J ELECTRICAL 8A - 1

ELECTRICAL

GROUP INDEX

Group Group

AUDIO SYSTEMS ........................ 8F

BATTERY/STARTER/GENERATOR SERVICE .... 8B

BATTERY/STARTING/CHARGING SYSTEMS

DIAGNOSTICS ......................... 8A

CHIME/BUZZER WARNING SYSTEMS ........ 8U

HORNS ................................ 8G

IGNITION SYSTEMS ...................... 8D

INSTRUMENT PANEL AND GAUGES ......... 8E

LAMPS ................................ 8L

OVERHEAD CONSOLE .................... 8C

POWER LOCKS .......................... 8P

POWER MIRRORS ....................... 8T

POWER SEATS .......................... 8R

POWER WINDOWS ....................... 8S

REAR WINDOW DEFOGGER ............... 8N

RESTRAINT SYSTEMS ................... 8M

TURN SIGNAL AND HAZARD WARNING

SYSTEMS ............................. 8J

VEHICLE SPEED CONTROL SYSTEM ......... 8H

WIPER AND WASHER SYSTEMS ............ 8K

XJ WIRING DIAGRAMS-LEFT HAND DRIVE ... 8W

XJ WIRING DIAGRAMS-RIGHT HAND DRIVE . 8W

YJ WIRING DIAGRAMS .................. 8W

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS

CONTENTS

page page

BATTERY ............................... 2

CHARGING SYSTEM ..................... 17

IGNITION-OFF DRAW .................... 10

SPECIFICATIONS ........................ 23

STARTING SYSTEM ...................... 11

USING ON-BOARD DIAGNOSTIC SYSTEM .... 22

GENERAL INFORMATION

The battery, starting, and charging systems operate

with one another; therefore, they must be tested as a

complete system. In order for the vehicle to start and

charge properly, all of the components involved in

these systems must perform within specifications.

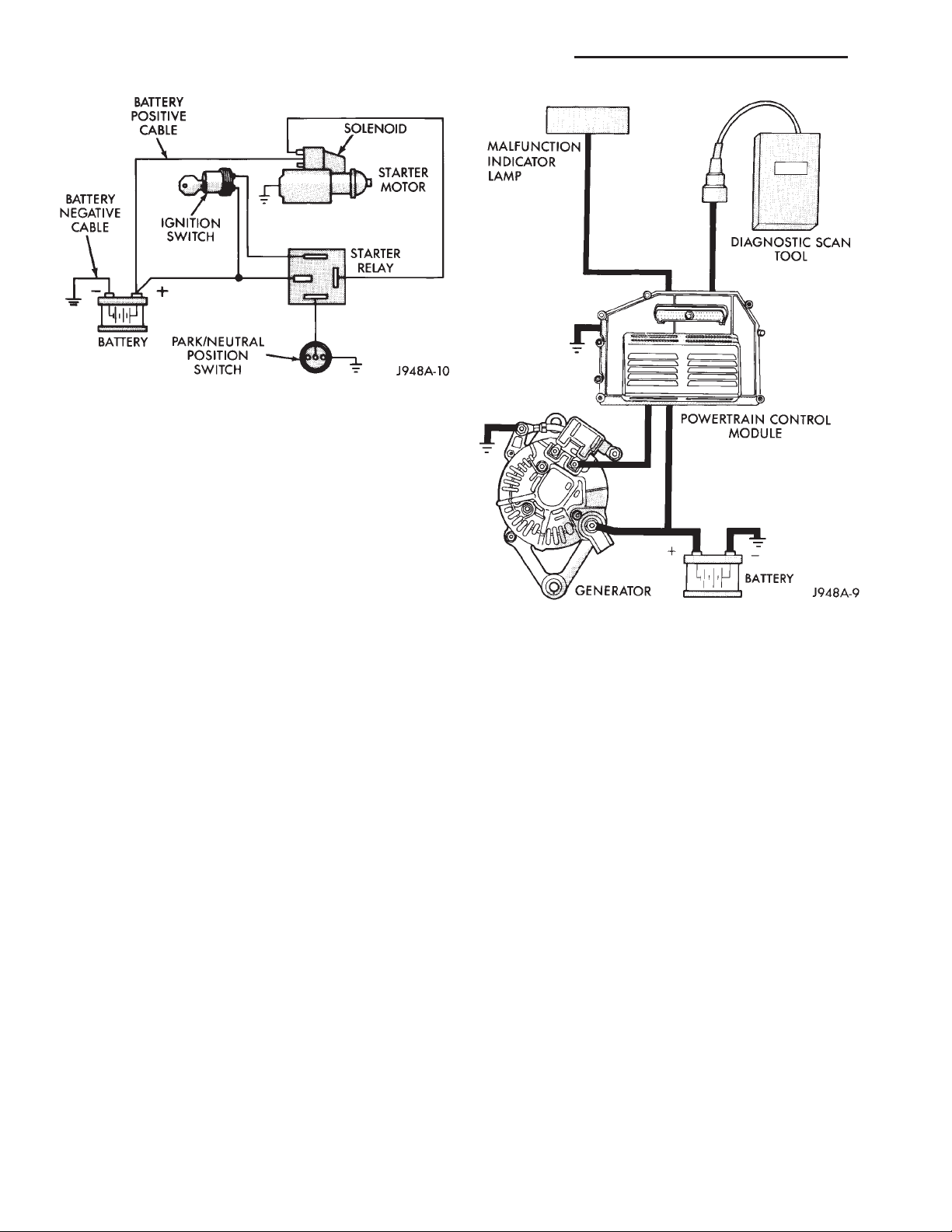

Group 8A covers battery, starting (Fig. 1) and

charging (Fig. 2) system diagnostic procedures. These

procedures include the most basic conventional diagnostic methods, to On-Board Diagnostics (OBD) built

into the Powertrain Control Module (PCM). Use of an

induction milliamp ammeter, volt/ohmmeter, battery

charger, carbon pile rheostat (load tester), and 12volt test lamp will be required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnostic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See Using On-Board Diagnostic System in this group for

more information.

