Page 1

JUMP TO:

Trouble Shooting

Warnings

Basic Diagnostics

Repairs

Maintenance

Wiring Diagram

LPEFI

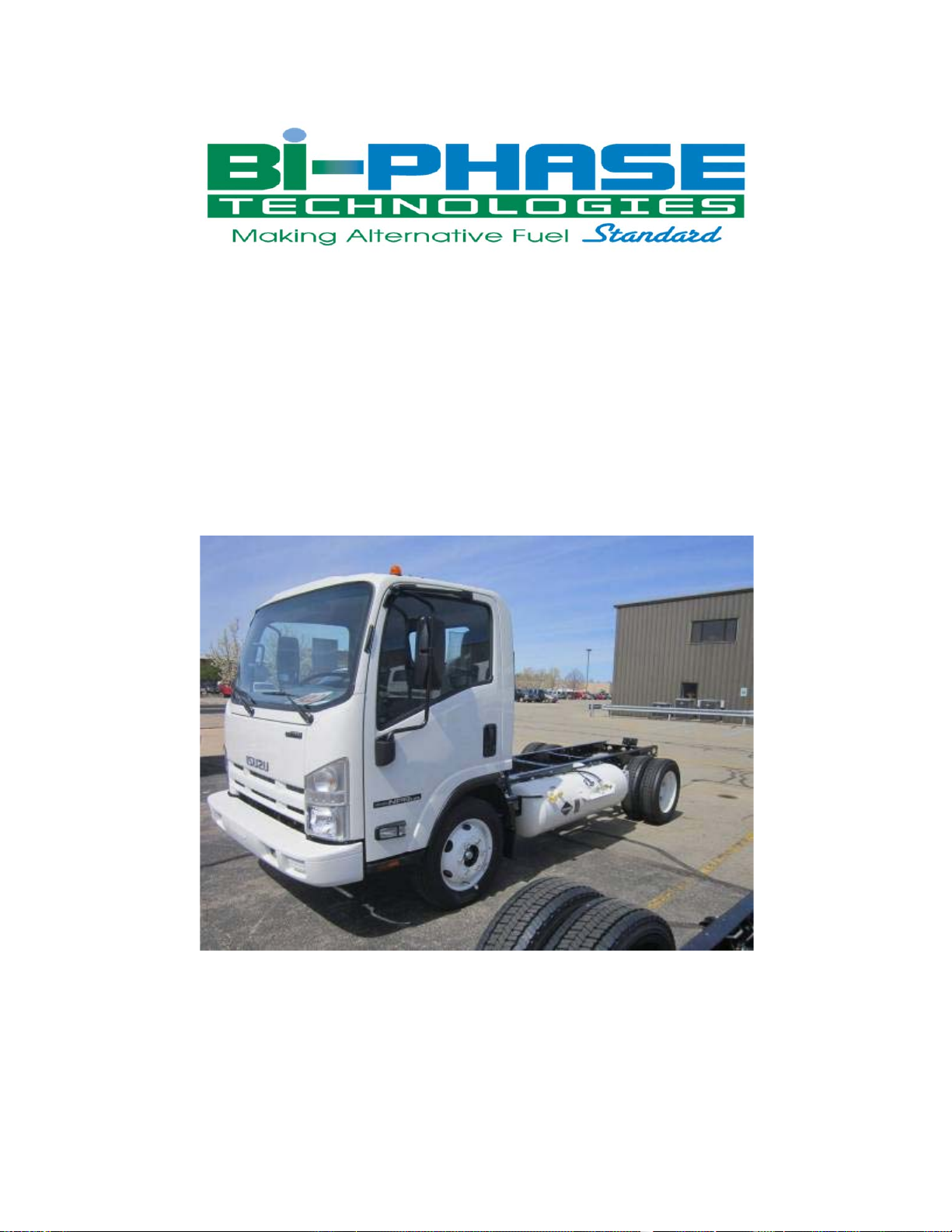

General Diagnostic Manual

2012 Isuzu NPR Trucks with 6.0 Liter Engine

Mono-Rail System

(Trinity Industries Tank Design)

October, 2012

Manual # M4-121-Isuzu

Bi-Phase Technologies, LLC

Eagan, Minnesota, U.S.A.

Page 2

This manual is for general diagnosis that applies to any LPEFI

system installed on any

vehicle. Where there is a difference in components or installation, it will be identified by

specific vehicle. The theory and diagnostics for the system are the same for any vehicle

that the system might be installed on. However, the system is calibrated to a specific

vehicle and some components, specifically injectors, cannot be interchanged.

In this manual you will find different approaches to diagnostics and troubleshooting. We

will reference specific OEM repair manuals where a technician may need to obtain the

OEM manual to complete the diagnostics. In many cases, the propane injection system

may not be the fault and further investigation of the engine control system may be

required. Remember the basics when troubleshooting. To prevent the replacement of

good components it is necessary to have a general knowledge of both the LPEFI

system

and the vehicle.

“Read all instructions before use to avoid injury”

Anyone who performs repairs to the LPEFI

system must be trained and

certified. This is a propane system and anyone who performs repairs must

have knowledge of Liquefied Petroleum Gases and understand safe

handling and characteristics of such. Some states may require a license to

work on propane vehicles. Consult your state or local authorities or your

state propane gas association. Bi-Phase Technologies is not responsible

for your oversight to comply with federal, state or local laws regulating

the installation or repair of propane gas systems.

The LPEFI

system is a sequential multi-port fuel injection system that injects propane in

a liquid state to the engine. It works the same way as a modern sequential multi-port

gasoline fuel injection system and can be diagnosed with the same diagnostic scanners

used for gasoline vehicles.

The LPEFI system is covered by U.S. and International patents. The LPEFI

system is

also certified to the United States E.P.A. standards.

The information in this manual is believed to be accurate as of its date of publication but

it is subject to change. Up-to-date information and changes, if any, can be requested

from Bi-Phase Technologies.

In the event of any safety-related changes, Bi-Phase Technologies will notify all

customers who returned the warranty registration card for the affected vehicles.

1

Page 3

2

TABLE OF CONTENTS

PropaneSafetyWarnings...................................................................................................................4‐5

FactsaboutPropane&PropanePoweredVehicles................................................................................6

ApproximatePropertiesofLPGases......................................................................................................7

Theory&Operation...........................................................................................................................8‐9

BasicDiagnostics............................................................................................................................10‐15

Checking&ReleasingFuelPressure..........................................................................................11‐12,21‐25

CheckingFuelLines.............................................................................................................................13‐14

CheckingFuelInjectors.......................................................................................................................14‐15

Electron

3SwitchBoxAmperageTestSpecifications..........................................................................................21

PressureTestingtheLPEFI

LPEFI

TroubleshootingbySymptom.........................................................................................................26‐33

icEn

gineManagement......................................................................................................16‐20

®

system(FlowChart)..............................................................................22‐24

®

PurgeLogic................................................................................................................................25

RepairProcedures..........................................................................................................................34‐53

Injectors..............................................................................................................................................35‐37

LPDM...................................................................................................................................................38‐44

FuelPump.............................................................................................................................................39

FuelLines...................................................................................................................................................45

TankControlBox(PurgeBox)...................................................................................................................46

Purgingthetank..................................................................................................................................47‐49

Drain/Evacuatingthetank..................................................................................................................50‐53

Mainte

SendingUnitValues............................................................................................................................55

WiringDiagram…………………………………………………………………………………………………………………………………60

Tank&HoseConfigurations...........................................................................................................61‐62

ServiceTools.......................................................................................................................................63

nance...............................................................................................................................

...54‐59

Page 4

Bi‐PhaseTechnologies,LLC

Page left blank for notes

3

Page 5

Bi-Phase Technologies

LPEFI Propane Safety

4

This is a safety alert symbol. It is used throughout this manual to alert you to

potential hazards. Whenever you see this symbol, you should read and obey the safety

warnings that follow. Failure to obey these warnings could result in serious personal

injury or property damage.

Warning: Never loosen fittings or vent any propane. Escaping

propane can cause frostbite and severe freeze burns. Wear

insulated PVC rubber gloves resistant to propane. Goggles

for protection against accidental release of pressurized

products and thermal protective clothing when handling

refrigerated liquids.

Propane is stored as a liquid. When you release liquid propane, it tries to evaporate as

quickly as it can, by absorbing heat from its surroundings. Everything it touches gets

chilled to -44 degrees F (-42 degrees C). If liquid propane sprays on your skin, it will

freeze it. Anyone who works with liquid propane must wear PVC insulated rubber

gloves.

