ITC 5"" Variable Speed Random Orbit Sander, SPT180V Operator's Manual

PROD. NO. 011461

MOD. NO. SPT180V

5" Variable Speed Random Orbit Sander

Operator’s Manual (p.2)

Ponceuse orbitale de 5 po à vitesse variable

Guide d’utilisation (p.6)

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures,

and warranty. Put it and the original sales invoice in a safe, dry place for

future reference.

CONSERVEZ CE GUIDE

Vous aurez besoin de ce guide pour les instructions de sécurité, les

procédures d’utilisation et la garantie. Conservez-le dans un endroit sûr et

sec pour référence future.

v.081201

IMPORTANT SAFETY INSTRUCTIONS

!

WARNING! When using electric tools, machines or equipment, basic safety

precautions should always be followed to reduce the risk of re, electric

shock, and personal injury.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp,

wet, or poorly lit locations. Don’t expose your tool to rain. Keep the work area

well lit. Don’t use tools in the presence of ammable gases or liquids.

ENGLISH

3. KEEP CHILDREN AND BYSTANDERS AWAY. All children should be kept

away from the work area. Don’t let them handle machines, tools or extension

cords. Visitors can be a distraction and are difcult to protect from injury.

4. GROUNDED TOOLS must be plugged into an outlet that itself is properly

installed and grounded. Grounding provides a low-resistance path to carry

electricity to ground away from the operator, should the tool malfunction electrically. Do not remove the grounding prong from the plug or alter the plug in

any way. If in doubt as to whether the outlet is properly grounded according

to code, check with a qualied electrician.

5. OBSERVE PROPER PRECAUTIONS REGARDING DOUBLE INSULATION. This tool is double insulated. It is equipped with a polarized plug. One

blade is wider than the other, so it will t into a polarized outlet only one way.

If you have difculty inserting the plug, try reversing it. If it still doesn’t t, do

not alter the plug; have a qualied electrician install a polarized outlet.

6. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures. When your

body is grounded the risk of electric shock increases. When working

wherever “live” electrical wires may be encountered, try to ascertain whether

there is a danger of shock. Even so, DO NOT TOUCH ANY METAL PARTS

FRANÇAIS

OF THE TOOL while using it. Hold the tool only by the plastic grip to prevent

electric shock if you contact a live wire.

7. DO NOT ABUSE THE CORD. Never carry your tool by the power cord or

pull on the cord to unplug it. Protect the cord from potential sources of damage: heat, oil & solvents, sharp edges, or moving parts. Replace damaged

cords immediately.

8. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED EXTENSION

CORD. An extension cord rated for outdoor use must be marked “W-A” or

“W”.

9. DO NOT EXPOSE ELECTRICAL POWER TOOLS TO MOISTURE. Rain or

wet conditions can cause water to enter the tool and lead to electric shock.

10. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FOR ITS LENGTH.

