2nd Generation

Multi-Fruit Juicer

Service Manual

June 2019

nd

2

Generation

Multi-Fruit Juicer

Service Manual

Copyright © John Bean Technologies Corporation 2019

JBT Corporation

400 Fairway Avenue

Lakeland, FL 33801

(863) 683-5411

Manual No. FNS-0014-060-EN

2 FNS-0014-060-EN June 2019 Rev A

Table of Contents

Important Safety Information ······································ 4

Specifications ··························································· 6

General Information ·················································· 7

Juicer Screen Descriptions ······································· 9

Maintenance ····························································· 22

Troubleshooting ······················································ 28

Rebuilding ······························································· 31

Illustrated Parts List ················································· 45

Electrical Drawings and Procedures ···························· 75

3 FNS-0014-060-EN June 2019 Rev A

North America

Fax: +1 863 680 3672

Europe

South Africa

Fax: +27 21 982 1136

www.jbtcorporation.com

Brazil

Latin America

Asia / Pacific

Fax: +86 21 6341 0708

FNS-0014-060

A

06/14/19

Initial release

Important Safety Information

You can help prevent personal injury and/or property damage.

Please read this manual carefully before operating the Multi-Fruit Juicer.

DO NOT attempt any operation until you understand exactly how the machine functions.

If uncertainty remains after studying this manual, please contact John Bean Technologies

Corporation.

We're here to help. With proper handling, the JBT Multi-Fruit Juicer will provide safe, efficient

and convenient service for years to come.

Revision History

Manual

Code

Rev. Date Change History

JBT Corporation

400 Fairway Ave

Lakeland, FL 33801

USA

Phone: +1 863 683 5411

JBT Máquinas e Equipamentos Industriais Ltda.

Av. Eng. Camilo Dinucci 4605

14808-900 Araraquara

São Paulo Brazil

Phone: +55 16 3301 2000

Fax: +55 16 3332 0565

JBT Corporation, S.L.

Julián Camarillo 26, 4º

28037 Madrid Spain

Phone: +34 91 304 00 45

Fax: +34 91 327 50 03

JBT Corporation

Carr. Mty-Saltillo Km 7—Bodega 4

Colonia Las Mitras

Santa Catarina, NL

Mexico 66350

Phone: +52 81 81 23 70 55

Fax: +52 81 81 23 70 54

JBT (Pty) Ltd.

Koper Street

Brackenfell

Cape Town, South Africa 7560

Phone: +27 21 982 1130

JBT (Shanghai) Co. Ltd.

Room 3002-3003

Haitong Security Building

No. 689 Guangdong Road

Shanghai 200001,

China

Phone: +86 21 6341 1616

4 FNS-0014-060-EN June 2019 Rev A

Safety Labels

The safety labels shown below appear on the Juice Extractor. Safety labels provide essential

instructions on how to avoid possible hazards.

Please, for your safety: FOLLOW THOSE INSTRUCTIONS AT ALL TIMES.

Should the Juicer safety labels become damaged or unreadable, contact JBT Corporation for

replacement labels.

Safety Instructions

Carefully review the following safety instructions.

Make them a habit when using the JBT Corporation Multi-Fruit Juicer.

1. If Juicer continues to run when any access cover is open, the interlock switch is defective.

Turn Juicer off immediately. Call for service.

2. Prevent unauthorized access to Juicer by locking all covers with supplied key.

3. Prevent unauthorized operation of Juicer by placing electrical plug inside cart door.

4. NEVER attempt to make any safety device inoperative.

5. NEVER operate or perform maintenance or repair work on the Juicer when taking any kind of

drug or sedative, when under the influence of alcohol, or when fatigued.

6. ALWAYS check adjustment of all nuts, bolts, and screws after installation, repair, or periodic

maintenance.

7. NEVER attempt to operate or transport machine if the caster wheels are damaged, do not roll

freely, or if front and rear brakes do not lock.

5 FNS-0014-060-EN June 2019 Rev A

Specifications

Technical Specifications

Fruit size: 2 1/2" to 3 3/4" diameter (6.5 cm to 9.5 cm)

Oranges — FL: ·································· 125 to 50 count

Oranges — CA: ································· 138 to 48 count

Grapefruit — FL: ································ 56 to 48 count

Hopper capacity: ································ 80 Ib. (2 cartons) (36 kg)

Reservoir capacity: ···························· 3.5 gal. (1 carton) (13.2 liters)

Waste container capacity: ···················· 40 Ib. of peel (2 cartons) (18 kg)

Three Speeds:·································· 25 fruit/minute, 29 fruit/minute, 33 fruit/minute

Electrical Specifications

115V, 60 Hz Single Phase 15 AMP Service on a dedicated circuit

10 GA. wire — up to 200 ft. from main breaker panel

or

220 VAC, 50 Hz / 60Hz Single Phase 16 AMP Service

10 GA. wire — up to 200 ft. from main breaker panel

Shipping Specifications

Height: 65.4" (166 cm)

Width: 26" (65 cm)

Depth: 35" (89 cm)

Weight: 711 Ibs (323 kg)

Patents

U.S. Patents - #4905586 and #4922814

and Patents Pending

6 FNS-0014-060-EN June 2019 Rev A

General Information

The JBT Corporation Juicer is designed to provide years of dependable service. It uses a

unique patented design to extract every available amount of juice from the fruit with the

least amount of peel oil. The peel is completely separated from the juice and juice sacs

before being compressed and strained.

The machine will juice all types of citrus — oranges, grapefruit, lemons, limes, tangerines,

etc. — without changing or adjusting parts. In fact, different varieties and sizes of fruit can

be juiced to create various fruit juice blends.

Clean-up is simple, requiring disassembly of only five parts. All waste material — peel,

membranes, and seeds — is collected in a disposable garbage bag for easy removal and

disposal.

The Juice Extractor is solidly built using heavy duty components in all assemblies, including

the drive. It is simple to operate and uses a minimal number of parts.

ALWAYS follow cleaning and maintenance schedules in this manual to prevent equipment

damage and maintain juicer performance.

Figure 1. 2nd Generation Multi-Fruit Juicer

7 FNS-0014-060-EN June 2019 Rev A

Figure 2. Juicing Components Assembly

8 FNS-0014-060-EN June 2019 Rev A

B

C

B C D A D

Juicer Screen Descriptions

Standard Start Screen

Self-Service Start Screen

A. Start Button – Starts juicing

B. Go to Settings – Options to change the juicing speed and the animation shown while juicing.

C. Go to Status – View various information about the unit.

D. Go to Service – Various settings for the juicer (service personnel only).

Access requires a password which is simply “1”.

9 FNS-0014-060-EN June 2019 Rev A

Service 1

A B C D E

F

A. Total Cycles – Indicates the total number of cycles the juicer has run. This is value can be

changed by clicking on it. This is only meant for cases where electrical boxes are being

replaced so that the total juicers cycles will not be lost.

B. Cycles since last service – Indicates how many cycles have run since the last time the juicer

was serviced.

C. Reset Service Date – The button to the right of this will reset the service date shown below as

well as on the status screen.

D. Last Service Date – This shows what the date of the last service was for the juicer. The format

for this date is: Month Day Year.

E. Support Phone Number – Phone number for the service company for the juicer. To change

the number, simply click on the number itself and a keyboard will appear. If desired, dashes and

symbols can be added by clicking the down arrow on the top left twice, the dash is next to the

enter button. Click the up arrow in the top left to return to the numbers. This phone number

appears for general users on the Status page and Safety Fault screen.

F. Constant speed setting – Setting for testing the juicer at a constant speed either slower or

faster than normal operation. To use this feature the juicer must be on the normal speed setting

(top option on the settings screen). Once on this setting, the juicer will operate at whatever

frequency is specified here between 15 and 90 Hz. For example, with this feature the juicer can

be set to run at 15 Hz to see if parts are interfering with each other. This is programed to

default to 60 Hz whenever the juicer is powered off so as not to affect customer operation.

10 FNS-0014-060-EN June 2019 Rev A

A

B D E C F

Service 2

A. Clock – To change the date and clock, click on the numbers. Date and time format are show

above. Time is based on 24 hour format

B. Machine number – Click the numbers to enter the juicer's serial number. The serial number

can be found on the plate on the back of the juicer towards the bottom. The number entered

here is also displayed on the status page for general users to view.

C. Store number – Optional feature for entering an identification number for the facility where the

juicer is located. Currently not used elsewhere in the software.

D. Safety Check – Only viable on certain juicers. This provides a warning (shown later) if a safety

sensor has failed or is unplugged.

a. Turning this on for juicers that do not support this feature (certain juicers with serial

number starting with 83 and 93) will cause the safety circuit fault to always be on,

regardless if the safeties work or not. Refer to Safety Circuit Fault screen to turn off.

E. Tap – Changes how the juicer is operated. When activated, the juicer will run when the tap

handle is depressed, there is no longer a start button. Be aware that this feature requires

several physical alterations to the juicer including removal of the tank, a new front door, tap

housing, new safety sensor assembly, and modified juice manifold.

F. Language – Selection page to determine what language all the text is displayed in, available

languages are shown next.

11 FNS-0014-060-EN June 2019 Rev A

Languages

Selection for the language of all of the text found in the software. If language is changed

accidentally this page can be reached from the start screen or tap screen by:

1. Enter service page (gear icon) – again password is "1".

2. Click the next button (right arrow) found on the bottom right.

3. Click the globe text bubble on the right.

There are currently six available languages as shown here.

12 FNS-0014-060-EN June 2019 Rev A

A

A

Processing Screens

These screens appear when the juicer is actively running.

There are two animations available which can be chosen on the settings page.

A. Stop Button – Juicer will continue to run until it reaches the point when the cups are farthest apart.

• NOTE 1 - In tap mode, the tap handle must be held down for this to function. Once the

juicer has stopped, then the handle can be released.

• NOTE 2 – if the positioning sensor is not functioning this stop button will cause the juicer

to stop immediately.

13 FNS-0014-060-EN June 2019 Rev A

Front Door Open

This screen indicates that the front door is not properly closed. The juicer will not run until the

door is fully closed

If this screen is appearing when the hopper door is open it indicates that the cables on the back

of the electrical panel are reversed. These are the two smaller plugs next two each other with

two cables entering the back of each plug. Switch these two plugs. Open the front door and

ensure the correct screen appears.

If this screen is always on it indicates that the front door safety sensor has malfunctioned. Verify

by swapping the safety cables on the back of the electrical panel. The error message should

switch to the hopper door and still remain on constantly. The cable assembly will need to be

replaced, make sure the cables are connected in their correct location if they had been swapped

for testing.

