄8" (1.7 cm) Stainless Steel – Order Part Number

W10675028

1¹⁄8" (2.9 cm) Black – Order Part Number W10731886

1¹⁄8" (2.9 cm) Stainless Steel – Order Part Number

W10731887

■ Backsplash Kits:

High 6" (15.2 cm) Black – Order Part Number W10655449

High 6" (15.2 cm) Stainless Steel – Order Part Number

W10655450

IMPORTANT: To avoid damage to your cabinets, check

with your builder or cabinet supplier to make sure that the

materials used will not discolor, delaminate, or sustain other

damage. This oven has been designed in accordance with the

requirements of UL and CSA International and complies with

the maximum allowable wood cabinet temperatures of 194°F

(90°C).

Mobile Home – Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part 280). When such

standard is not applicable, use the Standard for Manufactured

Home Installations, ANSI A225.1/NFPA 501A or with local

codes.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-A240-latest edition or with local

codes.

Mobile Home Installations Require:

■ When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the

standards listed above.

■ Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need

to be revised. See “Electrical Requirements – U.S.A. Only”

section.

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

Do not obstruct flow of combustion and ventilation air.

■ It is the installer’s responsibility to comply with installation

clearances specified on the model/serial/rating plate. The

model/serial/rating plate is located behind the oven door

on the top right-hand side of the oven frame.

■ The range should be located for convenient use in the

kitchen.

■ Recessed installations must provide complete enclosure

of the sides and rear of the range.

■ To eliminate the risk of burns or fire by reaching over the

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage

is to be provided, the risk can be reduced by installing a

range hood or microwave hood combination that projects

horizontally a minimum of 5" (12.7 cm) beyond the bottom

of the cabinets.

■ All openings in the wall or floor where range is to be

installed must be sealed.

■ Cabinet opening dimensions that are shown must be

used. Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the

anti-tip bracket shipped with the range, see “Install

Anti-Tip Bracket” section.

■ Grounded electrical supply is required. See the appropriate

“Electrical Requirements” section.

■ Proper gas supply connection must be available. See “Gas

Supply Requirements” section.

■ Contact a qualified floor covering installer to check that

the floor covering can withstand at least 200°F (93°C).

■ Use an insulated pad or ¼" (0.64 cm) plywood under

range if installing range over carpeting.

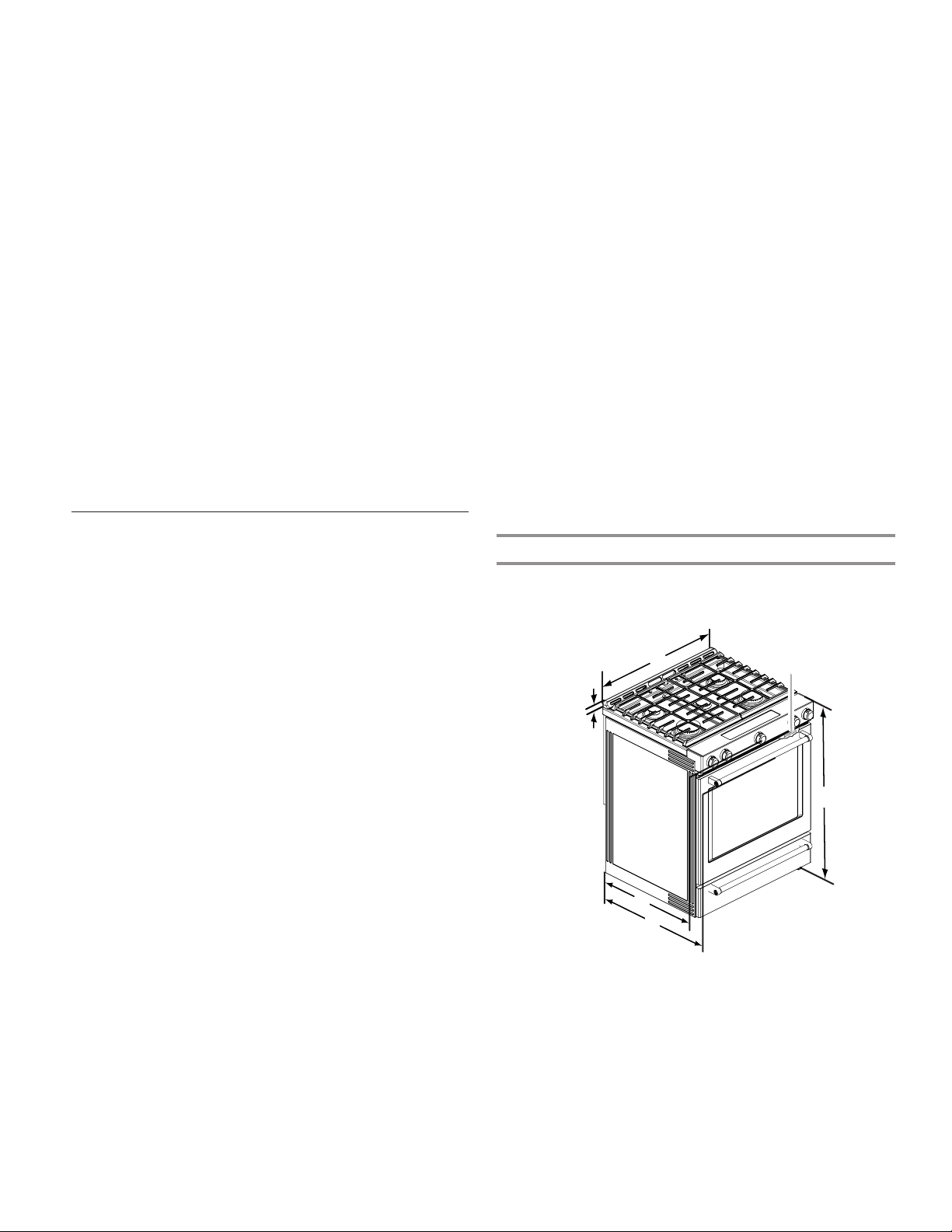

Product Dimensions

This manual covers several models. Your model may appear

different from the models depicted. Dimensions given are

maximum dimensions across all models.

B

E

F

A. 1³⁄16" (3.0 cm) height from

cooktop to top of vent

B. 297⁄8" (75.9 cm)

C. Model/serial/rating plate

(located behind the oven door

on the top right-hand side of

the oven frame)

D. 36" (91.4 cm) height to top of

cooktop edge with leveling

legs screwed in all the way*

E. 285⁄16" (71.9 cm) max. depth

from front of console to back

of range

F. 287⁄8" (73.3 cm) max. depth

from handle to back of range

IMPORTANT: Range must be level after installation. Follow

the instructions in the “Level Range” section. Using the cooktop

as a reference for leveling the range is not recommended.

* Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

C

D

5

Page 6

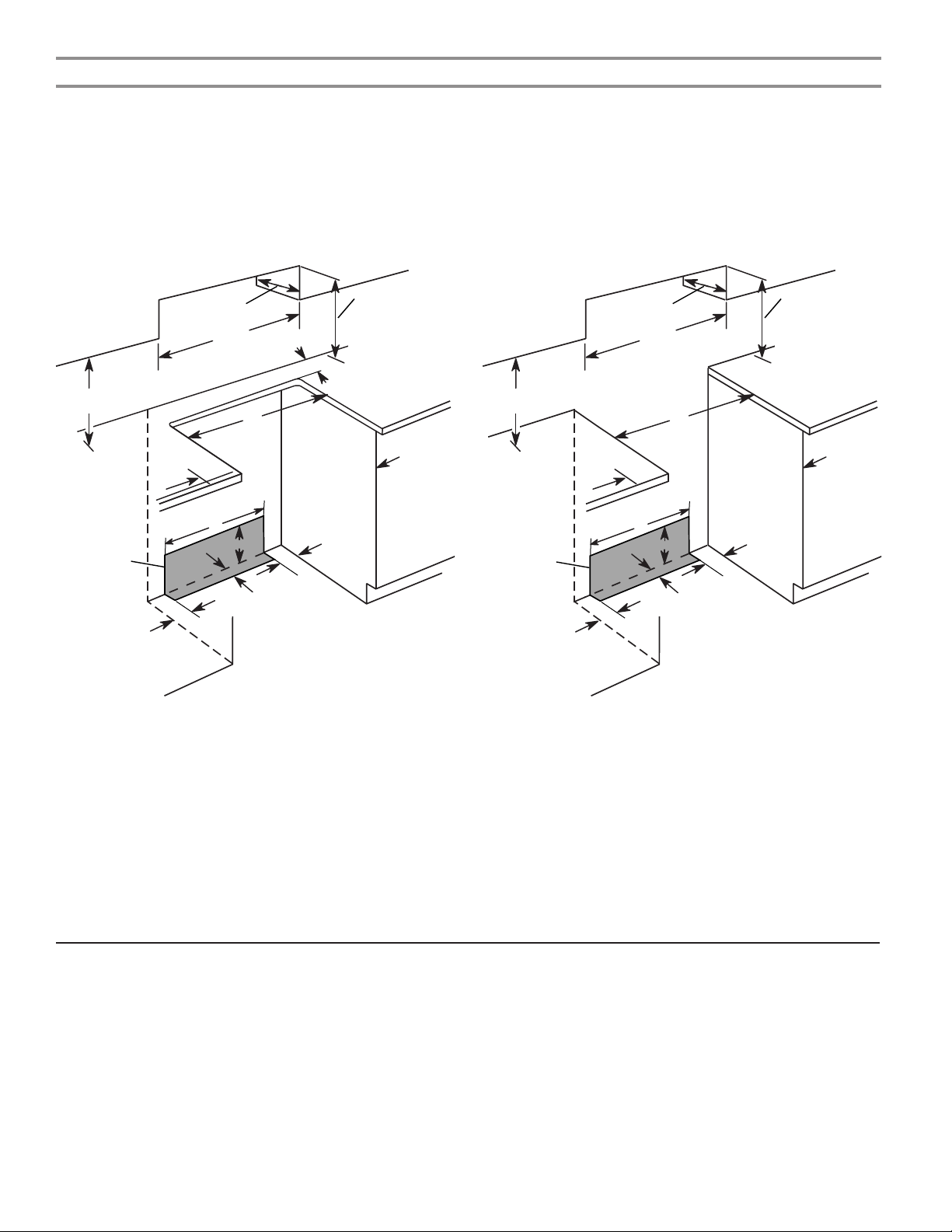

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm) countertop depth, 24" (61.0 cm) base cabinet depth and 36" (91.4 cm)

countertop height.