8A - 2 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS J

Fig. 1 Starting System Components (Typical)

BATTERY

GENERAL INFORMATION

The storage battery is a device used to store electrical energy potential in a chemical form. When an

electrical load is applied to the battery terminals, an

electrochemical reaction occurs within the battery.

This reaction causes the battery to discharge electrical current.

The battery is made up of 6 individual cells that

are connected in series. Each cell contains positively

charged plate groups made of lead oxide, and negatively charged plate groups made of sponge lead.

These dissimilar metal plates are submerged in a

sulfuric acid and water solution called electrolyte.

As the battery discharges, a gradual chemical

change takes place within each cell. The sulfuric acid

in the electrolyte combines with the plate materials,

causing both plates to change to lead sulfate. At the

same time, oxygen from the positive plate material

combines with hydrogen from the sulfuric acid, causing the electrolyte to become mainly water.

The chemical changes within the battery are

caused by movement of excess or free electrons between the positive and negative plate groups. This

Fig. 2 Charging System Components (Typical)

movement of electrons produces a flow of electrical

current through the load device attached to the battery terminals.

As the plate materials become more similar chemically, and the electrolyte becomes less acid, the voltage potential of each cell is reduced. However, by

charging the battery with a voltage higher than that

of the battery, the process is reversed.

Charging the battery gradually changes the sulfated lead plates back into sponge lead and lead oxide, and the water back into sulfuric acid. This action

restores the difference in electron charges deposited

on the plates, and the voltage potential of the battery

cells.

For a battery to remain useful, it must be able to

produce high-amperage current over an extended period. A battery must also be able to accept a charge,

so that its voltage potential may be restored.

In addition to producing and storing electrical energy, the battery serves as a capacitor or voltage stabilizer for the vehicle electrical system. It absorbs

abnormal or transient voltages caused by switching

of any of the vehicle’s electrical components.

The battery is vented to release excess gas that is

created when the battery is being charged or dis-

J BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 3

charged. However, even with these vents, hydrogen

gas can collect in or around the battery. If hydrogen

gas is exposed to flame or sparks, it can ignite.

If the electrolyte level is low, the battery could arc

internally and explode. If the battery is equipped

with removable cell caps, add distilled water whenever the electrolyte level is below the top of the

plates. If the battery cell caps cannot be removed, the

battery must be replaced when the electrolyte level is

low.

WARNING: DO NOT ATTEMPT TO ASSIST BOOST,

CHARGE, OR TEST BATTERY WHEN ELECTROLYTE LEVEL IS BELOW THE TOP OF THE PLATES.

PERSONAL INJURY MAY OCCUR.

BATTERY RATINGS

Currently, there are 2 commonly accepted methods

for rating and comparing battery performance. These

ratings are called Cold Cranking Amperage (CCA),

and Reserve Capacity (RC). Be certain that a replacement battery has CCA and RC ratings that equal or

exceed the original equipment specification for the

vehicle being serviced. See Battery Classifications

and Ratings charts in Specifications at the back of

this group.

COLD CRANKING AMPERAGE

The Cold Cranking Amperage (CCA) rating specifies how much current (in amperes) the battery can

deliver for 30 seconds at -17.7°C (0°F). Terminal voltage must not fall below 7.2 volts during or after the

30 second discharge. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

RESERVE CAPACITY

The Reserve Capacity (RC) rating specifies the

time (in minutes) it takes for battery terminal voltage to fall below 10.2 volts at a discharge rate of 25

amps. RC is determined with the battery fullycharged at 26.7°C (80°F). This rating estimates how

long the battery might last after a charging system

failure, under minimum electrical load.

DIAGNOSIS

The battery must be completely charged and the

top, posts, and terminal clamps should be properly

cleaned before diagnostic procedures are performed.

Refer to Group 8B - Battery/Starter/Generator Service for more information.

The condition of a battery is determined by two criteria:

(1) State-Of-Charge This can be determined by

viewing the built-in test indicator, by checking specific gravity of the electrolyte (hydrometer test), or by

checking battery voltage (open circuit voltage test).

(2) Cranking Capacity This can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

If the battery has a built-in test indicator, use this

test first. If it has no test indicator, but has removable cell caps, perform the hydrometer test first. If

cell caps are not removable, or a hydrometer is not

available, perform the open circuit voltage test first.

The battery must be charged before proceeding

with a load test if:

• the built-in test indicator has a black or dark color

visible

• the temperature corrected specific gravity is less

than 1.235

• the open circuit voltage is less than 12.4 volts.

A battery that will not accept a charge is faulty

and further testing is not required. A battery that is

fully-charged, but does not pass the load test is

faulty and must be replaced.

