Page 1

User Manual

Applies to:

Software version 1.4.16+

Firmware version 3.17+

Isothermal Technology Limited

Pine Grove

Southport

Merseyside

PR9 9AG

T: +44 (0)1704 543830

F: +44 (0)1701 544799

E: info@microk.co.uk

W: www.microk.co.uk

Page 2

CONTENTS

1 INTRODUCTION ............................................................................... 6

1.1 Unpacking ............................................................................................................................. 7

1.2 Safety ..................................................................................................................................... 7

1.3 Powering Up Your microK ................................................................................................. 9

1.4 A Quick Tour of Your microK ........................................................................................... 9

2 MAKING A MEASUREMENT (TUTORIALS) .................................. 12

2.1 Measuring Temperature with a Calibrated SPRT .......................................................... 12

2.2 Measuring Temperature with a Thermocouple .............................................................. 16

3 DRIVING YOUR MICROK ............................................................... 20

3.1 Introduction ........................................................................................................................ 20

3.2 The Startup Window ......................................................................................................... 20

3.3 The Main Window ............................................................................................................. 21

3.4 The Single Tab.................................................................................................................... 22

3.5 The Multi Tab .................................................................................................................... 25

3.6 The Settings Tab ................................................................................................................ 26

3.7 The Instrument Tab ........................................................................................................... 31

3.7.1 Edit Thermometers ........................................................................ 31

3.7.2 Edit Resistors ................................................................................ 34

3.7.3 Calibration .................................................................................... 35

3.7.4 Restart Software ............................................................................ 35

3.7.5 Update Software............................................................................ 36

3.7.6 Change Password .......................................................................... 36

3.7.7 Port Settings .................................................................................. 37

3.7.8 Set Date and Time ......................................................................... 38

3.7.9 Backup Data.................................................................................. 38

3.7.10 Clear Data Files ......................................................................... 39

3.7.11 Backup Configuration ............................................................... 39

3.7.12 Load Configuration ................................................................... 39

3.8 Using the Thermometer Database .................................................................................... 40

3.9 Using the Reference Resistors Database .......................................................................... 41

3.10 Saving Instrument Configurations .............................................................................. 41

3.11 Password Protection of Key Settings ........................................................................... 42

© Page 2 of 97 Issue: 1.04

Page 3

4 CONNECTING THERMOMETER SENSORS ................................. 43

4.1 The “Cable-Pod” Connectors ........................................................................................... 43

4.2 Connecting PRTs (4-wire) ................................................................................................. 43

4.3 Connecting PRTs (3-wire) ................................................................................................. 44

4.4 Connecting PRTs (2-wire) ................................................................................................. 44

4.5 Connecting Thermocouples (external Ice Point or WTP) .............................................. 45

4.6 Connecting Thermocouples (using RJ compensation) ................................................... 46

4.7 Connecting Thermistors .................................................................................................... 46

5 GOOD PRACTICE GUIDELINES .................................................... 48

5.1 Looking After Your microK ............................................................................................. 48

5.2 Making a Good Electrical Measurement ......................................................................... 48

6 THE MICROK TECHNOLOGY ........................................................ 51

6.1 The ADC ............................................................................................................................. 51

6.2 Substitution Topology ....................................................................................................... 53

6.3 Minimising Thermal EMFs .............................................................................................. 55

6.4 Solid-State Switching ......................................................................................................... 56

6.5 Inherent Stability ............................................................................................................... 56

6.6 Eliminating Self-Heating Effects ...................................................................................... 57

7 CALIBRATION ................................................................................ 58

7.1 Checking Calibration ........................................................................................................ 58

7.1.1 Checking the Master Current Source ..............................................58

7.1.2 Resistance Measurements ..............................................................59

7.1.2.1 Zero Ohms Check ..................................................................59

7.1.2.2 400 Ω Internal Reference Resistor..........................................60

7.1.2.3 100 Ω Internal Reference Resistor..........................................61

7.1.2.4 25 Ω Internal Reference Resistor ...........................................61

7.1.2.5 10 Ω Internal Reference Resistor ...........................................61

7.1.2.6 1 Ω Internal Reference Resistor .............................................61

7.1.3 Voltage Measurements ..................................................................62

7.1.3.1 Zero Voltage Offsets ..............................................................62

7.1.3.2 Voltage Span Check ...............................................................62

7.2 Adjusting Calibration ........................................................................................................ 63

7.2.1 Calibrate Master Current Source ....................................................64

7.2.2 Calibrating the 400 Ω Internal Reference Resistor .........................65

© Page 3 of 97 Issue: 1.04

Page 4

7.2.3 Calibrating the 100 Ω Internal Reference Resistor ......................... 66

7.2.4 Calibrating the 25 Ω Internal Reference Resistor ........................... 66

7.2.5 Calibrating the 10 Ω Internal Reference Resistor ........................... 66

7.2.6 Calibrating the 1 Ω Internal Reference Resistor ............................. 66

7.2.7 Calibrating Voltage Zeros ............................................................. 67

7.2.8 Calibrating Voltage Span .............................................................. 68

8 RS232 INTERFACE ........................................................................ 70

8.1 Establishing an RS232 Connection ................................................................................... 70

9 GPIB ................................................................................................ 73

9.1 GPIB Address ..................................................................................................................... 74

9.2 Establishing a GPIB Connection ...................................................................................... 74

10 SCPI COMMAND SET .................................................................... 75

10.1 Command Terminators ................................................................................................ 75

10.2 SCPI Command Structure ........................................................................................... 75

10.2.1 SCPI Numeric Suffices.............................................................. 77

10.2.2 Parameters ................................................................................. 77

10.2.3 Units ......................................................................................... 77

10.3 Making Measurements using SCPI Commands ......................................................... 79

10.3.1 Measuring Resistance using SCPI Commands ........................... 79

10.3.2 Measuring Voltage using SCPI Commands ............................... 80

10.4 SCPI Commands ........................................................................................................... 81

10.4.1 Command: *IDN? ..................................................................... 82

10.4.2 Command: *RST ....................................................................... 82

10.4.3 Command: SENSe:FUNCtion ................................................... 82

10.4.4 Command: SENSe:FUNCtion? ................................................. 82

10.4.5 Command: SENSe:CHANnel .................................................... 83

10.4.6 Command: SENSe:CHANnel? .................................................. 83

10.4.7 Command: SENSe:VOLTage:RANGe ...................................... 83

10.4.8 Command: SENSe:VOLTage:RANGe? .................................... 84

10.4.9 Command: SENSe:FRESistance:REFerence ............................. 84

10.4.10 Command: SENSe:FRESistance:REFerence? ............................ 84

10.4.11 Command: SENSe:FRESistance:RANGe .................................. 84

10.4.12 Command: SENSe:FRESistance:RANGe? ................................ 85

10.4.13 Command: SENSe:RATio:REFerence ....................................... 85

10.4.14 Command: SENSe:RATio:REFerence? ..................................... 85

10.4.15 Command: SENSe:RATio:RANGe ........................................... 86

10.4.16 Command: SENSe:RATio:RANGe? ......................................... 86

10.4.17 Command: INITiate .................................................................. 87

10.4.18 Command: FETCh? ................................................................... 87

10.4.19 Command: READ? ................................................................... 87

10.4.20 Command: READ#? ................................................................. 87

© Page 4 of 97 Issue: 1.04

Page 5

10.4.21 Command: MEASure:VOLTage? ..............................................88

10.4.22 Command: MEASure:FRES:REF? ............................................88

10.4.23 Command: MEASure:RAT:REF? ..............................................89

10.4.24 Command: CURRent .................................................................89

10.4.25 Command: TEST:CURRent .......................................................90

10.4.26 Command: CALibrate:CURRent ...............................................90

10.4.27 Command: CALibrate:REFerence .............................................90

10.4.28 Command: CALibrate:REFerence? ............................................90

10.4.29 Command: CALibrate:OFFSet ...................................................91

10.4.30 Command: CALibrate:OFFSet? .................................................91

10.4.31 Command: CALibrate:GAIN .....................................................91

10.4.32 Command: CALibrate:GAIN? ...................................................92

10.4.33 Command: CALibrate:PASSword .............................................92

10.4.34 Command: CALibrate:UNLock .................................................92

10.4.35 Command: CALibrate:LOCK ....................................................93

11 SPECIFICATION ............................................................................. 94

12 APPROVALS .................................................................................. 96

12.1 CE Declaration .............................................................................................................. 96

12.2 FCC Statement .............................................................................................................. 96

12.3 Standards Applied ........................................................................................................ 97

© Page 5 of 97 Issue: 1.04

Page 6

1 Introduction

The microK-400 and micro-800 are the only precision thermometry instruments

that can achieve sub mK precision and will work with all three common

thermometer sensors (PRTs, Thermocouples and Thermistors). They are based

on a completely new measurement technology, unique to these products, that

provides better accuracy and lower noise than comparables technologies (see

section 6). They are also the first instruments of their type to be completely solid-

state, making them highly reliable.

