Operator & Service Manual

Produce Plus Juicer

December 2015

Operator & Service Manual

Produce Plus Juicer

Copyright © John Bean Technologies Corporation 2015

JBT Corporation

400 Fairway Avenue

Lakeland, FL 33801

(863) 683-5411

Manual No. FNS-0004-060-EN

2 FNS-0004-060-EN December 2015 Rev B

Safety Information .............................................................. 4

Safety Instructions ............................................................ 6

Technical Specifications .................................................... 7

Important General Produce Information .......................... 9

Operating Instructions .................................................... 13

Equipment Check ............................................................ 13

Juicing .............................................................................. 14

Cleaning Instructions ...................................................... 16

Exploded View of Juicing Components ......................... 19

Maintenance ..................................................................... 20

Troubleshooting .............................................................. 23

Juicer Final Assembly Listing ........................................ 26

Cover Parts Listing ........................................................... 28

Feed Screw Assembly Listing ........................................ 31

Drive Assembly Listing ................................................... 32

Electrical Diagram & Assembly, 110 Volt Listing ........... 34

Enclosure, Start Switch Assembly Listing ..................... 37

Electrical & Gearbox Sub -Assembly Listing .................. 38

Electrical Panel A ssem bly Listing ................................... 39

Electrical Diagram & Assembly, 220 Volt Listing ........... 40

3 FNS-0004-060-EN December 2015 Rev B

North America

Fax: +1 863 680 3672

Europe

South Africa

Fax: +27 21 982 1136

www.jbtcorporation.com

Brazil

Latin America

Asia / Pacific

Fax: +86 21 6341 0708

Updates, modifications and alignment to JBT global version

control and inventory standar ds

IMPORTANT SAFETY INFORMATION

You can help prevent personal injury and/or property damage.

Please read this manual carefully before operating the JBT Corporation Juicer.

Do NOT attempt any operation until you understand exactly how the machine functions.

If uncertainty remains after studying this manual, please contact:

We're here to help. With proper handling, the JBT Corporation Juice Extractor will provide safe,

efficient and convenient service for years to come.

JBT Corporation

400 Fairway Ave

Lakeland, FL 33801

USA

Phone: +1 863 683 5411

JBT Máquinas e Equipamentos Industriais Ltda.

Av. Eng. Camilo Dinucci 4605

14808-900 Araraquara

São Paulo Brazil

Phone: +55 16 3301 2000

Fax: +55 16 3332 0565

Revision History

Manual Code

FNS-0002-060-EN A 11/01/14 Entire manual

Rev.

No.

Date Pages Change History

JBT Corporation, S.L.

Julián Camarillo 26, 4º

28037 Madrid Spain

Phone: +34 91 304 00 45

Fax: +34 91 327 50 03

JBT Corporation

Carr. Mty-Saltillo Km 7—Bodega 4

Colonia Las Mitras

Santa Catarina, NL

Mexico 66350

Phone: +52 81 81 23 70 55

Fax: +52 81 81 23 70 54

JBT (Pty) Ltd.

Koper Street

Brackenfell

Cape Town, South Africa 7560

Phone: +27 21 982 1130

JBT (Shanghai) Co. Ltd.

Room 3002-3003

Haitong Security Building

No. 689 Guangdong Road

Shanghai 200001,

China

Phone: +86 21 6341 1616

FNS-0002-060-EN B 12/15/15 Entire manual Addition of new Fresh'n Squeeze logo

4 FNS-0004-060-EN December 2015 Rev B

Safety Labels

The safety labels shown below appear on the Juicer. They provide essential instructions on how

to avoid possible hazards.

Please, for your safety: FOLLOW THOSE INSTRUCTIONS AT ALL TIMES.

Should the Juicer safety labels become damaged or unreadable, contact JBT Corporation for

replacement labels.

5 FNS-0004-060-EN December 2015 Rev B

Safety Instructions

Carefully review the following safety instructions.

Make them a habit when using the JBT Corporation Juicer.

1. If Juicer continues to run when any access cover is open, interlock switch is defective.

Turn Juicer off immediately. Call for service.

2. Prevent unauthorized access to Juicer by locking all covers with supplied key.

3. Prevent unauthorized operation of Juicer by placing electrical plug inside cart door.

4. NEVER attempt to make any safety device inoperative.

5. NEVER operate or perform maintenance or repair work on Juicer when taking any kind of

drug or sedative, when under the influence of alcohol, or when fatigued.

6. ALWAYS check adjustment of all nuts, bolts, and screws after installation, repair, or

periodic maintenance.

6 FNS-0004-060-EN December 2015 Rev B

TECHNICAL SPECIFICATIONS

Produce size: ………………………. No restrictions, up to pineapple

Hopper capacity: ............. .......…….. 12 - 15 Ib. depending on produce

Reservoir capac ity:.................…….. 5 qts.

Waste container capacity: .....……... 40 Ibs.

Speed:....................................……... 4 minutes for full hopper

(12 – 20 gallons/hour)

ELECTRICAL SPECIFIC ATIONS

115V 60Hz Single Phase 20 AMP Service

Dedicated line needed for Juicer.

Use 12 GA. wire minimum up to 100 ft. from main breaker panel, 10 GA. up to 200 ft.

SHIPPING SPECIFICATIONS

Height: 63-1/2"

Width: 24"

Depth: 29"

Weight: 350 Ibs.

7 FNS-0004-060-EN December 2015 Rev B

GENERAL INFORMATION

The Fresh'n Squeeze® Produce Plus Juicer is designed to provide years of dependable service

with significantly less downtime and maintenance. It uses a unique patented design to extract

every available amount of juice from the produce. This Juicer was designed to run high quality

fruits and vegetables mentioned on Page 10 only. To process citrus use our Fresh'n Squeeze

®

Multi-Fruit Juicer.

