Page 1

Page 2

Body Builders Guide

I

Page 3

Body Builders Guide

General Motors Isuzu Commercial Truck, LLC

(GMICT) and American Isuzu Motors Inc.

Is striving to provide you with the most upto-date and accurate information possible.

If you have any suggestion to improve the

Body Builder's Guide, please call GMICT

Application Engineering. In the West Coast

call 1-562-229-5314 and in the East Coast

call 1-404-257-3013

Notice of Rights

All rights reserved. No part of this book may be

reproduced or transmitted in any form or by any

means, electronic, mechanical, recording or

otherwise, without the prior written permission.

Notice of Liability

All specifications contained in this Body Builders Guide

are based on the latest product information available

at the time of publication. The manufacturer reserves

the right to discontinue or change at anytime without

prior notice, any parts, material, colors, special

equipment, specifications, designs and models.

Made and printed in the USA.

II

Page 4

Contents

Introduction

FMVSS

EPA Requirements

Installation of Body & Special Equipment

Clearances

Body Installations

Prohibited Attachment Areas

Subframe Mounting

Crew Cab Body/Frame Requirements

Modification of the Frame

Fluid Lines

Electrical Wiring & Harnessing

Maximum Allowable Current

Exhaust System

Fuel System

Rear Lighting

Servicability

Wheelbase Alteration

Hydraulic Brake System

Body Application Summary Chart

NPR, NPR HD/W3500 W4500 Gas

NPR, NPR HD/W3500 W4500 Diesel

NQR/W5500 Diesel

NPR HD, NQR/W4500 W500 Crew Cab Diesel

FRR/WT

Mechanical & Cab Specifications

Engine Horsepower & Torque Chart

GVW/GCW Ratings

Rear Frame Height Chart

Clutch Engagement Torque

Paint Code Chart

N/W Series Towing Procedure

*

FRR/WT Series Towing Procedure

FSR, FTR & FVR Series Towing Procedure

Weight Distribution

Glossary of Dimensions

Weight Distribution Formulas

Recommended Weight Distribution

Trailer Weight

Performance Calculations

Highway Limits

Federal Bridge Formula Table

Commodity & Material Weights

Approximate Weight of Commodites & Materials

Vehicle Specifications Index

NPR, NPR HD/W3500 W4500 Gas

NPR, NPR HD/W3500 W4500 Diesel

NQR/W5500 Diesel

NPR, NPR HD NQR/W4500 W500 Crew Cab Diesel

FRR/WT

FSR, FTR & FVR

*

NPR, NPR HD/W3500 W4500 Gas Cab Chssis Electrical

NPR, NPR HD NQR/W3500 W4500 Diesel Cab Chssis Electrical

NPR HD NQR/W4500 W500 Crew Cab Electrical

FRR, FSR, FTR & FVR Cab Chassis Electrical

*

*Note: 2002 FSR, FTR and FVR

Weight Distribution Concepts

Weight Restriction

Gross Axle Weight Rating

Weighing the Vehicle

Tire Inflation

Center of Gravity

III

Page 5

IV

Page 6

Introduction

This guide has been provided as an aid to final stage manufacturers in determining conformity to the applicable

Emission Control and Federal Motor Vehicle Safety Standards. Final stage manufacturers should maintain current

knowledge of all Emission Regulations and Federal Motor Vehicle Safety Standards and be aware of their specific

responsibility in regards to each standard.

Any manufacturer making material alterations to this incomplete vehicle during the process of manufacturing the

completed vehicle should be constantly alert to all effects, direct or indirect, on other components, assemblies or

systems caused by such alterations. No alterations should be made to the incomplete vehicle that directly or

indirectly results in any either component, assembly or system being in nonconformance with applicable Emission

Regulations or Federal Motor Vehicle Safety Standards.

General Motors Isuzu Commercial Truck, LLC (GMICT) and American Isuzu Motors Inc. will honor its warranty

commitment (for the cab-chassis only), to the ultimate consumer, provided: (1) the final stage manufacturer has

not made any alterations or modifications which do not conform to any applicable laws, regulations or standards, or

adversely affect the operation of the cab-chassis; and (2) the final stage manufacturer complied with the instructions contained in this guide with respect to the completion of the vehicle. Otherwise, the warranty becomes the

responsibility of the final stage manufacturer.

The final stage manufacturer is solely responsible for the final certification of the vehicle and for compliance with

Emission Control and Federal Motor Vehicle Safety Standards. The information contained in this guide has been

provided for the final stage manufacturer’s information and guidance.

This guide contains information pertaining to the NPR/W Gas, NPR/W Diesel, NQR/W Diesel, NPR HD/NQR/W

Diesel Crew Cab and FRR/WT Series Chassis Cab and Janesville assembled FSR, FTR and FVR Chassis Cab.

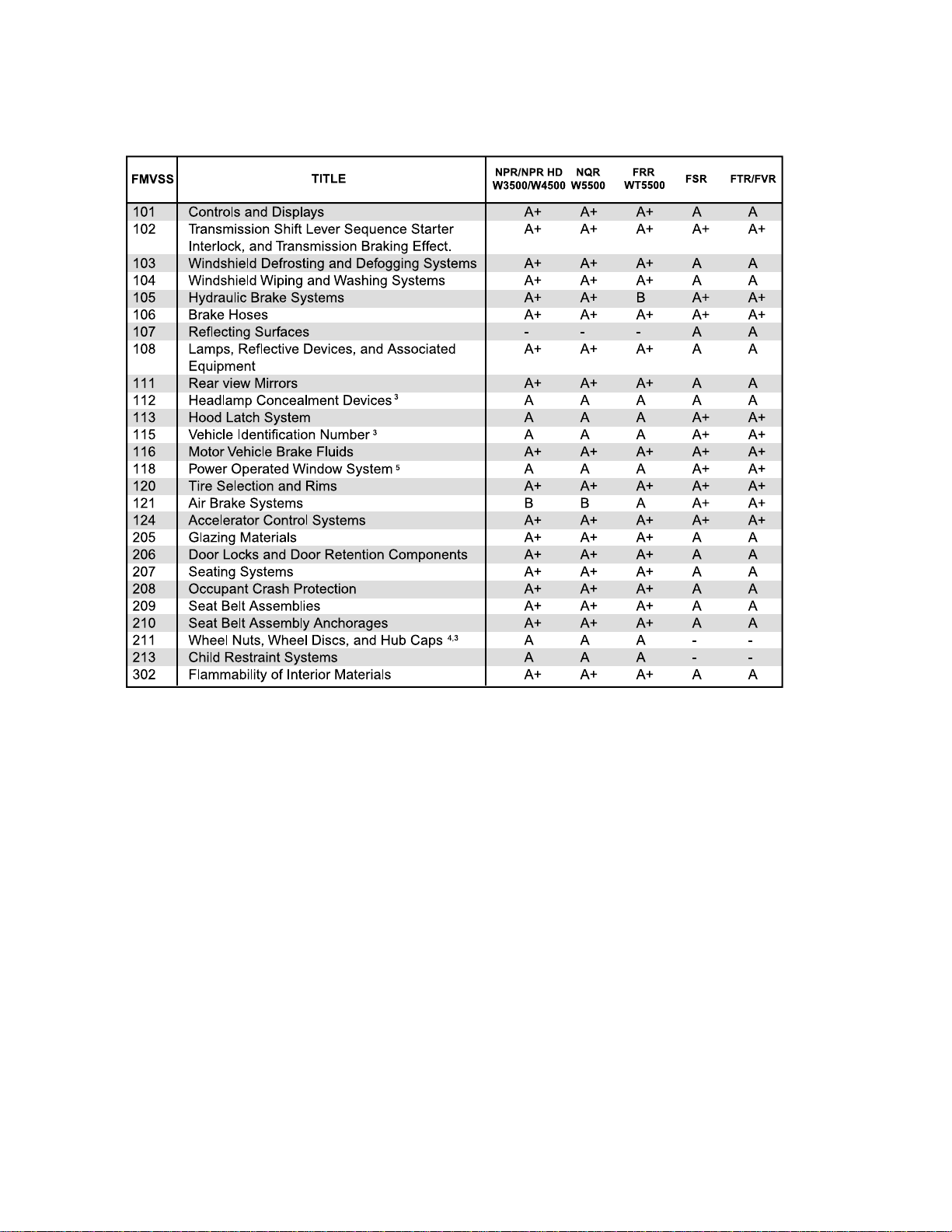

Following is a list of Federal Motor Vehicle Safety Standards applicable to those vehicles with a GVWR greater than

10,000 lbs. Please refer to the following chart.

V

Page 7

FMVSS Chart

NOTE: This chart is only a guide, for complete information please refer to "Document for Incomplete Vehicle”

provided with each chassis.

Chart Legend:

A Incomplete vehicle; when completed will conform providing no alterations have been made affecting items

covered by FMVSS regulations and "Document for Incomplete Vehicle.

B Incomplete vehicle; when completed by the final manufacturer will conform providing it is completed in

compliance with FMVSS regulations and "Document for Incomplete Vehicle."

+ Meets Canadian Motor Vehicle Safety Standards bearing same FMVSS number.

3 Canadian MVSS only.

4 Not applicable to truck or bus.

5 Not applicable to trucks with a GVWR greater than 10,000 LBS.

VI

Page 8

EPA Requirements

NPR/W Gas, NPR/W Diesel, NQR/W Diesel, NPR HD/NQR/W Diesel Crew Cab and FRR/WT Series Chassis Cab

To assure that U.S.A. and Canada Emission Requirements are met, this Incomplete Vehicle must be completed in

strict accordance with all instructions contained in this document, especially the following instructions which relate

to:

A. Exhaust emission related components

B. Noise emission related components

C. Labels

[A] EXHAUST EMISSION RELA TED COMPONENTS

Compliance of this vehicle with EP A, California and Canada Requirements will be maintained providing

no alterations are made to the components or systems identified below:

1) DIESEL VEHICLES 2) GASOLINE VEHICLES

Injection Pump Vehicle Control Module (VCM)

Injector and High Pressure Lines Fuel Management System

Turbocharger Air Induction System

Charge Air Cooler and Charge Ignition System

Air Cooler Hoses Catalytic Converter System

Engine Control Module (ECM) Positive Crankcase V entilation System

Engine Speed Sensor Exhaust Gas Recirculation System

Engine Coolant T emperature Sensor Evaporative Emission Control System

Intake Manifold Miscellaneous Items Used in Above Systems

Catalytic converter and its location

V ariable swirl system

Exhaust Gas Recirculation System

ADDITIONAL CANADA MOTOR VEHICLE SAFETY ST ANDARD

CMVSS NO. 1 101-EMISSION DEVICE

CMVSS NO. 1 102-CRANKCASE EMISSION (GASOLINE ENGINE ONLY)

CMVSS NO. 1 103-EXHAUST EMISSIONS

CMVSS NO. 1 104-OPACITY (DIESEL ENGINE ONL Y)

CMVSS NO. 1 105- EVAPORATIVE EMISSION (GASOLINE ENGINE ONLY)

[B] NOISE

Compliance of this vehicle with EP A and Canada requirements will be maintained providing no

alterations are made to the components or systems.

CMVSS NO. 1 106-NOISE

This incomplete vehicle, when completed, will conform to the above standards except CMVSS-1106 providing no

alterations are made which effect the function, physical or mechanical properties, environment, locations or vital

spatial clearances of the components identified below:

* Engine assembly

Exhaust emission control system

P.C.V. system (if equipped)

* Intake system

* Exhaust system

Fuel system (if equipped)

* Transmission assembly

* Axle

* Tires

* Fan and drive

Diesel fuel injection controls (if equipped)

Turbocharger and associated controls (if equipped)

* Catalytic converter and its location

V ariable swirl system (if equipped)

VII

Page 9

Conformity with CMVSS 1 106 is not determined solely by the design of the incomplete vehicle. When completed, it

should conform to CMVSS 1 106 providing no alterations are made to the noise attenuation components identified

thus * in the above list.

[C] LABELS

The Emission control related information labels which are permanently affixed are required by government

regulation and must not be obstructed from view or defaced so as to impair its visibility or legibility .

P A R T 3 : Radio Noise

CANADIAN RADIO INTERFERENCE REGULA TIONS

[A] The following statement is applicable to NPR/W Series Chassis-Cab (Gasoline Engine Only).

This incomplete Vehicle, when completed, will conform to the above regulations providing no alterations or substitutions are made which affect any parts or components identified below:

A. Distributor

B. Ignition Wires

C. Spark Plug Wires

FSR, FTR & FVR

U.S. ENVIRONMENT AL PROTECTION AGENCY AND STA TE OF CALIFORNIA EMISSION REQUIREMENTS

To assure that EPA and California Emission Certificate Requirements are met, this incomplete vehicle must be

completed in strict accordance with all instructions contained in this document, especially the following instructions

which relate to:

A. Exhaust emission related components

B. Labels

[D] EXHAUST EMISSION RELATED COMPONENTS

Compliance of this vehicle with EP A and California Certification Requirements will be maintained providing

no alterations are made to the components or systems identified below:

1. DIESEL VEHICLES

Injection Pump

Injector and High Pressure Lines

Turbocharger

Charge Air Cooler and Charge Air Cooler Hoses

Engine Control Module (ECM)

Engine Speed Sensor

Engine Coolant Temperature Sensor (6HE1-TC only)

Intake Manifold

Catalytic converter and its location (6HE1-TC only)

Air cylinder for variable swirl system (6HE1-TCS only)

[E] LABELS

The Emission control related information labels which are permanently affixed are required by government regula-

tion and must not be obstructed from view or defaced so as to impair its visibility or legibility .

VIII

Page 10

CANADIAN MOTOR VEHICLE SAFETY STANDARDS

CMVSS NO. 1 101-EMISSION DEVICE

CMVSS NO. 1 103-EXHAUST EMISSIONS

CMVSS NO. 1 104-OPACITY

CMVSS NO. 1 106-NOISE

This incomplete vehicle, when completed, will conform to the above standards except CMVSS 1106 providing no

alterations are made which affect the function, physical or mechanical properties, environment, locations or vital

spatial clearances of the components identified below:

Engine assembly*

Exhaust emission control system

P.C.V . system

Intake system*

Exhaust system*

Fuel system

Transmission assembly*

Axle*

Tires*

Fan and drive*

Diesel fuel injection controls

Turbocharger and associated controls

Catalytic converter and its location (6HE1-TC only) *

Air cylinder for variable swirl system (6HE1- TCS only)

Conformity with CMVSS 1 106 is not determined solely by the design of the incomplete vehicle. When completed, it

should conform to CMVSS 1 106 providing no alterations are made to the noise attenuation components identified

thus * in the above list.

Compliance of this vehicle with EP A and California Certification Requirements will be maintained providing no

alterations are made to the components or systems identified below:

Air Inlet System

Diesel Fuel Injection Controls

Engine Assembly with all Components of Exhaust Emission Control System

Exhaust System

Fuel System

Turbocharger and Associated Controls

IX

Page 11

Installation of Body & Special Equipment

Installation of Body

&

Special Equipment

April 2002 1

Page 12

Installation of Body & Special Equipment

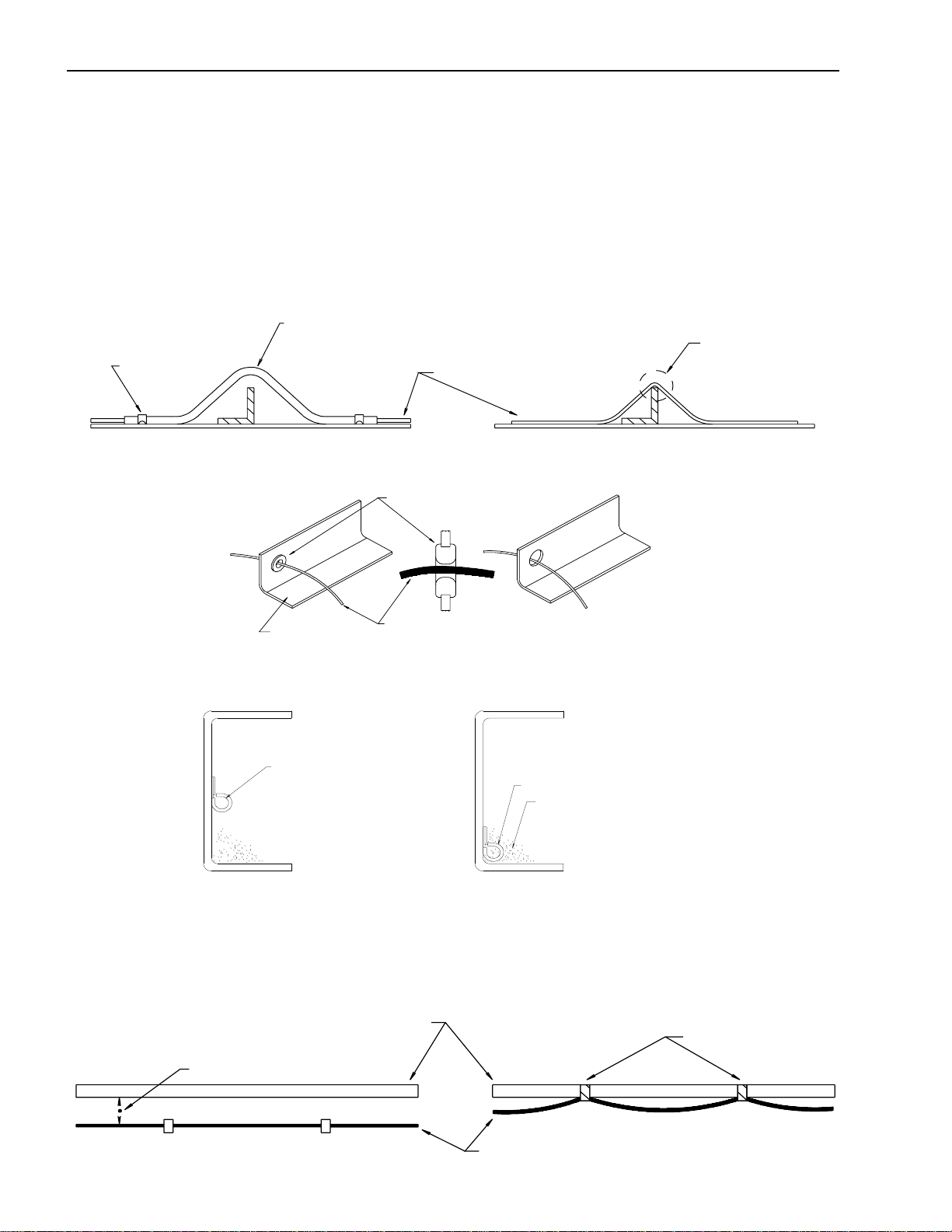

Clearances

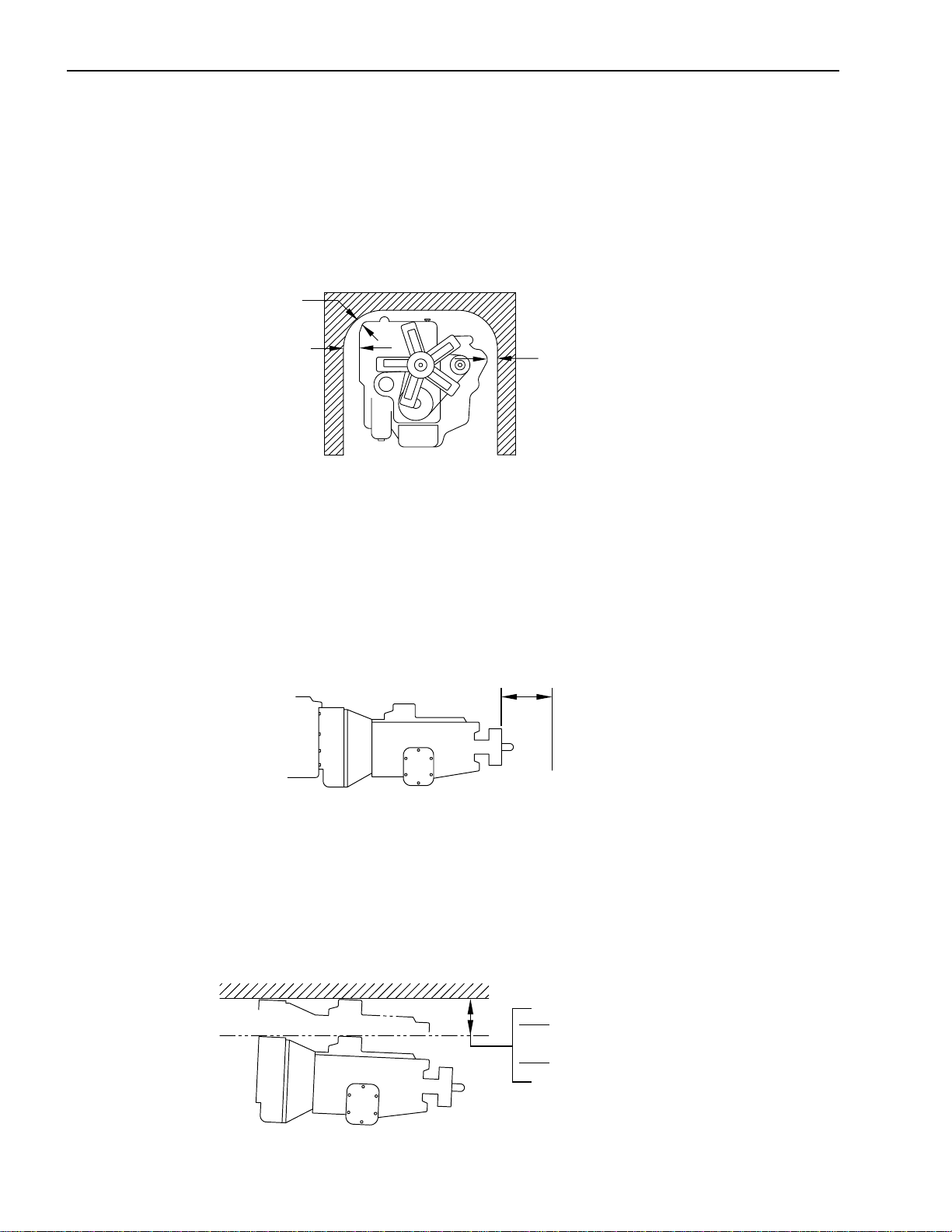

Engine

At least 1.6 inch clearance should be maintained around the engine. No obstacles should be added in front of the

radiator or intercooler.

1.6 Inch

Clearance

1.6 Inch

Clearance

Engine

1.6 Inch

Clearance

Transmission

The transmission is removed from the rear. Enough clearance must be provided to allow rearward movement of the

transmission assembly. Clearance should be sufficient to allow 5 to 6 inches unrestricted movement of the

transmission assembly. In addition, provide at least 2 inches clearance around the control lever on the side of the

transmission to allow free movement without any binding.

5-6 Inch

Engine

Clearance

Transmission

At least 6 inches clearance should be maintained above the transmission to allow easy removal of the upper cover

for manual transmissions. At least 2 inches clearance should be maintained above the automatic transmission to

allow for transmission removal.

5.9

Inches or More M/T

(150)

2.0

Inches or More A/T

(58)

Transmission

2 April 2002

Page 13

Installation of Body & Special Equipment

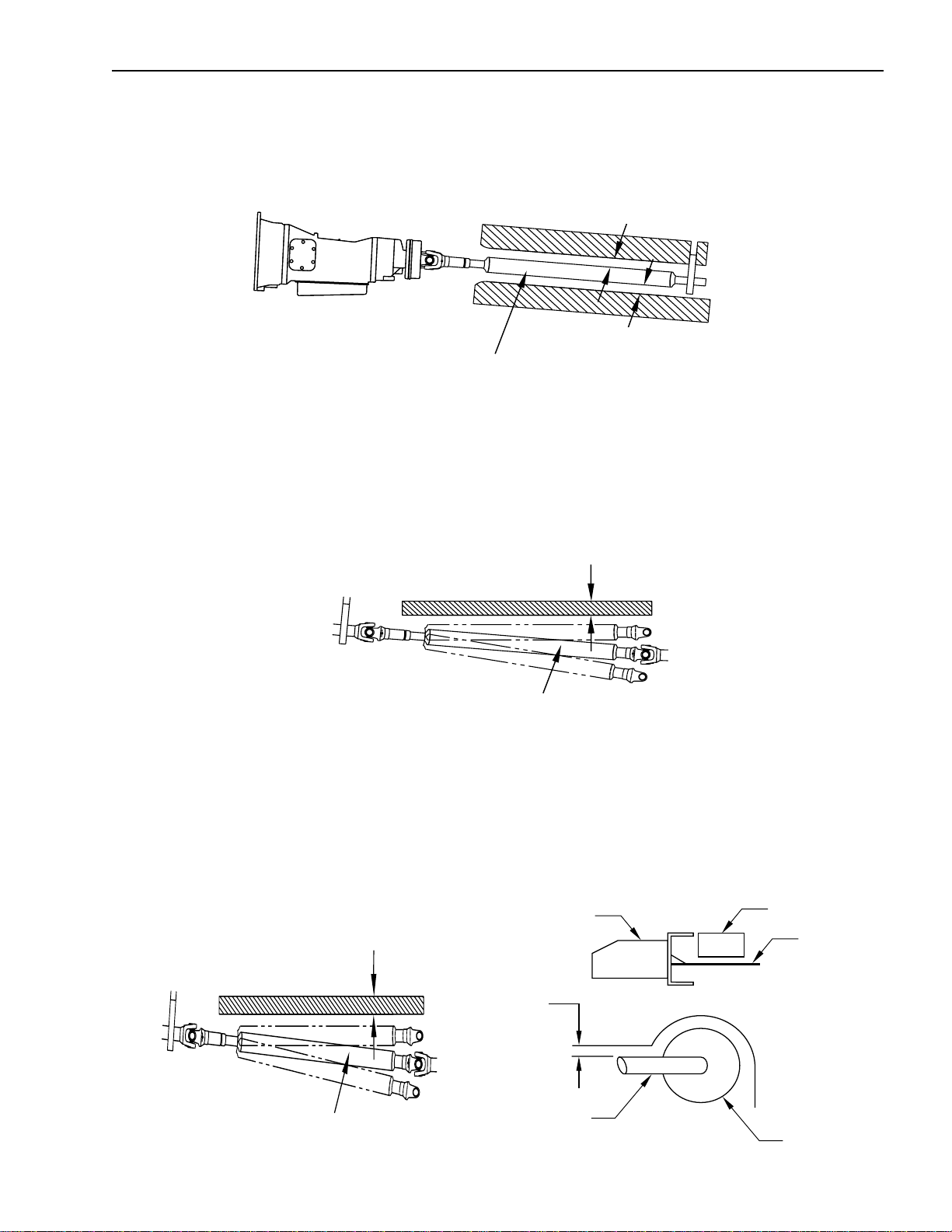

Front and Center Propeller Shafts

At least 1.25 inch clearance should be maintained around front and center propeller shafts.

1.25 Inches or more

1.25 Inches or more

Front Propellar Shaft

Rear Propeller Shaft

With the rear springs at maximum deflection, at least 1.25 inch clearance should be provided over the rear propeller

shaft.

1.25 Inches or more

Front Propellar Shaft

Exhaust System

If flammable materials such as wood are used in the body, provide at least 3.9 inches clearance between the body

and any parts of the exhaust pipe, muffler and catalytic converter. If it is impossible to maintain this minimum

clearance, use a heat shield. Also use a heat shield if an oil pump or line is located above the exhaust pipe, muffler

or catalytic converter.

Tool Box

1.25 Inches or more

3.9 Inch

Clerance

Oil Pump

Heat Shield

Front Propellar Shaft

April 2002 3

Exhaust Pipe

Muffler

Page 14

Installation of Body & Special Equipment

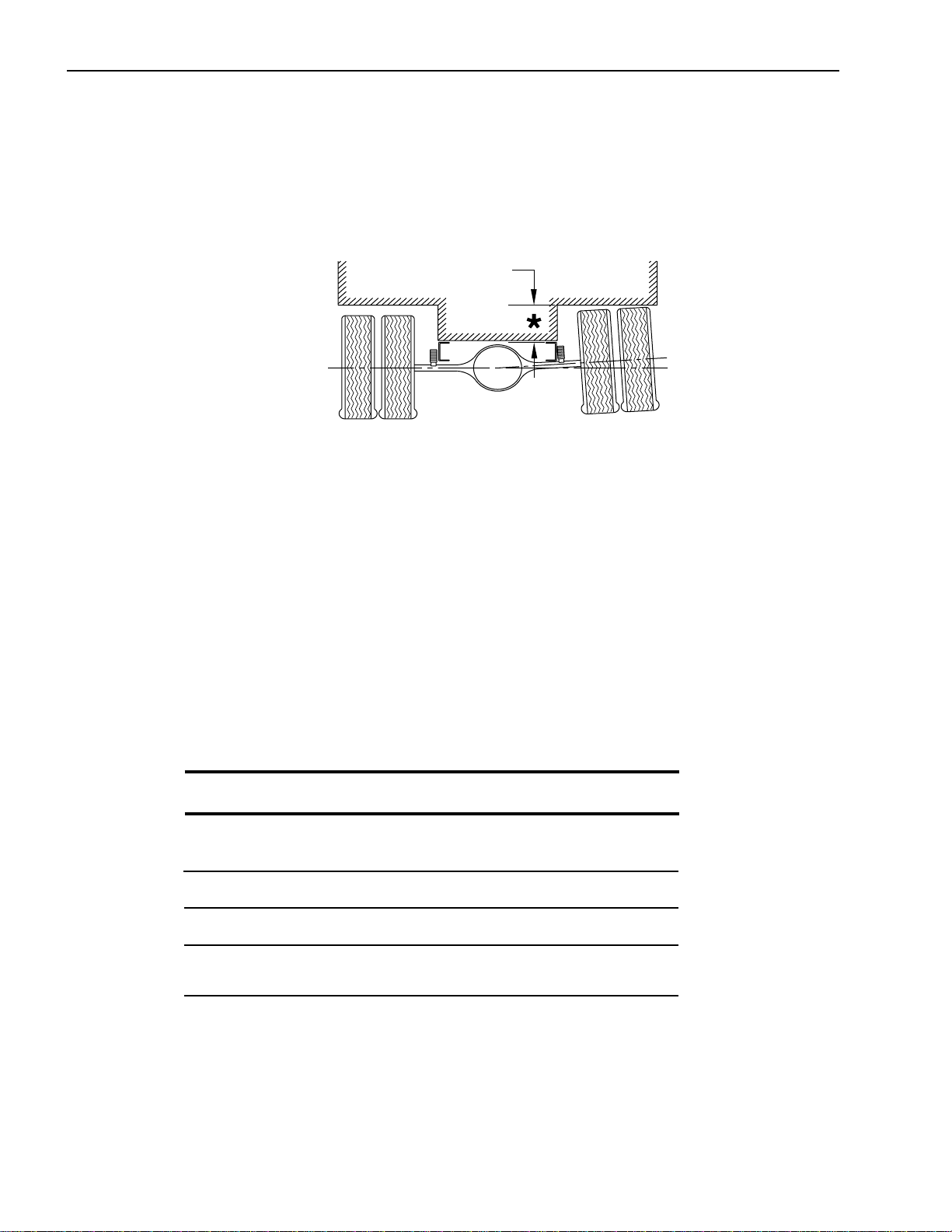

Rear Wheel and Axle

The design and installation of the body should allow sufficient clearance for full vertical movement of the rear wheels

and axle when the vehicle travels over rough or unlevel surfaces.

Rear of Body

*NOTE: For recomended clearances

please refer to the Rear Axle Chart in

each models respective section.

Normal Rear

Axle Center Line

Rear Wheels

Over High Spot

Rear Wheels

Over Obstacle

Other Clearances

Transmission control cable may be broken if it is bent by or interferes with the body and its fixtures. To prevent this,

1 inch minimum clearance should be provided. When cable is detached for body mounting, be sure not to bend the

cable.

Accessibility to the grease nipple on the rear spring bracket/shackle should be provided so that serviceability with a

grease gun is not hampered.

MINIMUM

PARTS CLEARANCE LOCATION

Brake Hose 6.7 in. Axle side

1.6 in. Frame side

Parking Brake Cable 1.2 in. -------Fuel Hose 1.6 in. -------Shock Absorber 2.4 in. Axle Side

1.2 in. Frame Side

4 April 2002

Page 15

Installation of Body & Special Equipment

Body Installation

Chassis

To maintain the performance of the truck chassis, either a side member or subframe should always be used for body

mounting. Body mounting with low rigidity will often adversely affect riding comfort.

Special Equipment on the Chassis

When installing special equipment on the chassis, extra consideration must be given to the weight and construction

of the equipment to assure proper distribution of the load. Localization of the load should be prevented. All special

equipment should be properly secured into position. We recommend the use of subframe members when installing

special equipment.

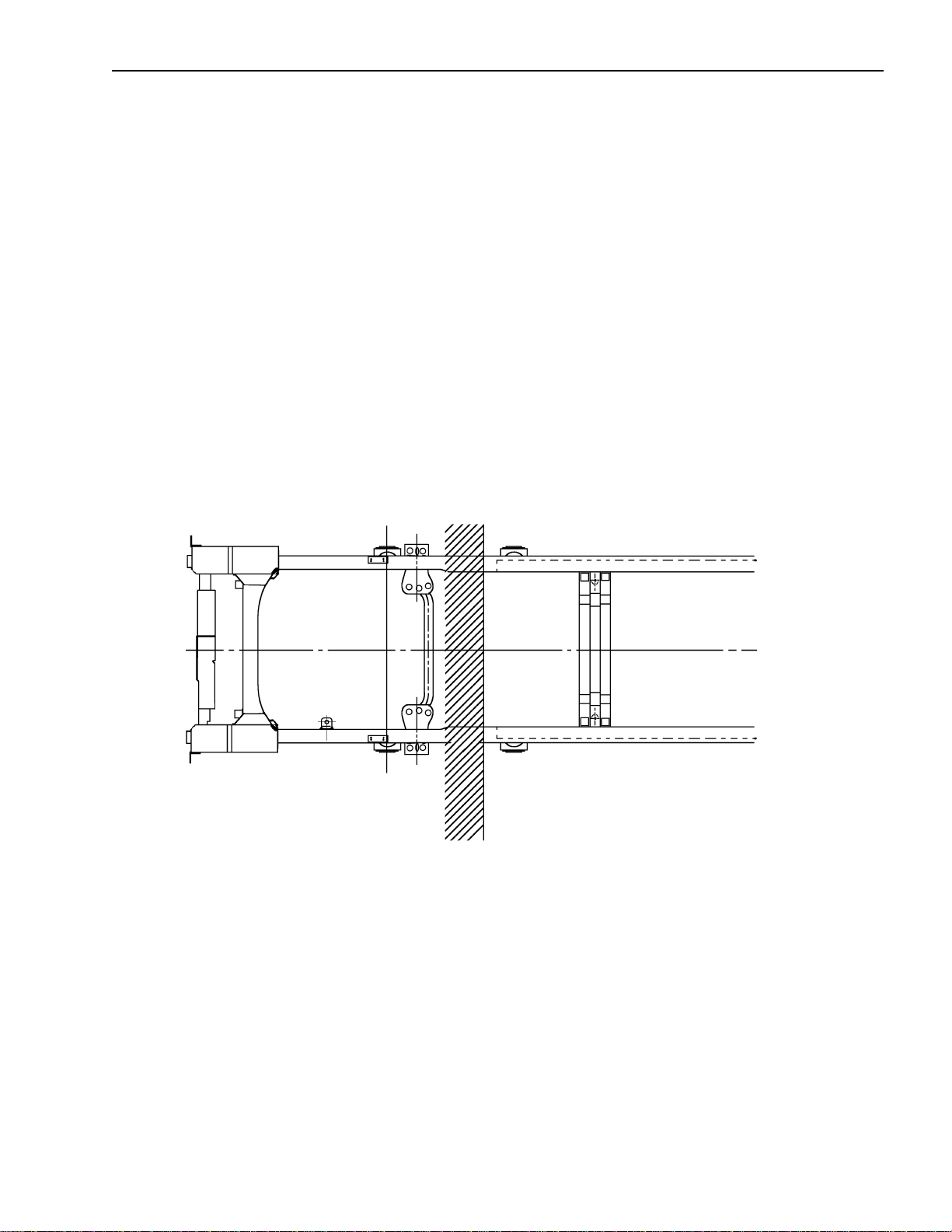

Subframe Design and Mounting

The subframe assembly should be mounted as close to the cab as possible. It should be contoured to match the shape

and dimensions of the chassis frame as closely as possible.