Despite their sophistication, these instruments are very easy to use. There are no

knobs and dials, just a colour touch screen that makes use of the familiar

Windows CE™ operating system. If you use a Windows™ operating system on

your PC, you will find these instruments intuitive and easy to use. The USB port

on the front panel allows you to plug in and use other devices that work with

Windows CE™ such as a mouse, keyboard or flash drive.

Readings can be displayed in resistance ratio, ohms, volts or temperature units

(°C, °F or K). Algorithms for conversion to temperature include:

PRTs: ITS-90

Callendar-Van Dusen (IEC751 or custom

coefficients)

Thermocouples: IEC584-1 (for type B, E, J, K, N, R, S, T)

Type L polynomial

Gold Platinum Reference Function Polynomial

Thermistor: Steinhart-Hart

This manual provides a comprehensive guide to using the instrument. We

recognise that you will probably not wish to read it through at this time so

suggest you read the safety section below, take one of the tutorials in section 2

© Page 6 of 97 Issue: 1.04

Page 7

and then refer back to the manual using the list of contents to find additional

information as required.

1.1 Unpacking

Your microK product should comprise the following items:

microK precision thermometer

power lead suitable for your country

this user manual

If any item is missing or damaged, please report this immediately to your

supplier. If possible, we recommend that you retain the packaging material in

case you need to return the instrument for calibration or service since it has been

!

designed to ensure that your microK is properly protected during transportation.

1.2 Safety

The microK is a precision instrument, designed for use in a laboratory. It

complies with the requirements of safety standard EN61010-1 (2001) and is

therefore safe to use in laboratory or light industrial environments. It is not

intended for use outdoors or in extreme environments (refer to specification in

Section 11).

The microK is likely to be connected to thermometer sensors in use and the

operator should take care to ensure that the complete system is safe. For

example, metal sheathed thermometers may be connected to the microK and then

placed in a furnace powered from a 230V electrical supply. Single fault

conditions in such a furnace could lead to the thermometer wires and therefore

the front terminals of the microK becoming electrically live and therefore a

hazard to the operator. Suitable precautions should be taken, such as using an

isolating transformer in the supply to such a furnace. If you require further advice

on safety issues, please contact Isothermal Technology or one of our appointed

distributors - we have extensive experience of thermometry and can provide

advice and equipment to help you.

© Page 7 of 97 Issue: 1.04

Page 8

Retain these instructions. Use only as specified in these operating instructions or

the intrinsic protection may be impaired.

Please observe the following safety precautions:

Do not use your microK if it is damaged

Only connect to an earthed supply socket. THIS UNIT IS CLASS 1

CONSTRUCTION AND MUST BE EARTHED!

Connect only to a power supply with a voltage corresponding to that on

the rating plate

This equipment is for indoor use and will meet its performance figures

within an ambient temperature range of 5°C to 40°C with maximum

relative humidity of 80% for temperatures up to 31ºC decreasing linearly

to 50% RH at 40ºC

Equipment is for operation at installation category II (transient voltages)

and pollution degree ll in accordance with IEC 664 at altitudes up to 2000

metres

Before replacing a fuse, DISCONNECT THE EQUIPMENT FROM THE

ELECTRICAL SUPPLY

The fuse is contained in the IEC socket on the rear panel. It must only be

replaced with a fuse of the type and rating marked on the rear panel

If a replacement fuse fails immediately, contact your local service agent.

DO NOT replace with a higher value

Always use the power cord supplied. Your sales outlet can provide a lead

suitable for your country

This equipment is for use in moderate climates only. NEVER use the

equipment in damp or wet conditions

Avoid excessive heat, humidity, dust & vibration

Do not place liquid filled containers on the equipment

Do not use where the equipment (or any associated accessories) may be

subjected to dripping or splashing liquids

Ensure that the power switch is easily accessible to allow the unit to be

switched off

The equipment weighs 13kg; use the handles provided. Always

disconnect the equipment from the electrical supply and any ancillary

units before moving

Ensure that tabletop equipment is placed on a solid, level surface, which

is able to support its weight (and that of any attached accessories)

Ensure all cables and wires are routed safely to avoid tripping: also to

avoid sharp bends and pinches

Clean only with a damp cloth. Do not wet or allow moisture to penetrate

the unit. Do not use solvents. See section 5.1 for details of cleaning

procedure

The product should be subjected to regular in-service inspections as

required by local regulations; a yearly interval is suggested

Verify that the supply cordset is undamaged and that the enclosure is

bonded to protective earth. Do not apply earth test currents to any front

panel terminal nor to the shrouds of the USB, RS232 or GPIB connectors

© Page 8 of 97 Issue: 1.04

Page 9

The product is designed to comply with EN 61010-1 and can be flash

tested. It is fitted with radio frequency interference suppressors.

Therefore it is recommended that only a D.C. test be performed.

Performing flash tests repeatedly can damage insulation

This equipment contains no user-serviceable parts. Refer all repairs to

qualified service personnel. Contact Isothermal Technology or one of our

appointed distributors for details of approved service outlets

1.3 Powering Up Your microK

The microK operates on any standard AC electrical supply (88-264V RMS at 47-

63Hz) so unless your supply is unusual you can simply use the power cord

provided to connect your microK to a suitable electrical outlet.

The power switch is located at the rear of the instrument, immediately below the

IEC connector. When you turn your microK on it will go through a standard

!

Windows CE™ boot sequence and then display a Window containing the

Resume button. Pressing Resume restarts the microK in the configuration it was

in prior to the last power down, you will then see the Main Window and be ready

to operate your instrument.

Before pressing the Resume button, make sure that any thermometers attached

will not be damaged by the sense currents that will be applied (the last values

used). If there is a problem, disconnect your sensors before proceeding and then

reconnect them after changing the sense current to the required values.