CERTIFICATIONS

UL - Approved

CUL - Approved (Canada)

NSF (National Sanitation Foundation) - Approved

8 FNS-0004-060-EN December 2015 Rev B

IMPORTANT GENERAL PRODUCE INFORMATION

Juicing fruits and vegetables requires that the highest quality standards be maintained. This is

also important for handling all produce and salad bar items. Failure to maintain these high

standards can lead to the growth of bacteria which can be harmful to your customers. By

following the procedures in this manual you can operate a safe and profitable juicing business.

CONDITION OF PRODUCE

Use only fresh, high quality produce from reliable vendors;

DO NOT use rotten, spotted, molded, or old fruit for juicing.

DO NOT use juicer as a cull disposal program for your produce.

DO NOT juice skin type produce (tomatoes) with splits in them. All of this will increase harmf ul

bacteria growth; such as, Salmonella, E. Coli, etc.

DO wash all produce with clean, fresh, drinking water only.

DO keep all produce cold (40°F). This will inhibit the growth of harmful bacteria.

DO keep in cooler until ready to juice.

JUICE HANDLING

Make sure that the containers and lids for filling are sanitized. Also, it is best to use the smallest

containers possible to prevent spoilage before consumption. Filled containers should be

refr igerat ed (34°- 40°F) immediately after filling; if put on ice, make sure entire container is

submerged. Limit shelf life for produce juice to one day in the store. Juice every day; do not

produce excessive juice inventory.

Juice must be consumed within three days.

9 FNS-0004-060-EN December 2015 Rev B

GENERAL PRODUCE INFORM ATION

NOTE: All fresh produce must be washed thoroughly and kept refrigerated before

juicing to maintain high juice quality standards. Culls must never be used.

Types of produce

Apples

All types; we recommend Washington Apples. Best if three different types are blended equally,

e.g. Red Delicious, Golden Delicious & Granny Smith.

Carrots

All types; but, California varieties are the best. Remove green portion. Some extra large

diameter (horse) carrots may have to be cut up.

Pineapple

Remove stem and peel.

Grapes

All types and blends. Remove stems to get a less bitter taste. Seedless grapes are preferred.

Celery

Remove top leafs and bottom core.

Tomatoes

Don't use low acid varieties and make sure there are no splits in skin.

Both conditions may allow fast, harmful, bacteria growth.

Pears, Nectarines, & Peaches

Remove all pits; may not give satisfactory juice due to thick consistency, but can be used for

blending with other fruits like apples and oranges.

Strawberries, Cranberries, Blueberries

All types.

Kiwi

Peeled only.

Rhubarb, Spinach

For blending with other juices only; do not drink unblended because of their high oxalic acid

content. Never use Rhubarb leaves due to high oxalic acid.

Melons

Caution: Never juice melons because of their high pH which encourages harmful

bacteria growth such as Salmonella.

Citrus

Not recommended due to the high peel oil content of the skin. Use the Fresh'n Squeeze™

Multi-Fruit Juicer for citrus.