Danger: Do not remove any valves, bulkheads, or fittings from a

tank unless the tank has been drained completely. The

pressure inside a propane tank can push a loosened

bulkhead or valve out with enough force to cause injury or

death.

Propane is stored under pressure. When you remove a valve or bulkhead from the tank, all

of the pressure is released at once in a violent rush. Always drain the tank before you work

on it. Failure to do this will result in damage to the tank or valves and can result in severe

injury or death. You should drain the tank by the fuel transfer method and/or by using a

flare stack in an approved safe manner. Your propane supplier can help you with this.

_______________________________________________________________________

Page 6

Bi-Phase Technologies

LPEFI Propane Safety

_______________________________________________________________________

Warning: Keep all sources of ignition away from propane vehicles

while the fuel system is being serviced. Even if the tank

and fuel lines are empty, there may still be flammable

vapors near the vehicle.

Do not allow smoking, sparks, flames, recent or running vehicles or other sources of

ignition when fueling, servicing and vented propane. Failure to do this could result in

fire or explosion, causing severe property damage, injury or death.

_______________________________________________________________________

Warning: Do not disconnect any propane hoses unless they have been

properly drained completely.

Propane in the hoses is kept under pressure, even when the engine is off. When you

disconnect a hose; the internal pressure is released all at once. Always drain the fuel

lines before you disconnect them. Failure to do this can result in damage to the hose

fitting and possible injury. See repair procedures in this manual for instructions.

________________________________________________________________ _______

5

Danger: Do not vent or release propane indoors or near sewers, pits

or low lying areas. Propane can accumulate in low spots,

creating a fire hazard. Propane can also displace oxygen,

creating a suffocation hazard.

Propane is heavier than air. It can fill low, sheltered areas with flammable vapors. If

these vapors are ignited, they can create a fire or explosion, causing severe property

damage, injury or death. Never release propane near sewers, pits or indoors.

_______________________________________________________________________

Page 7

Bi-Phase Technologies

LPEFI Facts about Propane & Propane Powered Vehicles

Propane gas is the most widely used alternative fuel, with nearly 4 million vehicles

worldwide running on propane. More than 350,000 vehicles run on propane in the U.S.

according to the U.S. Department of Energy’s Alternative Fuels Data Center.

Propane powered vehicles offer the best combination of durability, performance and

driving range.

The first propane powered vehicle ran in 1913.

Bi-Phase Technologies’ LPEFI

(Liquid Propane Electronic Fuel Injection) system has

surpassed other technologies today by introducing liquid fuel injection. This technology

improves power, efficiency and operating characteristics. For more information, call for

our General Information and Training Manual.

Safety comes first is a motto you should always live by. Without knowledge of a

product, it is hard to follow this motto. In our manuals we try to stress the need for

knowledge and provide warning signs to alert you.

It is your responsibility to know the law. National Fire Protection Association (NFPA)

has manuals to help you understand safe handling of many products. We recommend

that you obtain and read their NFPA #58, Standard for the Storage and Handling of

Liquefied Petroleum Gases.

A number of training programs and efforts have been implemented throughout the

country. The National Propane Gas Association has developed a Certified Employee

Training Program (CETP), which provides service personnel with a complete technical

training curriculum. We encourage you to contact your state propane gas association or

the National Propane Gas Association for more information on how you can benefit from

such programs. Visit www.propanesafety.com or www.npga.org for more information.

6

Page 8

Bi-Phase Technologies

LPEFI Approximate Properties of LP Gases

(Commercial Propane)

C

3H8

Specific gravity of liquid (water = 1) at 60 degrees F. 0.504

Initial boiling point at 14.7 psia, in degrees F. - 44.0

Weight in pounds per gallon of liquid at 60 degrees F. 4.24

Cubic ft. of vapor per gallon at 60 degrees F. 36.38

Cubic ft. of vapor per pound at 60 degrees F. 8.66

Specific gravity of vapor (air = 1) at 60 degrees F. 1.50

Ignition temperature in air, in degrees F. 920 to 1120

Maximum flame temperature in air, in degrees F. 3,595

Limits of flammability in air

Percent of vapor in air/gas mixture

Lower 2.15

Upper 9.60

Air/Fuel ratio by volume 15.6:1

Air/Fuel ratio by weight 24:1

Octane number as it relates to gasoline 98 to 102

Heating values

BTU per cubic foot 2,488

BTU per pound 21,548

BTU per gallon 91,500

Chemical formula C

Vapor pressure in psig

70 degrees F 127

100 degrees F 196

105 degrees F 210

3H8

7

Page 9

L

I

y

Bi-Phase Technologies

PEF

Theor

& Operation

Introduction

This article covers basic description and operation of the LPEFI system. Read this information before

diagnosing vehicles or systems with which you are not completely familiar.

The LPEFI System

The LPEFI

system is a direct replacement propane fuel injection system. It replaces the gasoline fuel

injection system and works the same as a gasoline fuel injection system with the exception it injects

propane, in a liquid state, into the intake port. The gasoline system electronic engine management stays the

same and controls the LPEFI

system just as it did the gasoline injection system. Onboard diagnostics

remain unchanged so the same scan tool and diagnostic approach remains equal to a gasoline system. The

only change in electronic engine management is the fuel enrichment strategy on start up. Gasoline needs a

very rich fuel mixture to start the engine and differs greatly based on outside ambient temperatures. With

propane this fuel enrichment requirement is much less, thus reducing the level of start up emissions

compared with gasoline. The LPEFI

system accomplishes this start up fuel enrichment strategy by

recalibrating the PCM for propane fuel enrichment.

The LPEFI

system consists of three main components: the tank, the fuel lines and the injectors. The tank

is located to the rear or middle of the vehicle and the lines are routed forward to the engine compartment

where the injector rail assemblies are mounted in the same position as the original gasoline injector rails

were installed.

The Tank (ASME design, 312.5 p.s.i. working/design pressure)

The fuel tank is the most complicated area of the system. It includes an internal electric fuel pump & filter,

fuel supply & return valves, baffle that keeps the pump submerged in liquid propane and various other

valves, fuel level float assembly, pressure relief valve, overfill prevention device, and liquid service valve.

LPEFI

fuel delivery to the injectors and an optional tank, which only transfers fuel to the main fuel tank based on

fuel level inputs to a transfer module. The main fuel tank fuel pump increases or boosts the tank pressure

by 35 to 50 psi. No matter what the propane tank internal pressure is, the pump boost remains the same.

This is how the propane stays a liquid throughout the liquid supply section of the system. The fuel is

supplied to the injectors and whether the injector is open or not fuel passes through a cooling bushing in the

injector and is returned to the tank. This is called a refrigeration cycle and also aids in maintaining the fuel

in a liquid state throughout the supply passageways in the system. Because propane easily vaporizes, when

the refrigeration cycle stops (when the engine is turned off) or if the return valve malfunctions closed, the

propane will vaporize and cause a loss in power or hard hot restarting. To help in hot restarting, the system

goes through a purge cycle for 10 to 15 seconds before every start up attempt. This strategy is built into the

system’s electronic tank control box. See more about hot restart/hot soak in this manual.

vehicles may have one or two tanks. If it is fitted with two tanks, a main tank, which controls all

8

Page 10

Bi-Phase Technologies

LPEFI Theory & Operation

The Fuel Lines

The fuel lines consist of two flexible hoses, one inside the other, in a concentric arrangement. The nylon

inner line supplies liquid propane to the injectors while the area between the outside of the inner line and

the larger outer hose is the fuel return passage.

The concentric fuel line design has a number of benefits:

1. Cuts the number of possible leak points in half,

2. Reduces vapor-lock in the supply line by using the return fuel passage as insulation,

3. Postpones the vapor-lock that occurs after a hot engine is shut off,

4. Shortens the purge cycle time needed to restart a hot engine.

The Injectors

The LPEFI

injectors that they replace. The injector electrical circuit resistance value is 13-15, similar to a gasoline

injector.

Each fuel injector has a supply passage and a return passage. The fuel injector rails have the same

concentric design as the fuel lines. The passage in the injector from the supply section to the return section

is restricted by a cooling bushing. As liquid propane passes through the cooling bushing, a pressure

reduction takes place, which causes the propane to vaporize and effectively cools the area around the

supply section. This is called a refrigeration cycle and aids in maintaining the fuel in a liquid state for all

driving conditions, regardless of the outside temperature.

