Page 1

TNV_OperationManual_T4(under 19kW).book Page i Wednesday, June 17, 2015 11:23 AM

TNV Operation Manual

INTRODUCTION

To help you enjoy your Isuzu C series engine for

many years to come, please follow these

recommendations:

• Read and understand this Operation Manual

before you operate the machine to ensure that

you follow safe operating practices and

maintenance procedures.

• Keep this Operation Manual in a con venient plac e

for easy access.

• If this Operation Manual is lost or damaged, order

a new one from your Isuzu Distributor.

• Make sure this manual is transferred to

subsequent owners. This manual should be

considered a permanent part of the engine and

remain with it.

• Constant efforts are made to improve the quality

and performance of Isuzu products, so some

details included in this Operation Manual may

differ slightly from your engine. If you have any

questions about these differences , please contact

your Isuzu Distributor.

• The specifications and components (instrument

panel, fuel tank, etc.) described in this manual

may differ from ones installed on your machine.

Please refer to the manual provided by the

manufacturer of these components.

i

Page 2

TNV_OperationManual_T4(under 19kW).book Page ii Wednesday, J une 17, 2015 11:23 AM

INTRODUCTION

RECORD OF OWNERSHIP

Take a few moments to record the information you need when you contact Isuzu for service, parts or

literature.

Engine model:________________________________________________________________________

Engine serial No.: _____________________________________________________________________

Date purchased: ______________________________________________________________________

Dealer: ______________________________________________________________________________

Dealer phone: ________________________________________________________________________

SYMBOL EXPLANATION

The following symbols are used throughout this manual to identify specific engine model information

This symbol indicates information pertaining to the following indirect injection engines:

• 3CH1-NGZG01

• 3CH1-SDZP01

• 3CJ1-NGZG01

• 3CJ1-SDZP01

All of the models conform to the engine emission regulations (EPA 2013 rules).

This symbol indicates information pertaining to the following direct injection engines:

•3CE1

This model conform to the engine emission regulations (EPA 2013 rules).

ii

Page 3

TNV_OperationManual_T4(under 19kW).book Page iii Wednesday, June 17, 2015 11:23 AM

TABLE OF

CONTENTS

Introduction............................................................................................... i

Record of Ownership........................................................................... ii

Symbol Explanation............................................................................. ii

Table of Contents ................................................................................... iii

Isuzu Engine After Service .................................................................... 1

Isuzu Genuine Parts........................................................................... 2

Emission-Related Installation Instructions (REF) ............................... 2

Installation of Nonroad Engines into Equipment........................... 2

Allowable Air Intake Restriction and Exhaust Back Pressure....... 2

Allowable Air Intake Restriction.................................................... 2

Allowable Exhaust Back Pressure................................................ 2

Safety....................................................................................................... 3

Safety Statements .............................................................................. 3

Safety Precautions.............................................................................. 4

Before You Operate...................................................................... 4

During Operation and Maintenance.............................................. 4

Product Overview................................................................................. 13

Isuzu C series Engine Features and Applications............................ 13

Component Identification.................................................................. 14

Location of Labels............................................................................. 17

Function of Major Engine Components ............................................ 18

Function of Cooling System Components ........................................ 20

Electronic Control System ................................................................ 21

Main Electronic Control Components and Features......................... 24

iii

Page 4

TNV_OperationManual_T4(under 19kW).book Page iv Wednesday, June 17, 2015 11:23 AM

TABLE OF CONTENTS

Gauges and Indicators...................................................................... 26

Gauges........................................................................................ 26

Indicators..................................................................................... 27

Gauges and Indicators of Electronic Control System........................ 28

Gauges........................................................................................ 28

Indicators..................................................................................... 28

Controls............................................................................................. 29

Key Switch................................................................................... 29

Glow Plugs.................................................................................. 30

Governor Lever ........................................................................... 30

Engine Stop Solenoid (IDI Engines)............................................ 31

Speed Control of Electronically Controlled Engines.................... 31

Electronic Engine Speed Control ................................................ 32

Before You Operate .............................................................................. 35

Diesel Fuel ........................................................................................ 36

Diesel Fuel Specifications........................................................... 36

Filling the Fuel Tank.................................................................... 41

Priming the Fuel System............................................................. 42

Engine Oil.......................................................................................... 43

Engine Oil Specifications............................................................. 43

Engine Oil Viscosity..................................................................... 44

Checking Engine Oil.................................................................... 44

Adding Engine Oil........................................................................ 44

Engine Oil Capacity (Typical)...................................................... 45

Engine Coolant.................................................................................. 46

Engine Coolant Specifications..................................................... 47

Filling Radiator with Engine Coolant ........................................... 47

Daily Check of the Cooling System............................................. 48

Engine Coolant Capacity (Typical).............................................. 48

Daily Checks ..................................................................................... 49

Visual Checks.............................................................................. 49

Check Diesel Fuel, Engine Oil and Engine Coolant Levels......... 49

Check Engine Speed Control...................................................... 49

Check Operator’s Console.......................................................... 50

Check Indicators.......................................................................... 50

Engine Operation .................................................................................. 53

Starting Engine.................................................................................. 54

Cold Start Device .............................................................................. 56

High-altitude Injection Control Device............................................... 56

Checking the Engine During Operation............................................ 57

Adjust Engine Speed......................................................................... 59

Shutting Down the Engine................................................................. 60

iv

Page 5

TNV_OperationManual_T4(under 19kW).book Page v Wednesday, June 17, 2015 11:23 AM

Periodic Maintenance........................................................................... 61

Precautions....................................................................................... 62

The Importance of Periodic Maintenance................................... 62

Performing Periodic Maintenance............................................... 62

The Importance of Daily Checks................................................. 62

Keep a Log of Engine Hours and Daily Checks.......................... 62

Isuzu Replacement Parts............................................................ 62

Tools Required ........................................................................... 62

Ask Your Isuzu Distributor For Help ........................................... 62

Required EPA/ARB Maintenance USA Only.............................. 62

EPA/ARB Installation Requirements USA Only.......................... 63

Tightening Fasteners.................................................................. 63

Standard Torque Chart..................................................................... 63

Periodic Maintenance Schedule....................................................... 64

Periodic Maintenance Chart ....................................................... 64

Periodic Maintenance Procedures.................................................... 66

After Initial 50 Hours of Operation .............................................. 66

Every 50 Hours of Operation ...................................................... 71

Every 250 Hours of Operation .................................................... 75

Every 500 Hours of Operation .................................................... 79

Every 1000 Hours of Operation .................................................. 83

Every 1500 Hours of Operation .................................................. 85

Every 2000 Hours of Operation .................................................. 86

Every 3000 Hours of Operation .................................................. 87

Troubleshooting ................................................................................... 89

Troubleshooting Chart...................................................................... 90

Troubleshooting of Electronic Control System.................................. 92

Fault Detection Capability........................................................... 92

Troubleshooting Information............................................................. 94

List of Possible Faults of Electronically Controlled Engines............. 95

Long-Term Storage .............................................................................. 99

Before You Place the Engine In Long-Term Storage ..................... 100

Returning the Engine to Service..................................................... 101

Specifications ..................................................................................... 103

Engine General Specifications........................................................ 104

Principal Engine Specifications....................................................... 105

TABLE OF CONTENTS

v

Page 6

TNV_OperationManual_T4(under 19kW).book Page vi Wednesday, June 17, 2015 11:23 AM

TABLE OF CONTENTS

This Page Intentionally Left Blank

vi

Page 7

TNV_OperationManual_T4(under 19kW).book Page 1 Wednesday, June 17, 2015 11:23 AM

TNV Operation Manual

ISUZU ENGINE

AFTER SERVICE

Please feel free to contact your Isuzu distributor for

periodical inspection and maintenance.

1

Page 8

TNV_OperationManual_T4(under 19kW).book Page 2 Wednesday, June 17, 2015 11:23 AM

ISUZU ENGINE AFTER SERVICE

ISUZU GENUINE PARTS

The Isuzu genuine parts are identical with those of used in the

engine production, and accordingly, they are warranted by Isuzu

Motors Limited.

The Isuzu genuine parts are supplied by the Isuzu distributors or

the authorized parts suppliers. Please designate "Isuzu Genuine

Parts" when you need engine parts.

EMISSION-RELATED INSTALLATION INSTRUCTIONS (REF)

Failing to follow these instructions when installing a certified engine in a piece of nonroad equipment

violates Federal Law (40 CFR1068.105(B)), subject to fines or other penalties as described in the clean air

act.

Installation of Nonroad Engines into Equipment

To ensure engines operate under the certified configurations, Isuzu has established defined application

requirements when installing any certified engine into a piece of equipment. The instructions outlined below

are included in our certification process and any failure to comply will be considered tampering.

Isuzu certifies engines to operate under variable speed or constant speed conditions. Engines certified as

constant speed are prohibited from installation into variable speed applications. The emission control

information label will identify an engine certified as constant speed.