10 FNS-0004-060-EN December 2015 Rev B

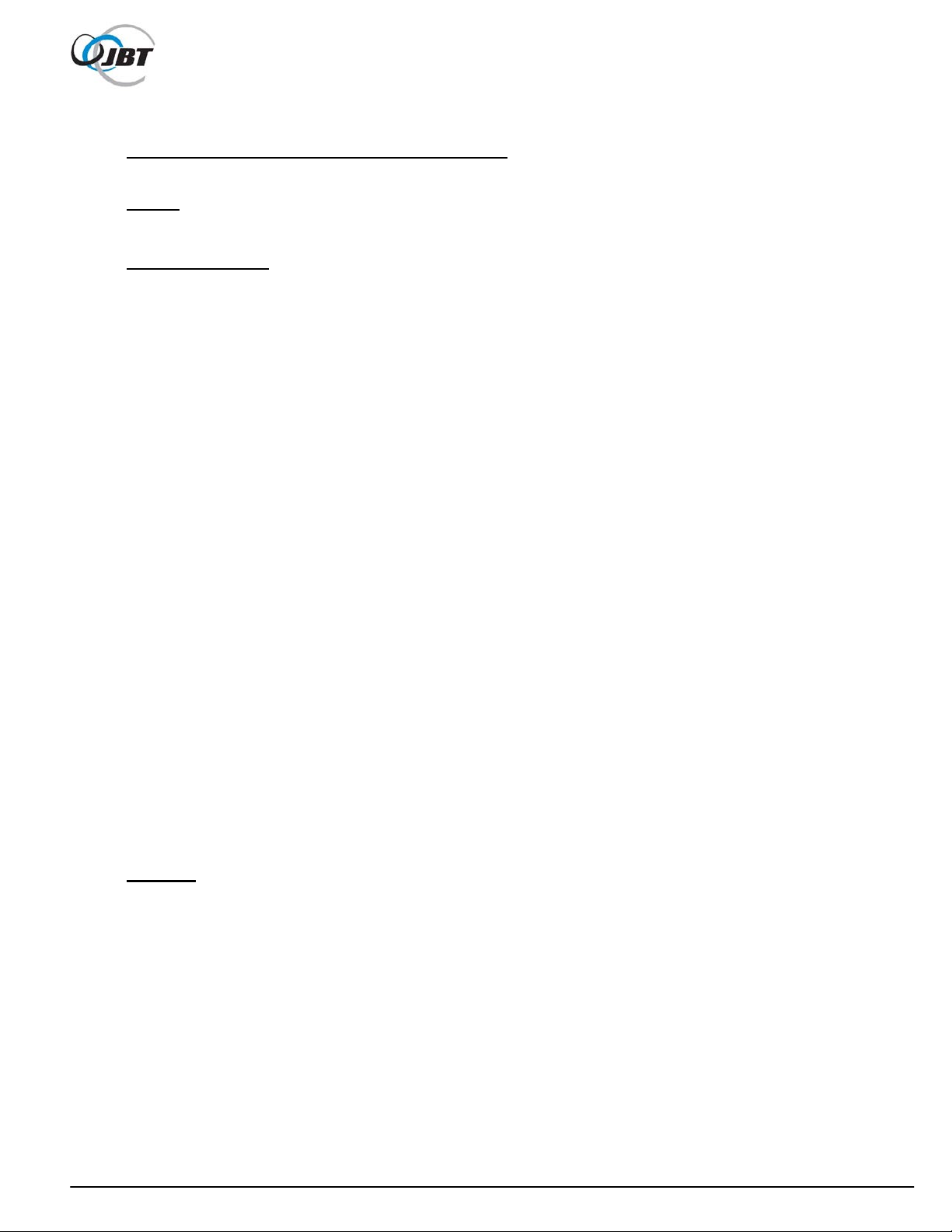

Figure 1a. Produce Plus Juicer

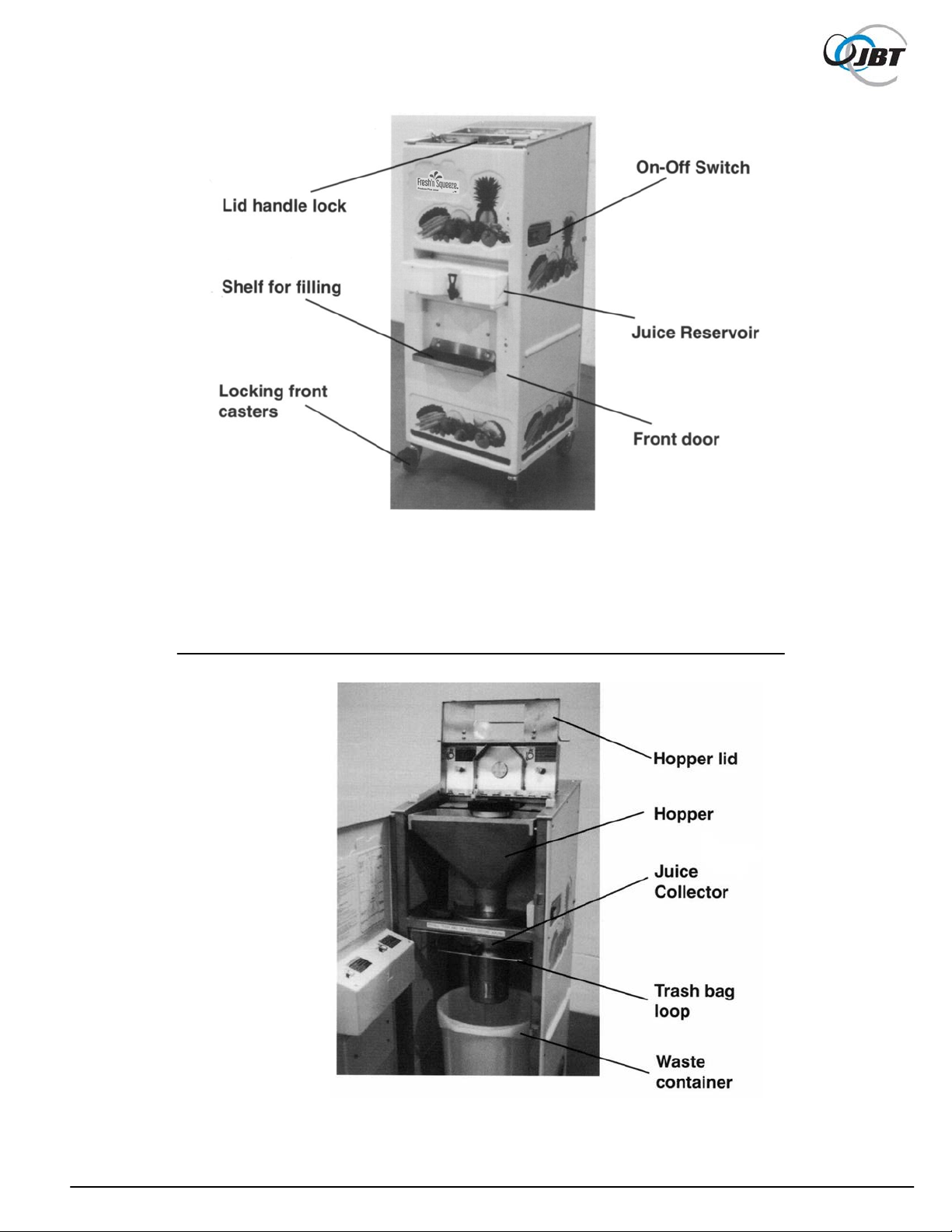

Figure 1b. Juicing Components Assembly

11 FNS-0004-060-EN December 2015 Rev B

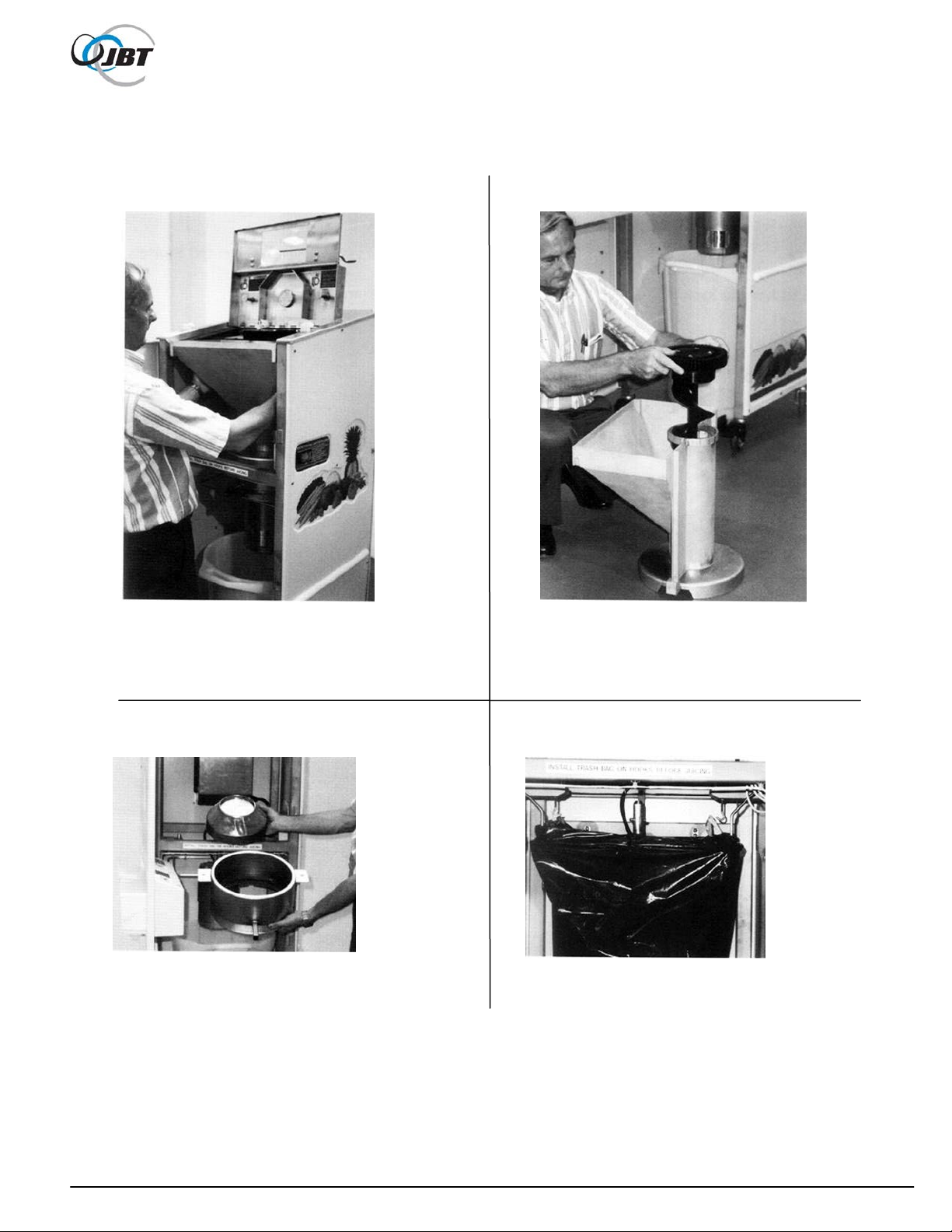

Figure 1c. Lifting out hopper Figure 1d. Lifting screw out of hopper

Figure 1e. Juice collector Figure 1f. Trash bag installed

12 FNS-0004-060-EN December 2015 Rev B

OPERATING INSTRUCTIONS

EQUIPMENT CHECK

Before plugging the JBT Corporation Juicer into an electrical outlet, the following steps

must be performed:

1. Make sure the juicer is clean per cleaning instructions.

2. Juice only in a clean, cool, dry location. The produce department sales floor is

typically the best location.

3. Locate the Juicer on a level surface.

This will prevent fruit feed problems.

4. Lock both front casters.

To lock, push down on caster with foot. To unlock, push again with foot.

5. Check waste container.

Open cart door to verify that waste container is in place. Make sure a plastic bag is

attached to the hooks above the waste container (recommend the "Hefty Cinch Sak

30 gallon capacity or equivalent, drawstring type).

6. Check juicing components.

Use key to unlock juicing components cover. Open cover and check that juicing

components are installed and securely fastened. See Figure 1b.

7. Close and lock all access covers.

There are two separate access covers: Hopper cover and juicing components door cover.

Never operate Juicer unless all covers are in place.

8. Make sure juice reservoir is firmly in place.

9. Make sure juice reservoir faucet is in the closed position.

10. Check the hopper for foreign objects.

Remove any foreign objects found in the hopper.

11. Make sure floor area around juicer is clean and free of obstructions and water.

®

",

W hen water is necessary, wear appropriate non-slip footwear.

13 FNS-0004-060-EN December 2015 Rev B

OPERATING INSTRUCTIONS

Juicing

Wash hands thoroughly before Juicing.

1. Bulk Feed

Unlock and open the hopper cover. Dump up to 15 Ibs. of produce into the hopper. Do not