The injector delivers propane in a liquid state into the intake port. It vaporizes immediately upon exiting

the injector. This rapidly expanding liquid cools the incoming air to the engine often resulting in a little

more horsepower than the gasoline system could achieve, not to mention the inherently improved exhaust

emissions that propane is known for.

system injectors are designed specifically for liquid propane. They mimic the gasoline fuel

9

Page 11

L

I

g

10

Bi-Phase Technologies

PEF

Basic Dia

nostics

All Models

Introduction

The following diagnostic steps may help prevent overlooking a simple problem. The first step in

diagnosing any drive-ability problem is verifying the customer’s complaint with a test drive under the

conditions the problem reportedly occurred.

Always perform a careful and complete visual inspection first. Most engine control problems result from

mechanical breakdowns, poor electrical connections or damaged/misrouted vacuum hoses. Before

condemning the LPEFI

Visual Inspection

Visually inspect all electrical wiring, looking for chafed, stretched, cut or pinched wiring. Ensure electrical

connectors fit tightly and are not corroded. Visually inspect for any loose or drop harness looms coming in

contact with the injector rails or components. Visually inspect all vacuum hoses and ensure they are

properly routed – not pinched, cut or disconnected. Visually inspect the secondary ignition wires, spark

plugs and ignition coils. Ignition weakness shows up much sooner on propane fueled engines than a

gasoline engine. Visually inspect each, injector insulator housing for cracks, cuts or o-ring sealing at the

manifold or at the top o-ring of the insulator housing (injector repair in this manual). Listen to the fuel

pump operation and the opening “click” of the fuel supply valve. Initiate a purge cycle by turning the

ignition key to the on position (purge logic chart in this manual).

Preliminary Checks

Check that the following systems and components are in good condition and operating properly before

diagnosing problems in the LPEFI

1. Battery condition

2. State of tune (ignition system)

3. All wiring and vacuum connections

4. Air cleaner and ducting

5. Cooling system

Mechanical Inspection

system, perform each test listed in this article.

fuel system.

Warning: DO NOT use the ignition switch during compression test on fuel injected

vehicles. Use a remote starter to crank the engine. Fuel injectors on many models are triggered by

the ignition during cranking mode, which can cause a flammable fuel mixture in the intake manifold

when performing a compression test.

Compression – Check engine mechanical condition with a compression gauge, vacuum gauge or an engine

analyzer. Compression pressures are considered within specifications if the lowest reading cylinder is

within 75 percent of the highest reading cylinder.

Page 12

L

I

g

11

Bi-Phase Technologies

PEF

Basic Dia

nostics

Mechanical Inspection, cont’d

Exhaust system back pressure – The exhaust system can be checked with a vacuum or pressure gauge.

Remove the O

exhaust back pressure is greater than 1¾ to 2 psi., the exhaust system or catalytic converter is plugged. If a

vacuum gauge is used, connect the vacuum gauge hose to an intake manifold port and start the engine.

Observe the vacuum gauge. Open the throttle part way and hold steady. If the vacuum gauge reading

slowly drops after stabilizing, the exhaust system should be checked for a restriction. Also, if the vacuum

gauge will not drop below 3” Hg on a wide open throttle condition or WOT loaded condition, check the

exhaust system for restriction. Leaks in the exhaust system, if upstream from an O

fuel control problems due to oxygen dilution in the exhaust, which causes inaccurate O

sensor and connect a 0-5 psi pressure gauge. Run the engine at 2500 RPMs and if the

2

sensor, can also cause

2

sensor response.

2

Fuel System

Engine does not crank – Check for hydrostatic lock (water or liquid in a cylinder). Repair as needed.

Check for starting and charging system problems.

Engine cranks but will not start

1. Check fuel tank contents and fuel gauge accuracy

2. Check ignition system for good secondary current at the spark plugs – if no spark exists or if spark

is weak, repair ignition system problem first

3. Check fuel lines and fittings for leaks – if no leaks are found, check fuel delivery system for

proper pressure; check for +12 volts to fuel delivery system

4. Check for defective fuel injector; a leaking fuel injector could cause a rich (flooded) condition and

cause a no-start; initiate a purge cycle and after the purge cycle is complete listen at the intake

manifold for injector leaks; open the throttle plate, smell and listen, pull the PCV valve and smell

and listen, lift the injector rail out of the manifold (without disconnecting fuel line) and visually

inspect

5. Check the ECT, coolant temperature sensor – confirm the ECT is in proper working condition

and; if the sensor is faulty

Warning: Always relieve fuel pressure before disconnecting any fuel injection related

component. DO NOT allow uncontrolled fuel release. Never loosen fittings or vent any

propane unless you are wearing insulated PVC rubber gloves; escaping liquid propane can

cause frostbite and severe freeze burns. Do not disconnect any propane hoses or remove any

injectors unless the fuel lines have been properly drained completely. Never release fuel

indoors or in an area where vapors could accumulate – source of ignition could ignite the air

fuel mixture and cause severe injury and property damage.

Fuel Pressure Release

To prevent the fuel pump and fuel supply valve from opening during repair, disconnect battery and/or

electronic tank control box – always disconnect negative battery terminal first.

1. Remove the fuel system Schrader Valve cap on the LPDM

2. The fuel pressure test gauge has a long drain hose; route the drain hose to a flare stack or other

receptacle for flammable propane vapor; never release propane indoors

3. Install the brass collar from the fuel pressure test gauge to the Schrader Valve, with the grooved

end facing out

Page 13

L

I

g

12

Bi-Phase Technologies

PEF

Basic Dia

nostics

Fuel Pressure Release, cont’d

4. Make sure the small thumb valve next to the gauge on the Bi-Phase gauge set is closed

5. Connect the test gauge to the collar; this connection will press the center pin on the Schrader

Valve releasing propane into the hose; this is a sensitive connection and must be confirmed; if the

pressure gauge does not react or reacts slowly, push in on this connection to confirm it has

penetrated the center pin of the Schrader Valve; the brass collar has some adjustments and may

also require oiling the o-ring occasionally

6. Open the valve near the pressure gauge to drain the propane through the long hose; note that the

Schrader Valve does not drain the tank – it only drains the main fuel line and the injectors

7. When the gauge reads “0” and there is no pressure exiting the end of the hose, you may disconnect

the fuel lines or injectors as needed (more detailed procedures and photos on page 36)

Warning: Do not remove the LPDM or any tank valves from the tank at this time.

Propane tank is under pressure. The procedure described previously only drains the fuel

lines for service. Serious injury or death could occur.

Fuel Pressure

Internal tank pressure must be established first. Use the 3-switch diagnostic box from Bi-Phase

Technologies, turn on the fuel supply valve rocker switch and push the fuel return valve “push” switch.

Hold down the fuel return valve switch for 30 seconds or until fuel pressure stabilizes. This is internal tank

pressure. When checking fuel pressures over a given time always recheck internal tank pressure due to

changes in ambient temperature.

When diagnosing the system it is very important to consider this information as it affects the accuracy of

your diagnosis. Boost Pressure = 35 to 50 p.s.i. (pressure over internal tank pressure)

Fuel pressure with return valve open (all models) – With the return valve open or during a purge cycle

the fuel pressure will be 5 to 15 psi below normal operating pressure (internal tank pressure plus boost

pressure). Should the pressure drop more than 15 psi. evacuate the fuel in the fuel lines (reference the

procedures in this manual), remove the primary hose and inspect the white nylon inner liquid supply line in

the primary hose at the LPDM. It could require that you visually inspect all hoses for proper inner liquid

supply line length.

Fuel pressure should always be confirmed first. If fuel pressure is not within specification the system will

malfunction. Fuel pressure can cause many types of drive ability complaints.

Page 14

Bi-Phase Technologies

LPEFI Basic Diagnostics

13

Concentric Fuel Lines

As previously discussed, the fuel lines of the LPEFI

supply and fuel return to be accomplished inside one fuel hose. There are many benefits to this design as

mentioned in the theory section of this manual.

