WORKSHOP MANUAL

NHR • NKR • NPR

ENGINE

4J SERIES

SECTION 6

MEMO

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

NOTICE

Before using this Workshop Manual to assist you in performing

vehicle service and maintenance operations, it is reco mmended

that you carefully read and thoroughly understand the

information contained in Section 0A under the headings

“GENERAL REPAIR INSTRUCTIONS” and “HOW TO USE THIS

MANUAL”.

All material contained in this Manual is based on the latest

product information available at the time of publication.

All rights are reserved to make changes at any time without prior

notice.

Applicable Model : NHR55. NKR55. NPR55. NPR69

This manual is applicable to 1994 year model and later vehicles

.

THIS MANUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION NO. CONTENTS

00 Service Information

6A Engine Mechanical

6A1 4JB1/4JB1T/4JB1-TC/4JG2 Engine

6B Engine Cooling

6C Fuel System

6D Engine Electrical

6E Exhaust Gas Reci rculation (EGR) System

6F Exhaust

6G Turbocharger

SERVICE INFORMATION 00 – 1

HOME

SECTION 00

SERVICE INFORMATION

CONTENTS

PAGE

Troubleshooting .............................................................................................................. 00 -2

Main Data and Specifications......................................................................................... 00 -30

Service Standard ............................................................................................................. 00 -34

Servicing........................................................................................................................... 00 -38

Fixing Torque...................................................................................................................00 -51

Special Tools.................................................................................................................... 00 -60

00 – 2 SERVICE INFORMATION

TROUBLESHOOTING

CONTENTS

PAGE

Hard Starting.................................................................................................................... 00 - 3

Starter Inoperative....................................................................................................... 00 - 3

Starter Motor Operates but Engine Does Not Turn Over......................................... 00 - 3

Engine Turns Over but Does Not Start...................................................................... 00 - 4

Quick-on Start System................................................................................................ 00 - 5

Unstable Idling.................................................................................................................00 - 6

Insufficient Power............................................................................................................ 00 - 7

Excessive Fuel Consumption......................................................................................... 00 - 9

Excessive Oil Consumption............................................................................................ 00 - 9

Overheating...................................................................................................................... 00 - 10

White Exhaust Smoke..................................................................................................... 00 - 10

Dark Exhaust Smoke....................................................................................................... 00 -11

Oil Pressure Does Not Rise............................................................................................ 00 - 11

Abnormal Engine Noise .................................................................................................. 00 -12

Engine Knocking......................................................................................................... 00 - 12

Gas Leakage Noise...................................................................................................... 00 -12

Continuous Noise........................................................................................................ 00 - 12

Slapping Noise............................................................................................................. 00 -13

Engine Cooling Trouble .................................................................................................. 00 -14

Engine Electrical Part Trouble........................................................................................ 00 - 15

Turbocharger ................................................................................................................... 00 -20

Lubrication Chart............................................................................................................. 00 - 29

