Page 1

Installation Guide

For SF12Mi and SF15i Models Only

Part Number: 351940-001

Page 2

CONTENTS

Working Load Limit

General Hardware

Proper Use of Forged Shoulder Eyebolt

Proper Sling Termination

Rigging Connections

Attachment to Structures

Technical Specifications - SF12Mi

Technical Specifications - SF15i

Product Dimensions

Inspection, Maintenance and Liability

Resources and JBL Contact Information

3

4

4

5

6

7-8

9

10

11

12

12

2

Who Is Protected By The JBL Warranty?

Your JBL Warranty protects the original owner and all subsequent o wners so long as:A.) Your JBL product has

been purchased in the Continental United States, Hawaii or Alaska.(This W arr anty does not apply to JBL products purchased elsewhere except for purchases by military outlets. Other purchasers should contact the local

JBL distributor for warranty inf ormation.);and B.) The original dated bill of sale is presented whene v er w arranty

service is required.

The JBL Limited Warranty on professional loudspeaker products (except for enclosures) remains in effect for

five years from the date of the first consumer purchase.JBL amplifiers are warranted for three years from the

date of original purchase. Enclosures and all other JBL products are warranted for two years from the date of

original purchase.

What Does The JBL Warranty Cover?

Except as specified below, your JBL Warranty covers all defects in material and workmanship. The following

are not covered:Damage caused by accident, misuse, abuse, product modification or neglect;damage occurring during shipment; damage resulting from failure to follow instructions contained in your Instruction Manual;

damage resulting from the performance of repairs by someone not authorized by JBL;claims based upon any

misrepresentations by the seller; any JBL product on which the serial number has been defaced, modified or

removed.

Who Pays For What?

JBL will pay all labor and material expenses f or all repairs covered by this warranty. Please be sure to save the

original shipping cartons because a charge will be made if replacement car tons are requested. Payment of

shipping charges is discussed in the next section of this warranty.

How To Obtain Warranty Performance?

If your JBL product ever needs service, write or telephone us at JBL Incor porated (Attn: Customer Ser vice

Department), 8500 Balboa Boulevard, PO. Box 2200, Northridge, California 91329 (818/893-8411). We may

direct you to an authorized JBL Service Agency or ask you to send your unit to the factory for repair. Either

way, you'll need to present the original bill of sale to establish the date of purchase. Please do not ship your

JBL product to the factory without prior authorization. If transportation of y our JBL product presents any un usual difficulties, please advise us and we may make special arrangements with you. Otherwise, you are responsible for transporting your product for repair or arranging for its transportation and for payment of any initial

shipping charges. However, we will pay the return shipping charges if repairs are covered by the warranty.

