Page 1

INSTRUCTION BOOK

Model DC 3018

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

followings:

Read all instructions before using this appliance.

DANGER— To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing machine

from the electric outlet immediately after using and before cleaning.

2. Always unplug before replacing a sewing machine bulb. Replace bulb with same type rated 12 Volts,

5 Watts.

WARNING— To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by

or near children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination,

repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this sewing

machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine

needle.

11.Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as

threading the needle, changing the needle, threading the bobbin or changing the presser foot, and

the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

The design and specifications are subject to change without a prior notice.

Page 3

TABLE OF CONTENTS

KNOW YOUR MACHINE

Name of Parts ........................................................... 2

Standard Accessories ............................................... 3

Extension table.......................................................... 3

GETTING READY TO SEW

Connecting the Power Supply .................................. 4

Controlling Sewing Speed ........................................ 4

Speed control slider ................................................ 4

Foot control............................................................. 4

Function Buttons and Keys....................................... 5

Reverse button ....................................................... 5

Auto-Lock button..................................................... 5

Up/Down needle button .......................................... 5

Mode key ................................................................ 6

Direct pattern selection........................................... 6

Dropping the Feed Dog ............................................ 7

Changing the Presser Foot....................................... 7

Detaching and Attaching the Foot Holder................. 7

Raising and Lowering the Presser Foot ................... 8

Balancing Thread Tension ........................................ 8

Auto tension............................................................ 8

Manual tension adjustment..................................... 8

Changing Needles .................................................... 9

Winding the Bobbin................................................. 10

Removing the bobbin............................................ 10

Setting the spool of thread.................................... 10

Additional spool pin............................................... 10

Threading for bobbin winding ............................... 10

Inserting the bobbin ...............................................11

Threading the Machine ........................................... 12

Built-in Needle Threader......................................... 13

Drawing Up the Bobbin Thread .............................. 13

Button Sewing........................................................ 26

Zipper Sewing ........................................................ 27

Attaching the zipper foot ...................................... 27

Fabric preparation for zipper sewing.................... 27

To sew.................................................................. 27

Blind Hem............................................................... 29

DECORATIVE STITCHES

Knit stitch................................................................ 30

Satin Stitches ......................................................... 30

Applique Sewing .................................................... 31

Patchwork .............................................................. 31

Pattern Combination .............................................. 32

Correcting Distorted Stretch Patterns .................... 33

CARE AND MAINTENANCE

Replacing the Light Bulb ........................................ 33

Cleaning the Hook Race ........................................ 34

Inserting the bobbin holder................................... 34

Problems and Warning Signals.............................. 35

Troubleshooting ..................................................... 36

BASIC STITCHES

Straight Stitch ......................................................... 14

To sew ................................................................... 14

Changing sewing direction ................................... 14

Securing a seam................................................... 14

Altering the stitch length ....................................... 15

Altering the needle drop position.......................... 15

Using the seam guide lines .................................. 16

To sew from the edge of thick fabric ..................... 16

Variety of Straight Stitches and

Recommended Feet ............................................... 17

Zigzag Stitches ....................................................... 18

Altering the stitch width......................................... 18

Altering the stitch length ....................................... 18

Variety of Overcasting Stitches............................... 19

Overcasting with zigzag stitch .............................. 19

Multiple zigzag stitches (Tricot stitch)................... 19

