Page 1

66

|

SOLUTIONS FOR PRIMARY & SECONDARY LABORATORIES

Stirred Liquid Baths

-65 to -80°C

785 Parallel Tube

g

Uncertainties to <1mK

g

Physical separation of heating from Calibration Volume

g

Three models covering -80 to 300°C

Isotech calibration baths employ sophisticated designs to

ensure calibration to the smallest of uncertainties. In 1986

Isotech purchased the interests of H N Irving & Sons

Temperature division which had specialised in providing high

quality baths to NPL and other international laboratories.

The knowledge and concepts from this scientific instrument

manufacturer were used in the development of the Isotech

815 and 915 Parallel Tube Liquid Baths. Whilst there is a

higher cost compared to simple designs the quality and

pedigree is unmatched.

The key feature is the physical separation of the chamber in

which the liquid is heated or cooled from the chamber that

contains the calibration volume in which the thermometers are

placed.

The geometry of parallel tube is also important, with the shape

and angle of the curves optimised for temperature uniformity.

The new Libra Model 785 achieves this with the same parallel

tube assembly as used in the 915 packaged into a different

case and now with internal refrigeration can be used to lower

temperatures.

The cooling power varies dynamically with the benefit of

giving greater stability at lower temperatures.

Model All Models 785L 785M 785H

Temp Range -80°C - 125°C -40°C - 125°C 30°C - 300°C

Volume 98mm Diameter, 485mm Deep

Absolute Stability ±0.0025°C ±0.006°C ±0.006°C ±0.006°C

Direct in Liquid (Water, 50°C) (Methanol, -80°C) (Methanol, -40°C) (C10 Oil, 125°C)

Vertical Uniformity From <1mK - See evaluation report

Heating time 25°C to 125°C < 50 mins (C10 Oil) 30°C to 250°C < 150 mins (VH Oil)

Cooling time 0°C to -80°C < 300 mins 10°C to -40°C < 180 mins (Methanol) (Methanol)

Display Resolution (Whole Range): 0.01°C 0.01°C 0.01°C

Liquid Height (Above Surface) 3mm 3mm 3mm

Design Parallel Tube: Separate Calibration and Mixing Chambers

Communications Includes Serial Interface, PC Cable and Software

Dimensions 485mm wide, 525mm deep, 1150mm high

Weight 78kg 68kg 48kg

Safety Compliant to CE Regulations

Power 2.8kW 1kW 800W

108-130 or 208-240V, 50/60Hz

Whilst the bath has a maximum immersion of 485mm the fluid

requirement is just 8.5 litres. This helps to lower operating

costs as many other baths require a much larger volume of

fluid, which in turn can be costly.

