Page 1

MEDUSA 510/511 SERIES

MEDUSA 510 / 511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Isotech North America

158 Brentwood Drive, Unit 4

Colchester, VT 05446

Phone: 802-863-8050

Fax: 802-863-8125

www.isotechna.com

sales@isotechna.com

The company is always willin g to give technical advice and assistance where appropriate.

Equally, because of the programme of continual development and improvement we reserve the

right to amend or alter characteristics and design without prior notice. This pu bl i cation is for

information only.

Page 1 of 54

Page 2

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

CONTENTS

PAGE

3 - 4 EMC Information

5

6

7 Guarantee

8

9

10, Unpacking & Initial Inspection

11,12,13

14,15

16 Adjusting the Timer

17,18

19

20

21,22

23,24 Operating the Controller

25,26,27,28

29,30

31

32 Using the PC Interface

33,34

35

36 Initial Testing

37

38

39 Figure 3

40

41,42

43,44 Appendix 3 - Indicator Configuration

DESCRIPTION

Health & Safety Instructions

Do’s and Don’ts

Cautionary Note

Transit Clamp Notice

Introduction

Mode of Operation

Thermometric Fixed Points (a tutorial note)

How to measure the true temperature insi d e the accessories

supplied with the Medusa

Specification

Performance Graphs

Operating the Indicator

Connecting a Current Transmitter (up to 20mA)

Selecting Configuration Level

Testing Thermostats

Operating the Medusa 511

Using Cal Notepad

Diagnostics

Maintenance

Figure 2

Appendix 1 - Trouble Shooting

Appendix 2 - Accessories

Page 2 of 54

Page 3

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

EMC INFORMATION

This product meets the requirements of the European Directive on Electromagnetic Compatibility

(EMC) 89/336/EEC as amended by EC Directive 92 /3 1 /E EC and the European Low Voltage

Directive 73/25/EEC, amended by 93/68/EEC. To ensure emission compliance please ensure that

any serial communications connecting leads (RS232 or RS422(485)) are fully screened.

The product meets the susceptibility requirements of EN 50082-1, criterion B.

Symbol Identification Publication Description

ISO3864 Caution

(Refer to Handbook)

IEC 417

ELECTRICAL SAFETY

This equipment must be correctly earthed.

This equipment is a Class 1 Appliance. A protective earth is used to ensure the conductive parts

can not become live in the event of a failure of the insulation.

The protective conductor of the flexible mains cable which is coloured green/yellow MUST be

connected to a suitable earth.

Caution, Hot Surface

The blue conductor should be connected to Neutral and the Brown conductor to Live (Line).

Page 3 of 54

Page 4

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Warning: Internal mains voltage hazard. Do not remove the panels.

There are no user serviceable parts inside. Contact your nearest Isotech agent for repair.

Voltage transients on the supply must not exceed 2.5kV.

Conductive pollution, eg. Carbon dust, must be excluded from the apparatus. EN61010 pollution

degree 2.

The apparatus has two inpu t co nn ectors for temperature sensors, see Figure 2. These inputs

are only suitable for either a thermocouple or resistance thermometer. No other sensor or signal

may be connected.

ENVIRONMENTAL RATINGS

Operating Temperature

Relative Humidity 5-95%, non condensing

5-35°C

Page 4 of 54

Page 5

HEALTH AND SAFETY INSTRUCTIONS

1. Read all of this handbook before use.

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

2.

3.

4.

5.

6.

7. Do not dismantle the apparatus.

8.

9.

10. There are no user serviceable parts inside. Contact your nearest Isotech agent for

Wear appropriate protective clothing.

Operators of this equipment should be adequately trained in the handling of hot and cold

items and liquids.

Do not use th e apparatus for jobs other than those for which it was designed, ie. the

calibration of thermometers.

Do not handle the apparatus when it is hot (or cold), unl ess we aring the appropriate

protective clothing and having the necessary training.

Do not drill, modify or otherwise change the shape of the apparatus.

Do not use the apparatus outside its recommended temperature range.

If cased, do not return the apparatus to its carrying case until the unit has cooled.

repair.

11. En su re materials, especially flammable materials are kept away from hot parts of t he

apparatus, to prevent fire risk.

Page 5 of 54

Page 6

MEDUSA MODEL 510/511

‘DO’S AND DON’TS’

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

DO NOT handle the accessories when they are very hot or very cold.

DO NOT place hot or cold accessories back in the carrying case

DO NOT use the pocket designed for the black body source sensor to measure the temperature

of the insert or surface calibrator.

DO use that pocket for pre-warming or storage.

DO NOT spill liquids inside the Medusa.

DO NOT rely on the controller to tell you the temperature of the insert. It’s job is only to provide

an isothermal volume. It is the calibrated working standard that is used to measure actual

temperature.

Page 6 of 54

Page 7

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

GUARANTEE

This instrument has been manufactured to exacting standards and is guaranteed for twelve

months against electrical break-down or mechanical failure caused through defective material

or workmanship, provided the failure is not the result of misuse. In the event of failure

covered by this guarantee, the instrument must be returned, carriage paid, to the supplier for

examination and will be replaced or repaired at our option.

FRAGILE CERAMIC AND/OR GLASS PARTS ARE NOT COVERED BY THIS GUARANTEE

INTERFERENCE WITH, OR FAILURE TO PROPERLY MAINTAIN THIS INSTRUMENT MAY

INVALIDATE THIS GUARANTEE

RECOMMENDATION

The life of your ISOTECH Instrument will be prolonged if regular maintenance and cleaning to

remove general dust and debris is carried out.

Serial No:.............................................

Date:.....................................................