Overcasting stitch ................................................. 19

Buttonholes ............................................................. 20

Variety of buttonholes ............................................. 20

Square buttonhole .................................................. 20

To sew ................................................................... 21

Altering the buttonhole width ................................ 23

Altering buttonhole stitch density.......................... 23

Double layer buttonhole.......................................... 23

Round end and keyhole buttonholes ...................... 24

Corded buttonholes ................................................ 25

1

Page 4

10

11

12

13

14

15

27

31

30

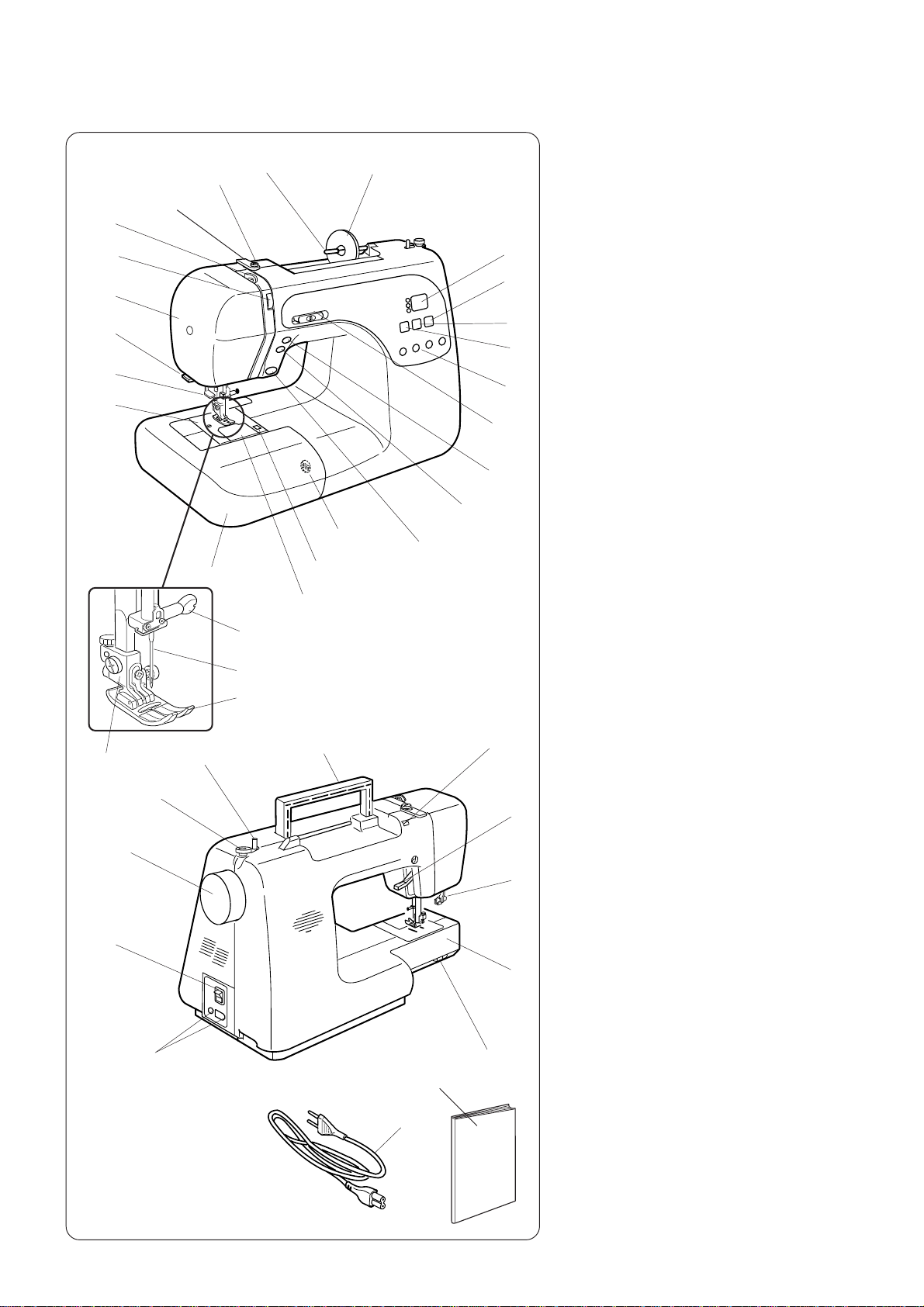

KNOW YOUR MACHINE

Name of Parts

7

8

6

9

23

22

21

19

20

16

18

17

24

25

26

28

38

29

1. Direct pattern selection buttons

2. Mode selection button

3. Plus (+) button

4. Minus (–) button

5. Indicator window

6. Spool holder (large)

5

7. Spool pin

4

8. Bobbin winding thread guide

9. Thread guide

10. Thread take-up lever

3

11.Tension regulating dial

2

12. Face plate

13. Thread cutter

1

14. Needle threader

15. Needle plate

16. Extension table (accessory storage)

17. Hook cover plate

18. Hook cover plate release button

19. Stitch balance adjusting dial

20. Reverse button

21. Auto-lock button

22. Up/down needle button

23. Speed control slider

24. Needle clamp screw

25. Needle

26. Zigzag foot A

27. Foot holder

28. Carrying handle

29. Bobbin winder spindle

30. Bobbin winder stopper

31. Hand wheel

32. Power switch

33. Machine sockets

34. Drop-feed lever

35. Free arm

36. Buttonhole lever

37

37. Presser foot lifter

38. Hole for additional spool pin

39. Power supply cord

36

40. Instruction book

32

33

35

34

40

39

2

Page 5

q

w

123

45 6

78 9

Standard Accessories

The standard accessories are stored in the

extension table.

q Extension table

w Standard accessories

1. Zipper Foot E

2. Satin Stitch Foot F

3. Automatic Buttonhole Foot R

4. Screwdriver

5. Bobbins

6. Set of Needles

7. Seam Ripper

8. Additional spool pin

9. Spool Holder (Large)

10. Spool Holder (Small)

11. Spool stand

12. Felt

q

11 1210

Extension table

w

The extension table provides an added sewing

surface and can be easily removed for free arm

sewing.

• Detaching extension table

Pull the table away from the machine, as

illustrated.

• Free arm sewing

Free arm sewing is useful for darning socks or

mending knees, elbows or areas of wear in

children’s clothes.

• Attaching extension table

Push the extension table until it snaps into the

machine.

q Projection

w Hole

3

Page 6

q

GETTING READY TO SEW

Connecting the Power Supply

Turn off the power switch.

Insert the foot control plug into the machine socket.

Insert the machine plug into the machine socket.

Insert the power supply plug into the wall outlet.

Turn on the power switch.

e

r

y

q Power Switch

w Foot Control Plug

e Machine Socket

r Machine Plug

t Power Supply Plug

y Wall Outlet

w

t

Operating Instructions:

The symbol "O" of a switch indicates the "off" position of a switch.

For appliances with a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this

plug is intended to fit in a polarized outlet only one way. If it does not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any way.

For Y our Safety:

While in operation, always keep your eyes on the

sewing area, and do not touch any moving parts such

as the thread take-up lever, handwheel or needle.

Always turn off the power switch and unplug from the

power supply:

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Do not place anything on the foot control, otherwise

the machine will run intermittently.

When the power is turned on, the indicator window will

show a test pattern then will indicate 01.

Controlling Sewing Speed

Speed control slider

You can limit the maximum sewing speed with the

speed control slider according to your sewing needs.

To increase sewing speed, slide it to the right.

To decrease sewing speed, slide it to the left.

Foot control

Pressing on the foot control can vary sewing speed.

The harder you press the foot control, the faster the

machine runs.

NOTES:

The machine runs at the maximum speed set by the

speed control slider when the foot control is fully

depressed.

Keep the foot control free from accumulation of lint,

dust and loose cloth.

Do not place anything on the foot control.

Operating Instructions:

Foot controller Model 21371 is for use with sewing

machine model DC3018.

4

Page 7

e

w

r

q

w

q

t

Function Buttons and Keys

q Reverse button

When stitch pattern 01, 02, 10 or 11 has been

selected, the machine will sew in reverse while the reverse

button is pressed.

If you press the reverse button when sewing any other

stitches, the machine will immediately sew locking stitches

and automatically stop.

w Auto-Lock button

When stitch pattern 01, 02, 10 or 11 has been

selected, the machine will immediately sew locking stitches

and automatically stop when the auto-lock button is

pressed.

When sewing any other stitches, the machine will sew

locking stitches at the end of the pattern being sewn and

automatically stop.

e

e Up/Down needle button

Press this button to bring the needle up or down.

The machine will stop with the needle up or down

depending on the needle position determined by this

button.

5

Page 8

r

(1)

