Page 1

MODEL 65300

3 TON LOW PROFILE

ALUMINUM FLOOR JACK

USER'S MANUAL

*This hydraulic jack conforms to all "ANSI / ASME" safety standards.

Jackco Transnational Inc. © 2010

South El Monte, CA

888-452-2526

To see more jackco products please visit our website at www.jackco.com

Page 2

FOR YOUR SAFETY

• Read these safety instructions carefully and keep this manual in an easy to nd place as

you may need to use it again.

• Non-compliance with these rules may result in injury or damage to the jack or the vehicle.

• Do not modify the jack in any way.

• Never exceed the rated capacity of the jack.

• This jack is a lifting device only and should never be used to move the vehicle.

• The jack should be supported on a solid and level ground. Never use the jack in a surface

where it may sink into the ground.

• Ensure that there are no persons inside the vehicle to be lifted. Switch off the engine and

apply the brake.

• Position the jack under the manufacturer’s recommended lifting point for the vehicle. Offcentered loads can slip and accidents may result.

• During raising and lowering of the load, precautions should be taken to avoid movement

of the vehicle. Trafc may cause the raised vehicle to rock during roadside use of the

jack.

• Never work under a raised vehicle without supporting it with mechanical/jack stands.

• Never position any part of your body near the movable parts of the jack.

• Ensure that there are no persons or obstructions underneath the vehicle prior to lowering.

• Do not adjust the overload bypass valve under any circumstance.

Use wheel chocks appropriately

2

.

Page 3

SPECIFICATION

Capacity: 3 tons Chassis Width: 13 in

Min Height : 3.75 in Saddle Diameter : 4.52 in

Max Height : 18.1 in Net Weight : 58 lbs

Length: 26.4 in

PRIOR TO OPERATION

Air may become trapped in the hydraulic system during transit.

To Purge Air

1.Insert the handle into the socket and secure it with the set screw provided.

2.Turn the handle counterclockwise until release valve is open, pump the jack several

times to purge the accumulated air in the system.

3.Turn the handle clockwise to close the release valve. The jack is now ready to use.

OPERATING INSTRUCTION

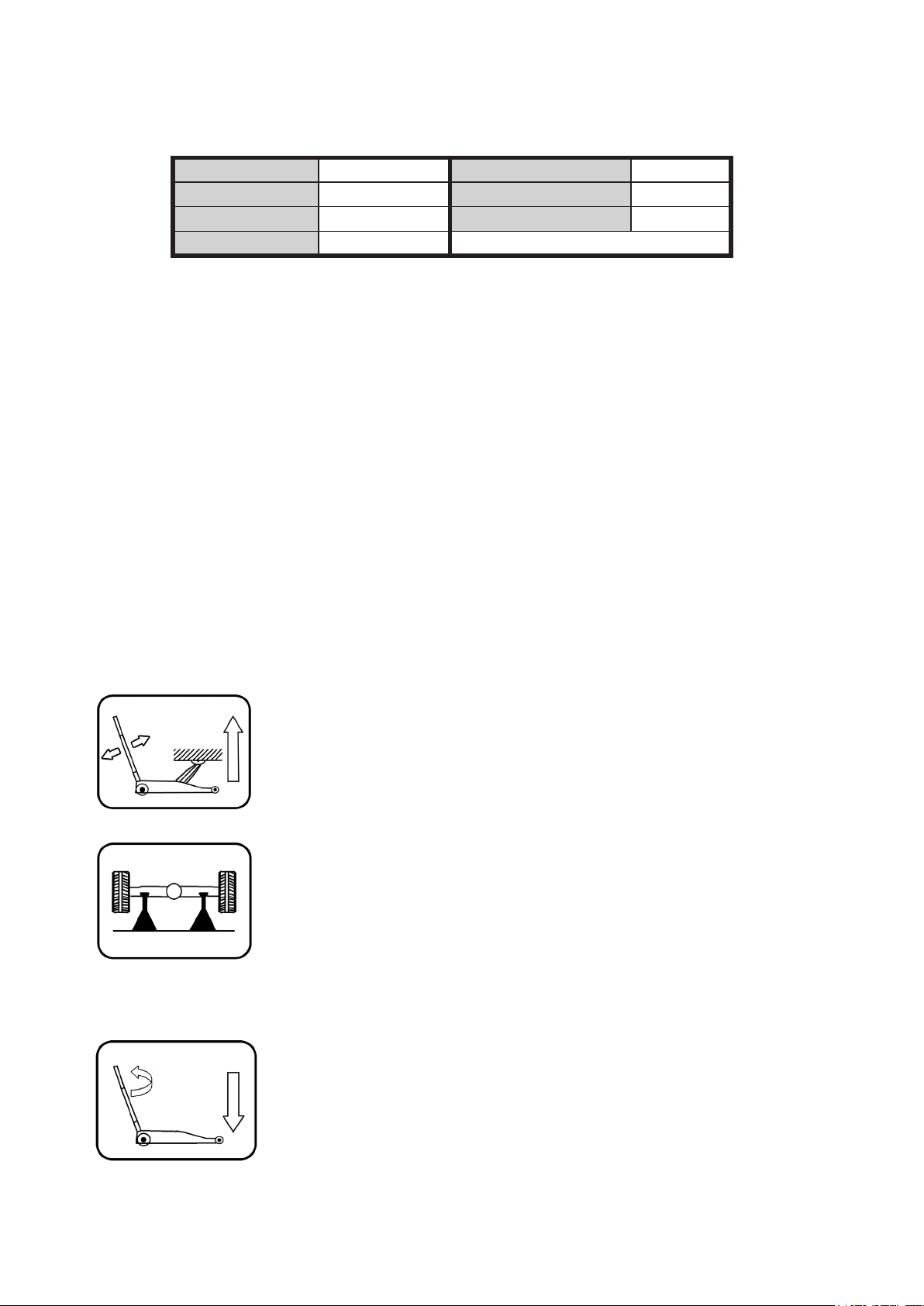

To Lift a Vehicle:

Turn the handle clockwise.