IMPORTANT: If installing a range hood or microwave hood combination above the range, follow the range hood or microwave

hood combination installation instructions for dimensional clearances above the cooktop surface.

Range may be installed next to combustible walls with zero clearance.

NOTE: When installed in a slide-in cutout, the front of oven door may protrude beyond the base cabinet.

Slide-in Cutout Freestanding Cutout

B

D

C

M

A

E

L

F

H

I

J

G

K

J

A. 18" (45.7 cm) upper side cabinet to countertop

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE*

E. 30" (76.2 cm) min. opening width

F. 3" (7.6 cm) min. clearance from both sides of range to side wall

or other combustible material

G. The shaded area is recommended for installation of rigid gas pipe

and grounded outlet

H. 203/8" (51.8 cm)

I. 7¹¹⁄16" (19.5 cm)

J. 4¹³⁄16" (12.2 cm)

K. 3¹¹⁄16" (9.4 cm) plus measurement of M

L. Cabinet door or hinges should not extend into the cutout

M. Remaining counter depth should not exceed 2¼" (5.7 cm)

B

D

C

A

E

L

F

H

I

J

G

K

J

A. 18" (45.7 cm) upper side cabinet to countertop

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE*

E. 30" (76.2 cm) min. opening width

F. 3" (7.6 cm) min. clearance from both sides of range to side wall

or other combustible material

G. The shaded area is recommended for installation of rigid gas pipe

and grounded outlet

H. 203/8" (51.8 cm)

I. 7¹¹⁄16" (19.5 cm)

J. 4¹³⁄16" (12.2 cm)

K. 3¹¹⁄16" (9.4 cm)

L. Cabinet door or hinges should not extend into the cutout

* NOTE: 24" (61.0 cm) minimum when bottom of wood or metal cabinet is shielded by not less than ¹⁄4" (0.64 cm) flame retardant millboard

covered with not less than No. 28 MSG sheet steel, 0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking platform and the bottom of an uncovered wood or metal cabinet.

6

Page 7

Electrical Requirements – U.S.A. Only

WARNING

Specified Rating of

Power Supply Cord Kit

Range Rating*

120/240 Volts 120/208 Volts Amps Temp Rating

8.8–16.5 kW 7.8–12.5 kW 40 or 50 194°F (90°C)

16.6–22.5 kW 12.6–18.5 kW 50 194°F (90°C)

* The NEC calculated load is less than the total connected load listed

on the model/serial/rating plate.

and Circuit Protection

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

Be sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical

Code, ANSI/ NFPA 70-latest edition and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as

to whether the appliance is properly grounded. Do not modify

the power supply cord plug. If it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

Electrical Connection

Check local codes and consult gas supplier. Check

existing electrical supply and gas supply. See “Gas Supply

Requirements” section.

It is recommended that all electrical connections be made by

a licensed, qualified electrical installer.

■ Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial/rating plate.

The model/serial/rating plate is located on the right vertical

surface of the oven door frame. Refer to the illustrations

in the “Product Dimensions” section of the “Location

Requirements” section.

■ This range is manufactured with a 4-wire power supply

cord rated at 240 volts, 40 amps, rated at 194°F (90°C)

and investigated for use with this range.

■ When a 4-wire, single phase 240 volt, 60 Hz., AC only

electrical supply is available, a 40-amp minimum circuit

protection is required on 30" (76.2 cm) ranges, fused

on both sides of the line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a UL or CSA International

Certified Power Cord intended to be plugged into

a standard 14-50R wall receptacle. Be sure the wall

receptacle is within reach of range’s final location.

■ Do not use an extension cord.

■ The wiring diagram is located on the back of the range

or in a clear plastic bag.

7

Page 8

Electrical Requirements – Canada Only

Gas Supply Requirements

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

Be sure that the electrical connection and wire size are

adequate and in conformance with the CSA Standard C22.1,

Canadian Electrical Code, Part 1 – latest edition, and all local

codes and ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

■ Check with a qualified electrical installer if you are not

sure the range is properly grounded.

Specified Rating of

Power Supply Cord Kit

Range Rating*

120/240 Volts 120/208 Volts Amps Temp Rating

8.8–16.5 kW 7.8–12.5 kW 40 or 50 194°F (90°C)

16.6–22.5 kW 12.6–18.5 kW 50 194°F (90°C)

* The NEC calculated load is less than the total connected load listed

on the model/serial/rating plate.

■ When a 4-wire, single phase 240 volt, 60 Hz., AC only

electrical supply is available, a 40-amp minimum circuit

protection is required on 30" (76.2 cm) ranges, fused on

both sides of the line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a UL or CSA International

Certified Power Cord intended to be plugged into a

standard 14-50R wall receptacle. Be sure the wall

receptacle is within reach of range’s final location.

and Circuit Protection

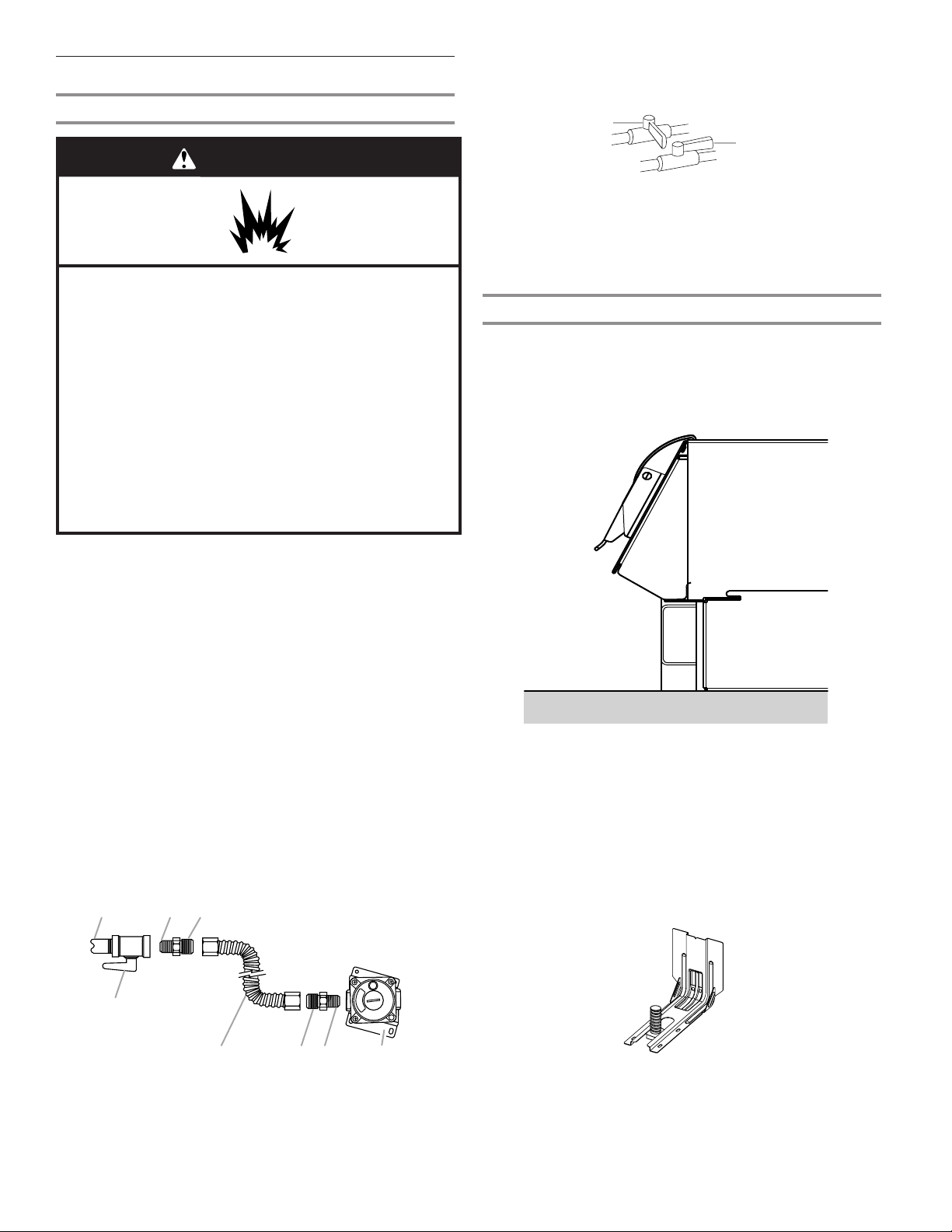

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local

codes and ordinances. In the absence of local codes,

installation must conform with American National Standard,

National Fuel Gas Code ANSI Z223.1 – latest edition or CAN/

CGA B149 – latest edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer’s instructions.