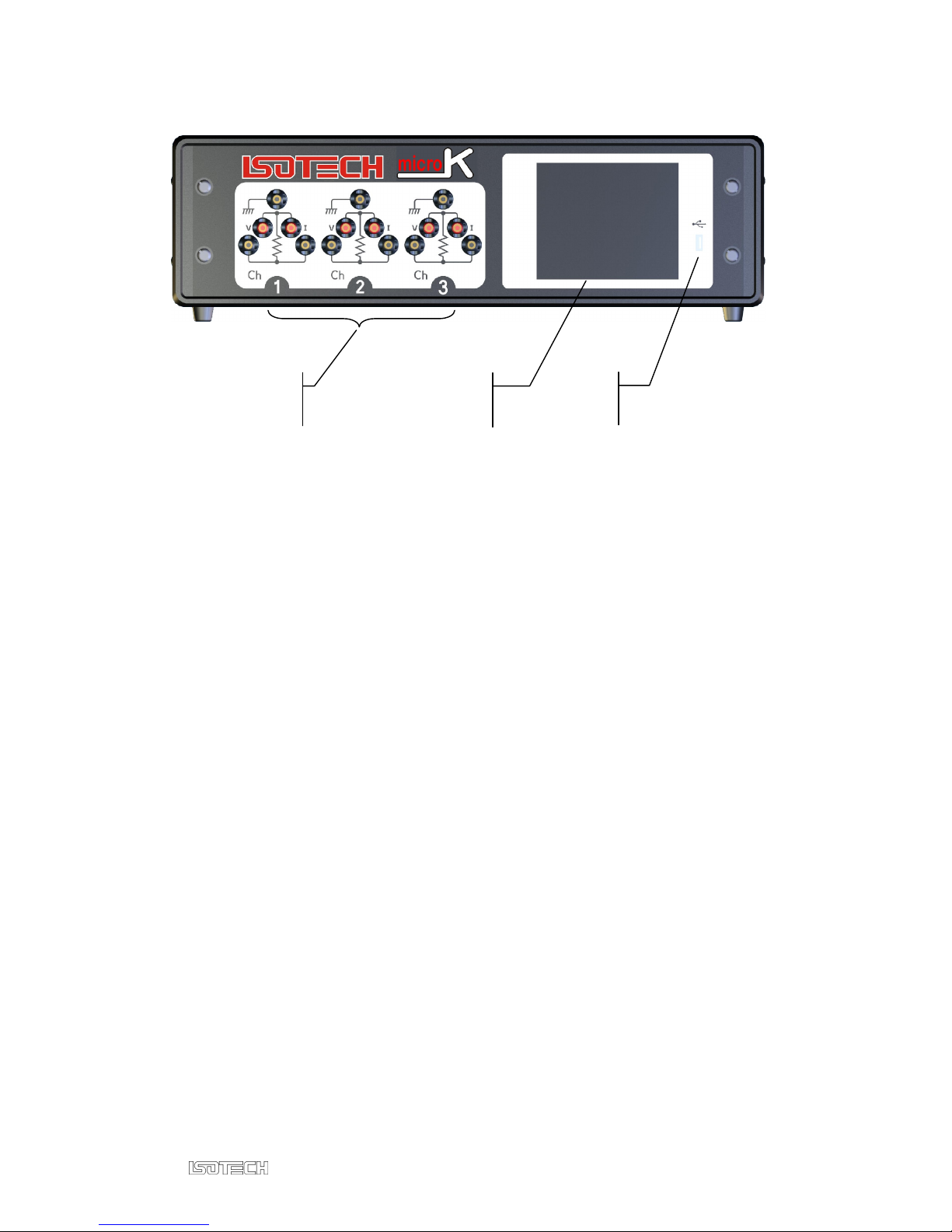

1.4 A Quick Tour of Your microK

On the front panel of your microK you will find the input terminals for the three

measurement channels, the touch screen/colour display and a USB connector:

© Page 9 of 97 Issue: 1.04

Page 10

USB

Input

Terminals

Touch Screen

& Display

Connector

Input Terminals: The input terminals accept 4mm plugs, spades or bare wires.

The current (I) and voltage sense (V) terminals are spaced on ¾” centres so that

standard BNC to 4mm adaptors (not supplied) can be used to connect to

thermometer sensors that have BNC terminations.

The contact material for the connectors is gold plated tellurium-copper, offering

extremely low thermal EMFs when connected to copper wires/connectors. This

is essential when using precision thermocouples.

Display: The display is a colour TFT VGA (640 x 480) LCD with a long-life

CCFL (cold-cathode fluorescent lamp) backlight. A touch panel is mounted in

front of the display so that you can control the instrument by simply touching the

buttons displayed on the LCD. The touch panel is an industrial grade components

offering good durability. It is intended to be operated with a finger. A stylus

intended for PDAs may also be used – never use a sharp object with the touch

panel as this will lead to premature failure.

The USB Connector: The USB connector is primarily intended to allow you to

connect a USB flash drive, store measurement results and transfer these to a PC.

The flash drive may also be used to backup the databases of thermometers,

reference resistors and instrument configurations for your microK.

© Page 10 of 97 Issue: 1.04

Page 11

Connector

(unused)

GPIB

Connector

Other USB devices such as a mouse, keyboard, keypad or USB hub may be

connected to the USB port and used, provided they utilise the standard class

drivers provided with the Windows CE™ operating system incorporated in your

microK.

On the rear panel of your microK you will find the electrical supply

connector/power switch/fuse module plus the interface connectors that allow you

to connect your instrument to a PC. The RS232 and GPIB ports allow you to

control the instrument and take measurements from a PC with your own software

(see section 8). The command protocol employs the widely used SCPI format

(see section 9 for details). The USB connector is provided for future expansion

and should not be used on this model.

IEC 60320-1

Power Connector

On/Off

Switch

Supply

Fuse

USB-B

Connector

RS232

© Page 11 of 97 Issue: 1.04

Page 12

2 Making a Measurement (Tutorials)

The operator interface is powered by the Windows CE™ operating system. With

the widespread use of Windows applications on PCs, driving your microK should

be fairly intuitive. As with most Windows™ applications, it is possible to

navigate your way through a process using a number of different paths, so rather

than describe each window and the function of each button and then leaving you

to work out how to operate the instrument, we provide you with a number of

tutorials that illustrate common applications. Even if these do not describe your

application, it is worth working through one of them since it will provide you

with a broad understanding of the wide range of features available on your

microK.

A traditional description of the function of all the features provided by the

operator interface is given in section 3.

2.1 Measuring Temperature with a Calibrated SPRT

From startup, press Resume to restart your microK:

© Page 12 of 97 Issue: 1.04

Page 13

Before making any measurement, you will have to enter information about the

thermometer into the microK’s database. When the main window opens, press

the Instrument tab:

In the Instrument tab, press Edit Thermometers:

You will be prompted to enter the password (set to “1234” initially, but this

should be changed before using the microK in a real measurement/calibration

application to ensure security – see section 3.7.6). Enter the password to open the

thermometer database window. Press New to create a new thermometer entry in

the database and enter data by pressing the up/down or ellipses buttons by each

field:

© Page 13 of 97 Issue: 1.04

Page 14

Press Coefficients to open the coefficients window. Press the ellipses buttons to

enter the calibration data for the thermometer from its calibration certificate:

Press OK to close the coefficients window and press OK again to close the

thermometer database window.

Press the Settings tab in the main window and disable channels 2 and 3 (this will

speed up measurements on channel 1, which we will be using) by using the

up/down buttons by the Channel box to select these channels and pressing

Disable. Use the up/down buttons to return to channel 1. Use the up/down (or

ellipses) buttons by each box to select the required settings:

© Page 14 of 97 Issue: 1.04

Page 15

The sense current is assumed to be 1mA in this tutorial. It can be set to other

values using the ellipses button by the Current mA box (see section 3.6).

Connect the SPRT to channel 1 (see section 4.2 for details on how to connect 4-

wire PRTs). The tutorial assumes you are using the internal 100Ω reference

resistor. To use an external reference resistor, first enter information on the

resistor into the microK’s database (see section 3.7.2), then in the Settings tab

select the channel to which the reference is connected in the Reference Channel

box and the reference resistor entry in the Reference Resistor box.

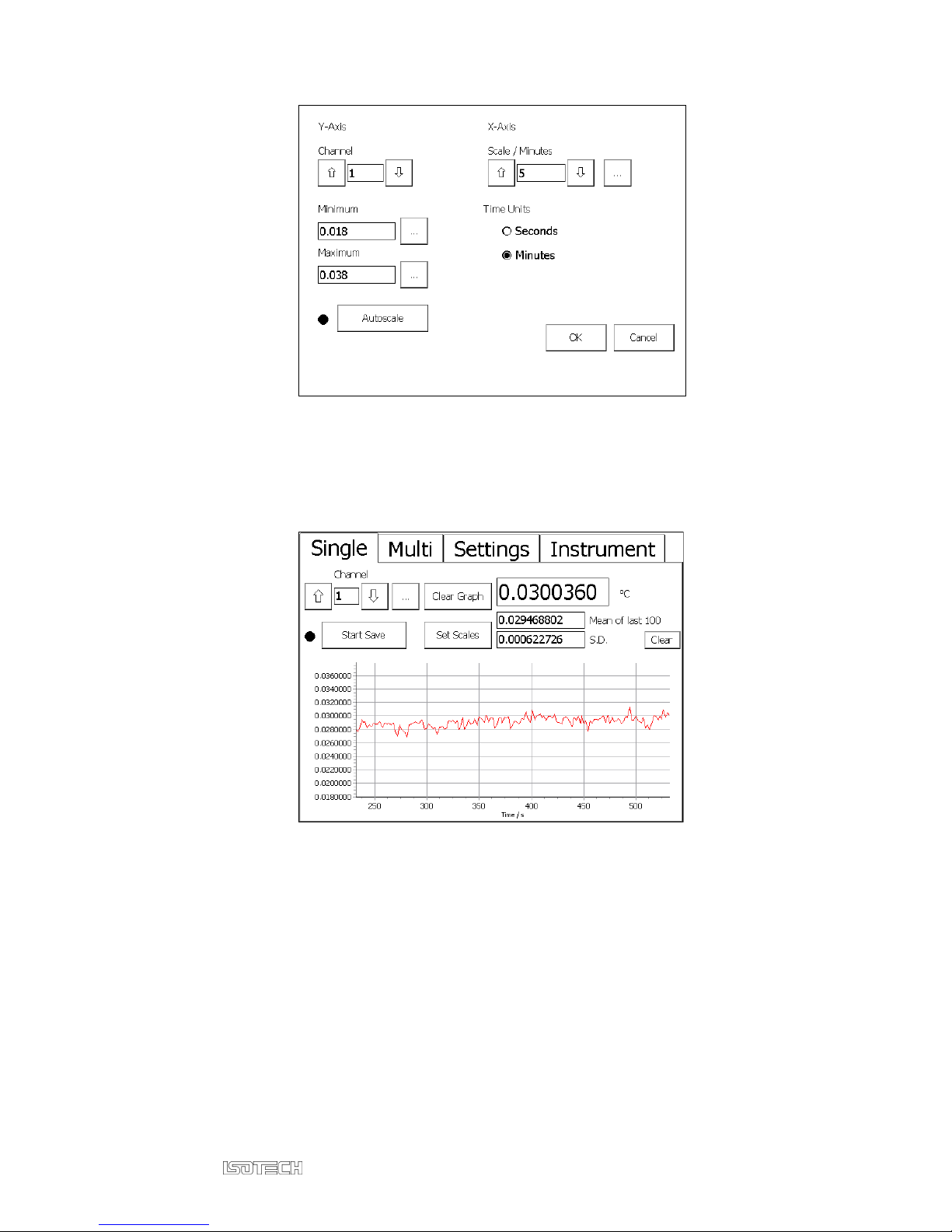

Press the Single tab to see the measurements in numeric and graphical form. Set

the graph scales manually by making a note of the current Mean value and

pressing Set Scales. This opens the graph scales window. Ensure that autoscaling

is turned off (press Autoscale to toggle autoscaling on/off, the status of

autoscaling is shown by the adjacent indicator). Use the ellipses buttons to set the

