INSTRUCTION BOOK

COVER PRO 900CP

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

followings:

Read all instructions before using this appliance.

DANGER— To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing machine

from the electric outlet immediately after using and before cleaning.

2. Always unplug before replacing a sewing machine bulb. Replace bulb with same type rated

15 Watts.

WARNING— To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by

or near children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination,

repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this sewing

machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine

needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as

threading the needle, changing the needle, threading the bobbin or changing the presser foot, and

the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

The design and specifications are subject to change without a prior notice.

795-800-003 (E)

Printed in Taiwan

TABLE OF CONTENTS

KNOW YOUR MACHINE

Names of Parts ..................................................................................................2

Standard Accessories ........................................................................................3

GETTING READY TO SEW

Connecting the Machine to the Power Supply ...................................................4

Controlling Sewing Speed..................................................................................4

How to Turn the Handwheel...............................................................................5

Opening and Closing the Looper Cover.............................................................5

Extension Table .................................................................................................5

Raising or Lowering the Presser Foot................................................................6

Removing the Presser Foot ...............................................................................6

Attaching the Presser Foot.................................................................................6

Adjustment of Foot Pressure..............................................................................6

Adjustment of Stitch Length ...............................................................................7

Adjustment of Differential Feed Ratio ................................................................7

Changing Needle ...............................................................................................8

How to use the needle threader/holder .................................................................... 8

Setting the Thread Guide Bar ............................................................................9

Setting the Spool Cones ....................................................................................9

Threading the Machine ....................................................................................10

Threading the needles............................................................................................ 11

How to use the threader .........................................................................................12

Threading the looper .............................................................................................. 13

STITCH TYPES

Cover Stitch......................................................................................................15

Balancing the thread tension.................................................................................. 15

Chain Stitch......................................................................................................16

Balancing the thread tension.................................................................................. 16

Finishing the Seam ..........................................................................................17

Beginning of the seam............................................................................................ 17

End of the seam ..................................................................................................... 17

Knotting the threads ............................................................................................... 17

Removing the Fabric in the Middle of the Stitching..........................................18

Hemming with the Cover Stitch........................................................................19

Free Arm Hemming ..........................................................................................19

Cover Stitch Applications .................................................................................20

CARE OF YOUR MACHINE

Cleaning the Feed Dogs and Looper Area.......................................................21

Replacing the Light Bulb ..................................................................................21

Troubleshooting................................................................................................22

1

KNOW YOUR MACHINE

Names of Parts

!5

!6

!4

!3

!2

!1

o

!0

i

u

y

q

@0

e

w

q Differential feed dial

w Stitch length dial

e Handwheel

r Spool stand

t Spool holder

t

y Spool pin

u Thread guide bar

r

i Thread guide post

o Thread guide plate

!0 Looper thread tension dial

!1 Carrying handle

!2 Right needle thread tension dial

!3 Pressure adjusting screw

!4 Left needle thread tension dial

!5 Looper

!65 Looper release knob

!7 Looper thread take-up lever

@1

@2

@3

!7

@8

!8

@9

@7

@6

!9

!8 Looper cover

!98 Power switch

@0 Machine socket

@1 Presser foot lifter

@2 Presser foot holder

@3 Thread cutter

@4 Extension table

@5 Needle plate

@6 Attachment mount

@7 Presser foot

@8 Left needle (#80/12)

@9 Right needle (#80/12)

