Jenn-Air JDS8850BD, JDS9860BD, JDS9865BD Service Manual

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

Dual Fuel

Slide-In

Range

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

JDS8850BD*

JDS9860BD*

JDS9865BD*

16026929

February 2006

© 2006 Maytag Services

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however ,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMA TION BEFORE BEGINNING REP AIRS.

Important Notices for Servicers and Consumers

!

To avoid risk of severe personal injury or death, disconnect power and/or gas before working/servicing on

appliance to avoid electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

WARNING

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.JENNAIR.COM............................................. 1-800-536-6247

CAIR Center in Canada.......................................... 1-800-688-2002

Recognize Safety Symbols, Words, and Labels

DANGER!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16026929 © 2006 Maytag Services

Table of Contents

Important Information ................................................... 2

Important Safety Information

All Appliances .......................................................... 4

Surface Cooking Units............................................. 5

Safety Practices for Servicer .................................. 5

Servicing.................................................................. 5

Receiving Oven ........................................................ 5

Connecting Range to Gas ........................................ 6

Extension Cords....................................................... 6

Using the Oven......................................................... 6

Ovens ....................................................................... 6

Self-Cleaning Ovens ................................................ 6

Glass/Ceramic Cooking Surfaces ............................ 6

Ventilation Hoods ..................................................... 7

Surface Element Fire............................................... 7

Oven Fires ............................................................... 7

Precautions ............................................................. 7

Product Safety Devices ........................................... 7

General Information

Cooking Nomenclature............................................. 8

Specifications .......................................................... 9

Placement of the Oven............................................. 9

Do Not Block Air Vents ............................................ 9

Location of Model Number ....................................... 9

Model Identification.................................................. 9

Service .................................................................... 9

Parts and Accessories............................................. 9

Extended Service Plan............................................. 9

Range Description ................................................. 10

Troubleshooting Procedures

Troubleshooting Chart............................................ 11

Description of Fault Codes for EOC III .................. 13

Fault Code Chart.................................................... 13

Oven Sensor, Meat Probe and Cooling Fan

Temperature Charts............................................ 14

Testing Procedures

Component Testing Procedures............................. 15

Control Testing Procedures ................................... 18

Electronic Oven Control (EOC III)

Testing Procedures ............................................ 19

Relay Logic for EOC III ......................................... 22

“Quick Test” Mode for EOC III ............................... 23

Description of Fault Codes for EOC III .................. 24

Fault Code Chart.................................................... 24

Disassembly Procedures

Removing and Replacing Range ............................ 25

Front Side Trim Removal........................................ 25

Cartridge Assembly Removal (Select Models)........ 25

Maintop Assembly Removal ................................... 25

Top Burner Assembly Removal (Select Models) .... 25

Lower Burner Assembly Removal (Select Models). 25

Spark Module Replacement ................................... 26

Manifold Assembly Removal................................... 26

Control Panel Assembly Removal........................... 26

Electronic Control Replacement............................. 26

Burner Switch Replacement................................... 26

Meat Probe Receptacle Replacement .................... 26

Back Panel Removal .............................................. 26

Cooling Fan Replacement...................................... 27

Hidden Bake Element Replacement

(Select Models)................................................... 27

Bake Element Replacement (Select Models).......... 27

Broil Element Replacement .................................... 27

Downdraft Blower Motor Removal (Select Models). 27

Convection Motor Removal..................................... 27

Convection Element Replacement.......................... 27

Oven Sensor Replacement..................................... 28

Regulator Replacement .......................................... 28

Oven Light Bulb/Oven Light Socket Replacement .. 28

Oven Vent/Smoke Eliminator Removal ................... 28

Oven Hi-Limit Thermostat Replacement ................. 28

Oven Door Latch Replacement .............................. 28

Bottom Access Panel Removal (Select Models)..... 29

Warming Drawer Removal (Select Models) ........... 29

Warming Drawer Element Removal

(Select Models)................................................... 29

Warming Drawer Hi-Limit Switch Replacement

(Select Models)................................................... 29

Oven Door Removal ............................................... 29

Oven Door Hinge Removal ..................................... 29

Oven Door Disassembly ........................................ 29

Warming Drawer Disassembly .............................. 29

Warming Drawer Track Disassembly .................... 29

Oven Door, Warming Drawer and Access Panel

Disassembly (Illustration).................................... 30

Appendix A: Installation Instructions .........................A-2

Appendix B: Use and Care Information ....................B-2

Appendix C: LP Conversion Instructions

Model JDS8850BD*..............................................C-2

Models JDS986*BD*.............................................C-5

© 2006 Maytag Services 16026929 3

Important Safety Information

!

WARNING

To reduce the risk of the appliance tipping, it must be

secured by a properly installed anti-tip bracket(s). To

make sure bracket has been installed properly , remove

the storage drawer and look under the range with a

flashlight. Bracket(s) must be engaged in the rear

corner of the range.

As with all appliances, there are certain rules to follow for

safe operation. V erify everyone who operates oven is

familiar with the operations and with these precautions.

Use appliance only for its intended purpose as

described. Pay close attention to the safety sections of

this manual. Recognize the safety section by looking for

the symbol or the word safety .

• ALL RANGES CAN TIP

• INJURY TO PERSONS

COULD RESULT

• INSTALL ANTI-TIP

BRACKET(S) PACKED

WITH RANGE

• SEE INSTALLATION

INSTRUCTIONS

!

WARNING

To avoid personal injury, do not sit, st and or lean on

oven door or oven drawer.

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, make sure your range has been properly

grounded and always disconnect it from main power

supply before any servicing.

!

WARNING

This appliance contains or produces a chemical or

chemicals which can cause death or serious illness

and which are known to the state of California to

cause cancer, birth defects or other reproductive

harm. To reduce the risk from substances in the fuel or

from fuel combustion make sure this appliance is

installed, operated, and maintained according to the

instructions in this booklet.

To avoid risk of electrical shock, property damage,

personal injury, or death, verify wiring is correct, if

components were replaced. Verify proper and

complete operation of unit after servicing.

!

WARNING

Recognize this symbol as a safety precaution.

!

WARNING

!

If the information in this manual is not followed exactly ,

a fire or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other

appliance.

WHA T TO DO IF YOU SMELL GAS

• Extinguish any open flame.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call fire

department.

Installation and service must be performed by an

authorized installer , service agency or gas supplier .

ALL APPLIANCES

1. Proper Installation—Be sure your appliance is

properly installed and grounded by a qualified

technician.

2. Never Use Your Appliance for Warming or Heating

the Room.

3. Do Not Leave Children Alone—Children should not

be alone or unattended in the area where the

appliance is in use. They should never be allowed to

sit or stand on any part of the appliance.

4. Wear Appropriate Apparel—Loose fitting or hanging

garments should never be worn while using

appliance.

4 16026929 © 2006 Maytag Services

Important Safety Information

5. User Servicing—Do not repair or replace any part of

the appliance unless specifically recommended in the

manual. All other servicing should be referred to a

qualified technician.

6. Storage in or on Appliance—Flammable materials

should not be stored in an oven or near surface

units.

7. Do Not Use Water on Grease Fires—Smother fire or

flame, or use dry chemical or foam-type extinguisher.

8. Use Only Dry Potholders—Moist or damp potholders

on hot surfaces may result in burns from steam. Do

not let potholder touch elements. Do not use a towel

or other bulky cloth.

SURFACE COOKING UNITS

1. Use Proper Pan Size—This appliance is equipped

with one or more surface units of different size.

Select utensils having flat bottoms large enough to

cover the surface unit heating element. The use of

undersized utensils will expose a portion of the

heating element to direct contact and may result in

ignition of clothing. Proper relationship of utensil to

burner will also improve efficiency.

2. Never Leave Surface Units Unattended at High Heat

Settings—Boilover causes smoking and greasy

spillovers that may ignite.

3. Protective Liners—Do not use aluminum foil to line

oven bottom. Improper installation of these liners may

result in a risk of electrical shock or fire.

4. Glazed Cooking Utensils—Do not use glass, ceramic,

earthware, or other glazed utensils. They can

damage smoothtop and can break due to sudden

change in temperature.

5. Utensil Handles Should be Turned Inward and Not

Extend Over Adjacent Surface Units—T o reduce the

risk of burns, ignition of flammable materials, and

spillage due to unintentional contact with the utensil,

the handle of a utensil should be positioned so that it

is turned inward, and does not extend over adjacent

surface units.

NOTE: The maximum gas supply pressure for these

models must not exceed 14 inches W.C.P.

Safety Practices for Servicer

Safe and satisfactory operation of gas ranges depends

upon its design and proper installation. However , there is

one more area of safety to be considered:

Servicing

Listed below are some general precautions and safety

practices which should be followed in order to protect

the service technician and consumer during service and

after service has been completed.

1. Gas smell—Extinguish any and all open flames and

open windows.

2. Turn gas of f—Service range with gas turned off

unless testing requires it.

3. Checking for gas leaks—Never check for leaks with

any kind of open flame. Soap and water solution

should be used for this purpose. Apply solution to

suspected area and watch for air bubbles which

indicates a leak. Correct leaks by tightening fittings,

screws, connections, applying approved compound,

or installing new parts.

4. Using lights—Use a hand flashlight when servicing

ranges or checking for gas leaks. Electric switches

should not be operated where leaks are suspected.

This will avoid creating arcing or sparks which could

ignite the gas. If electric lights are already turned on,

they should not be turned off.

5. Do not smoke—Never smoke while servicing gas

ranges, especially when working on piping that

contains or has contained gas.

6. Check range when service is completed—After

servicing, make visual checks on electrical

connection, and check for gas leaks. Inform

consumer of the condition of range before leaving.

7. Adhere to all local regulations and codes when

performing service.

Receiving Oven

• Installer needs to show consumer location of the range

gas shut-off valve and how to shut it off.

• Authorized servicer must install the range, in

accordance with the Installation Instructions.

Adjustments and service should be performed only by

authorized servicer.

• Plug range into a 120–volt grounded outlet only . Do

not remove round grounding prong from the plug. If in

doubt about grounding of the home electrical system, it

is consumers responsibility and obligation to have an

ungrounded outlet replaced with a properly grounded

three-prong outlet in accordance with the National

Electrical Code. Do not use an extension cord with this

appliance.

• Insure all packing materials are removed from the

range before operating it, to prevent fire or smoke

damage should the packing material ignite.

• Ensure range is correctly adjusted by a qualified

service technician or installer for the type of gas

(Natural or LP). Some ranges can be converted for

use with Natural or LP gas.

• With prolonged use of a range, high floor

temperatures could result. Many floor coverings will not

be able to withstand this kind of use. Never install

range over vinyl tile or linoleum that cannot withstand

high temperatures. Never install range directly over

carpeting.

© 2006 Maytag Services 16026929 5

Important Safety Information

Connecting Range to Gas

Install manual shut-off valve in gas line for easy

accessibility outside range. Be aware of the location of

the shut-off valve.

Extension Cords

Do not use an extension cord with this product.

Using the Oven

• Do not leave children alone or unattended where a

range is hot or in operation. They could be seriously

burned.

• Do not allow anyone to climb, stand or hang on the

door . They could damage the range and cause severe

personal injury .

• Wear proper apparel. Loose fitting or hanging

garments should never be worn when using oven.

Flammable material could ignite if brought in contact

with flame or hot oven surfaces which may cause

severe burns.

• Never use range for warming or heating a room. This

may cause burns, injuries, or a fire.

• Do not use water on grease fires.

• Do not let grease or other flammable materials collect

in or around range.

• Do not repair or replace any part of range unless it is

recommended in this manual.

• Use only dry potholders. Moist or damp potholders

used on hot surfaces may result in a burn from steam.

Do not let a potholder touch the flame. Do not use a

towel or a bulky cloth as a potholder .

• Never leave range unattended while cooking. Boilovers

can cause smoking and may ignite.

• Only certain types of glass/ceramic, earthenware, or

other glazed utensils are suitable for oven use.

Unsuitable utensils may break due to sudden

temperature change.

• Use care when opening oven door. Let hot air or steam

escape before removing or replacing food.

• Do not heat unopened food containers in oven.

Build-up of pressure may cause a container to burst

and result in injury.

• Keep range vent ducts unobstructed.

• Place oven racks in desired location while oven is

cool. If a rack must be moved while oven is hot, use a

dry potholder .

• Do not use aluminum foil to line oven bottom or racks.

Aluminum foil can cause a fire which will seriously

affect baking results, and damage porcelain surfaces.

• Do not touch interior surfaces of oven during or

immediately after use. Do not let clothing or other

flammable materials come in contact with bake or broil

burners.

• Other areas of the oven can become hot enough to

cause burns, such as vent openings, window, oven

door and oven racks.

• T o avoid steam burns, do not use a wet sponge or cloth

to wipe up spills on hot cooking area.

• Do not store combustible or flammable materials, such

as, gasoline or other flammable vapors and liquids

near or in oven.

• Do not clean oven door gasket located on back of the

door. Gasket is necessary to seal the oven and can be

damaged as a result of rubbing or being moved.

• Do not drape towels or any materials on oven door

handles. These items may ignite causing a fire.

OVENS

1. Use Care When Opening Door—Let hot air or steam

escape before removing or replacing food.

