Page 1

14

13

15 16

12

24

23

17

18

19

2

1

3

4

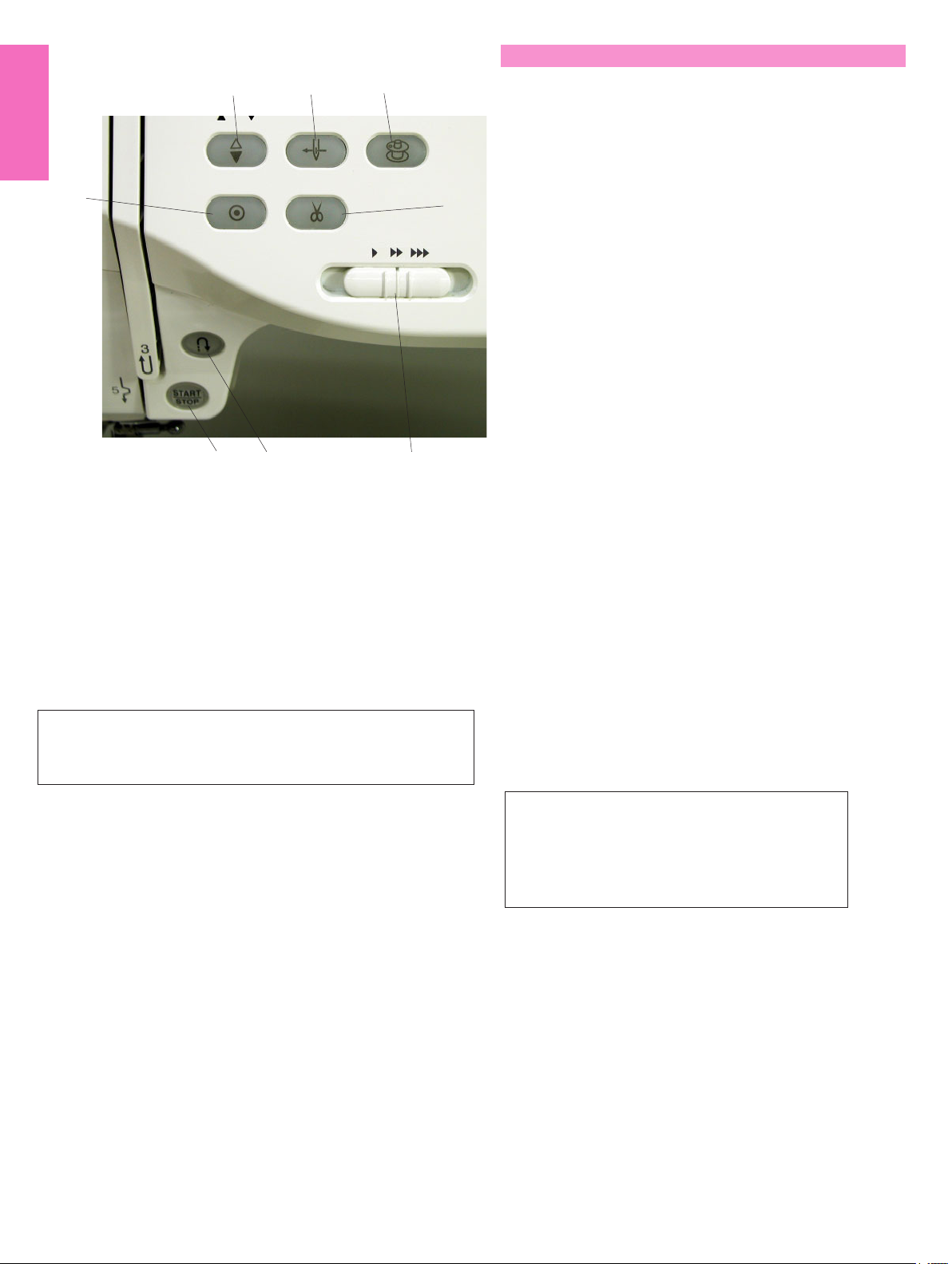

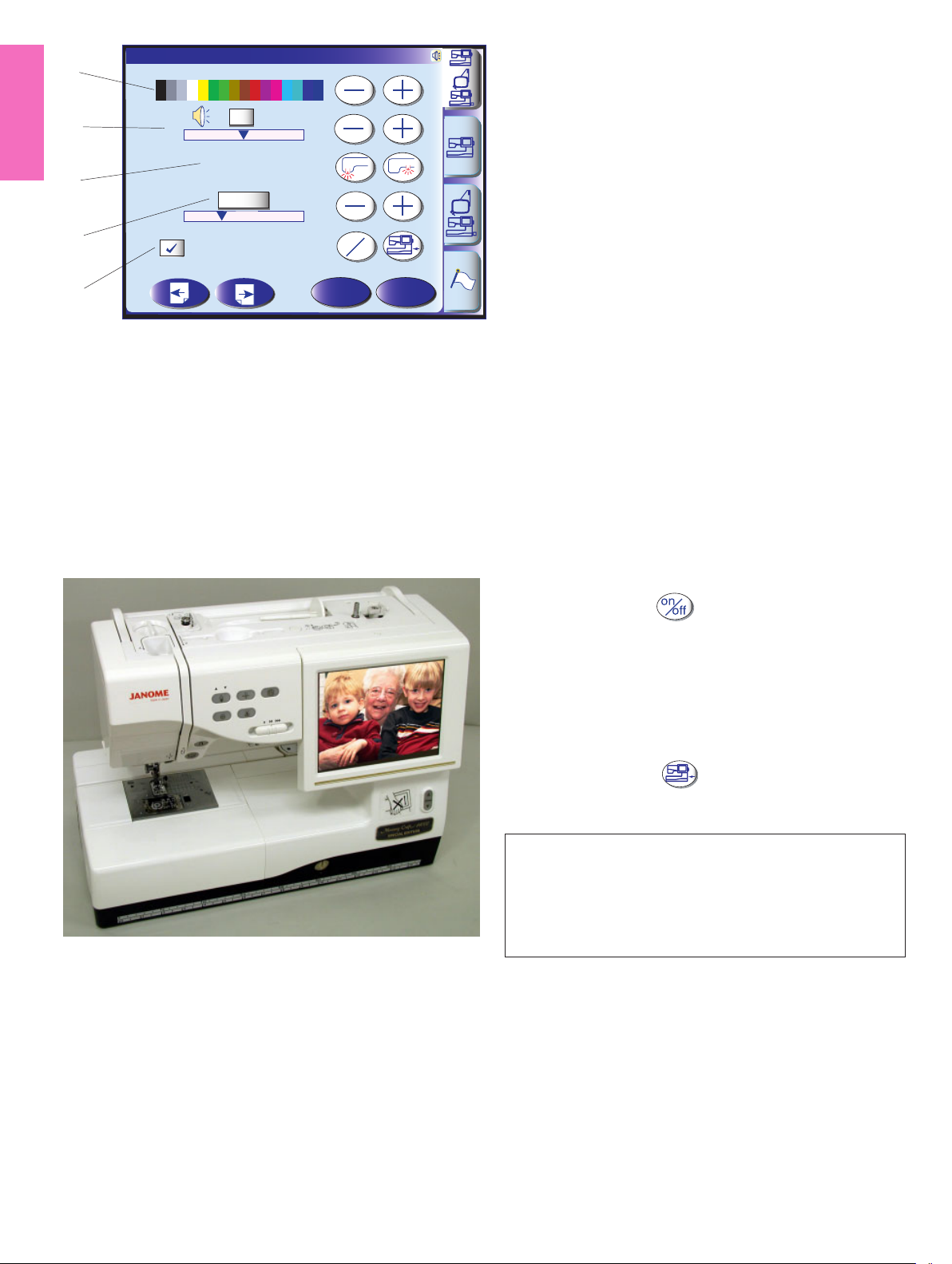

GETTING READY TO SEW

Names of Parts

1 Bobbin winder spindle

2 Bobbin winder stopper

3 Bobbin thread cutter

4 Visual touch screen

5 Screen up/down button

6 Knee lifter socket

7 Feed balancing dial

8 Extension table (accessory storage)

9 Hook cover release button

5

10 Hook cover plate

11 Needle plate

12 Automatic needle threader

13 Thread cutter/holder

7

8

21

22

6

20

9

14 Face plate

15 Foot pressure dial

16 Bobbin winding thread guide

17 Stylus holder (for the touch panel stylus)

18 Spool pin

19 Spool holder

20 Needle clamp screw

21 Needle

22 Zigzag foot A

23 Foot holder

24 Thumbscrew

25 Auto needle threader button

26 Bobbin winding button

27 Thread cutter button

28 Speed control slider

29 Start/stop button

30 Reverse button

31 Auto-lock button

32 Needle up/down button

31

11

32

29

25

30

10

26

27

28

2

Page 2

10

9

1 Carrying handle

1

2 Power switch

3 Machine socket

4 Carriage release lever

5 USB port (for direct PC link)

6 USB port (for CD-ROM drive/USB memory key)

7 Foot control jack

8 Card ejecting button

9 Card slot

10 Hand wheel

11 Buttonhole lever

2

8

12 Retractable carriage arm

13 Hard cover (accessory storage)

3

567

4

11

12

13

3

Page 3

1

Standard Accessories and Storage

The embroidery hoops, foot control, power supply cord,

knee lifter etc. can be conveniently stored in the hard cover.

2

3

11

4

12

1 Embroidery hoop-ST (with template)

2 Embroidery hoop-SQ (with template)

3 Foot control

5

4 Power supply cord

5 Knee lifter

6 Set of red tip needles

13

7 Bobbin thread for embroidery

8 Felts

9 Stabilizers

10 Template sheets for built-in embroidery designs

9

14

11 USB cable

12 Instruction book

13 Key icon reference chart

7

6

14 Instructional movie DVD

15 Handbook CD-ROM

16 MC11K Tools CD-ROM (with instruction booklet)

15

17 Cloth guide

18 Embroidery hoop-AQ (with template and clamps)

8

10

17

18

16

4

Page 4

1

15

The extension table provides a handy compartment for

storing various accessories.

11

13

2

3

4

5

6

7

8

9

10

12

16

17

20

18

19

21

22

23

24

25

1 Overcasting foot C

2 Rolled hem foot D

3 Zipper foot E

4 Satin stitch foot F

5 Blind hemming foot G

6 Cording foot H

7 Overedge foot M

8 1/4” seam foot O

9 Button sewing foot T

10 Automatic buttonhole foot R

11 Embroidery foot P

12 Darning foot P-2

13 Even feed foot with quilting bar

14 Quilting guide bar

15 Spool holder (large)

16 Spool holder (small)

17 Extra spool pin

18 Spool supporter

19 Felt cushion

20 Bobbins

21 Set of needles

22 Screwdriver

23 Screwdriver key

24 Scissors

25 Lint brush

26 Seam ripper (Buttonhole opener)

27 Button shank plate

28 Touch panel stylus

14

26

27

5

28

Page 5

Extension Table

The extension table provides an extended sewing area

and can be removed for free arm sewing.

1 Extension table

To detach:

Draw the table out to the left.

To attach:

Slide the table on the base and push the table to the

1

right.

Free arm sewing

Free-arm sewing is used for stitching sleeves, waist-

bands, pant legs or any other tubular garments.

It is also useful for darning socks or mending knees or

elbows.

For free arm sewing

1 Return the carriage to the home position (refer to

page 67).

2 Turn the power switch off.

3 Remove the extension table.

4 Hook your finger on the bottom of the fillet and draw

the fillet out to the left.

3

2 Fillet

For flat bed sewing

1 Return the carriage to the home position.

2 Turn the power switch off.

3 Insert the fillet and slide it to the right, between the

free arm and carriage base.

4 Attach the extension table.

3 Carriage base

4

4 Free arm

NOTE:

2

Do not pull or push the carriage base.

6

Page 6

Connecting the Power Supply

3

2

1

First mak sure the power switch is off and then insert

the foot control plug into the jack on the machine if you

wish to use foot control.

Insert the machine plug of the power supply cord into

the machine socket.

Insert the power supply plug into the wall outlet, and

turn the power switch on.

1 Power switch

2 Machine plug

3 Machine socket

NOTES:

Make sure to use the power supply cord that came with

the machine.

If you turn off the power switch, wait for 5 seconds

before turning it on again.

The foot control cannot be used in the embroidery mode.

WARNING:

While in operation, always keep your eyes on the

sewing area, and do not touch any moving parts such

as the thread take-up lever, handwheel or needle.

Always turn off the power switch and unplug the

machine from the power supply:

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Do not place anything on the Foot Control.

Operating Instructions:

The symbol “O” on a switch indicates the “off” position

of the switch.

2

1

For the U.S.A. and Canada only

Polarized plug (one blade wider than the other):

To reduce the risk of electric shock, this plug is intended

to fit in a polarized outlet only one way. If it does not fit

fully in the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

If you wish to use the foot control, pull out the cord from

the foot control and insert the pin connector into the

jack on the machine.

1 Foot control cord

2 Pin connector

Insert the machine plug of the power supply cord into

the machine socket.

Insert the power supply plug into the wall outlet, and

turn the power switch on.

CAUTION:

Do not pull the foot control cord beyond the red mark.

7

Page 7

Machine Operating Buttons

3

6

4

12

7

8

5

1 Start/stop button

Press this button to start or stop the machine. This button

can be used either in the ordinary sewing mode or

embroidery mode. In the ordinary sewing mode, the machine

starts running slowly for the first few stitches, it then runs at

the speed set by the speed control slider. The machine runs

slowly as long as this button is pressed.

The button will turn red when the machine is running, and

green, that it has been stopped.

NOTE:

The start/stop button cannot be used in the ordinary sewing

mode when the foot control is connected to the machine.

4 Auto-lock button

When sewing stitch pattern U1, U2, U8 or U9, the

machine will immediately sew locking stitches and

automatically stop when the auto-lock button is

pressed.

When sewing all other stitches, the machine will sew

to the end of the current pattern, sew locking stitches

and stop automatically.

The machine will trim the threads automatically after

locking the stitch when the auto thread cutting is

enabled (refer to page 22).

5 Speed control slider

This slider will set the maximum sewing speed in the

ordinary sewing mode (refer to page 9).

6 Auto needle threader button

Press this button and follow the step-by-step

instruction displayed on the visual touch screen to

thread the needle.

Refer to page 13.

7 Bobbin winding button

Press this button to wind the bobbin.

Refer to page 10.

8 Thread cutter button

Press this button after finishing sewing and the

machine will trim the threads automatically.

Refer to page 28.

2 Reverse button

When sewing stitch pattern U1, U2, U8 or U9, the machine

will sew in reverse as long as the reverse button is pressed.

If the stitch pattern U1, U2, U8 or U9 has been selected and

the foot control is not connected, the machine will start

sewing in reverse as long as the reverse button is pressed.

If you press the reverse button when sewing any other

stitches, the machine will immediately sew locking stitches

and automatically stop.

3 Needle up/down button

Press this button to bring the needle bar up or down.

NOTES:

The thread cutter button does not function:

- soon after turning on the power.

- when the presser foot is in the up position.

- when being pressed 4 times in a row.