Allowable Air Intake Restriction and Exhaust Back Pressure

Resistance to intake airflow and exhaust gas flow is generated in the intake and exhaust systems.

Exceeding the limitations will affect the operation of an engine and its certified configuration. Refer to the

installation requirements and limitations of the Isuzu C series Application Manual for the engine being

equipped with these systems.

Allowable Air Intake Restriction

Engine model

All models 2.94 (300) 6.23 (635)

Initial upper limit Upper limit for air cleaner replacement

Allowable air intake restriction kPa (mmAq)

Allowable Exhaust Back Pressure

Engine model

3CH1, 3CJ1 9.81 (1000) 11.77 (1200)

3CE1 12.75 (1300) 15.30 (1560)

Initial upper limit Upper limit for exhaust system cleaning

Allowable exhaust back p ressure kPa (mmAq)

2

Page 9

DANGER

WARNING

CAUTION

TNV_OperationManual_T4(under 19kW).book Page 3 Wednesday, June 17, 2015 11:23 AM

TNV Operation Manual

SAFETY

SAFETY STATEMENTS

Isuzu is concerned for your safety and your

machine’s condition. Safety statements are one of

the primary ways to call your attention to the

potential hazards associated with Isuzu C series

engine operation. Follow the precautions listed

throughout the manual before operation, during

operation and during periodic maintenance

procedures for your safety, the safety of others and

to protect the performance of your engine . Keep the

labels from becoming dirty or torn and replace them

if they are lost or damaged. Also, if you need to

replace a part that has a label attached to it, make

sure you order the new part and label at the same

time.

DANGER indicates a hazardous situation which,

if not avoided, will result in death or serious

injury.

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

This safety alert symbol appears with

most safety statements. It means

attention, become alert, your safety is

involved! Please read and abide by the

message that follows the safety alert

symbol.

NOTICE

NOTICE indicates a situation which can cause

damage to the machine, personal property and/or

the environment or cause the equipment to operate

improperly.

3

Page 10

NOTICENOTICE

DANGER

TNV_OperationManual_T4(under 19kW).book Page 4 Wednesday, June 17, 2015 11:23 AM

SAFETY

SAFETY PRECAUTIONS

Before You Operate

• Never permit any one to operate the

engine or driven machine without

proper training.

• Read and understand this Operation Manual

before you operate or service the machine to

ensure that you follow safe operating practices

and maintenance procedures.

• Machine safety signs and labels are additional

reminders for safe operating and maintenance

techniques.

• See your Isuzu Distributor for additional training.

During Operation and Maintenance

Scald Hazard!

• Never remove the radiator cap if

the engine is hot. Steam and hot

engine coolant will spurt out and

seriously burn you. Allow the

engine to cool down before you

attempt to remove the radiator

cap.

• Tighten the radiator cap securely after you

check the radiator. Stea m can spurt out during

engine operation if the cap is loose.

• Always check the level of the engine coolant

by observing the reserve tank.

• Failure to comply will result in death or

serious injury.

DANGER

Explosion Hazard!

• Keep the area around the battery

well-ventilated. While the engine

is running or the battery is

charging, hydrogen gas is

produced which can be easily

ignited.

• Keep sparks, open flame and any other form

of ignition away while the engine is running or

battery is charging.

• Never short out the battery terminals,

including when checking the remaining

battery charge. This will result in a spark and

may cause an explosion or fire. Use a

hydrometer to check the remaining battery

charge.

• If the electrolyte is frozen, slowly warm the

battery before you recharge it.

• Failure to comply will result in death or

serious injury.

Sudden Movement Hazard!

• Never start the engine by

shorting out the starter terminal

and the battery terminal

(Jump-start). The machine may

move suddenly if the machine

safety circuit is released, but

the gear is still engaged.

• Failure to comply will result in death or

serious injury.

4

Page 11

DANGER

(Continued)

TNV_OperationManual_T4(under 19kW).book Page 5 Wednesday, June 17, 2015 11:23 AM

DANGER

Fire and Explosion Hazard!

• Diesel fuel is extremely

flammable and explosive under

certain conditions.

• When you remove any fuel system component

to perform maintenance (such as changing

the fuel filter) place an approved container

under the opening to catch the fuel.

• Never use a shop rag to catch the fuel. Vapors

from the rag are flammable and explosive.

• Wipe up any spills immediately.

• Wear eye protection. The fuel system is under

pressure and fuel could spray out when you

remove any fuel system component.

• Only use the key switch to start the engine.

• Never jump-start the engine. Sparks caused

by shorting the battery to the starter terminals

may cause a fire or explosion.

• If the unit has an electric fuel pump, in the

case of DI engine, since air is automatically

bled, by keeping the key of the starter switch

in the ON position for 10 to 15 seconds, the

fuel system can be primed. If this is an IDI

engine, keep the key in the ON position

(within 15 seconds) until fuel without bubbles

comes out from the air bleeding bolt. Here, do

not turn the key to the START position.

• If the unit has a mechanical fuel pump, when

you prime the fuel system, operate the fuel

priming lever of the mechanical fuel pump

several times until the fuel filter cup is filled

with fuel. On top of that, operate the fuel feed

pump for several times until fuel without

bubbles comes out from the air bleeding bolt.

• Never use diesel fuel as a cleaning agent.

• Never remove the fuel cap with the engine

running.

• Only fill the fuel tank with diesel fuel. Filling

the fuel tank with gasoline may result in a fire

and will damage the engine.

• Never refuel with the engine running.

• Keep sparks, open flames or any other form of

ignition (match, cigarette, static electric

source) well away when refueling.

• Never overfill the fuel tank.

• Fill the fuel tank. Store any containers

containing fuel in a well-ventilated area, away

from any combustibles or sources of ignition.

• Be sure to place the diesel fuel container on

the ground when transferring the diesel fuel

from the pump to the container. Hold the hose

nozzle firmly against the side of the container

while filling it. This prevents static electricity

buildup which could cause sparks and ignite

fuel vapors.

• Never place diesel fuel or other flammable

material such as oil, hay or dried grass close

to the engine during engine operation or

shortly after shutdown.

• Before you operate the engine, check for fuel

leaks. Replace rubberized fuel hoses every

two years or every 2000 hours of engine

operation, whichever comes first, even if the

engine has been out of service. Rubberized

fuel lines tend to dry out and become brittle

after two years or 2000 hours of engine

operation, whichever comes first.

• When you prime the fuel system, operate the

fuel priming lever of the mechanical fuel pump

several times until the fuel filter cup is filled

with fuel.

• Failure to comply will result in death or

serious injury.

SAFETY

5

Page 12

DANGER

WARNING

TNV_OperationManual_T4(under 19kW).book Page 6 Wednesday, June 17, 2015 11:23 AM

SAFETY

Crush Hazard!

• When you need to transport an

engine for repair, have a helper

assist you to attach it to a hoist

and load it on a truck.

• Never stand under a hoisted engine. If the

hoist mechanism fails, the engine will fall on

you, causing death or serious injury.

• Failure to comply will result in death or

serious injury.

Sever Hazard!

• Keep hands and other body parts

away from moving/rotating parts

such as the cooling fan, flywheel

or PTO shaft.

• Wear tight-fitting clothing and keep your hair

short or tie it back while the engine is running.

• Remove all jewelry before you operate or

service the machine.

• Never start the engine in gear. Sudden

movement of the engine and/or machine

could cause death or serious personal injury.

• Never operate the engine without the guards

in place.

• Before you start the engine make sure that all

bystanders are clear of the area.

• Keep children and pets away while the engine

is operating.

• Check before starting the engine that any

tools or shop rags used during maintenance

have been removed from the area.

• Failure to comply could result in death or

serious injury.

• Never block windows, vents, or other means

of ventilation if the engine is operating in an

enclosed area. All internal combustion

engines create carbon monoxide gas during

operation. Accumulation of this gas within an

enclosure could cause illness or even death.

• Make sure that all connections are tightened

to specifications after repair is made to the

exhaust system.

• Failure to comply could result in death or

serious injury.

• Never operate the engine when you are feeling

ill.

• Failure to comply could result in death or

serious injury.

WARNING

Exhaust Hazard!

• Never operate the engine in an

enclosed area such as a garage,

tunnel, underground room,

manhole or ship’s hold without

proper ventilation.

WARNING

Alcohol and Drug Hazard!

• Never operate the engine while

you are under the influence of

alcohol or drugs.

6

Page 13

WARNING

WARNING

TNV_OperationManual_T4(under 19kW).book Page 7 Wednesday, June 17, 2015 11:23 AM

WARNING

Exposure Hazard!

• Wear personal protective

equipment such as gloves, work

shoes, eye and hearing

protection as required by the

task at hand.

• Never wear jewelry, unbuttoned cuffs, ties or

loose-fitting clothing when you are working

near moving/rotating parts such as the

cooling fan, flywheel or PTO shaft.