2. Do Not Heat Unopened Food Containers—Buildup of

pressure may cause container to burst and result in

injury.

3. Keep Oven Vent Duct s Unobstructed.

4. Placement of Oven Racks—Always place oven racks

in desired location while oven is cool. If rack is

removed while oven is hot, do not let potholder

contact hot heating element in oven.

SELF-CLEANING OVENS

1. Do Not Clean Door Gasket—The door gasket is

essential for a good seal. Care should be taken not to

rub, damage, or move the gasket.

2. Do Not Use Oven Cleaners—No commercial oven

cleaner or oven liner protective coating of any kind

should be used in or around any part of the liner.

3. Clean Only Parts Listed in Manual.

4. Before Self-Cleaning the Oven—Remove broiler pan,

oven racks, and other utensils.

5. Remove all items from range top and backguard.

GLASS/CERAMIC COOKING SURFACES

1. Do Not Cook on Broken Cooktop—If cooktop should

break, cleaning solutions and spillovers may

penetrate the broken cooktop and create a risk of

electrical shock. Contact a qualified technician

immediately.

2. Clean Cooktop With Caution—If a wet sponge or

cloth is used to wipe spills on a hot cooking area, be

careful to avoid a steam burn. Some cleaners can

produce fumes if applied to a hot surface.

6 16026929 © 2006 Maytag Services

Important Safety Information

VENTILA TION HOODS

1. Clean Ventilation Hoods Frequently—Grease should

not be allowed to accumulate on hood or filter .

2. When flaming foods under hood, turn fan off. The

fan, if operating, may spread the flame.

Due to the nature of cooking, fires can occur as a result

of over cooking or excessive grease. Though a fire is

unlikely, if one occurs, proceed as follows:

Surface Element Fire

1. Smother the fire with a nonflammable lid or baking

soda, or use a Class ABC or BC extinguisher. Not

water. Not salt. Not flour .

2. As soon as it is safe to do so, turn the surface

controls to “OFF”.

Oven Fires

1. If you see smoke from your oven, do not open oven

door .

2. Turn oven control to “OFF”.

3. As an added precaution, turn off power at main

circuit breaker or fuse box.

4. Turn on vent to remove smoke.

5. Allow food or grease to burn itself out in oven. Do not

open oven door.

6. If smoke and fire persist, call fire department.

7. If there is any damage to components, call an

authorized servicer .

Precautions

• Do not cook food directly on range top surface, always

use cookware.

• Do not mix household cleaning products. Chemical

mixtures may interact with objectionable or even

hazardous results.

• Do not put plastic items on warm cooking areas. They

may stick and melt.

• Do not slide rough objects across range top surface.

Scratching or metal marking can result.

• Do not use cookware with rough bottoms. They may

scratch smoothtop surface. Glass and ceramic

cookware should not be used.

• Do not use damp sponge or dishcloth to clean range

top. A film of soil-laden detergent water may collect on

range top. If this should happen, Amana Cleaning

Conditioning Cream removes this type of stain.

• Do not leave fat heating unless you remain nearby. Fat

can ignite if overheated by spilling onto hot surfaces.

• Do not allow pots to boil dry as this can cause damage

to cooking surface and pan.

• Do not use range top surface as a cutting board.

• Do not use range for storage or as a display counter.

Product Safety Devices

Safety devices and features have been engineered into

the product to protect consumer and servicer. Safety

devices must never be removed, bypassed, or altered in

such a manner as to defeat the purpose for which they

were intended.

Listed below are various safety devices together with the

reason each device is incorporated in the gas ranges.

Pressure Regulator Maintains proper/steady

gas pressure oven

controls. Regulator must

be set for the type of

gas being used, either

Natural or LP.

After servicing regulator,

make certain it is set

properly before

completing service.

Gas Burner Orifices Universal orifices are

used on most valves.

They must be adjusted

or set for the type of gas

being used Natural or

LP.

After servicing a valve or

orifice verify it is

adjusted properly before

completing service.

Grounded Oven Frame Ground prong on power

cord is connected to the

frame, usually a green

lead fastened by a

screw. In addition, any

part or component

capable of conducting

an electric current is

grounded by its

mounting.

If any ground wire,

screw, strap, nut, etc. is

removed for service, or

any reason, it must be

reconnected to its

original position with

original fastener before

the appliance is put into

operation again.

Failure to do so can

create a possible shock

hazard.

© 2006 Maytag Services 16026929 7

General Information

This manual provides basic instructions and suggestions

for handling, installing and servicing dual fuel ranges.

The directions, information, and warnings in this manual

are developed from experience with, and careful testing

of the product. If the unit is installed according to this

manual, it will operate properly and will require minimal

This manual contains information needed by authorized

service technicians to install and service dual fuel ranges.

There may be, however, some p arts which need further

explanation. Refer to the Installation Instructions, Use

and Care, Technical Sheets or the toll-free technical

support line.

servicing. A unit in proper operating order ensures the

consumer all the benefits provided by clean, modern gas

surface cooking and electric baking.

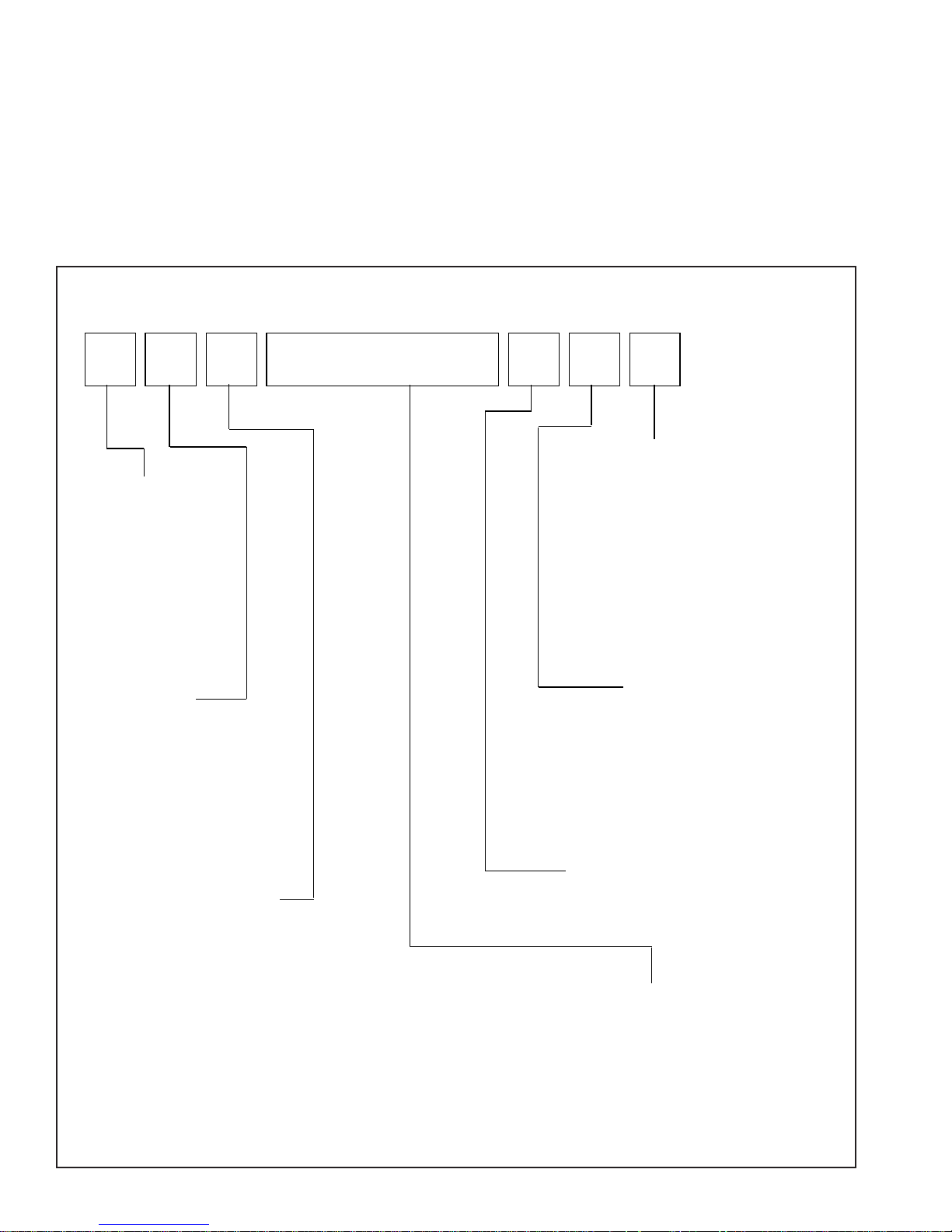

Cooki n g N o m en clature

J D S 9 8 6 5 B D P

A Almond on Almond

Brand

A Amana

C Magic Chef

G Graffer &

Sattler

H Hardwick

J Jenn-Air

M Maytag

N Norge

U Universal

Y Crosley

Fuel

B Butane

D Dual Fuel

E/J Electric

G Gas, Natural

L Liquid Propane

M Microwave

P Standing Pilot

X No Fuel

W Warming Drawer

Product Type

A Accessory/Cartridge

C Cooktop Updraft/Countertop

D Downdraft Cooktop or Warming Drawer

E Eyelevel Range

G Grill

L Range (20")

M Range (36")

P Drop In (24")

Q Wall Oven (27")

R Range, Free-Standing (30")

S Slide-In (30")

T Range Hood

V OTR

W Wall Oven

Y RV Range

ZRV Top

B Black

C Brushed Chrome

H Traditional White

L Traditional Almond

P Prostyle

Q Monochromatic Bisque

S Stainless

T Traditional Bisque

W White on White

F Frost White (True Color White)

N Natural Bisque (True Color Bisque )

A UL/AGA

C CSA/CGA/CUL

D Dual Listed

G 220-240 V / 50-60 Hz

M Military Model

P PSB Approved

X Exp ort 120 V / 60 Hz

This identifies the

production version.

1000-3999 Brands

4000-6999 Maytag/Amana

7000-9999 Jenn-Air

Color

Listing

(Singapore)

Produc t ion Code

Feature Content

8 16026929 © 2006 Maytag Services

General Information

Specifications

Refer to individual Technical Sheet for specification

information.

Placement of the Oven

This freestanding range must be placed in the kitchen or

comparable room. All safety guidelines must be followed

and free air flow around the range is essential.

Do Not Block Air Vents

All air vents must be kept clear during cooking. If air

vents are covered during operation, the oven may

overheat. If this occurs, a sensitive, thermal safety device

automatically removes power to the oven, rendering the

oven inoperable. The oven will remain in this state until it

has sufficiently cooled.

Location of Model Number

T o request service information or replacement p arts, the

service center will require the complete model, serial, and

manufacturing number of your slide-in range. The

number can be found on the oven frame behind the

storage/warming drawer . Slide the drawer open to

access the oven frame and view the data.

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an

authorized servicer:

• For Jenn-Air product call 1-800-462-9824 or visit the

Web Site at www.jennair .com

• For product inCanada call 1-800-688-2002 or visit the

Web Site at www.jennair .com

Warranty service must be performed by an authorized

servicer . We also recommend contacting an authorized

servicer, if service is required af ter warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. T o order accessories for your product call:

• For Jenn-Air product call 1-800-536-6247 or visit the

Web Site at www.jennair .com

• For product inCanada call 1-800-688-2002 or visit the

Web Site at www.jennair .com

Extended Service Plan

We offer long-term service protection for this new oven.

• Dependability PlusSM Extended Service Plan is

specially designed to supplement Jenn-Air’s strong

warranty. This plan covers parts, labor, and travel

charges.

Call 1-800-925-2020 for information.

Model Number

Access Panel

Model Identification

Complete enclosed registration card and promptly return.

