Page 1

MODEL 842

AIR HYDRAULIC PUMP

INSTRUCTION

Jackco Transnational Inc. © 2009

South El Monte, CA

888-452-2526 www.jackco.com

Page 2

FOR YOUR SAFETY

Read all instructions, warnings and cautions carefully. Follow all safety precautions to avoid personal injury

or property damage during system operation. Jackco cannot be responsible for damage or injury resulting

from unsafe product use, lack of maintenance or incorrect product and/or system operation. Contact Jackco

when in doubt as to the safety precautions and operations.

Failure to comply with the following cautions and warnings could cause equipment damage and personal

injury.

• Stay clear of loads supported by hydraulics.

A cylinder, when used as a load lifting device,

should never be used as a load holding device.

After the load had been raised or lowered,

it m u s t al w a y s be b locked m e chanicall y.

• Do not exceed equipment rating never attempt

to lift a load weighing more than the capacity

of the cylinder. Overloading causes equipment

failure a n d possible personal i n j u r y. The

cylinders are designed for a maximum pressure

of 10,000 psi. Do not connect a jack or cylinder

to a p ump w i t h a h i g h e r p r e s s u r e rating.

• The system o p e r a t i n g pressure m u s t not

exceed the pressure rating of t h e lowest

ra t e d c o m po ne n t in th e sys t e m . Ins t al l

pressur e gaug es in the system to m onitor

o p e r a t i n g pr e s s u r e . It is yo u r wi n d o w

t o w h a t i s h a p p e n i n g i n th e s y s t e m .

• Onl y use hyd raulic c ylinde rs in a cou pled

s y s t e m . N e v e r u s e a c y l i n d e r w i t h

unconnected couplers. If the cylinder becomes

extremely overloaded, components can fail

catastrophically causing severe personal injury.

• BE S U R E SET U P IS STA B L E BE FO RE

LIFTING LOAD.

Cy l i n d e r s sh o u l d be pl a c e d on a fl a t

sur f ace that can supp ort the load . Where

applicab le, use a cylin der bas e for added

stability. Do not weld or otherwise modify the

cylinder to attach a base or other support.

• Avoid situations where loads are not directly

centered on the cylinder plunger. Off-center

loads produce considerable strain on cylinders

and plungers. In addition, the load may slip

or fall, causing potentially dangerous results.

• To avoid personal injury keep hands and feet away

from cylinder and work piece during operation.

• NEVER set the relief valve to a higher pressure

than the maximum rated pressure of the pump.

Higher settings may result in equipment damage

and/or personal injury. Do no remove relief valve.

• Do not handle pressurized hoses. Escaping oil

under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

• Avoid damaging hydraulic hose. Avoid sharp bends

and kinks when routing hydraulic hoses. Using a

bent or kinked hose will cause severe backpressure.

Sharp bends and kinks will internally damage the

house leading to premature hose failure.

• Do not drop heavy objects on hose.

A sharp impact may cause internal damage to hose

wire strands. Applying pressure to a damaged hose

may cause it to rupture.

• Do not lift hydraulic equipment by the hoses or

swivel couplers. Use the carrying handle or other

means of safe transport.

• Keep hydraulic equipment away from flames and

heat. Excessive heat will soften packing and seals,

resulting in fluid leaks. Heat also weakens hose

materials and packings. For optimum performance

do not expose equipment to temperatures of 150°F

or higher. Protect hoses and cylinders from weld

spatter.

• Immediately replace worn or damaged parts

genuine JACKCO parts. Standard grade parts

will break causing personal injury and property

damage. JACKCO parts are designed to fit

properly and withstand high loads.

