Jenn-Air CCGX2420, CCGX2620 Installation Manual

"3

SEALEDGASC00KTOPS [][][]_.IENN-AIR |

CCGX2420ANDCCGX2620,o__Es-r_OU.T.ST._ET,.O.T.."_O".,._0_0_

J

INSTALLATION

MANUAL

SPECIALWARNING:Improperinstallation,adjustment,alteration,service,maintenanceoruse

ofappliancecanresultinseriousinjuryorpropertydamage.

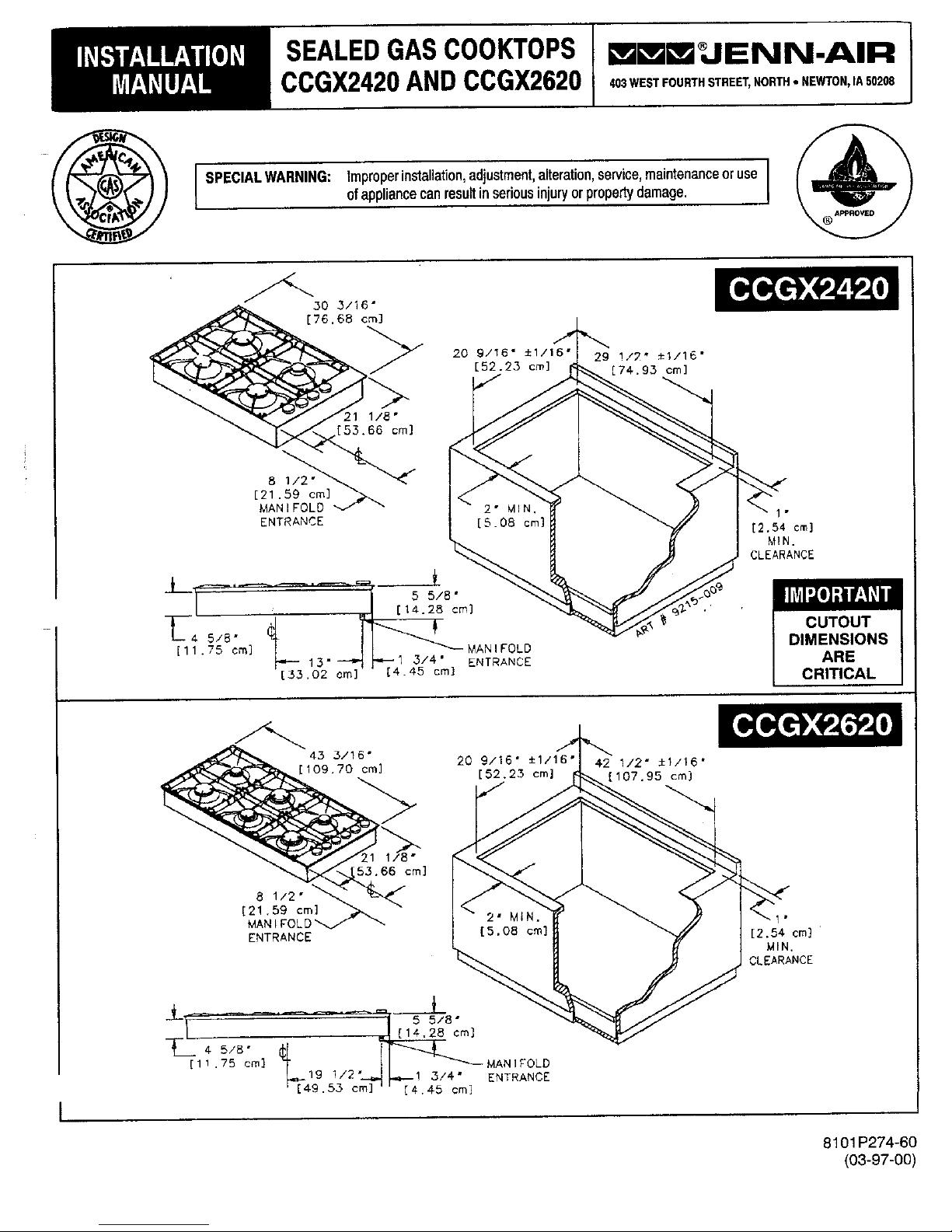

CCGX2420

30 .3/ 16_ 6"_ 29

76.68 cm]

20 9/16" _:1/16" 29 1-'2" :t:1116"

1/8 "

[53.66 cm] / .// I _"_'_.",_"-.-'_. I

8 1/2"

[2159 om] ">.. I_ _ _

MAmFOLD_ _ I " 2- UrN." _ _)

ENTRANCE [_.08 cm] y [2.54¢.]M,N.