14 FNS-0014-060-EN June 2019 Rev A

Hopper Door Open

This screen indicates that the hopper door or fruit loading door on top is open. The juicer will not

run while this door is open

If this screen is appearing when the front door is open it indicates that the cables on the back of

the electrical panel are reversed. These are the two smaller plugs next two each other with two

cables entering the back of each plug. Switch these two plugs. Open the hopper door and

ensure the correct screen appears.

If this screen is always on then it indicates that the hopper door safety sensor has malfunctioned.

Verify by swapping the safety cables on the back of the electrical panel. The error message

should switch to the front door and still remain on constantly. The cable assembly will need to be

replaced, make sure the cables are connected in their correct location if they had been swapped

for testing.

15 FNS-0014-060-EN June 2019 Rev A

A

B

Settings Screen

A. Speed setting - The juicer can run at 25, 29, or 33 fruit per minute. Be aware that some harder

or larger fruit may not process at the higher speeds, attempting to do so could lead the juicer to

stall repeatedly.

B. Display setting – Controls the animation seen while the juicer is running (the processing

screens shown previously).

16 FNS-0014-060-EN June 2019 Rev A

A B C

D

E

Status Screen

This mirrors a lot of the information on the service screen but here it cannot be edited.

A. Total Cycles – Indicates the total number of cycles the juicer has run.

B. Cycles since last service – Shows how many cycles have run since the last time the juicer

was serviced.

C. Last Service Date – Date of the last service was for the juicer.

Format for this date is: Month Day Year.

D. Support Phone Number – Phone number for the service company for the juicer.

E. Juicer serial number – Serial number for the juicer.

17 FNS-0014-060-EN June 2019 Rev A

Juice Tank Full

When this screen appears it means that the juice tank is full and the juicer has stopped. The

juicer will not run again until juice is removed from the tank.

Motor Fault

If this screen appears it means that motor has stopped. This is usually caused by a blockage,

large fruit, hard fruit, frozen fruit, or something else. Press the button for the juicer to restart. If

the error continues, the blockage will need to be removed manually. *Always power off the juicer

before attempting to clear any blockage.

In some rare cases the juicer may need to be manually moved in order to clear the blockage.

If this screen appears often, it may mean the juicer is being run at too high of a speed for the

fruit being used. Try using one of the slower speeds to prevent this.

18 FNS-0014-060-EN June 2019 Rev A

Position Sensor Error

This error message occurs because the juicer is operating, but the position sensor (also referred

to as TDC or Top Dead Center sensor) has not been detected. The juicer is still capable of

running, but several features will be disabled. These features include:

1. The speed settings will not function properly, this could lead to the juicer stalling often.

Normal operation at the two faster speeds the juicer will slow while pressing the fruit to

achieve more power. If the position sensor is not detected, the juicer will not slow down and

instead run constantly at the faster speed. This will likely lead the juicer to stall more

because it does not have the power to properly press the fruit.

2. Pressing the stop button now will cause the juicer to stop immediately instead of running

until the cups are farthest apart.

3. Cycle counts will no longer be tracked.

Unplug the juicer and open the back panel, make sure that the safety sensor is connected.

If the sensor seems to work intermittently, check the position and mounting bracket used to hold

the position sensor. The bracket is not symmetrical and should be mounted so that the sensor

holes are near the back of the juicer and away from the juicing components. Also, the sensor

itself has slots so when mounted, the sensor should be pushed towards the back of the juicer as

much as possible.

Improper positioning can cause the juicer to double count cycles. If work is done on this sensor,

be sure to check the cycle count. Run the juicer for five cycles and recheck the cycle count.

19 FNS-0014-060-EN June 2019 Rev A

A

Safety Circuit Fault

When this message occurs it indicates there is a problem with one of the safety sensors. The

juicer will not run until the problem has been fixed.

It is possible one of the cables is not connected. Turn off the juicer and verify that all cables are

connected properly.

If the cables are connected, then it is possible a safety sensor has failed. Follow the procedure

for checking safety circuits in the “Electrical Drawings and Procedures” section of this manual to

determine which sensor is faulty.

This screen can be disabled. There is a hidden button in the bottom right corner (A), this pulls

up the password which is the same as for the service screen. Once on the service screen, go to

the second service screen and turn off the safety check.

NOTE: This will not fix a problem, if a cable is unplugged or safety has failed, the juicer will

still not run.

20 FNS-0014-060-EN June 2019 Rev A

Battery Warning

If this error message occurs, it indicates that the battery in the touch screen is running low. The

juicers are setup so they should run if the battery dies. However, in some cases the software will

be lost and the juicer will not operate. It is best to replace the battery as soon as possible.

Refer to the battery replacement procedure in the “Electrical Drawings and Procedures” section

of this manual.

If the battery was just replaced and the screen still appears, ensure the correct battery was

used, the battery is firmly seated, and there are no smudges or fingerprints on the battery when

it is inserted.

21 FNS-0014-060-EN June 2019 Rev A

Maintenance

Before performing any maintenance,

DISCONNECT ELECTRICAL PLUG.

LOCK FRONT AND REAR CASTER WHEELS.

After every juice run:

1. Check cutter and knives for sharpness.

Refer to Figure 6 to determine condition of cutter.

If dull, sharpen with a whetstone provided.

Refer to Figure 6 to sharpen cutter.

If cutter is severely damaged or rolled over, replace cutter.

a. Cutter removal:

CAUTION: CUTTER AND KNIVES ARE SHARP.

b. Cutter installation:

Disassemble juicing components (Figure 2). Loosen set screw under front knife (make sure

screw is backed out far enough to clear cutter). Cutter should lift out, if not, tap the cutter

lightly from inside the juice manifold with a 1-1/4" diameter rod (hammer handle).

Install red protective cap provided onto cutter. After red protective cap is installed, remove

cutter. Handle cutter with care to avoid direct contact with sharp edge.

Align arrows on cutter and juice manifold to seat cutter. Make sure cutter is fully seated.

Tighten set screw. (DO NOT over-tighten.)

22 FNS-0014-060-EN June 2019 Rev A

Figure 6. Sharpening Cutter

23 FNS-0014-060-EN June 2019 Rev A

Maintenance (continued)

2. Check orifice tube for damage.

Refer to Figure 7.

Replace tube when:

a. Chunks are missing from top end.

b. Score marks 1/32" or deeper appear along the length of the tube.

Figure 7. Severely Damaged Orifice Tube

3. Check for loose or missing nuts and bolts.

a. Tighten or replace nuts and bolts as necessary.

b. DO NOT exceed torque ranges specified.

c. ALWAYS use JBT Corporation recommended spare parts.

24 FNS-0014-060-EN June 2019 Rev A

Figure 8. Proper Orifice Tube Installation

25 FNS-0014-060-EN June 2019 Rev A

Periodic Inspection

Perform the following steps every week.

1. Test all access cover interlock switches.

Juicer should stop automatically when any access cover is opened. Individually open and

close the front door and hopper access door. If juicer continues to run when front door or

hopper access is opened, the interlock switch is defective.

Stop the juicer and replace the defective interlock switch immediately.

See Troubleshooting Section.

2. Inspect casters for damage or wear.

Caster must roll freely and front and rear brakes must lock.

3. Check all fasteners for tightness.

Check especially on the Sprockets, Crank Arms, Fruit Lift and Hopper.

4. Check chain for tightness.

Refer to Figure 9.

Chain should have 1/4 inch maximum slack on top side. To adjust, loosen the tensioning bolt

located on the chain tensioner until 1/4 inch of slack is measured.

CAUTION: DO NOT OVER TIGHTEN CHAIN.

5. Check chain and sprockets for rust.

Lubricate chain and sprockets should rust appear. JBT Select FG Spray (Non-Drip),

p/n 575054, is recommended.

6. Lubricate grease fittings with JBT Select 2FG grease, p/n 575066.

Figure 9. Checking Chain Slack

26 FNS-0014-060-EN June 2019 Rev A

7. Check gear motor.

If Juicer has been laid on its side for any reason (i.e., during shipping), or if there is any

evidence of oil leak, check oil level and add oil, if necessary. Refer To Figure 10.

Use FUCHS FM220 GEAR OIL FG only.

8. Check hopper.

To remove hopper, fruit lift (upper cup drive) must be in down position. Remove two spanner

screws using spanner wrench. Remove hopper.

Figure 10. Gear Motor

27 FNS-0014-060-EN June 2019 Rev A

Troubleshooting

• Juicer will not turn on

1. Juicer is not plugged into electrical outlet.

2. Building circuit breaker or GFI has tripped (reset).

3. Loose wire connection.

Check that all electrical connections are properly installed and secured.

4. On/Off power switch is disconnected

a. Unplug the juicer.

b. With the Front door open loosen the four screws holding the electrical box closed.

c. On the backside of the lid insure that the two black wires (103 and 104) are connected to the

On/Off switch.

d. If power switch is broken replace lid of electrical box or the entire box.

• Juicer starts, but shuts off

1. Juicer is tripping GFCI outlet

Certain GFCI outlets will not support the juicer. Have electrician replace with a compatible outlet.

Known compatible outlets include all models of Legrand 1597 for 15 Amp service and all models of

Legrand 2097 for 20 Amp service. Others may work as well

2. Building circuit breaker is not properly rated for 15 Amps.

3. Extension cord or wiring is too long.

Shorten extension cord or use heavier gauge wire. (See Page 6 "Electrical Specifications")

4. All covers not completely closed (including cart).

Juicer may be flexing when squeezing fruit, causing switch to open. Make sure all latches are

completely locked.

5. The hopper and door cables are reversed.

a. Unplug juicer.

b. Remove the hopper access panel.

c. Unplug the hopper and front door cables (two smaller connectors on top and farthest from

access panel).

d. Switch the cables and plug them back in.

• Juicer will not start

1. Covers are not completely closed.

Open and close both doors, make sure the sensors are securely fastened and then ensure the

doors are firmly closed.

2. Safety sensor has failed. Refer to checking safety sensors to identify broken safety sensor

and replace as necessary.

3. Loose wire inside electrical box

28 FNS-0014-060-EN June 2019 Rev A

Troubleshooting (continued)

• Safety Circuit Fault screen will not go away

1. Safety sensors are not connected properly.

a. Turn off Juicer and unplug from outlet.

b. Remove the hopper access panel.

c. Insure that all the cables on the back of the electrical box are installed and the twist locks on

the connectors are tight.

2. A safety sensor has failed.

a. Follow procedures for checking safety circuits in the “Electrical Drawings and Procedures”

section of this manual.

b. If Faulty sensor is found, replace safety sensor and cable assembly.

3. Electrical box does not support safety circuit monitoring (Only perform these steps if

previous troubleshooting steps do not fix the problem, the process will disable this function

on the juicer)

a. Click in the bottom right corner of the fault screen.

b. Enter the password for accessing the service screen.

c. Enter the second service page.

d. Turn off the safety check.