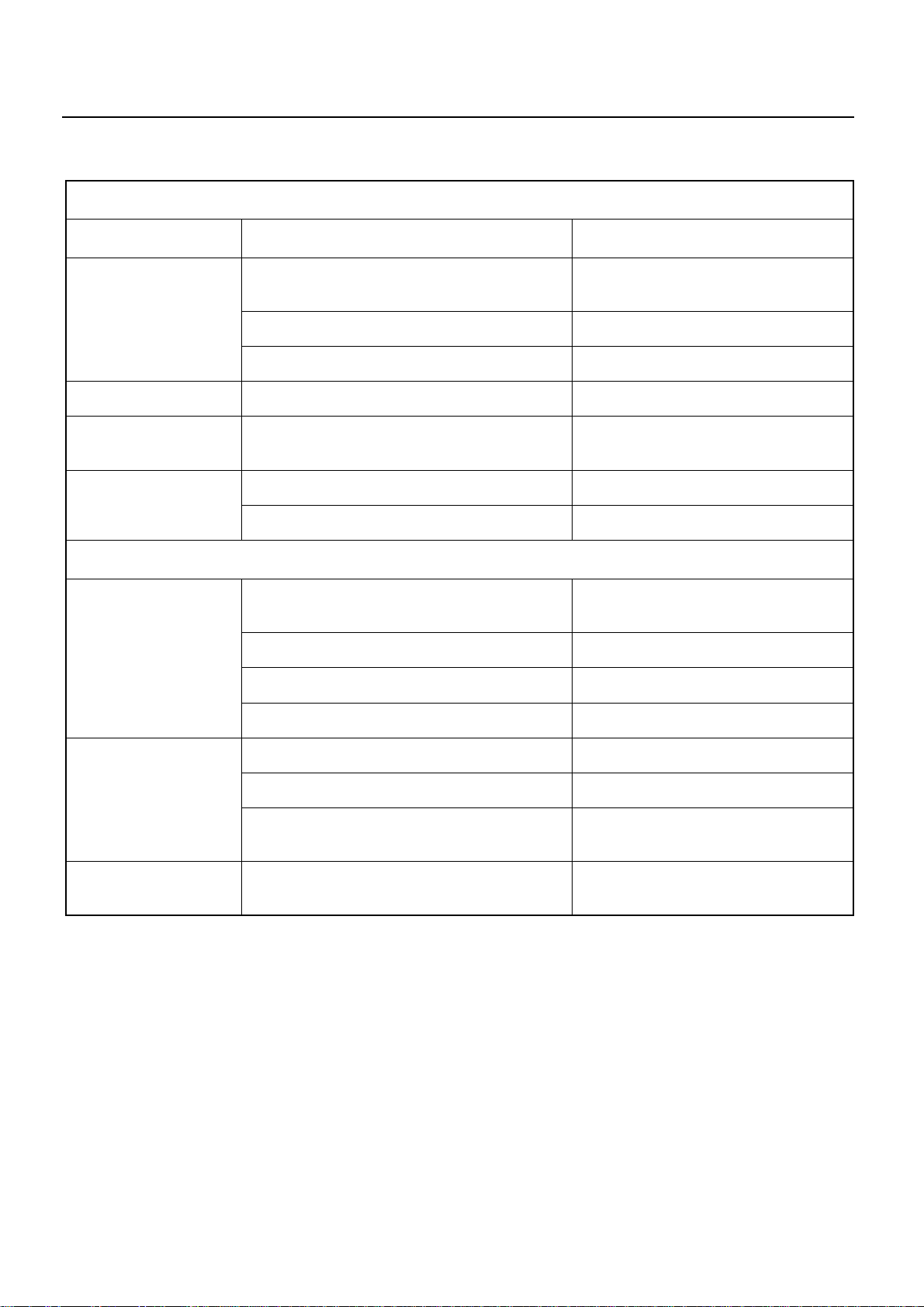

SERVICE INFORMATION 00 – 3

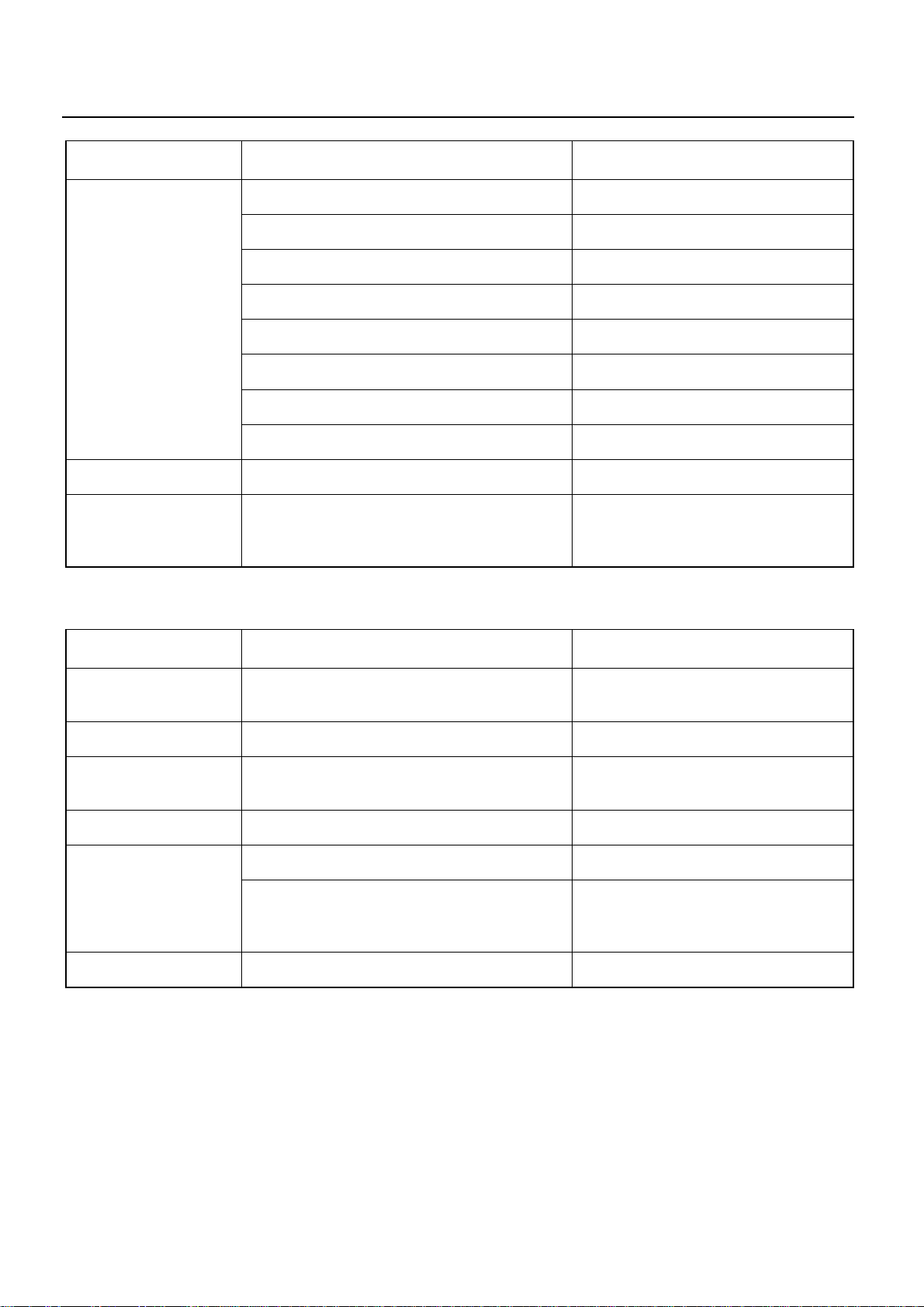

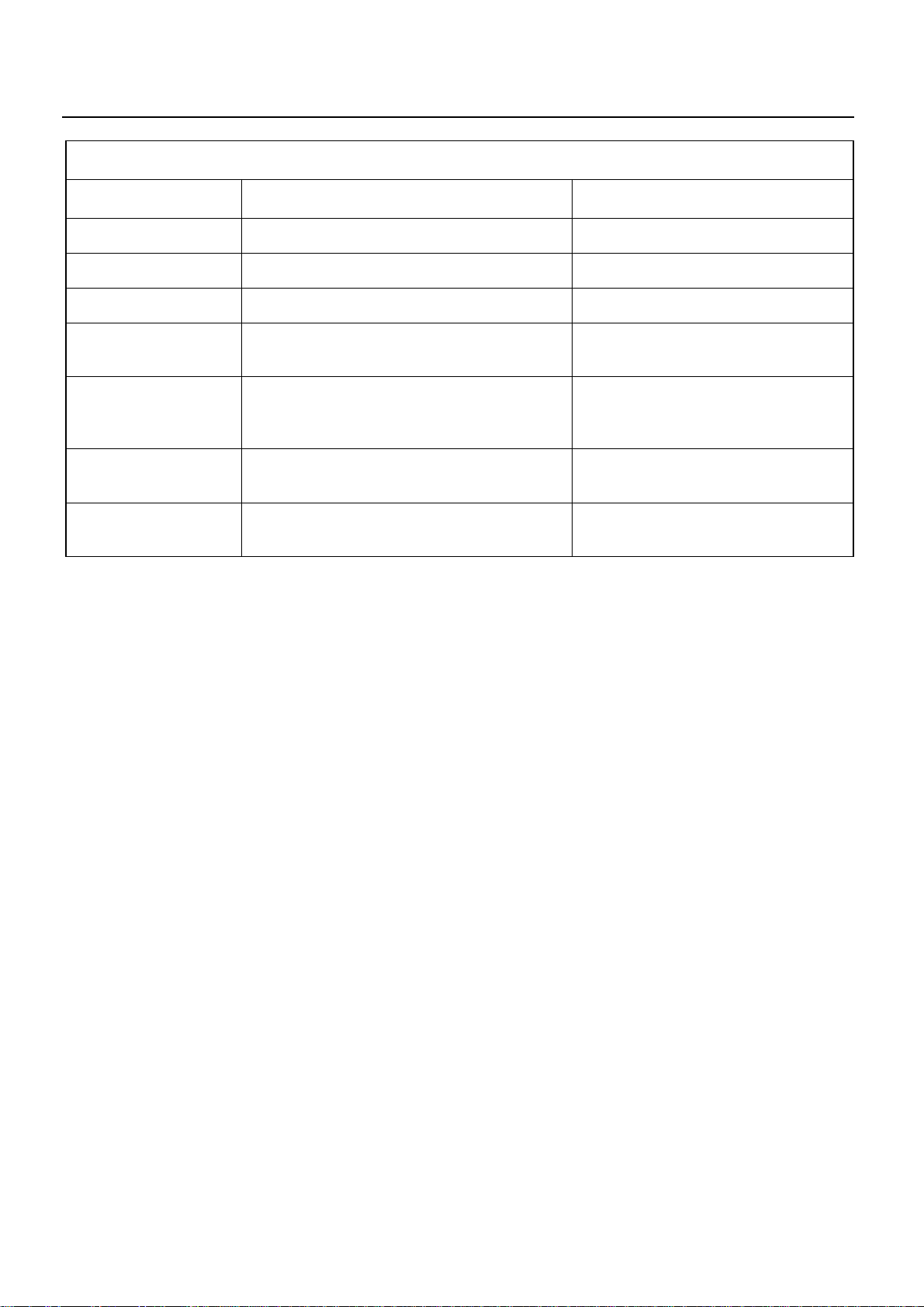

1.HARD STARTING

1. STARTER INOPERATIVE

Checkpoint Possible cause Correction

Battery

Fusible link Fusible link shorted Replace the fusible link

Starter switch Defective starter switch or starter relay Replace the starter switch or the

Loose battery cable terminal poor

connections due to rusting

Battery discharged or weak Recharge or replace the battery

Fan belt loose or broken Adjust or replace the fan belt

Defective magnetic switch or starter relay Repair or replace the magnetic switchStarter motor