#0 Feed dogs

@4

#0

@5

2

q

t

w

e

y

r

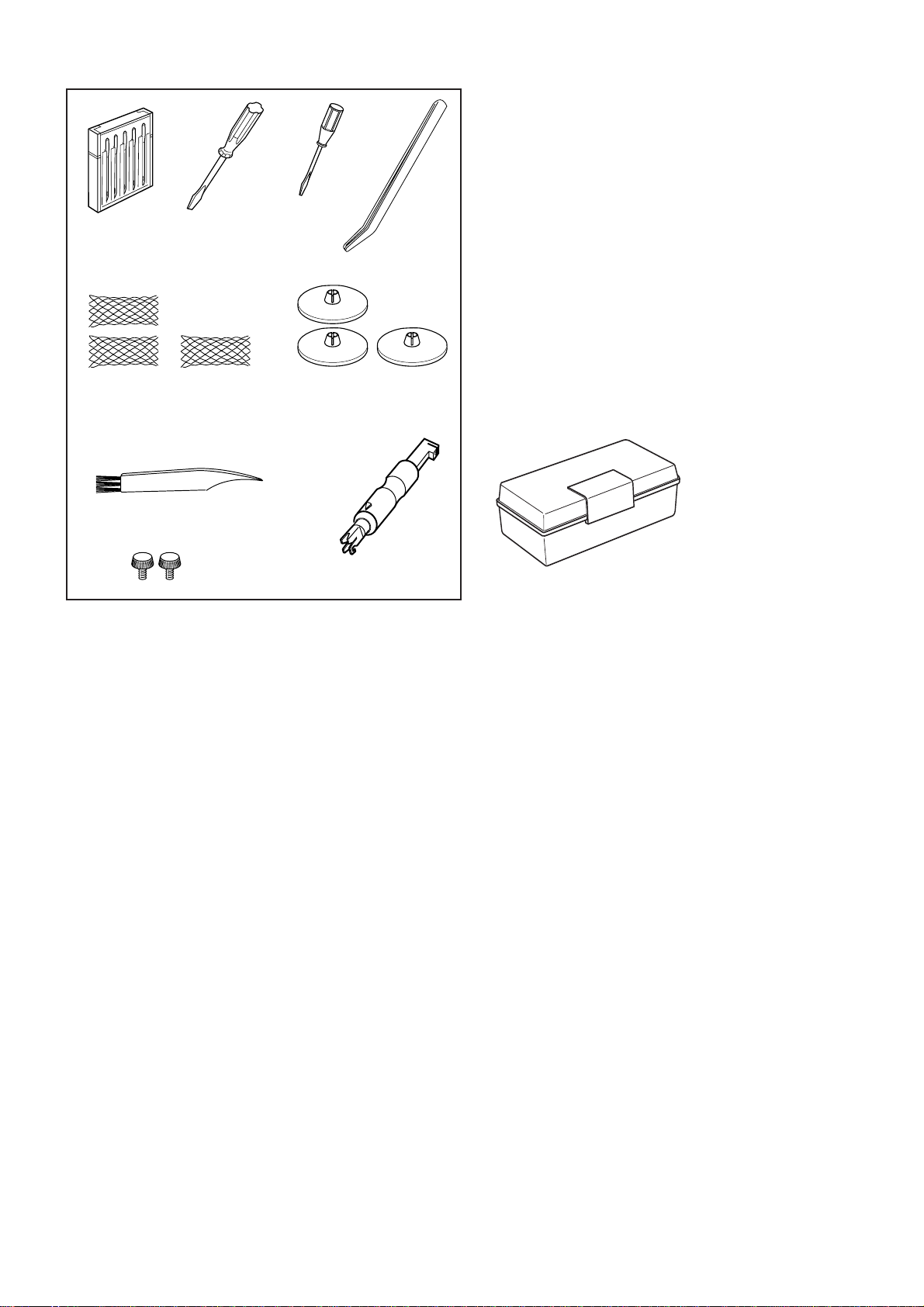

Standard Accessories

q Set of needles: 2 X #80/12, 3 X #90/14

(Schmetz EL X 705)

w Screwdriver (Large)

e Screwdriver (Small)

r Tweezers

t Nets

y Spool holder caps

u Lint brush

i Needle threader

o Attachment screws (for fixing optional accessories)

(Refer to the instructions of the optional

accessory)

!0 Accessory box

u

i

!0

o

3

y

q

e

w

t

r

GETTING READY TO SEW

Connecting the Machine to the Power Supply

1 Turn off the power switch, and connect the

machine plug to the machine socket.

2 Connect the power supply plug to your power

supply.

3 Turn on the power switch.

q Power switch

w Machine plug

e Machine socket

r Power supply plug

t Power supply

y Foot control

q

Operating Instructions:

• The symbol “O” of a switch indicates the

“off” position of a switch.

• For appliances with a polarized plug (one

blade wider than the other): To reduce the

risk of electric shock, this plug is intended

to fit in a polarized outlet only one way. If

it does not fit fully in the outlet, reverse

the plug. If it still does not fit, contact a

qualified electrician to install the proper

outlet. Do not modify the plug in any way.