8

Page 8

Utility(U)

Straight Stitch

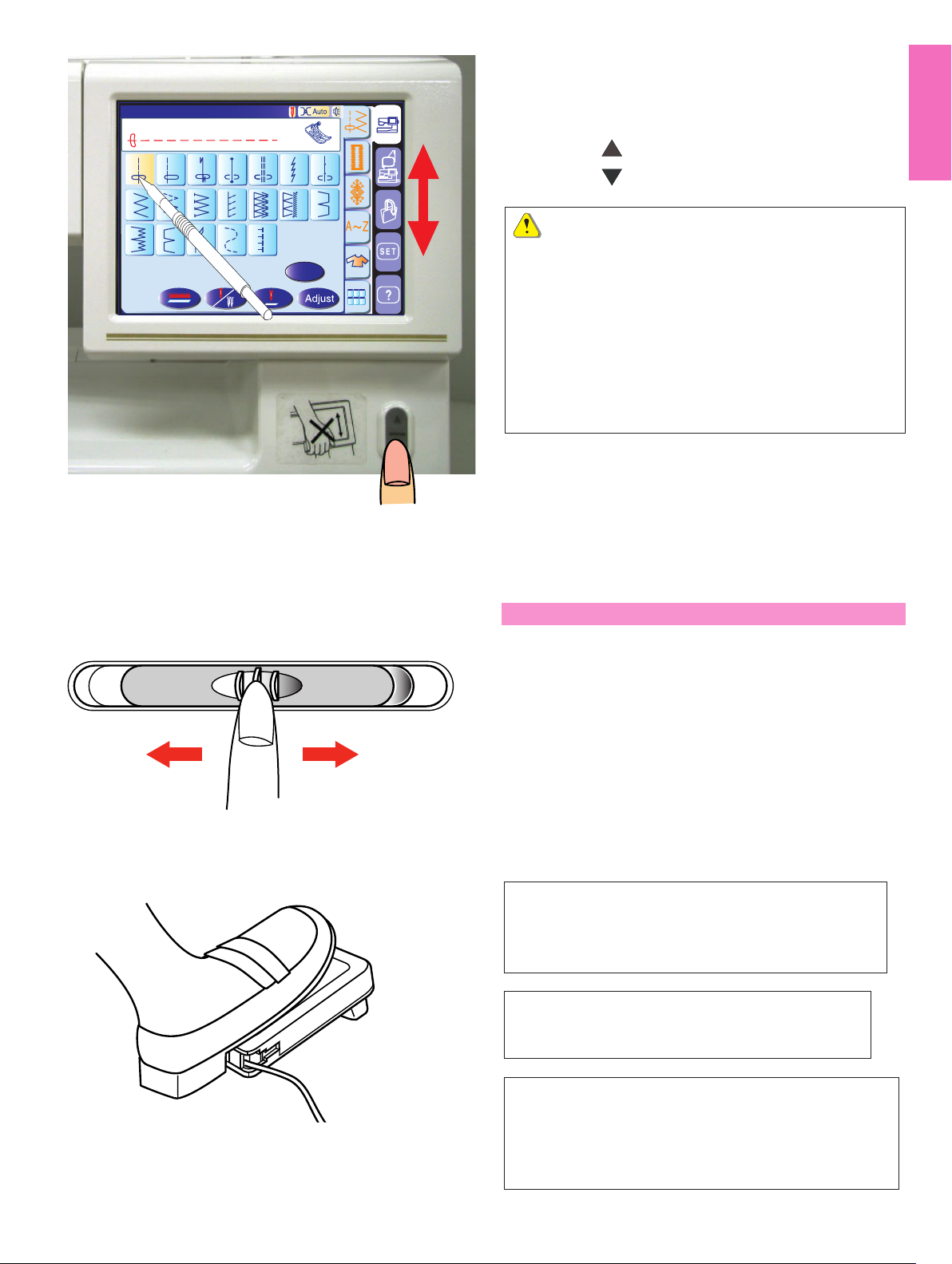

Screen up/down button

The visual touch screen can be raised to open (clear)

the space for handling fabrics etc.

A

1

2

4

3

5

7

6

Pressing the button raises the screen, while

pressing the button lowers the screen.

8

9

10

11

15

16

17

13

12

1918

14

CAUTION:

Be sure to store the visual touch screen in the lowest

B

position before carrying or storing the machine to

prevent the screen from damage by impact.

Do not force to move the visual touch screen by hand.

Do not press the surface of the visual touch screen

with hard or sharp objects like pencils, screwdrivers or

the like. Use the touch panel stylus to press the visual

touch screen.

Controlling Sewing Speed

Speed control slider

You can limit the maximum sewing speed with the

speed control slider according to your sewing needs.

To increase the sewing speed, move the slider to the right.

To decrease the sewing speed, move the slider to the left.

Foot control

Pressing on the foot control can vary sewing speed.

The harder you press the foot control, the faster the

machine runs.

NOTE:

The machine runs at the maximum speed set by the

speed control slider when the foot control is fully

depressed.

Operating Instructions:

Foot controller Model 21371 is for use with sewing

machine model MC 11000.

NOTE:

This machine is equipped with an automatic shutdown

safety feature to prevent overheating whenever the

machine is running overloaded. Follow the safety

instructions that appear on the visual touch screen.

9

Page 9

Setting the Spool of Thread

Lift up the spool pin. Place the spool of thread on the

spool pin with the thread coming off the spool as

shown. Attach the large spool holder, and press it firmly

against the spool of thread.

NOTE:

Use the small spool holder to hold narrow or small

spools of thread.

Extra spool pin

Use the extra spool pin when you need to wind a

bobbin without unthreading the machine while working

on a sewing project.

Insert the extra spool pin into the spool supporter and

then into the hole beside the horizontal spool pin.

1

2

Place the felt cushion on the spool pin and place a

spool of thread on it as shown.

NOTE:

The extra spool pin is also used for twin needle

sewing.

Winding the Bobbin

This machine has an exclusive motor for bobbin

winding, which allows you to wind the bobbin while

stitching.

1 Slide the hook cover release button to the right, and

remove the hook cover plate.

2 Lift out the bobbin from the bobbin holder.

3

3 Pull the thread from the spool and pass the thread

through the thread guide.

Draw the thread around and under the bobbin

winding tension disk.

4

5

6

4 Pass the thread through the hole in the bobbin from

the inside to the outside.

5 Put the bobbin on the bobbin winder spindle.

Push the bobbin winder stopper to the left.

6 Hold the free end of the thread in your hand and

press the bobbin winding button .

Press the bobbin winding button again to stop the

bobbin when it has wound several layers, and cut

the thread close to the hole in the bobbin .

NOTE:

10

Use the Janome plastic bobbins for horizontal hook

(marked with “J”). Using other bobbins, such as

prewound paper bobbins, may cause stitching problem

or damage to the bobbin case.

Page 10

7

7 Press the bobbin winding button again .

When the bobbin is fully wound, the bobbin winder

stopper returns to the original position and the

machine will stop automatically.

Cut the thread with the thread cutter.

1

2

3

(A)

4

Inserting the Bobbin

1 Place the bobbin in the bobbin holder with the thread

running off counterclockwise.

2 Guide the thread into the front notch (A) on the

bobbin holder.

3 Draw the thread to the left, sliding it between the

tension spring blades.

4 Continue to draw the thread lightly until the thread

slips into the side notch (B).

(B)

5

5 Pull out about 10 cm (4") of thread to the rear.

Reattach the hook cover plate.

NOTE:

A threading chart is shown on the hook cover plate for

your reference.

11

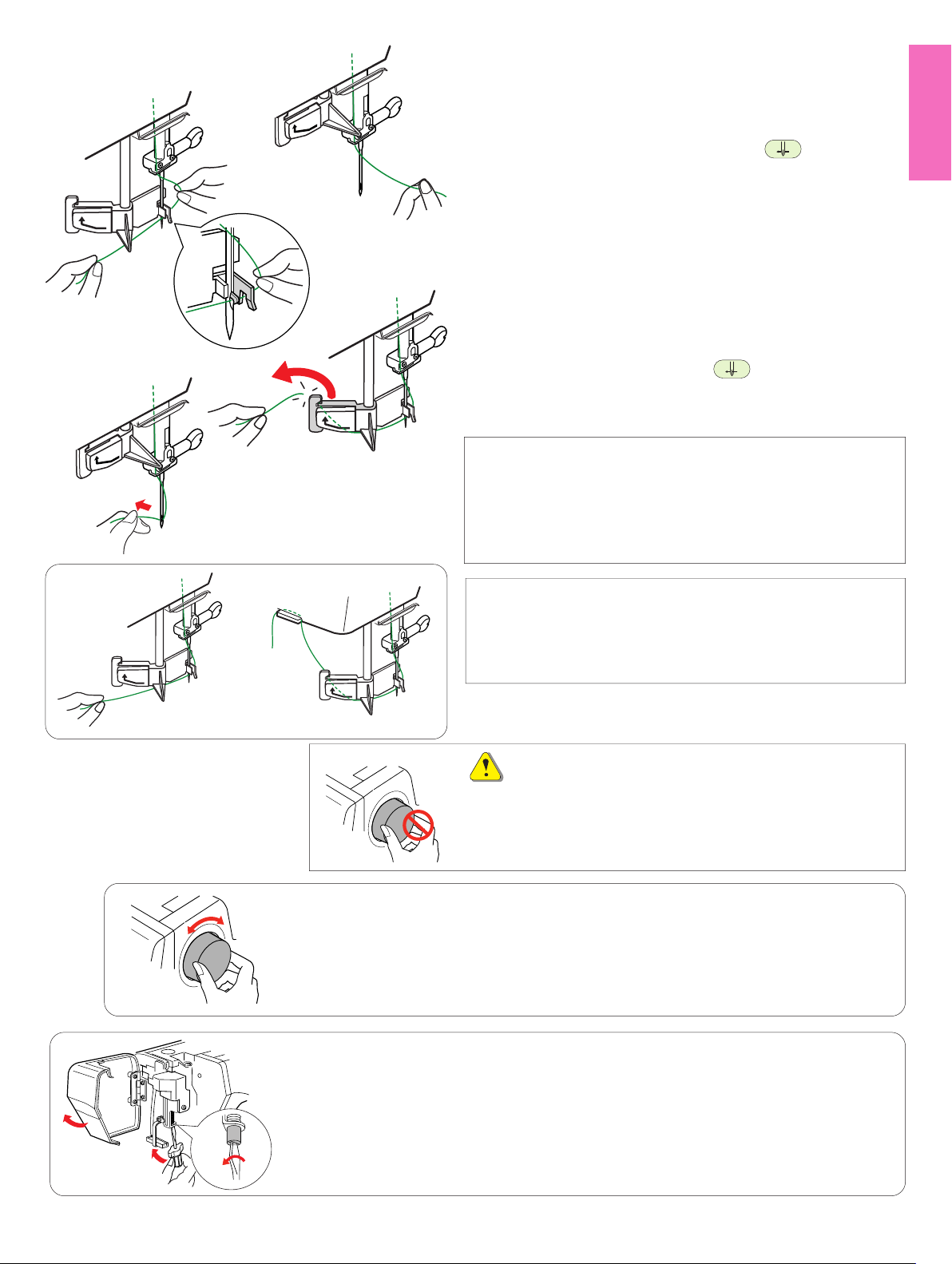

Page 11

Threading the Machine

Raise the presser foot. Press the needle up/down

button twice to raise the needle.

Turn the power switch off.

1 Draw the thread from the spool. Hold the thread with

1

both hands and pass the thread under the thread

guide plate. Tug the thread until it snaps.

2

2 Draw the thread down along the right channel and

around the bottom of the guide plate.

3 Pull the thread up along the left channel to the

3

4

thread take-up lever.

4 Firmly draw the thread up to the take-up lever and

down into its eye from the right to the left, while

holding the thread at the spool.

5

5 Then pull the thread down along the left channel

and through the lower thread guide.

6 Slide the thread behind the needle bar thread guide

on the left.

6

7 Thread the needle with the automatic needle

threader (refer to the next page).

7

12

Page 12

1

Using the Automatic Needle Threader

Turn the power switch on and lower the presser foot.

2

1 Hold the end of the needle thread gently.

2 Press the auto needle threader button . The threader

lowers automatically and the hook comes out through

the needle eye from behind it.

3 Pull the thread down around the thread guide, then

pass the thread from the right and under the hook as

shown.

4

3

5

4 Draw the thread to the left and slip it into the slit of the

thread holder from the bottom and cut the thread with

the thread cutter as shown.

5 Press the auto threader button again. The threader

goes up automatically and pulls the thread out through

the needle eye. Pull the loop of thread to the back.

NOTES:

The automatic needle threader works well on the needles

Nos. 11-14, sewing threads Nos. 50-90 and Janome

embroidery threads.

Thick threads, Nos. 20 and 30, are not suitable for the

automatic needle threader.

NOTES:

You may need to hold the thread end with your hand when

threading certain kinds of threads.

When threading monofilament thread, hang the thread end

on the thread holder on the face plate.

CAUTION:

Do not turn the handwheel while the automatic needle

threader is in the lowered position to prevent it from

damage. Do not touch the automatic needle threader while it

is moving.

If the automatic needle threader is locked by turning the handwheel accidentally,

release it as follows:

Carefully turn the handwheel to move the needle up or down a little, so that it frees the

automatic needle threader.

Press the auto needle threader button to restore the automatic needle threader to the

up position.

If the automatic needle threader will not return to the up position by pressing the auto

needle threader button, correct it as follows:

1. Turn the power switch off.

2. Open the face plate.

3. Turn the threader shaft counterclockwise to release the hook from the needle eye.

4. Turn the power switch on and the automatic needle threader will return to the up

position.

5. Close the face plate.

13

Page 13

Drawing Up the Bobbin Thread

1

2

3

1 Raise the presser foot lifter.

2 Hold the needle thread with your finger and press

the up/down needle button twice to pick up the

bobbin thread.

3 Draw up the needle thread to bring up a loop of the

bobbin thread.

4

4 Slide 10 cm (4") of both threads to the back under

the presser foot.

14

Page 14

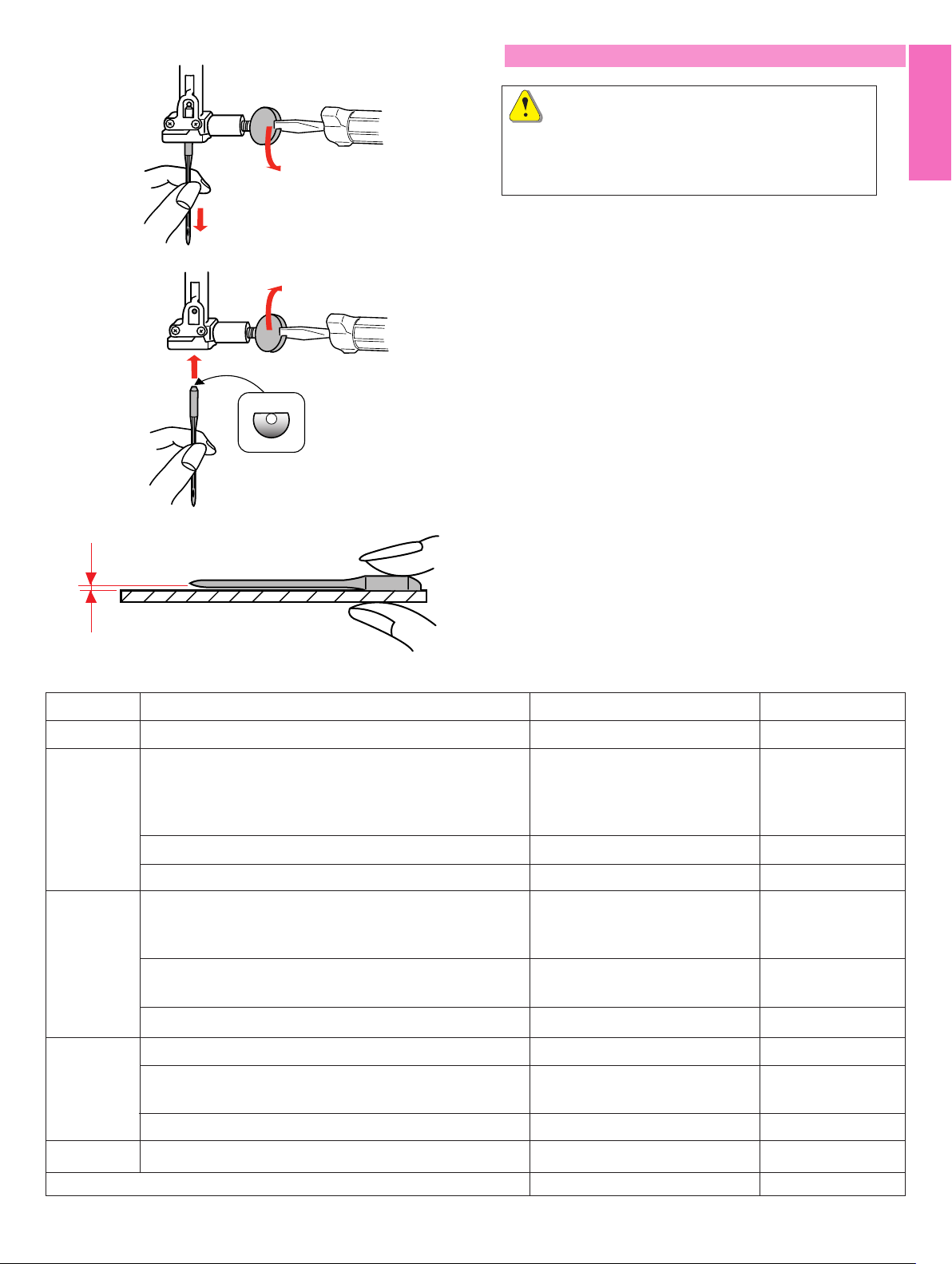

Changing Needles

CAUTION:

Always make sure to turn the power switch off and

disconnect the machine from power supply before

changing the needle.