force lid closed; remove some produce, if hopper is too full.

2. Turn on Juicer

Push the "ON-OFF" button to "ON" position.

3. Automatic Shut-Off

Juicer may shut off with produce in hopper due to high juice level in reservoir. There is a

high level shut-off to prevent the overflow of juice.

4. Turn-off Juicer

Push the "ON-OFF" switch to the "OFF" position.

5. Stir Juice

Use stirrer handle to stir juice in reservoir before filling containers. Fill containers

immediately. DO NOT let juice stand in the reservoir.

6. Discard the first 1 - 2 ounces of juice produced.

This will ensure that any prior contamination or residue is eliminated.

7. Taste each batch of juice for quality before filling containers.

Discard poor tasting product.

8. Fill Containers

Place sterile container under juice reservoir faucet. Open faucet by depressing handle until

container is full. Fill shelf has two adjustments for short and tall containers. Cap juice

immediately and refrigerate at 34°-40°F. All bottles must be coded with three days shelf life

maximum. (See Juice Handling Section)

14 FNS-0004-060-EN December 2015 Rev B

OPERATING INSTRUCTIONS

9. Juicing Different Produce

It is not necessary to fully clean Juicer if immediately switching to another type of juice. Fill a

one gallon container with drinking water. Open hopper and use 1/2 gallon water to rinse leftover product residue. Close hopper and turn on juicer. Pour the remaining 1/2 gallon water

into funnel type hole on top of hopper lid. Remove water from reservoir and rinse throughly.

Proceed to juice the next type of produce.

Water being poured into hole in hopper

10. Clean Juicer

If finished juicing, clean Juicer immediately.

(See next page for cleaning instructions.)

15 FNS-0004-060-EN December 2015 Rev B

CLEANING INSTRUCTIONS

Thorough cleaning of all Juicer components is a necessity.

Do not take any short-cuts in cleaning or sanitizing.

ALWAYS follow cleaning and maintenance schedules in this manual to prevent

equipment damage.

Clean Juicer immediately after juicing. Use a clean soft towel or sponge to wipe equipment

parts. Never use abrasive pads such as steel wool, etc.