Isotech North America

158 Brentwood Drive, Unit 4

Colchester, VT 05446

Phone: 802-863-8050

Fax: 802-863-8125

www.isotechna.com

sales@isotechna.com

Page 7 of 54

Page 8

MEDUSA 510/511 SERIES

ISSUE 10 - 11/05

CAUTIONARY NOTE

ISOTECH PRODUCTS ARE INTENDED FOR USE BY TECHNICALLY

TRAINED AND COMPETENT PERSONNEL FAMILIAR WITH GOOD

MEASUREMENT PRACTICES.

IT IS EXPECTED THAT PERSONNEL USING THIS EQUIPMENT WILL

BE COMPETENT WITH THE MANA GE M ENT OF APPARATUS

WHICH MAY BE POWERED OR UNDER EXTREMES OF

TEMPERATURE, AND ARE ABLE TO APPRECIATE THE HAZARDS

WHICH MAY BE ASSOCIATED WITH, AND THE PRECAUTIONS TO

BE TAKEN WITH, SUCH EQUIPMENT.

HANDBOOK

Page 8 of 54

Page 9

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Page 9 of 54

Page 10

TRANSIT CLAMP

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

EVERY EFFORT HAS BEEN MADE TO PACKAGE THIS UNIT FOR TRANSPORT AND TO

ENSURE ITS GOOD CONDITION ON ARRIVAL AT ITS DESTINATION

BEFORE COM M ISSIONING IT IS NECESSARY TO REMOVE THE FURNACE CORE TRANSIT

CLAMP. TO AVOID DAMAGE PLEASE FOLLOW INSTRUCTIONS

1.

2. Remove the 4 bolts securing the transit clamp to the side of the unit. Slacken each

3.

4. Normal commissioning procedure may now be followed.

5.

Slacken the central nut using the required tube spanner; the insertion of a screwdriver

through the tube spanner will prevent the central stud turning.

screw equally by degrees and then completely remove the screws.

Gently lift the transit clamp vertically; a central tube which has secured the furnace core

will then slide out. The 4 screws should then be replaced to secure the handles to the

side of the unit.

Keep the transit clamp and use it if the furnace is ever transported.

Page 10 of 54

Page 11

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Page 11 of 54

Page 12

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

UNPACKING AND INITIAL INSPECTION

Our Packing Department uses custom designed packaging to send out your unit, but as accidents

can still happen in transit, you are advised, after unpacking the unit, to inspect it for any sign of

shipping damage, and confirm that your delivery is in accordance with the packing note. If you

find any damage or that part of the delivery is missing notify us or our a gen t, and the carrier

immediately. If the u n i t i s damaged you should keep the packing for possible insurance

assessment.

ELECTRICITY SUPPLY

Before connecting to the electricity supply please familiarise yourse l f wi th the parts of the

handbook relevant to your model.

Your unit's supply voltage requirement is specified on a plate on the instrument along with the

serial number. All Medusa i nstruments will work on an electricity supply frequency of 50Hz or

60Hz.

The apparatus is provided with an approved power cord. If the plug is not sui ta b l e for your

lo

c

at

io

n

then the plug should be removed and replaced with an appropriate plug.

Take care to ensure the old plug is disposed safely.

The cable is colour coded as follows:

COLOUR FUNCTION

Green/yellow Earth (Ground)

Brown Live (line)

Blue

Neutral

Please ensure that your unit is correctly connected to the electricity supply.

THE APPARATUS MUST BE CORRECTLY EARTHED (GROUNDED)

Page 12 of 54

Page 13

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

The units on/off switch is located on the power inlet. Take care NOT to switch the unit off when

it is hot - allow to cool first.

Page 13 of 54

Page 14

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

INTRODUCTION

The Medusa range of products allows unprecedented flexibility for the calibration of temperature

sensors. The Medusa may be used with the following options:

1.

2.

3. A Black Body Source

4.

The Medusa is available in two variants. The Basic (B) model which incorporates a single

temperature controller. The Potts and Site (S) model also include a temperature indicator and

timer.

COMPARISON CALIBRATION:

By definition, one compares industrial thermometers to a calibrated standard.

There are 3 methods commonly used.

1)

Using the controller as the “calibrate d standard” this method means that the complete bath is

calibrated by comparing the controller reading to a calibrated standard placed in the bath.

This is a common method but is unsafe since the control sensor is

An ITS-90 Fixed Point Apparatus

As a Metal Block Bath

A Surface Sensor Calibrator

USING THE CONTROLLER

a)

b) in the wrong place to give correct temperature of the insert

For these reasons it fails to satisfy ISO9000 and gives large uncertainties.

inaccessible

Page 14 of 54

Page 15

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

2)

Here an indicator and external calibrate d sen sor are used to measure the temperature of the

insert. This arrangement gives good accurate and re liable results. To recalibrate however it

does mean sending the whole calibrator back to the calibration laboratory. This, the calibrator is

self-contained, self-sufficient and meets ISO9000 requirements.

USING THE INDICATOR - (Not Basic (B) Model)

Page 15 of 54

Page 16

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

3)

Here a separate indicator and calibrated sensor are used to measure the inserts temperature.

This can give the most accurate and reliable results, depending on the indicator.

It means that the calibrator does not need calibrating only the indicator and it’s calibrated sensor

need re-calibration, but this option is more bulky, expensive and less portable than 2) It also

meets ISO9000 requirements.

USING EXTERNAL STANDARDS

Page 16 of 54

Page 17

MODE OF OPERATION

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

1)

The ITS-90 fixed point function of the Medusa is well suited for fast , co nveni ent, mess free

calibration of thermometers to uncertainties as low at 0.001°C.

The special cell is placed into the Medusa calibration well.

The equipment incorporates a timer which can change temperatures to a l l ow MELTING or

FREEZING of a Cell. Once initiated the Cell can be arranged to be on the melt plateau during the

day and automatically frozen and bought back to the melt plateau overnight.

