Aseptic Fillers

Mod. AF 2000 Imperial

Mod. AF 200 Classic

Mod. ABF 2000

JBT Aseptic Fillers

Features and benefits

Designed to fill fluids, concentrates, and particulate products,

JBT’s aseptic fillers provide: high production speed achieved by a

newly designed head system, improved reliability from a fully PLC

controlled self diagnostic operational mode, greater versatility

by meeting various packing standards with different products,

complete sanitation by an automatic CIP system, aseptic filling

chamber which can be opened without losing asepticity, roller

conveyors under the dosing and filling platform to eliminate

palletizers or similar devices, “steam only” sterilization of the filler

head(s). No Chemicals or sterile gas (sterile water, nitrogen, etc.)

used, increased profitability by keeping consistent fill weight

accuracy and by reducing labour costs.

AF 200 Classic AF 2000 Imperial ABF 2000

Size of pre-sterilized

bags

Handling

Spout diameter (inches)

Versions

Working speed

Processable products

10-220 l (5-60 gal)

Drums in a line

1" 1"-2" 1"-2" 2"-2,5"-3" with sealed spout

Single head

Twin head

30 bags/h (220 l) (SH)

55-60 bags/h (220 l) (TH)

With pH<4,5 With pH<4,5

Products/Uses Application

Would you like your Ideal aseptic filler to fill various size bags?

Would you also like your aseptic filler to provide high production

speed, fill weight accuracy, and reduced labour costs? JBT’s

total commitment to fruit and vegetable processing has lead to

the development of an Innovative series of Aseptic Fillers. They

have been created to satisfy your needs, improve your overall

operating efficiency, minimize downtime for maintenance, ease

clean up and, why not, make it aesthetically pleasant. Flexible

and reliable, our aseptic fillers can fill various size bags with

different size spouts. JBT’s aseptic fillers have easy to operate

control system therefore with only a few minor regulations the

filler is quickly and efficiently adapted to meet your filling needs.

220 l (55-60 gal)

1200 l (300 gal)

4 drums on pallet

Bins/Eurobins

Single head

Twin head

Triple head

30 bags/h (220 l) (SH)

5-6

bags

/h (1300 l) (SH)

55-60

bags

/h (220 l) (TH)

12

bags

/h (1300 l) (TH)

220 l (55-60 gal)

1200 l (300 gal)

4 drums on pallet

Bins/Eurobins

Single head

Twin head

25 bags/h (220 l) (SH)

50 bags/h (220 l) (TH)