Defective starter motor Repair or replace the starter motor

Clean and/or retighten the battery

cable terminal

Starter relay

2. STARTER MOTOR OPERATES BUT ENGINE DOES NOT TURN OVER

Battery

Loose battery cable terminal Clean and/or retighten the battery

cable terminal

Poor connections due to rusting Recharge or replace the battery

Battery discharged or weak Recharge or replace the battery

Fan belt loose or broken Adjust or replace the fan belt

Starter

Engine Piston, crank bearing seizure, or other

Defective pinion gear Replace the pinion gear

Defective magnetic switch Repair or replace the magnetic switch

Brush wear, Weak brush spring Replace the brush and/or the brush

damage

spring

Repair or replace the related parts

00 – 4 SERVICE INFORMATION

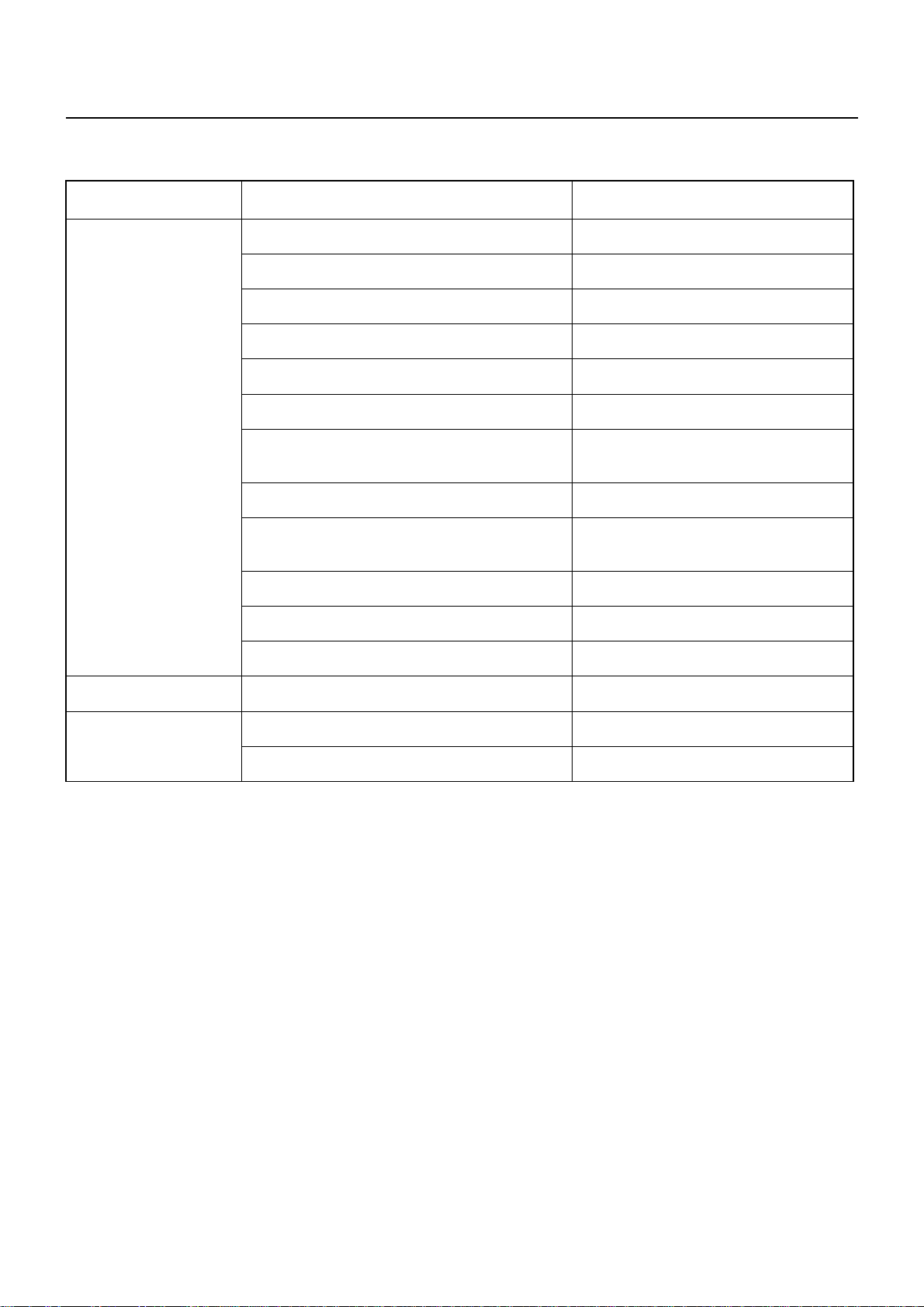

3. ENGINE TURNS OVER BUT DOES NOT START

Checkpoint Possible cause Correction

Engine stop

mechanism

Defective fuel cut solenoid valve Replace the fuel cut solenoid valve

FUEL IS NOT BEING DELIVERED TO THE INJECTION PUMP

Fuel Fuel tank is empty Fill the fuel tank

Fuel piping Clogged or damaged fuel lines. Loose fuel

line connection

Fuel filter

Fuel system Air in the fuel system Bleed the air from the fuel system

Fuel feed pump Defective feed pump Repair or replace the feed pump

Fuel filter overflow valve does not close Repair or replace the fuel filter

Clogged fuel filter element Replace the fuel filter element or the

Repair or replace the fuel lines

Retighten the fuel line connection

overflow valve

filter cartridge

FUEL IS BEING DELIVERED TO THE INJECTION PUMP

Fuel

Use of the wrong fuel Use the correct fuel

Water particles in the fuel Change the fuel

Fuel system

Injection pump

Air in the injection pump Bleed the air from the fuel system

Injection nozzle stickingInjection nozzle

Injection nozzle injection starting pressure

too low

Improper spray condition

Defective fuel injection nozzle resulting in the

fuel drippage after fuel injection

Defective injection pump control rack

operation

Injection pump plunger worn or stuck Replace the injection pump plunger

Injection pump drive shaft seizure or other

damage

Injection pump governor spring seizure Replace the injection pump governor

Adjust or replace the injection nozzle

Replace the delivery valve

Repair or replace the injection pump

control rack

assembly

Replace the injection drive shaft

spring

SERVICE INFORMATION 00 – 5

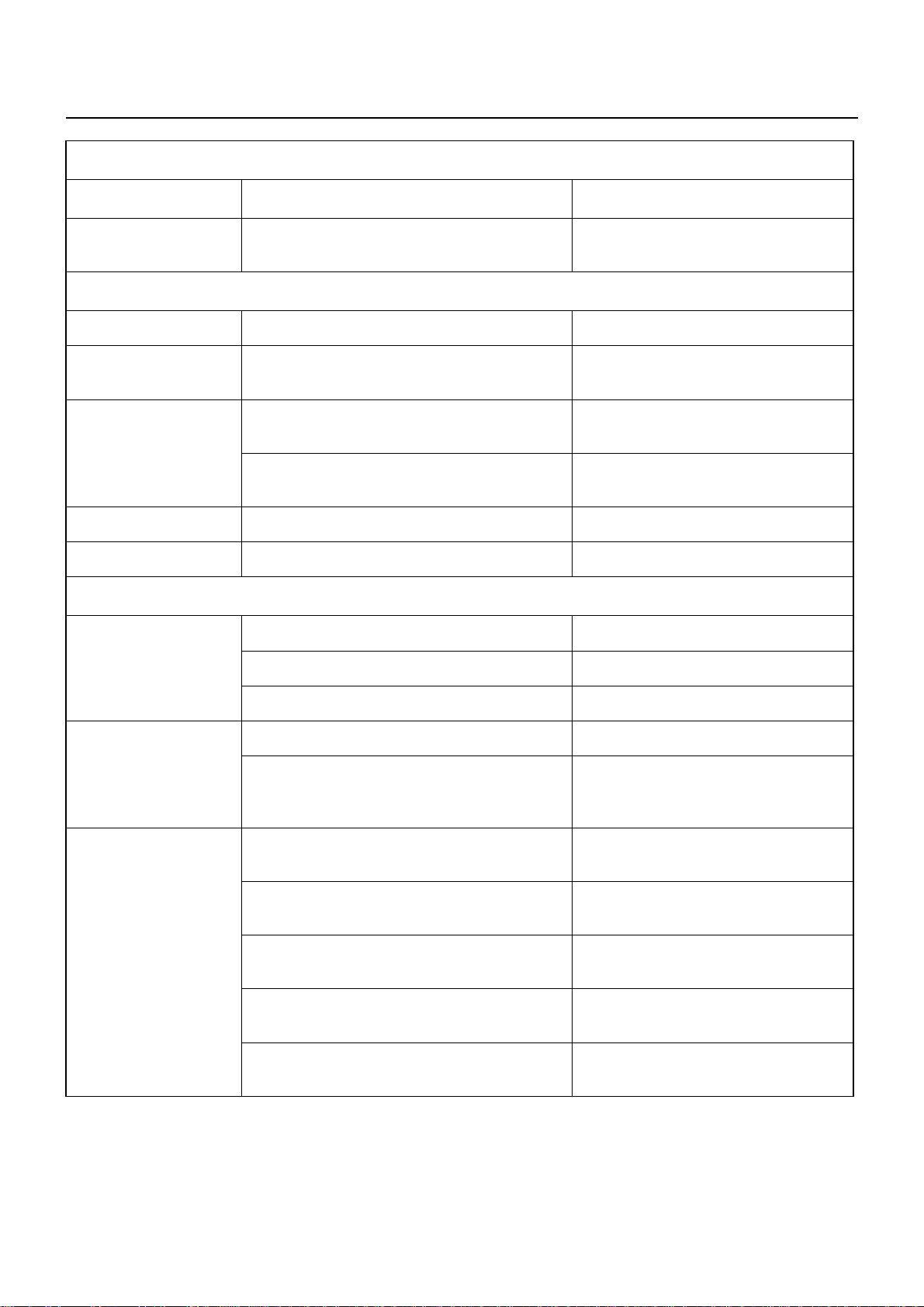

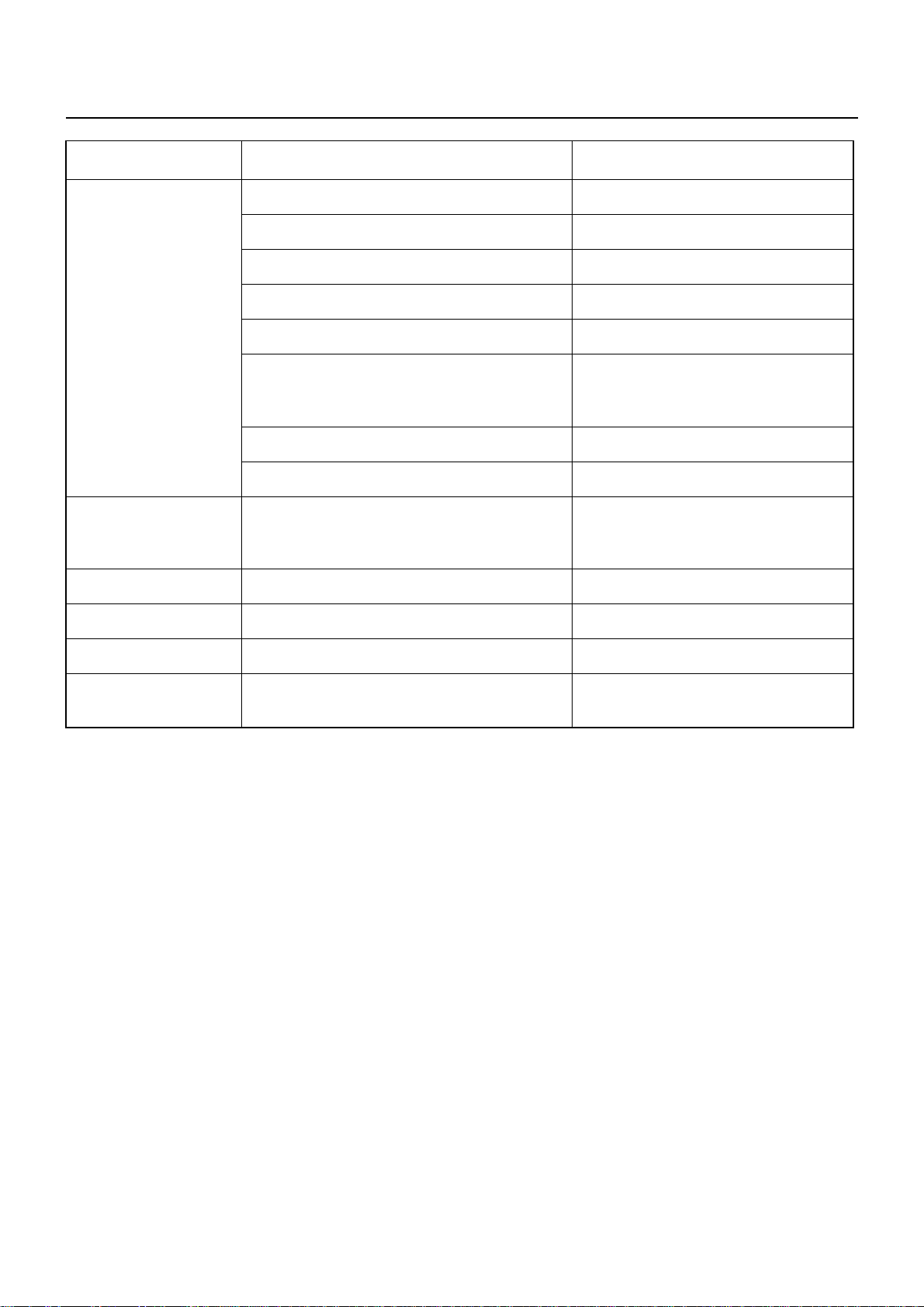

4. QUICK-ON START SYSTEM

PREPARATION

1 Disconnect the thermoswitch connector.

2. Determine whether or not the glow plugs are receiving power.

a) Make sure that the starter switch is “OFF”.

b) Connect a voltmeter between one of the glow plugs and the cylinder wall.

c) Move the starter switch to the “ON” position.

The voltmeter needle will show the souse voltage (12V) if the glow plugs are receiving power.

If the voltmeter needle does not move, the glow plugs are not receiving power.

3. Perform the troubleshooting procedure.

GLOW PLUGS ARE RECEIVING POWER

Checkpoint Possible cause Correction

Glow plug indicator

light does not turn on

Quick-on start timer Defective quick-on start timer Replace the quick-on start timer

Glow plug indicator

light turns on the 0.3

seconds

Glow plug indicator

light turns on for 3.5

seconds

Thermoswitch Defective thermoswitch Replace the thermoswitch

Glow plug continuity No glow plug continuity Replace the glow plugs

Defective indicator light bulb Replace the indicator light bulb

Defective quick-on start timer Replace the quick-on start timer

Return the starter switch to the “ON” position

from the “START” position after the engine

starts if the glow plug relay remains on less

than 14 seconds, the quick-on start timer is

defective

Move the starter switch from the “OFF”

position to the “ON” position if the glow plug

relay remains on less than 14 seconds, the

quick-on start timer is defective

Replace the quick-on start timer

Replace the quick-on start timer

GLOW PLUGS ARE NOT RECEIVING POWER

Glow plug indicator

light does not turn on

Quick-on start timer Defective quick-on start timer Replace the quick-on start timer

Broken indicator light fuse Replace the fuse

00 – 6 SERVICE INFORMATION

GLOW PLUGS ARE NOT RECEIVING POWER (Cont’d)

Checkpoint Possible cause Correction

Glow plug indicator

light turns on for 3.5

seconds

Defective glow plug relay

The glow plug relay does not turn on after the

starter switch is moved from the “OFF”

position to the “ON” position

Defective quick-on start timer Replace the quick-on start timer

Defective glow plug relay wiring harness Repair or replace the wiring harness

Defective fusible link or wiring harness

The glow plug relay turns on when the starter

switch is moved from the “OFF” position to

the “ON” position

Replace the glow plug relay

Replace the fusible link or the wiring

harness

2. UNSTABLE IDLING

Checkpoint Possible cause Correction

Idling system Idling improperly adjusted Adjust the idling

Fast idling speed Defective fast idling speed control device Repair or replace the fast idling speed

control device

Accelerator control

system

Accelerator control system improperly

adjusted

Adjust the accelerator control system

Fuel system

Fuel filter Clogged fuel filter element Replace the fuel filter element or the

Fuel feed pump Defective fuel feed pump Repair or replace the fuel feed pump

Injection pump Defective delivery valve resulting in fuel

Fuel system leakage or blockage Repair or replace the fuel system

Air in the fuel system Bleed the air from the fuel system

Water particles in the fuel system Change the fuel

fuel filter cartridge

Injection nozzle sticking Replace the injection nozzleInjection nozzle

Injection nozzle injection starting pressure

too low

Improper spray condition

drippage after fuel injection

Adjust or replace the injection nozzle

Replace the delivery valve

SERVICE INFORMATION 00 – 7

Checkpoint Possible cause Correction

Injection pump

(Cont’d)

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Compression pressure Blown out cylinder head gasket. Worn

Injection timing improperly adjusted Adjust the injection timing

Insufficient injection volume Adjust the injection volume

Defective idle spring Replace the idle spring

Defective governor lever operation Repair or replace the governor lever

Regulator valve improperly adjustment Adjust or replace the regulator valve

Broken plunger spring Replace the plunger spring

Worn plunger Replace the plunger assembly

Worn cam disc Replace the cam disc

Replace the related parts

cylinder liner.