Rear End of the Cab

April 2002 5

Page 16

Installation of Body & Special Equipment

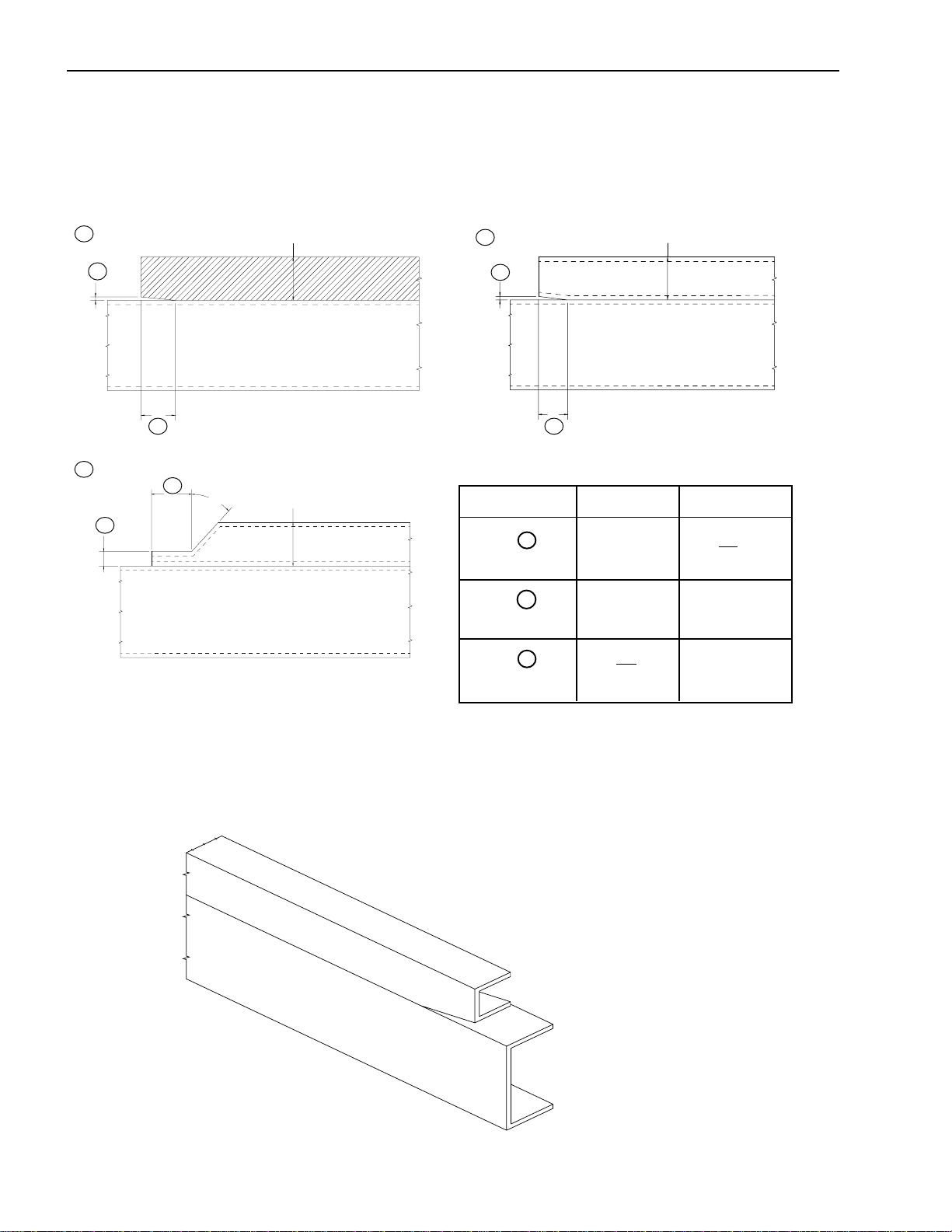

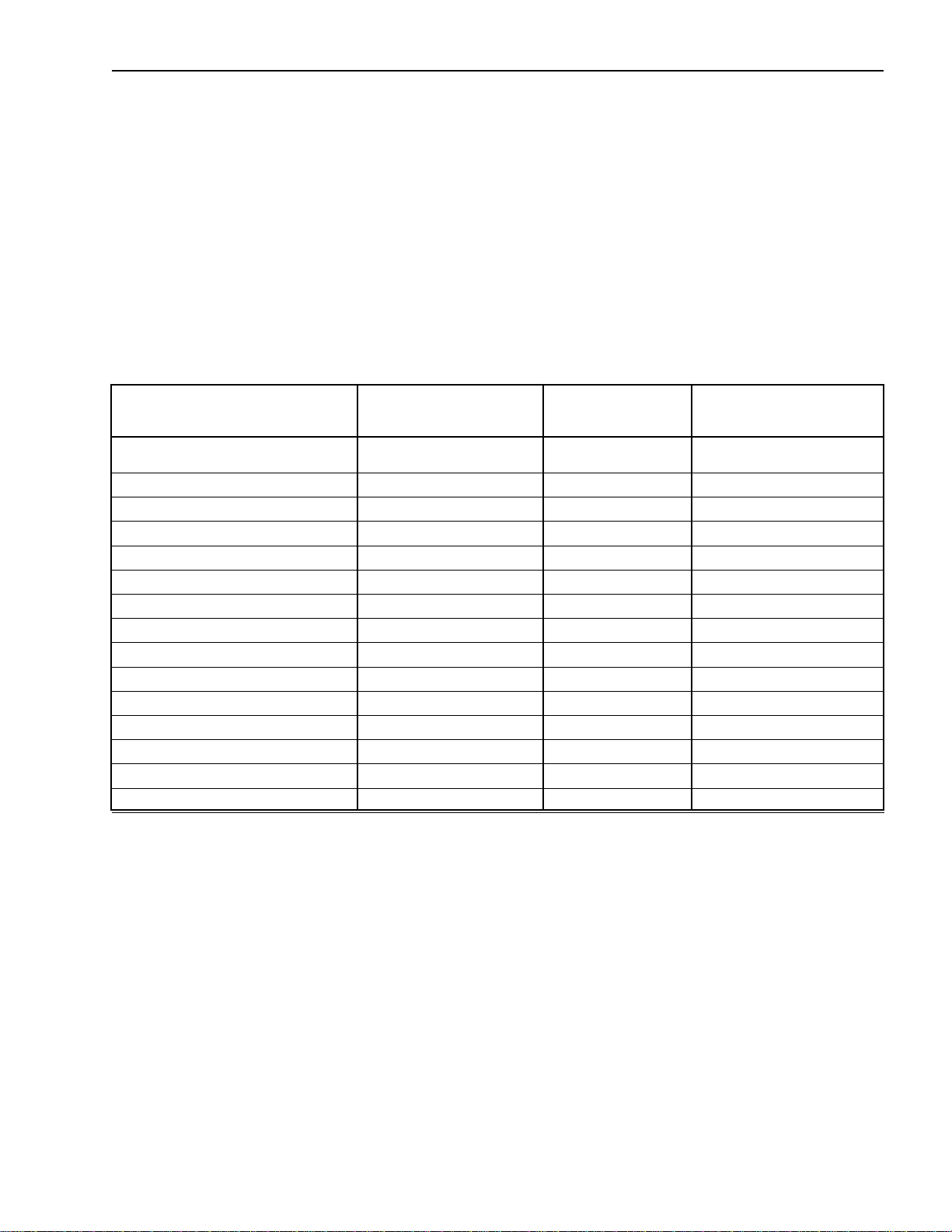

Subframe Contour

Contouring of the front end of the subframe members as shown in the three illustrations below will prevent stresses

from being concentrated on certain areas of the chassis frame.

1

A

3

A

Wooden subframe

B

B

45

o

H

H

Steel subframe

2

Steel subframe

A

B

Drawing A B

1 0.2 in. H

2 0.2 in. H or more

3 H H or more

H

2 ~ H

3

When using a steel subframe, do not close the end of the subframe.

Steel subframe

Chassis frame

6 April 2002

Page 17

Installation of Body & Special Equipment

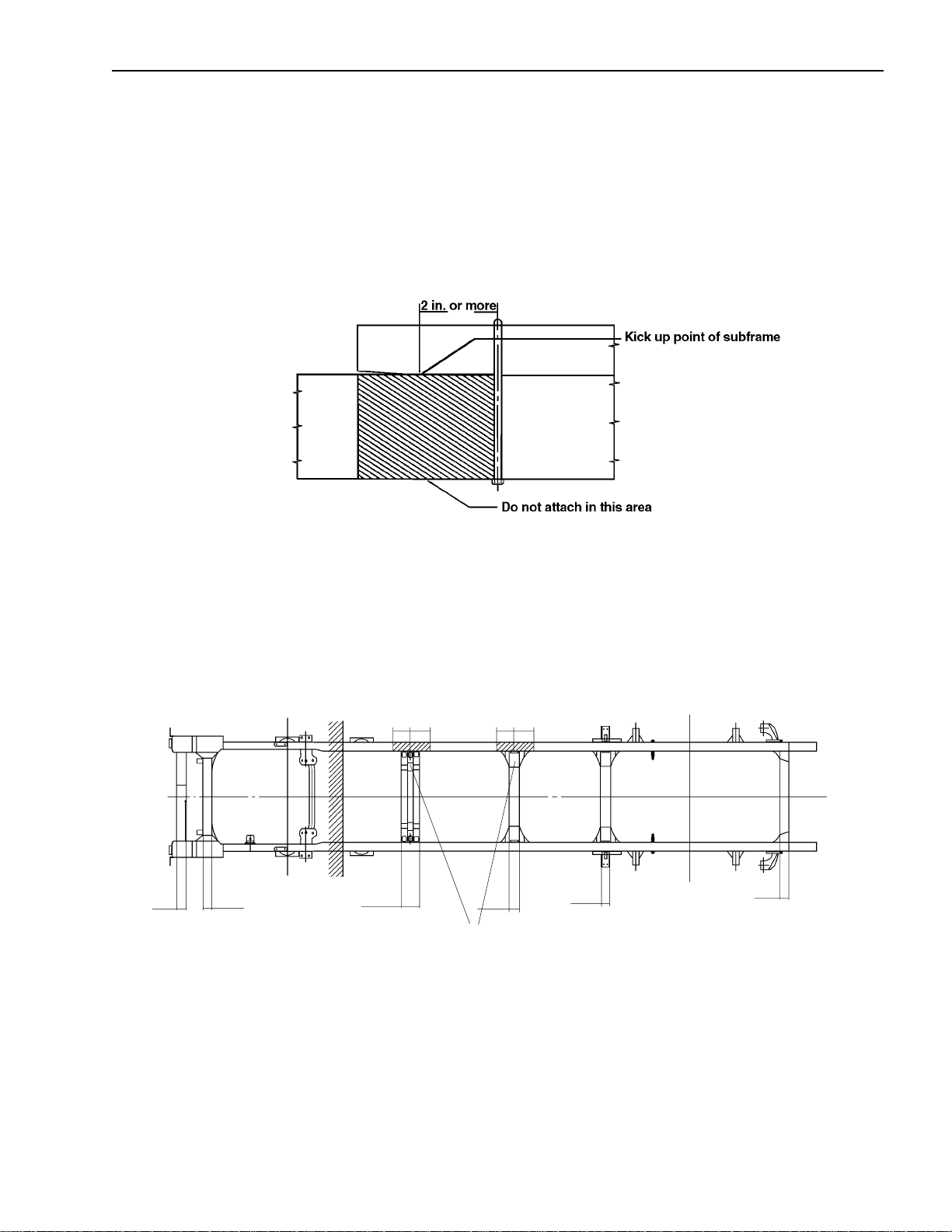

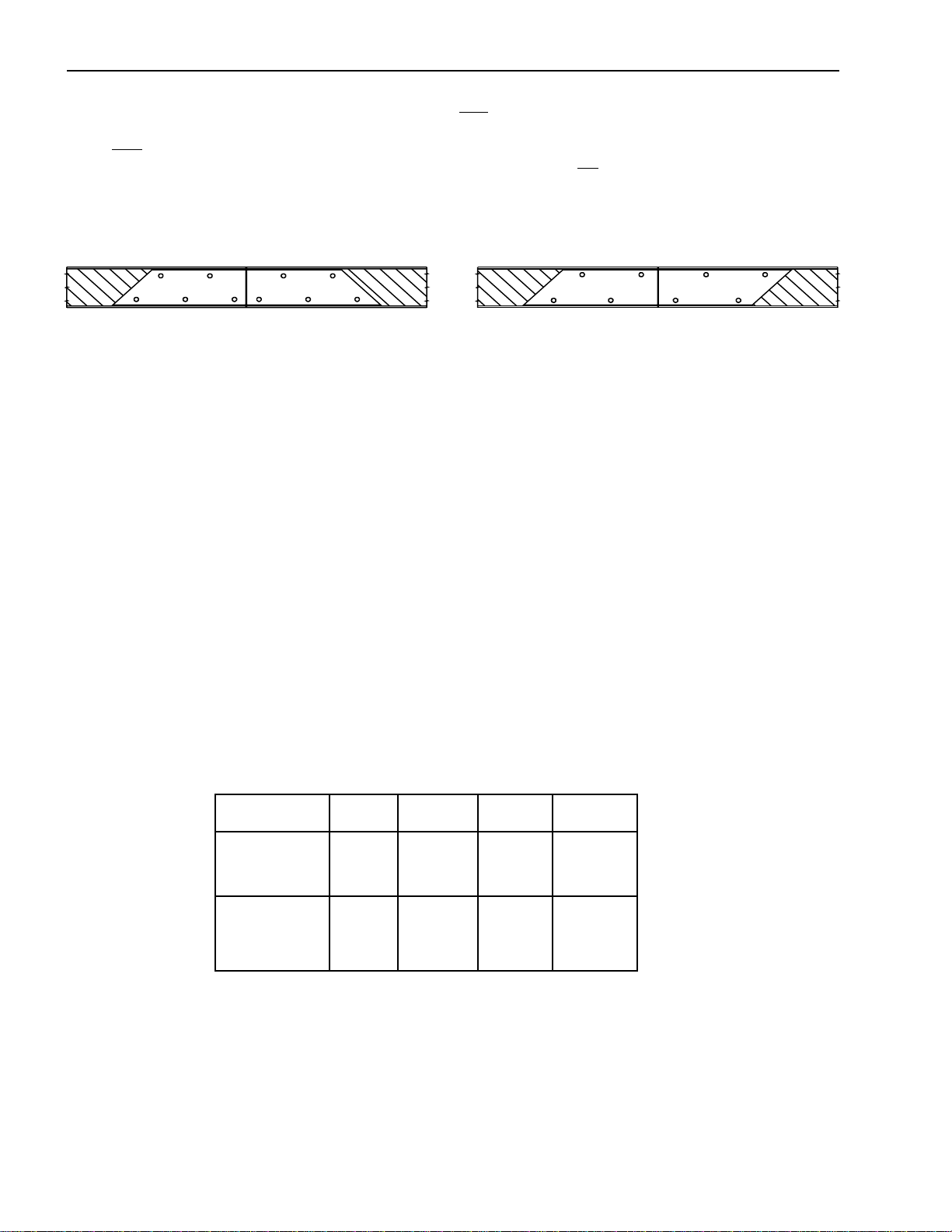

Prohibited Attachment Areas

Do not attach the subframe with a bolt on bracket to the chassis frame at the points indicated by shading in the following

illustrations.

1. At the front end of the subframe. The attaching bolt or bracket must be at least 2 inches behind the kick

up point of the subframe.

2. Within 8 inches of bends in the chassis frame or the attachment points of any cross members.

3.3

8 in. 8 in

6.1

8 in. 8 in

3.1

Do not attach in these areas.