Page 3

Working Load Limit

3

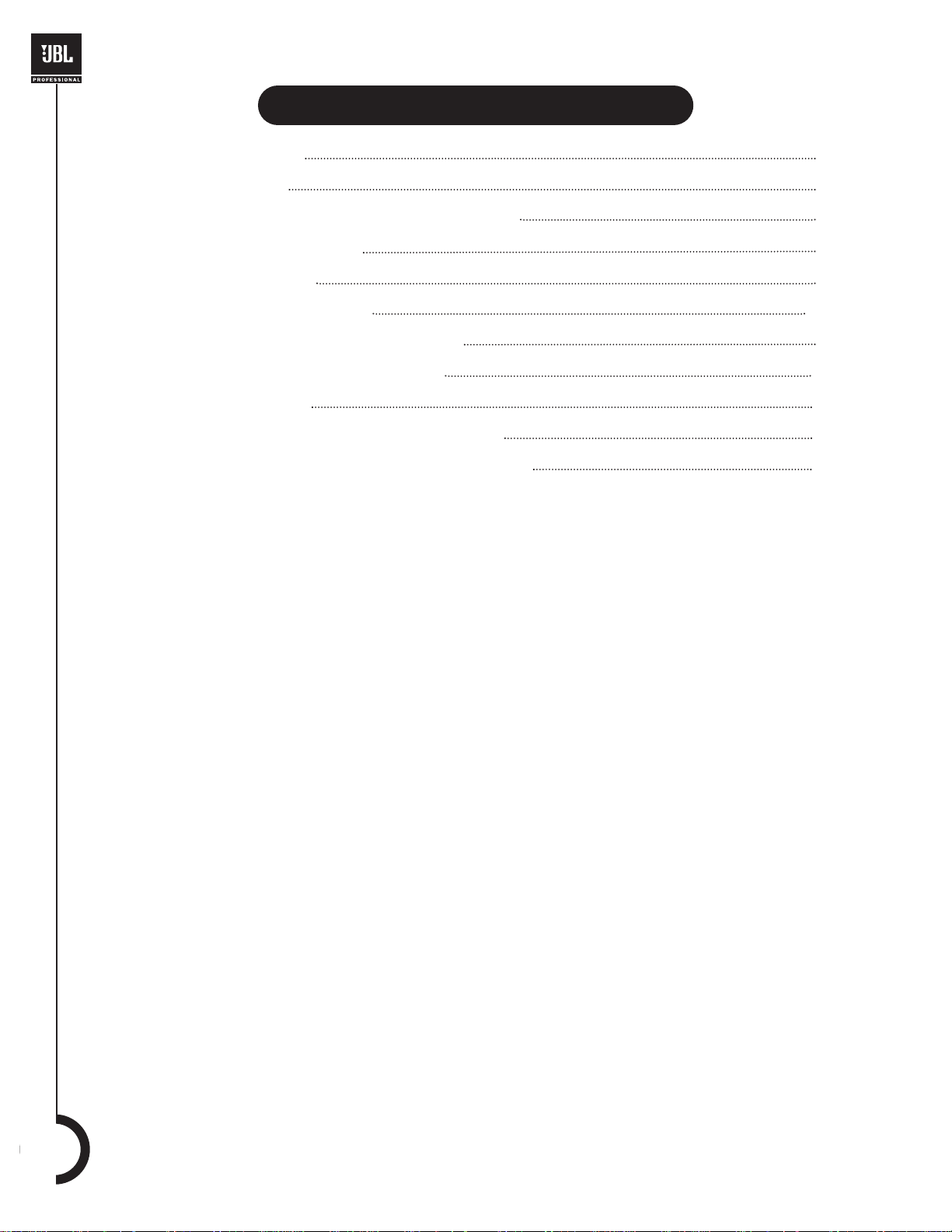

The JBL SoundFactor Install loudspeakers are supplied with built-in internal braces to be used with the

supplied forged shoulder ey ebolts or other approv ed f astener .The system is designed to f acilitate the suspension of the loudspeaker by a qualified person familiar with rigging hardware and industry practices.

IMPORTANT! You must ensure that ALL installation procedures specified in this manual

are carefully followed. Improper installation may result in damage, injury or death.

The working load limit (WLL) of any JBL SoundFactor Install loudspeaker is maintained as long as no

more than one loudspeaker is suspended by a minimum of two primary suspension points with no additional load placed on the loudspeaker enclosure.The JBL SoundFactor Install loudspeakers are intended for SINGLE-BOX SUSPENSION ONLY. DO NOT HANG A SECOND SPEAKER FROM A SOUNDFACTOR INSTALL SPEAKER.

Secondary

Load

Secondary

Load

Primary

Load

Primary

Load

Primary

Load

Secondary

Load

Primary

Load

SF15i

SF12Mi

Page 4

Proper Use of Forged Shoulder Eyebolt

General Hardware Information

4

Any hardware used in an overhead suspension application must be load rated for the intended use.

Generally, this type of hardware is available from rigging supply houses; industrial supply catalogs and

specialized rigging distributors.Local hardware stores do not usually stock these products.Hardware that

is intended for ov erhead suspension will comply with ASME B30.20 and will be manuf actured under product traceability controls. Compliant hardware will be referenced with a working load limit (WLL) and a

traceability code.

All SoundFactor Install loudspeakers include a rigging hardware kit (part# 229-00009-01) which includes

3 forged shoulder eyebolts and 3 washers.When installing these speakers, use hardware found in the kit

provided. For additional rigging components, consult with a professional rigging hardware supplier.

Sources for specialized rigging hardware may be found on page 11.