Piston ring sticking

3. INSUFFICIENT POWER

Checkpoint Possible cause Correction

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Fuel Water particle in the fuel Replace fuel

Fuel filter Clogged fuel filter element Replace the fuel filter element or the

fuel filter cartridge

Fuel feed pump Defective fuel feed pump Repair or replace the fuel feed pump

Injection nozzle sticking Replace the injection nozzleInjection nozzle

Injection nozzle injection starting pressure

too low

Improper spray condition

Fuel injection pipes Fuel injection pipes damaged or obstructed Replace the fuel injection pipes

Adjust or replace the injection nozzle

00 – 8 SERVICE INFORMATION

Checkpoint Possible cause Correction

Injection pump

Compression pressure Blown out cylinder head gasket. Worn

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Valve spring Valve spring weak or broken Replace the valve spring

Defective regulating valve Repair or replace the regulating valve

Defective delivery valve Replace the delivery valve

Defective timer Repair or replace the timer

Worn cam disc Replace the cam disc

Improper control lever operation Adjust or replace the control lever

Defective injection timing Adjust the injection timing

Repair or replace the injection pump

timer

Weak governor spring Replace the governor spring

Worn plunger Replace the plunger assembly

Replace the related parts

cylinder liner.

Piston ring sticking

Exhaust system Exhaust pipe clogged Clean the exhaust pipe

Full load adjusting

screw seal

Open and improperly set adjusting screw

seal

Adjust and reseal the adjusting screw

SERVICE INFORMATION 00 – 9

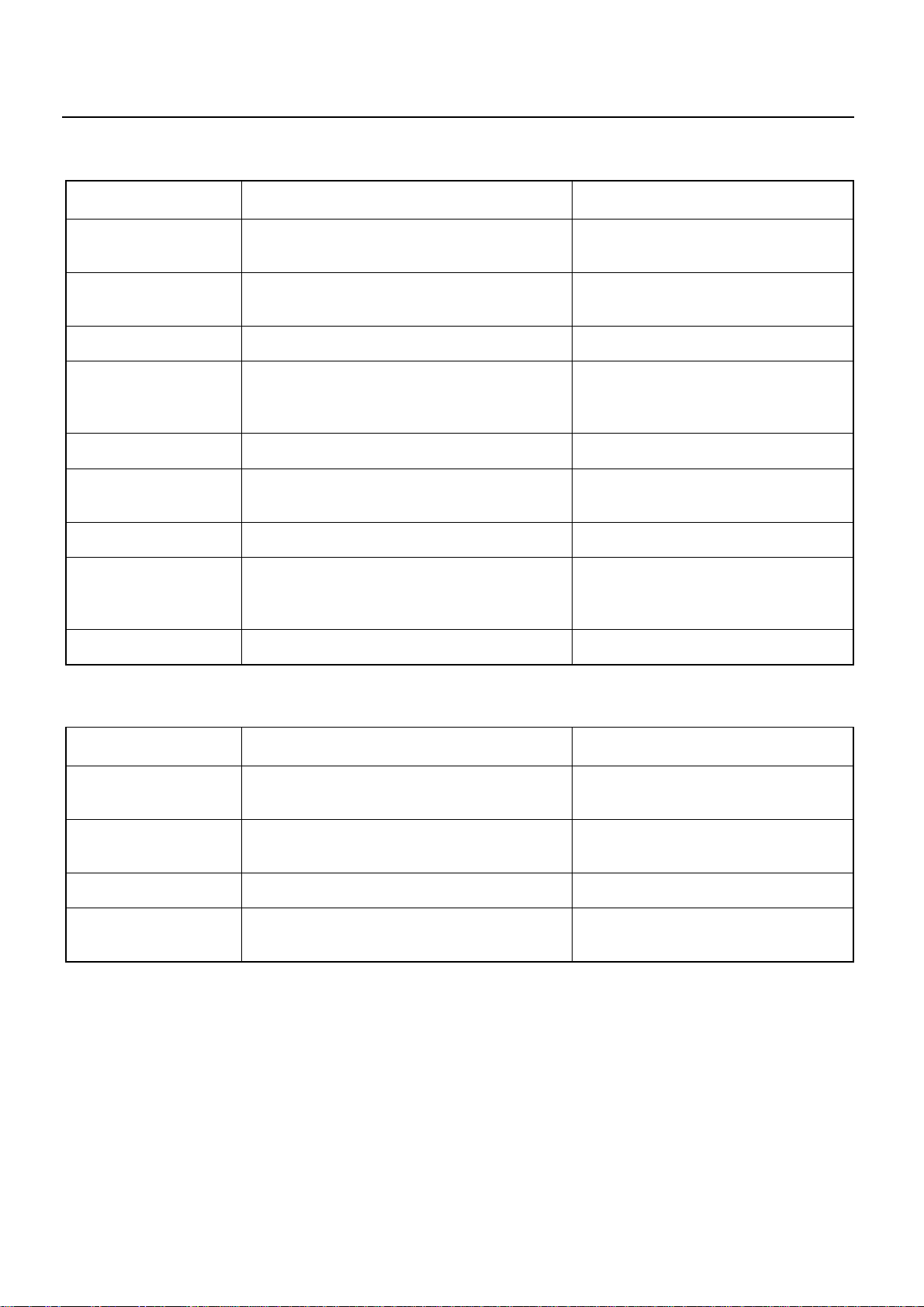

4. EXCESSIVE FUEL CONSUMPTION

Checkpoint Possible cause Correction

Fuel system Fuel leakage Repair or replace the fuel system

related parts

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Idling speed Poorly adjusted idling speed Adjust the idling speed

Injection nozzle Injection nozzle injection starting pressure

too low

Improper spray condition

Fuel injection timing Fuel injection timing improperly Adjust the fuel injection timing

Injection pump Defective Delivery valve resulting is fuel

drippage after fuel injection

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Compression pressure Blown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking

Valve spring Valve spring weak or broken Replace the valve spring

Adjust or replace the injection nozzle

Replace the delivery valve

Replace the related parts

5. EXCESSIVE OIL CONSUMPTION

Checkpoint Possible cause Correction

Engine oil Engine oil unsuitable

Too much engine oil

Replace the engine oil

Correct the engine oil level

Oil seal and gasket Oil leakage from the oil seal and/or the

gasket

Air breather Clogged air breather Clean the air breather

Intake and exhaust

valve

Worn valve stems and valve guides Replace the intake and exhaust

Replace the oil seal and/or the gasket

valves and the valve guides

00 – 10 SERVICE INFORMATION

6. OVERHEATING

Checkpoint Possible cause Correction

Cooling water Insufficient cooling water Replenish the cooling water

Fan clutch Oil leakage from the fan clutch Replace the fan clutch

Fan belt Fan belt loose or cracked causing slippage Replace the fan belt

Radiator Defective radiator cap or clogged radiator

core

Water pump Defective water pump Repair or replace the water pump

Cylinder head and

cylinder body sealing

cap

Thermostat Defective thermostat Replace the thermostat

Cooling system Cooling system clogged by foreign material Clean the foreign material from the

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Defective sealing cap resulting in water

leakage

Replace the radiator cap or clean the

radiator core

Replace the sealing cap

cooling system

7. WHITE EXHAUST SMOKE

Checkpoint Possible cause Correction

Cooling water Insufficient cooling water Replace the cooling water

Fuel Water particles in the fuel Replace the fuel

Fuel injection timing Delayed fuel injection timing Adjust the fuel injection timing

Compression pressure Blown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking

Inlet and exhaust valve

Valves seals

Defective valve seals.

Worn valves stems and valve guides

Replace the related parts

Replace the valve seals, the valves,

and the valve guides

SERVICE INFORMATION 00 – 11

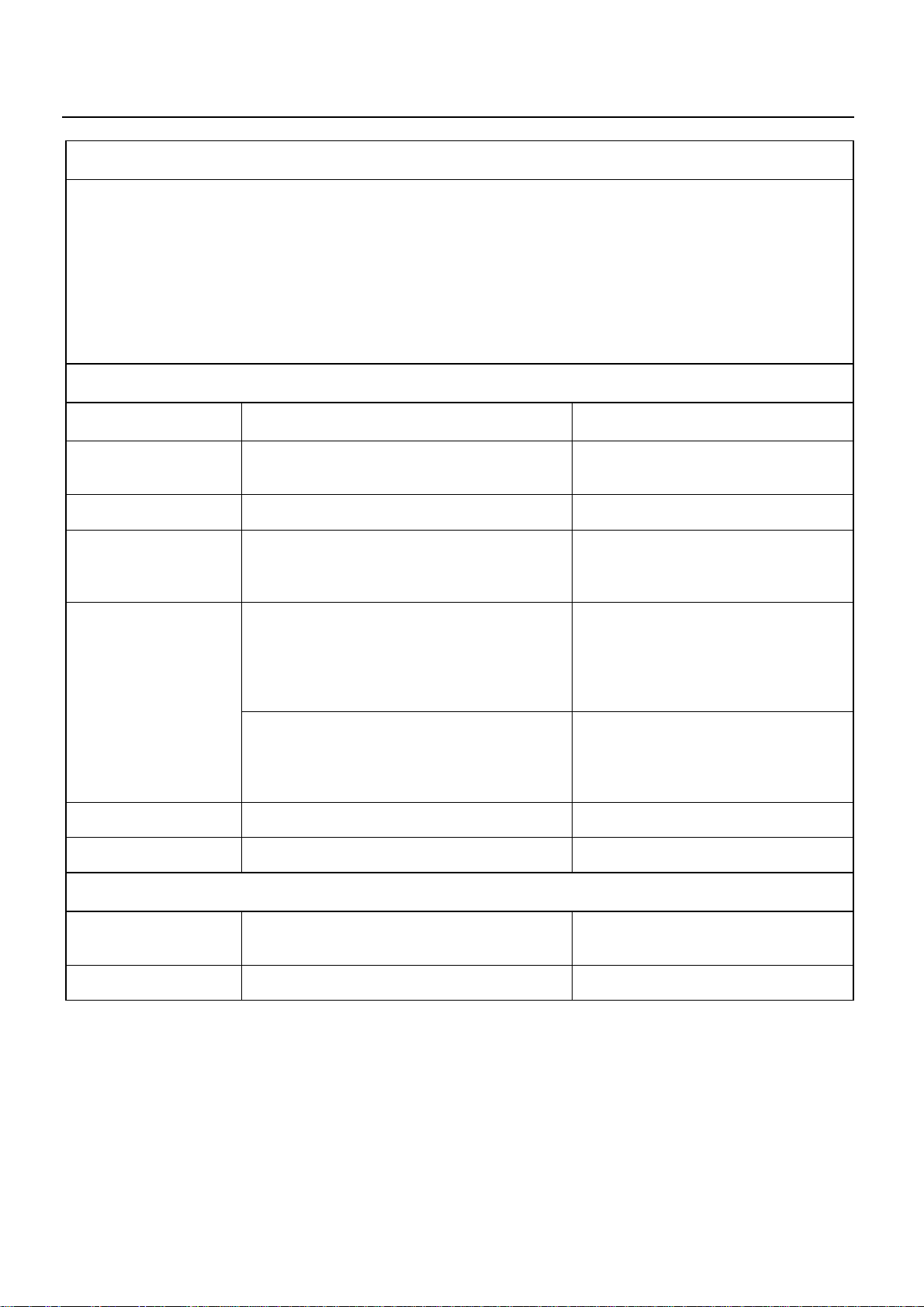

8. DARK EXHAUST SMOKE

Checkpoint Possible cause Correction

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Injection nozzle Injection nozzle injection starting pressure

too low

Improper spray condition

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Defective delivery valve resulting in fuel

drippage after fuel injection

Excessive injection volume Adjust the injection volume

Adjust or replace the injection nozzle

Replace the delivery valveInjection pump

9. OIL PRESSURE DOES NOT RISE

Checkpoint Possible cause Correction

Engine oil Improper viscosity engine oil.