• Hydraulic equipment must only be serviced by a

qualified hydraulic technician. For repair service,

contact JACKCO Inc. To protect your warranty, use

Page 3

INSTRUCTION

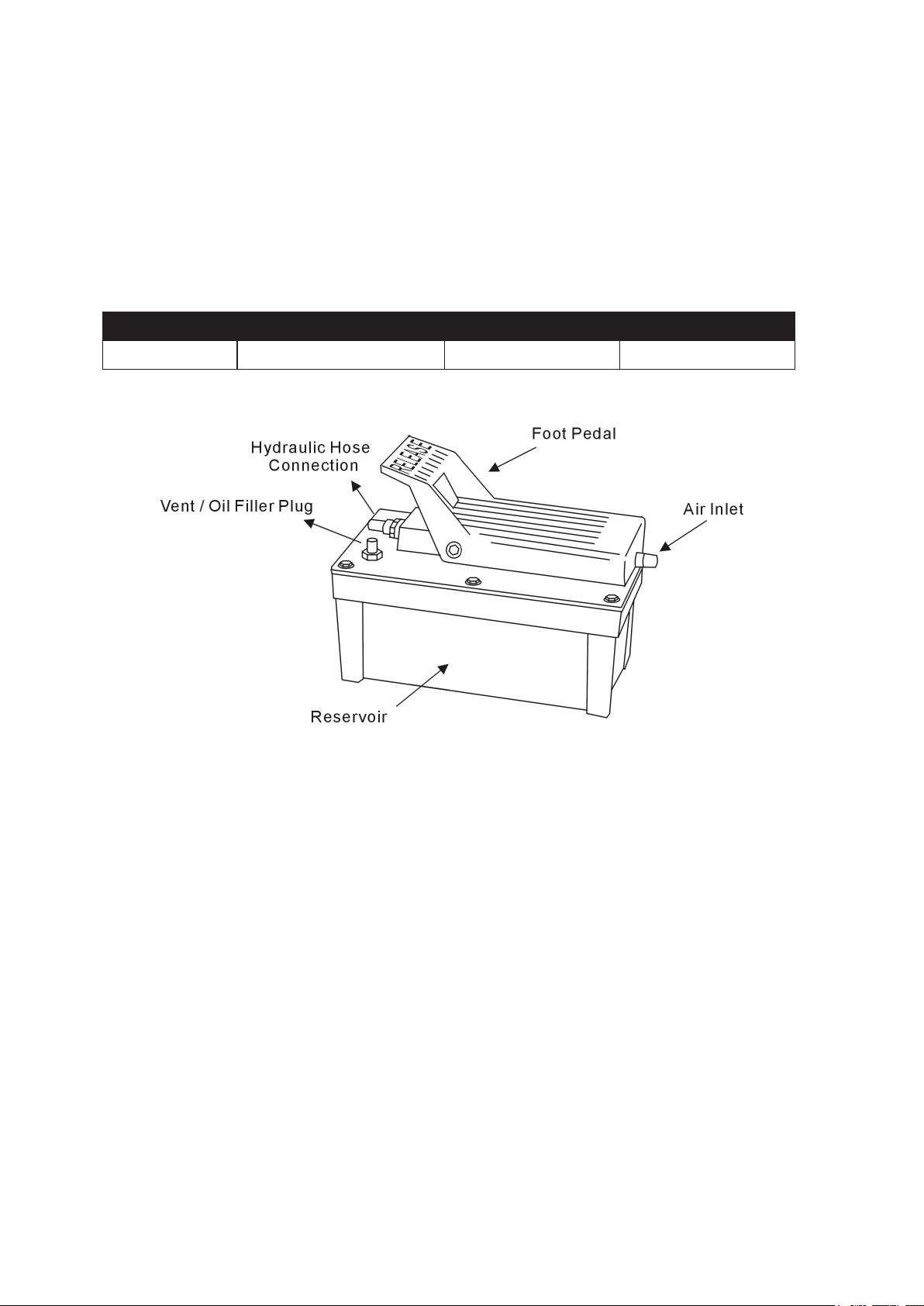

PRODUCT DESCRIPTION

-10,000 PSI AIR Hydraulic Pump designed to operate @90-120 PSI air source.

-This equipment allows quick displacement of hydraulic uid up to 1600 c.c/97 cu.in..

-Foot pedal design delivers a smooth, controllable flow to and from the intended

application.

