Page 1

MODEL 66500A /66510A

5 TON / 10 TON

AIR/HYDRAULIC

FLOOR JACK

USER'S MANUAL

*This hydraulic jack conforms to all "ANSI / ASME" safety standards.

Jackco Transnational Inc. © 2012

South El Monte, CA

888-452-2526

To see more jackco products please visit our website at www.jackco.com

Page 2

FOR YOUR SAFETY

• Read these safety instructions carefully and keep this manual in an easy to nd place as

you may need to use it again.

• Non-compliance with these rules may result in injury or damage to the jack or the vehicle.

• Do not modify the jack in any way.

• Never exceed the rated capacity of the jack.

• This jack is a lifting device only and should never be used to move the vehicle.

• The jack should be supported on a solid and level ground. Never use the jack in a surface

where it may sink into the ground.

• Ensure that there are no persons inside the vehicle to be lifted. Switch off the engine and

apply the brake.

• Position the jack under the manufacturer’s recommended lifting point for the vehicle. Offcentered loads can slip and accidents may result.

• During raising and lowering of the load, precautions should be taken to avoid movement

of the vehicle. Trafc may cause the raised vehicle to rock during roadside use of the

jack.

• Never work under a raised vehicle without supporting it with mechanical/jack stands.

• Never position any part of your body near the movable parts of the jack.

• Ensure that there are no persons or obstructions underneath the vehicle prior to lowering.

• Do not adjust the overload bypass valve under any circumstance.

Use wheel chocks appropriately

2

.

Page 3

SPECIFICATION

Capacity:

Max Height :

Min Height :

Capacity:

Max Height :

Min Height :

5 Ton

560 mm/ 22 inch

150 mm / 5.9 inch

10 Ton

560 mm / 22 inch

160 mm / 6.2 inch

Lifting Height :

Gross Weight

Net Weight :

Lifting Height :

Gross Weight

Net Weight :

SETUP

Assemble the handle

1. Loosen the bolt on the handle socket.

2. Insert the handle.

3. Tighten the bolt.

Bleed Air From the Service Jack

Air can accumulate within a hydraulic system during

shipment or after prolonged use. This entrapped air

causes the jack to respond slowly or feel “spongy”

To remover the air:

1. Open the release valve by turning the release knob

counterclockwise.

2. Pump the jack handle six full strokes.

3. Close the release valve by turning release know

clockwise.

4. If the jack does no immediately respond, respond,

repeat Steps1-3.