3.12.9

2.8

April 2002 7

Page 18

Installation of Body & Special Equipment

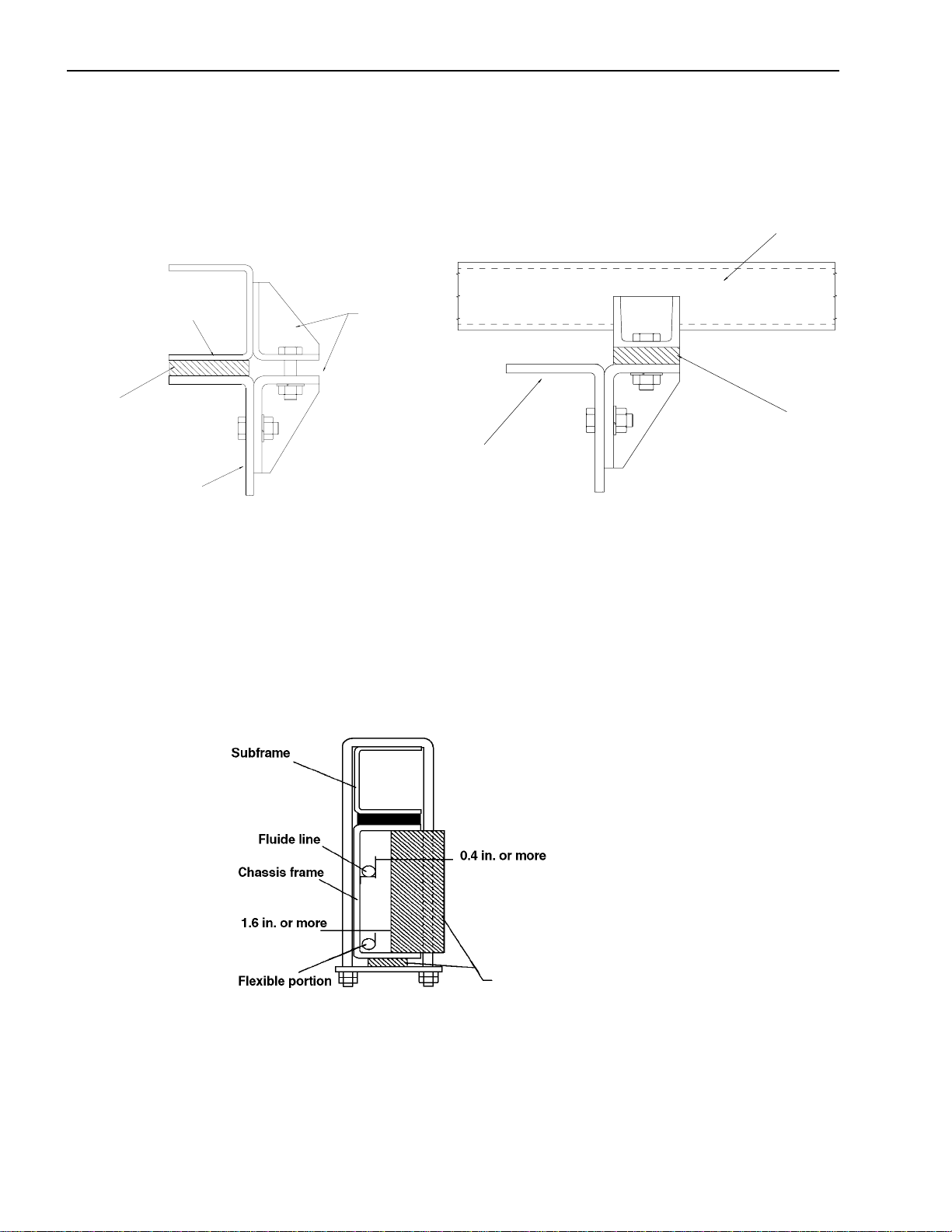

Subframe Mounting

Bracket Installation

Mounting brackets should be clamped to the chassis frame using bolts. For proper positions in which to install the

bolts, refer to the preceding section and the section “Modifications to the Chassis Frame.”

Bolster

Subframe member

Cushioning material

Chassis frame

Bracket

Cushioning material

Chassis frame

U-bolt Installation

When U-bolts are used to retain the subframe, reinforcement blocks must be installed in the frame members. This

will prevent distortion of the frame flange as they are tightened. The drawing indicates the correct placement of

reinforcement blocks. If you use wood blocks, be sure that there is sufficient clearance between them and any parts

of the exhaust system.

If any fluid lines or electric cables are located near the reinforcement blocks, you must provide at least 0.4 inch

clearance between rigid or stationary portions, and at least 1.6 inch between moveable or flexible portions of the lines.

Reinforcement block

(Reinforcement blocks should be mounted

securely in installed position)

For the installation positions of the U-bolts, refer to “Prohibited Attachment Areas.”

8 April 2002

Page 19

Installation of Body & Special Equipment

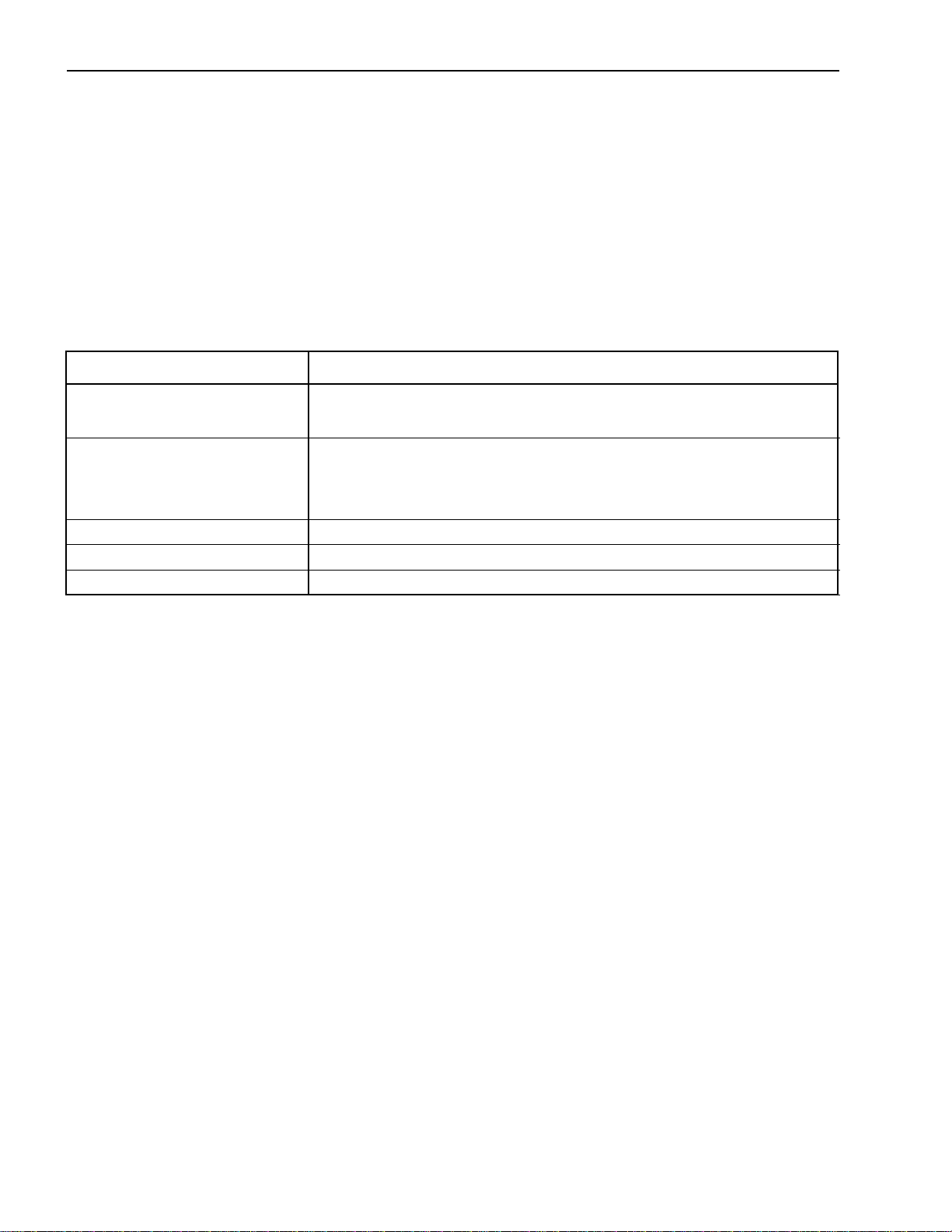

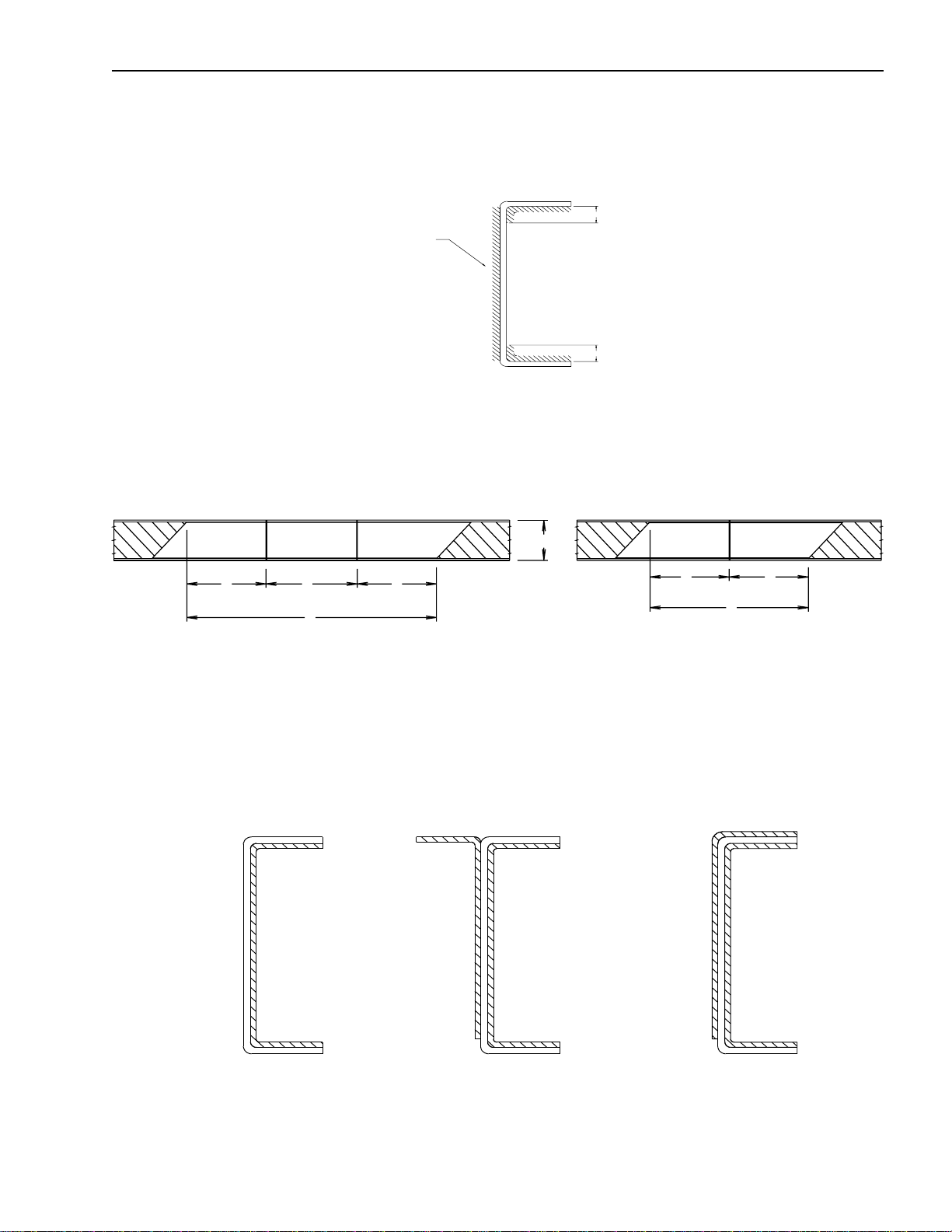

Crew Cab Body/Frame Requirement

The Crew Cab NPR HD/W4500 and NQR/W5500 will be available in two wheelbases, 150 and 176 inches. Effective

CA will be 84.7 and 110.7 inches. On this model chassis General Motors Isuzu Commercial Truck, LLC (GMICT)

and American Isuzu Motors Inc. will require that the body installed on the chassis have an understructure

manufactured with any of the following structural steel "C" channels:

4"x1-5/8", 7.25 lbs/ft = ok

5"x1-3/4", 6.7 or 9.0 lbs/ft = ok

6"x2", 8.2, 10.5 or 13.0 lbs/ft = ok

Modification of the Frame

Modification of chassis frame should be kept to an absolute minimum. Modification work should be performed

according the instructions in the following paragraphs.

When modification is complete, chassis frame members should be carefully inspected to eliminate the possibility of

any safety-related defects.

NOTE: PLEASE REFER TO NOTES ON CHASSIS FRAME MODIFICATION WITH ANTILOCK BRAKES ON PAGES 27 AND 28

Working on Chassis Frame

The chassis frame is designed and built with consideration for proper load distribution. Sufficient physical strength

is provided when the load is evenly distributed. Installation of special equipment on the chassis frame can cause

variations in load distribution. If even distribution of load is not kept in mind when the equipment is installed, localization

of stresses on specific areas of the frame could cause cracking of the chassis frame members or other problems,

even if the total weight of the equipment is within the design limit.

The chassis frame is designed as an integral unit. Therefore, we do not recommend cutting the chassis frame

under any circumstances.

Drilling and Welding

IMPORTANT NOTE

For vehicles equipped with electronic or hydra-matic

transmissions electric arc welding must be done with the

negative battery cable disconnected.

1. Do not drill or weld in the shaded portions of the chassis frame members. Do not weld with 0.8 inch from th edges

of any existing holes.

2. Hold the length of any welding beads within 1.2-2.0 inch. Allow at least 1.6 inch between adjacent welding beads.

3. All holes must be drilled. Do not use a torch to make any holes.

4. All riveting must be done with cold rivets. Do not use hot rivets.

5. The flange of the chassis frame must not be cut under any circumstances.

6. The subframe must be attached to the chassis frame with bolts. Do not weld.

B

A

Dimensions: A - not more than 0.51 in. in diameter

C

April 2002 9

B - must be more than 0.8 in.

C - must be more than 1.0 in.

Page 20

Installation of Body & Special Equipment

Reinforcement of Chassis Frame

Reinforcements must be installed to prevent the considerable variation in the section modulus. They must be welded

so as to avoid localized stresses.

The frame of the NPR/W3500, NPR GAS/W4500 and NQR/W5500 is made of SAPH440 mild steel. The frame of

the FRR is made of HT540A. See the FSR, FTR and FVR section for frame material specifications.

The drawings below illustrates correct and incorrect methods of frame reinforcement.

Welding

1. Keep reinforcement plates and chassis frame free from moisture and water.

2. Avoid cooling with water after welding.

3. Use a suitable means to protect pipes, wires, rubber parts, leaf springs, etc. against heat and

affect of sputtering.

4. Remove fuel tank assembly when welding portions near the fuel tank.

5. Remove coat of paint completely when welding painted areas.

SATISFACTORY

o

45

Fluid Lines

Reinforcement

Plug weld or rivet

UNSATISFACTORY

Frame rail

Frame rail

Reinforcement

Welding is prohibited

Do not disturb the layout of any brake lines or fuel lines unless absolutely necessary. When modification is needed,

follow the instructions below carefully to ensure safety. Brake fluid lines must not be cut and spliced under any

circumstances. We do not recommend the cutting or splicing of any fuel lines, but if it is absolutely necessary, be

sure that the correct fitting and tools are used to form the joint, and then pressure test the joint. Steel lines are metric

sizes.

Preparation of Additional Lines

1. Where possible, use only genuine Isuzu lines as supplied by authorized Isuzu dealers.

2. Use the correct metric flaring and bending tools to form the lines.

3. Avoid repeated bending. Do not use heat for flaring and bending the lines. Before and after

forming the new lines, examine them carefully for scratches, distortion, dents and the presence

of any foreign matter.