• Always tie back long hair when you are

working near moving/rotating parts such as a

cooling fan, flywheel, or PTO shaft.

• Never operate the engine while wearing a

headset to listen to music or radio because it

will be difficult to hear the alert signals.

• Failure to comply could result in death or

serious injury.

• Failure to comply could result in death or

serious injury.

WARNING

Burn Hazard!

• Wait until the engine cools before

you drain the engine coolant. Hot

engine coolant may splash and

burn you.

• Never check for a fuel leak with your hands.

• If you must drain the engine oil while it is still

hot, stay clear of the hot engine oil to avoid

being burned.

• Always wear eye protection.

• Keep your hands and other body parts away

from hot engine surfaces such as the muffler,

exhaust pipe, turbocharger (if equipped) and

engine block during operation and shortly

after you shut the engine down. These

surfaces are extremely hot while the engine is

operating and could seriously burn you.

• Failure to comply could result in death or

serious injury.

Always use a piece of wood or cardboard.

Have your Isuzu Distributor repair the

damage.

• Failure to comply could result in death or

serious injury.

SAFETY

Burn Hazard!

• Batteries contain sulfuric acid.

Never allow battery fluid to come

in contact with clothing, skin or

eyes. Severe burns could result.

Always wear safety goggles and

protective clothing when

servicing the battery. If battery

fluid contacts the eyes and/or

skin, immediately flush the

affected area with a large amount

of clean water and obtain prompt

medical treatment.

High-Pressure Hazard!

• Avoid skin contact with the

high-pressure diesel fuel spray

caused by a fuel system leak

such as a broken fuel injection

line. High-pressure fuel can

penetrate your skin and result in

serious injury. If you are e xposed

to high-pressure fuel spray,

obtain prompt medical treatment.

7

Page 14

WARNING

WARNING

WARNING

CAUTION

TNV_OperationManual_T4(under 19kW).book Page 8 Wednesday, June 17, 2015 11:23 AM

SAFETY

Shock Hazard!

• Turn off the battery switch (if

equipped) or disconnect the

negative battery cable before

servicing the electrical system.

• Check the electrical harnesses for cracks,

abrasions, and damaged or corroded

connectors. Always keep the connectors and

terminals clean.

• Failure to comply could result in death or

serious injury.

• Failure to comply may result in minor or

moderate injury.

CAUTION

Coolant Hazard!

• Wear eye protection

and rubber gloves

when you handle

long life or extended

life engine coolant. If

contact with the eyes

or skin should occur,

flush eyes and wash

immediately with

clean water.

Entanglement Hazard!

• Stop the engine before you begin

to service it.

• Never leave the key in the key switch when

you are servicing the engine. Someone may

accidentally start the engine and not realize

you are servicing it. This could result in a

serious injury.

• If you must service the engine while it is

operating, remove all jewelry, tie back long

hair, and keep your hands, other body parts

and clothing away from moving/rotating parts.

• Failure to comply could result in death or

serious injury.

Sudden Movement Hazard!

• Engaging the transmission or PTO at an

elevated engine speed could result in

unexpected movement of the equipment.

• Failure to comply could result in death or

serious injury.

CAUTION

Flying Object Hazard!

• Always wear eye protection when

servicing the engine and when

using compressed air or

high-pressure water. Dust, flying

debris, compressed air,

pressurized water or steam may

injure your eyes.

• Failure to comply may result in minor or

moderate injury.

• When using a 120 V system only, push the

change-over switch to the right (120 V).

• The main switch should always be kept in the

ON position during operation.

• Before starting the engine, always turn the

switches on the working instruments (lighting

apparatus, motor, etc.) to their OFF position. If

the switches are not OFF, the sudden

application of load when the engine is started

could be very dangerous.

8

Page 15

NOTICE

TNV_OperationManual_T4(under 19kW).book Page 9 Wednesday, June 17, 2015 11:23 AM

NOTICE

• Only use diesel fuels recommended by Isuzu for

the best engine performance, to prevent engine

damage and to comply with EPA/ARB warranty

requirements.

• Only use clean diesel fuel.

Never attempt to adjust the low or high idle speed

limit screw. This may impair the safety and

performance of the machine and shorten its life. If

adjustment is ever required, contact your Isuzu

Distributor.

SAFETY

• Never remove the primary strainer (if equipped)

from the fuel tank filler port. If removed, dirt and

debris could get into the fuel system causing it to

clog.

• Only use the engine oil specified. Other engine

oils may affect warranty coverage, cause internal

engine components to seize and/or shorten

engine life.

• Prevent dirt and debris from contaminating the

engine oil. Carefully clean the oil cap/dipstick and

the surrounding area before you remove the cap.

• Never mix different types of engine oil. This may

adversely affect the lubricating properties of the

engine oil.

• Never overfill the engine with engine oil.

• Always keep the oil level between the upper and

lower lines on the oil cap/dipstick.

• Never overfill. Overfilling may result in white

exhaust smoke, engine overspeed or internal

damage.

If any problem is noted during the visual check, the

necessary corrective action should be taken before

you operate the engine.

New engine break-in:

• On the initial engine start-up, allow the engine to

idle for approximately 15 minutes while y ou check

for proper engine oil pressure, diesel fuel leaks,

engine oil leaks, coolant leaks, and for proper

operation of the indicators and/or gauges.

• During the first hour of operation, vary the engine

speed and the load on the engine. Short periods

of maximum engine speed and load are

desirable. Avoid prolonged operation at minimum

or maximum engine speeds and loads f or the next

four to five hours.

• During the break-in period, carefully observe the

engine oil pressure and engine temperature.

• During the break-in period, check the engine oil

and coolant levels frequently.

• Only use the engine coolant specified. Other

engine coolants may affect warranty coverage,

cause an internal buildup of rust and scale and/or

shorten engine life.

• Prevent dirt and debris from contaminating the

engine coolant. Carefully clean the radiator cap

and the surrounding area before you remove the

cap.

• Never mix different types of engine coolants. This

may adversely affect the properties of the engine

coolant.

If any indicator fails to illuminate when the key

switch is in the ON position, see your Isuzu

Distributor for service before operating the engine.

Never hold the key in the START position for longer

than 15 seconds or the starter motor will overheat.

9

Page 16

NOTICE

TNV_OperationManual_T4(under 19kW).book Page 10 Wednesda y, June 17, 2015 11:23 AM

SAFETY

If the engine fails to start:

Wait until the engine comes to a complete stop

before you attempt to start it again. Engaging the

starter while the engine is still rotating will result in

damage to the starter and flywheel.

Never use an engine starting aid such as ether.

Engine damage will result.

Observe the following environmental operating

conditions to maintain engine performance and

avoid premature engine wear:

• Avoid operating in extremely dusty conditions.

• Avoid operating in the presence of chemical

gases or fumes.

• Avoid operating in a corrosive atmosphere such

as salt water spray.

NOTICE

Never engage the starter motor while the engine is

running. This may damage the starter motor pinion

and/or ring gear.

Make sure the engine is installed on a le v el surf ace.

If a continuously running engine is installed at an

angle greater than (30°) in any direction or if an

engine runs for short periods of time (less than

three minutes) at an angle greater than (35°) i n an y

direction, engine oil may enter the combustion

chamber causing excessive engine speed and

white exhaust smoke. This may cause serious

engine damage.

If any indicator illuminates during engine operation,

stop the engine immediately. Determine the cause

and repair the problem before you continue to

operate the engine.

The illustrations and descriptions of optional

equipment in this manual, such as the operator’s

console, are for a typical engine installation. Refer

to the documentation supplied by the optional

equipment manufacturer for specific operation and

maintenance instructions.

• Never install the engine in a floodplain unless

proper precautions are taken to avoid being

subject to a flood.

• Never expose the engine to the rain.

• The standard range of ambient temperatures for

the normal operation of Isuzu engines is from

-15 °C (+5 °F) to +45 °C (+113 °F).

• If the ambient temperature exceeds +45 °C

(+113 °F) the engine may overheat and cause

the engine oil to break down.

• If the ambient temperature is below -15 °C (+5 °F)

the engine will be hard to start and the engine oil

may not flow easily.

• Contact your Isuzu Distributor if the engine wi ll be

operated outside of this standard temperature

range.

• Contact your Isuzu Distributor if the engine wi ll be

operated at high altitude. High altitude reduces

engine power, de-stabilizes operation and

generates exhaust gas that exceeds the

specification amount in design.

10

Page 17

NOTICE

TNV_OperationManual_T4(under 19kW).book Page 11 Wednesda y, June 17, 2015 11:23 AM

NOTICE

• When the engine is operated in dusty conditions,

clean the air cleaner element more frequently.

• Never operate the engine with the air cleaner

element(s) removed. This may allow foreign

material to enter the engine and damage it.