If registration card is missing:

• For Jenn-Air product call 1-800-536 -6247 or visit the

Web Site at www.jennair .com

• For product inCanada call 1-800-688-2002 or visit the

Web Site at www.jennair .com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

© 2006 Maytag Services 16026929 9

Range Description

Range Description

Burner Control Valves

Electronic Control

Touchpad

Bake Element

Oven Light

Top Surface

Burners and Grates

Top Surface

Burners and Grates

Burner Control Valves

Oven Cavity

Broil Element

Convection Fan

Pressure Regulator

(Back side

of Range)

Warming

Drawer

Rating Label

Model Number

10 16026929 © 2006 Maytag Services

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury, or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

WARNING

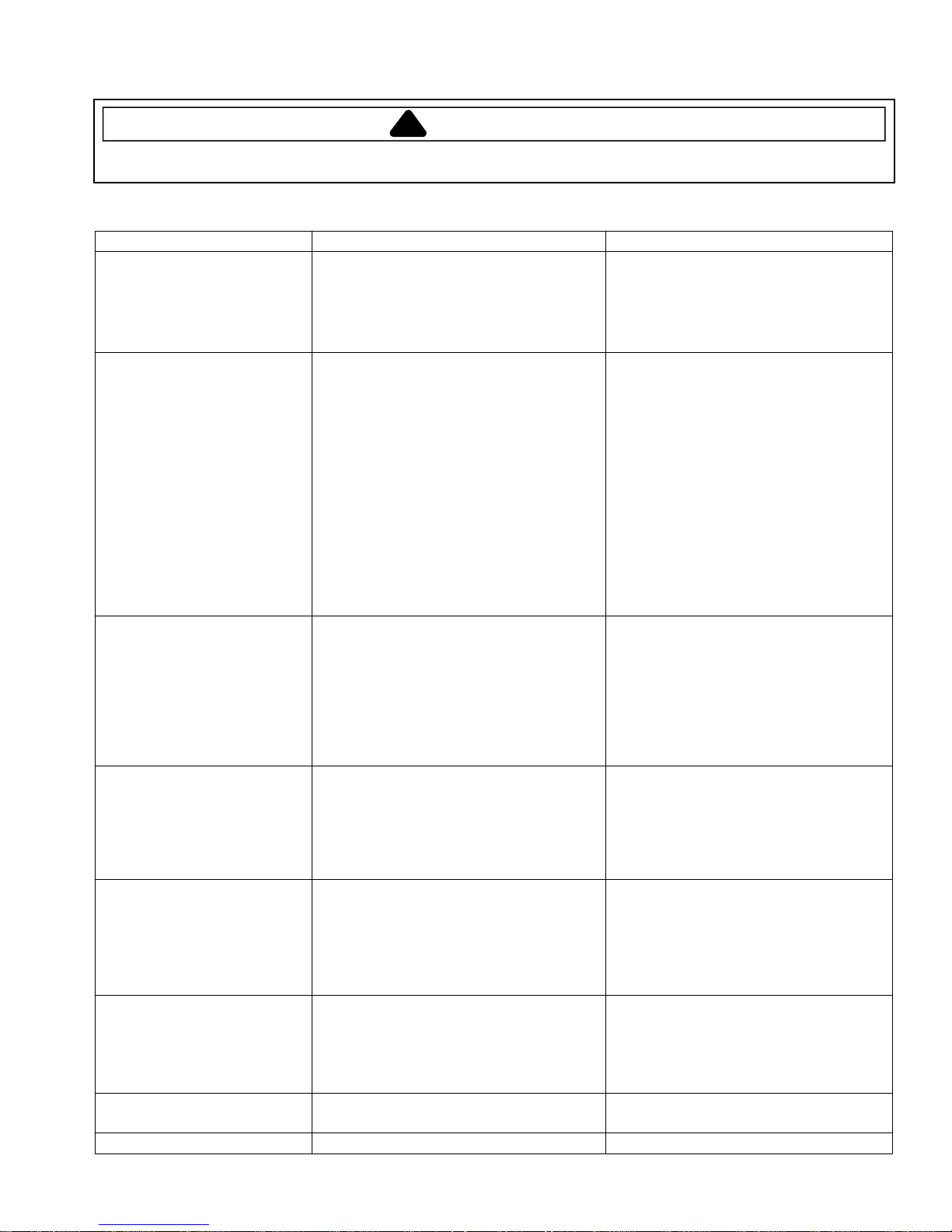

Troubleshooting Chart

Problem Possible Cause Correction

Poor ground on burner cap .......................

Burners will not ignite; no

spark at top burner.

Burner will not ignite. No

spark to burner ignitors

when burner knob is rotated

to "LITE" position.

No spark or only random

spark at one ignitor.

Unit continues to spark after

knob is turned to OFF

position.

No oven operation in bake or

broil.

No bake element operation Open bake element...................................

Oven smokes/odor first few

times of usage.

Failure Codes. Electronically Controlled ...........................

Weak or failed spark module ....................

Low gas pressure......................................

Clogged burner port ..................................

No 120 VAC to range................................

Micro switch contacts not closing .............

Faulty wiring. Bad connection at burner

electrode and electrode socket.................

Inoperative spark module .........................

Electrode dirty. Burner cap dirty ...............

Cracked or broken electrode, electrode

wire or electrode socket ............................

Check for cracked ignitor or pinched

ignitor wire ................................................

Poor continuity to burner cap....................

Bad ground connection or lack of

continuity to ground or ignitor ...................

Cracked or broken ignitor extension

lead ...........................................................

Shorted valve switch/harness ...................

Switch has slipped off the valve................

No voltage to control. ................................

No voltage from control .............................

Loose wire connection or broken wire ......

Loose wire connection or broken wire ......

Open bake relay........................................

Normal ......................................................

• Clean burner cap.

• Replace spark module.

• Verify pressure 4" WCP for natural,

10" WCP for LP.

• Clean burner cap.

• Verify voltage at wall outlet.

• Check wiring against appropriate

wiring diagram. Verify all terminals

and connections are correct and

tight. Check micro switch contacts.

• Check wiring against appropriate

wiring diagram. Verify all terminals

and connections are correct and

tight.

• Check module according to testing

procedures information.

• Clean electrode or burner cap.

• Replace electrode.

• Replace ignitor lead or electrode.

• Clean burner cap and lead.

• Tighten ground connection and

correct any breaks in ground path

from ignitor path to unit ground path.

• Replace ignitor lead.

• Replace switch/harness. If shorting

is caused by excessive spillovers,

customer education is advised.

• Carefully reposition switch on valve

and rotate from OFF to high, several

times to verify switch is not broken.

• Check for 120 VAC at control. If no

voltage check power source.

• Check 120 VAC to ignitor, if no

voltage, replace control.

• Verify all connections are clean and

tight, replace broken wire.

• Check element for continuity,

replace if failed.

• Verify all connections are clean and

tight, replace broken wire.

• Verify 240 VAC at bake element.

• Minor smoking and/or odor is normal

the first few times of oven usage.

• See "Fault Code Chart."

© 2006 Maytag Services 16026929 11

Troubleshooting Procedures

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

!

To avoid risk of electrical shock, personal injury, or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

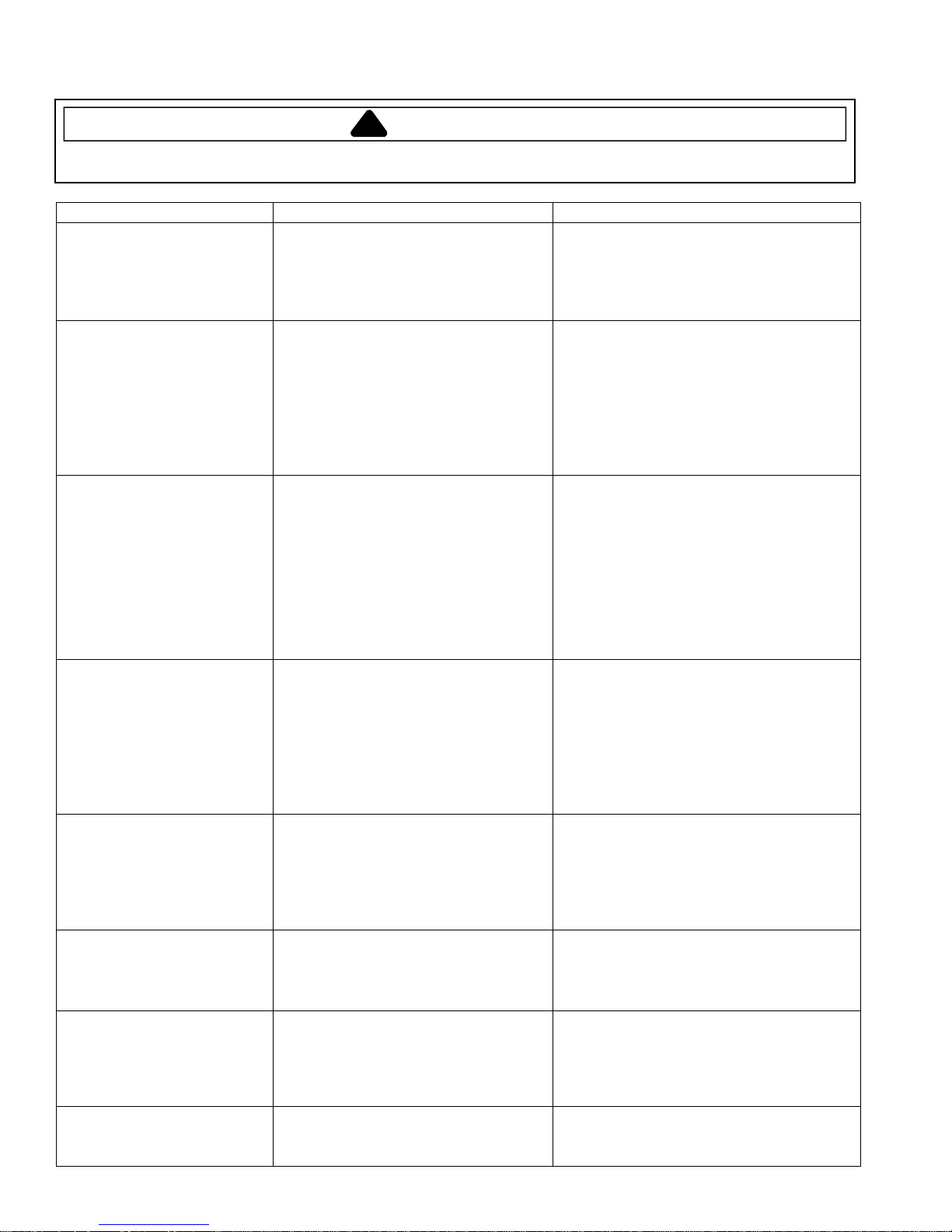

Problem Possible Cause Correction

No broil element operation Open broil element................................

Loose wire connection or broken wire ..

Open broil relay.....................................

Failed ignitor..........................................

Gas pressure too high...........................

No gas flows to burner.

Ignitor glows red.

Fan motor does not operate.

Oven not operating.

Clock and timer not working.

Oven light does not operate.

Oven door will not unlock. Oven is self-cleaning.............................

Self-clean cycle not working.

Failed gas valve ....................................

Loose wire connection or broken wire ..

No power to fan motor ..........................

Failed fan motor or winding/frozen

shaft ......................................................

Programming error ................................

Power outage ........................................

Unit in Sabbath mode ...........................

Power outage ........................................

Electronic Control locked ......................

Failed oven lamp...................................

Failed wiring ..........................................

Failed light socket .................................

Oven is still hot......................................

Programming error ................................

Door lock ...............................................

WARNING

• Check element for continuity, replace if

failed.

• Verify all connections are clean and

tight, replace broken wire.

• Verify 240 VAC at broil element.

• Check ignitor current draw, 3.2 – 3.6

Amps. Replace ignitor, if it fails test.

• Check for correct gas pressure. Natural

gas pressure should be 4" WCP and LP

gas pressure should be 10" WCP.

• Check gas valve for continuity.

• Verify all connections are clean and

tight, replace broken wire.

• Check for 120 VAC supplied at fan

motor. If no voltage is present, check

for broken or loose wiring between fan

motor and relay board. If voltage is

present at fan motor, go to the next

step.

• Check motor winding for continuity.

Check for a frozen motor shaft. Check

for broken wiring between motor and

neutral terminal block.

• Switch circuit breaker off to oven for five

minutes and try oven again.

• Verify power is present at unit and

circuit breaker is not tripped.

• Replace household fuse, but do not

fuse capacity.

• Refer to Use & Care manual and

remove unit from Sabbath mode.

• Verify power is present at unit and

circuit breaker is not tripped.

• Replace household fuse, but do not

fuse capacity.

• Refer to Use and Care manual and

unlock electronic control.

• Check lamp and replace as necessary.

• Check for broken, loose or dirty

connections.

• Check light socket for continuity.

• Allow cycle to complete.

• Will not unlock until unit has cooled to

safe temperature. Forcing door open

voids warranty. Blow cool air on door

latch area to quicken process.

• Turn off circuit breaker for five minutes

and try oven again.

• Verify door lock energizes & engages.