Raise the needle by pressing the up/down needle

button and lower the presser foot.

Turn the power switch off.

Loosen the needle clamp screw by turning it counter-

clockwise.

Remove the needle from the clamp.

Insert a new needle into the needle clamp with the flat

side of the needle to the rear.

When inserting the needle into the needle clamp, push

it up against the stopper pin and tighten the needle

clamp screw firmly with a screwdriver.

Fabrics and needle chart

Weight

Very Light

Light

Medium

Fabric

Chiffon, Georgette, Fine Lace, Organdy Net, Tulle

Batiste, Voile, Lawn, Pure Silk, Crepe de Chine, Sheer

Crepe, Chambray, Handkerchief Linen, Gingham,

Challis, Percale, Wool Crepe, Peau de Soie, Taffeta,

Satin, Silk Surah, Satin-backed Crepe, Qiana

Single Knits, Jersey, Swim wear, and Tricot

Leather Suede

Flannel, Velour, Velvet, Muslin, Velveteen, Poplin,

Corduroy, Broadcloth, Linen, Chintz, Gabardine, Felt,

Terry, Burlap, Quilted Fabrics

Double Knits, (synthetic and natural) Stretch Velour,

Stretch Terry, Sweater Knits

Leather, Vinyl, Suede

To check needle straightness, place the flat side of the

needle onto something flat (a needle plate, glass etc.)

The gap between the needle and the flat surface should

be consistent.

Never use a blunt needle.

Type of Needle

Universal, Ball Point

Blue Tipped Needle

Universal

Blue Tipped Needle, Ball Point

Wedge Point Leather Needle

Universal

Ball Point

Wedge Point Leather Needle

Needle Size

9 (65)

11 (75)

11 (75), 12 (80)

11 (75)

11 (75)

14 (90)

14 (90)

14 (90)

Heavy

Very Heavy

Denim, Sailcloth, Ticking

Double Faced Wool, Heavy Coating, Fake Fur,

Drapery Fabrics

Leather, Suede

Canvas, Duck, Upholstery Fabrics

Topstitching for Special Finish

15

Denim Needle

Universal

Wedge Point Leather Needle

Universal

Topstitching Needle

16 (100)

16 (100)

16 (100), 18 (110)

16 (100)

14 (90)

Page 15

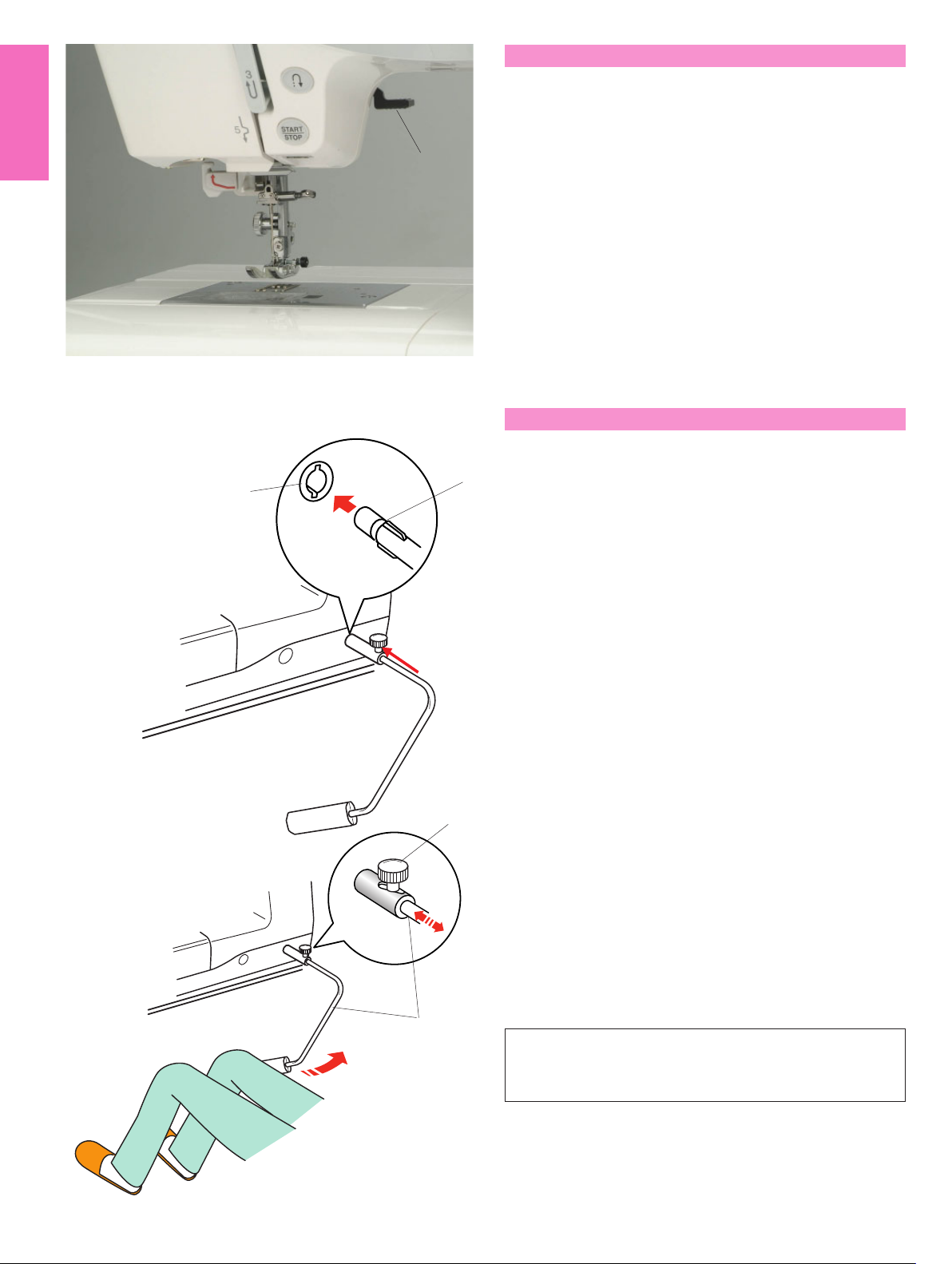

Raising and Lowering the Presser Foot

The presser foot lifter raises and lowers the presser

foot.

1 Presser foot lifter

1

You can raise the presser foot about 6 mm (1/4")

higher than the normal up position by exerting more

pressure when lifting the presser foot lifter. This helps

you to place the layers of thick fabrics or embroidery

hoops under the foot.

Knee Lifter

The knee lifter is extremely helpful when sewing

patchwork, quilting etc, since it allows you to handle

1

2

the fabric while your knee controls the presser foot.

Attaching the knee lifter

Match the ribs on the knee lifter with the notches in the

knee lifter socket and insert the knee lifter.

1 Knee lifter

2 Knee lifter socket

Adjusting the knee lifter

The angle of knee lifter can be adjusted to fit your

knee.

Loosen the setscrew and slide the angle bar in or out

to adjust the angle of the knee lifter.

3

4

Tighten the setscrew to secure the angle bar.

3 Setscrew

4 Angle bar

Using the knee lifter

Push the knee lifter with your knee to easily move the

presser foot up and down.

You can control how high the foot rises by the amount

of knee pressure you exert.

NOTE:

Do not touch the knee lifter while stitching, otherwise

the fabric will not be fed smoothly.

16

Page 16

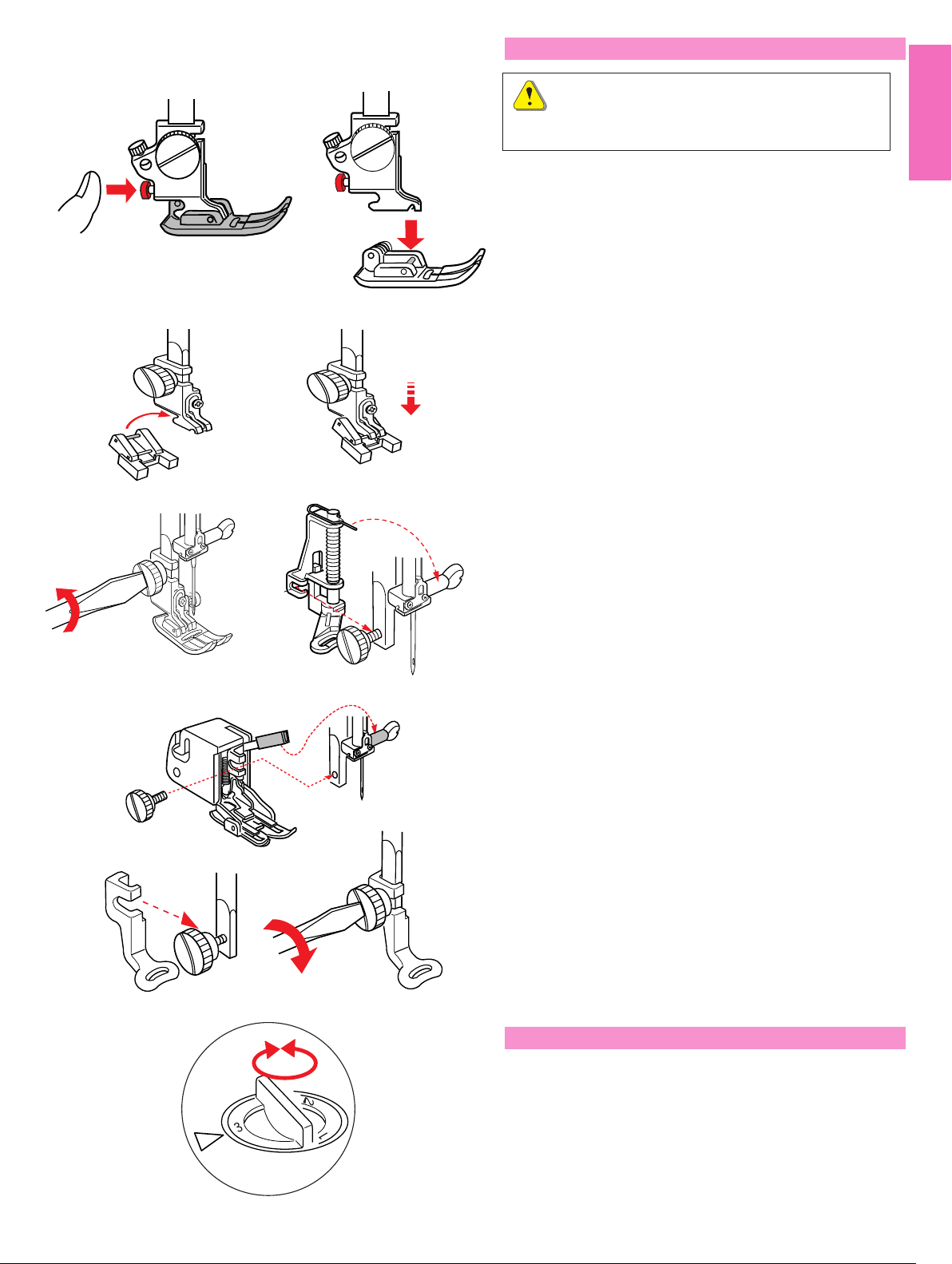

Removing and Attaching the Presser Foot

WARNING:

Turn the power switch off before changing the presser

foot.

Removing the presser foot

Raise the needle to its highest position and raise the

presser foot lifter.

Press the red button on the back of the foot holder.

The presser foot will drop off.

Attaching the presser foot

Place the presser foot you wish to use so that the pin

on the foot lies just under the groove of the foot holder.

Lower the presser bar to lock the foot in place.

Button sewing foot T

Insert the rear pin on the foot into the groove of the foot

holder.

Gently lower the presser bar while holding the foot with

your fingers.

Darning foot P-2

Loosen the thumbscrew and remove the foot holder.

Attach the darning foot P-2 to the presser bar putting

the pin on the needle clamp screw.

Tighten the thumbscrew firmly with the screwdriver.

Even feed foot

Loosen the thumbscrew and remove the foot holder.

Attach the even feed foot to the presser bar with the

lever over the needle clamp screw and secure it with

the thumbscrew.

Embroidery foot P

Loosen the thumbscrew and remove the foot holder.

Attach embroidery foot P to the presser bar from be-

hind.

Tighten the thumbscrew securely with the screwdriver.

Adjusting the Foot Pressure

The foot pressure control dial should be set at “3” for

regular sewing.

Reduce the pressure to “2” for appliqué, cutwork, drawn

work, basting and embroidery.

Set the dial at “1” when sewing extra fine fabrics.