y-axis limits to be 0.005°C above and below the current mean value. Use the

radio and up/down buttons to set the x-axis to 5 minutes:

© Page 15 of 97 Issue: 1.04

Page 16

Press OK to return to the main window. The measurement system will now

accumulate data and after 5 minutes the graph will begin to scroll to show the

last 5 minutes of data:

2.2 Measuring Temperature with a Thermocouple

From startup, press Resume to restart your microK:

© Page 16 of 97 Issue: 1.04

Page 17

This tutorial describes the use of an uncalibrated type-N thermocouple. The

microK can be used with calibrated thermocouples, in which case you will need

to enter information about the thermometer into the microK’s database and (see

section 3.7.1) and select this thermometer entry from the Thermometer box in the

Settings tab (see later in this tutorial). When the main window opens, press the

Settings tab:

In the Settings tab disable channels 2 and 3 (this will speed up measurements on

channel 1, which we will be using) by using the up/down buttons by the Channel

box to select these channels and pressing Disable. Use the up/down buttons to

return to channel 1. Use the up/down buttons by each box to select the required

settings:

© Page 17 of 97 Issue: 1.04

Page 18

The reference junction is assumed to be an ice point in this tutorial. It can be set

to the water triple-point or to use a temperature measured by one of the other

channels (see sections 3.6 and 4.6) if using reference junction compensation.

Connect the N-type thermocouple to channel 1 (see section 4.5 for details on how

to connect thermocouples). Press the Single tab to see the measurements in

numeric and graphical form. Set the graph scales manually by making a note of

the current Mean value and pressing Set Scales. This opens the graph scales

window. Ensure that autoscaling is turned off (press Autoscale to toggle

autoscaling on/off, the status of autoscaling is shown by the adjacent indicator).

Use the ellipses buttons to set the y-axis limits to be 0.01°C above and below the

current mean value. Use the radio and up/down buttons to set the x-axis to 5

minutes:

© Page 18 of 97 Issue: 1.04

Page 19

Press OK to return to the main window. The measurement system will now

accumulate data and after 5 minutes the graph will begin to scroll to show the

last 5 minutes of data:

© Page 19 of 97 Issue: 1.04

Page 20

3 Driving Your microK

3.1 Introduction

The operator interface for the microK is provided through the touch screen and

colour display. The software is written in Microsoft’s new C# language and runs

under the Windows CE™ operating system. This provides a familiar and easy to

use interface.

The buttons in the microK software have been sized and positioned to allow you

to operate the instrument with your finger. If numeric or alphanumeric data needs

to be entered, a ‘soft’ keyboard window appears. If you are unfamiliar with touch

screen devices such as PDAs, you may initially feel that the touch screen

interface is slow compared with using a mouse and keyboard, but with a little

practice you should quickly become comfortable with the technology and

appreciate its benefits. However, if you prefer to use a USB mouse or keyboard,

you can simply plug these into the USB connector on the front panel. They will

immediately become active provided they use the standard class drivers built into

the Windows CE™ operating system used in the microK. To use more than one

USB device, simply plug a USB hub into the front panel connector.

Calibration data entered into the microK’s database is password protected and

includes recalibration dates (the microK will alert you if you try to use a

thermometer or reference resistor after its recalibration date). This feature

ensures the integrity of your measurements and helps you to comply with the

requirements of accreditation bodies.

3.2 The Startup Window

When power is applied to the microK, it goes through a Windows CE™ boot

sequence that loads the operating system and then starts the microK application.

The Startup Window then appears showing the microK’s model and serial

number together with the version numbers for the measurement system firmware

and microK software used. The window also lists the details of any

© Page 20 of 97 Issue: 1.04

Page 21

“microsKanner” multiplexers connected to the microK (the microsKanner

manual describes how to use “microsKanner” multiplexers with your microK

bridge). The Startup Window contains the Resume button:

!

Resume: Pressing the Resume button places the microK in the state it was in

prior to its last power down. Before pressing Resume, make sure that any

thermometers attached will not be damaged by the sense currents that will be

applied (the last values used). If there is a problem, disconnect your sensors

before proceeding and then reconnect them after changing the sense current to

the required values.

3.3 The Main Window

Having pressed Resume in the Startup Window, the user is presented with the

Main Window.

© Page 21 of 97 Issue: 1.04

Page 22

displays all three ch

annels in numeric form

allows you to configure the channels to perform the

All functions to control the microK are available in this Window, which is

divided into four tabs:

Single

displays a single channel in numeric and graphical form

Multi

Settings

required measurement

Instrument

allows you to enter information on the thermometers and

reference resistors used with the instrument into its

database. It also allows you to save/load measurement

data and instrument configurations in the database and to

change instrument settings such as the GPIB address,

time/date and security passwords

The Main Window opens with the Single tab selected.

3.4 The Single Tab

Select this tab to see a single channel in both numeric and graphical form:

© Page 22 of 97 Issue: 1.04

Page 23

Channel box: Use the up/down buttons by the Channel box to select the channel

you wish to view. Alternatively press the ellipses button to open a numeric entry

window and select the channel directly. The ellipses button is particularly useful

when the microK is used with microsKanner multiplexers, which can provide up

to 90 expansion channels. You can only view channels that are enabled, so if a

channel is disabled in the Settings tab it will not appear in the sequence and will

not be measured. This means that the up/down buttons have no effect if only one

channel is enabled.

The numeric display shows the last reading together with the mean and standard

deviation of the most recent of readings (the number of readings in the statistics

is set in the Settings tab).

Clear Graph: Press the Clear Graph button to clear the graph and re-start the

autoscaling feature. This can be used to eliminate the effect of a large transient

result (perhaps caused when changing connections to the thermometer) on the

autoscaling function.

Clear button: Press the Clear button to clear (reset) the statistics.

Set Scales button: Use the Set Scales button to open a new window and set the x

and y axes for the graphical output:

© Page 23 of 97 Issue: 1.04

Page 24

In this window, use the up/down buttons by the Channel box to select the

channel whose scales you wish to change (the window opens with the currently

displayed channel selected). Use the radio buttons to select either Seconds or

Minutes as the units. Use the up/down buttons by the Scale / Seconds box to

change the x-axis (time) scale (the same x axis scale is used for all channels). Or,

press the ellipses button to open a Numeric Keypad window and enter the

required scale directly. Any value between 1 second and 1000 minutes

(inclusive) may be used.

Use the ellipses by the Minimum and Maximum boxes to open a Numeric Keypad

window and set the y-axis scale. Alternatively, press the Autoscale button to

scale the y-axis so that it will show all the readings. The indicator by the

Autoscale button shows whether autoscaling is active.

The numeric and graphical outputs are updated as new readings are made. The

time between readings depends on the settings for that channel and any other

channels that are also enabled. This can vary between 2 seconds and 5 minutes.

The measurement sample time for a PRT or thermistor is <2s and for a

thermocouple it is <1s. The reading rate for three PRTs with one sample per

reading will therefore be <6s.