It works this way:-

The Medusa automatically switches on some 2 to 3 hours be f ore the working day starts and

gets the cell onto its melt plateau. The indicator tells the user on their arrival in the morning that

the melt has begun and calibration can commence.

If left unused the melt continues to 6 to 12 hours and probably during the night the timer switches

the apparatus off to re-freeze the cell, the cycle is repeated each day, giving the user the fixed

point all day, every day without attention except to occasionally clean the fan filter if it becomes

clogged with dust.

ITS-90 FIXED POINT CALIBRATION

The Medusa works by having a controller which is set about 1°C above the fixed point which

is inside the apparatus It has an indicator with a thermometer which is used to monitor the state

of the fixed point cell. It is also fitted with a timer to automatically switch on and off the

apparatus.

Indium, Tin Lead and Zinc Fixed Points all look the same, being an ingot of pure metal placed in

a graphite crucible which, to keep dirt, moisture and air out are sealed, usually in quartz glass.

To avoid the use of quartz glass the graphite crucibles are sealed into metallic containers without

contamination of the pure ingot inside the crucible.

On power up the timer is set to run at setpoint 1 for 20 hours at setpoint 2 for 4 hours.

Page 17 of 54

Page 18

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

2)

The metal block bath function of the Medusa i s well suited for fast, convenient, mess free

calibration of temperature sensors.

The Medusa metal insert is placed into the calibration well.

The thermometers under test are placed into suitable holes in metal insert, see accessory page.

A calibrated reference probe should be placed into the insert and the actual temperature can be

read from the temperature indicator.

For traceable calibration the actual value of the insert temperature should be recorded along with

the values from the sensors under test.

3)

The black body function of the Medusa is well suited for fast, convenient, mess free calibration

of infra-red temperature sensors.

The Medusa black body target, see accessory page, is placed into the calibration well. The

units under test should be aligned with the target.

METAL BLOCK BATH

BLACK BODY SOURCE

A calibrated reference probe should be placed into the hole in the block a nd the actual

temperature can be read from the temperature indicator to which the infra red thermometer(s)

are compared.

4)

The surface sensor function of the Medusa is well suited fo r f ast, convenient, mess free

calibration of most surface temperature sensors.

The Medusa surface sensor insert, see accessory page, is placed into the calibration well.

A cal i b ra t ed pro be, see accessory page, is placed in the pocket of the surface sensor insert

and connected to the temperature indicator. Surface sensors are placed on top of the insert and

when stable compared to the calibrated probe.

SURFACE SENSOR CALIBRATION

Page 18 of 54

Page 19

ADJUSTING THE TIMER

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Page 19 of 54

Page 20

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

THERMOMETRIC FIXED POINTS (a tutorial note)

Temperature scales used in science and ind ustry are defined by a series of "fixed points",

which are realised by establishing thermal conditions under wh i ch pure materials exhibit

equilibrium between two or three phases. A scale assigns numerical values to the temperatures

at which these phase equilibria exist. For example, the temperature at which pure water exists

simultaneously in its liquid, solid and gas phases (triple point) has been assigned the numerical

value of 0.01°C on the International Temperature Scale, and the value of 273.16K on the Kelvin

Thermodynamic Temperature Scale. Examples of other defining fixed points of the International

Temperature Scale of 1990 are the respective liquid-solid equilibria of tin, zinc and silver under

1 standard atmosphere pressure.

In some important disciplines it is desirable to realise a thermometric fixed point between 0 and

100°C, frequently in the vicinity of body or environmental-temperature. The melting temperature

of high purity gallium, 29.7646°C, is a fixed point that can be useful in this context.

The solid-liquid equilibrium point of gallium is realised in cells such as those shown in figure 1.

A quantity of pure gallium is contained in a vessel which provides, also, a re-entrant well for

insertion of a thermometer. The cycle for realising the melt equilibrium is as follows:

The galli u m sta rts in a single phase, assumed for present purposes to be liquid. The cell is

placed in a cold environment until the gallium has solidified. The phase-change of the metal can

be determined by tracing the temperature of the well. As the metal cools from the liquid phase,

the temperature will begin to fall. An initial smooth drop in temperature will be observed, and then

at some tempera ture b e l ow the freezing temperature there will be seen a reversal and a

subsequent rise in temperature. This "undercool" phenomenon is characteristic of many pu re

materials, most of which can remain liquid at temperatures below their normal freezing points (if

the metal were initially solid, the temperature would fall uninterruptedly to that of the cold

environment).

The reversal takes place as the first crystalline solid forms in the liquid; the temperature rises to

the liquid-solid equilibrium plateau temperature as the metal gives up latent heat on freezing,

remaining thereafter at this temperature until the metal is completely solid. Beyond this stage

there will be a smooth drop in temperature to that of surrounding environment.

To establish the melting condition, the cell is then transferred to an environment maintained at a

temperature slightly above the melt temperature of gallium. This environment may be a stirred

fluid bath of sufficient heat capacity and control capability, or may be the Medusa POT TS or

Gallium Temperature Standard Apparatus Model 17402B which is designed automatically to raise

the temperature of the cell to initiate melting of the metal and then to maintain it at a correct level.

The temperature to which the cell is exposed to melt the metal does not determine the solid-liquid

equilib ri um temperature, but it can have a substantial effect on the duration of the (constanttemperature) melt plateau.

Page 20 of 54

Page 21

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

The monitoring thermometer will indicate a rise in temperature in the well as the solid gallium

approaches the melt temperature. Then, beyond the instant at which liquid first begins to form,

the temperature will remain constant until all the metal has melted. The end of the melt plateau

is signalled by a rise in well temperature to the temperature of the surrounding environment. An

ITL 17401 gallium cell used in the Model 17402B system can give a plateau duration of at least

12 hours.

