Pear Preparation System

Mod. C8P

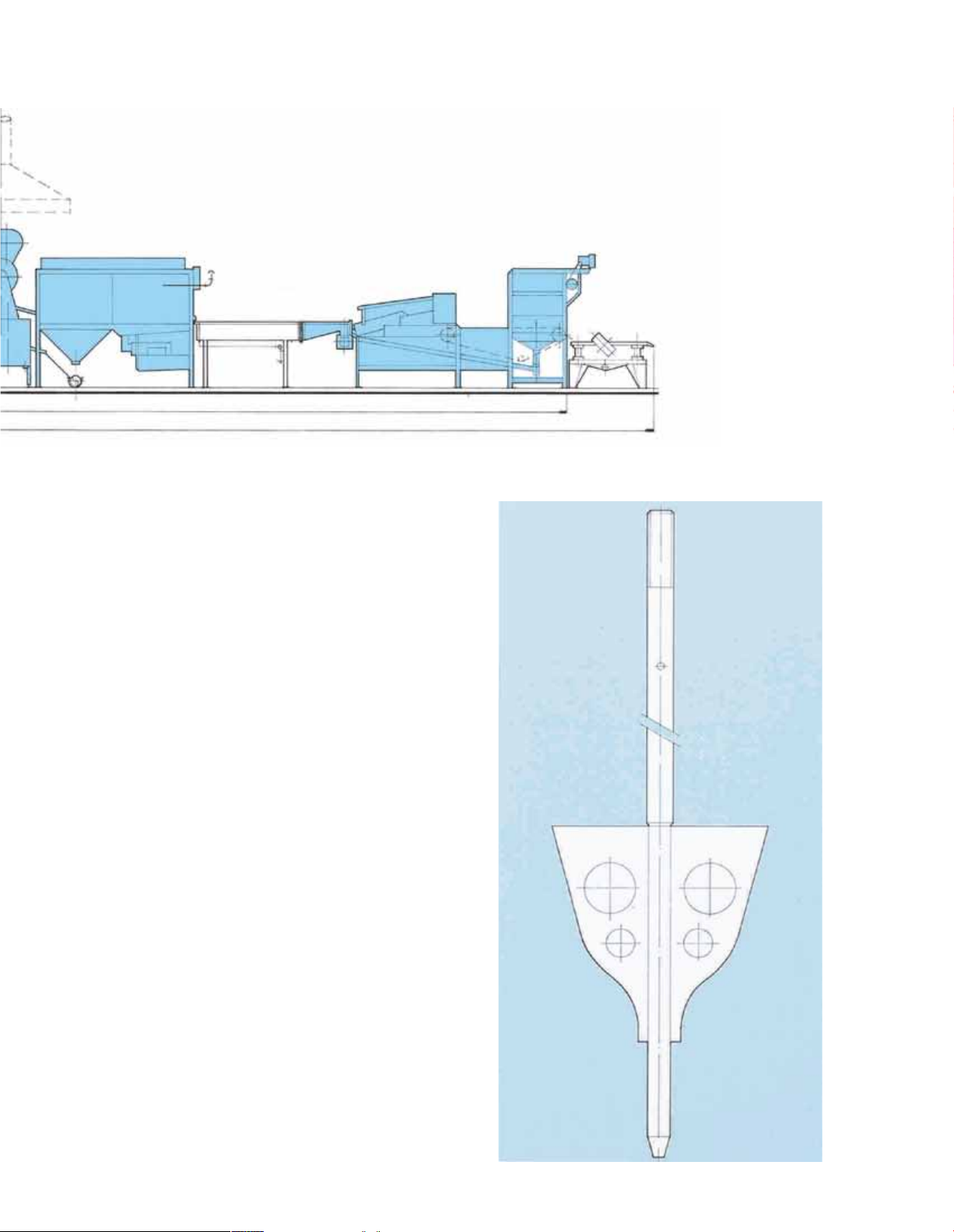

Typical Installation

Purpose

The JBT C8 Pear Preparation System is designed to peel, stem, seed

cell and optionally slice pears, in a high speed, continuous operation.