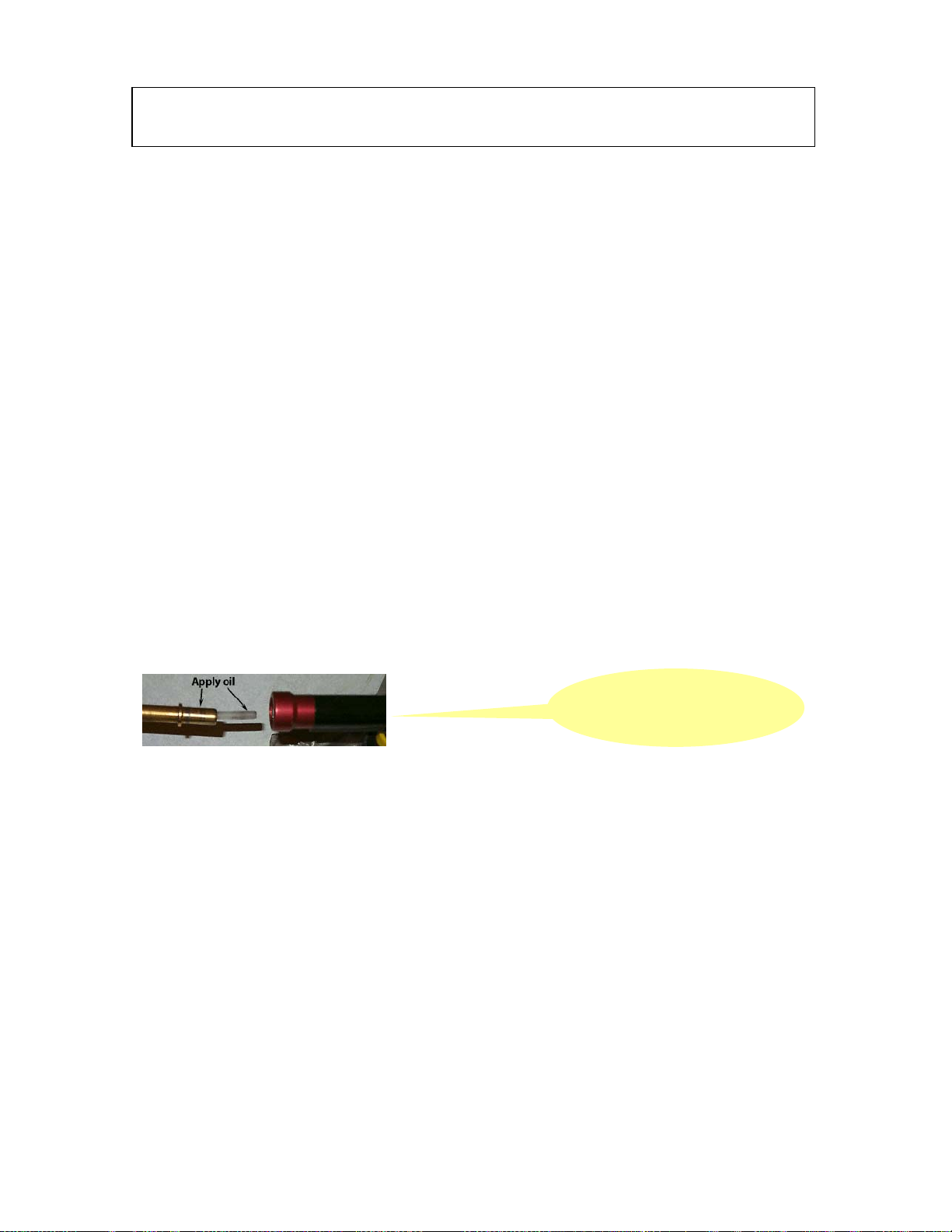

The sealing of the white nylon inner line to all the specific components of the system is very critical. If this

seal is lost, damaged or not made the vehicle will experience hard starting when hot, reduced power under

load, unbalanced injectors (rail to rail or bank to bank) and in extreme cases a no-start condition.

It is very difficult to install the lines and caution should be taken when assembling the concentric fuel lines

that connect from the LPDM and the injector rails. The inner lines are small and easily crimped (kinked)

during installation to the fuel rail. Also damage to the O ring seal in the rail may occur. It is recommended

to coat the metal hose end fitting and the white nylon inner line with clean motor oil before attempting

installation. If the white nylon inner line is crimped during installation or repair of the system a new hose

assembly must be obtained. The white nylon inner line is custom fit to each larger outer hose. Do not

assemble the hose with a crimped inner line; it will cause drive-ability problems. Years of process

development have caused the installation to be more difficult. However, at this time there is no other way

to rely on a proper fit and reliability.

Each white nylon inner line is sealed by a single o-ring located below the inner line alignment bushing

(finger bushing). This is found in each hose port whether it is the LPDM, or the injector rail end fitting.

See illustration below.

system are a concentric design. They permit fuel

Injector rail end fitting & hose

utilizing quick disconnect

much like gasoline

Page 15

Bi-Phase Technologies

LPEFI Basic Diagnostics

Fuel Injectors

Fuel Injector check

1. Connect a tachometer to the engine; run the engine at idle; disconnect and reconnect injectors

individually (this may also be accomplished with a scan tool); if each injector causes a momentary

drop in engine speed of at least 100 RPMs, injectors are giving proper fuel delivery; RPM drop

should only be momentary as the IAC (idle air control) will attempt to reestablish correct idle

RPM

2. Replace any injectors that do not cause sufficient drop in engine speed; when test is complete, turn

engine off; to check curb idle, refer to the emission control specification on the decal in the engine

compartment or the OEM service manual for the particular vehicle

3. With the system pressurized listen, smell, spray with leak detection fluid and visually inspect

injectors for fuel leaks from the injector tip and housing; open the throttle plate to listen and smell,

or without disconnecting the fuel lines lift the injector rail out of the intake manifold to visually

verify that no injector leaks fuel; if an injector sprays fuel or leaks externally without an electrical

demand, the injector must be replaced

4. The fuel injector housing is a heat insulator and is installed over the injector itself, even though it

may look as one piece; the injector insulator housing is sealed onto the injector with one or two

o-rings, depending on the design revision level of the injector; the early single o-ring sealed

injector housing may lose its seal causing a vacuum leak; an injector should hold a vacuum if

checked from the bottom of the housing with a hand operated vacuum pump (reference injector

repair in this manual)

5. The fuel injectors are calibrated for each specific engine; injectors are also assembled on each rail

within a specific range of flow; if an injector from a different engine family is installed it could

cause an out-of-balance situation and set a diagnostic trouble code in the PCM

Fuel injector circuit – Disconnect all injector harness connectors. Use a digital ohmmeter to check

resistance across the terminals of each injector. The nominal resistance for each injector is 12.6 to 13.8Ω.

An acceptable range is 12Ω to 15Ω, but not to exceed 2Ω between the lowest reading injector to the highest

reading injector. If there is greater than 2Ω difference, choose and replace the highest or lowest resistance

injector, whichever corresponds, to achieve a range inside 2Ω. If the resistance test proves an open circuit

the injector must be replaced. Refer to the OEM service manual and wiring diagram for more information

if the wiring harness is at fault.

Ignition Checks

(Note: On many newer vehicles if an ignition failure occurs, the ignition system may continue to operate

with limited ability. Diagnostic trouble codes should be present if this occurs and the engine may be hard

to start. The ignition timing will also be fixed or no change in timing with RPM or load changes.)

Initial Inspection

1. Visually inspect ignition system components and wiring for evidence of damage or loose

connections; check condition of spark plugs, spark plug wires and distributor cap and rotor (if

equipped); repair or replace damaged components

2. Ensure idle speed and ignition timing is correct; check all components that could affect ignition

timing; refer to OEM specifications

Crankshaft position sensor

Camshaft position sensor and/or sensor timing

Crankshaft end play

Timing belt or timing chain condition, worn timing gears, chain or belt can cause erratic

timing

MAP or MAF sensor signals

For more detailed information refer to the OEM repair manual

3. Ensure spark plug wires are properly connected and routed in correct firing order

14

Page 16

Bi-Phase Technologies

LPEFI Basic Diagnostics

Ignition Checks, cont’d

4. Check for spark – Disconnect a spark plug wire from a spark plug; connect a spark plug tester

between the spark plug wire and ground; crank engine and check for a strong consistent spark;

repeat test for each spark plug wire; if no spark is present check ignition coil primary wiring, coil

output or refer to OEM repair manual; if spark appears to be inconsistent do the same as

previously mentioned, but confirm the condition of the spark plug wire and repeat test; an ignition

scope analyzer is also recommended for checking ignition condition; an approved spark plug tester

must be used to prevent damage to ignition control components

5. Using a digital ohmmeter check the resistance of each spark plug wire; high tension wire

resistance should be 4000 to 7000Ω per foot; replace as necessary

6. Check power to coil – Disconnect primary wiring to coil/coils; turn on ignition and measure

voltage of primary positive voltage wire to coil connector; if less than 10 volts repair battery

condition or primary positive voltage wire

7. Check coil/coils – Disconnect coil, using a digital ohmmeter measure resistance of ignition coil

between primary wire terminals; measure resistance between ignition coil’s secondary terminals

and positive primary terminal; refer to appropriate OEM repair manual for exact resistance values

15

Page 17

Bi-Phase Technologies

LPEFI Electronic Engine Management

16

Introduction

The LPEFI

engines. The design intent was to allow direct replacement of the gasoline fuel system to the LPEFI

system was developed and designed for use on modern sequential fuel injected gasoline

system with no change in the original gasoline electronic engine control strategy or onboard diagnostics.