17

Page 17

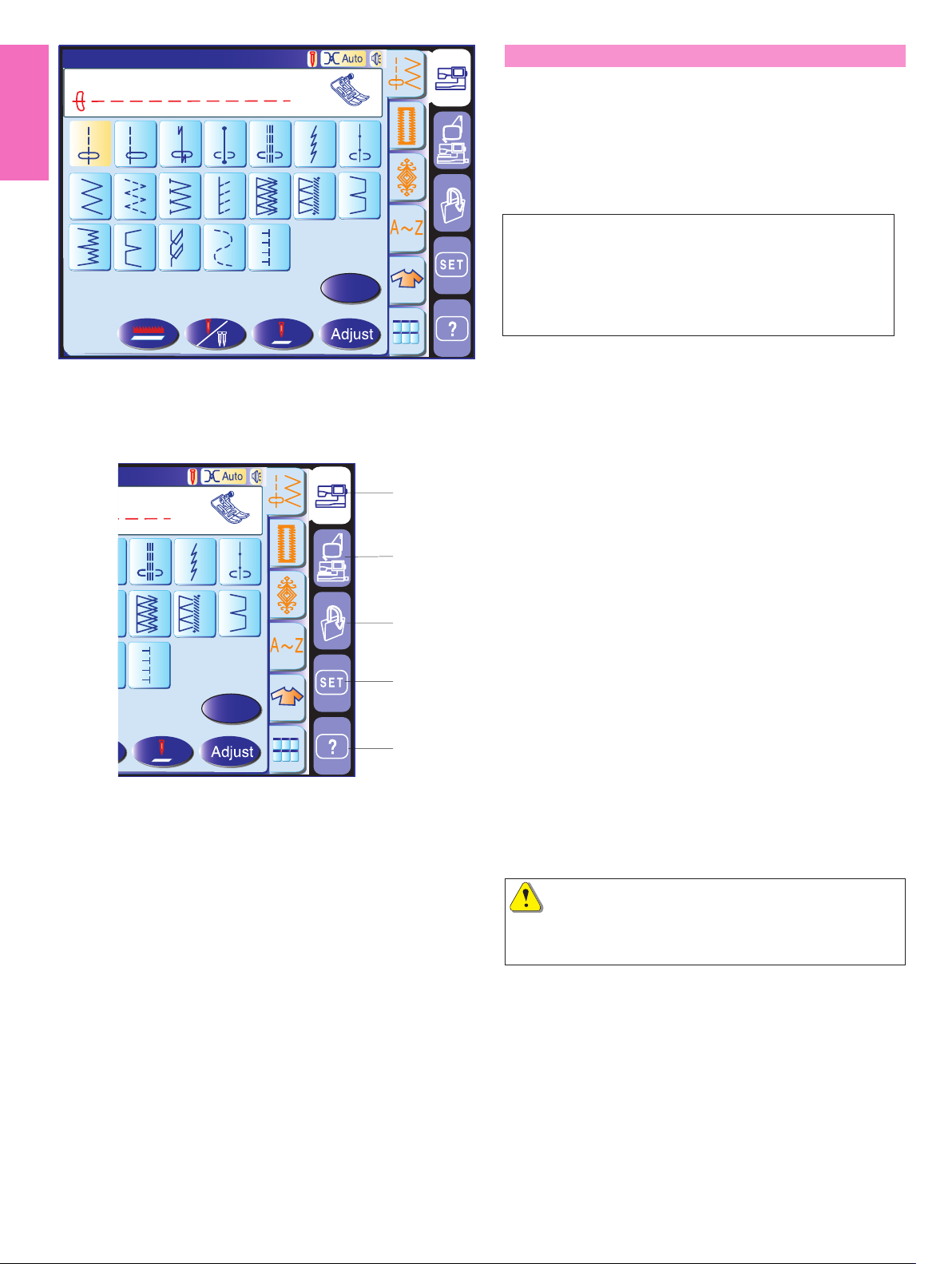

Utility(U)

Straight Stitch

1

2

8

9

10

Mode Selection

A

4

12

5

13

3

11

7

6

14

When you turn on the power switch, the visual touch

screen will show the opening “welcome” window, then

the ordinary sewing mode will appear after a few

seconds.

The machine will be set for straight stitch sewing.

15

16

17

1918

NOTE:

After turning on the power, it takes several seconds for

the pattern selection window to be displayed on the

B

visual touch screen.

(This is the required boot up time and is not a defect.)

Mode selection keys

1 Ordinary sewing mode key

Press this key to enter the ordinary sewing mode.

2 Embroidery mode key

A

4

5

7

6

1

2

1

14

13

12

3

198

4

B

Press this key to enter the embroidery mode.

3 Open file key

Press this key to open files such as programmed stitch

patterns and embroidery designs you have saved.

4 Set mode key

Press this key to enter the setting mode. In this mode,

you can customize the machine settings to your prefer-

ence. The machine settings for ordinary sewing, em-

broidery, language selection and common settings are

5

available in this mode.

5 Help movie key

Press this key to view the on-screen movie on the

essential operations.

CAUTION:

Do not press the surface of the visual touch screen with

hard or sharp objects like pencils, screwdrivers or the like.

18

Page 18

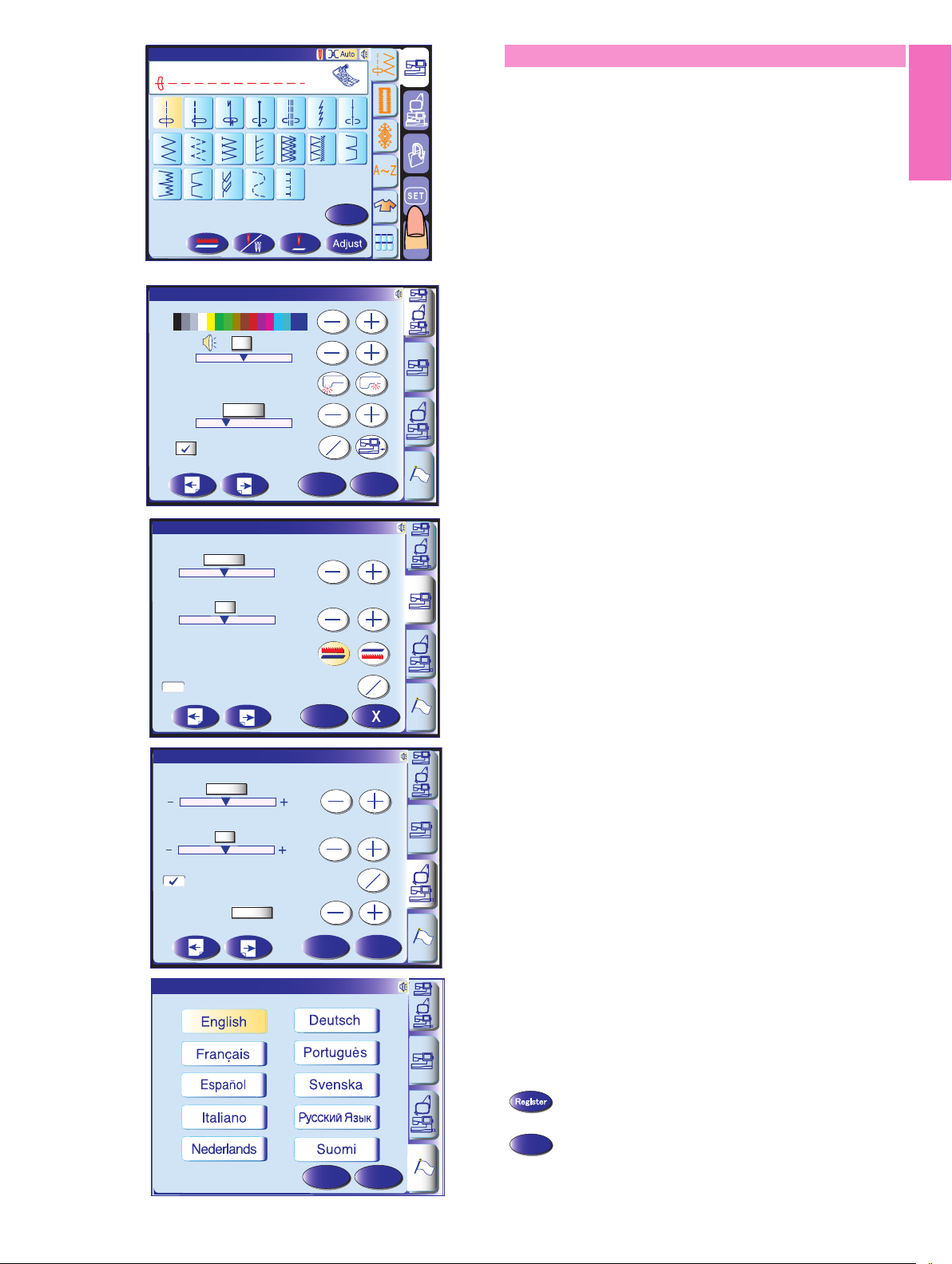

SET1

Register

10 mim

5

X

Utility(U)

Straight Stitch

1

8

15

16

A

Machine Settings

2

9

4

3

10

17

5

12

11

1918

7

6

13

14

B

Set mode key

When you press the set mode key, you can customize

the machine settings.

Press one of the 4 setting mode keys to select the

mode to customize.

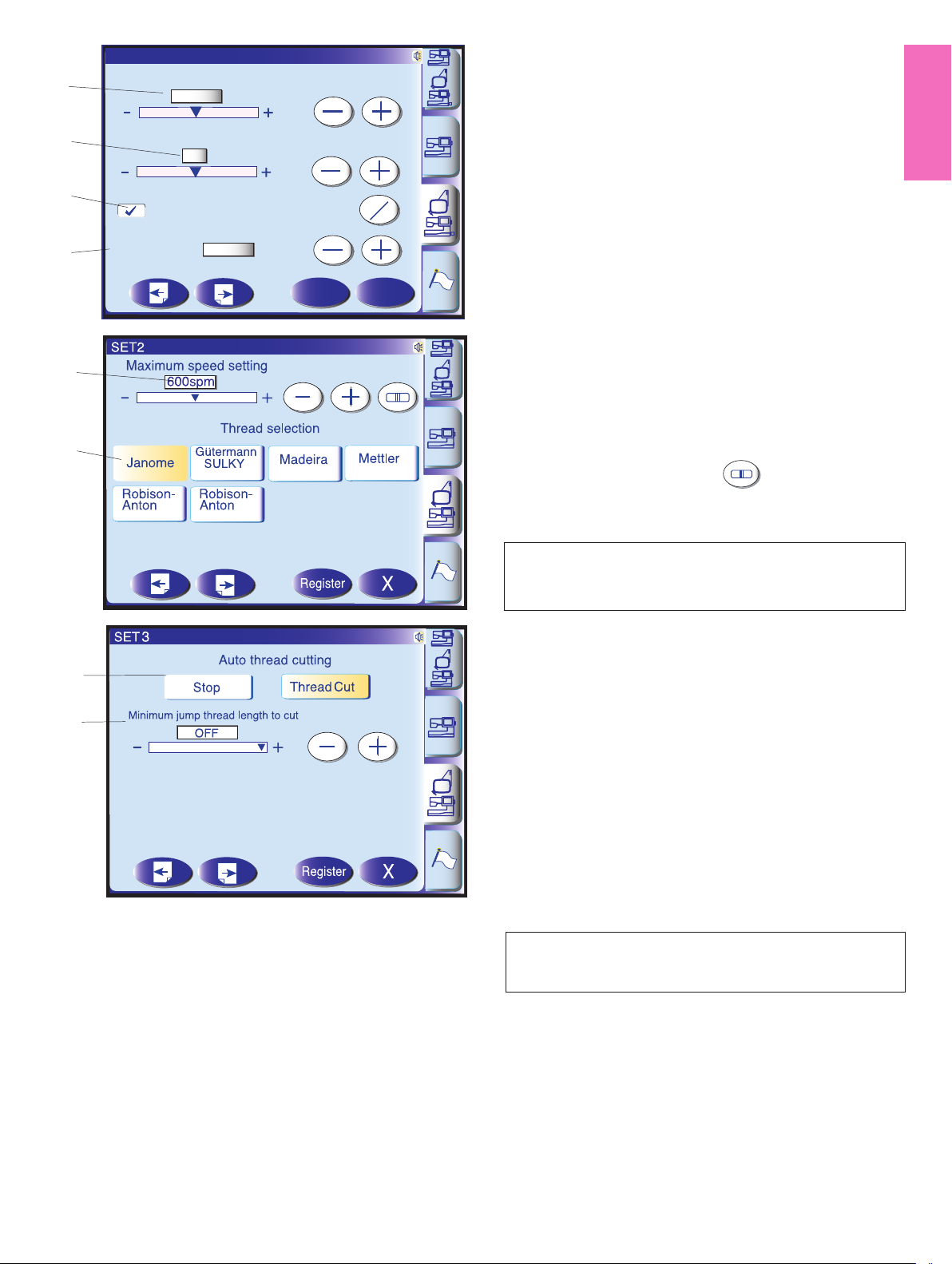

SET1

1

SET1

2

-

Remaining Bobbin Thread

-

SET1

3

Screen Contrast

5

-

Sewing Light

Eco Mode

10 mim

-

Screen Saver

Auto Tension

Auto

+

2

+

Feed Dog

Thread Cut after Auto-Lock

Auto Tension

Auto

+

+

Register

Register

1 Common setting mode

In this mode, the machine settings or function for both

ordinary sewing and embroidery can be customized or

executed.

on

off

X

2 Ordinary sewing setting mode

In this mode, the machine settings or function for

ordinary sewing can be customized or executed.

on

off

3 Embroidery setting mode

In this mode, the machine settings or function for

embroidery can be customized or executed.

Remaining Bobbin Thread

Grid Line

Grid Size

4

Language

2

10mm

Language Selection

Register

Register

on

off

X

4 Language selection mode (Flag mode)

In this mode, you can select one of 10 languages for

the messages displayed on the screen.

Registering the custom settings

After customizing the settings, press the register key

to enable the new settings.

To cancel the changes to the settings, press the exit key

and the setting mode window will close.

X

19

Page 19

SET1

SET1

Register

10 mim

5

1

Screen Contrast

Common settings

2

-

3

-

4

5

5

Sewing Light

Eco Mode

10 mim

Screen Saver

+

+

Register

on

off

X

The contrast of the visual touch screen can be adjusted

with “+” or “–“ key.

2 Sound

The buzzer sound can be adjusted with the “+” or “–“

key. To mute the buzzer, set the value to “0”.

3 Sewing light options

The dual sewing lights can be turned on or off

individually.

4 Eco mode

The sewing lights will turn off, and the visual touch

screen will display go dark if you have not used the

machine for a while. Touching the screen will turn on

the lights and screen.

The eco mode timer can be set from 1 to 30 minutes by

pressing the “+” or “–“ key.

1 Screen contrast

5 Screen saver

Press the on/off key to check the box. so the

screen will show the screen saver instead of entering

the eco mode.

You can also create your original screen saver for the

MC 11000 with the Screen Saver tool.

Save the data in an ATA PC card or USB memory key,

and insert it into the port of the MC 11000.

Press the import key to import the screen saver

from the ATA PC card or USB memory key.

NOTES:

The Screen Saver Tool is available in the MC11K Tools

CD-ROM included in the standard accessories.

For instructions on installation and operation of the

software, refer to the separate instruction booklet.

