Page 1

07610-003-20-17

March 14, 2006

Rack Conveyor Dishmachine

Maintenance Instructions

Motor Assembly

Replacement

Page 2

MAINTENANCE INSTRUCTIONS

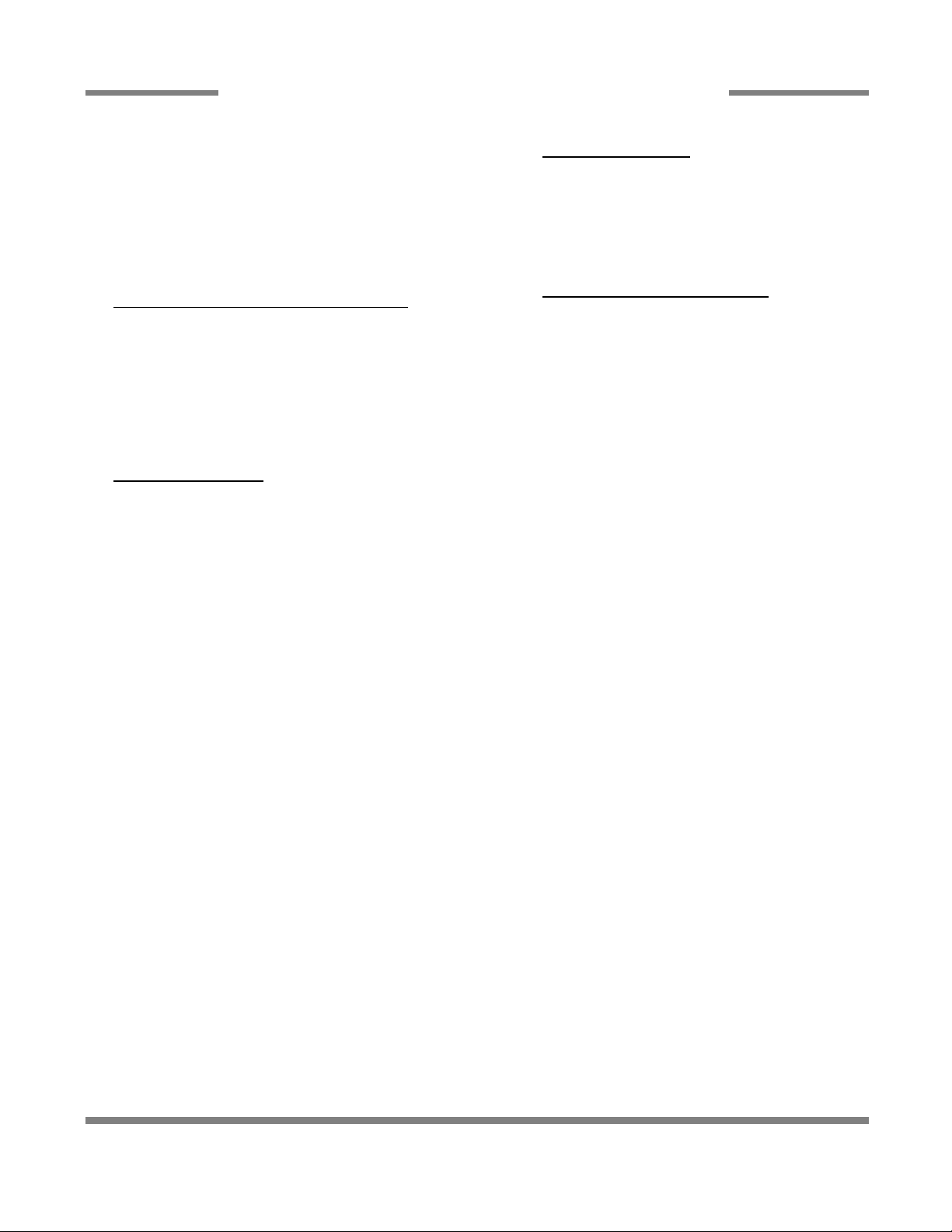

3. With the band clamp loosened, carefully remove it from the back

end of the motor. Once the clamp is removed, examine it to deter

-

mine if it needs to be replaced as well. If it is broken in any spots

or shows signs of metal fatigue, it is best to order a new one. The

purpose of the clamp and the attached support bracket is to keep

the weight of the motor from pulling on the tub, damaging it. It is

absolutely necessary that this component be replaced once the

REPLACING CONVEYOR MOTOR

The instructions provided here are for maintenance personnel only. Unauthorized persons should not attempt any of the

steps contained in these instructions.