The maximum air intake restriction, in terms of

differential pressure measurement, must not

exceed 0.90 psi (6.23 kPa; 635 mmAq). Clean or

replace the air cleaner element if the air intake

restriction exceeds the above mentioned value.

Establish a periodic maintenance plan according to

the engine application and make sure you perform

the required periodic maintenance at intervals

indicated. Failure to follow these guidelines will

impair the engine’s safety and performance

characteristics, shorten the engine’s life and may

affect the warranty coverage on your engine.

Consult your Isuzu Distributor for assistance when

checking items marked with a

Make it a habit to perform daily checks. See Daily

Checks in the Before You Operate Section of this

manual.

SAFETY

●

.

For maximum engine life, Isuzu recommends that

when shutting the engine down, you allow the

engine to idle, without load, for five minutes. This

will allow the engine components that operate at

high temperatures, such as the turbocharger (if

equipped) and exhaust system, to cool slightly

before the engine itself is shut down.

• Never attempt to modify the engine’s design or

safety features such as defeating the engine

speed limit control or the diesel fuel injection

quantity control.

• Modifications may impair the engine’s safety and

performance characteristics and shorten the

engine’s life. Any alterations to this engine may

void its warranty. Be sure to use Isuzu genuine

replacement parts.

Protect the air cleaner, turbocharger (if equipped)

and electric components from damage when you

use steam or high-pressure water to clean the

engine.

Periodic maintenance prevents unexpected

downtime, reduces the number of accidents due to

poor machine performance and helps extend the

life of the engine.

The tightening torque in the Standard Torque Chart

in the Periodic Maintenance Section of this manual

should be applied only to the bolts with a “7” head.

(JIS strength classification: 7T)

• Apply 60 % torque to bolts that are

not listed.

• Apply 80 % torque when tightened to

aluminum alloy.

Never use high-pressure water or compressed air

at greater than 28 psi (193 kPa; 19686 mmAq) or a

wire brush to clean the radiator fins. Radiator fins

damage easily.

11

Page 18

NOTICE

TNV_OperationManual_T4(under 19kW).book Page 12 Wednesda y, June 17, 2015 11:23 AM

SAFETY

• Always be environmentally

responsible.

• Follow the guidelines of the EPA or other

governmental agencies for the proper disposal of

hazardous materials such as engine oil, diesel

fuel and engine coolant. Consult the local

authorities or reclamation facility.

• Never dispose of hazardous materials

irresponsibly by dumping them into a sewer, on

the ground, or into ground water or waterways.

• Failure to follow these procedures may seriously

harm the environment.

Precautions for handling desiccant

Disposal:

This material is disposable as non-flammable.

howev er , the bag is flammab le and if it is necessary ,

then tear the bag and discard the bag and the

contents separately.

It is desirable to bury the contents in the bag under

ground.

Dispose in accordance with the disposal standards

for industrial waste defined by local laws and

regulations.

Handling:

The contents of the bag do not leak out in the

normal use.

Take the following emergency measures, however,

if the contents leak out.

NOTICE

• If the contents get on the skin, rinse thoroughly

with running water.

• If the contents get in the eyes, rinse thoroughly

with water. Consult with doctors when any

abnormalities are found.

• If the contents get in the mouth, rinse thoroughly

with water. Drink water to dilute if the content is

swallowed, though a small amount is harmless.

Consult with doctors when any abnormalities are

found.

Characteristics of materials:

• Calcium Chloride (CaCl

• Grain Polysaccharide Approx. 28 %

• Grain Skins Approx. 9 %

• Ethylene Polymer (Bag) Approx. 5 %

Hazard information:

• Explosiveness None

• Inflammability Inflammable

• Combustibility None

• Oxidation None

) Approx. 57 %

2

12

Page 19

TNV_OperationManual_T4(under 19kW).book Page 13 Wednesda y, June 17, 2015 11:23 AM

TNV Operation Manual

PRODUCT

OVERVIEW

ISUZU C SERIES ENGINE FEATURES AND APPLICATIONS

Isuzu C series engine is environmentally friendly

and is designed to:

• Lower the amount of exhaust gas emissions.

• Reduce engine noise and vibration.

• Be easy to start thanks to the specially designed

fuel injection pump and combustion system.

• Be economical to run because diesel fuel and

engine oil consumption are reduced.

• Be easy to operate due to the mi nimum amount o f

required maintenance and their compact design.

• Be durable and reliable due in part to the newly

designed fuel injection valve and fuel injection

pump.

Isuzu C series engine is designed to supply power

to a wide variety of driven machines including:

• Construction

• Agriculture

• Power generation

We are sure that you will agree these features

provide excellent value in an industrial diesel

engine.

These engines are designed to deliver power to

driven machines by means of a “direct coupled

drive” or “belt drive.” In direct coupled drive engine

applications, the engine’s flywheel housing or end

plate is coupled directly to the driven machine. In

belt drive engine applications, a belt drive is used to

power the driven machine. If you have applications

that require a belt drive and/or front power take-off

(PTO), please contact your Isuzu Distributor.

The engine is designed for a wide range of

applications. Options, such as fuel tank, control

panel, indicators, gauges and alarms, are available

to customize the application.

Since designing the application and installing the

engine require special knowledge and skill, always

consult your Isuzu Distributor for these services.

They will help you:

• Select optional equipment. Optional equipment

should be selected to match the work conditions

and environment.

• Maximize engine performance with a minimum

amount of downtime and safety related incidents

by carefully matching the characteristics of the

engine with the driven machine.

• Plan for safe fuel piping, e xhaust piping, elec trical

wiring, ventilation and accurate engine installation.

• Design your applications so they meet

requirements of the local authorities.

13

Page 20

12 3

4

5

67891011

12

13

14

15

16

17

18

19

20 21

22

23

24

25

045080-00X00

TNV_OperationManual_T4(under 19kW).book Page 14 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