SPECIFICATION

Capacity Pump Size (L x W x H) Usable Volume Oil Oil Outlet Size

10,000 PSI 10” x 5.6”x 8.3” 1600c.c./97 cu.in. 3/8 NPT

IMPORTANT

1. Check for leaks in the system and repair as needed. Before repairs are made, disconnect

air inlet and hydraulic connection, then depressurize reservoir. Do so simply by depressing

the pedal for a few seconds.

2. Replace worn / damaged parts and assemblies with original new parts.

3. Use adequate eye protection when operating or near this equipment.

4. Check connections before use.

OPERATION

1. Pull up the air-vent before use.

2. Connect to a hydraulic cylinder, then to air source of at least 100 PSI, and then depress

foot pedal slowly until motor starts to move.

3. Operate pump until desired position is reached. To stop, release pressure on the pedal.

4. To retract, simply press down on the “RELEASE” portion of the foot pedal.

Page 4

AIR REMOVAL

Removing air from the hydraulic system will help the cylinder to advance and retract smoothly.

Pump with Single-Acting Cylinder

• Position pump at higher elevation than cylinder.

• Position cylinder with plunger end down (up if using pull cylinder)

• Operate pump to fully extend the cylinder (retract if using pull cylinder)

• Depress release valve to retract cylinder (extend if a pull cylinder). This will force the trapped

air to move up to the pump reservoir.

• Repeat the above steps as necessary.

• Add oil if necessary.

• Return vent/ll cap to operating position.

How to ll the reservoir

1. Disconnect hydraulic coupler from application, remove air supply from pump.

2. Remove the vent /oil ller plug.

3. Fill reservoir to within ½ inch of the opening.

4. Wipe off any spilled uid and install oil ller plug.

NOTE:

Use only quality hydraulic fluid. Never use brake fluid, transmission fluid, motor oil

etc. Use of other than quality hydraulic oil will void the warranty and damage the

equipment.

AIR SUPPLY

• To obtain maximum performance and rated hydraulic pressure, air pressure should be 100 psi

minimum.

• To insure trouble-free performance, your air supply equipment should be equipped with an air

lter/dryer and the compressor tank should be drained of water everyday.

LUBRICATION

• To insure long service life, add a few drops of # 30 oil into the air inlet once a week.

MAINTENANCE

Use only recommended JACKCO hydraulic oil with theses pumps to promote long pump life and

protect your warranty. Contact your JACKCO representative for more information on these products

and their applications.

KEEPING OIL LINES CLEAN

When coupler halves are disconnected, always screw on dust caps. Use every precaution to guard

unit against entrance of dirt because foreign matter may cause pump, cylinder or valve failure.

CHANGING THE OIL

• Drain all oil and rell with clean JACKCO hydraulic oil every 12 months, if pump is used in dirty

environments, change the oil more often.

• Remove vent/ll cap or plug from reservoir

• Tilt pump to drain out old oil.

Page 5

TROUBLESHOOTING

Problem Possible Cause Solution

Cylinder does not

advance, advances

slowly, or advances in

spurts.

1. Oil level in pump reservoir is

low.

2. Release valve open.

3. Loose hydraulic coupler.

4. Load is too heavy.

5. Air trapped in system.

6. Cylinder plunger binding.

1. Add old according the maintenance

instructions.

2. Close the release valve.

3. Check that all couplers are fully tightened.

4. Do not attempt to lift more than rated

tonnage.

5. Remove air according to the instructions.

6. Check for damage to cylinder. Have

cylinder serviced by a qualified hydraulic

technician.

Cylinder advance,

but does not hold

pressure.

Cylinder does not

retract, retracts part

way, or retracts more

slowly than normal.

1. Leaking connection.

2. Leaking seals.

3. Internal leakage in pump.

1. Pump reservoir is over-lled

2. Loose hydraulic coupler.

3. Air trapped in system.

4.Cylinder retraction spring

broken or other cylinder

damage.

1. Check that all connections are tight and

leak free.