12 16026929

© 2006 Maytag Services

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

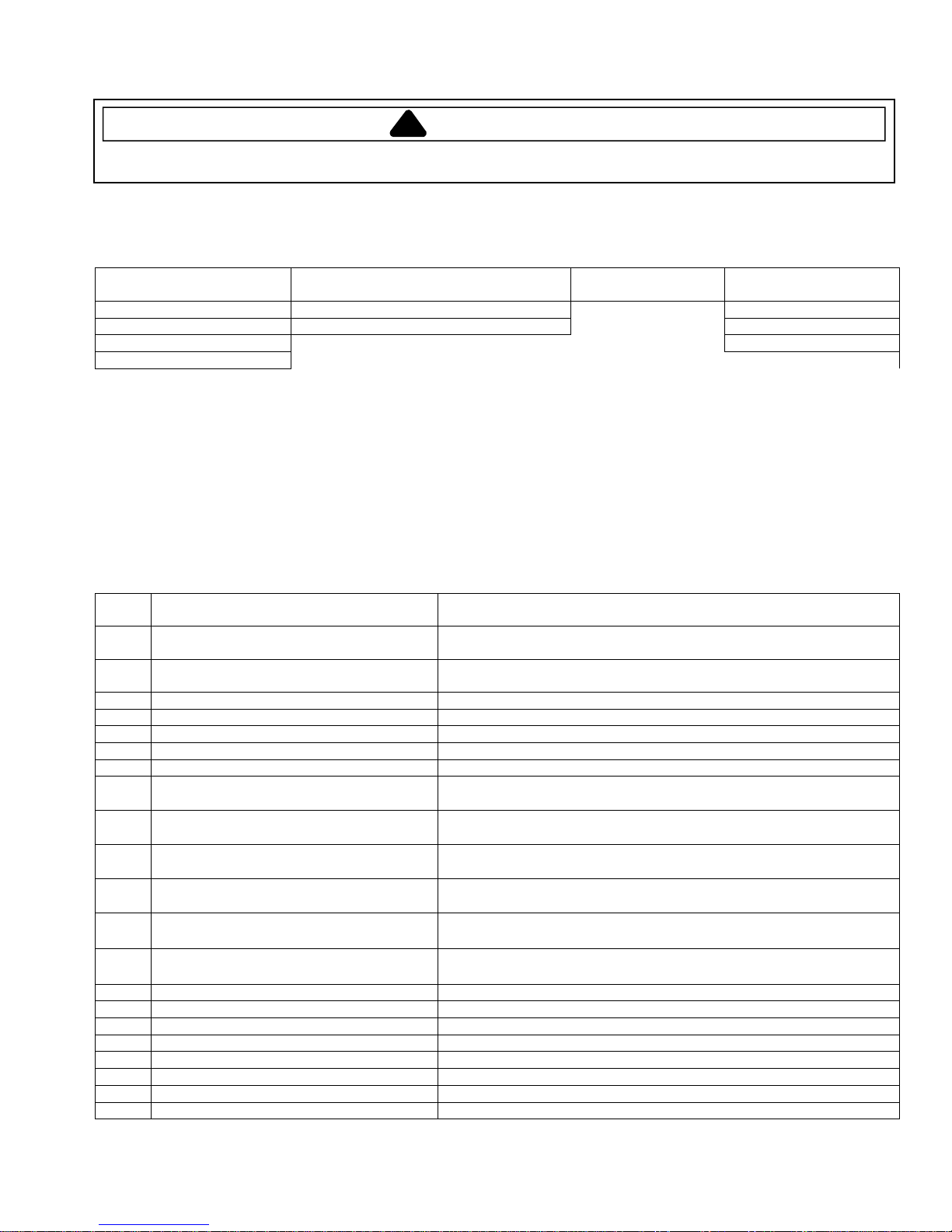

Description of Fault Codes for EOC III

Each fault code consists of 4 digits and is structured as follows:

1st (Leftmost) Digit:

Primary Failure System

1 – Local to Control System d – Diagnostic Failure (measurable)

3 – Sensor or Meat Probe c – Control-Related Error (not measurable)

4 – Input to Control System

9 – Door Lock

2nd Digit: Alpha-Character 3rd Digit: Secondary

Failure Mechanism

4th Digit : Oven

Cavity Number

1 – Upper (Single) Oven

2 – Lower Oven

c – Control System

If a fault is detected, then one of the following three messages will be scrolled on the display:

FAULT DETECTED PRESS ENTER TO TRY AGAIN. This message displays when a fault is detected while a

cooking function is active. Clear by pressing the Cancel keypad.

FEATURE NOT AVAILABLE. This message displays when a fault is detected while entering data during initial

programming and also when a locked out function is detected. Clear by pressing any key.

FAULT DETECTED DISABLE POWER TO CLEAR. This message displays when a runaway temperature condition

is detected while the control is in idle mode. Press any key to clear the message, but the fault remains until the

control senses a Power-On reset.

Fault Code Chart

Fault

Code

1c1c Shorted key.

1c2c Membrane keyboard disconnected.

1c4c Board – to – Board communication failure. Replace control.

1c6c EEPROM hardware fault. Replace control.

1c7c Control not calibrated. Replace control.

1c8c EEPROM CRC error – User Options. Replace control.

1c81 EEPROM CRC error – Cook Profile. Replace control.

1d11 Unlocked runaway temperature – 600° F

1d21 Locked runaway temperature – 950° F

3d11 Temperature sensor open.

3d21 Temperature sensor shorted.

3d41 Meat probe shorted.

3d51 Meat probe not calibrated.

4d11 Door switch not closed when locked. Check connections, switch, harness, and motor. If OK, replace control.

4d21 No cooling fan rotation. Check cooling fan motor and harness. If OK, replace control.

4d31 Cooling fan on when de-energized. Check cooling fan motor and harness. If OK, replace control.

4d41 Cooling fan overspeed. Check cooling fan motor and harness. If OK, replace control.

4d51 Door switch circuit fault. Check connections, harness, and motor. If OK, replace control.

9d11 Latch will not lock. Check wire connections. If OK, replace motorized door lock.

9d21 Latch will not unlock. Check wire connections. If OK, replace motorized door lock.

9d31 Latch both locked and unlocked. Check wire connections. If OK, replace motorized door lock.

Description Component to Troubleshoot/Replace

Ensure ribbon cable is securely connected, inspect ribbon cable and

connector (shorts, breakage, corrosion, etc.). If OK, replace control.

Ensure ribbon cable is securely connected, inspect ribbon cable and

connector (shorts, breakage, corrosion, etc.). If OK, replace control.

Ohm sensor and harness (see "Oven Sensor" chart). If OK, change

control.

Ohm sensor and harness (see "Oven Sensor" chart). If OK, change

control.

Check connections, sensor (see "Oven Sensor" chart) and harness. If

OK, replace control.

Check connections, sensor (see "Oven Sensor" chart) and harness. If

OK, replace control.

Check probe jack and harness. If OK, check meat probe (see "Meat

Probe" chart).

Check probe jack and harness. If OK, check meat probe (see "Meat

Probe" chart).

© 2006 Maytag Services 16026929 13

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury, or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

WARNING

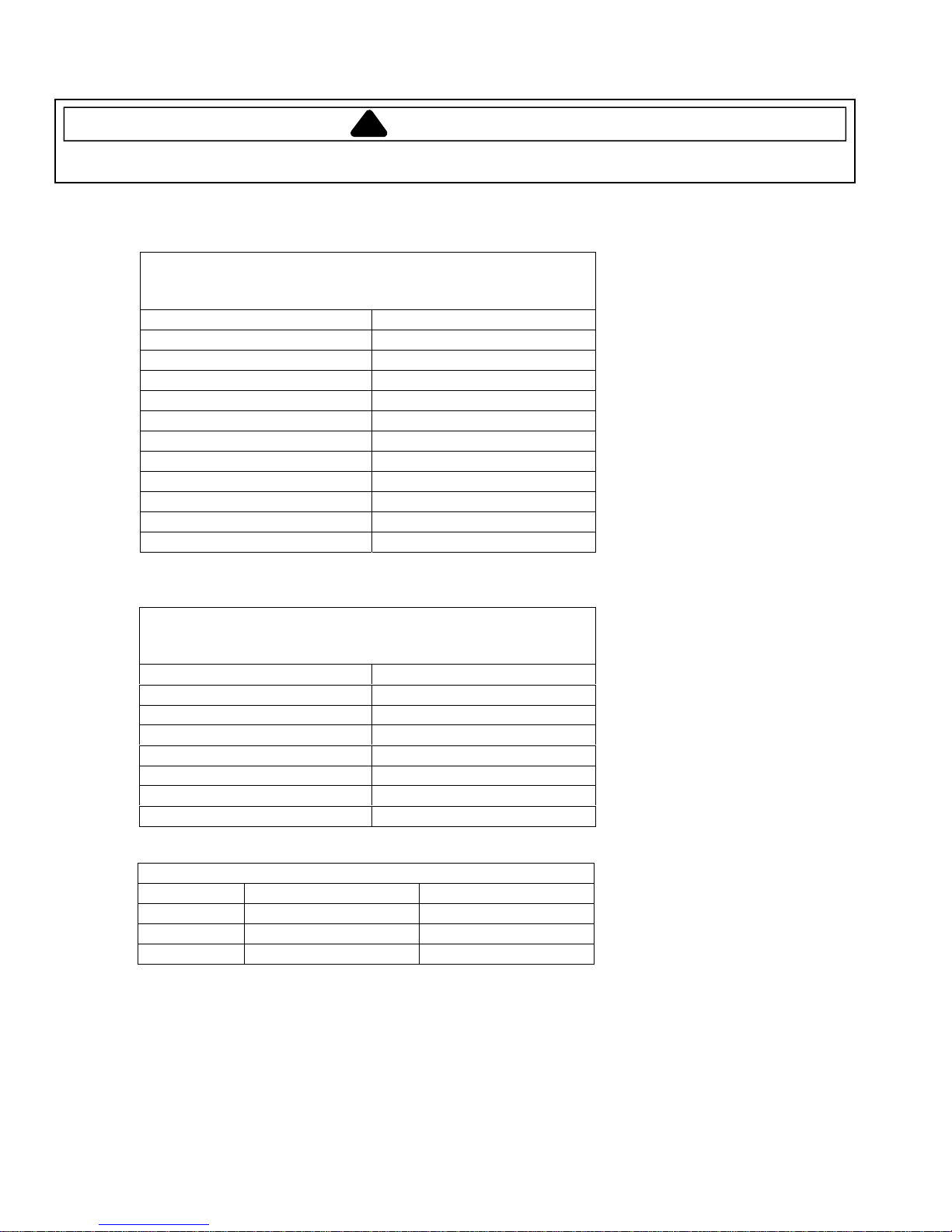

Oven Sensor, Meat Probe and Cooling Fan Temperature Charts

Sensor Type: RTD 1000Ω platinum

Calibration: 1654 Ω (350° F / 177° C)

Temperature F (C) Resistance (Ohms)

100 (38) 1143

200 (94) 1350

300 (149) 1553

350 (177) 1654

400 (204) 1753

500 (260) 1949

600 (316) 2142

700 (371) 2331

800 (427) 2516

900 (483) 2697

1000 (538) 2874

Type: NTC Thermistor

Calibration: 9938 Ω (150° F / 65.5° C)

Temperature F (C) Resistance (Ohms)

32 (0) 163300

68 (20) 62450

95 (35) 32660

122 (50) 18020

158 (70) 8760

185 (85) 5360

212 (100) 3400

MODE FAN ON TEMP F (C) FAN OFF TEMP F (C)

Bake 300 (148.9 C) 275 (135 C)

Broil Immediately 275 (135 C)

Clean Immediately 275 (135 C)