High and low

acidity

1. Steam circuit

1

2

3

4

5

6

7

8

9

10

2. Product circuit

3. Steam condenser barrel

4. Steam condensate extraction

5. Sterilization circuit

6. Filling head

7. Bin filling

8. Drums on pallet filling

9. Hydraulic powerpack

10. Operator working zone

1. Products for AF 2000 Imperial and AF 200 Classic

2. AF 2000 Imperial

3. AF 200 Classic with size changeover for small bags

4. AF 200 Classic

5. Products for ABF 2000

6. ABF 2000

1

2

4

5

Dairy

Products

SUITABLE FOR LOW

ACID PRODUCTS

3

6

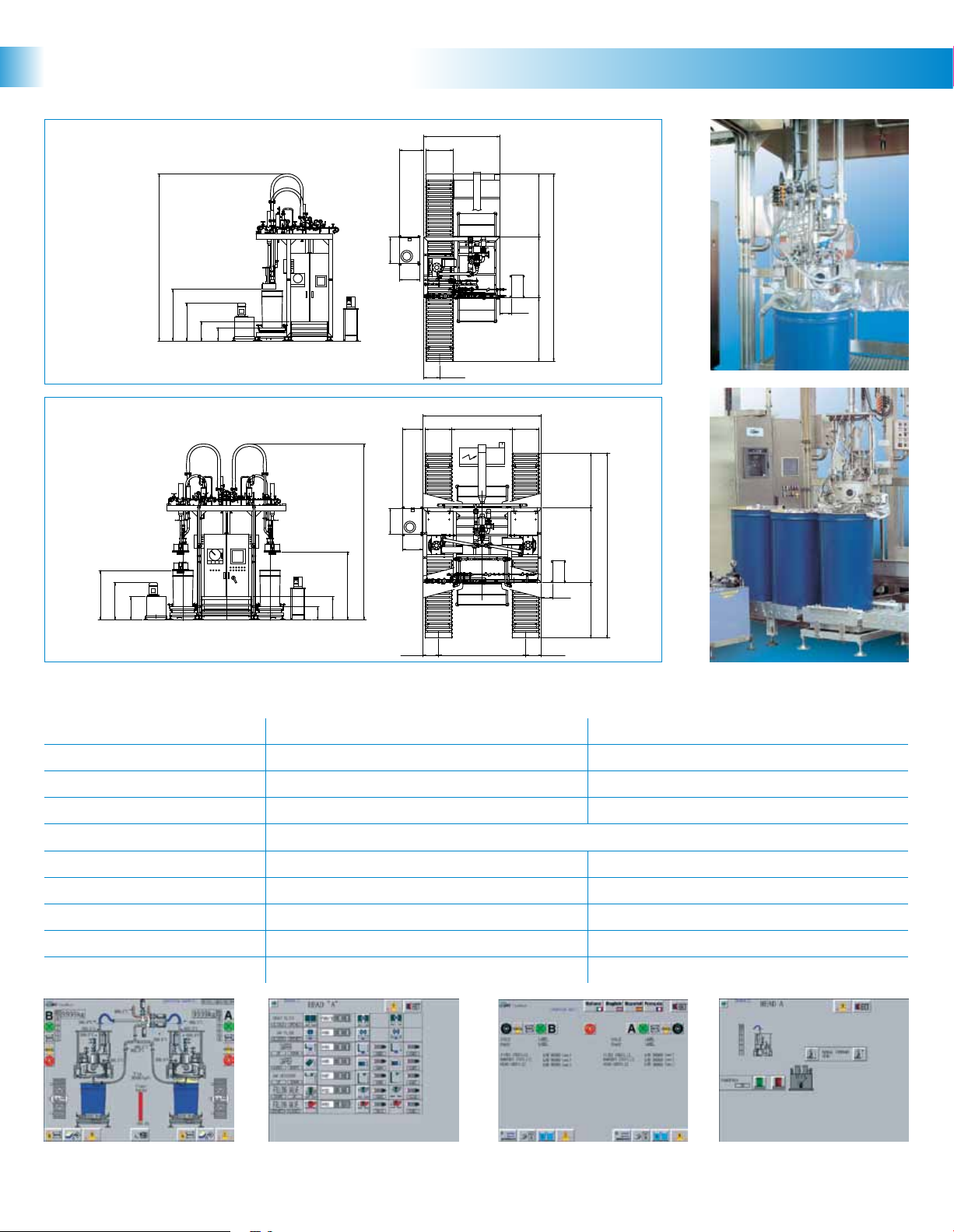

AF 200 Classic

Version AF 200 SH

C

1360

Version AF 200 TH

1000

515

710

710

420

B

B

1620

300

710

1660 1660

1660

A

1480

A

2000

635

690

530

D

540

690

C

530

1320

1000

620

1820

D

615

420

2330

300

1480

420

Approximate Specifications

Aseptic Filler version AF 200 TH AF 200 SH

Overall length (A)

Overall width (B) 3170 mm (10'-4 51/64") 2000 mm (6'-6 47/64")

Overall height (C) 4705 mm (15'-5 15/64") 4930 mm (14'-4 53/64")

Feed height drums (D) 350 mm (1'-1 25/32")

Horsepower total 3 kW 1,5 kW

Water consumption 0,8 m

Net weight 3200 Kg (7055 lb) 1000 Kg (2204 lb)

Steam consumption 200 Kg/h (441 lbs/h) 8÷10 bar (120÷150 psi) 110 Kg/h (245 lbs/h) 8÷10 bar (120÷150 psi)

Air

6 Nm3/h (3.6 Ncu ft/min.) 6÷8 bar (90÷120 psi)

4960 mm (

16'-3 9/2")

3

/h (210 US gall/h) 0,4 m3/h (110 US gall/h)