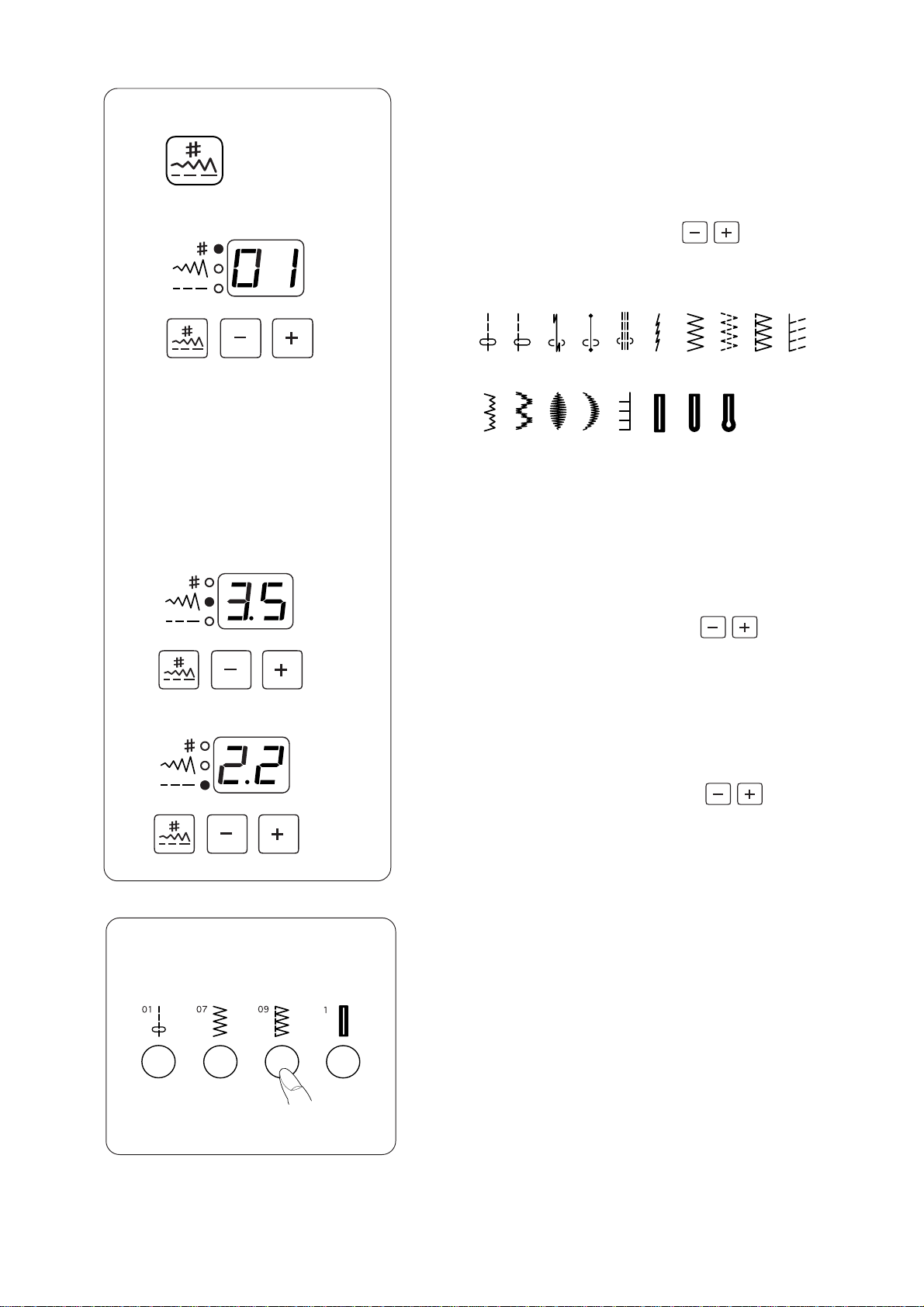

r Mode key

Each time you press this key the mode will change in

the following order:

(1) Pattern selection mode

The green light on the top will be on.

To select the pattern, press the key until the

pattern number of the desired stitch is indicated (see

the stitch chart below).

05

01

A

11

02

12

03

04

A

A

13

A

14

06

A

A

15

16 17 18

07

08

09

10

A

A

C

A

(2)

(3)

F

G

F

F

F

R

R

R

(2) Stitch width adjusting mode

The green light in the middle will light up.

The stitch width of the selected pattern will be

indicated.

To alter the stitch width, press the key.

(3) Stitch length adjusting mode

The green light on the bottom will light up.

The stitch length of the selected pattern will be

indicated.

To alter the stitch length, press the key.

t

t Direct pattern selection

The 4 most commonly used stitches can be directly

selected by pressing the button under the pattern

6

icon.

6

Page 9

q

Dropping the Feed Dog

The feed dog can be lowered by the drop feed lever

for sewing on buttons etc.

r

q

w

e

Shift the drop-feed lever to the right to lower the feed

dog.

Shift the lever to the left to raise the feed dog, it will

return to the up position when the machine is started.

q Down position

w Up position

e Feed dog

r Hand wheel

NOTE:

The feed dog should be in the up position for regular

sewing. Turn the handwheel toward you to check if

the feed dog comes up after setting the lever in the

up position.

Changing the Presser Foot

CAUTION:

Turn OFF the power switch before changing the foot.

Always use the proper foot for the selected pattern.

The wrong foot can cause the needle to break.

To snap off:

Raise the needle and presser foot.

Press the red button on the back of the foot holder

and the foot will drop.

q Red Button

w

q

q

e

w

r

To snap on:

Place the presser foot so the pin on the foot lies just

under the groove of the foot holder.

Lower the foot holder to lock the foot in place.

w Groove

e Pin

Each foot is marked with a letter for identification.

r Identification Letter

Detaching and Attaching the Foot Holder

WARNING:

Turn OFF the power switch before detaching or

attaching the foot holder.

To detach:

Raise the presser bar and turn the setscrew

counterclockwise to remove the foot holder.

q Setscrew

w Foot holder

To attach:

Align the hole in the foot holder with the threaded

hole in the presser bar and insert the setscrew

through the hole.

Tighten the setscrew by turning it clockwise.

7

Page 10

e

w

q

e

w

Raising and Lowering the Presser Foot

The Presser foot lifter raises and lowers the presser

foot.

You can raise the presser foot about 6 mm (1/4")

higher than the normal up position by exerting more

pressure when lifting the presser foot lifter. This

allows for easy removal of the presser foot and helps

you to place thick fabric under the foot.

q Presser foot lifter

w Normal up position

e Extra lift

Balancing Thread Tension

t

e

w

t

q

r

y

y

Auto tension

This machine features an Auto setting in the tension

control, which covers a wide range of sewing

conditions. Set the tension regulating dial at "A" for

general sewing, unless specifically indicated in this

manual.

q Tension regulating dial

w Setting mark

Balanced tension:

The ideal straight stitch has threads locked between

two layers of fabric

For an ideal zigzag stitch, the bobbin thread does not

show on the right side of the fabric, and the needle

thread shows slightly on the wrong side of the fabric.

e Needle thread

r Bobbin thread

t Right side of the fabric

y Wrong side of the fabric

Manual tension adjustment

Manual tension adjustment may be needed

depending on the sewing materials, layers of fabric

and other sewing conditions.

t

Needle thread tension is too tight:

-if the bobbin thread appears on the right side of the

fabric.

Loosen the needle thread tension by moving the dial

to a lower number.

y

Needle thread tension is too loose:

-if the needle thread appears on the wrong side of the

fabric.

Tighten the needle thread tension by moving the dial

to a higher number.