COOLING FAN TEMPERATURES

OVEN SENSOR

MEAT PROBE

14 16026929

© 2006 Maytag Services

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

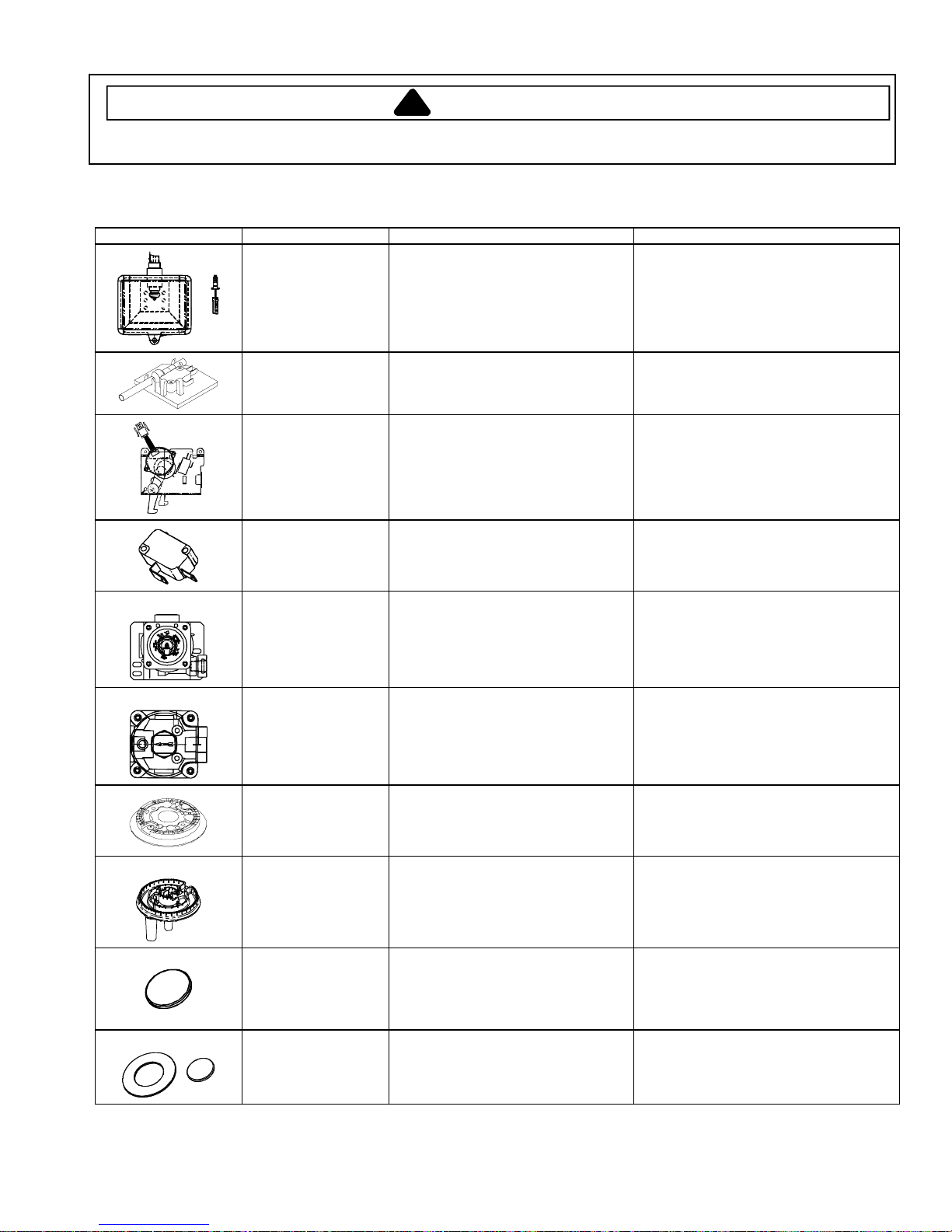

Component Testing Procedures

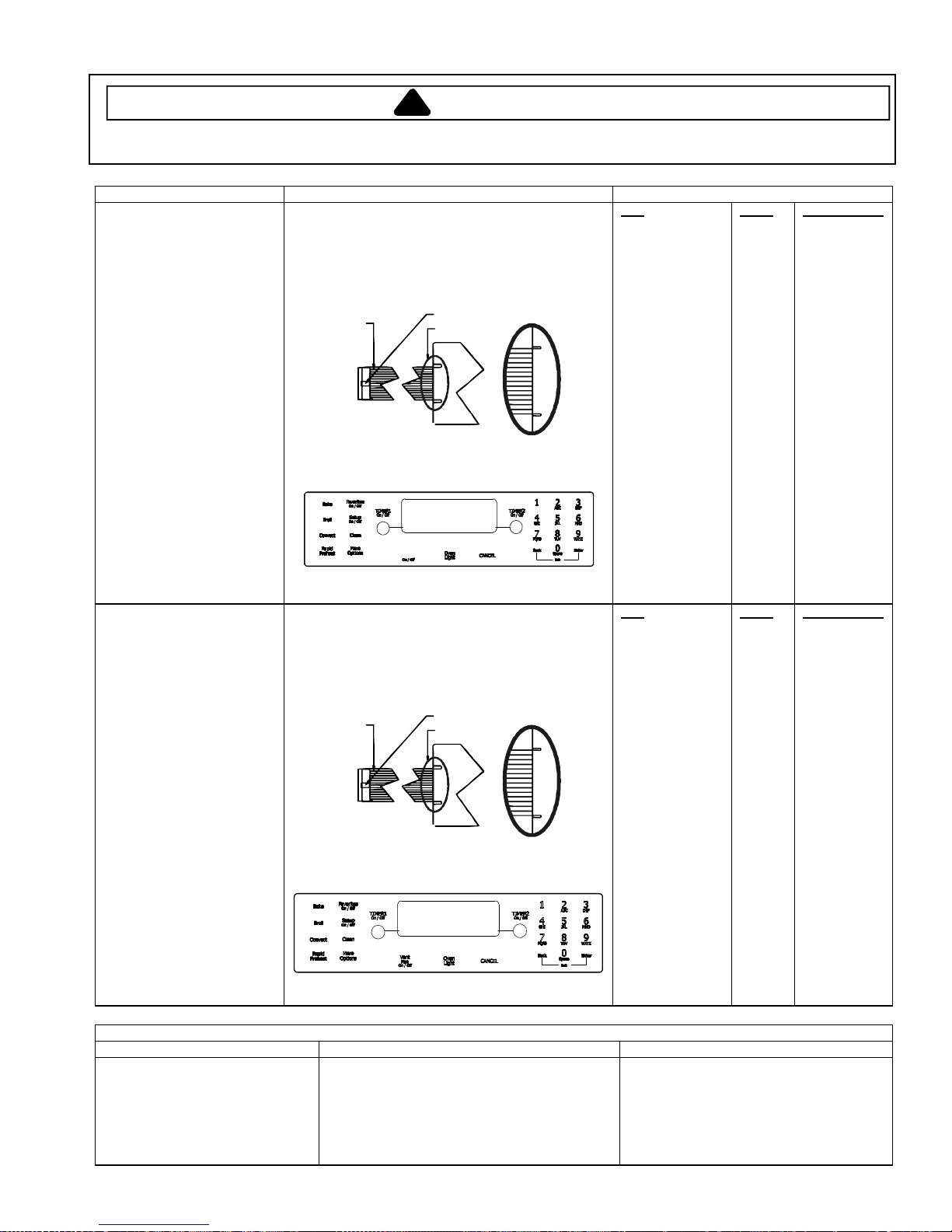

Illustration Component Test Procedure Results

C

(JDS8850BD*)

N

O

O

M

Oven light & housing Disconnect connector and test

resistance of terminals...........................

Measure voltage at oven light................

Door plunger switch Remove switch from unit and measure

the following points:

Door closed........................................

Door open..........................................

Autolatch assembly Disconnect wires and test for

continuity per wiring diagram..................

Refer to Parts Manual for correct

autolatch switch associated with the

correct manufacturing number.

Door lock switch Switch connection in the following

positions:

Door latch locked................................

Door latch unlocked ............................

Pressure regulator Verify gas pressure (W.C.P.). .................

If on LP service verify proper gas

supply conversion.

Verify bulb is properly inserted.

Continuity with bulb inserted.

120 VAC, see wiring diagram for terminal

identification.

If voltage is not present at oven light,

check wiring or light switches.

COM-NO= Continuity (closed)

COM-NO= Infinity (open)

See wiring diagram for schematic layout.

Common is in neutral position unless

locking or unlocking autolatch assembly.

COM-NO= Continuity (closed)

COM-NO= Infinity (open)

5" Natural

10" LP/propane

(JDS986*BD*)

(JDS8850BD*)

(JDS8850BD*)

Pressure regulator Verify gas pressure (W.C.P.). .................

5" Natural

10" LP/propane

If on LP service verify proper gas

supply conversion.

Top surface burner

5 K btu

9.2 K btu

16 K btu

Top surface,

dual burner

15 K btu

Verify gas is supplied.............................

Verify cap is positioned correctly ...........

Verify gas is supplied.............................

Verify cap is positioned correctly ...........

Gas supplied.

Check for obstructions in burner ports.

Gas supplied.

Check for obstructions in burner ports.

Inner: 3 K btu

Outer: 12 K btu

Top surface,

Verify cap is positioned correctly ........... Check for obstructions in burner ports.

burner cap

5 K btu

9.2 K btu

16 K btu

Top surface,

Verify cap is positioned correctly ........... Check for obstructions in burner ports.

burner cap, dual

(inner and outer

burners)

©2005 Maytag Services 16026929 15

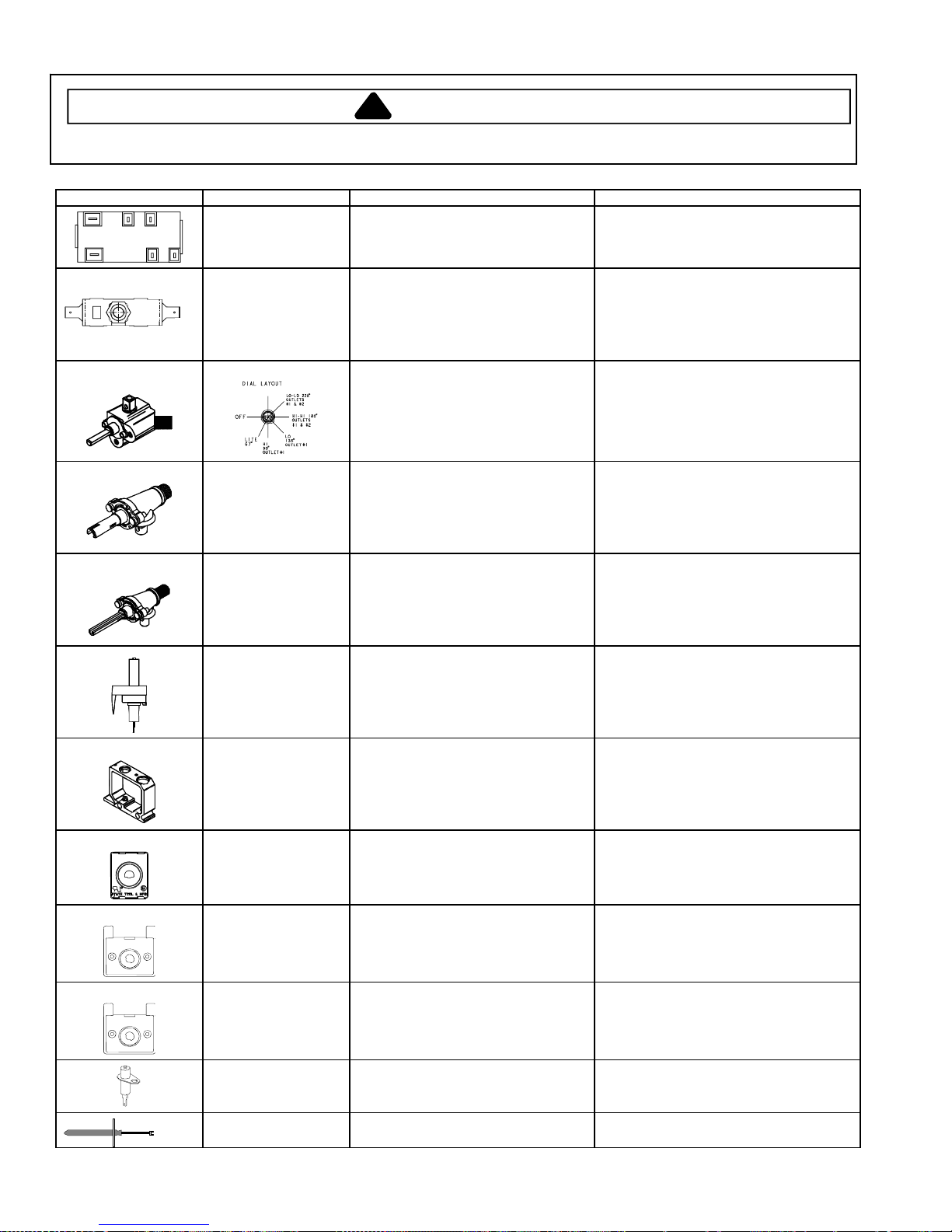

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

Illustration Component Test Procedure Results

L

(JDS8850BD*)

(JDS986*BD*)

AB

A1

B1N

Spark module 4 + 0 Test for voltage at terminals L and N .....

Check polarity and ground .....................

Snap switch

(pan switch)

NOTE: Downdraft

fan will not engage

if this switch is not

Test for voltage at terminals ...................

Disconnect wiring and check for

continuity in LITE position ......................

activated.

Dual burner valve

Verify gas is supplied .............................

Orifices adjusted for

Natural or LP.

Burner valve,

push-to-turn, 270°

5 K btu

9.2 K btu

16 K btu

Burner valve,

push-to-turn, 270°,

E-burner

Verify gas is supplied .............................

Orifice adjusted for

Natural or LP.

Adjust set screw for simmer control.

Verify gas is supplied .............................

Orifice adjusted for

Natural or LP.

Orifice holder

5 K btu

9.2 K btu

16 K btu

Adjust set screw for simmer control.

Verify gas pressure ................................

Check orifice for debris ..........................

120 VAC

See wiring diagram.

120 VAC

Continuity in LITE position.

Gas supplied.

Gas supplied.

Gas supplied.

5" Natural

10" LP/propane

Clean as needed.

(JDS8850BD*)

(JDS8850BD*)

(JDS986*BD*)

(JDS986*BD*)

Orifice holder,

dual burner

12 K btu

3 K btu

Verify gas pressure ................................

Check orifice for debris ..........................

5" Natural

10" LP/propane

Clean as needed.

Spark switch Test for voltage at terminals ...................

Disconnect wiring and check for

continuity in LITE position ......................

Spark switch Test for voltage at terminals ...................

Disconnect wiring and check for

continuity in LITE position ......................

120 VAC

Continuity in LITE position.

120 VAC

Continuity in LITE position.

Double valve switch Test for voltage at terminals...................

Disconnect wiring and check for

continuity in LITE position ......................

120 VAC

Continuity in LITE position.

Spark ignition

electrode

Test for resistance of spark lead ............

Test ignitor to chassis ............................

Continuity

No continuity from ignitor to chassis.

Temperature sensor Measure resistance................................ Approx 1000 Ω at room temperature,

75° F (23.8° C).