Type of Gas

Natural Gas:

■ This range is factory-set for use with Natural gas. See “Gas

Conversions” section. The model/serial/rating plate located

on the oven frame behind the top right-hand side of the

oven door has information on the types of gas that can be

used. If the types of gas listed do not include the type of

gas available, check with the local gas supplier.

LP Gas Conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the

gas specified on the model/serial/rating plate for use with

a different gas without consulting the serving gas supplier.

See “Gas Conversions” section.

■ Do not use an extension cord.

■ The wiring diagram is located on the back of the range

or in a clear plastic bag.

8

Gas Supply Line

■ Provide a gas supply line of ¾" (1.9 cm) rigid pipe to the

range location. A smaller size pipe on longer runs may

result in insufficient gas supply. With LP gas, piping or

tubing size can be ½" (1.3 cm) minimum. Usually, LP gas

suppliers determine the size and materials used in the

system.

NOTE: Pipe-joint compounds that resist the action of LP

gas must be used. Do not use TEFLON®† tape.

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Page 9

Flexible Metal Appliance Connector:

A

C

■ If local codes permit, a new CSA design-certified, 4 to

5 ft (122 to 152.4 cm) long, ½" or ¾" (1.3 or 1.9 cm) I.D.

(inside diameter), flexible metal appliance connector may

be used for connecting range to the gas supply line.

■ A ½" (1.3 cm) male pipe thread is needed for connection

to the female pipe threads of the inlet to the appliance

pressure regulator.

■ Do not kink or damage the flexible metal tubing when

moving the range.

■ Must include a shut-off valve:

The supply line must be equipped with a manual shut-off

valve. This valve should be located in the same room but

external to the range opening, such as an adjacent cabinet.

It should be in a location that allows ease of opening and

closing. Do not block access to shut-off valve. The valve

is for turning on or shutting off gas to the range.

B

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" (2.5 cm) water column pressure above the manifold

pressure shown on the model/serial/rating plate.

Line Pressure Testing Above ½ psi Gauge (14" WCP)

The range and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of ½ psi (3.5 kPa).

Line Pressure Testing at ½ psi Gauge (14" WCP) or Lower

The range must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.5 kPa).

INSTALLATION

INSTRUCTIONS

Unpack Range

WARNING

A. Gas supply line

B. Shut-off valve “open” position

C. To range

Gas Pressure Regulator

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows

for proper operation:

Natural Gas:

Minimum pressure: 5" WCP

Maximum pressure: 14" WCP

LP Gas:

Minimum pressure: 11" WCP

Maximum pressure: 14" WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial/rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced

at a rate of 4% for each 1,000 ft (304.8 m) above sea level

(not applicable for Canada).

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range. Do not dispose of

anything until the installation is complete.

2. Remove oven racks and parts package from oven and

shipping materials.

3. To remove cardboard bottom, first take 4 cardboard corners

from the carton. Stack one cardboard corner on top of

another. Repeat with the other 2 corners. Place them

lengthwise on the floor behind the range to support

the range when it is laid on its back.

4. Using 2 or more people, firmly grasp the range and gently

lay it on its back on the cardboard corners.

5. Remove cardboard bottom.

The leveling legs can be adjusted while the range is on its back.

See the “Adjust Leveling Legs” section.

NOTE: To place range back up into a standing position, put

a sheet of cardboard or hardboard on the floor in front of range

to protect the flooring. Using 2 or more people, stand range

back up onto the cardboard or hardboard.

9

Page 10

B

Adjust Leveling Legs

1. If range height adjustment is necessary, use a wrench

or pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the

range supported on 2 legs after the range has been placed

back to a standing position.

NOTE: To place range back up into a standing position, put

a sheet of cardboard or hardboard in front of range. Using

2 or more people, stand range back up onto the cardboard

or hardboard.

Install Anti-Tip Bracket

WARNING

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

2. Measure the distance from the top of the counter

to the floor.

3. Measure the distance from the top of the cooktop to

the bottom of the leveling legs. This distance should be

the same. If it is not, adjust the leveling legs to the correct

height. The leveling legs can be loosened to add up to

a maximum of 1" (2.5 cm). A minimum of ³⁄16" (5 mm)

is needed to engage the anti-tip bracket.

NOTE: If height adjustment is made when range is

standing, tilt the range back to adjust the front legs,

and then tilt forward to adjust the rear legs.

4. When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the

anti-tip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

NOTE: If a Trim Kit will be used, the top of the cooktop

should be higher than the counter. See the Installation

Instructions included with the Trim Kit for the correct height.

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket from the inside of the oven.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor, you can use the wall

mounting method. If you are installing the range in a mobile

home, you must secure the range to the floor.

This anti-tip bracket and screws can be used with wood

or metal studs.

3. Determine and mark center line of the cutout space. The

mounting bracket can be installed on either the left-hand

or right-hand side of the cutout. Position mounting bracket

against the wall in the cutout so that the V-notch of the

bracket is 12½" (31.8 cm) from center line as shown.

Centerline

A

A. 12½" (31.8 cm)

B. Bracket V-notch

10

Page 11

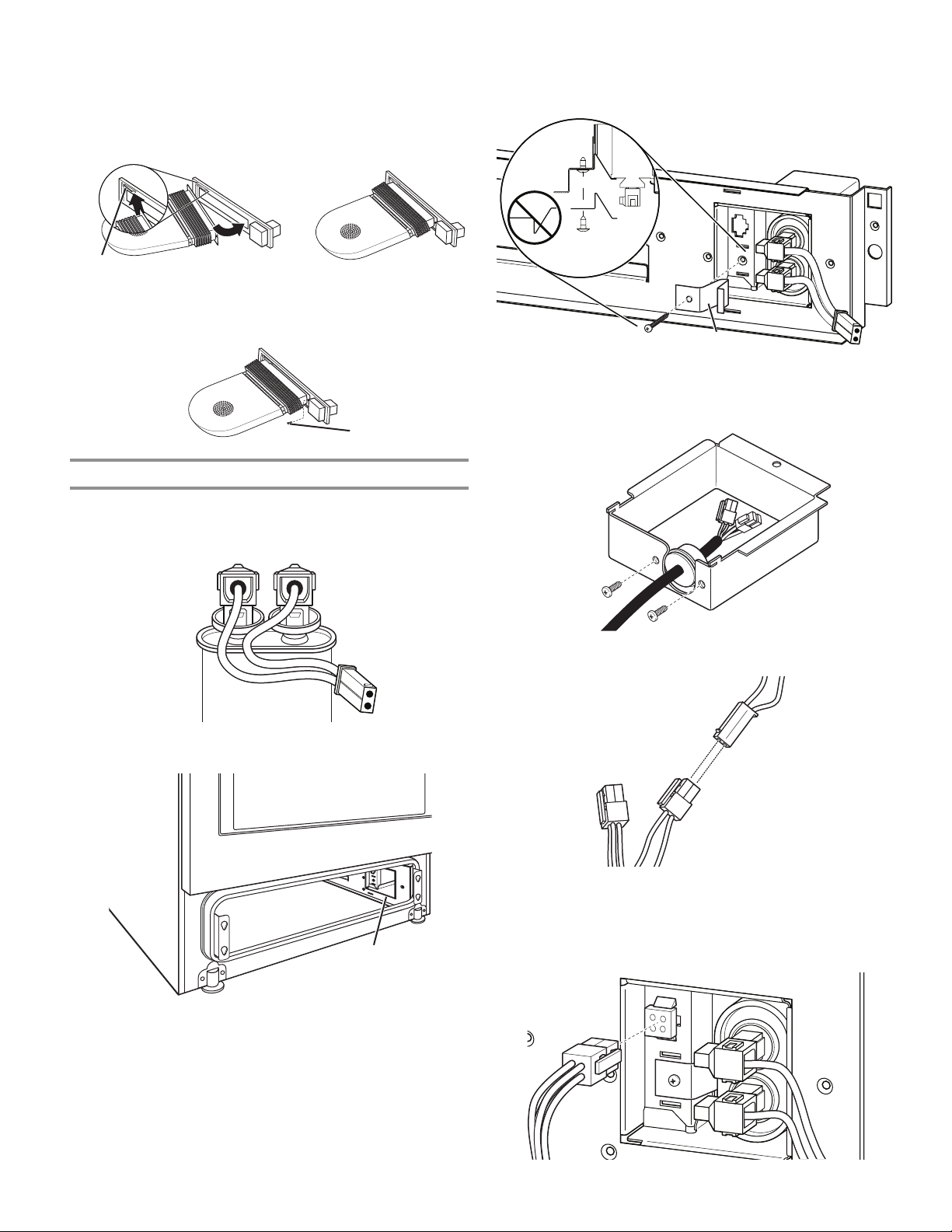

4. Drill two ¹⁄8" (3 mm) holes that correspond to the bracket

holes of the determined mounting method. See the following

illustrations.