NOTE: This does not fix an issue, it just disables the screen. If performed on a juicer with this

feature, the juicer will not run. The issue must be fixed and the safety check needs to be turned

back on.

• Juicer runs extremely slowly

1. Constant speed feature has been enabled.

a. Turn juicer off and back on to correct

2. Variable frequency drive programing has been changed

a. Refer to the procedure for re-programing the VFD in the “Electrical Drawings and Procedures”

section of this manual.

b. Follow procedure at the bottom for a Factory Reset

c. Return to the top and follow procedure to program the drive from the beginning

3. PLC terminal strip not firmly connected

a. Unplug the juicer

b. Loosen the four screws on the front of the electrical box

c. On the back side of the lid make sure the green strips connected to the PLC are fully seated

29 FNS-0014-060-EN June 2019 Rev A

Troubleshooting (continued)

• Juicer stalls trying to squeeze fruit

1. Fruit has part of stem on it.

Turn off Juicer and unplug . Remove fruit from the Juicer and restart.

2. Peel is too thick.

Turn off Juicer and unplug. Remove fruit from the Juicer and restart.

3. Juicer is operating too quickly.

Use a lower speed setting on the settings page.

4. Turn off Juicer and unplug . Remove fruit from the Juicer and restart.

5. Cutter is damaged.

CAUTION: CUTTER AND KNIVES ARE SHARP.

a. Sharpen or replace cutter as specified in Maintenance section.

b. Install red protective cap onto cutter.

c. After red protective cap is installed, remove cutter. Handle cutter with care to avoid contact

with sharp edge.

• Juicer runs with covers open or off

Defective interlock switch. Replace immediately.

• Juicer emits "squealing" sound during operation

Spray food grade lubricant on all rotating parts.

Lubricate grease fittings on machine.

If noise continues, rod end or bearing may be defective.

• Scraping noise coming from hopper area

Fruit lift mechanism is dragging on hopper.

See Page 23, Item 8 under “Periodic inspection”.

NOTE: IF AN OPERATIONAL PROBLEM PERSISTS AFTER TROUBLESHOOTING,

CONTACT JBT SERVICE FOR ASSISTANCE.

30 FNS-0014-060-EN June 2019 Rev A

Rebuilding

It is best to replace all bearings at the same time.

Instructions for replacing all bearings, Refer to Service Videos for more details.

1. Remove reservoir and all juicing components.

2. Remove Front Door and All Covers, Sides and Top.

Remove hopper lid prior to removing top cover so interlock switch and cable does not need to be

removed. Place the assembled hopper lid on top of the frame.

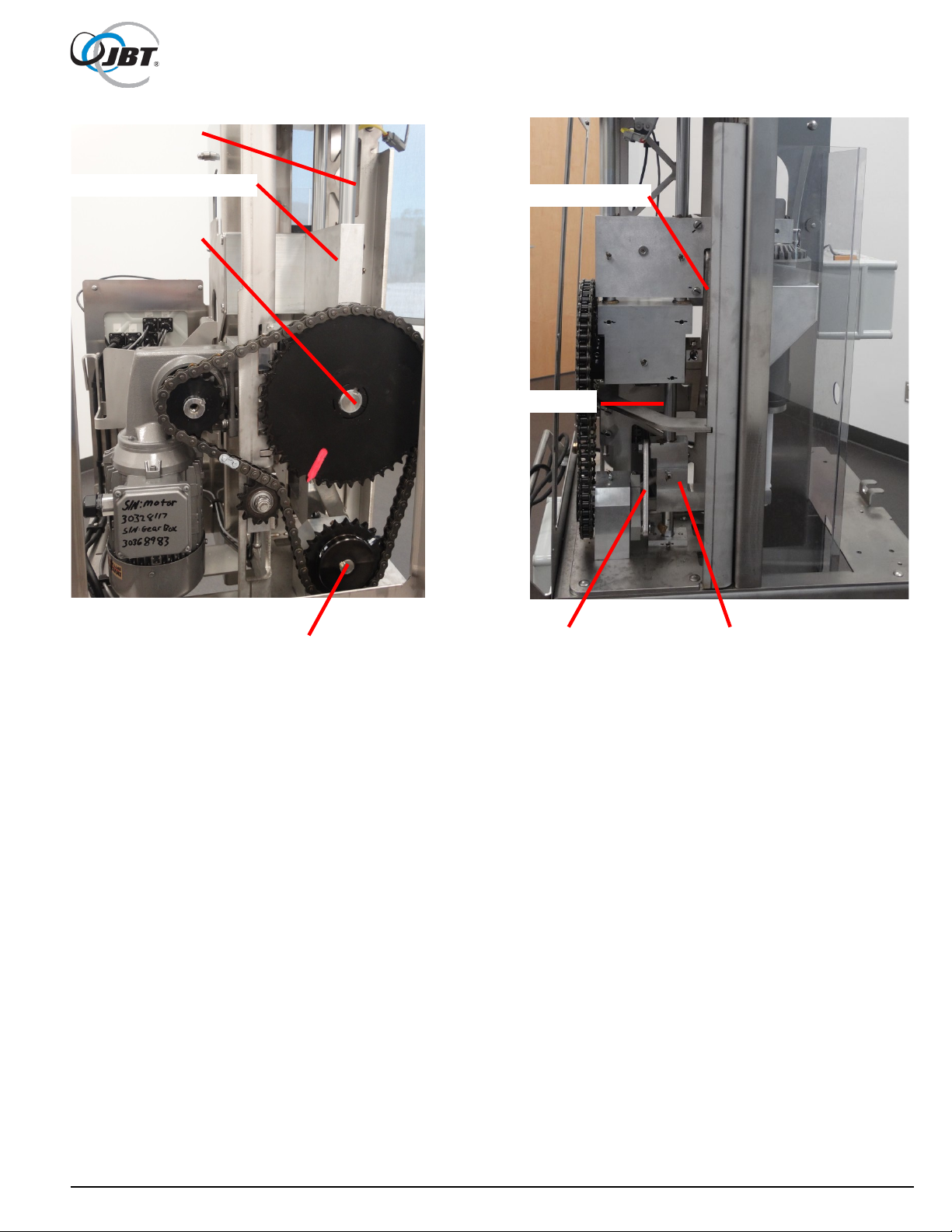

Refer to Figures 11 and 12.

Figure 11. Juicer with All Covers Removed

31 FNS-0014-060-EN June 2019 Rev A

Upper Linear Shafts

Upper Cup Drive Assembly

Upper Rotary Shaft

Upper Drive Crank Arm

Lower Rotary Shaft

Lower Drive Crank Arm

Lower Orifice Drive Assm.

Lower Linear Shaft

Figure 12. Back View of Juicer

32 FNS-0014-060-EN June 2019 Rev A

Rebuilding (Continued)

3. With all side covers removed, use 3/16” and 5/16" Allen wrenches to loosen the set

screw and the socket head cap screw on crank arm for upper cup drive .

(Use Motor Shaft Service Tool 06010400 to rotate gear motor as necessary).

Refer to Figure 13.

Repeat above steps on crank arm for lower drive.

Refer to Figure 14.

Figure 13. Using Allen Wrench to Loosen Upper Cup Crank Arm

Figure 14. Loosening Lower Crank Arm

33 FNS-0014-060-EN June 2019 Rev A

Rebuilding (Continued)

4. Remove linear shafts.

With a 3/16" Allen wrench, loosen set screws at top and bottom of all three shafts.

Back screws out at least 1/4" to clear flats on shafts. If shafts are stuck, use bearing removal

puller with 3/8"-16 x 2" hex head cap screw to break free shafts.

(Note: Lower Shaft will be removed downward through the waste bin area)

Refer to Figure 15.

5. Lift out upper and lower drive arms with linkages still attached.

Refer to Figure 16.

6. Disassemble linkages arms from drive and crank arms.

Note location and numbers of washers and spacers.

7. Using a similar process to step 4 Remove sprockets from shafts and then shafts from

frame.

Pull or pry on large diameter upper drive sprocket, repeat for lower drive sprocket.

Refer to Figure 17.

.

Figure 15. Removal of Linear Shafts

34 FNS-0014-060-EN June 2019 Rev A

Figure 16. Removal of Upper and Lower Drive Arms with Linkages and Crank Arms

Figure 17. Loosen Set Screws and Socket Head Screws and Remove Sprockets

35 FNS-0014-060-EN June 2019 Rev A

Bearing Removal Slug – 1" (Inside)

Bearing Removal Puller

1/2-13 Nut

Bearing Removal Rod

Bearing Removal Driver

Rebuilding (Continued)

Some instructions below show the Generation 1 Juicer but the procedures are the same.

8. Remove sleeve bearings from upper and lower drive arms.

Refer to Figures 18 and 19.

Bearings can be pulled out using puller, 1" removal slug, and short threaded removal rod; or can

be driven or pressed out using driver. New bearings can be installed by compression (Figure 20)

by using installation pilot, installation washer and long threaded installation rod, or just use

installation pilot and press bearings into place. Light coat of Teflon

diameter of bearings.