16 16026929 © 2006 Maytag Services

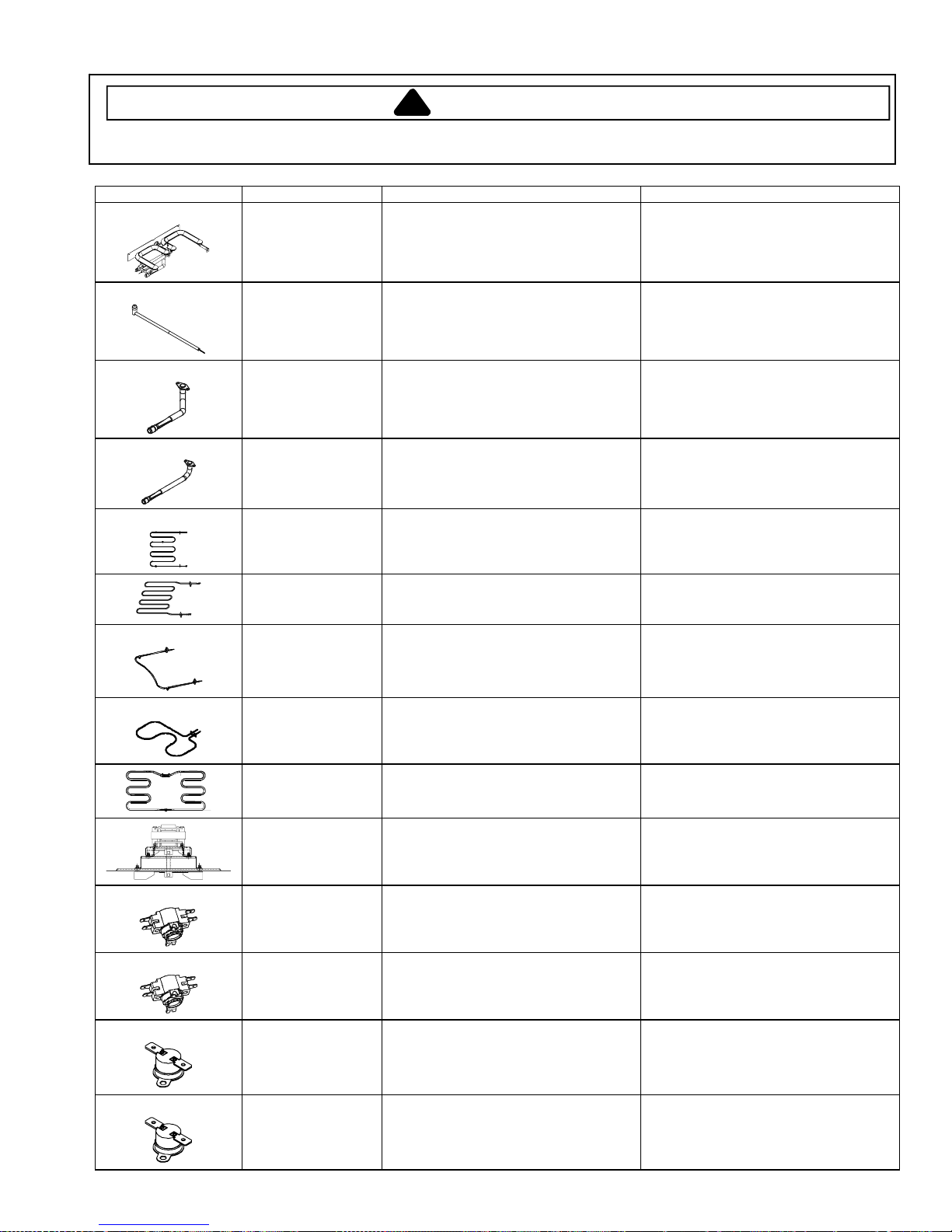

Testing Procedures

.

.

.

.

.

.

.

.

.

.

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

Illustration Component Test Procedure Results

(JDS986*BD*)

E-burner assembly Verify gas is supplied .................................Gas supplied,

Check for obstructions in burner ports.

(JDS986*BD*)

E-burner ignitor Test for resistance of spark lead ...............

Test ignitor to chassis................................

Continuity.

No continuity from ignitor to chassis.

(JDS986*BD*)

(JDS986*BD*)

(JDS8850BD*)

(JDS986*BD*)

(JDS8850BD*)

(JDS8850BD*)

(JDS986*BD*)

(JDS8850BD*)

E-burner tube, front Nominal air shutter setting.........................

Tolerance ..................................................

E-burner tube, rear Nominal air shutter setting.........................

Tolerance ..................................................

Hidden bake

element

Disconnect wiring to element and

measure cold resistance of terminals........

Measure voltage at bake element..............

Broil element Disconnect wiring to element and

measure cold resistance of terminals........

Measure voltage at broil element ..............

Bake element Disconnect wiring to element and

measure cold resistance of terminals........

Measure voltage at bake element..............

Warmer element Disconnect wiring to element and

measure cold resistance of terminals........

Measure voltage at broil element ..............

Convection element Disconnect wiring to element and

measure cold resistance of terminals........

Convection motor,

2-speed

Measure voltage at convect element.........

Measure voltage........................................

Check motor windings to ground ...............

Oven limit switch Normally closed, verify operation:

Open: 209° to 221° F (98° to 105° C) ......

Closed: 144° to 166° F (62° to 74° C) .....

Oven limit switch Normally closed, verify operation:

Open: 253° to 267° F (123° to 131° C) ....

Closed: 188° to 212° F (87° to 100° C) ...

Hi-limit temperature

switch

(Warming Drawer)

Normally closed, verify operation:

Open: 135° to 145° F (57° to 63° C) ........

Closed: 114° to 126° F (46° to 52° C) .....

.250 1/4"

.031 Approx. 1/32"

.250 1/4"

.031 Approx. 1/32"

Approx. 20 Ω.

240 VAC.

Approx. 12.5 to 18 Ω.

240 VAC.

Approx. 22 Ω.

240 VAC.

Approx. 12.5 to 18 Ω.

120 VAC.

Approx. 16.5 Ω.

240 VAC.

120 VAC. (tolerance: 105 to 135 VAC)

No continuity.

RPM, Lo-speed: Approx. 1440 to 2040

RPM, Hi-speed: Approx. 1860 to 2460

Infinite.

Continuity.

Infinite.

Continuity.

Infinite.

Continuity.

(JDS8850BD*)

Hi-limit temperature

switch

(Warming Drawer)

© 2006 Maytag Services 16026929 17

Normally closed, verify operation:

Open: 95° to 105° F (35° to 41° C)..........

Closed: 79° to 91° F (26° to 33° C) .........

Infinite.

Continuity.

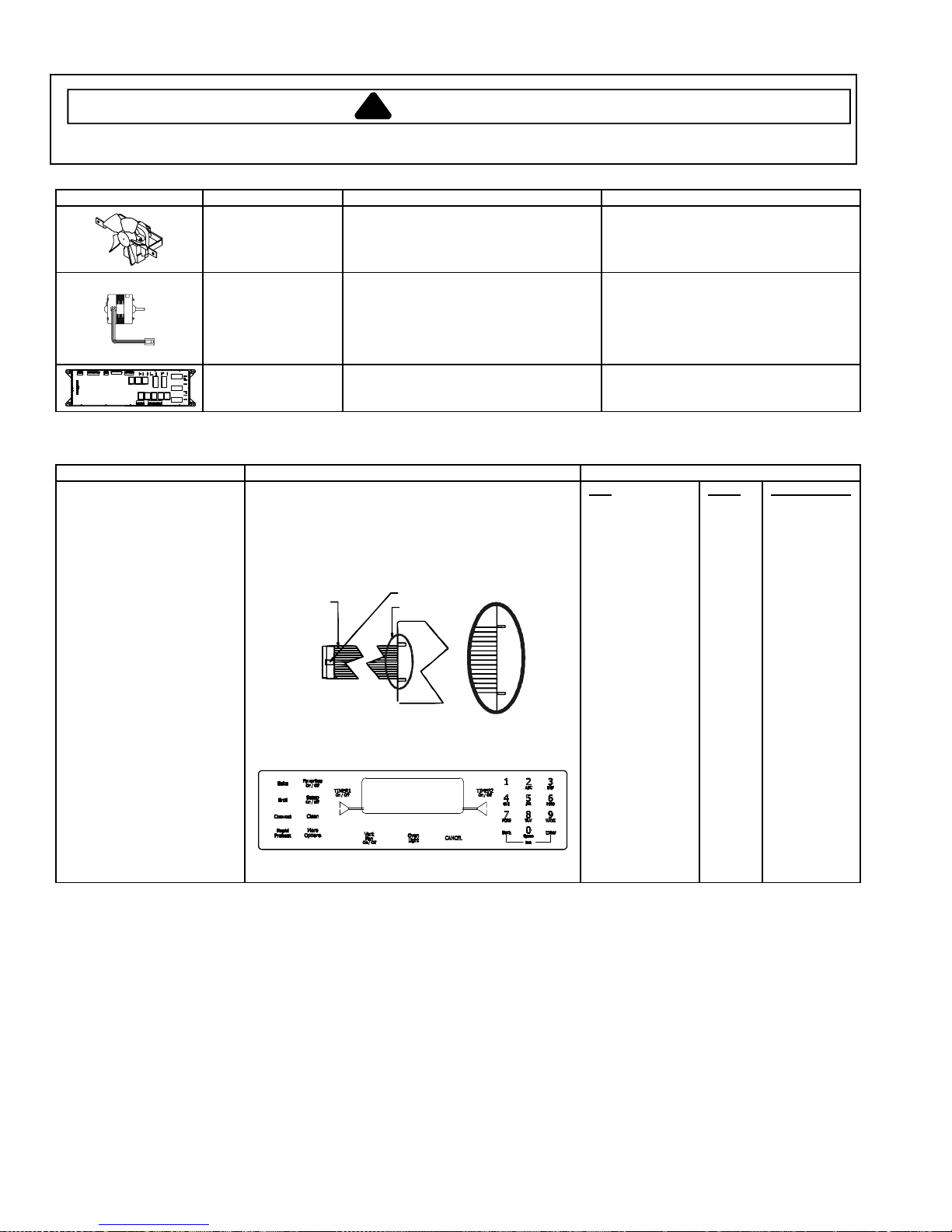

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

Illustration Component Test Procedure Results

Cooling fan motor Measure voltage ........................................

Check motor windings to ground................

120 VAC.

No continuity.

RPM: Approx. 1670 to 2070

AMPERAGE: Approx. .22

120 VAC.

No continuity.

RPM: 1550

AMPERAGE: Approx. 2.4

(JDS986*BD*)

Downdraft motor

NOTE: Downdraft

fan will not engage

if pan (snap)

switch is not

Measure voltage ........................................

Check motor windings to ground................

activated.

Electronic control NOTE: To avoid equipment damage,

use caution when checking electronic

control circuitry voltages.