Completely discharged batteries may take

several hours to accept a charge. See Charging

Completely Discharged Battery.

A battery is fully-charged when:

• all cells are gassing freely during charging

• a green color is visible in the sight glass of the

built-in test indicator

• three corrected specific gravity tests, taken at

1-hour intervals, indicate no increase in specific gravity

• open circuit voltage is 12.4 volts or greater.

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnormal battery discharging:

(1) Corroded battery posts and terminals.

(2) Loose or worn generator drive belt.

(3) Electrical loads that exceed the output of the

charging system, possibly due to equipment installed

after manufacture or repeated short trip use.

(4) Slow driving speeds (heavy traffic conditions) or

prolonged idling with high-amperage draw systems

in use.

(5) Faulty circuit or component causing excessive

ignition-off draw. See Ignition-Off Draw in this group

for diagnosis.

(6) Faulty charging system.

(7) Faulty or incorrect battery.

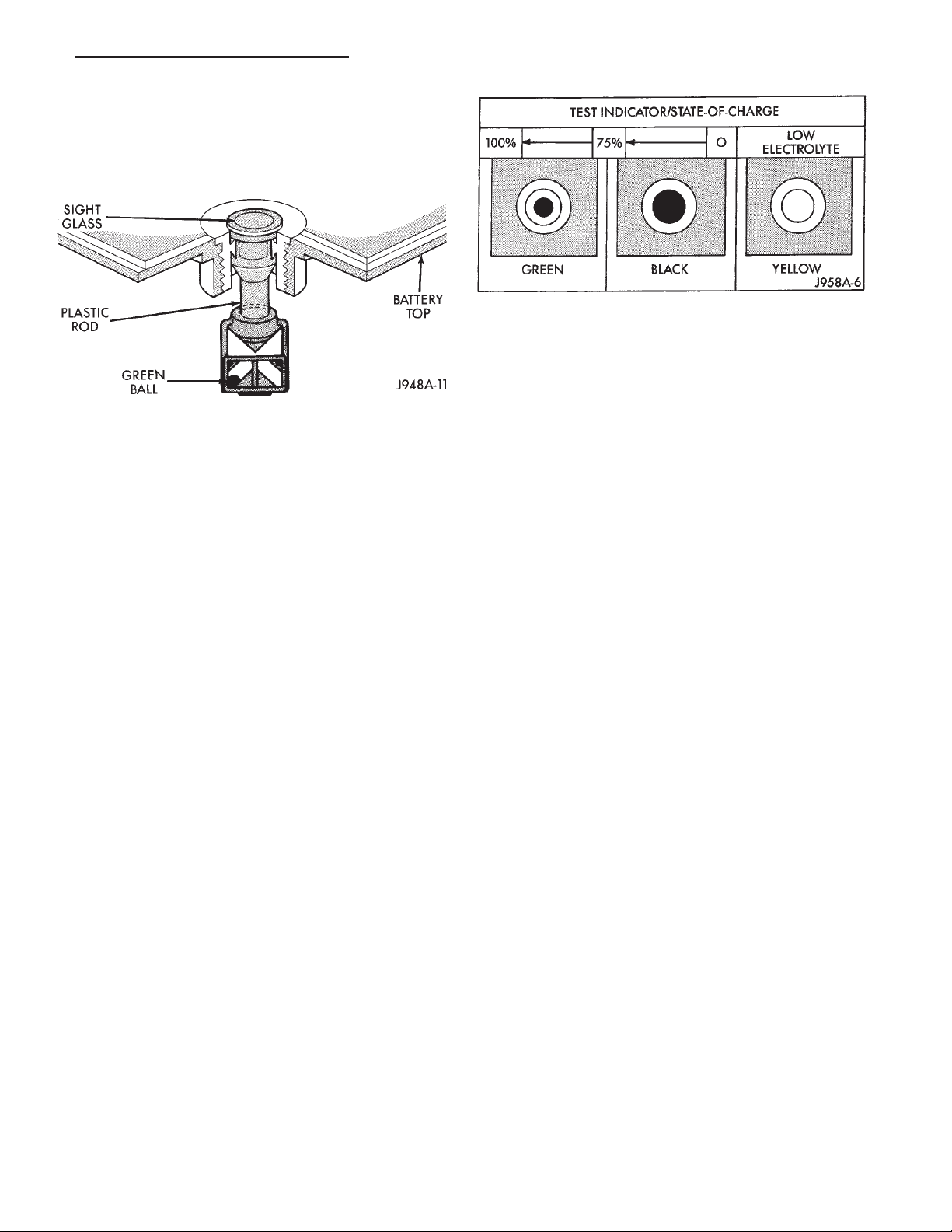

BUILT-IN TEST INDICATOR

A test indicator (hydrometer) built into the top of

the battery case, provides visual information for battery testing (Fig. 1). It is important when using the

test indicator that the battery be level and have a

clean sight glass to see correct indications. Additional

light may be required to view indicator.