20

Page 20

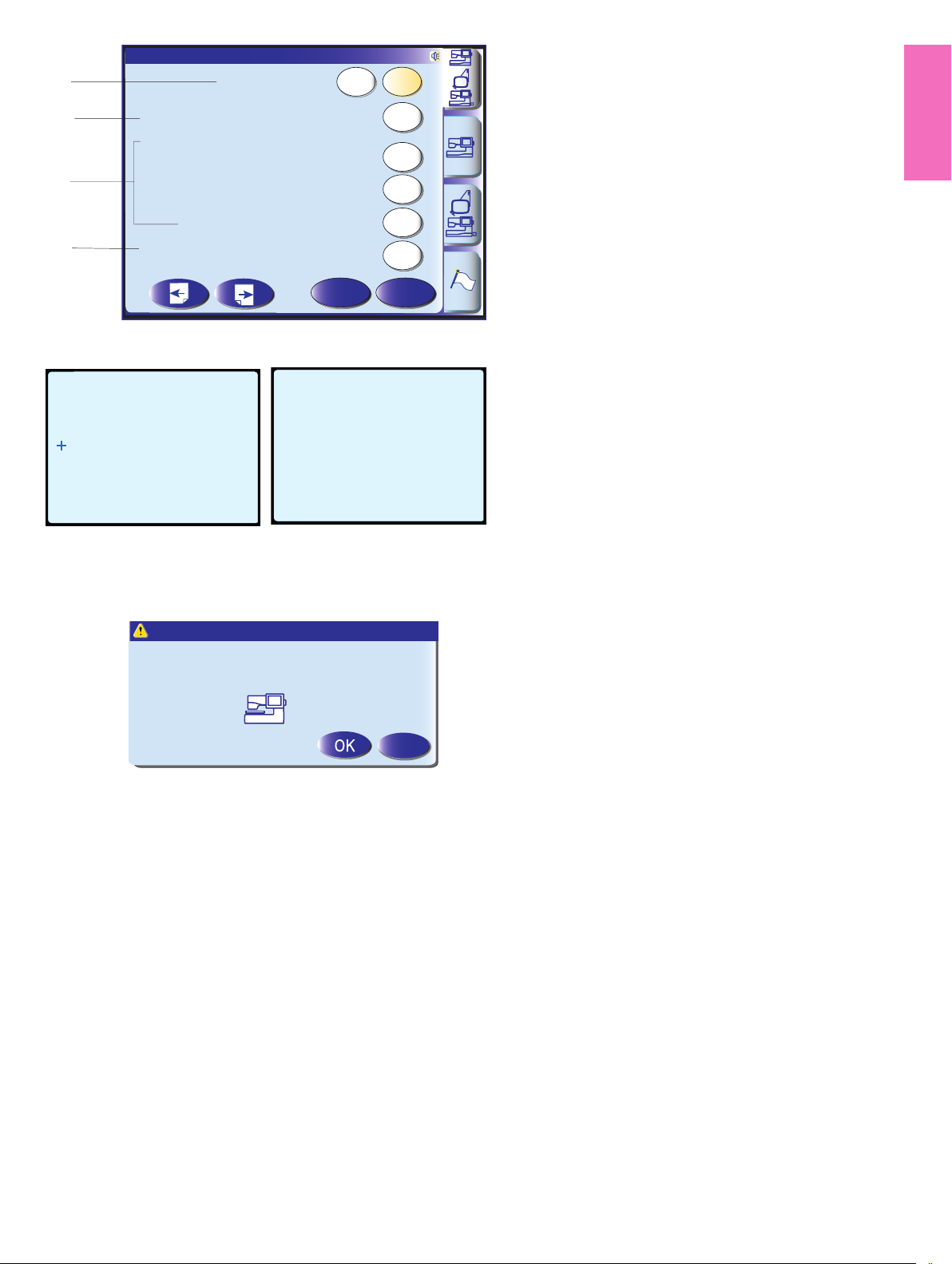

SET2

SET2

Register

Yes

Yes

Yes

Yes

Yes

mm

inch

1

inch/mm

mm

1 Inch/mm options

You can set your machine's measuring unit to either

inch or millimeter by pressing the “inch” or “mm” key.

2

3

Touch Screen Calibration

Format

Built-in Memory

ATA PC Card

Yes

Yes

Yes

The default unit setting is millimeter.

4

(A)

USB Memory

Reset all to defaults

Touch Screen Calibration

PRESS MARK (+).

Format Memory?

All the stored data will be erased.

(B)

Built-in

Yes

Yes

Register

Touch Screen Calibration

END

X

X

2 Touch screen calibration

If you think the touch panel keys are out of alignment,

you can correct it in the key position adjustment

window.

When you press the key, window (A) will be shown.

With your finger, press the black cross as it appears in

order. When you press the last black cross, the window

(B) will be shown. The window will close and go back to

the original screen with the new setting being

registered.

3 Formatting the memory

If the internal memory, ATA PC card or USB memory

key does not function due to damage to the memory

bank, you need to re-enable it by formatting the

memory.

4 Resetting all to default

Press the yes key to reset all the parameters to the

original values (factory settings).

21

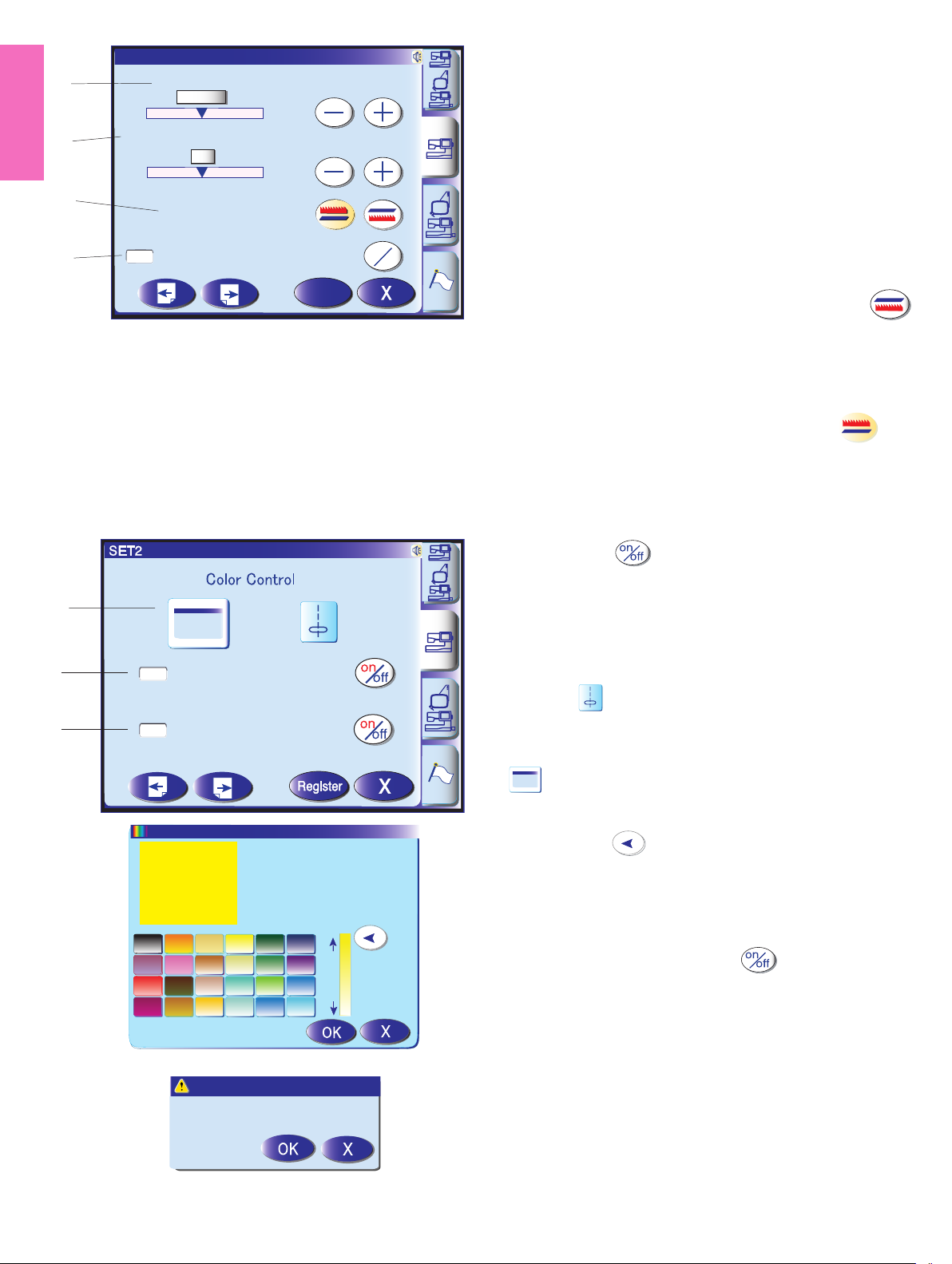

Page 21

SET1

1

2

3

Auto Tension

Auto

-

Remaining Bobbin Thread

2

-

Feed Dog

+

+

Ordinary sewing mode settings

1 Auto thread tension

The auto thread tension level can be adjusted with the

“+” or “–“ key.

2 Low bobbin thread warning

The low bobbin thread warning level can be adjusted

with the “+” or “–“ key.

4

Thread Cut after Auto-Lock

Register

on

off

3 Drop feed option

This option allows you to sew the decorative stitches

with the feed dog lowered. Press the drop feed key

to lower the feed dog. When you start the machine, the

warning message will appear to advise you to raise the

feed dog, however you can continue sewing with the

feed dog lowered.

To raise the feed dog, return to the ordinary sewing

setting mode and press the raise feed dog key

then press the register key.

4 Auto thread cutting

In the following cases, the machine will trim the threads

and stop automatically, if you check the box by pressing

the “on/off” key .

1. Pressing the auto lock button

2. The auto lock stitch is programmed.

5

3. Sewing monogram

4. Sewing the pictograph patterns

6

7

Favorite Stitch

Adjustment

Resume Mode

5 Color options

Press the key to select one of the 3 colors for the

pattern selection keys, which will display in the color

shown.

To change the screen background color, press the

key to open the custom color window.

To select the hue, press one of the 24 color tiles.

To change the shade of the selected color, press and

drag the slider up or down.

Resume last pattern?

6 Favorite stitch adjustment on/off

If you wish to save the altered settings for the utility

stitches for future use, press the key to check the

box on.

7 Resume Mode

When Resume Mode is enabled, the last pattern

sewn before turning the power off will be resumed

when the power is turned on again.

To enable Resume Mode, press the on/off key to

check the box on.

When you turn the power on, the confirmation

window will open.

Press the OK key to resume the last sewn pattern.

22

Page 22

SET1

1

Auto Tension

Auto

Embroidery mode settings

1 Auto thread tension

The auto thread tension level can be adjusted with

2

Remaining Bobbin Thread

2

the “+” or “–“ key.

2 Low bobbin thread warning

The low bobbin thread warning level can be adjusted

3

4

Grid Line

Grid Size

10mm

Register

on

off

X

with the “+” or “–“ key.

3 Grid on/off

To show the grid, press the on/off key to check the box.

To hide the grid, press the on/off key again to uncheck

the box.

4 Grid size

The grid size can be changed by pressing the “+” or

“–“ key.

5

5 Embroidery maximum speed

The maximum embroidery sewing speed can be

changed from 400 to 800 spm in 100 spm intervals by

pressing the “+” or “–“ key or with the speed control

6

Rayon 40

Polyneon 40

Poly Sheen

slider.

Press the speed control slider key if you wish to

change the embroidery sewing speed with the speed

Polyester 40

Rayon 40

control slider. The speed can also be changed while the

machine is running.

NOTE:

Reduce the sewing speed when sewing patterns with

narrow zigzag stitches that tend to distort at high speed.

6 Thread selection

There are five brands of embroidery thread to choose

7

from. Press the key of the thread you wish to use. The

color code of the selected brand will be shown on the

color/part key along with the name of the color.

8

7 Auto thread cutting

The machine will trim the threads automatically when it

stops for changing the thread to the next color.

Select “Stop” to turn off auto thread cutting.

8 Jump thread cutting

Press the “–” or “+” key to set the minimum length of

jump thread to be cut. The machine will automatically

cut jump threads longer than the length selected.

To turn this function off, press the “+” key until “OFF” is

indicated.

NOTE:

This function is disabled when a design pattern for the

hoop FA is selected.

23

Page 23

9

10

Resume Mode

9 Color options

Press the key to select one of the 3 colors for the

pattern selection keys, which will display in the color

shown.

To change the screen background color, press the

key to open the custom color window.

Refer to page 22.

10 Resume Mode

When Resume Mode is enabled, the last stitch sewn

before turning the power off will be resumed when the

power is turned on again.

To enable Resume Mode, press the on/off key to check

the box on.

When you turn the power on, the confirmation window

will open.

Press the OK key to resume the last stitch of the sewn

pattern.

Language

1

2

3

4

5

Language Selection

6

7

8

9

10

Register

Language Selection (Flag mode)

You can select one of the following 10 languages by

pressing the corresponding key.

1 English 2 French 3 Spanish

4 Italian 5 Dutch 6 German

7 Portuguese 8 Swedish 9 Russian

10 Finnish

X

24

Page 24

?

㻃㻃

Winding the bobbin

㻃㻃㻃

Threading the machine

㻃㻃㻃

Auto Needle Threader

Sensor Buttonholes

㻃㻃

Adjusting patterns

Changing needles

㻃㻃

Embroidery settings

Auto Needle Threader

Auto Needle Threader

Winding the bobbin

㻃㻃

Sensor Buttonholes

㻃

Embroidery settings

㻃㻃

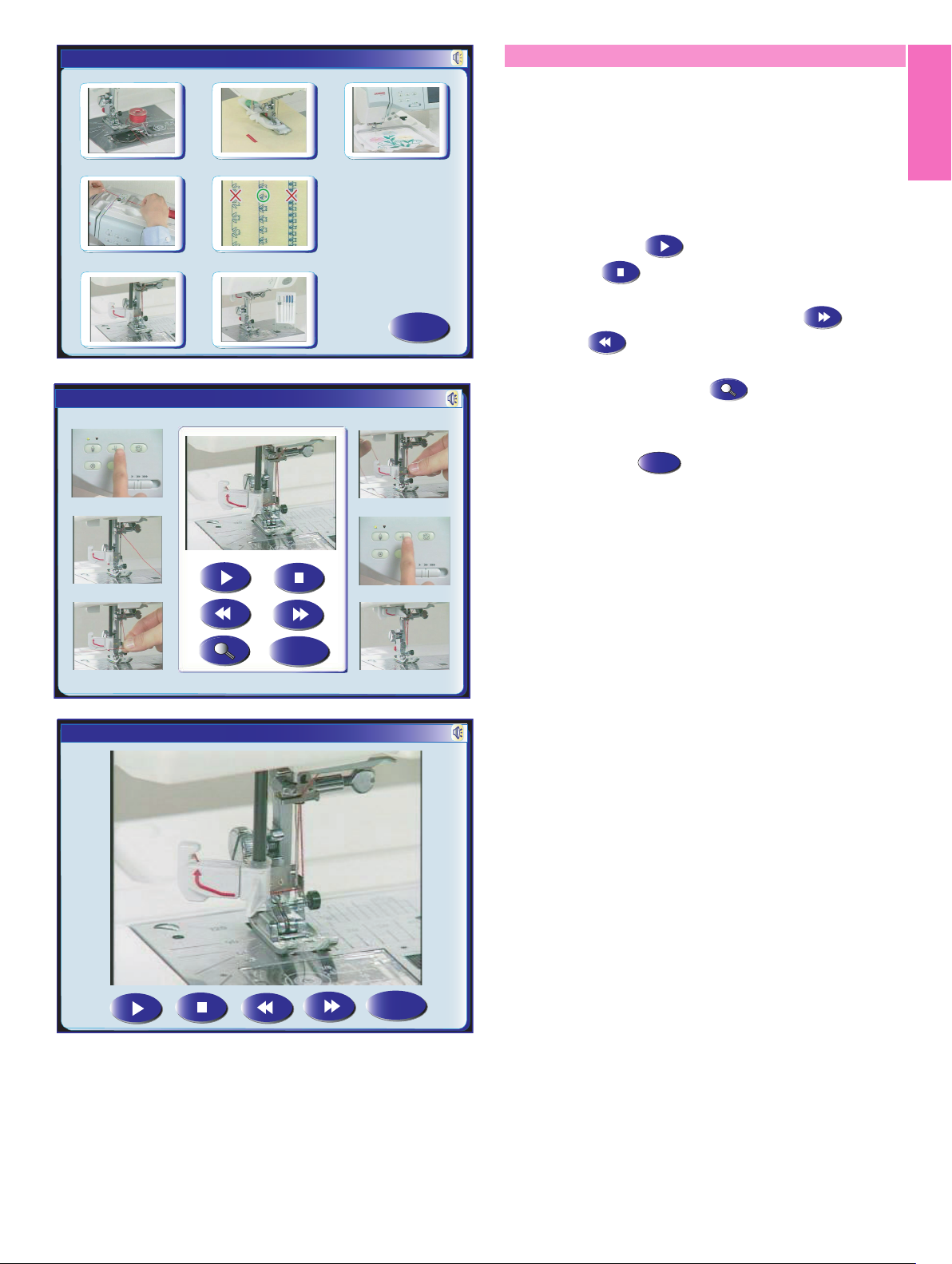

On-screen Help Movie

Press the help key to open the help movie menu.