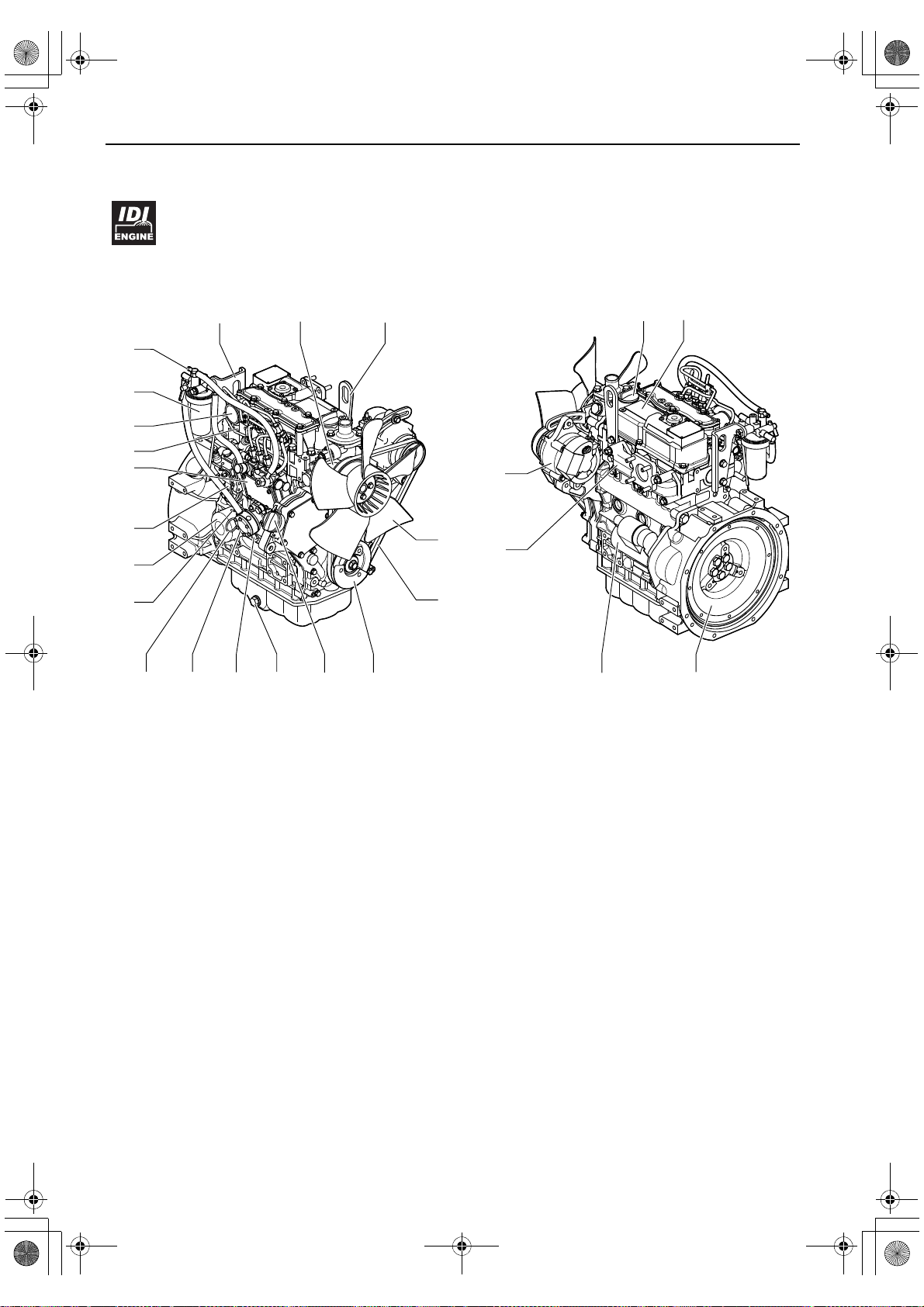

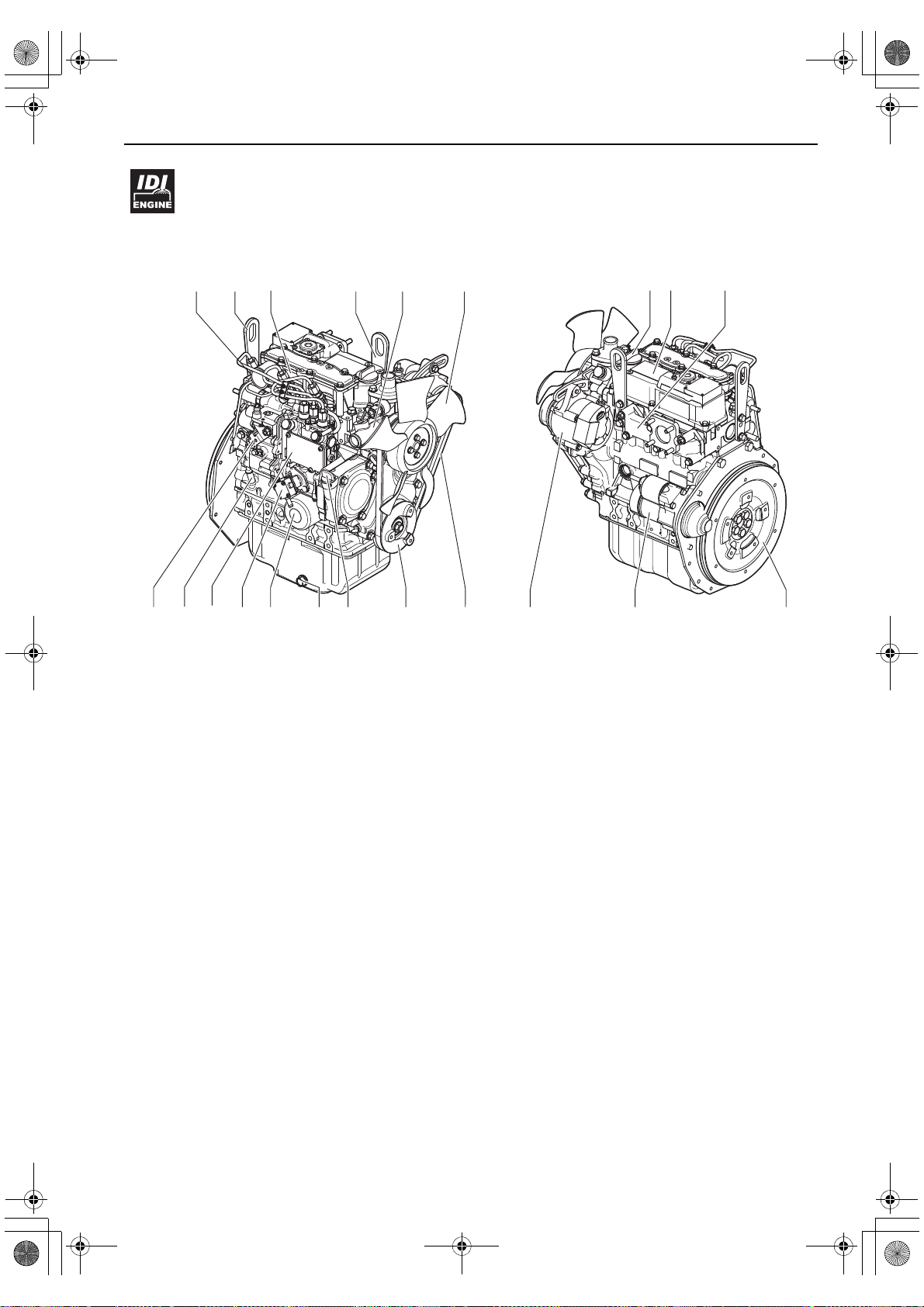

COMPONENT IDENTIFICATION

3CH1-NGZG01, 3CH1-SDZP01, 3CJ1-NGZG01

Figure 1 shows where major indirect injection engine components are located.

1 – Lifting eye (flywheel end)

2 – Engine coolant pump

3 – Lifting eye (engine cooling fan end)

4 – Engine cooling fan

5 – V-belt

6 – Crankshaft V-pulley

7 – Side filler port (eng in e oi l)

8 – Drain plug (engine oil)*

9 – Fuel inlet

10–Mechanical fu el pump

11– D ip st ick (engi ne oi l)

12– Fuel priming lever

13– Engi ne oil filter

* Engine oil drain plug location may vary based on oil pan options.

14

Figure 1

14– G over nor lever

15– Fuel injection pump

16– Intak e manifold

17– Ai r intake port (from air cleaner)

18– Fuel filter

19–Fuel return to fuel tank

20–Top filler port (engine oil)

21–Rocker arm cover

22– Flywheel

23–Star ter motor

24– Exhaust manifold

25– Alternator

Page 21

044905-00X00

123 4 5 6

789101112131415

16 17 18

192021

TNV_OperationManual_T4(under 19kW).book Page 15 Wednesda y, June 17, 2015 11:23 AM

3CJ1-SDZP01

Figure 2 shows where major indirect injection engine components are located.

PRODUCT OVERVIEW

1 – Air intake port (from air cleaner)

2 – Lifting eye (flywheel end)

3 – Intake manifold

4 – Lifting eye (engine cooling fan end)

5 – Engine coolant pump

6 – Engine cooling fan

7–V-belt

8 – Crankshaft V-pulley

9 – Side filler port (engine oi l)

10– D ra in plu g (e ngine oil)*

11–Engine oil filt er

* Engine oil drain plug location may vary based on oil pan options.

12– Mec hanical fuel pump

13– Fuel injection pump

14–Dipstick (engine oil)

15– Governor lever

16– Top filler port (engine oil)

17 – Rocker arm cover

18– Exhaust manifold

19–Flywheel

20–Starter motor

21–Alternator

Figure 2

15

Page 22

045002-00X00

231

456789101112

1

3

1

4

1

5

16 17 18

19202122

TNV_OperationManual_T4(under 19kW).book Page 16 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

3CE1

Figure 3 shows where major direct injection engine components are located.

1 – Lifting eye (flywheel end)

2 – Lifting eye (engine cooling fan end)

3 – Engine coolant pump

4 – Engine cooling fan

5 – Crankshaft V-pulley

6 – V-belt

7 – Side filler port (eng in e oi l)

8 – Engine oil cooler

9 – Fuel injection pump

10– Engi ne oil filter

11–Intake manifold

12– Dipstick (engine oil)

13– Fuel filter

14–Fuel return to fuel tank

15– Fuel inlet

16–Top filler port (engine oil)

17 – Rocker arm cover

18– EGR valve

19– Flywheel

20–Star ter motor

21– Exhaust manifold

22– Alternator

Figure 3

* Engine oil drain plug location may vary based on oil pan options.

16

Page 23

1

K0000585A

045044-00X01

TNV_OperationManual_T4(under 19kW).book Page 17 Wednesda y, June 17, 2015 11:23 AM

LOCATION OF LABELS

Figure 4 shows the location of regulatory and safety labels on Isuzu C series indirect injection

model engine.

The typical location of the emission control

2

Figure 4

information label is shown (Figure 4, (1)).

Typical location of the engine nameplate is shown

(Figure 4, (2)).

PRODUCT OVERVIEW

Figure 5 shows the location of regulatory and safety labels on Isuzu C series direct injection

model engine.

12

Figure 5

■ Location of labels/nameplates on direct injection model engines

Model Engine nameplate EPA/ARB certification label

3CE1 On the top of the locker arm cover (cooling

fan end) Figure 5, (2)

On the top of the locker arm cover

(flywheel end) Figure 5, (1)

17

Page 24

TNV_OperationManual_T4(under 19kW).book Page 18 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

FUNCTION OF MAJOR ENGINE COMPONENTS

Components Functions

Air cleaner The air cleaner prevents airbo rn e contaminants from entering the engine.

Since the air cleaner is application specific, it must be carefully selected by

an application engineer. It is not part of the basic engine package as shipped

from the Isuzu factory. Periodic replacement of the air cleaner filter element

is necessary. See the Periodic Maintena nce Schedule on page 64 for the

replacement frequency.