With this said, it is very important that a technician understands electronic engine management theory. In

this section we will not attempt to write the book on electronic engine control or self-diagnostics, but

briefly explain some theory and operation of the general idea of electronic engine management and some

areas that will help in the diagnosis of the LPEFI

system. For details on specific vehicles you should refer

to the OEM repair manuals.

Electronic Engine Management

Power-train control module – The PCM monitors engine operating conditions by input received from

engine sensors. Control output actuators supply the function of fuel supply, incoming air, timing, ignition,

EGR, evaporative emission control to provide the demanded operating condition the driver or the PCM

desires based on the inputs from the engine sensors. The implementation of electronic engine management

brought many benefits:

1. Improved exhaust emissions,

2. Improved power,

3. Improved fuel economy,

4. Improved durability & reliability, and

5. On-board self diagnostics.

Since the first generations of electronic engine management, about 1980, many improvements have been

made. Today all vehicle manufacturers comply with the standards of OBD II (on-board diagnostics second

generation). OBD II did drastically change the way electronic engine management is carried out but it did

not change the original input versus output control strategy. It did require that the names for sensors and

actuators used are common from manufacturer to manufacturer, the same data link connector be used and a

generic list of trouble codes and data are retrievable by aftermarket diagnostic scan tools. In addition, more

monitors were added to track degradation of emission control components and warning flags that would

turn on the malfunction indicator lamp for things like cylinder misfire or catalytic converter failure.

Manufacturers began implementation of OBD II as early as 1994 on select vehicles with a goal to be

completed with light duty trucks by 1996. Today, they are still adding to it and implementing it on heavier

vehicles.

The engine control system consists of the PCM, relays, modules, sensors, switches and actuators. The

PCM sends out electrical reference signals to engine sensors and then analyzes the return signals. The

engine sensors supply specific information to the PCM, in the form of electrical signals, to determine

engine operating conditions.

In the event of a sensor or actuator failure, the PCM initiates an alternative strategy or failure mode to

allow the vehicle to maintain drive ability. In the event of PCM failure a limited operating strategy will be

activated. This provides minimal engine operation and any self-test or feedback systems will stop. The

malfunction indicator lamp will come on and stay on until the vehicle is repaired or until the PCM has

determined that all signals have returned within operating limits and then the PCM will resume normal

operation.

Vehicles are equipped with different combinations of input devices. Not all devices are used on all models.

To determine the input devices used on a specific model refer to the appropriate OEM repair manual and

wiring diagrams.

Page 18

Bi-Phase Technologies

LPEFI Electronic Engine Management

17

Electronic Engine Management, cont’d

Some common input devices

Crankshaft position sensor

Camshaft position sensor

Engine coolant temperature sensor

Inlet air temperature sensor

Oxygen sensor

Throttle position sensor

Mass air flow sensor

Manifold absolute pressure sensor

Vehicle speed sensor

EGR position sensor

Knock sensor

Output signals are signals that send a demand to an actuator; some common actuators

Fuel injectors

Fuel pump

Idle air control or idle speed control

EGR control

Canister purge control solenoid

Spark control

MIL (malfunction indicator lamp)

Transmission controls

There are many more inputs and outputs, these are some common ones. Vehicles are equipped with

different combinations of computer-controlled components. Not all vehicles are equipped with the same

components. Always refer to the specific OEM repair manuals and information.

Self-Diagnostics

With the capability to see data through the use of a scan tool and to verify areas of trouble by checking for

diagnostic trouble codes, today’s electronics have given us more ways to verify where and what the

problem might be. Each vehicle manufacturer has written steps in troubleshooting a vehicle. If the scan

tool leads you to a specific trouble area refer to the OEM written test to troubleshoot accurately. Some

aftermarket manuals are very good in diagnosing electronic engine controls.

To prevent the replacement of good components and wasting precious time, verify engine condition and

basic tune-up requirements before condemning electronic engine control components. If your scan tool

immediately warns of a bad sensor, check it first but remember that an out-of-tune engine or an engine with

internal mechanical deficiencies can trigger diagnostic trouble codes.

DTCs, diagnostic trouble codes, are generated when there is a gross error with a sensor signal, input or

output signal or the PCM can no longer control something, meaning fuel mixture, timing, EGR, canister

purge and so on. Many times a DTC is generated but the fault is not necessarily the same as the DTC. For

example, a vacuum leak may cause an oxygen sensor activity code or a fuel control code. In this situation

the vacuum leak is the problem but it affected the electronic control of fuel which could cause you to

replace an injector if you did not check thoroughly or even the replacement of an oxygen sensor.

Always remember the basics and eliminate all the easy things first.

Page 19

Bi-Phase Technologies

LPEFI Electronic Engine Management

18

Self-Diagnostics, cont’d

Retrieving DTCs, diagnostic trouble codes, is always a good place to start when trouble shooting a

problem. If there are multiple DTCs, you need to evaluate them and troubleshoot with the first DTC listed.

Write down all the DTCs listed and investigate what each one stands for. Open up the data information

available and investigate the area of concern established by the DTCs listed. See if there is any correlation

between the DTC and the data associated with it. Many times you may find that the data reveals proper

function and there is no reason for generating a DTC. If this is the case, look at the freeze frame data, if

available, and see under what conditions the DTC was generated. This will help in diagnosing the problem.

The data information is very helpful. First, you can look at sensor and actuator activity live. This is very

effective diagnostics. Today, it is very important that a technician knows and understands on-board

diagnostics. It can save time and money, which benefits both the technician and the customer.

When diagnosing the LPEFI

stream.

ECT (engine coolant temperature)

IAT (intake air temperature)

IAC (idle air control)

STFT B1 and B2 (short term fuel trim bank 1 and bank 2)

LTFT B1 and B2 (long term fuel trim bank 1 and bank 2)

PW B1 and B2 (average injector pulse width bank 1 and bank 2)

02S11 (oxygen sensor bank 1 front sensor)

02S21 (oxygen sensor bank 2 front sensor)

It is very important that you know the meaning of the PID (parameter identification) names in the data

stream and understand the values displayed. In this manual we will only talk about a few of these terms.

Refer to OEM repair manual for a more detailed explanation. Many of the PID addresses are easy to

identify but some of the acronyms are confusing, and having an OEM repair manual or Mitchell manual is

very helpful. The more you work with electronic diagnostics the more familiar you will become.

Important PIDs, Explanation

ECT (engine coolant temperature) – The data is displayed as degrees F or C depending on your selection

for English or metric display. Engine coolant temperature is important because the learning function of the

computer does not begin until the engine reaches a programmed temperature. This temperature may vary

depending on vehicle model. For example a Ford may not begin to learn until the temperature reaches 165

degrees F. Always perform final diagnosis when the engine is at full operating temperature.

IAT (intake air temperature) – The data is displayed as degrees F or C depending on your selection for

English or metric display.

IAC (idle air control) – The data is displayed in % or counts. % is the percent of time it is on, 50% would

be half open or 75% would ¾ open. Counts would be the same, the higher the count the more open the

valve is. This could be important when a vacuum leak is suspected. Always refer to the OEM repair

manual for the operating range as each model varies.

STFT B1 or B2 (short term fuel trim) – This is displayed either in positive or negative percentages (%) or

in counts. Short term fuel trim is adjustments to fuel delivery, as it is happening at the moment you look at

it. The closer to 0% or 128 counts the better the fuel control is. A negative percentage indicates a rich

condition and the fuel control is subtracting fuel or adjusting the fuel delivery leaner while a positive

percentage is a lean condition and fuel control is adding fuel or adjusting the fuel delivery richer.

system, there are some PID values you may want to look at from the data

Page 20

Bi-Phase Technologies

LPEFI

Electronic Engine Management

19

Important PIDs, Explanation

STFT B1 or B2, cont’d

If it is displayed in counts the range for counts is 0 to 255. The middle of the range is 128 and any reading

less than 128 is a rich condition while any reading greater than 128 is a lean condition. This does not mean

the engine is running rich or lean, but means that fuel delivery is rich/lean and fuel control is adjusting from

that point to optimize fuel delivery for emissions, economy and drive ability. If the range of control

reaches the limit, lean or rich, then the engine is running lean or rich and the computer can no longer

control the fuel mixture and a DTC will be logged in the computer’s memory. If the computer recognizes

this in a second drive cycle it will illuminate the MIL, (malfunction indicator lamp or check engine light).