10 April 2002

Page 21

Installation of Body & Special Equipment

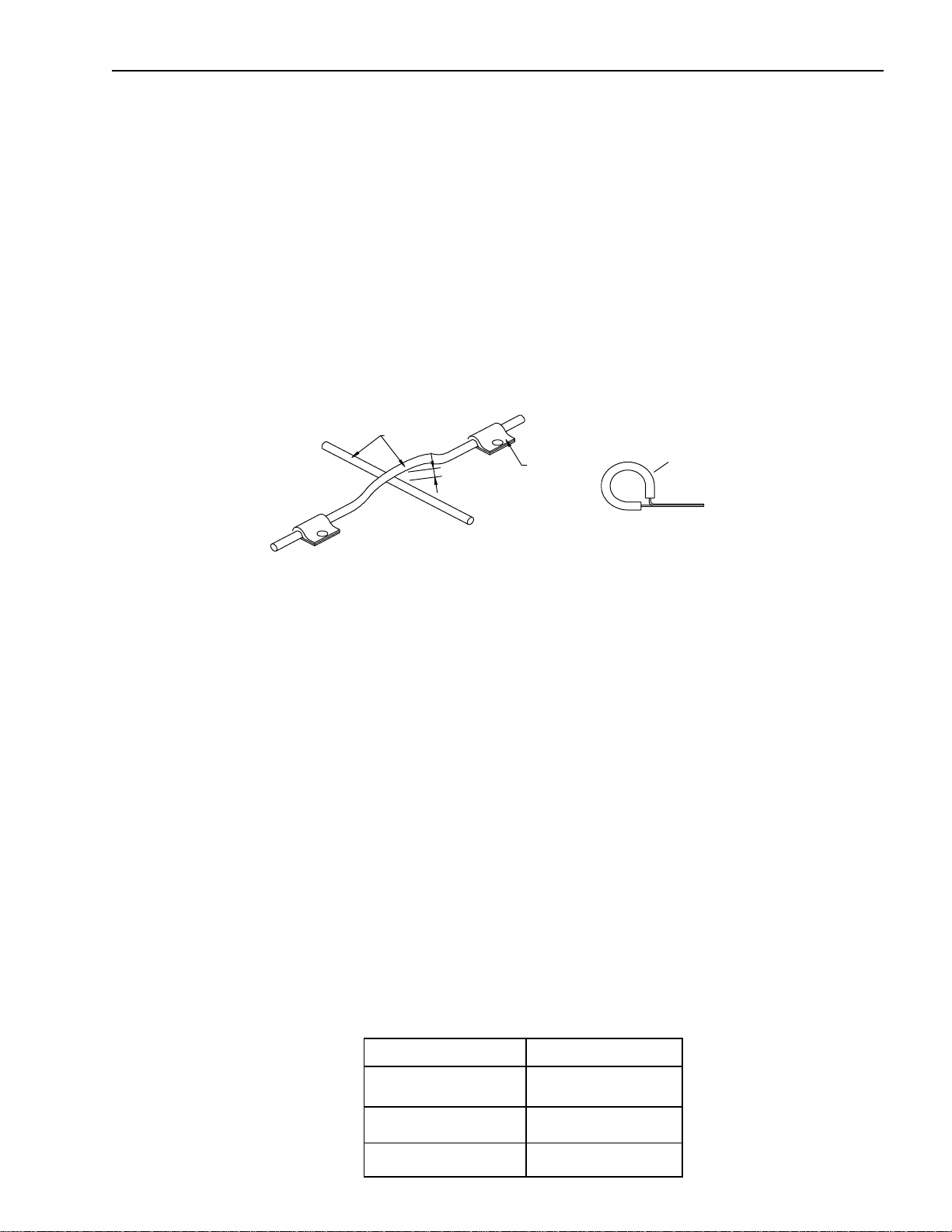

Installation of Additional Lines

Install new lines away from adjacent parts and away from any sources of heat.

1. A minimum clearance of 0.4 inch must be maintained between lines. Where necessary, clip the

lines into position in order to maintain this minimum clearance.

2. Minimize any crossing between lines. If a crossing is unavoidable, use the following procedure:

a. At least 0.4 inch clearance should be maintained between lines at the crossing point.

b. If the 0.4 inch clearance cannot be maintained, or if the lines are subject to vibration, clip

them securely.

3. Plan the bends and clipping points of the lines to minimize vibration and the resulting fatigue.

4. Use rust-proofed clips and apply vinyl coating to the portions of the lines to be clipped.

5. Install new lines in positions where they are protected against water, dirt, grit, sand, rocks and

other foreign matter that can come from above or below, or can be flung up by the wheels.

Lines

Clip

0.4 in. or more

Vinyl

Clip

Electrical Wiring and Harnessing

To increase the reliability of the wiring, all frame harnesses are covered with corrugated vinyl tubing. The following instructions apply to extending or modifying these harnesses. See the Electrical Section for information on

commonly used circuits in the NPR, NQR, FRR and W-Series. The FSR, FTR and FVR wiring information can

be found in the service manuals.

Wiring

1. Most wiring connections on Isuzu vehicles are made with terminals. We recommend the use of

terminals when splicing cables and wires.

2. When splicing, use new wire of the same gauge, and do not make splices inside the corrugated

tubing.

3. When making connections to the end of the harness, make sure the connections are electrically

perfect. Use insulating tape as needed to prevent the entry of water, which results in short

circuits and/or corrosion.

4. When making new circuits, or modifying circuits already installed, make the cables only just taut

enough to remove any slack. Use clips or grommets where required to protect cables from heat

or sharp edges. When cables must run near the exhaust system, see the instructions in the

“Exhaust System” section.

5. Always use rustproof clips, and apply vinyl coating to that portion of the clips in direct contact

with the harnesses. No scotch clips or connectors.

6. To minimize the vibration of the harness, clipping points should be set up according to the table.

Harness Diameter Clip Distance

less than 0.2 in. less than 11.8 in.

0.2 in. ~ 0.4 in. approx. 15.7 in.

0.4 in. ~ 0.8 in. approx. 19.7 in.

April 2002 11

Page 22

Installation of Body & Special Equipment

7. When changing the length of the battery cable, do not cut or splice the existing cable. Make up a

new cable of the correct length and wire gauge for the load and distance, without splices.

8. When using connectors, use a socket (female) connector on the electrical source side and a

plug (male) connector on the electrical load side to lower the possibility of a short circuit when

disconnected.

9. When connecting cables to moving or vibrating parts such as the engine or transmission, be

sure to maintain sufficient slack in the wiring to absorb the vibration. Follow the example of

existing cables connected by Isuzu. Keep flexible cables clear of other parts.

10. Do not use vinyl tape in the engine compartment. The heat will tend to make it peel off. Use

plated steel clips coated with rubber or vinyl.

Vinyl tube

Clip

Harness

Direct contact*

SATISFACTORY

Rubber grommet

Steel plate

SATISFACTORY

Electric wire

* Cables should not be in contact with sharp edges or pierced holes.

Harness

SATISFACTORY UNSATISFACTORY

UNSATISFACTORY

UNSATISFACTORY

Harness*

The harness receives

the adverse affect of

dirt, grit, or water

* Harnesses should not be installed on inside lower face of the chassis frame.

* Harnesses should not be taped to fuel lines or other lines. A sufficient clearance should be maintained between

harness and pipe lines.

Line

When parallel: 0.4 in. or more

When across: 0.8 in. or more

Harness

12 April 2002

UNSATISFACTORYSATISFACTORY

Taping*

Page 23

Installation of Body & Special Equipment

Wire Color Code

The electrical circuits of the N/W and FRR/WT Series Chassis Cab are connected with low-voltage stranded wire for

automotive applications. The color coding standards are as follows for the N/W and FRR/WT Series Chassis Cab.

Refer to FSR, FTR and FVR service manual for those vehicle wiring color codes.

(1) Black B Starter circuits and grounds

(2) White W Generator (alternator) circuit

(3) Red R Lighting circuit

(4) Green G Signal circuit

(5) Yellow Y Instrument circuit

(6) Brown Br Accessory circuit

(7) Light Green Lg Other circuit

(8) Blue L Windshield wiper motor circuit

Maximum Allowable Current

Harness Design AWG No. of wires/ Cross sectional Maximum allowable

Diameter (mm) equivalent wire diameter (mm) area (mm2) current (Amps)

100 00 217/0.80 109.1 363

85 0 169/0.80 84.96 305

60 1 127/0.80 63.84 248

50 1 108/0.80 54.29 223

40 1 85/0.80 42.73 191

30 2 70/0.80 35.19 171

20 4 41/0.80 20.61 123

15 6 84/0.45 13.36 93

8 8 50/0.45 7.952 68

5 8 65/0.32 5.228 51

3 12 41/0.32 3.297 39

2 14 26/0.32 2.091 29

1.25 16 16/0.32 1.287 21

0.85 18 11/0.32 0.8846 17

0.5 20 7/0.32 0.5629 13

Reference: The values given in the “maximum allowable current” column are based on the ambient temperature

condition of 104o F with temperature increase of 104o F.

Electrical System Modifications

Modifications/add-on wiring must be carefully reviewed to ensure compatibility with the base vehicle wiring by

reviewing system schematics, wire routing paths, harness connections, etc. Due to the wide range of

modifications that may be required for vocational needs, it is not feasible for the O.E.M. to take into account all

potential revisions. For this reason, any person modifying existing vehicle wiring must assume responsibility that

the revisions have not degraded the electrical system performance. Any add-on wiring needs to be properly

fused and routed to prevent cut, pinch, and chafe problems, as well as avoid exposure to excessive heat. Care

must be exercised that existing vehicle interfaces do not have their current load capabilities exceeded, and that

the respective control devices are not overloaded. Added wire size should be at least as large as the wire to

which it is attaching in order for fuse protection to be maintained.

A Packard electric wiring repair kit is available through Kent-Moore (P/N J38125-B) (Phone # 1-800-345-2233)

This kit contains instructions, tools and components for making repairs to wiring harness components. This kit

would also greatly assist in accomplishing necessary add-on wiring such as body marker lamps, so that system

April 2002 13

Page 24

Installation of Body & Special Equipment

reliability/durability is maintained.

Electrical wiring components can be obtained through your authorized Isuzu/GM dealers. Packard Electric

components are also available through Pioneer Standard Company (1-00-PACKARD). Pioneer may also be able

to assist in making necessary wiring additions by providing custom wiring stubs or jumpers to your specifications.

Exhaust System

Modification of the exhaust system should be avoided. If modifications are absolutely necessary, the following points

should be maintained.

1. Maintain the clearance specified in the table on the next page between all parts of the exhaust system and

any fuel lines, brake lines, brake hoses, electrical cables, etc. The exhaust outlet should not point toward

any of these parts.

CLEARANCE

Brake Lines 2.4 in. or more. (If the combined section of a group of parallel brake lines is

more than 7.8 in., a clearance of 7 in. or more should be provided.)

Flexible brake hoses 3.9 in. or more. (The temperature of flexible brake hoses should not exceed

158o F. If the highest temperature is not measurable, a clearance of more

than 15.7 in. should be maintained between the hoses and the exhaust

system.

Wiring harnesses and cables 3.9 in. or more.

Steel fuel lines 3.1 in. or more.

Rubber or vinyl fuel hoses 5.9 in. or more.

2. If a tool box is installed, it should preferably be made from steel. If a wooden tool box is

installed, at least 7.8 inches clearance should maintained between the tool box and any parts of

the exhaust system.

3. If the exhaust system is modified, it is the responsibility of those making the modification to

ensure that the noise level meets appropriate standards.

Fuel System

Relocation of the fuel tank, or installation of additional fuel tanks is not recommended. If modifications to the fuel

system are unavoidable, follow these recommendations:

1. Maintain adequate clearance between the fuel tank and any other device or structure.

2. Do no connect an additional fuel hose.

Rear Lighting

Brackets installed are temporary. Please do not use these brackets for body installation.

Serviceability

No matter what other modifications or changes are made, access to components requiring daily preventive

maintenance or other routine service must not be obstructed. This includes:

1. Inspection, filling and draining of engine oil and cooling water.

2. Inspection, filling and draining of transmission fluid.

14 April 2002

Page 25

Installation of Body & Special Equipment

3. Adjustment, removal and installation of the fan belts.

4. Inspection, filling and removal of the battery and battery cover.

5. Inspection and filling of brake fluid.

6. Inspection and bleeding of the brake system and servo unit.

7. Maintenance of clearance for tightening of check bolt on brake safety cylinder.

8. Operation of the spare tire carrier, including mounting and dismounting of the spare tire.

9. Adjustment, removal and installation of distributor and/or cover.

WHEELBASE ALTERATION

With certain applications, it may become necessary to alter the wheelbase of the chassis. The next two sections

provide the suggested guidelines for accomplishing either shortening or lengthening of the wheelbase.

SHORTENING/LENGTHENING THE WHEELBASE WITHOUT ALTERING THE FRAME

Since the frame is an integral part of the chassis, it is recommended that the frame not be cut if it is possible to avoid

it. When shortening/lengthening the wheelbase on some models, it is possible to do so without cutting the frame. This

is possible on models which have a straight frame rail. If the chassis does not have a straight frame rail, it may still

be necessary to cut the frame. For instructions on shortening/lengthening these chassis, refer to the ALTERING THE

WHEELBASE BY ALTERING THE FRAME section of this book. Otherwise, the wheelbase may be shortened/

lengthened by removing the rear suspension, drilling new suspension mounting holes at the appropriate spot in the

frame, and sliding the rear suspension, suspension liner, and suspension crossmembers forward or aft. The

suspension and suspension crossmembers' rivet holes left in the frame rail flange must be filled with GRADE 8 bolts

and hardened steel washers at both the bolt head and nut, HUC bolts or GRADE 8 flanged bolts and hardened steel

washers at the nut. When shortening/lengthening the wheelbase in this manner, the following guidelines must be

adhered to:

1. All frame drilling must comply with the DRILLING AND WELDING section of this book.

2. All rivet holes left in the frame rail flange from the suspension and suspension crossmembers

must be either filled with GRADE 8 bolts and hardened steel washers at both the bolt head and

nut, HUC bolts or GRADE 8 flanged bolts and hardened steel washers at the nut.

3. The components required to be slid forward or aft are the suspension and suspension hangers,

suspension crossmembers and suspension frame liner.

ALTERING THE WHEELBASE BY ALTERING THE FRAME

Even on a straight frame rail, it may be desirable to cut the frame and lengthen or shorten the wheelbase rather than

simply sliding the rear suspension back or forward. The following section offers some guidelines and suggestions

for cutting and lengthening or shortening the frame.

GLOSSARY OF TERMS-CHASSIS WHEELBASE ALTERATION

CA - Length from back-of-cab to rear axle center line in inches.

AL - Added length (in case of a lengthened wheelbase). Difference between WB (new) and WB (old).

SL - Shortened length (in case of shortened wheelbase). Difference between WB (old) and WB (new).

April 2002 15

Page 26

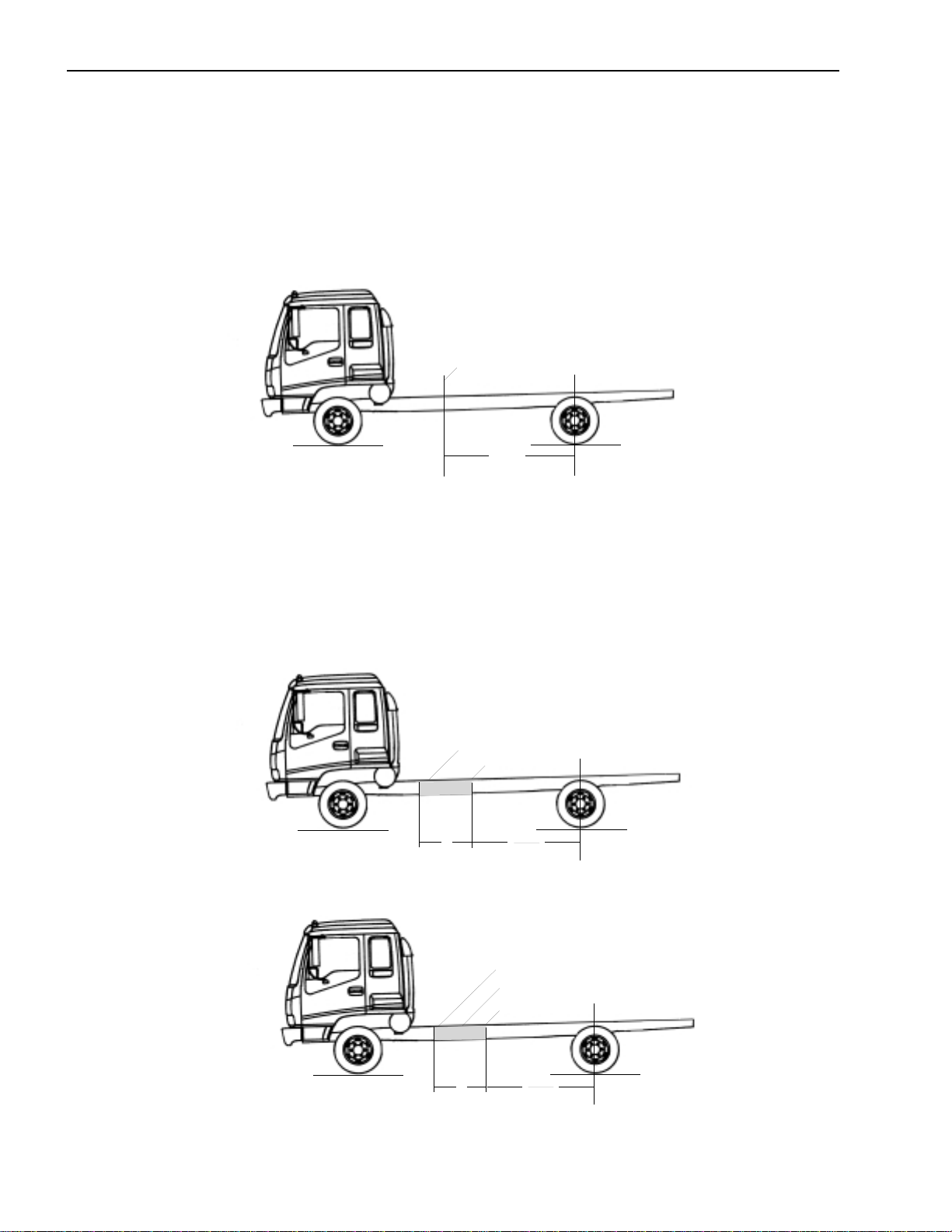

Installation of Body & Special Equipment

1. Determine the added length (AL) or shortened length (SL) required to lengthen or shorten chassis.

(For added wheelbase: New CA = CA + AL; For shortened wheelbase: New CA = CA - SL)

2. Obtain the material to be used as the insert for the lengthened wheelbase in the correct length (AL). The

insert must have the same cross sectional dimensions and yield strength as the original frame rail.