The recommended cleaner is JBT Corporation brand CorKlean. CorKlean is a low-foaming

alkaline equipment cleaner. It is safe on aluminum, 100% water soluble and free rinsing.

CorKlean has been especially formulated for cleaning food processing equipment and is USDA

accepted. Follow instructions on cleaner label for dilution.

1. Turn-off Juicer.

2. DISCONNECT ELECTRICAL PLUG.

3. Pull Juicer to clean-up area, if one is available.

16 FNS-0004-060-EN December 2015 Rev B

CLEANING INSTRUCTIONS

4. a. With both hands lift hopper up and out, with plastic feed screw in it.

b. Remove juice collector pan.

CAUTION: TEETH ON GRATER ARE SHARP.

c. Remove screen assembly; remove large pieces of product from inside of screen and

place into waste container.

d. Remove trash bag from hooks; then, remove waste container.

e. Remove juice reservoir and fill shelf.

5. If possible, hose down inside and outside of Juicer with hot drinking water; if not, with waste

container in place, sponge or spray juicing area with cleaning solution. Rinse with hot

drinking water. Be sure to clean stainless steel drive gear. Wipe dry.

6. With a hose or spray nozzle, rinse off all juicing components with clean hot water.

A hard spray on screen assembly will remove all stuck product. Make sure to remove

plastic feed screw from hopper.

7. Prepare a cleaning solution of clean hot water and CorKlean in a sink or large container. .

Follow instructions on cleaner label for dilution..

8. Use brush provided to scrub all juicing components in the solution; (never use a wire brush).

Pay particular attention to cleaning the screen and grater plate. Be careful, the grater teeth

are sharp. If stains are not easily removed, allow juicing components to soak for ten

minutes or longer.

9. Rinse all juicing components with clean hot water; then, thoroughly rinse with sanitizer

solution per manufacturer's mixing directions and safety precautions. Allow to air dry.

10. Re-assemble Juicer per assembly instructions.

17 FNS-0004-060-EN December 2015 Rev B

CLEANING INSTRUCTIONS

11. Install trash bag onto loop and hooks.

12. Make sure waste container is in place.

13. Re-install reservoir and fill shelf with grate.

14. Air dry by turning Juicer on for a minute or two.

15. If reservoir or covers become stained, or mold appears on inside of covers, clean with

appropriate disinfectant cleaner. Follow manufacturer’s directions and safety precautions.

Rinse thoroughly with water.

16. Clean grease marks from covers. Follow manufacturer’s directions and safety precautions.

18 FNS-0004-060-EN December 2015 Rev B

19 FNS-0004-060-EN December 2015 Rev B

MAINTENANCE

Before performing any maintenance,

DISCONNECT ELECTRICAL PLUG.

Juicer requires no lubrication.

DO NOT LUBRICATE ANY BEARING, ROD END, OR SHAFT.

After every juice run:

1. Check screen assembly for damage, or missing mounting screws. Replace if

necessary.

a. Screen removal:

With a flat type screwdriver, remove (4) mounting screws as shown in photo.

CAUTION: Teeth on grater ar e sha rp

Removing mounti ng screws

20 FNS-0004-060-EN December 2015 Rev B

MAINTENANCE

b. Screen Installation:

Reassemble, making sure screws are securely tightened. Reinstall in Juicer. Jog

2. Check grater on screen assembly for missing teeth. If any are missing, replace

3. Check grater on screen assembly for worn teeth.

If out er rows of teeth are almost completely worn down, replace grater.

4. Check large plastic gear on top of feed screw for damage.

5. Check large plastic feed screw for damage.

6. Check for damaged or missing feed screw tip. Replace if less than 1/32" thick. Remove

Juicer to make sure there is no interference.

immediately. DO NOT use.

a. If burred, use knife or file to dress-up corners and edges.

b. If teeth are missing, replace gear.

c. Replace by removing four socket head screws.

DO NOT over-tighten when reassembling.

a. If burred, use knife or file to dress-up.

by turning tip to the left.

21 FNS-0004-060-EN December 2015 Rev B

MAINTENANCE

7. Check motor drive pin. Make sure it is in place and centered in shaft.

8. Check for loose or missing nuts and bolts.

a. Tighten or replace nuts and bolts as necessary.

ALWAYS use JBT Corporation recommended spare parts.

22 FNS-0004-060-EN December 2015 Rev B

TROUBLE SHOOTING

CAUTION: NEVER reach into moving parts to clear a jam,

no matter how simple it seems.

Juicer will not start.

1. Extractor is not plugged into electrical outlet.

2. Building circuit breaker has tripped.

3. All covers are not completely closed including cart and back (cover).

4. High level in reservoir has shut juicer off. Shut off level is approx. 3/4 full.

5. Equipment is jammed.

Call for service.

6. "ON-OFF" switch is defective.

Call for service.

Juicer will not start; but, buzzing sound comes from "ON-OFF" switch.

1. Overloaded circuit.

Machine needs to be on separate (its own) electrical circuit.

2. One or more covers partially closed causing intermittent contact of interlock switch.

3. Low voltage to machine.

Use 110 volts minimum.

Juicer starts, but shuts off.

1. Building circuit breaker is not rated for 20 Amps.

2. Extension cord or wiring is too long.

Eliminate extension cord or use heavier gauge wire.

(See "Specifications")

3. All covers are not completely closed.

Close any open covers.

4. One or more covers has a defective interlock switch.

Turn off Extractor. Call for service.

5. Juice in reservoir has reached max. level - approx. 3/4 full.

Juicer runs with covers open or off.

Turn off Juicer. Call for service.

23 FNS-0004-060-EN December 2015 Rev B

Produce Bridging in Hopper

1. Hopper has dirt or wax built-up.

Clean Hopper.

2. Extremely large carrots.

Break into two pieces before loading into hopper.

Vibration Noise

1. Screen assembly is off balance due to large amount of matted/dry product (especially if

running celery or pineapple) on side of screen.

Remove screen assembly and remove dry product. Reassemble.