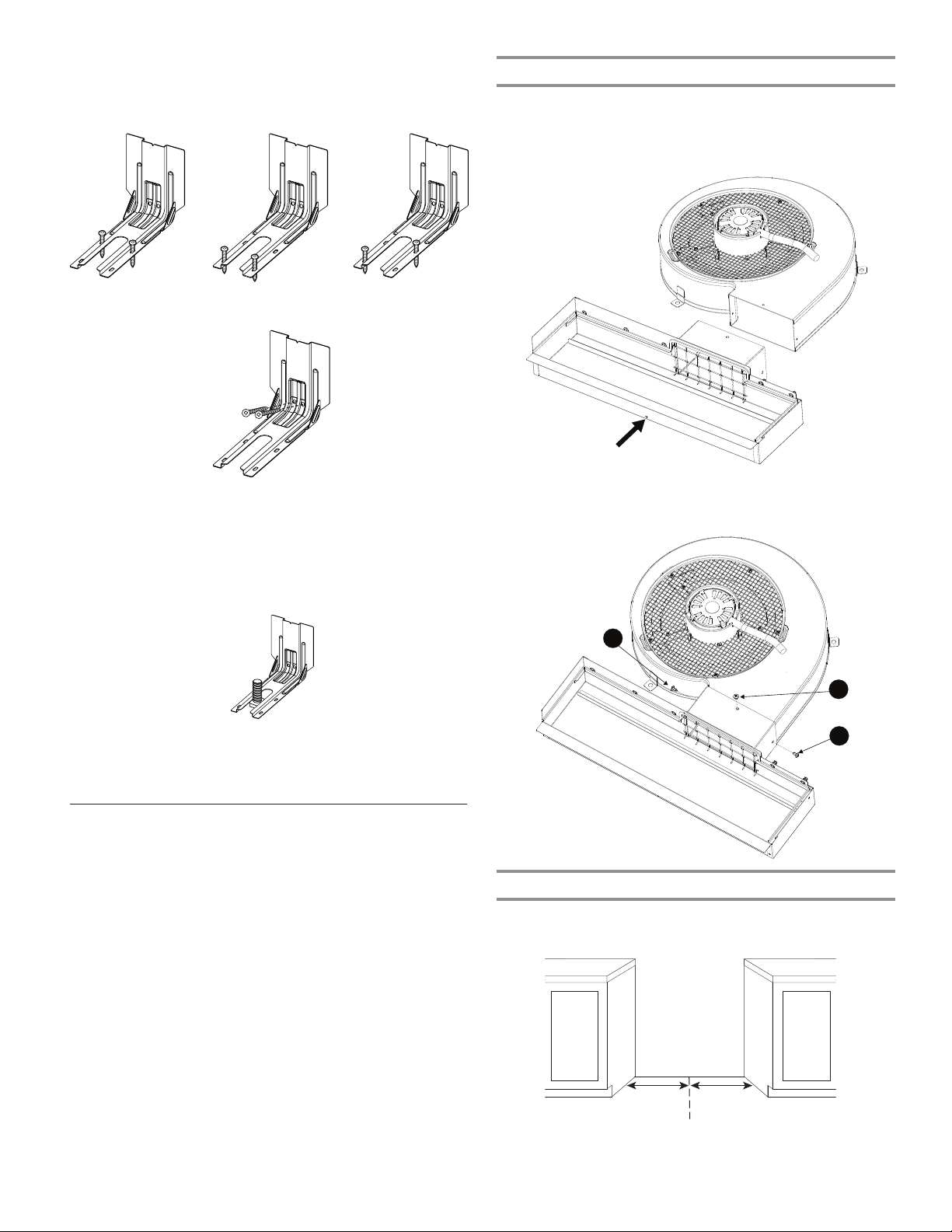

Floor Mounting

Rear position Front position Diagonal (2 options)

Wall Mounting

Assemble Recirculation Housing

1. Slide the Lower Filter Enclosure over the blower assembly

outlet.

NOTE: Lower Filter Enclosure must be disassembled from

the Upper Filter Enclosure for proper installation.

5. Using the two #10 x 15⁄8" (4.1 cm) Phillips-head screws

provided, mount anti-tip bracket to the wall or floor.

6. Move range close enough to opening to allow for final

electrical connections. Remove shipping base, cardboard

or hardboard from under range.

7. Move range into its final location, making sure rear leveling

leg slides into anti-tip bracket.

8. Move range forward onto shipping base, cardboard

or hardboard to continue installing the range, using

the following installation instructions.

Install Recirculation Blower Assembly

Items Needed:

■ Blower Assembly (located under range)

■ Lower Filter Enclosure (Remove (5) M5 x 15 mm screws

to disassemble from Upper Filter Enclosure)

■ (3) Felt Pads

■ (3) #10 x 1" screws

■ Aluminum tape

The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see “Install Anti-Tip Bracket”

section.

2. Secure the Lower Filter Enclosure to the blower motor with

the three (3) #8 – 3/8" screws provided. Seal connection with

aluminum tape.

1

2

3

Position the Blower

1. Determine and mark the center line on the floor of the

cabinet opening.

A

A. Center line

11

Page 12

2. Without blower or service connections installed, fit

the range in its final installation position.

3. Remove the Front Lower Access Panel of the range

by gently lifting on the panel; then pull outward.

2

1

4. Place level on the oven bottom, as indicated in one of

the two figures below, depending on the size of the level.

Check with the level side to side and front to back. If range

is not level, use a wrench or pliers to adjust leveling legs up

or down until the range is level.

NOTE: Range must be level for satisfactory baking

performance and best cleaning results using AquaLift®

Self-Clean Technology.

8. Remove five felt pads from the gasket strip (found

in the blower accessory kit).

9. Remove the paper backing from the felt pads and apply

to the bottom of the three (3) blower motor tabs and two

(2) to the bottom of the Lower Filter Enclosure.

NOTE: Felt pads reduce motor noise and aid in mounting

to uneven floors.

10. Position the blower assembly from “Assemble

Recirculation Housing” so the front edge of the Lower

Filter Enclosure is aligned with the mark made in step 4.

Align the center mark of the Lower Filter Enclosure with

the center line previously marked on the floor.

1

2

3

Secure the Blower

5. Place a strip of masking tape on the floor, in front

of the lower front frame, and mark a line flush with

the front of the frame.

NOTE: Be sure to keep the line even with the front frame.

6. Remove the range from opening. Be sure not to remove

tape during range removal.

7. Offset the line marked in step 5 by 1" (2.5 cm) towards

the rear of the range opening.

1. Drill three Z\," (3 mm) pilot holes using the blower motor

tabs as guides.

2. Mount the blower motor to the floor with the three #10 x 1"

screws provided.

1

3

2

NOTE: If the range height adjustment is significant,

the blower may need to be shimmed to ensure proper

installation.

3. Remove masking tape from floor.

12

†® AQUALIFT is a registered trademark of Whirlpool, U.S.A.

Page 13

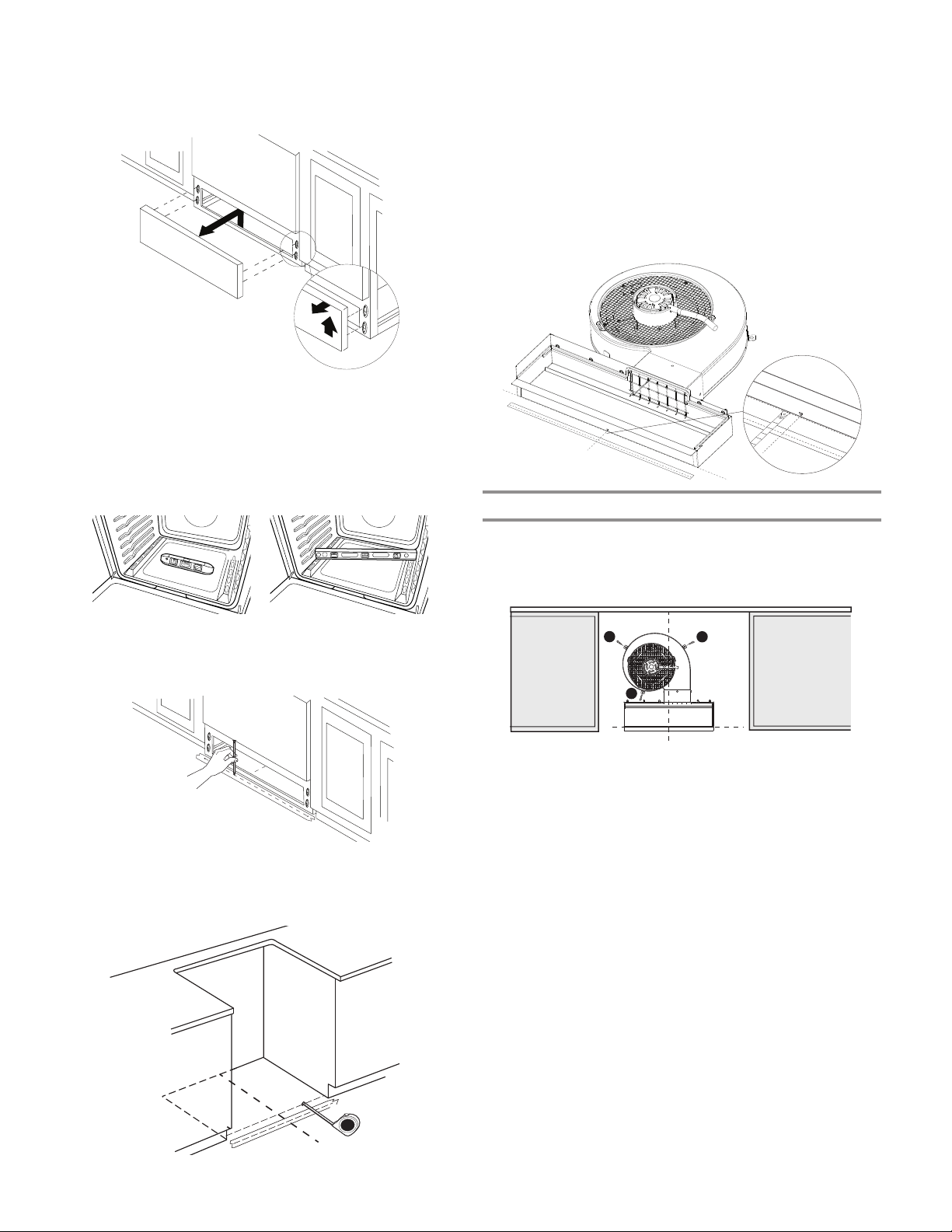

Install Blower

Install Blower Cover

1. Locate blower motor cover.

2. Run the blower motor wires with strain relief through

the small opening in the blower motor cover, starting

from the inside and feeding out.