The melting cycle is now complete. The material in the cell is entirely in the liquid phase. Another

cycle may be started immediately, if desired.

17cc of water should be poured into the re-entrant tube to allow proper conduction between cell

and thermometer.

For the hi g he st a c c u r a c y

measuremen ts (to less than 0.1mK of the

ITS-90 value) an ho u r shou l d e l apse

between switching t o m e l t a n d

c o m m e n c i n g m e a s u r e m e n t s .

Alternatively, once the melt has began the

water in the well ca n b e repl ace d b y

warm water at say 40°C t o initiate a melt

round the re-entrant tube. See CCT96/8 for

additional guidance.

Page 21 of 54

Page 22

HINT

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

HOW TO MEASURE THE TRUE TEMPERATURE INSIDE THE ACCESSORIES SUPPLIED

WITH THE MEDUSA SERIES

The controller of the Medusa controls and read s the temperature of the block surrounding the

deep calibration well.

There are various accessories including the surface calibration insert, black bo d y etc. These

adapt the Medusa to perform varied calibration functions.

None of these accessories actually get to the block te m perature and hence the controller’s

temperature because each accessory has a different i m m ersi o n characteristic. For this reason

the Medusa like all comparison baths requires a reference thermometer to indicate the true

temperature inside the accessory.

Remember the following:-

THE CONTROLLER

The controller is used to set a constant temperature and create an isothermal environment for

the comparison calibration of temperature sensors.

THE REFERENCE THERMOMETER

The Reference Thermometer is placed in the accessory or insert and measures the true

temperature inside the insert or accessory.

Page 22 of 54

Page 23

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

THE INDUSTRIAL THERMOM ETER

The Industrial thermometer is p l ace d in the accessory or insert and is compared to the True

Temperature as indicated by the reference thermometer. An insert will typically have a 1%

immersion error. For more details see - Depths of Immersion. Tavener J. P. Volume 9.2. Isotech

Journal of Thermometry pages 79-87.

SPECIFICATION

Voltage : 230VAC (or 115VAC) see ratings plate

Power : 1800W

Supply Frequency

Maximum Operating Temperature : Medusa 1 - 550°C

Minimum Operating Temperature : Medusa 1 - 30°C

Stability (Absolute over 30 Minutes)

Metal Block Bath : ±0.03°C

Black Body Source : ±0.3°C

ITS-90 Fixed Point Apparatus

: ±0.0002°C

: 50/60Hz

Medusa 2/Medusa 511 - 700°C

Medusa 2/Medusa 511 - 35°C

Calibration Volume : 45mm dia by 285mm deep

Standard Insert Hole Dimensions: : 6 x 8mm

Page 23 of 54

Page 24

Insert Options

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

: Standard 6x8mm x 250mm deep

: Adjustable Height Equalising Block

: Special drilling available to customer

requirements.

: Blank

Dimensions (not including handle)

Weight : Medusa 1 - 17Kg

: Height 430mm

Width 310mm

Depth 300mm

Medusa 2/Medusa 511 - 26kg

Page 24 of 54

Page 25

MEDUSA 510/511 SERIES

MEDUSA 1 PERFORMANCE GRAPHS

HANDBOOK

ISSUE 10 - 11/05

Page 25 of 54

Page 26

MEDUSA 510/511 SERIES

MEDUSA 2 PERFORMANCE GRAPHS

HANDBOOK

ISSUE 10 - 11/05

Page 26 of 54

Page 27

OPERATING THE MEDUSA

FRONT PANEL LAYOUT

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

The Temperature Controller

The controller has a dual display, the upper display indicates the nominal block temperature, and

the lower display indicates the desired temperature or setpoint.

Altering the Setpoint

To change the setpoint of the controller simply use the UP and DOWN keys to raise and lower

the setpoint to the required value. The lower display changes to indicate the new setpoint.

Press scroll button to select setpoint 1 (SP1) or setpoint 2 (SP2).

Advanced Controller Features

Setpoint Ramp Rate

By default the Dry Blocks are configured to hea t (and cool) as quickly as possible. There may

be some calibration applications where it is advantageous to limit the heating (or cooling rate).

An example might be when testing bimetallic thermostats, by forcing the Dry Block to heat at a

controlled rate it is easier to determine the temperature at which the thermostat changes state.

The Dry Block can have its heating rate limited with the Setpoint Ramp Rate feature. This feature

is accessed from the Scroll key. Depress the key until the display shows,

Page 27 of 54

Page 28

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

SPrr

On the Upper Display, the lower display will show the current value from OFF (default) to 999.9.

The desired rate is set here with the UP and DOWN keys, the units are °C/min.

When the SP rr is active the controller display will show "RUN", the lower setpoint display will

now automatically update with th e current value, known as the working setpoint. The setpoint

can be seen by pressing either the UP and DOWN key.

The Setpoint ramp rate operates when the bath is heating and cooling.

Instrument Address

The controller has a configurable "address" which is used for PC co mmunications. Each

instrument has an address, this allows several inst ruments to be connected in parallel on the

same communications bus. The default value is 1. This address would only need to be changed

if more than one Dry Block is connected to the same PC port.

To check the Address value press the scroll key until the top display indicates,

Addr

The lower display will show the current value that can be modified with the UP and DOWN keys.

Monitoring the Controller Status

A row of beacons indicate the controllers status as follows,

OP1

OP2 Cool Output (Only for models which operate below 0°C)

REM

Units

Momentary pressing the Scroll key will show the controller units °C or °F.

The Temperature Indicator (Not Basic (B) Models)

The site models include an electronic temperature indicator. The indicator can be configured for

the desired sensor type, and for custom calibration data. The customer calibration data can be

set ON or OFF.