Start Save button: Press the Start Save button to record all the measurements

being made. You will then be offered the choice (buttons) of storing the data to

the Internal “DiskOnChip” (solid state drive) memory or an External USB flash

© Page 24 of 97 Issue: 1.04

Page 25

drive. Data stored to the internal memory can subsequently be transferred to an

external USB flash drive using the Backup Data button in the Instrument tab (see

section 3.7.9). The internal memory used has a capacity of at least 32Mbytes; this

will accommodate approximately 1,300,000 PRT readings or about 30 days of

continuous logging at the fastest rate. Select the destination for the data to open

an Alpha-Numeric Keyboard window and enter a filename. An automatically

incrementing default name will appear in the entry box, press OK to accept this

or use the backspace and alpha-numeric keys to enter your preferred filename. If

you try to use a filename that has already been used, you will have to enter the

password to proceed (see section 3.11 for details on password protection). The

Shift key toggles the alpha keys between upper and lower case. The indicator by

the Start Save button in the Single tab shows whether readings are being recorded

to a file. The measurements are written to the file in comma delimited ASCII text

form allowing easy importation into Microsoft Excel™ or other applications.

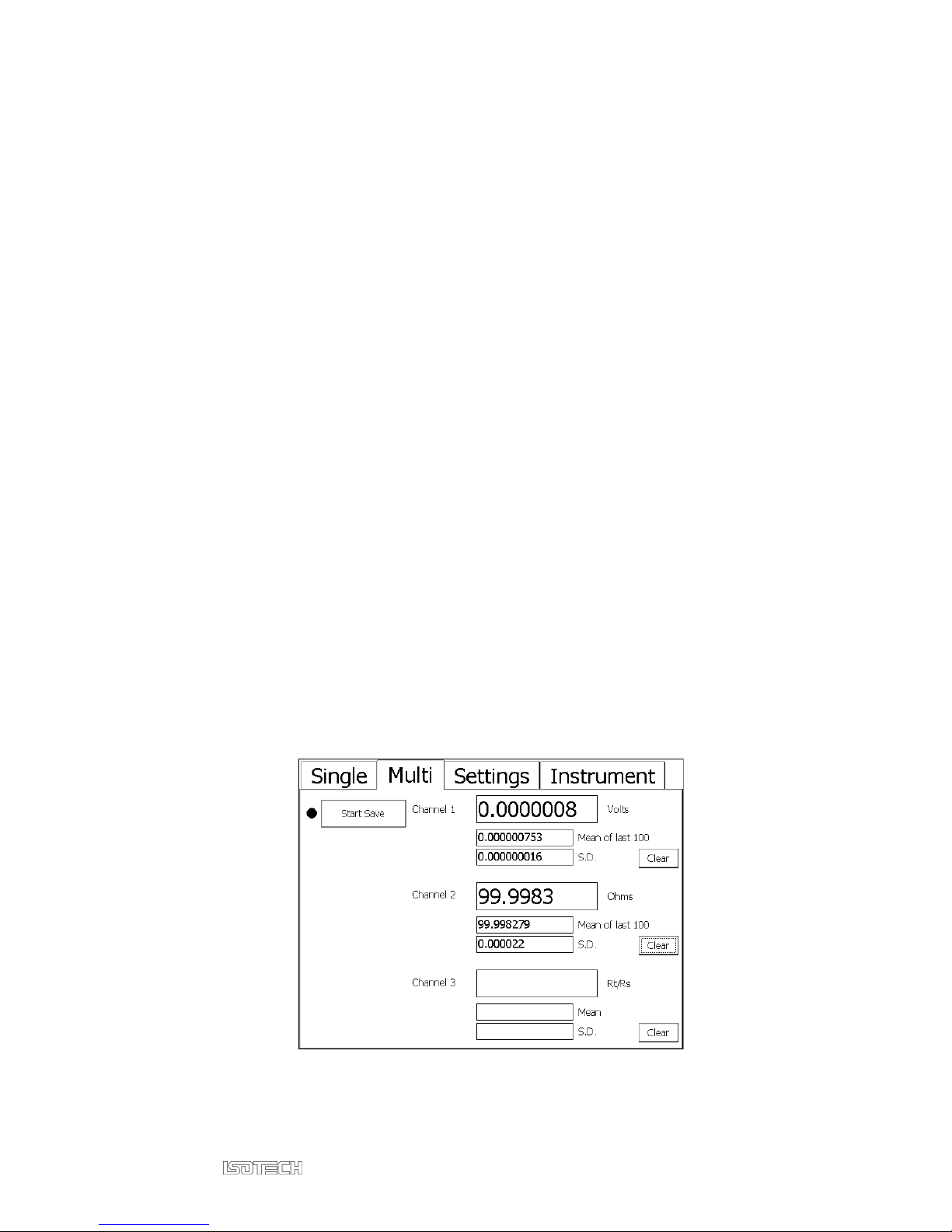

3.5 The Multi Tab

Select this tab to see all three channels in numeric form only. The numeric

display shows the last reading together with the mean and standard deviation for

the most recent readings (the number of readings in the statistics is set in the

Settings tab) for each of the channels that are enabled.

© Page 25 of 97 Issue: 1.04

Page 26

Clear buttons: Press the Clear button to clear (reset) the statistics for each

channel

The displayed values are updated as new readings are taken. The time between

readings depends on the settings for that channel and any other channels that are

also enabled. This can vary between 2 seconds and 5 minutes. The measurement

time for a PRT or thermistor is <2s and for a thermocouple it is <1s. The reading

rate for three PRTs with one sample per reading will therefore be <6s.

Start Save: Press the Start Save button to record all the measurements being

made. You will then be offered the choice (buttons) of storing the data to the

Internal “DiskOnChip” (solid state drive) memory or an External USB Flash

Drive. Data stored to the internal memory can subsequently be transferred to an

external USB Flash Drive using the Backup Data button on the Instrument tab

(see section 3.7.9). The internal memory used has a capacity to at least

32Mbytes; this will accommodate approximately 1,300,000 PRT readings or

about 30 days of continuous logging at the fastest rate. Select the destination for

the data to open an Alpha-Numeric Keyboard window and enter a filename. An

automatically incrementing default name will appear in the entry box, press OK

to accept this or use the backspace and alpha-numeric keys to enter your

preferred filename. If you try to use a filename that has already been used, you

will have to enter the password to proceed (see section 3.11 for details on

password protection). The Shift key toggles the alpha keys between upper and

lower case. The indicator by the Start Save button in the Multi tab shows whether

readings are being recorded to a file. The measurements are written to the file in

comma delimited ASCII text form allowing easy importation into Microsoft

Excel™ or other applications.

3.6 The Settings Tab

Select this tab to configure each channel for the required measurements.

© Page 26 of 97 Issue: 1.04

Page 27

Channel box: Use the up/down buttons to select the channel you wish to

configure. Alternatively press the ellipses button to open a numeric entry window

and select the channel directly. The ellipses button is particularly useful when the

microK is used with microsKanner multiplexers, which can provide up to 90

expansion channels.

Enable/Disable button: Use this button to enable or disable a channel. Disable

unused channels to skip measurements on that channel and reduce the cycle time

through the channels. The nearby indicator shows whether the currently selected

channel is enabled.

Thermometer box: Use the up/down buttons to select the required thermometer.

Initially this box will contain only default PRT, Thermocouple or Thermistor.

You can use these entries for uncalibrated thermometer sensors. If you add

thermometers to the microK’s Thermometer Database (see section 3.7.1), these

will also appear in the list within this box. The ellipses button opens a list of all

available thermometers and is useful if you have a large number of entries in the

database.

Conversion box: If the selected thermometer is one of the default types, you can

use the up-down buttons to select a standard polynomial function for converting

the thermometer’s base measurement to temperature. If the selected thermometer

© Page 27 of 97 Issue: 1.04

Page 28

is one that your have created in the Thermometer Database this box will be fixed

and will be the conversion type defined for that thermometer.

Range box: Use the up/down buttons to select the required range. The microK

has three ranges for each thermometer type. Use the 0.125V range for all

thermocouples as this provides the most suitable input voltage range. The

resistance ranges offered depend on the sense current (use the ellipses button by

the Current box in this tab to change the current). Choose a resistance range that

is greater than or equal to both the highest thermometer resistance and reference

resistor value you intend to use.

Reference Channel box (PRTs and thermistors only): Use the up/down

buttons to select the reference resistor used in the resistance measurement; either

one of the internal reference resistors or the channel to which an external

resistance standard is connected. Alternatively press the ellipses button to open

the Reference Channel window and select the channel directly. The External

button in this window allows you to select one of the microK’s three external

channels or any expansion channel provided by a microsKanner.

Reference Resistor box (PRTs and thermistors only): If an internal reference

resistor was selected in the Reference Channel box, this box will show the

calibrated value of that resistor. If one of the input channels was selected in the

Reference Channel box, this box will contain a list of the reference resistors in

the microK’s database (entered using the Edit Resistors button in the Instrument

tab – see section 3.7.2) and “Uncalibrated”. Select the required resistor using the

up/down buttons. Select “Uncalibrated” if you only want to make a resistance

ratio measurement between two channels. The ellipses button opens a list of all

available reference resistors and is useful if you have a large number of entries in

the database.