4920 mm

3 Nm3/h (1.8 Ncu ft/min.) 120÷150 bar (90÷120 psi)

Main page Manual control page Machine status page

Head vertical displacement page

AF 2000 Imperial

Version AF 2000 SH

3360

2115

Version AF 2000 TH

3360

2115

D

830

830

1327

A

C

D

C

1835 1900 1835

810

1600

950

B

1330

1835

A

1900

1835

950

B

810

3200

1330

950

Approximate Specifications

Aseptic Filler version AF 2000 TH AF 2000 SH

Overall length (A)

Overall width (B) 5100 mm (16'-8 25/32") 3300 mm (10'-9 59/64")

Overall height (C) 5000 mm (16'-4 27/32")

Feed height pallet base (D) 603 mm (1'-11 3/4")

Horsepower total 15 kW 7 kW

3

Water consumption 0,8 m

/h (210 US gall/h) 0,4 m3/h (110 US gall/h)

Net weight 7500 Kg (16535 lb) 5500 Kg (12126 lb)

Steam consumption 200 Kg/h (441 lbs/h) 8÷10 bar (120÷150 psi) 110 Kg/h (245 lbs/h) 8÷10 bar (120÷150 psi)

Air

6 Nm3/h (3.6 Ncu ft/min.) 6÷8 bar (90÷120 psi) 3 Nm3/h (1.8 Ncu ft/min.) 6÷8 bar (90÷120 psi)

5570 mm (

18'-3 19/64")

Main page Manual control page M.c.p. up-down filling headM.c.p. rotating table

ABF 2000

Features and benefits of JBT FranRica

Aseptic Fillers mod. “ABF 2000”

Designed to fill bulk packaging of low and high acid purees,

pulps, pastes, particulates and sauces.

The JBT FranRica Aseptic Bag Filling Systems offer the food

processing industry a highly effective and reliable aseptic method

of bulk packaging high and low acid food products, including:

• tomato paste

• vegetable and fruit purees

• particulates

• concentrates

• sauces

• soups

• dairy and many other delicate products.

Patented Fill Tube

The filler uses a revolutionary design of filling tube which

eliminates the traditional stem and plug configuration.

The patented fill tube has the following advantages:

• Possibility of having a fill tube with a free diameter comparable

with the inner diameter of the container mouth, without

forming obstacles. This allows to use the device for products

containing pieces of considerable size, with no risks of

damage or clogging

• Lower backpressure of the system

thanks to the increased passage crosssection for the product, which in turn

reduces the stress on the product and

the subsequent risk of damage

• Advantages in the filling of containers with

highly viscous products, in terms of greater

flow rate and lower backpressure.

Proven Commercially Superior

The aseptic filler is proven in commercial operation to be the

most mechanically and aseptically reliable bag filler available,

providing the following significant advantages:

• The use of a hermetically sealed empty bag ensures the bag

will remain sterile before it is filled

• High pressure saturated steam is used for sterilization of the

fitment, cap and exposed portion of the filler prior to each

filling cycle. NO CHEMICALS are required

• The sealing of the fill valve on the interior of the fitment keeps

product completely away from the package sealing area

• The hermetic heat sealing of the fitment with an aluminium foil

lid provides a tamper evident closure and a superior oxygen

barrier

• The cleaning of the fill valve with sterile condensate after each

fill cycle ensures that product will not come into contact with

the next bag fitment seal area

• The overall aseptic design of

the filler allows uninterrupted

operation throughout a

complete tomato/fruit season,

maximizing your plant’s

efficiency.

The result of these unique

features has allowed aseptic

tomato paste plants to operate

their systems over 90 days

continuously without spoilage

and without need for shutdown to

clean and resterilize the system.

Aseptic dice tomato operations

have processed three weeks prior

to clean up and resterilization.