Insufficient engine oil

Oil pressure gauge or

unit

Oil pressure indicator

light

Oil filter Clogged oil filter element Replace the oil filter element or the oil

Defective oil pressure gauge or unit

Defective indicator light

Replace the engine oil

Correct the engine oil volume

Repair or replace the oil pressure

gauge or unit

Replace the indicator light

filter cartridge

Relief valve and bypass valve

Rocker arm shaft Worn rocker arm bushing Replace the rocker arm bushing

Camshaft Worn camshaft and camshaft bearing Replace the camshaft and the

Crankshaft and

bearings

Relief valve sticking and/or weak by-pass

valve spring

Clogged oil pump strainer Clean the oil pump strainerOil pump

Worn oil pump related parts Replace the oil pump related parts

Worn crankshaft and bearings Replace the crankshaft and/or the

Replace the relief valve and/or the by-

pass valve spring

camshaft bearing

bearings

00 – 12 SERVICE INFORMATION

10. ABNORMAL ENGINE NOISE

1. ENGINE KNOCKING

Check to see that the engine has been thoroughly warmed up before beginning the troubleshooting procedure.

Checkpoint Possible cause Correction

Fuel Fuel unsuitable Replace the fuel

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Injection nozzle Improper injection nozzle starting pressure

and spray condition

Compression pressure Blown out head gasket

Broken piston ring

Adjust or replace the injection nozzle

Replace the head gasket or the piston

ring

2. GAS LEAKAGE NOISE

Exhaust pipes Loosely connected exhaust pipes. Broken

exhaust pipes

Injection nozzles

and/or glow plugs

Exhaust manifold Loosely connected exhaust manifold and/or

Cylinder head gasket Damaged cylinder head gasket Replace the cylinder head gasket

Loose injection nozzles and/or glow plugs Replace the washers

glow plugs

Tighten the exhaust pipe connections

Replace the exhaust pipes

Tighten the injection nozzles and/or

the glow plugs

Tighten the exhaust manifold

connections

3. CONTINUOUS NOISE

Fan belt Loose fan belt Readjust the fan belt tension

Cooling fan Loose cooling fan Retighten the cooling fan

Water pump bearing Worn or damaged water pump bearing Replace the water pump bearing

Generator or vacuum

pump

Valve clearance Clearance improperly adjust Adjust the valve clearances

Defective generator or vacuum pump Repair or replace the generator or the

vacuum pump

SERVICE INFORMATION 00 – 13

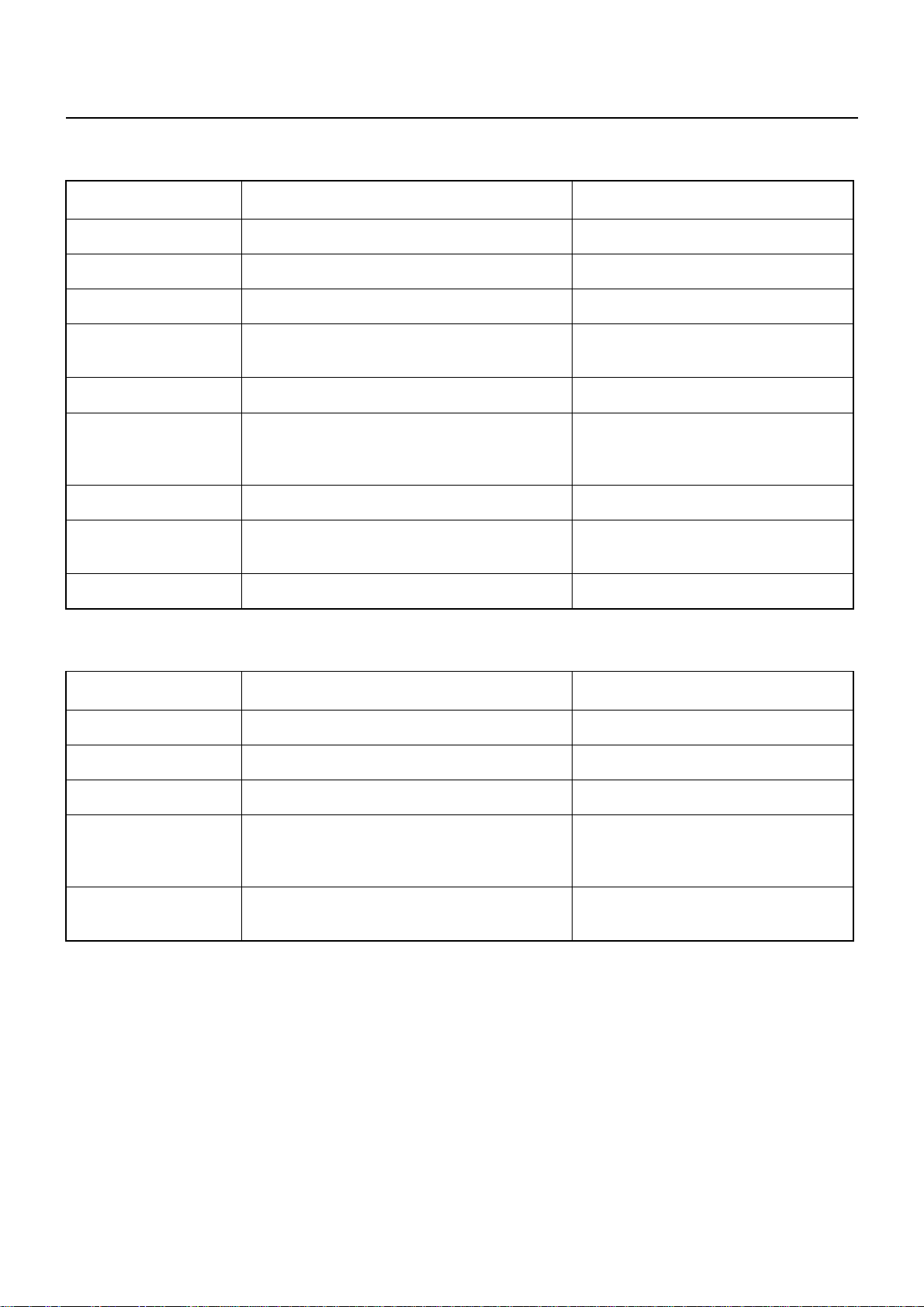

4. SLAPPING NOISE

Checkpoint Possible cause Correction

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Rocker arm Damaged rocker arm Replace the rocker arm

Flywheel Loose flywheel bolts Retighten the flywheel bolts

Crankshaft and thrust

bearings

Crankshaft and

connecting rod

bearings

Connecting rod

bushing and piston pin

Piston and cylinder

liner

Worn or damaged crankshaft and/or thrust

bearings

Worn or damaged crankshaft and/or

connecting rod bearings

Worn or damaged connecting rod bushing

and piston pin

Worn or damaged piston and cylinder liner. Replace the piston and the cylinder

Replace the crankshaft and/or the

thrust bearings

Replace the crankshaft and/or the

connecting rod bearings

Replace the connecting rod bushing

and/or the piston pin

liner.