Starter motor The starter motor is powered by the battery. When you turn the key swit ch

in the operator’s console t o the START position, the starter motor engages

with the ring gear installed on the flywheel and starts the flywheel i n motion.

Alternator The alternator is driven by a V-belt which is po wer ed by the crankshaft

V-pulley. The alternator su ppl i es ele ct ric ity t o the engine systems and

charges the battery while the engine is running.

Dipstick (engine oil) The engine oil dipstick is used to deter m i ne t he am ount of engine oil in the

crankcase.

Side and top filler port (engine oil) You can fill the crankcase with engine oil from either the side or top filler

port depending upon which on e is mo st convenient.

Engine oil filter The engine oil filter removes conta m in ant s and sedi m ent from the engine

oil. Periodic replacemen t o f the en gi ne oil filter is necessary. See the

Periodic Maintenance Schedule on page 64 for the replacement frequency.

Engine oil cooler

(if equipped)

Fuel tank The fuel tank is a reservoir that holds diesel fuel. When fuel leaves the fuel

Water separator The water separator removes contaminants, sediment and water fro m

Electric fuel pump The electric fuel pump ma kes sure there is a constant supply of diesel fuel

The engine oil cooler helps to keep the engine oil cool. Engine coolant from

the cooling system is circulated by the coolant pump through an adapter at

the base of the engine to the oil co ol er and then t o th e cy linder block and

back to the coolant pump.

tank it goes to the water separator. Next, fuel is pumped to the fuel filter by

the electric or mechanical fuel pump. Next the fuel goes to the fuel injection

pump. Since fuel is used to keep the fuel injection pump cool and lubricated,

more fuel than necess ar y enters the injection pump. When the injectio n

pump pressure reaches a preset value, a relief valve allows excess fuel to

be returned back to the fue l tank . The f uel t ank is a required engine

component.

diesel fuel going to the fuel filter . Thi s is a re quired component of the fuel

system and is standard equipment with every engine. The separator is

installed between the fue l tank and the fu el pum p. Per iodically drain the

water from the water separator using the drain valve at the bottom of the

separator.

to the fuel injection pump. The electric fuel pump is electro-magnetic and

runs on 12 V DC. An electric fuel pump may be installed as an option or as

standard equipment. Standard equipment may vary based on engine model

and specification. If an electric fuel pump is installed, turn the key switch to

the ON position for 10 to 15 seconds to prime the fuel system.

18

Page 25

TNV_OperationManual_T4(under 19kW).book Page 19 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

Components Functions

Mechanical fuel pump

Fuel priming lever

Fuel filter The fuel filter removes contaminant s and sediments from the diesel fuel.

The mechanical fuel pump is a diaphragm-type of pump and is installed on

the fuel injection pump body. The mechanical fuel pump is driven by a cam

on the camshaft of the fuel injection pump. An electric fuel pump is available

as an option. The mechanical fuel pump is not installed on the fuel injection

pump if the electric fuel pump opt i on i s i nstalled.

If the unit has a mechanical fu el pum p, a fuel priming lever on the

mechanical fuel pump primes the fuel system. The fuel system needs to be

primed before you start the engine for the first time, if you run out of fuel, or

if fuel system service is perf ormed. To prime the fuel system, operate the

fuel priming lever until the cup in the fuel filter is full of fuel.

Periodic replacement of the fu el filte r is nec essary. See the Periodic

Maintenance Schedule on page 64 for the replacement frequency. Please

note that the word “diesel” is implied thr oughout this manual when the

word “fuel” is used.

19

Page 26

TNV_OperationManual_T4(under 19kW).book Page 20 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

FUNCTION OF COOLING SYSTEM COMPONENTS

Components Functions

Cooling system The C series engine is liqu id-c ool ed by means of a cooling system. The

cooling system cons ist s of a rad i at or , radi at or cap, engine cooling fan,

engine coolant pump , ther m ostat, and reserve tank. Note that all cooling

system components are required for pr oper engine operation. Since

some of the components ar e application specific, they must be

carefully selected by an application engineer. The application specific

items are not part of the basic engine package as shipped from the

Isuzu factory.

• Engine cooling fan The engine cooling fan is dri ven by a V-belt which is powered by the

cranksha ft V-pu lley . The purp ose of t he engin e cooli ng fan is t o circ ulate ai r

through the radiator.

• Engine coolant pump The engine coolant pump circulates the engine coolant through the cylinder

block and cylinder hea d an d returns the engine coolant to the radiator.

• Radiator The radiator acts as a heat exchanger. As the engine coolant circulates

through the cylinder block it absorbs heat. The heat in the engine coolant is

dissipated in the radiator. As the engine cooling fan circulates air through the

radiator, the heat is transferred to the air.

• Radiator cap The radia t or cap controls t he cooling syst em pressure. The cooling system

is pressurized to raise the boiling point of the engine coolant. As the engine

coolant temperatur e rises, the system pressure and the coolant vo lu m e

increases. When the pressure reaches a preset value, the release valve in

the radiator cap opens and the excess engine coolant flows into the reserve

tank. As the engine coolan t tem perature is reduced, the system pressure

and volume is reduced and the vacu um valve in the radiator cap opens

allowing engine coolant to flow from the reserve tank back into the radiator.

• Reserve tank The reserve tank contai ns the overflow of engine coolant from the radiator.

If you need to add engine coolant to the system, add it to the reserve tank,

not the radiator.

• Thermostat A thermostat is placed in the cooling system to prevent engine coolant from

circulating into the radiator until the engine coolant temperature reaches a

preset temperature. When the engine is cold, no engine coolant flows

through the radiator. Once the engine reaches its operating temperature the

thermostat opens and allows engine coolant to flow through the radiator. By

letting the engine warm up as qu ickl y as pos sibl e, th e t her m ostat reduces

engine wear, deposi t s and e m i ssions.

20

Page 27

WARNING

WARNING

TNV_OperationManual_T4(under 19kW).book Page 21 Wednesda y, June 17, 2015 11:23 AM

ELECTRONIC CONTROL SYSTEM

3CE1

WARNING

• Never use the E-ECU for other purposes than

intended or in other ways than specified by

Isuzu. Doing so could result in the violation of

emission control regulations and will void the

product warranty.

• Improper use or misuse of the E-ECU may

result in death or serious injury due to an

abrupt and unexpected increase in engine

speed.

WARNING

• Be sure to use the E-ECU in conjunction with

the engines whose models or serial numbers

are specified by Isuzu.

Other E-ECU/engine combinations than

specified will void the engine warranty.

• Improper use or misuse of the E-ECU may

result in death or serious injury due to an

abrupt and unexpected increase in engine

speed.

• Replacing the fuel injection pump involves

rewriting the fuel injection data in the E-ECU.

Be sure to contact your Isuzu Distributor

before replacing the fuel injection pump.

Failure to rewrite the fuel injection data before

replacing the fuel injection pump will void the

engine warranty.

• Improper use or misuse of the E-ECU may

result in death or serious injury due to an

abrupt and unexpected increase in engine

speed.

• Replacing the E-ECU involves migrating the

fuel injection data to the existing E-ECU to the

new unit. Be sure to contact your Isuzu

Distributor before replacing the E-ECU.

Failure to migrate the fuel injection data

before replacing the E-ECU will void the

engine warranty.

• Improper use or misuse of the E-ECU may

result in death or serious injury due to an

abrupt and unexpected increase in engine

speed.

PRODUCT OVERVIEW

21

Page 28

NOTICE

NOTICE

NOTICE

TNV_OperationManual_T4(under 19kW).book Page 22 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

Shut down the engine if the fault indicator comes

on.

Continuing running the engine with the fault

indicator being on may result in a serious

malfunction of or damage to the engine, and will

void the engine warranty.

• Do not plug or unplug the E-ECU f or a period of at

least 6 seconds after power to the unit has been

turned on or off.

• Do not touch connector pins of the E-ECU with

bare hands.

Doing so may result in corrosion of the connector

pins and/or damage to the internal circuits of the

E-ECU due to static electricity.

NOTICE

Do not energize the starter for a period of longer

than 15 seconds.

Take a pause of at least 30 seconds between

energization of the starter.

Otherwise the starter could suffer damage.

• High-pressure washing not recommended.

• Avoid using high-pressure washing for electronic

or electric devices installed in, on or around the

engine, including the E-ECU, relays and harness

couplers.

Otherwise such devices ma y suff er malfunction due

to water ingress into them.

• Do not force a measuring probe into the female

coupler.

Doing so may cause contact failure of the

connector pins, resulting in malfunction of the

E-ECU.

• Take care to prevent water from entering the

couplers when plugging or unplugging the

connector.

Water inside the couplers may cause corrosion,

resulting in malfunction of the E-ECU.