How to Order 785L 785M 785H

Refer to Evaluation Report for Full Details

Page 2

67

SOLUTIONS FOR PRIMARY & SECONDARY LABORATORIES

|

785 Operation

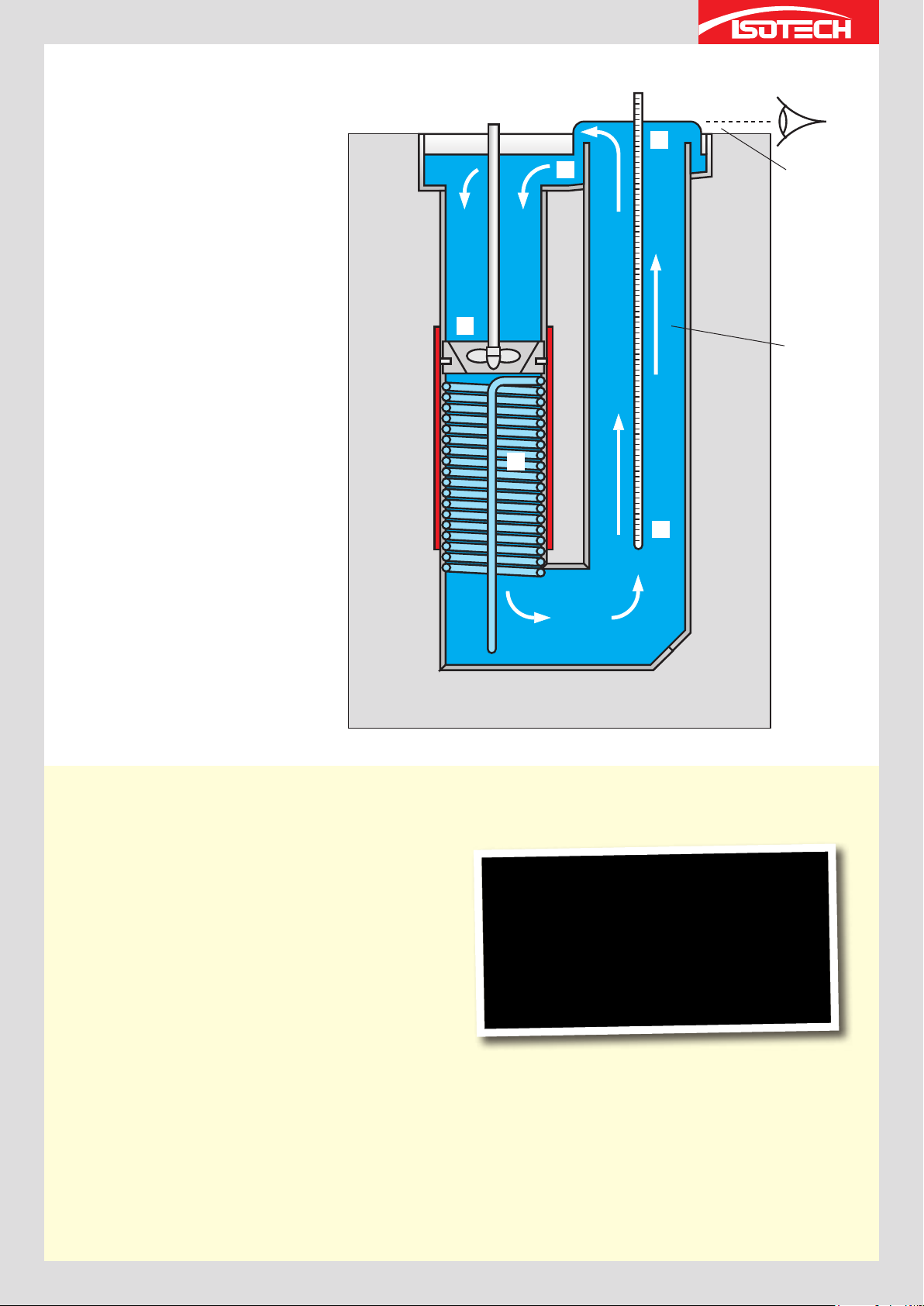

1. The Liquid Flows Down into the

Mixing Chamber through an orifice

plate, the flow rate of which is

adjustable from the front panel.

2

. Cooling / Heating Chamber,

circular design for optimum flow

and uniformity.

3

. The calibration chamber is

separate from the cooling /

heating chamber.

4

. The Liquid flows over a weir a little

higher than the bath lid suiting

total immersion liquid in glass

thermometers.

5

. The Liquid flows into a large

volume liquid tray which caters for

the expansion of the liquid as it

is heated. The liquid re-circulates

around the bath.

6

. High Efficiency Thermal Insulation.

4

5

Liquid height

typically 3mm

above top

surface

1

Seperate

callibration

volume

2

3

Advanced parallel tube design

Lowest Comparison Calibration Uncertainties

Isotech best practise for comparison calibration of

resistance thermometers is to determine the resistance

of the thermometer under test by directly comparing it

to a Standard Platinum Resistance Thermometer.

The comparison is made using a thermometry bridge,

such as the microK, to measure the resistance ratio of

the two thermometers. An advantage of this approach

is that if both thermometers are of the same type both

will follow the same temperature fluctuations and the

resistance ratio will remain very stable. This method can

largely eliminate the effects of the bath stability, what

is needed is temperature uniformity in the calibration

volume, it needs to be isothermal.

The physical separation of the calibration chamber

from the heating and cooling chamber along with

the attention to the segments and contours provide

an isothermal volume that is superior to other baths.

The result a comparison bath providing the lowest

comparison calibration uncertainties, reflected in our

UKAS schedule.

Page 3

Accessories for 785 & 915

These baths can be supplied with a range of accessories including equalising blocks, a support assembly for up 12 LIG

thermometers and a monocular to aid reading the scale of a L.I.G. Thermometer.

There are a range of supports to hold various fixed point cells, Slim and Optimal, allowing the bath to realise ITS-90 fixed

point cells to sub mK uncertainties.

Refer to ‘Liquid Selection Guide’ on page 77 for information on liquids and important Health and Safety Information.

915/01a Variable depth aluminium equalising block

containing four drilled pockets 8mm

diameter by 160mm deep in which

temperature sensors can be placed and is

suitable for use with silicon oils.

The equalising block is suspended centrally

within the calibration tube and is easily

removed.

915/01b As an alternative to the above a copper

equalising block, dimensionally the same

as 915/01a, may be supplied. This block is

more suitable for use in water and other

liquids.

915/D Increased depth Calibration Tube

(915 only)

915/02 This assembly will hold up to 12 liquid in

Assembly. Working volume is 100mm

diameter by 530mm deep. This variant

allows for the calibration of very long

thermometers, typically the calibration of

long liquid in glass thermometers.

glass thermometers (maximum diameter

12.7mm) radially and a centre mounted

standard sensor. The assembly may be

rotated allowing systematic calibration.

The assembly is designed for partial or full

immersion thermometer types.

915/05 Calibration Tube Cover. The cover consists

of a square enclosure containing baffles

and fits over the calibration tube area

insulating the circulating liquid from

ambient air. Access for temperature probes

remains at the top of the enclosure. An

equalising block may also be supported

from this assembly. Maximum operating

temperature 180°C.

915/03 Monocular and Support. Useful for viewing

and magnifying the liquid column within the

thermometer being calibrated. This

ancillary piece of equipment is used in

conjunction with 915/02 Liquid in Glass

Thermometer Support Kit.

NOTE: Read all safety information concerning

liquids which you intend to use in the

bath and use only approved liquids.

Fixed Point Calibration ITS-90

Cell Basket Assemblies

(Excluding Cells)

915-05-43 Small Mercury Cell Kit

915-05-44 Large Mercury Cell Kit

915-05-41 Small Water Triple Point Cell Kit

915-05-40 Large Water Triple Point Cell Kit

915-05-39 Small Gallium Cell Kit

915-05-38 Large Gallium Cell Kit

915-05-42 Slim Cell Kit

68

SOLUTIONS FOR PRIMARY & SECONDARY LABORATORIES

|

Loading...

Loading...