Strain relief

3. Feed blower motor wire through opening and place the

strain relief bracket to the inside of the blower cover. Install

and tighten the two (2) provided #8–18 x 3⁄8" screws to

secure the strain relief bracket.

5. Remove paper from the rear of the rectangular felt pad

and apply adhesive side of felt to the bellow flange.

NOTE: This step is important to ensure maximum

blower performance.

6. Apply blower motor cover to the blower. Slightly spread the

cover retainer spring to allow the cover to drop into position

on the blower motor. Ensure the blower cover retainer ring

is securely locked in place.

NOTE: The blower motor cover will not properly install

if the motor wire is on the top of the motor.

Incorrect

Incorrect Correct

Correct

4. Reposition the blower motor cover retainer spring

as illustrated.

7. Rotate blower motor cover so the bellows are facing

towards the right of the installation, and position the

bellows so the bellow flange is facing the floor as illustrated.

8. Move blower motor wire to the front of the installation.

13

Page 14

Make Utility Connections

ABC

EFG

H

A

B

Make Gas Connection

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Complete Connection

1. Open the manual shut-off valve in the gas supply line.

The valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

2. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear,

a leak is indicated. Correct any leak found.

Connect Blower Assembly to Range

1. Remove the cardboard or hardboard from under the range.

2. Using 2 or more people, gently move the range into its final

location.

3. Ensure the front edge of the Lower Filter Enclosure is above

the lower front frame cross support.

This range is factory-set for use with Natural gas. To use this

range with LP gas, see the “Gas Conversions” section before

connecting this range to the gas supply. Gas conversions from

Natural gas to LP gas or from LP gas to Natural gas must be

done by a qualified installer.

Typical Flexible Connection

1. Apply pipe-joint compound made for use with LP gas to

the smaller thread ends of the flexible connector adapters.

See B and G in the following illustration.

2. Attach one adapter to the gas pressure regulator and

the other adapter to the gas shut-off valve. Tighten both

adapters, being certain not to move or turn the gas

pressure regulator.

3. Use a 15⁄16" (2.4 cm) combination wrench and an adjustable

wrench to attach the flexible connector to the adapters.

IMPORTANT: All connections must be wrench-tightened.

Do not make connections to the gas regulator too tight.

Making the connections too tight may crack the regulator

and cause a gas leak. Do not allow the regulator to turn

when tightening fittings.

NOTE: If the Lower Filter Enclosure is below the Lower Front

Frame Cross Support, the blower may need to be shimmed.

4. Check to ensure the flexible metal gas connector and

electrical cord are not kinked. Use a flashlight to look

underneath the bottom of and behind the range.

5. Verify that the anti-tip bracket is installed and engaged.

a. Use a flashlight to look underneath the bottom

of and behind the range.

b. Visually check that the rear range foot is inserted

into the slot of the anti-tip bracket.

A. ½" (1.3 cm) or ¾" (1.9 cm)

gas pipe

B. Use pipe-joint compound.

C. Adapter

D. Manual gas shut-off valve

14

D

E. Flexible connector

F. Adapter (must have ½"

[1.3 cm] male pipe thread)

G. Use pipe-joint compound.

H. Gas pressure regulator

Page 15

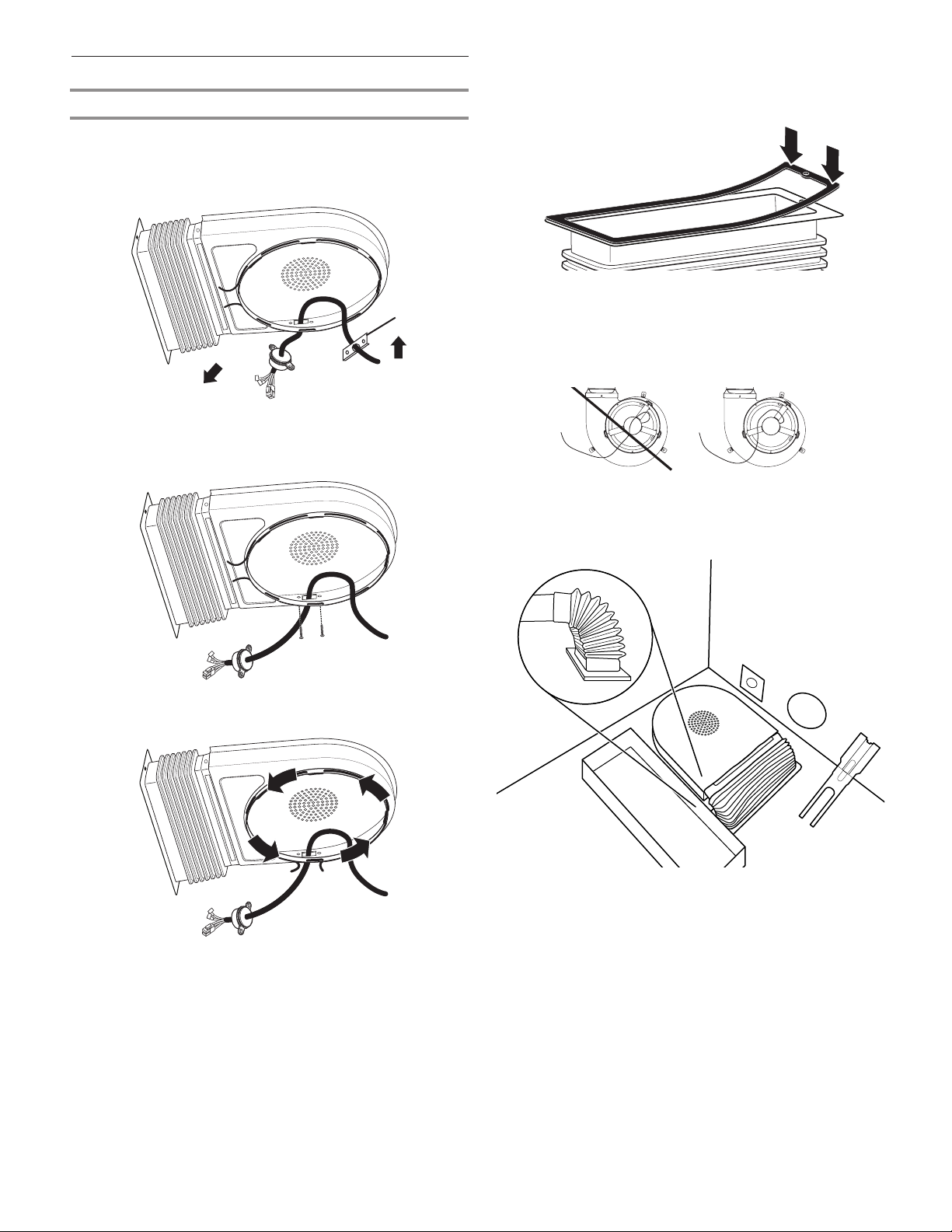

6. Visually check that there is an air gap between the Blower

Motor Cover and the bottom of the range to ensure proper

blower motor ventilation.

7. Rotate blower motor cover so the bellows are in their final

position. Ensure the rear of the bellow flange is engaged

in the retaining bracket.

3. Place capacitor in tray.

4. Secure the capacitor with the capacitor retention bracket;

then, install the bracket screw.

Retaining

bracket

Rotate cover

Final position

8 Secure the front of the blower bellow flange to the range

frame with the supplied #8–18 x 3⁄8" screw.

Screw

Connect Blower Electrical Parts

1. Locate the capacitor (in Blower Motor Kit).

NOTE: The capacitor is supplied with a small harness

that terminates in a two-pin connector as shown.

Post 1 Post 2

Retention

bracket

5. Secure the blower motor strain relief, near the quick

connection end, to the blower electrical terminal cover

with the two provided screws.

6. Locate the two-pin connector on the blower motor wire

harness and connect it to the two-pin capacitor connector.

2. Locate the capacitor storage tray in front of the blower

bellow connection point in the lower right side of the range.

Capacitor

storage tray

7. Locate the 4-pin connector on the blower motor wire

and plug it into the terminal connection point directly

behind the capacitor storage tray.

NOTE: The terminal release (clip point) will be facing

toward the front of the range.

15

Page 16

8. Install blower electrical terminal cover.

NOTE: When replacing cover, insert the terminal cover

tabs in the corresponding slots in the range, and push

the terminal cover rearward to engage.

9. Install terminal cover screw.

2

1

2. Using the five (5) M5 x 15 mm screws and the previously

disassembled lock washers, securely fasten the Upper

Filter Enclosure to the Lower Filter Enclosure.

3

Complete Filter Assembly

You Will Need

■ Upper Filter Enclosure

■ (5) M5 x 15 mm screws and lock washers

■ 8" Phillips screwdriver

■ Air filter

■ Enclosure Front

1. Attach the Upper Filter Enclosure to the Lower Filter

Enclosure by sliding the Upper Filter Enclosure straight

back into the Lower Filter Enclosure.