Reference Junction box (thermocouples only): This contains 0°C, 0.01°C and

a list of any input channels that have been configured to measure temperature.

Choose 0°C or 0.01°C if you are using an external reference junction in an ice-

point bath or water triple point respectively. Choose one of the measurement

channels if you want to measure the temperature of the reference junction with a

© Page 28 of 97 Issue: 1.04

Page 29

thermometer sensor on that channel. The software will not allow you to use a

thermocouple channel as the reference junction sensor (to avoid circular

dependencies). You must specify a thermometer sensor for the reference junction

channel that includes temperature conversion otherwise it will not appear in the

Reference Junction box.

Units box: Use the up/down buttons to select the required units. The base units

(resistance ratio “Rt/Rs” for PRTs or thermistors and “Volts” for thermocouples)

are always available. “Ohms” will also be available (for PRTs and thermistors) if

the value of the reference resistor is available (Reference Resistor not set to

“Uncalibrated”). If the thermometer sensor chosen has a temperature conversion

specified, then temperature units °C, °F and K are also available.

Current box (PRTs and thermistors only): Press the ellipses button to change

the sense current. Use the buttons in the window that then opens to select the

required sense current:

The standard PRT sense currents are available directly through the buttons

provided. Press the Custom button to specify a different value (range 0 to 10mA),

this will then open a Numeric Keypad window.

Buttons for ÷√2 and ×√2 are included to make extrapolation to zero power easier

since changing the current in a resistor by a factor of √2 changes the power

dissipated by a factor of 2. A PRT’s calibration may be defined at a specified

current. Alternatively, it may be specified at zero power. In this case, you need to

© Page 29 of 97 Issue: 1.04

Page 30

determine what the resistance of the PRT would be at zero power. This is most

easily done by measuring its resistance at the normal sense current and then

increasing the current by a factor of √2 and repeating the measurement. If you

subtract the change in resistance from the first resistance value (at nominal

current) this gives you the resistance of the PRT at zero power. Alternatively, the

second measurement can be made at a current that has been reduced by a factor

of √2. In this case the change in resistance should be subtracted from the second

resistance value (current scaled by √2) to determine the zero power resistance.

The accuracy of the current source is 0.4%, so the uncertainty associated with

this extrapolation back to zero power is only 0.8% of the measured resistance

change, which should be very small. Other factors such as the fact that the PRT

is not a constant resistance and so the power dissipated has changed between the

two measurements are insignificant.

Samples per Reading box: Use the up/down buttons to select the number of

samples you want to average together to form a single reading. Alternatively,

press the ellipses button to open a Numeric Keypad window and enter the

required number directly. The number of samples may be between 1 and 100

inclusive.

Increasing the number of samples will slow down the rate at which readings are

made, but will also reduce the uncertainty associated with these readings (as

shown by the standard deviations reported in the “Single” and “Multi” tabs). This

uncertainty reduction is proportional to the square-root of the number of samples

(for example: selecting 9 samples per reading will reduce the uncertainty

associated with each reading by a factor of 3).

Readings in Rolling Statistics box: Use the up-down buttons to select the

number of samples in the rolling statistics. Alternatively press the ellipses button

to open a Numeric Keypad window and enter the value directly. Values between

1 and 1000 (inclusive) may be used.

© Page 30 of 97 Issue: 1.04

Page 31

3.7 The Instrument Tab

Select this tab to enter information into the microK’s database (for thermometers

and reference resistors), adjust instrument settings (GPIB address, time, date and

passwords), backup/load instrument configurations or update the software:

3.7.1 Edit Thermometers

Press Edit Thermometers to create, edit or delete a thermometer in the database.

You will be prompted to enter the password in order to proceed.

Thermometer box: Use the up/down buttons to select the thermometer you wish

to edit or delete. Alternatively press the New key to create a new thermometer

© Page 31 of 97 Issue: 1.04

Page 32

entry. The default thermometer types are included in the list but cannot be edited

or deleted.

Thermometer Name box: This box contains the name of the selected

thermometer. If you are creating a new thermometer entry, the ellipses button by

the box becomes active. Press this button to open an Alpha-Numeric Keyboard

window and enter a name. The Shift key toggles the alpha keys between upper

and lower case.

Manufacturer’s Name box: This box contains the manufacturer of the selected

thermometer. If you are creating a new thermometer entry, the ellipses button by

the box becomes active. Press this button to open an Alpha-Numeric Keyboard

window and enter a name. The Shift key toggles the alpha keys between upper

and lower case.

Serial Number box: This box contains the serial number of the selected

thermometer. If you are creating a new thermometer entry, the ellipses button by

the box becomes active. Press this button to open an Alpha-Numeric Keyboard

window and enter a serial number. The Shift key toggles the alpha keys between

upper and lower case.

Calibration Due box: This box contains the date when calibration is due for the

selected thermometer. If you are creating a new thermometer entry, the ellipses

button by the box becomes active. Press this button to open a Date Entry window

and enter a date. The ellipses buttons by the Day, Month and Year boxes in the

Date Entry window open a Numeric Keypad window. Dates are checked for

validity (including leap years) for dates up to 31st December 2099.

Thermometer Type box: This box contains the type of thermometer (PRT,

Thermocouple or Thermistor). If you are creating a new thermometer entry, use

the up/down buttons to select the thermometer type.

Min Temperature box: This box contains the minimum operating temperature

for the selected thermometer. If you are creating a new thermometer entry, the

ellipses button by the box becomes active. Press this button to open a Numeric

© Page 32 of 97 Issue: 1.04

Page 33

Keypad window and enter the minimum operating temperature for the

thermometer.

Max Temperature box: This box contains the maximum operating temperature

for the selected thermometer. If you are creating a new thermometer entry, the

ellipses button by the box becomes active. Press this button to open a Numeric

Keypad window and enter the maximum operating temperature for the

thermometer.

Conversion box: This box contains the conversion to temperature units used for

the selected thermometer. If you are creating a new thermometer entry, use the

up/down buttons to select the required conversion.

Coefficients button: This button opens a window that allows you to enter the

coefficients required for the temperature conversion. In the case of ITS-90, or

thermocouples, these are the coefficients for the deviation function (the base

conversion coefficients are fixed):

New button: Press this button to make a new thermometer entry into the

microK’s database (ellipses and up/down buttons by the boxes then become

active).

Delete button: Press this button to delete the selected thermometer (or the

current entry for a new thermometer) from the database.

OK button: Press this button to confirm the changes and close the Window.

© Page 33 of 97 Issue: 1.04

Page 34

3.7.2 Edit Resistors

Press the Edit Resistors button to create, edit or delete a reference resistor in the

database. You will be prompted to enter the password in order to proceed.

Resistor box: Use the up/down buttons to select the reference resistor you wish

to edit or delete. Alternatively press the New key to create a new reference

resistor entry. The internal reference resistors are included in the list but cannot

be edited or deleted.

Resistor Name box: This box contains the name of the selected reference

resistor. If you are creating a new reference resistor entry, the ellipses button by

the box becomes active. Press this button to open an Alpha-Numeric Keyboard

window and enter a name. The Shift key toggles the alpha keys between upper

and lower case.

Manufacturer’s Name box: This box contains the manufacturer of the selected

reference resistor. If you are creating a new reference resistor entry, the ellipses

button by the box becomes active. Press this button to open an Alpha-Numeric

Keyboard window and enter a name. The Shift key toggles the alpha keys

between upper and lower case.

Serial Number box: This box contains the serial number of the selected

reference resistor. If you are creating a new reference resistor entry, the ellipses

button by the box becomes active. Press this button to open an Alpha-Numeric

© Page 34 of 97 Issue: 1.04

Page 35

Keyboard window and enter a serial number. The Shift key toggles the alpha

keys between upper and lower case.

Calibration Due box: This box contains the date when calibration is due for the

selected reference resistor. If you are creating a new reference resistor entry, the

ellipses button by the box becomes active. Press this button to open a Date Entry

window and enter a date. The ellipses buttons by the Day, Month and Year boxes

in the Date Entry window open a Numeric Keypad window. Dates are checked

for validity (including leap years) for dates up to 31st December 2099.

Value box: This box contains the calibrated value for the selected reference

resistor. If you are creating a new reference resistor entry, press the ellipses

button to open a Numeric Keypad window and enter the calibrated resistance

value (in ohms).