3. Divide the new CA by two (2). Measure (new CA)/2 from the center of the rear axle forward and mark this

point on the chassis frame (see figure below).

Cut Point

1/2 New CA

4. Cut the chassis frame at this point. If the wheelbase is to be lengthened, addition of the previously

obtained insert (of length AL determined in step 1) will be made at this time. If the wheelbase is to be

shortened, measure the distance (SL) forward of this cut and remove a length (SL) section from the

chassis frame (see figure below). Insure that an adequate area on the frame remains for the required

addition of the necessary reinforcements. These are the only suggested places for cutting the frame and

reinforcements but may be changed upon the advice of General Motors Isuzu Commercial Truck, LLC

(GMICT) and American Isuzu Motors Inc. Application Engineering.

Section to be Added

Cut Point

AL

Lengthening the Wheelbase

New CA

2

Second Cut Point

Section to be Removed

First Cut Point

SL

New CA

2

Shortening the Wheelbase

16 April 2002

Page 27

Installation of Body & Special Equipment

5. When welding the insert (length AL for wheelbase lengthening) to the original frame rail, a continuous butt weld

must be used at the splices. When shortening the wheelbase, weld the ends of the chassis frame together with

a continuous butt weld over the junction of the frame ends. Weld both the inside and outside of the frame rails

using welding techniques prescribed by established welding standards (ref. SAE J1147) and in accordance with

this guide. An example of this weld is shown below.

BUTT WELD 100 % - Weld can be inside or outside

of member or, as shown, a combination of both

1.0 in. or more

1.0 in. or more

6. Determine the appropriate additional internal reinforcements which are required using this equation:

Reinforcement Length = AL + 6 x (original frame rail web depth).

The figure below shows how this reinforcement is to be placed over the extended or shortened section of the

frame rail.

D

AL3 x D 3 x D

6 x D + AL

Lengthened Wheelbase

3 x D

Shortened Wheelbase

3 x D

6 x D

D = Original frame rail web depth

The suggested cross section of this reinforcement is a snug fit inner channel. If the new wheelbase exceeds

the upper limit of the optional wheelbases of this model, i.e.; a “long bridge”, it may be necessary to use an “inverted

L” reinforcement in addition to the snug fit channel reinforcement (see figures below). Application Engineering should

be consulted for approval of such cases. It should be noted that these methods of reinforcements, and any other

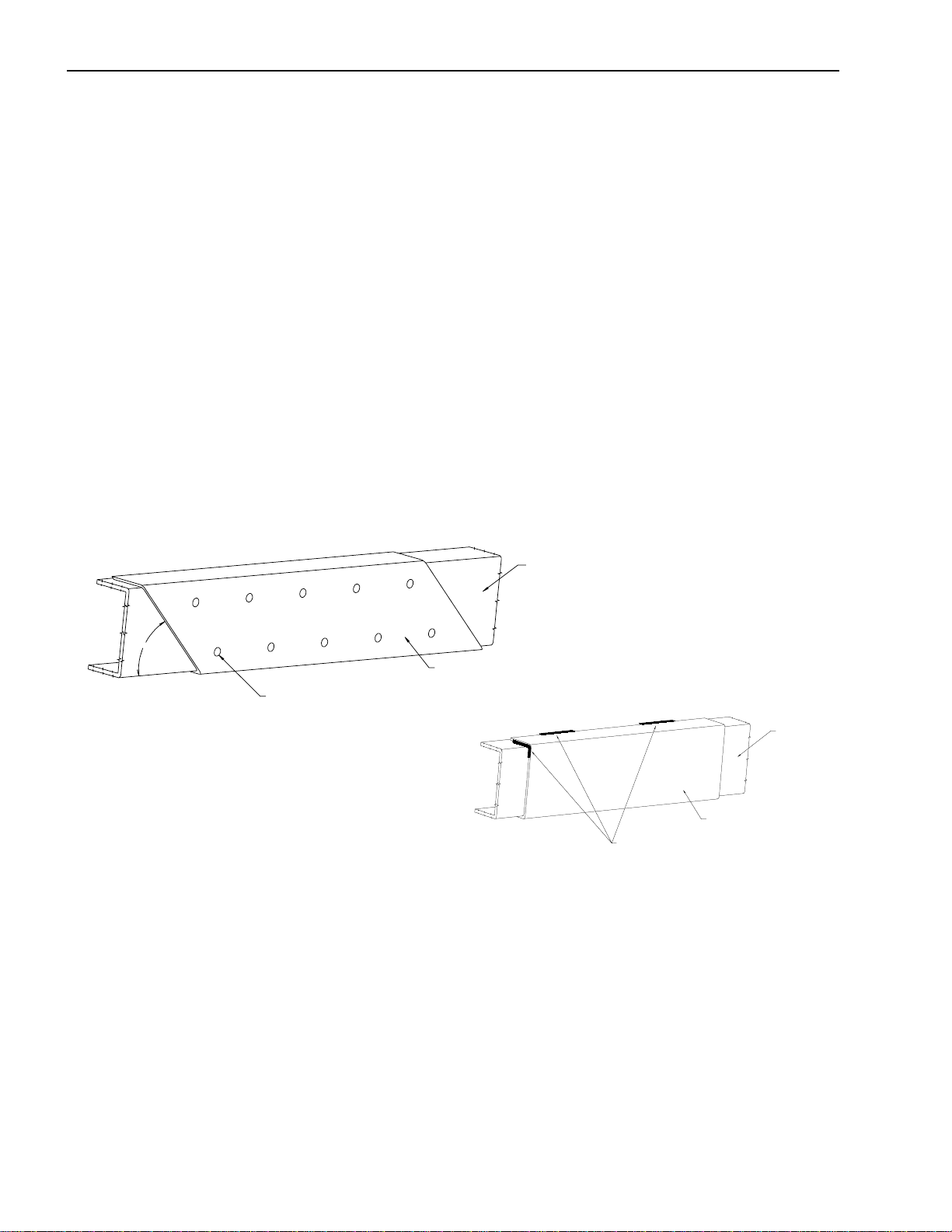

methods which may be used, require a 45 degree angled cut at both ends to avoid stress concentrations in the frame

(note the figures under item 7).

OR

Snug fit inner channel with "Inverted L" for "Long Bridge" wheelbasesSnug fit inner channel

April 2002 17

Page 28

Installation of Body & Special Equipment

7. The reinforcements must be fastened securely to only the web of the original chassis frame rail. The

reinforcement must be held rigidly in place using either HUC bolts, GRADE 8 bolts and hardened steel washers

at both the bolt head and nut, or GRADE 8 flanged bolts and hardened steel washers at the nut. Below are some

suggested bolt patterns. It should be noted that these bolt patterns must not align the bolts vertically, i.e.: the bolt

pattern must be staggered.

8. Lengthening the frame will also require extending the brake lines, basic chassis electrical harnesses, excluding

ABS wiring harness. It is recommended that the original brake lines be removed and replaced with brake lines

of the same diameter as the original lines and of the appropriate length. The electrical harness must be extended

in accordance with the ELECTRICAL WIRING AND HARNESSING section of this book.

9. The propeller shafts’ overall length will also need to be lengthened or shortened. If the extension is within the limits

of the optional wheelbases of the respective model, the exact propeller shaft lengths and angles are given on or

about Page 12 of the respective sections of this book. If the modified wheelbase exceeds the optional wheelbases

of the respective model, the following guidelines must be adhered to:

A. Propeller Shaft Length

The maximum propeller shaft lengths (pin to pin) for the respective models are shown in the table below.

NPR NPR GAS NQR FRR

Propeller

Shaft 3.25 3.0 3.0 4.0

Diameter (in)

Maximum

Propeller Shaft 50.8 50.8 50.8 62.0

Length (in)

18 April 2002

Page 29

Installation of Body & Special Equipment

B. Propeller Shaft Angles

The maximum propeller shaft angles, with respect to the previous shaft, are shown in the table below.

NPR/W NPR/W GAS NQR/W FRR/WT

Maximum Propeller

Shaft Angle 5.7

o

5.1

o

5.7

o

5.5

o

C. The propeller shaft angles must be designed such that the angles will cancel to avoid propeller shaft whip.

D. The propeller shaft yokes must be assembled such that the propeller shaft yokes are “in phase.” “In

phase” means that the yokes at either end of a given propeller shaft assembly are in the same plane.

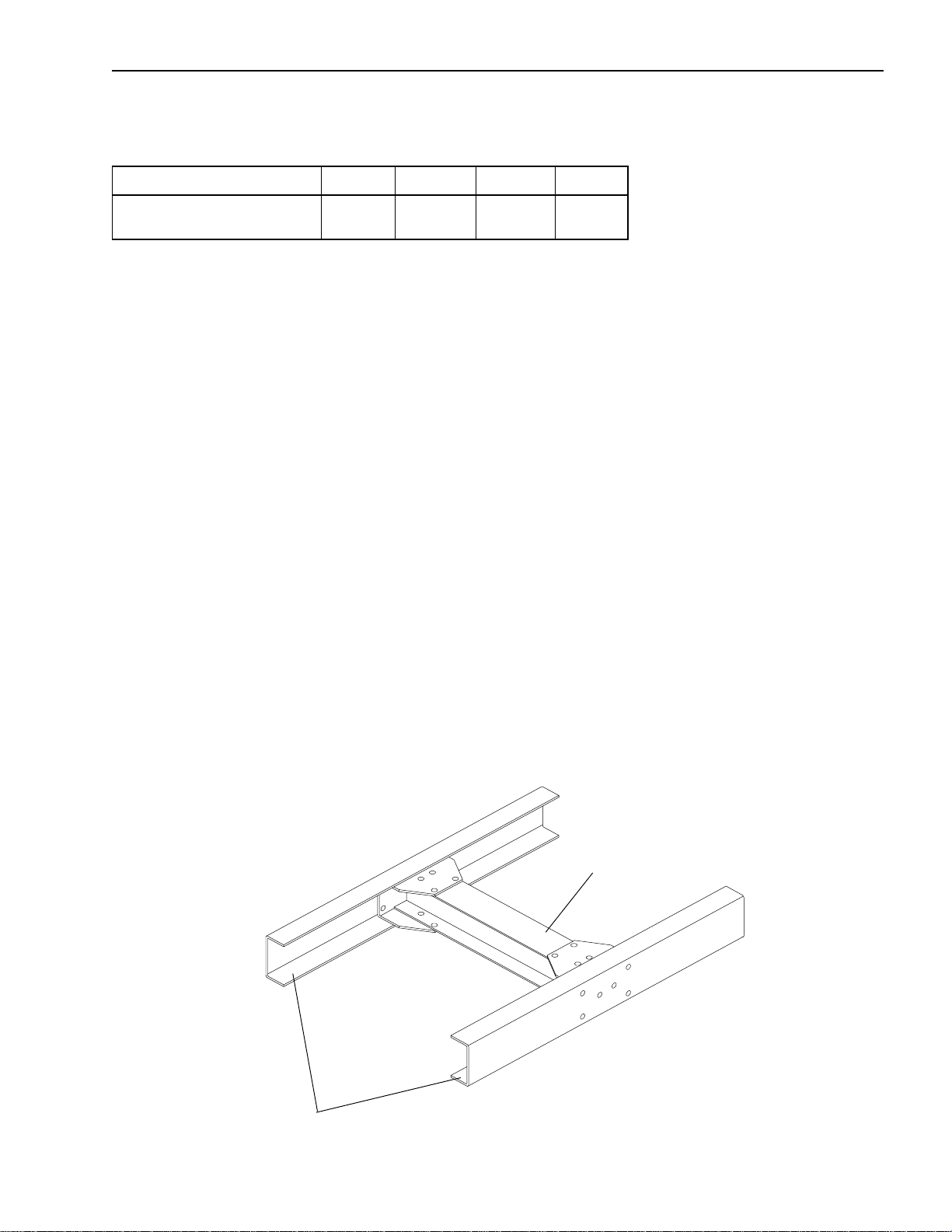

10. Extending the frame will also require relocation and/or addition of crossmembers. If the extension is within the

limits of the optional wheelbases of the respective model, the exact cross member locations and dimensions

are given in the respective model sections of this book. If the modified wheelbase exceeds the optional

wheelbases of the respective model, the following guidelines must be adhered to:

A. The cross member location will largely be determined by the propeller shaft lengths and where the center

carrier bearing locations are for the propeller shaft assembly.

B. A cross member must be located at the front and rear spring hangers of the rear suspension (refer to the

appropriate section of this book to see where these suspension cross members are to be located).

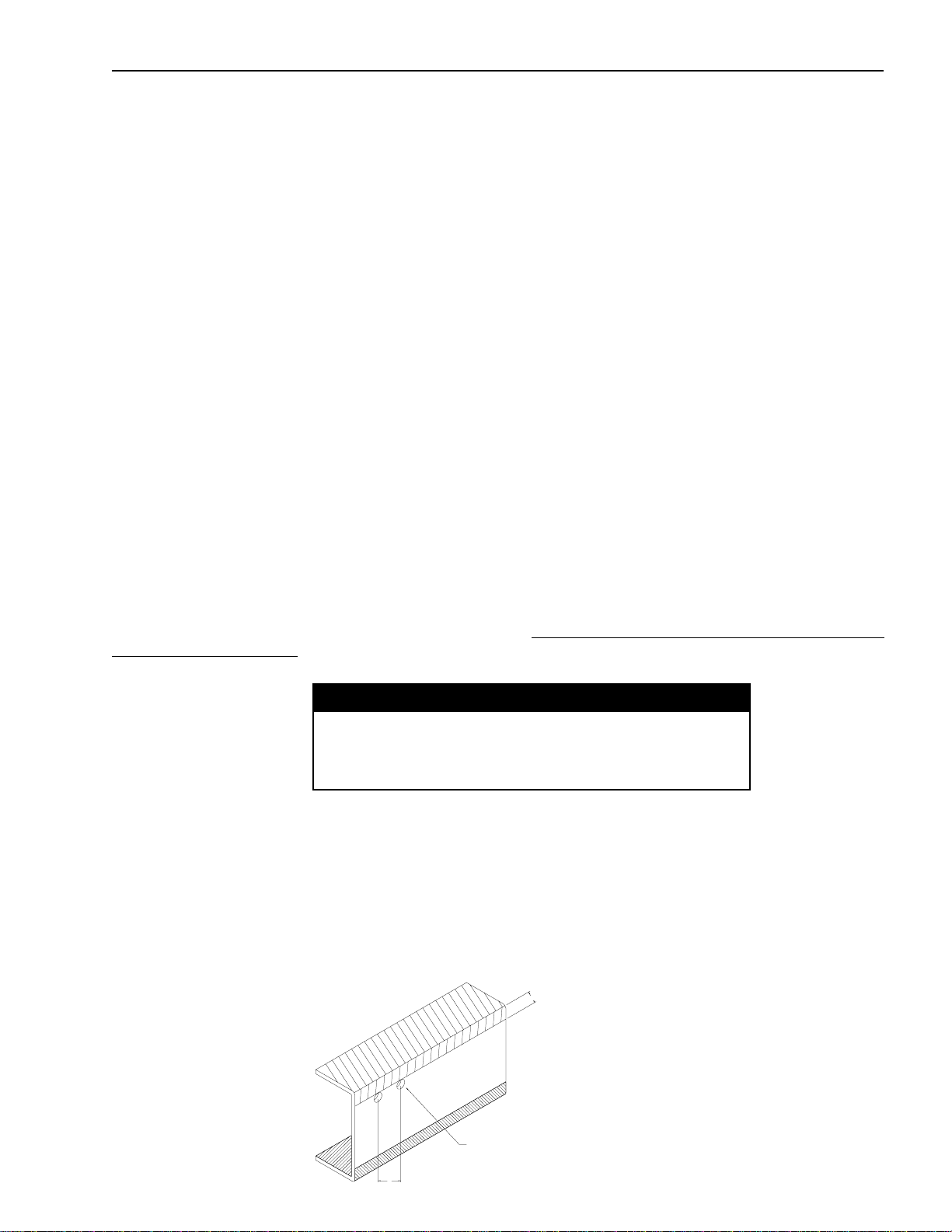

C. The cross member must be constructed such that it supports both the upper and lower flange on each

frame rail (see drawing below). A cross member such as the one below may be constructed, or Isuzu

cross members may be obtained from your Isuzu parts dealer.