CLEARANCE

[11.75 cm] | f [ .... _-MANIFOLD

13" _-t _ 1 .3/4" ENTRANCE

IMPORTANT

CUTOUT

DIMENSIONS

ARE

[33,02 ore] [4.45 cm] CRITICAL

CCGX2620

/_'_ 43 3/16 ° 16,'_42

CLEARANCE

--_-_'-'_ ...... • 15 518 m

I_,, 19 1/2 _ _---1 3/4' ENTRANCE

['"49.53 crn] [4.45 cm_ ' ' - " " ]

1

8101 P274-60

(03-97-00)

INSTALLING CABINETRY OVER YOUR JENN-AIR

COOKTOP INSTALLATION OF APPLIANCE:

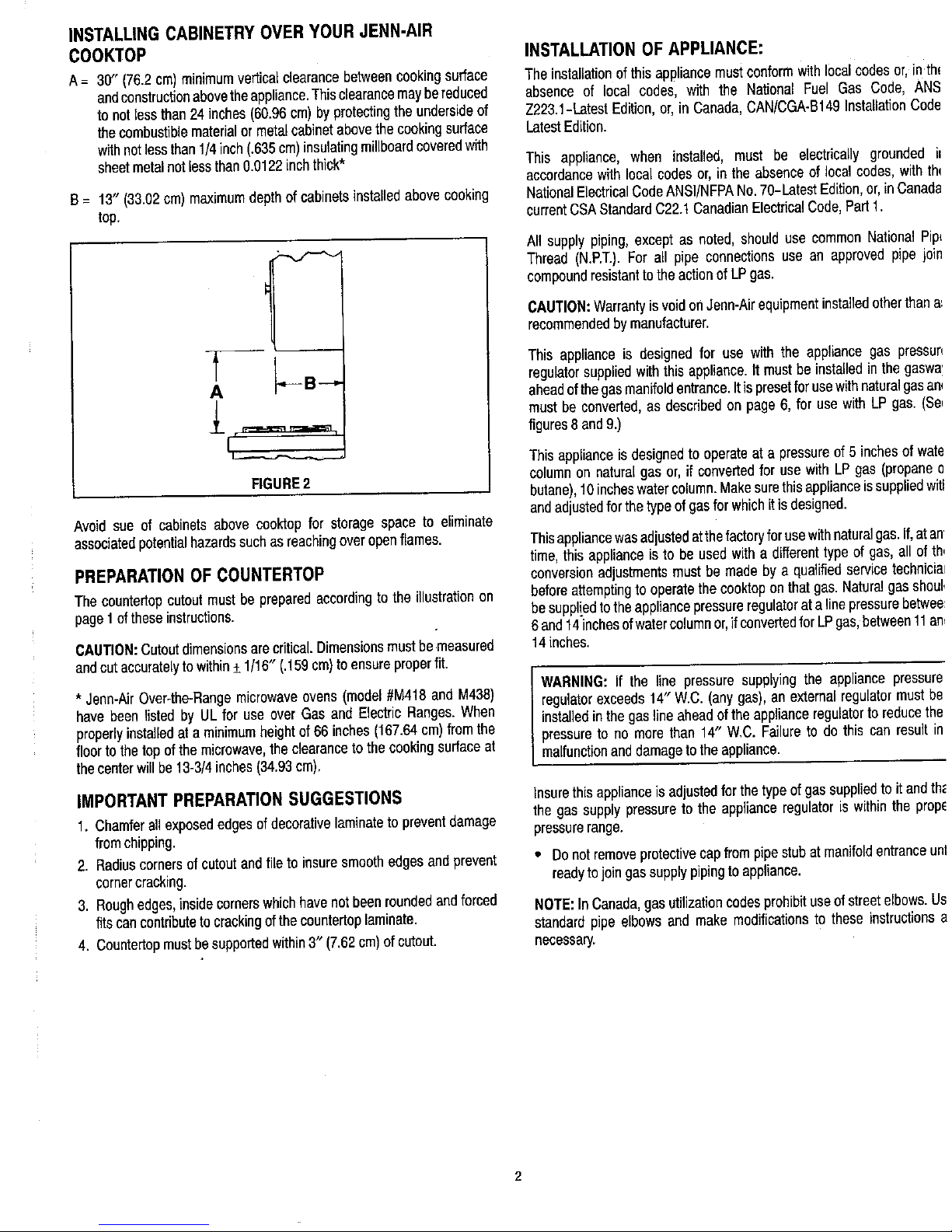

A= 30"(76.2cm)minimumverticalclearancebetweencookingsurface Theinstallationofthisappliancemustconformwithlocalcodesor,inth_