®

grease can be used on outer

36 FNS-0014-060-EN June 2019 Rev A

Figure 18. Removing Bearings from Upper Drive Arm

Bearing Installation Washer

Bearing Installation Rod

Bearing Installation Pilot

Figure 19. Removing Bearings from Lower Drive Arm

37 FNS-0014-060-EN June 2019 Rev A

Figure 20. Installation of Bearings into Drive Arms

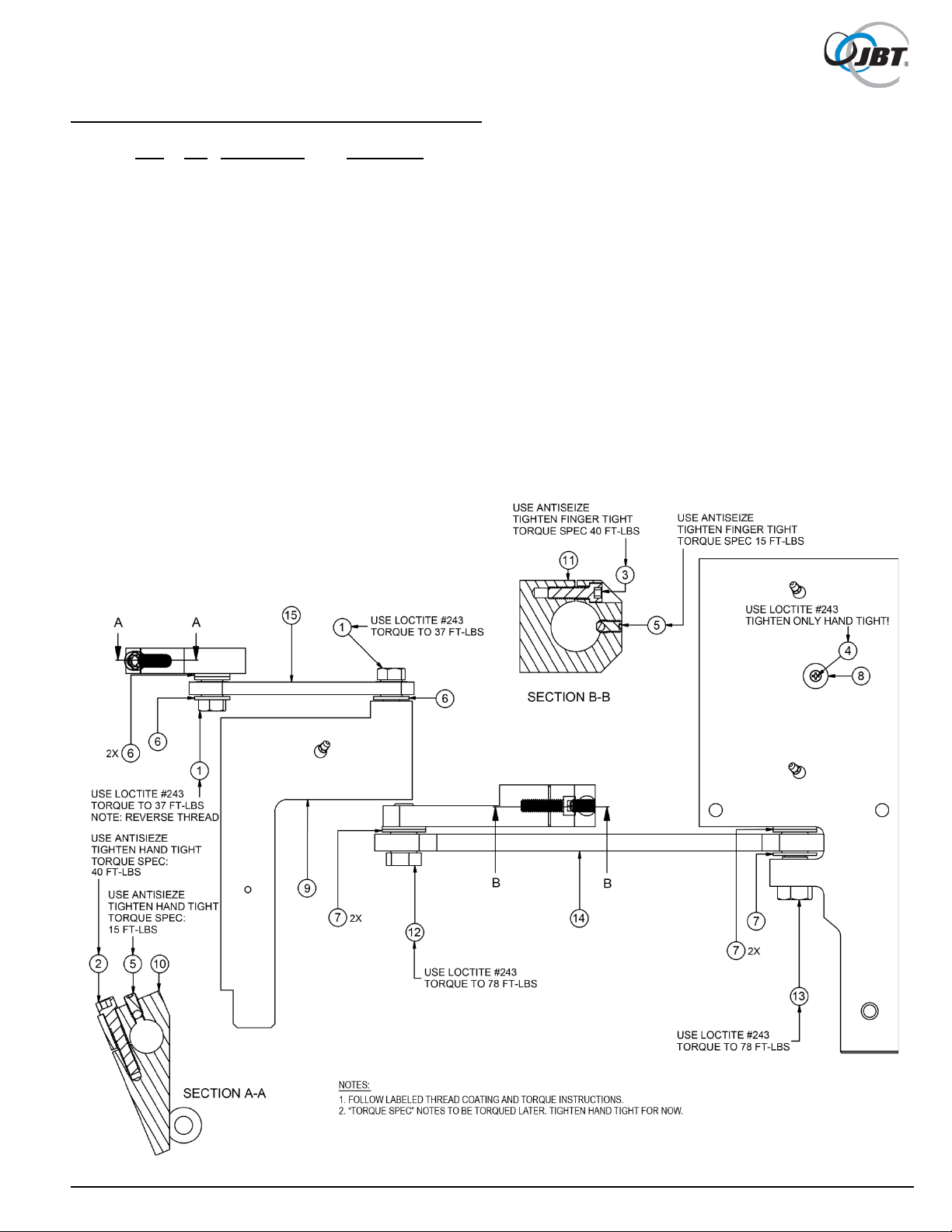

Rebuilding (Continued)

9. Reassemble rod end assemblies to drive arms, again making sure left hand threaded

ends are on the crank arms.

Refer to Figures 21 and 22.

Use Loctite #242 on all fasteners. Tighten to torques as shown. Make sure rod end lock

spacer is installed on rod end in upper drive arm. Make sure plastic bearing buttons are

installed on each side of lower drive arm.

Figure 21. Completed Assembly of Upper Cup Drive Arm

38 FNS-0014-060-EN June 2019 Rev A

Figure 22. Completed Assembly of Lower Drive Arm

39 FNS-0014-060-EN June 2019 Rev A

Rebuilding (Continued)

10. Remove sleeve bearings from main frame.

Refer to Figures 23 and 24.

The outer upper drive shaft bearing can be removed using puller, 1-1/2" removal slug, and short

threaded removal rod.

The inner bearing can be removed the same way, or can be pressed out using driver. The lower

shaft bearing can be removed the same way except using 1" removal slug. New bearings can be

installed by compression (Figure 25) by using installation pilot, installation washer, and long

threaded installation rod. Light coat of Teflon grease can be used on outer diameter of bearings to

aid in installation.

11. There are thrust washers next to each bearing on the main frame. Make sure the old

ones have been removed and new ones installed.

One side of thrust washer is plain metal. Silicone this side and glue them to the frames

(Typical 4 places).

DO NOT get silicone on surface of any bearing. Refer to Figure 26.

12. Before reassembling, check all shafts for excessive wear; replace as necessary.

Reassemble parts in the reverse order of removal. DO NOT forget to put keys back into crank

arms.

On both crank arms, be sure to tighten socket head cap screw first. And then the set screw.

Tighten fasteners to torques shown.

Lubricate all grease fittings if provided.

Figure 23. Removing Bearing from Lower Rotary Drive

40 FNS-0014-060-EN June 2019 Rev A

Bearing Removal Rod

Bearing Removal Slug 1-1/4"

Figure 24. Removing Bearing from Upper Rotary Drive

41 FNS-0014-060-EN June 2019 Rev A

Figure 25. Installation of Bearings and Thrust Washers

ROTATION

Align Marks

Rebuilding (Continued)

Figure 26. Thrust Washer on Both Sides

13. Before installing chain, align timing marks as shown.

Refer to Figure 27.

This is critical to operation of the machine. Adjust chain as shown in Maintenance section.

42 FNS-0014-060-EN June 2019 Rev A

Figure 27. Alignment of Timing Marks

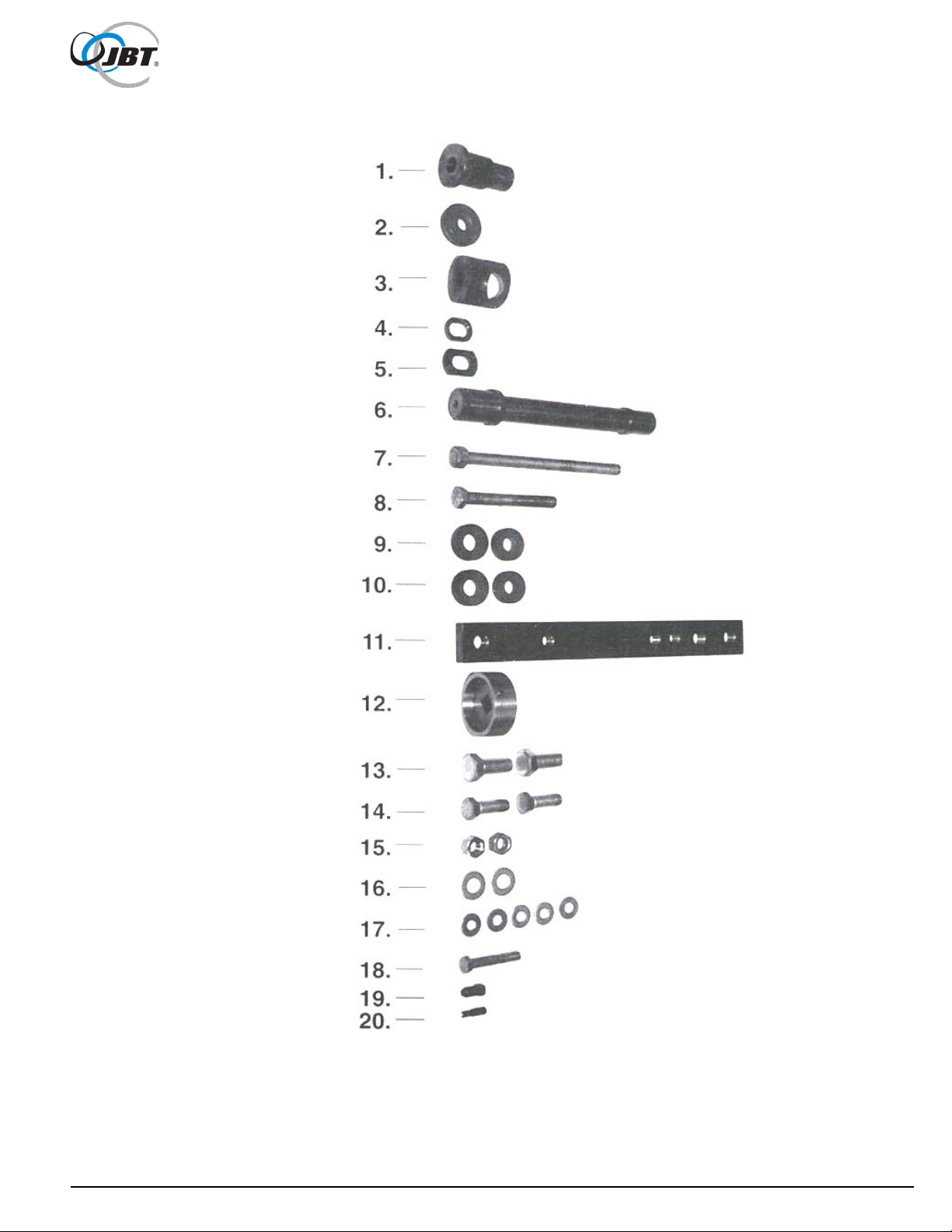

Item

Part Number

Description

1

06000180

Tool, Bearing Installation Pilot

2

06000181

Tool, Bearing Installation Washer

3

06000182

Tool, Bearing Puller

4

06000183

Tool, Bearing Removal Slug 1"

5

06010507

Tool, Bearing Removal Slug 1-1/4"

6

06010508

Tool, Bearing Removal Driver

7

06000186

Tool, Bearing Installation Rod

8

06000187

Tool, Bearing Removal Rod

9

06000188

Tool, Washer, Rod End, 1/2"

10

06000189

Tool, Washer, Rod End, 5/8"

12

06010400

Tool, Adapter, Hand Crank

13

004350648

Screw, Cap, Hex, 5/8-11 x 1-1/2", C/G

14

004350571

Screw, Cap, Hex, 1/2-13 x 1-1/2", Full Thread, C/G

15

004110063

Nut, Hex,1/2-13, Grade 8 Steel

16

004815100

Washer, Plain Narrow, 1/2", C/G

17

004815080

Washer, Plain Narrow, 3/8", C/G

18

004350407

Screw, Cap, Hex, 3/8-16 x 2", C/G

19

009733032

Bit, Drilled Spanner #14, ¼ Hex (Not Pictured)

20

009998004

Bit, Spanner Insert, #8, 1/4 Hex

06010509

Kit, Tool, CJ & MFJ (Includes above Items 1 - 20)

Other Multi-Fruit Juicer Kits

06010510

Kit, Complete Overhaul w/ shafts

Cleaning Components & Other Parts

009080326

Brush, 1-1/16" x 8"