• Avoid plugging/unplugging the connector more

than approx. 10 times.

Frequent plugging/unplugging of the connector

may cause contact failure of the connector pins,

resulting in malfunction of the E-ECU.

• Do not use the E-ECU that has ev er suffered drop

impact.

NOTICE

Always check the battery for proper charge.

Otherwise the electronically controlled engines may

fail to start.

22

Page 29

E-ECU

CSD

Engine speed

sensor

Rack position

sensor

Eco-governor

Fuel injection pump

Actuator

Intake Exhaust

EGR-Valve

Piston

Liner

Inj.Nozzle

Re-circulation

EGR

Starting aid

Coolant temperature

sensor

Starter

Operator's console

Stop switch

Key switch

OFF

Accelerator sensor

CAN

Engine

ON

START

TNV_OperationManual_T4(under 19kW).book Page 23 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

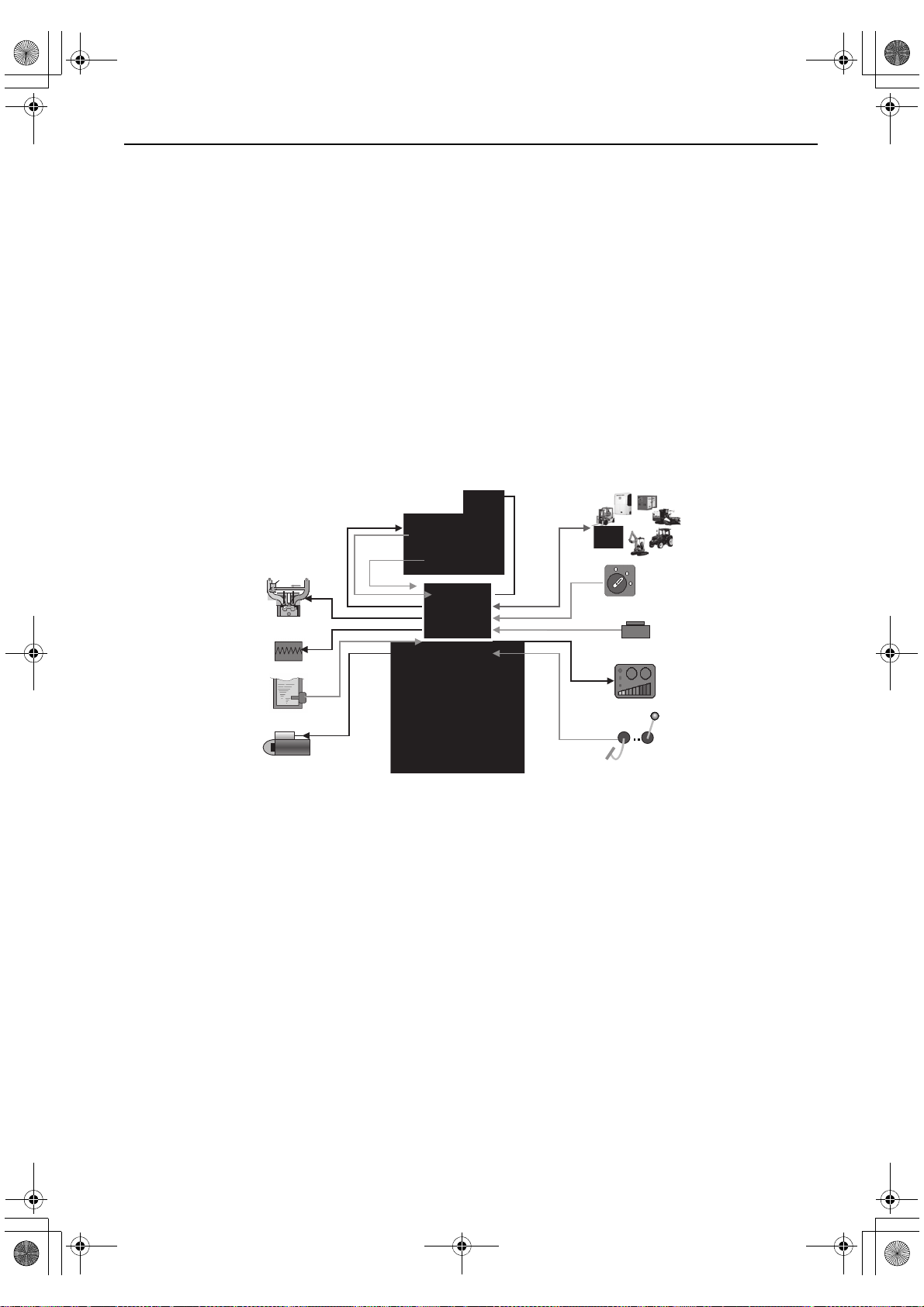

Model 3CE1 engine come with the Exhaust Gas

Recirculation (EGR) system to conform to the

engine emission regulations (EPA 2013 rules).

The EGR system and an electronic governor

(Eco-governor) constitute an electronic engine

control system.

The electronic engine control system regulates the

exhaust gas recirculation flow rate and the fuel

injection volume depending on the engine load and

speed signals from the engine controller (E-ECU),

so that the exhaust gas is kept clean according to

the emission control regulations. Figure 6

illustrates the electronic engine control system.

Features of the electronic engine control system

include:

• Engine speed control schemes

Droop control/Low-idling speed up/Auto

deceleration/High-idling speed down/Black smok e

suppression

• Starting aid

Auto preheating/After heating

• Engine failure detection

• CAN communication with the control system of

the driven machine

Consult the operation manual for the driven

machine for applicability of the features that

depends on the machine.

Figure 6

23

Page 30

TNV_OperationManual_T4(under 19kW).book Page 24 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

MAIN ELECTRONIC CONTROL COMPONENTS AND FEATURES

3CE1

Component/feature Description

Engine controller (E-E CU ) Adjusts the rack position of the fuel injec tion pump depending

on the speed command signal from the accelerator sensor, thus

regulating the engine speed and power. The engine controller

also regulates the opening of the EGR valve depending on the

engine speed and power. It serves as the master station for the

following component s/ control features.

Electronic governor (Eco-governor) Consists of the engine speed sensor, rack actuator, etc., and is

directly connected to the fuel injection pump in order to regulate

the rack position of the fue l injection pump depending on the

signals communicat ed wit h the E-ECU.

Fuel injection pump (fo r Ec o- gov ernor) Is of single plunger type and equipped with a CSD solenoid

valve that allows the fue l injection timing to advance and the

injection quantity to incr ease, thereby improving the cold start

performance of the engine.

EGR valve Controls the exhaust gas r eci r culation flow rate depending on

the engine speed/load signals from the E-ECU. It is installed on

the top of the exhaust man ifold.

Accelerator sensor Unlike mechanical governors, the Eco-governor has no

governor lever. The accelerator sensor serves as the governor

lever to provide the speed command signal (voltage signal) to

the E-ECU for engine speed control. It is installed in the

operator cabin of the driven machine. Constant speed engines

for e.g. generator use do not require accelerator sensors

because the engine speed can be shifted via a switch on the

operator's console.

Optional CAN communication capa bil ity is available as an option.

Fault indicator Is installed on the operat or ’s console. If a fault occurs in the

E-ECU or Eco-governor, the fault indicator flashes alerting the

operator to a fault. The number of flashes and/or the flashing

pattern vary depending on the type or source of the fault,

Optional

Engine diagnosis tool Allows the operator to troubleshoo t the cause of a problem

Option for service

Engine coolant temper at ure sensor Allows the C SD and ERG to be controlled in engine cold-start

enabling quick-fix.

based on detailed information regarding the problem occurring

in the E-ECU or Eco-governor. This tool can also be used for

data maintenance tasks including programming and mapping.

See Troubleshooting Char t on page 90.

conditions.

24

Page 31

TNV_OperationManual_T4(under 19kW).book Page 25 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

Component/feature Description

ON-glow at start Optional When the key switch is turned to the ON position, the glow plugs

are energized for up to 15 sec onds. The duration of

energization depends on t he engine coolant temperature. The

HEAT indicator is on during ener gization. When the i ndicator

goes out, turn the key switch to the START position to start the

engine.

Droop control Reduces the engine spee d by a certain percentage from no

load to full (rated) load in steady state operation. The same

percentage droop i s maintained even when the load increases

at any no-load speed.

Isochronous control Optional Offers a constant engine speed from no load to full load. The

engine speed does not decrease even when the load i ncreases

at any no-load speed.

Low-idling speed up

Increases the low-idling speed to up to 1000 min

depending on the engine coolant temperature. When the

coolant temperature reaches a predetermined value, this

feature returns the engine speed to the normal low idl e setting,

thus reducing the warm-up time.

High-idling speed down Optional Decreases the high-idling spe ed depending on the engine

coolant temperature. When the coolant temperature falls to a

predetermined value, this fe at ur e re tu rn s t he engine speed to

the normal high idle settin g, th us m i ni m i zi ng t he e m issi on of

white smoke at low temper at ures.