Warning: many of the instructions and steps within

this document require the use of tools. Only authorized per sonnel should ever perform any maintenance procedure on

the dishmachine!

PREPARATION

1. Power must be secured to the unit at the service breaker. Tag or lock out the service breaker to prevent accidental or

unauthorized energizing of the machine.

2. Ensure that incoming water to the machine is secured

either by use of a shut-off valve or disconnecting the incoming

water line.

3. Ensure that the dishmachine has been completely

drained of water and has been allowed to cool down prior to beginning this maintenance procedure.

STEPS

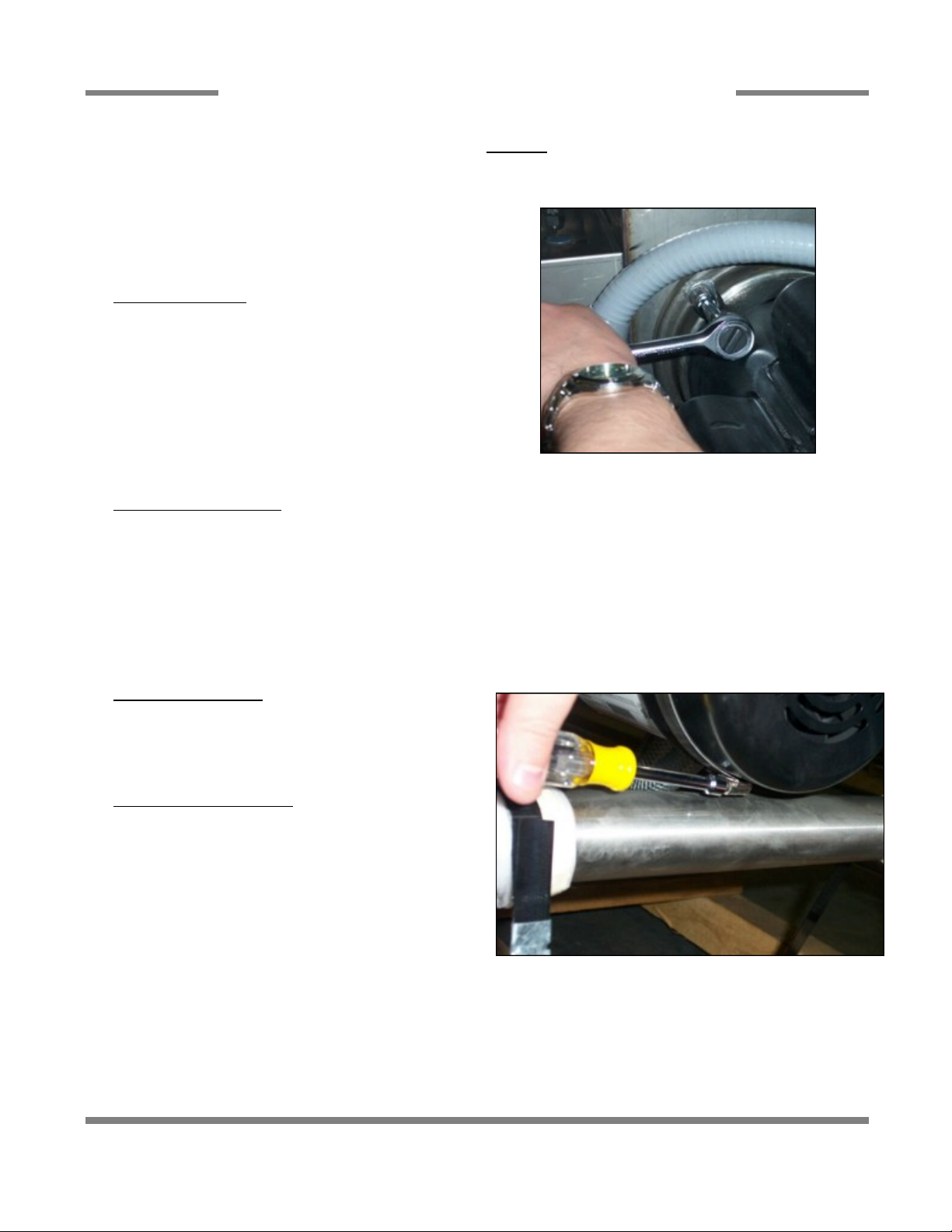

1. Remove the (4) nuts holding the mounting plate in position.

Removing the mounting plate nuts with the 9/16” socket

TOOLS REQUIRED

The following tools will be needed to perform this mainte-

nance evolution:

1. 7/16” socket and ratchet with extension

2. 9/16” socket and ratchet with extension

3. 5/16” Allen wrench

4. 5/16” nutdriver

5. Large flathead screwdriver

6. Small flathead screwdriver

TIME REQUIRED

It is estimated that it will take (1) person one and a half

hours to perform this task, not including all of the items indicated in

the section entitled “PREPARATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempting

this maintenance procedure. Become familiar with the parts and

what actions need to be taken. This will save time in the long run!