Foot controller Model YC-482-J

is for use with sewing

machine model 900P.

Controlling Sewing Speed

Sewing speed can be varied by the foot control.

The harder you press on the control, the faster the

machine runs.

Step on the foot control with the presser foot lifter up, and

practice controlling the speed.

q Foot control

For Your Safety:

* While the machine is in operation, always keep your

eyes on the sewing area, and do not touch any moving

parts such as the thread take-up lever, loopers,

handwheel or needles.

*Always disconnect the machine from the power

supply:

— when leaving the machine unattended.

— when attaching or removing parts.

— when threading or cleaning the machine.

* Do not place anything on the foot control,

except when the machine is in use.

4

q

How to Turn the Handwheel

Always turn the handwheel toward you

(Counterclockwise).

q Handwheel

(B)

q

w

e

(A)

Opening and Closing the Looper Cover

To open: (A)

While pushing with the thumb to the right as far as it will

go, pull the looper cover toward you.

To close: (B)

Lift the looper cover and push it against the machine.

The looper cover snaps into its position automatically.

q Looper cover

Extension Table

The extension table provides added sewing surface and

can be easily removed for free arm sewing.

Detaching the table:

Pull the table away from the machine.

q Extension table

Attaching the table:

Align the pin on the table with the hole in the machine.

Push the extension table until it snaps into the machine.

w Pin

e Hole

q

5

w

Raising or Lowering the Presser Foot

By raising or lowering the presser foot lifter, the presser

foot goes up or down.

* While in operation, keep the presser foot lowered

except when threading the machine or test

running without threads.

w

q

e

w

q

e

q

NOTE:

Thread tension will be released when the presser foot

lifter is raised.

q Presser foot

w Presser foot lifter

Removing the Presser Foot

1 Turn off the power switch and unplug the

machine.

2 Turn the handwheel toward you to raise the needle.

Raise the presser foot.

3Press the lever located on the back of the foot

holder. The presser foot will drop off.

q Handwheel

w Lever

e Foot holder

Attaching the Presser Foot

1 Turn off the power switch and unplug the

machine.

2Place the presser foot so that the pin on the foot

lies just under the groove of the foot holder.

3 Lower the foot holder to lock the foot into place.

4 Raise the presser foot lifter to check that the

presser foot is secure.

10 mm

r

e

w

q

q Foot holder

w Groove

e Pin

Adjustment of Foot Pressure

It is not necessary to adjust the presser foot’s pressure

for normal sewing.

When you sew heavy or lightweight fabrics, turn the

adjusting screw:

–– clockwise for heavyweight fabric.

–– counterclockwise for Iight weight fabric.

* For regular sewing, set the adjusting screw so

the head protrudes 10 mm from the top of the

machine.

q To decrease

w To increase

e Adjusting screw

r Top of the machine

6

Adjustment of Stitch Length

To adjust the stitch length, turn the dial.

The larger the number, the longer the stitch.

The stitch length can be adjusted from 1 to 4 mm.

w

w

q

e

w

w

r

r

q Stitch length dial

w Setting mark

e To lengthen

r To shorten

* For regular sewing, set the stitch length at 3 – 3.5.

Adjustment of Differential Feed Ratio

The differential feed ratio can be altered by turning the

dial.

The number on the dial indicates the ratio between the

main and the sub feed motion.

•Set the dial at 1.0 for regular sewing.

•Set the dial at a lower number when sewing fine fabrics

that tend to pucker.

• Set the dial at a higher number when sewing stretch

fabrics such as knits, jersey and tricot.

q

q Differential feed dial

w Setting mark

e To shrink

r To stretch

e

7

Changing Needle

e

r

w

t

q

WARNING:

Turn the power switch off and unplug the machine

before changing needles.

Turn the handwheel toward you to raise the needle to its

highest position.

q Handwheel

Then loosen the needle clamp screw for the needle you

are going to remove.

w Needle clamp screw

e Small screwdriver

Insert a new needle into the needle clamp with the flat

side to the back and push it up against the stopper, then

tighten the needle clamp screw.

r Flat side

t Stopper

How to use the needle threader/holder

To attach the needle easily, use the end of the needle

threader to hold the needle.

Insert a needle into the needle threader/holder with

the flat side facing back as shown.

y

Hold the stem and insert the needle into the needle

clamp and push it up as far as it will go.