Heat Output

This beacon indicates activity on the PC interface

Page 28 of 54

Page 29

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Page 29 of 54

Page 30

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Setting the Input Type

A 100 Ohm resistance thermometer can be connected to the PRT Connector or a thermocouple

may be connected to the miniature TC Connector.

Ensure that only a PRT or a TC is connected at any one time. If a PRT and TC are

connected simultaneously the indicator will read in error.

Check that any sensor placed into the Medusa is suitable for the temperature range. Sensors

can be damaged if taken outside their normal operating limits.

The desired sensor type is easily set, press the Scroll key until the upper display indicates,

inPt

On the upper display. The lower display will show the current set sensor type,

J.tc J thermocouple

K.tc

L.tc

r.tc R thermocouple (Pt/Pt13%Rh)

b.tc

n.tc

t.tc T thermocouple

S.tc

PL.2

rtd 100 platinum resistance thermometer.

T012

Again the value can be modified with the UP and DOWN keys.

Enabling / Disabling Custom Calibration

Custom calibration allows the indicator to be programmed to suit a particular temperature sensor.

This allows the indicator to automatically show the true temperature, without having to manually

apply a correction.

K thermocouple

L thermocouple

B thermocouple (Pt30%Rh/Pt6%Rh)

N thermocouple

S thermocouple (Pt/Pt10%Rh)

PL 2 thermocouple

E thermocouple

When the Custom or User Calibration is active the indicator will show the REM b eacon lit

continuously. The use of User calibratio n can make a significant difference to the accuracy of

Page 30 of 54

Page 31

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

the instrument, and this REM beacon provides a clear and continuous indication of the calibration

status. Iso tech will configure and set user calibration when the Dry Block is ordered with a

temperature sensor.

To alter the calibration status press the Scroll key until the upper display shows,

CAL

The lower display will indicate either,

USEr

Or

FACt

Use the UP and DOWN keys to toggle between the two values.

for user calibration

for factory calibration of the indicator, i.e. User Cal OFF

When calibrating an unknown sensor against a calibrated probe it may be necessary to switch

the calibration off for the unknown, and on for the calibrated probe.

Instrument Address

Like the con tro ller, the indicator has a configurable "address" which is used for PC

communications. Each i nstrument has an address; this allows several instruments to be

connected in parallel on the same communications bus. The default value is 2 (The controller

defaults to 1). This address wo uld only need to be changed if more than one Dry Block is

connected to the same PC port.

To check the Address value press the scroll key until the top display indicates,

Addr

The lower display will show the current value that can be modified with the UP and DOWN keys.

Monitoring the Indicator Status

For the indicator the REM beacon is lit continuously when the user calibration is active, the REM

beacon flashes when the PC communications port is active.

Units

Momentary pressing the Scroll key will show the controller units °C or °F.

Page 31 of 54

Page 32

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Advanced Indicator Operation

The indicator can be configured with up to five custom calibration points; the points contain "data

pairs". First the temperature (point) and secondly the Error (offset) at this temperature point.

Isotech Dry Block calibration certificates will show the values to suit a particular sensor.

These values can be inspected, and modified with the following procedure,

Press the PAGE key until the display indicates,

ACCS

LiSt

Press the SCROLL key until the display shows,

Goto

OPEr

Press the UP key until the display shows

Goto

conF

Press the Scroll Key twice, when the display will show,

inSt

Conf

Press the Page Key until the controller shows

CAL

Conf

Now use the Scroll key to examine the data pairs. The values can be modified with the UP and

DOWN keys.

To exit this mode press the Page key until the top display shows,

Exit

Page 32 of 54

Page 33

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

And th en set t he lower display to YES. While in this mode take care not to modify other

parameters - a full list of all the parameters can be found in appendix 3.

Page 33 of 54

Page 34

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

CALIBRATION DATA EXAMPLE

A maximum of five points may be entered, shown as Pnt 1 to Pnt 5 for the temperature point and

Ofs 1 to Ofs 5 for the offset values.

The Pnt values must be entered in ascending order.

Set a Pnt to a value lower than the previous point to disable it.

The indicator would be programmed with the following data:

Pnt 1 100

Pnt 2 300 Ofs 2 1.1

Pnt 3 500 Ofs 3 2.1

Pnt 4 -999

Pnt 5 -999 Ofs 5 0

Ofs 1 0.8

Ofs 4 0

Page 34 of 54

Page 35

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

CONNECTING A CURRENT TRANSMITTER (UP TO 20MA)

The transmitter should be powered externally, a 2.49 current sense resistor is fitted internally

and this allows the indicator to read mA.

1.

2. Access configuration level.

SELECTING CONFIGURATION LEVEL

From the input type menu select “mV”.

Page 35 of 54

Page 36

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Page 36 of 54

Page 37

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Testing Thermostats

The Site model can be used the Isotech Cal Notepad software for the testing of thermostats and

other thermal switches with volt free co n ta ct s. Ca l Notepad can capture the temperature at

which a switch opens or closes. It can also perform a hysteresis test. Refer to the Cal Notepad

manual for details. Ensure only voltage free contacts are connected. Do not allow any voltage

signal to be connected - doing so many damage the equipment and present a safety hazard.

Page 37 of 54

Page 38

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

OPERATING THE MEDUSA 511

The Medusa 511 is a 3 Zone Block Bath used to create an even temperature profile along the

part of the block in which fixed point cells will sit.

The main heater is used to set the required temperature the top and bottom heaters are used to

compensate for the end effect heat losses.

The top and bottom heater control settings are preset for the Aluminium Point - unless the

Medusa is supplied with an alternative ITS-90 fixed point.

To change the offsets (e.g for tin and indium points) the offsets may need to be reduced. The

offsets are simply changed with the up and down buttons of the respective controller.