410 mm / 16.1 inch

106 kg/ 233 lbs

92 kg / 202 lbs

400 mm / 15.7 inch

156 kg / 343 lbs

139 kg / 306 lbs

OPERATING INSTRUCTION

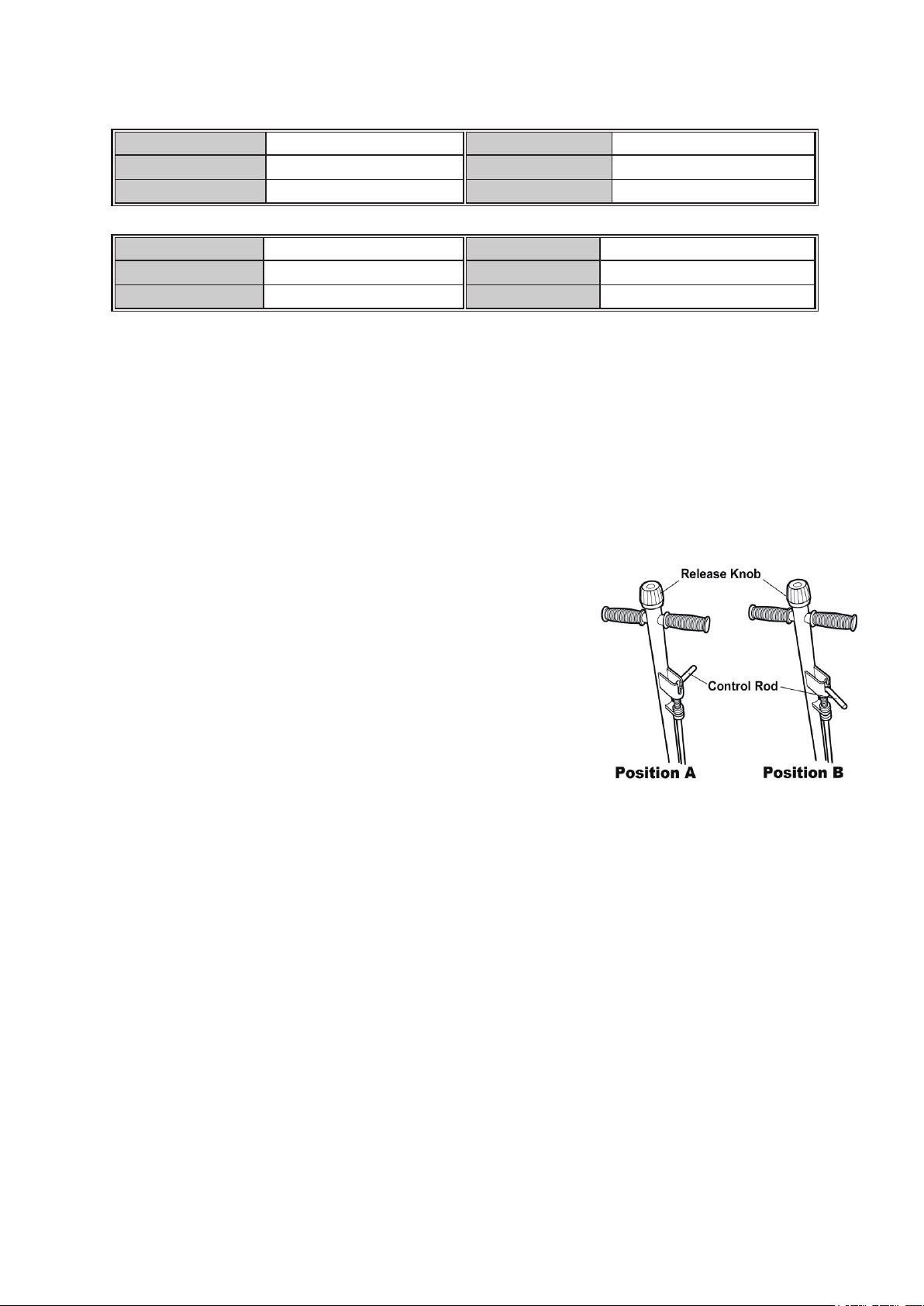

(

Refer to the illustration above

Control Rod in Position A: Allows you to pump the jack using the handle.

Control Rod in Position B: Locks the handle in place in three different positions.

1. Connect the shop air supply to the jack (shop air should be clean, dry and

regulated at 85-120 psi)

2. Turn release knob completely counterclockwise, and place the control rod in

position A.

3. Position the jack under the vehicle using the manufacture’s recommended lifting

points on the chassis. The jack must be free to roll without any obstructions while

lifting or lowering the vehicle. The wheels of the vehicle must be in the straightahead position, with the emergency brake released.

4. Turn the release knob on the jack completely clockwise. Operate the air valve,

pump the jack handle, or pump the food pedal until the saddle touches the

vehicle. Check the placement of the saddle lugs. Finish lifting the vehicle.

5. Place approved safety stands under the vehicle at points that will provide support.

Before working on the vehicle, SLOWLY lower the vehicle onto the safety stands

by turning the release knob counterclockwise.

)

3

Page 4

Preventive Maintenance

Important: Dirt is the greatest single cause of failure in hydraulic units. Keep the

service jack clean and well lubricated to prevent foreign matter from entering the

system. If the jack has been exposed to rain, snow, sand or grit, it must be cleaned

before it is used.

• Store the jack in a well-protected area where it will not be exposed to corrosive

vapors, abrasive dust, or any other harmful elements.

• Refer to the illustration, and regularly (at least once per month) lubricate the

moving parts shown.

• Add grease to upper arm grease nipple (shown) every three months.

• If necessary, add approved anti-wear hydraulic jack oil. Important: the use of

alcohol, hydraulic brake fluid, detergent motor oil, or transmission oil could

damage the seals and result in jack failure.

• Inspect the jack before each use. Take corrective action if any of the following

problems are found:

a. Cracked or damaged frame b. excessive wear , bending, or other damage

c. Leaking hydraulic uid d. Scored, damaged piston rod

e. Malfunctioning swivel heads or

adjusting screws

g. Modied or altered equipment

4

f. Loose hardware

Page 5

TROUBLESHOOTING

Caution: To prevent personal injury, all inspection, maintenance, and repair

procedures must be performed when the jack is free of load.

Trouble Cause Solution

Jack does not lift

1. Release valve is open

2. Low/ no oil in reservoir

3. Air-locked system

4. Load is above capacity of jack.

5. Delivery vale and/or bypass

valve not working correctly.

6. Packing worn out of defective.

7. Leak in air line

8. Inadequate air pressure.

Jack lifts only partially 1.too much or not enough oil 1.Check oil level

1. Close release valve.

2. Fill with oil and bleed system.

3. Bleed system.

4. Use correct equipment.

5. Clean to remove dirt or foreign

matter. Replace oil.

6. Install seal kit.

7. Locate leak; tighten

connections

8 Set air pressure to 85-120 psi

Jack advances slowly 1. Pump not working correctly.

2. Leaking seals.

Jack lifts load, but

doesn’t hold

1. Cylinder packing is leaking.

2.Valve not working correctly

(suction, delivery, release, or

bypass)

1. Install seal kit, or replace power

unit.

2. Install seal kit.

1. Install seal kit.

2. Inspect Calves. Clean and

repair seat surfaces.