andconstructionabovetheappliance.Thisclearancemaybereducedabsenceof localcodes,withthe NationalFuelGas Code,ANS

tonotlessthan24inches(60.96cm)byprotectingtheundersideof Z223.1-LatestEdition,or,inCanada,CAN/CGA-B149InstallationCod_

thecombustiblematerialormetalcabinetabovethecookingsurface LatestEdition.

withnotlessthan1/4inch(.635cm)insulatingmi]lboardcoveredwith

sheetmetalnotlessthan0.0122inchthick* This appliance,when installed,mustbe electricallygroundedi

accordancewithlocalcodesor,intheabsenceoflocalcodes,withth

B= 13"(33.02cm)maximumdepthofcabinetsinstalledabovecooking NationalElectricalCodeANSI/NFPANo.70-LatestEdition,or,inCanad_

top. currentCSAStandardC22.1CanadianElectricalCede,Part1.

All supplypiping,exceptas noted,shouldusecommonNationalPip

Thread(N.P.TJ.Forall pipeconnectionsusean approvedpipejolt

compoundresistanttotheactionofLPgas.

CAUTION:Warrantyisvoidor_Jenn-Airequipmentinstalledotherthana

recommendedbymanufacturer.

/ Thisapplianceis designedfor usewiththeappliancegaspressur

A _ B ,' regulatorsuppliedwiththisappliance.It mustbeinstalledinthegaswa

aheadofthegasmanifoldentrance.Itispresetforusewithnaturalgasan

mustbeconverted,asdescribedonpage6,forusewithLPgas.(Se

,_ figures8and9.)

I

Thisapplianceisdesignedto operateatapressureof5 inchesofwat¢

FIGURE2 columnonnaturalgasor,if convertedforusewithLPgas(propane(

butane),10incheswatercolumn.Makesurethisapplianceissuppliedwi!

andadjustedforthetypeof gasforwhichitisdesigned.

Avoidsueof cabinetsabovecooktopfor storagespaceto eliminate

associatedpotentialhazardssuchasreachingoveropenflames. Thisappliancewasadjustedatthefactoryforusewithnaturalgas.If,ata

time,thisapplianceis tobe usedwitha differenttypeofgas,all oftl

PREPARATIONOF COUNTERTOP conversionadjustmentsmustbemadebyaqualifiedservicetechnicil

Thecountertopcutoutmustbepreparedaccordingtotheillustrationon beforeattemptingtooperatethecooktoponthatgas.Naturalgasshot

page1oftheseinstructions, besuppl!edtotheappliancepressureregulatoratalinepressurebetwe,

6andf4inchesofwatercolumnor,ifconvertedforLFgas,betweenff a_

CAUTION:Cutoutdimensionsarecritical.Dimensionsmustbemeasured t4inches.

andcutaccuratelytowithin± 1/16"(.159cm)toensureproperfit.

WARNING:If the line pressuresupplyingtheappliancepressur_

* Jenn-AirOver-the-Rangemicrowaveovens(model#1V1418andM438) regulatorexceeds14"W.C.(anygas),anexternalregulatormustbc

havebeenlistedbyULforuseoverGasandElectricRanges.When installedinthegaslineaheadoftheapplianceregulatortoreduceth(

properlyinstalledataminimumheightof66 inches(167.64cm)fromthe pressuretonomorethan14"W.C.Failuretodothiscanresultir

floortothetopofthemicrowave,theclearancetothecookingsurfaceat malfunctionanddamagetotheappliance.

thecenterwillbe13-3/4inches(34.93cm).

IMPORTANT PREPARATIONSUGGESTIONS Insurethisapplianceis adjustedforthetypeofgassuppliedtoitandtl'

thegassupplypressuretotheapplianceregulatoriswithintheprop

I. Chamferallexposededgesofdecorativelaminatetopreventdamage pressurerange.

fromchipping.