The STFT has a back up to extend its range of control. It is called LTFT, long term fuel trim, and if the

STFT is controlling too far to the lean or rich side of the middle of the range of control, the LTFT will learn

and allow the STFT to control closer to the middle of the range. This allows the STFT to have a much

longer time period of control. This allows the degradation of the air filter, the fuel filter, fuel injectors,

engine oil contamination, PCV, fuel pump and anything that can affect fuel and air delivery. For example,

when a very dirty air filter is replaced the fuel control will readjust over time or the same with a fuel filter

or the same after an injector is replaced.

LTFT (long term fuel trim) – This is displayed in either positive or negative percentages (%) or in counts.

It is also shown for bank one and bank two. Long term fuel trim is adjustments to fuel delivery over time.

The closer to 0% or 128 counts the better the fuel control is. A negative percentage indicates a rich

condition and the fuel control is subtracting fuel or adjusting the fuel delivery leaner, while a positive

percentage is a lean condition and fuel control is adding fuel or adjusting the fuel delivery richer. If it is

displayed in counts the range for counts is 0 to 255. The middle of the range is 128 and any reading less

than 128 is a rich condition while any reading greater than 128 is a lean condition. This does not mean the

engine is running rich or lean, but means that fuel delivery is rich/lean and fuel control is adjusting from

that point to optimize fuel delivery for emissions, economy and drive ability. If the range of control

reaches the limit, lean or rich, then the engine is running lean or rich and the computer can no longer

control the fuel mixture and a DTC will be logged in the computer’s memory. If the computer recognizes

this in a second drive cycle it will illuminate the MIL, (malfunction indicator lamp or check engine light).

LTFT levels adjust over time as previously mentioned and causes or allows the STFT to maintain control

closer to the middle of the control range. This allows rapid changes to fuel control for better response and

performance. The LTFT is like a fine-tuning function. This gives the STFT a much longer time period of

control. This allows the degradation of the air filter, the fuel filter, fuel injectors, engine oil contamination,

PCV, fuel pump and anything that can affect fuel and air delivery. For example, when a very dirty air filter

is replaced, the fuel control will readjust over time or the same with a fuel filter or the same after an

injector is replaced. If the battery is changed or disconnected it will reset fuel trim and a learning process

could take a few hundred miles. However, for diagnosis purposes bringing the vehicle to full operating

temperature and a short drive will give you an idea of where the controls stabilize. Anytime the STFT

values are stabilized close to the middle of the range of control the LTFT values should be accurate. If the

air filter is clean, the engine oil is not contaminated and the engine condition is good the LTFT values are a

good indicator of how well the injectors are calibrated. It is also helpful to review the LTFT values at

different load conditions, such as cruising at 45 mph or at a wide open throttle situation. If power seems

low and wide open throttle values are very lean this would give you something to look for.

Page 21

20

Bi-Phase Technologies

LPEFI Electronic Engine Management

Important PIDs, Explanation, cont’d

The LPEFI

gasoline injectors. What we want to look for when diagnosing the LPEFI

within 10% or about 40 counts of each other. For instance –2% bank one and –8% bank two would be

okay. It is normal to also see LTFT values at -17% on either bank but we would not want to see a richer

condition or -20% numbers. If the LTFT values are on the leaner end of the control range, other problems

may exist if the value is higher than +12% or 176 counts. Four counts equal approximately 1%.

system will not have LTFT values as good or as close to the middle of the control range as

system is for the values to be

PW (injector pulse width) – The length of time the injector solenoid is energized or the injector is open,

displayed in milliseconds and averaged for each bank of the engine. Naturally the injector pulse width is

lower at idle than it is at cruise and higher than cruise during a loaded condition. Comparing the PW values

could identify an area of concern. For example, if you identified a weak injector during the fuel injector

check in the basic diagnostic procedure section of this manual, it could show up here by displaying a

different PW on the bank that had the weak injector. Most of the time, injector pulse width will be between

2 and 5 milliseconds at idle. The scan tool only displays an average pulse width for each bank of cylinders.

Each bank is normally within a few tenths of each other. If not, refer to checking fuel injectors in basic

diagnostic procedures.

O2S11 or HO2S11 – Oxygen sensor or heated oxygen sensor bank one sensor one

O2S21 or HO2S21 – Oxygen sensor or heated oxygen sensor bank two sensor one

Most oxygen sensors today are equipped with an internal heater to speed up the amount of time it takes for

electronic engine management to reach closed loop. An oxygen sensor is not active until it reaches a

temperature of approximately 570 degrees F. Oxygen sensors create voltage and can be called a galvanic

battery. A low voltage signal is a lean fuel mixture indication and a high voltage signal is a rich fuel

mixture indication. The maximum voltage an oxygen sensor will generate is approximately 1000 millivolts

or one volt. The oxygen sensor actually measures oxygen content in the exhaust stream. If a rich mixture

exists, there is a lack of oxygen compared to the outside ambient atmosphere. This lack of oxygen causes

the oxygen sensor to create voltage. If the amount of oxygen in the exhaust stream is equal to the amount

in the atmosphere, no voltage will be generated. Oxygen sensors are sensitive to silicones and could

become coated and decrease the reaction time or activity. Oxygen sensor signal is something worth

verifying and not only at idle, but at different engine load conditions. Most vehicles today consider an

oxygen sensor signal of 0.45 volts as stoichiometric. The fuel control is based on oxygen sensor voltage

and if fuel control is working properly, oxygen sensor voltage will move below and above the 0.45 volts.

The number of times in a given period that the oxygen sensor signal crosses above or below the 0.45 volts

is called cross counts and the PCM monitors this activity to know how fuel control is functioning as well as

for fuel delivery decisions.

Page 22

L

I

g

21

Bi-Phase Technologies

PEF

Pressure Testin

the LPEFISystem

3 Switch Box Test Switches

3 Switch Box Connectors

Page 23

22

Bi-Phase Technologies

LPEFI Pressure Testing the LPEFI

System

Page 24

Bi-Phase Technologies

LPEFI Pressure Testing the LPEFI

System

23

Page 25

24

Page 26

25

LPEFI® Purge Logic

Page 27

L

I

g by Symp

26

Bi-Phase Technologies

PEF

Troubleshootin

Introduction

Before diagnosing symptoms or intermittent

faults, perform steps in basic diagnostic

procedures and appropriate self-diagnostics with

a scan tool. Use this section to diagnose

problems existing when DTCs, diagnostic

trouble codes, are not present.

Symptom checks can direct the technician to

malfunctioning component(s) for further

diagnosis. A symptom should lead to a specific

component test and/or adjustment.

Symptoms

Symptom checks cannot be used properly unless

the problem occurs while the vehicle is being

tested. To reduce diagnostic time, ensure basic

diagnostic procedures and self-diagnostics were

performed before diagnosing a symptom. Some

symptoms are:

No crank

Hard start cold/long crank

Hard start hot/long crank

No start/normal crank

Low idle speed

High idle speed

Rough idle

Stalls but restarts (hot or cold)

Stalls but does not restart

Stalls during acceleration

Stalls during deceleration

Stalls during steady speed driving

Stalls after vehicle stops

Stalls when put in gear

Stalls while idling

Starts but stumbles and stalls

Hesitates

Surges

Backfires, misfires or cuts out during

acceleration

Backfires, misfires or cuts out during

deceleration

Bucks & jerks

Engine knocks or rattles, spark knocks

Loss of power during cruise or all the time

Loss of power during heavy load condition,

wide open throttle

Poor fuel economy

Failed emissions

tom

Runs rough all the time

High oil consumption

Engine runs hot

Engine runs cold

Fire comes out of exhaust

LPEFI

Smell of propane

Slow fuel filling or no fill

Unable to evacuate fuel lines through

No fuel transfer from optional secondary

Noisy fuel pump or noise in tank

Fuel pump does not shut off

No purge cycle

Injector leaks with no electrical command

Injector insulator housing cracked or not

Specific Symptoms

Schrader Valve

transfer tank

sealing (vacuum leak)

Symptom Diagnosis

No Crank

Check battery connections

Check the start motor

Check appropriate fuses and fuse links

On A/T models check park/neutral safety

switch

On M/T models check clutch switch

Check starter circuitry

Check for seized/hydro locked engine

Check flywheel

Check ignition switch

Hard start cold/long crank

Check battery charge condition

Check ignition primary voltage during crank

& secondary wiring

Check for vacuum leaks

Check fuel pressure (pump boost)