00 – 14 SERVICE INFORMATION

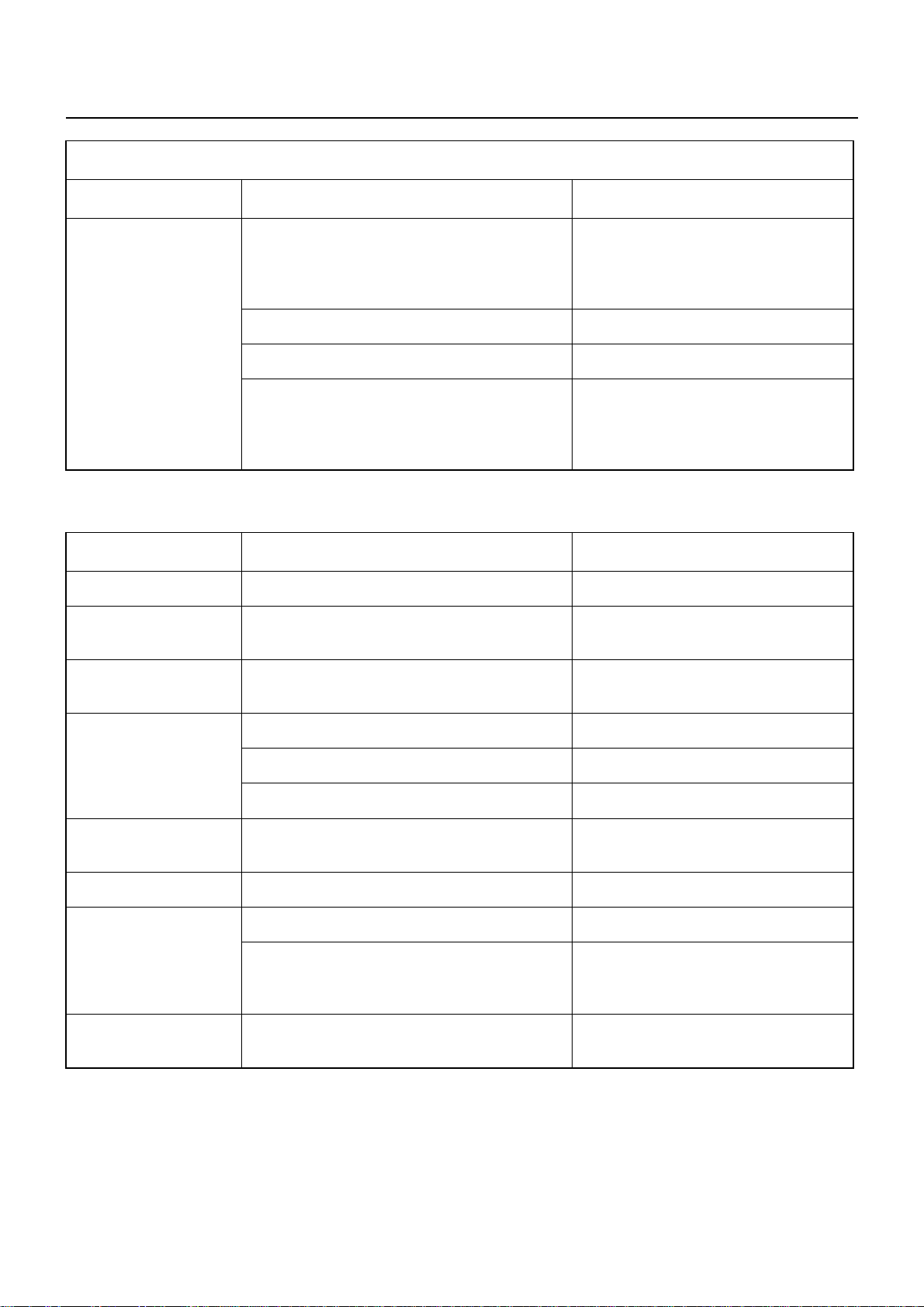

11. ENGINE COOLING TROUBLE

Checkpoint Possible cause Correction

Engine overheating

Low coolant level Replenish

Thermo unit faulty Replace

Faulty thermostat Replace

Faulty coolant unit Repair or replace

Clogged radiator Clean or replace

Faulty radiator cap Replace

Low engine oil level or use of improper

engine oil

Damaged cylinder head gasket Replace

Clogged exhaust system Clean exhaust system or replace

Loose fan belt Adjust

Excessive fuel injected Adjust

Improper injection timing Adjust

Replenish or change oil

Replenish

faulty parts

Engine overcooling Faulty thermostat Replace

Faulty thermostat ReplaceToo long engine

warm-up time

Thermo unit faulty Replace

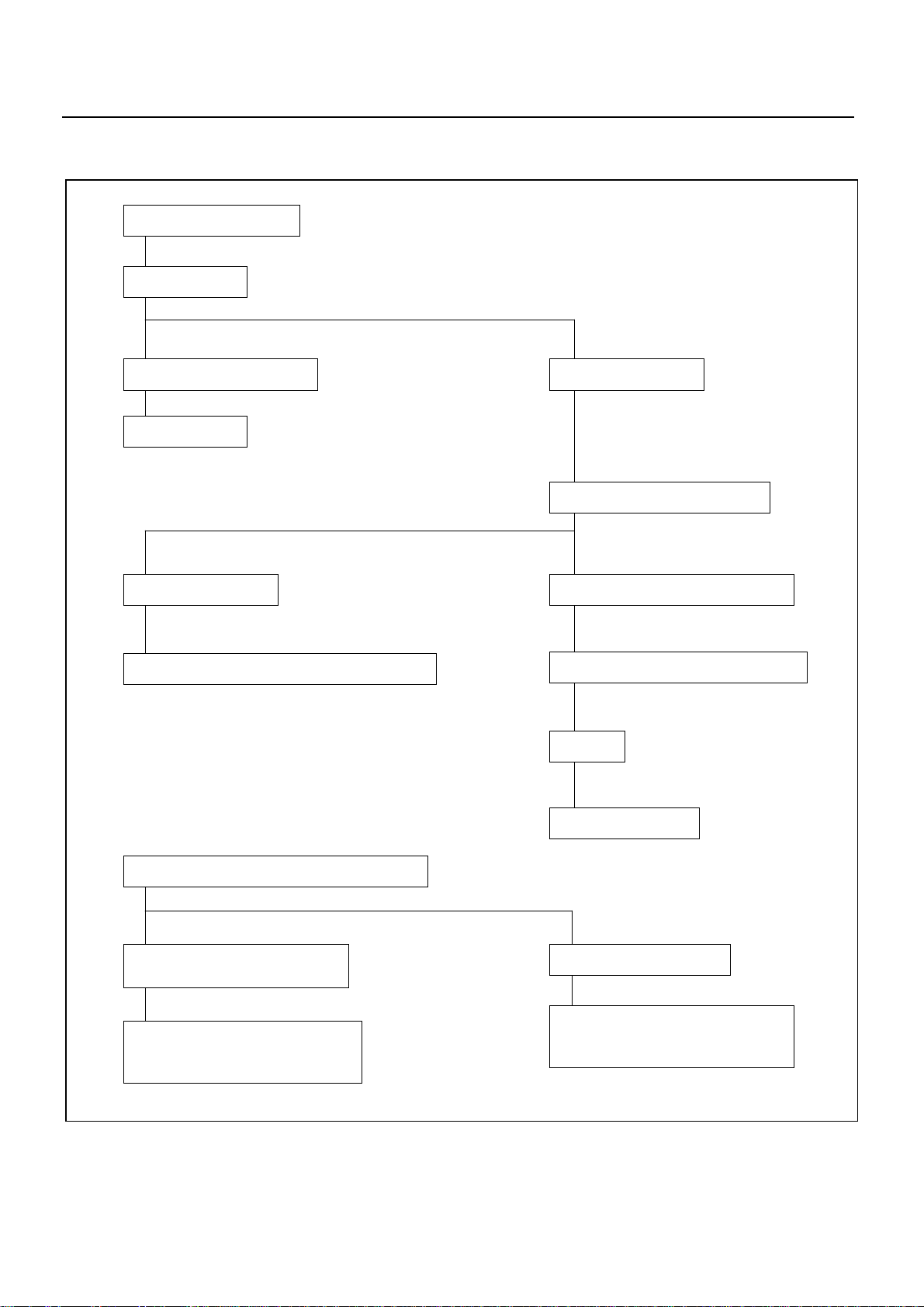

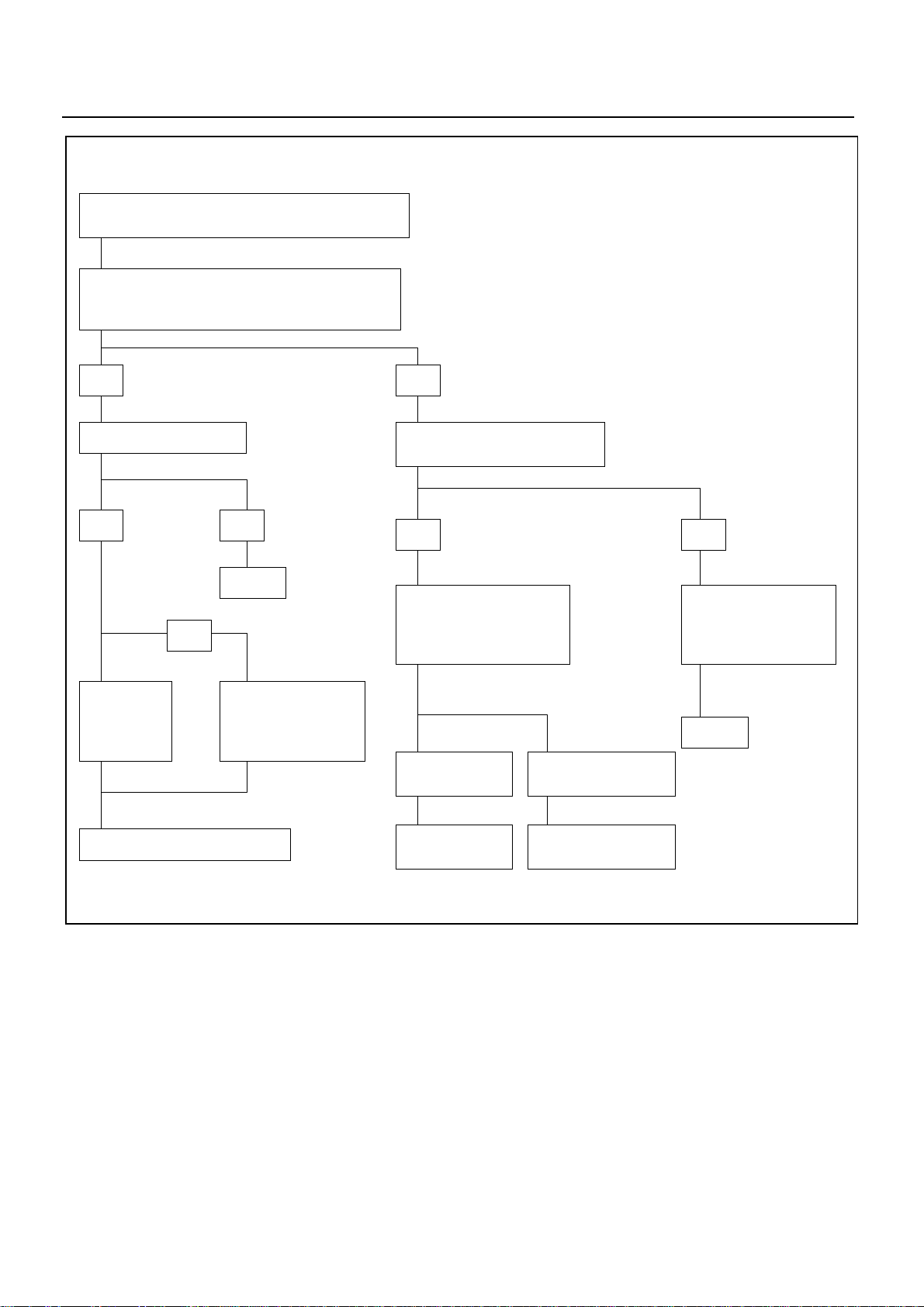

12. ENGINE ELECTRICAL PART TROUBLE

STARTER DOES NOT RUN

CHECK BATTERY

SERVICE INFORMATION 00 – 15

CHARGING FAILURE OR LIFE

CHECK BATTERY

CONNECTION FAILURE

CLEAN BATTERY TERMINALS, AND RECONNECT

BATTERY IS NORMAL

CHECK TERMINAL CONNECTION

TERMINAL CONNECTION IS NORMAL

CHECK STARTER OR STARTER SWITCH

FAILURE

REPAIR OR REPLACE

TURN ON HEAD LAMP AND STARTER SWITCH

HEAD LAMP DOES NOT COME ON

OR IT IS EXTREMELY DARK

a) LACK OF BATTERY CHARGING

b) SHORT-CIRCUIT IN STARTER OIL

c) FAULTY STARTER PARTS

HEAD LAMP ILLUMINATES

a) DISCONNECT STARTER CIRCUIT

b) DISCONNECT STARTER COIL