Tighten the needle clamp screw firmly while supporting

the holder in place.

Pull the holder down to remove it.

y Needle threader/holder

NOTES:

Use Schmetz needles EL X 705 size 80/12 or EL X 705

size 90/14.

Do not use any needle which is bent or blunt.

8

q

Setting the Thread Guide Bar

Pull the thread guide bar up as far as it will go.

t

r

w

Turn the thread guide bar so that the thread guides are

right above the spool pins.

q Thread guide bar

w Thread guide

e Spool pin

r Stoppers

t Thread guide post

e

NOTE:

Make sure the two stoppers on the thread guide post, as

shown, are set in at the correct position.

w

w

t

e

q

y

r

Setting the Spool Cones

Place the spool cones on the spool holders.

If the thread slips down from a spool cone during

threading and/or sewing, put a net over the spool cone

as illustrated to prevent jamming.

q Spool cone

w Spool holder

e Net

When using small spools, remove the spool holders from

the spool pins.

r Small spool of thread

t Spool pin

Place the spool with its slit side up, and put the spool

holder cap on top of it.

y Spool holder cap

9

Threading the Machine

1

23

Turn the power switch off and unplug the

machine before threading the machine.

2

1

Thread the machine in the following order:

1 Left needle thread

2Right needle thread

3 Looper thread

WARNING:

q

w

Raise the presser foot lifter.

q Presser foot lifter

NOTE:

Always thread the machine with the presser foot raised.

Turn the handwheel toward you to bring the needles to

their highest position.

w Handwheel

10

1

Threading the needles

2

6

3

7

4

5

8

9

10

1

q

Thread each needle in the following steps:

1 Draw the thread through the Left side thread

guide bar from back to front as shown (A).

NOTE:

(A)

If the thread is coming out from the thread guide notch,

pass the thread through the thread guide hole again as

shown (B).

q Thread guide bar

(B)

2

w

2 Pass the thread through the holes on the right side

of the thread guide plate as illustrated.

w Thread guide plate

11

3

4

e

3Hold the thread at both ends and tug gently to

ensure the thread is correctly inserted between

the tension disks. ( If the presser foot lifter is

raised, the thread easily inserts between the

tension discs.)

e Tension dial

r Tension disks

t

r

u

5 6

i

y

i

8

7

o

!0

4 Pass the thread through the thread guide (A) from the

right.

t Thread guide (A)

5 Draw the thread to the left and pass it through the

thread guide (B).

Draw the thread up and slip it behind the take-up

lever cover.

y Thread guide (B)

u Take-up lever cover

6 Pull the thread down and slip it behind the thread

guide (C) from the right.

i Thread guide (C)

7 Thread each needle as follows:

Left Needle (A): Pass the thread behind the thread

guide plate from the left. Pass the thread between the

left and center prongs.

Right needle (B): Pass the thread behind the thread

guide plate from the right. Pass the thread between

the right and center prongs.

o Thread guide plate

!0 Prongs

8 Slip all the threads behind the needle bar thread

guide from the right.

Thread each needle with the threader (see below).

!1 Needle bar thread guide

(A)

!1

(B)

How to use the threader

1

4

q

r

e

2

5

t

3

1Hold the grip of the threader with the triangle mark up.

Insert the thread into the slit of the Y-shaped notch.

q Triangle mark

w Y-shaped notch

2Place the V-shaped notch over the needle just above

the needle eye.

3Slide the threader down along the needle while

pushing it against the needle, until the threader pin

enters into the needle eye.

e V-shaped notch

r Threader pin

4 Push the threader and the thread will go through the

needle eye.

5 Remove the threader from the needle. Then pick up

the loop of the thread with the hook. Pull the thread

end out to the back.

t Hook

12

Threading the looper

1

2

3

8

7

4

q

(B)

6

5

Thread the looper in the following steps:

(A)

1Draw the thread through the right side thread

guide bar from back to front as shown (A).