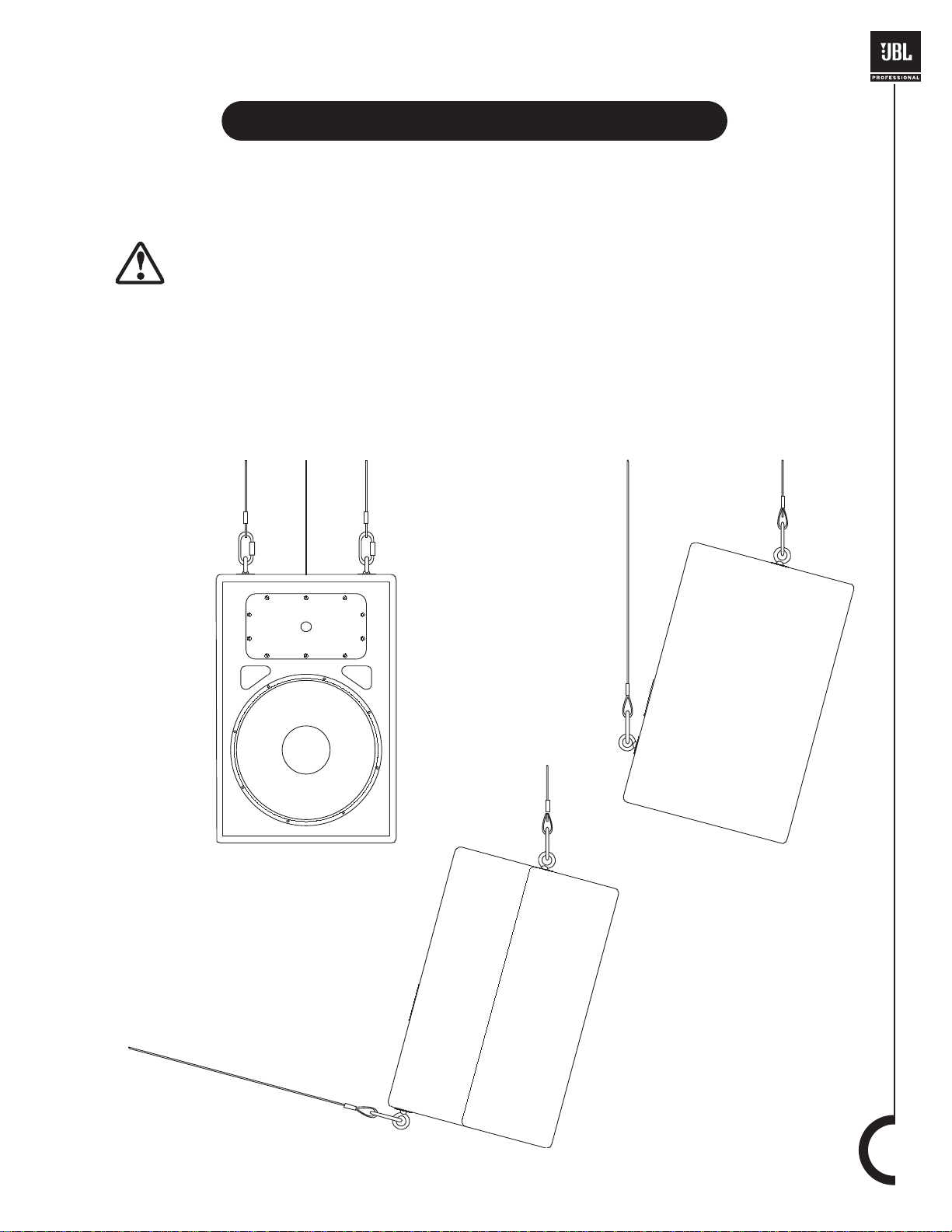

The JBL SoundFactor Install loudspeak ers are supplied with three f orged M10-1.5 x 35 mm shoulder ey ebolts with appropriate ratings and certified standards compliance, for use in overhead suspension applications.To install the eyebolts into the provided threaded holes on the loudspeaker, first remove the factory installed, flat head machine screw using a 6 mm hex key wrench. The M10-1.5 threaded internal

brace is accessible once the flat head machine screw is removed. Deposit thread lock adhesive, following the adhesive manuf acturer's instructions, onto the threaded tip of the eyebolt.Install the forged shoulder eyebolt as a replacement f or the machine screw, being careful not to cross-thread the fasteners.There

should be little resistance when installing any fastener. As a general rule for "soft surface" installations

such as a wooden surface, the suggested torque is achie ved by installing the fastener until snug and then

rotating the fastener an additional 180 degrees (1/2 turn).