The System can be used interchangeably for canned cocktail and

sliced pears.

Benefits/Features

Low Operating Costs - result from the substantial reduction or

complete elimination of the need to pre-size the pears. Self adjusting

flights and coring knives used in this System handle practically all

sizes of pears, at random, with maximum yields.

Only two attendants are required to check fruit alignment, thereby

saving most of the feed labor required with hand-fed knife peelers.

Maximum Yield - is achieved by caustic peeling, by which means

only the skin is removed from the fruit. This technique eliminates

the peeling away of the flesh, which is a characteristic of live knife

techniques. Precise, self adjusting coring knives also contribute to

maximum yield.

High Quality - results from the fact that only the skins are removed,

leaving the shape of the fruit in its natural contour. The coring knives

also remove unsightly and tough textured stem fibres and seeds.

Construction/Operation

The C8 P System consists of four (4) components as follows:

• Caustic Applicator

• Transol* Steam Valve

• Peel Remover / Washer

• Coring Section which includes aligning, coring, seed-celling, and

slicing.

In operation, pears of uniform ripeness are conveyed to the machine’s

feed station where they are shuffle-fed into a caustic applicator. The

fruit remains in the caustic solution for a predetermined time which is

variable. The holding period density and temperature of the solution

are according to required peeling conditions. Emerging from the

solution, the fruit is transferred to an elevator which carries it into a

high pressure steam valve (Transol *). The steam pressure is easily

adjusted by setting indicating controller.

Upon completion of this steam exposure cycle, the fruit is discharged

to a rotary rubber cord washer that removes the loosened skins from

the fruit.

The washer employs an internal spiral which moves the fruit gently

through the drum as it rotates. The walls of the drum are constructed

of molded rubber cords spaced at 1” (25.4 mm) centers.

The softened peel is removed from the fruit by the combined action of

rubbing against the rubber cords and other pears. Approximately 95%

of the peel is removed in the first half of the washer and drops through

the rubber cords to a chute where it can be collected and removed as

a solid waste. In the second half of the washer 10-12 gpm (38-45 l/

min.) of water is used to rinse any remaining lye from the surface of

the fruit. This water is kept completely separate from the solid waste

material.

CORING HEADS remove cores and stems from pears held stem down

in individual cups. Seed celling and slicing steps follow.

Weight Approx

C8 complete 7892 kg

Peeling section 1814 kg

Steamer valve 2268 kg

Washer 1360 kg

Coring section 2450 kg

From the washing section, the peeled pears are flumed or conveyed to

a shuffle-feeding device that meters them into the aligner.

The aligner gently drops the fruit, 8 at a time, onto the coring section

conveyor. Each flight has 8 plastic cups which are formed to accept

the fruit in a stem-down position.

An orifice is provided at the bottom of each cup for refuse removal.

The cops are in an open position as the fruit is fed into them.

Upon receipt of the fruit, the cups automatically adjust to the fruit

size and close sufficiently to cradle it, thus placing the fruit in proper

alignment for coring and stemming operations.

Two operators, one on either side of the aligner conveyor, are

sufficient to orient any fruit that may be off center.

The conveyor operates continuously at the rate of 50 flights per

minute, giving a total through-put of 400 pears a minute.

Indexing with the travel of the flight conveyor is a coring/stemming

section.

As each flight enters this section, stemming tubes enter the inverted

pears at the butt end and discharge the stems through the orifices of

the plastic cups.

At a subsequent station, in this same section, the pears are

automatically measured for length by the coring assembly after which,

the core is removed by a live knife that self-adjusts for the depth of

the core.

The calyx cut is made simultaneously and the refuse is flushed out of

the fruit by a water spray.

The flight then travels to the slicing section where the fruit may be

halved, quartered or sliced by means of overhead knives.