Scraping Noise

1. Juicing components not assembled properly and/or product on mounting surfaces.

Check, clean, and re-assemble.

2. Foreign object on grater (seed, rock, etc.)

Remove Hopper and remove object.

Large Pieces of Product in Juice

1. Juicing components not assembled properly

Clean and re-assemble.

2. Damaged screen assembly

Check for holes and replace if necessary.

24 FNS-0004-060-EN December 2015 Rev B

TROUBLESHOOTING

Waste Product on Floor

1. Trash bag not installed or not installed properly. See photo on page 12.

Juice on Floor

1. High level shut off in reservoir not adjusted properly.

Adjust so juicer shuts off before juice level gets to hole in back of reservoir - approx . 3/4 full.

Hopper Cover Will Not Stay in up Position

1. Call For Service.

25 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

1

1

060-05004-F

Cover Parts Details See Pag es 28 through 30

2

1

060-05067-01

Feed Screw Assembly Details See Page 31

3

1

060-05051-B

Hold Down

4

2

004-352-280

Screw, Cap Hex, 1/4-28 x 3/4" Lg, S.S.

5

2

060-05081-B

Hopper Lid Retainer

6

1

060-05105-C

Hopper Lid

7

4

004-501-060

Screw, Cap Hex Head, S/L,1/4-20 x 1" Lg, S.S.

8

1

007-055-526

Clevis

9

1

009-715-098

Gas Spring

10

2

060-05029-B

Hold Down, Hopper Handle

11

1

060-05130

Hopper, S.S. (replaces 06 0 -05013)

12

1

060-05042-C

Juice Collector

13

4

004-385-009

Screw, Mach, Flat Head, #6-32 X 1/2" Lg,S.S.

14

1

060-05088-C

Grater Disc & Hub Assembly – Includes Item 14a

14a

1

060-05087-C

Grater Disc only

15

1

060-05037-C

Screen

16

1

060-05058-B

Key Ring & Key

17

1

060-05028-C

Handle, Hopper Lid

18

6

004-401-022

Screw, Mach., Truss Head, #10-24 x 3/ 8" Lg, S.S.

19

1

060-05055-B

View Window, Hopper

20

4

004-816-060

Washer, Plain, 1/4"

21

1

060-00120-B

Sign, Warning, Covers

22

1

060-00176-B

Sign, Warning, Spanish

23

1

060-00082-B

Label, Hopper English (Not Shown)

25

2

004-111-035

Nut Hex,1/4-28, S.S.

26

1

009-080-327

Brush, Veg. (Not Shown)

27

1

009-080-328

Brush, Valve (Not Shown)

28

1

009-425-020

Spare Key (Not Shown)

29

1

060-05080-B

Label, Cord

30

1

004-111-040

Nut Hex, 5/16-18, S.S.

31

1

060-05083-C

Waste Chute

32

3

004-352-312

Screw, Cap Hex, 5/16-18 x 5/8" Lg, S.S.

33

4

004-806-050

Lock Washer, 1/4"

34

1

060-02087-B

Safety Key

35

2

004-392-174

Screw, Mach., Pan Head, #8-32 x 1/2" Lg

36

2

060-02059-B

Button Nut, #8-32

37

1

006-200-481

Safety Key, Angled

38

2

004-401-022

Screw, Mach., Truss Head, #10-24 x 3/ 8" Lg, S.S.

39

1

060-00082-B

Label, Hopper Spanish (Not Shown)

After 2013:

4

2

060-05137

Threaded Rod, Hopper Lid

10

1

060-05136

Handle, Hopper Lide

25

2

004-116015

Nut Hex,1/4-20, S.S.

Juicer Final Assembly 060-05000-R

26 FNS-0004-060-EN December 2015 Rev B

27 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

1

1

060-05002-F

Drive Assembly Details See Pages 32 through 33

2

1

060-05027-C

Float Frame

3

1

009-210-013

Float

4

1

060-00140-B

Magnet Holder

5

1

006-210-291

Magnet

6

1

060-05026-C

Reservoir Stirrer

7

4

060-05021-B

Pin, Shelf Hanger

8

1

060-05019-C

Shelf, Fill Container

9

1

060-05020-C

Grate, Fill Container

10

1

060-05063-B

Faucet

11

1

060-05073-B

Jam Nut

12

1

009-210-018

Washer

13

1

060-05006-C

Lid, Juice Reservoir

14

1

060-05005-D

Reservoir, Juice

15

1

060-05011-F

Door

16

32

004-401-032

Screw, Mach., Truss Head, #10-24 x 1" Lg, S.S.

17

1

060-05043-B

Access Plate, Back Cover

18

1

004-156-041

Nut, Hex, Self-Locking, #10-24, S.S.

19

1

060-05008-C

Cover, Back

20

1

060-05056-D

Cover, Top

21

1

060-05010-C

Cover, Right Side

22

1

060-05009-C

Cover, Left Side

23

1

060-00148-B

Label, Trash Bag

24

4

004-156-049

Nut, Hex, Self-Locking, 1/4-20, S.S.

25

1

009-092-020

Waste Container

26

1

060-05057-C

Handle

27

2

060-05030-B

Lid Handle Lock

28

4

004-401-033

Screw, Mach., Truss Head, #10-24 x 1-1/4" Lg, S.S.

29

6

004-816-052

Washer, Plain #10, S.S.

30

13

004-401-022

Screw, Mach., Truss Head, #10-24 x 3/ 8" Lg, S.S.

31

1

060-00122-B

Label, Moving Juicer

32

1

015-03935-B

Name Plate, Domestic

32

1

015-03938-B

Name Plate, Export

33

8

004-265-016

Pop Rivet, 1/8 x 1/4

34

1

015-03934-B

Patent Plate

35

1

060-05068-C

Assembly Decal

36

1

060-05069-C

Cleaning Decal

37

1

060-05076-B

Mounting Plate for Decals

38

1

060-05072-B

Label, Wash Produce

39

2

009-395-017

Plastic Knob

40

2

004-397-142

Screw, Mach., Round Head, #10-32 x 1/2" Lg, S.S.