A s a f i r s t

ap p ro xi ma tion the

o ffset s m a y b e

reduced proportionally

with temperature.

Offsets may be checked and optimized by

placing a small thermocoupl e adjustment

to the block. By ra i si ng and lowering t he

thermocoupl e the profile can be obtained

and t h en o p ti mise by adjustment of the

controllers.

Page 38 of 54

Page 39

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Using the PC Interface

The Plus models include an RS422 PC interface and a special converter cable that allows use

with the a standard RS232 port. When using the bath with an RS232 port it is essential that this

co nvert er cable is used. Replacement cables are available from Isotech, part number

ISO-232-432. A further lead is available as an option, Part Number ISO-422-422 lead which

permits up to 5 instruments to be daisy chained together.

The benefit of this approach is that a number of calibration baths may be connected together in

a "dai

s y ch a

i n " co n

fi gu ra ti

on - and

t h e n

l i nk e d

to a s i n

g l e R S

23 2 ,

se e d i a

g ra m.

Note: The RS 422 standard specifies a maximum lead length of 1200M (4000ft). A true RS422

port will be required to realise such lead lengths. The Isotech conversion leads are suitable for

maximum combined lead lengths of 10M that is adequate for most applications.

Connections

For RS232 use simply connect the Isotech cable, a 9 to 25 pin converter is included to suit PCs

with a 25 pin serial converter.

Page 39 of 54

Page 40

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

RS422 Connections

Pin

4 Tx+ A

5

8

9 Rx- B

1

Using the Interface

The models are supplied with Cal NotePad as standard. This easy to use package is compatible

with MS Windows 9x. A handbook for Cal NotePad can be found on the first installation disk in

Adobe PDF format. If required a free Ado b e PDF reader can be downloaded from,

www.adobe.com.

CAL NOTEPAD

Connection

Tx- B

Rx+ A

Common

Cal Note p ad ca n be used to log and display values from the Dry Blocks and an optional

temperature indicator.

Minimum System Requirements

CNP requires Windows 95 / 98, a minimum of 5Mb of free hard drive space and free serial ports

for the instruments to be connected.

Dev elopment

CNP was developed by Isothermal Technology using LabVIEW from National Instruments.

License

Use of the Cal NotePad software program "CNP" is as granted in this license agreement. In using

the CNP

software the user "licensee" is agreeing to the terms of the license. You must read and understand

the terms of this license before using CNP.

1, This license permits licensee to use CNP software on a single computer. The user may make

copies for back up and archival purposes freely as long as the software is only ever in use on a

single computer at any one time. Please enquire about multi-user licenses.

2, CNP is protected by international copyright laws and treaties. CNP must not be distributed to third

parties.

3, CNP must not be reversed engineered, disassembled or de-compiled. Licensee may transfer the

software to a third party provided that no copies or upgrades of CNP are retained.

4, It is the responsibility of the user to ensure the validity of all stored results and printed certificates.

Isothermal Technology Ltd accept no responsibility for any errors caused by inappropriate use,

incorrect set up or any other cause; including defects in the software.

5, Limited Warranty. Isothermal Technology warrants that CNP will perform substantially a s

Page 40 of 54

Page 41

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

described in this manual for a period of 90 days from receipt. Any distribution media will under

normal used be guaranteed for a period of 90 days.

NO OTHER WARRANTIES, EXCEPT AS STATED ABOVE. The software and documentation is

provided "as is" without warranty of any kind and no other warranties (either expressed or implied)

are made with regard to CNP. Isothermal Technology does not warrant, guarantee or make any

representations regarding the use or results of the use of the software or documentation and does

not warrant that the operation of CNP will be error free.

In no event will Isothermal Technology, its employees, agents or other associated people be liable

for direct, indirect, incidental or c onsequential damages, expenses, lost profits, business

interruption, lost business information or other damages arising out the use or inability to use CNP.

The license fee reflects this allocation of risk.

CNP is not designed for situations where the results can threaten or cause injury to humans.

Page 41 of 54

Page 42

Installing Cal NotePad

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

1

2

3.

4 Should you ever need to uninstall the software then use the Add/Remove Programs

Starting Cal NotePad

From a Standard Installation:

Click the START button

Highlight PROGRAMS

Select I so

tech - Sel

e c t Cal

pad

Insert CNP DISK 1 into the disk drive

Click on the START button on the task bar, select RUN, type A:\SETUP (Where A: is your

drive letter) then click OK

Follow the prompts which will install the application and necessary LabVIEW run time

support files.

option from the Control Panel.

Protocol

Page 42 of 54

Page 43

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

The instruments use the "Eurotherm EI BiSynch Protocol"

If required, e.g. for writing custom software the technical details are available from our website

at, www.isotech.co.uk/refer.html

Diagnostic alarms

These indicate that a fault exists in either the controller, indicator or the connected sensor.

Controller Error Messages

The instruments include powerful diagnostics and in the unlikely event of an internal failure, or

a sensor error, one of the following error messages may be displayed.

Display

show s

EE.Er Electrical ly Erasable Memory Error:

S.br Sensor Break:

HW.Er Hardw are error :

LLLL Out of Di splay range, low reading For Controller: Contact Isotech

HHHH Out of Display range, hi gh readi ng For Controller: Contact Isotech

What it means What to do about it

For Controller: Contact Isotech

The value of an operator or

configuration parameter has been

corrupted

Input sensor is unreliable or the input

signal is out of range.

Indication that a module is of the wrong

type, missing or faulty

For Indicator: Check Config

Against Data in Appendix

For Controller: Contact Isotech

For Indicator: Check a sensor is

connected.