The load imposed on the eye of the eyebolt fastener must remain in the plane of the eye only.When anything other than a straight-line pull is used, the provided forged, shoulder eyebolt load rating must be

adjusted as follows:

Direction of Pull Adjusted Working Load

45 degrees 25% of rated working load

In-Line

45º

90º

Do Not

Load

Page 5

5

Proper Sling Termination

The slings described herein are "suspension slings" and are different from "lifting slings" as defined by

government regulatory bodies. Do NOT use hardware chain.The JBL SoundFactor Install loudspeakers

must be used in static suspension applications only. Wire rope suspension slings are suggested for all

installations requiring suspension of the JBL SoundFactor Install loudspeakers.The suggested wire rope

is identified as 1/8" 7 x 19 Galvanized Aircraft Cable (1/8- 7 x 19 GAC).The minimum working load limit

(WLL) of this type of wire rope is 400 lb / 181 kg when terminated properly.If sling lengths are pre-determined and the wire rope slings are fabricated at a rigging supplier, the suggested termination is identified

as "swaged Flemish eye terminations with heavy thimbles and certification tags." If sling lengths cannot

be predetermined and slings must be fabricated on site, the suggested termination is identified as either

a load rated "compression sleeve" or a forged "wire rope clip". Compression sleeves, such as the

Nicopress devices, require a specialized compression tool and associated check gauge.Wire rope clips

require an end-wrench, socket wrench, and/or adjustable wrench (spanner).The following table defines

the load rating adjustments associated with each termination type if the terminations are made according to manufacturer's instructions:

Termination T ype Adjusted Working Load

Swagged Flemish Eye 100% of wire rope rating

Load Rated Compression Sleeve 100% of wire rope rating

Forged Wire Rope Clip 80% of wire rope rating

Nicopress Oval Sleeve

Finished Eye Splice

Live

End

Dead

End

Saddle

U-Bolt

Page 6

Rigging Connections

6

Some installations require the use of a removable connection between the structure and the loudspeaker.Hardware commonly used for these applications includes:

Some installations require the adjustment of the length of one or more slings. Common hardware used

for these applications include:

Quick Link

Used in-line with only one wire

rope per end. Only use load rated

quick links, which will have the

WLL imprinted on the component.

Screw Pin Anchor Shackle

Used in-line or at an angle up to

45 degrees and can combine two

wire ropes into one. A mouse wire

(aka safety wire) must be used

after installation.

Turnbuckle

Used in-line with only one wire rope per end

and can be adjusted to length. A mouse wire

must be used after adjustment is complete.

Note: Use only turnbuckles with closed,

forged eyes.

Page 7

7

Attachment to Structures

A licensed Professional Engineer must approve the placement and method of attachment to the

structure prior to the installation of any overhead object. The following performance standards

should be provided to the Professional Engineer for design purposes; Uniform Building Code as applicable, Municipal Building Code as applicable, Seismic Code as applicable, and a minimum of a 5:1 design

factor throughout the suspension system.

The installation of the hardware and method of attachment must be carried out in the manner specified

by the Professional Engineer. Improper installation may result in damage, injury or death.

The following renderings represent some of the common methods of attaching to a structure.These renderings are intended as a reference only, and are not appropriate for many installation circumstances. In

the following illustrations, the structure component is shown in solid black while the attachment hardware

is drawn as an outline.