Auto deceleration Optional Brings the running engine in low idle mode automatically when

the accelerator pedal is not operated for a predetermined period

of time. When the pedal is operated, i.e., the accelerator sensor

is activated, the low idle mode is cancelled.

-1

(rpm)

25

Page 32

NOTICE

K0000023A

4

12

3

10

20

20

40

100

180

220

250

60

80

0

30

40

0

x100

RPM

VDO

VDO

PSI

F

C

0

1

2

3

4

5

bar

80

100

120

0

AUX

MC-704HP-G4

K0000024A

1

2

4

3

TNV_OperationManual_T4(under 19kW).book Page 26 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

GAUGES AND INDICATORS

The operator’s console provides you with the

means to start and stop the unit and a series of

gauges and indicators that inform you about the

current status of the engine. This is a required

engine component. Since the operator’s console is

application specific, it must be carefully sel ected by

an application engineer. It is not part of the basic

engine package as shipped from the Isuzu factory.

The illustrations and descriptions of optional

equipment in this manual, such as the operator’s

console, are for a typical engine installation. Refer

to the documentation supplied by the optional

equipment manufacturer for specific operation and

maintenance instructions.

Gauges

The following gauges are located on a typical

operator’s console. Some operator’s consoles may

not have the gauges described here or may have

different gauges.

Figure 7

Figure 8

Tachometer - The tachometer display

(Figure 7, (1)) or (Figure 8, (1)) shows the engine

speed in revolutions per minute (RPM).

Engine coolant temperature - The engine coolant

temperature display (Figure 7, (2)) or

(Figure 8, (2)) shows the temperature of the engine

coolant.

Engine oil pressure - The engine oil pressure

display (Figure 7, (3)) or (Figure 8, (3)) shows the

pressure of the engine oil.

Hour meter - The hour meter display

(Figure 7, (4)) or (Figure 8, (4)) shows the total

number of hours the engine has run. This is useful

for planning the Periodic Maintenance Procedures

on page 66.

26

Page 33

10

20

20

40

100

180

220

250

60

80

0

30

40

0

x100

RPM

VDO

VDO

PSI

F

C

0

1

2

3

4

5

bar

80

100

120

0

AUX

MC-704HP-G4

K0000024B

1

2

3

4

5

2

3

4

5

K0000025B

TNV_OperationManual_T4(under 19kW).book Page 27 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

Indicators

The following indicators are located on a typical

operator’s console.

Figure 9

1

HEAT indicator (Figure 9, (1)) - For the “ON-glow”

type of the starter switch that does not have the

HEAT position in the counterclockwise direction of

the ON position, by turning the key to the ON

position, the preheating function automatically

activates, and the HEAT indicator (Figure 9, (1))

lights up. 4 seconds after the indicator turns off is

when to start the operation. In the case of 3CE1

(DI), the indicator goes off after 15 seconds. Please

refer to HEAT on page 28 about the HEAT indicator

of the electronic controlled engine.

HEAT indicator (Figure 10, (1)) - When cold

starting the engine, in order to activate the glow

plug, the starter key needs to be turned to the

HEAT position (left side of OFF) (Figure 10, (5)).

By turning the key to the HEAT position and

keeping it at that position, the HEAT indicator

(Figure 10, (1)) lights up, and after 4 seconds, it

turns off. The time the indicator turns off is when to

start the operation. In the case of 3CE1 (DI), the

indicator goes off after 15 seconds.

Battery charge (Figure 9, (2)) or (Figure 10, (2)) When the key is turned to the ON position, the

charge indicator lights up. When the engine is

started, the alternator (or dynamo) generates

power, and the battery starts charging. Then the

indicator goes off. This indicator will also come on

when there is a problem in the charging system.

This indicator does not tell you the charging timing

(when the battery is low). See Troubleshooting

Chart on page 90.

Engine oil pressure (Figure 9, (3)) or

(Figure 10, (3)) - This indicator will come on if the

engine oil pressure is below or exceeds normal

limits. See Troubleshooting Chart on page 90.

Engine coolant temperature (Figure 9, (4)) or

(Figure 10, (4)) - This indicator will come on if the

engine coolant temperature exceeds normal limits.

See Troubleshooting Chart on page 90.

Figure 10

Auxiliary (Figure 9, (5)) - Used for special

applications.

27

Page 34

NOTICE

1

2

3

4

5

6

7

8

Optional key switch: Turning it

to ON energizes the glow plugs

automatically.

TNV_OperationManual_T4(under 19kW).book Page 28 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

GAUGES AND INDICATORS OF ELECTRONIC CONTROL SYSTEM

3CE1

Gauges

The following gauges are located on a typical

operator’s console of the electronically controlled

engines. Some operator’s consoles may not have

the gauges described here or may have different

gauges.

The illustrations and descriptions of optional

equipment in this manual, such as the operator’s

console, are for a typical engine installation. Refer

to the documentation supplied by the optional

equipment manufacturer for specific operation and

maintenance instructions.

Indicators

The following indicators are located on a typical

operator’s console.

See the Gauges and Indicators section for

description of indicators that are not described

below.

Fault (F igur e 11, (1)) (optio nal) - T his indica tor will

flash if a fault occurs in the E -ECU or Eco-governor .

The number of flashes and/or the flashing pattern

vary depending on the type or source of the fault.

See Troubleshooting Chart on page 90.

Auxiliary (Figure 11, (2)) - Rese rved as an

optional fault indicator.

HEAT (Figure 11, (3)) - This indicator will come on

when the glow plugs are energized when cold

starting the engine. For the electronic controlled

engine, by turning the key switch to the ON position

(Figure 11, (7)), the ECU detects the temperature

of the engine coolant, and the HEAT indicator turns

on for a preset period of time (Maximum 15

seconds), then the glow plug will be preheated. The

time the lamp came off is when to start the

operation.

When an optional after heater is installed, it is

energized for up to 80 sec. after the engine has

started, during which, however, the indicator is not

on.

Others (optional) - Other optional indicators

including those for indicating the air cleaner is

clogged or the water separator is filled with water

can also be installed on the console. See the

operation manual f or the driv en machine f or detai ls .

Machine events including alarms and faults are all

stored in memory of the E-ECU and can be loaded

into the service tool.

Figure 11

Figure 11 Typical Operator’s Console

28

Page 35

NOTICE

10

20

20

40

100

180

220

250

60

80

0

30

40

0

x100

RPM

VDO

VDO

PSI

F

C

0

1

2

3

4

5

bar

80

100

120

0

AUX

1

2

3

K0000011A

TNV_OperationManual_T4(under 19kW).book Page 29 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

CONTROLS

Key Switch

The key s witch for the operator’s console illustrated

in Figure 12 has three positio ns - OFF, ON, START

and HEAT.

MC-704HP-G4

Figure 12

NOTICE

For maximum engine life, Isuzu recommends that

when shutting the engine down, you allow the

engine to idle, without load, for five minutes. This

will allow the engine components that operate at

high temperatures, such as the turbocharger (if

equipped) and exhaust system, to cool slightly

before the engine itself is shut down.

OFF (key straight up and down) (Figure 12, (1))

and (Figure 13, (1)) - When y ou turn the key to this

position the engine shuts down. Electric current to

the gauges and indicators is shut off. You can insert

and remove the key in this position.

ON (Figure 12, (2)) and (Figure 13, (2)) - This is

the position the key will be in when the engine is

running. When the engine is not running, use this

position to energize the gauges, indicators, electric

fuel pump and auxiliary devices.

Never hold the key in the START position for longer

than 15 seconds or the starter motor will overheat.

START (Figure 12, (3)) and (Figure 13, (3)) - Turn

the key to this position to start the engine. As soon

as the engine starts, release the key and it will

automatically return to the ON position. Some key

switches may be equipped with a feature that

prevents you from turning the key to the START

position while the engine is running. When

operating a key switch with this feature, you cannot

turn the key to the START position without first

returning the key to the OFF position.

The key swi tch for the operator’s console illustrated

in Figure 13 has four positions - OFF, ON, START,

and HEAT.

29

Page 36

NOTICE

NOTICE

1

2

3

4

K0000021A

K0000648A

3

1

2

TNV_OperationManual_T4(under 19kW).book Page 30 Wednesda y, June 17, 2015 11:23 AM

PRODUCT OVERVIEW

Glow Plugs

Glow plugs help make the engine easy to start at

cold temperatures. During the engine starting

sequence, the glow plugs are activated for

approximately 4 seconds (15 seconds in case of

3CE1). After the pre-heat indicator goes out, the

engine can be started.

These plugs are installed in the cylinder head swirl

chambers for IDI engines or in the combustion

chambers for DI engines.

Governor Lever

Figure 13

For maximum engine life, Isuzu recommends that

when shutting the engine down, you allow the

engine to idle, without load, for five minutes. This