003091001

CorKlean Cleaner

009710031

Stone, Sharpening

003460053

Lubricant, W/ Teflon, 3 Oz Tube

003460057

Lubricant, W/ Teflon, 14 Oz Can

003015905

Silicone, White, 3 Oz Tube

009092018

Cutter Cap

Rebuild Tooling Kit & Spare Parts Kit, 06010509

43 FNS-0014-060-EN June 2019 Rev A

Figure 28. Rebuild Tool Kit

44 FNS-0014-060-EN June 2019 Rev A

6. Motor Mount Blocks

51

7. Bottom Bearing Block, Orifice Tube Block

52

15. Splash Guards

60

16. Splash Shield Guides, Fruit Guides

61

17. Fruit Lift, Hopper Mounting

62

25. Decals, 3-Piece, Large Logo (Optional)

70

26. Juicing Components

71

27. Self-Service Juicing Components

72

Illustrated Parts Lists

Assembly drawings in this chapter provide a list of part numbers for replaceable parts

available for the 2

provided:

Parts List / Parts Drawing Page

1. Cart, Tool Holder Mounting 46

2. Main Stainless Steel Center Frame 47

3. Center Plate 48

4. Cup Mounting Blocks, Lower Cup 49

5. Centering Drive Block 50

8. Rotating Assembly, Lower and Upper 53

9. Sliding Shafts 54

nd

Generation Multi-Fruit Juicer. The following parts list/drawings are

10. Rotating Shafts, Thrust Bearings 55

11. Wiring Routing Tabs, Weld Stubs 56

12. Chain Tensioner 57

13. Chain, Sprocket and Motor Mounting 58

14. Grease Fittings 59

18. HMI Mounting, Proximity Sensors for Float and TDC 63

19. Electrical Connections 64

20. Hopper 65

21. Hopper Top Cover, Lid and Sensors 66

22. Panels, Left and Rear 67

23. Service Panel, Right Panel 68

24. Decals (Standard) 69

28. Splash Shield, Waste Bin, Tools and Accessories 73

29. Doors, Latches and Hinges 74

45 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

1

06010103

Cart Assembly

2

1

06010291

Tool Holder

1. Cart, Tool Holder Mounting

Figure 29. Cart

46 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

12

004011032

Bolt, Carriage, 3/8-16 X 1-1/4" Lg, 304SS

2

9

004156074

Nut, Hex, S/L, Light, 3/18-16, 304SS

3

19

004816086

Washer, Flat, 3/8", SS

4

1

06010231

Frame, 2nd Gen MFJ, Machined

2. Main Stainless Steel Center Frame

47 FNS-0014-060-EN June 2019 Rev A

Figure 30. Main Stainless Steel Center Frame

Item

Qty

Part Number

Description

1

12

004011032

Bolt, Carriage, 3/8-16 X 1-1/4" Lg, 304SS

2

1

004156072

Nut, Hex, S/L, Heavy, 3/18-16, 304SS

3

7

004156074

Nut, Hex, S/L, Light, 3/18-16, 304SS

4

15

004816086

Washer, Flat, 3/8", SS

5

1

06010194

Plate, Formed, Juicing Area

3. Center Plate

48 FNS-0014-060-EN June 2019 Rev A

Figure 31. Center Plate

Item

Qty

Part Number

Description

1

2

004210030

Pin, Dowel, 3/8" Diameter X 7/8" Lg, 304SS

2

4

004210044

Pin, Dowel, 1/4" Diameter X 1-1/8" Lg, SS

3

6

004415013

Screw, Shoulder, 3/8" X 5/8" Lg, 1/2" Shoulder, 18-8SS

4

1

06010227

Cup Mount, LH

5

1

06010232

Cup Mount, RH

4. Cup Mounting Blocks, Lower Cup

Figure 32. Cup Mounting Blocks, Lower Cup

49 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

4

004415014

Screw, Shoulder, 1/2" X 3/4" Lg, 3/8-16 Thread, 18-8SS

2

4

06010069

Spacer, Alignment Block

5. Centering Drive Block

50 FNS-0014-060-EN June 2019 Rev A

Figure 33. Centering Drive Block

Item

Qty

Part Number

Description

1

4

004415051

Screw, Socket Head, 3/8-16 Thread, 3" Lg, 18-8SS

2

4

004701002

Stud, Fully Threaded, 3/8-16, 2-1/4" Lg, 18-8SS

3

2

06010071

Spacer, Right Angle Motor Mounting

6. Motor Mount Blocks

51 FNS-0014-060-EN June 2019 Rev A

Figure 34. Motor Mount Blocks

Item

Qty

Part Number

Description

1

1

003030296

Bar, Flat, Aluminum, 3" X 5"

2

4

004352397

Screw, Cap, Hex, Full Thread, 3/8-16 X 1-1/2", SS

3

16

004806070

Washer, Lock, 3/8" Reg, SS

7. Bottom Bearing Block, Orifice Tube Drive Block

Figure 35. Bottom Bearing Block, Orifice Tube Drive Block

52 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

2

004352571

Screw, Cap, Hex, 1/2-13 X 1-1/2", SS

2

2

004355051

Screw, Cap, Hex, Socket Head, 3/8-16 X 2", S/L, Alloy

3

1

004356109

Screw, Cap, Hex, Socket Head, 3/8-16 X 1-1/4", S/L,. Steel

4

1

004385057

Screw, Flat Head, Hex, 8-32 X 1/2" Lg, 304SS, Nylock, Pellet

5

9

0043541138

Screw, Cap, Hex, Socket Set Cup Point, 3/8-16

6

4

004816100

Washer, Plain N, 1/2", SS

7

5

004816120

Washer, Plain N, 5/8", SS

8

1

007143009

Counter Sunk Disc, Magnetic, 3/4" OD

9

1

06000011

Arm, Orifice Tube Drive

10

1

06000058

Crank, Orifice Tube Drive

11

1

06010242

Crank, Upper Cup Drive

12

1

06010258

Screw, Upper Cup Crank, LH

13

1

06010323

Upper Arm Bolt

14

1

06010174

Assembly, Arm, Link, Upper Cup

15

1

06010175

Assembly, Arm, Link, Orifice Drive

16

1

06000057

Lock, Rod End

8. Rotating Assembly, Lower and Upper

Figure 36. Rotating Assembly, Lower and Upper

53 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

5

004352395

Screw, Cap, Hex, 3/8 X 1, SS

2

9

0043541138

Screw, Cap, Hex, Socket Set Cup Point, 3/8-16

3

16

004806070

Washer, Lock, 3/8" Reg, SS

4

2

06000064

Upper Cup Drive Linear Shaft

5

1

06000063

Linear Orifice Drive Shaft

6

1

06010064

Block, Guide, Upper Cup Guide Rods

7

1

06010065

Block, Guide, Orifice Rod

8

6

005098731

Bearing, 1"

9. Sliding Shafts

54 FNS-0014-060-EN June 2019 Rev A

Figure 37. Sliding Shafts

Item

Qty

Part Number

Description

1

2

005062805

Washer, Thrust,1-1/2" ID X 2-1/2" OD

2

2

005098112

Thrust Washer

3

1

005576061

Key, Square, 1/4" X 3/4" Lg, 416SS

4

2

005576286

Key, Square, 3/8" X 1-1/4" Lg, 304SS

5

1

06006061

Shaft, Rotary Orifice Drive

6

1

06006101

Rotary Main Drive Shaft

7

2

005098731

Bearing, 1"

8

2

005098772

Bearing, 1-1/2"

10. Rotating Shafts, Thrust Bearings

55 FNS-0014-060-EN June 2019 Rev A

Figure 38. Rotating Shafts, Thrust Bearings

Item

Qty

Part Number

Description

1

18

004705106

Stud, Weld, Threaded Flange, #10-24 X 3/4" Lg, SS

2

20

004156041

Nut, Hex, S/L, #10-24, SS

3

5

006270314

Clamp, Chemical Resistant, 7/16" ID, 1" Line

4

1

006270317

Clamp, Chemical Resistant, 1/4" ID, 1" Line

5

3

006270318

Clamp, Chemical Resistant, 7/16" ID, 2" Line

6

9

006270319

Clamp, Chemical Resistant, 1/4" ID, 2" Line

11. Wiring Routing Tabs, Weld Stubs

56 FNS-0014-060-EN June 2019 Rev A

Figure 39. Wiring Routing Tabs, Weld Stubs

Item

Qty

Part Number

Description

1

1

004116026

Nut, Jam, 3/8-16, SS

2

1

004156118

Nut, Hex, S/L, Thin, 5/8-11, SS

3

2

004352392

Screw, Cap, Hex, 3/8-16 X 7/8" Lg, 304SS

4

1

004352415

Screw, Cap, Hex, Full Thread, 3/8-16 X 3-1/2" Lg, SS

5

16

004806070

Washer, Lock, 3/8" Reg, SS

6

1

004605030

Spacer, Unthreaded, 1" OD, 3/8" Lg, 5/8" Screw, 18-8SS

7

1

005806374

Sprocket, Idler, #60, 12T, 3/4" P, 1-9/16" Diameter

8

1

06010171

Mount, Chain Tensioner

9

1

06010355

Bolt, Idler Sprocket, Cut to Length

10

1

06010367

Chain Tensioner Washer, 5/8"