41

2

004-816-052

Washer, Plain, #10

42

1

060-00175-B

Label, Moving Juicer, Spa nish

Cover Parts 060-05004-F

28 FNS-0004-060-EN December 2015 Rev B

29 FNS-0004-060-EN December 2015 Rev B

30 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

1

1

060-05045-D

Feed Screw

2

1

060-05050-B

Tip, Feed Screw

3

1

060-05031-B

Gear, Feed Screw

4

4

004-356-117

Screw, Cap, Socket, 3/8-16 x 2" Lg, S.S.

Feed Screw Assembly 060-05067-01

31 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

1

1

060-05003-F

Frame Weldment

2

2

009-080-530

Caster

3

2

009-080-531

Caster w/ Brake

4

1

060-05099

110V/60Hz Field Replac ement Motor

5

1

060-05007-C

Motor Clamp

6

3

004-352-398

Screw, Cap Hex, 3/8-16 x 1-1/4" Lg, S.S.

7

3

004-111-048

Nut Hex, 3/8-16, S.S.

8

1

060-05079-B

Pin, Motor Drive

9

2

060-05077-B

Bag Hook

10

4

004-111-022

Nut Hex, #10-24, S.S.

11

2

060-05048-B

Pin- Hopper Lower

12

1

060-05066-D

Electrical Assembly, 110 Volt, 60 Hz

Details See Pages 34 through 36

13

6

004-401-022

Screw, Mach, Truss Head, #10-24 x 3/8 Phillips, S.S.

14

1

060-05047-D

Bag Loop

15

2

060-05049-B

Pin, Hopper Upper

16

2

004-506-089

Screw Cap Socket, 1/4-20 x 5/8" Lg, Nylok, S.S.

17

1

060-05052-B

Waste Container Hanger

18

2

060-05078-B

Cleaning Tool Hook

21

1

060-05108-B

Slinger, Motor Shaft

22

3

004-806-070

Washer, Lock, 3/8" (Motor-3 Required)

220V/50Hz Motors:

12

1

060-05066-D

Electrical Assembly, 220 Volt, 50 Hz

Details See Pages 40 through 42

20

1

060-05102

220V/50Hz Field Replac ement Motor

Tools for Motor Replace ment:

1 060-05090

Motor Mounting Fixture

1 060-05142

Grater, Gap Tool, Gage

1 060-05143

Hub Grater Drive Tool

1 060-05144

Hub/Disk Assembly

1 060-05145

Hopper Spacer, Gage

Drive Assembly 060-05002-F

32 FNS-0004-060-EN December 2015 Rev B

33 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

2 5

009-097-003

Cable Tie

4

1

060-05060-C

Enclosure, Start Switch Assembly

5

2

004-401-022

Screw Mach., Truss, #10-24 x 3/8" Lg, Phillips, S.S.

6

1

060-05074-B

Cord Type SJO 4 Cond 16 G A

7

1

006-270-141

Cable Mount Small

8

1

060-05065-C

Electrical & Gearbox Sub-Assembly

9

3

006-220-014

Terminal, # 10 Ring End 10-12 G A.

10

4

004-156-063

Nut Hex, 5/16-18 Self-Locking, S.S.

11

1

006-210-290

Proximity Switch (NC)

12

1

006-080-071

Power Cord #12/3 x 10'-0" Lg

13

4

004-111-022

Nut, Hex, #10-24, S.S.

14

4

004-816-070

Washer Plain, 5/16, S.S.

15

2

006-221-082

1/4 Spade Term 16 GA

16

1

006-221-084

1/8 Spade-Fem-20 GA

17

1

004-397-129

Screw Mach., Round Hea d, # 10 -24 x 1/4" Lg

18

4

009-654-002

Cable Retainer

19

2

006-200-482

Switch, Interlock, Sch mersal #AZ15

20

1

007-143-370

Fitting, Strain Relief, 90º

21

1

007-143-395

Fitting, Strain Relief, Straight

22

1

006-080-073

Cord, 14/2 x 42"

23

1

006-080-073

Cord, 14/2 x 27"

24

2

004-401-026

Screw, Mach., Truss Head, #10-24 x 5/8" Lg, S.S.

25

4

004-816-052

Washer, Plain, #10

26

1

004-401-032

Screw, Mach., Truss Head, #10-24 x 1" Lg, S.S.

27

2

004-440-011

Screw Type “F”, #6-32 x 1/2" Lg, S.S.

28

1

007-143-474

Fitting, Strain Relief, 90°

29

1

007-143-396

Fitting, Straight Strain Relief

Electrical Diagram & Assembly, 110 Volt 060-05066-D

34 FNS-0004-060-EN December 2015 Rev B

35 FNS-0004-060-EN December 2015 Rev B

36 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

1

1

060-05059-C

Enclosure, Electrical

2

1

006-060-078

Strain Relief Fit t in g

3

1

006-060-077

Strain Relief Fit t in g

4

1

006-221-079

Terminal Block, Phoenix #G 5/6

5

1

006-200-474

Switch, On/Off, Weber #AHWTHD15Z4

6

1

009-235-073

Switch Gasket

7

2

004-440-001

Screw, Type “F”, #4-40 x 3/4" Lg, S.S.

8

2

004-440-011

Screw, Type “F”, #6-32 x 1/2" Lg, S.S.

9

2

060-05064-B

Spacer, Terminal Bloc k

10

1

007-486-118

Sealing Ring, Hubbell #205-09-001

11

1

007-146-010

Nut, Tru-Seal, 1/2 NPT

12

1

060-00096-03

Wire, White, 20 GA x 5"

13

1

006-221-084

1/8 Spade Female 20 GA

14

A/R

009-455-002

Marker Pins, Phoenix #B NB:1-6

15

2

004-440-010

Screw, Type “F”, #4-40 x 3/8" Lg, S.S.