2. Radiuscornersofcutoutandfileto insuresmoothedgesandprevent • Donotremoveprotectivecapfrompipestubatmanifoldentranceur

cornercracking, readytojoingassupplypipingtoappliance.

3. Roughedges,insidecornerswhichhavenotbeenroundedandforced NOTE:InCanada,gasutilizationcodesprohibituseofstreetelbows.U

fitscancontributetocrackingofthecounterfoplaminate, standardpipeelbowsandmakemodificationstotheseinstructions

4. Countertopmustbesupportedwithin3"(7.62cm)ofcutout, necessary.

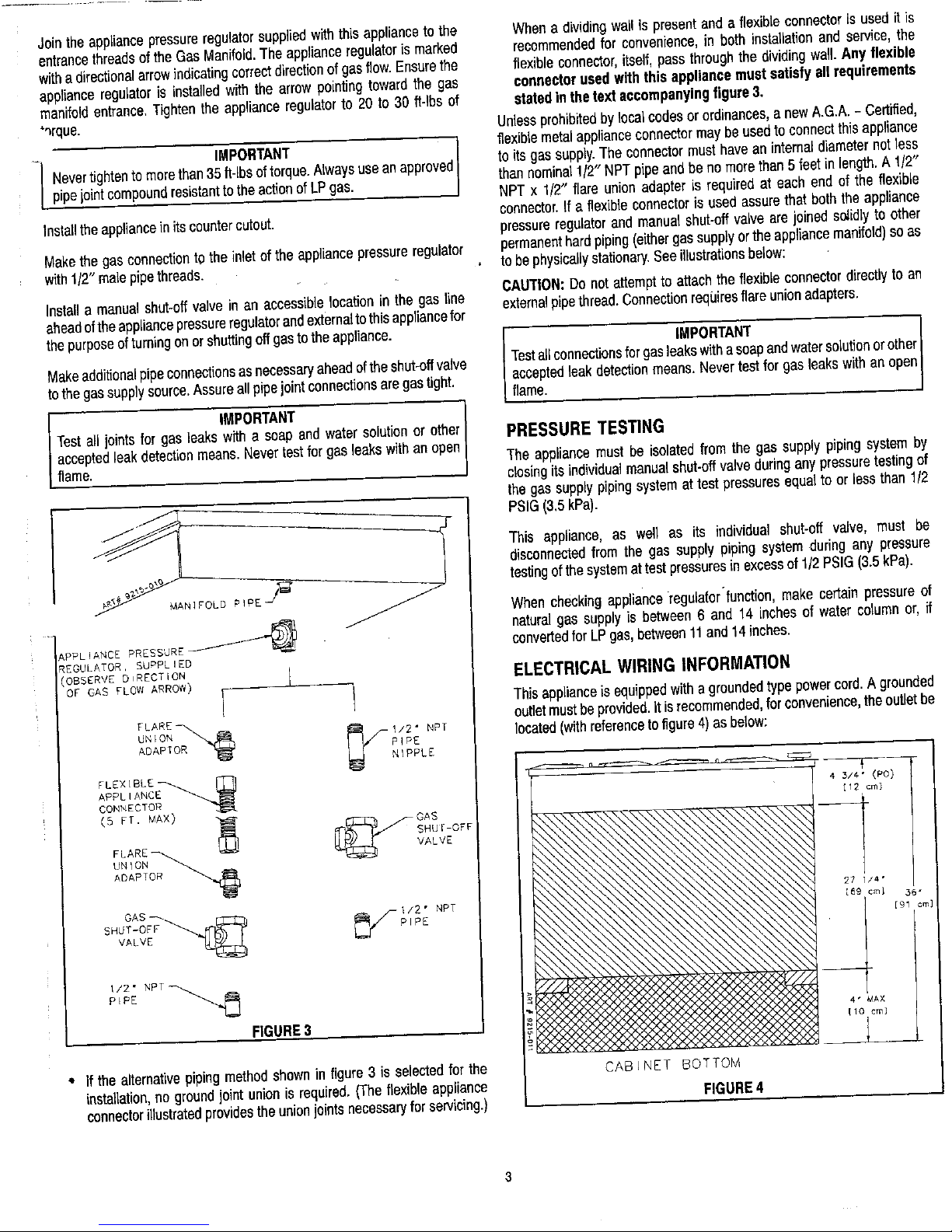

Jointheappliancepressureregulatorsuppliedwiththisappliancetothe Whena dividingwallis presentandaflexibleconnectorisuseditis