Check injectors for leakage, causing a

rich/flooded condition

Check air cleaner & incoming air ducts

Check engine mechanical condition,

compression

Page 28

Bi-Phase Technologies

L

I

g by Symp

PEF

Troubleshootin

27

tom

Symptom Diagnosis, cont’d

Hard start hot/long crank

Check battery charge condition

Check ignition primary voltage during crank

& secondary wiring

Check for vacuum leaks

Check fuel pressure (pump boost)

Check injectors for leakage, causing a

rich/flooded condition

Check air cleaner & incoming air ducts for

restriction

Check nylon inner liquid supply fuel lines

and the o-ring seals for the nylon inner line

Check engine mechanical condition,

compression test

No start/normal crank

Check battery charge condition & fuel level

Check the LPEFI

Check ignition primary voltage during crank

& secondary wiring

Check for vacuum leaks

Check fuel pressure including operation of

pump and supply & return valves

Check wiring at electronic tank control box

Check injectors for leakage, causing a

rich/flooded condition

Check air cleaner & incoming air ducts for

restriction

Check injector wiring harness & individual

injector connectors

Check injector power wire voltage

Check that injectors are delivering fuel

Injector diagnosis

Low idle speed

Check idle air control wiring harness

connector or ETC, if equipped

Check base timing

Check engine mechanical condition,

compression test

Confirm IAC/ETC controls idle speed

Check and/or adjust minimum idle, refer to

OEM repair manual for specification

Check air cleaner and incoming air ducts

High idle speed

Check IAC/ETC wiring harness connector

Check base timing

Confirm IAC/ETC controls idle speed

Check for vacuum leaks

Check intake manifold gasket for vacuum

leaks

Check and/or adjust minimum idle, refer to

OEM repair manual for specification

system 30-amp fuse

Check EGR valve

Check throttle linkage

Check throttle plate for a closing obstruction

Check incoming air intake ducts

Check PCV

Check canister purge vacuum lines &

evaporative emissions lines, if equipped

before the LPEFI

Rough idle

Check ignition secondary wiring

Check spark plugs

Check for vacuum leaks

Check PCV

Check air cleaner and incoming air ducts &

sealing around MAF sensor

Check fuel injector wiring harness and

individual injector electrical connectors

Check fuel system operating pressure

Check fuel injectors, conduct balance test as

described in basic diagnostic procedures

Check engine mechanical condition,

compression test

Check cooling fan blades for cracks or

bends

Check for broken engine mounts

Check all wiring connectors for intermittent

failure/disconnect

Check for flooded condition/leaking fuel

injector, see basic diagnostic procedures

system installation

Page 29

L

I

g by Symp

Bi-Phase Technologies

PEF

Troubleshootin

28

tom

Symptom Diagnosis, cont’d

Stalls but restarts (hot or cold)

Check and/or adjust minimum idle speed per

the OEM repair manual specification

Check IAC/ETC wiring harness connector

Confirm IAC/ETC controls idle speed

Check for vacuum leaks

Check PCV

Check for restricted air cleaner or incoming

air ducts

Check MAF

Check exhaust for restriction, see basic

diagnostic procedures

Check EGR valve

Check engine mechanical condition,

compression test

Verify there are no leaking fuel injectors,

see basic diagnostic procedures

Check for lean fuel injectors, verify long

term fuel trims

Check fuel pressure

Check wiring & wiring harness connectors

for intermittent failure/disconnect at

electronic tank control box and all LPEFI

wiring connections & OEM connections

Stalls but does not restart

Check fuel pressure and confirm the

LPEFI

system refrigeration cycle is

working, i.e. inner liquid supply line not

sealing, fuel pressure is too low, fuel return

valve malfunction; see basic diagnostic

procedures

Verify ignition voltage is not dropping out,

primary or secondary ignition

Check the LPEFI

system 30-amp fuse

Verify engine is not overheating

Verify engine oil level

Check all wiring connectors for intermittent

failure/disconnect

Check for flooded condition/leaking fuel

injector, see basic diagnostic procedures

Stalls during acceleration

Check all wiring connections

Check ignition voltage & ignition switch

Check primary & secondary ignition voltage

Check for vacuum leaks

Check for excessive lean or rich conditions,

leaking injector

Check exhaust back pressure, see basic

diagnostic procedures

Check for intermittent fuel pump or fuel

supply valve or return valve malfunction

Stalls during deceleration

Check fuel level

Check and/or adjust minimum idle speed per

the OEM repair manual specification

Check IAC/ETC wiring harness connector

Confirm IAC/ETC controls idle speed

Check for vacuum leaks

Check PCV

Check for restricted air cleaner or incoming

air ducts

Check MAF

Check exhaust for restriction, see basic

diagnostic procedures

Check EGR valve

Check engine mechanical condition,

compression test

Verify there are no leaking fuel injectors,

see basic diagnostic procedures

Check for lean fuel injectors, verify long

term fuel trims

Check fuel pressure

Check wiring & wiring harness connectors

for intermittent failure/disconnect at

electronic tank control box and all LPEFI

wiring connections & OEM connections

Stalls during steady speed driving

Check all wiring connections

Check ignition voltage & ignition switch

Check primary & secondary ignition voltage

Check for vacuum leaks

Check for excessive lean or rich conditions,

leaking injector

Check exhaust back pressure, see basic

diagnostic procedures

Check for intermittent fuel pump or fuel

supply valve malfunction

Stalls after vehicle stops

Check fuel level

Check and/or adjust minimum idle speed per

the OEM repair manual specification

Check IAC/ETC wiring harness connector

Confirm IAC/ETC controls idle speed

If equipped with electronic throttle control

check accelerator pedal and throttle plate

control

Check for vacuum leaks

Check PCB

Page 30

L

I

g by Symp

29

Bi-Phase Technologies

PEF

Troubleshootin

Symptom Diagnosis, cont’d

Stalls after vehicle stops, cont’d

Check for restricted air cleaner or incoming

air ducts

Check MAF

Check exhaust for restriction, see basic

diagnostic procedures

Check EGR valve

Check engine mechanical condition,

compression test

Verify there are no leaking fuel injectors,

see basic diagnostic procedures

Check for lean fuel injectors, verify long

term fuel trims

Check fuel pressure

Check wiring & wiring harness connectors

for intermittent failure/disconnect at

electronic tank control box and all LPEFI

wiring connections & OEM connections

Stalls when put in gear

Check and/or adjust minimum idle speed per

the OEM repair manual specification

Check IAC/ETC wiring harness connector

Confirm IAC/ETC controls idle speed

Check for vacuum leaks

Check PCV

Check for restricted air cleaner or incoming

air ducts

Check MAF

Check exhaust for restriction, see basic

diagnostic procedures

Check EGR valve

Check engine mechanical condition,

compression test

Verify there are no leaking fuel injectors,

see basic diagnostic procedures

Check for lean fuel injectors, verify long

term fuel trims

Check fuel pressure

Check wiring & wiring harness connectors

for intermittent failure/disconnect at

electronic tank control box and all LPEFI

wiring connections & OEM connections

tom

Stalls while idling

Check fuel level, insure the fuel pump baffle

area is not running out of fuel

Check and/or adjust minimum idle speed per

the OEM repair manual specification

Check IAC/ETC wiring harness connector

Confirm IAC/ETC controls idle speed

If equipped with electronic throttle control

check accelerator pedal and throttle plate

control

Check for vacuum leaks

Check PCV

Check for restricted air cleaner or incoming

air ducts

Check for interruption in ignition circuit

voltage, primary & secondary; intermittent

voltage drop

Check MAF

Check exhaust for restriction, see basic

diagnostic procedures

Check EGR valve

Check engine mechanical condition,

compression test

Verify there are no leaking fuel injectors,

see basic diagnostic procedures

Check for lean fuel injectors, verify long

term fuel trims

Check fuel pressure

Check wiring & wiring harness connectors

for intermittent failure/disconnect at

electronic tank control box and all LPEFI

wiring connections & OEM connections

Starts but stumbles and stalls

Check fuel level

Complete the purge cycle, repeat the purge

cycle, try purging twice

Verify fuel pressures; pump, fuel supply

valve operation

Check and/or adjust minimum idle speed per

the OEM repair manual specification

Check primary ignition voltage, ignition

switch

If equipped, check electronic throttle

control, (accelerator pedal assembly or

throttle plate actuator)

Confirm injectors are sealing (no leaking

injectors)