The final position of the Upper Filter Enclosure is to be

resting on the back shelf of the Lower Filter Enclosure with

the tabs of the Upper Filter Enclosure engaged in the Lower

Filter Enclosure.

3. Install Air Filter into the housing and then rotate it to its final

position.

NOTE: Confirm the Air Flow indicator, marked on the Air

Filter, points toward the front of the range.

1

Side View of Assembled Filter Housing

2

3

4. Install the Enclosure Front by slightly tilting it towards you,

placing in the housing and rotating it up into the final

position.

1

2

3

NOTE: Cabinets and range removed from image for

clarification.

16

Side View of Assembled Filter Housing

Page 17

5. Latch the Enclosure Front to the housing by positioning the

front clasps in the slots on the top of the housing; then, push

down on the clasp handles.

6. Install the new Front Lower Access Panel that shipped with

the duct-free kit, by aligning the studs with the keyhole slots

on the range. Press the Front Lower Access Panel forward

into the slots and push downward to engage the studs.

Oven Door

For normal range use, it is not suggested to remove the oven

door. However, if removal is necessary, make sure the oven

is off and cool. Then follow these instructions.

NOTE: The oven door is heavy.

To Remove:

1. Open oven door all the way.

2. Pinch the hinge latch between two fingers and pull forward.

Repeat on other side of oven door.

A

A. Hinge latch

3. Close the oven door as far as it will shut.

4. Lift the oven door while holding both sides.

Continue to push the oven door closed and pull it away

from the oven door frame.

1

2

7. See “Replacing Air Filter” section for servicing.

Make Electrical Connection

Plug into grounded outlet. See the appropriate “Electrical

Requirements” section.

Verify Anti-Tip Bracket

Is Installed and Engaged

1. Ensure range is in its final location.

2. Remove the front lower access panel.

3. Use a flashlight to look underneath the bottom of the range.

4. Visually check that the rear range foot is inserted into

the slot of the anti-tip bracket.

5. Replace the front lower access panel.

IMPORTANT: If the range is moved to adjust the leveling legs,

verify that the anti-tip bracket is engaged by repeating steps

1 to 5.

To Replace:

1. Insert both hanger arms into the door. Be sure that the

hinge notches are engaged in the oven door frame.

A

A. Hinge notch

2. Open the oven door. The door should be able to open all

the way.

3. Move the hinge levers back to the locked position. Check

that the door is free to open and close and is level while

closed. If it is not, repeat the removal and installation

procedures.

17

Page 18

Complete Installation

1. Remove cooktop burner caps and bases from package

containing parts. Place the burner bases as indicated

by the following illustration:

A

B D

A. Small

B. Large

C. Medium

D. Large

2. Align the gas tube opening in the burner base with the orifice

holder on the cooktop and the igniter electrode with the

notch in the burner base.

A

B

C

E

D

A. Burner cap

B. Gas tube opening

C. Burner base

D. Igniter electrode

E. Orifice holder

3. Place the burner caps on the appropriate burner bases.

IMPORTANT: The bottom of the small and medium caps are

different. Do not put the wrong size burner cap on the burner

base.

C

4. Place burner grates over burners and caps.

5. Check to ensure the flexible metal gas connector and

electrical cord are not kinked. Use a flashlight to look

underneath the bottom of and behind the range.

6. Check that all parts are now installed. If there is an extra

part, go back through the steps to see which step was

skipped.

7. Check that you have all of your tools.

8. Check that you have all of the range accessories,

especially oven racks. These accessories may be

in the range packaging.

9. Dispose of/recycle all packaging materials.

10. Check that the range is level. See the “Level Range”

section.

11. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see

the “Range Care” section of the Use and Care Guide.

12. Read the Use and Care Guide.

13. Turn on surface burners and oven. Confirm surface burner

flame height by reviewing the “Adjust Flame Height”

section, and adjust flame if necessary. See the Use

and Care Guide for instructions on range operation.

NOTE: Odors and smoke are normal when the oven is

used the first few times.

If Range Does Not Operate, Check the Following:

■ Household fuse is intact and tight, or circuit breaker has

not tripped.

■ Gas pressure regulator shut-off valve is in the open

position.

■ Range is plugged into a grounded outlet.

■ Electrical supply is connected.

IMPORTANT: If the range control displays an “F9” or

“F9, E0” error code, the electrical outlet in the home may

be miswired. Disconnect power and contact a qualified

electrician to verify the electrical supply.

14. When the range has been on for 5 minutes, check for heat.

If the range is cold, turn off the range and check that the

gas supply line shut-off valve is open.

■ If the gas supply line shut-off valve is closed, open it,

and then repeat the 5-minute test as outlined above.

■ If the gas supply line shut-off valve is open, close it,

and contact a qualified technician.

Small cap Medium cap Large cap

Burner caps should be level when properly positioned.

If burner caps are not properly positioned, surface burners

will not light. The burner cap should not rock or wobble

when properly aligned.

A

B

A. Incorrect

B. Correct

18

Page 19

Initial Lighting and Gas Flame Adjustments

A

B

Standard Surface Burners

Push in and turn each control knob to the ignite position.

The flame should light within 4 seconds. The first time a burner

is lit, it may take longer than 4 seconds to light because of air

in the gas line.

If Burners Do Not Light Properly:

■ Turn cooktop control knob to the off position.

■ Check that the range is plugged into a grounded 3 prong

outlet. Check that the circuit breaker has not tripped

or the household fuse has not blown.

■ Check that the gas shut-off valves are set to the open

position.

■ Check that burner caps are properly positioned on

burner bases.

GAS CONVERSIONS

Gas conversions from Natural gas to LP gas or from LP gas

to Natural gas must be done by a qualified installer.

Repeat start-up. If a burner does not light at this point, turn

the control knobs to the off position and contact your dealer

or authorized service company for assistance. Please reference

the “Warranty” section of the Use and Care Guide to contact

service.

If the cooktop “low” burner flame needs to be adjusted for

any of the burners, see the “Adjust Flame Height” section.

If You Need Assistance or Service:

Please reference the “Warranty” section of the Use and Care

Guide to contact service.

Electronic Ignition System

Cooktop burners use electronic igniters in place of standing

pilots. When the cooktop control knob is turned to the ignite

position, the system creates a spark to light the burner.

All cooktop burners will spark, but only the burner with the

control knob turned to the ignite position will produce a flame.

This sparking continues as long as the control knob is turned

to the ignite position.

LP Gas Conversion

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shut-off valve to the closed position.

C

A. To range

B. Shut-off valve (closed position)

2. Unplug range or disconnect power.

C. Gas supply line

19

Page 20

To Convert Gas Pressure Regulator

A

A

A

B

A

B

(Natural Gas to LP Gas)

1. Move the range out from the wall.

2. Locate the gas pressure regulator at the lower right

corner on the back of the range.

To Convert Surface Burners (Natural Gas to LP Gas)

1. If installed, remove the burner grates.

2. Remove the burner caps.

3. Remove the burner base.

C

D

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

3. Remove the front lower panel of the range.

4. Disconnect the blower motor electrical connections.

5. Disconnect the downdraft blower bellows from the range.

6. Unscrew the metal cover and unscrew the blue regulator

cap. Keep the washer in place.

A

B

C

A. Metal cover

B. Washer

C. Blue regulator cap

7. Flip the blue regulator cap over and screw it back into

the metal cover.

A. Igniter electrode

B. Burner cap

C. Gas tube opening

D. Burner base

4. Apply masking tape to the end of a 9⁄32" (7 mm) nut driver

to help hold the gas orifice spud in the nut driver while

changing it. Press nut driver down onto the gas orifice spud

and remove by turning it counterclockwise and lifting out.

Set gas orifice spud aside.

B

A

D

C

A. Igniter electrode

B. Orifice spud

C. Orifice spud holder

D. Screws

5. Remove the orifice spuds shipped in the literature package

in the oven. Gas orifice spuds are stamped with a number,

marked with 1 or 2 color dots, and have a groove in the hex

area. Replace the Natural gas orifice spud with the correct

LP gas orifice spud.

A

A. LP groove

A. Natural gas position

B. LP gas position

8. Screw the metal cover securely back into place.

Do not overtighten.

20

Page 21

Refer to the following chart for correct LP gas orifice spud

A

B

A

ratings and to spud holder card for proper placement.

Natural Gas Conversion

LP Gas Orifice Spud Chart for Surface Burners

Burner

Rating/Type Color Size (mm)

15,000 BTU/

Stacked*

14,200

BTU/ Ultra/

Stacked*

8,000 BTU/

Semi

5,000 BTU/

Auxi

1,200 BTU/

Stacked/

Simmer*

*Not in all kits/models.

NOTE: Refer to the model/serial/rating plate located on the

oven frame behind the top right-hand side of the oven door

for proper sizing of spuds for each burner location.

6. Place Natural gas orifice spuds in the orifice spud bag.

IMPORTANT: Keep the Natural gas orifice spuds in case

of reinstallation with Natural gas.

7. Replace the burner base.

8. Replace burner cap.

9. Repeat steps 1 to 7 for the remaining burners.

Silver

Black/

Orange

Silver 1.05 L105 LF/RF

Red/

Orange

Red/

Blue

Black/

Orange

1.05

0.32

0.85 L85 RR/CTR

0.65 L65 LR

0.32 L32 LF (Simmer)

ID

Number Placement

L105

L32

LF

Complete Installation (Natural Gas to LP Gas)

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shut-off valve to the closed position.

C

1. Refer to the “Make Gas Connection” section for proper

connection of the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition and operation.