3. Bleed system.

3. Air-locked system.

Jack leaks oil 1. worn or damaged seals 1. install seal kit

Jack Will not retrack 1. Release valve is closed 1.open or clean release valve.

Air motor won’t run or

runs erratically

1. Leak in air line.

2. Inadequate air pressure

3. Air piston is sticking

1. locate leak, tighten

connections, or replace hose.

2. Set air pressure to 85-120 psi.

3. Lube air motor by adding a

small amount of oil to jack’s air

inlet

5

Page 6

PARTS LIST

Page 7

Part No. Description Q’ty Part No. Description Q’ty Part No. Description Q’ty

2-2 Washer 2 3-6 Handle 1 4-24 O-ring 2

2-3 O-ring 1 3-7 Sleeve 2 4-25 O-ring 1

2-4 Piston rod 1 3-8 Knob 1 4-26 Rear cover 1

1-2 Front wheel 2 2-13 Ball seat 1 3-17 Convey Rod 1

1-1 Frame 1 2-12 Steel ball 1 3-16 Universal Joint ass’y 1

1-5 Grease tting 3 2-16 Sealing washer 1 4-1 Copper Washer 2

1-4 Snap ring 4 2-15 Screw 1 3-19 Pin 2

1-3 Washer 2 2-14 Spring 1 3-18 Washer 1

1-11 Spring 1 2-22 O-ring 1 4-7 Copper Washer 1

1-13 Bolt 1 2-24 Release valve rod 1 4-9 Bolt 8

1-12 Bolt 2 2-23 O-ring 1 4-8 Nut 1

1-10 Nut 2 2-21 Steel ball 1 4-6 Washer 1

1-16 Rear wheel 2 2-27 Oil valve body 1 4-12 Air pump housing 1

1-14 Snap ring 2 2-25 Pin 1 4-10 Front cover 1

1-17 Nut 4 2-28 Nylon gasket 1 4-13 Nut 1

1-15 Shaft 1 2-26 Copper washer 2 4-11 Steel ball 4

1-20 Washer 1 2-31 Washer 2 4-16 Cylinder pump plunger 1

1-19 Shaft 1 2-30 O-ring 2 4-15 Washer 1

1-18 Snap ring 2 2-29 Cylinder pump 1 4-14 Spring 1

1-23 Spring 1 3-1 Handle socket 1 4-19 Air release rod 1

1-22 Connection bar 1 2-33 Cylinder Pump Plunger 1 4-18 O-ring 1

1-21 Pin 1 2-32 Pin 1 4-17 Piston body A 1

1-24 Snap ring 2 3-2 Pedal 1 4-20 O-ring 2

1-9 Lock washer 2 2-20 Bolt 1 4-5 Oil seal 1

1-7 Bolt 2 2-18 Steel ball 1 4-3 Nylon gasket 1

1-8 Saddle 1 2-19 Copper washer 1 4-4 Pump cylinder 1

1-6 Rod link 2 2-17 Bolt 1 4-2 Oil Valve Body 1

2-1 Snap ring 1 3-5 Bolt 1 4-23 Air seal 1

1-26 Cover board 1 3-4 Washer 1 4-22 Bolt 3

1-25 Shaft 1 3-3 Nut 1 4-21 Piston body B 1

2-5 Piston ring 1 3-9 Pin 1 4-27 Snap ring 1

2-6 Sealing washer 1 3-10 Control nod 1 4-28 Snap ring 1

2-9 Snap ring 1 3-13 Screw 3 4-31 O-ring 3

2-7 O-ring 1 3-11 Spring 1 4-29 O-ring 2

2-8 O-ring retainer 1 3-12 Washer 3 4-30 Air valve 1

2-11 Oil ller plug 1 3-15 Spring 1

2-10 Oil cylinder ass’y 1 3-14 Rod Joint 1 4-32 Nylon gasket 2

Page 8

LIMITED ONE YEAR WARRANTY

Jackco Transnational Inc. warrants all Jackco equipment and tools to the original purchaser against any manufacturing defect in material or

workmanship for a period of one (1) year from the original date of purchase. If the defective equipment or tool is determined to be covered under

this warranty, it shall be repaired or replaced at manufacturer's discretion without charge, provided that the equipment or tool must be returned

with proof of purchase to the dealer and freight prepaid, if returned to the manufacturer. This warranty shall not apply to damage due to accident,

negligent use, and lack of maintenance, abuse or applications other than the specic function the equipment or tool is designed for.

No other warranties, expressed or implied, including those of merchantability or tness for particular purpose shall be applicable to Jackco

except as specifically stated herein. In no event shall Jackco be liable to any party for any special, direct, indirect, consequential, punitive

damage of any nature caused by the sale or use of the equipment or tool.

Note: This warranty gives the original purchaser specic legal rights which may very from state to state.

Jackco Transnational Inc. © 2012

South El Monte, CA

888-452-2526 www.jackco.com

Loading...

Loading...