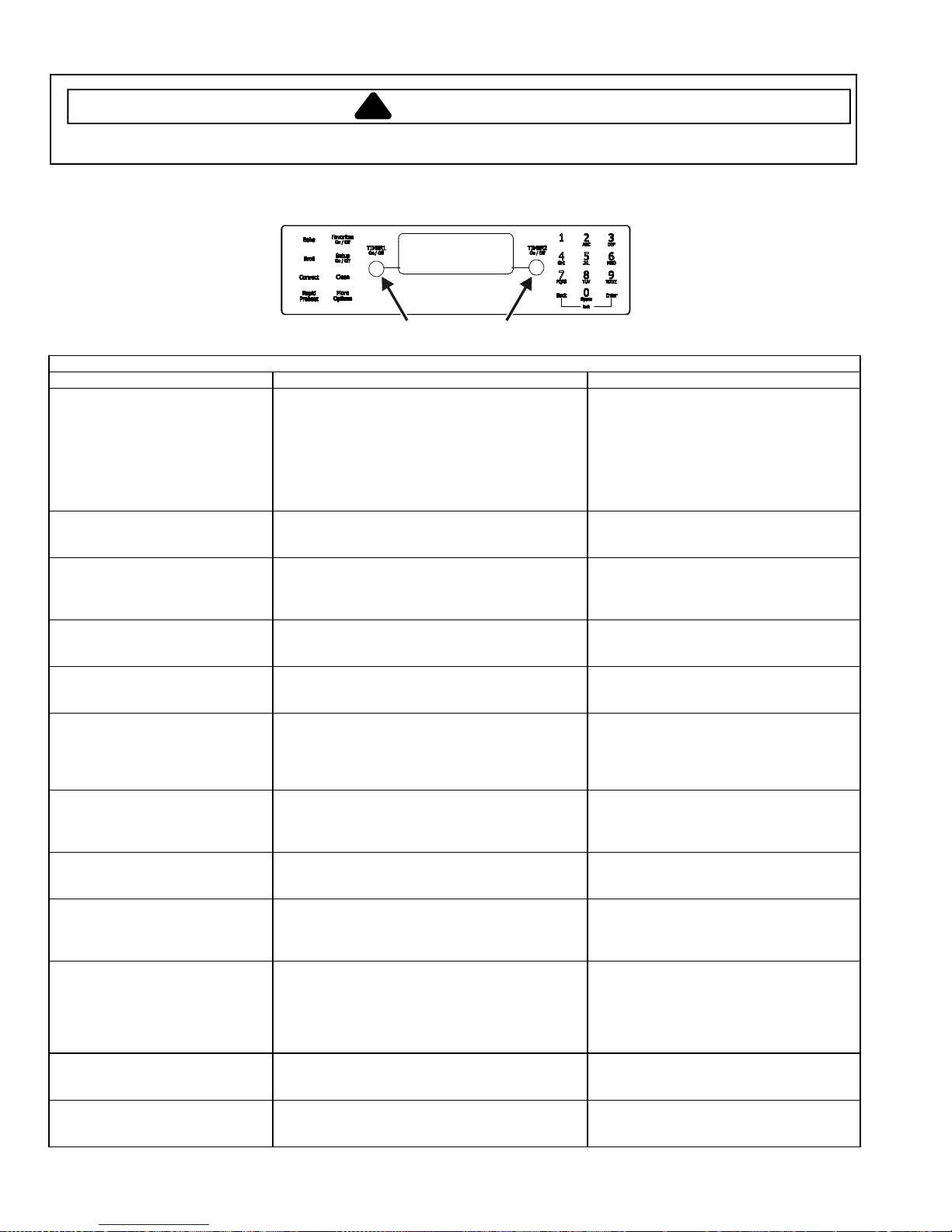

Control Testing Procedures

Control Component Test Procedure Results

Switch membrane assembly

JDS9865BD*

Closed circuitry resistance

(defined as continuity): 2000 Max Ω

Pins 1 & 7 are shorted together for control

configuration purposes

Trace # 1

Latch

See Detail B

Detail B

Pad

1

2

3

4

5

6

7

8

9

0

Cancel

Bake

Broil

Convect

Clean

Favorites

Rapid Preheat

Vent Fan

More Options

Setup

ATM 1

ATM 2

Back

Enter

Timer 1

Timer 2

Oven Light

Trace

2 & 7

2 & 8

2 & 9

2 & 10

2 & 11

2 & 12

3 & 6

3 & 7

3 & 8

2 & 6

4 & 9

4 & 10

4 & 11

5 & 9

5 & 7

4 & 12

5 & 10

5 & 11

5 & 8

5 & 6

4 & 6

4 & 7

3 & 9

3 & 10

3 & 11

3 & 12

4 & 8

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

18 16026929 © 2006 Maytag Services

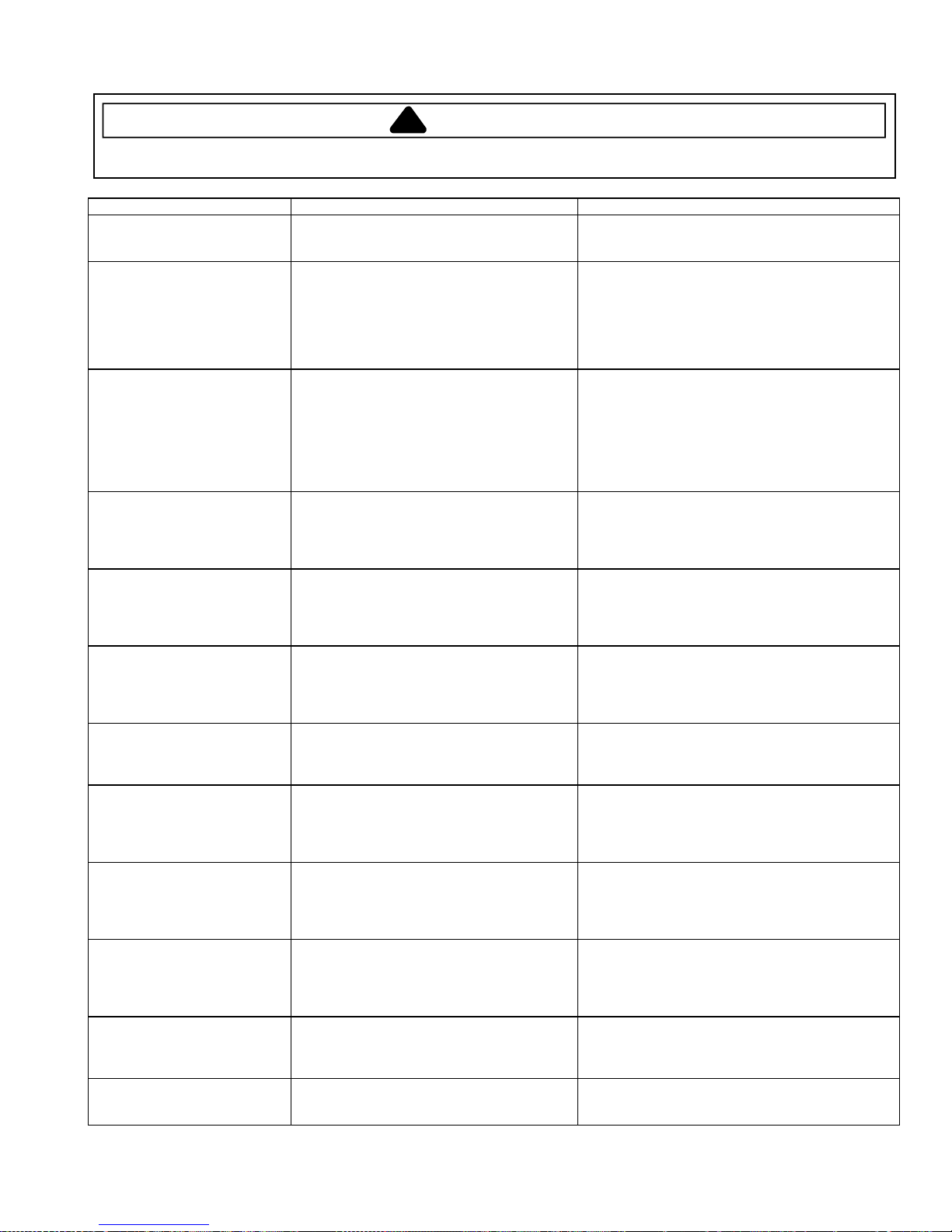

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

Control Component Test Procedure Results

Switch membrane assembly

JDS8850BD*

Switch membrane assembly

JDS9860BD*

Closed circuitry resistance

(defined as continuity): 2000 Max Ω

Pins 1 & 7 are shorted together for control

configuration purposes

Trace # 1

Latch

See Detail B

Detail B

Warm

Drawe r

Closed circuitry resistance

(defined as continuity): 2000 Max Ω

Pins 1 & 7 are shorted together for control

configuration purposes

Trace # 1

Latch

See Detail B

Detail B

Pad

1

2

3

4

5

6

7

8

9

0

Cancel

Bake

Broil

Convect

Clean

Favorites

Rapid Preheat

Warming Drawer

More Options

Setup

ATM 1

ATM 2

Back

Enter

Timer 1

Timer 2

Oven Light

Pad

1

2

3

4

5

6

7

8

9

0

Cancel

Bake

Broil

Convect

Clean

Favorites

Rapid Preheat

Vent Fan

More Options

Setup

ATM 1

ATM 2

Back

Enter

Timer 1

Timer 2

Oven Light

Trace

2 & 7

2 & 8

2 & 9

2 & 10

2 & 11

2 & 12

3 & 6

3 & 7

3 & 8

2 & 6

4 & 9

4 & 10

4 & 11

5 & 9

5 & 7

4 & 12

5 & 10

5 & 11

5 & 8

5 & 6

4 & 6

4 & 7

3 & 9

3 & 10

3 & 11

3 & 12

4 & 8

Trace

2 & 7

2 & 8

2 & 9

2 & 10

2 & 11

2 & 12

3 & 6

3 & 7

3 & 8

2 & 6

4 & 9

4 & 10

4 & 11

5 & 9

5 & 7

4 & 12

5 & 10

5 & 11

5 & 8

5 & 6

4 & 6

4 & 7

3 & 9

3 & 10

3 & 11

3 & 12

4 & 8

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

ELECTRONIC OVEN CONTROL III TESTING/PROGRAMMING PROCEDURES

Feature Access Procedure Modification Procedure

Control Reset

Resets control to factory default

values.

Press the Setup pad, then press the right ATM

pad until SERVICE displays. Press the left

ATM pad to select SERVICE menu options.

Press and hold the Back and Enter pads

for 5 seconds to enter SERVICE menu

options. Press the right ATM pad to scroll

to CONTROL RESET. Press the left ATM

pad to select CONTROL RESET, then

press the left ATM pad again to reset the

control logic. Press Setup to exit.

© 2006 Maytag Services 16026929 19

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

Electronic Oven Control (EOC) III Testing Procedures

Warm

Drawer

ELECTRONIC OVEN CONTROL III TESTING/PROGRAMMING PROCEDURES

Feature Access Procedure Modification Procedure

Oven Temperature Adjustm ent

Determines oven cavity offset

temperature (range from -35° F to

+35° F, or -21° C to +21° C).

Time Options

Determines control time, day of

week, 12/24 hour clock.

Time Set

Determines time of day (Monday

thru Sunday) to display on control.

Day of Week

Determines day of week (Monday

thru Sunday) to display on control

12/24-Hour Clock Display

Determines 12-hour or 24-hour

clock display on control.

Clock & Day Display Disable

Determines if time of day and day

of week will display on control.

Language Display

Determines language display on

control (English, French, or

Spanish).

C/F (Celsius/Fahrenheit) Display

Determines temperature display

on control (C or F).

Auto Convection

When enabled, reduces the

Convection Bake and Pastry

temperatures by 25° F (-3.9° C).

Sabbath Mode

Bases on the Jewish guidelines for

Sabbath/Holiday requirements.

Tone Options

Determines cook tones, timer tones

and volume settings.

12-Hour Shutoff

Disables 12-hour shutoff, allowing

the oven to operate indefinitely.

ATM PADS

Press the Setup pad, then press the right ATM

pad until TEMP ADJUST displays. Press the left

ATM pad to select oven TEMP ADJUSTMENT

settings.

Press the Setup pad, then the left ATM pad to

select TIME OPTIONS.

Press the Setup pad, then the left ATM pad, then

the left ATM pad again to set the time of day

clock.

Press the Setup pad, then the left ATM pad, then

press the right ATM pad until DAY displays. Press

the left ATM pad to select the day.

Press the Setup pad, then the left ATM pad, then

press the right ATM pad until 12/24HR displays.

Press the left ATM pad to select 12/24 HR clock.

Press the Setup pad, then press the right ATM

pad until DISABLE displays. Press the left ATM

pad to select DISABLE settings.

Press the Setup pad, then press the right ATM

pad until LANGUAGE displays. Press the left

ATM pad to select LANGUAGE settings.

Press the Setup pad, then press the right ATM

pad until C/F displays. Press the left ATM pad to

select C/F settings.

Press the Setup pad, then press the right ATM

pad until AUTO CONVECT displays. Press the

left ATM pad to select AUTO CONVECT settings.

Press the Setup pad, then press the right ATM

pad until SABBATH displays. Press the left ATM

pad to select SABBATH settings.

Press the Setup pad, then press the right ATM

pad until TONES displays. Press the left ATM pad

to select TONES options.

Press the Setup pad, then press the right ATM

pad until 12HR Shutoff displays. Press the left

ATM pad to select 12-HOUR SHUTOFF settings.

Enter the offset temperature setting desired

using the digits pads. Press the right ATM

pad for + temperature adjustment, or the

left ATM pad for – temperature adjustment.

Press 0 to reset control back to no

temperature adjustment. Wait 3 seconds

for the control to accept the request. Press

Setup to exit.

Press the right ATM pad to scroll to the

desired function to modify.

Enter the correct time using the digits pads

and press Enter. Press the left ATM pad

to select AM or the right ATM pad to select

PM. Press Setup to exit.

Press the right ATM pad until the correct

day displays, then press the left ATM pad

to select. Press Setup to exit.

Press the left ATM pad to select 12-hour

clock, or the right ATM pad to select 24hour clock. Press Setup to exit.

Press the left ATM pad to select TIME, or

the right ATM pad to scroll to DAY, then

press the left ATM pad. Press the left ATM

pad to turn display on or the right ATM pad

to turn display off. Press Setup to exit.

Press the right ATM pad until the correct

language displays (English, French or

Spanish), then press the left ATM pad.

Press Setup to exit.

Press the left ATM pad to select Celsius or

the right ATM pad to select Fahrenheit.

Press Setup to exit.

Press the left ATM pad to turn on auto

convect, or the right ATM pad to turn off

auto convect. Press Setup to exit.

Press the left ATM pad to select Manual

Sabbath mode, or the right ATM pad to

select Auto Sabbath mode. Press the left

ATM pad to turn on Sabbath mode, or the

right ATM pad to turn off Sabbath mode.

Press Setup to exit.

Press the right ATM pad to scroll to the

desired tone to modify.

Press the left ATM pad to turn on 12-hour

shutoff, or the right ATM pad to turn off 12hour shutoff. Press Setup to exit.

20 16026929 © 2006 Maytag Services

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

208/240 V Setting

Determines range operating

voltage (208 or 240 VDC).

Cook Tones

Determines the number and

duration of cook time reminder

chimes.

Timers Tones

Determines the number and

duration of timer reminder

chimes.

Volume

Determines volumes of cook

and timer tones.

Energy Saver Mode

Enables a 1 watt standby

feature. If no pad is pressed

within 5 minutes, the control

enters a sleep mode.

Demo Mode

Enables a 1 watt standby

feature. If no pad is pressed

within 5 minutes, the control

enters into a sleep mode.

Service Mode

Enables access to service

menus.

Test Access

Enables access to service

menus.

Faults Access

Displays the 10 most recent

faults produced by the

controller.

Software Versions Access

Displays the software and

EEPROM revision levels.

Display Test

Illuminates all lamps on the

control.

Control Lockout

Disables the keypad control

and locks the oven cavity door.