3. Refer to the “Adjust Flame Height” section for burner flame

adjustments.

IMPORTANT: You may have to adjust the low setting for

each cooktop burner.

Checking for proper cooktop burner flame is very important.

Natural gas flames do not have yellow tips.

4. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete this

procedure.

IMPORTANT: Make sure to save the orifices that have

just been replaced in the conversion.

A. To range

B. Shut-off valve (closed position)

C. Gas supply line

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator

(LP Gas to Natural Gas)

1. Move the range out from the wall.

2. Locate the gas pressure regulator at the lower right

corner on the back of the range.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

3. Remove the front lower panel of the range.

4. Disconnect the blower motor electrical connections.

5. Disconnect the downdraft blower bellows from the range.

21

Page 22

6. Unscrew the metal cover and unscrew the blue regulator

A

B

A

B

cap. Keep the washer in place.

A

B

4. Apply masking tape to the end of a 9⁄32" (7 mm) nut driver

to help hold the gas orifice spud in the nut driver while

changing it. Press nut driver down onto the gas orifice

spud and remove by turning it counterclockwise and

lifting out. Set gas orifice spud aside.

B

A

D

C

A. Metal cover

B. Washer

C. Blue regulator cap

7. Flip the blue regulator cap over and screw it back into

the metal cover.

A

A. LP gas position

B. Natural gas position

8. Screw the metal cover securely back into place.

Do not overtighten.

To Convert Surface Burners (LP Gas to Natural Gas)

1. If they are installed, remove the burner grates.

2. Remove the burner caps.

3. Remove the burner base.

C

D

A. Igniter electrode

B. Burner cap

C. Gas tube opening

D. Burner base

C

A. Igniter electrode

B. Orifice spud

C. Orifice spud holder

D. Screws

5. Gas orifice spuds are stamped with a number on the side.

Replace the LP gas orifice spud with the correct Natural Gas

orifice spud.

XXX

A

A. Stamped number

Refer to the following chart for the correct Natural Gas

orifice spud placement.

Natural Gas Orifice Spud Chart

Burner Rating Color Size (mm) ID Number

19,000 BTU (ST) White/Gray 1.84 184

17,000 BTU (ST) N/A 1.75 175

17,000 BTU White/Blue 1.90 190

15,000 BTU White/Green 1.80 180

9,200 BTU White/Black 1.35 135

8,000 BTU White/Yellow 1.25 125

5,000 BTU White/Orange 1.00 100

1,200 BTU Black 0.52 52

NOTE: Refer to the model/serial/rating plate located on the

oven frame behind the top right-hand side of the oven door

for proper sizing of spuds for each burner location.

6. Place LP gas orifice spuds in the orifice spud bag.

IMPORTANT: Keep the LP gas orifice spuds in case

of reinstallation with LP gas.

7. Replace the burner base.

8. Replace the burner cap.

9. Repeat steps 1 to 7 for the remaining burners.

22

Page 23

Complete Installation (LP Gas to Natural Gas)

B

C

C

1. Refer to the “Make Gas Connection” section for proper

connection of the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition and operation.

3. Refer to the “Adjust Flame Height” section for burner

flame adjustments.

IMPORTANT: You may have to adjust the low setting for

each cooktop burner.

Checking for proper cooktop burner flame is very important.

Natural gas flames do not have yellow tips.

4. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete this

procedure.

3. Replace the control knob.

4. Test the flame by turning the control from the low position

to the high position, checking the flame at each setting.

5. Repeat the previous steps for each burner.

To Adjust Double Burner (On Some Models):

1. Light burner and turn to lowest setting where both inner

and outer burners are lit.

2. Remove the control knob.

Hold the knob stem with a pair of pliers. Use a small

flat-blade screwdriver to turn the screw located in the

center of the control knob stem until the flame is the

proper size. Turning the screw clockwise will increase

the flame size, and turning the screw counterclockwise

will decrease the flame size.

IMPORTANT: Make sure to save the orifices that have

just been replaced in the conversion.

Adjust Flame Height

Adjust Surface Burner Flame

Adjust the height of top burner flames. The cooktop “low”

burner flame should be a steady blue flame approximately ¼"

(6 mm) high. LP gas flames have a slightly yellow tip.

A

A. Low flame

B. High flame

To Adjust Standard Burner:

The flame can be adjusted using the adjustment screw

in the center of the valve stem. The valve stem is located

directly underneath the control knob.

If the “Low” Flame Needs to be Adjusted:

1. Light one burner and turn to lowest setting.

2. Remove the control knob.

Hold the knob stem with a pair of pliers. Use a small

flat-blade screwdriver to turn the screw located in the

center of the control knob stem until the flame is the

proper size. Turning the screw clockwise will increase

the flame size, and turning the screw counterclockwise

will decrease the flame size.

A

B

A. Control knob stem

B. Screwdriver

C. Pliers

3. Replace the control knob.

4. Test the flame by turning the control from the low position

to the high position, checking the flame at each setting.

A

B

A. Control knob stem

B. Screwdriver

C. Pliers

23

Page 24

REPLACING AIR FILTER

The Duct Free Filter System is designed to require minimal

attention between filter changes. The filter is designed to last

for 6 months of average usage.

The housing can be cleaned with a paper towel and household

cleaners or with a cloth and warm soapy water. No special

cleaners are required.

IMPORTANT: Before cleaning and replacing the filter, make

sure all controls are off and the oven and cooktop are cool.

Items you Will Need:

■ New Filter (PN# W10748931)

Changing the Filter:

1. Remove Front Lower Access Panel.

4. Thoroughly clean and dry the filter housing. You can clean

the housing with a paper towel and household cleaners

or with a cloth and warm soapy water. No special cleaners

are required.

5. Install Air Filter into the housing and then rotate it to its final

position.

NOTE: Confirm the Air Flow indicator, marked on the filter,

points towards the front of the range.

1

Side View of Assembled Filter Housing

2

3

6. Install the Enclosure Front by slightly tilting it towards

you, placing in the housing, and rotating it up into the

final position.

1

2

1

2. Unlatch and remove the Enclosure Front.

3

2

1

3. Remove the Air Filter by gripping the two tabs at the top

of the filter.

3

2

1

2

3

Side View of Assembled Filter Housing

7. Latch the Enclosure Front to the housing by positioning the

front clasps in the slots on the top of the housing; then, push

down on the clasp handles.

8. Replace the Front Lower Access Panel by aligning the studs

with the keyhole slots on the range. Press the access panel

forward into the slots and push downward to engage the

studs.

24

1

2

Page 25

SÉCURITÉ DE LA CUISINIÈRE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

IMPORTANT : Ne pas installer un système de ventilation avec évacuation de l'air vers le bas, qui évacuerait l'air vers cet

appareil de cuisson à gaz. Ce type de système de ventilation peut causer des problèmes d'allumage et de combustion avec cet

appareil de cuisson à gaz et entraîner des blessures corporelles ou le fonctionnement non désiré de cet appareil.

25

Page 26

AVERTISSEMENT

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisinière, ce qui peut causer un

décès.

Fixer la bride antibasculement au plancher ou au mur, conformément aux instructions

d'installation.

Faire glisser de nouveau la cuisinière de façon à ce que le pied arrière de la cuisinière se

trouve dans la fente de la bride antibasculement.

Réengager la bride antibasculement si la cuisinière a été déplacée.

Ne pas faire fonctionner la cuisinière si la bride antibasculement n'est pas installée et engagée.

Le non-respect de ces instructions peut causer un décès ou des brûlures graves aux enfants et

aux adultes.

Pour vérifier que la bride antibasculement est bien installée et engagée :

Bride

antibasculement

Pied de

la cuisinière

Avertissements de la proposition 65 de l'État de Californie :

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par l’État de Californie pour être à l’origine de

cancers.

AVERTISSEMENT : Ce produit contient au moins un produit chimique connu par l’État de Californie pour être à l’origine de

malformations et autres déficiences de naissance.

• Faire glisser la cuisinière vers l'avant.

• Vérifier que la bride antibasculement est bien fixée au plancher ou au mur.

• Faire de nouveau glisser la cuisinière vers l'arrière de sorte que le pied de la cuisinière

se trouve sous la bride antibasculement.

• Voir les instructions d'installation pour plus de détails.

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant

d’entreprendre l’installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils nécessaires

■ Mètre-ruban

■ Tournevis Phillips

■ Tournevis à lame

plate

■ Tournevis à lame

plate de ¹⁄8"

(3 mm)

■ Niveau

■ Perceuse

■ Clef à molette

■ Pinces

26

■ Lampe de poche

■ Ruban adhésif de masquage

■ Composé d’étanchéité des

raccords filetés – résistant

au gaz naturel et gaz propane

■ Foret à maçonnerie à pointe

carburée de 3⁄16" (4,8 mm) (pour

planchers en béton/céramique)

■ Solution non corrosive

de détection des fuites

■ Ruban aluminium à tôle

■ Clé à tuyauterie

■ Clé mixte de

15

(2,4 cm)

■ Foret de ¹⁄8"

(3,2 mm) (pour

plancher de bois)

■ Crayon ou

marqueur

Pour la conversion pour

l’alimentation au gaz propane/

⁄16"

gaz naturel

■ Clé mixte de ½" (13 mm)

■ Tourne-écrou ¼" (6 mm)

■ Tourne-écrou

9

⁄32" (7 mm)

Page 27

Pièces fournies

Vérifier que toutes les pièces sont présentes. Certaines pièces

sont assemblées pour la livraison et doivent être démontées.