8

Page 11

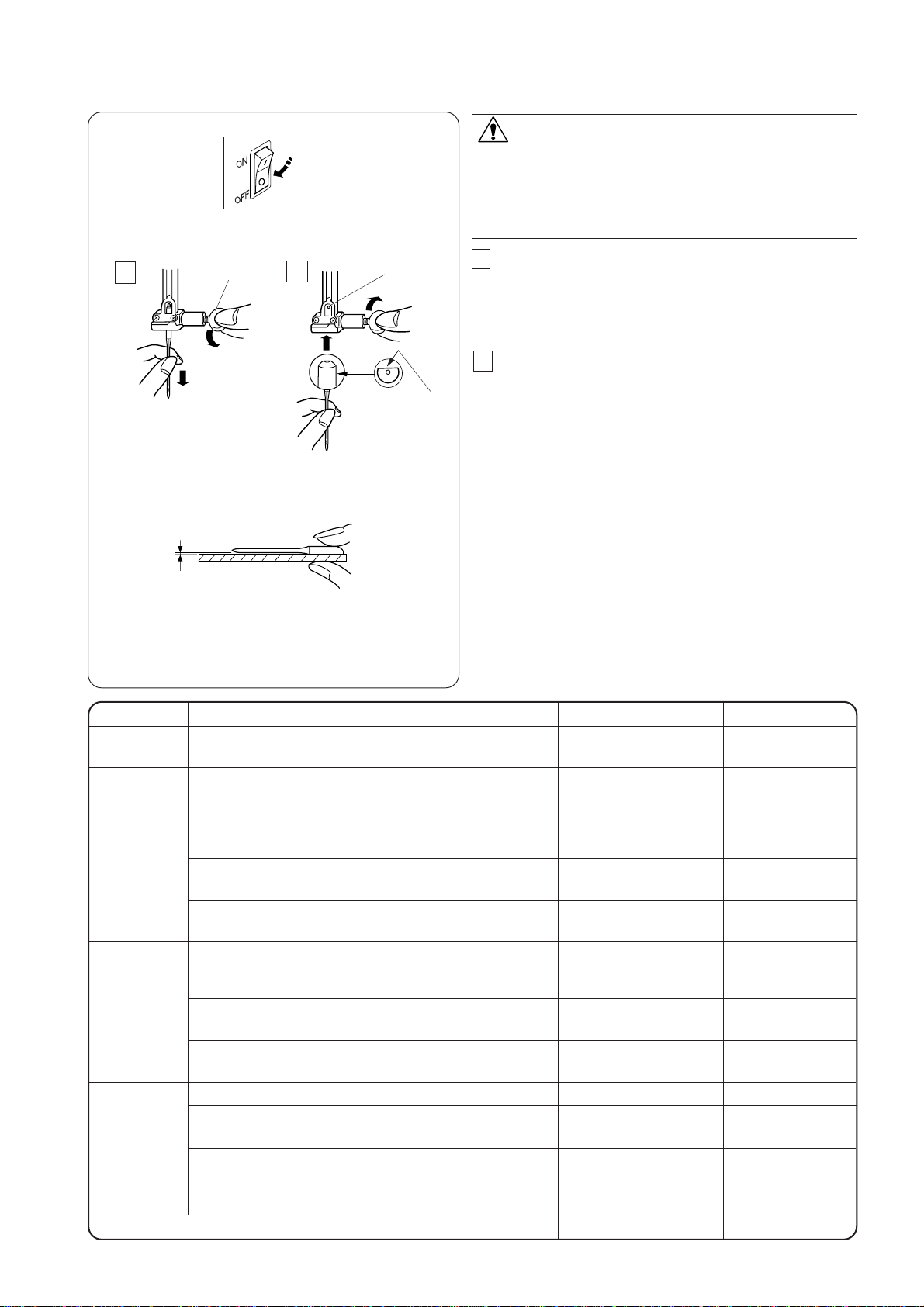

Changing Needles

CAUTION:

Always make sure to turn the power switch off and

disconnect the machine from power supply before

changing the needle. Raise the needle by pressing

the up/down needle button and lower the presser foot.

Turn off the power switch.

1

q

2

w

1 Loosen the needle clamp screw by turning it

counterclockwise.

Remove the needle from the clamp.

q Needle clamp screw

2Insert a new needle into the needle clamp with the

flat side of the needle to the rear.

e

When inserting the needle into the needle clamp,

push it up against the stopper pin and tighten the

needle clamp screw firmly.

w Stopper pin

e Flat side

To check needle straightness, place the flat side of the

needle onto something flat (a needle plate, glass etc.)

The gap between the needle and the flat surface

should be consistent.

r

Never use a blunt needle.

r Gap

WEIGHT

Very Light

Light

Medium

Heavy

FABRIC

Chiffon, Georgette, Fine Lace, Organdy

Net, Tulle

Batiste, Voile, Lawn, Pure Silk, Crepe de Chine,

Sheer Crepe, Chambray, Handkerchief Linen,

Gingham, Challis, Percale, Wool Crepe, Peau de

Soie, Taffeta, Satin, Silk Surah, Satin-backed

Crepe, Qiana

Single Knits, Jersey, Swimwear, and Tricot

Leather Suede

Flannel, Velour, Velvet, Muslin, Velveteen,

Poplin, Corduroy, Broadcloth, Linen, Chintz,

Gabardine, Felt, Terry, Burlap, Quilted Fabrics

Double Knits, (synthetic and natural) Stretch

Velour, Stretch Terry, Sweater Knits

Leather, Vinyl, Suede

Denim, Sailcloth, Ticking

Double Faced Wool, Heavy Coating, Fake Fur,

Drapery Fabrics

Leather, Suede

TYPE of NEEDLE

Universal

Ball Point

Blue Tipped Needle

Universal

Blue Tipped Needle

Ball Point

Wedge Point

Leather Needle

Universal

Ball Point

Wedge Point

Leather Needle

Denim Needle

Universal

Wedge Point

Leather Needle

NEEDLE SIZE

9 (65)

9 (65)

11 (75)

11 (75)

12 (80)

11 (75)

11 (75)

11 (75)

14 (90)

14 (90)

14 (90)

16 (100)

16 (100)

16 (100)

18 (110)

Very Heavy

Canvas, Duck, Upholstery Fabrics

Topstitching for Special Finishes

Universal

Topstitching Needle

16 (100)

14 (90)

9

Page 12

Winding the Bobbin

1

r

Removing the bobbin

1 Slide the hook cover plate release button to the

right, and remove the hook cover plate.

q Hook cover plate release button

w Hook cover plate

q

2

e

w

q

w

q

w

e

2

1

2 Lift out the bobbin from the bobbin holder.

e Bobbin

Setting the spool of thread

Lift up the spool pin. Place the spool of thread on the

spool pin with the thread coming off the spool as

shown.

q Large spool holder

Attach the large spool holder, and press it firmly

against the spool of thread.

Use the small spool holder to hold narrow or small

spools of thread.

w Small spool holder

Additional spool pin

Use the additional spool pin when you need to wind

the bobbin without unthreading the machine while

working on a sewing project.

Insert the additional spool pin into the spool stand

and then into the hole in the machine.

Place the felt on the spool pin and place a spool of

thread on it as shown.

q Additional spool pin

w Felt

e Hole

r Spool stand

Threading for bobbin winding

1 Set the speed control lever at .

Guide the thread around the thread guide.

q Thread guide

q

2

3

w

4

5

2 Pass the thread through the hole in the bobbin

from the inside to the outside. Put the bobbin on

the bobbin winder spindle.

w Bobbin winder spindle

3 Push the bobbin winder spindle to the right.

The indicator will show .

4 Hold the free end of the thread in your hand and

depress the foot control.

Stop the machine after the bobbin has spun

several times, and cut the thread close to the hole

in the bobbin.

5 Depress the foot control again. When the bobbin

is fully wound, it will stop automatically.

Release the foot control and return the bobbin

winder spindle to its original position by moving it

to the left, and cut the thread with a pair of

scissors. Remove the bobbin from the bobbin

winder spindle.

NOTE:

The machine will not sew until the spindle has been

returned to the left.

10

Page 13

Inserting the bobbin

1

q

1Place the bobbin in the bobbin holder with the

thread running off counterclockwise.

q Thread

w Bobbin holder

w

2

2 Guide the thread into the notch on the front of the

bobbin holder.

e Notch on the front

e

3

3 Draw the thread to the left, sliding it between

the tension spring blades.

r Spring blades

r

4

4 Continue to draw the thread lightly until the thread

slips into the notch on the side.

t Notch on the side

t

5

y

5 Pull out about 10 cm (4") of thread to the rear.

Reattach the hook cover plate.

NOTE:

A threading chart is shown on the hook cover plate

for your reference.

y Threading chart

11

Page 14

Threading the Machine

Raise the presser foot.

Press the Up/Down needle

q

1

2

4

1 Draw the thread from the spool. Hold the upper

thread at the spool with your finger.

q Hold the thread

button to raise the thread

take-up lever to its highest

position.

3

5

2Slip the thread under the thread guide from the

2

w

e

right and down along the right channel.