Confirm injectors are not leaking a vacuum

(check injector insulator housing seals and

holds a vacuum)

Page 31

L

I

g by Symp

Bi-Phase Technologies

PEF

Troubleshootin

Symptom Diagnosis, cont’d

Hesitates

Check fuel level

Verify fuel pressures; pump, fuel supply

valve operation

If equipped with electronic throttle control,

check accelerator pedal and throttle plate

control actuator

Verify no leaking injectors (injectors leak

fuel when there’s no demand)

Verify no vacuum leaks

Check ignition system, primary & secondary

Perform a hot restart – hot soak for 20

minutes and confirm restart is fast &

smooth; if not, check fuel lines, specifically

inner fuel line sealing or crimped; see hot

soak

Surges

Check fuel level

Verify fuel pressures

Check injectors (fuel leaking/tip leaks or

vacuum leaks)

Check for vacuum leaks

Check ignition system, primary and

secondary

Check EGR valve

Check ignition timing

If equipped, check electronic throttle control

Check PCM control and sensors, MAF,

MAP, O2 sensors, etc; some sensors can

malfunction and not set a trouble code; refer

to OEM guidelines to verify sensor condition

Backfires, misfires or cuts out during

acceleration

Check fuel level

Verify fuel pressures

Check ignition timing, on distributor-less

ignition systems camshaft sensor or

crankshaft sensor could be faulty

Check for vacuum leaks

Check for leaking injectors or vacuum leaks

on injector housings

Check hot restart after 20-minute hot soak

Check ignition system, primary and

secondary

Check O2 sensors, visually monitor scan

tool during failure

30

tom

Backfires, misfires or cuts out during

deceleration

Check fuel level

Verify fuel pressures

eck ignition timing

Ch

Check for vac

Check for leaking injectors (leaking fuel

between pulses causes rich condition

Check long term fuel trim for rich condition

Check ignition system, primary and

secondary

Check injectors, long term fuel trims

injector fuel leaks or vacuum leaks at

injector housings

Check hot restart after 20-minute hot soak

Check O2 sensors, visually monitor scan

tool during failure

Buck & jerks

Check fuel level

Verify fuel pressures

Visually inspect fuel supply inner nylon line

Check ignition system, primary and

secondary

Check EGR valve

If equipped, check ETC (accelerator pedal

and throttle plate actuator)

Check for vacuum leaks

Check O2 sensors, monitor scan tool during

failure

Check hot restart after 20-minute hot soak

Engine knocks or rattles, spark knocks

Check oil level

Check cooling system

Check engine condition

Check ignition timing

Check camshaft and crankshaft position

sensors

Check knock sensor circuit

Check MAF and/or MAP sensors

uum leaks

Page 32

L

I

g by Symp

Bi-Phase Technologies

PEF

Troubleshootin

Symptom Diagnosis, cont’d

Loss of power during cruise or all the time

Check engine compression

Check fuel pressures

Check hot restart after 20-minute hot soak

Check long term fuel trims for very lean

injectors

Check for vacuum leaks

Check MAF and/or MAP sensors

Check ignition system, primary & secondary

Check ignition timing

Loss of power during heavy load condition,

wide open throttle

Check exhaust system, back pressure

Check fuel pressures

Check injectors, long term fuel trims,

injector fuel leaks or vacuum leaks at

injector housings

Check hot restart after 20-minute hot soak

Check ignition system, primary and

secondary

Check incoming air flow, air filter, fresh air

hose to filter

Poor fuel economy

Check incoming air flow, air filter, fresh air

hose to filter

Check fuel injectors, long term fuel trim,

injector fuel leaks

Check for vacuum leaks – vacuum leaks can

cause a lean condition, which causes a rich

fuel demand

Check PCV

Failed Emissions

Slow O2 sensor - Fluid leaks, wrong RTV

Check spark plugs

Check catalytic converter

Leaking injector

Runs rough all the time

Check ignition system, primary and

secondary

Check for vacuum leaks

Check injectors, resistance values for open

circuit

Check engine condition, compression

High oil consumption

Check engine condition, compression

Check PCV

back pressure

Check exha

Check oil change interval, use recommended

oil grade

Engine runs hot

Check cooling level and for leaks

ust

31

tom

Check water pump

Check thermostat

Check temperature gauge

Check exhaust back pressure

Check engine condition, blown head gasket?

Engine runs cold

Check thermostat

Check temperature gauge & sending unit

Fire comes out of exhaust

Check injectors, leaking fuel between pulses

Check for vacuum leaks

Check exhaust back pressure

Check O2 sensors

Check ignition timing per OEM

recommended inspection procedure

LPEFI® system specific symptoms

Smell of propane

Inspect entire system for fuel leaks using

bubble test method with approved leak

detection fluid or electronic leak detector

(all tank valves, hose fittings, system

components i.e. LPDM, hoses, injector rail

end and injectors)

Inspect injector for leaks, leaking through

tip without an electrical command

Inspect injector insulator housings for

damaged or leaking o-rings

Inspect injector housing screws for leaks

when system is charged with fuel

Check exhaust mixtures using an exhaust

gas analyzer or monitor scan tool data

stream for out of specified range long term

fuel trims

Slow fuel filling or no fill

Replace fuel fill filter, special Bi-Phase

OEM part (5 micron)

Check fuel level – if fuel liquid level is at

80% the automatic stop fill valve will stop

the filling process, possibly will allow very

slow filling after shut down

NO FILL – check automatic stop orientation

Compare vehicle tank pressure with filling

station tank pressure; if it is < 70 p.s.i.

difference, there may be a problem with the

dispensing station pump or pump bypass

adjustment; it also may be required to safely

lower the pressure in the vehicle’s fuel tank

Check fuel level in propane station fuel

storage tank

Check the remote fill valve for obstruction

or faulty check valve

Page 33

L

I

g by Symp

Bi-Phase Technologies

PEF

Troubleshootin

Unable to evacuate fuel in fuel lines through

Schrader Valve

Confirm pressure gauge hose connecting

fitting is penetrating the Schrader Valve

Confirm there is fuel in the line by manually

opening the Schrader Valve using a

Schrader Valve service tool; note: wear

gloves when opening Schrader Valve and do

not release propane indoors or in a restricted

space area

If fuel pressure does not decrease or does

not decrease completely from the fuel lines

when attempting to evacuate the fuel line,

replace the LPDM

No fuel transfer from optional (secondary)

transfer tank to main (primary) tank

Check power +12 volts and ground (-) to the

Control module and relay

Confirm the resistance value of the fuel

level gauge sending unit matches the fuel

control module; refer to page 55 for correct

resistance value.

Using the Bi-Phase 3-switch box, manually

run pump on transfer tank to confirm it runs

With transfer tank LPDM disconnected,

bleed the fuel out of the transfer hose,

disconnect the hose from the LPDM and

install a tee with a gauge, reconnect to

LPDM; run the pump manually; after the

transfer line is refilled with fuel, turn the

pump off and note the line pressure;

Turn the pump back on, if the fuel pump

boosts pressure increases by 10 to 20 psi the

pump is good

(Note: the primary tank should be at less

than 50% liquid level)

If the pump does not run, the amperage

exceeds 15 amps or is less than 6 amps,

replace the fuel pump

Check the automatic stop fill device in the

primary tank (the stop fill valve that the

transfer tank pumps to) for correct

operation.

Try to initiate a fuel transfer; to simulate a

level difference, remove each fuel level

gauge sending unit from the tank; note: only

remove the two very small Phillips head

screws on the sending unit and lift the

sending unit out of the float assembly head

o Leave the sending units connected

electrically

32

tom

o Using a magnet, position each

sending unit to an equal fuel level

o Start the engine

o Move the primary tank’s sending

unit the transfer tank pump should

come on; if it does not, turn off the

key/engine

Synchronize the sending units to equal fuel

levels; start the engine; move the primary

tank’s sending unit and listen for transfer

tank pump to start running

y following the

If the fuel transfer work

previous simulation, but fails to work when

the vehicle is on the road you may need to

simulate the over the road conditions

Install pressure gauges on both tanks, a 0 to

250/350 on the vapor service valve or the

fixed liquid level gauge; also install a gauge,

in a prepared tee, in the transfer hose

between the secondary and primary tank

The vehicle should be driven for an hour or

the time it takes to create heat and a fuel

level differential of 15% to 20%

Note the tank pressure in each tank

If the tank pressure in the primary tank is 50

to 80 psi. more than the secondary (transfer)

tank, a fuel transfer may not be

accomplished

Diagnose the reason there is such a pressure