Check that only a PRT or a TC is

Connected (Not both)

Contact Isotech

For Indicator: Check Sensor and

Connections

For Indicator: Check Sensor and

Connections

Err1 Error 1: ROM self-test fail Consult Isotech

Err2 Error 2: RAM sel f-test fail Consult Isotech

Page 43 of 54

Page 44

MEDUSA 510/511 SERIES

Err3 Error 3: Watchdog fail Consult Isotech

HANDBOOK

ISSUE 10 - 11/05

Err4 Error 4: Keyboard failure

Stuck button, or a button was pressed

during power up.

Err5 Error 5: Input ci rcuit fai lure Consult Isotech

Pwr.F Power fai l ure. The line voltage is too

low

INITIAL TESTING

This unit was fully tested befo re de spa t ch to you but please check its operation as outlined

below.

After connecting the Medusa to the electricity supply, the temperature controller display

will show the temperature of the block and the last set-point value. The controller and

indicator both go through a self-test sequence first.

Change the set-point to 100C and observe that the block temperature rises and settles to this

value. Place a thermometer in the insert in the block and connect it to the suitably configured

indicator. Confirm that the indicator agrees within ±2C of the controller.

Switch the power off and then on

without touching any of the

controller buttons.

Check that the supply to the

controller is within the rated limits

Your unit should have performed as described above and can now be used for calibration.

If any probl ems or faults arise during these tests please contact us or our agents for help and

advice.

IMPORTANT NOTICE

The controller's function settings are preset and will not require adjustment.

Page 44 of 54

Page 45

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

MAINTENANCE

Maintenance is limit to keeping the apparatus and the calibration volume clean and free from

debris.

There are no internal user serviceable parts.

Repair and maintenance must be carried out by Isothermal Technology Limited or an approved

agent.

Page 45 of 54

Page 46

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

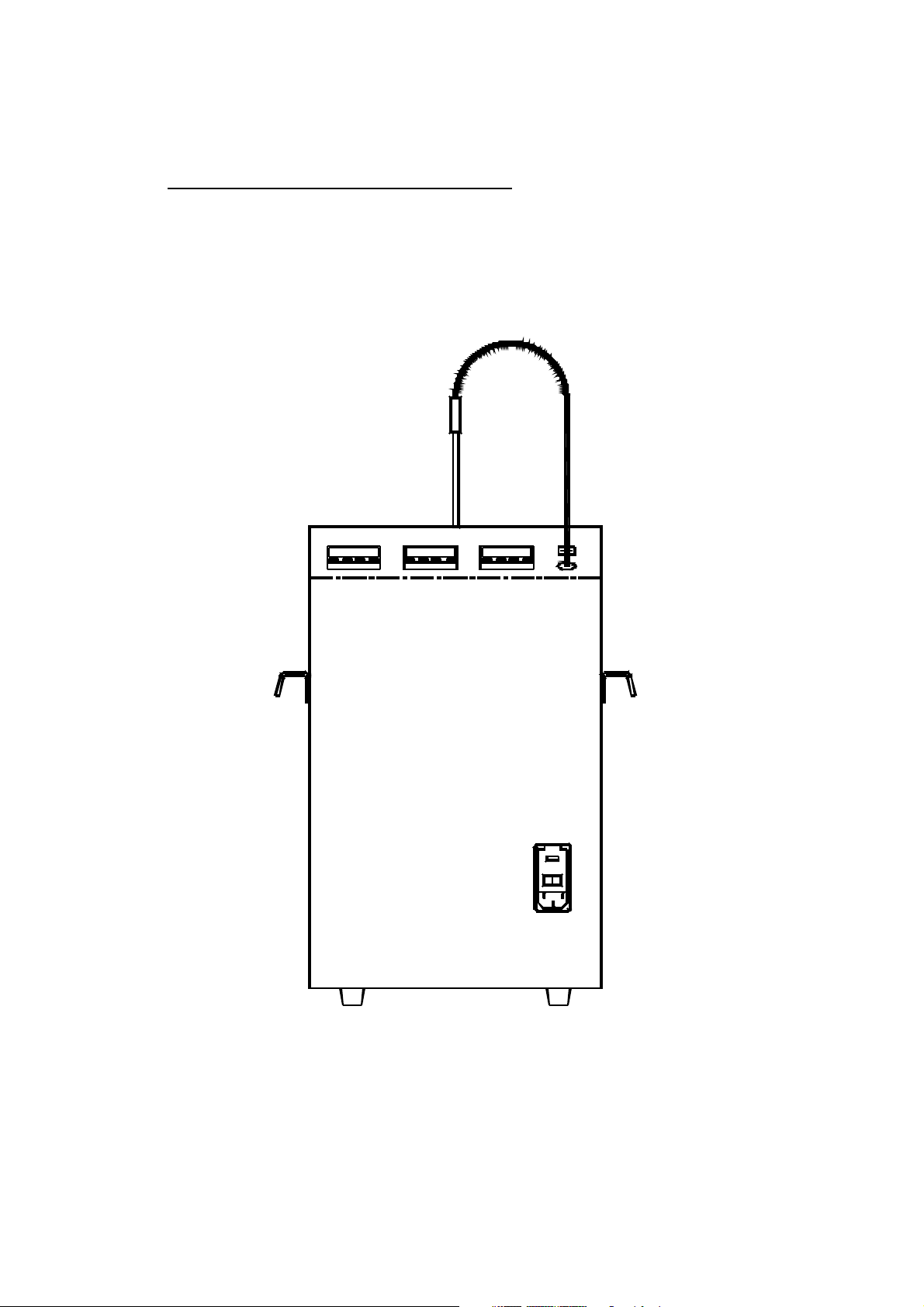

FIGURE 2

Page 46 of 54

Page 47

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

A

B Timer

C Temperature indicator

D

E T/C input

F Power entry module - comprising power

G Timer

H Switch contact

Note: Only co n ne ct a therm oco u ple o r pl atinu m

resistance thermometer to the input con ne ct ors. Ensure

that only one sensor is connected at any time.