8A - 4 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS J

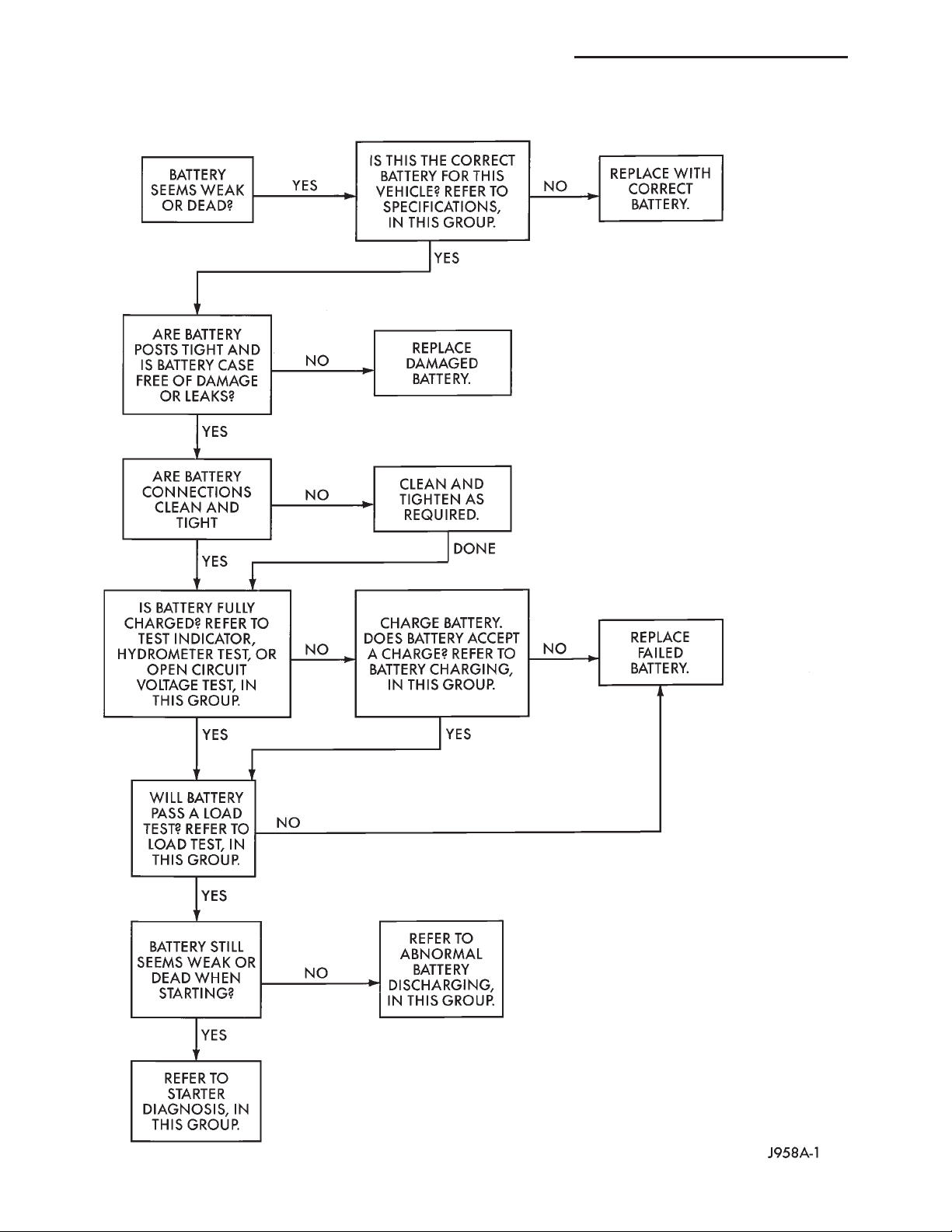

BATTERY DIAGNOSIS

J BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 5

WARNING: DO NOT USE OPEN FLAME AS A

SOURCE OF ADDITIONAL LIGHT FOR VIEWING

TEST INDICATOR. EXPLOSIVE HYDROGEN GAS

MAY BE PRESENT IN THE AREA SURROUNDING

BATTERY.

Fig. 2 Built-In Test Indicator Sight Glass

HYDROMETER TEST

The hydrometer test reveals the battery state-ofcharge by measuring the specific gravity of the electrolyte. This test cannot be performed on batteries

Fig. 1 Built-In Test Indicator

Like a hydrometer, the built-in test indicator measures the specific gravity of the electrolyte. Specific

gravity will indicate battery state-of-charge. However, the test indicator will not indicate cranking capacity of the battery. See Load Test in this group for

more information.

Look into the sight glass and note the color of the

indicator (Fig. 2). Refer to the following description,

as the color indicates:

GREEN—indicates 75% to 100% state-of-charge.

The battery is adequately charged for further testing or return to use. If the vehicle will not crank for

a minimum of 15 seconds with a fully-charged battery, perform Load Test.

BLACK OR DARK—indicates 0% to 75% state-ofcharge.

The battery is inadequately charged and must be

charged until green indicator (Fig. 2) is visible in

sight glass (12.4 volts or more) before the battery is

tested further or returned to use. See Abnormal Battery Discharging in this group to diagnose cause of

discharged condition.

YELLOW OR BRIGHT—indicates low electrolyte

level.

The electrolyte level in the battery is below test indicator (Fig. 2). A maintenance-free battery with nonremovable cell caps must be replaced if electrolyte

level is low. Water can be added to a low-maintenance battery with removable cell caps. A low electrolyte level may be caused by an over-charging

condition. See Charging System in this group to diagnose an over-charging condition.