entrancethreadsoftheGasManifold.Theapplianceregulatorismarked recommendedfor convenience,in bothinstallationandservice,the

withadirectionalarrowindicatingcorrectdirectionofgasflow.Ensurethe flexibleconnector,itself,passthroughthedividingwall.Anyflexible

applianceregulatoris installedwiththearrowpointingtowardthegas connectorusedwiththisappliancemustsatisfyallrequirements

manifoldentrance.Tightentheapplianceregulatorto 20to30 ft-lbsof statedinthetextaccompanyingfigure3.

"nrque. UnlessprohibitedbyIDealcodesorordinances,anewA.G.A.- Certified,

IMPORTANT I flexiblemetalapplianceconnectormaybeusedtoconnectthisappliance

- Nevertightentomorethan35ft-lbsoftorque.Alwaysuseanapproved to itsgassupply.TheconnectormusthaveaninternaldiameternetlesspipejentcompoundresistanttotheactionofLPgas. thannominal1/2"NPTpipeandbenomorethan5feetinlength.A 1/2"

NPTx 1/2"flareunionadapteris requiredateachendof the flexible

Installtheapplianceinitscountercutout, connector,if a flexibleconnectorisusedassurethatboththeappliance

pressureregulatorandmanualshut-oftvalvearejoinedsolidlyto other

Makethegasconnectiontotheinletoftheappliancepressureregulator permanenthardpiping(eithergassupplyortheappliancemanifold)soas

with112"malepipethreads, tobephysicallystationary.Seeillustrationsbelow:

CAUTION:Donotattempttoattachtheflexibleconnectordirectlytoan

Installa manualshut-offvalveinan accessibleIDeationinthegasline externalpipethread.Connectionrequiresflareunionadapters.

aheadoftheappliancepressureregulatorandexternaltothisappliancefor

thepurposeofturningonorshuttingoffgastotheappliance. IMPORTANT

Makeadditionalpipeconnectionsasnecessaryaheadoftheshut-offvalve Testallconnectionsforgasleakswithasoapandwatersolutionorother

tothegassupplysource.Assurea;;pipejointconnectionsaregastight, acceptedleakdetedionmeans.Nevertestforgasleakswithanopen

fame.

IMPORTANT

Testalljointsforgasleakswitha soapandwatersolutionor other PRESSURE TESTING

acceptedleakdetectionmeans.Nevertestforgasleakswithanopen

flame. Theappliancemustbeisolatedfromthegassupplypipingsystemby

closingitsindividualmanualshut-offvalveduringanypressuretestingof

thegassupplypipingsystemat testpressuresequaltoor lessthan1/'2

PS/G(3.5kPa).

"_ This appliance,as well as its indMduaJshut-offvalve,must be

disconnectedfromthe gassupplypipingsystemduringany pressure

testingofthesystemattestpressuresinexcessof lj2 PSIG(3.5kPa).

MANIFOLD P_PE

Whencheckingapplianceregulator'function,makecertainpressureof

naturalgas supplyis between6 and 14inchesof watercolumnor,if

_,PPLlANCEPRESSURE/- convertedforLPgas,between11and14inches.

_EGULATOR, SUPPLIED

(OSSERvEO,R_CT_O. ELECTRICALWIRINGINFORMATION

0r GAS FLOW ARROW)

appliance equipped agroundedtypepower grounded

This is with cord.A

outletmustbeprovided,itisrecommended,forconvenience,theoutletbe

FLAREos_@

UNION 1/2" NPT located(withreferencetofigure4)asbelow:

ADAPT P IPE

NIPPLE

FL_×_LE_...__ -- _....

APRL IANCE

CONNECTQ

-1

SHU[ OFF

FLARE VALVE

UNION _

ADAPTOR _-_

GAS_ 1/2" NPT

SHUT-OFFvALVE_ _PIPE

1/2" NPT-_

P_PE _

FIGURE3 /

t

• If thealternativepipingmethodshowninfigure3 is selectedforthe CABINET BOTTOM

installation,nogroundjoint unionisrequired.(Theflexibleappliance FIGURE4

connectorillustratedprovidestheunionjointsnecessaryforservicing,)

Loading...

Loading...