You can view 7 topics of essential operations of the

machine.

Threading the machine

㻃㻃㻃

Auto Needle Threader

㻃㻃㻃

Auto Needle Threader

1

2

3

Adjusting patterns

㻃㻃

Changing needles

㻃

Select the help topic you wish to view by pressing the

thumbnail, and the movie window will open.

Press the play key to start the movie and press

the stop key to stop playing.

You can search the movie in forward or reverse

X

direction by pressing the fast forward key or

rewind key .

Pressing the full screen key enlarges the movie

4

5

6

window to full screen.

Press the exit key to close the current window.

X

Auto Needle Threader

X

X

25

Page 25

L.S

L.S

1

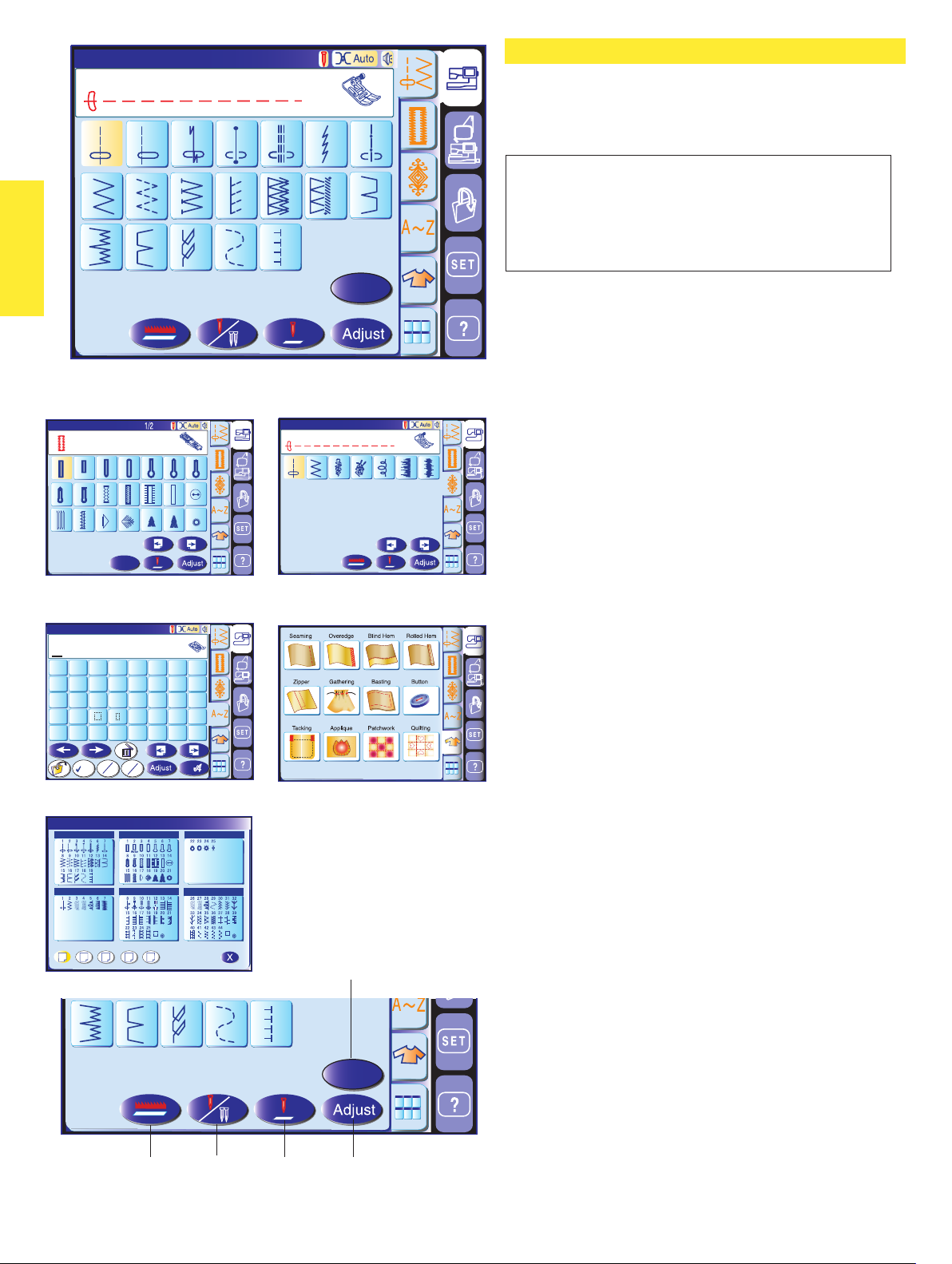

Utility(U)

Straight Stitch

ORDINARY SEWING MODE

A

1

2

4

3

5

7

6

The stitches in the ordinary sewing mode are

classified into 6 groups.

Press one of the tabs to select the group.

8

9

10

11

15

16

17

13

12

14

1918

B

23

Buttonholes(B)

Sensor BH

Pull down BH Lever.

2

1

Auto

9

8

15 16

17 18 19 20 21

5

3

10

B

6

4

13

11

12

4

Monogram

Block

A B C D E F G H

IJKLMNOP

QRSTUVWX

YZ . & 01

2 4567893

M

1/3

L

A

a

S

6

Quick Reference

Utility(U)

1 2 3

Buttonholes(B)

R

7

14

F

A

Auto

Buttonholes(B)

Quilting(Q)

Straight Stitch

1

2

5

1/5

1/5

43

A

7

5

6

NOTE:

In this manual, pattern number refers t the initial for

each group or category.

For example pattern #15 in the buttonholes and

specialty stitches is refered as pattern B15.

1 Utility stitches (U)

You can select utility stitches for seaming, overcasting,

blind hemming, basting and shell tucking.

2 Buttonholes and specialty stitches (B)

There are various styles of buttonholes, button sewing

stitch, darning, tacking, fly stitches and eyelets

available in this section.

3 Decorative stitches

This group consists of 5 categories, i.e. (Q) patchwork/

quilting, (H) heirloom stitches/cross stitches,

(S) decorative satin stitches, (D) decorative stitches and

(P) pictograph stitches.

These stitches and patterns are programmable.

4 Monogramming

You can sew letterings as well as combinations of

characters and symbol patterns.

5 Sewing applications

You can select the proper stitch for a specific sewing

project and fabric type from the designated applications

in this group.

Quilting(Q)

Quilting(Q)

1 2 3 4 5

4

15

5

Quilting(Q)

16 17 1918

1

23

6 Quick menu (Quick reference)

6

You can select the desired stitch from the categorized

stitch list. You can jump to the desired page of the menu

by pressing the page key (see page 62).

5

Function keys

1 Drop feed key: To drop or raise the feed dogs.

2 Twin needle key: To set the stitch width for twin

needle sewing. The key will be grayed out if the

selected stitch is not suitable for twin needle sewing.

B

3 Needle position key: To set the needle position to

stop, up or down when the machine stops.

4 Adjust key: To open the manual setting window for

altering the stitch settings.

5 Start over key: To sew again from the first stitch of

4

26

the pattern.

Page 26

Utility(U)

Straight Stitch

Utility Stitches

A

1

2

4

3

5

7

6

Straight stitches

Patterns U1 to U6 are straight stitches for seaming.

8

9

10

11

15

16

17

13

12

1918

14

Press the pattern selection key of the desired stitch.

Starting to sew

Raise the presser foot and position the fabric next to a

seam guideline on the needle plate. Lower the needle

B

to the point where you want to start.

Pull the needle and bobbin threads towards the rear.

Press the start/stop button or foot control. Gently guide

the fabric along the seam guideline letting the fabric

feed naturally.

Sewing from the edge of thick fabric

The black button on the zigzag foot locks the foot in the

horizontal position.

This is helpful when you start sewing at the extreme

edge of thick fabrics or sewing across a hem.

Lower the needle into the fabric at the point where you

wish to start sewing.

Lower the foot while pushing in the black button. The

foot will be locked in the horizontal position to avoid

slipping.

Changing sewing direction:

Stop the machine and bring the needle down into the

fabrics by pressing the needle up/down button.

Raise the presser foot.

Pivot the fabric around the needle to change the sewing

direction as desired.

Lower the presser foot and start sewing in a new

direction.

27

Page 27

Securing seams

For fastening the ends of seams, press the reverse

button and sew several reverse stitches.

The machine sews in reverse as long as you press and

hold the reverse button.

Press the reverse button once when sewing the

lock-a-matic stitch (pattern U3) or locking stitch (pattern

U4) and the machine will lock the stitches off and stop

automatically.

Cutting threads

After finishing sewing, press the thread cutter button

to cut the threads.

NOTES:

The thread cutter button does not function when the

presser foot is raised.

To start the next seam, it is recommended to bring the

bobbin thread up and pull both needle and bobbin

threads to the back under the presser foot.

Use the thread cutter on the face plate to cut

specialized or thick threads if the auto thread cutter

does not work well.

To use the thread cutter on the face plate, remove the

fabric and draw it to the back.

Pull the treads up and slip them between the thread

cutter and face plate from behind.

Pull the threads toward you to cut.

Using the seam guide lines

The seam guides on the needle plate and hook cover

help you measure seam allowance.

NOTE:

The numbers on the needle plate indicate the distance

from the center needle position in millimeters and

inches.

Angle scale on the needle plate

You can easily seam patchwork pieces at the desired

angle without marking by using the unique angle scales

on the needle plate.

The angle scales are marked at 45, 60, 90 and 120

degrees.

28

Page 28

U1

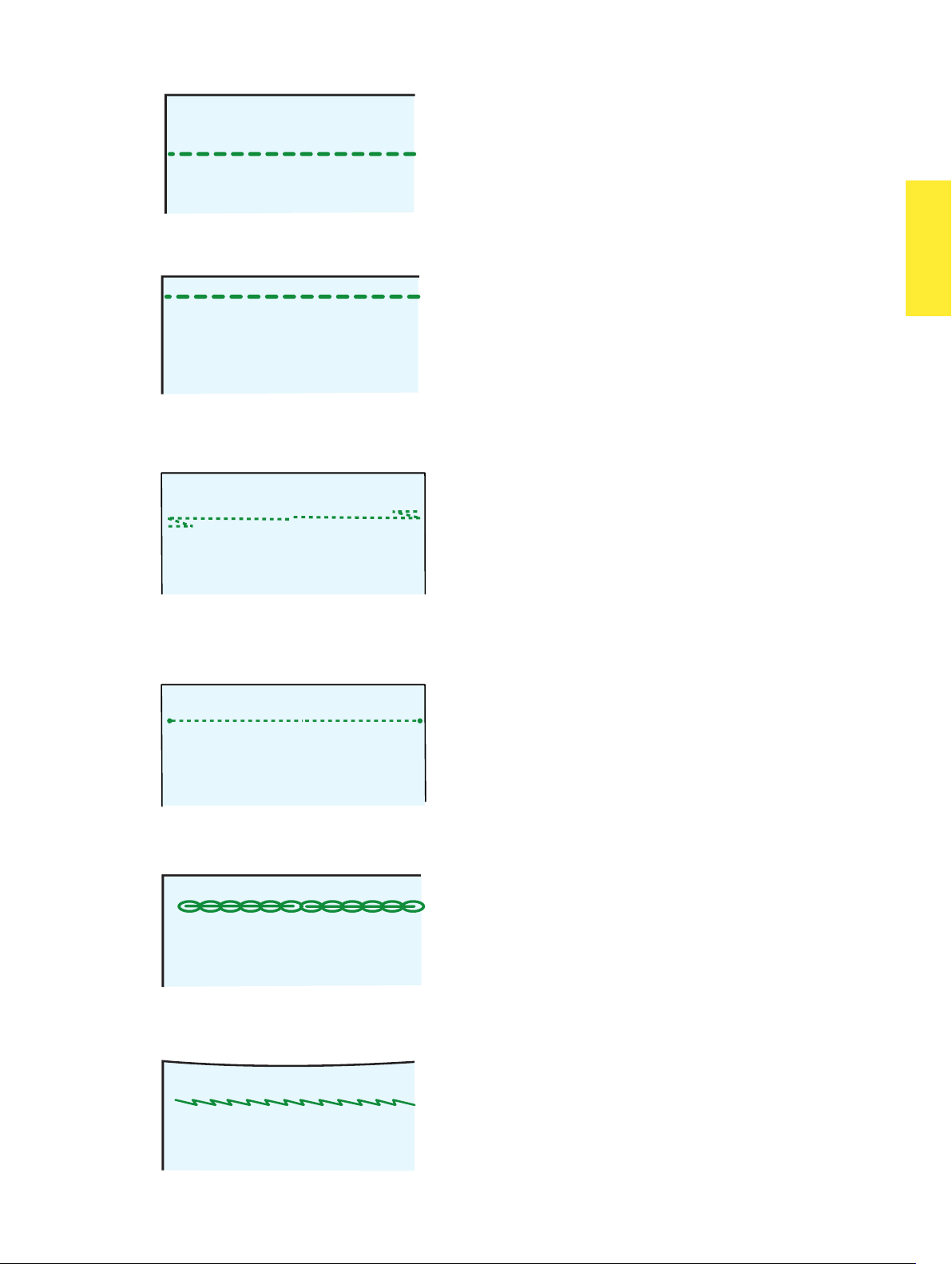

Variety of straight stitches

U1 Straight stitch in center needle position

Use this stitch for seaming, zipper sewing, rolled

hemming etc.

U2

U3

U4

U2 Straight stitch in left needle position

Use this stitch to seam fabrics close to the edge.

U3 Lock-a-matic stitch

Use this stitch to secure the beginning and the end of a

seam with backstitching.

When you reach the end of the seam, press the reverse

button once.

The machine will sew four reverse stitches, four forward

stitches, and then stop sewing automatically.

U4 Locking stitch

This unique stitch is used where an invisible locking

stitch is needed.

Lower the needle close to the front edge of the fabric.

The machine will sew several locking stitches in place

and continue sewing forward.

When you press the reverse button at the end of the

seam, the machine will sew several locking stitches in

place, then stop sewing automatically.

U5

U6

U5 Triple stretch stitch

This strong, durable stitch is recommended for areas

where both elasticity and strength are needed to ensure

comfort and durability.

Use it to reinforce areas such as crotch and armhole

seams.

Also use it when constructing items such as backpacks

for extra strength.

U6 Stretch stitch

This is a narrow stretch stitch designed to eliminate

puckering on knit fabrics and bias seams, while

permitting the seam to be pressed completely open flat.