H-Beam Clamp (custom)

hardware as provided

Channel Beam Clamp (custom)

hardware as provided

Box Beam

Channel Beam

Beam Clamp

hardware as provided

H-Beam Clamp (custom)

hardware as provided

I-Beam

H-Beam

Page 8

Attachment to Structures

8

Angle Beam Clamp (custom)

hardware as provided

OSR Fitting

grade 8 or B7 fasteners

Wire Rope Sling (standard)

sling and SPA shackle

OSR Fitting

concrete anchors

Angle Beam

Wood Beam

Round Beam

Concrete Beam

Mounting Plate (standard/custom)

concrete anchors with epoxy

Brick Wall

Mounting Plate (standard/custom)

grade 8 or B7 fasteners

Metal Stud

Page 9

9

Specifications - SF12Mi

SF12Mi

System Type: 12" 2-way, stage monitor

Frequency Range (-10 dB):² 60 Hz - 16 kHz

Frequency Response (±3 dB):² 70 Hz - 12 kHz

Sensitivity (1w/1m): 98 dB SPL

Nominal Impedance: 8 Ω

Power Capacity:¹ 250 watts

Peak Power Capacity:¹ 1000 watts

Maximum SPL: 129 dB

Nominal Dispersion: 90° x 50°

Crossover Frequency: 1.8 kHz

Dimensions (H x W x D): 584.2 mm x 393.7 mm x 317.5 mm

(23 in x 15.5 in x 12.6 in)

Weight: 19.5 kg (43 lbs.)

Shipping Weight: 22.0 kg (48.5 lbs.)

High Frequency Driver: JBL 2412 1" exit compression driver mounted on Progressive Transition™ Waveguide

Low Frequency Driver: JBL M112-8

Input Connectors: Neutrik® Speakon® NL-4 (x1);1/4" TS phone jack (x1);parallel

Enclosure Construction: 19 mm (3/4 in) MDF (Medium Density Fiberboard);with glued and mechanically fastened joint

detail;covered in black carpet.

Grille: 18 gauge, powder-coated steel

Suspension: 3x M10 threaded suspension points

Suspension Kit: 3x 10 mm forged shoulder eyebolts with washers

Notes:

1."Power Capacity" and "Peak Power Capacity" ratings are based on the average and peak power handling capacity of product

samples subjected to a 100 hour power test of the system design using IEC filtered random noise with a crest factor of 6 dB.

2."Frequency Range" and "Frequency Response" are based on half-space response.

TIP

TIP

GRD

GRD

+

-

+

-

HPF

LPF

JBL PROFESSIONAL

Northridge, CA USA

Made in USA

MODEL SF12

IN / OUT

(PARALLEL JACKS)

8 OHMS

±1 FULL-RANGE

±2 N/C

1-1-1+

1+

Page 10

Specifications - SF15i

10

SF15i

System Type: 15" 2-way, sound-reinforcement speaker

Frequency Range (-10 dB):² 38 Hz - 16 kHz

Frequency Response (±3 dB):² 50 Hz - 12.5 kHz

Sensitivity (1w/1m): 98 dB SPL

Nominal Impedance: 8 Ω

Power Capacity:¹ 250 watts

Peak Power Capacity:¹ 1000 watts

Maximum SPL: 128 dB

Nominal Dispersion: 90° x 50°

Crossover Frequency: 1.6 kHz

Dimensions (H x W x D): 698.5 mm x 459.9 mm x 431.8 mm

(27.5 in x 18.11 in x 17 in)

Weight: 27.4 kg (60.5 lbs.)

Shipping Weight: 30.4 kg (67.0 lbs.)

High Frequency Driver: JBL 2412, 1" exit compression driver mounted on Progressive Transition™ Waveguide

Low Frequency Driver: JBL M115-8A

Input Connectors: Parallel Neutrik® Speakon® NL-4 (x1);1/4" TS phone jack (x1)

Enclosure Construction: 19 mm (3/4 in) MDF (Medium Density Fiberboard);with glued and mechanically fastened joint

detail;covered in black carpet.

Grille: 18 gauge, powder-coated steel

Suspension: 3x M10 threaded suspension points

Suspension Kit: 3x 10 mm forged shoulder eyebolts with washer

Notes:

1."Power Capacity" and "Peak Power Capacity" ratings are based on the average and peak power handling capacity of product samples subjected to a 100 hour power test of the system design using IEC filtered random noise with a crest factor of 6 dB.

2."Frequency Range" and "Frequency Response" are based on half-space response.