WARNING: DO NOT ATTEMPT TO CHARGE, TEST,

OR ASSIST BOOST BATTERY WHEN YELLOW OR

BRIGHT COLOR IS VISIBLE IN SIGHT GLASS OF

TEST INDICATOR. LOW ELECTROLYTE LEVEL CAN

ALLOW BATTERY TO ARC INTERNALLY AND EXPLODE. PERSONAL INJURY MAY OCCUR.

with non-removable cell caps. If battery has non-removable cell caps, see Built-In Test Indicator or Open

Circuit Voltage Test.

Specific gravity is a comparison of the density of

the electrolyte to the density of pure water. Pure water has a specific gravity of 1.000, and sulfuric acid

has a specific gravity of 1.835. Sulfuric acid makes

up approximately 35% of the electrolyte by weight, or

24% by volume.

In a fully-charged battery the electrolyte will have

a temperature corrected specific gravity of 1.260 to

1.290. However, a specific gravity of 1.235 or above is

satisfactory for battery load testing and/or return to

service.

Before testing, visually inspect battery for any

damage (cracked case or cover, loose posts, etc.) that

would cause the battery to be faulty. Then remove

cell caps and check electrolyte level. Add distilled water if electrolyte level is below the top of the battery

plates.

To use the hydrometer correctly, hold it with the

top surface of the electrolyte at eye level. Refer to the

hydrometer manufacturer’s instructions for correct

use of hydrometer. Remove only enough electrolyte

from the battery so the float is off the bottom of the

hydrometer barrel with pressure on the bulb released.

Exercise care when inserting the tip of the hydrometer into a cell to avoid damaging the plate separators. Damaged plate separators can cause premature

battery failure.

Hydrometer floats are generally calibrated to indicate the specific gravity correctly only at 26.7°C

(80°F). When testing the specific gravity at any other

temperature, a correction factor is required.

The correction factor is approximately a specific

gravity value of 0.004, referred to as 4 points of specific gravity. For each 5.5°C above 26.7°C (10°F above

80°F), add 4 points. For each 5.5°C below 26.7°C

(10°F below 80°F), subtract 4 points. Always correct

8A - 6 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS J

the specific gravity for temperature variation. Test

the specific gravity of the electrolyte in each battery

cell.

Example: A battery is tested at -12.2°C (10°F) and

has a specific gravity of 1.240. Determine the actual

specific gravity as follows:

(1) Determine the number of degrees above or below 26.7°C (80°F):

26.6°C - -12.2°C = 38.8°C (80°F - 10°F = 70°F)

(2) Divide the result from step 1 by 5.5 (10):

38.8°C/5.5 = 7 (70°F/10 = 7)

(3) Multiply the result from step 2 by the temperature correction factor (0.004):

7 x 0.004 = 0.028

(4) The temperature at testing was below 26.7°C

(80°F); therefore, the temperature correction is subtracted:

1.240 - 0.028 = 1.212

The corrected specific gravity of the battery in this

example is 1.212.

If the specific gravity of all cells is above 1.235, but

variation between cells is more than 50 points

(0.050), the battery should be replaced.

If the specific gravity of one or more cells is less

than 1.235, charge the battery at a rate of approximately 5 amperes. Continue charging until 3 consecutive specific gravity tests, taken at 1-hour intervals,

are constant. If the cell specific gravity variation is

more than 50 points (0.050) at the end of the charge

period, replace the battery.

When the specific gravity of all cells is above 1.235,

and cell variation is less than 50 points (0.050), the

battery may be load tested.