Be sure that the thread passes between the

tension disks.

w Thread guide

e Right channel

r Tension disks

3

r

3 Then draw the thread around the bottom of the

thread guide plate.

t Thread guide plate

t

4

y

3

6

5

7

u

4 Firmly draw the thread up along the left channel to

the take-up lever and down into its eye from the

right to the left.

y Thread take-up lever

5 Then down through the lower thread guide.

u Lower thread guide

6Slide the thread behind the needle bar thread

guide on the left.

i Needle bar thread guide

i

7 Thread the needle from front to back by hand or

use the built-in needle threader (see page 13).

12

Page 15

Built-in Needle Threader

1 Raise the needle to its highest position by turning

1

q

the hand wheel toward you.

Turn the power switch off.

Lower the presser foot.

Depress the needle threader knob as far as it will

go. The hook comes out through the needle eye

from behind.

q Needle threader knob

w Hook

w

2

2 Draw the thread down around the threader guide

and under the hook.

e Threader guide

r

3 Release the threader knob slowly while holding the

thread end with your hand. A loop of the thread is

pulled up through the needle eye.

4

3

e

w

4 Remove the loop from the threader and pull out the

thread end from the needle eye.

NOTES:

The automatic threader works well with threads #5090 and needles #11-16, as well as the blue tipped

needle.

Drawing Up the Bobbin Thread

1

1Raise the Presser Foot Lifter.

Turn the power switch on.

2 Hold the needle thread with your finger and press

2

w

the Up/Down needle button twice to pick up the

bobbin thread.

Draw up the needle thread to bring up a loop of the

bobbin thread.

q

q Needle thread

e

3

q

w Bobbin thread

e Up/Down needle button

3 Slide 10 cm (4") of both threads to the back under

thepresser foot.

w

13

Page 16

q

w

BASIC STITCHES

Straight Stitch

Machine Settings

q Pattern: #01

w Presser foot: Zigzag foot A

To sew

Raise the presser foot and position the fabric next to

a seam guide line on the needle plate. Lower the

needle into the fabric where you wish to start.

Pull the needle and bobbin threads to the back.

Lower the presser foot.

Depress the foot control to start sewing. Gently guide

the fabric along the seam guide line.

Changing sewing direction:

Stop the machine a few stitches before the end of a

seam. Press the up/down needle button a few times

until the needle falls on the end of the seam.

q Up/Down needle button

e

q

w

Raise the presser foot.

Pivot the fabric around the needle to change the

sewing direction as desired.

Lower the presser foot and start sewing in a new

direction.

Securing a seam

For fastening the beginning of a seam, press the

reverse button and sew several reverse stitches.

Release the reverse button to sew forward.

w Reverse button

For fastening the ends of a seam, press the reverse

button at the end of the seam.

Sew a few stitches in reverse to fasten the seam.

Raise the presser foot and pull the fabric to the back

to remove it.

To cut the threads, pull the fabric to draw the threads

up to the thread cutter as shown.

The threads are cut a proper length to start the next

seam.

e Thread cutter

When pattern #03 (lock-a-matic stitch) is selected:

The machine will sew reverse stitches at the

beginning of a seam automatically, and at the end of

the seam by pressing the reverse button once.

14

Page 17

Altering the stitch length

The stitch length can be altered between 0.0 and 5.0.

Press the mode key to activate stitch length

adjustment (the bottom green light lights up).

The preset value 2.2 will be indicated.

Press the plus (+) key to increase the stitch length.

Press the minus (–) key to decrease the stitch length.

Altering the needle drop position

The needle drop position of the following stitches can

be altered:

Press the mode key to activate stitch width

adjustment (the middle green light lights up).

The preset value "3.5" will be indicated.

Press the plus (+) key to move the needle drop to the

right.

Press the minus (–) key to move the needle drop to

the left.

15

Page 18

w

e

Using the seam guide lines

The seam guides on the needle plate and hook cover

help you to measure seam allowances.

NOTE:

The number indicates the distance from the center

needle position.

q Guide lines

w Center needle position

e Edge of the fabric

q

q

Number

Distance

(cm)

Distance

(inch)

To sew from the edge of thick fabric:

The black button on the zigzag foot locks the foot in

the horizontal position.

This is helpful when starting sewing from the extreme

edge of thick fabrics or sewing across a hem.

Lower the needle into the fabric at the point where you

wish to start sewing.

Lower the foot while pushing in the black button.

The foot will be locked in the horizontal position to

avoid slipping.

The foot will be unlocked after sewing a few stitches.

q Black button

15 20 4/8 5/8 6/8

1.5 2.0

4/8 5/8 6/8

16

Page 19

Variety of Straight Stitches and Recommended Foot

#01, #02 Straight stitch: Zigzag foot A

Pattern #01 is for seaming and for zipper sewing.

Pattern #02 is for seaming the edge of fabrics.

#03 Lock-a-matic stitch: Zigzag foot A

Use this stitch to secure the beginning and the end of a seam with

backstitching.

When you reach the end of the seam, press the Reverse Button once.

The machine will sew four reverse stitches, four forward stitches, and

then stop sewing automatically.

#04 Locking stitch: Zigzag foot A

This unique stitch is used where an invisible locking stitch is needed.

Lower the needle close to the front edge of the fabric.

The machine will sew several locking stitches in place and continue

sewing forward.

When you press the reverse button at the end of the seam, the machine

will sew several locking stitches in place, then stop sewing automatically.

#05 Triple stretch stitch: Zigzag foot A

This strong, durable stitch is recommended for areas where both

elasticity and strength are needed to ensure comfort and durability.

Use it to reinforce areas such as crotch and armhole seams.

Also use it when constructing items such as backpacks for extra

strength.

#06 Stretch stitch: Zigzag foot A

This is a narrow stretch stitch designed to eliminate puckering on knit

fabrics and bias seams, while allowing the seam to be pressed

completely open flat.

17

Page 20

q

Zigzag Stitch

Machine Settings

7

w

q Pattern: #07

w Presser foot: Zigzag foot A

The zigzag stitch is used for various sewing needs

including overcasting. It can be used on most woven

fabrics.

A dense zigzag stitch can also be used for appliqué.

Altering the stitch width

q

The stitch width can be altered between 0.0 and 7.0.

Press the mode key to activate stitch length

adjustment (the middle green light lights up).

The preset value "5.0" will be indicated.

Press the plus (+) key to increase the stitch width.

Press the minus (–) key to decrease the stitch width.

q Stitch width

Altering the stitch length

The stitch length can be altered between 0.0 and 5.0.

Press the mode key to activate stitch length

adjustment (the bottom green light lighys up).

The preset value 2.0 will be indicated.

w

Press the plus (+) key to increase the stitch length.

Press the minus (–) key to decrease the stitch length.

w Stitch length

NOTE:

The stitch length and width can be altered while

stitching.

18

Page 21

q

Variety of Overcasting Stitches

CAUTION:

When you use the overedge foot C, you must set the zigzag width at 5.0

or wider to prevent the needle from hitting the wires on the foot.

Overcasting with zigzag stitch

q

w

Machine Settings

q Pattern: #07

w Presser foot: Zigzag foot A or

Overedge foot C (optional item)

Place the fabric edge next to the guide of the foot and

then sew.

q Guide

NOTES:

The overedge foot is an optional item.