New button: Press this button to make a new thermometer entry into the

microK’s database (ellipses and up/down buttons by the boxes then become

active).

Delete button: Press this button to delete the selected reference resistor (or the

current entry for a new reference resistor) from the database.

OK button: Press this button to confirm the changes and close the Window.

3.7.3 Calibration

Press the Calibration button to open a Date Entry window and set a recalibration

date for your microK. The microK will warn you if you attempt to use it past this

recalibration date (you can disregard the warning and continue to use it, but the

warning will continue to re-appear every hour until the out-of-calibration issue is

resolved).

3.7.4 Restart Software

Press the Restart Software button to restart the microK software. This is useful if

you have added or removed microsKanners and want to re-invoke the automatic

discovery process without cycling the power.

© Page 35 of 97 Issue: 1.04

Page 36

3.7.5 Update Software

Press the Update Software button to update the software or firmware in your

microK. The software runs on a 32-bit processor and provides the operator

interface. The firmware runs on an 8-bit processor and controls the low-level

hardware in the microK.

The new software (microk.exe) or firmware (microK version x_xx.hex) should

be located in the root directory of a USB flash drive connected to the front panel

USB connector (some USB flash drives can take a long time to enumerate in

Windows CE™ and become visible to the software. You should therefore wait

15 seconds between plugging in the drive and pressing the button). You will be

warned that this operation will restart the software, press Yes if you wish to

continue. If the software finds a more recent software or firmware on the flash

drive you will be advised of the version levels and offered the opportunity to

update to the later version, you will also be prompted to enter the password

before proceeding. If the flash drive does not contain a more recent version, the

software will simply restart.

If you are updating the firmware, you will need to cycle the power to the microK

(instruction provided on-screen) before the update process starts (it will take

about 5 minutes). The update software will only update either the software or

firmware at each attempt, so if you are updating both you will need to press

Update Software twice.

The software automatically checks any USB flash drive connected to the front

panel at start-up. If a more recent software version is found, you will be offered

the opportunity to upgrade. Some flash drives enumerate too slowly and so are

not detected during the start-up routine; in this case you should use the manual

update procedure described above.

3.7.6 Change Password

Press the Change Password button to change the security password. (see section

3.11 for details of password protected settings). A window will then open to

allow you to change the password.

© Page 36 of 97 Issue: 1.04

Page 37

You will need to enter the old password and the new one (twice to ensure that it

has been correctly entered). Press the ellipses buttons by each of the password

boxes to open an Alpha-Numeric Keyboard window and enter the relevant

password. Your microK is shipped with the password set to “1234”. This should

be changed, for security reasons, before using your instrument in earnest.

3.7.7 Port Settings

Press Port Settings to view and change the microK’s GPIB address:

Press the ellipses button to open a numeric entry window and change the GPIB

address (valid range 1 to 30 inclusive). The Baud Rate box reports the baud rate

for the RS232 port, but this cannot be changed.

© Page 37 of 97 Issue: 1.04

Page 38

3.7.8 Set Date and Time

Press Set Date and Time to change the date and/or time. This opens a window to

allow you to enter the current date and time and to select the date format

(dd/mm/yyyy or mm/dd/yyyy):

Press the ellipses buttons by each box to open a Numeric keypad window and

enter the required value.

Press OK to save the changes and close the window. Press Cancel to close the

window without making any changes.

3.7.9 Backup Data

Press Backup Data to transfer data that has been saved to the internal memory

(see section 3.4 or 3.5) to an external USB Flash Drive. You need to plug a USB

Flash Drive into the front of the microK in order to use this facility. With some

Flash Drives, it can take up to 15 seconds for these to enumerate and therefore be

recognised by the Windows CE operating system, you therefore need to wait for

15s after plugging in the USB Flash Drive before attempting to transfer the data

(otherwise a “No external drive present” warning will appear).

If a file with the same name is already present on the USB flash drive, you will

be asked whether you wish to over-write it. To proceed, you will need to enter

the password.

© Page 38 of 97 Issue: 1.04

Page 39

Files are transferred to the USB flash drive in directory

\\microKData\serialnumber\data, where “serialnumber” is the serial number of

the microK used to make the measurements. This means that you can have

duplicate filenames for measurements, provided they are made with different

instruments.

3.7.10 Clear Data Files

Press Clear Data Files to delete the data files from the internal memory, this

frees up space for new files to be recorded. You will be prompted to enter the

password before proceeding.

Unless you are sure that you do not need any of the files in the internal memory,

you should transfer all files from the internal memory to a USB flash drive (see

section 3.7.9) before using this feature.

3.7.11 Backup Configuration

Press Backup Configuration to save the current configuration (settings) of the

microK. You will be prompted to enter the password before proceeding. You will

then be offered the choice (buttons) of storing the configuration to the Internal

“DiskOnChip” (solid state drive) memory or an External USB flash drive. Press

the required button to open an Alpha-Numeric Keyboard window and enter a

name for the configuration.

Configurations stored to a USB flash drive are located in directory

\\microKData\serialnumber\backups, where “serialnumber” is the serial number

if the microK. This means that you can have duplicate configuration names

(filenames) for measurements provided they apply to different instruments. If

you want to transfer a configuration from one microK to another, you will need

to move the configuration file manually on the USB flash drive between the sub-

directories for the two microKs.

3.7.12 Load Configuration

Press Load Configuration to load a configuration (settings) for the microK. You

will be prompted to enter the password before proceeding. You will then be

offered the choice (buttons) of loading the configuration from the Internal

© Page 39 of 97 Issue: 1.04

Page 40

“DiskOnChip” (solid state drive) memory or an External USB flash drive. Press

the required button and then use the up/down buttons to select the required

configuration. Press OK to load the configuration, or press Cancel to close the

Window without loading the configuration.

3.8 Using the Thermometer Database

The microK contains a database that allows you to enter, review and edit

information about the thermometers you use. You can then select a thermometer

from this database and all the parameters associated with it will be loaded and

used by the measurement system. This means that you do not need to enter

information such as the calibration coefficients each time you use the

thermometer and therefore avoids the associated risk of data entry errors.

The database also allows you to enter calibration due dates to ensure that you do

not unwittingly use devices beyond their recalibration date. The microK will

warn you if you attempt to use a thermometer past its recalibration date (you can

disregard the warning and continue to use the thermometer, but the warning will

continue to re-appear every hour until the out-of-calibration issue is resolved).

Enter data on the thermometers you use as reference standards or measurement

devices into the microK’s database (see section 3.7.1). You can then use one of

these thermometers by selecting it in the Thermometer box in the Settings tab

(see section 3.6).

The database allows you to enter information about the thermometer:

Thermometer Name (the name you use to refer to the thermometer)

Manufacturer’s name

Serial Number

Calibration Due date

Thermometer Type

Minimum Temperature (operating)

Maximum Temperature (operating)

Conversion (algorithm for converting base reading to temperature)

Information in the database is password protected to help you comply with the

requirements of accreditation bodies.

© Page 40 of 97 Issue: 1.04

Page 41

3.9 Using the Reference Resistors Database

The microK contains a database that allows you to enter, review and edit

information about the reference resistors you use. You can then select a reference

resistor from this database and all the parameters associated with it will be

loaded and used by the measurement system. This means that you do not need to

enter its value each time you use it and therefore avoids the associated risk of

data entry errors.

The database also allows you to enter calibration due dates to ensure that you do

not unwittingly use devices beyond their calibration interval. The microK will

warn you if you attempt to use a reference resistor past its recalibration date (you

can disregard the warning and continue to use it, but the warning will continue to

re-appear every hour until the out-of-calibration issue is resolved).

Enter data on the reference resistors you use with your resistance thermometers

into the microK’s database (see section 3.7.2). You can then use one of these

reference resistors using the Reference Resistor box in the Settings tab (see

section 3.6).

The database allows you to enter information about the reference resistor:

Resistor Name (the name you use to refer to the resistor)

Manufacturer’s name

Serial Number

Calibration Due date

Value (calibrated value in ohms)

Information in the database is password protected to help you comply with the

requirements of accreditation bodies.

3.10 Saving Instrument Configurations

You can save the current configuration (settings) for the microK using the

Backup Configuration button in the Instrument tab (see section 3.7.11). This is

useful if you use the microK in a number of different ways (for example at

different times you may use it to perform fixed-point calibrations on single

SPRTs and comparison calibrations of a thermocouple against two SPRTs). You

© Page 41 of 97 Issue: 1.04

Page 42

can then reload the required configuration (see section 3.7.12) rather than having

to enter all the setting for that particular measurement configuration individually.