c) FAULTY STARTER SWITCH

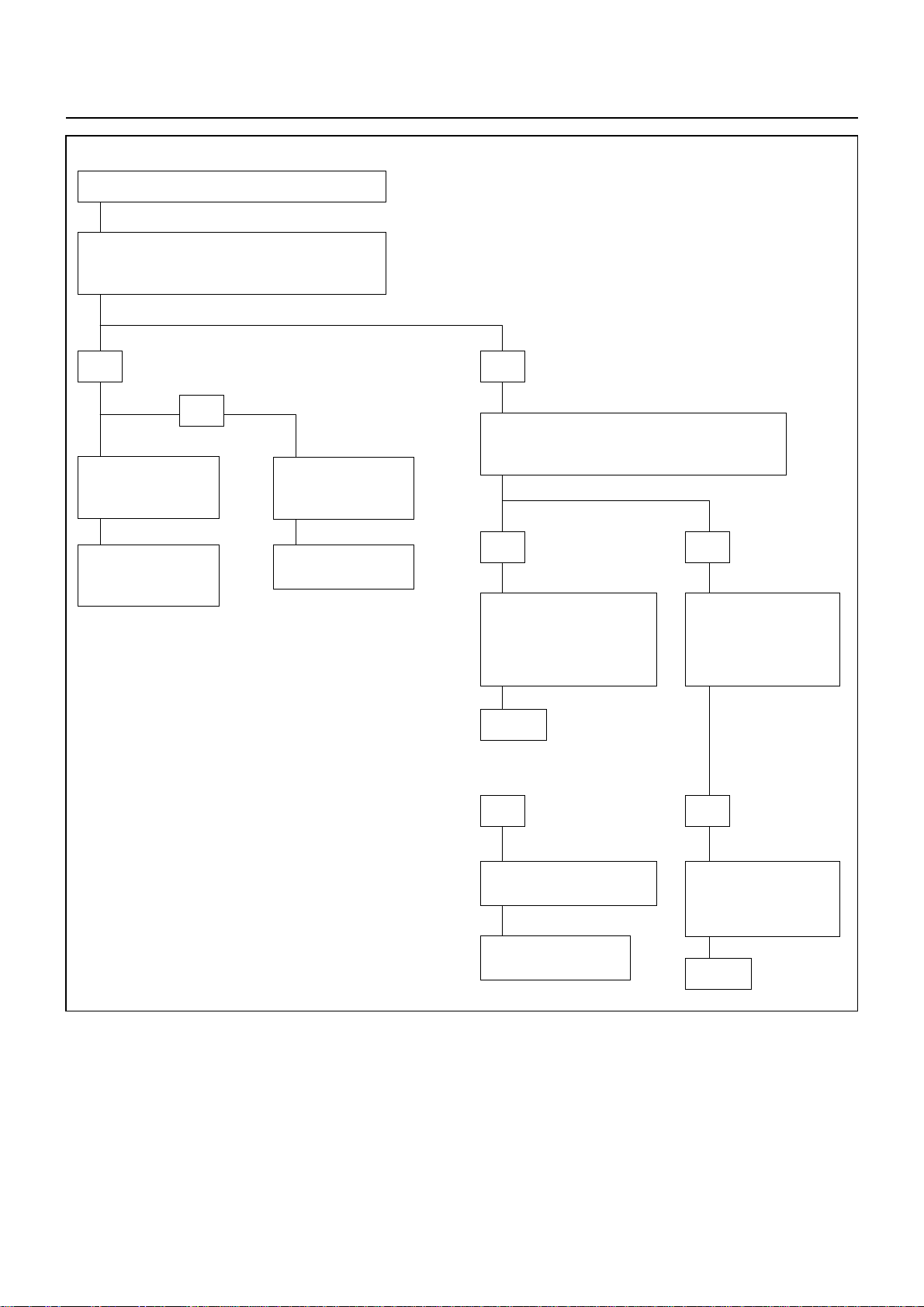

00 – 16 SERVICE INFORMATION

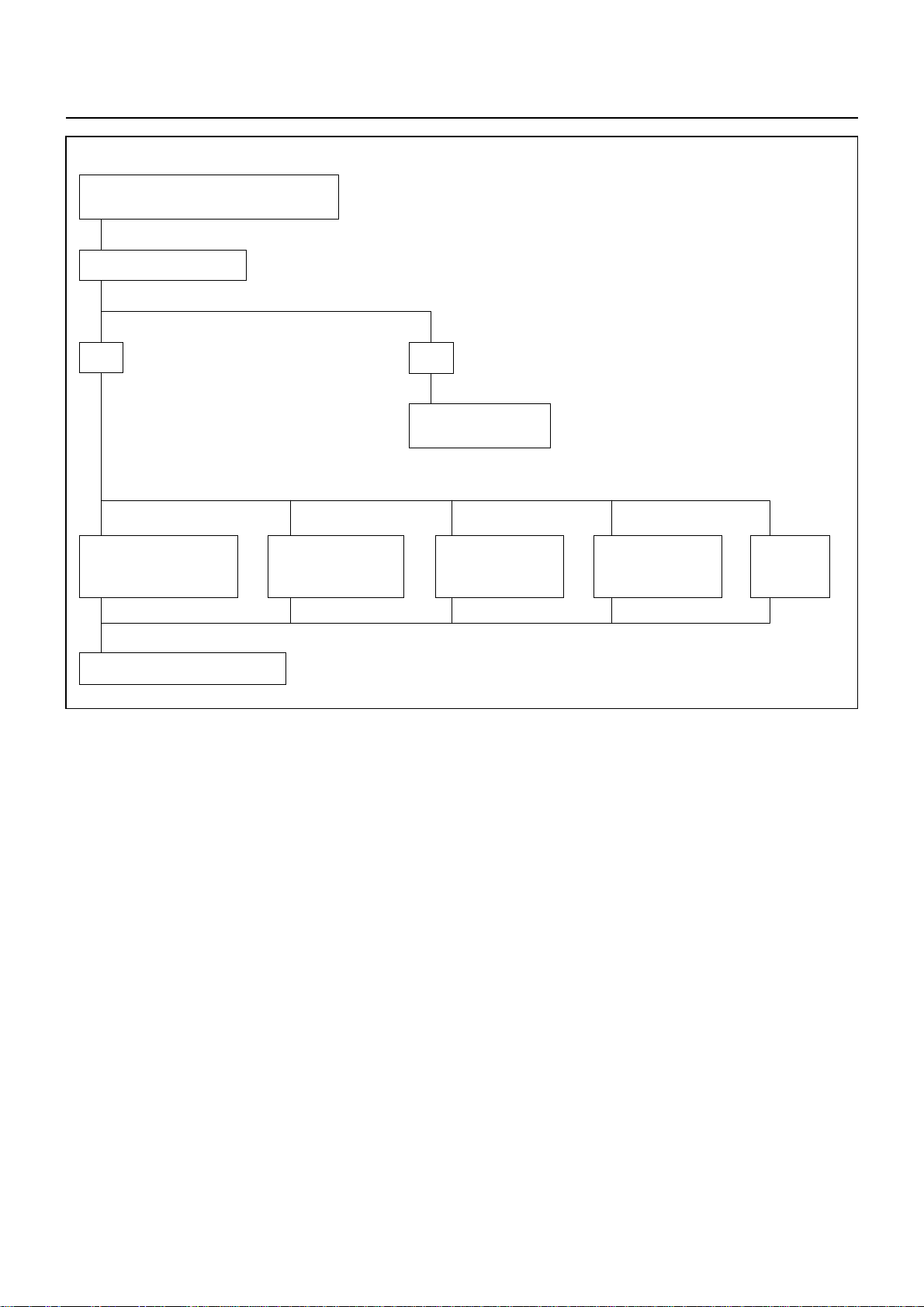

FAULTY MESHING OF PINION AND RING GEAR

CHECK IF BATTERY VOLTAGE IS PRESENT AT

MAGNETIC SWITCH TERMINAL “S” WHEN

STARTER SWITCH IS TURNED TO “START (ST)”

YES

OR

EXTREME WEAR OF

PINION AND RING

GEAR

REPAIR OR REPLACE

STARTER, REPLACE

RING GEAR

STARTER SLIDING

RESISTANCE IS

LARGE

REPAIR OR REPLACE

STARTER

NO

UNDER THIS CONDITION, CHECK IF VOLTAGE

OF CONNECTOR 3BW ON MAGNETIC SWITCH

OF RESTART RELAY IS NORMAL

YES NO

DISCONNECTION OR

FAULTY CONNECTION

BETWEEN STARTER

SWITCH AND MAGNETIC

SWITCH

REPAIR

YES NO

CHECK IF VOLTAGE IS

PRESENT AT WIRING

CONNECTOR 3BW ON

STARTER SWITCH OF

RESTART RELAY

FAULTY CONNECTION OF

STARTER SWITCH

REPLACE STARTER

SWITCH

DISCONNECTION OR

FAULTY CONNECTION

BETWEEN STARTER

SWITCH AND BATTERY

REPAIR

MAGNETIC SWITCH DOES NOT OPERATE THOUGH

STARTER SWITCH IS TURNED TO “START (ST)”

CHECK IF VOLTAGE IS PRESENT AT MAGNETIC

SWITCH TERMINAL “S” WHEN STARTER SWITCH IS

TURNED TO “START (ST)”

SERVICE INFORMATION 00 – 17

YES

YES

YES

CHECK GROUND CABLE

YES NO

REPAIR

OR

PINION

SLIDING

PART DOES

NOT MOVE

MAGNETIC SWITCH

OR COIL IS

DISCONNECTED OR

BURNED OUT

NO

CHECK IF INDICATOR LAMP ON

METER COMES ON NORMALLY

YES NO

CHECK CONTINUITY

STARTER SWITCH AND

MAGNETIC SWITCH

TERMINAL “S”