Additional crossmember

Frame rails

April 2002 19

Page 30

Installation of Body & Special Equipment

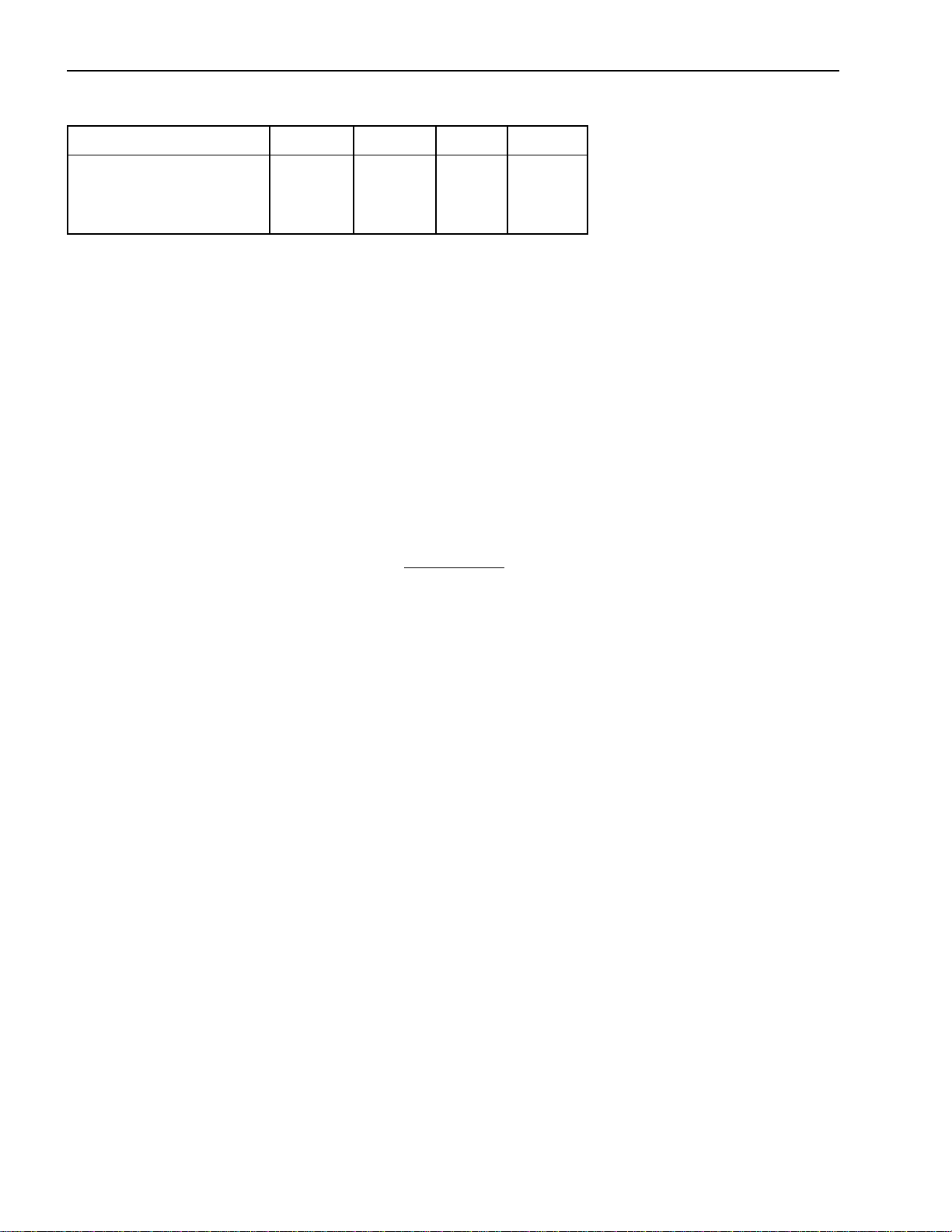

D. The maximum distance between crossmembers for the respective models is given in the table below.

NPR/W NPR/W GAS NQR/W FRR/WT

Maximum Distance 35.7 35.7 35.7 49.8

Between Cross

Members (in)

E. The drilling for any additional holes in the frame rails must comply to the DRILLING AND WELDING

section of this book.

11. All other aspects of lengthening or shortening the wheelbase must comply with the applicable section of

this Body Builder's Guide. For special applications and longer than recommended body lengths, GMICT

Application Engineering must be consulted for approval. In the West Coast call 1-562-229-5314 and in

the East Coast call 1-404-257-3013

12. Please contact applications engineering for guidelines on N/W SERIES CHASSIS frame modifications when

the vehicle is equipped with an Antilock Brake System.

FRR SERIES CHASSIS

Please contact applications engineering for guidelines on FRR SERIES CHASSIS frame modifications when the

vehicle is equipped with an Antilock Brake System

FSR FTR FVR

WHEN MAKING WHEELBASE MODIFICATIONS TO THE 1997, MODEL YEAR AND ABOVE FSR, FTR, AND

FVR HYDRAULIC BRAKE CHASSIS AND AIR BRAKE CHASSIS THE FOLLOWING SHOULD BE STRICTLY

OBSERVED.

13. The Crew Cab NPR HD/W4500 and NQR/W5500 will be available in two wheelbases, 150 and 176 inches.

Effective CA will be 84.7 and 110.7 inches. On this model chassis General Motors Isuzu Commercial Trucks

will require that the body installed on the chassis have an understructure manufactured with any of the following

structural steel "C" channels:

4"x1-5/8", 7.25 lbs/ft = ok

5"x1-3/4", 6.7 or 9.0 lbs/ft = ok

6"x2", 8.2, 10.5 or 13.0 lbs/ft = ok

HYDRAULIC BRAKE SYSTEM

1. BEFORE WORK BEGINS

As with any electrical work on the chassis the battery should be disconnected before electrical work is started.

2. ABS PROGRAM

The antilock brake system (ABS) computer will hold its codes when disconnected and reprogramming as a result

of battery disconnection will not be necessary. If the wheelbase is changed the trim level of the ABS system

must be readjusted per the instructions in the service manual. An Authorized Isuzu dealer should do this

reprogramming using appropriate tools.

For your reference and to help you determine if the system needs to be reprogrammed the following provisions

apply to all ABS systems with hydraulic brakes. The ABS module has four (4) programs: A, B, C, and D. These

programs are tied to the wheelbase and axle combination of the chassis. (The axle and wheel base codes can be

found on the passenger’s visor.)

A is for the FL1 axle and covers wheelbase from 140 (FQT), 158 (EG5), 170 (EH8) inches.

B is for the FL2 axle and covers wheelbase from 140 (FQT), 158 (EG5), 170 (EH8), 188 (EK8), 200 (EM2)

inches.

20 April 2002

Page 31

Installation of Body & Special Equipment

C is for the FL1 axle and covers wheelbase from 188 (EK8), 200 (EM2), 218 (FPL), 233 (EQ8), 248 (ES5)

inches.

D is for the FL2 axle and covers wheelbase from 218 (FPL), 233 (EQ8), 248 (ES5) inches.

Moving between program/ wheelbase groups A, B, C or D will require that the system be reprogrammed

Moving wheelbase within a program group will not require reprogramming.

3. ABS COMPUTER LOCATION

a. The ABS computer is located under the cab on the front crossmember and is an integral part of the brake

fluid modulation system. These components can not be relocated.

4. ABS ELECTRICAL HARNESSES

a. The harness can not be cut and spliced

b. The only approved way to make the harness longer is to purchase the appropriate wheelbase harness

from the Isuzu parts department

c. Extra wire resulting from a frame shortening can be coiled and secured to the frame.

5. HYDRAULIC BRAKE LINES

a. Hydraulic brake lines should be shortened or lengthened using appropriate fittings and steel lines.

AIR BRAKE SYSTEM

1. BEFORE WORK BEGINS

a. As with any electrical work on the chassis the battery should be disconnected before electrical work is

started.

2. ABS PROGRAM

The antilock brake system (ABS) computer will hold its codes when disconnected and reprogramming as a result

of battery disconnection will not be necessary. If the front axle is changed the trim level of the ABS system must

be readjusted per the instructions in the service manual. An Authorized Isuzu dealer using the appropriate tools

should do this reprogramming.

3. ABS COMPUTER LOCATION

a. The ABS computer is located back of cab on the power steering bracket. This component can not be

relocated.

15. ABS ELECTRICAL HARNESSES

a. The harness can not be cut and spliced

b. The only approved way to make the harness longer is to purchase the appropriate wheelbase harness

from the Isuzu parts department.

c. Extra wire resulting from a frame shortening can be coiled and secured to the frame.

8 AIR BRAKE LINES

a. Air brake lines should be shortened or lengthened using appropriate fittings and hose material.

April 2002 21

Page 32

Installation of Body & Special Equipment

22 April 2002

Page 33

Body Applicaton Summary Chart

Body Application

Summary Chart

April 2002 23

Page 34

Body Application Summary Chart

2002 GAS & 2003 DIESEL MODEL YEAR BODY APPLICA TION SUMMARY CHART

MODEL/GVWR WB BOC 10 ft. 12 ft. 14 ft. 16 ft. 18 ft. 20 ft. 22 ft. 24 ft.

NPR/W3500 GAS 109 9.25 X X

12,000 lbs 132.5 9.25 X

150 9.25 X X

176 9.25 X

NPR HD/W4500 GAS 109 9.25 X X

14,050 lbs 132.5 9.25 X

150 9.25 X X

176 9.25 X

NPR/W3500 DSL 109 9.25 X

12,000 lbs 132.5 9.25 X

150 9.25 X X

176 9.25 X

NPR HD/W4500 DSL 109 9.25 X

14,500 lbs 132.5 9.25 X

150 9.25 X X

176 9.25 X

(1)

(1)

(1)

(1)

NPR HD/W4500 CREW

CAB DSL 150 4.2 X

14,500 lbs 176 4.2 X

(3)

(4)

NQR/W5500 DSL 109 9.25 X

17,950 lbs 132.5 9.25 X

150 9.25 X X

176 9.25 X

NQR/W5500 CREW

CAB DSL 150 4.2 X

17,950 lbs 176 4.2 X

(3)

(4)

MT/AT

FRR/WT5500 DSL 14 8 7.5/10 X

(2)

X

18000/19,500 167 7.5/10 X

179 7.5/10 X

191 7.5/10 X

218

10.0/10

Notes:

1. NPR, NPR HD/W3500 W4500 Diesel 20’ ft. body requires Isuzu/GM Application Engineering Department approval.

2. BOC 10.0 inches. For MT

X

UNIT: INCH

3. 16’ Dovetail landscape (12’ deck plus 4’ dovetail).

4. 18’ Dovetail landscape (14’ deck plus 4’ dovetail).

Important

Body selection recommendations are based on water level weight distribution and no accessories, liftgate or refrigeration units. This

table is intended for reference and does not preclude the necessity for an accurate weight distribution calculation.

24 April 2002

Page 35

Body Applicaton Summary Chart

2002 GAS & 2003 DIESEL MODEL YEAR*

BODY & PAYLOAD WEIGHT DISTRIBUTION

(% FRONT/% REAR)

MODEL GVWR WB CA CE OAL BOC 10 12 14 16 18 20

AUTOMATIC TRANSMISSION

NPR/W3500 GAS 12,000 109 88.4 131.5 199.5 9.25 18/82 7/93

NPR HD/W4500 GAS 14,050 109 88.4 131.5 199.5 9.25 18/82 7/93

NPR/W3500 GAS 12,000 132.5 111.9 155 223 9.25 14/86

NPR HD/W4500 GAS 14,050 132.5 111.9 155 223 9.25 14/86

NPR/W3500 GAS 12,000 150 129.4 172.5 240.5 9.25 16/84 8/92

NPR HD/W4500 GAS 14,050 150 129.4 172.5 240.5 9.25 16/84 8/92

NPR/W3500 GAS 12,000 176 155.4 198.5 266.3 9.25 15/85

NPR HD/W4500 GAS 14,050 176 155.4 198.5 266.3 9.25 15/85

MODEL GVWR WB CA CE OAL BOC 10 12 14 16 18 20

MANUAL/AUTOMATIC TRANSMISSION

NPR/W3500 DSL 12,000 109 88.4 131.5 199.5 9.25 7/93

NPR HD/W4500 DSL 14,500 109 88.4 131.5 199.5 9.25 7/93

NPR/W3500 DSL 12,000 132.5 111.9 155 223 9.25 14/86

NPR HD/W4500 DSL 14,500 132.5 111.9 155 223 9.25 14/86

NPR/W3500 DSL 12,000 150 129.4 172.5 240.5 9.25 16/84 8/92

NPR HD/W4500 DSL 14,500 150 129.4 172.5 240.5 9.25 16/84 8/92

NPR/W3500 DSL 12,000 176 155.4 198.5 266.3 9.25 15/85

NPR HD/W4500 DSL 14,500 176 155.4 198.5 266.3 9.25 15/85

MODEL GVWR WB CA CE OAL BOC 10 12 14 16 18 20

MANUAL/AUTOMATIC TRANSMISSION

NQR/W5500 DSL 17,950 109 88.4 131.5 199.5 9.25 7/93

NQR/W5500 DSL 17,950 132.5 111.9 155 223 9.25 14/86

NQR/W5500 DSL 17,950 150 129.4 172.5 240.5 9.25 16.84 8/92

NQR/W5500 DSL 17,950 176 155.4 198.5 266.3 9.25 15/85 8/92

*NPR, NPR HD/W3500, W4500 GAS and DIESEL 20 foot body requires Isuzu/GM Application Engineeering Department approval.

IMPORTANT:

Weight distribution percentages listed do not include added accessories, liftgate or refrigeration units.

Percentages based on water-level distribution of body and payload weight which is determined by subtracting

chassis wet weight (including 200 lb. driver) from GVWR. These tables are intended for reference and do not

preclude the necessity for an accurate weight distribution calculation.

April 2002 25

Page 36

Body Application Summary Chart

2003 MODEL YEAR DIESEL CREW CAB BODY & PAYLOAD WEIGHT DISTRIBUTION

(% FRONT/% REAR)

MODEL GVWR WB CA CE OAL BOC 10 12 14 16

NPR HD/W4500 CREW CAB DSL 14,500 150 88.9 132 240.5 4.2 8/92

NPR HD/W4500 CREW CAB DSL 14,500 176 114.9 158 266.5 4.2 15/85

MODEL GVWR WB CA CE OAL BOC 10 12 14 16

NQR HD/W5500 CREW CAB DSL 17,850 150 88.9 132 240.5 4.2 16/84 8/92

NQR HD/W5500 CREW CAB DSL 17,850 176 114.9 158 266.5 4.2 15/85 8/92

IMPORTANT:

Weight distribution percentages listed do not include added accessories, liftgate or refrigeration units.

Percentages based on water-level distribution of body and payload weight which is determined by subtracting

chassis wet weight (including 200 lb. driver and a crew of 6 @200 lbs each) from GVWR. These tables are

intended for reference and do not preclude the necessity for an accurate weight distribution calculation.

26 April 2002

Page 37

Manual Transmission

Body Applicaton Summary Chart

2003 MODEL YEAR

BODY & PAYLOAD WEIGHT DISTRIBUTION

(% FRONT/% REAR)

MODEL GVWR WB CA CE OAL BOC 14 16 18 20 22 24

FRR/WT5500 18000/19500 148 117.1 180.6 259.3 7.5 16/841 10/90

FRR/WT5500 18000/19500 167 136.2 206.5 285.2 7.5 12/88

FRR/WT5500 18000/19500 179 148.0 226.2 304.9 7.5 11/89

FRR/WT5500 18000/19500 191 159.8 243.9 322.2 7.5 11/89

FRR/WT5500 18000/19500 218 187.4 283.3 362.0 10.0 15/85

Automatic Transmission

MODEL GVWR WB CA CE OAL BOC 14 16 18 20 22 24

FRR/WT5500 18000/19500 148 117.1 180.6 259.3 10 15/85 7/93

FRR/WT5500 18000/19500 167 136.2 206.5 285.2 10 10/90

FRR/WT5500 18000/19500 179 148.0 226.2 304.9 10 9/91

FRR/WT5500 18000/19500 191 159.8 243.9 322.2 10 9/91

FRR/WT5500 18000/19500 218 187.4 283.3 362.0 10 15/85

NOTES:

1. BOC 10.0 Inches. For MT

IMPORTANT:

Weight distribution percentages listed do not include added accessories, liftgate or refrigeration units.

Percentages based on water-level distribution of body and payload weight which is determined by subtracting

chassis wet weight (including 200 lb. driver) from GVWR. These tables are intended for reference and do not

preclude the necessity for an accurate weight distribution calculation.

April 2002 27

Page 38

Mechanical & Cab Specifications

Mechanical

Cab Specifications

&

26 April 2002

Page 39

Mechanical & Cab Specifications

The following table presents Net versus Gross Horsepower and Torque ratings for 2003 Isuzu/W-Series Truck

Product Engines:

ENGINE NET HP

1

NET TORQUE

MODEL APPLICATION HP/RPM LBS-FT/RPM HP/RPM LBS-FT/RPM

GMPT- NPR/W3500,

5.7L-V8 NPR HD/W4500

N/A N /A 250/4400 330/2800

GAS

ISUZU NPR/W3500,

4HE1-TC NPR HD/W4500 137/2800 268/1300 142/2800 275/1300

M/T DIESEL

ISUZU NPR/W3500,

4HE1-TC NPR HD/W4500, 169/2700 339/2000 175/2700 347/2000

A/T NQR/W5500

DIESEL

ISUZU NQR/

4HE1-TC W5500 169/2700 339/2000 175/2700 347/2000

M/T DIESEL

1

GROSS HP

1

GROSS TORQUE

1

ISUZU FRR/

6HK1-TC WT5500 193/2400 426/1500 200/2400 441/1500

M/T DIESEL

ISUZU FRR/

6HK1-TC WT5500 193/2400 426/1500 200/2400 441/1500

A/T DIESEL

NOTE: 1. Horsepower and Torque Ratings measured under SAE J1349 standards.