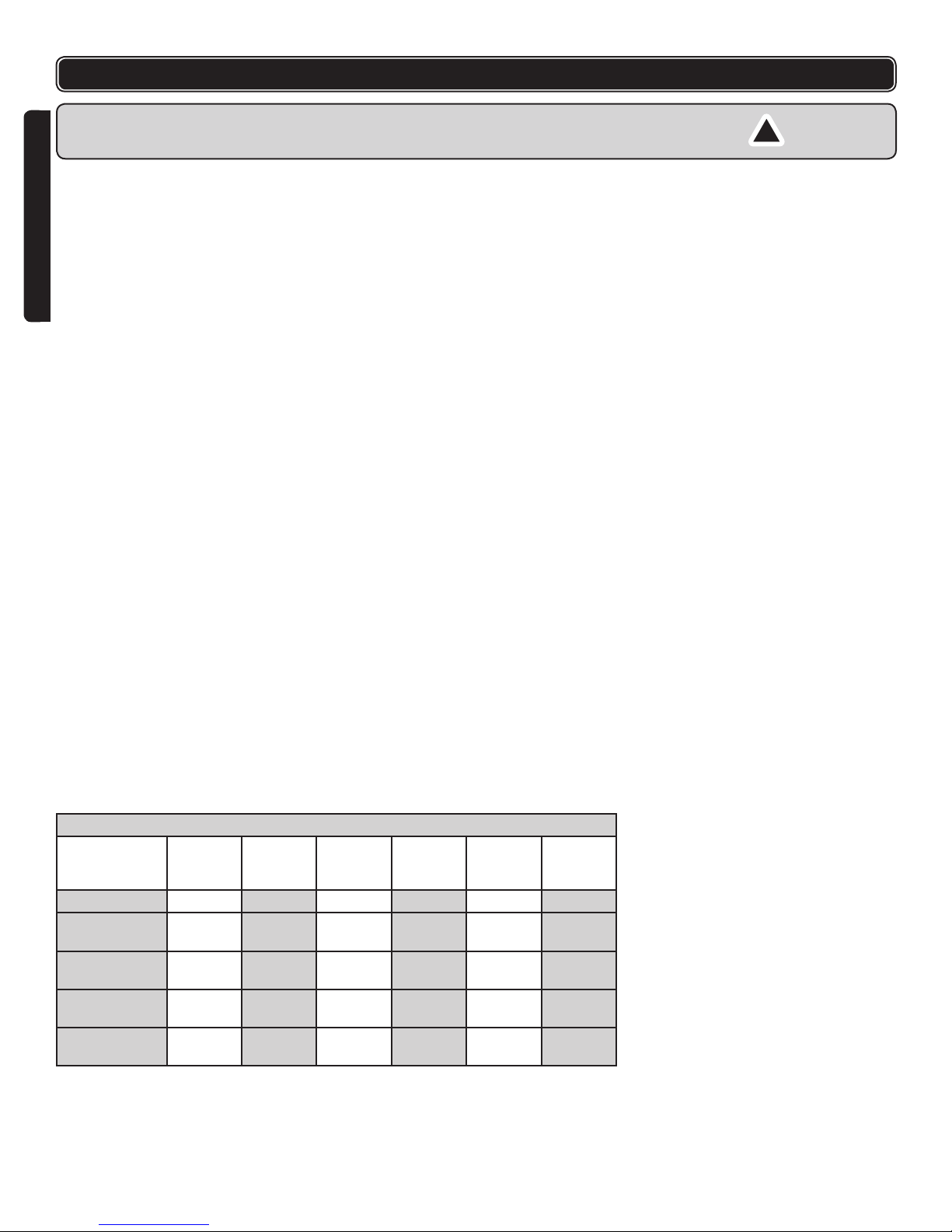

Recommended Minimum Wire Gauge for Extension Cords

Amps from

Tool

Nameplate

0 - 5 amps 16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

5.1 - 8 amps 16 ga. 16 ga. 14 ga. 12 ga. 10 ga. Do Not

8.1 - 12 amps 14 ga. 14 ga. 12 ga. 10 ga. Do Not

12.1 - 15 amps 12 ga. 12 ga. 10 ga. 10 ga. Do Not

15.1 - 20 amps 10 ga. 10 ga. 10 ga. Do Not

7.62 m

(25') long

15.24 m

(50') long

22.86 m

(75') long

30.48 m

(100')

long

Use

45.72 m

(150')

long

Use

Use

Do Not

Use

60.96 m

(200')

long

Use

Do Not

Use

Do Not

Use

Do Not

Use

11. STORE IDLE EQUIPMENT. Store equipment in a dry area to inhibit rust.

Equipment also should be in a high location or locked up to keep out of reach

of children.

12. DON’T FORCE THE TOOL. It will do the job better and more safely at the

rate for which it was intended.

2

IMPORTANT SAFETY INSTRUCTIONS

!

13. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the

work of a larger industrial tool. Don’t use a tool for a purpose for which it was

not intended.

14. DRESS PROPERLY. Don’t wear loose clothing or jewelry; they can be

caught in moving parts. Protective, non-electrically conductive gloves and

non-skid footwear are recommended when working. Wear protective hair

covering to contain long hair and keep it from harm.

15. USE EYE PROTECTION. Use a full-face mask if the work you’re doing

produces metal lings, dust or wood chips. Goggles are acceptable in other

situations. Wear a clean dust mask if the work involves creating a lot of ne

or coarse dust.

16. SECURE WORK. Use clamps or a vise to hold the work. It’s safer than using

your hands and it frees both hands to operate the tool.

17. DON’T OVERREACH. Keep proper footing and balance at all times. Do not

reach over or across machines that are running.

18. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and safe performance.

Follow instructions for lubricating and changing accessories. Keep handles

dry, clean and free from oil and grease.

19. AVOID UNINTENTIONAL STARTING. Be sure the switch is in the OFF posi-

tion before plugging in.