Temperature

PRT input

input, fuse and switch

FIGURE 3

511 3 ZONE VERSION - 110V VERSION

controller

socket

socket

enable/disable

Page 47 of 54

Page 48

A Temperature controller

B

C Temperature indicator

D PRT input socket

E

F RS 422 comms socket

G On/Off switch

H Cable entry gland

I Switch contact (thermostat)

J

K Top zone controller

L Bottom zone controller

Timer

T/C input socket

Timer enable/disable

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Note: Fuses and fuse carriers mounted internally. Accessed by removing the ye l low cover.

Factory set as: 110 Volt - Live - 20A Fuse, 0 Volt - Neutral - Link (can be exchanged for fuse

if required)

APPENDIX 1

MEDUSA SERIES

TROUBLE SHOOTING

1.

2. Indicator reads incorrectly

Unit fails to operate

Check fuse. If fuse blows repeatedly consult Isotech or local agent.

Two sensors connected simultaneously.

Page 48 of 54

Page 49

MEDUSA 510/511 SERIES

Indicator incorrectly configured - refer to ‘Operating the Medusa’ section.

HANDBOOK

ISSUE 10 - 11/05

3.

Cannot establish PC Communications

For RS232 you must use the Isotech adaptor cable.

Ensure the addresses of the controller and indicator match those set in Cal Notepad.

Ensure each controller and indicator are set to a unique address.

Refer to ‘Using the PC Interface’ section and the Cal Notepad manual for further details.

APPENDIX 2

ACCESSORIES PARTS LIST FOR MEDUSA 510

Standard Dry Block Insert 510-06-01

Blank Insert

510-06-02

Page 49 of 54

Page 50

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Adjustable Equalising Block

Blackbody Target Kit 510-06-05

Surface Sensor Calibrator Kit 580-06-06

Surface Sensor Probe

Surface Sensor Insert 510-02-02

Slim Gallium Melting Point CellM 17401M

Slim Indium Fixed Point Cell M 17668M

Slim Tin Fixed Point Cell

Slim Lead Fixed Point Cell M 17670M

Slim Zinc Fixed Point Cell M 17671M

M 17669M

510-06-04

935-14-49

ACCESSORIES

Semi-Standard PRT

Inconel Cell Basket 510-05-00

Storage Case 931-22-58

935-14-95/DB

APPENDIX 2

ACCESSORIES PARTS LIST FOR MEDUSA 511

Page 50 of 54

Page 51

Adjustable Equalising Block 511-06-04

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Blackbody Target Kit

Surface Sensor Calibrator Kit 511-06-06

Surface Sensor Probe 935-14-49

Surface Sensor Insert

Slim Indium Fixed Point Cell M 17668M

Slim Tin Fixed Point Cell M 17669M

Slim Lead Fixed Point Cell M 17670M

Slim Zinc Fixed Point Cell

Slim Aluminium Fixed Point CellM 17672M

ACCESSORIES

511-06-05

510-02-02C

M 17671M

Semi-Standard PRT 935-14-95/DB

Inconel Cell Basket

Storage Case 931-22-58

511-05-01

Page 51 of 54

Page 52

APPENDIX 3

INDICATOR CONFIGURATION (Reference Only)

Config.INST

Name Description Value

unit Instrument Units `C (0)

dEcP Decimal Places in Display NN.NN

CtrL Control Type PID (0)

Act Control Action REV (0)

COOL Cooling Type LIN (0)

PwrF Power Feedback Enable OFF (0)

Pdtr Manual/Auto Transfer PD

Control

FoP Forced Output Enable NO (0)

Sbrt Sensor Break Type SB.OP (0)

rnGH Process Value High Limit 670

rnGL Process Value Low Limit 0.00

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

NO (0)

Config.IP

Config.CAL

Name Description Value

inPt Linearisation Type RTD

CJC CJC Type EXT

imP Sensor break impedance AUTO (1)

Name Description Value

UCAL User Calibration Enable YES (1)

Pnt1 User Cal Point 1 0

Pnt5 User Cal Point 5 -99.00

OFS1 User Cal Offset 1 0.00

Pnt2 User Cal Point 2 -99

OFS2 User Cal Offset 2 0.00

Pnt3 User Cal Point 3 -99

OFS3 User Cal Offset 3 0.00

Pnt4 User Cal Point 4 -99.00

OFS4 User Cal Offset 4 0.00

OFS5 User Cal Offset 5 -99.00

Note: User Cal values are unique to each instrument. If available set values to those from

Page 52 of 54

Page 53

calibration certificate

Config.AL

Name Description Value

AL_1 Alarm 1 Type OFF (0)

Ltch1 Alarm 1 Latching NO (0)

AL_2 Alarm 2 Type OFF (0)

Ltch2 Alarm 2 Latching NO (0)

AL_3 Alarm 3 Type OFF (0)

Ltch3 Alarm 3 Latching NO (0)

AL_4 Alarm 4 Type OFF (0)

Ltch4 Alarm 4 Latching NO (0)

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Config.HA

Config.1A

Config.2A

Name Description Value

id Module Identity CMS (7)

Func Module Function CMS (65)

bAud Baud Rate 9600 (0)

Prty Comms Parity NONE (0)

rES Comms Resolution FUL (0)

Name Description Value

id Module Identity LOG (3)

Func Module function NONE (0)

SEnS Sense of Output NOR (0)

Name Description Value

id Module Identity LOG (3)

Func Module function NONE (0)

SEnS Sense of Output NOR (0)

Page 53 of 54

Page 54

MEDUSA 510/511 SERIES

HANDBOOK

ISSUE 10 - 11/05

Page 54 of 54

Loading...

Loading...