TIP

TIP

GRD

GRD

+

-

+

-

HPF

LPF

JBL PROFESSIONAL

Northridge, CA USA

Made in USA

MODEL SF15

IN / OUT

(PARALLEL JACKS)

8 OHMS

±1 FULL-RANGE

±2 N/C

1-1-1+

1+

Page 11

11

Product Dimensions

12.7 in

323 mm

60º

12 in

305 mm

8.4 in

213 mm

7.8 in

198 mm

3.9 in

99 mm

15.5 in

394 mm

2x O .45 in

11.4 mm

15.5 in

394 mm

22.7 in

577 mm

O .45 in

11.4 mm

1.8 in

45.7 mm

12.7 in

323 mm

8.4 in

213 mm

SF12Mi

27.2 in

691 mm

2x 2.4 in

60.9 mm

17 in

432 mm

18.5 in

470 mm

13.8 in

351 mm

3.8 in

96.5 mm

8.9 in

226 mm

5.4 in

137 mm

2x 82.5º

2x O .45 in

11.4 mm

8.0 in

203 mm

2x 1.75 in

44.5 mm

O .45 in

11.4 mm

3.5 in

88.9 mm

9.25 in

235 mm

17 in

432 mm

SF15i

Page 12

Mailing Address: Shipping Address:

JBL Professional JBL Professional

8500 Balboa Blvd. 8370 Balboa Blvd., Dock D

Northridge, CA 91329 Northridge, CA 91329

Customer Service: On the World Wide Web:

Monday through Friday www.jblpro.com

8:00am - 5:00pm

pacific coast time in the U.S.A. Product Registration:

(800) 8JBLPRO (800.852.5776) Register your product online at

www.jblproservice.com www.jblpro.com/registration

© Copyright 2003 JBL Professional

JBL Professional Contacts

Inspection, Maintenance and Liability

Suspension systems are comprised of mechanical devices and, as such, they require regular inspection and routine main

tenance to ensure that safety has not been compromised.The JBL SoundFactor Install loudspeakers and associated suspension components must be inspected f

or fatigue at least annually and immediately following exposure to impact,

mechanical shoc

k, fire, water or other hazard.The inspection must include a visual survey of all corners and load bearing

surfaces for signs of cracking, water damage, de-lamination, and any other condition that may decrease the strength of

the loudspeaker enclosure or associated suspension components. The forged shoulder eyebolts provided with the JBL

SoundFactor Install loudspeakers m ust be inspected for fatigue at least annually.The inspection must include a visual survey of the material for signs of corrosion, bending or any other condition that may decrease the strength of the fastener.

Additionally, the eyebolts must be checked for possible spin-out of the enclosure.For all other hardware and fittings, refer

to the hardware manufacturer's inspection and maintenance guidelines f or process. Should any signs of unsafe conditions

be observed, repair or replacement of the deteriorated component(s) must be completed before anyone other than someone performing the repair is allowed access to the vicinity of the unsafe condition.

Note:

The working load limit (WLL) of the JBL SoundFactor Install loudspeakers includes;a design factor equivalent to or

exceeding ASME B30.20, VBG70, VBG9a and the manufacturer's proprietary performance standard.

All implied warranties, including warranties of merchantability and fitness for particular pur pose, are limited in duration to

the length of the warranty. JBL's liability shall in no event exceed the cost of any defective product and shall not include

incidental or consequential damages of any kind, even if JBL has been advised of the possibility. Some states do not allow

limitations on how long certain warranties last and/or do not allow exclusion of incidental or consequential damages, so

the above limitations and exclusions may not apply to you.This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

JBL is not responsible for the application of its products for any purpose or the misuse of this information for any purpose.

Furthermore, JBL is not responsible for the abuse of its products caused by av oiding compliance with inspection and maintenance procedures or any other abuse.

Allen Products ATM Fly-Ware

(562) 424-1100 (888) RIG-MORE / (310) 834-5914

1635 E. Burnett Street 2100 South Wilmington Avenue

Signal Hill, CA 90806 Carson, CA 90810

www.allenproducts.com www.atmflyware.com

M.A.N. Flying Systems McMaster Carr

20 Sidar Road Various locations through the United States.

Brook Road Industrial estate For a location near you, visit them online at

Rayleigh, Essex SS6 7XF www.mcmaster.com

www.manfly.co.uk

JBL Professional - Tech Note V1 No. 14

“Basic Principles For Suspending Loudspeakers”

www.jblpro.com/technote/tn_v1n14.pdf

Resources

Loading...

Loading...