CHECK STARTER

RELAY

FAULTY CONNECTION

OR STARTER SWITCH

DISCONNECTION OR

FAULTY CONNECTION

BETWEEN BATTERY

AND STARTER SWITCH

REPAIR

REPAIR OR REPLACE STARTER

CHECK CLUTCH

START

REPLACE STARTER

SWITCH

00 – 18 SERVICE INFORMATION

PINION MESHES WITH RING GEAR BUT

ENGINE DOES NOT RUN

CHECK GROUND CABLE

YES

FAULTY CONNECTION

OF BRUSH AND

COMMUTATOR

REPAIR OR REPLACE STARTER

BURNED-OUT

MAGNETIC

STARTER SWITCH

NO

REPAIR OR REPLACE

GROUND CABLE

DISCONNECTION

OR DAMAGE OF

FIELD COIL

DISCONNECTION

OR DAMAGED OF

ARMATURE COIL

SLIP OF

PINION

CLUTCH

SERVICE INFORMATION 00 – 19

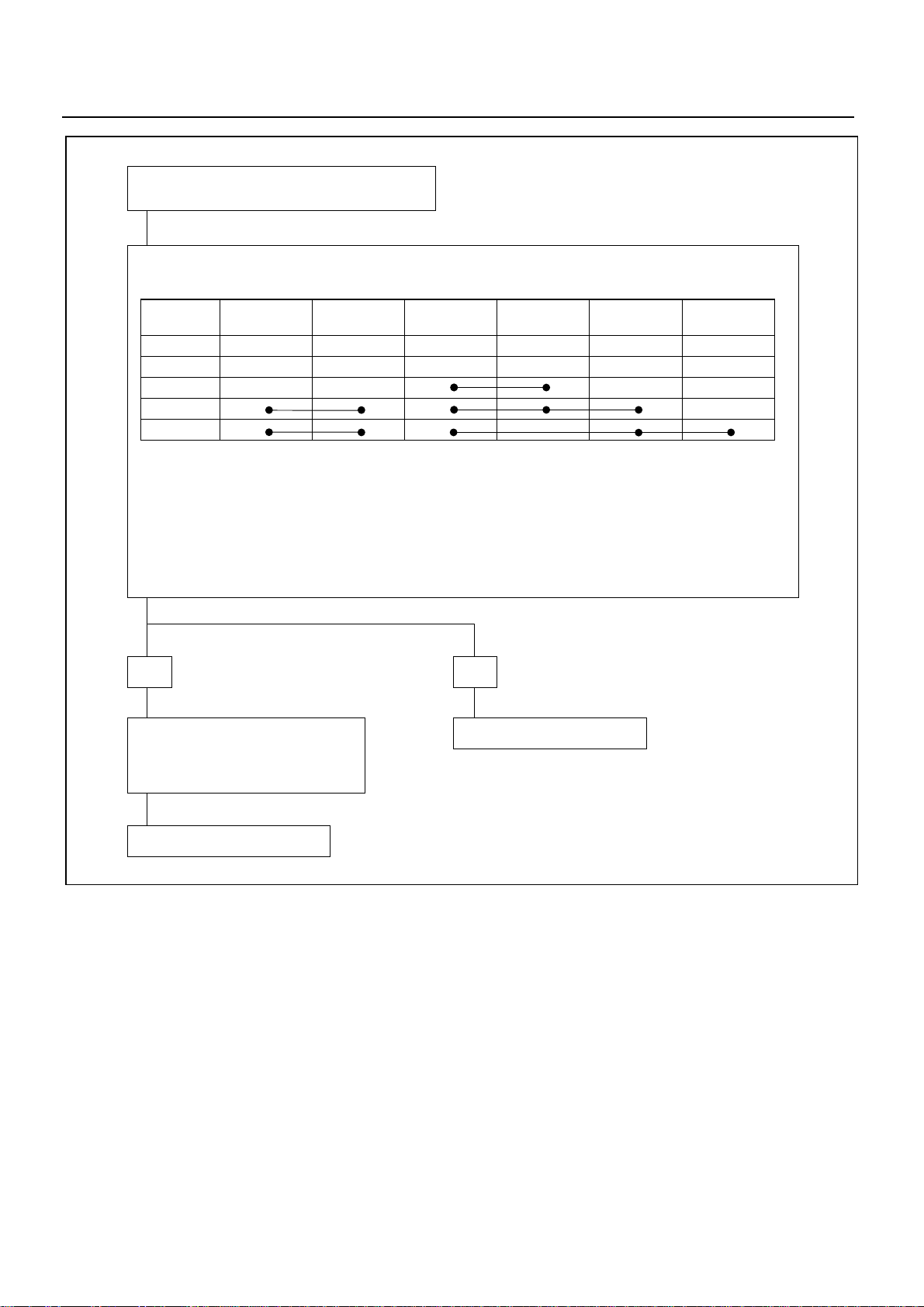

STARTER DOES NOT STOP THOUGH STARTER

SWITCH IS RETURNED TO “ON” FROM “START”

DISCONNECTED STARTER SWITCH WIRING CONNECTOR, AND CHECK STARTER SWITCH OPERATION.

KEY

POSITION

LOCK

OFF

ACC

ON

START

THERE MUST BE NO CONTINUITY EXCEPT ABOVE LINES.

YES

MAGNETIC SWITCH CONTACTS ARE

FUSED AND NOT MOVED, OR A

RETURN SPRING IS BROKEN OR

DETERIORATED

BATTERY

B1

IGNITION

IG1

BATTERYB2ACCESSORIES

ACC

IGNITION

NO

REPLACE STARTER SWITCH

IG2

STARTER

ST

REPLACE MAGNETIC SWITCH

00 – 20 SERVICE INFORMATION

1) ENGINE HAS LESS THAN NORMAL POWER

Checkpoint Trouble Cause Countermeasure

13. TURBOCHARGER

Air cleaner Restricted Clean or replace

OKOK

Intake pipe and hose Restricted Clean or replace

OK

Compressor/Intake manifold Loose (Leaking) Repair

OK

Exhaust manifold/turbine inlet Loose (Leaking) Repair

OK

NG

NG

NG

NG

NG

Exhaust piping and silencers Restricted Clean or replace

OK

Air breather Restricted Clean or replace

OK

Boost compensator

(Injection pump)

Continued on the next page

NG

NG

Defective Repair or replace

Checkpoint Trouble Cause Countermeasure

Continued from the previous page

OK

SERVICE INFORMATION 00 – 21

Compressor wheel Impact damage Replace

OKOK

Turbine wheel Impact damage Replace

OK

Rotating assembly Dragging or seized Replace

NG

NG

NG

Carbon build-up Replace

NG

00 – 22 SERVICE INFORMATION

Checkpoint Trouble Cause Countermeasure

2) BLUE OR BLACK SMOKE

Air cleaner or intercooler Restricted Clean, repair, or replace

OKOK

Turbocharger oil seal Leakage Replace

OK

Turbocharger oil drain pipe Restricted Repair or replace

OK

Air breather Restricted Clean

OK

NG

NG

NG

NG

Boost compensator

(Injection pump)

OK

Compressor wheel Impact damage Replace

OK

Turbine wheel Impact damage Replace

Continued on the next page

NG

Defective Repair or replace

NG

NG

Checkpoint Trouble Cause Countermeasure

Continued from the previous page

OK

SERVICE INFORMATION 00 – 23

Center housing oil drain passage Restricted Clean or replace

NG

00 – 24 SERVICE INFORMATION

Checkpoint Trouble Cause Countermeasure

3) EXCESSIVE OIL CONSUMPTION

Air breather Restricted Clean

OKOK

Boost compensator

(Injection pump)

OK

Turbocharger oil seal Leakage Replace

OK

Turbocharger oil drain pipe Restricted Clean or replace

OK

NG

NG

Defective Repair or replace

NG

NG

NG

Turbine wheel Impact damage Replace

OK

Compressor wheel Impact damage Replace

OK

Oil pressure Excessive Repair

Continued on the next page

NG

NG

Checkpoint Trouble Cause Countermeasure

Continued from the previous page

OK

SERVICE INFORMATION 00 – 25

Center housing oil drain passage

NG

Restricted Clean or replace

00 – 26 SERVICE INFORMATION

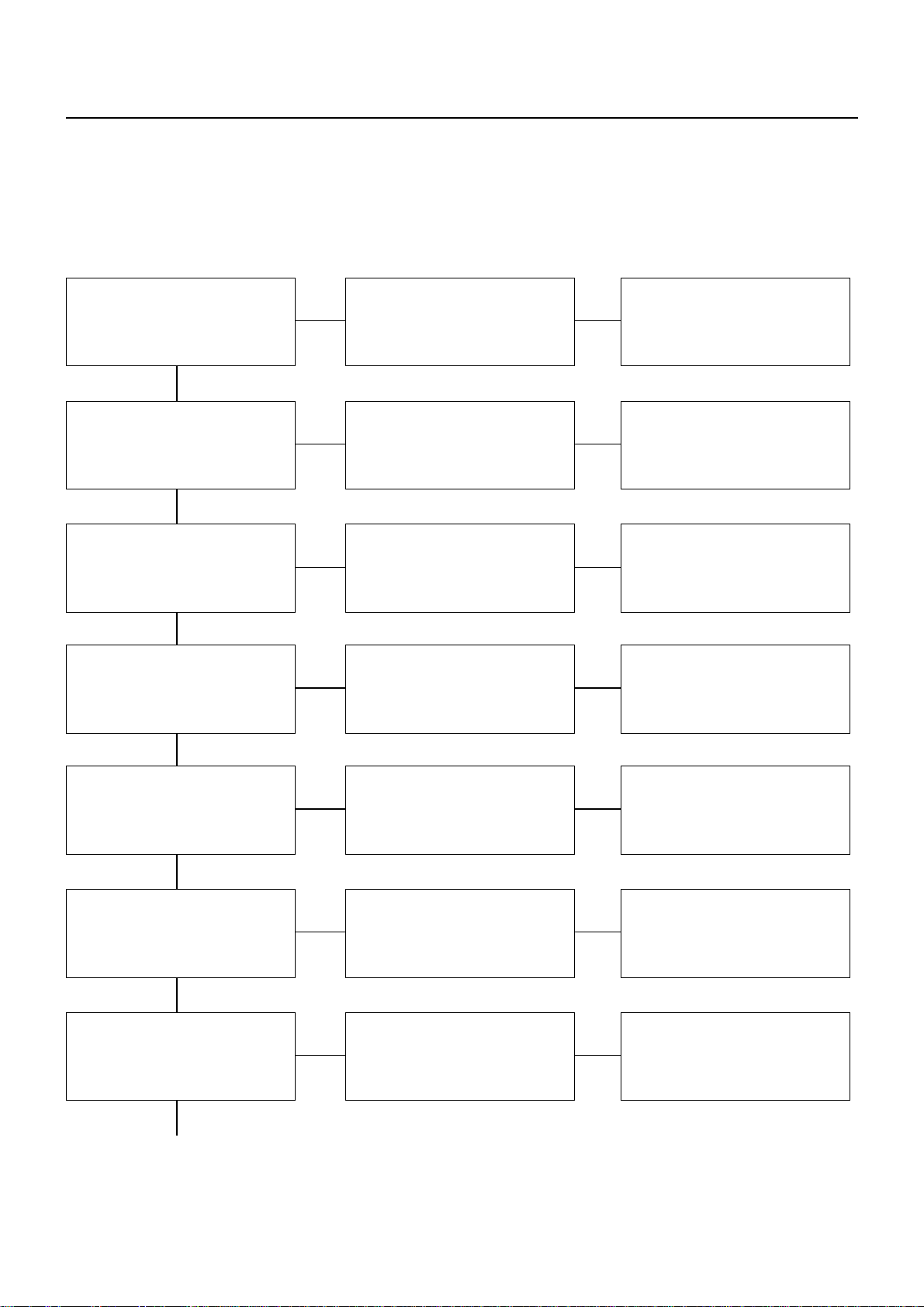

4) EXCESSIVE TURBOCHARGER NOISE

Checkpoint Trouble Cause Countermeasure

Intake and exhaust

system joints

OKOK

Intake and exhaust system

gaskets

OK

Turbocharger rotating parts Rough rotation Replace

Compressor wheel

NG

NG

NG

NG

Restricted Repair

Damaged Replace

Rubbing against housing Repair or replace

OK

Turbine wheel

Continued on the next page

NG

NG

NG

NG

Damaged Replace

Rubbing against housing Repair or replace

Damaged Replace

Carbon deposits Clean or replace

Loading...

Loading...