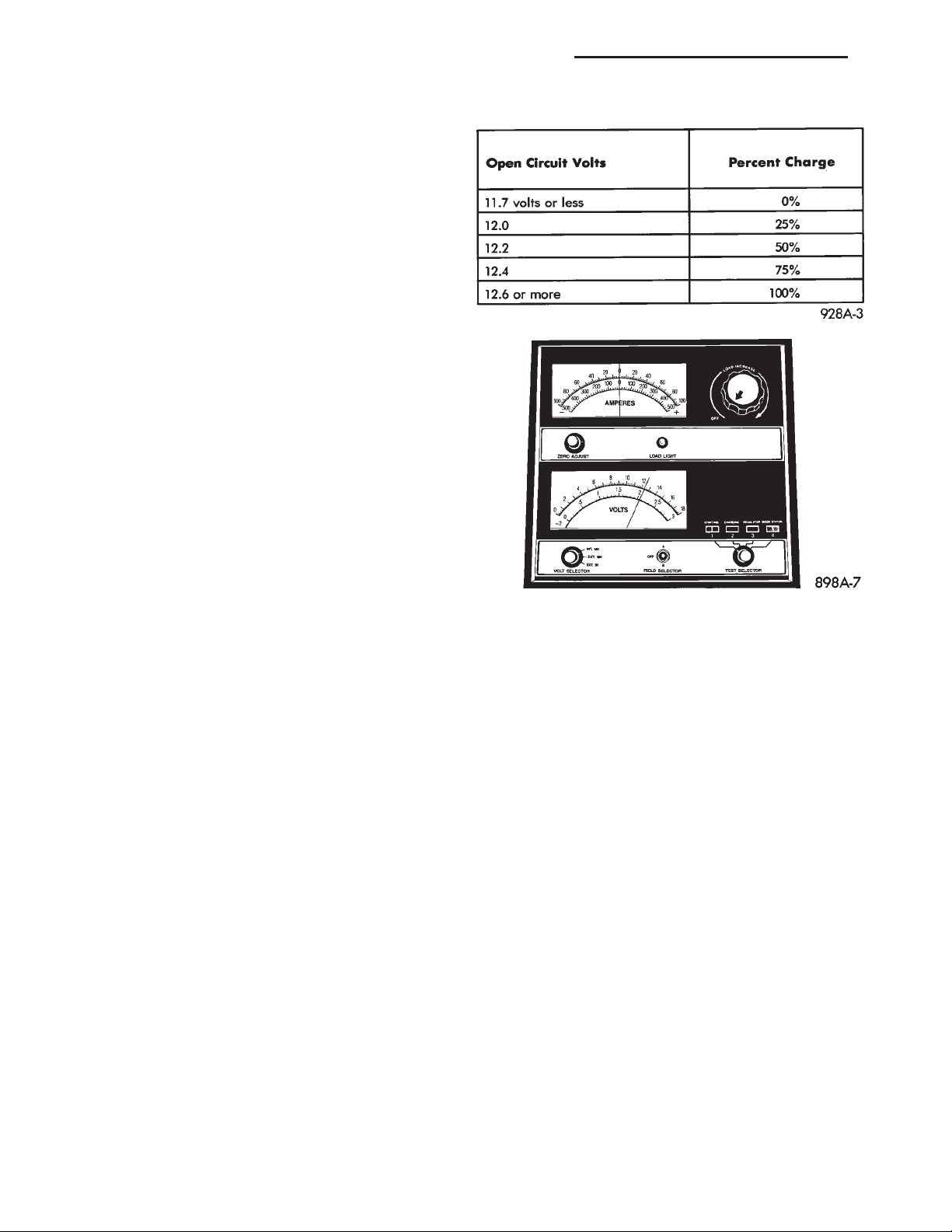

OPEN CIRCUIT VOLTAGE TEST

A battery open circuit voltage (no load) test will

show state-of-charge of a battery. This test can be

used in place of the hydrometer test if a hydrometer

is not available, or for maintenance-free batteries

with non-removable cell caps.

Before proceeding with this test or load test,

completely charge battery as described in Battery Charging in this group.

Test battery open circuit voltage as follows:

(1) Before measuring open circuit voltage the surface charge must be removed from the battery. Turn

headlamps on for 15 seconds, then allow up to 5 minutes for voltage to stabilize.

(2) Remove both battery cables, negative first.

(3) Using a voltmeter connected to the battery

posts (refer to instructions provided with voltmeter)

measure open circuit voltage (Fig. 3).

See Open Circuit Voltage chart. This voltage reading will indicate state-of-charge, but will not reveal

cranking capacity. If a battery has an open circuit

voltage reading of 12.4 volts or greater, it may be

load tested. A battery that will not endure a load test

is faulty and must be replaced.