2. The procedures demonstrated in this manual are

shown being performed on an AJ-44 rack conveyor dishmachine.

The actual maintenance steps, however, apply to any wash, prewash or power rinse motor found on a Jackson rack conveyor dishmachine.

3. These basic instructions will apply to all prewash, wash

and power rinse motors found on AJ, TS and TSC series

machines.

2. Loosen the band clamp on the back end of the motor.

maintenance procedure is completed.

Loosening the band clamp on the back end of the motor.

Conveyor Motor Replacement Instructions 07610-003-20-17 Rev. A

Issued: 03-14-2006 Revised: N/A

2

Page 3

MAINTENANCE INSTRUCTIONS

10. Remove the wiring cover on the new motor assembly and pull

11. Run the conduit to the motor, pulling the machine wires through

12. Rewire the motor exactly the same way the old one was wired

and/or refer to the motor schematic to determine how the motor

should be wired for the incoming power. If you require help on this,

do not hesitate to contact Jackson Technical Service. Ensure that

all wiring is done in accordance with national, state and local codes

13. Place the new motor gasket on the tub over the mounting

14. Carefully lift the motor assembly and slide it onto the mounting

REPLACING CONVEYOR MOTOR

Removing the rear clamp

4. Remove the motor support bracket.

Removing the motor support bracket

5. With the motor support bracket removed, gently pull back on the

motor. You may have to move it from side to side, but it should start

to move back. Pull it completely away from the mounting studs on

the tub and set down gently to work on it.

6. Remove the gasket from the tub.

Removing the pump gasket

the wires free. Install the conduit fitting.

and into the motor wiring box.

as applicable.

7. Use a screwdriver to remove the wiring cover from the motor

wiring box. Take note of how the motor is wired up because you will

have to wire it up the exact same way when you install the new

motor.

8. Remove the conduit fitting from the motor wiring box.

9. Pull the conduit away from the motor and set old motor to the

side. Dispose of the old motor in accordance with warranty or

national/state/local guidelines, whichever may apply.

Conveyor Motor Replacement Instructions 07610-003-20-17 Rev. A

Issued: 03-14-2006 Revised: N/A

Remounting the wash motor assembly

studs.

studs.

15. Re-install the mounting hardware and tighten down.

3

Page 4

Jackson MSC Inc. provides technical support for all of the

dishmachines detailed in this manual. We strongly recommend that

-

port staff. Please have this manual with you when you call so that

our staff can refer you, if necessary, to the proper page. Technical

support is available from 8:00 a.m. to 5:00 p.m. (EST), Monday

through Friday. Technical support is not available on holidays.

Contact technical support toll free at 1-888-800-5672. Please

remember that technical support is available for service personnel

MAINTENANCE INSTRUCTIONS

REPLACING CONVEYOR MOTOR

16. Attach the motor support rear clamp.

17. Adjust the motor support bracket so that the motor assembly is

level and tighten down.

18. Attach the motor wiring cover.

AFTER MAINTENANCE ACTIONS

Reconnect the incoming water (if disconnected) and turn

on. Then restore power to the unit. Run the unit for at least 10 minutes to ensure there are no leaks. If you hear any grinding sounds

while the motor is running, immediately shut off the unit and secure

power and water. There is a serious problem that must be

addressed. If any problems arise you can contact Jackson

Technical Service.

SPECIAL NOTES

Work performed on Jackson dishmachines by unautho rized or unqualified personnel may void the warranty. Before beginning this or any other maintenance evolution on a unit under warranty, you should contact a certified Jackson technician or Jackson

Technical Service. You can find a list of qualified service agencies

in the back of you unit’s installation manual.

SPECIAL PARTS

Bracket, Motor Support

05700-021-73-42

Clamp, Motor Support

04730-002-32-15

CONTACT INFORMATION

you refer to this manual before making a call to our technical sup

only.

Conveyor Motor Replacement Instructions 07610-003-20-17 Rev. A

Issued: 03-14-2006 Revised: N/A

4

Loading...

Loading...