3.11 Password Protection of Key Settings

All settings and parameters that affect measurements are password protected.

This helps you to establish working procedures that meet the requirements of

accreditation bodies and should alleviate some of the concerns that accreditation

bodies have about the integrity of measurements.

You need to enter the password to perform the following tasks:

create/edit/delete a thermometer database entry

create/edit/delete a reference resistors database entry

backup internal data to a USB flash drive

overwrite a data file on the USB flash drive

delete internal data files

backup a configuration

load a configuration

change the password

upgrade the software

© Page 42 of 97 Issue: 1.04

Page 43

4 Connecting Thermometer Sensors

4.1 The “Cable-Pod” Connectors

The Eichmann “Cable-Pod”™ connectors used on the microK have gold-plated

tellurium-copper contacts. These generate exceptionally low thermal EMFs when

connected to the copper terminations used on standards grade thermocouples.

The connectors accept 4mm plugs, bare wires or spade terminations.

Additionally, they are spaced on 19mm (¾”) pitch so that they can be used with

standard 4mm-to-BNC adaptors (not supplied) for connecting to BNC terminated

SPRTs. The mechanism is designed so that the clamping surface does not rotate

as it clamps the wire in order to avoid damaging it.

!

The “Cable-Pod”™ mechanism is made from a high strength polymer but

nonetheless may be subject to mechanical damage if the connectors are over

tightened. Please tighten the terminals to a light “finger-tight” level in order to

ensure that they are not subject to undue wear or premature failure. This is all

that is required electrically – do not try to use the connector to provide strain

relief or tension a cable.

4.2 Connecting PRTs (4-wire)

The microK’s resistance measurement system is optimised for high accuracy, 4-

wire resistance measurement. The PRT should be connected to the chosen input

channel in accordance with the schematic shown on the microK’s front panel, as

follows:

© Page 43 of 97 Issue: 1.04

V I

SPRT

Page 44

The top terminal should be connected to the screen of the SPRT’s lead to

minimise electrical noise picked up by the wires.

4.3 Connecting PRTs (3-wire)

The microK can be connected to 3-wire PRTs, although it will not automatically

compensate for cable resistance. The two red terminals should be connected

together and then connected to the ‘single’ end of the 3-wire PRT as follows:

V I

PRT

The connection to the ‘single’ end of the 3-wire PRT should be short (have a low

resistance) in order to minimise the effect of lead resistance on the measurement.

The top terminal should be connected to the screen of the PRT’s lead to minimise

electrical noise picked up by the wires.

4.4 Connecting PRTs (2-wire)

The microK can be connected to 2-wire PRTs. The two red and two black

measurement terminals should be connected together and then connected to the

PRT as follows:

V I

© Page 44 of 97 Issue: 1.04

PRT

Page 45

The connections to the PRT should be short (low resistance) in order to minimise

the effect of lead resistance on the measurement. Alternatively, the connections

can use remote sensing (using the 4-wire measurement capability of the microK)

to eliminate the effect of lead resistance completely. In this arrangement, the

current and voltage sense connections are kept separate and are only joined close

to the PRT:

V I

PRT

The top terminal should be connected to the screen of the PRT’s lead to minimise

electrical noise picked up by the wires.

4.5 Connecting Thermocouples (external Ice Point or

WTP)

The microK’s measurement system uses active guarding. As a result, the voltage

measurement system is floating until it is connected to the sense current

terminals. In order to measure the voltage on a thermocouple, the two current

terminals should be connected to each other and to the red voltage sense

terminal:

Thermocouple

V I

Measurement

The most accurate thermocouple measurements are made with the reference

Reference

JunctionJunction

junction immersed in an ice-point bath (or water-triple-point). The microK

© Page 45 of 97 Issue: 1.04

Page 46

supports this arrangement by allowing you to specify the temperature of the

reference junction as 0°C or 0.01°C (see section 3.6).

4.6 Connecting Thermocouples (using RJ compensation)

It is possible to measure the temperature of the reference junction and

compensate for the associated EMF at this junction. The reference junction can

be measured using a PRT or thermistor connected to another measurement

channel:

Thermocouple

Measurement

V I

Reference

JunctionJunction

PRT

V I

The microK supports this arrangement by allowing you to use a temperature

measured by another input channel as the reference junction temperature. This

technique is less accurate than using an ice-point (or water-triple-point) due to

the additional uncertainties associated with the PRT used to monitor the

reference junction and any temperature gradients that result in a difference

between the temperature of the PRT and the reference junction.

4.7 Connecting Thermistors

The microK can be connected to thermistors using the same arrangement as for

2-wire PRTs (see section 4.4):

© Page 46 of 97 Issue: 1.04

Page 47

V I

THERMISTOR

Because the resistance of thermistors used for temperature measurement is much

higher than for PRTs, lead resistance is not normally a problem.

Use an external reference resistor with thermistors since the resistance of the

internal standards is too low. Thermistors have much higher temperature

coefficients than PRT, so the tolerances on the reference resistor are

correspondingly less demanding, making them relatively inexpensive.

The top terminal should be connected to the screen of the thermistor’s lead to

minimise electrical noise picked up by the wires. The high resistance of

thermistors makes them more prone to picking up electrical noise, it is therefore

even more important to use a screened cable and connect this to the screen

terminal on the microK than when using PRTs.

© Page 47 of 97 Issue: 1.04

Page 48

5 Good Practice Guidelines

5.1 Looking After Your microK

Your microK is a precision electronic instrument intended for indoor use in a

laboratory or office environment. Nonetheless, it has been designed to be as

robust as practical and will provide many years of service, provided it is properly

maintained.

We recommend that you return your microK to Isothermal Technology or one of

our approved service centres on an annual basis for calibration. Isothermal

Technology has developed a calibration kit for the microK. Contact Isothermal

Technology or one of our appointed distributors if you wish to purchase a kit to

calibrate the microK yourself. The microK should require little maintenance

between calibrations other than routine cleaning.

Under no circumstances should you use sharp or unsuitable objects (such as ball-

point pens) on the touch screen as this will lead to premature failure. It is also a

good idea to ensure that you have clean hands when using the touch screen. You

should ensure that you do not have contaminants such as adhesives or solvents

on you fingers when touching the screen as these will be difficult to remove

without damaging the screen.

The touch screen can be cleaned with a damp (not wet) cloth. Use either a

proprietary screen cleaner (suitable for PC flat panel displays) or water and a

little mild liquid soap on a lint-free cloth to wipe the touch screen. Dry the screen

immediately after cleaning with a lint-free cloth. The rest of the microK should

not require cleaning as often as the display, and can be cleaned in the same way

as the screen. Never use abrasive cleaners (such as ‘cream’ cleaners) on your

microK.

5.2 Making a Good Electrical Measurement

Although the microK is intended for use in temperature metrology, its base

measurements are electrical (resistance or voltage). The limited sensitivity of

© Page 48 of 97 Issue: 1.04

Page 49

PRTs and thermocouples means that in order to achieve uncertainties at the mK

level, we need to make electrical measurements that rival those of a good

electrical metrology laboratory. For example, for a 25Ω SPRT a 1mK

temperature uncertainty corresponds to 100µ Ω resistance uncertainty. With a

1mA sense current, this corresponds to a voltage uncertainty of 0.1µV.

The microK has been optimised for electromagnetic compatibility (minimising

emissions and maximising immunity). However, since the microK is capable of

measuring to such low signal levels it is worthwhile adopting good electrical

measurement practices. Here are a few guidelines:

The most sensitive points are the inputs to the microK (measuring to

better than 0.1µV). Whilst the microK will work satisfactorily with just a

four wire connection to the PRT or reference resistor (using the voltage

sense and current terminals marked “V” and “I” respectively), it is better

to use a screened cable and to connect the screen to the measurement

ground terminal above the input terminals:

Screen (Measurement Ground) Terminal

V I

SPRT or

Reference Resistor

The screen should also be connected to the outer sheath of the SPRT (if it

is metal clad) or the case of the reference resistor. The use of screened

cables is more important when the microK is used with thermistors, which

have a higher resistance than PRTs or thermocouples.

Keep the cables to the microK input terminals away from other cables

that might be sources of electrical noise (for example electrical supplies

to furnaces).

The insulation in high temperature furnaces (any that ‘glow’) begins to

conduct at higher temperatures. This can cause high common-mode

voltages on any thermometer in the furnace. Whilst the microK is

designed to reject common-mode DC and AC signals (at both 50 and

© Page 49 of 97 Issue: 1.04

Page 50

60Hz), it is good practice to minimise them. It is common practice to use

a metal equalising block in a furnace when performing comparison