12. Chain Tensioner

57 FNS-0014-060-EN June 2019 Rev A

Figure 40. Chain Tensioner

Item

Qty

Part Number

Description

1

4

004110066

Lock Nut, Nylon Insert, Thin, 3/8-16, 18-8SS

2

2

004355051

Screw, Cap, Hex, Socket Head, 3/8-16 X 2" Lg, S/L, Alloy

3

2

004541112

Screw, Set, Hex, S/L, 5/16-18 X 3/4" Lg, C/G

4

9

004541138

Screw, Socket Set, Cup Point, 3/8-16

5

4

004701002

Stud, Fully Threaded, 3/8-16 X 2-1/4" Lg, 18-8SS

6

16

004806070

Washer, Lock, 3/8" Reg, SS

7

1

005220148

Chain, #60, Single Strand, Plus (1) Con, (1) Half Link, Steel

8

1

005576242

Key, Square, 1/4" X 1" Lg, 416SS

9

1

005804235

Sprocket, Wear Resistant, 1-1/4", 16T, ANSI60 Chain

10

1

06000065

Sprocket, Orifice Drive

11

1

06006120

Sprocket, Upper Cup Drive Arm

13. Chain, Sprocket and Motor Mounting

Figure 41. Chain, Sprocket and Motor Mounting

58 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

2

007120205

Fitting, Grease, 1/4-28 x 45mm

14. Grease Fittings

59 FNS-0014-060-EN June 2019 Rev A

Figure 42. Grease Fittings

Item

Qty

Part Number

Description

1

20

004156041

Nut, Hex, S/L, #10-24, SS

2

15

004385055

Screw, Machine, Flat Head,#10-24 X 1" Lg, Phillips Head

3

10

004816052

Washer, Plain, #10, SS

4

1

06010216

Splash Guard, Upper

5

1

06010217

Splash Guard, Lower

6

1

06010262

Upper Guard Cover, Upper Splash Guard

7

1

06010263

Lower Guard Base, Lower Splash Guard

8

1

06010264

Lower Guard Cover, Lower Splash Guard

15. Splash Guards

60 FNS-0014-060-EN June 2019 Rev A

Figure 43. Splash Guards

Item

Qty

Part Number

Description

1

2

004111048

Nut, Hex, 3/8-16, SS

2

2

004392170

Screw, Machine, Pan, #10-24 X 1/2" Lg, Phillips Head, 304SS

3

2

004397075

Screw, Round Head, Pan, 10-24 Threaded, 7/8" Lg, Phillips Head, 18-8SS

4

2

004405008

Screw, Set, Cup Point, 3/8-16 X 1-1/4" Lg, 18-8SS

5

4

004501152

Screw, Cap, Hex, S/L, 3/8-16 X 1" Lg, SS

6

16

004806070

Washer, Lock, 3/8", SS

7

10

004816052

Washer, Plain, #10, SS

8

15

004816086

Washer, Flat, 3/8", 7/8" Diameter, SS

9

1

06010207

Reservoir Slide Base

10

1

06010244

Mount, Splash Shield

11

1

06010329

Fruit Guide Kit, Small Fruit

16. Splash Shield Guides, Fruit Guides

Figure 44. Splash Shield Guides, Fruit Guides

61 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

5

004352395

Screw, Cap, Hex, 3/8" X 1" Lg, SS

2

2

004352410

Screw, Cap, Hex, 3/8-16 X 2-1/4" Lg, 304SS

3

2

004356104

Screw, Cap, Hex, Socket Head, 3/8-16 X 1" Lg, 316SS

4

52

004401023

Screw, Phillips Head, Extra Wide, 8-32 Threaded, SS

5

1

004605029

Standoff, Hex, 5/8" X 1-2/3" Lg, 18-8SS

6

4

004816080

Washer, Plain, 3/8" N, 304SS

7

15

004816086

Washer, Flat, 3/8", 7/8" Diameter, SS

8

1

06010240

Fruit Lift, Mount Block

9

1

06010243

Mount, Hopper, Bolt

17. Fruit Lift, Hopper Mounting

62 FNS-0014-060-EN June 2019 Rev A

Figure 45. Fruit Lift, Hopper Mounting

Item

Qty

Part Number

Description

1

4

004011032

Nut, Hex, 1/4-20, SS

2

4

004156014

Nut, Hex, S/L, 4-40, SS

3

4

004156053

Nut, Hex, S/L, Light, Thin, 1/4-20, 304SS

4

4

004356064

Screw, Cap, Socket Head, 1/4-20 X 1-1/4" Lg, SS

5

4

004396116

Screw, Round, Bind, Slot, Extra Wide, 4-40 Threaded, 5/8" Lg, SS

6

52

004401023

Screw, Phillips, Extra Wide, 8-32 Threaded, 1/4" Lg, SS

7

4

004816060

Washer, Plain, 1/4" N, SS

8

6

004816095

Washer, #6, .149" ID, .625" OD, Oversized, 304SS

9

1

06010118

Electrical Panel Assembly

10

2

06010305

Proximity Switch Assembly, Normally Open Connection

11

1

06010306

TDC Sensor Bracket

18. HMI Mounting, Proximity Sensors for Float and TDC

Figure 46. HMI Mounting, Proximity Sensors for Float and TDC

63 FNS-0014-060-EN June 2019 Rev A

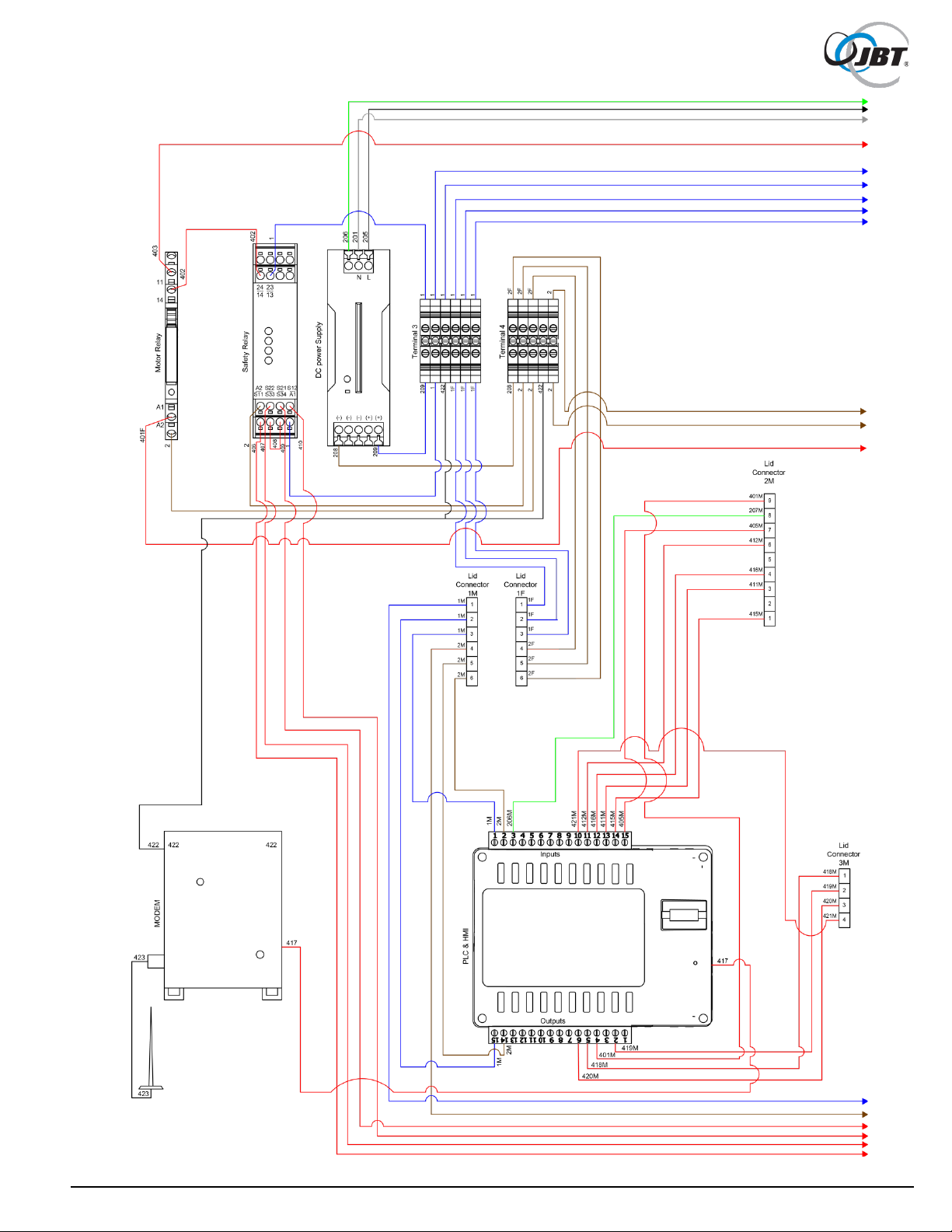

19. Electrical Connections

Figure 47. Electrical Connections

64 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

1

06010162

Hopper Assembly

2

2

06010254

Screw, Spanner, Hopper

20. Hopper

65 FNS-0014-060-EN June 2019 Rev A

Figure 48. Hopper

Item

Qty

Part Number

Description

1

6

004156032

Nut, Hex, S/L, Light, 8-32, 304SS

2

8

004385178

Screw, Span, Flat, 8-32 Threaded, 3/4" Lg, 18-8SS

3

52

004401023

Screw, Phillips, Extra Wide, 8-32 Threaded, 1/4" Lg, SS

4

1

006090018

Plug, Knockout, 7/8" ID Hole, Gray Nylon

5

2

009080421

Rubber Push-In Bumper with Tight-Grip Stem

6

2

009284961

Torque Hinge, Concealed, SS

21. Hopper Top Cover, Lid and Sensors

Figure 49. Hopper Top Cover, Lid and Sensors

66 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

12

004011032

Bolt, Carriage, 3/8-16 X 1-1/4" Lg, 304SS

2

4

004100004

Nut, Cap, Acorn, High Crown, #8-32, SS

3

4

004100018

Nut, Cap, Acorn, 3/8-16, SS

4

14

004156166

Nut, Acorn, Lock, Distorted Thread, 8-32. 18-8SS

5

4

004260017

Rivet, Pop, 1/8", SS

6

14

004385174

Screw, Round, Drilled Spanner, Extra Wide, 8-32 X 1/2", SS

7

52

004401023

Screw, Phillips Head, Extra Wide, #8-32 Threaded, SS

8

2

004510107

Screw, Button Head, 3/8-16 X 1" Lg, Philips, 18-8SS

9

15

004816086

Washer, Flat, 3/8", SS

10

14

004816105

Washer, Oversized, #8, 18-8SS

11

2

009284050

Female Hinge

12

1

01503948

Name Plate

13

1

06006311

Side Cover, LH

14

1

06006312

Glass, LH Side

15

1

06010179

Bracket, Handle, Right

16

1

06010180

Handle, MFJ Cart

17

1

06010209

Gasket, Window

22. Panels, Left and Rear

67 FNS-0014-060-EN June 2019 Rev A

Figure 50. Panels, Left and Rear

Item

Qty

Part Number

Description

1

6

004156032

Nut, Hex, S/L, Light, 8-32, 304SS

2

4

004385178

Screw, Span, Flat, 8-32 Threaded, 3/4" Lg, 18-8SS

3

2

004392175

Screw, Machine, Pan, 8-32 X 3/4" Lg, 304SS

4

52

004401023

Screw, Phillips, Pan, Extra Wide, 8-32 Threaded, 1/4" Lg, SS

5

1

06010349

Cover Assembly, RH Side

23. Service Panel, Right Panel

Figure 51. Service Panel, Right Panel, Decals

68 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

1

009450032

Decal, Fresh N' Squeeze Logo

2

1

009450040

Decal, Cleaning Components

3

1

06000104

Decal, Warning Label, Sheer/Hand Crush, English/Spanish

24. Decals (Standard)

69 FNS-0014-060-EN June 2019 Rev A

Figure 52. Decals (Standard)

Item

Qty

Part Number

Description

1

3

009450245

Decal, MFJ, Logo, Fresh 'N Squeeze, 10.25" X 22", Matte, Vinyl

25. Decals, 3-Piece, Large Logo (Optional)

Figure 53. Decals, 3-Piece, Large Logo (Optional)