OPEN CIRCUIT VOLTAGE

Fig. 3 Testing Open Circuit Voltage

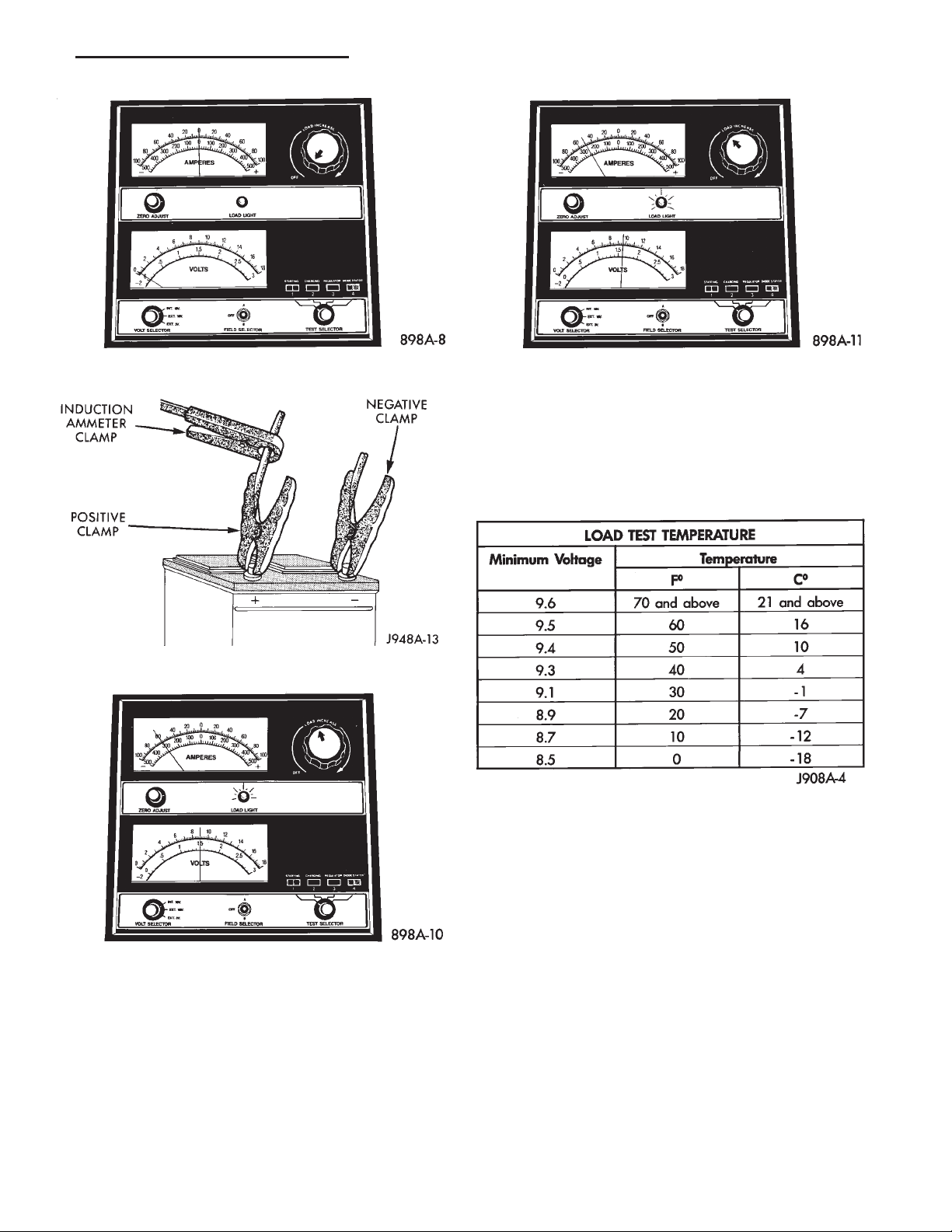

LOAD TEST

A battery load test will verify battery cranking capacity. The test is based on the Cold Cranking Amperage (CCA) rating of the battery. See Battery

Classifications and Ratings chart in Specifications, at

the back of this group.

WARNING: IF BATTERY SHOWS SIGNS OF FREEZING, LEAKING, LOOSE POSTS, OR LOW ELECTROLYTE LEVEL, DO NOT LOAD TEST. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

Before performing load test, the battery must

be FULLY-CHARGED.

(1) Remove both battery cables, negative first. Battery top and posts should be clean.

(2) Connect a suitable volt-ammeter-load tester

(Fig. 4) to the battery posts (Fig. 5). Refer to operating instructions provided with the tester being used.

Check the open circuit voltage (no load) of the battery. Open circuit voltage must be 12.4 volts or

greater.

(3) Rotate the load control knob (carbon pile rheostat) to apply a 300 amp load for 15 seconds, then return the control knob to OFF (Fig. 6). This will

remove the surface charge from the battery.

(4) Allow the battery to stabilize to open circuit

voltage. It may take up to 5 minutes for voltage to

stabilize.

J BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 7

Fig. 4 Volt-Amps-Load Tester (Typical)

Fig. 5 Volt-Ammeter-Load Tester Connections

Fig. 6 Remove Surface Charge from Battery

(5) Rotate the load control knob to maintain a load

equal to 50% of CCA rating (Fig. 7). After 15 seconds,

record the loaded voltage reading, then return the

load control knob to OFF.

(6) Voltage drop will vary with battery temperature at the time of the load test. Battery temperature

can be estimated by the ambient temperature over

the past several hours. If the battery has been

charged, boosted, or loaded a few minutes prior to

Fig. 7 Load 50% CCA Rating - Note Voltage

test, the battery will be somewhat warmer. See Load

Test Temperature chart for proper loaded voltage

reading.

(7) If the voltmeter reading falls below 9.6 volts, at

a minimum battery temperature of 21°C (70°F), replace the battery.

BATTERY CHARGING

A battery is fully-charged when:

• all cells are gassing freely during charging

• a green color is visible in sight glass of built-in

test indicator

• three corrected specific gravity tests, taken at

1-hour intervals, indicate no increase in specific gravity

• open circuit voltage is 12.4 volts or above.

WARNING: DO NOT ASSIST BOOST OR CHARGE A

BATTERY THAT HAS LOW ELECTROLYTE LEVEL

OR IS FROZEN. BATTERY MAY ARC INTERNALLY

AND EXPLODE.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND BATTERY. DO NOT SMOKE, USE

FLAME, OR CREATE SPARKS NEAR BATTERY.

8A - 8 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS J

WARNING: POISONOUS AND CAUSTIC. BATTERY

CONTAINS SULFURIC ACID. AVOID CONTACT WITH

SKIN, EYES, OR CLOTHING. IN EVENT OF CONTACT, FLUSH WITH WATER AND CALL PHYSICIAN

IMMEDIATELY. KEEP OUT OF REACH OF CHILDREN.

CAUTION: Always disconnect the battery negative

cable before charging battery to avoid damage to

electrical system components. Do not exceed 16.0

volts while charging battery.

Battery electrolyte will bubble inside battery case

during normal battery charging. If the electrolyte

boils, or is discharged from the vent holes while

charging, immediately reduce charging rate or turn

OFF charger and evaluate battery condition.

Battery should not be hot to the touch. If the

battery feels hot to the touch, turn OFF

charger and let battery cool before continuing

charging operation.

Some battery chargers are equipped with polarity

sensing circuitry. This circuitry protects the charger

and/or battery from being damaged if improperly connected.

If the battery state-of-charge is too low for the polarity sensing circuitry to detect, the charger will not

operate. This makes it appear that the battery will

not accept charging current. Refer to instructions

provided with the battery charger being used to bypass the polarity sensing circuitry.