GVW/GCW Ratings

The following table presents GVW ratings and corresponding GCW ratings for each model truck:

TRUCK MODEL TRANSMISSION GVWR (lbs) GCWR (lbs)

NPR/W3500 GAS AUTOMATIC 12,000 15,000

NPR HD/W4500 GAS AUTOMATIC 14,050 17,050

NPR/W3500 DIESEL AUTOMATIC 12,000 18,00 0

NPR/W3500 DIESEL MANUAL 12,000 18,000

NPR HD/W4500 DIESEL AUTOMATIC 14,500 19,500

NPR HD/W4500 DIESEL MANUAL 14,500 20,500

NQR/W5500 DIESEL AUTOMATIC 17,950 19,500

NQR/W5500 DIESEL MANUAL 17,950 22,500

FRR/WT5500 DIESEL AUTOMATIC 18,000/19,500 26,000

FRR/WT5500 DIESEL MANUAL 18,000/19,500 30,000

1

2

1 The NPR/W3500, NPR HD/W4500 and NQR/W500 are note approved for Hot Shot applications.

2 GCWR 20,950 with addition of optional Isuzu Transmission Oil Cooler.

April 2002 27

Page 40

Mechanical & Cab Specifications

The following chart provides the rear frame height for each model/GVWR with standard tires:

GVWR STANDARD FRAME HT (in)

MODEL (lbs) TIRE FH STD. TIRES

NPR/W3500 GAS

NPR HD/W4500 GAS

NPR/W3500 DIESEL

NPR HD/W4500 DIESEL

NQR/W5500 DIESEL 17,950

FRR/WT5500 DIESEL 18,000/19,500

FSR/FTR/FVR (2) (2) (2)

(1) 191 and 218 WB have frame height of 37.3 inches

(2) Refer to FSR, FTR, and FVR section

11,050 215/85R-16E 32

14,050 225/70R-19.5F 32.75

12,000 215/85R-16E 32

14,050 215/85R-16E 32

225/70R-19.5F 32.8

225/70R-19.5F 35.3 (1)

CLUTCH ENGAGEMENT TORQUE CHART

The following table provides the engagement torque of the engines currently in use in Isuzu medium duty trucks:

Torque at

Engine (lbs-ft) (RPM)

ISUZU 4HE1-TC (142 HP) 260 1,000

ISUZU 4HE1-TC (175 HP) 265 1,000

ISUZU 6HK1-TC (200 HP) 331 1,000

ISUZU 6HK1-TC (230 HP) 368 1,000

28 April 2002

Page 41

Mechanical & Cab Specifications

April 2002 29

Page 42

30 April 2002

CV CHART 2

ISUZU

PAINT

CODE

301-W-30102 N/A Accuride White

B302-P801-0 730 Adriatic B lue ( Soli d)

W301-P801-0 729 Arc White

WE8774 N/A *Bright Red

0133-P1 N/A Calm White

WE5398 N/A *Dark Green Gray

U715-P801-0 809 Doeskin Tan

0172-P1 844 Glacier White

WE9907 N/A *Medium Adriatic Blue

B721-P801-0 801 Medium Blue

N507-P901-0 845 Polar Silver

R725-P801-0 810 Red Orange

WE9885 N/A *Rose Black

G021-P801-0 989 Sunbelt Green

U716-P801-0 815 Tangier Orange

Y719-P801-0 812 Wheatland Yellow

G705-P801-0 807 Woodland Green

ISUZU

OPTION

CODE

ISUZU

COLOR

NAME

AKZO

NOBEL

CODE

FLNA40154

FLNA50274

FLNA40156

FLNA30252

FLNA40252

FLNA90856

FLNA80050

FLNA40155

FLNA90857

FLNA50172

FLNA91205

FLNA20079

FLNA90858

FLNA60290

FLNA20080

FLNA10182

FLNA60181

BASF

R-M

CODE

RM25319 IS-25319

730 730

RM25318 IS-25318

27427 IS-27427

HS14391 IS-820

27425 IS-27425

27406 IS-U715

RM15602 IS-844

27426 IS-27426

27403 IS-B721

23664 845

27407 IS-R725

27428 IS-27428

605301 989

27409 IS-U716

27408 IS-Y719

27404 IS-G705

BASF

GLAS

CODE

DUPONT

CODE

F2499 8AR8 91513

W9775 2NV9B 19320

W9774 2NV8 91512

C8508 TC78B 75057

G8477 KK27 91522

B9329 2NP9B 36575

B8462 KPL5B 28613

H8620 ND92 90330

B9321 2NY4B 190401

B8041 KPL2B 190217

F2193 EPW3B 36658

B8250 KPL4B 61784

B9218 1AB2B 95057

M6682 WMK4 401420

B9043 KPL6B 61785

B9042 KPL7B 83931

B8046 KPL3B 48339

ICI

AUTO

COLOR

PPG

CODE

SHERWIN

WILLIAMS/

MARTIN

SENOUR

51548 15593

57541 50287

51400 10280

34983 34169

34657 16222

47155 65071

56203 21882

35478 10281

46829 56120

56143 55934

56991 73192

56202 21881

45738 74223

61559 67847

56204 21883

56144 21884

56201 64962

SPIES

HECKER

CODE

STANDOX

301-W-30102

730

729

N/A

0133-P1

N/A

809

844

N/A

801

845

810

N/A

989

815

812

807

Mechanical & Cab Specifications

NOTES:

1. ST ANDBOX uses paint code found in vehicle for paint identification.

2. GM-Based colors. No Isuzu Option Code.

Page 43

Mechanical & Cab Specifications

N/W Series Towing Procedures

NOTE: When towing, disconnect the propeller shaft at the rear

axle to ensure the automatic transmission is not damaged.

Proper equipment must be used to prevent damage to vehicles during any towing. State and local laws which apply to

vehicles in tow must be followed. Vehicles should not be towed at speeds in excess of 55 mph (90 km/h). Connect to the

main structural parts of the vehicle. DO NOT attach to bumpers, tow hooks or brackets. Use only equipment designed for

this purpose. Follow the instructions of the wrecker manufacturer. A safety chain system must be used. The procedures

below must be followed when towing to prevent possible damage.

FRONT END TOWING (FRONT WHEELS OFF GROUND)

To prepare a disabled vehicle for front end towing with front wheels

raised off the ground, the following steps are necessary:

• Block the rear wheels of the disabled vehicle.

• Disconnect the propeller shafts at the rear axle. Secure the propeller shafts to the frame or crossmember.

• If there is damage or suspected damage to the rear axle, remove the axle shafts.

• Cover the hub openings to prevent the loss of lubricant or entry of dirt or foreign objects.

• Place 4” x 4” wood beam against the towing guide behind the bumper. (If no 4” x 4” is available, then remove the bumper.)

Ensure towing chains do not contact the horns or the bumper.

1. Horns

2. Bumper (removed for towing)

3. Filler

AFTER TOWING

After towing the vehicle, block the rear wheels and install axle shafts or propeller shaft. Apply the parking brake before

disconnecting from the towing vehicle.

FRONT END TOWING (ALL WHEELS ON THE GROUND)

Your vehicle may be towed on all wheels provided the steering is operable. Remember that power steering and brakes will

not have power assist. There must be a tow bar installed between the towing vehicle and the disabled vehicle.

1. Bumper

2. Towing Chain

3. Towing GUide

4. Front Axle

5. Tow Hook

To prepare a disabled vehicle for front end towing with all wheels on the ground, the following steps are necessary:

• Block the wheels of the disabled vehicle.

• Disconnect the propeller shafts at the rear axle. Secure the propeller shafts to the frame or crossmember.

• Provide wood blocking to prevent towing chains and bar from contacting the bumper.

• If there is damage or suspected damage to the rear axle, remove the axle shafts.

• Cover the hub openings to prevent the loss of lubricant or entry of dirt or foreign objects.

April 2002 31

Page 44

Mechanical & Cab Specifications

After Towing

After towing the vehicle, block the rear wheels and install axle shafts or propeller shaft. Apply the parking brake before

disconnecting from the towing vehicle. Check and fill rear axle with oil if required.

REAR END TOWING

When towing a vehicle with rear wheels raised, secure the steering wheel to maintain straight-ahead position. Make certain

that the front axle is not loaded above the front axle Gross Axle Weight Rating (GAWR) as indicated on the vehicle’s VIN

and Weight Rating plate.

SPECIAL TOWING INSTRUCTIONS

1. All state and local laws regarding such items as warning signals, night illumination, speed, etc., must be followed.

2. Safety chains must be used.

3. No vehicle should ever be towed over 55 mph (90 km/h).

4. Loose or protruding parts of damaged vehicles should be secured prior to moving.

5. A safety chain system completely independent of the primary lifting and towing attacment must be used.

6. Operators should refrain from going under a vehicle which is being lifted by the towing equipment unless the vehicle is

adequately supported by safety stands.

7. No towing operation which for any reason jeopardizes the safety of the wrecker operator or any bystanders or other

motorists should be attempted.

FRR/WT TOWING PROCEDURE

Y our vehicle should be towed by an authorized dealership or professional towing service to prevent damage.

Proper equipment must be used and state (Provincial in Canada) and local laws, which apply to vehicles in tow,

must be followed. Vehicles should not be towed in excess of 55 mph (90 km/h).

Connect to the main structural parts of the vehicle. Do not attach to bumpers, tow hooks or brackets. Use only

equipment designed for this purpose. Follow the instructions of the wrecker manufacturer.

A safety chain system must be used.

FRONT END TOWING (FRONT WHEELS OFF THE GROUND)

BEFORE TOWING

Block the rear wheels of the disabled vehicle.

Release the parking brake as described under “Air Operated Parking Brake” in this section.

Drain rear axle oil and remove the axle shafts. Cover the hub openings to prevent the loss of lubricant or entry of

dirt or foreign objects.

AFTER TOWING

After towing the vehicle, block the rear wheels, remove the covers from the hub openings and install the axle

shafts. Apply the parking brake before disconnecting from the towing vehicle. Check and fill rear axle with oil if

required.

FRONT END TOWING (ALL WHEELS ON THE GROUND)

Y our vehicle may be towed on all wheels provided the steering is operable. Remember that power steering will

not have power assist. If air pressure is exhausted, the vehicle will not have brakes. There must be a tow bar

installed between the towing and the disabled vehicle.

BEFORE TOWING

Block the wheels of the disabled vehicle.

Disconnect the propshaft at the rear axle. Secure the propshaft to the frame or crossmember.

If there is, damage or suspected damage to the rear axle, drain oil and remove the axle shafts. Cover the hub

openings to prevent the loss of lubricant or entry of dirt or foreign objects.

AFTER TOWING

After towing the vehicle, block the rear wheels and install axle and propeller shafts. Check for proper phasing of

universal joints. Apply the parking brake before disconnecting from the towing vehicle. Check and fill rear axle

with oil if required.

32 April 2002

Page 45

Mechanical & Cab Specifications

REAR END TOWING (REAR WHEELS OFF THE GROUND)

BEFORE TOWING

Secure the steering wheel to maintain straight-ahead position. Make certain that the front axle is not loaded

above the front axle Gross Axle Weight Rating (GAWR) as indicated on the vehicle’s VIN and Weight Rating

plate.

AFTER TOWING

Block the rear wheels and release the steering. Apply the parking brake before disconnecting from the towing

vehicle. Check and fill the rear axle with oil as required.

SPECIAL TOWING INSTRUCTIONS

1 . Call your local authorized dealership or professional towing service.

2. All state and local laws regarding such items as warning signals, night illumination, speed, etc. must be

followed.

3. Safety chains must be used.

4. No vehicle should ever be towed over 55 mph (90 km/h).

5. Loose or protruding parts of damaged vehicles should be secured before moving.

6. A safety chain system completely independent of the primary lifting and towing attachment must be used.

7. Operators should refrain from going under a vehicle, which is being lifted by the towing equipment unless the

vehicle is adequately supported by safety stands.

8. No towing operation, which for any reason jeopardizes the safety of the wrecker operator or any bystanders or

other motorists, should be attempted.

FSR, FTR & FVR SERIES TOWING PROCEDURE

CAUTION

• Never let passengers ride in a vehicle that is being towed.

• Never tow faster than safe or posted speeds.

• Never tow with damaged parts not fully secured.

• Never get under your vehicle after it has been lifted.

• Always use separate safety chains on each side when towing a vehicle.

Try to have a GM/Isuzu dealer or a professional towing service any tow your vehicle. They can provide the right

equipment and knowledge to tow it without damage.

Before you do anything, turn on the hazard warning flashers (if they have not been damaged).

When you call, tell the towing service:

• That your vehicle has rear-wheel drive.

• The make, model and year of your vehicle.

• Whether you can still move the shift lever.

• An estimation of the total weight plus cargo so that the towing company can use the proper equipment.

• If there was an accident, what was damaged.

When the towing service arrives, let the tow operator know that the owner’s manual contains detailed towing

instructions. The operator may want to see them.

April 2002 33

Page 46

Mechanical & Cab Specifications

T owing Your Vehicle From the Front (Front Wheels Off the Ground)

BEFORE TOWING

Block the rear- wheels of the disabled vehicle. On vehicles with air brakes, release the emergency brake system

by compressing brake chamber springs as outlined in this section. (Note: This is to prevent the possibility of the

emergency brake being applied during towing.)

On vehicles with hydraulic brakes, release the parking brake fully by moving the lever handle to the fully released

position.

T owing the Vehicle with the Front Bumper Removed

1. Remove the front bumper.

2. Connect and lock the lift chains to the front axle, outside of the spring

anchor plates as shown.

3. Connect lift chains to the tow bar and raise the tow bar until lift chain slack

has been taken up.

4. Raise the vehicle to the required height.

Rear Axle

Disconnect the propshaft at the rear axle. Secure the propshaft to the frame or crossmember.

After T owing

Block the rear wheels and install axle and propeller shafts.

Check for proper phasing of universal joints. Apply the emergency brake system before disconnecting from the

towing vehicle. Check and fill the rear axle with oil as required.

T owing Your Vehicle From the Front (All Wheels On the Ground)

Your vehicle may be towed on all wheels provided the steering is working. Remember that the power brakes and

power steering will not have power assist. Vehicles with air brakes will not have brakes. There must be a tow bar

installed between the towing vehicle and the disabled vehicle.

Before T owing

Block the wheels of the disabled vehicle. On vehicles with air brakes, release the emergency brake system by

compressing brake chamber springs as outlined in this section. (Note: This is to prevent the possibility of the

emergency brake being applied during towing.)

On vehicles with hydraulic brakes, release the parking brake fully by moving the lever handle to the fully released

position.

If there is, damage or suspected damage to the axle(s), remove the axle shafts. Cover the hub openings to

prevent the loss of lubricant or entry of dirt or foreign objects.

After T owing

Block the rear wheels and install axle and propshafts. Check for proper phasing of universal joints. Apply the

parking brake system before disconnecting from the towing vehicle. Check and fill rear axle with oil as required.

T owing Your Vehicle From the Rear (Rear Wheels Off the Ground)

CAUTION

• Never let passengers ride in a vehicle that is being towed.

• Never tow faster than safe or posted speeds.

• Never tow with damaged parts not fully secured.

• Never get under your vehicle after it has been lifted.

• Always use separate safety chains on each side when towing a vehicle.

34 April 2002

Page 47

Mechanical & Cab Specifications

Before T owing

Secure the steering wheel to maintain straight-ahead position. Make certain that the front axle is not loaded

above the front axle Gross Axle Weight Rating (GAWR) as indicated on the vehicle’ s Certification/T ire label.

After T owing

Block the rear wheels and release the steering wheel. Apply the parking brake system before disconnecting from

the towing vehicle. Check and fill the rear axle with oil as required.

Releasing Air-Operated Parking Brakes

If your vehicle has air brakes, you could have a special towing problem. If your vehicle has to be towed because

you had a complete loss of air pressure from both systems, the parking brakes may have applied. The tow

operator can release the brakes manually by using the following steps. Then your vehicle can be with all wheels

or just the rear wheels on the ground.

1. Block the wheels of the vehicle.

2. Remove the release stud and nut from the side pocket of the brake chamber. Some chambers have studs that

are visible at all times.

3. Remove the rubber cap from the rear of the chamber.

4. Put the release stud, nut and flat washer into the chamber.

5. Turn the stud clockwise one quarter of a turn.

6. Using a 3/4" wrench, turn the stud nut clockwise several turns to release the brakes. Follow the same procedure to release the other brake.

7. At the repair facility , apply air pressure of at least 70 psi (480 kPa) to the brake chambers, either from an

external air supply or the vehicle’s air system.

8. Turn the stud nut counterclockwise several turns. Remove the stud from the chamber.

9. Put the stud into the side pocket of the chamber, and replace the rubber cap.

April 2002 35

Page 48

Weight Restrictions & Specifications

Weight Distribution

Concepts

April 2002 31

Page 49

Weight Restrictions & Specifications

Weight Restrictions

The Gross Vehicle Weight Rating (GVWR) and the Gross Axle Weight Rating (GAWR) of each Incomplete Vehicle

are specified on the cover of its Incomplete Vehicle Document in conformance to the requirements of Part 568.4 of

the Federal Motor Vehicle Safety Regulations. The final stage manufacturer is responsible under Part 567.5, to place

the GVWR and the GAWR of each axle on the Final Vehicle Certification Label. The regulation states that the

appropriate rating “shall not be less than the sum of the unloaded vehicle weight, rated cargo load, and 150 pounds

times the vehicle’s designated seating capacity.”

Unloaded vehicle weight means the weight of a vehicle with maximum capacity of all fluids necessary for operation

of the vehicle, but without cargo or occupants.

During completion of this vehicle, GVWR and GAWR may be affected in various ways, including but not limited to

the following:

1) The installation of a body or equipment that exceeds the rated capacities of the Incomplete Vehicle.

2) The addition of designated seating positions which exceeds the rated capacities of this Incomplete

Vehicle.

3) Alterations or substitution of any components such as axles, springs, tires, wheels, frame, steering and

brake systems that may affect the rated capacities of this Incomplete Vehicle.