When overcasting with the zigzag foot, carefully guide

the fabric so the needle falls off the edge when it

swings to the right.

7

qw

8

q

09

w

Multiple zigzag stitch (Tricot stitch)

Machine Settings

q Pattern: #08

w Presser foot: Zigzag foot A

This stitch is used to finish a raw edge of synthetics

and other stretch fabrics that tend to pucker.

Sew along the fabric edge leaving an adequate seam

allowance.

After sewing, trim the seam allowance close to the

stitches.

Overcasting stitch

Machine Settings

q Pattern: #09

w Presser foot: Zigzag foot A or

Overedge foot C (optional item)

q

This stitch can be used to simultaneously seam and

overcast edges of fabrics.

Use this stitch when you do not need to open seams flat.

Place the fabric edge next to the guide of the foot and

then sew.

q Guide

NOTES:

The overedge foot is an optional item.

When overcasting with the zigzag foot, carefully

guide the fabric so the needle falls off the edge when

it swings to the right.

19

Page 22

Buttonholes

Variety of buttonholes

#16 Square buttonhole

This square buttonhole is widely used on medium to

heavy weight fabrics.

The buttonhole size is automatically determined by

placing a button in the rear of the foot.

#17 Round-end buttonhole

1

1

This buttonhole is used on fine to medium weight

fabrics especially for blouses and children’s clothes.

#18 Keyhole buttonhole

The Keyhole Buttonhole is widely used on medium to

heavy weight fabrics. It is also suitable for larger and

thicker buttons.

q

w

Square buttonhole

Machine Settings

q Pattern: #16

w Presser foot: Automatic buttonhole foot R

NOTES:

• The size of a buttonhole is automatically set by

placing a button in the rear of automatic buttonhole

foot R.

• The button holder of the foot takes a button size of

0.5 cm (3/16 ”) to 2.5 cm (1”) in diameter.

• It is sometimes necessary to change the buttonhole

size to match certain heavy or specific fabrics and

threads.

• Make a test buttonhole on an extra piece of the

fabric to check your settings.

• The preset width of the buttonhole is suitable for

ordinary buttons.

• Apply an interfacing to stretch or fine fabrics.

20

Page 23

To sew

1

1Press the up/down needle button to raise the

needle.

q

w

Attach the automatic buttonhole foot R snapping

the pin into the groove of the foot holder.

q Groove

w Pin

2

A

e

B

R

2 Pull the button holder to the back, and place

the button in it. Push it together tightly to the

button.

NOTE:

If the button is extremely thick, make a test

buttonhole on an extra piece of the fabric.

If it is difficult to fit the button through the test

buttonhole, you can lengthen the buttonhole by

pulling the button holder back a little. The length of

the buttonhole will be increased.

e Button Holder

r Extra gap

r

3

3 Pull the buttonhole lever down as far as it will go.

t Buttonhole Lever

t

4

i

!0

y

u

!1

4Insert the corner of the fabric under the foot.

Press the up/down needle button twice.

Remove the fabric to the left to draw the needle

o

21

thread through the hole of the foot.

Place the garment under the foot, and lower the

needle at the starting point of the buttonhole

mark.

Then lower the automatic buttonhole foot R.

y Buttonhole Mark

u Starting Point

NOTE:

Make sure there is no gap between the slider and

stopper, otherwise the left and right lengths will be

different.

i Slider

o No gap

!0 Stopper

!1 Sewing gap

Page 24

5

5 Start the machine to sew the buttonhole.

The buttonhole will be automatically sewn.

Step 1

Step 2

Step 3

Step 4

Å´

Å´

Å´

Step 1: The machine will sew the front bartack and

the left row first.

Then it goes back to the starting point with

straight stitch.

Step 2: The machine will sew the right row.

Step 3: The machine will sew the back bartack.

Step 4: The machine will stop automatically and a dot

will blink.

!2 Blinking dot

To sew another buttonhole, raise the presser foot.

Move the fabric to where the next buttonhole is to be

sewn, then lower the foot and start the machine.

!2

NOTE:

If you select other pattern without raising the presser

foot or buttonhole lever after buttonhole sewing, the

indicator will show a warning sign.

Raise the presser foot and buttonhole lever, then

select the pattern.

6

1

!3

1

!5

!4

7

6 Remove the fabric and place a pin just below the

bartack at each end to prevent accidentally

cutting stitches. Cut the opening with the seam

ripper. Use an eyelet punch to open a keyhole

buttonhole.

!3 Pin

!4 Seam ripper

!5 Eyelet punch

7 When buttonhole sewing is finished, push the

buttonhole lever upward as far as it will go.

t Buttonhole lever

t

22

Page 25

Altering the buttonhole width

Press the mode key to activate the stitch width

adjustment.

Press the plus (+) key to increase the buttonhole

width.

Press the minus (–) key to decrease the buttonhole

width.

q Narrower buttonhole

w Wider buttonhole

q

w

* The width can be altered between 2.5 and 7.0.

Altering the buttonhole stitch density

Press the mode key to activate the stitch length

adjustment.

Press the plus (+) key to make the stitch sparser.

Press the minus (–) key to make the stitch denser.

* The stitch density can be altered between 0.2 and

0.8.

NOTE:

The indicator shows the stitch width or density while

sewing. When the buttonhole is completed, the

indicator will show the pattern number .

Step-1

Step-2

Step-3

Step-4

Double layer buttonhole

To make a solid and sturdy buttonhole, sew another

layer of buttonhole over the previous stitches.

After the buttonhole is finished, simply start the

machine again.

Do not raise the foot or buttonhole lever.

The machine will sew another buttonhole in the

following order and stop automatically when it is

completed:

Step 1: Straight stitching in reverse to go back to the

starting point

Step 2: Front bartack and left row

Step 3: Right row

Step 4: Back bartack and locking stitches at the end

The machine will stop automatically.

NOTE:

A double layer buttonhole can be sewn when the dot

is blinking.

23

Page 26

q

Round-end and keyhole buttonholes

1

1

w

Machine settings

q Stitch pattern: #17 or #18

w Foot: Automatic buttonhole foot R

1

w

1

q

Sewing procedure is the same as for the square

buttonhole #16.

q Starting point

w Bartacking

w

q

Altering the buttonhole width

Round-end buttonhole

Press the mode key to activate the stitch width

1

q

w

adjustment.

Press the plus (+) key to increase the buttonhole

width.

Press the minus (–) key to decrease the buttonhole

width.

q Narrower buttonhole

w Wider buttonhole

* The width can be altered between 2.5 and 5.5.

Keyhole buttonhole

Press the mode key to activate the stitch width

1

q

w

adjustment.

Press the plus (+) key to increase the buttonhole

width.

Press the minus (–) key to decrease the buttonhole

width.

q Narrower buttonhole

w Wider buttonhole

* The width can be altered between 5.0 and 7.0.

* See page 23 for altering the stitch density.

24

Page 27

qw

1 2

q

w

Corded buttonhole

Machine Settings

q Pattern: #16

w Presser foot: Automatic buttonhole foot R

To sew a corded buttonhole, follow the same

procedure as for a sensor buttonhole.