In a cocktail operation, the fruit is generally left whole.

Most processors provide for final trimming and inspection after the

coring section.

Capacity

400 fruits/minute

Slicing Knife Assembly

Utility - Requirements Electrical

kW 19

HP 26

Volt 380

Hz 50

Lye 3,78÷8 l/h 50% NaOH-H2O

Steam 314 kg/h - 6÷8 bar

Air 30÷60 l/min. - 6÷8 bar

Water 38÷45 l/min. - 4 bar

We are your single source for

profitable processing solutions

JBT is a leading provider of integrated food processing

solutions.

From single machines to complete processing lines, we

enhance value and capture quality, nutrition and taste in

food products.

With a local presence on six continents, JBT can

quickly provide our customers and partners in the

food processing industry with the know-how, service,

and support needed to succeed in today’s competitive

marketplace.

Corporate Social

Responsibility

at JBT

www.jbtcorporation.com

Or for specific product lines:

www.jbtcitrus.com

www.jbtfruit.com

www.jbttomato.com

www.jbttuna.com

Asia Pacific

John Bean Technologies (Shanghai) Co., Ltd.

Room 1908, Hongwell International Plaza,

1600 West Zhongshan Rd.,

Xuhui District, Shanghai 200235,

China

Phone: +86.21.3339.1588

Fax: +86.21.3339.1599

infoasia-jbtfoodtech@jbtc.com

Part of the technology presented in this brochure may be patented.

JBT, whose policy is to continuously improve its products, reserves

the right to discontinue or change specifications, models or design

without notice and without incurring obligation.

Europe

John Bean Technologies SpA

Via Mantova 63/A

43122 Parma

Italy

Phone: +39.0521.908.411

Fax: +39.0521.460.897

sales.parma@jbtc.com

North America

John Bean Technologies Corporation

400 Fairway Avenue

Lakeland, FL 33801

USA

Phone: +1.863.683.5411

Fax: +1.863.680.3672

citrus.info@jbtc.com

John Bean Technologies (Thailand) Ltd.

No. 159/26 Serm-Mit Tower

Room no. 1602-3 Sukhumvit 21 Road

Klongtoey Nua Sub-district, Wattana District

Bangkok 10110 Thailand

Phone: +66.2.257.4000

Fax: +66.2.261.4099

infoasia-jbtfoodtech@jbtc.com

John Bean Technologies NV

Breedstraat 3

9100 Sint-Niklaas

Belgium

Phone: +32.3.780.1211

Fax: +32.3.777.7955

fpsd.info@jbtc.com

John Bean Technologies Corporation

2300 Industrial Avenue

Madera CA 93639

USA

Phone: +1.559.661.3200

Fax: +1.559.661.3156

madera.fpsd@jbtc.com

South Africa

John Bean Technologies (Pty) Ltd.

Koper Street

Brackenfell

Cape Town, South Africa 7560

Phone: +27.21.982.1130

Fax: +27.21.982.1136

capetown.parts@jbtc.com

John Bean Technologies Spain, S.L.U.

Autovia A-2, km 34,400

28805 Alcalá de Henares

Madrid, Spain

Phone: +34.91.304.0045

Fax: +34.91.327.5003

foodtech.spain@jbtc.com

South America

John Bean Technologies Máq. e Equip. Ind. Ltda.

Av. Eng Camilo Dinucci 4605

14808-900 Araraquara, São Paulo

Brazil

Phone: +55.16.3301.2000

Fax: +55.16.3301.2144

latinamerica.info@jbtc.com

Latin America

JBT de México S de RL de CV

Camino Real a San Andrés Cholula No. 2612

Col. San Bernardino Tlaxcalancingo

72820 San Andrés Cholula, Puebla

México

Phone: +52.222.329.4902

Fax: +52.222.329.4903

citrus.info@jbtc.com

621-EN - May 2015

Loading...

Loading...