BODY STRAIGHTENER

10 TON CAPACITY

MODEL 851/857

USER'S MANUAL

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp or wet work areas

invite injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to

handle this product. Do not allow children in the work area.

3. STORE IDLE EQUIPMENT. When not in use , tools and equipment should

be stored in a dry location to inhibit rust. Always lock up tools and equipment

and keep out of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF

ALCOHOL OR DRUGS. Read warning labels on prescriptions to determine

if your judgment of reflexes are impaired while taking drugs. If there is any doubt,

do not attempt to use this product.

5. USE EYE PROTECTION. Wear ANSI approved safety impact eye glasses

when using this product. ANSI approved impact eye glasses are available form

Harbor Freight Tools.

6. DRESS SAFELY. Non-skid footwear or safety shoes should be used when

working with this product. Do not wear loose clothing or jewelry as hey can

become caught in moving parts. Wear a protective hair covering to prevent

long hair form becoming caught in moving parts. If wearing a long-sleeve shirt,

roll sleeves up above elbows.

7. DO NOT OVERREACH. Keep proper footing and balance at all times to

prevent tripping, falling, back injury, etcetera.

8.STAY ALERT. Watch what you are doing at all times. Use common sense.

Do not use this product when you are tired or distracted form the job at hand.

9.CHECK FOR DAMAGED PARTS. Before using this product, carefully

check that it will operate properly and perform its intended function. Check

for damaged parts and any other conditions that may affect the operation of

this product. Replace or repair damaged or worn parts immediately.

10.MAINTAIN THIS PRODUCT FOR THE RIGHT JOB. There are certain

applications for which this product was designed. Do not use small equipment,

tools or attachments to do the work of larger industrial equipment, tools or

attachments to do the work of larger industrial equipment, loose or attachments.

Do not use this product for a purpose for which it was not intended.

1.

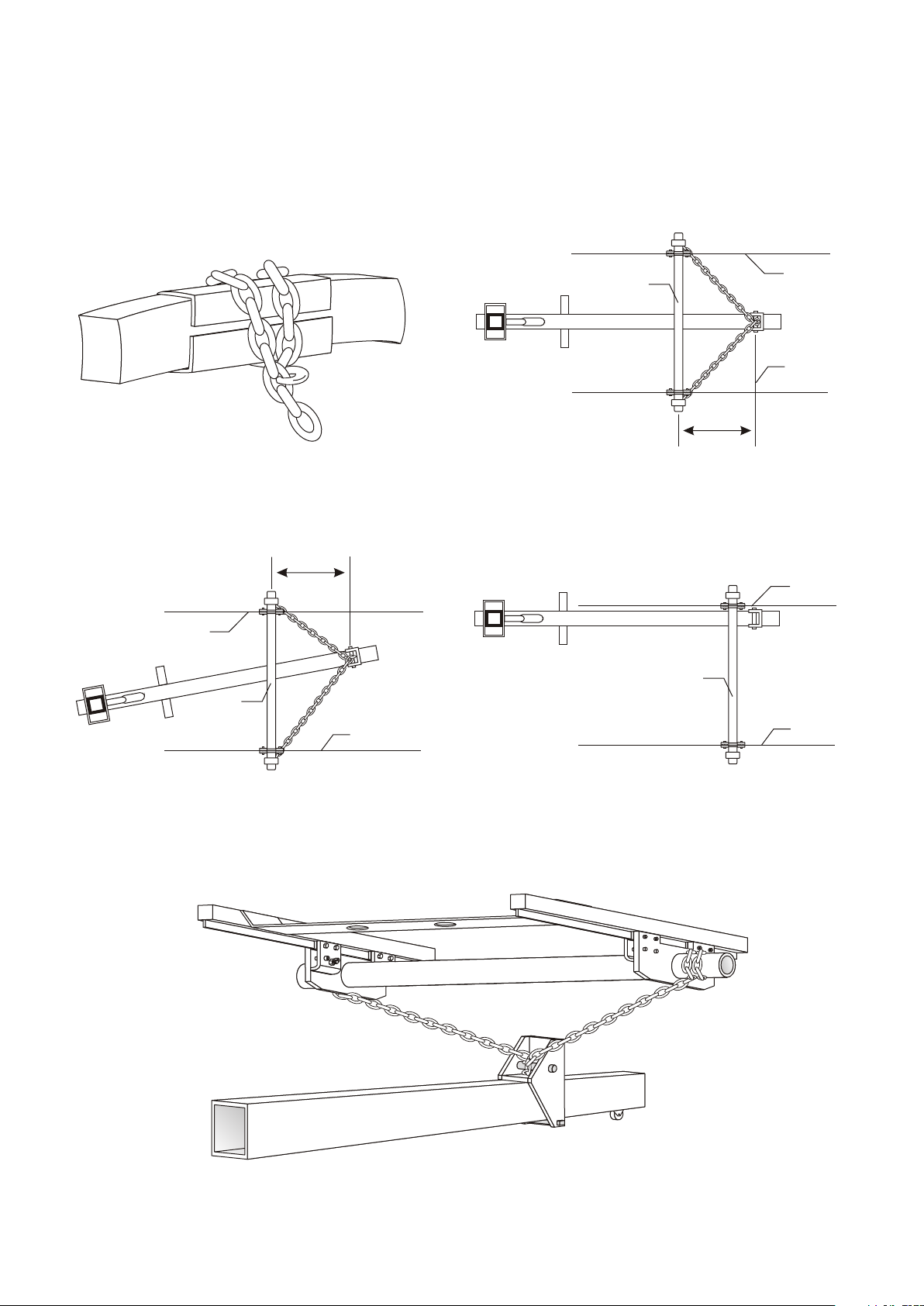

HOW TO SET UP THE FRAME STARIGHTENER

Frames and bodies are bent and distorted by collision with a relatively large area of the car bearing the impact.

However, the correction procedure utilizes, powerful, concentrated loads at key points which can cause local

crushing of frame members, etc., if these points are not property padded to spread the load over a large area.

Illustration of recommended anchoring procedures are shown below for efficient use of the under body anchoring

System.

Box frames and channel sections should be padded

with short pieces of angles iron to prevent damage to

the corner of the section when a chain is wrapped around the frame section.

24"Min

Pinch Weld

Cross Tube

Cross Tube

24"Min

Pinch Weld

Pinch Weld

Proper anchoring for a heavy fore and aft pull utilizes

the underbody anchoring system as shown here.

Pinch Weld

Cross Tube

Pinch Weld

For a diagonal pull, the underbody anchoring system

provides atachment to both rocker panels, for better

efficiency and less damage. The anchoring loads are

spread across both sides of the car.

Pinch Weld

For pulling on one side only, it is best to attach the cross

tube to both rocker panels. Anchor your body straightener

to the cross tube. This will prevent unwanted rolling of the

underbody clamps on the pinch weld.

The underbody clamp secures to the pinch welds allows more

versatile positioning of the body straightener.

2.

Loading...

Loading...