Feature Access Procedure Modification Procedure

Press the Setup pad, then press the right

ATM pad until 208/240 displays. Press the

left ATM pad to select 208/240 V settings.

Press the Setup pad, then press the right

ATM pad until TONES displays. Press the

left ATM pad. Press the left ATM pad again

to select COOK TONES settings.

Press the Setup pad, then press the right

ATM pad until TONES displays. Press the

left ATM pad. Press the right ATM pad to

scroll to TIMERS TONES. Press the left ATM

pad to select TIMERS TONES settings.

Press the Setup pad, then press the right

ATM pad until TONES displays. Press the

left ATM pad to select VOLUME settings.

Press the Setup pad, then press the right

ATM pad until ENERGY SAVER displays.

Press the left ATM pad to select ENERGY

SAVER mode settings.

Press the Setup pad, then press the right

ATM pad until DEMO displays. Press the left

ATM pad to select DEMO mode settings.

Press the Setup pad, then press the right

ATM pad until SERVICE displays. Press the

left ATM pad to select SERVICE menu

options.

Press the Setup pad, then press the right

ATM pad until SERVICE displays. Press the

left ATM pad to select SERVICE menu

options.

Press the Setup pad, then press the right

ATM pad until SERVICE displays. Press the

left ATM pad to select SERVICE menu

options.

Press the Setup pad, then press the right

ATM pad until SERVICE displays. Press the

left ATM pad to select SERVICE menu

options.

Press the Setup pad, then press the right

ATM pad until SERVICE displays. Press the

left ATM pad to select SERVICE menu

options.

Press the Back and Setup pads

simultaneously for 5 seconds to lock.

Press the left ATM pad to select 208 VDC, or the

right ATM pad to select 240 VDC. Press Setup to

exit.

Press the left ATM pad to select 1 – 30 (1 chime

every 30 seconds after the initial 4 chimes), or

press the right ATM pad to scroll to 1 – 60 (1 chime

every 60 seconds after the initial 4 chimes) or 1

BEEP (no additional chimes after the initial 4

chimes). Press the left ATM pad to select the

desired setting. Press Setup to exit.

Press the left ATM pad to select 2 – 30, or 2

chimes every 30 seconds for up to 5 minutes (after

the initial chime), or press the right ATM pad to

scroll to 2 – 60, or 2 chimes every 60 seconds for

up to 30 minutes (after the initial chime), or 1 BEEP

(no additional chimes after the initial chime). Press

the left ATM pad to select the desired setting.

Press Setup to exit.

Press the right ATM pad until VOLUME displays.

Press the left ATM pad. Press the left ATM pad to

select HIGH, or the right ATM pad to scroll to

MEDIUM or LOW. Press the left ATM pad to select

desired setting. Press Setup to exit.

Press the left ATM pad to enter the energy saver

mode or the right ATM pad to exit the energy saver

mode. Press Setup to exit.

Press the left ATM pad to enable the DEMO mode

or the right ATM pad to exit the DEMO mode.

Once the DEMO mode begins, press any key to

exit. Press Setup to exit, also.

Press and hold the Back and Enter pads for 5

seconds to enter SERVICE menu options. Press

Setup to exit.

Press and hold the Back and Enter pads for 5

seconds to enter SERVICE menu options. Press

the right ATM pad to scroll to TEST menu. Press

the left ATM pad to select TEST options. Press

Setup to exit.

Press and hold the Back and Enter pads for 5

seconds to enter SERVICE menu options. Press

the right ATM pad to scroll to the FAULTS menu.

Press the left ATM pad to select FAULTS options.

Press Setup to exit.

Press and hold the Back and Enter pads for 5

seconds to enter SERVICE menu options. Press

the right ATM pad to scroll to the VERSIONS

menu. Press the left ATM pad to view. Press

Setup to exit.

Press and hold the Back and Enter pads for 5

seconds to enter SERVICE menu options. Press

the right ATM pad to scroll to DISPLAY TEST.

Press the left ATM pad. Press Setup to exit.

Press the Back and Setup pads simultaneously for

5 seconds to unlock.

© 2006 Maytag Services 16026929 21

Testing Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

WARNING

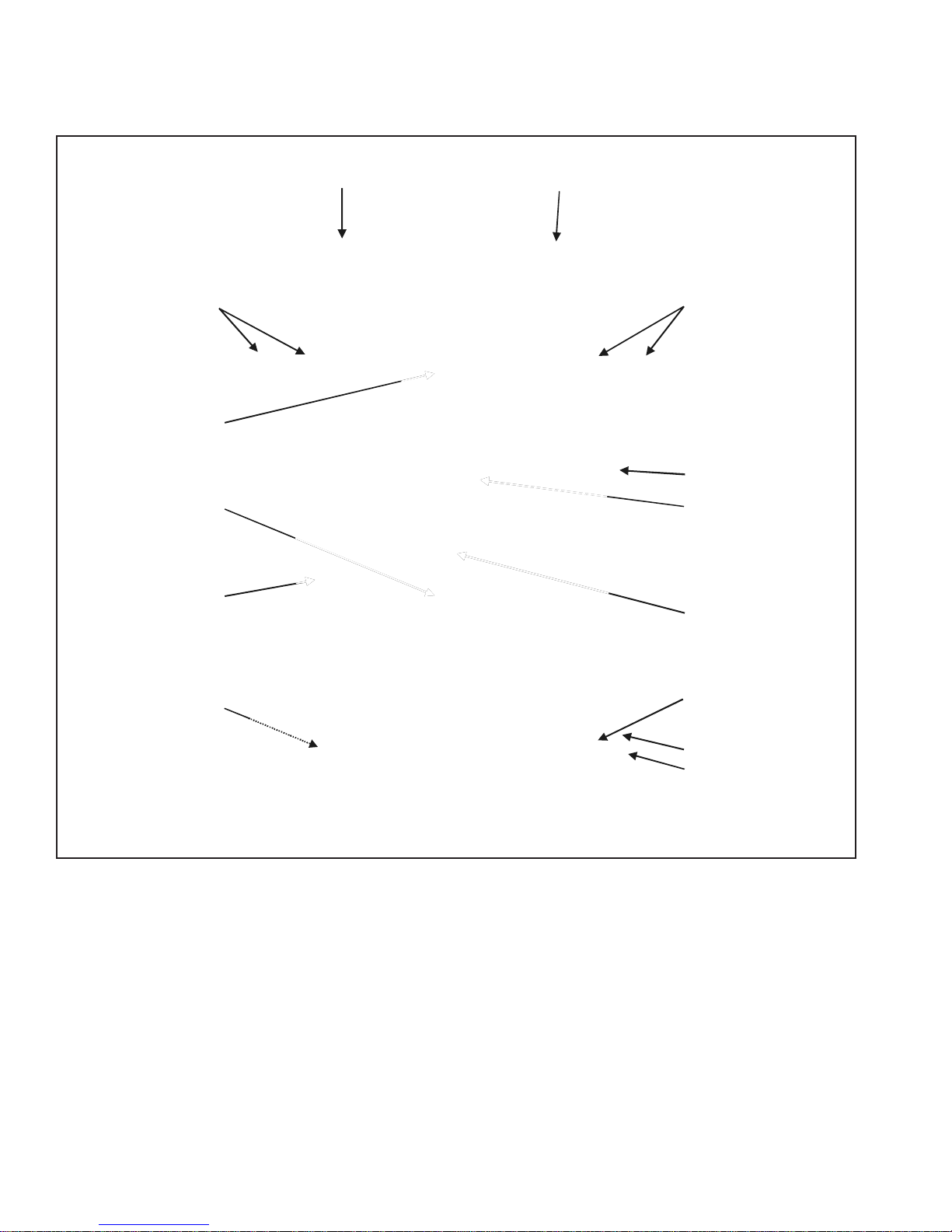

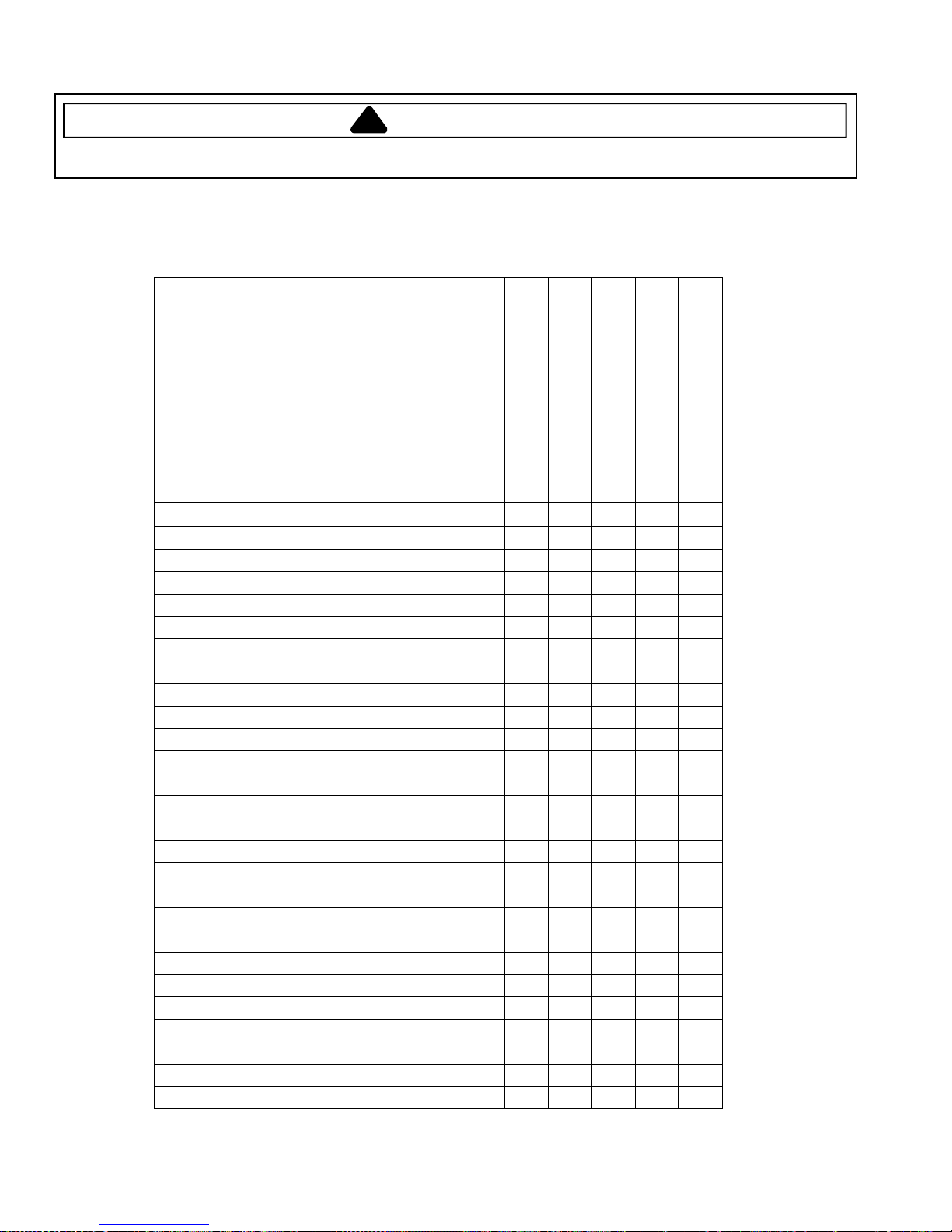

Relay Logic for EOC III

NOTE: Subsequent changes implemented after the release of this technical sheet may have altered the parameters

identified in this chart.

INDEX

± - OFF

O - ON

- CYCLING

- ON OR OFF (DETERMINED BY

USER INPUT)

COOKING MODE

IDLE

BAKE RAPID PREHEAT O

BAKE PREHEAT O

BAKE

HIGH BROIL PREHEAT

HIGH BROIL

LOW BROIL PREHEAT

LOW BROIL

CLEAN PREHEAT

CLEAN

KEEP WARM PREHEAT

KEEP WARM

WARMING DRAWER HIGH

WARMING DRAWER LOW

CONVECT ROAST PREHEAT

CONVECT ROAST

CONVECT BAKE RAPID PREHEAT

CONVECT BAKE PREHEAT

CONVECT BAKE

CONVECT PASTRY RAPID PREHEAT

CONVECT PASTRY PREHEAT

CONVECT PASTRY

THAW-SERVE

DRYING PREHEAT

DRYING

RAPID PROOFING

STANDARD PROOFING

*Convection fan stops when oven door is opened.

BAKE ELEMENT

BROIL ELEMENT

CONVECT ELEMENT

CONVECT FAN

r r r r r

r r r r

r r r r

r r r r

O

r

r

r

r

O

r r r r

r r r r

r r

r r

r r

r r

r r

r r

r r

r r

r r

r r

r r

r r

r r r

r r r

O

r r r

r r r

r r r

r r

r r r r

r r r r

O

O

O

r r

O*

r

O

r r

O

r r

r r

O

O*

r

O

O*

r

O*

r

r r r

O

r r

r r

O O

O

r

r r

WARMING DRAWER

OVEN LIGHT

r

22 16026929

© 2006 Maytag Services

Loading...

Loading...