2. Locate leak(s) and have equipment

serviced by qualied hydraulic technician.

3. Have pump serviced b y a qualified

hydraulic technician.

1. Drain oil level to ll mark.

2. Check that all couplers are fully tightened.

3. Remove air according to the instructions.

4. Have cylinder serviced by a qualified

hydraulic technician.

Page 6

Model: 842 Parts List

Page 7

1

1

1

1

4

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

2

1

1

1

O-ring 1

Description Q'TY

60

Part #

1

Q'TY

Cup Seal

Description

Bolt M4

61 Air Valve Stem

62

1

Nut

Copper Ring 1

Spring

63

64 Air Valve Body

1

Spring

Back-up Ring 1

Plug 1

O-ring 1

65

66

1

1

Plunger

Cap Washer

O-ring 1

O-ring 1

Release

67 Bolt 3/16 x 32 L

68 Plastlook

69

70

71B

1

2

O-ring

Back-up Ring 2

1

Piston 1

O-ring

Mufer

Snap-Ring "C"

72

73

74

1

1

1

Spring

Seal Cap

Valve Stem

Reducer

75 Pump Base Right

76 Bolt 3/16 x 45 L

77

1

1

3

Seal Cap

Piston Gland

Bolt 3/16 x 13 L

Spindle

Hose Plug

78

79

1

1

Spring

Filler Plug-Breather

Release Seal(optional)

80 Snap-Ring "E"

81 Filler Plug

82 Filler Plug Seal

83

84

1

2

1

4

4

Stem

Bolt 1/4 x 4 L

Motor Body Gland

Gasket

Copper Ring

Release Clip(optional)

85

86

87

1

1

Base

Gasket 1

O-ring

Spring

Across Gasket

88

89

6

O-ring

Bolt 3/16 x 6 L 6

31

32

Part #

1

Q'TY

Description

01 Treadle

Part #

33

1

1

Packing

Reservoir

02

03

34

35

36

37

1

Pump Base

04

05 Set Screw 2

2

Spring 1

Bearing φ 7/32"

06

07

38 Stem

39

40

1

Spring Safety

09

Adjustment Bolt 1

10

Spring Safety Valve 1

08

41

42 Stem

43

1

Bearing φ 9/32"

11

1

O-ring 1

12

13 Check valve kit

44

43-1

1

1

Filter

Snap-Ring "C" R22

14

15

45

46

1

1

Spring

Spring Safety Valve

16

17

47

48 Motor Sleeve

49 Bolt 3/16 x 7L

50

51

1

Bearing φ 1/8"

18

Sleeve 1

19

1

Pin

20

1

1

O-ring

Piston Ring

21

22

52

53 Spring Washer 1/4

1

1

Spring

23 Return Valve

24

54

55

1

O-ring 3

Spring

25

26

56

57

58

59

2

1

Back-up Ring

Pump High Pressure

27

28

1

O-ring 1

Pump Cylinder

29

30

Page 8

LIMITED ONE YEAR WARRANTY

Jackco Transnational Inc. warrants all Jackco equipment and tools to the original purchaser against any manufacturing defect in material or workmanship for a period of one

(1) year from the original date of purchase. If the defective equipment or tool is determined to be covered under this warranty, it shall be repaired or replaced at manufacturer's

discretion without charge, provided that the equipment or tool must be returned with proof of purchase to the dealer and freight prepaid, if returned to the manufacturer. This

warranty shall not apply to damage due to accident, negligent use, and lack of maintenance, abu se or applications other t han the speci c function the equipment or tool is

designed for.

No other warranties, expressed or implied, including those of merchantability or tness for particular purpose shall be applicable to Jackco except as specically stated herein. In

no event shall Jackco be liable to any party for any special, direct, indirect, consequential, punitive damage of any nature caused by the sale or use of the equipment or tool.

Note: This warranty gives the original purchaser specic legal rights which may very from state to state.

Jackco Transnational Inc. © 2009

South El Monte, CA

888-452-2526 www.jackco.com

Loading...

Loading...