29

Page 29

Utility(U)

Straight Stitch

1

2

Manual stitch settings

A

4

3

5

7

6

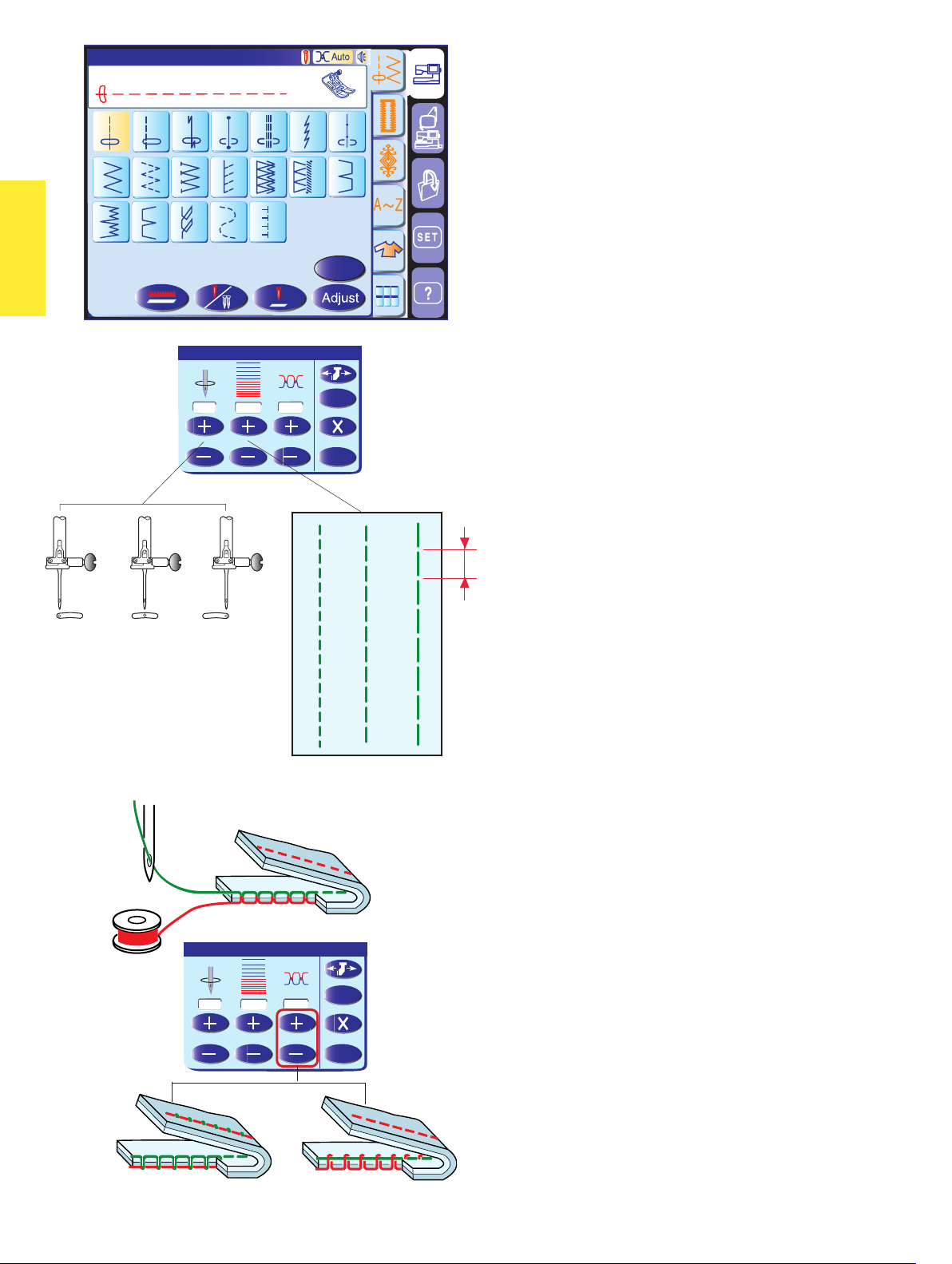

When you press the adjust key, the screen shows the

manual setting window.

8

9

10

11

13

12

14

You can alter the needle drop position of the straight

stitches, stitch length and needle thread tension.

15

16

17

1918

B

Adjust

Press the “+” key to move the needle drop position to

the right.

Press the “–” key to move the needle drop position to

the left.

Press the “+” or “–“ key in the middle to alter the stitch

length.

3.5

2.20

4.2

Default

OK

0.0

3.5

Adjust

7.0

3.5

2.20

4.2

This machine is equipped with automatic thread tension

control, however you may need to manually adjust the

tension balance depending on the sewing condition, or

you can fine-tune the thread tension to suit your prefer-

ence.

Press the “+” key to increase the tension.

Press the “–” key to decease the tension.

Default

OK

30

Page 30

Utility(U)

Zigzag Stitch

1

8

15

3

2

910

16

17

A

4

6

5

7

Zigzag stitches are used for various sewing needs

including overcasting. These stitches can be used on

most woven fabrics

Zigzag stitches

11

1918

14

A dense zigzag stitch can also be used for appliqué.

13

12

B

Adjust

5.0

1.50

3.0

Default

OK

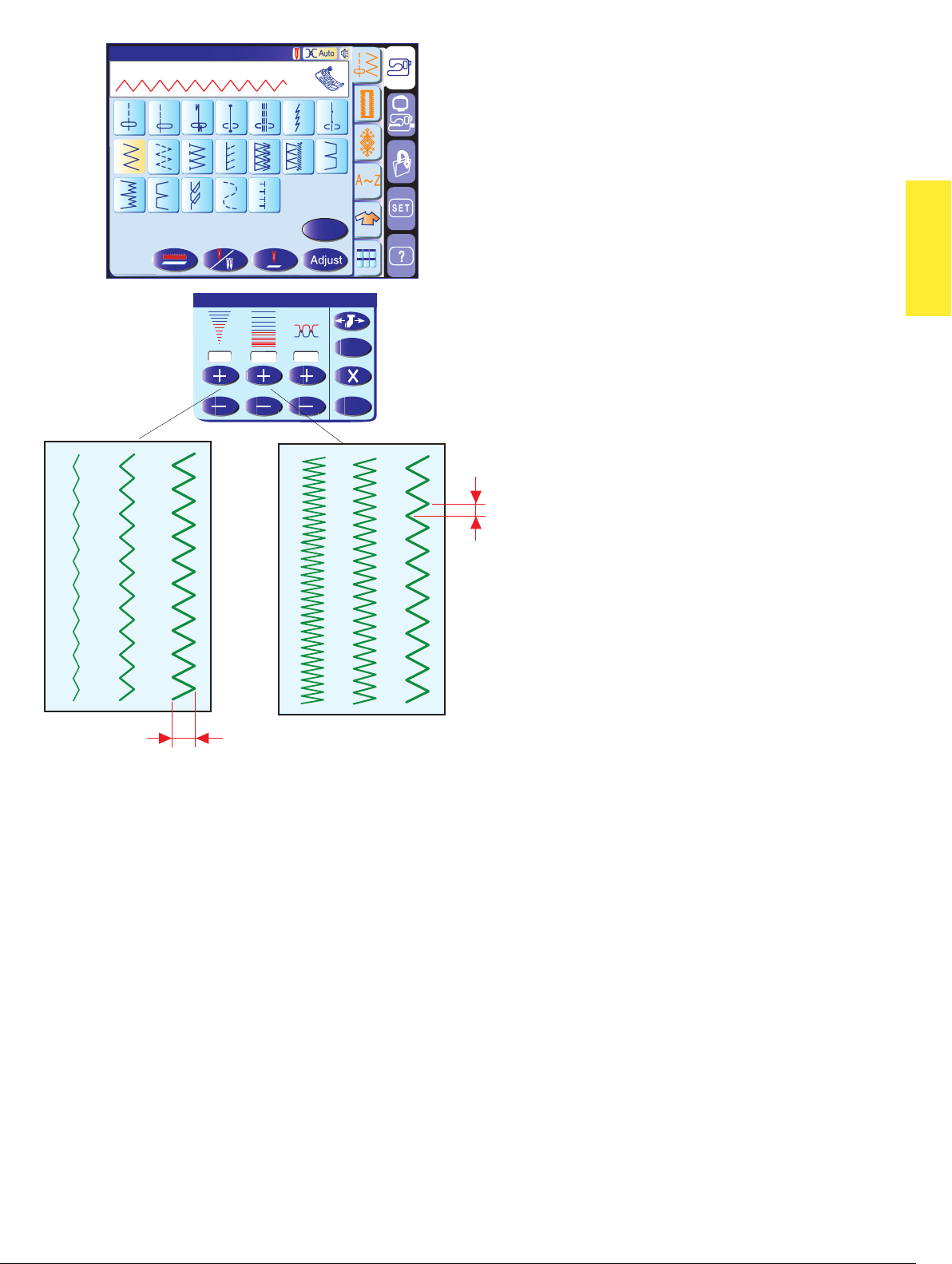

Manual stitch settings

When you press the adjust key, the screen shows the

manual setting window.

You can alter the stitch width (or needle drop position of

the straight stitches), stitch length and needle thread

tension.

Press the “+” or “–“ key below the property that you

wish to change.

31

Page 31

Adjust

3.5

Utility(U)

Straight Stitch

1

8

15

2.20

4.2

4

Cloth Guide

CAUTION:

Always provide sufficient space to the left of the

3

1

2

A

2

9

16

3

10

17

Default

OK

4

5

12

11

1918

7

6

13

14

B

15

mm

40302010

mm

Default

OK

machine when using the cloth guide.

Do not use the cloth guide when the buttonhole foot R

is attached.

If you wish to use the optional clothsetter table with the

cloth guide, attach the extension table to prevent the

carriage from hitting the table.

Attaching the cloth guide

Insert the pins on the cloth guide into the carriage

holes. Turn the attaching knob clockwise to secure the

cloth guide.

Remove the fillet if necessary.

1 Pins

2 Cloth Guide

3 Carriage Holes

4 Attaching knob

Setting the cloth guide position

Press the adjust key to open the manual setting

window.

Press the cloth guide key.

The visual touch screen will show a warning message.

Press the OK key.

The cloth guide adjustment window will open.

Press the “+” or “–” key to move the cloth guide to the

desired position.

The cloth guide position is indicated on the scale bar

and the distance from the center needle drop position

is indicated by millimeter or inch.

Press the OK key to register the setting and close the

cloth guide adjustment window.

Default

NOTE:

The machine will not run if the cloth guide adjustment

window is open.

Press the default key to return the cloth guide to the

2

mm

40302010

mm

default position (15 mm or 5/8”).

Make sure to return the carriage to the stored position

by pressing the cloth guide storage key and

remove the cloth guide after sewing is finished.

OK

Overcasting with the Cloth Guide

Select pattern U10 and use the overedge foot C.

Set the cloth guide position at 2 mm (1/16˝) and sew.

32

Page 32

U10

U9

U11

Variety of overcasting stitches

U9 Multiple zigzag stitch (tricot stitch): Zigzag foot A

This stitch is used to finish a raw edge of synthetics and

other stretch fabrics that tend to pucker.

Sew along the fabric edge leaving an adequate seam

allowance. After sewing, trim off the seam allowance

closer to the stitches.

U10 Overcasting stitch: Overedge foot C

This stitch can be used to simultaneously seam and

overcast edges of fabrics.

Use this stitch when you do not need to open seams

flat.

Place the fabric edge next to the guide of the foot and

then sew.

U11 Knit stitch: Zigzag foot A

This stitch is recommended for sewing such fabrics as

synthetic knits and stretch velour as it provides the

greatest amount of elasticity and strength.

Sew along the fabric edge leaving an adequate seam

allowance.

After sewing, trim the seam allowance close to the

stitches.

U12

U13

U12 Double overedge stitch: Overedge foot C

This stitch is excellent for fabrics that tend to fray

extensively such as linens and gabardines.

Two rows of zigzag stitches are simultaneously sewn

over the edge to insure that the fabric will not ravel.

U13 Overlock stitch: Overcasting foot M

This stitch finishes the edges of fabric similar to a

commercial overlocking machine for a professional

look. The stitch width cannot be adjusted.

CAUTION:

When you use overedge foot C or overcasting foot M,

you must set the zigzag width at 5.0 or wider to prevent

the needle from hitting the foot wires.

33

Page 33

Utility(U)

Blind Hem

1

Blind hemming

G

2

3

5

4

7

6

Select pattern U14 for woven fabrics or pattern U15 for

stretch fabrics.

15

8

(A)

9

10

16

17

12

11

1918

14

13

NOTE:

The stitch width of patterns U14 and U15 cannot

be changed, but the needle drop position will move.

B

1 cm

(B)

0.5 cm

How to fold the fabric

Fold the fabric to form a hem leaving a 0.5 cm (1/4”)

allowance as shown.

(A) Medium to heavy fabrics: The raw edge should be

overcasted.

(B) Fine fabrics: Fold the raw edge 1 cm (1/2”).

To sew

Position the fabric so that the fold comes to the left side

of the guide on the foot. Lower the presser foot.

Adjust the position of the needle drop if necessary.

Sew guiding the fold along the guide.

After sewing is finished, open the fabric flat.

The seam on the right side of the fabric is almost

invisible.

0.5 cm

Adjust

0.60

2.00

3.4

Default

OK

Adjusting the needle drop position

Press the adjust key to open the manual setting

window.

Press the “+” key to move the needle drop positions to

the left.

Press the “–“ key to move the needle drop positions to

the right.

Press the OK key to register the settings.

The needle should just pierce the folded edge when it

comes over to the left side.

NOTE:

The needle drop position will move, while the stitch

width remains consistent.

34

Page 34

Utility(U)

Knit Stitch

1

Visible hemming

F

2

3

5

4

7

6

Select pattern U17.

8

9

10

15

16

17

12

11

1918

14

13

B

Fold and press a single hem. Place the fabric with the

right side up.

Sew along the fold at the desired depth.

Trim the excess on the wrong side.

35

Page 35

Buttonholes and Specialty Stitches

Variety of buttonholes

B1

B2

B3

B4

B5

B6

AUTO

B1 Sensor (Square) buttonhole

This square buttonhole is widely used on medium to heavy weight fabrics. The

buttonhole size is automatically determined by placing a button in the foot.

B2 Auto (Square) buttonhole

This is also a square buttonhole similar to the sensor square buttonhole, but you can

manually set the buttonhole size and you memorize the size to sew buttonholes of

the same size.

B3 Round end buttonhole

This buttonhole is used on fine to medium weight fabrics especially for blouses and

children's clothes.

B4 Fine fabric buttonhole

This buttonhole is rounded at both ends and is used on fine, delicate fabrics such as

fine silk.

B5 Keyhole buttonhole

The keyhole buttonhole is widely used on medium to heavy weight fabrics. It is also

suitable for larger and thicker buttons.

B6 Rounded keyhole buttonhole

This buttonhole is used for thicker buttons on medium weight fabrics.

B7

B8

B9

B10

B11

B12

B13

B7 Tailored buttonhole

This buttonhole is durable and used for thick buttons and heavy fabrics.

B8 Keyhole buttonhole (tapered reinforced end)

This buttonhole is used for tailored clothing, woven cloth etc.

B9 Keyhole buttonhole (heavy reinforced end)

This buttonhole is used for tailored clothing, jackets, particularly men's wear, woven

cloth etc.

B10 Stretch buttonhole

This buttonhole can be used on stretch fabrics. It can also be used as a decorative

buttonhole.

B11 Knit Buttonhole

This buttonhole is suitable for knit fabrics. It can also be used as a decorative buttonhole.

B12 Antique buttonhole

This buttonhole looks like the heirloom stitch. It has an attractive handmade appearance and makes a nice decorative buttonhole.

B13 Welted buttonhole

This is a template pattern for the hand sewn welted (bound) buttonhole.

NOTE:

B3-B13 are sensor buttonholes and the sewing procedure is the same as B1.

36

Page 36

Buttonholes(B)

Sensor BH

Pull down BH Lever.

2

1

Auto

9

8

15 16

R

5

3

4

11

10

17 18 19 20 21

6

13

12

B

Sensor (Square) buttonhole

7

14

Select pattern B1.

To sew

1 Attach the automatic buttonhole foot R snapping the

pin into the groove of the foot holder. Raise the

presser foot.

2 Pull the button holder to the rear, and place the

button in it. Push it tightly against the button.

1

2

NOTES:

The buttonhole size is automatically set by placing a

button into the button holder in the rear of the automatic

buttonhole foot R.

The button holder of the foot takes a button size of up to

2.5 cm (1") in diameter.