Move the handle up and down. Use the full stroke of the piston for

greater speed.

Support the vehicle with appropriate jack stands.

To Lower a vehicle:

Lift the vehicle to remove the jack stands, ensuring that there are

no persons or obstructions under the vehicle. Turn the handle

counter-clockwise.

3

Page 4

MAINTENANCE

Important:

Both the maintenance and repair of the jack may only be performed by

qualied persons, who have sufcient knowledge of the hydraulic system used in these

jacks

Regularly lubricate the moving parts in the wheels, arms, handle

and pump roller pin.

• Only original replacement parts should be used.

Extremely Important:

never use brake uid.

• When the jack is not in use, make sure the lifting arm is fully retracted to avoid

corrosion.

• Keep the jack in a clean, dry place and out of children’s reach.

• Replace the hydraulic fluid in the reservoir at least once a year. To check the

hydraulic uid level, lower the lifting arm completely.

• The hydraulic uid level should be just below the ller plug. Replenish if necessary,

and reinstall the rubber filler plug. Excessive hydraulic oil may render the jack

inoperative.

• Inspect the jack before each use. Take corrective action or remove the jack from

service if any of the following problems are found:

a. Cracked or damaged frame b. Leaking hydraulic uid

c. Scored, damaged piston rod d. Loose hardware

e. Modied equipment

• Keep warning labels and instructional decals clean and readable. You may use a

mild soap solution to wash external surfaces of the jack.

4

Page 5

TROUBLESHOOTING

Caution: To prevent personal injury, all inspection, maintenance, and repair

procedures must be performed when the jack is free of load.

Trouble Cause Solution

1.Release valve is open 1. Verify the release valve is

closed. Release valve may

need cleaning.

Jack does not lift

2.Low/no hydraulic uid in

reservoir

3. Air trapped in hydraulic system 3. Follow the purge air

4.Load is above capacity of jack 4. Use correct equipment

2. Fill with approved hydraulic

uid and bleed system

procedure

Jack lifts only partially

Jack advance slowly

Jack lifts load,

but doesn’t hold

5.Delivery valve and/or bypass

valve not working correctly

5. Clean to remove dirt or

foreign objects from the

system. Replace hydraulic

uid

6.Seals worn or defective 6.Replace seals

1.Too much or not enough

1. Check hydraulic uid level

hydraulic uid

1.Pump not working correctly 1.Rework pump

2.Seals leaking 2.Replace seals/O-rings

1.Cylinder packing is leaking 1.Replace packing

2.Valve not working

correctly(suction, delivery,

2.Inspect valves. Replace if

necessary

release, or bypass)

3. Air trapped in hydraulic system 3. follow the purge air

procedure

Jack leaks hydraulic

uid

Jack will not retract

1.Worn or damaged seals 1.Replace seals

1. Release valve is closed 1.Open the release valve by

turning the handle counterclockwise (CCW). Maybe

necessary to clean release

valve.

5

Page 6

PARTS LIST

Page 7

1 Saddle Pad 1 10 Rear Caster Assembly 2

Part No. Description Q'ty Part No. Description Q'ty

2 Saddle Screw 1 11 Nut M12 4

3 Saddle 1 12 Handle Yoke 1

4 Saddle Base 1 13 Handle Set Screw 1

5 Lift Arm Assembly 1 14 Handle, Upper Section 1

6 Radius Rod 2 15 Handle, Lower Section 1

7 Front Wheel 2 16 Handle Bumper 1

8 Carrying Handle 2 17 Tie Rod 1

9 Side Plate 2 18 Power Unit Assembly 1

Page 8

LIMITED ONE YEAR WARRANTY

Jackco Transnational Inc. warrants all Jackco equipment and tools to the original purchaser against any manufacturing defect in material or

workmanship for a period of one (1) year from the original date of purchase. If the defective equipment or tool is determined to be covered under

this warranty, it shall be repaired or replaced at manufacturer's discretion without charge, provided that the equipment or tool must be returned

with proof of purchase to the dealer and freight prepaid, if returned to the manufacturer. This warranty shall not apply to damage due to accident,

negligent use, and lack of maintenance, abuse or applications other than the specic function the equipment or tool is designed for.

No other warranties, expressed or implied, including those of merchantability or tness for particular purpose shall be applicable to Jackco

except as specifically stated herein. In no event shall Jackco be liable to any party for any special, direct, indirect, consequential, punitive

damage of any nature caused by the sale or use of the equipment or tool.

Note: This warranty gives the original purchaser specic legal rights which may very from state to state.

Jackco Transnational Inc. © 2009

South El Monte, CA

888-452-2526 www.jackco.com

Loading...

Loading...