NOTE:

If the thread is coming out from the thread guide notch,

pass the thread through the thread guide hole again as

shown (B).

q Thread guide bar

w

2 Pass the thread through the holes on the right side

of the thread guide plate as illustrated.

w Thread guide plate

13

3Hold the thread at both ends and tug gently to

3

4

e

ensure the thread is correctly inserted between

the tension disks. ( If the presser foot lifter is

raised, the thread easily inserts between the

tension disks.)

e Tension dial

r Tension disks

5

6 7

y

t

r

4 Pass the thread through the looper thread guide (A)

from the right.

t Looper thread guide (A)

5 Pass the thread through the eyes of the looper

take-up levers.

y Looper take-up lever

NOTE:

Be sure to raise the needles to the highest position so

the eyes of the looper take-up levers will align.

6Slip the thread behind the looper thread guide (B)

from the right.

u Looper thread guide (B)

8 9

i

!0

u

o

7 Pull the looper release knob and the looper will slant

to the right for easy access.

i Looper release knob

8 Pass the thread through the eye of the looper thread

guide (D) then through the eye of looper.

Draw the thread end 4” (10 cm) to the back.

o Looper thread guide (D)

!0 Eye of the looper

NOTE:

You may use a pair of tweezers.

9 Push the looper in the direction of the arrow, back to

the original position.

14

STITCH TYPES

q

w

w

Cover Stitch

This stitch forms 5 mm wide two parallel rows of the

straight stitch on the right side, widely used on cuffs and

stretch welts of T-shirts etc.

q Left needle

w Right needle

Type of Fabric

Light to

medium weight

Heavyweight

NOTE: The machine is installed with the #80/12 needles.

Fine knits

Fine Jersey

Jersey

Fleece

Needle Size

80/12 or

90/14

90/14

Balancing the thread tension

1 Set the tension dials as follows:

q Left needle thread tension dial: 4

w Right needle thread tension dial: 4

e Looper thread tension dial: 2

Type of Thread

#60-90 Spun

#60 Spun

44 2

q

w

r

e

(A)

(B)

2 Check the tension balance by test stitching on the

same fabric and threads as actual garment. Fine-tune

the tension as necessary.

Balanced tension:

The rows of stitches on the right side of the fabric are

straight and even. The looper thread forms a row of

squares with diagonals.

q Wrong side of the fabric

w Looper thread

e Left needle thread

r Right needle thread

(A) If the needle thread tension is too loose:

– The stitches on the right side are irregular and loose.

– There is a gap between head and tail of the looper

thread crossing points.

Tighten the needle thread tension, and/or loosen the

looper thread tension to correct it.

(B) If the needle thread tension is too tight:

– The fabric puckers.

Loosen the needle thread tension, and/or tighten the

looper thread tension to correct it.

15

Chain Stitch

This stitch is sewn with a single needle and forms a chain

of looper thread on the wrong side of the fabric.

This is a durable and flexible stitch used for seaming knit

fabrics, attaching elastics, attaching bias tapes etc.

Thread one of the three needles and looper. Remove the

needles not to be used (see page 8).

NOTE:

Tighten the needle clamp screw on the side that is not

being used to prevent losing the screws.

q

w

33 2

w

q

e

Balancing the thread tension

1 Set the tension dials as follows:

q Needle thread tension dial: 3

w Looper thread tension dial: 2

NOTE:

Adjust the tension dial for the needle being used.

2 Check the tension balance by test stitching on the

same fabric and threads as actual garment. Fine-tune

the tension as necessary.

Balanced tension:

The straight stitch on the right side of the fabric is straight

and even. The looper thread forms a chain.

q Wrong side of the fabric

w Looper thread

e Needle thread

(A) If the needle thread tension is too loose:

– The stitch on the right side is irregular and loose.

–The needle thread forms loops on the wrong side of

the fabric.

Tighten the needle thread tension, and/or loosen the

looper thread tension to correct it.

(A)

(B)

(B) If the needle thread tension is too tight:

– The fabric puckers.

Loosen the needle thread tension, and/or tighten the

looper thread tension to correct it.

16

e

w

q

Finishing the Seam

To achieve the best results, use a piece of scrap fabric at

the beginning and end of the seam.

Beginning of the seam

1 Raise the presser foot and insert a piece of scrap

fabric under the foot. Lower the foot and turn the

handwheel several times toward you.