70 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

1

004220037

Pin, Quick Release, Ring Grip

2

1

004406003

Screw, Machine, Round, #4-40 X 3/16" Lg, 304SS

3

1

06000004

Cup, Lower, Machined

4

1

06000022

Nozzle, Straight, FDA Grade

5

1

06000027

Cup, Upper, Assembly

6

1

06000225

Cutter and Knives, Machined

7

2

06000098

Nut, Spanner

8

1

06000108

Manifold, Juice

9

1

06010073

Screw, Spanner

10

1

06010143

Tube, Orifice, Snap In

11

1

007486119

O-Ring, Nozzle, Viton, 1/16" Section

26. Juicing Components

71 FNS-0014-060-EN June 2019 Rev A

Figure 54. Juicing Components

27. Self-Service Specific Juicing Components

Item

Qty

Part Number

Description

1

1

06010494

Handle Momentary

1a 1 06010495

Handle Continuous

2

1

06010485

Spout Cap

3

1

06010482

Spout Body

4

1

06010479

Self-Service Housing

5

1

06010442

Manifold with Vent

6

1

06010429

Drip Tray Cover

7

1

009210043

Seat Cup

8

1

009210042

Stem

9

1

009210041

Spring

10

1

007486119

O-Ring Nozzle

Figure 55. Splash Shield, Waste Bin, Tools and Accessories

72 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

1

003091001-2

Cleaner, Corklean, 2 lbs

2

1

009080327

Brush, Dish

3

1

009080328

Brush, Tube, 1"

4

1

009092018

Cap, Cover

5

1

009092023

Waste Container, 21" X 17" X 12", Polyethylene, Grey

6

1

009710031

Stone, Sharpening, Half Round

7

1

06000077

Tool, Wrench, 5/16" Diameter

8

1

06000084

Rod, Orifice Clean Out

9

1

06001127

Cleaning Component Kit

10

1

06010188

Splash Shield

11

1

06010359

Triple Fruit Sizer, Hand-Held

28. Splash Shield, Waste Bin, Tools and Accessories

Figure 56. Splash Shield, Waste Bin, Tools and Accessories

73 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

2

004385176

Screw, Span, Pan, 8-32 Threaded, 5/8" Lg, 18-8SS

2

1

06010146

Drip Tray Weldment

3

1

06010147

Drip Tray Cover

4

1

06010315

Door Assembly

4a

1

06010411

Self Service Door Assembly

29. Door, Latches and Hinges

74 FNS-0014-060-EN June 2019 Rev A

Figure 57. Door, Latches and Hinges

Parts List / Parts Drawing

Page

31. VFD Enclosure Assembly, 06010366

77

32. Electrical Panel Assembly, 06010118

78

Electrical Drawings and Procedures

Electrical drawings in this chapter provide a list of part numbers for replaceable parts

available for the 2

provided:

30. Drive, Motor Wiring, 3-Phase, 230V/460V, 50 Hz/60 Hz, 06010357 76

Wiring Schematic, Electrical Panel 81

Wire Table, Electrical Panel 83

33. Programming the VFD 84

34. Procedure to Check Safety Cable Assemblies 85

35. PLC Battery Replacement Procedure 92

nd

Generation Multi-Fruit Juicer. The following parts list/drawings are

75 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1

1

005617345

Gear Motor, Worm,1.5 HP,3 PH, 230V/460V, 50,Hz/60Hz, 1:25 Gear, 1.25 Shaft

2

1

06010366

VFD Enclosure Assembly

30. Drive, Motor Wiring, 3-Phase, 230V/460V, 50 Hz/60 Hz, 06010357

Figure 58. Drive, Motor Wiring, 3-Phase, 230V/460V, 50 Hz/60 Hz

76 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1 1 06010360

Enclosure, VFD, Add Holes

2 1 06010358

Back Panel, VFD

3 1 06010317

HMI-VFD Power Cord

4 1 06010316

VFD-Motor Power Cord

5 1 06010314

HMI-VFD Signal Cord

6 1 06010311

Rear Enclosure Bracket

7 1 006280536

VFD, 115/230V, 50Hz/60Hz, 1.5 HP-2 HP, UL

8

12

004816052

Washer, Plain, #10, SS

9 4 004401023

Screw, Phillips head, Extra Wide, 8-32" Threaded, 2/8" Lg

10

4

004356062

Screw, Cap Socket, 1/4-20 X 1: Lg, SS

11

8

004156042

Nut, Hex, S/L,Thin,10-24, 304SS

12

4

004111032

Nut, Hex, 1/4-20, SS

13

4

004011051

Bolt, Carriage,10-24 X 1/2" Lg, Square Neck, Full Thread, SS

31. VFD Enclosure Assembly, 06010366

Figure 59. VFD Enclosure Assembly

77 FNS-0014-060-EN June 2019 Rev A

Item

Qty

Part Number

Description

1 3 003435022

Gasket, Flange, 0.862", Shell Size 13, Neoprene

2 2 003435023

Gasket, Flange, 1.1", Shell Size 17, Neoprene

3

20

004260007

Rivet, Blind, 1/8" Diameter X 7/16" Lg, SS

4 4 004397137

Screw, Machine, Round, 10-24 X 3/8" Lg, 304SS

5

20

Purchased

Rivet Washer

6

10

006010046

Strip, Terminal, Type UK5N

7 1 006010047

Din Rail, Perforated,1.5" 89 mm (3.5")

8 1 006010047

Din Rail, Perforated, 1.5" 137 mm (5.4")

9 1 006010048

Barrier, End, Type D-UK 4/10

10

2

006010049

Bar, Jumper, FB1 10-6, (Jumps 10 Terminals)

11

1

006020076

Circuit Breaker, On/Off, Metal, 28V

12

1

006070033

Contactor,12-600CAV, 50-60 Hz, 12-220 VDC

13

1

006070100

Connector, Housing, 9-Pole, Female Push In, Nylon,11A

14

1

006070101

Connector, Housing, 9-Pole, Male Push In, Nylon,11A

15

1

006070102

Connector, Housing, 6-Pole,Female Push In, Nylon,11A

16

1

006070103

Connector, Housing, 6-Pole, Male Push In, Nylon,11A

17

19

006070104

Connector, Push In, Female, 13.5A 20AWG-14AWG, Brass

18

19

006070105

Connector, Push In, Male,13.5A 20AWG-14AWG, Brass

19

1

006070106

Connector, Male, Signal/Power, Push-In, 4-Pole,14A

20

1

006070107

Connector, Female, Signal/Power, Push-In, 4-Pole,14A

21

27

006080138

Connector Pin, Male, 20-24 GA, 13A, Plated Brass

22

1

006090376

Enclosure, Polycarbonate,10.9" X 7.4" X 7.1", Insulated, Sealed

23

1

006160071

Relay, Overload, 12-16A

24

1

006160110

Relay, Din Rain Mount, 24V,12mA, 6A Rating, 400 VAC

25

1

006160136

Safety Relay, Din Rail Mount, 24 VAC, 24 VDC

26

2

006210482

Terminal Block, Double Level, 26 AWG-12 AWG, 20A, 300V

27

2

006220044

Terminal, Q-Disc, Flame Retardant, 90 Degree, 12-10 AWG, Yellow

28

2

006221106

Terminal, Ground, Type USLKG25

29

2

006221179

Terminal Block, End Cover, Gray Plastic

30

3

006221180

End Stop, Din Rail 1, 3, Gray, IP20

31

1

006260041

Wire, Stranded, 22AWG, 300V, AC, Tin Plated, Black5

32

1

006260042

Wire, Stranded, 22AWG, 300V, AC, Tin Plated, Red

33

1

006260043

Wire, Stranded, 22AWG, 300V, AC, Tin Plated, Blue

34

1

006260044

Wire, Stranded, 22AWG, 300V,AC, Tin Plated, Brown

35

1

006260045

Wire, Stranded,12AWG, 300V, AC, Tin Plated, Black

36

1

006260047

Wire, Stranded,12AWG, 300V, AC, Tin Plated, Green

37

1

006260048

Wire, Stranded,12AWG, 300V, AC, Tin Plated, White

38

3

006270199

Connector, Housing, 9-Pin, Male

39

1

006280578

Power Supply, 100-240 VAC, 50-60 Hz, 60W

40

1

006280643

Touch Screen, PLC HMI ,4.3" Screen, 24VDC

41

1

006280822

Module, Serial Port, Comm

42

3

007660098

Seal, Peripheral, SZ 13

43

2

007660099

Seal, Peripheral, SZ 17

44

6

009097007

Cable Holder, ADH, Plastic,1/4" Diameter, 5/8" X 3/8" X 3/4"

45

1

06010253

Control Panel Gasket

46

1

06010259

Bezel, Control Panel

47

1

06010271

Back Panel

48

2

06010319

3-Conductor Receptacle

49

1

Purchased

Safety Label, Read Operators Manual

50

1

Purchased

Safety Label, Danger Risk Of Electrical Shock

32. Electrical Panel Assembly, 06010118

78 FNS-0014-060-EN June 2019 Rev A

Figure 60. Electrical Panel Assembly (Sheet 1 of 2)

79 FNS-0014-060-EN June 2019 Rev A

Figure 61. Electrical Panel Assembly (Sheet 2 of 2)

80 FNS-0014-060-EN June 2019 Rev A

Figure 62. Wiring Schematic, Electrical Panel (Sheet 1 of 2)

81 FNS-0014-060-EN June 2019 Rev A

Figure 63. Wiring Schematic, Electrical Panel (Sheet 2 of 2)

82 FNS-0014-060-EN June 2019 Rev A

Figure 64. Wire Table, Electrical Panel

83 FNS-0014-060-EN June 2019 Rev A

Setting

New Value

Purpose

0.01

05.00

Motor Amps

0.04

0002

Setting to enable operation with GFCI outlets

1.01

0002

Disable the Reverse button

1.05

0004

Auto restart all faults except short circuit (PLC also has its own restart)

1.07

0001

Number of restart attempts

2.02

0002

Disables up or down buttons (does not apply during programing)

** WARNING: Machine will start after next setting is entered. Make sure all safeties are in place

before the value is entered**

2.03

0002

Disables the Local mode (Local/Remote button on VFD)

3.01

15.00

Lower frequency limit (changing this will disrupt normal operation)

3.02

90.00

Upper frequency limit (changing this will disrupt normal operation)

3.03

000.2

Acceleration speed

3.04

000.3

De-acceleration speed

4.04

0001

Display the motor current

4.05

0001

Display the motor voltage

5.00

0001

Enables the motor stall detection

33. Programming the VFD

1. With the machine plugged in, turn the power on using the button next to the touch screen.

2. Ensure that both the hopper door and front door are firmly closed.

3. Press the green Start button on the touch screen.

4. At the back of the machine, remove the cover over the VFD.

5. Make sure the Stop LED at the top is lighted. If it is not, press the “Run/Stop” button.

6. Press the “Program/Display” Button until the PGM LED is on.

7. Use the “</Reset” button to change which digit is flashing.

8. Use the “^” and “v” buttons to change the selected digit

9. When the proper setting is selected, press “Read/Enter” to display the current value

10. If necessary, use the arrow buttons from Step 7 and 8 to change the value

11. Once proper value has been entered, press “Read/Enter” and move to the next (if value is

already correct then press “Read/Enter” without changing anything)

12. The screen should display “END” then return to the setting.

13. Again use buttons from step 7 and 8 to select the next setting.

14. Settings to be changed (left column) and the value to change to (right column - take note of the

decimal place each time a value is entered as it is not always in the same place):

15. When complete, replace the cover on the VFD.

16. Return to the touch screen and acknowledge the error and power the machine off and back on.

17. Machine should be ready to run.

To Factory reset the Drive:

1. Complete step 1 thropugh step 8 above.

2. Go to setting 6.10.

3. Change the value to “1111” and press the “Read/Enter” button.

4. VFD is now ready to be reprogrammed, return to step 7 above.

84 FNS-0014-060-EN June 2019 Rev A

34. Procedure to Check Safety Cable Assemblies

If either of the following occurs, there is likely an issue with one of the safety sensors found on

the MFJ:

• Pressing the start button but nothing happens.