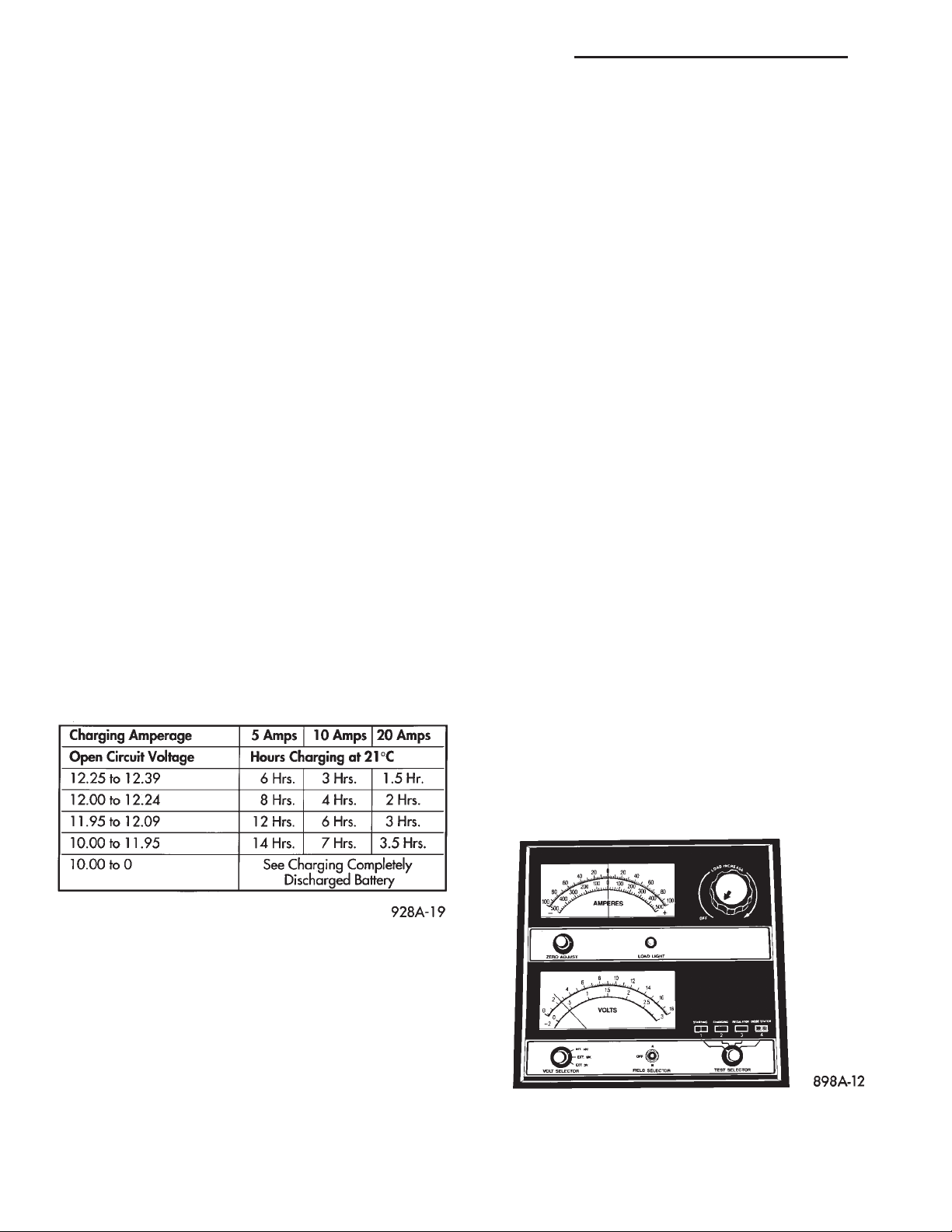

BATTERY CHARGING TIME TABLE

(1) Battery Capacity—A completely discharged

heavy-duty battery requires twice the recharging

time of a small capacity battery.

WARNING: NEVER EXCEED 20 AMPS WHEN

CHARGING A COLD (-1°C/30°F) BATTERY. PERSONAL INJURY MAY RESULT.

(2) Temperature—A longer time will be needed to

charge a battery at -18°C (0°F) than at 27°C (80°F).

When a fast charger is connected to a cold battery,

current accepted by the battery will be very low at

first. As the battery warms, it will accept a higher

charging current rate.

(3) Charger Capacity—A charger that supplies

only 5 amperes will require a longer charging time. A

charger that supplies 20 amperes or more requires a

shorter charging time.

(4) State-Of-Charge—A completely discharged

battery requires more charging time than a partially

discharged battery. Electrolyte is nearly pure water

in a completely discharged battery. At first, the

charging current (amperage) will be low. As the battery charges, the specific gravity of the electrolyte

will gradually rise.

CHARGING COMPLETELY DISCHARGED BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless this procedure is properly followed, a good battery may be

needlessly replaced.

(1) Measure voltage at battery posts with a voltmeter, accurate to 1/10 (0.10) volt (Fig. 8). If the reading

is below 10 volts, the charge current will be low. It

could take some time before the battery accepts a

current greater than a few milliamperes. Such low

current may not be detectable on ammeters built into

many chargers.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. If the battery will endure a load test, return

the battery to use. If the battery will not endure a

load test, it must be replaced.

Clean and inspect battery holddowns, tray, terminals, posts, and top before completing service. Refer

to Group 8B - Battery/Starter/Generator Service for

more information.

CHARGING TIME REQUIRED

The time required to charge a battery will vary, depending upon the following factors:

Fig. 8 Voltmeter Accurate to 1/10 Volt Connected

(2) Disconnect battery negative cable. Connect

charger leads. Some battery chargers are equipped

Loading...

Loading...