Version ABF 2000 SH

3210

2050

D

100

B

285,5

800

1835

C

A

1835 1900

1327

950 1600

1700

87,5100

810

200

800

Version ABF 2000 TH

3210

D

C

2050

100

1325

1835

A

1900

1835

950 3200

1875

810

B

1325

620

800

1000

1115

950

Approximate Specifications

Aseptic Filler version ABF 2000 TH ABF 2000 SH

Overall length (A)

Overall width (B) 6900 mm (22'-8") 4300 mm (14'-1 19/64")

Overall height (C) 5530 mm (18'-2")

Feed height pallet base (D) 603 mm (1'-11 3/4")

Horsepower total 12 kW 8 kW

3

Water consumption 2,8 m

/h (740 US gall/h) 1,4 m3/h (370 US gall/h)

Net weight 8500 Kg (18740 lb) 5100 Kg (11244 lb)

5570 mm (

18'-3")

Steam consumption 460 Kg/h (1014 lbs/h) 6÷8 bar (90÷120 psi) 230 Kg/h (507 lbs/h) 6÷8 bar (90÷120 psi)

Air

Main page of the version with

Sterilizer

6 Nm3/h (3.6 Ncu ft/min.) 6÷8 bar (90÷120 psi) 3 Nm3/h (1.8 Ncu ft/min.) 6÷8 bar (90÷120 psi)

Main page of the version with

Flash Cooler

displacement

Page of rollerway movementPage of head vertical

We are your single source for

profitable processing solutions

JBT is a leading provider of integrated food processing

solutions.

From single machines to complete processing lines, we

enhance value and capture quality, nutrition and taste in

food products.

With a local presence on six continents, JBT can

quickly provide our customers and partners in the

food processing industry with the know-how, service,

and support needed to succeed in today’s competitive

marketplace.

Corporate Social

Responsibility

at JBT

www.jbtcorporation.com

Or for specific product lines:

www.jbtcitrus.com

www.jbtfruit.com

www.jbttomato.com

www.jbttuna.com

Asia Pacific

John Bean Technologies (Shanghai) Co., Ltd.

Room 1908, Hongwell International Plaza,

1600 West Zhongshan Rd.,

Xuhui District, Shanghai 200235,

China

Phone: +86.21.3339.1588

Fax: +86.21.3339.1599

infoasia-jbtfoodtech@jbtc.com

Part of the technology presented in this brochure may be patented.

JBT, whose policy is to continuously improve its products, reserves

the right to discontinue or change specifications, models or design

without notice and without incurring obligation.

Europe

John Bean Technologies SpA

Via Mantova 63/A

43122 Parma

Italy

Phone: +39.0521.908.411

Fax: +39.0521.460.897

sales.parma@jbtc.com

North America

John Bean Technologies Corporation

400 Fairway Avenue

Lakeland, FL 33801

USA

Phone: +1.863.683.5411

Fax: +1.863.680.3672

citrus.info@jbtc.com

John Bean Technologies (Thailand) Ltd.

No. 159/26 Serm-Mit Tower

Room no. 1602-3 Sukhumvit 21 Road

Klongtoey Nua Sub-district, Wattana District

Bangkok 10110 Thailand

Phone: +66.2.257.4000

Fax: +66.2.261.4099

infoasia-jbtfoodtech@jbtc.com

John Bean Technologies NV

Breedstraat 3

9100 Sint-Niklaas

Belgium

Phone: +32.3.780.1211

Fax: +32.3.777.7955

fpsd.info@jbtc.com

John Bean Technologies Corporation

2300 Industrial Avenue

Madera CA 93639

USA

Phone: +1.559.661.3200

Fax: +1.559.661.3156

madera.fpsd@jbtc.com

South Africa

John Bean Technologies (Pty) Ltd.

Koper Street

Brackenfell

Cape Town, South Africa 7560

Phone: +27.21.982.1130

Fax: +27.21.982.1136

capetown.parts@jbtc.com

John Bean Technologies Spain, S.L.U.

Autovia A-2, km 34,400

28805 Alcalá de Henares

Madrid, Spain

Phone: +34.91.304.0045

Fax: +34.91.327.5003

foodtech.spain@jbtc.com

South America

John Bean Technologies Máq. e Equip. Ind. Ltda.

Av. Eng Camilo Dinucci 4605

14808-900 Araraquara, São Paulo

Brazil

Phone: +55.16.3301.2000

Fax: +55.16.3301.2144

latinamerica.info@jbtc.com

Latin America

JBT de México S de RL de CV

Camino Real a San Andrés Cholula No. 2612

Col. San Bernardino Tlaxcalancingo

72820 San Andrés Cholula, Puebla

México

Phone: +52.222.329.4902

Fax: +52.222.329.4903

citrus.info@jbtc.com

213-EN - May 2015

Loading...

Loading...