■

Filtre à air (no de pièce W10748931)

■

Partie inférieure du boîtier de filtre

■ Partie supérieure du boîtier de filtre

■ Devant du boîtier

■ Panneau d’accès avant inférieur

■

(5) Vis M5 x 15 mm et rondelles (démonter la partie

inférieure et supérieure du boîtier)

■

(3) Vis #8 – 3/8" (incluse dans le sac de pièces)

REMARQUE : L’adaptateur

d’échappement de

l’ensemble d’installation

du ventilateur et le panneau

d’accès inférieur livrés avec

la cuisinière ne seront pas

utilisés.

Pièces nécessaires

Pour commander, voir la section “Assistance ou service”

du Guide d’utilisation et d’entretien :

– Papier d’aluminium, ruban

Consulter les codes locaux en vigueur et le fournisseur de

gaz. Déterminer les caractéristiques des sources disponibles

d’électricité et gaz. Voir la section “Spécifications électriques”

et “Spécifications de l’alimentation en gaz” correspondante.

Il est recommandé de faire réaliser tous les raccordements

électriques par un électricien qualifié agréé.

Pièces facultatives

Pour acheter ces accessoires ou d’autres, se reporter

à la section “Accessoires” du guide d’utilisation et d’entretien

pour les informations de contact.

■ Trousses de garnitures latérales :

5

⁄8" (1,7 cm) Noir – Commander la pièce numéro W10675026

5

⁄8" (1,7 cm) Acier inoxydable – Commander la pièce

numéro W10675028

1¹⁄8" (2,9 cm) Noir – Commander la pièce numéro W10731886

1¹⁄8" (2,9 cm) Acier inoxydable – Commander la pièce

numéro W10731887

■ Panneaux anti-éclaboussures :

Hauteur 6" (15,2 cm) Noir : Commander la pièce

numéro W10655449

Hauteur 6" (15,2 cm) Acier inoxydable : Commander

la pièce numéro W10655450

REMARQUE : Ce manuel concerne plusieurs modèles. Votre

produit peut être différent de cette image.

27

Page 28

Exigences d’emplacement

A

IMPORTANT : Observer les dispositions de tous les codes

et règlements en vigueur. Ne pas obstruer le flux de combustion

et de ventilation.

■ C’est à l’installateur qu’incombe la responsabilité de respecter

Dimensions du produit

Ce manuel concerne plusieurs modèles. Votre modèle peut

différer de ceux illustrés. Les dimensions indiquées sont

les dimensions maximales sur tous les modèles.

les distances de séparation spécifiées sur la plaque signalétique.

La plaque signalétique se trouve derrière la porte du four, dans

le coin supérieur droit du châssis.

■ La cuisinière doit être installée à un endroit pratique dans

B

C

la cuisine.

■ Dans le cas d’une cuisinière encastrée, l’enceinte doit recouvrir

complètement les côtés et l’arrière de la cuisinière.

■ Afin de supprimer le risque de brûlures ou d’incendie lié au fait

de se pencher au-dessus des plaques de cuisson chaudes,

les placards de rangement au-dessus des plaques doivent être

évités. Si des placards de rangement sont prévus, le risque peut

être réduit par l’installation d’une hotte de cuisinière ou d’un

D

ensemble hotte/micro-ondes dépassant horizontalement de 5"

(12,7 cm) au moins par rapport au bas des placards.

■ Toutes les ouvertures dans le mur ou le plancher de

l’emplacement d’installation de la cuisinière doivent être scellées.

■ Respecter les dimensions indiquées pour les ouvertures

à découper dans les meubles. Ces dimensions constituent

les valeurs minimales des dégagements.

■ La bride antibasculement doit être installée. Pour l’installation de

E

F

la bride antibasculement fournie avec la cuisinière, voir la section

“Installation de la bride antibasculement”.

■ Une source d’électricité avec liaison à la terre est nécessaire.

Voir la section “Spécifications électriques” correspondante.

■ Un raccordement adéquat à l’alimentation en gaz doit être

disponible. Voir la section “Spécifications de l’alimentation

en gaz”.

■ Contacter un installateur de revêtement de sol qualifié,

qui pourra déterminer si le revêtement de sol peut résister

à une température d’au moins 200°F (93°C).

■ Dans le cas de l’installation de la cuisinière sur une moquette,

placer sous la cuisinière un tapis isolant ou une plaque de

contreplaqué de ¼" (0,64 cm).

IMPORTANT : Afin d’éviter d’endommager les placards, consulter

l’installateur ou le fabricant des placards pour déterminer si les matériaux

utilisés peuvent subir une décoloration, une déstratification ou d’autres

dommages. Ce four a été conçu conformément aux exigences des

normes UL et CSA International et respecte les températures maximales

permises de 194°F (90°C) pour les placards en bois.

A. 1³⁄16" (3,0 cm) de la table de

cuisson au sommet de l’évent

B. 297⁄8" (75,9 cm)

C. Plaque signalétique (située

derrière la porte du four, dans

le coin supérieur droit du

châssis)

D. 36" (91,4 cm) jusqu’à la

bordure de la table de

cuisson, pieds de nivellement

complètement rétractés*

E. 285⁄16" 71,9 cm) de profondeur

maximale de l’avant de la

console à l’arrière de la

cuisinière

F. 287⁄8" (73,3 cm) de profondeur

maximale entre la poignée et

l’arrière de la cuisinière

IMPORTANT : La cuisinière doit être d’aplomb après

l’installation. Suivre les instructions de la section “Réglage

de l’aplomb de la cuisinière”. Il n’est pas recommandé

d’utiliser la table de cuisson comme référence pour établir

l’aplomb de la cuisinière.

* La cuisinière peut être surélevée d’environ 1" (2,5 cm)

en ajustant les pieds de nivellement.

Résidence mobile – Spécifications additionnelles

à respecter lors de l’installation

L’installation de cette cuisinière doit être conforme aux dispositions

de la norme Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280 (anciennement Federal Standard for Mobile

Home Construction and Safety, Title 24, HUD Part 280). Lorsque cette

norme n’est pas applicable, l’installation doit satisfaire aux critères

de la norme Standard for Manufactured Home Installations, ANSI

A225.1/NFPA 501A ou aux dispositions des codes locaux.

Au Canada, l’installation de cette cuisinière doit satisfaire aux

stipulations de la version la plus récente de la norme CAN/CSA-A240

ou des codes locaux en vigueur.

Autres critères à respecter pour une installation en résidence

mobile :

■ Dans le cas de l’installation de cette cuisinière dans une

résidence mobile, la cuisinière doit être fixée au plancher durant

tout déplacement du véhicule. Toute méthode de fixation de

la cuisinière est adéquate dans la mesure où elle satisfait aux

critères des normes mentionnées ci-dessus.

■ Pour une installation en résidence mobile, un câble ou cordon

d’alimentation à quatre conducteurs doit être utilisé. Le câblage

de l’appareil devra être révisé. Voir la section “Raccordement

électrique”.

28

Page 29

Dimensions du placard

Les dimensions de l’ouverture entre les placards correspondent à une installation entre des placards de 25" (64,0 cm)

de profondeur, avec plan de travail de 24" (61,0 cm) de profondeur et de 36" (91,4 cm) de hauteur.

IMPORTANT : En cas d’installation d’une hotte ou d’un ensemble hotte/four à micro-ondes au-dessus de la cuisinière, suivre les

instructions fournies avec ces appareils concernant les dégagements à respecter au-dessus de la surface de la table de cuisson.

Une cuisinière peut être installée à côté de parois combustibles sans aucun espace.

REMARQUE : Lorsqu’une cuisinière encastrée est glissée dans une ouverture prévue à cet effet, l’avant de la porte du four peut

dépasser du meuble.

Découpe pour cuisinière encastrée Découpe pour cuisinière autoportante

B

C

B

C

D

D

M

A

E

L

F

H

I

J

G

K

J

A. 18" (45,7 cm) entre le placard latéral supérieur et le plan de travail

B. 13" (33 cm) de profondeur maximale du placard supérieur

C. 30" (76,2 cm) de largeur min. d’ouverture

D. Pour le dégagement minimum par rapport au dessus de la table

de cuisson, voir la REMARQUE*

E. Largeur min. d’ouverture 30" (76,2 cm)

F. Dégagement minimal de 3" (7,6 cm) entre l’un ou l’autre côté de la

cuisinière et la paroi latérale ou d’autres matériaux combustibles

G. Il est recommandé d’effectuer l’installation de la canalisation de gaz

rigide et de la prise reliée à la terre dans cette zone grisée

H. 203/8" (51,8 cm)

I. 7¹¹⁄16" (19,5 cm)

J. 4¹³⁄16" (12,2 cm)

K. 3¹¹⁄16" (9,4 cm) plus la mesure de M

L. La porte du placard ou ses charnières ne doit pas dépasser

à l’intérieur de l’ouverture

M. La profondeur restante du plan de travail ne doit pas dépasser

2¼" (5,7 cm)

* REMARQUE : Distance de séparation de 24" (61,0 cm) ou plus lorsque le fond d’un placard de bois ou de métal est protégé par une planche

ignifugée d’au moins ¼" (0,64 cm) recouverte d’une feuille métallique d’épaisseur égale ou supérieure à : acier calibre 28 MSG, acier inoxydable

0,015" (0,4 mm), aluminium 0,024" (0,6 mm) ou cuivre 0,020" (0,5 mm).

Distance de séparation minimale de 30" (76,2 cm) entre le dessus de la table de cuisson et le fond d’un placard de bois ou de métal non protégé.

A

E