16

1

006-221-082

1/4 Spade Term 16 GA

17

1

006-221-083

1/4 Spade Term 12 GA

18

1

006-260-068

Wire, Black, 16 GA x 10" Lg

Enclosure, Start Swit c h Assembly 060-05060C

37 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

1

1

060-05033-F

Electrical Box

2

1

060-05062-C

Panel Assembly, Electrical

3

1

005-617-149

Gearmotor

4

1

060-05032-B

Gear, Stainless Steel

5

1

005-576-223

Key, Sq. 3/16 x 1" Lg, S.S.

6

2

004-541-111

Screw, Set, Self-Locking, 5/16-18 x 3/4" Lg, S.S.

7

1

060-05070-B

Drain Vent

8

1

006-270-194

Connector, Cord, Hubbell #NHC-1023-CRN

9

2

006-060-077

Connector, Cord, 1/2 NPT x 1/ 2 Cord, T&B #2673

10

6

004-401-022

Screw, Mach., Truss Head, #10-24 x 3/ 8" Lg, S.S.

11

3

007-486-118

Sealing Ring

12

3

007-146-010

Nut, Tru-Seal, 1/2 NPT

13

4

004-352-280

Screw, Cap Hex, 1/4-28 x 3/4" Lg, S.S.

Electrical & Gearbox Sub-Assembly 060-05065-C

38 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

1 1

060-05061-C

Panel, Electrical

2 or 11

1

006-035-023

Capacitor, 340-408 MFD, 110V (Supplied with Moto r)

3 or 12

1

006-035-024

Capacitor, 25 MFD, 110V (Supplied with Motor)

4

1

006-035-025

Capacitor, 15 MFD, 60 or 50 Hz (Supplied with Gearmotor)

5

1

006-221-080

Terminal Block, Phoenix #G 5/12

6

2

004-440-001

Screw, Type “F”, #4-40 x 3/4" Lg, S.S.

7

2

009-723-039

Clamp, Capicator, Richc o #UM S-32-45

8

3

004-397-077

Screw Mach., Round Head, # 8-32 x 1/2" Lg

9

A/R

009-455-003

Marker Pins, Phoenix #B NB:1-12

10

2

006-221-082

1/4 Spade Term 16 GA

11

1

006-035-026

Capacitor, 460-552 MFD, 220V (Supplied with Motor)

12

1

006-035-029

Capacitor, 30 MFD, 220V

Items 2 & 3 are for 110 Volt Motors, It ems 11 & 1 2 are for 220 Volt Motors

Electrical Panel Assembly 060-05062C

39 FNS-0004-060-EN December 2015 Rev B

Item

Qty

Part Number

Description

2

5

009-097-003

Cable Tie

3

2

004-440-011

Screw Type “F”, #6-32 x 1/2" Lg, S.S.

4

1

060-05060-C

Enclosure, Start Switch Assembly

5

2

004-401-022

Screw Mach., Truss, #10-24 x 3/8" Lg, Phillips, S.S.

6

1

060-05104-B

Cord, 4 Cond 16 GA

7

1

006-270-141

Cable Mount Small

8

1

060-05065-C

Electrical & Gearbox Sub-Assembly

9

3

006-220-014

Terminal, # 10 Ring End 10-12 G A.

10

4

004-156-063

Nut Hex, 5/16-18 Self-Locking, S.S.

11

1

006-210-290

Proximity Switch (NC)

12

1

006-080-072

Power Cord #14/3 x 10'-0" Lg

13

4

004-111-022

Nut Hex, #10-24, S.S.

14

4

004-816-070

Washer Plain, 5/16, S.S.

15

2

006-221-082

1/4 Spade Term 16 GA

16

1

006-221-084

1/8 Spade-Fem-20 GA

17

1

004-397-129

Screw Mach., Round Head, # 10-24 x 1/4" Lg

18

4

009-654-002

Cable Retainer

19

1

060-05092-C

Enclosure, Transfor mer

20

1

060-05091-C

Plate, Mounting, Transformer

21

1

006-240-030

Transformer, Signal #M4L-2-10

22

2

006-270-194

Connector, Cord, Hubbell #NHC-1023-CRN

23

2

007-486-118

Sealing Ring

24

2

007-146-010

Nut, Tru-Seal, 1/2 NPT

25

2

060-05070-B

Drain Vent

26

4

004-401-022

Screw, Mach., Truss Head, #10-24 x 3/8" Lg, S.S.

27

4

004-605-007

Stand-Off, Male/Female #10-32 Thread, S.S.

28

4

004-156-043

Nut Hex, #10-32, Self-Locking, S.S.

29

2

004-392-172

Screw, Hex, Socket Head, 1/4-28 x 3/4" Lg, S.S.

30

2

004-816-063

Washer, Plain, 1/4", S.S.

31

3

006-220-004

Terminal, # 10 Ring End 16-14 G A

32

1

004-397-129

Screw, Mach., Round Head, #10-24 x 1/4" Lg, S.S.

33

1

006-080-079

Cord #12/3 x 28" Lg

34

1

Plug

Determined by Machines Destintation

35

1

060-05094-B

Grommet

36

2

006-200-482

Switch, Interlock, Sch mersal #AZ15

37

1

007-143-370

Fitting, Strain Relief, 90º

38

1

007-143-395

Fitting, Strain Relief, Straight

39

1

006-080-073

Cord, 14/2 x 42"

40

1

006-080-073

Cord, 14/2 x 27"

41

2

004-401-026

Screw, Mach., Truss Head, #10-24 x 5/8" Lg, S.S.

42

4

004-816-052

Washer, Plain, #10

43

1

004-401-032

Screw, Mach., Truss Head, #10-24 x 1" Lg, S.S.

44

1

007-143-474

Fitting, Strain Relief, 90°

45

1

007-143-396

Fitting, Straight Strain Relief

Electrical Diagram & Assembly, 220 Volt 060-05093-D

40 FNS-0004-060-EN December 2015 Rev B

41 FNS-0004-060-EN December 2015 Rev B

220 VOLT MACHINE

42 FNS-0004-060-EN December 2015 Rev B

Loading...

Loading...