1With the automatic buttonhole foot R raised, hook

the filler cord on the spur on the back of the

buttonhole foot.

2Bring the ends of cord toward you under the

buttonhole foot clearing the front end.

Hook the ends of the filler cord into the forks on

the front of the buttonhole foot to hold them tight.

q Spur

w Forks

e Cord

3 4

5

3 Lower the needle into the garment where the

buttonhole will start and lower the foot.

e

4 Lower the buttonhole lever and buttonhole foot.

Start the machine and sew the buttonhole over the

filler cord.

The machine stops automatically when finished.

NOTES:

Set the stitch width in accordance with the thickness

of the filler cord used.

To cut the buttonhole opening, refer to page 22.

5 Remove the fabric from the machine and cut the

6

sewing threads.

6 Pull the left end of the filler cord to tighten it.

Thread the end of the cord through a darning

needle and draw it to the wrong side of the fabric

and cut.

25

Page 28

qw

7

e

Button Sewing

Machine Settings

q Pattern: #07

w Presser foot: Satin stitch foot F

e Feed dog: Dropped

Unthread the needle thread.

Adjust the stitch width so that the needle enters

both holes in the button.

Place a button on the fabric and lower the needle

by turning the handwheel, so that the needle

enters into the left hole in the button.

Align the holes in the button with the slot on the

foot and lower it to hold the button in place.

Turn the handwheel to lower the needle into the

right hole in the button.

Adjust the stitch width if necessary.

Rethread the machine and sew about 10 stitches

at a slow speed (set the speed control alider at ).

Raise the presser foot and remove the fabric.

Trim both needle and bobbin threads at the

beginning.

Cut both threads leaving 20 cm (8”) tails.

Pull the bobbin thread to bring the needle thread to

the wrong side of the fabric then knot the threads.

After sewing is finished, raise the feed dog.

26

Page 29

qw

q

w

(A)

(B)

Zipper Sewing

Machine Settings

1 Pattern: #01

2 Presser foot: Zipper foot E

CAUTION:

When sewing with the zipper foot, make sure to use

pattern "01 (straight stitch with the center needle

position). Otherwise the needle may hit the foot and

possibly break.

Attaching the zipper foot

(A) Attach zipper foot E with the pin on the right-

hand side to the groove to sew the left side of

the zipper.

(B) Attach zipper foot E with the pin on the left-

hand side to the groove to sew the right side of

the zipper.

q Groove

w Pin

1

Fabric preparation for zipper sewing

q

e

w

t

y

r

i

u

o

2

q

!0

!1

!3

!2

!4

1 Add 1 cm (3/8”) to the zipper size. This is the

overall opening Size.

q Right side of the fabric

w 1 cm (3/8”)

e Opening size

r Zipper size

t Slider

y Zipper teeth

u Zipper tape

i Wrong side of the fabric

o End of the opening

2 Place the right sides of the fabric together and

sew to the end of the zipper opening. Fasten the

seam with reverse stitching.

Increase the stitch length manually to 5 mm

(3/16”) and loosen the tension to “1” to sew the

zipper opening with basting stitches.

!0 2 cm (13/16”) seam allowance

!1 Basting stitches

!2 Reverse stitches

!3 End of opening

!4 Seam line

1

w

q

e

To sew

1 Fold back the left seam allowance. Turn under the

right seam allowance to form a 0.2 to 0.3 cm (1/8")

fold. Place the zipper teeth next to the fold and

pin it in place.

r

t

y

u

27

q Lower fabric

w End of the zipper opening

e Zipper teeth

r 0.2 to 0.3 cm (1/8”)

t Wrong side of the upper fabric

y Opening size

u Fold

Page 30

2

2 Set the stitch length back to “2.2” and thread

tension to "A".

Attach zipper foot E with the pin on the righthand side.

Sew through the fold and zipper tape guiding the

zipper teeth along the edge of the foot.

3

i

3 Stop sewing 5 cm (2") before the foot reaches the

slider on the zipper tape.

Lower the needle slightly into the fabric.

Raise the foot and open the zipper.

Lower the foot and stitch the remainder of the

seam.

i Slider

o 5 cm (2”)

o

4

!0

4 Close the zipper and spread the fabric open flat

with the right side up.

Baste the upper fabric and zipper tape together.

!0 Basting

5 6

7

1 cm (3/8")

!1

!0

!2

5Reattach zipper foot E with the left pin.

Sew 1 cm (3/8") across the end of the opening with

reverse stitches. Stitch through the fabric and

zipper tape.

!1 End of the opening

6 Stop sewing about 5 cm (2”) from the top of the

zipper.

Lower the needle slightly into the fabric, raise the

foot, remove the basting stitches and open the

zipper.

!2 Basting Stitches

7Move the slider behind the presser foot.

Lower the presser foot and stitch the remainder of

the seam.

After finishing, remove the basting stitches.

!0 Basting stitches

28

Page 31

Blind Hem

Machine settings

q

w

1

q

w

q

w

2

q Stitch pattern: #11

w Foot: Blind hem foot G (optional item)

NOTE:

The blind hem foot is an optional item.

Starting to sew

1On heavy weight fabrics that ravel, the raw edge

should be overcast first.

Fold the hem leaving a 0.4 – 0.7 cm margin as

illustrated.

q Wrong side of fabric

w 0.4~0.7 cm (1/8”~1/4”)

2 Place the fabric so the needle just pierces the

edge of the fold when the needle swings to the left.

Lower the presser foot.

3 There is a sliding guide on the blind hem foot that

allows you to precisely control where the

needle pierces the edge of the fabric fold.

Turn the screw to align the left side of the guide

3

e

r

t

4

y

on the foot with the fold.

Sew, guiding the folded edge along the guide

on the foot.

e Guide screw

r Guide

t Fold edge

4 Open the fabric after sewing.

y Right side of fabric

* If the needle pierces too far left, the stitches will

show on the right side of the fabric.

NOTE:

When sewing a blind hem with the zigzag foot, carefully guide the fabric so the needle just pierces the

edge of the fold.

29

Page 32

qw

0

12 13 14

q

w

DECORATIVE STITCHES

Knit Stitch

Machine Settings

q Pattern: #10

w Presser foot: Zigzag foot A

This stitch is recommended for sewing such fabrics as

synthetic knits and stretch velour as it provides the

greatest amount of elasticity and strength.

Sew along the fabric edge leaving an adequate seam

allowance. After sewing, trim off the seam allowance

close to the stitches.

Satin Stitch

Machine Settings

q Pattern: #12 to #14

w Presser foot: Satin stitch foot F

For better sewing results, the interfacing should be used

on the wrong side of fabric when on stretch or elastic

fabrics.

Press auto-lock button while sewing the last pattern, and

machine will stop automatically after the last pattern is

finished.

30

Page 33

q

q

15

Applique Sewing

Machine Settings

w

q Pattern: #15

w Presser foot: Satin stitch foot F

Place the applique on the fabric and baste it in

place. Sew, guiding the edge of the applique along

the slit on the foot, so that the needle falls off the

edge of the applique when it swings to the right.

NOTE:

When changing the sewing direction at a corner or

curve, lower the needle into the applique at the left

swing and turn the fabric to a new direction.