If the button is extremely thick, make a test buttonhole

3

on an extra piece of the fabric. If it is difficult to fit the

button through the test buttonhole, you can lengthen the

4

buttonhole by pulling the button holder back a little. The

length of the buttonhole will be increased.

3 Pull the buttonhole lever down as far as it will go.

4 Press the start/stop button to sew the buttonhole.

Step-1

Step-2 Step-3

NOTE:

A warning message will appear and the machine will

stop automatically if you start to sew a buttonhole

without pulling down the buttonhole lever.

Press the exit key and pull down the buttonhole lever to

5

restart.

Pull down BH Lever.

X

6

No gap

5 When buttonhole sewing is finished, push the

buttonhole lever up as far as it will go.

6 Remove the fabric and place a pin just below the

bartack at each end to prevent accidentally cutting

threads. Cut the opening with the seam ripper. Use

an eyelet puncher to open a keyhole buttonhole.

NOTE:

Make sure there is no gap between the slider and front

stopper, otherwise the left and right lengths will be

different.

37

Page 37

Buttonholes(B)

Auto BH

Pull Button Holder firml

2

1

Auto

9

8

15 16

Step 1

Sew to length required,

then press " ".

y.

3

10

17 18 19 20 21

5

4

11

12

R

6

13

B

Automatic (square) buttonhole

Select pattern B2.

7

Pull the button holder all the way out.

Mark the buttonhole position on the fabric. Insert the

14

fabric under the foot. Press the up/down needle button

twice. Remove the fabric to the left to draw the needle

thread through the hole of the foot.

Place the garment under the foot, and lower the needle

at the starting point.

Then lower the automatic buttonhole foot R.

NOTES:

You do not need to pull down the buttonhole lever.

If you wish to change the buttonhole width and stitch

density press the adjust key.

If you wish to sew a buttonhole longer than the size

permitted by the automatic buttonhole foot R, use satin

stitch foot F.

Step-1

Sew the left side up to the required length of buttonhole

and stop the machine. Then press the reverse button.

Step-2

R

Start sewing again, and the machine sews back with a

straight stitch.

Stop the machine when you reach the starting point.

Then press the reverse button.

Step 2

Sew up to start position,

then press " ".

Step 3

Sew to the end,

then press " ".

Step 4

Machine stops when

BH is completed.

Restart for the same size.

Different size

R

Step-3

Start sewing again, and the machine sews the front

bartack and right side of the buttonhole.

Stop the machine when you reach the ending point.

Then press the reverse button.

R

Step-4

Start sewing again, and machine sews the back bartack

and locking stitches then stops automatically.

After sewing is finished, a message will appear.

R

To make the next buttonhole, position the fabric and

start sewing again. The message dilsappears and the

machine will sew another buttonhole identical to the first

one then stop automatically.

To sew the next button hole in a different size press the

exit key .

X

NOTE:

To cut the buttonhole opening, refer to the instructions

on the previous page.

38

Page 38

Corded buttonhole

To sew a corded buttonhole, follow the same

procedure as for the sensor buttonhole; refer to the

instructions on page 37.

Select the pattern B1.

With the Automatic buttonhole foot R raised, hook the

2

1

filler cord on the spur on the back of the buttonhole

foot.

Bring the ends of cord toward you under the

buttonhole foot clearing the front end.

Hook the ends of the filler cord into the forks on the

front of the automatic buttonhole foot R to hold them

tight.

1 Spur

2 Forks

Lower the needle into the garment where the

buttonhole will start and lower the foot.

Press the start/stop button or foot control to sew the

buttonhole.

Each side of the buttonhole and the bartacks will be

sewn over the cord. The machine stops automatically

when finished.

Adjust

5.0

0.45

3.4

Default

OK

Remove the fabric from the machine and cut the

sewing threads only.

Pull the left end of the filler cord to tighten.

Cut the filler cord as close to the buttonhole as possible.

NOTES:

Set the stitch width in accordance with the thickness

of the cord used.

Cut the filler cord if it is stitched to the fabric and cannot

be pulled, cut the filler cord at both ends.

To cut the buttonhole opening, refer to the instructions

on page 37.

Manual settings

Altering buttonhole width

Press the adjust key and the manual setting window

will open.

Press the “+” key to increase the buttonhole width.

Press the “–“ key to decrease the buttonhole width.

Press the OK key to register the settings.

Altering buttonhole stitch density

Press the “+” key to make the buttonhole stitches less

dense.

Press the “–“ key to make the buttonhole stitches

denser.

39

Page 39

Buttonholes(B)

X

Darning

Sew to length required,

then press " ".

2

1

Auto

9

8

R

5

6

3

4

7

The MC 11000 automatically darns rips and holes.

Large and small holes can be mended quickly and

easily with this unique stitch.

Darning

11

10

13

12

14

15 16

2

17 18 19 20 21

B

1

3

Select pattern B15.

1. Attach the automatic buttonhole foot R and pull the

button holder all the way out.

To sew

2. Depress the foot control and sew to the required

length, then press the reverse button. The darning

length has now been determined.

Depress the foot control and continue sewing until

the machine stops automatically.

3. Sew another layer of darning over the first layer, at a

right angle to it.

Adjust

1

5.0

Restart for the same size.

Different size

9

4.2

Default

OK

2 cm

(+)

0.7 cm

(–)

NOTE:

The maximum length of darning is 2 cm (3/4”) and the

maximum width is 0.7 cm (1/4”).

To sew the same size darning

Simply depress the foot control to sew another darning

in the same size.

To sew the next darn in a different size, press the exit

key.

To adjust the evenness of darning stitches:

You can correct the unevenness of darning by pressing

the “–“ or”+” key.

If the left corner is lower than the right side, press the

key to correct it, and vice versa.

40

Page 40

Buttonholes(B)

X

Tacking

Sew to length required,

then press " ".

2

1

Auto

9

8

F

5

6

3

4

11

10

12

7

13

14

Tacking is used to reinforce pockets, crotches and belt

carriers where extra strength is needed.

Select pattern B16 and attach the satin stitch foot F.

Tacking

15 16

17 18 19 20 21

B

To sew

Depress the foot control and sew to the required length,

then press the reverse button. The tacking length has

now been determined.

Restart for the same size.

Different size

1.5 cm

NOTE:

The maximum length of tacking is 1.5 cm (5/8”).

To sew the same size tack

To sew another tack in the same size, simply depress

the foot control until the machine stops automatically.

To sew the next tack in a different size, press the exit

key.

41

Page 41

Buttonholes(B)

Tacking

2

1

Auto

9

8

F

5

6

3

4

11

10

12

7

13

14

The fly stitch is a triangle tacking stitch for use at a

zipper fly bottom and side pockets of men's pants.

Attach the satin stitch foot F.

Fly stitches (B19, B20)

15 16

17 18 19 20 21

B

To sew:

Place the garment under the foot and lower the needle

at the bottom of the zipper fly.

Sew the stitch until the machine stops automatically.

Buttonholes(B)

Eyelet

2

1

Auto

9

8

15 16

5

3

4

11

10

17 18 19 20 21

6

13

12

B

F

7

14

Adjust

S2

2.6

Eyelet

The Eyelet is used for belt holes etc.

Select pattern B21-25 and attach the satin stitch foot F.

Depress the foot control to sew. The machine will stop

automatically when completed.

Open the eyelet with an awl, puncher or pointed

scissors.

To correct the shape of an eyelet:

If the eyelet is open, press the “–“ key.

If the eyelet overlaps, press the “+” key.

Default

OK

42

Page 42

Twin Needle Sewing

Some of the utility stitches and decorative stitches can

be sewn with a twin needle.

CAUTIONS:

Turn the power switch off before changing the needle.

Use the twin needle included in the standard

accessories.

NOTE:

When you sew patterns with the twin needle, test the

stitches first before you sew.

Use the zigzag foot A or satin stitch foot F for twin

needle sewing.

Insert the extra spool pin and spool supporter. Then put

a felt cushion and spool on it.

Draw both threads from the spools and pass them

through the threading points from 1 to 5.

Make sure that the two strands of thread from the

spools do not get tangled.

Pictograph(P)

Decorative

1

8

15

16

2

9

10

17 18 19

NOTES:

Make sure each thread winds off from the spools as

shown.

1/2

F

5

4

3

11

6

7

13

12

14

Threading from points 1 to 5 is the same as for a single

needle.

Slip one of the threads through the needle bar thread

guide on the left, and the other one on the right.

Thread the needles from the front to back.

NOTES:

The Automatic needle threader cannot be used for the

twin needle.

When changing the sewing direction, raise the needle

and turn the fabric.

Select the pattern then press the twin needle key.

If the selected pattern is not suitable for twin needle

sewing, the twin needle key will gray out and be

disabled.

After twin needle sewing is finished, press the twin

needle key and the warning message will appear.

Press the OK key and replace the twin needle with a

single needle.

43

Page 43

Decorative Stitches

The patterns in this section are programmable and you

can make a pattern combination.

Patchwork and quilting stitches (Q)

Stitches in this group are for patchwork, quilting and

appliqué.

NOTE:

Patterns Q1 to Q7 are not programmable.

Satin(S)

Decorative

1

8

15

2

9

16

1/3

1/2

4

3

11

10

17 18 19

X1

Heirloom stitches (H)

This group provides the heirloom stitches and cross

stitches for craft sewing and home décor.

Decorative satin stitches (S)

F

5

6

7

13

12

14

The stitches in this group can be elongated up to 5

times their original length while the stitch density

remains the same.

To elongate the stitch, press the adjust key to open the

manual setting window.

Press the “+” key to increase the elongation ratio or

press the “–“ key to decrease the elongation ratio.

The stitch density and width can also be altered.

X2

X3

X4

X5

Press the OK key to register the elongation ratio.

Decorative stitches (D)

Some utility stitches are included as programmable

stitches in this group. The number beside the stitch

image on the straight stitch key indicates stitch counts

of a programmable unit.

Pictograph stitches (P)

There are 24 stitch patterns of seasonal motifs and

cute designs for embellishing children’s wear.

44

Page 44

Cording

Use the cording foot H to sew over one or three strands

of cording.

Knitting yarns, embroidery flosses, lace threads and

fine wool tarns can be used for cording.

Attach the cording foot H.

Select pattern S2 for three strands cording.

NOTE:

Pattern U9 (multiple zigzagg stitch) can also be used.

Insert three strands of cording under the spring on the

foot. Make sure to pass each strand separately under

the spring.

1 Spring

1

Pull 10 cm (4”) of strands under the foot and to the rear.

The grooves on the bottom of the foot will hold cordings

in place while stitching over the cordings.

Sew carefully over the cordings while guiding the

strands parallel and even.

For a single strand cording, insert a strand into the

center groove on the foot.

Select pattern U8 (zigzag stitch) and adjust the stitch

width in accordance to the thickness of the cording.

45

Page 45

Quilting(Q)

Straight Stitch

1

2

43

1/5

Patchwork and Quilting (Q)

A

5

7

6

Stitches in this group are for patchwork and quilting.

Patterns Q1 to Q7 on the first page are special stitches

for quilting, grouped together to make use of the drop

feed option.

The drop feed key is displayed in the pattern selection

window, in place of the programming related keys.

Using the quilting guide bar

The quilting guide bar is helpful when sewing parallel,

evenly spaced rows of stitching.

Two kinds of quilting guide bars are included in the

standard accessories, one for use with the zigzag foot

and the other is for even feed foot.

To attach the quilting guide bar for the zigzag foot:

Loosen the screw on the back of the foot holder and

insert the quilting bar into the hole of the foot holder.

Set the quilting guide bar at the desired spacing, and

retighten the screw.

Sew rows of stitching while tracing the previous row of

stitching with the quilting guide bar.

To attach the quilting guide bar for the even feed

foot:

Push the quilting bar down into the slot on the plastic

cover of the even feed foot.

Shift the quilting guide bar at the desired spacing.

Sew rows of stitching while tracing the previous row of

stitching with the quilting guide bar.

Hand-look quilt stitches

Patterns Q63 to Q67 are special stitches for quilting

F

which look like hand sewn stitches.

Use a transparent nylon thread for the needle and ordinary

sewing thread for the bobbin.

The bobbin thread is pulled up on the right side of the

fabric and the stitches will look as if sewn by hand.

46

Page 46

Programming Pattern Combinations

Function keys

1 Program key

Press this key to program pattern combinations. When

you press this key, the cursor keys, delete key, memory

check key and save file key will be displayed.

2 Cursor keys

Press the cursor keys to move the cursor to the right or

left. Use these keys to select a pattern to delete or

adjust.

3 Delete key

F

2

Press this key to delete the selected pattern.

4 Mirror image key

Press this key to program a mirror image of the

selected pattern.

5 Page keys

Press key to view the previous page.

Press key to view the next page.

M

67

1

3

M

ABCDEFGHIJKLMNO

1

1/1

6 Save file key

5

4

Press this key to save the programmed pattern

combination.

7 Memory check key/Start over key

Press this key to review the programmed patterns.

This key will change to the start over key after

starting the machine.

Pressing the start over key allows you to sew the

programmed patterns from the beginning.

B

X

47

Page 47

Satin(S)

Locking Stitch

2

1

9

8

1/2

F

5

4

3

6

7

Programming the auto lock stitch

The auto lock stitch can be programmed at the end

of the pattern combination.

This stitch is included on each of the programmable

11

10

13

12

14

stitch pages.

15

16

17 18 19

Press the auto lock stitch after programming the

pattern combination.

The machine will sew the patterns and lock the stitch at

M

the end of the combination then stop automatically.

NOTE:

If the auto thread cutting is enabled in the ordinary

sewing mode setting, the machine will trim the threads

after the auto lock stitch (refer to page 22).

Programming French Knot

F

Example: Expanding the space between French Knots

Press the program key.

Select the pattern D13 (French Knot).

Select the pattern D1. Two counts of straight stitch will

be inserted.

Select the pattern D13.

Select the pattern D2. Three counts of straight stitch

will be inserted.

M

Start to sew. The machine will sew the programmed

French Knots repeatedly.

48

Page 48

1

Satin(S) 1/2

Decorative

3

2

1

9

8

15

16

10

17 18 19

M

3

Satin(S) 1/2

Decorative

3

2

1

9

8

10

Editing the stitch pattern combination

F

Example: To program the combination of patterns S19,

D61 and mirror image of S19

5

4

11

4

11

6

7

13

12

14

2

Decorative(D)

Decorative

58

55

62

69 70

F

5

6

7

13

12

14

57

56

64

63

71

M

59

65

66

72

73

F

60

61

67

68

1 Open the satin stitch page and press

the program key. Select pattern S19.

2 Open page 4 of the decorative

stitch page. Select pattern D64.

3 Open the satin stitch page again.

Press the mirror image key and

select pattern S19.

15

16

17 18 19

M

5

Satin(S) 1/2

Decorative

3

2

1

9

8

15

16

M

10

17 18 19

4

Satin(S) 1/2

Decorative

5

4

3

2

1

9

8

15

16

F

5

4

11

6

7

13

12

14

M

11

10

17 18 19

12

F

6

7

13

14

Editing the stitch pattern combination

Example: To replace pattern D64 of the

above example with pattern D51

4 Press the cursor key to move the

cursor under pattern D64.

5 Press the delete key and pattern

D64 will be deleted.

6

Decorative(D) 3/8

Decorative

36

F

38

37

39

41

40

42

6 Open the page 3 of the decorative

stitch page. Select the pattern D51.

Pattern D51 will be inserted

44

51

45

52 53 54

43

50

46

48

47

49

before the cursor.

Save File

Location :

New

A1

A10

A11

A2

A3

Rename

Built-in

A4

A5

A6

A7