Depress the foot control to start sewing slowly.

q Handwheel

2 Stop sewing at the end of the scrap fabric.

Insert the work fabric after the scrap as shown, then

start sewing on the work fabric.

w Scrap fabric

e Work fabric

t

r

End of the seam

3 Stop sewing at the end of the work fabric.

Insert another piece of scrap fabric after the work

fabric as shown, then sew through the scrap.

r Another scrap fabric

4 Cut the connecting threads between the work fabric

and scrap fabric.

t Connecting threads

Knotting the threads

Draw the needle threads to the wrong side of the

fabric by using a pair of tweezers and knot them together.

17

Removing the Fabric in the Middle

of the Stitching

1

q

1Raise the needles to their highest position by turning

the handwheel toward you.

q Handwheel

2

w

3

4

2 Raise the presser foot with the presser foot lifter.

w Presser foot lifter

3 Pull the needle threads before the needle eyes.

This prevents the threads from being caught when

removing the fabric.

4 Pull the fabric to the rear.

5

5Remove the fabric and cut the threads with the thread

cutter.

e Thread cutter

e

18

w

Hemming with the Cover Stitch

1 Fold up the edge of the fabric to the wrong side and

press.

e

2Draw a line with a tailor’s chalk on the right side of the

fabric to mark the fabric edge.

3Place the fabric so the left needle drops just to the

left side of the marked line. Lower the presser foot.

4 Sew carefully along the marked line.

q

r

5After finishing sewing, raise the presser foot and

remove the fabric to the rear.

6 Draw the needle threads to the wrong side of the

fabric and knot them together.

q Marked line

w Left needle

e Right needle

r Right side of the fabric

Free Arm Hemming

The extension table can be detached for free arm

hemming on the tubular parts of the garments, such as

sleeves, cuffs etc.

1Detach the extension table (see page 5).

2Stitch the hem in the same way as hemming with

cover stitch.

3 Continue to sew over the stitches 2” (4 to 5 cm)

beyond the beginning of the seam and stop the

machine.

Cut the threads at the beginning and at the end.

19

e

w

q

Cover Stitch Applications

Hemming on sleeves and waistlines

q Sleeve

w Waistline

q

Attaching laces and tapes

q Tape or lace

w Right side of the fabric

e Wrong side of the fabric

w

w

w

Attaching elastics

q Right side of the fabric

w Wrong side of the fabric

e Elastic

q

e

Decorative stitch

q Right side of the fabric

w Wrong side of the fabric

q

20

CARE OF YOUR MACHINE

2

1

w

3

e

q

5

4

Cleaning the Feed Dogs and Looper Area

WARNING:

Turn the power switch off and unplug the machine

before cleaning.

NOTE:

Do not dismantle the machine in any way other than

what is explained in this section.

1 Remove the presser foot and needles.

2Remove the setscrew and needle plate.

3Clean the feed dogs with a lint brush.

q Setscrew

w Needle plate

e Lint brush

r

q

e

w

4Open the looper cover and clean the looper and

surrounding area with the lint brush.

5 Replace the needle plate, needles and presser foot.

Close the looper cover.

r Looper cover

Replacing the Light Bulb

WARNING:

Turn the power off before replacing the light bulb.

The bulb could be HOT, wait until it has cooled

down before touching it.

1 Remove the setscrew and face plate.

2 Push up and twist the bulb counterclockwise (in the

direction “A”) to remove it.

Push up and twist the bulb clockwise (in the

direction “B”) to replace it.

e

A

B

3 Attach the face plate with the setscrew.

q Setscrew

w Face plate

e Light bulb

21

Troubleshooting

Problem

Needle thread

breaks.

Needle bends or

breaks.

Skipped stitches

Seam puckering

Machine does not

operate.

Cause

1. The machine is not threaded correctly.

2. The thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is not set correctly.

5. A wrong needle is used.

1. The needle is bent or blunt.

2. The needle is not set correctly.

3. The needle clamp screw is loose.

4. The fabric is forcedly pulled.

1. The needle is not set correctly.

2. The needle is bent or blunt.

3. The tension is out of balance.

4. The machine is not threaded correctly.

1. The tension is out of balance.

1. The machine is not connected to the power supply.

2. The foot control is not plugged in firmly.

Reference

See pages 10-14.

See pages 15, 16.

See page 8.

See page 8.

See page 8.

See page 8.

See page 8.

See page 8.

Do not pull the fabric.

See page 8.

See page 8.

See pages 15, 16.

See pages 10-14.

See pages 15, 16.

See page 4.

See page 4.

22

Loading...

Loading...