• The safety circuit fault screen appears and all cables are plugged in.

In these cases, which safety has failed will need to be determined before it can be replaced.

Tools that are necessary for this procedure:

• Digital multimeter – preferably with audible continuity

• Spanner bit

• A second person to actuate the sensors is helpful, but not necessary (simply involves

holding magnet up to the sensor and removing it)

Necessary steps:

1. Power off the machine and unplug it from the wall.

2. Remove one of the safety magnets to use manually on the sensors. Refer to Figure 65.

Figure 65. Location of Front Door Safety Magnet

3. Remove the side access panel on the hopper to access the rear of the electrical panel.

Refer to Figure 66.

85 FNS-0014-060-EN June 2019 Rev A

Figure 66. Hopper with Side Access Panel Removed

4. The safety cables will need to be disconnected. These are the two connectors on the top

far side of the panel; each has two cables coming out of them. Refer to Figure 67.

Figure 67. Location of Safety Cables

86 FNS-0014-060-EN June 2019 Rev A

5. Bring the connectors to the side panel so they can be accessed with the multimeter.

Refer to Figure 68.

Figure 68. Access to Connectors

6. Locate the numbers and the socket associated with each connector.

Refer to Figure 69.

Figure 69. Connector Numbering

7. Select the connector for the front door safety.

8. Place the multimeter’s leads into sockets 4 and 7. Refer to Figure 70.

Figure 70. Multimeter Lead Positions

NOTE: At this point, it is beneficial to have someone assist. If no one is available, it will

be necessary to hold the leads in the sockets with one hand. Refer to Figure 71.

87 FNS-0014-060-EN June 2019 Rev A

Figure 71. Holding Multimeter Leads

9. While holding the leads to the connector, take the magnet removed from the door

previously and align it with the sensor. Refer to Figure 72.

10. If the sensor is working properly, there should be continuity between these sockets.

11. Remove the magnet and the sockets should lose continuity. It is important to remove the

magnet and check for loss of continuity because the sensor can become stuck in the on

position. Therefore, it needs to be confirmed that the sensor turns off and on.

12. If the multimeter does not see continuity, make sure that the magnet is lined up properly.

Remove it and line it up again (sometimes if the magnet is held up to the sensor crookedly

at first, the sensor will not register it and the magnet must be pulled away and realigned).

Also check that the multimeter leads are still firmly set in the appropriate sockets. It is

easy for them to slip while trying to position the magnet

13. If the magnet was aligned correctly, the leads are firmly in their correct sockets, and there

is still no continuity, then the sensor is bad and will need to be replaced. Continue onto

the next sensor to make sure it is still working properly and does not need to be replaced

as well. Alternatively, if continuity is detected all the time even when the magnet is not

present, then the safety is bad and needs to be replaced.

Figure 72. Magnet Positioning

88 FNS-0014-060-EN June 2019 Rev A

14. If the sensor is working properly, move the leads to sockets 8 and 9. Refer to Figure 73.

Figure 73. Multimeter Leads, Sockets 8 and 9

15. Align magnet with the sensor or have your assistant hold it to the sensor. Refer to Figure 74.

Figure 74. Magnet Positioning

16. As with before, if the sensor is working, continuity shuld exist when the magnet aligns

with the sensor and turn off when the magnet is removed.

17. Once completed with the door sensor, set that connector aside and select the hopper

safety’s connector.

18. The same process is repeated starting with placing the leads in sockets 4 and 7 again.

Refer to Figure 75.

Figure 75. Multimeter Leads, Sockets 4 and 7

89 FNS-0014-060-EN June 2019 Rev A

19. Align the magnet with the sensor in the top corner of the hopper’s lid. The magnets are

not coded and work for either sensor. Refer to Figure 76.

Figure 76. Magnet Positioning

20. Repeat the procedure from before; if continuity is detected when magnet is present and

shuts off when removed, the safety is okay.

21. If no continuity is not detected or always detected, realign the magnet and check the

position of the leads. If the problem persists, the safety needs to be replaced.

22. Once completed, move the leads to sockets 8 and 9 on the connector.

Refer to Figure 77.

Figure 77. Multimeter Leads, Sockets 8 and 9

23. As before, align the magnet and check for continuity. If continuity is detected when

magnet is present and shuts off when removed, the safety is okay. If no continuity is

detected or always detected, realign the magnet and check the position of the leads.

If the problem persists, the safety needs to be replaced.

24. Replace the necessary safety sensor and cable assemblies.

25. Reattach the connectors to the back of the electrical panel. Attach the hopper connector

first to the furthest receptacle. If the door connector is attached first, it is more difficult to

attach the hopper connector.

26. Make sure the juicer is working properly.

27. Open the front door and make sure the correct screen appears on the touch screen.

If the hopper open screen appears while the front door is open, then the connectors are

put on the wrong receptacle and need to be switched.

90 FNS-0014-060-EN June 2019 Rev A

35. PLC Battery Replacement

When the PLC battery needs to be replaced, the following message will be displayed on the Operator

Screen:

The machine can continue to be operated, but eventually the battery will fail and the control system will

lose some functionality. Saved data, such as cycle count, service phone number and service date, could

be lost and would have to be re-entered. To prevent loss of control system functions, JBT recommends

replacing the battery as soon as possible following a low battery warning message.

Recommended replacement battery: Renata CR2450N (alternative batteries may not work)

Necessary steps:

1. Before powering down the machine, take a picture of the status screen or record the cycle

count, phone number, and machine serial number (battery removal can occasionally cause

these values to be lost, requiring them to be re-entered).

2. Disconnect power plug.

3. Using a flat head screwdriver, open the main electrical box.

NOTE: To prevent plastic screw damage, insert screwdriver into the deeper slot of the plastic

screw, as shown in Figure 78.

Figure 78. Opening Main Electrical Box

4. Disconnect the cable harnesses in order to remove the lid. Refer to Figure 79.

Figure 79. Disconnect Cable Harnesses

91 FNS-0014-060-EN June 2019 Rev A

5. Be careful when removing the black wires on the overload. If possible, hold the overload

itself and rock the connector back and forth to remove the black wires. Refer to Figure 80.

Figure 80. Disconnect Overload Connections

6. Place the lid on a clean flat surface with the touch screen facing down, make sure there is

nothing that will scratch or harm the screen. Setting on a clean cloth is preferable.

7. Locate the two green wire terminal strips on the PLC (large black device on the inside of the

lid) and detach both of them. May need to use a flat head screwdriver to gently pry them out

(wires can be left connected to the wire clamps). Refer to Figure 81.

Figure 81. Detach Terminal Strips

Use a phillips head screwdriver to remove the four screws located in the corners of the PLC

cover. Do not remove the screws that come off the sides of the PLC. Refer to Figure 82.

Figure 82. Location of PLC Cover Screws (4)

92 FNS-0014-060-EN June 2019 Rev A

8. Grip the upper circuit board by the two green strips and gently lift up. If necessary, hold the

lower circuit board in place while lifting upper circuit board.. Refer to Figure 83.

Figure 83. Upper Circuit Board Removal

9. Locate, remove and replace the bad battery with a new battery (CR2450N). One side of the

battery housing has a cutout. Lift the battery up from this side and pull out of the housing.

Replace with new battery.. Refer to Figure 84.

NOTE: Make sure new battery is clean and free of smudges and firmly seated.

A loose battery can cause a battery warning message to be displayed even for a new

battery.

Figure 84. Battery Replacement

93 FNS-0014-060-EN June 2019 Rev A

10. THIS STEP IS VERY DELICATE - PROCEED CAUTIOUSLY.

a. Reinstall the circuit board that was removed, there are two sets of pins on the circuit

board that must be lined up on connectors. Refer to Figure 85.

Figure 85. Align Circuit Board Pins and Reinstall

b. To do this, find the side of the PLC with a small notch on it and find the small piece on the

edge of the board that lines up with this.. Refer to Figure 86.

Figure 86. Location of Notch on Side of PLC

c. Make sure the board lines up with the housing. As seen in the picture above, the ends of the

green strip should match to the PLC housing.

94 FNS-0014-060-EN June 2019 Rev A

d. Gently push the board down until the green strip is resting on the housing. Refer to Figure 87

Figure 87. Gently Push Down on Board

11. Replace the back cover of the PLC.

12. Reinsert the four screws that were removed from cover. There are two different size screws

used, the short ones go to the lower end of the cover while the longer screws are on the

higher end, closest to the on and off switch.

Refer to Figure 88.

Figure 88. PLC Cover Screws

13. Reattach both green wire terminal strips. Use the numbering system on the PLC to

insure the proper connections.

The terminal strip with 6 wires goes on the side with 0V over the 1 position and V+ over

the 15. The terminal strip with 9 or 10 wires (depending on model) goes on the side with

I0 under 15 and V+ under 1. Refer to Figure 89.

Figure 89. Reattach Terminal Strips

95 FNS-0014-060-EN June 2019 Rev A

14. Insure both terminal strips are firmly seated. Leaving them loose can lead to intermittent

issues during operation or leave the machine unable to run. Refer to Figure 90.

Figure 90. Firmly Seat Terminal Strips

15. Reattach electrical box lid including the two black wires and three cable harnesses that were

disconnected in Step 4.

16. Close electrical box and tighten plastic screws with flat head screwdriver.

17. Reconnect electrical plug.

18. Power up the machine and ensure that the battery warning message does not reappear.

(If the new battery was not properly seated, the warning message will likely appear within