20. ALWAYS CHECK AND MAKE SURE TO REMOVE ANY ADJUSTING

KEYS OR WRENCHES before turning the tool on. Left attached, these parts

can y off a rotating part and result in personal injury.

21. DO NOT USE THE TOOL IF IT CANNOT BE SWITCHED ON OR OFF.

Have your tool repaired before using it.

22. DISCONNNECT THE PLUG FROM POWER BEFORE MAKING ANY

ADJUSTMENTS. Changing attachments or accessories can be dangerous if

the tool could accidentally start.

23. STAY ALERT. Watch what you are doing & use common sense. Don’t oper-

ate any tool when you are tired.

24. CHECK FOR DAMAGED PARTS. Before using this tool, any part that is

damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mountings, and other conditions

that may affect its operation. Inspect screws and tighten any ones that are

loose. Any part that is damaged should be properly repaired or replaced by

an authorized service centre unless otherwise indicated elsewhere in the instruction manual. Have defective switches replaced by an authorized service

centre. Don’t use the tool if switch does not turn it on and off properly.

25. REPLACEMENT PARTS. When servicing, use only identical replacement

parts.

26. SERVICE AND REPAIRS should be made by qualied repair technicians at

an authorized repair centre. Improperly repaired tools could cause serious

shock or injury

ENGLISH

FRANÇAIS

SAFETY PRECAUTIONS FOR RANDOM ORBIT SANDER

= ALWAYS CHECK THE SPEED RATING OF ACCESSORIES. This tool will

spin accessories at 12,000 rpm. Accessories not rated for speeds this high

will very likely y apart and could cause serious injury.

WARNING! The warnings, cautions and instructions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator that common sense and caution are

factors which cannot be built into this product, but must be supplied by the

operator.

v.081201 3

SPECIFICATIONS

Your new ITC SPT180V comprises:

5" Variable Speed Random Orbital Sander

Dust bag

Sandpaper disc

=Voltage:120 volts AC, 60Hz.

=Current rating: 2.5 amps

=Variable speed: 4,000 - 12,000 OPM (Oscillations Per Minute)

The 5" Variable Speed Random Orbital Sander is designed for sanding and

ENGLISH

polishing a variety of materials. Its high speed allows fast material removal while

sanding and the random orbiting feature virtually eliminates the swirl marks

usually left by rotating sanders.

OPERATING PROCEDURES

SANDING DISCS

Your 5" Variable Speed Random Orbital Sander is designed to accept only

5" (125 mm) diameter hook and loop sanding discs with a pattern of 8 dust

collection holes (similar to those used by Makita™ sanders). The dust collection

holes allow sanding dust to be picked up and collected in the dust bag, reducing

the amount of material that collects between the grit particles of the sandpaper.

This extends the useful life of the sanding discs. Check also for any damage to

an abrasive disc before you install it.

CONTROL THE DUST IN THE WORKPLACE

=At the back of your sander, you can attach a dust collector hose, or if not

available, the supplied dust bag can be used.

FRANÇAIS

=Empty the bag whenever it is half full.

=The dust bag slides onto the extraction port at the back of the tool. There is

an L-shaped locking slot on the bottom of the dust bag’s plastic opening.

=Slide this slot over the small peg on the bottom of the dust port and twist the

bag counterclockwise slightly to secure it.

INSTALLING A SANDPAPER DISC

1. Unplug the sander.

2. Turn the tool upside down.

3. Place the paper, fuzzy side down on the sanding pad so that the holes in the

paper align with the dust extraction holes on the pad.

4. Press down on the paper rmly so the hooks in the pad engage the loops in

the fuzzy backing of the paper.

5. When removing paper do so slowly and gently. Tearing the paper off quickly

can shorten the life of the small plastic hooks on the sanding pad and result

in the sandpaper discs falling off in use.

RUNNING THE SPT180V

1. Plug in the tool.

2. Hold the tool rmly.

3. Check to make sure the abrasive disc is not obstructed.

4. While the tool is off the surface, press the switch on the front of the machine

with your index nger. Switching the tool on or off under load may damage it

and will cause excessive swirl markings on the workpiece.

5. Gently lower the sander onto the surface.

MAINTENANCE

= Keep the vents clear of dust and debris. This will help prevent possible

electrical shorts and ensure proper cooling.

= Keep the tool housing clean and free of oil and grease using mild soap and a

damp (not wet) cloth.

4

Loading...

Loading...