Patchwork

Machine Settings

8

w

q Pattern: #08

w Presser foot: Satin stitch foot F

Sew the seam with straight stitch and press seam allowance to open. Sew pattern #08 on the right side of

garment centering over the seam line.

31

Page 34

q

13 14

2

3

Pattern Combination

Machine Settings

w

1

q Pattern: #13 and #14 (example)

w Presser foot: Satin stitch foot F

To combine 2 units of pattern #13 and one unit of

pattern #14:

1 Sew pattern #13 and press the auto-lock button

while sewing the second unit.

The machine will stop automatically when the

second unit is completed.

q Auto-lock button

q

2 Select pattern #14. Press the auto-lock button and

start sewing.

3 Machine will sew one unit of pattern #14 and stop

automatically.

4 Repeat steps above.

32

Page 35

q

Correcting Distorted Stretch Patterns

The sewing results of the stretch patterns may vary

depending upon the sewing conditions, such as

sewing speed, type of the fabric, number of layers

etc.

Always test sew on a scrap piece of the fabric that

you wish to use.

If stretch stitch patterns are distorted, correct it with

the feed balancing dial.

q Feed balancing dial

w Neutral position

e Setting mark

w

e

Example: Pattern #09

e

t

w

t

(A)

r

(B)

u

(A): If the pattern is compressed, turn the feed

balancing dial in the direction of “+”.

(B): If the pattern is drawn out, turn the feed

balancing dial in the direction of “—”.

CARE AND MAINTENANCE

Replacing the Light Bulb

WARNING:

Turn the power off before replacing the light

bulb.

The bulb could be HOT, wait until it has cooled

down before touching it.

To remove:

Remove the cap and setscrew.

Unhook the hook from the rear cover and remove the

faceplate.

q Cap

w Setscrew

e Rear cover

r Hook

t Face plate

q

Pull out the light bulb from the lamp socket.

y Light bulb

u Lamp socket

y

To replace:

Insert the bulb into the opening of the socket.

Attach the face plate inserting the ribs and hook into

the rear cover. Secure the face plate with the

setscrew, and attach the cap.

NOTE:

Replace the bulb with the same type rated 12V, 5W

(part number 000026002).

33

Page 36

Cleaning the Hook Race

WARNING:

Turn the power switch off and unplug the machine

1

e

before cleaning.

q

w

2

r

3

t

r

4

y

u

NOTE:

Do not dismantle the machine in any way other than

what is explained in this section.

1 Remove the setscrew on the needle plate with a

screwdriver. Remove the needle plate.

q Screwdriver

w Setscrew

e Needle plate

2Take out the bobbin. Lift up the bobbin holder and

remove it.

r Bobbin holder

3 Clean the bobbin holder with a lint brush.

t Lint brush

4 Clean the feed dog and hook race with the lint brush.

y Feed dog

u Hook race

5 Clean the hook race with a soft dry cloth.

5

1

e

w

2

3

(You may also use a vacuum cleaner.)

Inserting the bobbin holder

1 Insert the bobbin holder.

2 The knob of the bobbin holder should fit next to the

stopper in the hook race.

q Knob

w Stopper

3 Reattach the needle plate, aligning the needle plate

guide pins with the guide holes in the needle plate

and tighten the setscrew.

e Guide pins

r Guide holes

q

r

NOTE:

After cleaning the machine, make sure the needle and

presser foot are attached.

34

Page 37

Problems and Warning Signals

If a buzzer sounds and the indicator shows a warning sign, follow the guidance below.

Warning signal

Problem

The power is turned on with the foot control not

being connected.

The foot control is disconnected while sewing.

The machine is re-started too soon after it

has halted due to the overload.

Selecting a pattern after buttonhole is completed

with the buttonhole lever still lowered.

The bobbin winder spindle is shifted to the right

for bobbin winding.

The machine is malfunctioning due to a

problem in the electronic components.

Try this

Connect the foot control and restart

the machine.

Wait for at least 15 seconds to restart.

If threads are jamming, remove

jammed threads.

Raise the buttonhole lever and reselect the pattern.

Return the bobbin winder spindle

to the left.

Contact the service center or the

store where the machine was

purchased.

Audible signal

Pip

Pip-pip-pip

Pip-pip-peep

Peep

It is not abnormal that a faint humming sound is coming out from the internal motors.

The pattern selection key area may get warm when the machine has been used for hours.

The buzzer sounds when:

Normal operation

Invalid operation

Buttonhole sewing completed

Malfunction

35

Page 38

Troubleshooting

Condition

The needle thread

breaks.

The bobbin thread

breaks.

The needle breaks.

The needle thread

loops.

Cause

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is incorrectly inserted.

5. The needle thread and the bobbin thread are not set

properly under (drawn to the rear of) the presser foot

when sewing is starting.

6. The fabric is not drawn to the rear when sewing is

finished.

7. The thread is too heavy or too fine for the needle.

1. The bobbin thread is not threaded properly in the

bobbin holder.

2. Lint has collected in the bobbin holder.

3. The bobbin is damaged and doesn’t turn smoothly.

4. The thread is wound loosely on the bobbin.

1. Needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle clamp screw is too loose.

4. A proper foot is not used.

5. The fabric is not drawn to the rear when sewing is

finished.

6. The needle is too fine for the fabric being sewn.

1. The needle thraead tension is too loose.

2. The needle size is not suitable for the thread.

Reference

Page 12

Page 8

Page 9

Page 9

Page 14

Page 14

Page 9

Page 11

Page 34

Replace the bobbin

Re-wind the bobbin.

Page 9

Page 9

Page 9

Use proper foot.

Page 14

Page 9

Page 8

Page 9

Skipped stitches

Seam puckering

The cloth is not fed

smoothly.

The machine does not

work.

Patterns are distorted.

The buttonhole is not

sewn well.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle and/or thread are not suitable for the

fabric being sewn.

4. A blue needle is not being used for sewing stretch,

very fine fabrics and synthetics.

5. The needle thread is not threaded properly.

6. A poor quality needle is used.

1. The needle thread tension is too tight.

2. The needle thread is not threaded properly.

3. The needle is too heavy for the fabric being sewn.

4. The stitch length is too long for the fabric.

* Use a stabilizer for very fine fabrics.

1. The feed dog is packed with lint.

2. The stitches are too fine.

3. The feed dog was not raised after being lowered.

1. The machine is not plugged in.

2. Thread is caught in the hook race.

3. The bobbin winder spindle is still in the winding position.

1. The stitch is not balanced.

1. The stitch density is not suitable for the fabric being

sewn.

2. Interfacing is not being used with stretch fabrics.

Page 9

Page 9

Page 9

Page 9

Page 12

Replace the needle

Page 8

Page 12

Page 9

Make stitch shorter

Page 34

Make stitch longer

Page 7

Page 4

Page 34

Page 10

Page 33

Page 24

Page 20

Noisy operation

Due to heat from the internal electronic components, the indicator and function keys will be warm.

However, it does not affect the machine’s normal operation.

1. The feed dog is packed with lint.

2. Lint has collected in the bobbin holder.

36

Page 34

Page 34

Page 39

843-800-751 (E)

Printed in Taiwan

Loading...

Loading...